Thermo Scientific NITON XL3t 500 User Manual

NITON XL3t 500 Analyzer

User’s Guide

Version 6.5

About This User’s Guide ..................................................................i

Unpacking and Assembling Your NITON XRF Analyzer ...............i

The NITON XRF Analyzer Overview ..............................................ii

The Control Panel .............................................................................ii

Instrument Startup .............................................................................vi

Chapter 1 Applications ........................................................................ 1-1

The NAV Menu ..........................................................1-1

The Tools Menu ..........................................................1-2

Example Averaging....................................................... 1-5

Live Spectrum Feed......................................................1-6

Analyzing Bulk Samples ...............................................1-9

The Data Entry Screen............................................... 1-12

Changing the Data Entry Screen to Two Column .....1-14

Selecting Data Entry from View Data Mode .............. 1-18

Navigating the Data Entry Screen .............................. 1-19

The Virtual Keyboard ................................................1-20

The Measurement Screen...........................................1-22

Standard Soil Mode ...................................................1-23

Standard Soil Mode ...................................................1-24

The Measurement Screen...........................................1-25

Mining Cu/Zn Mode................................................. 1-27

The Measurement Screen...........................................1-29

Mining Ta/Hf Mode..................................................1-31

The Measurement Screen...........................................1-33

To Prepare or Not to Prepare - In Situ vs. Ex Situ .....1-35

Analysis of Unprepared Samples – In Situ..................1-36

On-site vs. Lab Analysis .............................................1-42

Analysis of Prepared Samples – Ex Situ ......................1-43

Cleaning Your Equipment: ........................................1-45

The View Data Screen ............................................... 1-49

The Erase All Data Screen.......................................... 1-53

The Erase Readings Screen.........................................1-54

The Calibrate Detector Screen ...................................1-61

The Calibrate Touch Screen Screen ...........................1-63

Calibrating the Touch Screen

Without Using the Touch Screen............................... 1-65

The Specs Screen........................................................ 1-67

The Date and Time Screen ........................................1-72

The Rotate Screen 180 Toggle ...................................1-73

The Adjust Backlight Screen ......................................1-74

Camera and Small Spot Video ................................... 1-75

Using the Small Spot.................................................. 1-78

The Hardware Setup Screen....................................... 1-79

The Filter Config Screen............................................1-84

The Language Settings Screen ....................................1-90

Thermo Scientific Table of Contents 1

The Printer Setup Screen ...........................................1-92

The Beep Setup Menu ...............................................1-94

The Data Entry Settings Menu ..................................1-96

The Safety Settings Menu ..........................................1-97

The Adjust Calibration Screen ...................................1-98

Calibration Factors...................................................1-100

Oxides vs. elemental concentrations .........................1-101

The Sort Element Display Menu.............................. 1-102

The Set Element Threshold Menu ...........................1-107

The Set Display Units Menu.................................... 1-112

Setting Display Units ...............................................1-112

Changing Sigma.......................................................1-113

Chapter 2 Routine Maintenance Guidelines ................................... 2-1

Battery Pack and Battery Charger................................. 2-1

Maintenance, Cleaning and Repairs ............................. 2-5

Replacing the Measurement Window........................... 2-6

Storing and Transporting Your XL3 Analyzer ..............2-8

Networking and Connectivity....................................2-11

Entering Data with a Barcode reader.......................... 2-27

Chapter 3 Radiation and General Safety ..........................................3-1

Radiation and General Safety ....................................... 3-1

Radiation Protection Basics..........................................3-1

How to Use the NITON XL3t Analyzer Safely............3-6

Safe Handling of Samples............................................. 3-9

Radiation Profile ........................................................ 3-10

Storage & Transportation ..........................................3-15

EMERGENCY PROCEDURES ............................... 3-16

Registration and Licensing .........................................3-19

Contact Information .................................................. 3-21

Appendices

Appendix A:.................................................. Appendices-i

Appendix B: ................................................ Appendices-iv

Appendix C:............................................... Appendices-vii

Appendix D: ................................................ Appendices-x

Appendix E: ............................................... Appendices-xii

Appendix F ................................................Appendices-xiv

Appendix F: ................................................Appendices-xv

Thermo Scientific Table of Contents 2

About This User’s Guide

WARNING! Do not attempt to use this analyzer without first reading and

understanding the entire User’s Guide!

CAUTION NITON Analyzers are not intrinsically safe analyzers in regard to

sparking. All pertinent Hot Work procedures should be followed in areas of

concern.

Unpacking and

Assembling Your

NITON XRF Analyzer

• Inspect the shipping carton for signs of damage such as crushed or water

damaged packaging. Immediately notify the shipping company and

Thermo Fisher Scientific, in the United States, toll free, at (800)

875-1578, or outside the United States, at +1-978-670-7460, if there is

any visible damage to the shipping container or any of its contents.

• Open the packing carton. If your analyzer is not packed in its carrying

case, please call Thermo Fisher Scientific immediately, in the United

States, toll free, at (800) 875-1578, or outside the United States, at

+1-978-670-7460.

• Verify the contents of the shipping container against the enclosed

packing list. If there are any discrepancies between the actual contents of

the shipping container and the enclosed packing list, please notify

Thermo Fisher Scientific immediately, in the United States, toll free, at

(800) 875-1578, or outside the United States, at +1-978-670-7460.

• Open the carrying case and visually inspect the analyzer for damage

before removing it from the case. Call the shipper and Thermo Fisher

Scientific if you find any damage to the case or its contents.

• Save the shipping carton and all packing materials. Store them in a safe,

dry area for reuse the next time that you ship the analyzer.

Thermo Scientific NITON XL3 Analyzer User’s Guide i

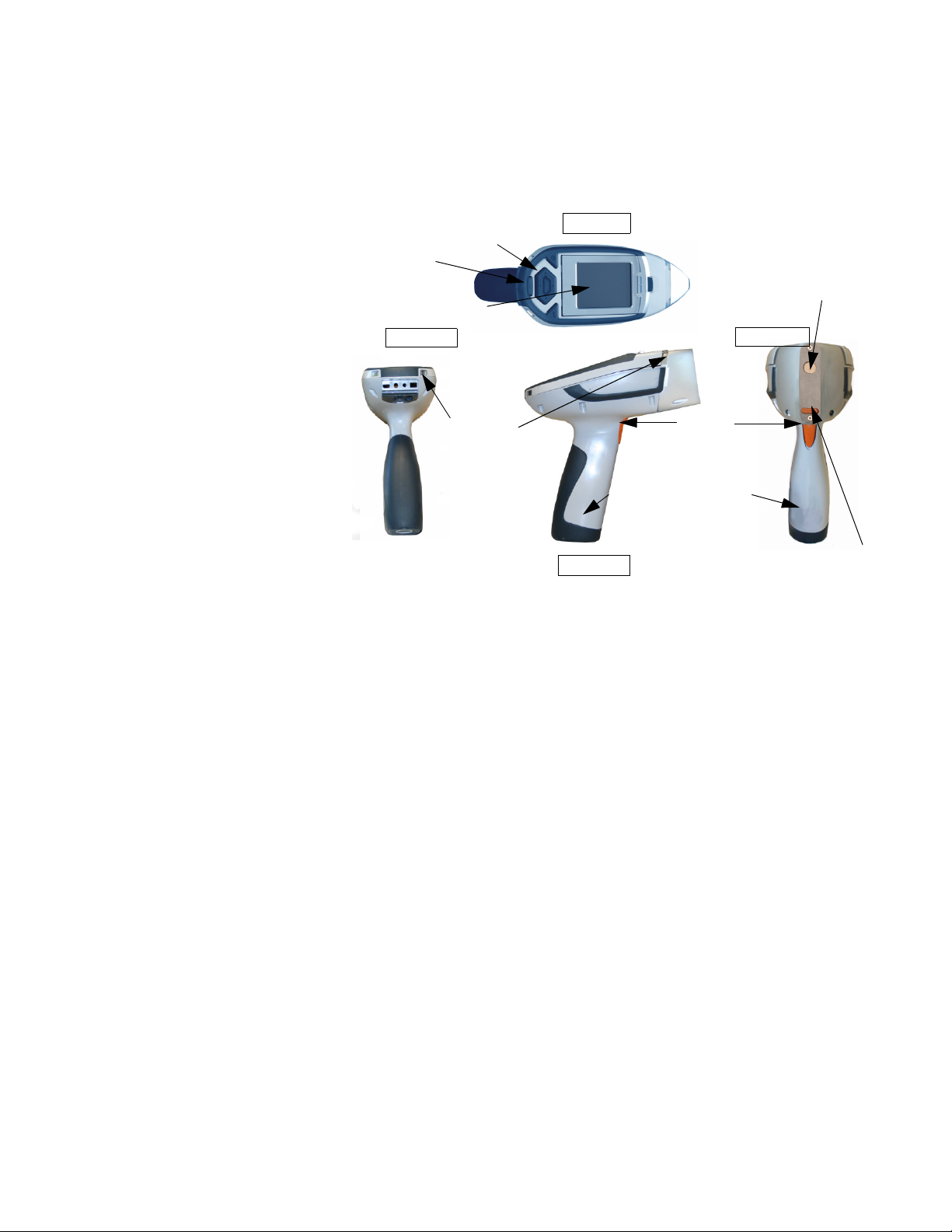

The NITON XRF

Top View

Rear View

Front View

Control panel

LED lights

Trigger

LCD touch screen

Measurement

Window

Proximity Sensor

Rear

Interlock

Battery Pack/Han-

dle

Side View

Analyzer Overview

The NITON XL3 Analyzer is a single unit, hand held, high performance

portable x-ray fluorescence (XRF) elemental analyzer.

