Page 1

Operating Instructions

Room control unit RSC and RSC-OT

Control System THETA

Page 2

Table of contents

USER LEVEL

Operating instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Operation start-up - language selection - device identification - standard display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Temperature settings required daytime temperature, required reduced temperature, required hot water temperature . . . . . . . . . . . . . . . . .7

Operational mode selection for heating and hot water (summary) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Function of operational modes holiday, absence, party, automatic, summer, permanent heating, permanent reduced heating, standby . . . . .9

Quick operational mode selection (automatic, party, absence, hot-water reloading) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Heating characteristics (heating curve) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Plant information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-133

Page 2

Page 3

PROGRAMMING LEVEL

LEVEL SUMMARY schematic block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-15

Level TIME PROGRAMS Programming, copying, reloading of standard programs, table for individual programs . . . . . . . . . . . . .16-22

Level TIME-DATE Time, calender year, calender month, calender day, automatic summer-/wintertime reset . . . . . . . . . . . . . .23

Level SYSTEM Language selection, clearing of time programs, control mode, summer switching-off . . . . . . . . . . . . . . . .22-26

Level DOMESTIC HOT WATER Economic temperature, legionella protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Level UNMIXED CIRCUIT Reduced mode, heating system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28-29

Alarm messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Technical specification

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Page 3

Page 4

Page 4

General operation

Operating instruments

Heating and set back programs

Displaying heating plant information

Setting heating characteristic

Setting daytime temperature

Setting domestic hot water temperature

Setting reduced temperature

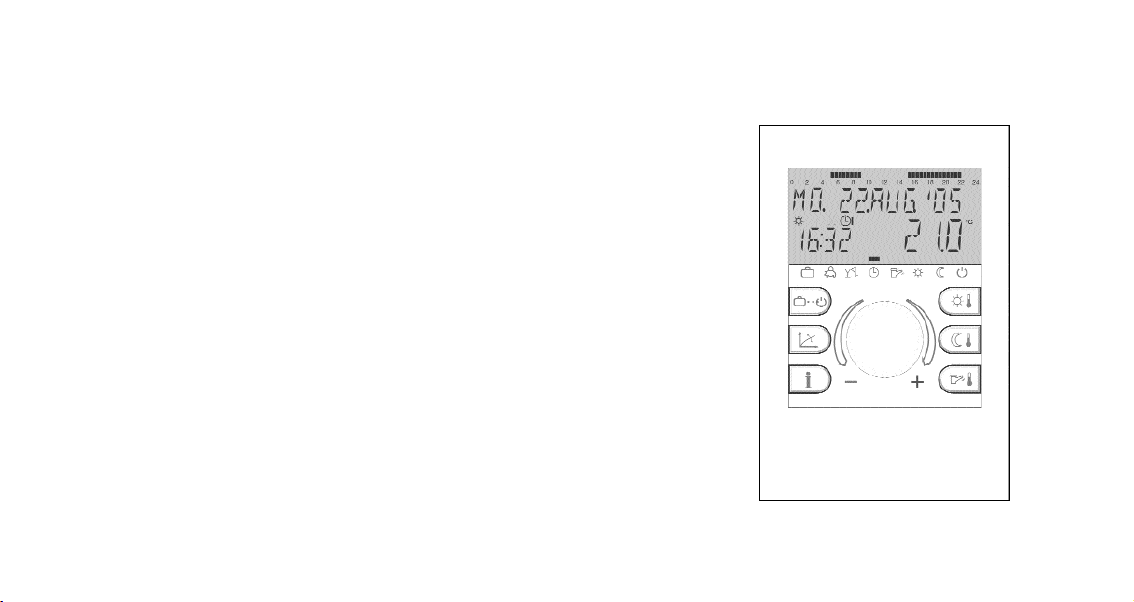

LCD-display

Rotary-push button

Page 5

Page 5

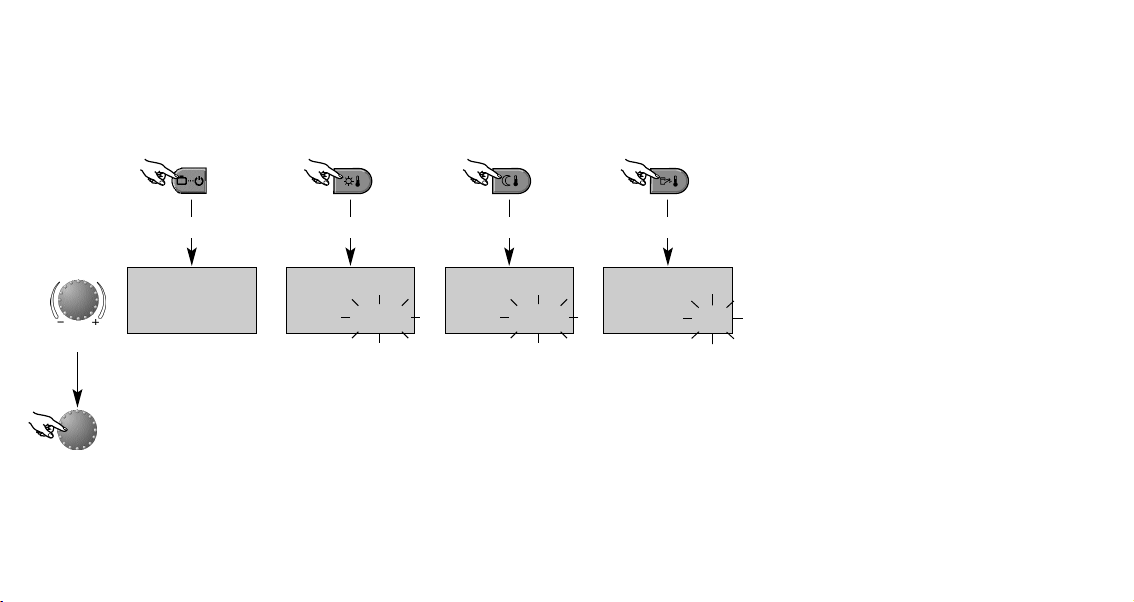

The center-positioned rotary-push button and the labeled keys guarantee a simple and easy operation.

