Page 1

Thermo Scientific

NESLAB EX Series

Bath/Circulator

Thermo Scientific Manual P/N U00696 Rev. 03/06/07

Installation

Operation

Basic Maintenance

Visit our Web site at:

http://www.thermo.com/tc

Product Service Information, Applications

Notes, MSDS Forms, e-mail.

Voice Info: (800) 258-0830

Page 2

Thermo Fisher Scientific

Sales, Service, and Customer Support

25 Nimble Hill Road

Newington, NH 03801

Tel : (800) 258-0830 or

(603) 436-9444

Fax : (603) 436-8411

www.thermo.com/tc

25 Nimble Hill Road

Newington, NH 03801

Tel: (800) 258-0830

Sales: 8:00 am to 5:00 pm

Service and Support: 8:00 am to 6:00 pm

Monday through Friday (Eastern Time)

Fax: (603) 4 36-8411

service.tc.us@thermofisher.com

Dieselstrasse 4

D-76227 Karlsruhe, Germany

Tel : +49 (0) 721 4094 444

Fax : +49 (0) 721 4094 300

Building 6, No. 27

Xin Jinqiao Rd., Shanghai 201206

Tel : +86(21) 68654588

Fax : +86(21) 64457830

info. china@thermofisher.com

Statement of Copyright

Copyright © 2007 Thermo Fisher Scientific. All rights reserved.

This manual is copyrighted by Thermo Fisher Scientific.

Users are forbidden to reproduce, republish, redistribute, or resell any materials from this manual

in either machine-readable form or any other form.

Page 3

Table of Contents

Preface

Compliance ..............................................................................................................2

WEEE/RoHS.............................................................................................................2

Unpacking ................................................................................................................2

After-sale Support ....................................................................................................3

Warranty................................................................................................................... 3

Feedback................................................................................................................. 3

Section I Safety

Warnings.................................................................................................................. 4

Section II General Information

Quick Reference Operating Procedures.................................................................6

Description............................................................................................................... 7

Specifications...........................................................................................................7

Section III Installation and Operation

Site .........................................................................................................................11

Electrical Requirements......................................................................................... 11

Plumbing Requirements ........................................................................................13

Tap Water Cooling Connections............................................................................14

Fluids .....................................................................................................................16

Filling Requirements..............................................................................................16

Controller (Digital One/Digital Plus) ...................................................................... 17

Start Up/Shut Down................................................................................................19

Setup/Tuning Loop ................................................................................................21

Controller (Digital Plus) .........................................................................................22

Computer Setup Loop ...........................................................................................24

Timer Setup Loop ..................................................................................................25

Offset Setup Loop ..................................................................................................26

Analog A I/O Port - Optional................................................................................... 27

High Temperature Cutout ......................................................................................28

Accessories............................................................................................................ 29

Section IV Basic Maintenance

Reservoir Fluid ......................................................................................................35

Reservoir Cleaning ................................................................................................35

Algae ...................................................................................................................... 35

Internal Temperature Sensor (rtd1) Calibration .................................................... 36

External Temperature Sensor (rtd2) Calibration ................................................... 37

Optional Analog Port/Calibration - Optional..........................................................38

Section V T roubleshooting

Error Codes ........................................................................................................... 39

External Sensor Connector ...................................................................................40

Checklist.................................................................................................................41

Service Assistance.................................................................................................42

Controller PID Values.............................................................................................42

BOM Decoder ........................................................................................................42

Displaying Software Version Number ....................................................................43

Appendix A Fluids

Appendix B NC Serial Communications Protocol

Appendix C International Quick Reference Guide

W ARRANTY

- 1 -

Page 4

Compliance

WEEE/RoHS

Preface

Listed to:

UL 61010-1 2nd Edition

CSA C22.2 #61010.1 2nd Edition

Products tested and found to be in compliance with the requirements defined in

the EMC standards defined by 89/336/EEC as well as Low Voltage Directive

(LVD) 73/23/EEC can be identified by the CE Mark on the rear of the unit. The

testing has demonstrated compliance with the following directives:

LVD, 73/23/EEC Complies with IEC/EN61010-1

EMC, 89/336/EEC IEC/EN61326-1

For any additional information, refer to the Declaration of Conformity that

shipped with the unit.

This product is required to comply with the European Union’s Waste Electrical

& Electronic Equipment (WEEE) Directive 2002/96/EC. It is marked with the

following symbol:

Unpacking

Thermo Fisher Scientific has contracted with one or more recycling/disposal

companies in each EU Member St ate, and this product should be disposed of or

recycled through them. Further information on Thermo Fisher Scientific’s

compliance with these Directives, the recyclers in your country , and information

on Thermo Scientific products which may assist the detection of substances

subject to the RoHS Directive are available at: www.thermo.com/WEEERoHS

Retain all cartons and packing material until the unit is operated and found to

be in good condition. If the unit shows external or internal damage contact the

transportation company and file a damage claim. Under ICC regulations, this is

your responsibility.

Out of Box Failure

An Out of Box Failure is defined as any product that fails to operate in conformance with sellers published specifications at initial power up. The unit must

be installed in accordance with manufacturer's recommended operating

conditions within 30 days of shipment from the seller.

Any product meeting the definition of an Out of Box Failure must be packed and

shipped back in the original packaging to Thermo Fisher Scientific for replacement with a new unit; Seller to pay the cost of shipping. Customer must receive

a Return Material Authorization (RMA) from Thermo Fisher prior to shipping the

unit.

- 2 -

Page 5

After-sale Support

Thermo Fisher Scientific Corporation is committed to customer service both

during and after the sale. If you have questions concerning the unit operation,

contact our Sales Department. If your unit fails to operate properly, or if you

have questions concerning spare parts or Service Contracts, contact our

Service Department. See the back side of the cover for contact information.

Before calling, please obtain the following information:

- unit BOM number_________________________________

- unit serial number ________________________________

- unit software version ______________________________

- voltage of power source ____________________________

The unit’s BOM number and serial number are printed on the name plate label

located on the rear of the unit. See page 42 for instructions on how to decode

your unit's BOM number. See page 43 for instructions on how to display the

software version.

Warranty

Feedback

BOM#: XXXXXXXXXXXX

S/N: XXXXXXXXX

XXX VOLT XX HZ X PH X.X AMP

Thermo Scientific NESLAB EX units have a warranty against defective parts

and workmanship for 24 months from date of shipment. See back page for

more details.

We appreciate any feedback you can give us on this manual. Please e-mail us

at neslabmanuals@thermofisher.com. Be sure to include the manual part

number and the revision date listed on the front cover.

- 3 -

Page 6

Warnings

Section I Safety

Warnings are posted throughout the manual. These warnings are designated

by an exclamation mark inside an equilateral triangle and text highlighted in

bold. Read and follow these important instructions. Failure to observe these

instructions can result in permanent damage to the unit, significant property

damage, or personal injury or death.

The lightning flash with arrow symbol, within an equilateral triangle, is intended

to alert the user to the presence of non-insulated "dangerous voltage" within

the unit's enclosure. The voltage may be of significant magnitude to constitute

a risk of electrical shock.

This label, engraved into the front of the tank lip, indicates the presence of hot

surfaces.

Make sure you read and understand all instructions and safety precautions

listed in this manual before installing or operating your unit. If you have any

questions concerning the operation of your unit or the information in this

manual, contact our Sales Department.

Performance of installation, operation, or maintenance procedures

other than those described in this manual may result in a hazardous

situation and may void the manufacturer's warranty.

Transport the unit with care. The units weigh approximately:

EX-7, 27 pounds (12 kilograms); EX-10, 32 pounds (15 kilograms);

EX-17, 36 pounds (16 kilograms); EX-35, 53 pounds (24 kilograms). Units

should be transported with equipment designed to lift these weights.

Observe all warning labels.

Never remove warning labels.

Never operate damaged or leaking equipment.

Never operate the unit without bath fluid in the bath.

The user is responsible for the fluid used. Never use pure ethylene

glycol as a bath fluid, the flash point of 100% ethylene glycol is 111°C.

100% ethylene glycol may produce flammable vapors that can be

ignited by an open flame or an ignition source. When mixed with

water, ethylene glycol is not flammable. Also, at high temperatures

pure ethylene glycol may produce hazardous vapors.

Always turn off the unit and disconnect the line cord from the power

source before performing any service or maintenance procedures, or

before moving the unit.

Always empty the bath before moving the unit.

Never operate equipment with damaged line cords.

Refer service and repairs to a qualified technician.

- 4 -

Page 7

Indicates heater status.

See page 17.

General Information

Section II General Information

Press to start/stop the

unit. See page 17.

Indicates the controller is

displaying the setpoint. Press

the arrow buttons to change the

value. See page 17.

Press to mute the alarm. See

page 22. Digital Plus controller

only.

Press to select external

sensor. See page 22. Digital

Plus controller only.

Indicates the controller is

displaying the unit's low

temperature alarm setpoint.

Press the arrow buttons to

change the value. See page 17.

Press to select the serial

communication mode.

See page 22. Digital Plus

controller only.

