Page 1

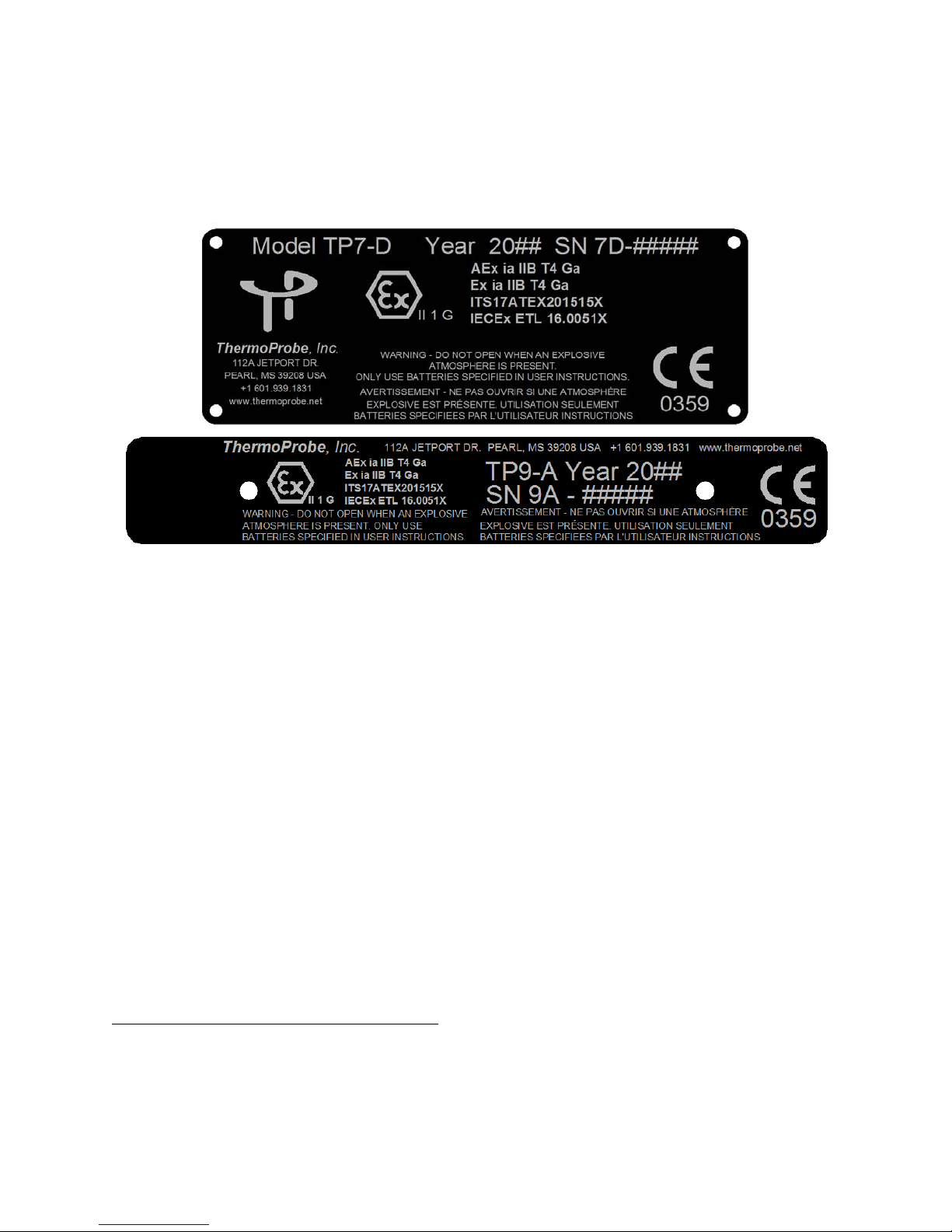

Thermoprobe Models TP7D and TP9A

English | Sp

ANUAL

TP7-D

TP9-A

SER

U

M

anish | French | Russian | Chinese

Page 2

EUDeclarationofConformityaccordingtodirective2014/34/EU(ATEX)

Thermoprobe,Inc.herebydeclarestheTP7‐DandTP9‐Aproductstobeinaccordancewiththefollowingstandards

anddirectives:

Nameandad

DescriptionofDevices

dressofManufacturer ThermoProbe,Inc.

112AJetportDr.

Pearl,MS39208USA

TP7‐DandTP9‐A

PortableElectronicThermometers

Ex-Designation

EC‐TypeExaminationCertificate

NotifiedBod

Auditingbod

AppliedHarmo

EN60079‐0:2012+A112013 Explosiveatmospheres–Part0:Equipment–Generalrequirements

EN60079‐11:2012 ExplosiveAtmospheres–Part11:EquipmentProtectionbyIntrinsic

AppliedEuropeanDire

2014/34/EU‐Equipmentandprotectivesystemsintendedforuseinpotentiallyexplosiveatmospheres

ThermoProbe,Inc.

LukeBartkiewicz

President

II 1 G Ex ia IIB T4 Ga

yIntertekTesting&CertificationLimited

y(QAN) IntertekTesting&CertificationLimited

nizedStandards

ctives

ITS17ATEX201515X

IntertekHouse

CleeveRoad

Leatherhead,

SurreyKT227SB,UK

IntertekHouse

CleeveRoad

Leatherhead,

SurreyKT227SB,UK

IdentificationNumber:0359

Safety‘i’

10/10/2017,JK

Page 3

USER INSTRUCTIONS - TP7-D & TP9-A

INTRODUCTION

This manual describes the basic function, use and safety instructions for a model TP7-D and TP9-A portable di gital

thermometer instrument.

REPLACING BATTERY

When the battery voltage is low, the low battery icon will show on the display.

When the battery voltage is very low, the backlight will no longer operate and the low battery icon will ‘blink’ on the

display.

Replace batteries as soon as possible in a safe location after the low battery is noticed. This will ensure backlight

operation, and avoid possible malfuncti oni ng. Do not at t em pt t o cal i brat e the i nst rument if the low battery indicator is

displayed.

WARNING:

Batteries must be changed in Non-hazardous area.

Batteries must be of correct approved type.

Batteries must be installed with correct polarity making sure the (+) end of the battery is aligned with (+)

symbol embossed in the b attery c ase.

Batteries must not be installed with polarity reversed where one cell could charge another cell.

New batteries must not be mixed with old batteries. Batteries must not be mixed with batteries of other

models or manufacturers.

a) Ensure the instrument is in a non-hazardous area & powered off.

b) Use a #2 Phillips drive to remove the 3 screws holding the front cover on the TP7-D or the 2 screws holding the

front cover on the TP9-A.

c) Use a #1 Phillips drive to remove the single screw from the battery cover. Remove the battery cover, push one

battery towards the spring contact and lift battery up from the holder, and then remove the r e maining bat tery.

d) Install each new battery making sure the (+) end of the battery is aligned with (+) symbol embossed in the battery

case.

e) Replace the retaining device and reinstall the cover.

CERTIFIED Batteries for the TP9-A and TP7-D are as follows:

Manufacturer Type Part Number

Duracell AA (LR6) Alkaline MN1500

Panasonic AA (LR6) Alkaline LR6XWA

GP (Gold Peak) AA (LR6) Alkaline GP15A

AUTHORIZED REPAIR

It is recommended that service beyond the scope of this m anual be performed by ThermoProbe, Inc. or one of its

authorized distributors.

See www.thermoprobe.net for video on proper use of this instrument. Refer to Am erican Pet roleum Institut e

measurement standard Chapter 7.2.

