Page 1

Remotely Controlled Power Switch Solutions

PDU4/4 AC Power Distribution Unit

PRODUCT MANUAL

AC POWER

DISTRIBUTION

Thinklogical, LLC®

100 Washington Street

Milford, Connecticut 06460 U.S.A.

Telephone: 1-203-647-8700

Fax: 1-203-783-9949

www.thinklogical.com

[Type text]

Page 2

®

PDU 4/4 Product Manual September, 2014

Page 1

PDU 4/4

®

Copyright Notice

Copyright © 2014. All rights reserved. Printed in the U.S.A.

Thinklogical, LLC®

100 Washington Street

Milford, Connecticut 06460 U.S.A.

Telephone: 1-203-647-8700

All trademarks and service marks are property of their respective owners.

Subject: PDU 4/4 AC Power Distribution Unit Product Manual

Release Date: September, 2014

Page 3

®

PDU 4/4 Product Manual September, 2014

Page 2

Table of Contents

PREFACE .............................................................................................................................................. 3

About Thinklogical ................................................................................................................................. 3

Note and Warning Symbols ................................................................................................................... 4

INTRODUCTION ......................................................................................................................... 4

Product Overview: The PDU4/4 ............................................................................................................ 4

1: THE PDU 4/4 AC POWER DISTRIBUTION UNIT ...................................................................... 5

Mounting The PDU 4/4 ................................................................................................................. 5

Front Panel LCD and Buttons ............................................................................................................... 6

Convection Cooling ............................................................................................................................... 6

Connecting the PDU 4/4 ........................................................................................................................ 6

The Rear Panel ..................................................................................................................................... 7

Power Connections ............................................................................................................................... 7

Domestic ............................................................................................................................................ 7

International ....................................................................................................................................... 7

Status LEDs ........................................................................................................................................... 7

USB Firmware Upgrade Ports ............................................................................................................... 7

Serial Interface ...................................................................................................................................... 7

Installation .............................................................................................................................................. 8

Port Setting Your Terminal Device ................................................................................................... 8

Cascading the PDU Chassis ............................................................................................................ 8

Box IDs .............................................................................................................................................. 8

Program Storage ............................................................................................................................... 9

Communicating with The PDU 4/4 ................................................................................................... 9

Programming Access ........................................................................................................................ 9

Log In ................................................................................................................................................ 9

Commands ............................................................................................................................................ 9

PDU 4/4 Technical Specifications ....................................................................................................... 15

PDU Models Available From Thinklogical ...................................................................................... 15

2: REGULATORY & SAFETY REQUIREMENTS ........................................................................ 15

Symbols Found On Our Products ................................................................................................... 15

Regulatory Compliance .................................................................................................................. 15

North America ................................................................................................................................. 16

Australia & New Zealand ................................................................................................................ 16

European Union .............................................................................................................................. 16

Standards with Which Our Products Comply ................................................................................. 16

Supplementary Information ................................................................................................................. 17

Product Serial Number ........................................................................................................................ 17

Connection to the Product ................................................................................................................... 17

3: THINKLOGICAL SUPPORT .................................................................................................. 18

Customer Support ............................................................................................................................... 18

Website ........................................................................................................................................... 18

Email ............................................................................................................................................... 18

Telephone ....................................................................................................................................... 18

Fax .................................................................................................................................................. 19

Product Support ................................................................................................................................... 19

Warranty ................................................................................................................................ ... 19

Return Authorization ....................................................................................................................... 19

APPENDIX A: PDU 4/4 QUICK START GUIDE .......................................................................... 20

Page 4

®

PDU 4/4 Product Manual September, 2014

Page 3

Preface

Thinklogical, LLC®

100 Washington St.

Milford, CT 06460

We, the Thinklogical team, are committed to understanding and

exceeding our customers’ requirements, the first time and every time.

About Thinklogical

Thinklogical is the leading manufacturer and provider of fiber optic KVM, video, audio, and peripheral

extension and switching solutions used in video-rich, big-data computing environments.

Thinklogical offers the only fiber optic KVM matrix switches and routers in the world

that are accredited to The Common Criteria, EAL4 and TEMPEST.

Governments, entertainment, scientific and industrial customers worldwide rely on Thinklogical’s products

and solutions for security, high performance, continuous operation and ease of integration. Thinklogical

products are designed and manufactured in the USA and are certified to the ISO 9001-2008 standard.

Thinklogical is headquartered in Milford, Connecticut and is privately held by Riverside Partners, LLC,

Boston, MA (http://www.riversidepartners.com). For more information about Thinklogical products and

services, please visit www.thinklogical.com.

Follow Thinklogical on LinkedIn at http://www.linkedin.com/company/thinklogical and on Facebook at

http://www.facebook.com/ThinklogicalUSA

Page 5

®

PDU 4/4 Product Manual September, 2014

Page 4

Note and Warning Symbols

BEFORE STARTING ANY PROCEDURE, IT IS RECOMMENDED

THAT YOU READ THE INSTRUCTIONS THOROUGHLY!

PDU 4/4 International AC (PDU-000003)

PDU 4/4 Domestic AC (PDU-000001)

Throughout this document you will notice certain symbols that bring your attention to important information.

These are Notes and Warnings. Examples are shown below.

Note: Important Notes appear in blue text preceded by a yellow exclamation point symbol, as

shown here.

A note is meant to call the reader’s attention to helpful information at a point in the text that is relevant to the

subject being discussed.

Warning! All Warnings appear in red text, followed by blue text, and preceded by a red stop

sign, as shown here.

A warning is meant to call the reader’s attention to critical information at a point in the text that is relevant to the

subject being discussed.

Introduction

Product Overview: The PDU 4/4

Thinklogical’s® PDU 4/4 Power Distribution Unit is an AC Power Switch that

remotely controls the power to eight separate devices per unit.

Eight individually-controlled AC power outlets may be switched off and on as desired.

Communicates with its control terminal using a serial interface.

Each PDU 4/4 has two banks of four outlets. Each individual outlet switches a maximum

of 10 Amperes. Each bank is rated at 15 Amperes total.