Controller. See page 17.

Press to select the timer

function. See page 23.

Digital Plus controller only.

High Temperature Cutout.

See page 28.

Press to change the

displayed value. See

page 17.

Press to sequence

through the three indicators

and accept the displayed

value. See page 17.

NOTE: None of the three

setpoint indicators are

visible unless this key is

pressed.

Press to select the

temperature offset

mode. See page 23.

Digital Plus controller only.

Indicates the controller is displaying

the high temperature alarm

setpoint. Press the arrow buttons

to change the value. See page 17.

Optional External Probe

Connector. Digital Plus

controller only. See page 40

.

Analog Output

Connector. Digital

Plus controller only.

See page 27.

Reservoir. See page 16.

Autorefill connection.

RS-232/RS-485

connections. See

Appendix B. Digital

Plus controller only.

1/8" OD Autorefill fluid

connection. See page 29.

1/4" MPT Pumping

Supply Connection. See

page 13.

1/4" MPT Pumping

Return Connection. See

page 13.

Drain. See page 13.

Tap water cooling.

See page 14.

- 5 -

Circuit

Breaker(s).

Power connection.

See page 11.

Page 8

Quick Reference Operating Procedures

Installation

Locate the unit on a sturdy work area. Ambient

temperatures should be inside the range of +50°F to

+104°F (+10°C to +40°C). The maximum operating

relative humidity is 80%.

Never place the unit in a location where excessive

General Information

heat, moisture, or corrosive materials are present.

Make sure the voltage of the power source meets

the specified voltage, ±10%.

The pump connections are located at the rear of the

pump box and are labelled and . These

connections are angled upward so the recirculating

fluid will drain back into the reservoir when the

hoses are disconnected. Both connections are

capped with stainless steel serrated plugs.

The pump lines have ¼" MPT for mating with

standard plumbing fittings. For your convenience

stainless steel adapters, ¼" FPT to 3/8" O.D.

serrated fitting, are provided.

The bath work area has a high and low level marker

to guide filling. The markers are 1 inch horizontal

slits located in the center of the stainless steel

baffle separating the work area and the pump

assembly. The correct fluid level falls between

these two markers. The unit will not start if the fluid

level is below the lower slit.

Temperature Adjustment

To display the temperature setpoint, press on

the controller. The indicator will illuminate and

the display will flash the current setpoint value. To

adjust the temperature setpoint, press the arrow

buttons until the desired temperature setpoint is

indicated. Press again to confirm the change.

The display will rapidly flash the new value for a

short time and then return to the recirculating fluid

temperature.

Periodic Maintenance

Periodically inspect the reservoir fluid. If cleaning is

necessary, flush the reservoir with a cleaning fluid

compatible with your application.

Before changing the reservoir fluid ensure it is

at a safe handling temperature.

Operation

Before starting the unit, double-check all electrical

and plumbing connections. Make sure the bath is

properly filled with fluid.

To start the unit, press . To turn the unit off

press again.

The LED indicates the status of the heater. It

illuminates to indicate the heater is on.

- 6 -

Page 9

Description

Specifications

Process Fluid

Temperature Range

The Thermo Scientific NESLAB EX Bath/Circulators are designed to provide

temperature control for applications requiring a fluid work area or pumping to an

external system.

Units consist of a circulation pump, seamless stainless steel bath, work area

cover, and a microprocessor temperature controller.

EX 7 EX 10 EX 17 EX 35

2

Ambient +12°C to +200°C

General Information

Temperature Stability

Pump Capacity

Heater (Watts)

115V/60 Hz Models

230V/50 Hz Models

100V/50-60Hz Models

Bath Work Area

(W x L x D)

Inches

Centimeters

3

4

5

6 5/8 x 7 x 6

16.8 x 17.8 x 15.2

±0.01°C

Meters Feet

4.9 16

e

3.7 12

r

u

s

s

e

r

P

2.4 8

1.2 4

0.8 1.6 2.4 3.2 4.0 Gpm

Flow

3691215Lpm

800 1600

2000 2000

800 1200

8 ¾ x 8 1/8 x 6

22.4 x 20.6 x 15.2

8¾ x 8 1/8 x 9

22.4 x 20.6 x 22.9

8 ¾ x 15 ½ x 12

22.4 x 39.4 x 30.5

Bath Volume

Gallons

Liters

Weight

6

Pounds

Kilograms

1.9

7.2

27

12.2

1. Specifications subject to change.

2. Above 80°C, baths are tested with silicone oil. This fluid is known to release a formaldehyde vapor (which is carcinogenic) above 150°C.

3. 37°C, 45°C, 60°C bath temperature. 20°C ambient. Measured at the center of the work area,

stable ambient. Sea level. For 37°C the work area cover was off, for 45°C and 60°C the work

area cover was on. No external flow. For some applications, agitation and stability above

ambient may be improved by connecting a small length of hose between the pump connections

on the rear of the unit.

4. 20°C ambient. 20°C bath temperature using water. Pump fully loaded. Sea level.

5. See next page for additional dimensions.

6. Add approximately 3 pounds (1.4 kilograms) for shipping weight.

3.0

11.3

32

14.5

4.8

18.1

36

16.3

9.6

36.3

53

24.0

- 7 -

Page 10

Unit Dimensions (inches)

C

General Information

30°

15/8

F

7

/8

3¼

15/8

D

23/8

B

Rear View Side View

Unit Dimensions

Dimension A

Dimension B

Dimension C

Dimension D

Crate Dimensions

(D x W x H)