10/2017, JK

Page 4

g

r

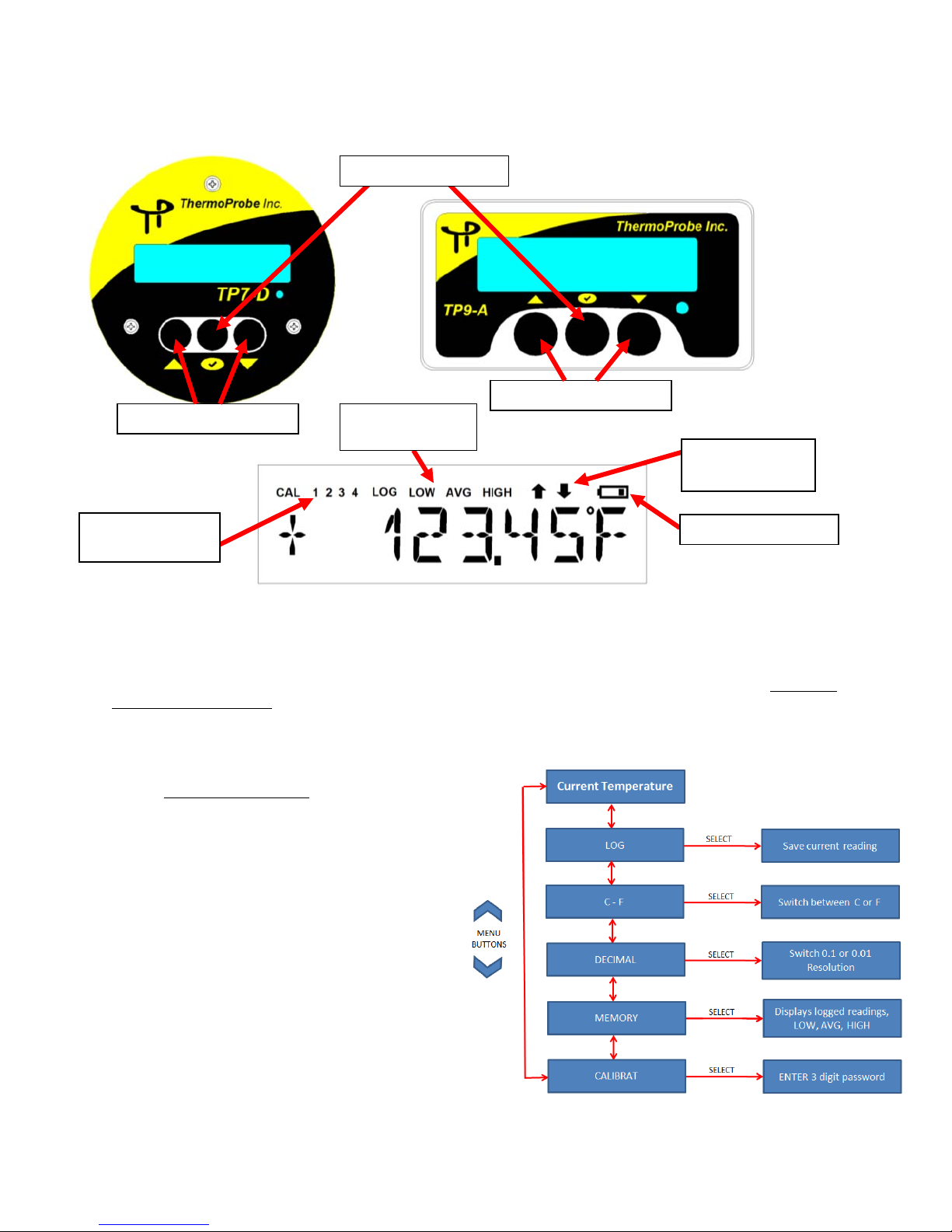

USER INTERFACE

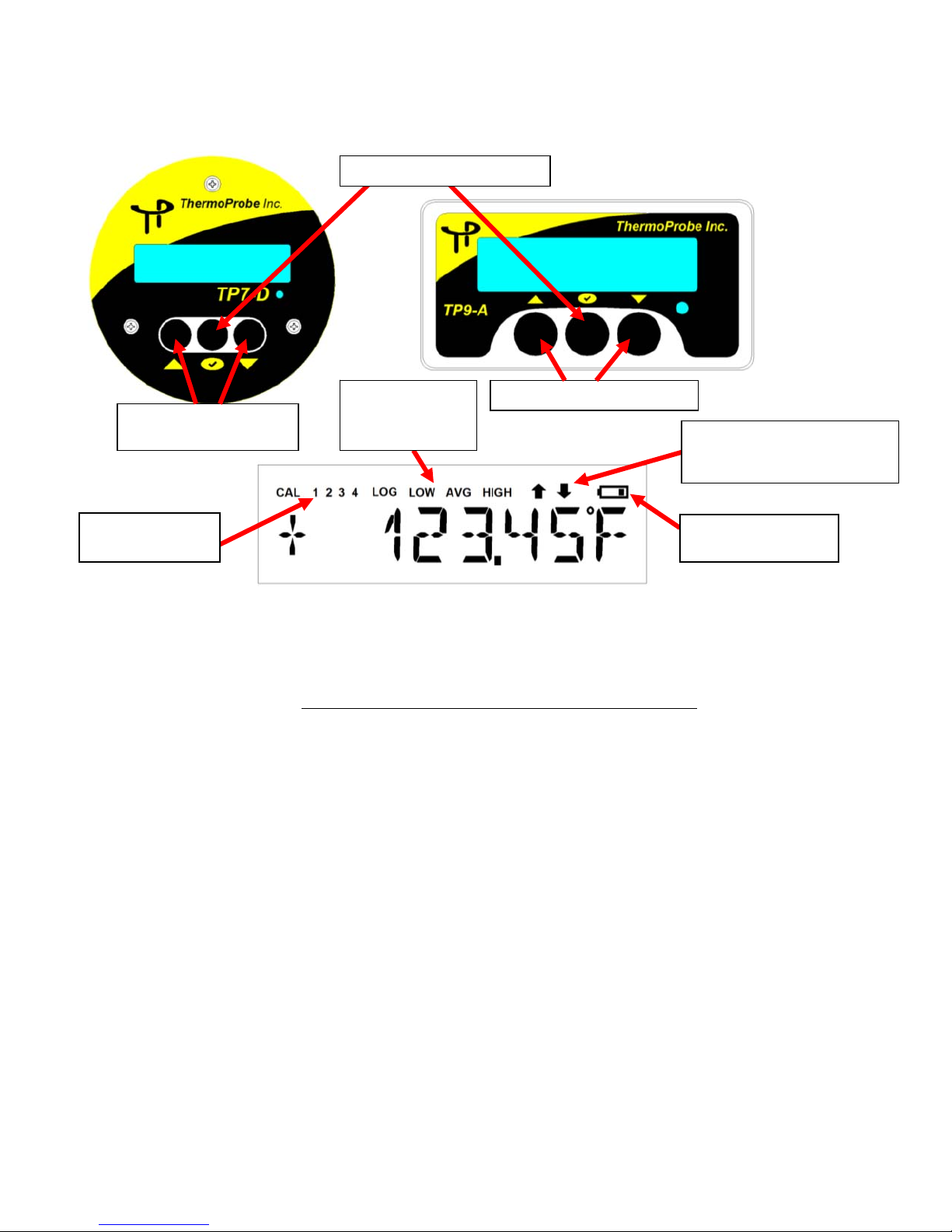

Power/Select Button

Up/Down Menu Buttons Icons for Memory

readin

s

Up/Down Menu Buttons

Temperature

indicating arrows

Indicators for

calibration points

Low battery indicato

Power Button:

Pressin

g the Power button once will turn on the device. (Note: The instrument will automatically power off 20 mi n ut e s

after the last button push.) Pressing and holding the “Power” button until it displays ‘OFF’ will turn off the instrument.

