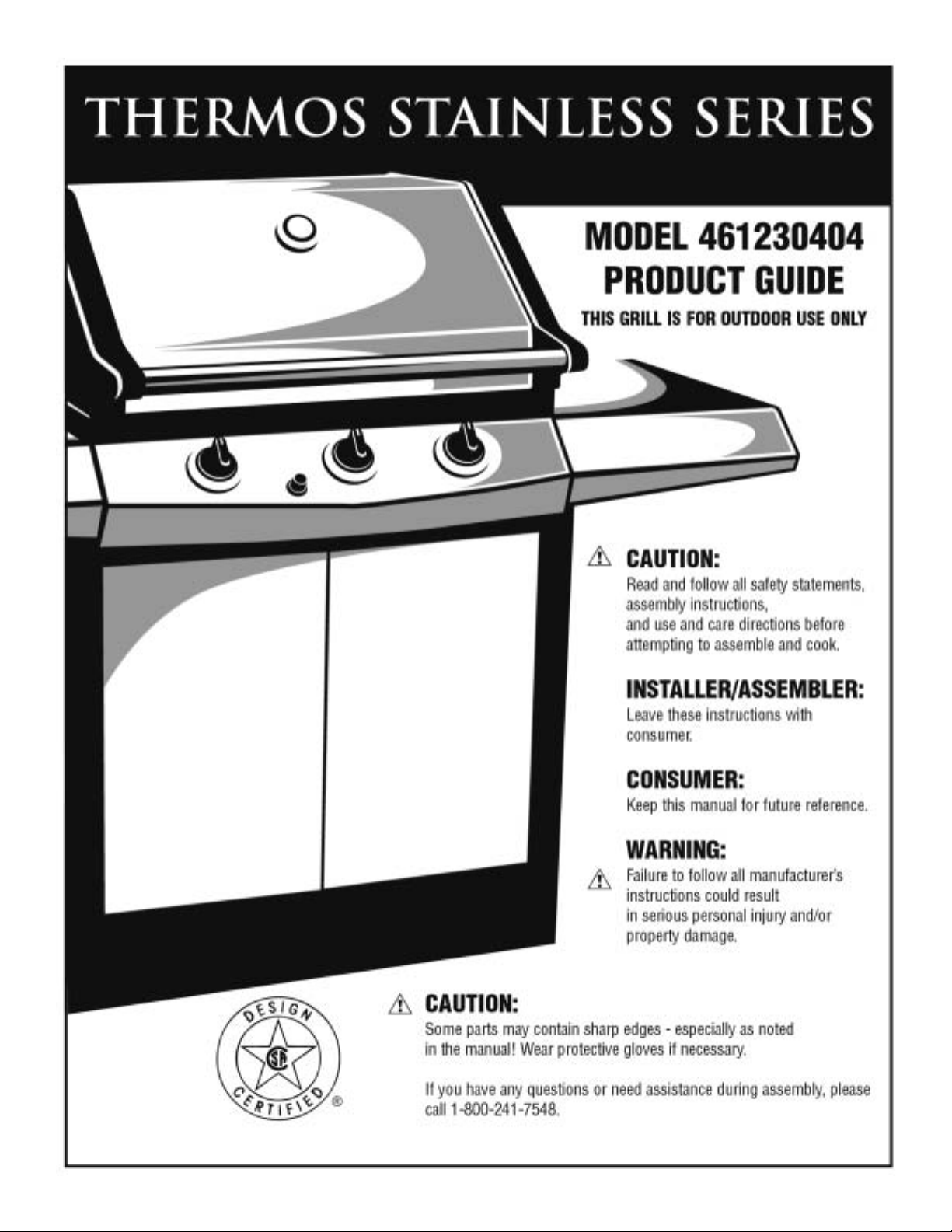

Page 1

461230404 • 80001008 • 10-09-03

Page 2

WARNING

FOR YOUR SAFETY

1. Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

2. An LP tank not connected for use shall

not be stored in the vicinity of this or any

other appliance.

FOR YOUR SAFETY

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flame.

3. Open lid.

4. If odor continues, immediately call your

gas supplier or your fire department.

Call Grill Service Center For Help And Parts

• If you need help or warranty parts call 1-800-241-7548 or send

a FAX to 1-706-576-6355.

Business hours: Open 24 hours – Seven days a week.

• To order non-warranty replacement parts or accessories (

cover, cleaners, paint

1-706-565-2121.

IMPORTANT: Fill out the product record information below.

) call 1-800-993-2677 or send a FAX to

grill

Installation Safety Precautions

•

Use grill only with LP (propane) gas and the regulator/valve

assembly supplied.

•

Grill installation must conform with local codes, or in their

absence with

Z223.1 CAN/CGA-B149.2 Propane Installation Code

Handling and storage of LP cylinders must conform to LP Gas

NFPA/ANSI 58.

Code Grill is not for use in or on recreational

vehicles and/or boats.

• All electrical accessories (such as rotisserie) must be

electrically grounded in accordance with local codes, or

National Electrical Code, ANSI / NFPA 70 Canadian

Electrical Code, CSA C22.1.

fuel supply hoses away from any hot surfaces.

• This grill is safety certified for use in the United States or

Canada only. Do not modify for use in any other location.

Modification will result in a safety hazard.

Safety Symbols

The symbols and boxes shown below explain what each heading

means. Read and follow all of the messages found throughout

the manual.

National Fuel Gas Code, NFPA 54 / ANSI

or .

or

Keep any electrical cords and/or

DANGER

DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

Model Number

Serial Number

See rating label on grill for serial number.

Date Purchased

CAUTION

For residential use only. Do not use for commercial

cooking.

WARNING

Combustion by-products produced when using this

product contain chemicals known to the State of

California to cause cancer, birth defects, and other

reproductive harm.

WARNING

WARNING: Be alert to the possibility of serious bodily injury

if the instructions are not followed. Be sure to read and

carefully follow all of the messages.

CAUTION

CAUTION: Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

2 • 461230404

Page 3

TABLE OF CONTENTS WARRANTY

For Your Safety......................................2

Grill Service Center...................................2

Product Record Information ............................2

Installation Safety Precautions ..........................2

Safety Symbols......................................2

Warranty ...........................................3

Parts List...........................................4

Parts Diagram.......................................5

Assembly ........................................6-15

Use and Care ...................................16-24

Manufacturer warrants to the original consumerpurchaser that this product shall be free from defects in

workmanship and materials under normal and reasonable

use and correct assembly (if assembled by consumerpurchaser), from date of purchase.

Stainless steel and die cast parts - 99 years

Electronic ignition and cast iron burners - 10 years

Remaining parts - 2 years

Manufacturer will, at its option, refinish or replace any

product or part found to be defective during the warranty

period. Manufacturer will require you to return the part(s)

claimed to be defective, for its inspection, freight or postage

prepaid.

If you wish to obtain performance of any obligation under

this limited warranty, you should write to:

Consumer Warranty / P.O. Box 1240

Columbus, GA 31902-1240

Manufacturer may require reasonable proof of purchase

and we suggest you keep your receipt. In the state of

California only, if refinishing or replacement of the product is

not commercially practicable, the retailer selling this product

or Manufacturer will refund the purchase price paid for the

product, less the amount directly attributable to use by the

original consumer-purchaser prior to discovery of the

nonconformity. In addition, in the state of California only, you

may take the product to the retail establishment from which it

was purchased or to any retail establishment selling this

product in order to obtain performance under this warranty.

