Page 1

NESLAB DIMAX

DI Maximum Cooler

Thermo Manual P/N U00858 Rev. 12/28/05

Installation-Operation-

Basic Service

Visit our Web site at:

http://www.thermo.com/tc

Product Service Information, Applications

Notes, MSDS Forms, e-mail.

Voice Info: (800) 258-0830

Page 2

Thermo Fisher Scientific

Sales, Service, and Customer Support

25 Nimble Hill Road

Newington, NH 03801

Tel : (800) 258-0830 or

(603) 436-9444

Fax : (603) 436-8411

www.thermofisher.com/tc

25 Nimble Hill Road

Newington, NH 03801

Tel: (800) 258-0830

Sales: 8:00 am to 5:00 pm

Service and Support: 8:00 am to 6:00 pm

Monday through Friday (Eastern Time)

Fax: (603) 436-8411

service.tc.us@thermofisher.com

Dieselstrasse 4

D-76227 Karlsruhe, Germany

Tel : +49 (0) 721 4094 444

Fax : +49 (0) 721 4094 300

info.tc.de@thermofisher.com

Building 6, No. 27

Xin Jinqiao Rd., Shanghai 201206

Tel : +86(21) 68654588

Fax : +86(21) 64457830

info.china@thermofisher.com

Statement of Copyright

Copyright © 2007 Thermo Fisher Scientific. All rights reserved.

This manual is copyrighted by Thermo Fisher Scientific.

Users are forbidden to reproduce, republish, redistribute, or resell any materials from this

manual in either machine-readable form or any other form.

Page 3

DIMAX DI MAXIMUM COOLER

PREFACE

SECTION I

Safety

SECTION II

General Information

SECTION III

Installation

SECTION IV

Operation

Compliance ............................................................................................ 3

Unpacking .............................................................................................. 3

After-sale Support ................................................................................... 3

Warnings ................................................................................................ 4

Description ............................................................................................. 5

Specifications ......................................................................................... 6

Site ......................................................................................................... 7

Facility Water Requirements................................................................... 7

Electrical Requirements .......................................................................... 7

Field Wiring Requirements ...................................................................... 7

Plumbing Requirements .......................................................................... 9

Fluids ..................................................................................................... 10

Filling Requirements ............................................................................... 10

Microprocessor Controller ....................................................................... 11

LEDs ...................................................................................................... 11

Fault Messages ...................................................................................... 16

SECTION V

Maintenance

Start Up .................................................................................................. 17

Flow Transducers ................................................................................... 18

Low Fluid Level Safety ............................................................................ 18

Autorefill ................................................................................................. 18

Emergency Off (EMO) ............................................................................ 18

Remote Interface .................................................................................... 19

Resistivity Sensor ................................................................................... 20

DeviceNet ............................................................................................... 20

DeviceNet Interface ................................................................................. 21

DeviceNet Messaging ............................................................................. 22

MODULE STATUS LED .......................................................................... 23

NETWORK STATUS LED ....................................................................... 23

Service Contracts ................................................................................... 25

Deionizing Cartridge ................................................................................ 25

Cleaning ................................................................................................. 25

- 1 -

Page 4

SECTION VI

Service & Troubleshooting

Algae ...................................................................................................... 26

Checklist ................................................................................................ 26

Service Assistance ................................................................................. 27

SECTION VII

Diagrams

Flow Diagram .......................................................................................... 28

Wiring Diagrams ..................................................................................... 29

- 2 -

Page 5

Compliance

Unpacking

Preface

Listed to:

UL 61010-1 2nd Edition

CSA C22.2 #61010.1 2nd Edition

Products tested and found to be in compliance with the requirements defined in

the EMC standards defined by 89/336/EEC as well as Low Voltage Directive

(LVD) 73/23/EEC can be identified by the CE Mark on the rear of the unit. The

testing has demonstrated compliance with the following directives:

LVD, 73/23/EEC Complies with IEC/EN61010-1

EMC, 89/336/EEC IEC/EN61326-1

For any additional information, refer to the Declaration of Conformity that

shipped with the unit.

Retain all cartons and packing material until the unit is operated and found to

be in good condition. If the unit shows external or internal damage, or does

not operate properly, contact the transportation company and file a damage

claim. Under ICC regulations, this is your responsibility.

After-sale Support

Thermo Electron Corporation is committed to customer service both during and

after the sale. If you have questions concerning the operation of your unit,

contact our Sales Department. If your unit fails to operate properly, or if you

have questions concerning spare parts or Service Contracts, contact our

Customer Service Department. Before calling, please obtain the following

information from the unit's serial number label:

- BOM number _________________________

- Serial number _________________________

- Software version (see page 14)____________

- 3 -

Page 6

Warnings

Section I Safety

Make sure you read and understand all instructions and safety precautions

listed in this manual before installing or operating your unit. If you have any

questions concerning the operation of your unit or the information in this

manual, contact our Sales Department (see After-sale Support).

Observe all warning labels.

Never remove warning labels.

Never operate damaged or leaking equipment.

Never operate the unit without cooling fluid in the reservoir.