Designed for rack mounting (1U) or desktop use

Available in both domestic and international models

Features redundant DC power supplies for built-in I/O and control circuits

Individually programmable Reboot Time Delay on each outlet

Solid state zero-crossing relays to minimize power spikes

Easily expandable, cascading configuration

Password Security

Front panel LCD for easy system set up and configuration

Current monitoring of each port

Software updates available at ftp.thinklogical.com

Page 6

®

PDU 4/4 Product Manual September, 2014

Page 5

Thinklogical’s easy to use PDU 4/4 Power Distribution Unit is an AC Power Switch that remotely controls the

8 Mounting

Bracket Screws

2 Mounting bracket

screws in four places.

RACK-MOUNT OR DESK-TOP OPTIONS:

Like all Thinklogical rack-mountable extenders,

the PDU 4/4 can be mounted in a standard EIA

19" rack or on a shelf or desk-top.

After removing power from the unit, each

mounting bracket, which is secured by four

screws, can be safely removed for desk-top

mounting without removing the cover.

All screws should be reinstalled after the

brackets have been removed.

power to eight separate devices which may be switched off and on as desired. This allows system

administrators, while communicating with the control terminal through a serial interface, to restart a “locked up”

network device from anywhere on the network.

Controls all devices with simple Power Off/On commands to reboot any one port, multiple ports, port groups or all

devices.

Power restarts can be sequenced using programmed time delays to minimize surge or to allow drive spin-up time.

Rear panel LEDs show the status of each port.

Any configuration can be easily expanded by cascading additional PDU 4/4 chassis with a single serial

cable for each added chassis. Up to sixteen PDU 4/4s can be cascaded together to control multiple systems from

one common user interface. A single serial interface integrates the control of all PDU 4/4s in any standard

application. (See Cascading the PDU Chassis on page 8.)

1. The PDU 4/4 Remote AC Power Distribution Unit

Mounting the PDU 4/4

You may choose to rack mount your PDU 4/4 or place it on a shelf or desktop (feet included). The front panel

LCD and navigation buttons should always be accessible. All connections are made at the rear of the chassis.

Rack Mount or Desktop

The PDU 4/4 may be installed in an EIA-standard 19 inch rack (1U tall), or placed on a shelf or desktop. For

shelf/desktop use, rubber feet are provided and the rack mount brackets may be removed. The PDU 4/4

chassis does not need to be opened or accessed. The sturdy metal case allows units to be stacked, as

required.

Note: Be sure to leave adequate ventilation space on both sides of the units (minimum 2”),

especially if units are being stacked.

Page 7

®

PDU 4/4 Product Manual September, 2014

Page 6

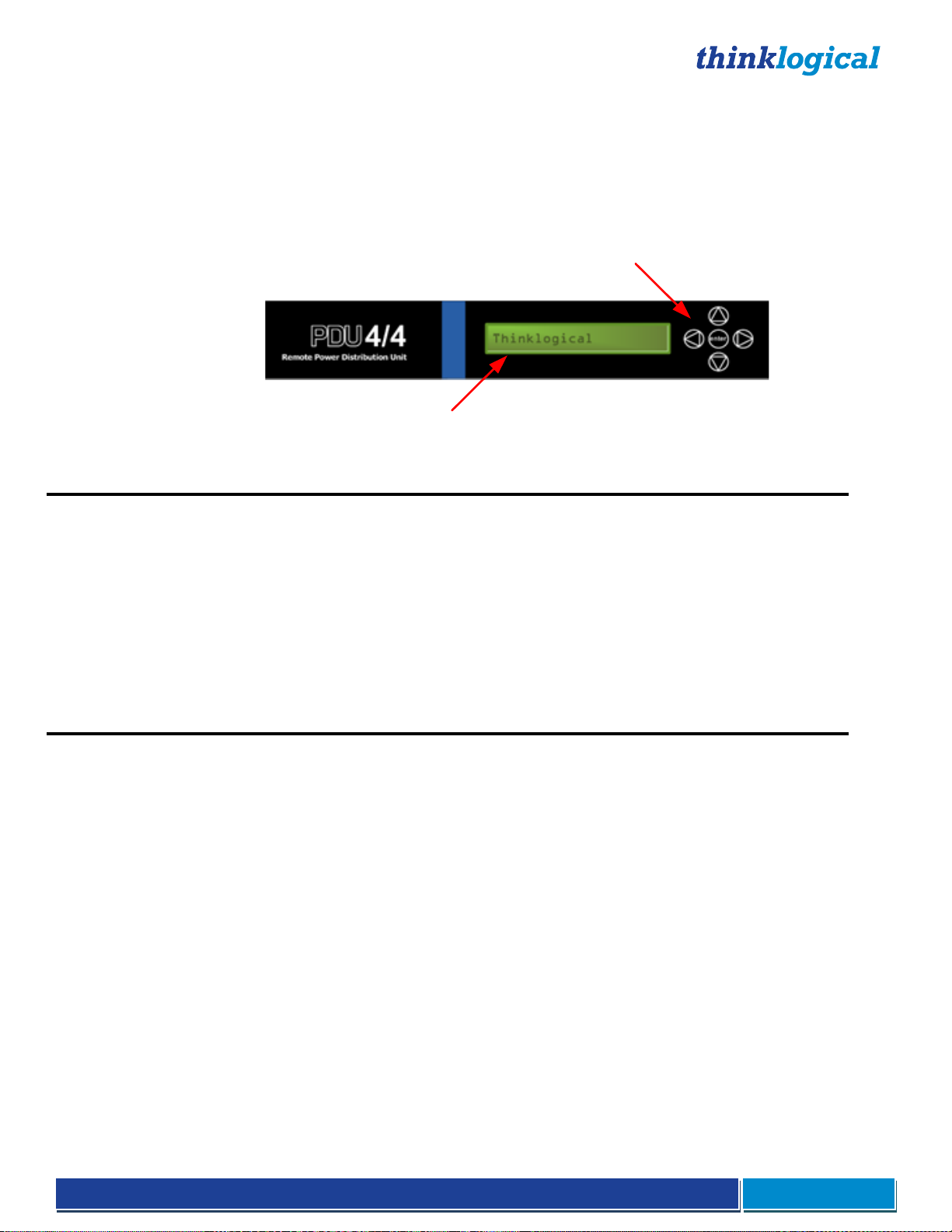

Front Panel LCD and Buttons

LCD Navigation Buttons

System Information and

Programming

The front-panel LCD should be visible and accessible for system setup. The navigation buttons are used

to configure the unit and to review existing PDU 4/4 configurations.