It is however recommended to read this manual attentively to be informed about the repeating steps.

– Each value in the display appears flashing and can be modified with the rotary-push button.

A flashing display is appropriately marked in this manual.

Turn to the right (+): Increase values

Turn to the left (-): Decrease values

– Press once: Acceptance of the selected and indicated value, store.

– Keep pressed: Entry into the programming level (level selection),

The last operation step will be stored automatically after approx. 60 seconds if it was not stored by

means of the rotary-push button.

Turn: select parameters, change values

Press once: confirm, store

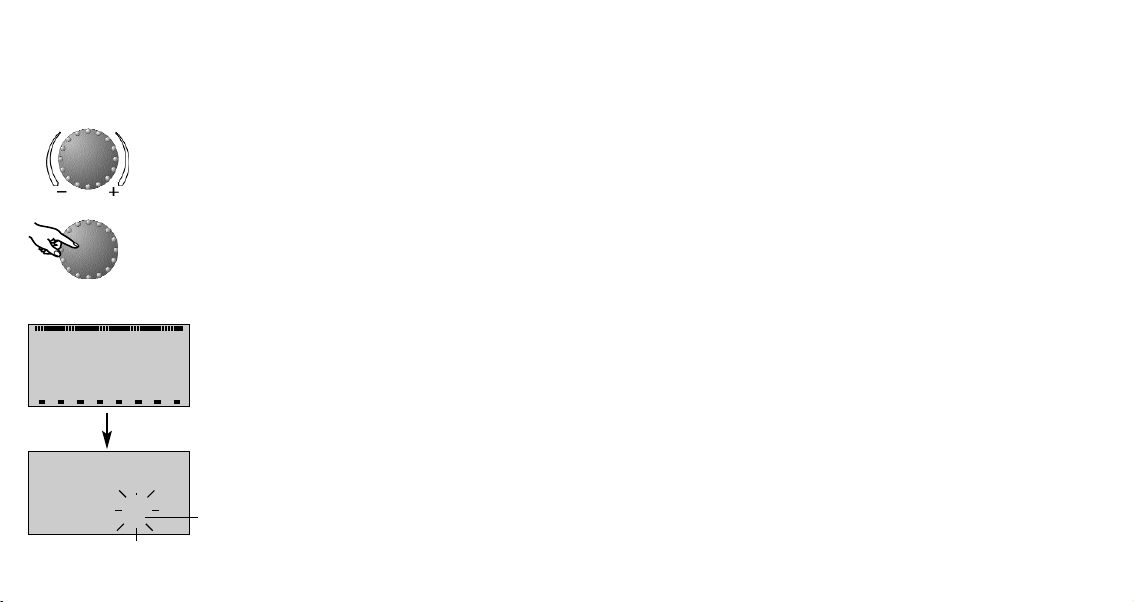

Start-up

In case of initiation of the plant or after every power failure a display test of the large display is carried out with automatic error diagnosis. At that all available segments and symbols will be displayed.

Language selection

In case of first initiation the desired language can be chosen after the display test. The languages DE,

GB, FR, IT, NL, ES, PT, HU, CZ, PL, RO, RU, TR, S, N can be selected.

Note: This display appears after every restart on day of first initiation until midnight. After that the

language can only be changed in the level SYSTEM - parameter LANGUAGE.

Symbolism used in this manual:

Operation

Language selection

Country code

DD

SPjACHWAHL

ff:f.f

f.f.f.f.f

f.f.f.f.f.f.f.f.f.f.f.f

°C

KWh

min

%

¾¾ ¿¿ ÀÀ ÁÁ ÄÄ

°C

KWh

min

%

Display test

0

2461012

18 2220

81416

24

Page 6

Page 6

Device identification

After the display test and/or the language selection the device identification momentary appears

with device type, interface and the corresponding number of software version.

Basic display

Provided that there is not any error message, the basic display indicates the date, time, heating

mode (

ë

= daytime temperature , ì= reduced set back temperature ) as well as the current boi-

ler temperature or, if released, the room temperature. Response time program. The cursor below

(

-

) indicates the current operating mode (see function of operating modes). The upper time bar

shows the heating periods and the corresponding operating times of the current weekday.

An activated summer switch-off is represented in the basic display by a sunshade symbol (

À

).

The heating mode symbols

ë

or ìwill be suppressed during an activated summer switch-off.

With acting frost protection function an ice crystal symbol appears in the basic display ( Á).