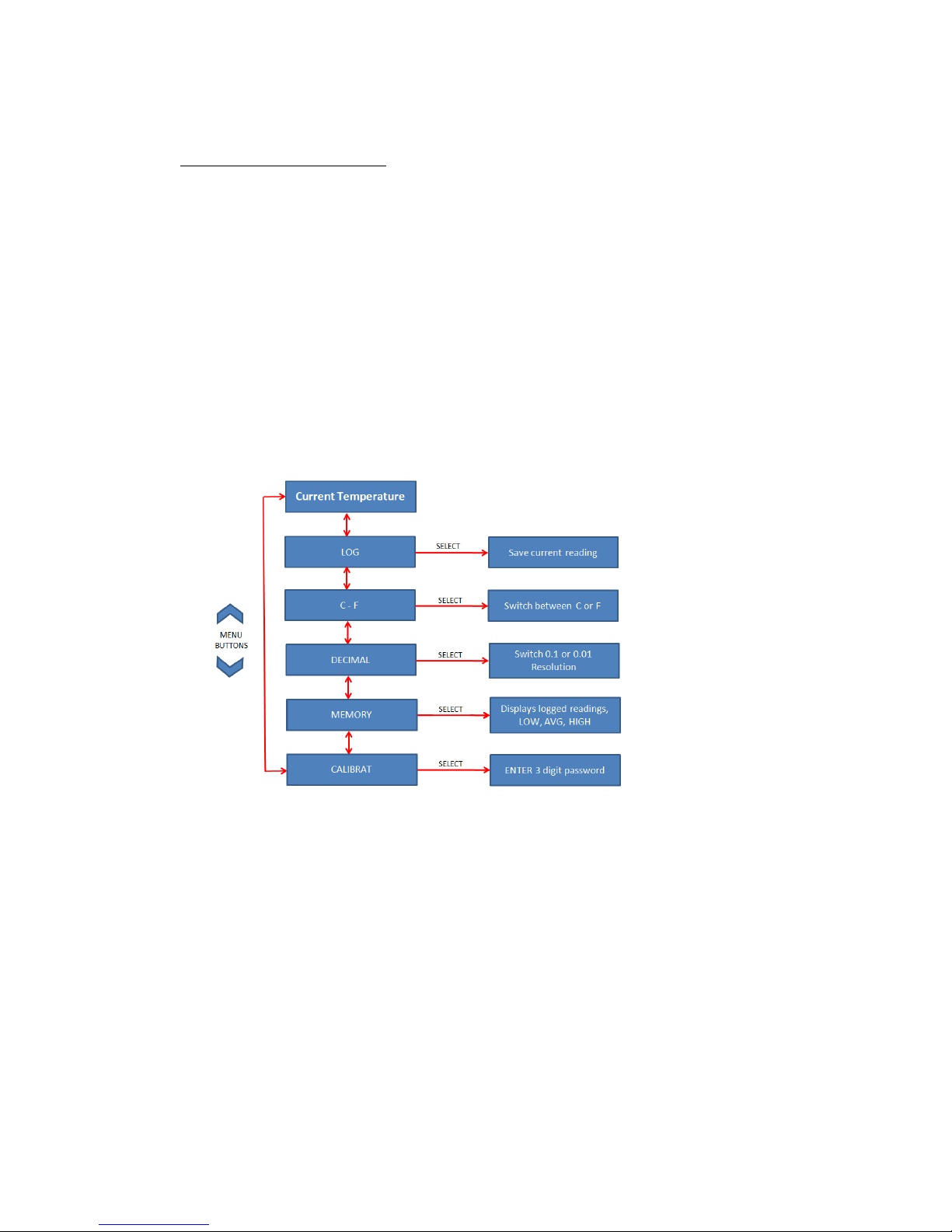

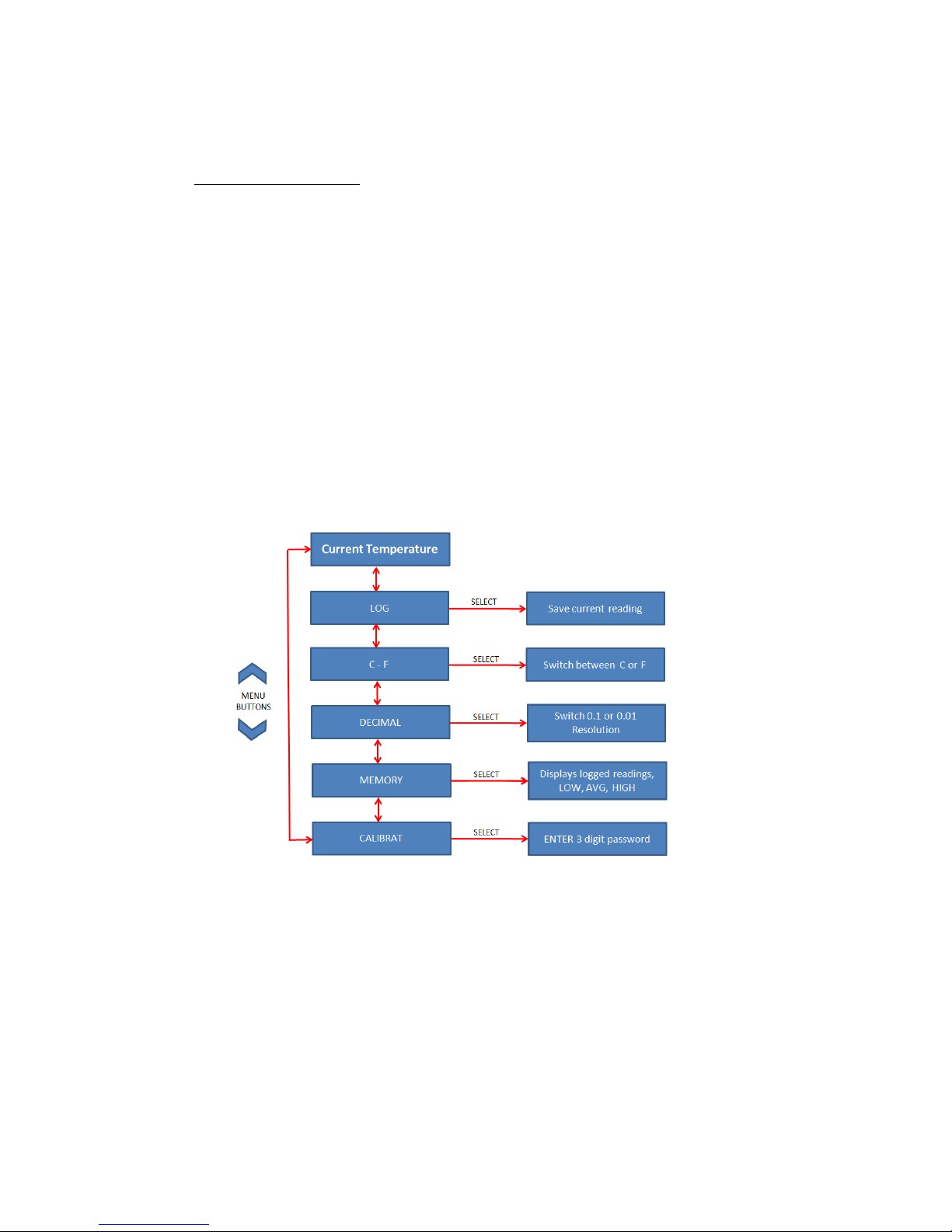

Selection MENU:

Use the “Up/Down” Menu buttons

Saves current stable temperature up to 4 readings

LOG:

C-F: Select Celsius or Fahrenheit temperature display

DECIMAL: Select 0.1 or 0.01 display resolution

MEMORY - Use “up/down” buttons to display:

Lowest reading

Average reading

Highest reading

Saved (Logged) readings 1-10

(Use CLR LOG to erase saved readings)

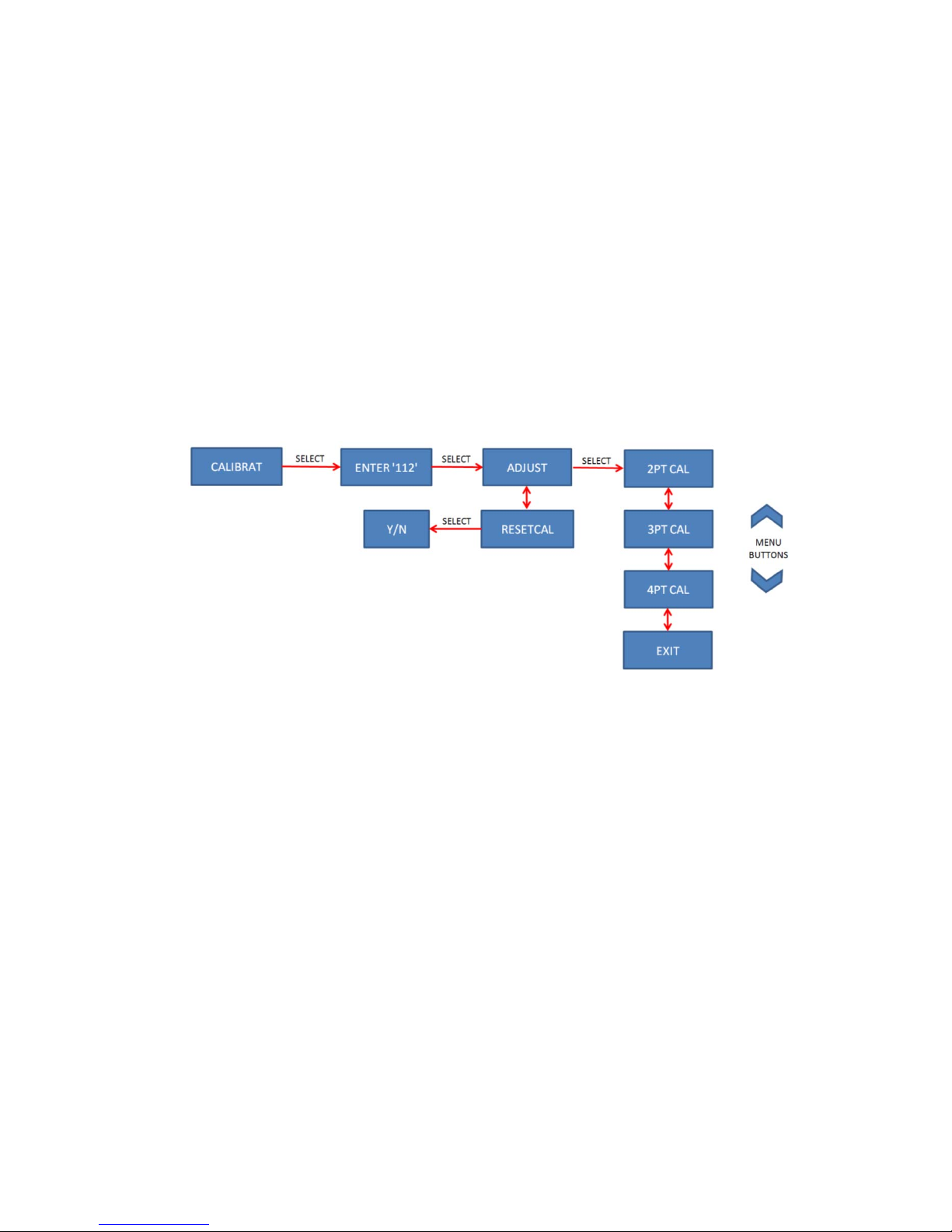

CALIBRAT: Enter calibration/adjustment mode

(Requires 3 digit password: 112) - See Calibration Procedure

for the following selections:

10/2017, JK

Page 5

Backlight

When the instrument is operating in low-light conditions a photocell will detect this situation and turn the backlight

on.

Temperature Logging

It is necessary for the temperature to be stable before logging temperature. The display arrows will flash 3 times when

the temperature reading has stabilized.