Use the Up and Down Arrow Buttons to scroll through the Main Menus (Port Power, System). Once the

main menu choice is shown on the display, press the Enter Button. Use the Left and Right Arrow Buttons

to navigate through the menu options.

The PDU 4/4 LCD menu is arranged as follows:

Display Modifiable Description

*Port Power

Port 1 Yes Display status of power on Port 1

Port 2 Yes Display status of power on Port 2

Port 3 Yes Display status of power on Port 3

Port 4 Yes Display status of power on Port 4

Port 5 Yes Display status of power on Port 5

Port 6 Yes Display status of power on Port 6

Port 7 Yes Display status of power on Port 7

Port 8 Yes Display status of power on Port 8

Display Modifiable Description

*System

DAISY Position No Location in DAISY Chain

Ctrl Rev No Revision of PDU

Offset Current (Tare)* Yes Calibrate current monitor on all ports.

Debug Values Yes Factory Debug Facility

*Offset Current (Tare) is only available from the front panel. This menu option sets a zero current reference and stores it

in non-volatile memory. To use this feature all ports must be off. Once the ports are off, set the Offset Current Tare to Yes,

it will revert back to No when the calibration is complete.

Convection Cooling

The PDU 4/4 does not require special cooling or ventilation other than what is normally provided in a standard

equipment rack. If mounted in an enclosed rack, the rack should have a ventilation fan to provide adequate

airflow through the unit(s).

Connecting the PDU 4/4

All physical connections to the product use industry-standard connectors. All connections are found at

the rear of the unit.

The rear panel consists of (2) AC Power Cords, (2) Circuit Breakers, (8) AC Power Outlets, (8) Port Status

LEDs, (1) USB Firmware Upgrade Port and (2) RJ45 Console Ports.

Page 8

®

PDU 4/4 Product Manual September, 2014

Page 7

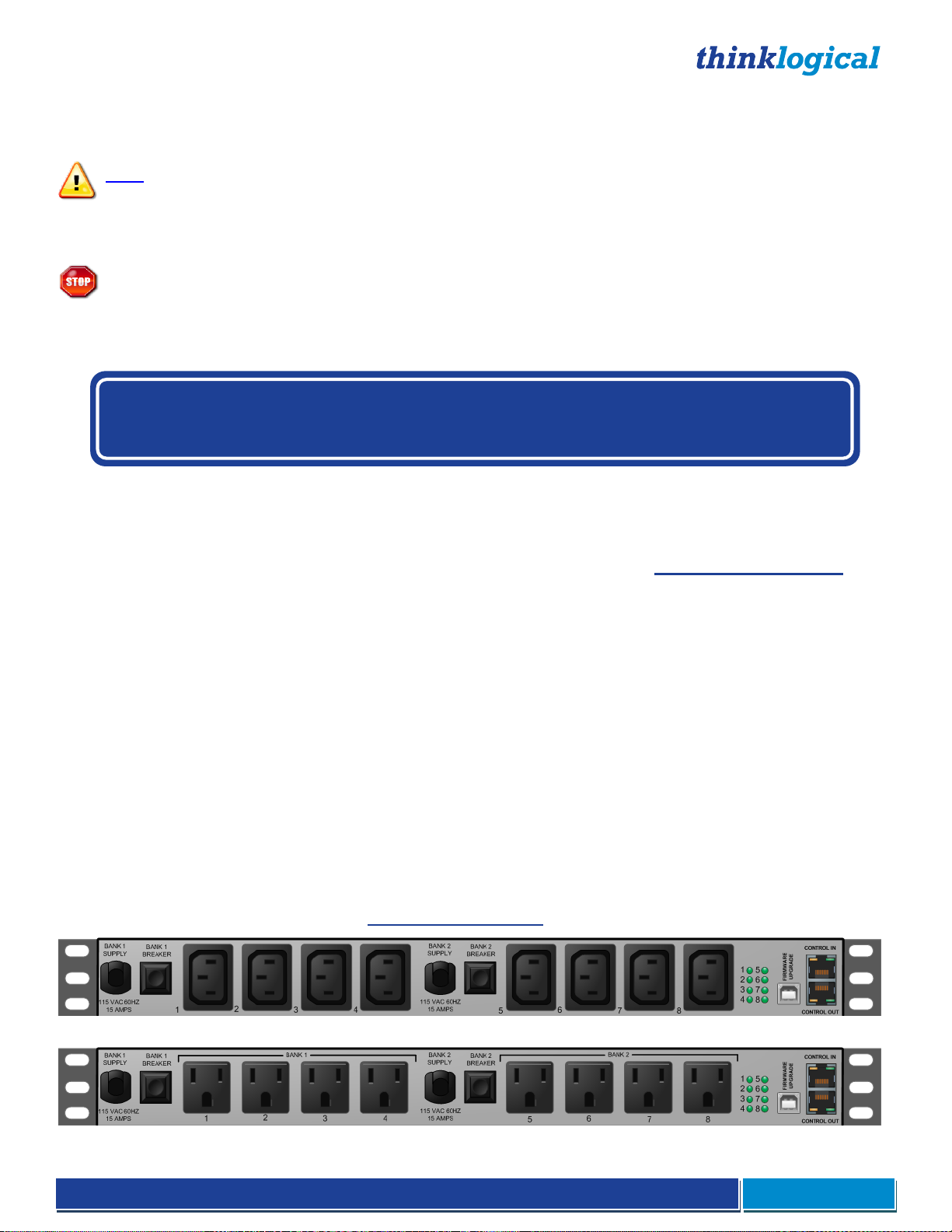

The Rear Panel

Power Connections

The rear panel features two outlet banks. Each bank consists of (1) AC Input Power Cord, (1) Power

Switch/Circuit Breaker, and (4) AC Power Outlets.