6622..55

1166::3322

MMOO.. 2222.. AAUUGG..;;0055

°C

ëë

0

2461012

18 2220

81416

24

Standard display

Actual boiler temperature

resp. room temperature

VV33..00

OOTT

RRSSCC

Device identification

Interface and software version

2222..55

1166::3322

MMOO.. 2222.. AAUUGG..;;0055

°C

ÀÀ

0

2461012

18 2220

81416

24

Standard display

Summer switching-off activated

2222..55

1166::3322

MMOO.. 2222.. AAUUGG..;;0055

°C

0

2461012

18 2220

81416

24

Standard display

Frost protection activated

ÁÁ

Heating cycles

Page 7

Page 7

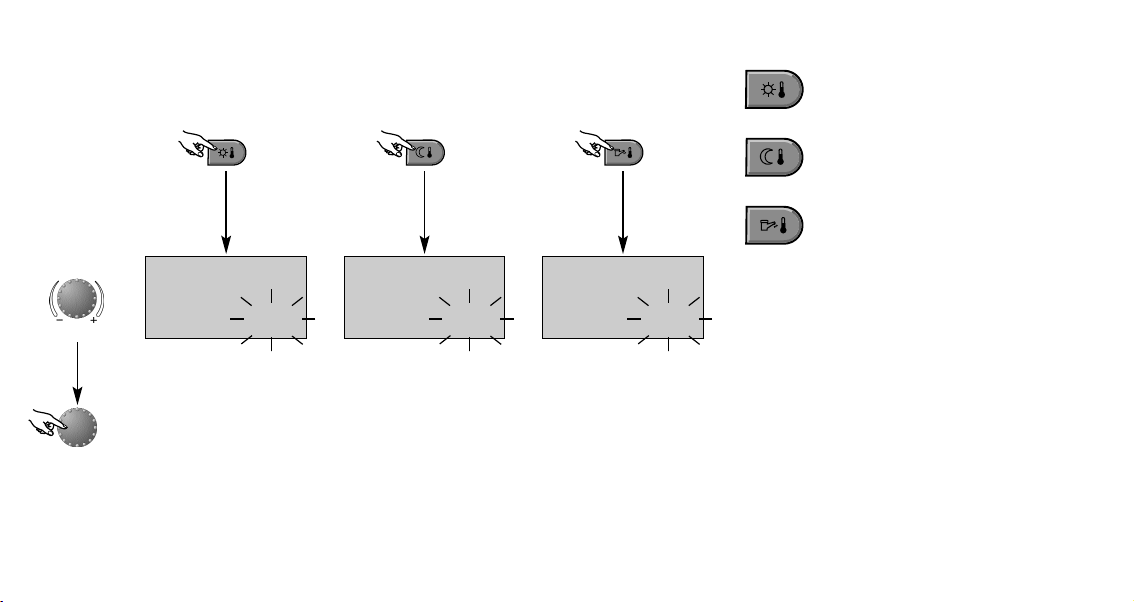

Setting range: 5.0 ... 30 °C

Factorypreset: 20 °C

This button is used to set the required daytime room temperature

T This button is used to set the required set

back room temperature

This button is used to set the required

domestic hot water temperature

Adjustment (standard display mode only):

After pressing the button for the required temperature the current value appears flashing and can

be adjusted directly with the rotary pushbutton.

Re-entry into the standard display is done by pressing the rotary-push button or the corresponding

temperature button or automatically after approx.

60 seconds.

20.0

jjOOOOMM-DDAAYY

°C

set

temperature

accept

Temperature settings

Setting range: 5.0 ... 30 °C

Factory preset: 16 °C

16.0

jjOOOOMM-NNIIGGHHTT

°C

Setting range: 5...80 °C

Factory preset: 50 °C

50.0

DDHHWW

°C

Required daytime

room temperature

Required set back

room temperature

Domestic hot water

temperature

DDAAYY

Page 8

Operational mode selection for heating and hot water

With this button the required operational mode is selected. It appears in plaintext on the display, simultanously a cursor at the lower edge of

the display points to the appertaining program symbol.

Select: Pressing the button

¢¢

, the previously selected operational mode appears flashing. The other operational modes can be selected and activa-

ted with the rotary-push button according to the following scheme.

Page 8

ABSENT TIL

STANDBY

27.08

HOLIDAY TTIL

02:30

PAjTY TTIL

HEATING

jED. HEATING

19:45

ABSENT TIL

AUTOMATIC

DDHHWW

SUMMEj

Entry into the previously selected heating operation mode

27.08

HOLIDAY TTIL

02

:

30

15:30

19

:

45

15:30

PAjTY TTIL

set date or time

Select required operational mode

Plant off

during holiday

Extend

heating operation

Domestic hot

water only

Interrupt

heating operation

Heating operation

via timer

Permanent

heating operation

Permanent red.

heating operation

Plant off

frost protection

accept, activate

activate, re-entry to standard display

Note: This mode is skipped in case of separate selection

(see »Function of operating modes« and »Level

SYSTEM - parameter CONTROL MODE«)

15:30

жзийклмн

жзийклмн жзийклмн жзийклмн жзийклмн жзийклмн жзийклмн жзийклмн

Page 9

Page 9

Functions of operational modes

Plant off

during holiday

24.09

1199::2277

HHOOLLIIDDAAYY TTIILL

19.30

1100::2277

AABBSSEENNTT TTIILL

02.27

1199::2277

PPAAjjTTYY TTIILL

1199::2277

MMOO.. 2222..AAUUGG.. ;;0055

1100::2277

SSUUMMMMEERR

1199::2277

HHEEAATTIINNGG

1199::2277

jjEEDD.. HHEEAATTIINNGG

19.0

1199::2277

SSTTAANNDDBBYY

°C

45.0

°C

72.0

°C

24.0

°C

56.5

°C

Interrupt

heating operation

Extend

heating operation

Heating operation

via timer

Domestic hot

water only

Permanent

heating operation

Permanent red.

heating operation

Plant off

frost protection

Setting range:

Actual date... actual

date + 250 days

Return to the previ-

ously selected operational mode at

0.00 o’clock of the

set return date.

Hot water operation is set to frost

protection temperature of 5 °C.

Earlier

termination:

Press button ¢,

select required operational mode with

rotary-push button

and press again to

activate.

Operating times:

(see level TIME PRO-

GRAMS)

Heating and domestic hot water operation automatically

according to settings

of temperature values (see Temperature

settings) and selected

operating times program.

Programming of individual operating times

see level TIME PRO-

GRAMS).

Setting

range

P1:

Heating operation is

interrupted until next

switching-on time of

current operating time

program (see level

TIME PROGRAMS)

0.5 ...24h:

Heating operation

is interrupted until

set time of return.

Earlier

termination:

Press button ¢,

select required operational mode with

rotary-push button

and press again to

activate.