If you wish to log the temperature, Press the “down” button once until LOG is displayed. Press the “Select” button

once to save a reading. An acknowle dgment of a sa ved reading will occur with a display of “LOG 1-10”. This can be

repeated for up to 10 saved readings.

The logged temperatures can be accessed from the MEMORY menu. Logged temperatures will display with the LOG

icon and a prefix (1,2,3,4,5,6,7,8,9,0) corresponding to the previously logged readings. The up/down b uttons can be

used to advance through the readings. Select EXIT to return to the temperature display.

Logged readings will be retained even after the unit is powered off. Logged readings can be cleared by going to the

Memory section of the Menu and selecting CLR LOG. New readings cannot be taken until the readings are cleared.

USB Memory

A micro-usb connection is available on the circuit board allowing access to calibration & logged data.

Warning: Do not access the circuit board in a hazardous location.

Lowest, Highest & Average readings

The lowest, highest and average readings can be accessed through the MEMORY menu. The readings are indicated

by the LOW, AVG or HIGH icons on the display. These readi ngs are not related to the logged readings, but are

determined from the temperature when the unit is powered on. These readings are deleted after the unit is powered

off.

Display Codes

OPEN CKT - Indicates the sensor is operating above its tem perature l imit, the Probe Assembly is open circuited

from a cut or broken section, or the cable is not properly inserted at the circuit board t ermi nal. The most common cause

is a damaged cable.

SHORT CKT - Indicates the sensor is operating below its temperature limit or the Probe Assem bly is short circuite d

due to a smashed or cut section. The most common cause is a damaged cable.

NONE – There are no logged readings saved in memory.

2 WIRE – A 2 wire probe connection has been detected.

3 WIRE – A 3 wire probe connection has been detected.

NO CAL – The device does not have stored calibration data for the temperature probe. Perform an

adjustment/calibration before use.

10/2017, JK

Page 6

Probe Types

The TP7-D or TP9-A can use either 2-wire or 3-wire probe assemblies.

ThermoProbe replacement probe assemblies are availa bl e i n different configurations. The cable length is available in

lengths up to 50 meters or 165 feet. Standard brass marki ngs are available applied in 5 fe et or 1 meter increments. The

sensors are available with 4 weight types. The probe assembly part confi gur at i ons are as fo l l ows:

REPLACING THE PROBE ASSEMBLY

NOTES:

1) Replacement of the probe assembly requires re-calibration of the device. Replacement should only be

done by experienced personnel and if calibration equipment is available.

2) Please refer to IEC/EN 60079-19 (Explosive atmospheres - Part 19: Equipment repair, overhaul and

reclamation) when making the repair.

3) Only use replacement probe assemblies obtained from ThermoProbe, Inc. or one of its authorized

distributors.

a) First fo

b) On the circuit board push the terminals clamps down and remove the wires noting the wire lead color code

arrangement. See Figure 1.

c) Set the cover and circuit board aside and remove the strain relief knot in cable assembly.

d) Unwrap the cable from the assembly and pull the cable free of the rubber grommet.

e) Insert the new cable wire through the rubber grommet and then pull several inches of cable past the grommet.

f) Tie a simple overhand knot in the cable at the grommet for strain relief and pull the knot up to the grommet.

g) On the circuit board, push the terminal clamp levers down and insert the new wire leads according to the terminal

color codes. The label indicates how to connect a 2 wire probe vs. a 3 wire probe (includes green wire). See Figure 1.

h) Reinstall the batteries and cover and re-spool the cable assembly.

i) Perform a calibration (see calibration procedure).

Figure 1: Probe Assembly Lead Attachment

llow REPLACING BATTERY instructions a through c to remove batteries.

White – positive sensor wire

Green –

Silver – negative sensor wire & shield wire

cable compensating wire (not used on 2 wire models)

10/2017, JK

Page 7

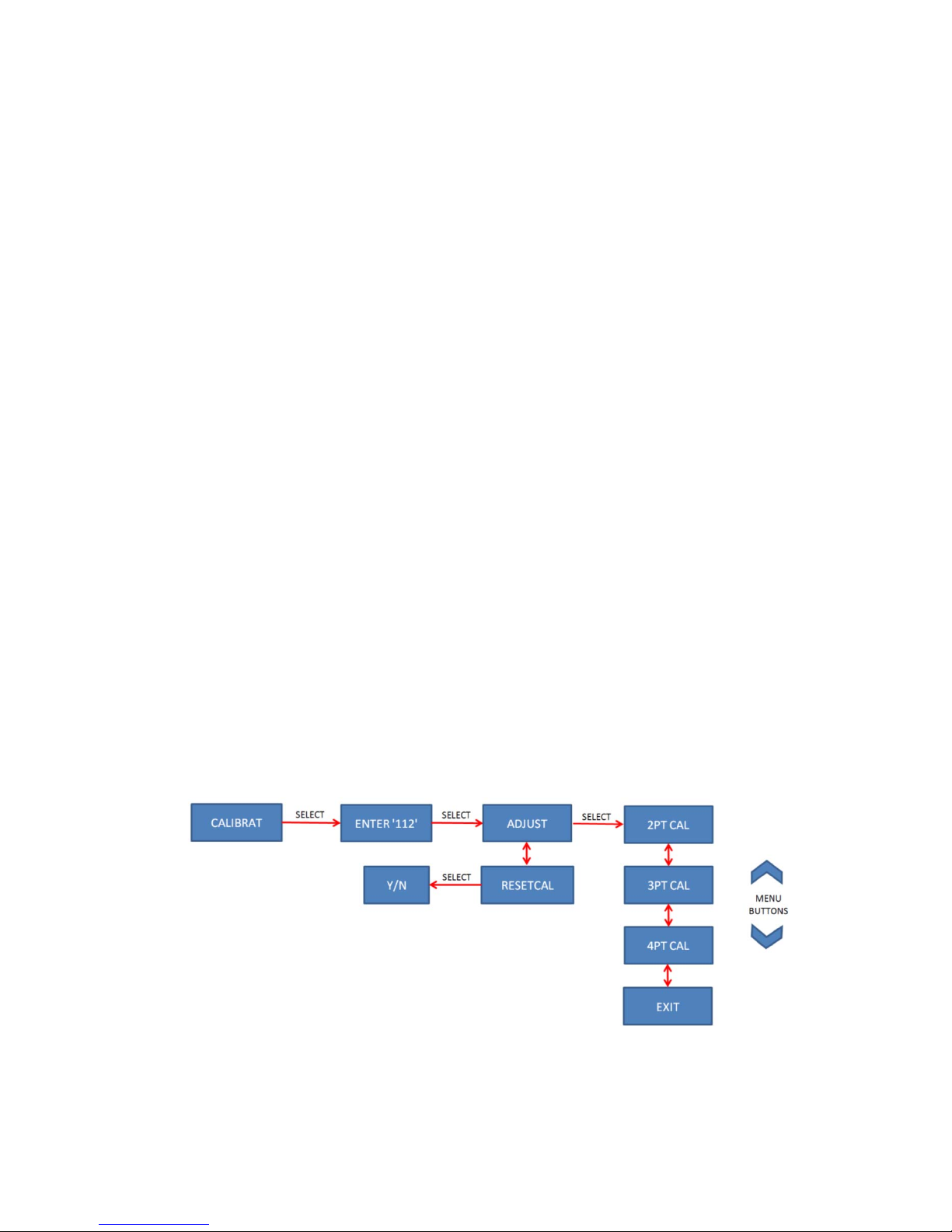

CALIBRATION PROCEDURE

The calibration mode should only be accessed by qualified personnel with proper equipment; otherwise

calibration integrity may be compromised. Read the following instructions carefully.

At least 2 points are required to make an adjustment. (2-Point calibration). Additional points can be taken

(3-Point or 4-Point calibration) to calibrate a large range of temperatures (e.g. 0°F to 300°F) or if you want

to match specific points in your range. You should include points at the bottom and top of the range. You

must have the proper equipment for every point of calibration.

Do not attempt to calibrate the instrument if the low battery indicator has been displayed since the new

calibration values may not be properly s tored to memory.

Refer to API 7.2 or another recognized standard for routine calibration verification recommendations.

Calibration must not be performed in any environment considered to be hazardous.

Equipment needed:

Ice Bath or other low temperature bath with reference thermometer.

Warm to hot fluid bath between 20°C (approx 68°F), or higher up to 90°C (approx 194°F) with reference

thermometer. (see Note)*

Optional high temperature oil bath at about 150°C/300°F and reference thermometer.

*Note for limited calibration: If entire range capability of instrument is not required, the 2 point high adjustment

can be made at a temperature relatively close to the common temperature of the liquid measured and accuracy

will be maintained within the limited range. For example: If liquid product to be measured is commonly less than

38°C (approx. 100°F), then a “high point” calib ra t io n c a n be made near that temperature. Temperature accuracy

above this calibration point cannot be assured.