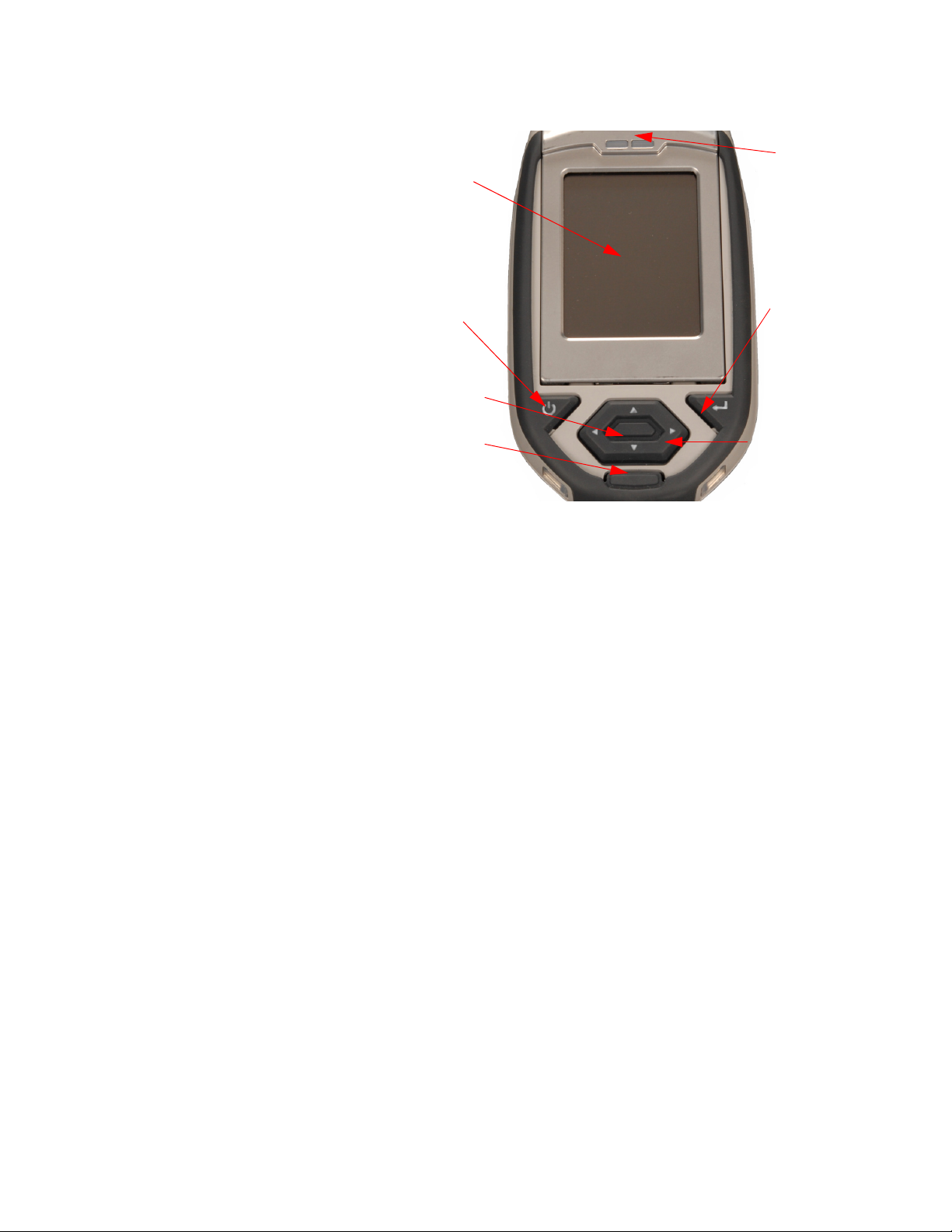

The Control Panel

Figure 0-1. Analyzer Overview

The control panel is located on the analyzer’s top housing, directly below the

LCD touch screen (see Figure 0-1). The control panel consists of a 4 way

touch pad, a center button, and two control buttons, one on each side.

Using either the control panel or the touch screen you may navigate through

all of the analyzer’s screens and menus. You can control the movement of the

screen cursor by pressing the four way control pad in one of four directions

to highlight each of the menu options. The Select button in the center of

the four way touch pad is used to select highlighted menu options. The

on/off/escape button both controls the power to the analyzer and serves as

an "escape" button. When the on/off/escape button is pushed and

immediately released, it functions as an "escape", and brings you back to the

Main Menu from the current screen in the menu system.

ii NITON XL3 Analyzer User’s Guide Thermo Scientific

Figure 0-2. The Control Panel

LCD touch

screen

On/off/escape

button

Clear/enter

button

4-way touch pad

Interlock button

Select button

LCD touch

screen catch

Push and hold the on/off/escape button for at least 3 seconds to turn the

analyzer on.Push the on/off/escape button and hold it down for about 10

seconds to shut off power to the analyzer from any screen in the menu

system.

You also have the option of operating the analyzer, including navigating the

menu system, by using the built in touch screen. To select a menu option,

tap on the icon once. The touch screen icons have the same functionality as

the four way touch pad, the on/off/escape button, and the select or enter

button. This User's Guide will refer to the process of choosing a course of

action by selecting an icon from a menu, either using the touch screen or

using the control panel buttons, as “selecting.”

Thermo Scientific NITON XL3 Analyzer User’s Guide iii

Selecting the Return icon works everywhere throughout the User Interface

to bring you back to the previous menu from the current menu in the menu

system. Use the on/off/escape button to return to the Main Menu.

The LCD Touch Screen

The LCD Touch

Screen

The LCD Touch Screen on your XL3 Analyzer is designed to swing up and

down to different angles for ease in viewing and interacting with your

analyzer. The LCD Touch Screen is connected to your analyzer along the

base of the screen, right above the Control panel. The screen is not designed

to separate from the analyzer, but can be adjusted to any arbitrary angle

between zero degrees - that is, flush with the analyzer - and 85 degrees,

which is almost perpendicular. The LCD Touch Screen will stay at any

given angle between these extremes until moved to a different angle. When

in closed position, the screen is secured by a catch at the top center of the

screen housing.

Figure 0-3. XL3 Analyzer Showing LCD Screen Tilted.

• To raise the LCD Touch Screen, disengage the catch at the top-center of

the LCD Touch Screen housing and gently pull the screen towards you

until it is at the best angle for your use.

• To close the LCD Touch Screen, gently push away from you along the

top edge of the screen housing. The screen will swing down until the

catch solidly engages with an audible click.

Note The LCD Touch Screen cannot be removed from your XL3 analyzer.

Removing or attempting to remove the LCD Touch Screen will damage

your analyzer and void your warranty.

Note Always close your LCD Touch Screen before storing or transporting

your XL3 analyzer.

iv NITON XL3 Analyzer User’s Guide Thermo Scientific

The Data Ports

Power Port

Serial Port

Remote Trigger Port

USB Port

The Data Ports

Figure 0-4. Data Ports on the XL3

USB Port The USB Port is a communications and control port, for uploading and

downloading data, configuration files, and software to the analyzer.

Remote Trigger Port The Remote Trigger Port controls the analyzer’s trigger function, for use

with the Extend-a-pole, In Situ Tripod, and test stands.

Serial Port The Serial Port is a communications and control port, for uploading and

downloading data, configuration files, and software to the analyzer.

Power Port The power port is used to run the XL3 under external power.

Thermo Scientific NITON XL3 Analyzer User’s Guide v

The Data Ports

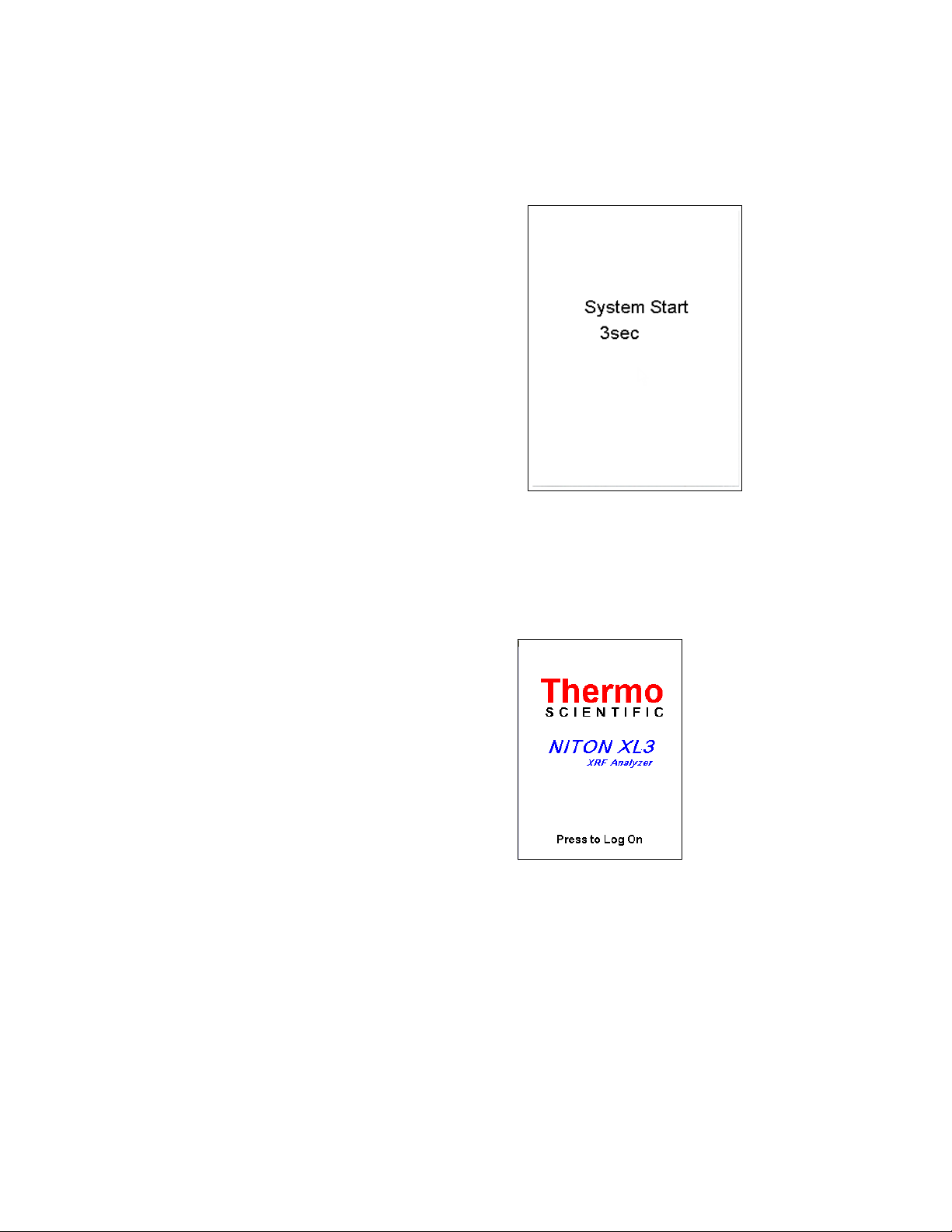

Instrument Startup

To turn on the analyzer, depress the on/off/escape button on the control

panel for approximately 10 seconds.

Figure 0-5. System Start Screen

On startup, the screen will be replaced by a Start Screen (see Figure 0-5)

which will automatically count down from 9 to 0 in increments of one

second.

Figure 0-6. Logon Screen

When the Start is complete, the Start Screen will be replaced by the Logon

screen (see Figure 0-6.) Tap anywhere on this screen to continue.

The Logon Screen will be replaced by a Warning Screen, see Figure 0-7,

advising you that this analyzer produces radiation when the lights are

flashing. You must acknowledge this warning by selecting the “Yes” button

before logging on. Selecting the “No” button will return you to the Logon

Screen.

vi NITON XL3 Analyzer User’s Guide Thermo Scientific

The Data Ports

Figure 0-7. Warning Screen

After selecting the “Yes” button, the Virtual Numeric Keypad becomes

available for you to log onto the analyzer.

Figure 0-8. Virtual Numeric Keypad for Logon

Thermo Scientific NITON XL3 Analyzer User’s Guide vii

The Data Ports

Select your 4 digit security code, followed by the enter (E) key. The

temporary password assigned by default is 1-2-3-4, followed by the “E” key.

If you enter an incorrect number, you can use the “<“ key to backspace over

it, ot use the “C” key to clear everything. After you have completed the log

on procedure, the word "USER" will appear on the bottom of the screen,

then the Main Menu will appear. Note that security codes are editable.

Please see the NDT manual for instructions on creating user-definable

passwords.

Check the date/time. The time should be set correctly for accurate and

verifiable record keeping (See Chapter 1 page 72).

Your analyzer can be stored and operated safely in temperatures from -5º C

(23º F) to 50º C (122º F). You will not be able to take a measurement if the

analyzer overheats. If it is hot to the touch, you should allow it to cool

before testing.