105°

EX 7 EX 10 EX 17 EX 35

14 5/8 14 5/8 17 5/8 20 5/8

9 1/4 11 3/8 11 3/8 11 3/8

8 3/8 8 3/8 11 3/8 14 3/8

½

17/8

1½

19 19 3/4 19 3/4 26 7/8

26½ x 18 x 33½ 31¼ x 15½ x 26½

A

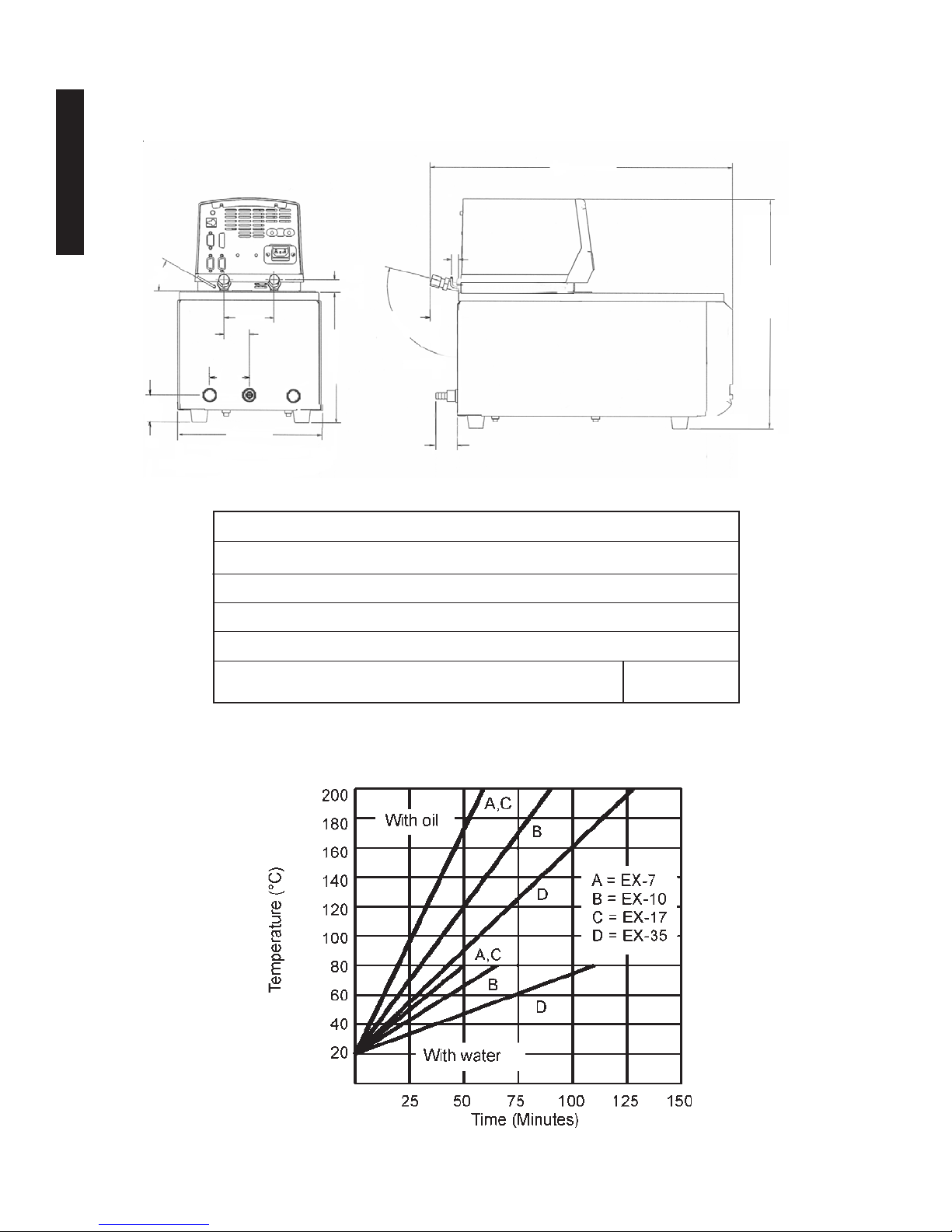

Time to Temperature

115V/60 Hz Models

- 8 -

Page 11

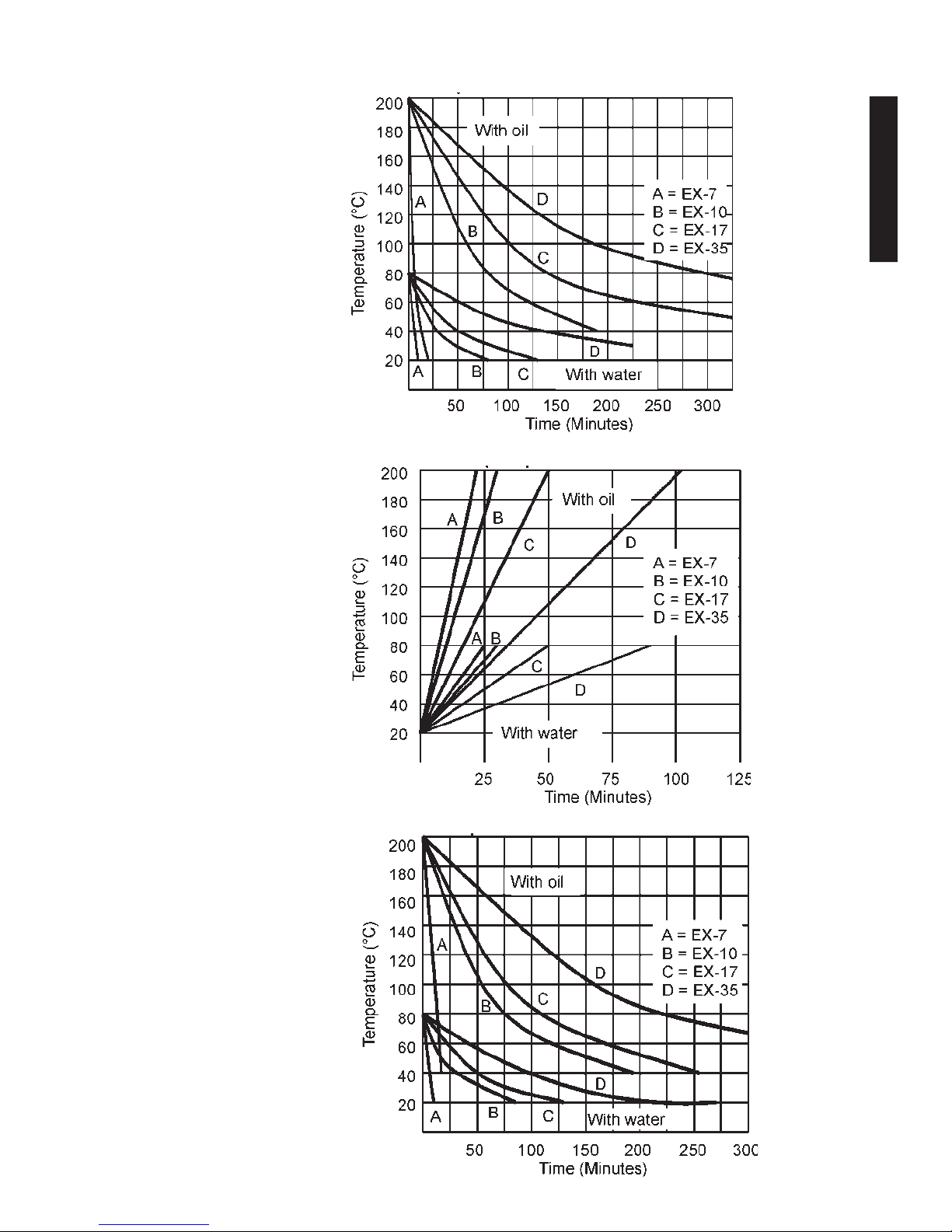

Time to Temperature

115V/60 Hz Models

230V/50 Hz Models

General Information

230V/50Hz Models

- 9 -

Page 12

Blank Page.

- 10 -

Page 13

Site

Electrical

Requirements

Section III Installation and Operation

Ambient Temperature Range +50°F to +104°F (+10°C to +40°C)

Maximum Operating Relative Humidity 80%.

Overvoltage Category II

Installation and Operation

Pollution Degree 2

Never place the unit in a location where excessive heat, moisture, or

corrosive materials are present.

The unit construction provides protection against the risk of electrical

shock by grounding appropriate metal parts. The protection may not

function unless the power cord is connected to a properly grounded

outlet. It is the user's responsibility to assure a proper ground connection is provided.

The user is responsible to ensure that the power cord provided meets local

electrical codes. If not, contact qualified installation personnel.

The unit is intended for use on a dedicated outlet. The EX has an internal

circuit protection that is equivalent (approx.) to the branch circuit rating. This

is to protect the EX, and is not intended as a substitute for branch circuit

protection.

Power Cord Set

230 Volt, 50 Hertz units do not come with a power cord set, To select the

proper power cord, follow these guidelines:

The cord set must consist of a plug, cable and receptacle.

If the unit is rated greater than 12 Amps, use a cord set rated for 20A.

If the unit is rated less than 12 Amps, use a cord set rated for 15A.

The cord set must be approved by local electrical authority or other

acceptable agency.

Ensure the plug is compatible with your local outlets and receptacles.

Refer to the serial number label on the rear of the unit to identify the specific

electrical requirements of your unit.Ensure the voltage of the power source

meets the specified voltage, ±10%.

- 11 -

Page 14

The following power options are available:

Installation and Operation

Unit Amps

1

Breaker Power Inlet

EX 7/10 115/60/1 9 15A IEC 320-C-13

100/50-60/1 10 15A IEC 320-C-13

230/50/1 10 15A IEC 320-C-19

EX 17/35 115/60/1 16 20A IEC 320-C-19

100/50-60/1 16 20A IEC 320-C-19

230/50/1 10 15A IEC 320-C-19

1. Average Amp draw.

Unit Type

1

Amperage Plug Type

115/60/1 15 NEMA 5-15

115/60/1 20 NEMA 5-20

100/50-60/1 15 NEMA 5-15

100/50-60/1 20 NEMA 5-20

230/50/1 All Country Specific

1. Power cord length, if supplied, is 2 meters.

- 12 -

Page 15

Plumbing Requirements

Ensure the unit is off before connecting tubing to the unit.

To prevent damage to the plumbing lines, always support the

fittings while installing/removing the pumping caps and lines.

Hose Connections

The pump connections are located at the rear of the pump box and are labelled

(pump outlet) and (pump inlet). These connections are bent upward

so the recirculating fluid will drain back into the reservoir when the hoses are

disconnected. Both connections are capped with stainless steel serrated plugs.

The pump lines have ¼" MPT for mating with standard plumbing fittings. For

your convenience stainless steel adapters, ¼" FPT to 3/8" O.D. serrated fitting,

are provided. (To assure proper fit, they should be installed using 1½ turns of

Teflon® tape around the threads.)

Make sure all tubing connections are securely clamped. Avoid running

tubing near radiators, hot water pipes, etc. If substantial lengths of tubing

are necessary, insulation may be required to prevent loss of cooling capacity.

Tubing and insulation are available from Thermo Fisher. Contact our Sales

Department for more information (see Preface, After-sale Support).

It is important to keep the distance between the unit and the external system

as short as possible, and to use the largest diameter tubing practical. Tubing

should be straight and without bends. If diameter reductions must be made,

make them at the inlet and outlet of the external system, not at the unit.

If substantial lengths of lines are required, they should be pre-filled with bath

fluid before connecting them to the unit. This will ensure that an adequate

amount of fluid will be in the bath once it is in operation.

Installation and Operation

Drain

Ensure the bath fluid is at a safe handling temperature before draining

the unit.

The unit is equipped with a drain located at the back of the unit labelled .

To drain the reservoir attach a hose to the barb and loosen the fitting. The

fitting has a stop to prevent it from coming off.

Pumping

The pump is designed to deliver a flow of 15 liters per minute (4 gallons per

minute) at 0 feet head. To prevent external circulation, the pump inlet and

outlet lines on the rear of the unit are capped. The caps must be removed when

external circulation is required.

To properly secure external hose connections to the unit, wrap Teflon® tape

around the pipe line threads before installation. Once the hose connections are

made, the hoses must be properly plumbed to an external system. It is

important the bath is not in operation until all plumbing is complete.