Always turn off the unit and disconnect the line cord from the power

source before performing any service or maintenance procedures.

Always empty the reservoir before moving the unit.

Always turn off the unit and disconnect the line cord from the power

source before moving the unit.

Additional safety warnings are posted throughout the manual. These warnings are designated by an exclamation mark inside an equilateral triangle with

text highlighted in bold. Read and follow these important instructions. Failure

to observe these instructions can result in permanent damage to the unit,

significant property damage, or personal injury or death.

- 4 -

Page 7

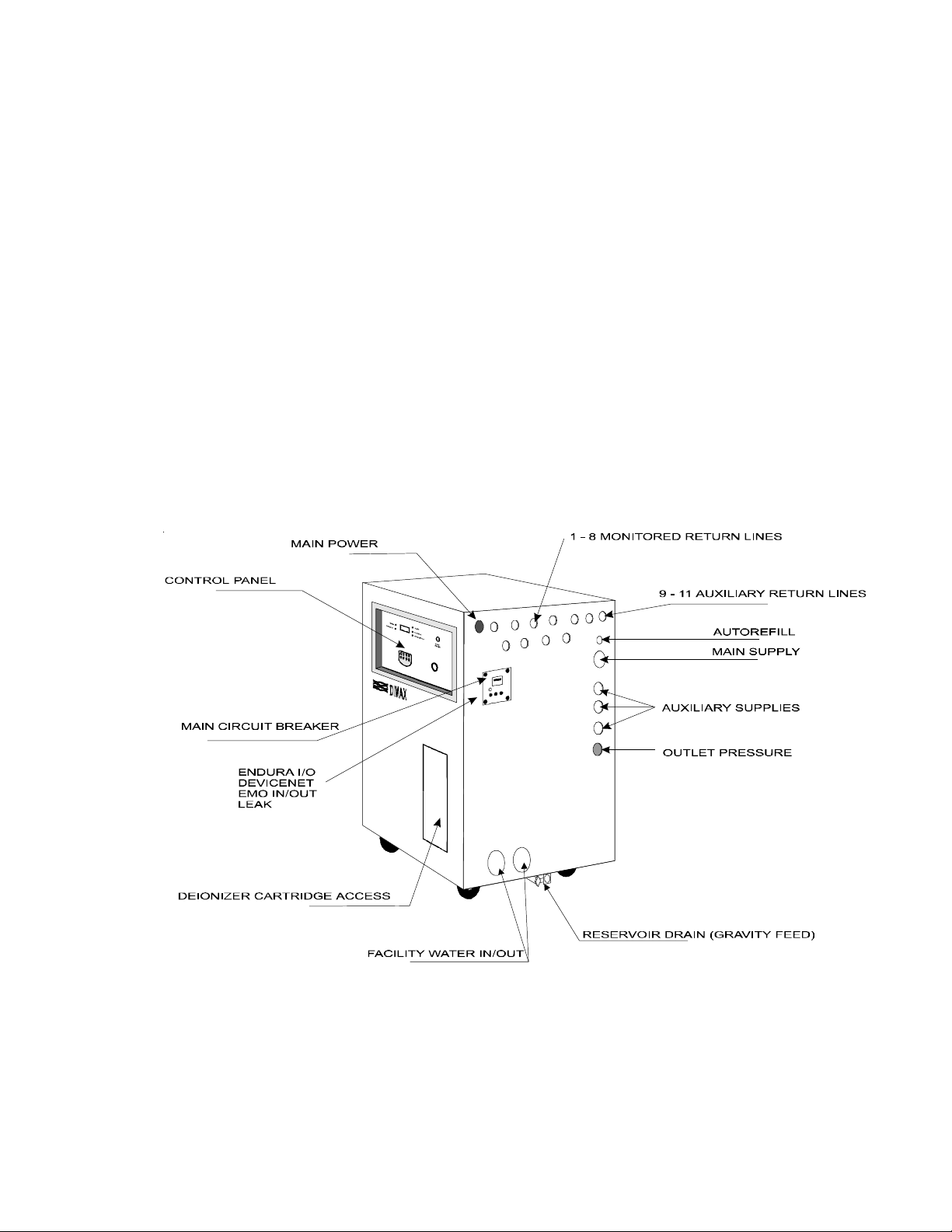

Description

Section II General Information

The DIMAX Liquid to Liquid Heat Exchanger is designed to remove heat

loads from liquid-cooled instruments. The unit uses facility cooling or tap

water as the secondary cooling medium to remove heat from the primaryfluid

in the closed recirculation loop.

The unit consists of a plate heat exchanger, recirculation pump, stainless

steel reservoir, built-in replaceable deionizing cartridge, and a microprocessor

controller. The controller monitors temperature, controls resistivity and

displays all fluid flows.

The unit has 11 return lines. The flow rate in 8 of these lines as well as the

facility flow line is monitored by flow transducers. The unit also has fluid level

sensors designed to protect the unit's pump and your application. A resistivity

sensor monitors resistivity and sends a signal to the controller when replacement is necessary.