This warranty does not include the cost on any

inconvenience or property damage due to failure of the

product and does not cover damage due to misuse, abuse,

accident, damage arising out of transportation of the product,

or damage incurred through commercial use of the product.

This express warranty is the sole warranty given by the

manufacturer and is in lieu of all other warranties, express or

implied, including implied warranty of merchantability or

fitness for a particular purpose. Neither Manufacturer dealers

nor the retail establishment selling this product has any

authority to make any warranties or to promise remedies in

addition to or inconsistent with those stated above.

Manufacturer's maximum liability, in any event, shall not

exceed the purchase price of the product paid by the original

consumer-purchaser. Some states do not allow the exclusion

or limitation of incidental or consequential damages. So the

above limitations or exclusions may not apply to you. This

warranty gives you specific legal rights and may also have

other rights which vary from state to state.

461230404 • 3

Page 4

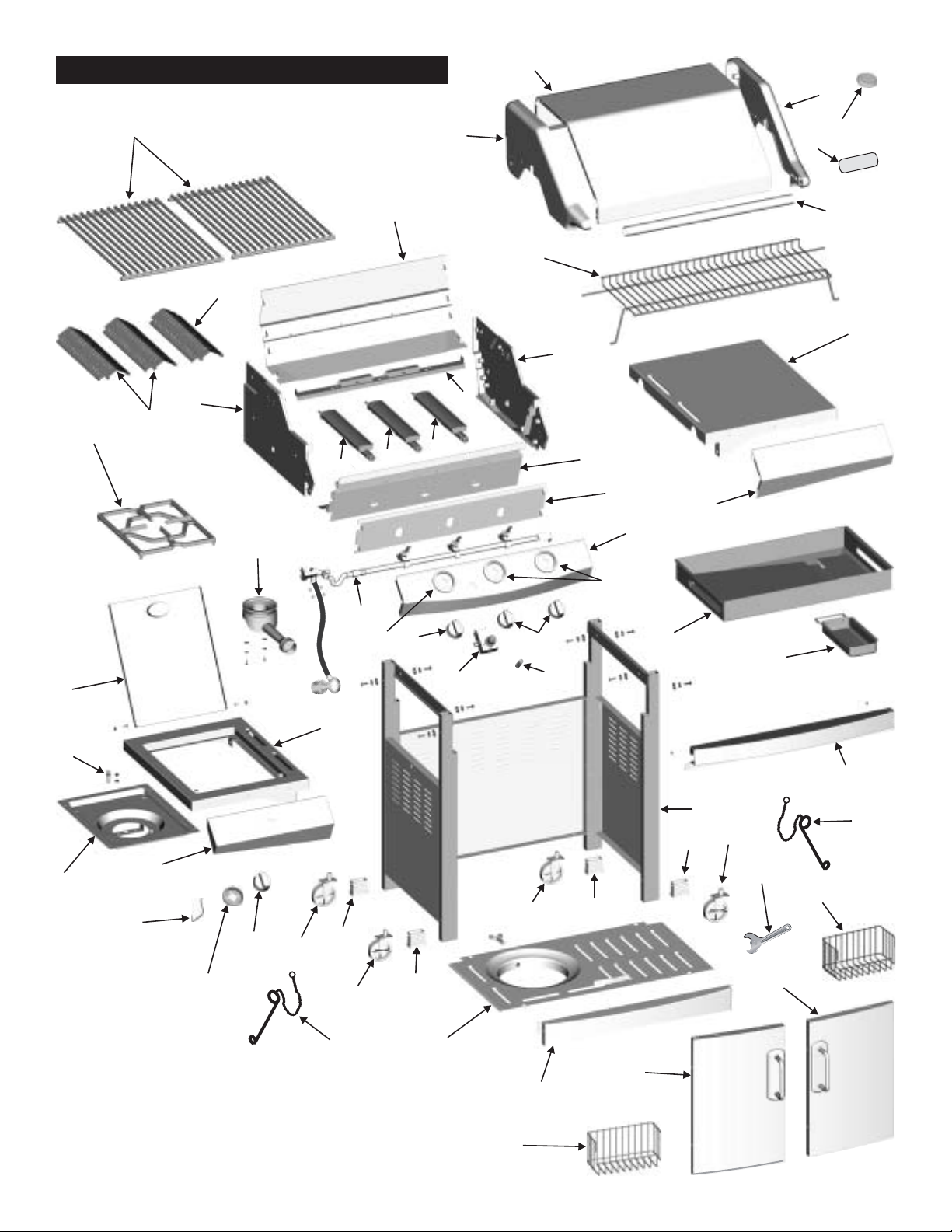

PARTS LIST – Model No. 461230404

Key Qty Description Part #

1 Grill Lid Assembly ...............80001001

A 1 Lid Insert........................80000302

B 1 Lid End Cap - Left ................80000303

C 1 Lid End Cap - Right ...............80000304

D 1 Lid Handle ......................80000305

E 1 Thermometer ....................80000096

F 1 Logo Plate ......................80001002

1 Grill Bottom Assembly............80001003

G 1 Grill Bottom Front Assembly.........80000651

H 1 Grill Bottom Rear Assembly .........80000018

I 1 Bottom End Cap - Left .............80000021

J 1 Bottom End Cap - Right ............80000022

K 3 Main Burner .....................80000023

L 3 Flametamer .....................80000947

M 1 Burner Brace/Carryover ............80000652

N 1 Ignitor Assembly..................80000653

O 1 Manifold Heat Shield ..............80000312

P 1 Control Panel ....................80001004

Q 4 Control Knob ....................80000035

R 4 Control Knob Bezel ...............80000034

S 1 Manifold/Hose/Regulator Assembly . . . 80000036

1 Sideburner Shelf Assembly........80001005

T 1 Sideburner Frame ................80000045

U 1 Sideburner Lid ...................80000316

V 1 Sideburner Pan ..................80000051

W 1 Sideburner Electrode ..............80000055

X 1 Sideburner Control Panel...........80001006

Y 1 Sideburner Assembly ..............80000277

Key Qty Description Part #

1 Cart Assembly ..................80000810

BB 1 Cart Frame ......................80000661

CC 4 Caster Socket....................80000076

DD 1 Bottom Shelf.....................80000317

EE 1 Bottom Rail......................80000800

FF 1 Door Assembly - Left ..............80000805

GG 1 Door Assembly - Right .............80000802

HH 1 Grease Tray .....................80000831

I I 1 Door Brace......................80000801

JJ 1 SwingAway Warming Rack .........80000263

KK 1 Condiment Basket - Left............80000266

LL 1 Condiment Basket - Right ..........80000267

MM 2 Locking Caster ...................80000268

NN 2 Fixed Caster.....................80000269

OO 1 Grease Receptacle................80000834

PP 2 Cooking Grate ...................80000293

QQ 1 Sideburner Grate .................80000282

RR 1 Caster Wrench ...................80000283

SS 1 AA Battery ......................80000284

TT 2 Match-Lighting Stick...............80000274

UU 1 Sideburner Valve Clip..............80000058

1 Hardware Pack...................80001007

1 Product Guide ...................80001008

1 Side Shelf Assembly .............80000059

Z 1 Side Shelf .......................80000060

AA 1 Side Shelf Panel..................80000064

Certified Grill Parts And Accessories®, Char-Broil and Design®, Char-Broil (Gas Grill Briquettes)®, Char-Diamonds®, Cooking Zone and Design®, Diamond Flame®, Executive Chef®, Faststart®, Flare

Fighter®, FlavorMaster®, Gas Grill Silouette and Design®, H2O Smoker®, Lava Flame®, MasterFlame®, MasterFlame Precision Cooking System®, PowerSpark®, Quantum®, VIP®, PrecisionFlame and

Design®, Sierra®, and TruFlame® are registered Trademarks of the W.C. Bradley Company. Thermos® is a registered trademark of the Thermos Company and its affiliates.