Setting

range:

P1:

Heating operation is

continued until next

switching-on time of

current operating time

program (see level

TIME PROGRAMS)

0.5 ...24h:

Heating operation

is continued until

end of party.

Earlier

termination:

Press button ¢,

select required operational mode with

rotary-push button

and press again to

activate.

Operating times:

(see level TIME PRO-

GRAMS)

Only hot water operation according to

settings of hot water

temperature (see

Temperature settings)

and selected operating times program.

The heating operation is interrupted and

frost protected.

Programming of individual operating times

see level TIME PRO-

GRAMS).

Permanent heating

and reduced hot

water operation

round the clock

according to the

settings of daytime

room temperature

and domestic hot

water temperature

(see Temperature

settings)

Permanent reduced heating and

reduced hot water

operation round

the clock according

to the settings of set

back temperature

(see Temperature

settings), reduced

heating mode (see

level UNMIXED

CIRCUIT) and hot

water economic

temperature (see

level DHW).

Heating and hot

water plant completly switched off

except for frost

protection mode.

жзийклмн

жзийклмн жзийклмн жзийклмн жзийклмн жзийклмн жзийклмн жзийклмн

Page 10

Manual hot water loading

To activate manual hot water loading outdoor of operation times the button

§§

has

to be pressed for about 3 seconds. This

turns on hot water preparation at any time

for a period which may to be adjusted with

the rotary pushbutton between 0 ...240

minutes. Pushing the rotary pushbutton

activates loading. Afterwards the controller

returns to program operation.

At adjustment 0.0 the loading is independent

of any time period. The tank will be loaded

up to the set DHW-temperature value once.

Short-time operational modes

Frequently used operating modes such as

PARTY or ABSENT or reloading the hot

water tank during set back mode can be selected quickly according to the left scheme.

Direct automatic mode

Pressing button

¢¢

for approx. 3 seconds

activates the automatic mode via timer inevitably. Functions and setting range see

Operational mode selection for heating and

hot water - Function of operational modes.

PPAAjjTTYY TTIILL

modify

if required

Quick operational mode selection

AABBSSEENNTT TTIILL

Setting range: 0...240 min

Factory preset: 0.0 min

0.0

11 TTIIMMEE DDHHWW

Party mode Absence mode Manual hot water loading

Page 10

3 sec 3 sec3 sec

02:50 19:45

min

MMOO.. 2222.. AAUUGG..;;0055

activate

Automatic mode

3 sec

62.5

1166::3322

°C

Page 11

This button regulates the heating characteristics of the heating circuit in relation to outdoor temperature.

The adjustment is dependent of the plant installation and

shows the relation between outdoor temperature and

heat generator (boiler) temperature.

The slope sets the change of the supply temperature, if the

outdoor temperature changes for 1 K.

Re-entry into the standard display is done be pressing

the button

££

again or automatically after approx.

60 seconds.

Setting the heating characteristics (heating curve)

Page 11

Diagram of heating curves

2.00

1.75

1.50

1.25

1.00

0.75

0.50

0.20

20 16 12 8 4 0 -4 -8 -12 -16 -20 Outdoor temp.(°C)

100

90

80

70

60

50

40

30

20

Heat generator temperature (°C)

(factory preset)

1.50

HHCC

HHEEAATT..CCUURRVVEE

Setting range: OFF (heating circuit eliminated)

0,20...3,50

Factory preset: 1,50

Modify

Slope

Store modification

Note: The heating slope should be modified only in small steps

and left for a while until steady condition can be obtained.

Changes to the slope should be made in intervalls of 0.1

every 1 or 2 days.

Page 12

This button displays all plant temperatures

and states of all circuits. The information can

be requested according to the direction with

the rotary-push button.

Turning rotary-push button clockwise

displays from all plant-specific temperatures

– the actual values and

– the nominal values (pressing rotary-push button)

– meter readings such as consumption data etc.

Turning rotary-push button anti-clockwise

displays from direct heating circuit resp. DHW circuit

– operational mode (holiday, absence, party, auto etc.)

– timer programm P1( P2 and P3 only when released)

– heating mode (daytime-, reduced-, ECO-mode)

– identification (direct circuit HC, hot water circuit DHW)

– status of heating- and DHW charging pump (on, off)

Inquire clockwise temperatures, consumption

datas one after the other

Examples:

Inquire anti-clockwise heat circuit information

one after the other

Examples:

13.5

OOUUTTSSIIDDEE

°C

Outdoor temperature

Page 12

ON

HHCC

AAUUTTOO-PP11 DDAAYY

14.5

88..00

OOUUTT MMIINN//MMAAXX

65.0

HHEEAATT GGEENNEEjj..

°C

°C

Outdoor temperatur

Minimum-maximum value

between 0.00h and 24.00 h

Heat generator temperature

(boiler temperature)

°C

ON

HHEEAATT GGEENNEEjj..

OFF

DDHHWW

AAUUTTOO-PP11 DDAAYY

Heat generator (boiler)

Domestic hot water circuit

11224455

SSTTAAjjTTSS

Heat generator starts

(number of starts)

45.0

jjEETTUUjjNN FFLLOOWW

135.0

EEXXHHAAUUSSTT

Return flow temperature

(only with return flow sensor)

Flue gas temperature

(only with flue gas sensor)

°C

°C

Direct heating circuit

(unmixed)

Entry into information level

Plant information

Page 13

Page13

shows

– operating status (on, off)

– number of service hours

– number of starts

of heat generator, boiler etc.

shows

– room thermostat function (heating on, off)

– current room temperature

if room sensor is activated

shows

– water pressure

if pressure sensor is present

225588

OOPPEERR.. HHOOUURRSS

Heat generator run time

number of service hours

52.0

DDHHWW

OFF

DDHHWW

TTHHEEjjMMOOSSTTAATT

°C

Hot-water temperature

(electronically controlled)

Hot-water thermostat

1)

(mechanically controlled)

Room thermostat function

2)

room max. temp. delimitation

21.0

OFF

HHCC

TTHHEEjjMMOOSSTTAATT

Room temperature

2)

Direct heating circuit

°C

resp.