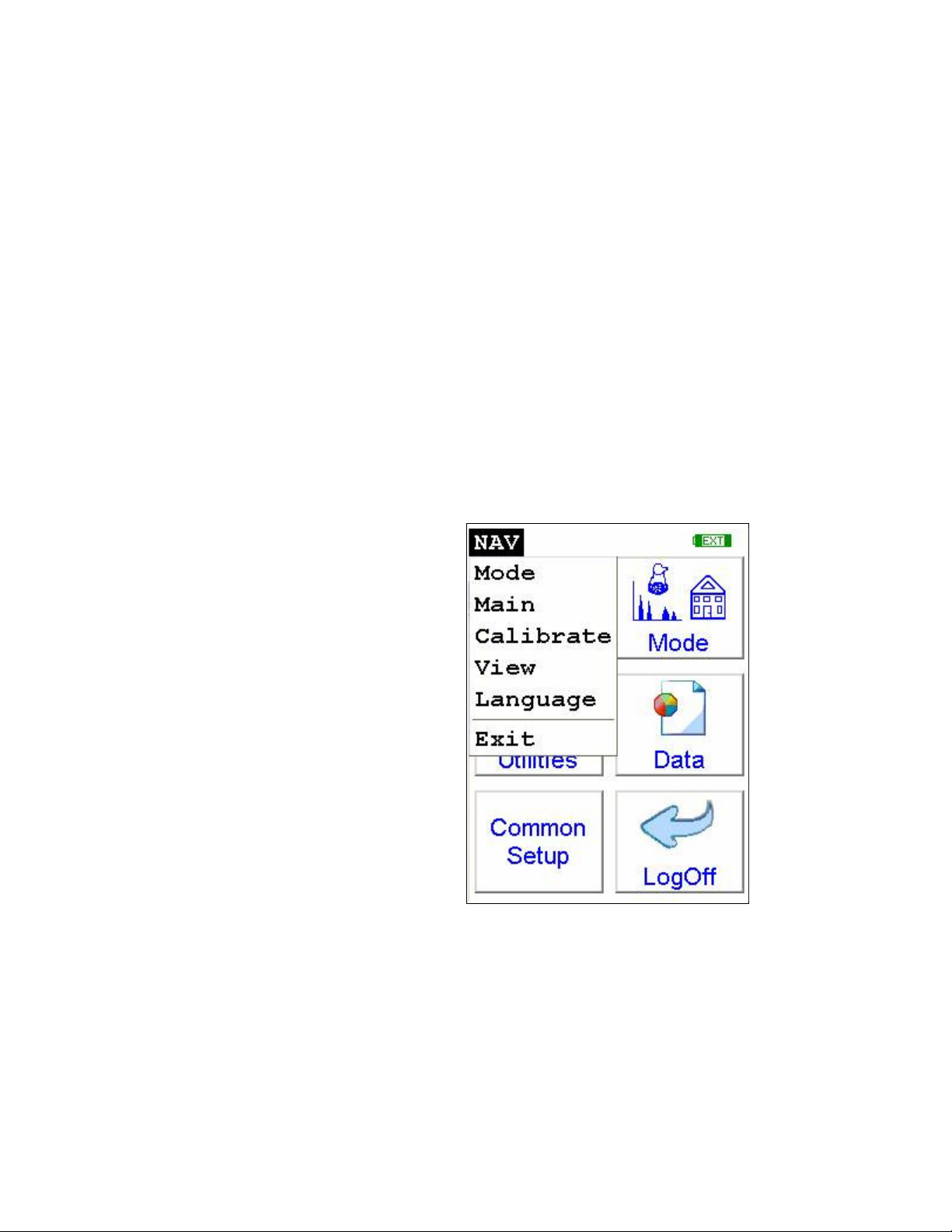

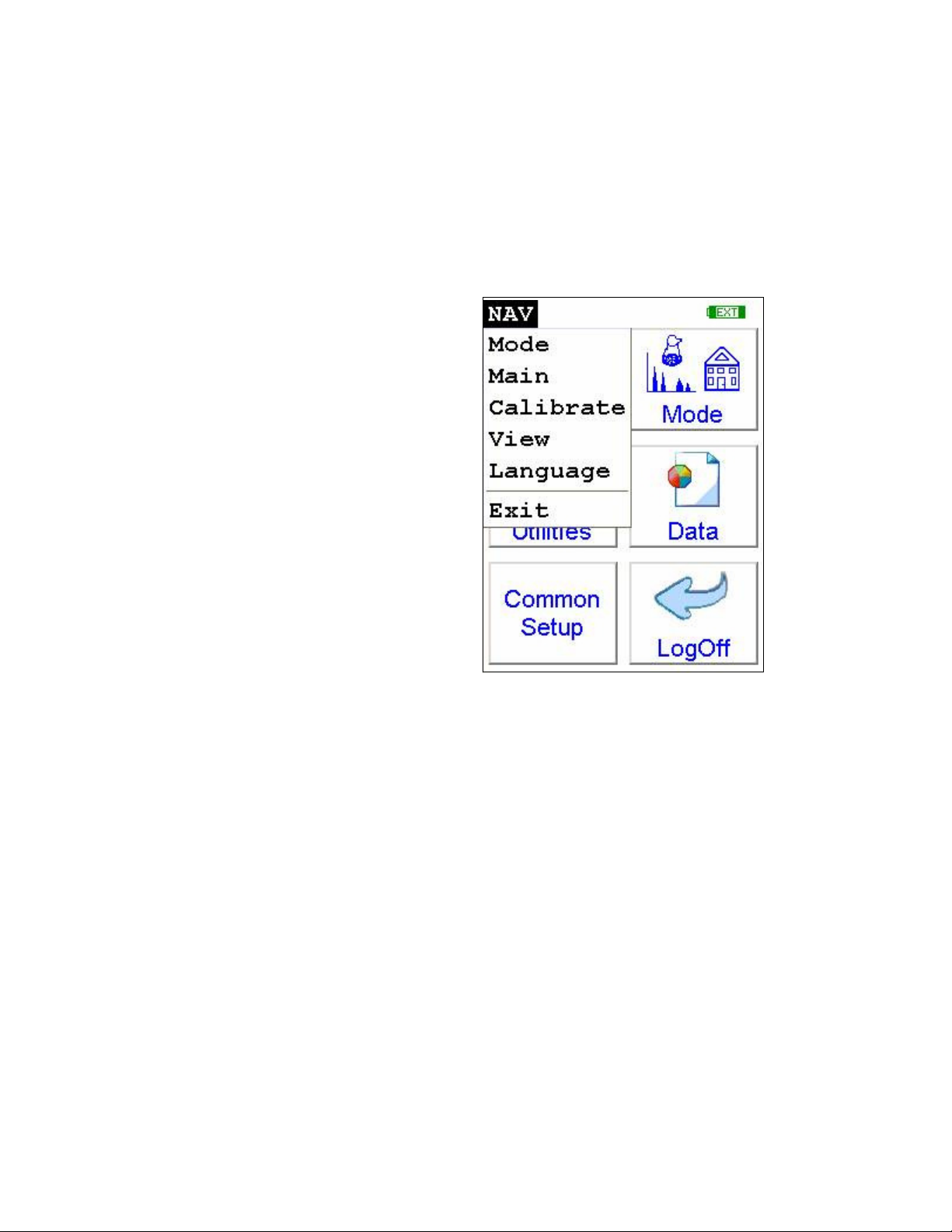

The NAV Menu

Figure 0-9. The NAV Menu

The Navigation Menu, or NAV Menu, is available in all screens, though

only through the touch screen interface. Within a menu, the particular

options available from the NAV Menu may change with the context. For

example, within the View Menu, the NAV Menu changes options

depending on the mode you are currently using.

viii NITON XL3 Analyzer User’s Guide Thermo Scientific

The Data Ports

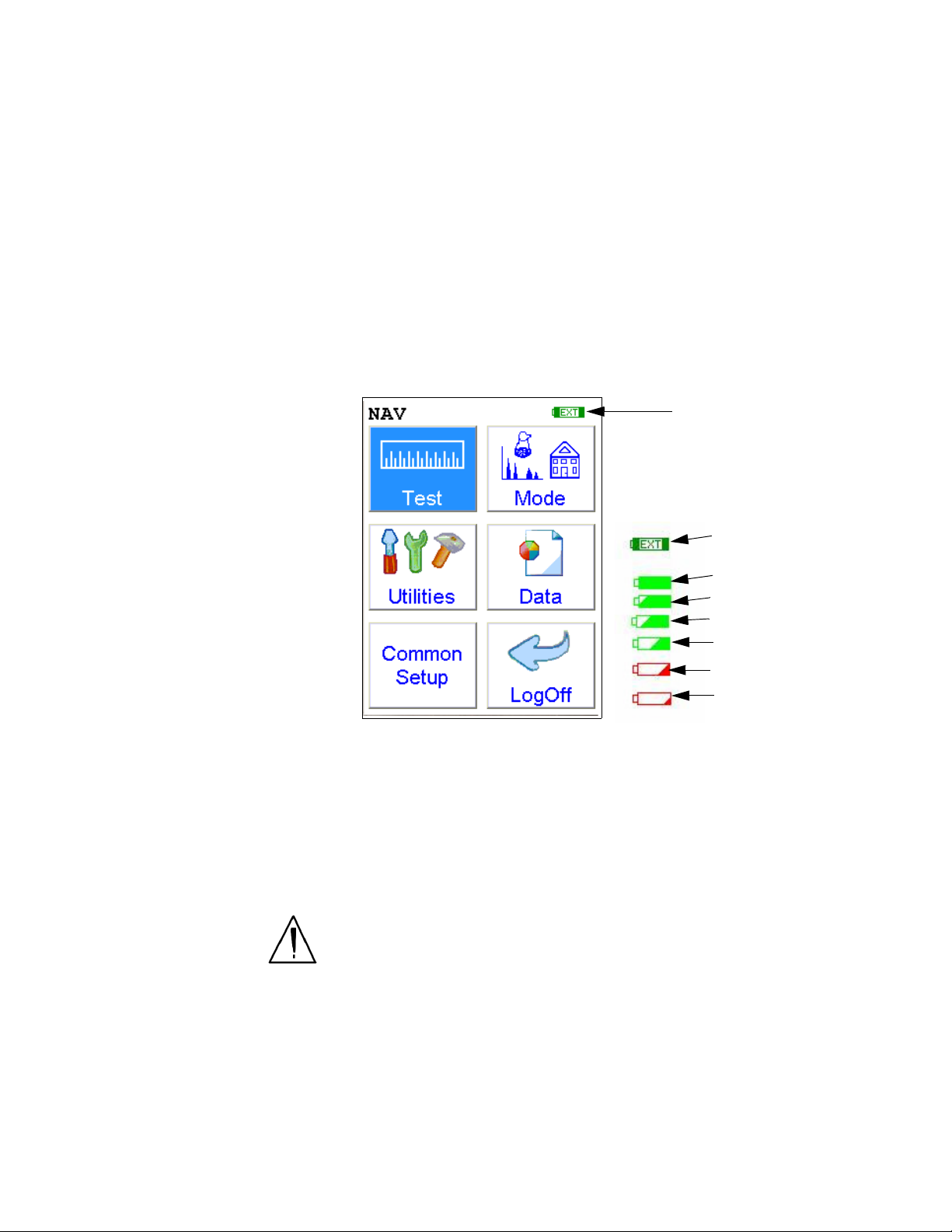

Battery Life Indicator

External Power Source

Full Battery

90% Battery Life

75% Battery Life

50% Battery Life

25% Battery Life

05% Battery Life

Battery Life Key

Access the NAV Menu by selecting the word NAV in the screen. A

drop-down menu of choices will appear. Selecting an option from the NAV

Menu will take you directly to a particular menu, no matter where you are

in the menu hierarchy. Selecting the “View” option from the NAV Menu,

for example, will bring you directly to the Data Menu.

The NAV Menu cannot be selected through the Control Panel.

The Battery Life Indicator

The Battery Life Indicator is visible on all screens in the menu system. The

indicator is visible in the top right portion of the screen, and graphically

shows you how much battery life is left, enabling you to change batteries as

needed to avoid unexpected shutdowns.