To calibrate proceed with the following steps:

1. Enter calibration mode by going to CALIBRAT in the selection Menu. When this is selected, the user will be

prompted to enter a 3 digit password. Using the “up/down” buttons allows each digit to be adjusted. Once the

correct value is set, advance to the next digit by pressing the “select” button. After the 3

“select” button to enter Calibration mode. If an incorrect password is entered, FAIL will display and the unit

will return to temperature mode. Once in Calibration mode the ‘CAL’ icon on the display will blink. The

calibration mode password is: 112

2. Select ADJUS

2PT CAL, 3PT CAL or 4PT CAL using the select button.

T from the calibration menu and then select the desired number of calibration points. Pick

NOTE: If the user is not ready to enter the calibration mode, the EXIT option can be chosen.

rd

digit is set press the

10/2017, JK

Page 8

3. T

he device is now in adj ustm en t m ode . The di spl ay will show ADD PT1. The “up/down” buttons can be used

to select a different point to adjust or CANCEL. If the CANCEL option is chosen then the calibration

procedure is exited and the prior calibration values are re-activated.

ADD PT1 = Lowest temperature point

ADD PT2 = the next higher temperature point

ADD PT3 = the next higher temperature point (only used in 3-point calibrati on or 4-point calibrati on mode)

ADD PT4 = the highest temperature point (only used in 4-point calibrati on mode)

ADJ DONE = Save and exit calibration mode (all points adjusted & valid)

CANCEL = Exit calibration mode without saving

Pick which point to adjust and press the select button to begin. The current temperature will display and the

CAL icon and the number of the point to adjust will now be blinki ng.

NOTES:

o Calibration can be performed to hundredths of a degree.

o The up/down buttons can be used to increase or decrease the display reading.

o Holding the up/down buttons adjusts 0.1 degrees increments.

o Momentary Presses of the up/down buttons for less than 0.5 seconds adjusts 0.01 degrees for every

press.

o The display arrows will flash 3 times when the temperature reading has stabilized.

o All points must be saved before selecting ADJ DONE. A DATA ERR message will display if all

points have not been saved or are not in increasing temperatures. (Ex: PT1 = 32F, PT2 = 120F, PT3

= 250F)

o While in calibration mode the temperature will display based on the prior calibration curve.

o The RESETCAL feature can be used to return the unit to a factory calibration curve.

(calibration/adjustment will still be required ).

o The RESETCAL (reset to factory calibration) feature should be used i f th e pro be is repl a ced usi ng

a 2-wire assembly instead of a 3-wire assembly or if prior calibration has caused the unit to read

excessively out of tolerance.

4. Once the temperature has stabilized, using a reference device check the actual temperature in the bath and use

the “up/down” buttons to adjust the device to the a ctual temperature. Once the device temperature matches the

actual temperature, press the select button to save the set ti ng. The display will show SAVE or EXIT. If

EXIT is selected it will return to the ADD PT1 menu. Once SAVE is

selected the display will advance to the

next temperature point for adjustment showing ADD PT…. The up/down buttons can be used to select a

different point to adjust or CANCEL. If the CANCEL option is chosen then the calibration procedure is exited

and the prior calibration values are re-activated.

o NOTE: Once SAVE is selected the temperature display will return to the previous reading until the

calibration is completed.

o NOTE: If SAVE is selected before the temperature has stabilized, the display will show NOT

STABLE. Wait for the temperature to stabilize before saving.

5. Move the probe to the next bath and repeat step 4. After you save the highest temperature point the display

will flash READY and the new calibration settings will be in effect. The buttons will now resume their

normal operating functions. The calibration setti ngs are saved to flash memory when the device is turned off.

The unit will not turn off automatically. Manually turning the unit off saves the calibration data.

ThermoProbe, Inc.

112A JETPORT DR.

PEARL, MS 39208

Tel: +1 601.939.1831

Fax: +1 601.355.1831

sales@thermoprobe.net

www.thermoprobe.net

10/2017, JK

Page 9

SAFETY INSTRUCTIONS - TP7-D & TP9-A REV 102017

These ThermoProbe instruments are intended for use in both hazardous (potentially flammable or explosive) and nonhazardous areas under dry conditions at ambient temperatures between -20 to 40°C.

The instruments are not intended for use in permanent outdoor installations and are not intended or tested for i cing

conditions.

stresses (e.g. vibration, heat, impact, etc.).

requirements.

a) The user must have a thorough knowledge of the products to be measured and must know of the safety precautions

to be taken when working with the material to be measured.

b) The instrument shall be checked concerning severe defects; check that instrument is com plete (i ncl uding

grounding/bonding cable), has good batteries, etc. If necessary, check measurement accuracy. If any defects are

found, the instrument should not be used until repairs have b een made.

c) The instrument, especially cable and probe, should be clean for safety and ease of use.

d) The physical measurement location should be evaluated for primary and secondary risks.

e) Power source must be removed before performing any maint enance.

f) Exchange of components other than the batte ri es may compromise ATEX/IECEx or other certifications and shall

only be undertaken by ThermoProbe or one of its qualified service providers. See also “Authorized Repair” section.

g) To reduce the risk of fire or explosion, this device must be bonded to the vessel according to clause 6.3.2 e),

IEC/EN 60079-14 before and during introduction into the vessel and shall remain bonded until the sensor probe is

completely withdrawn from the vessel.

h) The device must remain bonded to ground/earth using the provided connection whenever a hazardous atm osphere

could be present as well as d uri n g s i t uat i o ns wh ere electrostatic charging can occur such as the

the thermometer cable or filling or emptying of the tank.

CAUTION: In the event that any part of the instrument should become electrostatically charged in a potentially

hazardous location, follow company policies for testing and clearing the area of any hazardous gases before

attempting to bond the instrument to earth ground. If this is not possible allow sufficient time for the instrument to

naturally dissipate any charges before attempting to bond to earth ground. Given the atmosphere, this could take

several hours.

Additional means of protection should be used where the equipment may be exposed to excessive external

The user must have a working knowledge of appropriate safety

unwinding/winding of

GUIDANCE NOTE

Problems with aggressive substances and environments: Be aware of aggressive substances and that ext ra protection

may be needed.

Caustic soda, highly basic and acidic substances will erode aluminum and copper ground clip and wire. The Sensor-

Cable assembly has external surfaces of stainless steel and fluoropolymer material. Exposure to Excessive heat can

melt the plastic components of the instrument.

10/2017, JK

Page 10

SAFETY APPROVALS FOR TP7-D AND TP9-A:

AEx ia IIB T4 Ga

Applicable Standards are: Agency or Safety Designation

IEC 60079-0:Ed 6, IEC 60079-11:Ed 6 IECEx

EN 60079-0:2012 + A11 3013, EN60079-11:2012 Europe: ATEX

INTRINSIC SAFETY

Intrinsically safe equipment is defined as "equipment and wiring which is incapable of releasing sufficient electrical

or thermal energy under normal or abnormal conditions to cause ignition of a specific hazardous atmospheric mixture

in its most easily ignited concentration." (ISA-R P1 2.6 ) This is achieved by limiting the amount of powe r avai l a bl e t o

the electrical equipment in the hazardous area to a level below that whi ch will ignit e the gas es.

In order to have a fire or explosion, fuel, oxygen and a source of ignition must be present. An intrinsically safe system

assumes the fuel and oxygen is present in the atmosphere, but the system is designed so the electrical energy or

thermal energy of a particular instrument loop can never be great enough to cause ignition.

BATTERIES

WARNING:

Batteries must be changed in Non-hazardous area.

Batteries must be of correct approved type.

Batteries must be installed with correct polarity making sure the (+) end of the battery is aligned with (+)

symbol embossed in the b attery c ase.

New batteries must not be mixed with old batteries.

Batteries must not be mixed with batteries of other models or manufacturers.

Batteries must not be installed with polarity reversed where one cell could charge another cell.

CERTIFIED Batteries for the TP9-A and TP7-D are as follows:

Manufacturer Type Part Number

Duracell AA (LR6) Alkaline MN1500

Panasonic AA (LR6) Alkaline LR6XWA

GP (Gold Peak) AA (LR6) Alkaline GP15A

10/2017, JK

Page 11

INSTRUCCIONES PARA EL USUARIO - TP7-D Y TP9-A

INTRODUCCIÓN

Este manual describe las instrucciones básicas de funcionamiento, uso y seguridad, para los modelos de instrumento

de termómetro digital portátil TP7-D y TP9-A.

CAMBIO DE LA BATERÍA

Cuando la batería está baja, en la pantalla aparece el ícono de batería baja.

Cuando la batería está muybaja, la retroiluminación ya no funciona y el ícono de batería baja "parpadea" en la

pantalla.

Al reconocer que la carga de las baterías está baja, cámbielas tan pronto como sea posible y en un lugar seguro. Esto

garantiza el funcionamiento de la retroiluminación y evita el posible mal funcionamiento. No intente calibrar el

instrumento si el indicador de batería baja está encendido.

ADVERTENCIA:

Se deben cambiar las baterías en un área sin riesgos.

Las baterías deben ser del tipo aprobado correcto.

Se deben instalar las baterías con la polaridad correcta, asegurándose de que el lado (+) de la batería esté

alineado con el símbolo (+) realzado en el espacio de la batería.

