Page 1

PCC

1274

–

Issue

4

-

GB

THETFORD

LIMITED,

19 Oakham Drive

, Parkwood Industrial

Estate

USER AND INSTALLATION INSTRUCTIONS

USER AND INSTALLATION INSTRUCTIONS

FOR USE IN :- GB, IE, FR, NL, BE, LU, ES, IT, NO, DE, DK, SE

WARNING

• Read the instructions before use.

• Only use this appliance in a well ventilated area.

• This appliance must be installed in accordance with the regulations in force.

Rutland Road, Sheffield S3 9QY, ENGLAND.

TEL: + 44 (0) 114 273 8157 FAX: + 44 (0) 114 275 3094

Page 2

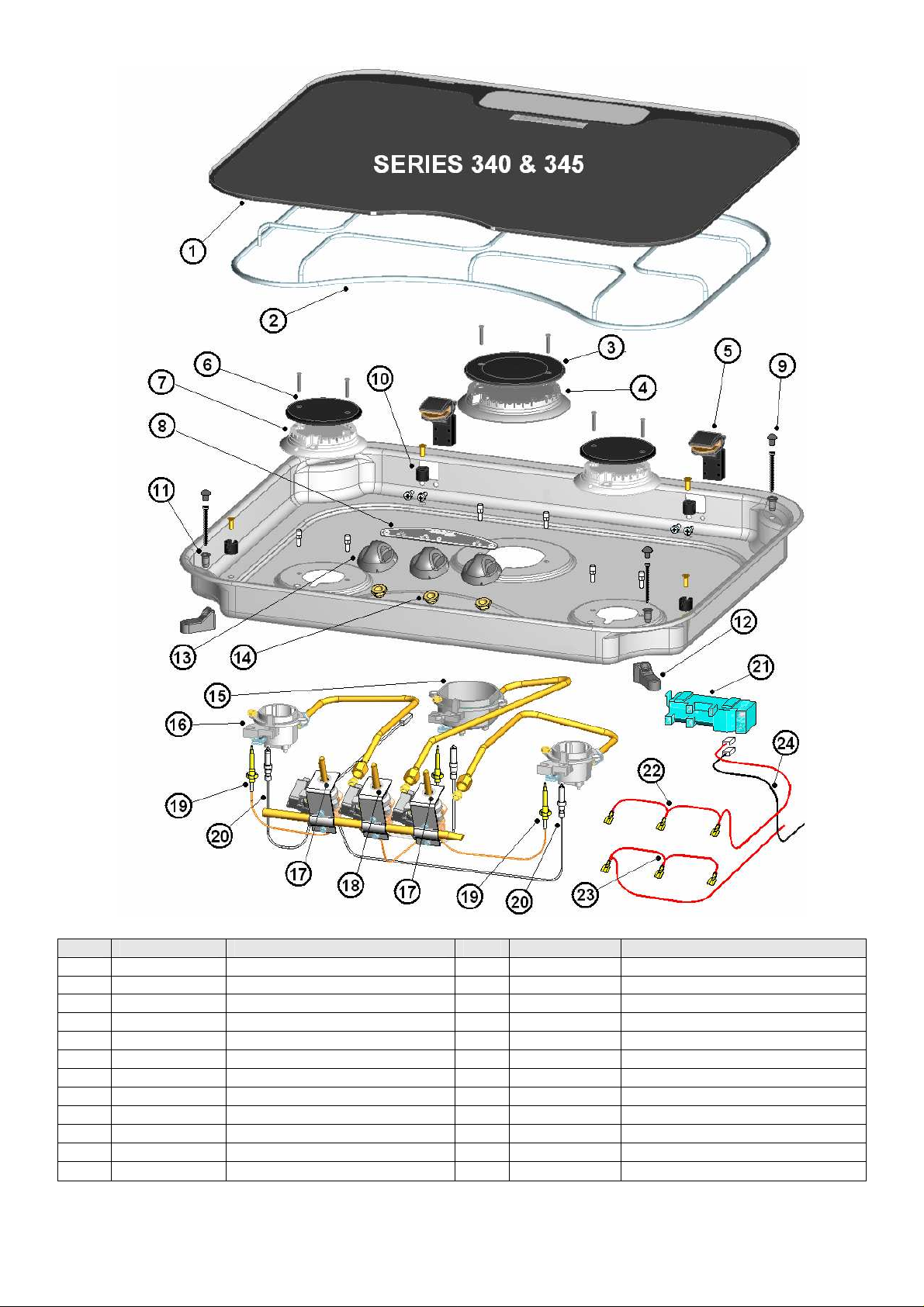

ITEM

1 S~G930.BK GLASS LID 2 S~PCC0691 PAN SUPPORT

3 S~PCC0833 RAPID BURNER CAP 4 S~PCC0832 RAPID BURNER SPREADER

5 S~PCC2003 HINGE 6 S~PCC0813 BURNER CAP

7 S~PCC0812 BURNER SPREADER 8 S~PCC1500 STICK ON FASCIA

9 S~PCX0390 BUMP STOP 10 S~PCC0647 PAN SUPPORT CLIP

11 S~PCX0415 FIXING BUSH 12 S~PCX0416 CLAMPING ARM

13 S~PCC0609 CONTROL KNOB 14 S~PCC0742 TAP FIXING NUT

15 S~PCC0799 RAPID BURNER CUP 16 S~PCC0797 BURNER CUP

17 S~PCC0737 CONTROL TAP (0.34 Bypass) 18 S~PCC07739 CONTROL TAP (0.45 Bypass)

19 S~PCC1130 THERMOCOUPLE 190MM 20 S~PCC1455 SPARK PROBE 600MM

21 S~PCC1403 SPARK GENERATOR (12V) 22 S~WIR0504 +VE WIRE TO GENERATOR

23 S~WIR0505 +VE WIRE TO BATTERY 24 S~WIR0200 -VE WIRE TO BATTERY

PART No DESCRIPTION ITEM PART No DESCRIPTION

2

Page 3

ITEM PART No DESCRIPTION ITEM PART No DESCRIPTION

1 S~G0940 GLASS LID 2 S~PCC0693

3 S~PCC0813 BURNER CAP 4 S~PCC0814

5 S~PCX0390 BUMP STOP 6 S~PCX0415 FIXING BUSH

7 S~PCC2003 HINGE 8 S~PCC647 CLIP, PAN SUPPORT

9 S~PCC1500 STICK ON FASCIA 10 S~PCX0416

11 S~PCC0609 CONTROL KNOB 12 S~PCC0742

13 S~PCC0797 BURNER CUP 14 S~PCC1190

15 S~PCC1453 SPARK PROBE 300MM 16 S~PCC0737

17 S~PCC1403 SPARK GENERATOR 18 S~WIR0505 +VE WIRE TO BATTERY

19 S~WIR0504 +VE WIRE TO GENERATOR 20 S~WIR0501 -VE WIRE TO BATTERY

21 S~PCC1132 THERMOCOUPLE 450MM 22 S~PCC1455 SPARK ELECTRODE 450MM

PAN SUPPORT

BURNER SPREADER

CLAMPING ARM

TAP FIXING NUT

THERMOCOUPLE 190MM