Bank 1 provides AC output power to Ports 1 through 4

Bank 2 provides AC output power to Ports 5 through 8

Domestic

Each AC Input Power Cord is outfitted with a NEMA 5-15P plug for all US/Domestic orders. Each Bank also

has a 15 Amp Power Switch/Circuit Breaker that supplies AC power to the bank of four switched outlets and

to the internal power supply. If only one Power Switch/Circuit Breaker is turned on, the internal, redundant

power supply will power the PDU and that one bank will provide AC output. If both banks are off, all outputs will

be off.

The four switched AC outlets per bank are NEMA 5-15R, nominal-115VAC power outlets. Bank 1 consists of

Ports/Outlets 1 through 4 and Bank 2 consists of Ports/Outlets 5 through 8. Each outlet is independently

controlled and can switch up to 10 Amperes. However, the total power draw for each bank of 4 outlet ports

must not exceed 15 Amperes.

Note: The total power draw for each bank of 4 outlet ports must not exceed 15 Amperes.

The two internal power supplies that are used to power the PDU system are redundant. This feature will allow

the unit to maintain power in the event of a DC Power Supply failure. Upon recovery from a power failure, the

PDU will return all Ports to the same state they were in prior to the power loss.

International

The International version of the PDU 4/4 has the same features as the Domestic version except for the

following:

Each of the (2) AC Input Power Cords are outfitted with an EU power plug.

Each of the (8) Switched AC Outlets are outfitted with a universal power outlet.

Status LEDs

The LEDs on the rear panel correspond to each of the (8) Switched AC Outlets. (For example, LED 1 shows

the status of Outlet/Port 1, LED 2 shows the status of Outlet/Port2, etc.) When the status light of an Outlet/Port

is green, the Outlet/Port has power.

USB Firmware Upgrade Port

There is a USB-B connector on the rear panel of the PDU for firmware upgrades. Firmware updates are

through a USB cable and an application that runs on a Windows (2000, XP, or Vista) PC.

Please visit http://ftp.thinklogical.com/ftp/visualization/updates for updates and instructions.

Serial Interface

The PDU 4/4 features (2) RJ45 serial connectors, labeled CONTROL IN and CONTROL OUT, on the rear

panel. If cascading multiple PDU units, the first PDU will be connected to the controlling terminal using the

CONTROL IN port. The CONTROL OUT port will be connected to the CONTROL IN port of the next unit using

a straight-through RJ45 cable, and so on.

Page 9

®

PDU 4/4 Product Manual September, 2014

Page 8

Installation

Secure

Console

Servers

SCS320 Secure Console Server

100-240V -, 0.5A, 50/60 Hz

T2A, 250 VAC

CAUTION!

Replace with same type and rating fuse.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

PORTS

NETWORK

CONSOLE

www.thinklogical.com

CPU or Terminal Device

To PDU 4/4 Units 3...16

Standard AC voltage OUT

(Unit 2 Bank 1)

PDU 4/4 Unit 1

PDU 4/4 Unit 2

Unit 1 Bank 1

Devices

Unit 2 Bank 1

Devices

Unit 2 Bank 2

Devices

Unit 1 Bank 2

Devices

Individual port status LEDs

Domestic PDU 4/4 Configuration

Standard AC voltage OUT

(Unit 2 Bank 2)

Standard AC voltage OUT

(Unit 1 Bank 1)

Standard AC voltage OUT

(Unit 1 Bank 2)

The PDU is designed to stand alone or to connect to a

Thinklogical Secure Console Server®. Each device port

of the Secure Console Server is a compatible RS-232

serial port designed to connect to the PDU’s CONTROL

IN port. The PDU is installed by first connecting to the

device port using commands in the Console Server, then

once connected, by using PDU commands.

Use an Ethernet cable to connect the desired device port to the PDU's CONTROL IN port. The connection is made

with the device port configured as follows:

Refer to the Console Server Manual for Console Server

information (available online at www.thinklogical.com

Port Setting for your Terminal Device

If your switch does not have a dedicated 'Power Manager' port, you may configure a serial port to the

following settings:

Configure an RS-232 serial port as a DTE (Data Terminal Equipment) port.

Configure the port for 9600 baud, 8 data bits, No Parity, 1 Stop Bit.

Cascading the PDU Chassis

If more than eight switched AC Power ports are required, the PDU 4/4 configuration can be expanded by daisychaining up to sixteen (16) PDU 4/4 chassis. The first PDU 4/4 assumes the “Master” role, with the Master PDU 4/4’s

CONTROL OUT Port connected to the next chassis CONTROL IN Port by an RJ45 serial cable.

Box IDs

Units are only assigned master or slave status after logging in. Before log in, all boxes display a box ID of 0. The first

box assumes the Master box ID of 1. Additional PDU 4/4 boxes are designated a “Slave” status and are

Page 10

®

PDU 4/4 Product Manual September, 2014

Page 9

automatically designated with the next sequential box ID (numbered 2 through 16). All commands issued to the

master unit referencing a slave unit will be passed on to the designated box. The program parameters for each PDU

4/4 are stored in that unit. The Master unit only passes commands to the slave units.

Note: If an intermediate unit in a daisy-chain of PDU 4/4’s loses power, the control and operation of

the PDU 4/4 configuration is interrupted at the unit without power.

Program Storage

All programmed data in the PDU 4/4 is stored in non-volatile memory. In the event of a power failure, the PDU 4/4

will return each port to its previous state (on or off) when power returns to the unit.

Note: Many PC-based communications packages can buffer the entered and displayed serial data so

that it may be copied and saved to a file. Users can then keep a copy of the programmed data for

reference.

Communicating with the PDU 4/4

Programming the System

The PDU 4/4 uses a simple serial user interface. It accepts commands from a serial terminal or terminal emulation

package. The command language also provides status information upon request.

In order to enter a command function, the user must gain access to the PDU 4/4 COMMAND MODE by entering a

password to log in. Each command is completed by pressing ‘Enter’ or ‘Carriage Return’ (<CR>).