Figure 0-10. Battery Life Indicator

The more green visible in the indicator, the higher the charge. The more red

visible in the indicator, the lower the charge. It’s best to charge one battery

while using the other, to avoid work slowdowns or stoppages due to battery

charge conditions.

WARNING! In the highly unlikely event that the x-ray tube remains on

when the trigger is not depressed, disconnect the battery pack immediately

to turn off the x-ray tube, and call Thermo Fisher Scientific’s Service

Department in the United States, toll free, at (800) 875-1578, or outside

the United States at +1-978-670-7460, or your local Authorized NITON

Analyzers Service Center.

Thermo Scientific NITON XL3 Analyzer User’s Guide ix

The Data Ports

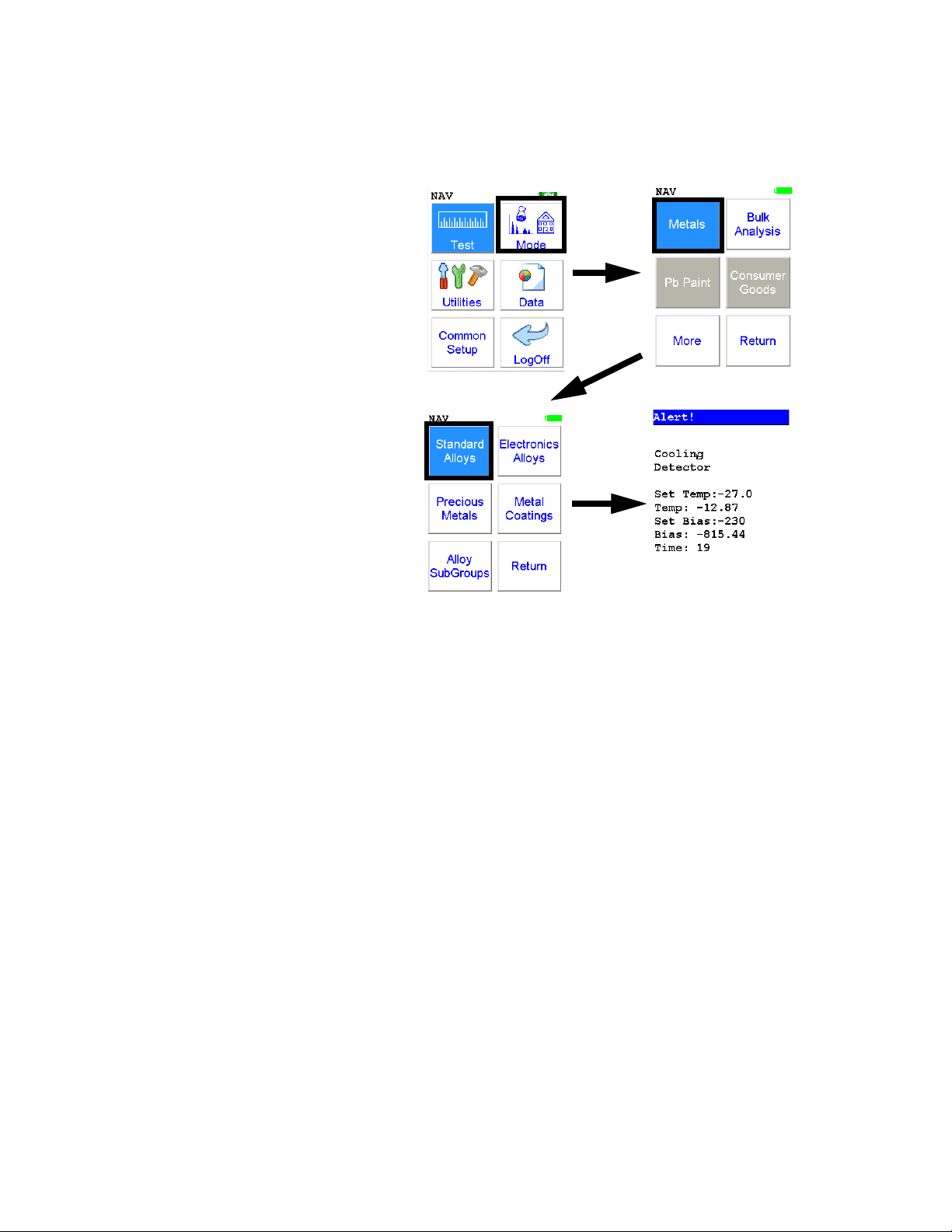

The Menu Path

The Menu Path shows you graphically how to get to the function being

described in several discrete steps from the universal start position, the Main

Menu.

Figure 0-11. Example Menu Path

In the Menu Path, the order is top to bottom, then if needed left to right,

starting with the Main Menu and ending with the function wanted. The

arrows show the succession of menus, while the icon to be selected is

highlighted by a heavy rectangular border.

This Menu path should be read as:

To get to this screen, starting at the Main Menu, select the Mode icon,

select the Metals icon, then select the Standard Alloys icon.

x NITON XL3 Analyzer User’s Guide Thermo Scientific

Applications

The NAV Menu

The NAV Menu

Chapter 1

The NAV Menu enables you to move between various menus and screens

directly, without going through the intervening screens. Select a destination

from the drop down menu and you will be brought directly to that menu or

screen.

Applications

Figure 1-1. The NAV Menu

Thermo Scientific NITON XL3 Analyzer User’s Guide 1-1

Applications

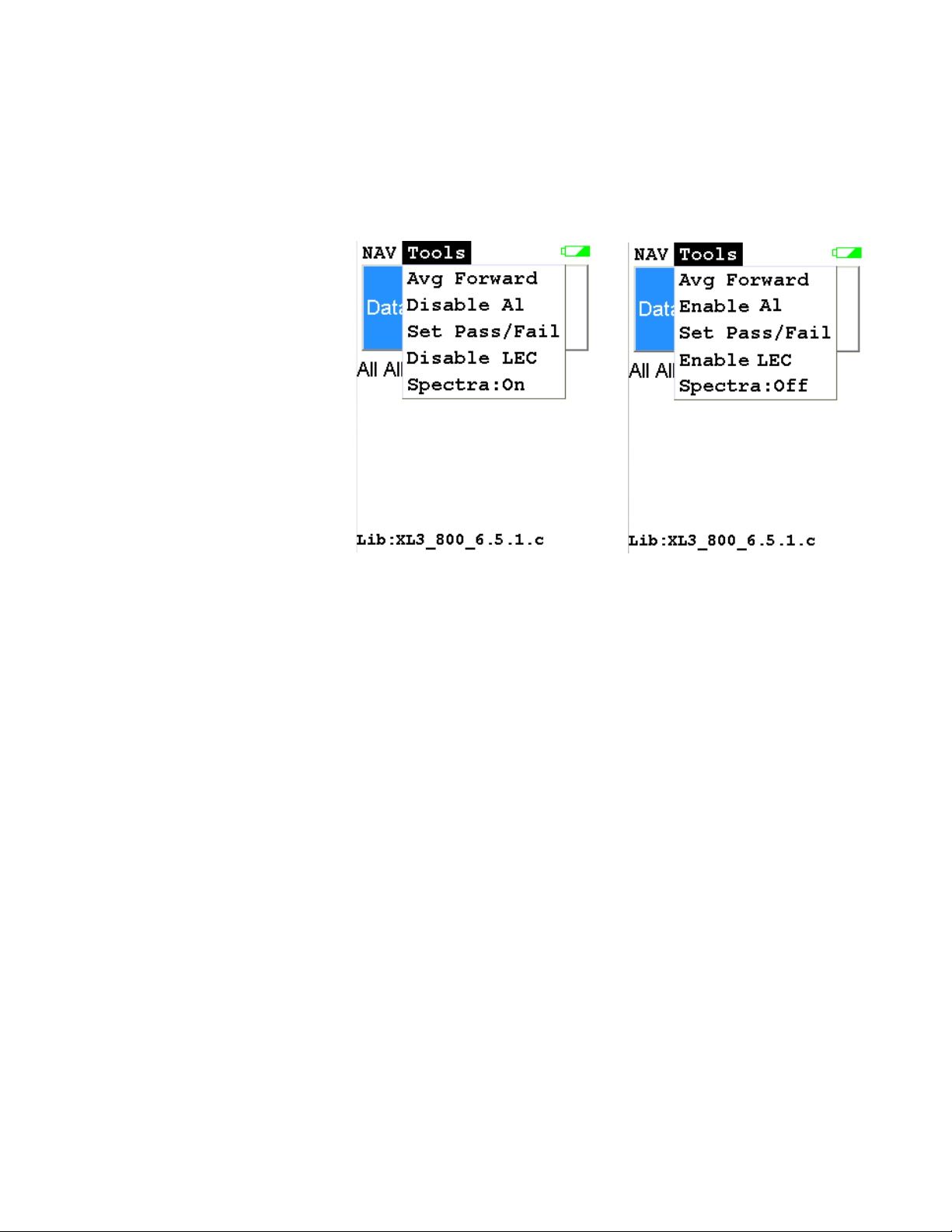

Tools Menu - All Enabled

Tools Menu - All Disabled

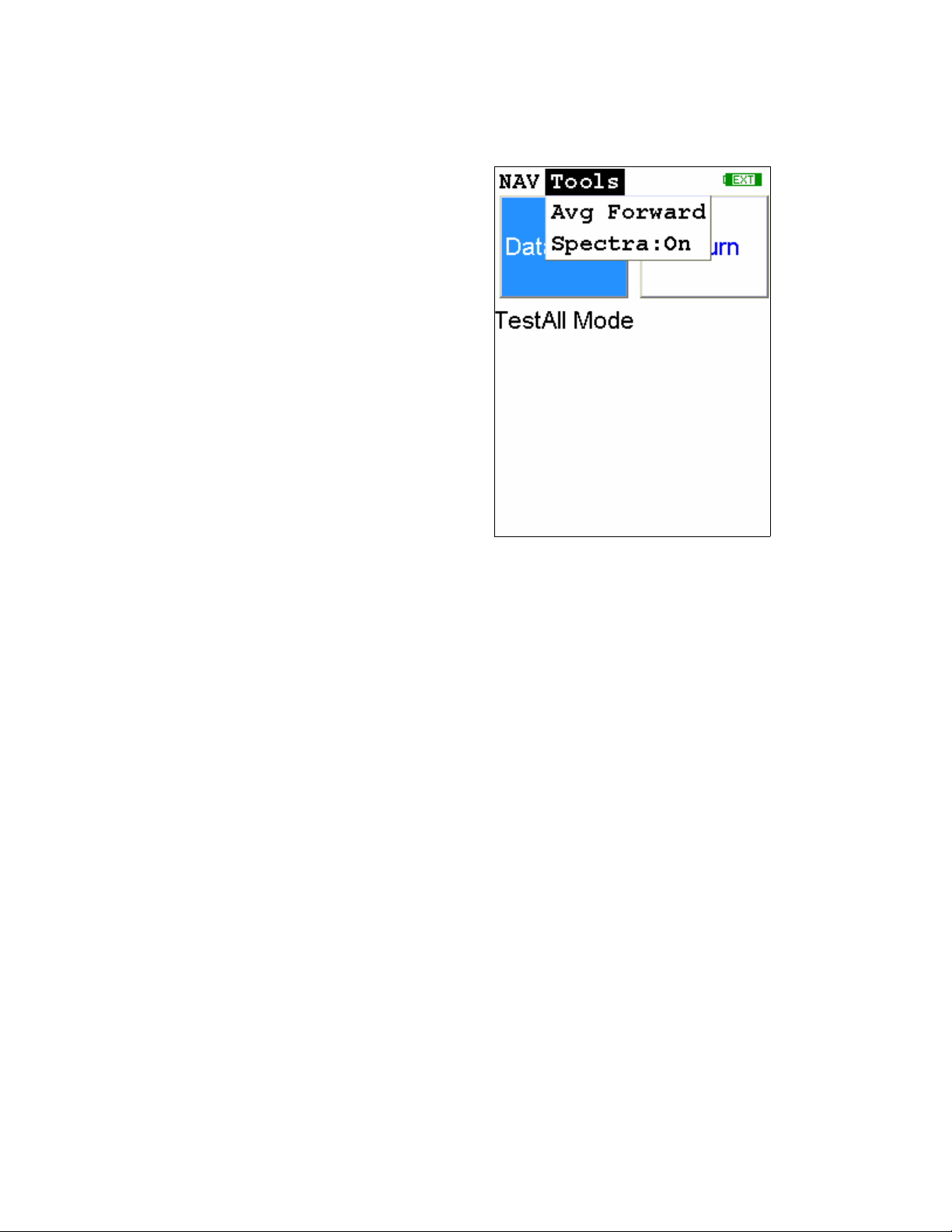

The Tools Menu

The Tools Menu

The Tools Menu enables you to perform common data-related tasks such as

printing and averaging. Select a task from the drop down menu to initiate

that task.