- 5 -

Page 8

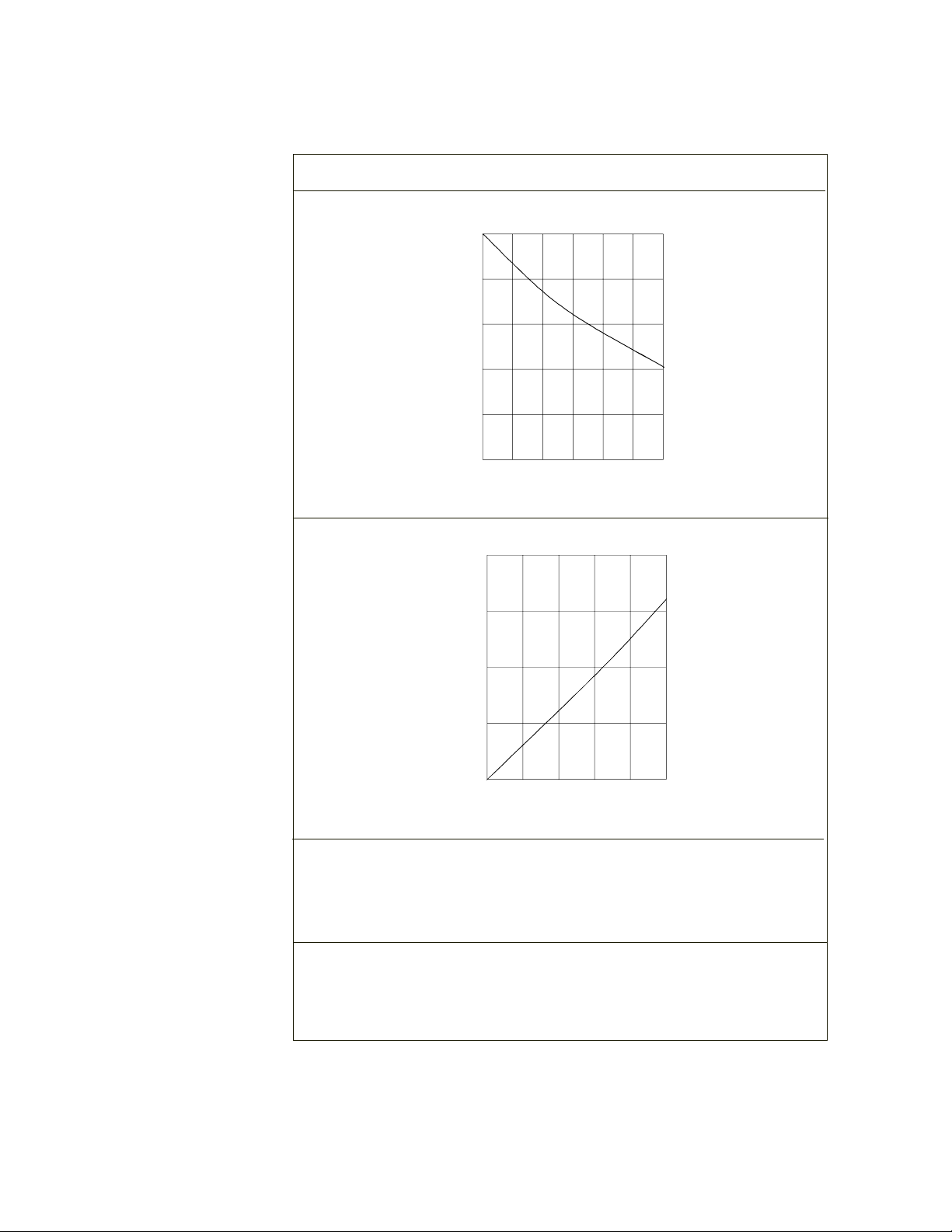

Specifications

Temperature Range

Pumping Capacity

Facility Water

Requirements

1

25

20

15

10

Pressure PSI

5

20

15

+20°C to +30°C

10 20 30 40 50 60

Flow rate (gallons per minute)

Reservoir Volume

Gallons

Liters

Unit Dimensions

(H x W x D)

Inches

Centimeters

10

Pressure PSI

5

10 20 30 40 50

Flow rate (gallons per minute)

68.0

257

55 x 32½ x 32½

139.7 x 82.6 x 82.6

1. Lower limit determined by facility water temperature.

- 6 -

Page 9

Site

Facility Water

Requirements

Section III Installation

The unit should be placed in a location with easy access to a facility cooling

water and a drain.

For proper ventilation, a minimum clearance of 6 inches ( 15 centimeters) at

the rear of the unit is necessary.

Never place the unit in a location where excessive heat, moisture, or

corrosive materials are present.

For the unit to operate at its full rated capacity, the facility water flow rate must

be at least 50 gallons per minute and the facility water temperature must be

between 17°C to 22°C. If the facility water does not meet these requirements,

the cooling capacity will be reduced.

Facility water supply should not exceed 100 psi and the maximum pressure

differential between facility water supply and return should not exceed 65 psi.

Electrical

Requirements

Field Wiring

Configuration

Refer to the serial number label on the rear of the unit for the specific

electrical requirements of your unit.