Artisan Collection by Char-Broil ™, C3 and Design™, Char-Broil and Design™, Flame Design™, FlavorTents™, Grill 2 Go™, Grillin’Stick™, Keeper of the Flame™, Keepers of the Flame™, Natural Grip™,

Outdoor Cooking Collection and Design™, Patio Bistro™, PrecisionFlame™, Pro-Check™, QuickSet Grills and Design™, SmokerTents™, The Big Easy™, The Minute Grill™, The Edge™, The Tuscan

Collection™, and The Urban Grill™ are Trademarks of the W.C. Bradley Company. Universal Grill Parts and Design™ is a trademark of the Thermos Company and its affiliates.

Protected under one or more of the following U.S. Patents: 4,598,692; 4,624,240; 4,747,391; 4,747,391; 4,817,583; 4,924,846; 4,989,579; 5,003,960; 5,076,256; 5,076,257; 5,090,398; 5,109,834; 5,224,676;

5,277,106; 5,421,319; 5,441,226; 5,452,707; 5,458,309; 5,566,606; 5,566,606; 5,579,755; 5,582,094; 5,613,486; 5,649,475; 5,706,797; 5,711,663; 5,765,543; 5,931,149; 5,996,573; 6,095,132; 6,135,104;

6,173,644B1; 6,279,566; 6,397,731; 6,418,923; 6,439,222; 6,523,461; D282,619; D339,714; D341,292; D343,337; D358,059; D361,466; D364,535; D372,637; D373,701; D377,735; D383,035; D397,910;

D405,643; D405,643; D406,005; D406,009; D413,043; D413,229; D413,229; D414,982; D415,388; D416,164; D416,441; D416,441; D417,587; D422,516; D423,274; D423,876; D428,303; D435,396; D436,004;

D438,059; D438,060; D438,427; D439,110; D442,505; D443,179; D443,354; D447,384; D447,385; D447,909; D448,610; D448,614; D448,615; D448,616; D448,975; D449,492; D451,759; D456,202S; D460,313

and D461,359. Canada: 87743; 87744; 92607; 92608 and 1,316,424. Other Patents Pending.

4 • 461230404

Page 5

PARTS DIAGRAM – Model No. 461230404

PP

A

C

E

B

E

F

F

H

D

JJ

L

Z

J

I

M

L

QQ

K

K

K

G

O

AA

P

Y

R

S

R

Q

Q

HH

OO

U

N

SS

T

W

II

BB

MM

CC

V

X

RR

TT

LL

CC

GG

UU

NN

Q

R

CC

NN

CC

MM

TT

DD

FF

EE

KK

461230404 • 5

Page 6

NOTE: Some grills parts shown in the assembly steps may differ slightly in appearance from

those on your particular grill model. However, the method of assembly remains the same.

ASSEMBLY – Model No. 461230404

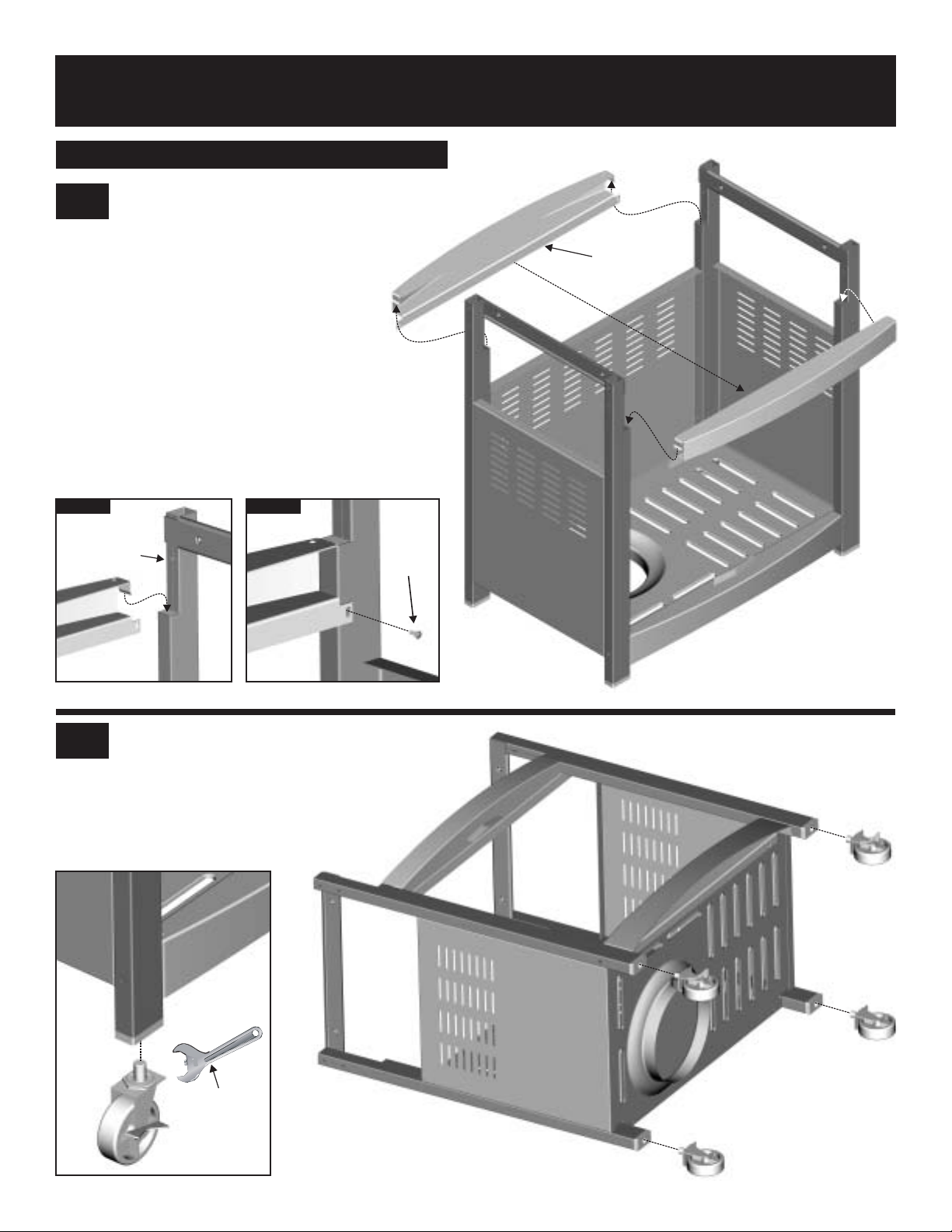

1

First

, remove door brace from rear legs. Place door

brace onto front legs as shown. Tabs on brace fit

inside legs. Secure brace to back of front legs using

one self-tap screw on each side.(WW)

4.2X10mm

Door brace

Rear view

Left front leg

Rear view

2

Attach , non-locking

locking casters to front legs

casters to rear legs. Tighten casters using the

caster wrench provided.