- 13 -

Page 16

Tap Water

Cooling Coils

Installation and Operation

The unit is equipped with a cooling coil located behind the stainless steel baffle

in the bath, see page 5. The coil is useful for maintaining near-ambient temperatures, or when cooling from elevated temperatures. Temperature stability

can also improve by circulating cold fluid through the coil. For best results, the

fluid should be at least 5°C below the temperature setpoint. The required fluid

flow rate depends on the type of fluid, the setpoint, and the desired stability.

The plumbing connections for the cooling coil are 3/8 inch OD stainless steel

tubes located on the lower rear of the unit. These connections will accept

3

/8 inch or 5/16 inch ID tubing. Tubing is available from Thermo Fisher.

Connect the cold fluid source to either fitting. Connect the other fitting to the

cold fluid return (or drain if tap water is being used).

- 14 -

Page 17

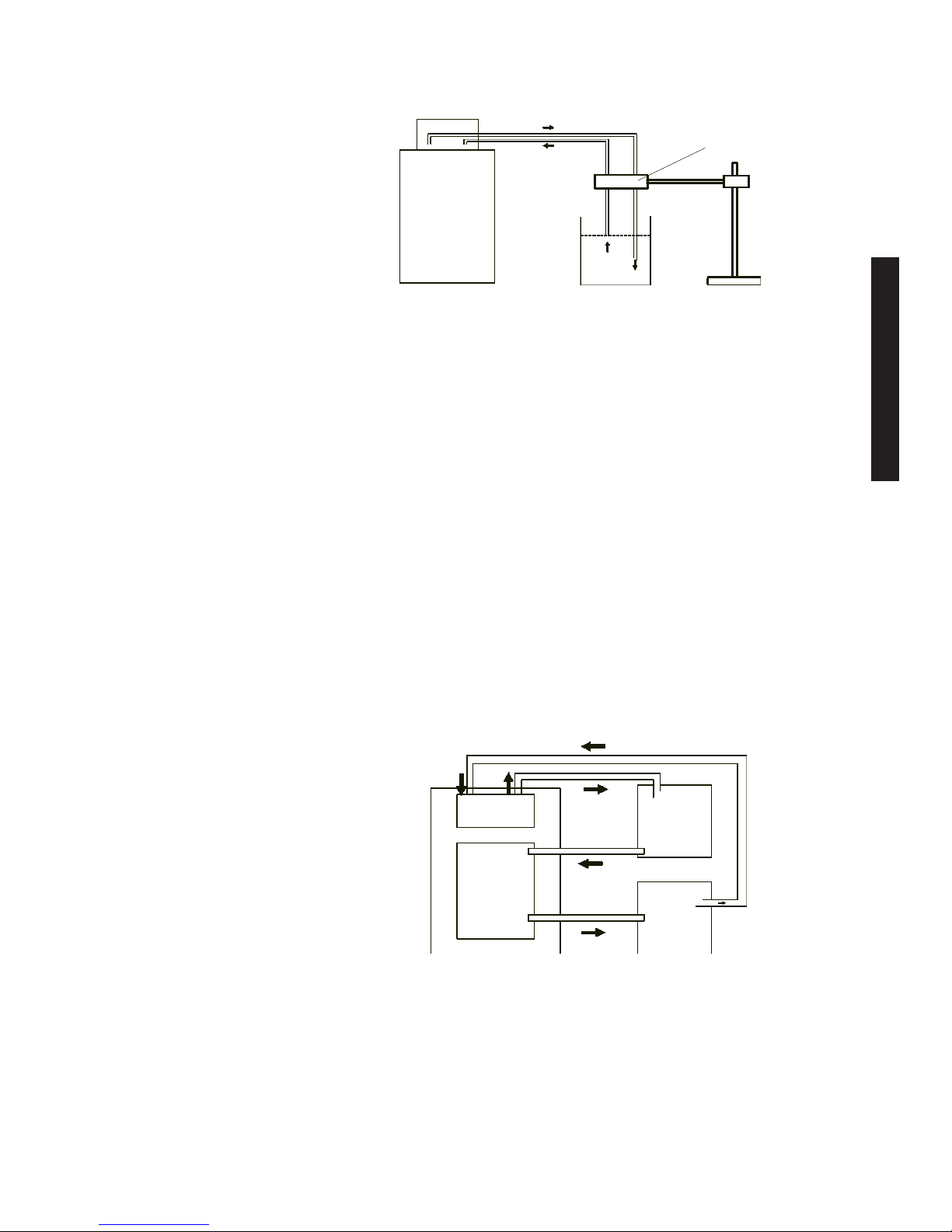

Circulating to an open container

Outlet

Levelling

Device

Inlet

Installation and Operation

Bath (Rear View)

Open Container

A stainless steel leveling device is available to aid circulation to an open

vessel. Contact our Sales Department for more information (see Preface).

Support the leveling device over the open container with a ringstand. Stagger

the tubes in the leveling device so one tube is submerged in the vessel fluid,

and the other tube is level with the fluid surface. Connect the deeper tube to

the pump outlet and the shorter tube to the pump inlet.

Adjust the flow rate using the accessory flow control valve connected to the

pump outlet, or by partially restricting the outlet tubing. When properly

adjusted, the pump inlet will draw an occasional air bubble to prevent over

flow, and the pump outlet will force fluid through the submerged tube to

prevent aeration of the vessel.

To avoid siphoning the bath work area when the unit is shut off, lift the

leveling device out of the vessel and above the level of the unit.

Circulating through two closed-loops

Pump Box

System #1

Bath

Work Area

System #2

Bath (Top View)

The pump can be used to circulate through two closed-loop systems. Connect

the shortest practical length of flexible tubing from the pump outlet to the inlet

of external system #1. Connect the outlet of system #1 directly into the bath

work area. Connect tubing from the bath work area to the inlet of system #2.

Connect the outlet of system #2 to the pump inlet.

- 15 -

Page 18

Fluids

Installation and Operation

The user is always responsible for the fluid used. Never use flammable

or corrosive fluids with this unit. The use of chlorine or sodium

hypochlorite in the baths will cause pitting that could damage the

heater coils.

Handling and disposal of liquids other than water should be done in

accordance with the fluid manufacturers specification and/or the MSDS

for the fluid us

For fluid selection consider application requirements, operating temperature

range, material compatibility, safety concerns, and environmental issues.

®

Wetted materials of bath include; 316 and 304 Stainless steels, Ryton

(PPS),

Teflon®(PTFE) and Ethlyene-Propylene rubber (EPDM).

Deionized (up to 18 MOhmcm) and distilled water are recommended to control

corrosion and algae bloom. See Water Quality Standards and Recommendation in Appendix A.

Filling

Requirements

Ethylene glycol and water, propylene glycol and water, silicone oil, and filtered

water are acceptable fluids. See Appendix A for additional information.

Please call Thermo Fisher customer service to discuss high temperature fluid

selections. However, we will often refer you to chemical companies specializing in heat transfer fluids.

Ensure the drain on the back of the unit is closed before filling the unit.

The bath work area has a high and low level marker to guide filling. The

markers are 1 inch horizontal slits located in the center of the stainless steel

baffle separating the work area and the pump assembly. The correct fluid

level falls between these two markers.

NOTE: The unit is equipped with a reservoir level float switch. The switch

prevents the unit from starting if the fluid is below the lower slit.

When pumping to an external system, keep extra fluid on hand to maintain

the proper level in both the circulating lines and the external system.

Avoid overfilling, fluids expand when heated.

- 16 -

Page 19

Controller

(Digital One/Digital Plus)

The controller controls temperature using a Proportional-Integral-Derivative

(PID) algorithm. It is designed with self-diagnostic features and easy to use

operator interface. Two controller options are available: Digital One and Digital

Plus. The information on the following two pages applies to both controllers.

The information on the following two pages applies to both controllers.

Installation and Operation

Yes

No

Digital One Controller

ON/OFF. Use this key to toggle the unit on or off and to clear error messages.

SCROLL . Use this key

to scroll through the controller's LEDs. It is also

used to save new changes.

YES/ARROW. Use this key to increment numerical values when setting

values and to accept new settings.

NO/ARROW. Use this key to decrement numerical values when setting

values and to abort new settings.

Indicates heater status. It illuminates to indicate the heater is adding heat from

the bath fluid. The indicator is off when heat is not being added.

- 17 -

Page 20

Installation and Operation

NOTE: The following indications are not visible until is depressed.

Setpoint. Indicates the controller is displaying the current setpoint.

Low Temperature Alarm. Indicates the controller is displaying the current

low temperature alarm.

High Temperature Alarm. Indicates the controller is displaying the current

high temperature alarm.

To adjust the displayed value use the arrow buttons. Pressing an arrow button

will cause the display to stop flashing and to indicate the new setpoint value.

Save the change by pressing SCROLL. The new setpoint value will rapidly flash

for two cycles and then the controller will return to the reservoir fluid temperature display.

If SCROLL is not pressed within 60 seconds the change will time out and revert

to the original setpoint. The controller will automatically return to the reservoir

fluid temperature display.

NOTE: You can not adjust the setpoint closer than 0.1°C of either temperature

limit, and you can not adjust either temperature limit within 0.1°C of the

setpoint. Trying to do so will cause the indicator to flash and, on Digital Plus

controllers, the alarm to beep.