For high-voltage 380-415/480V units only, ensure the voltage selector

switch is in the correct position to meet the power source rating. The

switch is located behind the main circuit breaker panel on the righthand side of the unit.

Ensure the voltage of the power source meets the specified voltage, ±10%.

Make sure an adequate ground connection is provided.

The configuration is a 3 phase, 4 wires with PE. Remove the circuit breaker

panel cover to access the DIMAX main circuit breaker (CB1). The Circuit

Breaker is rated for Ring Lugs (RL).

The copper wires of the multi-conductor flexible power cable are terminated

with ring lugs with #10 holes at both ends. Crimp the ring lugs.

One terminal is connected to the branch circuit breaker, and the other to CB1.

- 7 -

Page 10

at the mainframe

consult Thermo NESLAB

consult Thermo NESLAB

Table 1 Facilities Requirements

Facilities Type Fitting Size Fitting Type Material Pressure Flow Comments

Monitored return 1" FPT Brass ~5 psi >10gpm at <15psi

Auxiliary return 1" FPT Brass ~5 psi

Main Supply 2" FPT Brass 25 psi max 50gpm at <15psi

Auxiliary supply 1" FPT Brass 25 psi max

Facility water In/Out 2" FPT Brass 100 psi max 50gpm max Higher pressures-

- 8 -

Autorefill ½" FPT Brass 75 psi max Unregulated Higher pressures-

Reservoir Drain ½" FPT Brass Atmospheric N/A

Reservoir Overflow 1 FPT Brass Atmospheric N/A

Supplied

AC Power Input Customer N/A N/A N/A N/A

Page 11

Plumbing

Requirements

The multi-conductor cable has 3 current carrying conductors and 1 noncarrying conductor (Ground). Each cable conductor is made of stranded

copper, and is at least size AWG 12.

The multi-conductor flexible jacketed cable is type S, SO, ST and STO with

insulation rated for a minimum of 600 V, 75°C (140°F).

The multi-conductor cable enters the DIMAX through a flex-type, non-metallic,

¾ inch diameter strain relief. 3-4 inches of the insulated jacketed should

remain un-stripped for slippage purposes.

Each conductor is connected to the DIMAX main circuit breaker using the ring

lug. Torque each screw to 20 in-lbs.

The Ground conductor should be approximately 6 inches long in order to reach

the ground bus through the ring lug. Torque the screw as well to 20 in-lbs.

Before installing the unit to an instrument that previously used tap water as a

cooling fluid, flush the instrument several times to remove any rust or scale

that has built up. The manufacturer of the instrument should be able to

recommend a cleaning fluid for their equipment.

The plumbing connections are located on the right side of the unit and are

labelled FACILITY WATER OUT (2"FPT), FACILITY WATER IN (2"FPT), MAIN

SUPPLY (2"FPT), AUXILIARY SUPPLY 1 - 3 (1"FPT), RETURN LINES 1 - 8

(1"FPT), AUXILIARY RETURN LINES 9 -11 (1"FPT), AUTOREFILL (½" FPT),

and OVERFLOW (1"FPT).

Connect the SUPPLY line to the inlet of your application. Connect the eight

MONITORED RETURN LINES and the three UNMONITORED AUXILIARY

RETURN LINES to the applicable lines (monitored or unmonitored). Connect

the FACILITY WATER IN to the cooling water supply and the FACILITY

WATER OUT to the cooling water drain or return.

Flexible tubing, if used, should be of heavy wall or reinforced construction.

The FACILITY WATER IN is subjected to the maximum pressure of the

facility cooling water. Hose connections should be securely clamped and rated

to withstand the maximum pressure of the system. Facility water supply

should not exceed 100 psi. Avoid running tubing near radiators, hot water

pipes, etc. If substantial lengths of tubing are necessary, insulation

may be required to prevent loss of cooling capacity.

- 9 -

Page 12

Fluids

The units pump is capable of generating up to 40 psi. The SUPPLY plumbing

should be rated to withstand that pressure.

Tubing and insulation are available from Thermo. Contact our Sales Department

for more information (see Preface, After-sale Support).

It is important to keep the distance between the unit and the instrument being

cooled as short as possible, and to use the largest diameter tubing practical.

Tubing should be straight and without bends. If diameter reductions must be

made, they should be made at the inlet and outlet of the instrument being

cooled, not at the unit.

If substantial lengths of cooling lines are required, they should be pre-filled with

cooling fluid before connecting them to the unit.

Never use flammable or corrosive fluids with this unit.

Do not use automobile anti-freeze. Commercial anti-freeze contains

silicates that can damage the pump seals. Use of automobile antifreeze will void the manufacturers warranty.

Filling Requirements

The selected fluid must have a viscosity of 50 centistokes or less at the lowest

operating temperatures.

DEI water is the recommended fluid for operation.

NOTE: The DEI cartridge is intended for maintaining resistivity only. If tap water

is used the cartridge will not last very long and will take a long time to come up

to resistivity.

The reservoir must be filled with a minimum of 16 gallons to ensure the pump

head remains submerged.

The unit has a nominal evaporation rate of up to 2.5 gallons per day. Ensure

the autorefill system is installed.