WW

Locking casters

on front legs.

6 • 461230404

Caster

wrench

Page 7

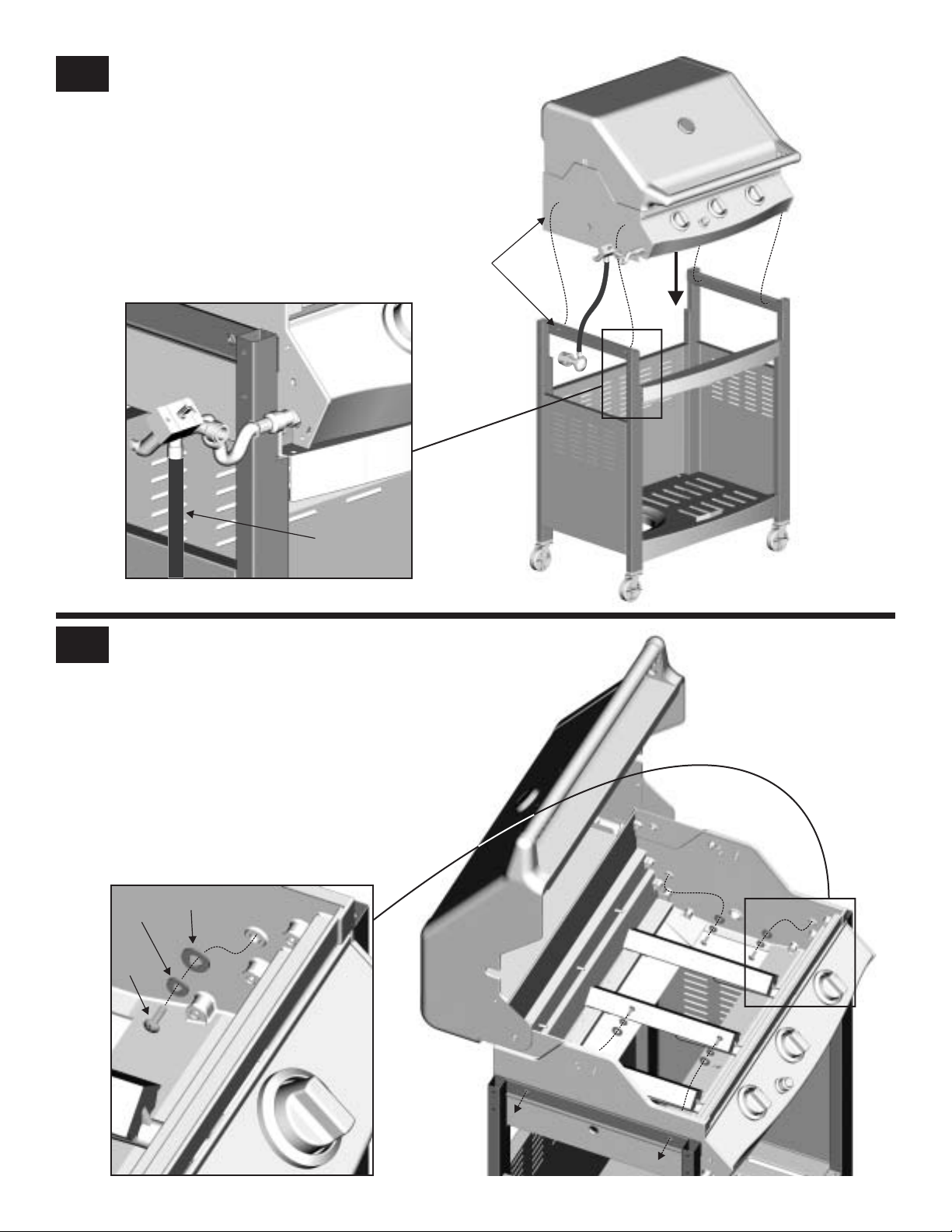

3

This step requires two people to lift and position grill

head onto cart.

Carefully lower the grill head onto the cart between the

two braces. Align the two holes on each side of the grill

head with the two holes on each brace. Make sure the

regulator hose is hanging outside the cart.

Align

holes

Regulator

hose

4

Secure grill head to leg braces using four screws ,

lock washers , and flat washers . Screws must

7mm (YY) 7mm (ZZ)

be attached from of grill head into brace.

Do not fully tighten screws until side shelf and sideburner

shelf are assembled.

inside

ZZ

YY

XX

1/4-20x3/4” (XX)