1)

display dependent on the type of heat generator

2

will be displayed only if the room sensor was activated before

RROOOOMMTTEEMMPP HHCC

1.4

HHYYDDRRAAUU.. PPRREESSSS

Hydraulic pressure

1)

(only it pressure sensor is present)

Page 14

Standard display

(Example: Operational mode AUTOMATIC )

Entry into the level selection

press knob for approx. 5 seconds

Programming level - Level summary

Schematic block diagram

Page 14

TIME- DATE

58.5

1199::4455

MMOO.. 2222..AAUUGG.. ;;0055

°C

SYSTEMTIMEPROGRAMS

DOMESTIC HOT

WATER (DHW)

UNMIXED

HEATINGCIRCUIT

TIME

YEAR

LANGUAGE

TIME PROGRAM

P1 P1-P3

back forward

SELECT CIRCUIT

HC (Heating)

DHW (Hot water)

WEEKDAY (Mo-Su)

Heating cycle (1...3)

Copying function

ECO-Temperature

reduced nominal

DHW-value

LEGIONELLA

PROTECTION

Day 1-7)

REDUCED

HEATING

ECO/Reduction

HEATINGSYSTEM

m-value

Underfl./rad./conv.

Select

Level

Entry:

DGB F I

back forward back forward

back forward

back forward

back forward

back forwardback forward

0

2461012

18 2220

81416

24

3sec

HEATING

CIRCUIT NAM E

Page 15

Selection and modification of parameters and

setting values

Entering into the programming level, principally the operating times

level (TIME PROGRAMS) appears at first. All other levels, such as

- SYSTEM

- DHW

- UNMIXED CIRCUIT

- DATE-TIME

can be selected directly via rotary-push button

By pressing the rotary-push button, the selected flashing level is

activated; the first value resp. parameter appears flashing. If necessary, it can be modified via the rotary-push button and accepted by

pressing again. If necessary, the following parameters can be treated in the same way.

Re-entry into the level selection is done via the info button

¤

, re-

entry into the standard display via the program-selection button

¤

or automatically after approx. 60 seconds.

Page 15

HEATINGEND

selected cycle

TEMPERATURE

selected cycle

DAY-MONTH

CHANGEOVER

Summer-Wintertime

HEATINGSTART

selected cycle

OPERATING MODE

common (1)

separate (2)

SUMMER

switching off

PARAM.-RESET

Reset to factory

preset

back forward

back forward

back forward

back forward

back forward

Page 16

Page 16

Select

Press for approx. 3 seconds

Programming of operating times

62.5

15:30

MO. 22. AUG.;05

°C

TIMEPjOGjAMS

HHCC

TIMEPjOGjAMS

DHW

TIMEPjOGjAMS

Enter operating times level

Standard display

accept

For example unmixed heating circuit HC

accept

With this mode of operation individual programs, other than standard programs for heating and hotwater mode can be set up. For this purpose after selecting the heating- resp. hot-water circuit the

factory preset standard program (P1) is called an can be overwritten individually.

For programming the operation times, for each week day maximum three heating cycles with one

switch-on and switch-off time each are available. Further more, the heating- resp. hot-water cycle can

be combined with a required room temperature resp. hot-water temperature for the duration of the

cycle.

select program P1...P3, if released

heating circuit

3sec

Page 17

accept

For example Tuesday - heating cycle 1

2200..00

MO-11

06.00-222.00

0

2461012

18 2220

14 16

24

°C

--..-

MO-22

--.-----. --

0

2461012

18 20

14

24

°C

8

2200..00

TU-11

06.00-222.00

0

2461012

18 2220

14 16

24

°C

8

--..-

TU-22

--.-----.--

0

2461012

18 2220

14 16

24

°C

8

--..-

SU-22

--.-----.--

0

2461012

18 2220

14 16816

22

- Wed - Thu - Fri - Sa t - Sun -

2200..00

TU-11

06.00-222.00

0

2461012

18 2220

14 16

24

°C

8

2200..00

TU-11

06.00-222.00

0

2461012

18 2220

14 16

24

°C

8

2200..00

TU-11

06.00-222.00

0

2461012

18 2220

14 16

24

°C

8

Select

Modify

Setting range 0.00...24.00 h

Setting range: 0.00...24.00 h

For heating circuit: Room temperatur

Setting range: 5.0...30.0 °C

For hot-water circuit: Hot-water temperature

Setting range: 10.0...80 .0 °C (resp. DHW-max)

Note: The 3

rd

heating cycle is skipped if the 2

nd

heating cycle does not include any operating times.

accept

accept

accept

Modify - Exit :

Confirm the selected flashing value by pressing the rotary-push button. Then set the new

required value and take over by pressing

the rotary-push button again.

Re-entry into the former step in done by

pressing the button

¤¤

,

exit into the stan-

dard display via the button

¢¢

or automati-

cally after approx. 60 seconds.

8

day and cycle

Modify

switching-off

time

Modify temperature

switching-on

time

Page 17

Page 18

Page 18

Select

Push for approx. 3 seconds

Copy operating times

62.5

15:30

MO. 22. AUG.;05

°C

TIMEPjOGjAMS

HHCC

TIMEPjOGjAMS

DDHHWW

TIMEPjOGjAMS

Enter operating times level

Standard display

heating circuit

accept

For example unmixed heating circuit HC

accept

DDAAYY

CCOOPPYY

2200..00

MO-11

06.00-222.00

0

2461012

18 2220

14 16

24

°C

8

copy functionSelect

Programming of operating times includes a extensive copying function which allows to copy any day of the week to other days (Mo..Su) resp. to the whole week

(1-7) or parts of a week such as workdays (1-5) or weekends (6-7).

select program P1...P3, if available

3sec

Page 19

Page 19

Source and destination are identical

Setting range:

Days (MO...SU) , whole week (1-7),

Working days (1-5), weekend (6-7)

accept

Example: Monday

MMOO

FjOM

COPY

Select source

Select

Confirmation

If necessary select and takte over further

destinations in the same way.