Autorefill will activate if the level is below 20 gallons and de-activate above 22.5

gallons.

The total reservoir capacity is 68 gallons (257 liters). To prevent siphoning, all

tank return lines are located at the top of the tank.

- 10 -

Page 13

Microprocessor

Controller

The controller has four different loops. An alphanumeric LCD display presents

numeric readings of various operating conditions within the chiller. Display

function is selected by pressing the appropriate keys to move through a menu

of available information.

Various controller loops allow the operator to display and/or alter different

parameters of the controller. When the controller is first powered up it goes

through a short self test and then enters the Operator Loop, displaying the

reservoir fluid temperature.

The various controller loops can be accessed from the Operators Loop by

pressing and holding the key combinations shown on the next four pages.

NOTE: Should you desire to return to the Operators Loop and abort any

changes, keep pressing LAST or NEXT until the display reads SAVE? Press

NO.

The YES key increments the value. The NO key decrements the value.

Pressing both keys for over three seconds accelerates the changing value.

The display will flash as soon as either key is depressed, and will continue to

flash until the ENTER key is pressed to accept the new value. The new value

will not be used by the controller until the ENTER key is depressed and the

display stops flashing.

LEDs

If the NEXT key is pressed while the value is flashing, the new value will not be

accepted. The display will stop flashing and the original value will be displayed.

In this case the NEXT key can be used to abort data entry. The display will not

sequence unless the NEXT key is depress again.

The yellow FAULT indicates a unit fault. The LCD display will indicate the

specific fault, see Fault Messages on page 16.

The green CARTRIDGE OK indicates the resistivity is above the low level

setpoint. The red REPLACE CARTRIDGE indicates the resistivity is below

the setpoint.

The bi-color MODULE STATUS LED indicates whether or not the device has

power and is operating properly. Reference page 23 for devicenet LED status.

The bi-color NETWORK STATUS LED indicates the status of the communication link. Reference page 23 for devicenet LED status.

- 11 -

Page 14

Operators Loop

When the controller is first powered it goes through a short self test and then

enters the Operators Loop, displaying the temperature of the fluid in the

reservoir, the resistivity of coolant leaving the chiller, the facility water flow

rate and any fault message.

By pressing the NEXT key the controller will step through the menus shown.

Figure 2 Operators Loop

TEMPERATURE displays the temperature of the coolant leaving the chiller in

°C. RESISTIVITY is the resistivity of the coolant leaving the chiller in megohms/cm. FACILITY WTR is the facility water flow rate in gallons per minute.

The most current fault message is also displayed.

FLOWS displays the flow rate in each of the eight process return lines (1 - 8)

and the facility water return line (F) in gallons per minute.

NOTE: Flow rate may be present but OFF will be displayed for any line if that

line's alarm is set to zero using the Setup Loop discussed on page 14.

STATUS displays the unit, pump and DI loop on time in hours.

- 12 -

Page 15

Setup Loop

The setup loop allows the operator to change the DI setpoints and flow alarm

limits.

To enter this loop you must be in the operators loop and displaying the temperature. Depress and hold the ENTER key while pressing the NEXT key.

Scroll through the SETUP menu using the NEXT or LAST key, press ENTER to

go to the desired sub-menu. Scroll through the sub-menu options using the

NEXT or LAST key, change the values using the YES or NO key. Leave the

sub-menu using the NEXT or LAST key. The display will indicate the save

prompt, press YES or NO.

NOTE: To disable the flow alarm for return lines which are off, set the flow

alarm to zero. At least one flow sensor must be set greater than zero for the

pump to come on.

- 13 -

Figure 3 Setup Loop

Page 16

Configuration Loop

The configuration loop allows you to configure frequency, enable the buzzer

and verify software version number.

To enter this loop you must be in the operators loop and displaying the

temperature. Depress and hold the ENTER key. While holding the ENTER

key enter the key sequence NO-YES-NO.

Scroll through the CONFIGURE menu using the NEXT or LAST key, press

ENTER to go to the desired sub-menu. Scroll through the sub-menu options

using the NEXT or LAST key, toggle the options using the YES or NO key.

Leave the sub-menu using the NEXT or LAST key. The display will indicate

the save prompt, press YES or NO.

Figure 5 Configuration Loop

- 14 -

Page 17

Calibration Loop

To enter this loop you must be in the operators loop and displaying the temperature. Depress and hold the ENTER

key. While holding the ENTER key enter the key sequence YES-NO-YES.

Use this loop to calibrate the RTD, resistivity, the range of the resistivity out signal (V/Mohm), the range of the

temperature out signal (100mV/°C) and the high and low flow calibration parameters.

Scroll through the CALIBRATE menu using the NEXT or LAST key, press ENTER to go to the desired sub-menu.

Scroll through the sub-menu options using the NEXT or LAST key, change the values using the YES or NO key.

Figure 4 Calibration Loop

Leave the sub-menu using the NEXT or LAST key. The display will indicate the save prompt, press YES or NO.

3) RESIST OUT?