461230404 • 7

Page 8

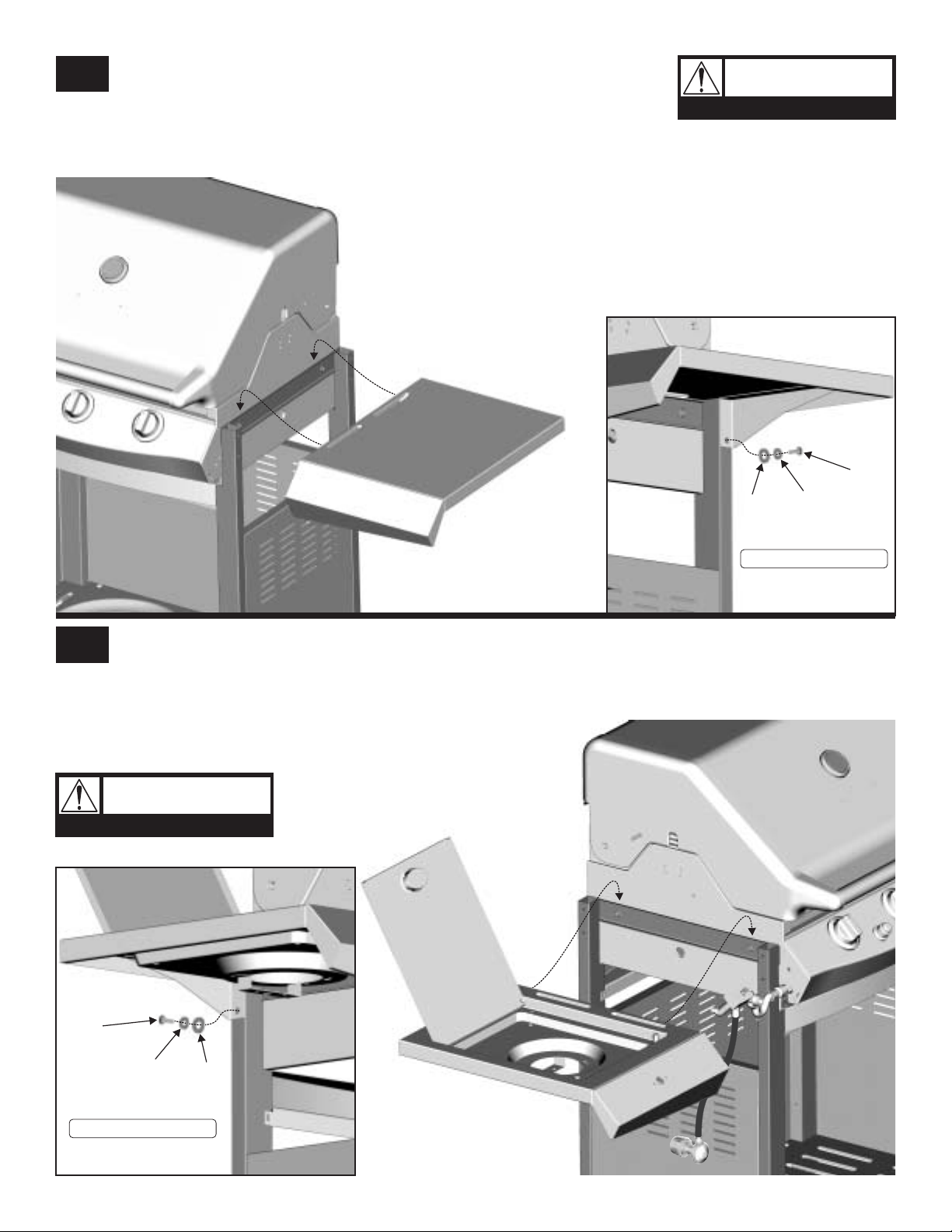

5

Place side shelf over right cart legs. Lip of shelf should fit between grill bottom and leg brace.

Secure shelf brackets to cart legs using one screw , lock washer ,

and flat washer on each bracket.

7mm (ZZ)

1/4-20x3/4” (XX) 7mm (YY)

CAUTION

SHARP EDGES! Wear gloves if necessary.

XX

6

Place sideburner shelf over left cart legs. Lip of shelf should fit between grill

bottom and leg brace. Secure shelf brackets to cart legs using one

1/4-20x3/4” (XX) 7mm (YY) 7mm (ZZ)

each bracket.

Fully tighten screws inside grill bottom at this time.

screw , lock washer , and flat washer on

CAUTION

SHARP EDGES! Wear gloves if necessary.

ZZ

Repeat on front bracket

YY

XX

YY

Repeat on front bracket

8 • 461230404

ZZ

Page 9

7

Remove the two screws (M4x10mm) and washers (4mm) from the

sideburner valve bracket.

Place sideburner valve under front of sideburner control panel so that

valve stem comes through large hole. Place sideburner bezel over valve

stem. Secure bezel to panel and valve using the two screws and

washers you removed from the valve bracket. Press control knob onto

valve stem.

Valve stem

Sideburner bezel

First, remove

screws and

washers from

bracket.

Sideburner

valve

8

Insert sideburner into shelf, placing end of burner over

sideburner valve. Valve should be in center hole of burner

tube. Make sure pin on bottom of burner is in center hole

in shelf bracket. Secure burner to bracket with two

#10-24x3/8” (AAA) 5mm (BBB)

and flat washers .

5mm (CCC) See illustration below for

correct burner-to-valve engagement

screws , lock washers ,

.

Sideburner

CCC

BBB

AAA

Pin

in hole

Correct

burner-to-valve

engagement

Valve should be

in center hole in

burner tube.

461230404 • 9

Page 10

9

Insert valve clip into small hole in bottom of burner, then snap other end of clip over sideburner valve. Beneath sideburner

shelf, attach sideburner ignitor wire to electrode. Place brass top on sideburner, then place sideburner grate onto shelf.

Valve clip

Sideburner

ignitor wire

10

Place flametamers (3) over burners by inserting tabs into slots in front of firebox.

Opposite ends of flametamers rest on pins in back of firebox.

Back of firebox

Flametamer

Front of firebox

Flametamer

10 • 461230404

Page 11

11

Place cooking grates into grill bottom.

Grate wires running front to back should

be facing upward . . . side to side wires

downward.

Side-to-side

wires on bottom.

12

SwingAway

To assemble SwingAway, first insert

pivot wire into holes in side of grill lid.

Second, insert leg wires into holes in

sides of grill bottom.

Pivot

wire

Leg wire

461230404 • 11

Page 12

13

Insert bottom door pin into hole in bottom

shelf. Press the top door pin down, align

with hole in door brace, release door pin.

Press pin

on door top

CAUTION

SHARP EDGES! Wear gloves if necessary.

14

Slide condiment

baskets into brackets on

back of both doors.

Smaller basket on left

door, larger basket on

right door.

12 • 461230404

Page 13

15

Hang the two match-lighting sticks and chains from the

small hooks on the left and right side panels.

16

Slide grease tray into back of grill.

Make sure drain hole

is on left side

461230404 • 13

Page 14

17

Slide grease receptacle into rails beneath grease tray.

CAUTION

• Failure to install receptacle on tray will cause hot

grease to drip from bottom of grill with risk of fire or

property damage.

18

LP tank is sold separately. Fill and leak check the tank (see Use & Care section) before attaching to grill and regulator.

Once tank has been filled and leak checked, place tank into tank hole in bottom shelf. Make sure tank valve is facing front

of grill. Secure tank with tank screw at rear of bottom shelf.

See Use & Care manual to perform the “Burner Flame

Check” and for important safety instructions before using.

CAUTION

Tank valve must face to front of cart once tank is attached.

Failure to install tank correctly may allow gas hose to be

damaged in operation, resulting in the risk of fire.

Tank screw

Grease

receptacle

14 • 461230404

Tank valve

facing front.

Page 15

19

VERY IMPORTANT!

Regulator and hose must pass hose bracket before connecting to LP tank. Read “

to the LP Tank

” in the Use and Care section of this manual.

Hose

Bracket

UNDER Connecting Regulator

Regulator and hose

must pass UNDER

hose bracket.

20

Unscrew ignitor cap and place AA

battery into ignitor slot with positive end

(+) facing outward. Screw ignitor cap

onto ignitor.

+

–

AA Battery

461230404 • 15

Page 16

USE AND CARE

LP Tank

• The LP tank used with your grill must meet the following

requirements:

DANGER

• Never fill the cylinder beyond 80% full. An overfilled

spare LP tank is hazardous due to possible gas

released from the safety relief valve.

• The safety relief valve on the LP tank could activate,

releasing gas, and cause an intense fire with risk of

property damage, serious injury or death.

• NEVER store a spare LP tank under or near grill or in

enclosed areas.

• If you see, smell or hear escaping gas, immediately get

away from the LP tank/grill and call your fire

department.

• All spare LP tanks must have safety caps installed on

the LP tank outlet.

LP Tank Removal, Transport And Storage

• Turn OFF all control knobs and LP tank valve. Turn coupling

nut counterclockwise by hand only - do not use tools to

disconnect. Loosen tank screw beneath bottom shelf, then lift

LP tank up and out of cart. Install safety cap onto LP tank

valve. Always use cap and strap supplied with valve. Failure to

use safety cap as directed may result in serious personal

injury and/or property damage.

•

Use LP tanks only with these required measurements: 12"

(30.5cm) (diameter) x 18" (45.7 cm) (tall) with 20 lb. (9 kg.)

capacity maximum.

• LP tanks must be constructed and marked in accordance with

specifications for LP tank of the U.S. Department of

Transportation (DOT). See LP tank collar for marking.

•

LP tank valve must have:

• Type 1 outlet compatible with

regulator or grill.

• Safety relief valve.

• UL listed Overfill Protection

Device (OPD). This OPD safety

feature is identified by a unique triangular hand wheel.

only LP tanks equipped with this type of valve.