Copy

11-55

TO

COPY MMO

OOKK

DAY

COPY

Setting range: Monday (MO)...Sunday (SU)

TO

COPY MMO

Select next destination

Example: Monday to Friday

Example: Saterday and Sunday

66-77

etc..

first destination

Modify - Exit :

Confirm the selected flashing value by pressing the rotary-push button. Then set the new

required value and take over by pressing

the rotary-push button again.

Re-entry into the former step in done by

pressing the button

¤¤

,

exit into the stan-

dard display via the button

¢¢

or automati-

cally after approx. 60 seconds.

Page 20

Page 20

Select

Push for approx. 3 seconds

Reloading of standard time programs - deleting of individual time programs

62.5

15:30

MO. 22. AUG.;05

°C

TIMEPjOGjAMS

HHCC

TIMEPjOGjAMS

DDEEFFAAUULLTT-TTIIMMEE

Enter operating times level

Standard display

accept

For example unmixed heating circuit HC

accept

Modify - Exit :

Confirm the selected flashing value by pressing the rotary-push button. Then set the new required value and take over by pressing the

rotary-push button again.

Re-entry into the former step in done by pressing the button

¤¤

,

exit into the standard display via the button

¢¢

or automatically after

approx. 60 seconds.

heating circuitSelect

DDEEFFAAUULLTT-TTIIMMEE

HHCC

DDEEFFAAUULLTT-TTIIMMEE

DDHHWW

DDEEFFAAUULLTT-TTIIMMEE

AALLLL

The standard programs do not get lost by overwriting with individual

programs. Individual programs however are cancelled at a later call

of the corresponding standard programs and have to be set up

again. For this purpose individual switching-on and switching-off times

should always be noted (see level TIME PROGRAMS - table for individual programs).

default time

3sec

Page 21

Reset

jjEESSEETT

OK

press approx. 3 seconds

Standard program was reloaded

Individual Program was deleted!

!

select program P1...P3, if released

1)

jjEESSEETT

HHCC

accept

Page 21

Standard time programs

Standard operating-times program P1

Circuit Day Heating from...to

Mo-Su 06.00 - 22.00 h

Unmixed

heating circuit (HC)

Mo-Su 05.00 - 22.00 h

Domestic

hot water (DHW)

1)

see level SYSTEM - parameter PROGRAM

Standard operating-times program P1

1)

Circuit Day Heating from...to

Mo-Th 06.00-08.00 16.00-22.00h

Fr 06.00-08.00 13.00-22.00h

Unmixed

heating circuit (HC)

Sa-Su 07.00-23.00h

Mo-Th 05.00-08.00 15.30-22.00h

Domestic

hot water (DHW)

Fr 05.00-08.00 12.30-22.00h

Sa-Su 06.00-23.00h

Standard operating-times program P3

1)

Circuit Day Heating from...to

Mo-Fr 07.00-18.00 h

Sa-Su reduced heating

Unmixed

heating circuit (HC)

Mo-Fr 06.00-18.00 h

Domestic

hot water (DHW)

Sa-Su reduced heating

3sec

Page 22

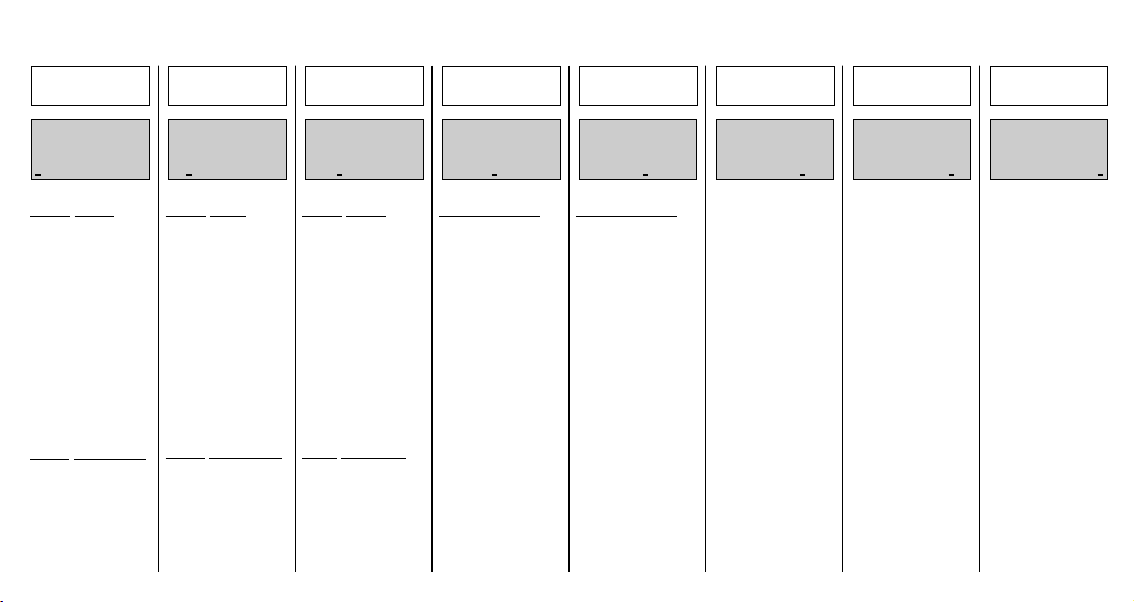

Day

Mon

Unmixed heating circuit (HC)