- 15 -

Page 18

Fault Messages

Fault messages are displayed in the Operators Loop and the alarm will sound.

The faults are proiritized. When a fault is cleared and RESET is pressed, the

next prioritized fault is displayed. The messages below are listed from highest

to lowest priority.

NOTE: Use the controller's MUTE button to silence the alarm.

LOW LEVEL CUTOUT

Displayed when the tank level is less than 16 gallons. The message clears

after the fault is cleared and the RESET button is depressed.

MOTOR OVERLOAD

Displayed when the motor overload trips. The message clears after the fault is

cleared and the RESET button is depressed.

RTD FAIL

Displayed when the temperature is over 100°C (RTD open circuit). The message clears after the fault is cleared and the RESET button is depressed.

WARNING LOW LEVEL

Displayed when the tank level is less than 20 gallons. The message clears

after the fault is cleared and the RESET button is depressed.

HIGH TEMPERATURE

Displayed when the temperature is over 40°C. The message clears after the

fault is cleared and the RESET button is depressed.

LOW FLOW

Displayed when a return line flow drops below the alarm setpoint. The message

clears after the fault is cleared and the RESET button is depressed.

REPLACE CARTRIDGE

Displayed when the resistivity drops below the low setpoint for more than one

hour. The message clears after the fault is cleared and the RESET button is

depressed.

RESISTIVITY HIGH

Displayed when the resistivity is greater than the high setpoint for more than

eight hours. The message clears after the fault is cleared and the RESET

button is depressed.

EMO

Displayed when the EMO button is depressed. The message self-clears when

the EMO is returned to the normal position.

- 16 -

Page 19

Start Up

Section IV Operation

Connect the unit to a power source, refer to Section III Installation. See unit

serial tag for power supply requirements.

Before starting the unit, check all plumbing connections and make sure the

circulating system (the DIMAX, your application, and the tubing that connects

them) has been properly filled with cooling fluid. The reservoir level must be

above the low level switches.

Close the main circuit breaker (CB1). The white POWER AVAILABLE light will

illuminate, and the controller initializes and displays the Operators Loop. If a

fault is present, it will be displayed. NOTE: Certain faults prevent the pump

from starting, see Fault Messages on previous page.

For units with the GFI option, be sure the GFI is in the ON position before

closing the circuit breaker and turning on the unit.

Depress the PUMP ON/OFF button on the controller to start the pump. At

least one flow sensor must be set greater than zero for the pump to come on.

The unit may need additional fluid after the pump starts.

NOTE: If the pump performance is marginal on initial start up the electrical

phase may be wrong. Open the top of the unit and observe the pump's rotation.

If it is wrong, shut the unit down and disconnect it from its power source. Swap

any two AC line conductors.

Depress the PUMP ON/OFF button on the controller to stop the pump. Turn

the unit off by opening CB1.

1(7:25.

67$786

02'8/(

67$786

7528%/(

&$575,'*( 2.

5(3/$&( &$575,'*(

32:(5

$9$,/$%/(

(02

- 17 -

Page 20

Flow Transducers

Low Fluid Level Safety

Autorefill

Flow transducers are connected to return lines one through eight as well as the

facility water inlet line. The transducers monitor the flow rate of the cooling fluid

returning from your application and the facility water flow. Flows are displayed

on the controller's Operators Loop. If any flow rate drops below the setpoint,

entered in the controller's Setup Loop, a flow error message appears and a flow

alarm sounds.

NOTE: If the setpoint is set to zero, the flow alarm is disabled.

If the reservoir fluid level drops to 20 gallons, a fault message is displayed on

the controller, the TROUBLE LED illuminates, and a remote signal alarm is

generated. The alarm has to be reset once the fault is cleared. If the level

drops below 16 gallons, the alarm sounds and the pump is de-energized.

The unit has a nominal evaporation rate of up to 2.5 gallons per day. Ensure

the autorefill system is installed.

If the reservoir fluid level drops below 20 gallons, the autorefill solenoid will

activate and fill the reservoir to approximately 22.5 gallons.

Emergency Off (EMO)

A guarded red mushroom shaped push-button switch with twist-to-reset is

provided in the front of the unit to turn off the unit in case of an emergency. The

button head is engraved with EMO in large white filled letters.

Activation of the EMO button will remove power from the main contactor coil

stopping operation of the unit.

Resetting of the EMO button will not restart the unit. After all hazards have

been removed and the EMO is reset, the unit must be reset by pushing the

PUMP ON button on the control panel.

- 18 -

Page 21

Remote Interface

The temperature of the cooling fluid and the status of the low flow and low fluid

detectors can be monitored by an external device using the monitor receptacle

located on the control panel.

Monitor receptacle

Pin #1 Flow monitor output (return #1), active if flow is satisfactory sink current.

Pin #2 Flow monitor output (return #2), active if flow is satisfactory sink current.

Pin #3 Flow monitor output (return #3), active if flow is satisfactory sink current.

Pin #4 Flow monitor output (return #4), active if flow is satisfactory sink current.

Pin #5 Flow monitor output (return #5), active if flow is satisfactory sink current.

Pin #6 Customer supplied 24VDC power supply to unit (+).