• LP tank must be arranged for vapor withdrawal and include

collar to protect LP tank valve.

OPD Hand Wheel

Use

LP (Liquefied Petroleum Gas)

• For

LP gas is nontoxic, odorless and colorless when produced.

Your Safety

cabbage) so that it can be smelled.

•

LP gas is highly flammable and may ignite unexpectedly when

mixed with air.

, LP gas has been given an odor (similar to rotten

LP Tank Valve

Safety Cap

Retainer Strap

• A disconnected LP tank in storage or being transported must

have a safety cap installed (as shown). Do not store an LP tank

in enclosed spaces such as a carport, garage, porch, covered

patio or other building. Never leave an LP tank inside a vehicle

which may become overheated by the sun.

LP Tank Filling

•

Use only licensed and experienced dealers.

• must purge new tank

LP dealer before filling.

• NEVER

Dealer should fill LP tank more than 80% of LP tank

volume. Volume of propane in tank will vary by temperature.

A frosty regulator indicates gas overfill. Immediately close LP

•

tank valve and call local LP gas dealer for assistance.

• Do not release liquid propane (LP) gas into the atmosphere.

This is a hazardous practice.

• To remove gas from LP tank, contact an LP dealer or call a

local fire department for assistance. Check the telephone

directory under “Gas Companies” for nearest certified LP

dealers.

• Do not store an LP tank in an area where children play.

16 • 461230404

Page 17

LP Tank Exchange

Connecting Regulator To The LP Tank

• Many retailers that sell grills offer you the option of replacing

your empty LP tank through an exchange service. Use only

those reputable exchange companies that inspect, precision fill,

test and certify their cylinders.

Exchange your tank only for

an OPD safety feature-equipped tank as described in the

"LP Tank" section of this manual.

Always keep new and exchanged LP tanks in upright position

•

during use, transit or storage.

•

Leak test new and exchanged LP tanks BEFORE

connecting to grill.

LP Tank Leak Test

For your safety

Leak test must be repeated each time LP tank is exchanged or

•

refilled.

Do not smoke during leak test.

•

Do not use an open flame to check for gas leaks.

•

Grill must be leak tested outdoors in a well-ventilated area,

•

away from ignition sources such as gas fired or electrical

appliances. During leak test, keep grill away from open flames

or sparks.

• Use a clean paintbrush and a 50/50 mild soap and water

solution.

in figure below.

s Do not use household cleaning agents. Damage to gas

train components can result.

Brush soapy solution onto areas indicated by arrows

1.

LP tank must be properly secured onto grill. (Refer to

assembly section.)

Turn all control knobs, including sideburner, to the OFF

2.

position.

Turn LP tank OFF by turning hand-wheel clockwise to a

3. full

.

stop

Remove the protective cap from LP tank valve. Always use

4.

cap and strap supplied with valve.

c

k

w

o

i

l

s

e

Strap and Cap

OPD Hand Wheel

Type 1 outlet with

thread on outside

Safety Relief Valve

C

f

f

O

Do not use a POL transport plug

(plastic part with external threads)!

It will defeat the safety feature of

the valve.

WARNING

If “growing” bubbles appear do not use or move the LP tank.

Contact an LP gas supplier or your fire department!

5. Make sure hose and regulator pass

UNDER hose bracket on cart (

last assembly step

). Hold regulator

see

and insert nipple into LP tank valve.

Hand-tighten the coupling nut, holding

regulator in a straight line with LP tank

valve so as not to cross-thread the

connection.

Nipple has to be centered

into the LP tank valve.

461230404 • 17

Page 18

Straight

Hold coupling nut and regulator

as shown for proper connection

to LP tank valve.

6.

Turn the coupling nut clockwise and tighten to a full stop. The

regulator will seal on the back-check feature in the LP tank

valve, resulting in some resistance.

An additional one-half to

three-quarters turn is required to complete the

connection. Tighten by hand only – do not use tools.

NOTE:

Leak Testing Valves, Hose and Regulator

1. Turn all grill control knobs to OFF.

2.

Be sure regulator is tightly connected to LP tank.

3.

Completely open LP tank valve by turning hand wheel

counterclockwise. If you hear a , turn gas off

immediately. There is a major leak at the connection.

before proceeding

4.

Brush soapy solution onto areas circled below.

.

rushing sound

Correct

If you cannot complete the connection, disconnect regulator and

repeat steps 5 and 6. If you are still unable to complete the

connection,

do not use this regulator!

WARNING

• Do not insert any foreign objects into the valve outlet. You

may damage the valve and cause a leak. Leaking propane

may result in explosion, fire, severe personal injury, or

death.

• Never attempt to attach this grill to the self-contained LP gas

system of a camper trailer or motor home.

• Do not use grill until leak-tested.

• If a leak is detected at any time, STOP and call the fire

department.

• If you cannot stop a gas leak, close LP tank

valve and call LP gas supplier or your fire department!

immediately

NOTE: Sideburner

control panel not

shown for clarity.

5. If “growing”

valve immediately and retighten connections.

be stopped do not try to repair.

bubbles appear, there is a leak. Close LP tank

If leaks cannot

Call for replacement parts.

Order new parts by giving the serial, model number and name

of items needed to the Grill Service Center at 1-800-241-7548

(U.S.) or 1-800-387-6057 (CANADA).

18 • 461230404

6.

Always close LP tank valve after performing leak test by

turning hand wheel clockwise.

Page 19

WARNING

For Safe Use Of Your Grill And To Avoid Serious

Injury:

Do not let children operate or play near grill.

•

Keep grill area clear and free from materials that burn.

•

Do not block holes in bottom or back of grill.

•

Check burner flames regularly.

•

Use grill only in well-ventilated space. NEVER use in

•

enclosed space such as carport, garage, porch, covered

patio, or under an overhead structure of any kind.

Do not use charcoal or ceramic briquets in a gas grill.

•

(

Unless briquets are supplied with your grill.)

• Use grill at least 3 ft. from any wall or surface.

10 ft. clearance to objects that can catch fire or sources of

ignition such as pilot lights on water heaters, live electrical

appliances, etc..

Maintain

Safety Tips

s

Before opening LP tank valve, check the coupling nut for

tightness.

s

When grill is not in use, turn off all control knobs and LP tank

valve.

s

Never move grill while in operation or still hot.

s

Use long-handled barbecue utensils and oven mitts to avoid

burns and splatters.

s

Maximum load for sideburner and side shelf is 10 lbs.

s

The grease receptacle be attached to grease tray and

emptied after each use. Do not remove grease receptacle

until grill has completely cooled.

s

If you notice grease or other hot material dripping from grill

onto valve, hose or regulator, turn off gas supply at once.

Determine the cause, correct it, then clean and inspect valve,

hose and regulator before continuing. Perform a leak test.

s

Keep ventilation openings in cylinder enclosure (grill cart) free

and clear of debris.

s

The regulator may make a humming or whistling noise during

operation. This will not affect safety or use of grill.

must

• Apartment Dwellers:

Check with management to learn the requirements and fire

codes for using an LP gas grill in your apartment complex. If

allowed, use outside on the ground floor with a three (3) foot

clearance from walls or rails. Do not use on or under

balconies.

• NEVER attempt to light burner with lid closed. A buildup

of non-ignited gas inside a closed grill is hazardous.

• Never operate grill with LP tank out of correct position

specified in assembly instructions.