Tue

Wed

Thu

Fri

Sat

Sun

1stcycle

From till

2ndcycle

from till

3rdcycle

from till

1stcycle

from till

2ndcycle

from till

3ndcycle

from till

1stcycle

from till

2ndcycle

from till

3rdcycle

from till

Operating times program P1 Operating times program P2 Operating times program P3

Day

Mon

Domestic hot-water circuit (DHW)

Tue

Wed

Thu

Fri

Sat

Sun

1stcycle

from till

2ndcycle

2

from till

3rdcycle

from till

1stcycle

from till

2ndcycle

from till

3rdcycle

from till

1stcycle

from

till

2ndcycle

from till

3rdcycle

from till

Page 22

Table for individual operating times and programs

Page 23

Page 23

TTIIMMEE-DDAATTEE

18:45

TTIIMMEE

22.08

MMOO

DDAAYY-MMOONNTTHH

AUTO

SSUU-WWII

CCHHAANNGGEE

2005

YYEEAAjj

Current time

Setting range:

0.00. . . 24.00 h

Calender year

Setting range:

2001. . . 2099

Calender day-month-weekday

Setting range: 01.01. . . 31.12.

Weekday is set automatically

Time changeover mode

Setting range:

Automatic: last Sunday in March & Oct.

Manual: no time reset

Entry:

The values to the left are factory presets and normally need

not be updated. If in some exceptional cases corrections should

be necessary, the values can be adapted to the real conditions.

The internal pre-programmed calender provides an automatic

time changeover at the yearly repeating summer-wintertime

dates.

If required, the automatic time changeover can be switched off

(manual reset).

TIME-DATE

Entry: see » Programming level - Level summary « .

Exit: via button

¢¢

or automatically after 60 seconds

Modify: Confirm selected flashing parameter by pressing

the rotary-push button. Then set the new required value via and accept by pressing the rotarypush button again. If necessary, correct the following parameters in the same way.

set time

set day & month

set changeover

set year

Page 24

Page 24

Entry:

SSYYSSTT..

SSYYSSTTEEMM

GB

SSYYSSTT..

LLAANNGGUUAAGGEE

P1

PPjjOOGGjjAAMM

Language

Setting range:

DE = German GB = English FR = French

IT = Italian NL = Dutch ES = Spanish

PT = Portuguese HU = Hungarian CZ = Czech

PL = Polish RO = Romanian RU = Russian

TR = Turkish S = Swedish N = Norwegian

Factory preset: DE

Operating times program

Setting range: P1, P1-P3

Factory preset: P1

SSYYSSTT..

SYSTEM

All information that appears in the display, is available in a number of languages. After entry as first parameter appears the language selection. The required language can be selected and accepted according to the above assignment.

Application: Use of the instrument at the corresponding

language area.

This parameter specifies the number of the released time programs. With setting P1 only one

operating-times program is avai-

lable, with setting P1-P3 all thr

ee programs are released and can

be selected for programming operating times.

Application: Shift work, different programs for summer,

transition period, winter etc.

This level includes general delimiting parameters and options

referring to the corresponding heating system

Entry: see » Programming level - Level summary « .

Exit: via button

¢¢

or automatically after 60 seconds

Modify: Confirm selected flashing parameter by pressing

the rotary-push button. Then set the new required value via and accept by pressing the rotarypush button again. If necessary, correct the following parameters in the same way.

next parameter

next parameter

Page 25

1

SSYYSSTT..

CCOONNTTjjOOLL MMOODDEE

Control mode

Setting range: 1 = common mode 2 = separated mode

Factory preset: 1

HHCC

OOPP.. MMOODDEE

Select

Circuit

accept

Operational mode

further operation see »Operational mode selection for heating and hot water« and »Temperature settings«

Page 25

Common control mode:

The selected operational mode (via button

¢¢

for Holiday,

Absence, Party, Automatic etc.) applies to the heating circuit and to

the hot-water circuit together.

Separated control mode:

The heating- and hot-water circuit can be assigned with own

operational mode.

Application: Objects with uniform seizure character (One-

family houses etc).

Application: Objects with different use of heating and hot-

water (for example heating operation in

Holiday mode, hot-water permanently in reduced mode).

next parameter

Unmixed circuit (HC), hot-water circuit (DHW)

Page 26

Page 26

20.0

SSOOMMMMEERR

Summer switch-off

Setting range: OFF, 10.0 to 30,0 °C

Factory preset: 20.0 °C

SSYYSSTT..

°C

Note: The active summer switch-off appears on the standard

display with a sunshade symbol.

Application: All objects which do not require a heating ope-

ration during summertime

This parameter specifies the heating delimiting value regarding

the average resp. current outdoor temperature and puts the

heating plant automatically out of service as soon as the outdoor temperature exceeds the set heating delimiting value.

During summer switch-off the pump of the heating circuit is

activated each day for approx. 10 seconds to protect it against

corrosion.

With setting OFF the summer switch-off is not effective.

Hot water preparation is not affected by summer switch-off.

Summer switch-off activated

jjEESSEETT

Reset: Press rotary-push button for approx. 5 sec. while

indication SET is flashing, until standard display

appears.

SSYYSSTT..

Parameter-reset

This function resets all individually entered values in the programming level to factory preset.

Exception: Time-date, operating times

SET

jjEESSEETT

SSYYSSTT..

next parameter

Important: Reset may only be executed if all individually

entered values shall be replaced by the factory

preset values!

!

6633..55

1166::3322

MMOO.. 2222.. AAUUGG..;;0055

°C

À

Page 27

Page 27

40.0

NNIIGGHHTT

DDHHWW

OFF

LLEEGGIIOONN.. PPjjOOTT..

Hot-water economic temperature

Setting range: 5.0 °C up to the required hot water temperature

Factory preset: 40.0 °C

Legionella protection (day)

Setting range: OFF, MO...SU, ALL

Factory preset: OFF

DDAAYY

This parameter determines the amount of the reduced hot-water

temperature outside the hot-water operating times (between the

hot-water cycles) as well as in the operational mode ABSENCE

for the duration of absence.