.

Avg Forward

Avg Back

Figure 1-2. The Tools Menu

The Tools Menu, like the NAV Menu, uses context sensitive menus. The

following is the most common menu set.

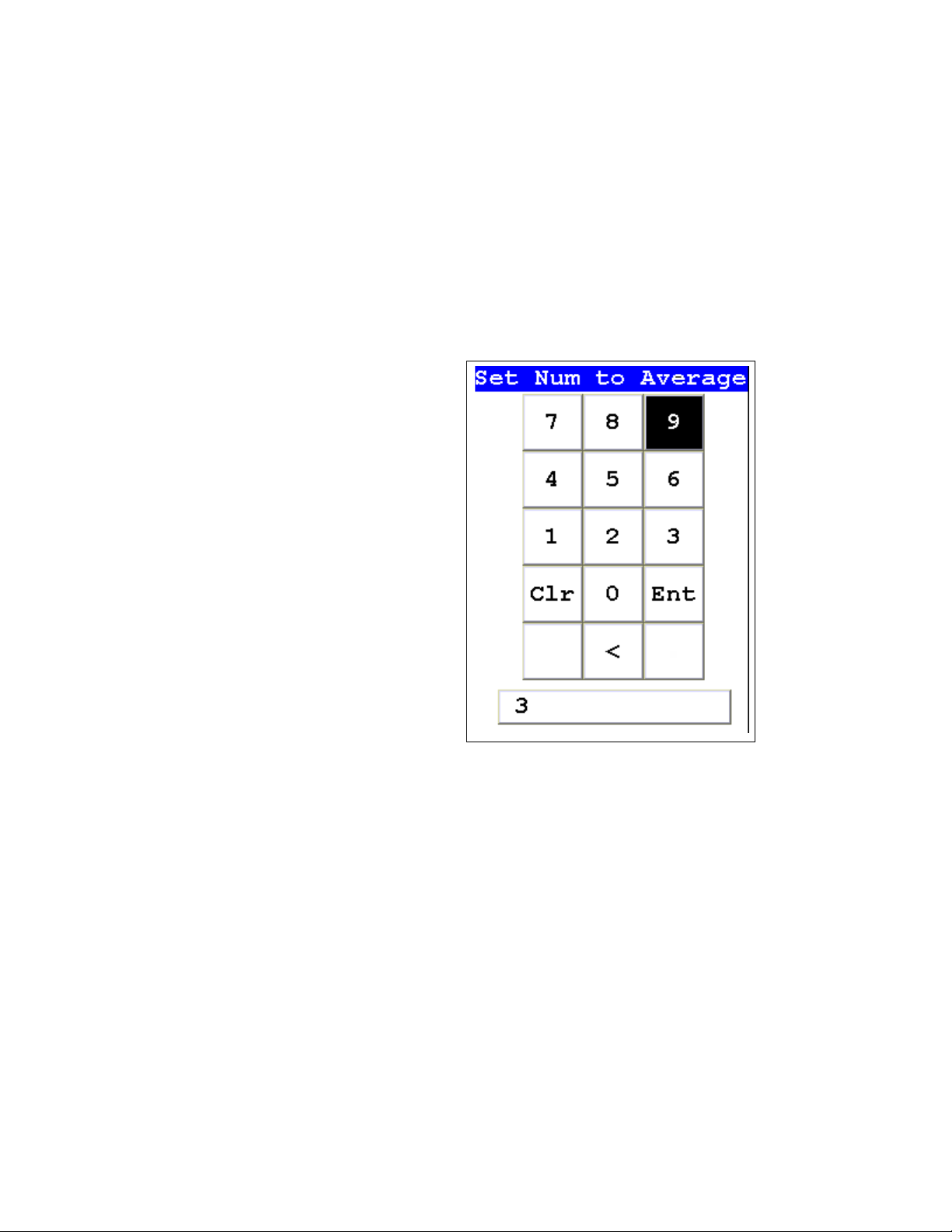

Enables you to average different readings together from this analysis

forward. Select Avg Forward to initiate future sample averaging. Avg

Forward will set up an automatic personal averaging protocol to be followed

until your analyzer is shut down, or this feature is disabled. To begin, select

the number of readings you want to average from the virtual numeric

keypad. Your analyzer will calculate an average reading after that number of

tests, and continue this pattern until stopped. For example, if you select 3

on the virtual keypad, the analyzer will automatically calculate, average, and

store a reading for every three tests you take, storing the individual readings

along the way.

Enables you to average different readings together from this analysis

backward. Select Avg Back to initiate backwards sample averaging. Avg

Back will take a number of readings you select and average their analytical

results. The range is counted from the last reading backward by the number

1-2 NITON XL3 Analyzer User’s Guide Thermo Scientific

Applications

The Tools Menu

of readings selected. If your last reading was #15, selecting 3 would average

readings #13, 14, and 15. The average is calculated, displayed, and stored

into memory as the next sequential reading number.

The range number is selected using a virtual keypad on your analyzer similar

to the keypad used for login. Select the digits in the range number from the

keypad, then select the “E” key to enter the number. “C” will clear all, and

“<“ will clear the last digit entered. The average will automatically be

displayed.

Figure 1-3. The Virtual Numeric Keypad for Averaging

Note You cannot average readings taken with different element lists - or with

different filter settings if the settings have different element lists - with either

Avg Back or Avg Forward. Alloy and Mining modes each use the same

element lists with the different filter settings, so averaging works when

switching between filter settings when in either of these modes. Thin Film

and Bulk modes both use different element lists for different filter settings,

and readings with different filter settings cannot be averaged when using

either of these modes. You can never average readings taken in different

modes.

Note The Tools Menu is only available when viewing readings, and the

menu is only accessible through the touch screen interface or NDTr.

Thermo Scientific NITON XL3 Analyzer User’s Guide 1-3

Applications

The Tools Menu

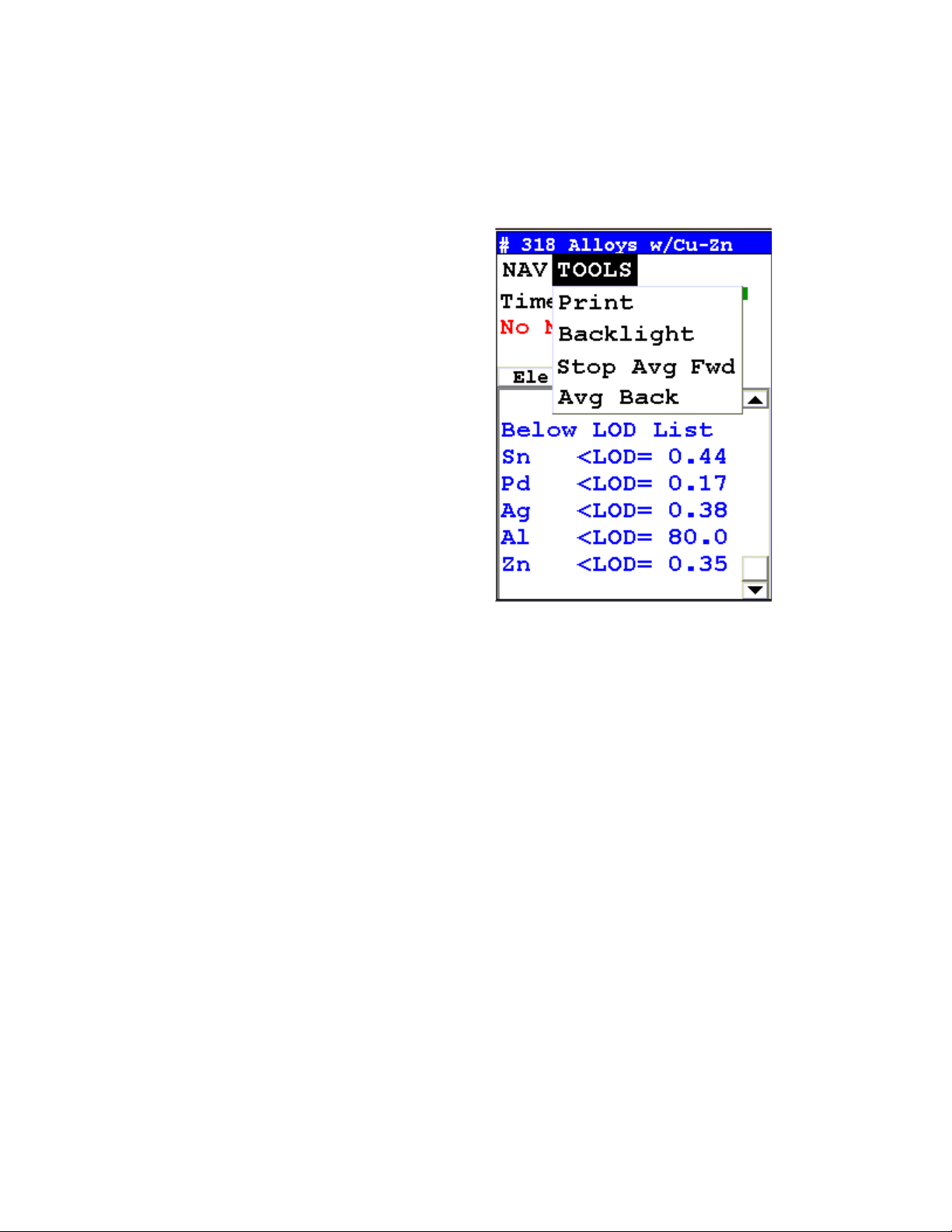

Stop Avg Fwd/Back

Avg Back and Avg Forward are toggles. The option on the Tools Menu

changes to its opposite when selected. To stop averaging, select Stop Avg

Fwd or Stop Avg Back from the Tools Menu as appropriate.