Note: In this document, ‘Enter’, ‘Return’ and <CR> represent the same action.

Programming Access

Once connected to the PDU 4/4’s CONTROL IN serial port, the following access and programming commands

may be used. Invalid commands or unauthorized access attempts will not affect the PDU 4/4. The programming

interface will automatically log out after 5 minutes of idle time.

1. Connect your programming terminal to the CONTROL IN port.

2. Press ‘Enter’ on the keyboard to establish communication. Your display should show “Password:”

If you do not get a Password prompt (or other activity), check your connections and your terminal’s configuration.

Log In

The PDU 4/4 is password protected at Log In. The factory-set password is pass (case-sensitive) which should be

changed by the System Administrator.

When Logged In, the command prompt will display PDU 4/4>

Commands

Command Principles

Serial Access

Commands are executed from the Serial terminal. You must log in order to access any programming commands.

Abbreviation

Commands may be abbreviated by typing only enough characters to differentiate 1 command from another.

Ports and Groups

Commands can be entered for individual Ports, either by name or by number; for a range of port numbers separated

by a dash (e.g., 5-8), any combination of port numbers, separated by a comma (e.g., 1,4,5,8); or for a Port Group.

A Port Group is created by assigning the same name to more than one Port. (The example group name Sun will be

used throughout this instruction.) The port name can then be used in a PDU 4/4 command.

Page 11

®

PDU 4/4 Product Manual September, 2014

Page 10

Global Commands

For configurations using multiple PDU 4/4 chassis, many commands will accept a box ID of zero (0) to

generate a Global Command that will execute the desired operation in all connected boxes.

Global commands include 0 (zero) to operate all connected PDU 4/4 box ID’s, and ALL or all for all port IDs within a

chassis or a number of cascaded chassis.

Command Replay

Commands may be “replayed” by pressing the up arrow.

HELP Command

A HELP command provides a summary of the commands and syntax for the PDU 4/4. Type “help” and press

Enter to access the HELP file at any time after logging in.

Command Help

To check the syntax of a command, type help, space, and the command name.

PDU 4/4> help

exit close session

quit close session

buttons <b> <e | d> front panel button enable/disable

help display this help or help for a command

history display command history

name <b> <name> <p#> name outlets

off <b> <p> turn an outlet or group of outlets off

on <b> <p> turn an outlet or group of outlets on

passwd change password

reboot <b> <p> reboot an outlet or group of outlets

rbdelay <b> <p> <dly> port reboot off time before reset

status <b> display outlet status

version <b> display software version(s)

<b> = (box # | all) <d> = disable <dly> = delay <e> = enable

<n> = name <t> = time <p> = (port # | name | all)

help - Help Menu

Typing help from the command line will access the HELP menu, which reviews the programming parameters for the

PDU 4/4 system.

Typing help ‘command name’ will give specific information for each command.

Exit / Quit

The Exit Command logs off the user and returns a Session Ended message. You will be immediately logged off of

the system. The System will automatically timeout and log off after 5 minutes of idle time (no terminal activity).

Note: Logging In starts a Timer that will automatically log off the current user if no activity is detected

for 5 minutes. In this case, the user will see Session Timed Out.

Buttons - Front Panel Button Enable/Disable

The Front Panel Buttons can be disabled to prevent unauthorized control of the outputs of the PDU 4/4. The LED

indicators will continue to operate, solid green LED for ON and no indicator for OFF. If buttons are enabled, selecting

on/off from the front panel will turn that outlet on or off immediately.

Page 12

®

PDU 4/4 Product Manual September, 2014

Page 11

The following commands are in alphabetical order. Do not type the angle brackets < > when entering data.

PDU 4/4> help buttons

Syntax buttons <b> <e | d>

Description: Enable or disable front panel button control.

<b> = (box # | all) <d> = disable <dly> = delay <e> = enable

<n> = name <t> = time <p> = (port # | name | all)

Examples:

Enable Front Panel Button control on Box 1 buttons 1 enable

Disable Front Panel Button control on all PDU 4/4s buttons 0 disable

history – Display Command History

The history command will show the past 16 commands. This data is not stored in non-volatile memory.

PDU 4/4> help history

Syntax: history

Description: Display previous command history.

<b> = (box # | all) <d> = disable <dly> = delay <e> = enable

<n> = name <t> = time <p> = (port # | name | all)

name - Define Port Names

The name command allows the user to assign names to each of the ports. Ports with identical names are grouped

together since commands can be issued to control the boxes by name or by port number.

The Port Names can be changed to any string of 1 to 16 characters (including all printable characters) not including

‘space’ or ‘comma’. Port names cannot start with a number.

PDU 4/4> help name

Syntax: name <b> <p> <n>

Description: Max.16 alphanumeric characters. The name must not start with a number.

<b> = (box # | all) <d> = disable <dly> = delay <e> = enable

<n> = name <t> = time <p> = (port # | name | all)

Ports and Boxes may be referred to by all, name (implying a group) or number.

Ranges of ports may be specified as 1-4 = 1,2,3,4. All may also be used.

The Define Port Names command allows the user to give each port an alias and allows the grouping of outlets. The

Port Number is not changed or affected by renaming the port, and may always be used to control the port.

Examples:

name 1 Sun 1,3,5 assigns the alias of Sun to Box 1, Ports 1, 3, and 5

name 0 Sun 1-4 assigns the alias of Sun to all Boxes, ports 1 through 4

name 0 Sun ALL assigns the alias of Sun to all Boxes, all ports

Default names are ‘DEVICE1’ through ‘DEVICE8’ for Ports 1-8, respectively.

Port Names must be between one and sixteen characters, and can include any printable characters except for ‘space’

or ’comma’. Port names cannot start with a number.

Port Groups

Port Groups can be created and controlled by assigning identical names to two or more ports. All ports with identical

names within one PDU 4/4 are grouped together provided the user enters an operational command for that name.

All ports with identical names in ALL daisy-chained PDU 4/4 chassis will be controlled provided the user enters a

valid GLOBAL (box ID = 0) command.

Page 13

®

PDU 4/4 Product Manual September, 2014

Page 12

off – Turn a Port Off

The off command is used to turn off a port or group of ports.