No se deben instalar las baterías con la polaridad invertida, donde una celda podría cargar otra celda

equivocada.

No se deben mezclar baterías nuevas con baterías viejas. No se deben mezclar las baterías de diferentes

modelos o fabricantes.

a) Asegúrese de que el instrumento esté en un área no peligrosa y que esté apagado.

b) Utilice un desatornillador Phillips n.º 2 para retirar los 3 tornillos que sostienen la tapa delantera en el TP7-D o

los 2 tornillos que sostienen la tapa delantera en el TP9-A.

c) Utilice un desatornillador Phillips n.º 1 para retirar el tornillo de la cubierta de la batería. Retire la cubierta de la

batería, empuje una batería hacia el contacto de resorte y saque la batería del espacio, luego retire la batería restante.

d) Instale cada batería nueva asegurándose de que el lado (+) de la batería esté alineado con el símbolo (+) realzado

en el espacio de la batería.

e) Vuelva a colocar el dispositivo de retención y reinstale la cubierta.

Las baterías CERTIFICADAS para el TP9-A y para el TP7-D son las siguientes:

Fabricante Tipo Número de parte

Duracell AA (LR6) Alcalina MN1500

Panasonic AA (LR6) Alcalina LR6XWA

GP (Gold Peak) AA (LR6) Alcalina GP15A

REPARACIÓN AUTORIZADA

Se recomienda que el mantenimiento que no esté incluido en el ámbito de este manual sea llevado a cabo por

ThermoProbe, Inc. o por uno de sus distribuido res aut o ri zad os.

10/2017, JK

Page 12

Vea en www.thermoprobe.net un video sobre el uso adecuado de este instrumento. Consulte el Capítulo 7.2 de la

norma de medición del Instituto Americano del Petróleo (American Petroleum Institute).

INTERFAZ DEL USUARIO

Botón de Encendido/Selección

Botones Arriba/Abajo Íconos para lecturas

de memoria

Botones Arriba/Abajo

Flechas

indicadoras de

temperatura

Indicadores de

puntos de

calibración

Indicador de batería

Botón de encendido:

Al

presionar una vez el botón de Encendido se enciende el dispositivo. (Nota: El in strumento se apaga

automáticamente 20 minutos después de la última presión en el botón).

hasta que la unidad muestra "OFF", se apaga el instrumento.

Al presionar y sostener el botón “Power”

10/2017, JK

Page 13

MENÚ de selección:

Utilice los botones de menú “Arriba/Abajo”

LOG: Guarda la temperatura estable actual por hasta 4 lecturas.

C-F: Selecciona grados Celsius o Fahrenheit para la temperatura que aparecerá en pantalla.

DECIMAL: Selecciona la resolución de 0.1 o 0.01 para la pantalla.

MEMORY - Utilice los botones “Arriba/Abajo” para mostrar:

Lectura más baja

Lectura promedio

Lectura más alta

Lecturas guardadas (Logged) 1-10

(Use CLR LOG para eliminar las lecturas guardadas)

CALIBRAT: Ingresa al modo de calibración/ajuste

(Requiere una contraseña de 3 dígitos: 112) - Cons ul t ar el Proce di mie nto de calibración

para las siguientes selecciones:

Retroiluminación

Cuando el instrumento opera en condiciones de baja iluminación, una fotocelda detecta la situación y enciende la

retroiluminación.

Registro de temperatura

Es necesario que la temperatura esté estable antes de registrarla. La flechas de la pantalla parpadean 3 veces cuando

la lectura de la temperatura se estabiliza.

Si desea registrar la temperatura, presione el botón “down” hasta que aparezca LOG. Presione el botón “Select”

una vez para guardar una lectura. Se presenta una confirmación de la lectura guardada mostrando “LOG 1-10”. Se

puede repetir esto para guardar hasta 10 lecturas.

Se puede acceder a las temperaturas guardadas desde el menú MEMORY. Las temperaturas guardadas se muestran

con el ícono LOG y un prefijo (1, 2, 3, 4, 5, 6, 7, 8, 9, 0) correspondiente a las lecturas guardadas previamente. Se

pueden usar los botones arriba/abajo para desplazarse entre las lecturas. Seleccione EXIT para regresar a la pantalla

de temperatura.

10/2017, JK

Page 14

ecturas guardadas se conservan incluso después de apagar la unidad. Se pueden eliminar las lecturas guardadas

Las l

al ingresar a la sección Memory y seleccionar CLR LOG. No se pueden tomar nuevas lecturas hasta que se

eliminan las lecturas.

Memoria USB

Hay una conexión micro-USB disponible en la tarjeta del circuito que permite acceder a la calibración y los datos

guardados.

Advertencia: No acceda a la tarjeta del circuito en un área peligrosa.

Lecturas mínima, máxima y promedio

Se puede acceder a las lecturas mínima, máxima y promedio a través del menú MEMORY. Las lecturas tienen una

indicación de ícono LOW (mínima), AVG (promedio) o HIGH (máxima) en la pantalla. Estas lecturas no están

relacionadas con las lecturas guardadas, se determinan a partir de la temperatura cuando se enciende la unidad.

Dichas lecturas se borran cuando se apaga la unidad.

Códigos de pantalla

OPEN CKT - Indica que el sensor está funcionando por encima de su límite de temperatura, se abre el circuito del

Ensamble del sensor de una sección cortada o rota o el cable no está insertado adecuadamente en la terminal de la

tarjeta de circuito. La causa más común es un cable dañado.

SHORT CKT - Indica que el sensor está funcionando por debajo de su límite de temperatura o que el Ensamble del

sensor está en cortocircuito debido a una sección rota o cortada. La causa más común es un cable dañado.

NONE – No hay lecturas guardadas en la memoria.

2 WIRE – Se detectó la conexión de una sonda de 2 cables.

3 WIRE – Se detectó la conexión de una sonda de 3 cables.

NO CAL – El dispositivo no tiene datos de calibración almacenados para la sonda de temperatura. Realice un

ajuste/una calibración antes del uso.

Tipos de sonda

El TP7-D o el TP9-A pueden utilizar ensambles de sonda de 2 o de 3 cables.

Los ensambles de sonda de reemplazo ThermoProbe están disponibles en diferentes configuraciones. Hay cables

disponibles en longitudes de hasta 50 met ros o 16 5 pi es. Hay marcas estándar de latón disponibles aplicadas en

incrementos de 5 pies o 1 metro. Los sensores están disponibles en 4 pesos diferentes. Las configuraciones de la

pieza del ensamble de sonda son las siguientes:

10/2017, JK

Page 15

REEMPLAZO DEL ENSAMBLE DE SONDA

NOTAS:

1) El reemplazo del ensamble de sonda requiere de una nueva calibración del dispositivo. El remplazo solo

debe hacerlo personal experimentado y solo si hay equipo de calibración disponible.

2) Consulte IEC/EN 60079-19 (Atmósferas explosivas - Parte 19: Reparación transformación o

recuperación de un equipo) al hacer la reparación.

3) Utilice únicamente ensambles de sonda de reemplazo obtenidos de ThermoProbe, Inc. o de uno de sus

distribuidores autorizados.

a) Siga primero las instrucciones de REEMPLAZO DE BATERÍA a hasta c para retirar las baterías.

b) En la tarjeta del circuito presione las abrazaderas de las terminales hacia abajo y retire los cables teniendo en

cuenta el arreglo por colores de las terminales de los cables conductores. Vea la Figura 1.

Blanco – cable positivo del sensor

Ver

de – cable de compensación (no usado en modelos de 2 cables)

Plateado – cable negativo del sensor y con blindaje

c) Coloque aparte la cubierta y la tarjeta de circuito y deshaga el nudo de alivio de tensión en el ensamble del cable.

d) Desenrolle el cable del ensamble y jale el cable para liberarlo del ojal de hule.

e) Inserte el nuevo cable a través del ojal de hule y luego jálelo varias pulgadas más allá del ojal.

f) Haga un nudo simple en el cable a la altura del ojal como alivio de tensión y jale el nudo contra el ojal.

g) Presione hacia abajo las palancas de las abrazaderas de las terminales e inserte las nuevas terminales de acuerdo

con el código de colores. La etiqueta indica la manera de conectar la sonda de 2 cables o la sonda de 3 cables

(incluye cable verde). Vea la Figura 1.

h) Vuelva a instalar las baterías y la cubierta y enrolle el ensamble del cable.

i) Realice una calibración (consulte el procedimiento de calibración).

Figura 1: Sujeción del cable del ensamble de sonda

PROCEDIMIENTO DE CALIBRACIÓN

Únicamente personal calificado y con el equipo adecuado debe acceder al modo de calibración, de otra

forma puede verse comprometida la integridad de la calibración. Lea cuidadosamente las siguientes

instrucciones.

Se requieren por lo menos 2 puntos para hacer un ajuste. (C al i bració n de 2 pu nt o s ). Se puede n t omar

puntos adicionales (calibración de 3 o 4 punt os) pa ra calib r a r un rang o amplio de temperaturas (p.ej. 0 °F a

300 °F) o si se desea hacer coincidir puntos específicos en el rango. Se deben incluir puntos en la parte

inferior y en la parte superior del rango. Se debe contar con el equipo adecuado para cada punto de

calibración.