Pin #7 Customer supplied 24VDC supply common.

Pin #8 Customer supplied +15VDC supply to unit (+).

Pin #9 Customer supplied ±15VDC common.

Pin #10 Customer supplied -15VDC supply to unit (-).

Pin #11 Temperature signal output (+). The temperature scale is 100mVDC/°C.

Pin #12 Analog signal output common (-).

Pin #13 Low fluid level monitor output, active if level is satisfactory sink current..

Pin #14 24VDC common output. Common connection for flow switches and low fluid level safeties.

Pin #15 Flow monitor output (return #6), active if flow is satisfactory sink current.

Pin #16 Flow monitor output (return #7), active if flow is satisfactory sink current.

Pin #17 Flow monitor output (return #8), active if flow is satisfactory sink current.

Pin #18 DI water resistivity output (1V/meg-ohn) , active if flow is satisfactory sink current.

Pin #19 Cartridge good/bad output, active if resistivity is above low resistivity setpoint.

Pin #20 Flow monitor output (facility water), active if flow is satisfactory sink current.

Flow monitors, low fluid level monitor, and cartridge monitor connections are

active (current sink to pin 14) when respective conditions are satisfactory, and

open when conditions are unsatisfactory (or when unit is off).

The temperature signal circuit has a differential output. Pin 12 must be

connected to ground in the monitoring system. This signal is only available if

the unit is on and 24VDC and ±15VDC is supplied to this connector.

- 19 -

Page 22

Resistivity

Sensor

Devicenet

The controller displays and maintains resistivity between adjustable setpoints.

If the resistivity goes above the high setpoint, the line through the DI cartridge

closes. Flow through the DI cartridge resumes when the resistivity drops to the

low setpoint. If the resistivity drops below the low setpoint for more than one

hour, a fault is displayed, the REPLACE CARTRIDGE LED illuminates and a

remote signal is generated.

NOTE: Every time the controller is energized, a four hour clock disables the

REPLACE CARTRIDGE fault.

The Node Address and baud rate are all set with three rotary switches on the

devicenet board, see illustration below.

SW1 and SW2 are used to set the MAC ID. The MAC ID can be set from 1 to

63. It is factory set at 60. SW1 is the Most Significant Digit (MSD) and SW2 is

the Least Significant Digit (LSD). To set the device to a MAC ID of 60, set

SW1 to 6, SW2 to 0.

SW3 is used to set the baud rate. The baud

rate is factory set to 500K.

SW3 position

0 = 125K

1 = 250K

2 = 500K

3 = Blank

NOTE: If the baud rate is changed, recycle

the controller for it to read the change.

- 20 -

Page 23

DeviceNet

Interface

Resistivity Scaling

Unsigned binary is used to represent the 0V to +10V range. 12 bits of resolution is available at the DeviceNet interface.

0 to +10V range

AI Digital Value Resistivity input to controller

(at the DeviceNet Interface)

0 0 Mohm

4095 20 Mohm

Flow Scaling

Unsigned binary is used to represent the 0V to +10V range. 12 bits of resolution is available at the DeviceNet interface.

Facility Flow

0 to +10V range

AI Digital Value Flow input to controller

(at the DeviceNet Interface)

0 0 gpm

4095 100 gpm

Process Flow

0 to +10V range

AI Digital Value Flow input to controller

(at the DeviceNet Interface)

0 0 gpm

4095 20 gpm

Temperature Scaling

Unsigned binary is used to represent the -5V to +5V range. 12 bits of resolution is available at the DeviceNet interface.

-5V to +5V range

AI Digital Value Temperature input to controller

(at the DeviceNet Interface)

0 0°C

2048 +50°C

4095 +100°C

- 21 -

Page 24

DeviceNet

Messaging

Poll Command Message:

Byte 7 6 5 4 3 2 1 0

0 PUMP

PUMP = Command for pump to be on or off. 1 = on, 0 = off..

Respond Message:

Byte 7 6 5 4 3 2 1 0

0 Water Temperature (LSB)

1 Water Temperature (MSB)

2 Water Resistivity (LSB)

3 Water Resistivity (MSB)

4 Flow 1 (LSB)

5 Flow 1 (MSB)

6 Flow 2 (LSB)

7 Flow 2 (MSB)

8 Flow 3 (LSB)

9 Flow 3 (MSB)

10 Flow 4 (LSB)

11 Flow 4 (MSB)

12 Flow 5 (LSB)

13 Flow 5 (MSB)

14 Flow 6 (LSB)

15 Flow 6 (MSB)

16 Flow 7 (LSB)

17 Flow 7 (MSB)

18 Flow 8 (LSB)

19 Flow 8 (MSB)

20 Facility Water Flow (LSB)

21 Facility Water Flow (MSB)

22 AF WLW PUMP FW CB WLF

2300000000

CB = Cartridge Good/Bad, 1 = Good, 0 = Bad

WLF = Water Level Low Fault, 1 = Good, 0 = Bad

FW = Facilities Water Flow, 1 = Good, 0 = Bad

PUMP=Status of Pump, 1 = ON, 0 = OFF

AF = Autorefill Status, 1 = ON. 0m = OFF

WLW = Water Level Warning, 1 = OK, 0 = OFF

Upon receipt of a poll command, we will send the 23 bytes of data through the

DeviceNet. The 23 byte response is in accordance to the Device Net fragmentation protocol of the DeviceNet Specification (revision 1.3).