On units with the Digital Plus controller, pressing the Mute button prior to

pressing SCROLL will abort any changes and return to the reservoir fluid

temperature display.

- 18 -

Page 21

Start Up/Shut Down

(Digital One/Digital Plus)

Installation and Operation

Controller

Pre-Start

Starting

Setpoint

Before starting the unit, double check all electrical and plumbing connections.

Ensure the bath reservoir is properly filled. The unit will not start if the reservoir

fluid level is below the lower horizontal slit.

The unit can be configured for automatic restart. If the unit shuts down as

a result of a losing power, once power is restored the unit will restart.

See Setup/Tuning Loop on page 21 to enable this feature.

Press . The controller does a self-test (sequences through the LEDs, and

Digital Plus units momentarily sound the alarm), then quickly displays the

setpoint before displaying the reservoir fluid temperature. The pump will start.

NOTE: If the unit's recirculating fluid is outside either temperature limit, the unit

will start but the appropriate indicator will flash until the fluid is within the limit.

To display/change the setpoint press until illuminates. The display

will flash the current setpoint value. Use the arrow buttons to change the value.

The controller will not allow you to enter a setpoint closer than 0.1°C of either

temperature alarm setting, see next page. Attempting to causes the indicator

to flash and, on Digital Plus controllers, sounds the alarm.

Once an arrow button is depressed starts to flash. If an arrow button is not

pressed within 10 seconds the display will return to the reservoir temperature.

On units with the Digital Plus controller, pressing Mute prior to pressing

SCROLL will abort any change and return you to the fluid temperature display.

Once the desired setpoint is displayed, press again to confirm the

change. The display will rapidly flash the new value twice and then return to the

recirculating fluid temperature. If the new value is not confirmed within 60

seconds the display will return to the fluid temperature and ignore any change.

- 19 -

Page 22

Low Temp Alarm

To display/change the low temperature alarm setting press until

illuminates. The display will flash the current limit value. Use the arrow buttons

to change the value. You can not set the alarm closer than 0.1°C below the

setpoint. Attempting to causes the indicator to flash and, on Digital Plus

controllers, sounds the alarm.

On units with the Digital Plus controller, pressing Mute prior to pressing

SCROLL will abort any change and return you to the fluid temperature display.

Once an arrow button is depressed starts to flash. If an arrow button is not

pressed within 10 seconds the display will return to the current reservoir

temperature.

Installation and Operation

High Temp Alarm

Once the desired setting is displayed, press again to confirm the change.

The display will rapidly flash the new value twice and then return to the recircu-

lating fluid temperature. If the new value is not confirmed within 60 seconds the

display will return to the fluid temperature and ignore any change.

To display/change the high temperature alarm setting press until

illuminates. The display will flash the current setting value. Use an the arrow

buttons to change the value. You can not set the alarm closer than 0.1°C

above the setpoint. Attempting to causes the indicator to flash and, on Digital

Plus controllers, sounds the alarm.

On units with the Digital Plus controller, pressing Mute prior to pressing

SCROLL will abort any change and return you to the fluid temperature display.

Once an arrow button is depressed starts to flash. If an arrow button is not

pressed within 10 seconds the display will return to the current reservoir

temperature.

Once the desired limit is displayed, press again to confirm the change.

The display will rapidly flash the new value twice and then return to the recircu-

lating fluid temperature. If the new value is not confirmed within 60 seconds the

display will return to the fluid temperature and ignore any change.

Stopping

To turn the unit off, press . The pump will stop.

- 20 -

Page 23

Setup/Tuning Loop

(Digital One/Digital Plus)

The Setup/Tuning Loop is used to tune the controller's PID parameters (HEAt);

enable/disable auto restart (AStrt); determine how the unit will react when a

fault occurs (FAUlt) — either shut down (on) or continue to run (oFF); and to

configure the temperature display to indicate to a tenth or a hundredth of a

degree (rES).

Installation and Operation

To enter the loop you must be displaying the reservoir fluid temperature, press

and hold and then press . The display will indicate tunE. Use the arrow

keys to sequence through the loop and to change a display. Use to

confirm any changes.

Thermo Fisher recommends that only

a qualified technician change PID

parameters. Incorrect PID values will

hamper unit performance. See page

42 for factory preset PID values.

Factory preset = off

Factory preset = off

Factory preset = 0.1

Changes made in the Tuning/Setup Loop take affect when

is pressed at

Yes

the StorE prompt. Pressing No at the prompt aborts all changes.

- 21 -

Page 24

Controller

(Digital Plus)

Mute

Installation and Operation

Sensor

Alarm. If the alarm sounds, use this button to toggle the alarm off and on. If

the cause of the alarm is cleared but then reoccurs, the alarm will sound again.

The button is also used to abort changes to the setpoint and temperature

alarms. It is also used to abort changes when configuring the unit for external

probe, serial communication, timer operation, or offset mode.

NOTE: Pressing and holding any of the following buttons for five seconds takes

you to their calibration or setup loop.

External Probe. Pressing the Sensor button displays the external probe

temperature and lights the LED indicating that the bath is monitoring and

controlling to this temperature. The unit will continue to monitor the internal

bath temperature to ensure the bath is running in a safe operating mode.

NOTE: If there is no sensor attached (or the circuit is open), or serial communications is enabled, the button will flash, and the alarm will beep three times.

The display will momentarily show an error message and then return to the

reservoir fluid temperature.

Computer

NOTE: The temperature display may drift for up to 10-15 seconds when

transitioning between temperature sensors. This is normal operation.

Serial Communication. Pressing Computer enables/disables the serial

communications mode of operation. In this mode all changes to the setpoint,

alarm limits, etc. must now be sent by a remote device using RS-232 or

RS-485 protocols. You can still view all settings locally but cannot alter them.

Once enabled, the Computer LED will flash when sending and receiving

signals. See Appendix B for additional information.

You can also turn the unit off by pressing but the unit will remain in the

serial communication mode. To restart, send another start command.

NOTE: If the unit is shut down in the serial communication mode and you need

to start the unit using the local controller, simultaneously depress and hold

both arrow keys for approximately 10 seconds. The display will then show the

internal probe temperature, and the alarm will sound. Press the

Computer

LED

and turn off the LED and disable serial communications. Turn the controller off

using . You can now start and operate the unit with the keypad.

To setup for serial communication see Computer Setup Loop on page 24.

- 22 -

Page 25

Timer

Offset

Timer. Pressing the Timer button enables/disables the Timer function of the

bath. You can define the current time, a turn-on time, and a turn-off time.

To setup the bath for timer operation see Timer Setup Loop on page 25.

If the bath is turned off using with the timer mode enabled, the Timer LED

will go out and the timer mode will be disabled. With the bath off, you have to

press the Timer button to enable the timer mode and light the LED.

NOTE: Enabling serial communications; time-on not defined; time-off not

defined; or clock not set, causes an error condition and disables the TIMER

mode. In this case the button will flash, the unit will beep three times, and the

display will momentarily show an error message.

If a power disruption occurs, the timer mode is disabled. The Timer Setup Loop

will have to be used to restore the settings.

Temperature Offset Mode. Pressing the Offset button, with the bath on,

enable/disables the temperature offset mode. This mode changes the temperature displayed on the bath a user defined amount. The LED will be lit when this

mode is enabled indicating that the temperature displayed is an offset value.

NOTE: The temperature offset only affects the displayed value when the offset

mode is enabled, the other setpoint values still dictate unit performance.

Installation and Operation

To setup the bath for offset mode operation see Offset Setup Loop on page 26.

If you press the Offset button when an offset has not been previously defined,

or if serial communications is enabled, the button will flash, the unit will beep

three times, and the display will momentarily show an error message. In either

case the function can not be enabled.

NOTE: Use this feature only when the bath is at a stable temperature.

In either local or Computer mode with offset disabled, the unit controls to and

displays the calibrated value for the internal or external probe, whichever is

selected.

In local mode with offset enabled, the unit still controls to the calibrated value,

not the offset value, for the internal or external probe. The display shows the

calibrated value with the offset value added.

In Computer mode with offset enabled, the unit still controls to the calibrated

values, not the offset value , for the internal or external probe. The display

shows the calibrated value with the offset value added. If you send a signal to

the bath to display internal or external probe temperatures, the calibrated value

is returned. If you send a signal to change the display value the offset value is

returned.

- 23 -

Page 26

Computer Setup Loop

(Digital Plus Only)

NOTE: The Computer Setup Loop is not available if the serial communications

mode is enabled. Review/change the settings before entering the mode.

Computer

Installation and Operation

XX.X

The Computer Setup Loop is used to set the serial communications protocol

parameters. With the bath on, press and hold the Computer button for five

seconds. The controller will display SErL. Press the arrow buttons to toggle

between 232 and 485. Press the Computer button to hold the protocol and

advance you through the loop to adjust the remaining parameters. Press the

arrow buttons to adjust any parameter. When StorE is displayed press YES to

accept any new values, NO to abort them.