PDU 4/4> help off

Syntax: off <b> <p>

Description: Turn an outlet or group of outlets off.

<b> = (box # | all) <d> = disable <dly> = delay <e> = enable

<n> = name <t> = time <p> = (port # | name | all)

Ports and Boxes may be referred to by all, name (implying a group) or number.

Ranges of ports may be specified as 1-4 = 1,2,3,4. All may also be used.

Any port may be referred to by either Port Numbers or Port Names. All ports with identical port names will be turned off

together (as a Port Group)

The keyword “all” is a valid argument

Examples:

Set Box 1, Ports 5 & 7 OFF off 1 5,7

Set all boxes, ports 1 through 5, OFF off 0 1-5

If Ports 1, 4 and 8 are named SUN in Box #2, then: off 2 SUN

set ports 1, 4 & 8 OFF in Box #2.

on – Turn a Port On

The on command is used to turn on a port or group of ports. If multiple ports are turned on in one command, the turn

on times are staggered by an “rbdelay” (reboot delay) value to each port.

PDU 4/4> help on

Syntax: on <b> <p>

Description: Turn an outlet or group of outlets on.

<b> = (box # | all) <d> = disable <dly> = delay <e> = enable

<n> = name <t> = time <p> = (port # | name | all)

Ports and Boxes may be referred to by all, name (implying a group) or number.

Ranges of ports may be specified as 1-4 = 1,2,3,4. All may also be used.

Any port may be referred to by either Port Numbers or Port Names. All ports with identical port names will be turned on

together (as a Port Group)

The keyword “all” is a valid argument

Examples:

Set Box 1, Ports 5 & 7 ON on 1 5,7

Set all boxes, ports 1 through 5, ON on 0 1-5

If Ports 1, 4 and 8 are named SUN in Box #2, then: on 2 SUN

sets ports 1, 4 & 8 ON in Box #2.

Note: In order to limit current surges, each port is turned on at “rbdelay” intervals. The first port in a

sequence will turn on immediately and the next will wait until its “rbdelay” has expired before turning

on, etc.

passwd - Change Password

The factory password of “pass” can be changed to any string of 1 to 16 characters (including all printable

characters), not including ‘space’ or ‘comma’, and the new password must not start with a number.

Page 14

®

PDU 4/4 Product Manual September, 2014

Page 13

PDU 4/4> help passwd

Syntax: passwd

Description: Change the log in password.

<b> = (box # | all) <d> = disable <dly> = delay <e> = enable

<n> = name <t> = time <p> = (port # | name | all)

PDU 4/4> passwd

Password: ***

Re-enter password: ***

reboot - Reboot Output

The Reboot Output command is used to turn a port, or ports, off, and then back on. The purpose is to ‘reboot’ a

server or device by cycling the power. Ports that are currently off will be turned on. Ports that are currently on will be

turned off, then back on. The reboot time duration for each port is assigned in the rbdelay time option.

Any Port may be referred to by either Port Numbers or Port Names. All ports with identical port names will be rebooted

together (i.e., a Port Group)

The keyword “all” is a valid argument

PDU 4/4> help reboot

Syntax: reboot <b> <p>

Description: Reboot an outlet or group of outlets.

<b> = (box # | all) <d> = disable <dly> = delay <e> = enable

<n> = name <t> = time <p> = (port # | name | all)

Ports and Boxes may be referred to by all, name (implying a group) or number.

Ranges of ports may be specified as 1-4 = 1,2,3,4. All may also be used.

Examples:

Reboot Box 1, Port 8 reboot 1 8

Reboot Box 1, Ports 1, 5, and 7 reboot 1 1,5,7

Cycle all outputs OFF/ON in Box #1 reboot 1 all

If Ports 1,2,3 in Box 2 are defined as SUN2, then reboot 2 SUN2

to Reboot ports 1,2,3 in box 2

Reboot all outputs in all boxes. reboot 0 all

Note: If any of the selected ports are already ON, they will be power cycled OFF, then after a delay,

back ON. Or if any of the selected ports are OFF, they will be power cycled ON.

rbdelay - Set Reboot Time

The reboot delay command sets the time duration that a Port will remain off before turning back on after issuing a

Reboot Command to the PDU 4/4. The Time duration is adjustable from 1 to 29 seconds. Each Port may be

individually programmed.

PDU 4/4> help rbdelay

Syntax: rbdelay <b> <p> <time>

Description: Time (1 to 29 seconds) an outlet remains off before turning back on.

<b> = (box # | all) <d> = disable <dly> = delay <e> = enable

<n> = name <t> = time <p> = (port # | name | all)

Ports and Boxes may be referred to by all, name (implying a group) or number.

Ranges of ports may be specified as 1-4 = 1,2,3,4. All may also be used.

Page 15

®

PDU 4/4 Product Manual September, 2014

Page 14

status - Display Port Status

Using the status command, the user can get a snapshot report of the status of each port.

PDU 4/4> help status

Syntax: status <b>

Description: Display outlet status for all connected PDU8(s)

<b> = (box # | all) <d> = disable <dly> = delay <e> = enable

<n> = name <t> = time <p> = (port # | name | all)

PDU 4/4> status 1

Box Number 1

Button function is Enabled

Temperature is 26 degrees C

Output Name Status Delay Current (mA)

1 Port1 OFF 12 0mA

2 Port2 OFF 12 0mA

3 Port3 OFF 12 0mA

4 Port4 OFF 12 0mA

5 Port5 OFF 12 0mA

6 Port6 OFF 12 0mA

7 Port7 OFF 12 0mA

8 Port8 OFF 12 0mA

Bank 1 Current Approx. mA (15A Max.)=0

Bank 2 Current Approx. mA (15A Max.)=0

OK

Page 16

®

PDU 4/4 Product Manual September, 2014

Page 15

PDU 4/4 Technical Specifications

PDU 4/4 AC Power Distribution Unit

Storage Temperature

-20 to 70°C (-4 to 158°F), 10 to 90% RH, non-condensing

Power Supply Voltage

100 to 240 VAC, 50/60 Hz

Power Consumption

10 Watts, typical

Heat Dissipation

34 BTUs per hour

Panel Connectors

(2) AC Power Cords

(2) Power Switch/Circuit Breakers

(8) AC Power Outlets

(8) Port Status LEDs

(1) USB-B - Firmware Upgrade Port

(2) Dual RJ45 – Control In/Out Serial Ports

Front Panel Display

2 x 24 Liquid Crystal Display

Operating Temperature & Humidity

0 to 50 °C (32 to 122 °F); 5 to 95% RH, non-condensing

Enclosure Dimensions

Approx. 12.25in x 17.50in x 1.75in high

(31.1cm x 44.5cm x 4.4cm high)

Weight

Shipping Weight

11 lb (4.99 kg)

18 lb (8.16 kg)

Compliance

Approvals for US, Canada and European Union

Warranty

12 months from date of shipment. Extensions available.