CONTROL TAP

3

Page 4

FIG. 1 OFF FULL RATE LOW RATE

CONTROL POSITIONS – ALL MODELS

FIG 2

RECOMMENDED PAN SIZES

SERIES 330 SERIES 340 & 345

4

Page 5

APPLIANCE LOCATION

Series 330, 340 & 345 the minimum allowable distance to combustible

materials is as shown below

FIG. 3

A= 200mm unless protected by a non-combustible heat barrier

B = 500mm minimum to fitment above appliance

5

Page 6

Fig. 4 WORKTOP CUTOUT – SERIES 330

A = Surface Mount Cutout

B = Flush Mount Cutout

6

Page 7

Fig. 5 WORKTOP CUTOUT – SERIES 340

A = Surface Mount Cutout

B = Flush Mount Cutout

7

Page 8

FIG. 6

SURFACE MOUNT FIXING – SERIES 330, 340 & 345

1 Surface mounting bezel 2 Glass Lid

3 Bump stop 4 Clamping bush

5 Worktop 6 Clamping arm

7 Clamping screw 8 Pressing

9 Flush mounting bezel

FIG. 7 FLUSH MOUNT FIXING – SERIES 330, 340 & 345

An additional 6mm deep rebate MUST be cut into the worktop to accept the

‘Flush Mounting Bezel’.

8

Page 9

CONTENTS

IMPORTANT

User’s Section

Specification ……………………………………………………Page 8

Introduction ……………………………………………………Page 9

Using the Appliance ……………………………………………………Page 10

Installation and Servicing

Installation Dimensions ……………………………………………………Pages 4-7

Specification ……………………………………………………Page 8

Installation Instructions ……………………………………………………Page 12

Maintenance & Servicing ……………………………………………………Page 13

Specification

Series 330 Series 340 Series 345

MODEL S~HB33000 S~HB34000 S~HB34500

Dimensions

(w x d X h)mm

480 X 480 X 100 540 X 445 X 100

540 X 445 X 100

Heat Input

Total heat input

Burner rating

Injector Size

Bypass Size

Spark Ignition

(Optional)

Sabaf 3 x 0.62mm Sabaf 3 x 0.62mm

Sabaf 3 x 0.34mm Sabaf 3 x 0.34mm

4.5kW 4.5kW 5.5Kw

3 x 1.5kW 3 x 1.5Kw

2 x 1.5kW

1 x 2.5kW

Sabaf 2 x 0.62mm

Sabaf 1 x 78mm

Sabaf 2 x 0.34mm

Sabaf 1 x 0.45mm

12v 12v 12v

Gas Category

CAT I3 + (28-30/37) CAT I

3

B/P

BUTANE (G30) 28 – 30 mbar BUTANE (G30) 30mbar

PROPANE (G31) 37mbar PROPANE (G31) 30mbar