Figure 1-4. The Tools Menu - Averaging Toggles

1-4 NITON XL3 Analyzer User’s Guide Thermo Scientific

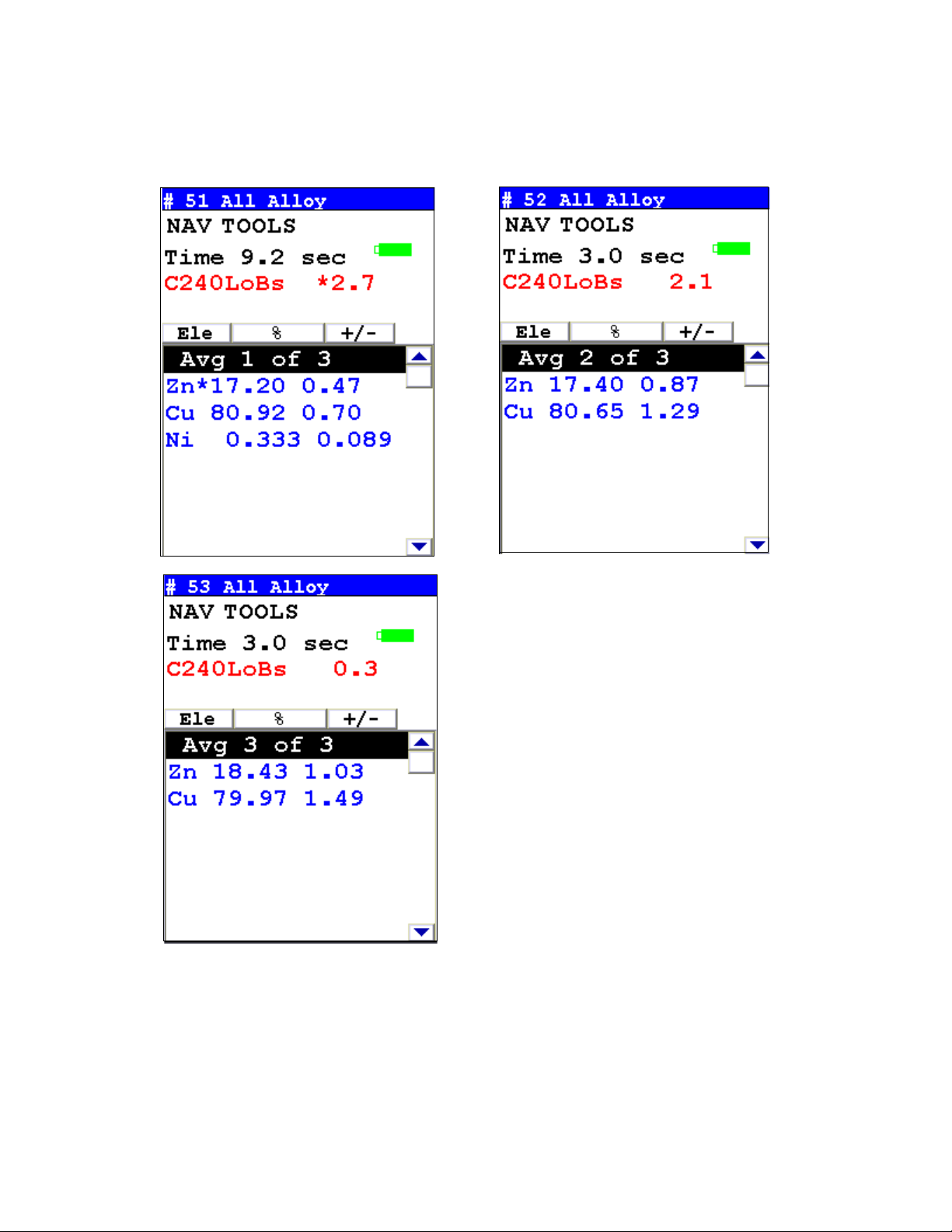

Example Averaging

Applications

Example Averaging

Figure 1-5. Averaging example: 3 readings

Thermo Scientific NITON XL3 Analyzer User’s Guide 1-5

Applications

Live Spectrum Feed

Live Spectrum Feed

The Tools Menu may contain a toggle option to display live spectra as

sample analysis occurs.

Figure 1-6. The Tools Menu showing the Spectra On/Off Toggle

1-6 NITON XL3 Analyzer User’s Guide Thermo Scientific

Applications

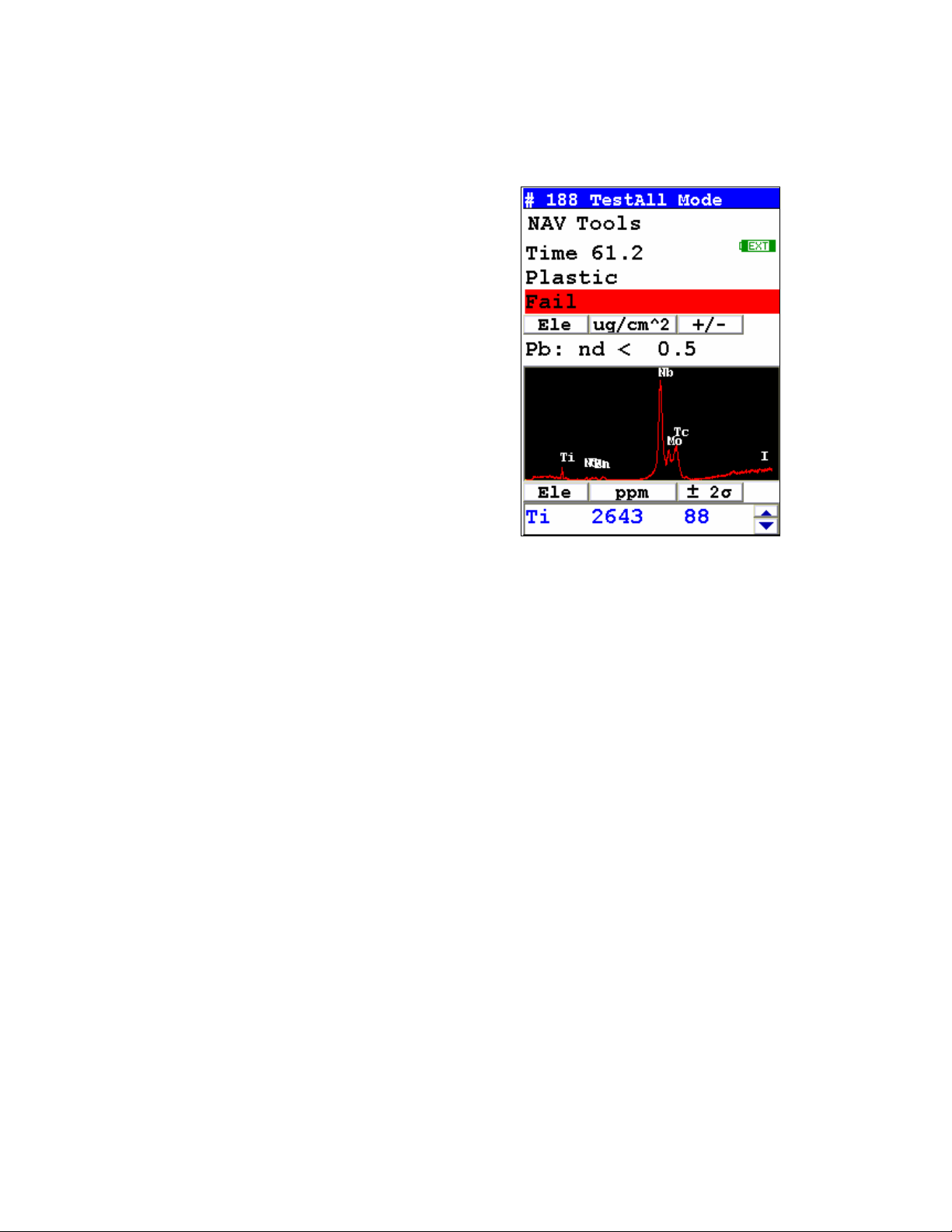

Live Spectrum Feed

Activating and

Deactivating the Live

Spectrum

From the Tools Menu, select Spectra : On to turn the Spectrun feed on.

Once the spectrum is displayed, selecting Spectra : Off from the Tools Menu

will stop the live spectrum display.

Figure 1-7. Test Screen Showing Live Spectrum

Thermo Scientific NITON XL3 Analyzer User’s Guide 1-7

Applications

Live Spectrum Feed

1-8 NITON XL3 Analyzer User’s Guide Thermo Scientific

Analyzing Bulk

Samples

Analyzing Bulk Samples

CAUTION Whenever you turn on your NITON Analyzer after it has been

off for more than 30 minutes, you should measure your check sample to

assure proper operation. If the instrument is not reading properly, you

should re-calibrate your NITON Analyzer's sample analysis electronics

before you start to take readings. When the instrument is turned on after

being off for more than 30 minutes, your NITON analyzer will require a 10

minute warm-up period before the instrument can be calibrated, unless this

10 minute warm-up period is manually overridden.

There are six different methods of operation for taking a sample

measurement, and your analyzer will be configured to use one of those

methods for soil samples, depending on the regulatory requirements of your

locality. These methods are:

• Trigger-Only method. With the Trigger-Only method, you only

need to place the measurement window close to the sample to be

analyzed and pull the trigger for sample analysis to be initiated.

• Trigger-and-Proximity-Sensor method. With the

Trigger-and-Proximity-Sensor method, you must place the

measurement window against the sample to be analyzed to engage

the proximity sensor on the front of the instrument, then pull the

trigger for sample analysis to be initiated.

• Momentary-Trigger-Touch-and-Proximity-Sensor method. With

the Momentary-Trigger-Touch-and-Proximity-Sensor method, you

must place the measurement window against the surface to be

analyzed to engage the proximity sensor on the front of the

instrument, then pull the trigger. The trigger may be released and

the reading will continue until you release the proximity button, or

other criteria (such as Max Time) are reached.

• Trigger-and-Interlock method. With the Trigger-and-Interlock

method, you need to place the measurement window close to the

sample to be analyzed, press and keep pressing the interlock button

at the rear of the instrument with your free hand, then pull the

trigger for sample analysis to be initiated.

Thermo Scientific NITON XL3 Analyzer User’s Guide 1-9

Analyzing Bulk Samples

• Trigger-Interlock-and-Proximity-Sensor method. With the

Trigger-Interlock-and-Proximity-Sensor method, you must place the

measurement window against the sample to be analyzed to engage

the proximity sensor on the front of the instrument, press and keep

pressing the interlock button at the rear of the instrument with your

free hand, then pull the trigger for sample analysis to be initiated.

• Easy Trigger method. With the Easy trigger method, you need only

place the measurement window against the sample area and pull the

trigger once to initiate a sample analysis. Your analyzer will

continuously sample the backscatter, using a complex internal

algorithm, to determine if the measurement window is against a

sample or pointing to the empty air. If it finds that there is no

sample directly against the measurement window, the analyzer will

stop directing radiation through the window as soon as this

determination is made.

Note The analyzer is constantly checking the backscatter characteristics to

determine if a sample is against the measurement window, whether or not

the Easy Trigger method is being used, and will shut off any radiation

directed through the window if it determines that there is no sample

present.

With any of these methods, analysis will stop if any one of the preconditions

are violated. For example, with the Trigger-Interlock-and-Proximity-Sensor

method, if the trigger or the Proximity Sensor or the Interlock is released,

the reading will stop immediately, and the X-ray tube will shut down.

After your NITON analyzer is calibrated, initiate a sample reading using the

appropriate method. If you attempt to initiate a sample reading using a

different method, the analyzer will inform you that one or more of the

preconditions need to be met in order for sample analysis to begin. Initiate

the proper preconditions for operation to turn on the x-ray tube, and begin

a measurement. Although the four LED lights will begin to flash as soon the

initiating preconditions are met, as a safety precaution, the x-ray tube will

not turn on immediately, and no reading will begin for approximately 0.5

seconds.