If the Computer button is not pressed for 60 seconds the function will time-out

and the changes will not be saved. Pressing the Mute button will also exit the

Computer Setup Loop and return you to the reservoir fluid temperature display.

Once enabled, the Computer LED will flash when sending and receiving

signals. See Appendix B for additional serial communication information.

Hold for 5 seconds

SErL

Computer

232

485

A In

Yes

No

Factory preset = RS232

A In = Analog In, Optional

See page 27.

Computer

19200

9600

bAud

Computer

Addr

Computer

No

StorE

Accept All Changes

Yes

4800

2400

1200

600

300

1 to 100

Factory preset = 19200

Yes

No

Factory preset = 1

Yes

(RS-485 only)

No

- 24 -

Page 27

Timer Setup Loop

(Digital Plus Only)

Timer

To set the timer, with the bath on, press and hold the Timer button for five

seconds to access the controller's Timer Setup Loop. The display will indicate

diSP. Use the arrow buttons to select the desired clock display. Press the

Timer button and the controller will display cloc. Use the arrow buttons to

display the correct time.

Press the Timer button and the controller will display t-On. Press the arrow

buttons to set the desired turn-on time. Press the Timer button and the

controller will display t-OFF. Press the arrow buttons to set the desired turn-off

time. Pressing the Timer button after entering the clock time will display StorE.

Press YES to accept the values, NO to abort them.

If the Timer button is not pressed for 60 seconds the function will time-out and

the changes will not be saved. Pressing the Mute will also exit the Timer Setup

Loop and return you to the temperature display.

If the bath is turned off using with the timer mode enabled, the Timer LED

will go out and the timer mode will be disabled. With the bath off, you have to

press the Timer button to enable the timer mode and light the LED.

NOTE: Enabling serial communications disables the

TIMER mode. If an error condition exists: serial

communications enabled; time-on not defined; time-off

not defined; or clock not set, the unit will beep and

will not enable the function. The display will then

indicate the reservoir fluid temperature.

If a power disruption occurs, the timer mode is

disabled. The Timer Setup Loop will have to be used

to restore the settings.

Installation and Operation

- 25 -

Page 28

Offset Setup Loop

(Digital Plus Only)

NOTE: Use this feature only when the bath is at a stable temperature.

Press the Offset button to display the current offset temperature value and

illuminate the LED.

Offset

Installation and Operation

To change the value press and hold the Offset button for five seconds to enter

the controller's Offset Setup Loop. The bath will alternately flash oFSEt with

the current temperature.

Use the arrow buttons to change the value. For example, if the bath is at

+40°C and the desired offset is +5°C, change the display to +45°C. Press the

Offset button once the desired offset is displayed. (If the Offset button is not

pressed the function will time-out and the change will not be saved.) The

display will show StorE. Press YES to accept the value, NO to abort it.

If, after pressing YES, the display returns to +40°C, not +45°C, the Offset

button was not depressed when you entered the Offset Setup Loop. Press the

Offset button to display the offset temperature and illuminate the LED.

XX.X

Offset

OFSEt

Offset

Hold for 5 seconds

xxx.x

Yes

No

No

StorE

Accept All Changes

Yes

NOTE: Offset only changes the display of the enabled probe. Setpoint and

alarm values will display the non-offset value.

If you press the Offset button when an offset is 0 or not defined, or if serial

communications is enabled, the button will flash, the unit will beep three times,

and the display will momentarily show an error message (Er53 for offset

undefined, Er54 for serial comm on). In either case the function can not be

enabled.

With offset disabled, the unit controls to and displays the calibrated value for

the internal or external probe, whichever is selected.

With offset enabled, the unit still controls to the calibrated value, not the offset

value, for the internal or external probe. The display shows the calibrated value

with the offset value added.

In Computer mode if you send a signal to the bath to display internal or

external probe temperatures, the calibrated value is returned. If you send a

signal to change the display value the offset value is returned.

- 26 -

Page 29

Analog Port - Optional

(Digital Plus Only)

A I/O Analog Port

The 15-pin female receptacle located on the rear of the controller is used for

optional analog interface.

The analog signal is setup using the unit's Computer Setup Loop. With the

bath on, press and hold the Computer button for five seconds. The controller

will display SErL. If needed, press the arrow buttons to toggle between 232,

485, and A In. With A In displayed, press the Computer button again until

StorE is displayed, press YES. Use the Computer button to enable/disable the

analog signal. The button will flash when A in is enabled.

Contact Ratings, Pins 1, 2, and 3

Maximum Voltage = 30 V AC/DC

Maximum Current = 1 Amps @ 30 V

Minimum permissible load 10uA, 10mVDC

Pin # Function

1 Status relay NO. Status relay pins 1 and 3 close on start up, and open

on stop and all errors.

Installation and Operation

2 Status relay NC. Status relay pins 2 and 3 open on start up, and close

on stop and all errors.

8 7 6 5 4 3 2 1

15 14 13 12 11 10 9

3 Status relay common

4- 5 Not used

6 Analog Ground. The analog ground is physically separated from the

power ground throughout the unit. To prevent offsets that result from

ground currents, the analog and power grounds are only connected at

the unit's power supply. Analog ground should only be used as a

reference pin.

7 Temp out. The fluid temperature, as measured by the enabled sensor,

can be read at this pin. The temperature scale is 10mV/°C, referenced

to analog ground, pin 6 (example: +150mV = +15.0°C).

8 Not used

9 Digital output ground, reference for pin 14. Digital output ground should

only be used as a reference pin.

10-13 Not used

1 4 Digital output +5VDC at 15mA max. 70mA max inrush current. This

power supply energizes on start up and de-energizes on stop and all

errors.

1 5 Setpoint in. The temperature setpoint can be controlled by applying a

known voltage to this pin. The temperature scale is 10mV/°C, refer-

enced to analog ground, pin 6 (example: +230mV = +23.0°C).

The analog output requires calibration, see page 38.

- 27 -

Page 30

High Temperature Cutout

(Digital One/Digital Plus)

Installation and Operation

Adjustable High Temperature Cutout

To protect your application, the adjustable High Temperature Cutout ensures

the heater will not exceed temperatures that can cause serious damage to

your unit. A single temperature sensor is located in the bath fluid. A High

Temperature fault occurs when the temperature of the sensor exceeds the set

temperature limit. The safety has a range of 0°C to 230±20°C.

In the event of a fault the unit will shut down and the controller will display HtC.

The cause of the fault must be identified and corrected before the unit can be

manually restarted.

The cutout is not preset and must be adjusted during initial installation. To set

the cutout, locate the small black adjustment dial on the rear of the controller.

Turn the dial fully clockwise and turn the power switch off then back on.

Start the unit. Adjust the setpoint for a few degrees higher than the highest

desired fluid temperature and allow the bath to stabilize at the temperature

setpoint. Turn the dial counterclockwise until you hear a click and the unit

shuts down.

Before you can restart the bath it has to cool down a few degrees. Then,

without moving the adjustment dial, turn the power switch off then back on.

NOTE: We recommend rechecking operation if the unit is moved.

High Temperature Cutout

Non-Adjustable High Temperature Cutout

For added safety, the unit also has a non-adjustable High Temperature Cutout.

With fluid in the bath, it is set to trip at 225°C ±8°C.

If the bath is empty, the cutout has a typical trip point of 300°C. The heater

temperature can continue to rise after the cutout trips up to approximately

314°C.

There will be no indication the High Temperature Cutout activated other than an

audible click. The unit will continue to run but the heater will no longer operate.

Service will be required.

- 28 -

Page 31

Accessories

(Digital One/Digital Plus)

Autorefill Accessory

The autorefill accessory attaches to the rear of the bath. The autorefill provides

makeup water to replace bath fluid lost to evaporation, etc. It will require a tap

water source. A reservoir level float switch and logic/signal are already installed

in the bath.

•Attach the autorefill module to the rear of the bath with the two 8-32 screws.

•Attach the capillary tubing from the compression fitting on the top of the

autorefill module to the autorefill inlet on the rear of the bath. Tighten all

compression fittings.

•Attach a tap water supply line to the tap water inlet on the autorefill module. A

compression fitting for 3/8” tubing is provided.

•Connect the control cable from the back of the control box to the side of the

autorefill module as shown in the illustration.

•Connect the power supply from the power supply inlet on the side of the

autorefill module to an appropriate power outlet.

When tap water is available, the bath is turned on, and the fluid reaches the

lower 1 inch horizontal level indicator located in the reservoir the autorefill

begins filling the bath. The autorefill shuts off when the fluid reaches the upper

indicator, or if the bath is turned off.

NOTE: Power the Autorefill Accessory with an AC Adapter that is UL Listed

with the following ratings:

- Class 2

Installation and Operation

- Input rated 100-240 VAC, 47-63 Hz, 0.4A

- Output rated 12VDC, 1.25A Max.