No intente calibrar el instrumento si el indicador de batería baja está encendido, ya que los valores de la

nueva calibración pueden no ser guardados adecuadamente en la memoria.

10/2017, JK

Page 16

Cons

No se debe realizar la calibración en un entorno considerado peligroso.

ulte API 7.2 o cualquier otra norma reconocida para obtener recomendaciones sobre la verificación

rutinaria de calibración.

Equipo necesario:

Baño de hielo u otro baño de baja temperatura con un termómetro de referencia.

Baño de fluido tibio o caliente entre 20 °C (aprox. 68 °F), o más, hasta 90 °C (aprox. 194 °F) con

termómetro de referencia (ver la Nota)*.

Baño opcional de aceite a alta temperatura a aproximadamente 150 °C/300 °F y termómetro de referencia.

*Nota para calibración limitada: Si no se requiere toda la capacidad del rango del instrumento, se puede realizar

el ajuste de 2 puntos altos a una temperatura relativamente cercana a la temperatura común del líquido medido y

la precisión se mantendrá dentro del rango limitado. Por ejemplo: Si el producto líquido a medir está , por lo

general, a menos de 38 °C (aprox. 100 °F), entonces se puede hacer una calibración de “punto alto” en el

entorno de esa temperatura. No se puede asegurar la precisión de la temperatura por encima de este punto de

calibración.

Siga los pasos siguientes para la calibración:

1. Ingrese al modo de calibración en CALIBRAT, en el Menú de selección. Cuando se selecciona esto, se le

pide al usuario que ingrese una contraseña de 3 dígitos. El uso de los botones “arriba/abajo” permite ajustar

cada dígito. Una vez establecido el valor correcto, avance al siguiente dígito presionando el botón “select”.

Después de ingresar el 3

ingresa una contraseña incorrecta, se muestra FAIL y la unidad vuelve al modo de temperatura. Una vez en

el modo de Calibración, parpadea el ícono "CAL" en la pantalla. La contraseña para el modo de

calibración es: 112

2. Seleccione

calibración. Seleccione 2PT CAL, 3PT CAL o 4PT CAL utilizando el botón de selección.

EXIT (Salir).

3. El dispositivo está ahora en el modo de ajuste. La pantalla muestra ADD PT1. Se pueden usar los botones

“arriba/abajo” para seleccionar un punto de ajuste diferente o CANCEL. Si se elige la opción CANCEL,

entonces se sale el procedimiento de calibración y se vuelven a activar los valores anteriores de calibración.

ADD PT1 = punto de temperatura mínima

ADD PT2 = el siguiente punto de temperatura más alta

ADJUST en el menú de calibración y luego seleccione la cantidad deseada de puntos de

NOTA: Si el usuario no está listo para ingresar al modo de calibración, se puede elegir la opción

er

dígito, presione el botón “select” para ingresar al modo de Calibración. Si se

10/2017, JK

Page 17

D PT3 = el siguiente punto de temperatura más alta (se usa únicamente en el modo de calibración de 3

AD

o 4 puntos)

ADD PT4 = el punto de temperatura más alta (se usa únicamente en el modo de calibración de 4 puntos)

ADJ DONE = Guardar y salir del modo de calibración (todos los puntos ajustados y válidos)

CANCEL = Salir del modo de calibración sin guardar

Seleccione el punto a ajustar y presione el botón "select" para iniciar. La temperatura actual se muestra y

parpadean el ícono CAL y el número del punto a ajustar.

NOTAS:

o La calibración se puede llevar a cabo hasta a centésimos de grado.

o Se pueden utilizar los botones arriba/abajo para aumentar o disminuir la lectura de la pantalla.

o Mantener presionados los botones arriba/abajo ajusta en incrementos de 0.1 grados.

o La presión momentánea de los botones arriba/abajo por menos de 0.5 segundos ajusta 0.01

grados para cada presión.

o La flechas de la pantalla parpadean 3 veces cuando la lectura de la temperatura se estabiliza.

o Se deben guardar todos los puntos antes de selecciona r ADJ DONE. Se muestra un mensaje

DATA ERR si no se han guardado todos los puntos o no están en temperaturas crecientes. (P. ej.:

PT1 = 32 °F, PT2 = 120 °F, PT3 = 250 °F)

o Mientras se está en el modo de calibración, se muestra la temperatura con base en la curva anterior

de calibración.

o Se puede usar la función RESETCAL para regresar la unidad a una curva de calibración de

fábrica. (de todos modos será necesaria una calibración o un ajuste).

o Se debe utilizar la función RESETCAL (restablecer la calibración de fábrica) si se cambia la

sonda usando un ensamble de 2 cables en lugar de un ensamble de 3 cables o si la calibración

anterior provoca que la unidad lea excesivamente fuera de la tolerancia.

4. Cuando se estabiliza la temperatura, verificar con un dispositivo de referencia la temperatura actual en el

baño y utilizar los botones “arriba/abajo” para ajustar el dispositivo a la temperatura real. Cuando la

temperatura en el dispositivo coincida con la temperatura real, presione el botón de selección para

guardar la configuración. La pantalla muestra SAVE o EXIT. Si se selecciona EXIT se vuelve al menú

ADD PT1. Cuando se selecciona SAVE la pantalla pasa al siguiente punto de temperatura a ajustar,

mostrando ADD PT…. Se pueden utilizar los botones arriba/abajo para seleccionar un punto difere nte a

ajustar o C

ANCEL. Si se elige la opción CANCEL, entonces se sale el procedimiento de calibración y se

vuelven a activar los valores anteriores de calibración.

o NOTA: Cuando se selecciona SAVE la pantalla de temperatura regresa a la lectura anterior hasta

finalizar la calibración.

o NOTA: Si se selecciona SAVE antes de que se estabilice la temperatura, la pantalla muestra NOT

STABLE. Espere a que se estabilice la temperatura antes de guardar.

5. Pase la sonda al siguiente baño y repita el paso 4. Después de guardar el punto de temperatura más alta, la

pantalla parpadea con el mensaje READY y la nueva calibración entra en efecto. Los botones retoman sus

funciones normales de operación. La calibración se guarda en la memoria flash cuando se apaga el

dispositivo. La unidad no se apaga automáticamente. Se guardan los datos de calibración al apagar

manualmente la unidad.

ThermoProbe, Inc.

112A JETPORT DR.

PEARL, MS 39208

Tel.: +1 601.939.1831

Fax: +1 601.355.1831

sales@thermoprobe.net

www.thermoprobe.net

10/2017, JK

Page 18

INSTRUCCIONES DE SEGURIDAD - TP7-D Y TP9-A

REV. 10/2017

Estos instrumentos ThermoProbe son para su uso tanto en áreas peligrosas (potencialmente inflamables o

explosivas) como no peligrosas, en condiciones secas y a una temperatura ambiente de entre -20 y 40°C.

Los instrumentos no fueron diseñados para usarse en instalaciones permanentes al aire libre y no fueron diseñados ni

sometidos a prueba en condiciones de congelación.

pudiera quedar expuesto a excesivas exigencias externas (p. ej. vibración, calor, impacto, etc.).

conocimiento operativo de los requisitos de seguridad correspondientes.

a) El usuario debe tener un amplio conocimiento de los productos a medir y conocer las precauciones de seguridad a

tomar cuando se trabaja con el material a medir.

b) Se debe revisar el instrumento para detectar defectos graves; controle que el instrumento esté completo

(incluyendo el cable de tierra/unión), que tenga baterías en buenas condiciones, etc. Si fuera necesario, verifique la

precisión de las mediciones. Si se encontrara algún defecto, no se debe utilizar el instrumento hasta que se lleven a

cabo las reparaciones.

c) El instrumento, en especial el cable y la sonda, debe estar limpio por razones de seguridad y de facilidad de uso.

d) Se deben evaluar los riesgos primarios y secundarios de la ubicación física de la medición.

e) Se debe retirar la fuente de energía antes de realizar cualquier operación de mantenimiento.

f) El cambio de componentes que no sean las baterías puede comprometer las certificaciones ATEX/IECEx u otras y

debe llevarlo a cabo ThermoProbe o de uno de sus proveedores de servicio calificados. Consulte también la sección

“Reparación autorizada”.

g) Para reducir el riesgo de incendio o explosión, se debe unir este dispositivo al recipiente conforme a la cláusula

6.3.2 e), IEC/EN 60079-14 antes y durante la introducción al recipiente y debe permanecer unido hasta que la sonda

se retire completamente del recipiente.

h) El dispositivo debe permanecer unido a tierra física utilizando la conexión provista y siempre que pueda haber

presencia de una atmósfera peligrosa, así como en situaciones donde se pueda presentar descarga electrostática,

como alenrollar/desenrollar el cable del termómetro o llenar o vaciar el tanque.

PRECAUCIÓN: En caso de que cualquier parte del instrumento quedara cargada electrostáticamente en una

ubicación potencialmente peligrosa, siga las políticas de la empresa para probar y despejar cualquier gas peligroso

del área antes de intentar unir el instrumento a la tierra física. Si esto no fuera posible, debe dar tiempo suficiente

para que el dispositivo disipe de manera natural cualquier carga antes de unirlo a la tierra física. Según el tipo de

atmósfera, esto puede tardar varias horas.