The legionella protection serves to avoid a legionella infestation

inside the hot-water tank and is activated on the selected weekday (Mon to Sun) or every day at 2.00 o’clock. If the hot-water

temperature should drop below 65 °C, the tank is reloaded.

With setting OFF this function is not effective.

°C

DDHHWW

DDHHWW

DOMESTIC HOT WATER

This level includes the necessary parameters for programming the

hot-water circuit except the hot-water operating-times.

Entry: see » Programming level - Level summary « .

Exit: via button

¢¢

or automatically after 60 seconds

Modify: Confirm selected flashing parameter by pressing

the rotary-push button. Then set the new required value via and accept by pressing the rotarypush button again. If necessary, correct the following parameters in the same way.

Application: Base temperature inside the hot-water tank in

order to avoid a cooling down of the tank.

Note: This parameter is skipped if a hot-water thermostat is

used instead of an electronic hot-water sensor.

Note: Other legionella protection times can be regulated

exclusively by the heating plant specialist.

Important: Danger of scalding! Use thermostatic mixing

valve on DHW outlet.

Entry:

next parameter

Page 28

Page 28

HHCC

UUNNMMIIXXEEDD CCIIRRCC..

ECO

HHCC

jjEEDD..HHEEAATTIINNGG

Reduced heating mode

Setting range: ECO, RED

Factory preset: ECO

Unmixed heating circuit (direct circuit)

This level includes the parameters required for programming

the heating circuit with the exception of the related operatingtimes programs.

Entry: see » Programming level - Level summary « .

Exit: via button

¢¢

or automatically after 60 seconds

Modify: Confirm selected flashing parameter by pressing

the rotary-push button. Then set the new required value via and accept by pressing the rotarypush button again. If necessary, correct the following parameters in the same way.

Application: Objects with high insulation values

Application: Objects with low insulation values

During the reduced operation the following modes can be selected:

ECO mode: At oudoor temperatures above the set plant frost

protection the heating circuit is switched off completely. At temperatures below frost protection the

heating circuit is controlled with reduced heating

characteristic according to the required reduced

temperature (see »Temperature setting« ).

RED mode: During the reduced mode the heating circuit pump

remains activated. The heating circuit is controlled

according to the reduced heating characteristic,

the temperature does not drop below the set minimum temperature value.

Entry:

next parameter

Page 29

Heating curve for underfloor heating systems

or other static heating surfaces

Normal standard heating curves for radiators

Heating curves for convectors

Special heating curves for ventilators with

high starting temperatures

1.0 0. . . 1.10

Application

Setting value

1.30. . . 2.20

3.00. . . 4.00

4.00. . . 10.0

Page 29

1. 30

HHEEAATT.. SSYYSSTTEEMM

Adaptation to the heating system

Setting range: 1,00 to 10.0

Factory preset: 1,30

HHCC

Applications:

The following setting values are recommended for the belowmentioned applications

This parameter refers to the type of the heating system

and has to be adapted to the power characteristic of the

corresponding consumer (underfloor systems, radiator,

convector). The setting value specifies the curvature of the

heating curve of the selected weather dependent heating

circuit and compensates the system-related efficiency losses at lower temperatures by a progressive heating curve

in conformity with the adjustment.

Heating circuit name

This is used to assign an individual, 5 character, abbreviated name to each heating circuit.

No individual name is assigned if the setting "empty" is

used. The default abbreviated name appears.

• The character that blinks can be altered using the rotary

knob according to the code number and accepted by

pressing the knob once. The remaining characters can

be altered in the same way.

• The individual heating circuit name display appears

- in the menu

- in the parameter tree

- in the info level

HHKK-NNAAMMEE

HHKK-NNAAMMEE

Page 30

Page 30

Example for alarm message »data bus«

(address error)

Error code 70

The instrument is equipped with an extensive error diagnostic features. The error displayed takes priority over other displays and

varies dependent on the model in question.

For alarm messages from burner control (ERROR Xn:m) the error

codes in the corresponding installation manuals have to be considered.

Note: Alarm messages only appear alternating with the stan-

dard display.

In case of alarm messages the heating specialist always

has to be informed!

10-00

EEjjjjOORR

OOUUTTSSIIDDEE

30-nn

EEjjjjOORR

HHEEAATT GGEENN..

50-44

EEjjjjOORR

DDHHWW

70-nn

EEjjjjOORR

BBUUSS

Example for alarm message »sensor«

(short or open circuit)

Error code 10...20

Example for alarm message »heat generator«

(flue gas temperature exceeded)

Error code 30...40...

1)

Example for logical alarm messages

(control functions)

Error code 50. . . 60

Alarm messages

!

1)

For these alarm messages the error codes of the heat generator in the

corresponding installation manuals have to be considered.

Page 31

Seite 31

Personal notes

Page 32

Technical specification

Supply voltage: Via data bus (DC-safety voltage by EN 60730)

Power consumption: 300 mW

Bus interface: T2B or OpenTherm according to model

Ambient temperature: 0...60 °C

Storage temperature: -25...60 °C

Protection type acc. to EN 60529: IP 30

Protection class acc. to EN 60730: III

Approval according to: VDE 60730

Casing dimensions (BxHxD): 90 x 138 x 28 mm

Casing material: ABS, antistatic

Electrical connections: 2-wire mode with plugable connection

Recommended cable: J-Y(St)Y 2 x 2 x 0.6 mm

2

Max. length of cable: 50 m

Data and timer back up: Min. 5 years from date of delivery

Accuracy of the internal clock ± 2s/day

Weight: Approx. 150 g

Subject to change Art. 0450017010 - 0811-30

Loading...

Loading...