Autorefill Control

Cable Attachment

Cap Tube

Tap Water Inlet

Autorefill Module

Description Part Number

100-115V/50/60Hz 611012000001

200-240V/50/60Hz, No line cord 611028000001

Power Supply Inlet

- 29 -

Page 32

Installation and Operation

Reservoir Overflow Device

The overflow device is designed to act as an automatic drain for the unit's

reservoir. The assembly is stainless steel with the exception of the drain fitting

which is Ryton®. The unit can still be drained as normal, but if the level reaches

the middle of the tee it will begin to overflow out the bent tube.

•Drain the unit's reservoir.

•Remove and discard the stop screw from the

bottom of the unit's drain housing.

•Remove the unit's drain fitting.

Vertical Tube

•Thread the overflow assembly into the

drain housing. (You can remove the

vertical tube assembly from the

Swagelok® fitting if there is a clearance

issue.)

Swagelok® Fitting

Drain Housing

•After threading the overflow assembly

in as far as it goes, loosen it back out

until the Swagelok® fitting is at the

Drain Fitting

(Install

finger tight)

top.

•Install one of the two supplied

4-40 x ¼” phillips head screws into

Overflow Assembly

the bottom of the drain housing where

the stop screw use to be. (Make sure this screw is tight so that the assembly

doesn’t turn and drain the tank.)

•Reinstall the vertical tube assembly into the Swagelok® if it was removed.

•Install the drain fitting into the end of the new assembly - finger tight.

•Install the other supplied 4-40 x ¼"phillips head screw into the bottom of the

overflow assembly. (This prevents the drain fitting from falling off the unit.)

Description Part Number

EX 7 and EX 10 overflow device 126000000044

EX 17 overflow device 126000000045

EX 35 overflow device 126000000046

- 30 -

Page 33

Stainless Steel Test Tube Racks

The following Stainless Steel test tube rack assemblies are available:

Uni t Test Tubes (maximum) Size (mm) Part Number

EX 7 49 13 126000000040

EX 7 25 18 126000000041

EX 10/17/35 72 13 126000000042

EX 10/17/35 42 18 126000000043

Installation and Operation

EX 35 Stainless Steel Shelf Set

Thermo Fisher offers two accessory shelves for use in the EX-35 bath.

The EX 35's reservoir is 12" deep. The 6" shelf makes the bath effectively 6"

deep. The 3" shelf makes the bath effectively 9" deep. The shelves can also

be stacked making the reservoir effectively 3" deep.

The shelves are Stainless Steel and are simply positioned into the work area.

The shelves are fully perforated to allow circulation throughout the bath area.

The smaller shelf is designed to nest inside the larger one for storage.

3" and 6" Shelves Thermo Fisher Scientific Part Number

126000000048

- 31 -

Page 34

Installation and Operation

The following accessories are also available from Thermo Fisher:

External Sensors (Digital Plus only)

Description Part Number

6"L X .187"DIA, 6' Lead, Stainless Steel probe 058520

18"L X .187"DIA, 6' Lead, Stainless Steel probe 058521

1.5"L X .187"DIA, 6' Lead, Stainless Steel probe 058522

1.5"L X .062"DIA, 6' Lead, Stainless Steel probe 058523

6"L X .187"DIA, 6' Lead, Teflon® probe 058524

6"L X .187"DIA, 15' Lead, Stainless Steel probe 126000000025

6"L X .187"DIA, 20' Lead, Stainless Steel probe 126000000029

6"L X .187"DIA, 30' Lead, Stainless Steel probe 126000000024

1.5"L X .187"DIA, 30' Lead, Stainless Steel probe 126000000033

GFCI* Breaker Line Cords (115V 60Hz units only)

Unit Description Part Number

15 Amp Units 125V/15A 4-6MA 126000000050

20 Amp Units 125V/20A 4-6MA 126000000051

RS-232/485 Communication Cables (Digital Plus only)

Description Part Number

10' Cable Assembly 083258

*Ground Fault Current Interrupter. An electrical safety device which opens a circuit upon

observation of electricity leaking to ground through an undefined path, most likely a human

being. GFCI receptacles are required by the NEC in many locations.

- 32 -

Page 35

Accessories

(Digital Plus Only)

RPC Remote Box

An RPC can control the bath from a remote location. It mirrors the controller

displays; and has the ability to store and run up to 16 programs. It operates by

sending and receiving information by RS-485 serial communication. It attaches

to the unit by an RS-485 cable with 9-pin D subminature connectors.

The remote can be mounted to the wall with an included wall bracket, or it can

be used on a desk top with the wall bracket removed.

HEAT

COOL

BATH ON

120.0°C

Typical RPC Display

MENU

SETPOINT

Description Part Number

RPC 100-115V/50/60Hz/1Ø 604012000401

(with NEMA 5-15P type plug)

Installation and Operation

RPC 100-240V/50/60Hz/1Ø 604028000401

(requires country specific line cord, not included)

10' Cable Assembly (included) 083258

25' Cable Assembly 426000000029

50' Cable Assembly 426000000030

75' Cable Assembly 426000000031

100' Cable Assembly 426000000032

200' Cable Assembly 426000000033

NOTE: Power the RPC with an AC Adapter that is UL Listed with the following

ratings:

- Class 2

- Input rated 100-240 VAC, 47-63 Hz, 0.4A

- Output rated 12VDC, 1.25A Max.

- 33 -

Page 36

Blank Page.

- 34 -

Page 37

Service Contracts

Reservoir Fluid

Section IV Basic Maintenance

To avoid electrical shock, disconnect the mains cord prior to removing

any access panels or covers.

Thermo Fisher Scientific offers on-site Service Contracts designed to provide

extended life and minimal down-time for your unit. For more information,

contact our Service Department (see Preface, After-sale Support).

Periodically inspect the reservoir fluid. If cleaning is necessary, flush the

reservoir with a cleaning fluid compatible with your application.

The reservoir fluid should be replaced periodically. Frequency depends on the

operating environment and time of usage.

Before changing the reservoir fluid ensure it is at a safe handling

temperature.

Reservoir Cleaning

Algae

Maintenance

Routine cleaning can be achieved by simply sponging down the seamless

stainless steel tank with tap water. (Dish washing detergent may be used but

the tank must be thoroughly rinsed.)

To restrict the growth of algae in the bath, we recommend that all circulation

lines be opaque. This will eliminate the entrance of light required for the growth

of most common algae.

We recommend the use of Chloramine-T, 1 gram per 3½ liters.

- 35 -

Page 38

Internal Temperature

X

Sensor (rdt1)

Calibration

Press and Hold

X.X

No

Yes

Should the bath fluid temperature display disagree with your calibrated reference thermometer, the internal temperature sensor (rtd1) may need calibration.

Do not pick calibration points that are outside the safe operating limits of the

fluid in your application. For example with water, 90°C and 5°C would be

typical calibration points.

No

Maintenance

CAL

rtd1

rdt3

A in

No

Yes

No

No

No

Release

NOTE: If it is more convenient, the low-end calibration can be performed before

doing the high-end.

Yes

rtd3 is used to calibrate the

refrigeration system, contact

Thermo Fisher.

Optional Display

r1 H

No

r1 L

No

Yes

Yes

r1 H

r1 L

Run the bath to a suitable highend calibration point. Place a

No

calibrated reference thermometer

Yes

200.0

in the bath. Ensure the fluid

temperature is stabilized. Press

Yes

and hold the NO button and then

press the YES button three

No

times. Release the NO button.

Yes

-40.0

The controller will display CAL.

Yes

Press YES and the controller will

display rdt1. Press YES again

and the controller will display

r1 H. Press YES again and the

controller will alternately flash

r1 H and the current probe temperature. Use the arrow

buttons to adjust the temperature to match the reference

thermometer.

Press the SCROLL and NO buttons as shown until

AoUt

No

Optional Display

StorE is displayed, press YES to accept the new value,

press No to abort it.

Repeat for the low-end temperature. Run the bath to a

No

StorE

suitable low-end calibration point. At the r1 L display use

the arrow buttons to adjust the temperature to match a

Accept All Changes

Yes

calibrated reference thermometer.

Press the SCROLL and NO buttons as shown until StorE is displayed, press

YES to accept the new value, press NO to abort it.

NOTE: Both the high and low temperatures must be entered for a valid calibration. If power is lost before the procedure is complete, critical data needed for

the calculation of calibration parameters will be lost. After pressing the YES

button at the StorE prompt wait several seconds before proceeding to ensure

that a bad calibration message does not appear. Premature use of the keypad

after pressing the YES button may cancel the bad calibration error message.

- 36 -

Page 39

External Temperature

Sensor (rtd2)

Calibration

(Digital Plus Only)

XX.X

Sensor

rtd2

No

No

StorE

Hold for 5 seconds

r2 H

Yes Yes

No

r2 L

No

Accept All Changes

Yes

When using any external sensor (rtd2) for the first time, Thermo Fisher recommends a calibration. This calibration will only affect the temperature read by

the external sensor.

Do not pick calibration points that are outside the safe operating limits of the

fluid in your application. For example with water, 90°C and 5°C would be

typical calibration points.

NOTE: If it is more convenient, the lowend calibration can be performed

before doing the high-end.