Note The four LED lights will blink during calibration.

1-10 NITON XL3 Analyzer User’s Guide Thermo Scientific

Analyzing Bulk Samples

WARNING! The preconditions for operation must be continued for the

duration of the reading. If the preconditions are violated, the x-ray tube will

turn off, the calibration shutter will close, and the measurement will end.

The four LED lights will stop blinking when the measurement is ended.

The flashing of the LED lights is not synchronized to minimize power

consumption.

To end the test, simply release the trigger mechanism, or any other

applicable preconditions.

WARNING! When all four LED lights are blinking, the x-ray tube is on.

This should only occur during a measurement, while the preconditions for

operation are met. On startup, the front pair of lights will blink. If the LED

lights blink at any other time, disconnect the battery pack and call Thermo

Scientific’s Service Department in the United States, toll free, at (800)

875-1578, or outside the United States, at +1-978-670-7460, or your local

Authorized NITON Analyzer Service Center.

Your NITON Analyzer will display the Results Screen throughout the

duration of each reading, The Results Screen is updated regularly

throughout the reading. When the reading is complete, a final screen update

will appear, and your NITON analyzer will display the final results of the

measurement which has just been completed.

WARNING! Do not attempt to take measurements while downloading

readings! This will generate an error requiring a system reset, and may

corrupt your stored readings, requiring all stored readings to be erased.

Thermo Scientific NITON XL3 Analyzer User’s Guide 1-11

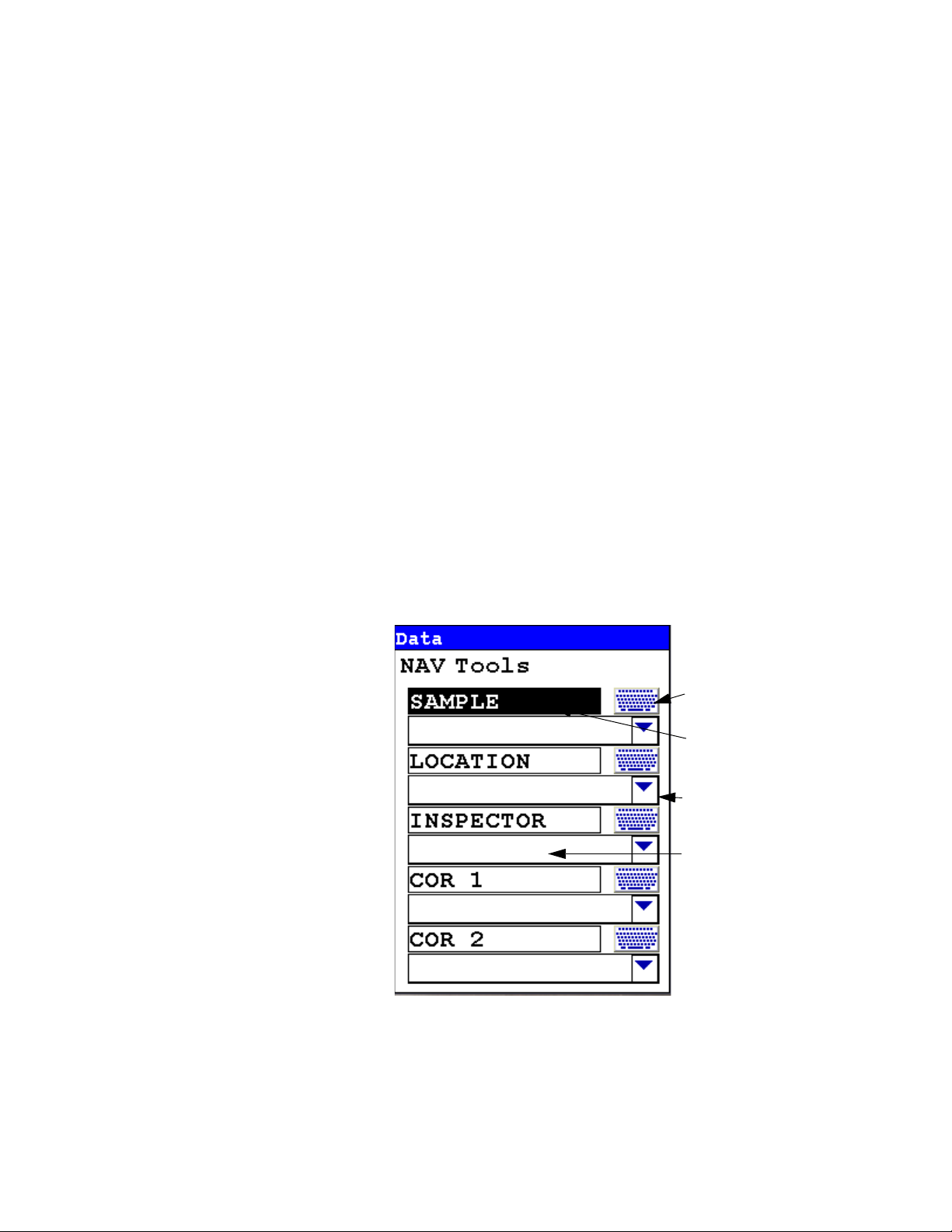

The Data Entry Screen

Virtual Keyboard

Button

Parameter Field

Name

Drop-down List

Button

Parameter Field

The Data Entry Screen

The Data Entry Screen is accessed whenever you select the Data Entry

icon from any screen. This screen allows you to input data in several

different fields, or categories, concerning your sample, in several different

ways:

• By selecting the Virtual Keyboard button and typing the parameter in

using the Virtual Keyboard.

• By creating a new, or editing your analyzer's existing, '.ndf' file through

the NDT program. You can then select from the various custom options

you have created using the Drop-down List button.

These fields are saved along with the subsequent reading, and allow you to

associate important information about the sample directly with the reading,

so that you have a full description of the sample tied into the reading itself.

Once you have input data into a field, that information carries over into the

next reading, so that you only have to input the information that has

changed since the last reading. For example, if you are analyzing several

samples of a particular lot, you only need to input the lot information once

during that series of readings, changing only the sample name.

Figure 1-1. The Data Entry Screen - First page

1-12 NITON XL3 Analyzer User’s Guide Thermo Scientific

The Data Entry Screen

This is the first section of the Data Entry Screen. There are five

parameters in this section.

Selecting Sample allows you to input the sample name parameter.

Selecting Location allows you to input the particular Location information,

if known.

Selecting Inspector allows you to input the parameter for the Inspector’s

name.

Selecting Cor1 allows you to input information on the sample’s origin

Latitude Coordinate.

Selecting Cor2 allows you to input information on the sample’s origin

Longitude Coordinate.

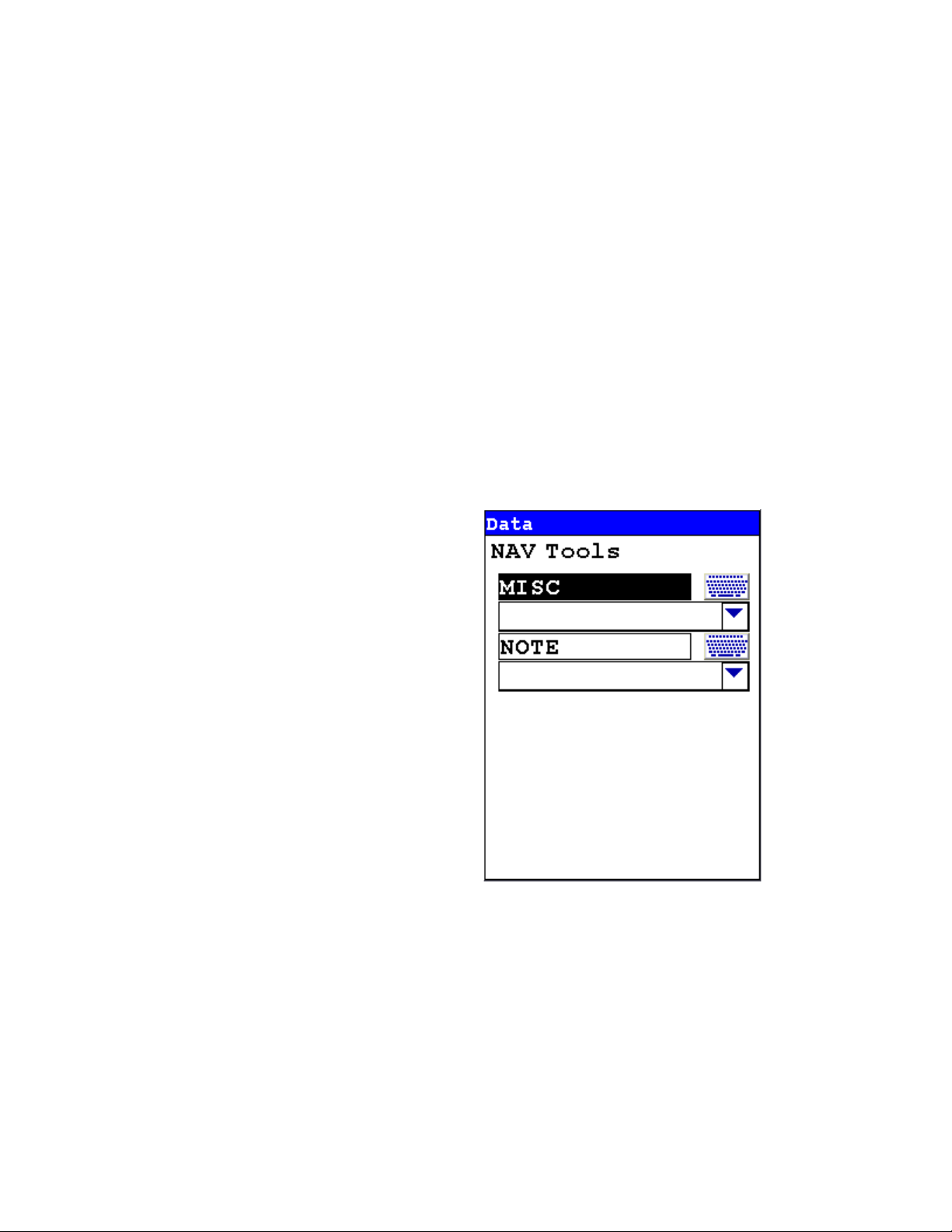

This is the second section of the Data Entry Screen. There are two

parameters in this section.

Selecting Misc allows you to input the any miscellaneous parameters.

Selecting Note allows you to input any Note information, if wanted.