PDU Models available from Thinklogical:

PDU-000001 PDU 4/4, AC Power Distribution Unit, Domestic, Serial Interface

PDU-000003 PDU 4/4, AC Power Distribution Unit, International, Serial Interface

PDU-000002 PDU2, 4x +5VDC Power Distribution Unit (PDU2 manual is on our website)

PDU-000012 PDU-12, 12x +5VDC Power Distribution Unit (PDU-12 manual is on our website)

2. Regulatory & Safety Requirements

Symbols Found on Our Products

Markings and labels on our products follow industry-standard conventions. Regulatory markings found on our

products comply with domestic and most international requirements.

Regulatory Compliance

Thinklogical® products are designed and made in the U.S.A. Products have been tested by a nationally

recognized testing laboratory and found to be compliant with the following standards (both domestic USA and

many international locations).

Page 17

®

PDU 4/4 Product Manual September, 2014

Page 16

North America

These products comply with the following standards:

Safety

ANSI/UL60950-1: 1st Edition (2003)

CAN/CSA C22.2 No. 60950-1-03

LASER Safety

CDRH 21CFR 1040.10

Class 1 LASER Product

Electromagnetic Interference

FCC CFR47, Part 15, Class A

Industry Canada ICES-003 Issue 2, Revision 1

Australia & New Zealand

This is a Class A product. In a domestic environment this product may cause radio interference, in which case

the user may be required to take adequate measures.

European Union

Declaration of Conformity

Manufacturer’s Name & Address: Thinklogical, LLC®

100 Washington Street

Milford, Connecticut 06460 USA

Telephone: 1-203-647-8700

Product Name

PDU 4/4. Models: PDU-000001 (domestic), PDU-000003 (international)

These products comply with the requirements of the Low Voltage Directive 72/23/EEC and the EMC Directive

89/336/EEC.

Standards with Which Our Products Comply

Safety

CENELEC EN 60950-1, (2006)

LASER Safety

IEC60825:2001 Parts 1 and 2

Class 1 LASER Product

Electromagnetic Emissions

EN55022: 1994 (IEC/CSPIR22: 1993)

EN61000-3-2/A14: 2000

EN61000-3-3: 1994

Electromagnetic Immunity

EN55024: 1998 Information Technology Equipment-Immunity Characteristics

EN61000-4-2: 1995 Electro-Static Discharge Test

EN61000-4-3: 1996 Radiated Immunity Field Test

EN61000-4-4: 1995 Electrical Fast Transient Test

EN61000-4-5: 1995 Power Supply Surge Test

EN61000-4-6: 1996 Conducted Immunity Test

EN61000-4-8: 1993 Magnetic Field Test

EN61000-4-11: 1994 Voltage Dips & Interrupts Test

Page 18

®

PDU 4/4 Product Manual September, 2014

Page 17

Supplementary Information

The following statements may be appropriate for certain geographical regions and might not apply to your

location.

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigencies du Règlement sur le matérial

brouilleur du Canada.

Warning! This is a Class A product. In a domestic environment, this product may cause radio

interference, in which case the user may be required to take adequate corrective measures.

Note: This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications in which case the user may be required to take adequate

corrective measures at their own expense.

Note: This Class A digital apparatus complies with Canadian ICES-003 and has been verified as

being compliant within the Class A limits of the FCC Radio Frequency Device Rules (FCC Title

47, Part 15, Subpart B CLASS 1), measured to CISPR 22: 1993 limits and methods of

measurement of Radio Disturbance Characteristics of Information Technology Equipment.

Note:

fields

Note:

be needed to comply with Immunity Requirements

The user may notice degraded audio performance in the presence of electromagnetic

.

If using a keyboard that is noise susceptible, a ferrite ring on the keyboard cable may

Product Serial Number

Thinklogical products have a unique serial number, which includes a date-code, printed on an adhesive label

that is affixed to the unit. The format for the date-code is 2 digits for the month, dash, 2 digits for the year, plus

four digits for a unique unit number. For example, 05-140125 indicates the unit was built in the 5th month of

2014, and is unit number 125. Connection to the Product

Connection to the Product

Connections and installation hardware for our products use industry-standard devices and methods. All wiring

connections to the customer equipment are designed to minimize proprietary or customized connectors and

cabling. Power connections are made with regionally appropriate power cords and approved methods.

Page 19

®

PDU 4/4 Product Manual September, 2014

Page 18

3. Thinklogical Support

Thank you for choosing Thinklogical® products for your application.

We appreciate your business and are dedicated to helping you successfully use our products.

is always here to help you.

To contact us, please use the following telephone numbers and internet-based methods:

®

Customer Support

Thinklogical is an engineering company and you will receive any information you require directly from

our most knowledgeable engineers. We believe that the first lines of support are design engineers that

developed each particular product. Therefore, your questions will be handled promptly by our in-house

engineers who are most familiar with your products.

Website

Check out our website for current product offerings, support information and general information about all of

the products we offer, including product information on all current systems, technical specification sheets, quick

start guides (for viewing online or for download), product diagrams showing physical connections and other

helpful information.

Internet: www.thinklogical.com

Note: Most online documents are stored as Adobe Acrobat “PDF” files. If you do not have the

Adobe Acrobat reader needed to view PDF files, visit www.adobe.com for a download.