• Always close LP tank valve and remove coupling nut

before moving LP tank from specified operation

position.

s

If you have a grill problem see the .

"Troubleshooting Section"

CAUTION

• Putting out grease fires by closing the lid is not

possible. Grills are well ventilated for safety reasons.

• Do not use water on a grease fire. Personal injury may

result. If a grease fire develops, turn knobs and LP tank

off.

• Do not leave grill unattended while preheating or

burning off food residue on HI. If grill has not been

regularly cleaned, a grease fire can occur that may

damage the product.

Ignitor Lighting

s

Do not lean over grill while lighting.

1. Open lid.

To ignite, turn center knob to HI, push and hold ELECTRONIC

2.

IGNITOR button.

If ignition does NOT take place within 5 seconds, turn all

3.

burner valves to OFF, wait 5 minutes, then repeat lighting

procedure.

To ignite left burner, turn left knob to HI.

4.

To ignite right burner, turn right knob to HI.

5.

Turn on gas at LP tank.

Lighting instructions continued on next page.

461230404 • 19

Page 20

CAUTION

If burner does not light, turn knobs to , wait 5

minutes, and try again. If the burner does not ignite with

the valve open, gas will continue to flow out of the burner

and could accidently ignite with risk of injury.

Match-Lighting

s Do not lean over grill while lighting.

1. Open lid.

2.

Place lit match into match lighting stick, then into lighting hole

on left and/or right side of grill.

Push in and turn right or left burner knob to HI. Be sure burner

3.

lights and stays lit.

Light adjacent burners in sequence by pushing knobs in and

4.

turning to HI.

Turn on gas at LP tank.

OFF

Burner Flame Check

• Remove grates and flametamers. Light burner, rotate knobs

from HI to LOW. You should see a smaller flame in LO position

than seen on HI. Always check flame prior to each use.

Perform flame check on sideburner. If only low flame is seen

refer to "Sudden drop or low flame" in the.Troubleshooting

Section

HI

LO

Turning Grill Off

• Turn all knobs to position. Turn LP tank off by turning

hand-wheel clockwise to a full stop.

OFF

Ignitor Check

• Turn gas off at LP tank.

button. "Click" should be heard and spark seen each time

between collector box or burner and electrodes. See

"Troubleshooting"

if no click or spark.

Press and hold electronic ignitor

Valve Check

• Important: Make sure gas is off at LP tank before checking

valves

. Knobs lock in position. To check valves, first

push in knobs and release, knobs should spring back. If knobs

do not spring back, replace valve assembly before using grill.

Turn knobs to position then turn back to position.

Valves should turn smoothly.

LO

OFF

OFF

Ignitor Lighting The Sideburner

s Do not lean over grill while lighting.

1.

To ignite sideburner, open sideburner cover.

2.

Turn sideburner knob to HI, push and hold ELECTRONIC

IGNITOR button.

3.

If sideburner does NOT light, turn knob to OFF, wait 5 minutes,

then repeat lighting procedure or use match.

Match Lighting

1.

To match light sideburner, open sideburner cover.

2.

Place lit match near burner.

3.

Push in and turn sideburner

knob counterclockwise.

Be sure burner lights

and stays lit.

Hose Check

•

Before each use, check to see if hoses are cut or worn.

Replace damaged hoses before using grill. Use only

valve/hose/regulator specified by manufacturer.

General Grill Cleaning

• Do not mistake brown or black accumulation of grease and

smoke for paint. Interiors of gas grills are not painted at the

(and should never be painted)

factory . Apply a strong solution

of detergent and water or use a grill cleaner with scrub brush

on insides of grill lid and bottom. Rinse and allow to completely

Do not apply a caustic grill/oven cleaner to painted

air dry.

surfaces.

Plastic parts:

• Wash with warm soapy water and wipe dry.

s

Do not use citrisol, abrasive cleaners, degreasers or a

concentrated grill cleaner on plastic parts. Damage to and

failure of parts can result.

• Porcelain surfaces:

residue can be wiped away with baking soda/water solution or

specially formulated cleaner. Use nonabrasive scouring powder

for stubborn stains.

• Painted surfaces:

cleaner and warm soapy water. Wipe dry with a soft

nonabrasive cloth.

Because of glass-like composition, most

Wash with mild detergent or nonabrasive

20 • 461230404

• Stainless steel surfaces:

appearance, wash with mild detergent and warm soapy water

and wipe dry with a soft cloth after each use. Baked-on grease

deposits may require the use of an abrasive plastic cleaning

pad.

To maintain your grill’s high quality

Page 21

CAUTION

NATURAL HAZARD • SPIDERS

FACT: Sometimes spiders and other small insects climb into

the burner tubes attached to the burners. The spiders spin

webs, build nests and lay eggs. The webs or nests

can be very small, but they are very strong

and can block the flow of gas. Clean

burners prior to use after storing, at the

beginning of grilling season or after a period

of one month not being used.

Spider guards are on the air intakes in an effort to reduce this

problem, but it will not eliminate it! An obstruction can result

in a "flashback" (a fire in the burner tubes). The grill may still

light, but the obstruction does not allow full gas flow to the

burners.

Cleaning The Burner Assembly

Follow these instructions to clean and/or replace parts of burner

assembly or if you have trouble igniting grill.

Turn gas off at control knobs and LP tank.

1.

2. Remove cooking grates, flametamers, grease tray and

grease receptacle.

3. Remove cotter pins from beneath each burner "foot" using a

screwdriver or needle nose pliers.

4. Carefully lift each burner up and away from valve openings.

We suggest three ways to clean the burner tubes. Use the one

easiest for you.

(A)

Bend a stiff wire (a light weight coat hanger works well)

into a small hook. Run the hook through each burner

tube and burner several times.

IF YOU EXPERIENCE THE FOLLOWING:

1.

Smell gas.

2.

Burner(s) will not light.

3.

A small yellow flame from burner (should be blue).

4.

Fire coming from around or behind control knob.

STOP!

Immediately turn off gas at LP tank!

SOLUTION:

Wait for grill to cool.

Follow the “ ” instructions.

Clean burners often. Use a 12” pipe cleaner to clean out the

burner tubes. You may also force a stream of water from a

hose nozzle through burner tubes to clean them.

Cleaning The Burner Assembly

Storing Your Grill

• Clean cooking grates.

• Store in dry location.

• When LP tank is connected to grill, store outdoors in a wellventilated space and out of reach of children.

• Cover grill if stored outdoors. Choose from a variety of grill

covers offered by manufacturer.

• Store grill indoors ONLY if LP tank is turned off and

disconnected, removed from grill and stored outdoors.

• When removing grill from storage, follow “

Assembly

” instructions before starting grill.

Cleaning the Burner

(B)

Use a narrow bottle brush with a flexible handle (do not

use a brass wire brush), run the brush through each

burner tube and burner several times.

(C) Wear eye protection:

the burner tube and out the burner ports. Check each

port to make sure air comes out each hole.

5. Wire brush entire outer surface of burner to remove food

residue and dirt.

6. Clean any blocked ports with a stiff wire such as an open

paper clip.

7. Check burner for damage, due to normal wear and corrosion

some holes may become enlarged. If any large cracks or

holes are found replace burner.

VERY IMPORTANT: Burner tubes must reengage valve

openings. See illustrations below.