Thermo Scientific NITON XL3 Analyzer User’s Guide 1-13

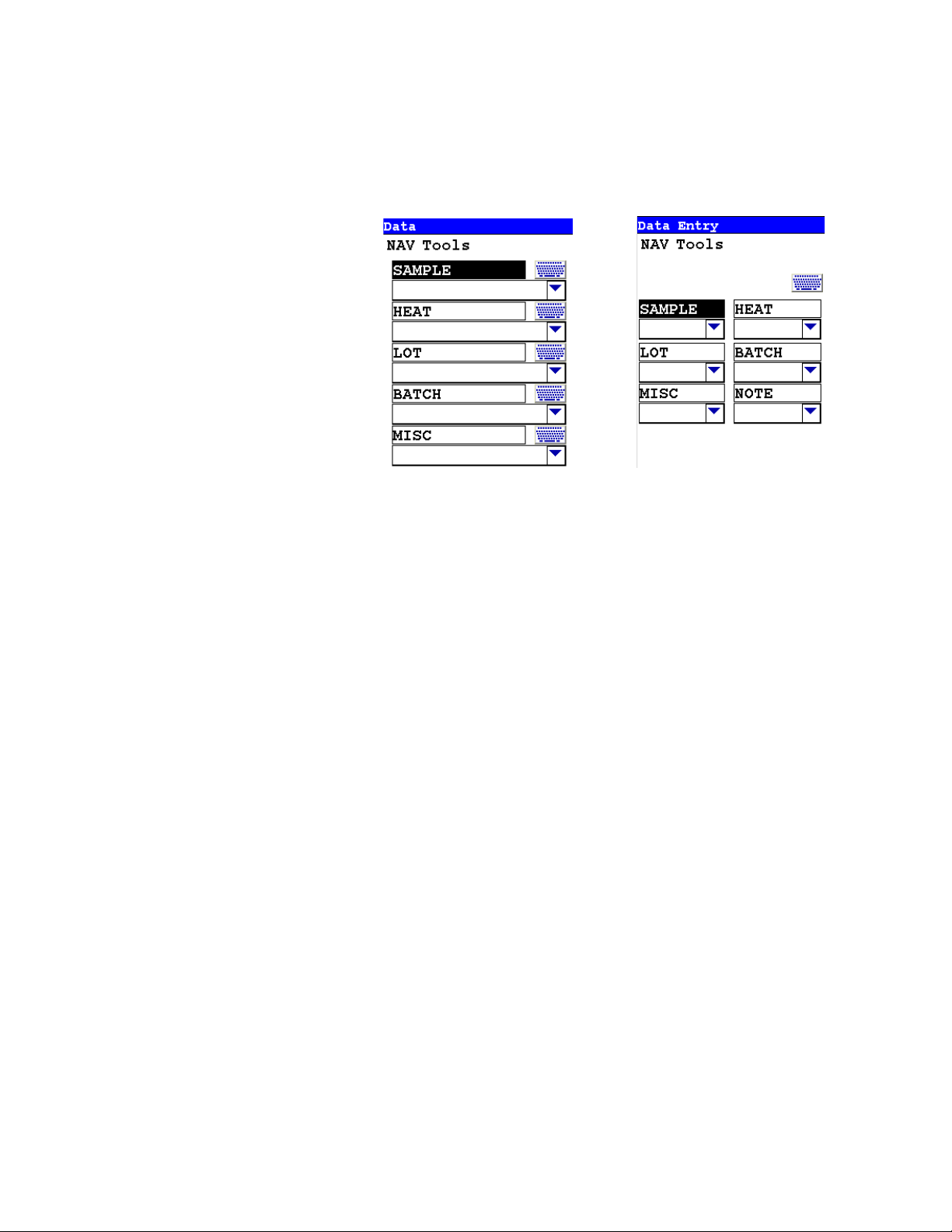

Changing the Data Entry Screen to Two Column

Changing the Data

Entry Screen to Two

Column

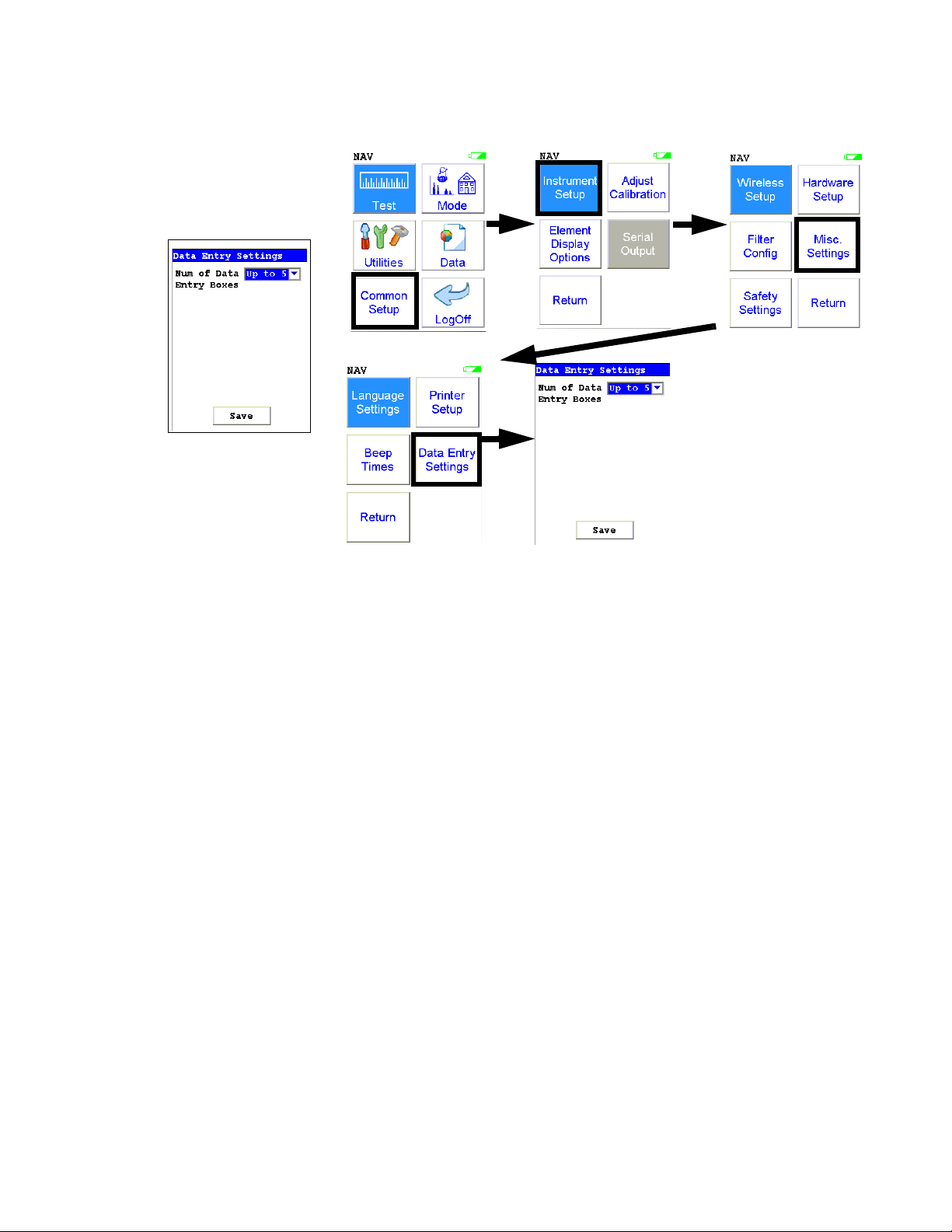

Figure 1-2. Data Entry Settings Menu Path

You can change the Data Entry display from the default single column to

two columns in order to fit all the fields on one page, if you prefer. Select the

Data Entry Settings icon from the Misc. Settings Menu to change your

preferences.

1-14 NITON XL3 Analyzer User’s Guide Thermo Scientific

Changing the Data Entry Screen to Two Column

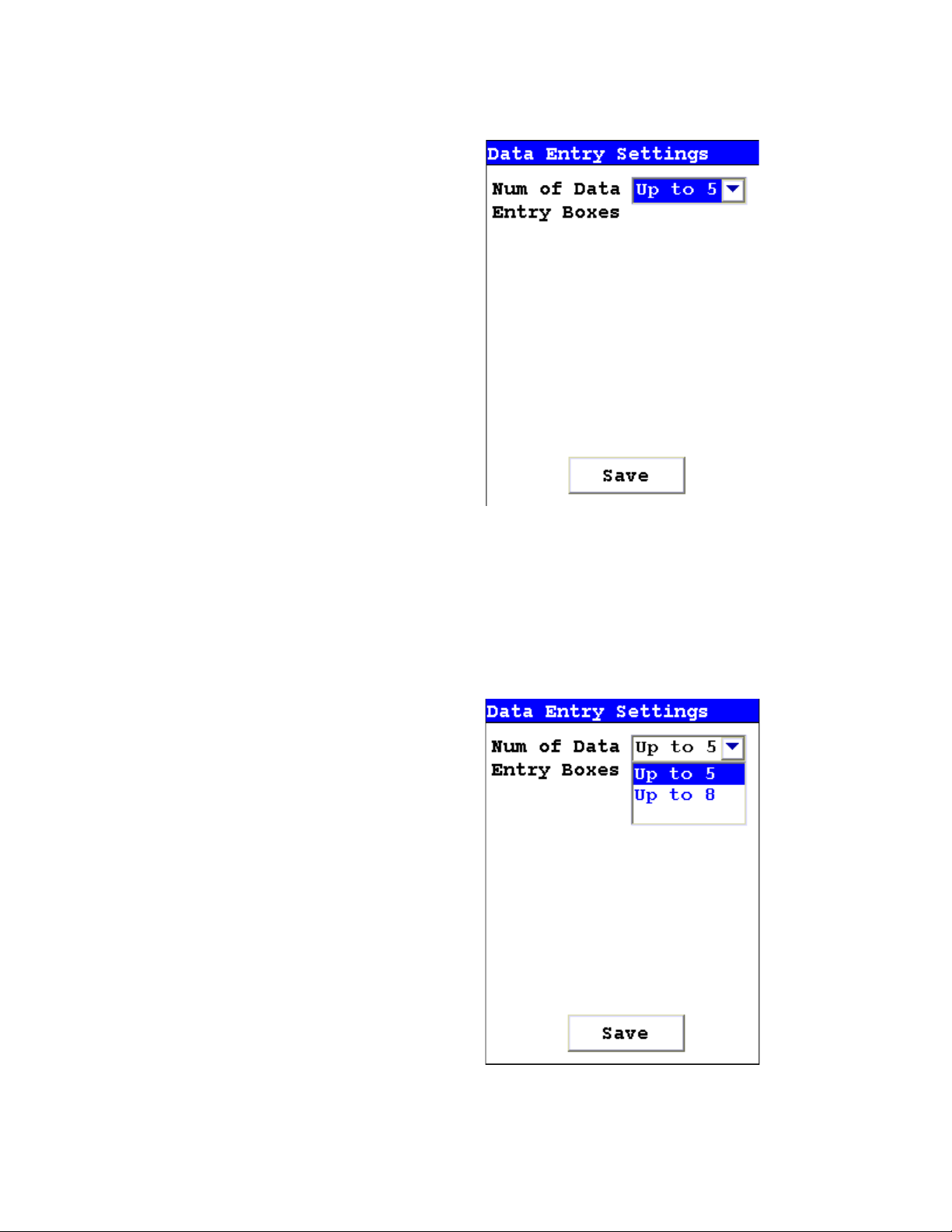

Figure 1-3. Data Entry Settings Screen

Selecting the triangle button to the side of the Num of Data Entry Boxes

field will open a drop down menu. From this menu you can choose between

showing up to five boxes per page, the default, and up to eight boxes per

page. Select the option you prefer, and select the Save button to save the

setting.

Figure 1-4. The Drop Down Menu

Thermo Scientific NITON XL3 Analyzer User’s Guide 1-15

Changing the Data Entry Screen to Two Column

Up to Five Boxes

Up To Eight Boxes

Under the default setting, a mode with more than five boxes will open up a

second page to display the remaining boxes. Under the optional setting, a

mode with up to eight boxes will display on one page, with the overflow

page not opening unless there are nine or more Data Entry boxes.

Figure 1-5. Comparing the Data Entry Display Options

With the default, up to five boxes, setting, the boxes are longer, and can

display more descriptive test. With the optional, up to eight, setting, the

boxes are shorter, but retain the full descriptive text internally. Choose

whichever settign you feel most comfoortable working with.

1-16 NITON XL3 Analyzer User’s Guide Thermo Scientific

Loading...

Loading...