• THIS APPLIANCE IS SUITABLE FOR USE WITH LIQUIFIED

PETROLEUM GAS (LPG) AND SHOULD NOT BE USED ON ANY

OTHER GAS

• USE ONLY THE GAS PRESSURES SPECIFIED ABOVE

• THIS APPLIANCE MUST BE EARTHED

9

Page 10

INTRODUCTION

IMPORTANT

This appliance is designed for cooking food, any other use is incorrect and dangerous. Failure

to install the appliance correctly or improper use could invalidate any warranty or liability claims

and lead to prosecution.

This appliance must be installed in accordance with the local, national and European

regulations in force. Particular attention shall be given to the requirements regarding ventilation.

Read the instructions before installing or using the appliance. The appliance MUST be installed

by an approved competent person.

Our policy is one of continuous development and improvement. Specifications and illustrations

may change subsequent to publication.

Provision of Ventilation

The use of a gas cooking appliance results in a production of heat and moisture in a room in

which it is installed. Ensure that the kitchen is well ventilated: keep natural ventilation holes

open or install a mechanical ventilation device, (mechanical extractor hood).

Prolonged intensive use of the appliance may call for additional ventilation, for example opening

a window, or more effective ventilation, for example increasing the level of mechanical

ventilation where present.

The room containing the cooker should have an air supply in accordance with local and

national/European standards.

Position

This appliance must be positioned free from draughts, which may affect the combustion, and in

a manner that will prevent the accumulation of unburnt gas. When in use ensure that air vents

are not inadvertently blocked or shut off.

Before using the appliance for the first time, remove any surface protection

film, ie plastic coating. Clean all surfaces with hot soapy water to remove any

residual protective covering of oil and rinse carefully.