8. Carefully replace burners.

9. Replace cotter pin beneath each burner.

10. Replace grease tray, grease receptacle, flametamers and

cooking grates.

Burner Valve

Use an air hose to force air into

461230404 • 21

Page 22

Indirect Cooking

Poultry and large cuts of meat cook slowly to perfection on

the grill by indirect heat. The heat from selected burners

circulates gently throughout the grill, cooking meat or poultry

without the touch of a direct flame. This method greatly reduces

flare-ups when cooking extra fatty cuts because there is no direct

flame to ignite the fats and juices that drip during cooking.

Indirect Cooking Instructions

• Always cook with the lid closed.

• Due to weather conditions, cooking times may vary. During

cold and windy conditions the temperature setting may need

to be increased to insure sufficient cooking temperatures.

Food Safety

Food safety is a very important part of enjoying the outdoor

cooking experience. To keep food safe from harmful bacteria,

follow these four basic steps:

Wash hands, utensils, and surfaces with hot soapy water

Clean:

before and after handling raw meat and poultry.

Separate:

foods to avoid cross contamination. Use a clean platter and

utensils when removing cooked foods.

Cook:

thermometer to ensure proper internal food temperatures.

Chill:

For more information call: USDA Meat and Poultry Hotline at

1-800-535-4555 In Washington, DC (202) 720-3333, 10:00 am4:00 pm EST.

Separate raw meats and poultry from ready-to-eat

Cook meat and poultry thoroughly to kill bacteria. Use a

Refrigerate prepared foods and leftovers promptly.

1 Burner Cooking

Cook with direct or indirect heat.

Best for smaller meals or foods.

Consumes less fuel.

ON

ON

How To Tell If Meat Is Grilled Thoroughly

•

Meat and poultry cooked on a grill often browns very fast on the

outside. Use a meat thermometer to be sure food has reached

a safe internal temperature, and cut into food to check for

visual signs of doneness.

•

Whole poultry should reach 180° F; breasts, 170° F. Juices

should run clear and flesh should not be pink.

•

Hamburgers made of any ground meat or poultry should reach

160° F, and be brown in the middle with no pink juices. Beef,

veal and lamb steaks, roasts and chops can be cooked to 145°

F. All cuts of pork should reach 160° F.

•

NEVER partially grill meat or poultry and finish cooking later.

Cook food completely to destroy harmful bacteria.

•

When reheating takeout foods or fully cooked meats like hot

dogs, grill to 165° F, or until steaming hot.

22 • 461230404

ON

2 Burner Cooking

Great indirect cooking on low.

Produces slow, even heating.

Ideal for slow roasting and baking.

Page 23

Troubleshooting

Problem

Burner(s) will not light

using ignitor.

Burner(s) will not

match light.

Possible Cause

• Wire and/or electrode covered with

cooking residue.

Electrode cracked or broken "sparks at

•

crack”.

• Electrode tip not in proper position.

Wires are loose or disconnected.

•

Wires are shorting (sparking) between

•

ignitor and electrode.

• Dead battery.

No gas flow.

•

Coupling nut and regulator not fully

•

connected.

Obstruction of gas flow.

•

Disengagement of burner to valve.

•

Is grill assembled correctly?

•

Prevention/Solution

•

Clean wire and/or electrode with rubbing alcohol and clean swab.

•

Replace electrode(s).

• Main Burners: Tip of electrode should be pointing toward tip of

collector box. The distance should be 1/8” to 1/4”, adjust if

necessary.

• Sideburner: Tip of electrode should be pointing toward gas port

opening on burner. The distance should be 1/8” to 3/16”, adjust if

necessary.

• Reconnect wires or replace electrode/wire assembly.

• Replace ignitor wire/electrode assembly.

• Replace with a new AA battery.

• Check to see if LP tank is empty. If LP tank is not empty, refer to

"Sudden drop in gas flow"

.

• Turn the coupling nut about one-half to three quarters additional

turn until solid stop. Tighten by hand only-do not use tools.

•

Clear burner tube(s).

• Reengage burner and valve.

• Check steps in assembly instructions.

Sudden drop in gas

flow or low flame.

Flames blow out.

Flare-up.

Persistent grease fire.

Flashback...

(fire in burner tube(s)).

Unable to fill LP tank.

Out of gas.

•

Excess flow valve tripped.

•

High or gusting winds.

•

Low on LP gas.

•

Excess flow valve tripped.

•

Grease buildup.

•

Excessive fat in meat.

•

Excessive cooking temperature.

•

Grease trapped by food buildup around

•

burner system.

• Burner and/or burner tubes are blocked.

Some dealers have older fill nozzles

•

with worn threads.

• Check for gas in LP tank.

• Turn off knobs, wait 30 seconds and light grill. If flames are still low,

turn off knobs and LP tank valve. Disconnect regulator. Reconnect

regulator and leak test. Turn on LP tank valve, wait 30 seconds and

then light grill.

• Turn front of grill to face wind or increase flame height.

• Refill LP tank.

• Refer to above.

"Sudden drop in gas flow"

• Clean grill.

• Trim fat from meat before grilling.

• Adjust (lower) temperature accordingly.

• Turn knobs to OFF. Turn gas off at LP tank. Leave lid in position and

let fire burn out.

After grill cools, remove and clean all parts.

• Turn knobs to OFF. Clean burner and/or burner tubes.

• The worn nozzles don't have enough "bite" to engage the valve. Try

a second LP dealer.

461230404 • 23

Page 24

Troubleshooting - Electronic Ignition

Problem

No sparks appear at

any electrodes when

ignition button is

pushed; no noise can

be heard from spark

module.

No sparks appear at

any electrodes when

ignition switch is

pushed; noise can be

heard from spark

module.

Possible Cause

• Battery not installed

properly.

• Dead battery.

• Button assembly not

installed properly.

• Faulty spark module.

• Output lead

connections not

complete.

Check Procedure

• Check battery orientation.

• Has battery been used

previously?

• Check to insure threads are

properly engaged. Button

should travel up and down

without binding.

• If no sparks are generated

with new battery and good

wire connections, module is

faulty.

• Are output connections on

and tight?

Prevention/Solution

• Install battery (make sure that “+” and “–”

connectors are oriented correctly, with “+” end up

and “–” end down.)

• Replace battery with new AA-size alkaline battery.

• Unscrew button cap assembly and reinstall, making

sure threads are aligned and engaged fully.

• Replace spark module assembly.

• Remove and reconnect all output connections at

module and electrodes.

Sparks are present

but not at all

electrodes and/or not

at full strength

• Output lead

connections not

complete.

• Arcing to grill away

from burner(s).

• Weak battery.

• Electrodes are wet.

• Electrodes cracked or

broken “sparks at

crack”.

• Are output connections on

and tight?

• If possible, observe grill in

dark location. Operate

ignition system and look for

arcing between output wires

and grill frame.

• All sparks present but weak

or at slow rate.

• Has moisture accumulated

on electrode and/or in burner

ports?

• Inspect electrodes for

cracks.

• Remove and reconnect all output connections at

module and electrodes.

• If sparks are observed other than from burner(s),

wire insulation may be damaged. Replace wires.

• Replace battery with a new AA-size alkaline battery.

• Use paper towel to remove moisture.

• Replace cracked or broken electrodes.

A Division of W.C. Bradley Co. • Columbus, GA 31902

Loading...

Loading...