- 22 -

Page 25

MODULE STATUS LED

NETWORK STATUS LED

The bi-color (green/red) LED provides device status. It indicates whether or not

the device has power and is operating properly.

Status LED Indication

No power Off Device not powered

Device operational Green Device operating in a normal condition

Device in standby Flashing Green Device needs commissioning due to

configuration missing, incomplete or

incorrect. Device may be in the

standby state

Minor fault Flashing Red Recoverable fault

Unrecoverable fault Red Device has an unrecoverable fault and

may need replacing

Device self test Flashing Device is in self test

Red/Green

The bi-color (green/red) LED indicates the status of the communication link.

Status LED Indication

Not powered/ Off Device not on line

Not on-line Device has not yet completed the

Dup_MAC_ID test

Device may not be powered, look at

MODULE status LED

On-line, Flashing Green Device on-line but has no connection in

not connected the established state

Device has passed the Dup_MAC_ID

test, is on-line, but has no established connection to other nodes

For a Group 2 Only device it means

that the device is not allocated to a

master

For a UCMM capable device it

means that the device has no

established connection

Link OK Green Device is on-line and has connections

on-line, connected in the established state

For a Group 2 Only device it means

that the device is not allocated to a

master

For a UCMM capable device it

means that the device has one or

more established connection

- 23 -

Page 26

Connection time-out Flashing Red One or more I/O connections are in the

timed-out state

Critical link failure Red Failed communication device. Device

has detected an error that has rendered it incapable of communicating

on the network (Duplicate MAC ID, or

Bus-off)

Communication faulted Flashing A specific communication faulted

and received an Red/Green device. Device has detected a

identify comm fault network access error and is in the

Request - Long communication faulted state. The

Protocol device has subsequently received and

accepted an identify communication

faulted request - Long Protocol

message

- 24 -

Page 27

Service Contracts

Deionizing Cartridge

Section V Maintenance

Thermo offers on-site Service Contracts that are designed to provide extended

life and minimal down-time for your unit. For more information, contact our

Service Department (see Preface, After-sale Support).

When the resistivity drops below the low setpoint for more than one hour the

REPLACE CARTRIDGE LED illuminates. This indicates replacement is

necessary.

Open the resistivity strap on the cartridge. Click open the quick disconnects

on the top and bottom of the cartridge and pull the cartridge from the unit.

Remove the hoses from both ends of the cartridge and then replace the

cartridge.

When reinstalling, ensure the flow arrow on the cartridge is pointing

up.

To avoid crimping damage, keep tubing clear of the door area.

Cleaning

Remove the reservoir to observe pure fluid flow. On the front side of the tank,

the center return line is purified fluid, the large return line is for auto refill, and

the other small return line is a pump protection bypass line.

Clean the strainer when the pressure decreases. Ensure the O-ring is seated

properly.

Clean the flow transducers every 12 - 18 months.

- 25 -

Page 28

Section VI Service & Troubleshooting

Algae

Checklist

For personal safety and equipment reliability, the following procedure

should only be performed by a qualified technician. Contact our Service Department for assistance (see Preface, After-sale Support).

To restrict the growth of algae in the reservoir, it is recommended that the

reservoir cover be kept in place and that all circulation lines be opaque. This

will eliminate the entrance of light which is required for the growth of most

common algae.

We recommend the use of Chloramine-T, 1 gram per 3.5 liters.

Unit does not start when turned on.

Check the unit's circuit breaker. For units with the GFI option, be sure the

GFI is in the ON position before closing the circuit breaker and turning on

the unit.Check fault messages.

Check fluid level in reservoir.

Check power supply.

No/poor controller display

Open up the top panel and locate 1INST. Turn the plastic pot screw .

(labelled R35) in the middle of 1INST to adjust the intensity.

Pump does not start.

At least one flow sensor must be set greater than zero for the pump to

come on.See page 14.

Poor pump performance on initial start up.

The electrical phase may be wrong. Open the top of the unit and observe

the pump's rotation. If it is wrong, shut the unit down and disconnect it from

its power source. Swap any two AC line conductors.

Unit continues to run for a short period and then stops.

Check reservoir level. The unit has a nominal evaporation rate of up to 2.5

gallons per day. Ensure the autorefill system is installed. Also, check total

system for leaks.

Make sure unit running on proper voltage.

- 26 -

Page 29

Service Assistance

If, after following these trouble shooting steps, your unit fails to operate

properly, contact our Service Department. Before calling, please obtain the following information:

BOM Number

Serial number

Software Version

Application

Type of fluid used

Temperature at which the problem occurs

Voltage at power supply of unit

Temperature of facility cooling water

Pressure of facility cooling water

- 27 -

Page 30

Section VIII Diagrams

Flow Diagram

- 28 -

Loading...

Loading...