10

Page 11

OPERATION

WARNING

IMPORTANT

Burner Operation

The burners on the appliance have fixed aeration and no adjustment is required. The burners

should flame as follows:-

Propane - The flames should burn quietly with a blue/green colour with no sign of yellow tips.

Butane - Normally on initial lighting, a small amount of yellow tipping will occur and then

• When cooking, young children should be kept away.

• Glass lids may shatter when heated. Turn off all burners before shutting

the lid.

• Spillage on the lid surface should be removed before opening the lid

slightly increases as the burner heats up.

• Series 330 - will support 200mm Ø pans on the outer burners and

180mm Ø pan on the central burner – see Fig. 2

• Series 340 & 345 will support 3 x 200mm Ø pans – see Fig. 2

• Avoid old or misshapen pans as these may cause instability.

• The lid must be opened fully prior to using the hotplate burners.

1. Ensure gas cylinder/supply is connected and turned on. In the event of a gas smell turn off at

gas cylinder/mains and contact supplier.

2. Flame supervision: Each burner is controlled individually and is monitored by a

thermocouple probe. In the event of the burner flames being accidentally extinguished, turn

off the burner control and do not attempt to re-ignite the burner for at least one minute.

3. To light: Push in the control knob and turn to full rate – see Fig.1. Hold a lighted match or

taper to the burner and push the control knob in and hold. It is necessary to hold the knob

depressed after the burner has ignited for approximately 10 - 15 seconds, to allow the

thermocouple probe to reach temperature, before releasing the knob. Should the flame go

out when the knob is released, the procedure should be repeated holding the knob

depressed for slightly longer.

4. For models fitted with optional Spark Ignition the procedure is similar:-

Models with Auto Spark Ignition – pushing the control knob automatically starts the

spark ignition circuit . To light the burner follow the procedure in (3) above except the

burner is automatically ignited.

Models with Manual Spark Ignition – follow the procedure in (3) above, except that the

burner can be ignited by depressing the ignition button located on the fascia.

If the burner has not lit within 15 seconds the control knob should be released and the

burner left for at least 1 minute before a further attempt to ignite the burner.

5. For simmering, turn the knob further anti-clockwise to the low rate position.

6. To turn off: Turn the control knob until the line on the control knob is aligned with the dot on

the control panel. Always make sure the control knob is in the off position when you have

finished using the hotplate burners.

11

Page 12

OPERATION

WARNING

DO'S AND DON'TS

DO read the user instructions carefully before using the appliance for the

DO allow the burners to heat before using for the first time, in order to expel any

DO clean the appliance regularly.

DO remove spills as soon as they occur.

DO check that controls are in the off position when finished.

DO NOT allow children near the appliance when in use. Turn pan handles away from the

DO NOT allow fats or oils to build up in the base of the hotplate.

DO NOT use abrasive cleaners or powders that will scratch the surfaces of the hotplate.

DO NOT under any circumstances use the appliance as a space heater.

LEAKS

If a smell of gas becomes apparent, the supply should be turned off at the cylinder

IMMEDIATELY.

Extinguish naked lights including cigarettes and pipes. Do not operate electrical switches. Open

all doors and windows to disperse any gas escape. Butane/Propane gas is heavier than air;

any gas escaping will therefore collect at low level. The strong unpleasant smell of gas will

enable the general area of the leak to be detected. Check that the gas is not escaping from an

unlit appliance. Never check for leaks with a naked flame; leak investigation should be carried

out using a leak detector spray or soapy solution.

The Glass lid has the tendency to snap shut towards the end of lowering.

This is caused by the travel lock action of the hinges as it is activated. Make

sure all fingers are removed from appliance when closing the lid.

first time.

smells before the introduction of food.

front so that they cannot be caught accidentally.