Email

Thinklogical is staffed Monday through Friday from 8:30am to 5:00pm, Eastern Time Zone. We will do our

best to respond to your email inquiries promptly. Please use one of the following email addresses:

info@thinklogical.com – Information on Thinklogical® and our products.

sales@thinklogical.com – Sales Department - orders, questions or issues.

support@thinklogical.com – Product support, technical issues or questions, product

repairs and request for Return Authorization.

Telephone

Product & Customer Support: 1-203-647-8700

US Commercial & Canada Sales: 1-203-647-8769

US Federal Government Sales: 1-203-647-8716

Toll Free in the Continental US: 1-800-291-3211

International Sales (Europe, Middle East, Africa): 1-203-647-8704

International Sales (Asia Pacific, Central & Latin America): 1-203-647-8734

Fax: 1-203-783-9949

Please contact our expert sales staff in Milford, CT. We are here Monday through Friday from 8:30am to

5:00pm, Eastern Time Zone. We’ll provide a representative’s direct dial phone number when you call.

Page 20

®

PDU 4/4 Product Manual September, 2014

Page 19

If leaving a voice message, please provide a preferred time to call back so we may reach you at your

convenience.

Our switchboard attendant will direct your call during regular business hours. We have an automated attendant

answering our main telephone switchboard after regular business hours and holidays. You can leave voice

messages for individuals at any time.

Fax

Our company facsimile number is 1-203-783-9949. Please indicate the nature of the fax on your cover sheet

and provide return contact information.

Product Support

Thinklogical’s support personnel are available Monday through Friday from 8:30am to 5:00pm, Eastern Time

Zone. If your application might require assistance at some time outside of our normal business hours, please

contact us beforehand and we will do our best to make arrangements to help you with your Thinklogical

products.

Warranty

Thinklogical® warrants this product against defects in materials and workmanship for a period of one year from

the date of delivery. Thinklogical and its suppliers disclaim any and all other warranties.

Note: Thinklogical products carry a one year warranty, with longer term available at time of

purchase on most products. Please refer to your product invoice for your products Warranty

Terms & Conditions.

Defect remedy shall be, repair or replacement of the product, provided that the defective product is returned to

the authorized dealer within a year from the date of delivery.

If you wish to return your device, contact the Thinklogical-authorized dealer where you purchased the device,

or if you purchased directly, call Thinklogical at 1-800-291-3211 (USA).

Return Authorization

If you have any issue with any Thinklogical product, have product questions or need technical assistance with

your Thinklogical system, please contact Customer Support at 1-800-291-3211 (USA only) or 1-203-647-

8700 and let us help.

If you must return a product to Thinklogical® directly, Customer Support will ask you to describe the problem

and will issue you a Return Merchandise Authorization number (RMA#).

Pack the device in its original box, if possible, and return it with the RMA# on the box.

Note: Do not return a product to Thinklogical® without a Return Material Authorization Number.

Return address for products with Return Material Authorization:

Thinklogical, LLC®

Attn: RMA#

100 Washington Street

Milford, CT 06460 USA

PH: 800-291-3211 (USA only)

Page 21

®

PDU 4/4 Product Manual September, 2014

Page 20

Appendix A: PDU 4/4 Quick Start Guide

QUICK START

GUIDE

QUICK START

GUIDE

PDU 4/4

CPU or Terminal Device

To PDU 4/4 Units 3...16

Standard AC voltage OUT

(Unit 2 Bank 1)

PDU 4/4 Unit 1

PDU 4/4 Unit 2

Unit 1 Bank 1

Devices

Unit 2 Bank 1

Devices

Unit 2 Bank 2

Devices

Unit 1 Bank 2

Devices

Individual port status LEDs

Each PDU4/4 system includes the following

features:

Eight individually-controlled AC power outlets

(available for both domestic and international)

Dual 15 Amp (max) circuits, four outlets per

circuit

Redundant DC power supplies for built-in I/O

and control circuits

Individually programmable Reboot Time

Delay on each outlet

Solid state zero-crossing relays to minimize

power spikes

Easily expandable configuration

Password Security User-definable Port Names and Port Groups

Front panel display for easy system set up

and configuration

Current monitoring of each port.

The PDU 4/4 is designed for desktop or 19"

rack mounting (1U).

Software updates available at

ftp.thinklogical.com

PDU_4-4_Domectic_manual_QSG

Domestic PDU 4/4 Configuration

Standard AC voltage OUT

(Unit 2 Bank 2)

Standard AC voltage OUT

(Unit 1 Bank 1)

Standard AC voltage OUT

(Unit 1 Bank 2)

Thinklogical’s® PDU 4/4 Power Distribution Unit is an AC Power Switch that remotely controls power to up to eight devices per unit.

The PDU 4/4 communicates with its control terminal using a serial interface and provides control to all devices with simple commands to turn power off or

on to reboot any one port, multiple ports, port groups or all devices.

Power restarts can be sequenced using programmed time delays to minimize surge or allow drive spin-up time.

Your configuration can be easily expanded with one serial cable for each PDU 4/4 unit added .

A single serial interface integrates the control of all PDU 4/4s in your application.

Up to sixteen PDU 4/4s can be cascaded together to control multiple systems from one common user interface.

Each outlet individually switches up to 10 Amperes maximum with each bank rated at 15 Amperes total.

Each PDU 4/4 utilizes two banks of four outlets and rear panel LEDs display the status of each port.

The on command is used to turn on a port or group of ports. Any port may be referred to by either Port Numbers or Port Names. All ports with identical port names will be turned on together (as a Port Group).

The off command is used to turn off a port or group of ports.

The reboot output command is used to ‘reboot’ a server or device by cycling power to a port or ports. Refer to the user’s manual for further commands.

Once connected to the PDU 4/4’s CONTROL IN serial port, the following access and programming commands may be used:

Press ‘Enter’ on the keyboard to establish communication. Your display will show “Password:” The factory-set password is pass and may be changed by the System

Administrator. When Logged In, the command prompt will show “PDU 4/4>”. Commands are executed from the Serial Terminal.

Loading...

Loading...