No

r2 H

Yes

200.0

Run the bath to a suitable high-end

calibration point. Place the sensor and

Yes

a calibrated reference thermometer in

the bath. Ensure the fluid temperature

No

is stabilized. Press and hold the

Yes

r2 L

Yes

-40.0

Yes

Sensor button for five seconds. The

controller will display rtd2. Press YES

and the controller will display r2 H.

Press YES and the display will

alternately flash r2 H and the current

probe temperature. Use the arrow

buttons to adjust the temperature to

match the reference thermometer.

Maintenance

Press the SCROLL and NO buttons until StorE is displayed, pressing YES

accepts the new value.

Repeat for the low-end temperature. Run the bath to a suitable low-end calibration point. At the r2 L display use the arrow buttons to adjust the temperature

to match a calibrated reference thermometer.

Pressing the SCROLL button after the low calibration will display StorE,

pressing YES accepts the new value.

If the SCROLL button is not pressed for 60 seconds the function will time-out

and the changes will not be saved. Pressing Mute will also exit the calibration

and return you to the reservoir fluid temperature display.

NOTE: Both the high and low temperatures must be entered for a valid calibration. If power is lost before the procedure is complete, critical data needed for

the calculation of calibration parameters will be lost. After pressing the YES

button at the StorE prompt wait several seconds before proceeding to ensure

that a bad calibration message does not appear. Premature use of the keypad

after pressing the YES button may cancel the bad calibration error message.

- 37 -

Page 40

Optional Analog Port/

Calibration (Digital Plus Only)

Press and Hold

XX.X

No

Yes

No

Re le a se

The analog signal is setup using the unit's Computer Setup Loop. With the

bath on, press and hold the Computer button for five seconds. The controller

will display SErL. If needed, press the arrow buttons to toggle between 232,

485, and A In. With A In displayed, press the Computer button again until

StorE is displayed, press YES. The Computer button will flash when A in is

enabled. Use the Computer button to enable/disable the analog signal.

No

CAL

Yes

rtd 1

No

rdt3

No

A in

No

Maintenance

AoUt

No

No

St o rE

The analog input and output are calibrated at the factory. If you need to

recalibrate follow the diagram until the display indicates A in.

Pressing YES at the A in display and the display will indicate A iH. Press

YES and the display will alternate between A iH and some value. Apply 2.5V

to the analog input pin 15, see page 27 (analog ground is pin 6). Measure the

precise value with a voltmeter.

Change the value on the bath display to match the voltmeter reading.

Yes

Yes

Yes

A iH

No

No

A iL

A oH

No

No

Yes

Yes

Yes

Yes

Accept All C hanges

A iH

A iL

A oH

A oL

Company preset values:

A iH = 2.5000

A iL = 0.0000

A oH = 2.5000

A oL = -.5000

x.xxxx

x.xxxx

x.xxxx

x.xxxx

Press SCROLL to check your value and

Yes

No

then press SCROLL again to display A iL.

If desired, repeat the procedure for A iL.

Yes

Apply 0V to pin 15. Measure the voltage

No

and change the displayed value to match it

Pressing YES at the AoUt display and the

Yes

display will indicate A oH. Press YES and

No

the display will alternate between A oH

and 2.5000, the bath will set the Temp Out

pin 7 output voltage to approximately 2.5V.

Yes

Measure the voltage and change the

No

displayed value to match it. Press

SCROLL to check your value and then

press SCROLL again to display A oL.

If desired, repeat the procedure for A oL.

The display will alternate between A oH

and -.5000, the bath will set the Temp Out

pin 7 output voltage to approximately

-0.5V. Measure the voltage and change the

value to match the meter.

At the StorE display press YES to save the calibration, press No to abort it.

NOTE: If error code Er16 appears you will need to recalibrate.

- 38 -

Page 41

Error Codes

Section V Troubleshooting

On Start Up:

ROM checksum. Check with Thermo Fisher

Test failure. Locks up the program

Display board failure. Clears when display board is fixed

Critical checksum failure. Check with Thermo Fisher

Operational Errors:

Asynchronous communication error, check serial interface

parameters

Bad calibration data entered using Calibration Loop. Redo calibration

Unusual Hardware Conditions

These errors will flash on the display and cannot be cleared. These are internal

controller problems.

through - Interrupt errors during runtime

Synchronous communication error - check connections

BOM invalid. Contact Thermo Fisher

Functional/ Machine Errors

Warnings self-clear after the cause of the error is identified and corrected.

Faults require pressing I/0 to clear the error message and then pressing

I/0 again to start the unit after the cause of the error is identified and corrected.

Error Display Indication

Low temp setpoint warning/fault, see page 21

Low level warning, fluid below safe operating level

High temp setpoint warning/fault, see page 21

Shorted external temperature sensor (rtd2)

Open external temperature sensor (rtd2)

Shorted internal temperature sensor (rtd1)

Open internal temperature sensor (rtd1)

Fluid low level fault - unit shuts down

Troubleshooting

High Temp fault - unit shuts down, see page 28

Continued on next page.

- 39 -

Page 42

External Sensor

1 2 3 4 5

6 7 8 9

Connector

Configuration error

Invalid timer setting, see page 25

Offset setting = ---, or not defined, see page 26

Feature not available because communication mode

is enabled

Unit reaction to warning/fault errors depend on how the unit is configured, see

Setup/Tuning Loop on page 21. The unit is shipped configured to continue

running. If any other code appears contact Thermo Fisher customer service.

The unit is equipped with a male 9-pin D-connector located on the rear of the

control box. The connector is used with an optional external sensor.

Pin # Function

1 3-wire RTD connection A

2 No connection

3 No connection

4 3-wire RTD connection A

5 No connection

6 No connection.

7 3-wire RTD connection B

8 No connection

9 No connection

Troubleshooting

Hardware Internal Connector Mating Connector

AMP Part# 745492-2 AMP Part# 745491-2

- 40 -

Page 43

Checklist

Unit will not start

On Digital Plus controllers, check Serial Communication Mode on or off.

Check reservoir. Unit will not start if the reservoir fluid is below the lower slit.

Check the line cord; ensure it is plugged in.

Check the position of the circuit breaker on the rear of the unit.

Check the controller for error codes, see previous page.

Make sure the voltage of the power source meets the specified voltage,

±10%. Refer to the serial number label on the rear of the unit to identify the

specific electrical requirements of your unit.

No external circulation

Check for obstructions, kinks, or leaks in the circulation tubing.

Circulation will cease when the pump head has been exceeded.

No/poor temperature control

Check Serial Communications Mode on or off.

Check controller PID values. See next page for factory preset values.

NOTE: Using high viscosity fluids at low temperatures may require PID adjustment, contact Thermo Fisher.

Perform internal temperature sensor calibration.

Check optional external sensor connection. Perform calibration.

High Temperature Cutout activated, see page 28.

Condensation

A gasket is available for EX 7 units to install under the controller in order to

prevent any condensation from leaking into the unit.

Part Numbers:

Gasket, Baffle 084900

Clamp 036198

Instructions U00922

No serial communications

All units are tested for serial communications before they leave the factory.

Ensure the Computer indicator on the controller is on.

Troubleshooting

Check all communications settings and commands, they must be exact. See

Appendix B.

Check all wiring for proper connections or possible shorts.

Software to verify serial communication is available from Thermo Fisher.

- 41 -

Page 44

m

Service Assistance

Controller PID Values

BOM Decoder

If, after following these troubleshooting steps, your unit fails to operate

properly, contact our Service Department for assistance (see Preface, Aftersale Support). Before calling, please obtain the following information:

- unit BOM number

- unit serial number

- software version

- voltage of power source

The factory set PID values are:

PI D

Heat 0.6 0.6 0.0

Thermo Fisher does not recommend changing the PID values. Incorrect PID

values will hamper unit performance.

The Bill of Material (BOM) number helps identify the configuration of your unit.

The number is printed on the label located on the rear of the unit.

Troubleshooting

Digit#

Unit Identifier

275 = EX-7

276 = EX-10

277 = EX-17

279 = EX-35

Condenser Cooling Mode

0 = None

Pump

20 = Z-Pump

99 = Custom

Voltage

03 = 11 5/60/1

11 = 100/50/1, 100/60/1

25 = 230/50/1

99 = Custo

Reserved

00

Controller

00 = Digital One

01 = Digital Plus

02 = Digital Plus w/Analog I/O 10 mV/ °C

99 = Custom

- 42 -

Page 45

Displaying Software

Version Number

(Digital One/Digital Plus)

These values will be needed when calling Thermo Fisher Scientific for sales/

service information. The controller can display the installed software version

number. For example, for a unit with software version 082645.1A:

1. Unit is running normally and displaying reservoir fluid temperature.

2. Press and hold No for at least 10 seconds. The display will show the first

two digits, for example: 08 .

3. Press

The display will show the remaining digits to the left of the decimal, for

example: 2645.

4. Press

The display will show the decimal point and the digit to the right of the

decimal point, for example, 1 .

5. Press

The display will show the revision letter, as its equivalent number, for

example, 1 = A.

6. Press

The display will flash between Csu and the software checksum value.

7. Press