12

Page 13

INSTALLATION

REGULATIONS AND STANDARDS

In your own interest of safety this appliance must be installed in accordance with the local,

national and European regulations in force. Particular attention shall be given to the

requirements regarding ventilation. Read the instructions before installing or using the

appliance. The appliance MUST be installed by an approved competent person.

Failure to install the appliance correctly could invalidate any warranty or liability claims and lead

to prosecution.

VENTILATION

This appliance is suitable for installation into Holiday Homes, Touring Caravans and Boats. In all

cases the national standards with regard to ventilation for the particular vehicle into which the

appliance is to be installed must be adhered to.

The European Standard EN1949 - "Specification for the installation of LPG systems in leisure

and other road vehicles", specifies that all appliances be installed in accordance with the

manufacturers instructions, including the adequate provision to avoid the accumulation of unburnt gases. We recommend a vent in the floor (minimum=130mm2 , maximum=3850mm2)

venting to the outside, to avoid the accumulation of un-burnt gases.

LOCATION OF APPLIANCE

This appliance maybe installed in a kitchen/kitchen diner but NOT in a room containing a bath or

a shower. LP gas appliances must not be fitted below ground level. e.g. in a basement.

POSITION

A direct distance of 200mm must exist between the edge of the burner and combustible material

unless protected by a layer of non-combustible material - see fig. 3. For models with a glass lid,

the distance to the rear of the appliance can be reduced to 110mm.

All combustible materials such as curtains and shelves must be kept well clear of the appliance.

Any fitments such as a cupboard above the appliance must have a minimum clearance of

500mm between the fitment and the top of the pan support.

This appliance must be positioned free from draughts, which may affect the combustion, and in

a manner that will prevent the accumulation of unburnt gas. When in use ensure that air vents

are not inadvertently blocked or shut off.

The underside of the appliance must be shielded. It is recommended the shield is fabricated

from non-combustible material, but if the enclosure is manufactured from combustible material,

a minimum air space of 100mm must exist between the material and the lowest part of the

appliance. THIS AIR SPACE MUST BE WELL VENTILATED

13

Page 14

INSTALLATION

IMPORTANT

INSTALLATION

The appliance can be installed either onto the worktop or inset – ie flush fitting. A cut-out should

be prepared in the worktop as shown in Figs. 4 & 5. If the appliance is to be flush mounted the

worktop cut-out will require an additional rebate as detailed in Figs. 4 & 5. and shown in Fig. 7.

Care should be taken to position the appliance central in the worktop cut-out to ensure an air

gap is maintained between the appliance and the sides of the cut-out. The appliance may then

be fixed in position by tightening the clamp screws.

GAS CONNECTION

The gas connection is made to a 8mm Ø inlet pipe, beneath and to the rear of the appliance.

Prior to connection remove the plastic protection plug from the fitting. It is recommended that

the appliance be connected by copper pipe, rubber tubing MUST NOT be used.

• Where Spark Ignition is fitted the appliance MUST be earthed

• After Installation the appliance MUST be tested for soundness

• The gas supply input pressure to which this appliance is connected, MUST

not rise or fall by more than 2.5 mbar (butane/propane) from nominal when

ALL appliances connected to the supply are OPERATED simultaneously. If

this appliance is not installed in accordance with the instructions and

tolerances detailed herein, we the manufacturer can not be held responsible

for any problems that occur, or poor performance that is

perceived/witnessed.

MAINTENANCE & SERVICING

This appliance needs little maintenance other than cleaning. All parts should be cleaned using

warm soapy water. Do not use abrasive cleaners, steel wool or cleansing powders. When

cleaning the burner ring it is essential to ensure that the holes do not become blocked. The

control knobs are a push fit and can be removed for cleaning. They are interchangeable without

affecting the sense of operation.

ALL SERVICING MUST BE CARRIED OUT BY AN APPROVED COMPETENT PERSON.

AFTER EACH SERVICE THE APPLIANCE MUST BE CHECKED FOR GAS SOUNDNESS.

14

Loading...

Loading...