Se deben utilizar otros medios de protección cuando el equipo

El usuario debe tener

NOTA DE ORIENTACIÓN

Problemas con sustancias y ambientes agresivos: Sea consciente de las sustancias agresivas y de la posible

necesidad de protección adicional.

La soda cáustica, y las sustancias de alto nivel básico o ácido corroen el broche y el cable de aluminio y cobre. El

ensamble de sensor y cable tiene superficies externas de acero inoxidable y un material fluoropolimérico. La

exposición a calor excesivo puede fundir los componentes plásticos del instrumento.

10/2017, JK

Page 19

APROBACIONES DE SEGURIDAD DEL TP7-D Y DEL TP9-A:

AEx ia IIB T4 Ga

Las normas pertinentes son: Agencia o designación de segurid ad

IEC 60079-0:Ed 6, IEC 60079-11:Ed 6 IECEx

EN 60079-0:2012 + A11 3013, EN60079-11:2012 Europa: ATEX

SEGURIDAD INTRÍNSECA

Se define al equipo intrínsecamente seguro como "equipo y cableado que no pueden liberar suficiente energía

térmica o eléctrica, ya sea bajo condiciones normales o anormales, como para provocar la ignición de una mezcla

atmosférica específica peligrosa en su concentración de mayor ignición" (ISA-RP12.6). Esto se logra al limitar la

cantidad de potencia disponible para el equipo eléctrico en el área peligrosa a un nivel inferior al necesario para que

se inflamen los gases.

Para que haya ignición o explosión, debe haber presencia de combustible, oxígeno y una fuente de ignición. Un

sistema intrínsecamente seguro asume que el combustible y el oxígeno están presentes en la atmósfera, pero el

sistema está diseñado de manera tal que la energía eléctrica o la energía térmica del circuito de un instrumento en

particular nunca sean suficientes para provocar la ignición.

BATERÍAS

ADVERTENCIA:

Se deben cambiar las baterías en un área sin riesgos.

Las baterías deben ser del tipo aprobado correcto.

Se deben instalar las baterías con la polaridad correcta, asegurándose de que el lado (+) de la batería esté

alineado con el símbolo (+) realzado en el espacio de la batería.

No se deben mezclar baterías nuevas con baterías viejas.

No se deben mezclar las baterías de diferentes modelos o fabricantes.

No se deben instalar las baterías con la polaridad invertida, donde una celda podría cargar otra celda

equivocada.

Las baterías CERTIFICADAS para el TP9-A y para el TP7-D son las siguientes:

Fabricante Tipo Número de parte

Duracell AA (LR6) Alcalina MN1500

Panasonic AA (LR6) Alcalina LR6XWA

GP (Gold Peak) AA (LR6) Alcalina GP15A

10/2017, JK

Page 20

INSTRUCTIONS D'UTILISATION – TP7-D et TP9-A

INTRODUCTION

Ce manuel décrit le fonctionnement de base et les instructions d’utilisation et de sécurité du thermomètre numérique

portable modèle TP7-D ou TP9-A.

REMPLACER LES PILES

Lorsque la tension des piles est faible, l’icône de pile faible s'affiche sur l’écran.

Lorsque la tension des piles est très faible, le rétroéclairage ne fonctionne plus et l’icône de pile faible « clignote »

sur l’écran.

Remplacez les piles dès que possible dans un endroit sûr après avoir remarqué l’indicateur de pile faible. Cela vous

permettra d’utiliser le rétroéclairage et évitera un éventuel dysfonctionnement. N’essayez pas d’étalonner

l’instrument si l’indicateur de pile faible est affiché.

ATTENTION :

Les piles doivent être changées dans une zone sans risques.

Les piles doivent être du type correct approuvé.

Les piles doivent être mises en place avec la polarité correcte : assurez-vous que l’extrémité (+) de la

batterie est alignée avec le symbole (+) inscrit en relief sur le boîtier de la pile.

Les piles ne doivent pas être mises en place avec une polarité inversée qui ferai t qu ’u ne pi le pourrai t en

charger une autre.

Les nouvelles piles ne doivent pas être mélangées avec d’anciennes piles. Les piles ne doivent pas être

mélangées avec des piles d’autres modèles ou fabricants.

a) Vérifiez que l’instrument se trouve dans une zone sans risques et qu’il est éteint.

b) Utilisez un tournevis cruciforme Phillips numéro 2 pour retirer les 3 vis en maintenant le couvercle supérieur du

TP7-D ou les 2 vis en maintenant le couvercle supérieur du TP9-A.

c) Utilisez un tournevis Phillips numéro 1 pour retirer la vis unique du cache-piles. Retirez le cache-piles, poussez

une pile vers le contact à ressort et soulevez-la hors du compartiment, puis retirez la pile restante.

d) Installez chaque nouvelle pile en faisant en sorte que l’extrémité (+) de la pile soit alignée avec le symbole (+)

inscrit en relief sur le boîtier de la pile.

e) Replacer le cache et remettez en place le couvercle.

Les piles CERTIFIÉES pour le TP9-A et le TP7-D sont les suivantes :

Fabricant Type Référence

Duracell AA (LR6) alcaline MN1500

Panasonic AA (LR6) alcaline LR6XWA

GP (Gold Peak) AA (LR6) alcaline GP15A

RÉPARATIONS AUTORISÉES

Il est recommandé de faire appel à ThermoProbe, Inc. ou à l’un de ses distributeurs autorisés pour toutes les

interventions dépassant le cadre de ce manuel.

10/2017, JK

Page 21

Consultez www.thermoprobe.net pour une vidéo sur l’utilisation adéquate de cet instrument. Référez-vous aux

normes de mesure de l’American Petroleum Institute décrites au chapitre 7.2.

INTERFACE UTILISATEUR

Bouton de marche/sélection

Boutons de menu

Icônes pour les

relevés en

mémoire

Boutons de menu

Flèches d’indication de

température

Indicateurs pour

les points

Indicateur de pile faible

Bouton Marche :

A

ppuyer une fois sur le bouton Marche pour allumer l'appareil. (Note : l’instrument s’éteindra automatiquement au

bout de 20 minutes d'inactivité.)

que le message « OFF » soit affiché.

Pour éteindre l'instrument, appuyer et maintenir le bouton « Marche » jusqu’à ce

10/2017, JK

Page 22

MENU Sélection :

Utilisez les boutons de menu « haut/bas »

LOG : Enregistre jusqu’à 4 relevés de la température actuelle stable

C-F : Sélectionne l’affichage de la température en degrés Celsius ou Fahrenheit

DECIMAL : Sélectionnez une résolution d’affichage de 0,1 ou 0,01

MEMORY – Utilisez les boutons « haut/bas » pour afficher :

le relevé le plu bas

le relevé moyen

le relevé le plus haut

Relevés sauvegardés (« log ») de 1 à 10

(Utilisez CLR LOG pour effacer les relevés enregistrés)

CALIBRAT : Passez en mode étalonnage/réglage

(Nécessite un mot de passe à 3 chiffres : 112 – Voir la pr océdure d'étalonnage

pour effectuer les sélections suivantes :

Rétroéclairage

Lorsque l’instrument fonctionne sous une faible luminosité, une cellule photoélectrique le détecte et active le

rétroéclairage.

Enregistrement des températures

La température doit être stable pour permettre l’enregistrement. Les flèches de l’affichage clignoteront 3 fois pour

indiquer que la température relevée est stable.

Si vous souhaitez enregistrer la température, appuyez une fois sur le bouton « bas » jusqu’à ce que LOG soit

affiché. Appuyez sur le bouton « Sélectionner » une fois pour enregistrer un relevé. L’enregistrement du relevé sera

confirmé par l’affichage de « LOG 1-10 ». Cette opération peut être répétée pour un maximum de 10 relevés

enregistrés.

10/2017, JK

Page 23

Il est possi

enregistrées seront affichées avec une icône LOG et un préfixe (1, 2, 3, 4, 5, 6, 7, 8, 9, 0) correspondant aux rele vés

enregistrés précédemment. Les boutons haut/bas peuvent être utilisés pour parcourir les enregistrements.

Sélectionnez EXIT pour revenir à l’affichage de la température.

Les relevés enregistrés seront conservés même après l’extinction de l’appareil. Les relevés enregistrés peuvent être

effacés en sélectionnant CLR LOG dans la section Mémoire du menu. Il est impossible de sauvegarder de

nouveaux relevés tant que les anciens ne sont pas effacés.

ble d’accéder aux températures enregistrées depuis le menu MEMORY (Mémoire). Les températures

Mémoire USB

Une connexion micro-USB disponible sur le circuit imprimé permet l’accès à l’étalonnage et aux données

enregistrées.

Attention : N’accédez pas au circuit imprimé dans un endroit dangereux.

Relevés le plus bas, moyen et le plus haut

Le menu MEMORY permet d’accéder aux relevés le plus bas, moyen et le plus haut. Ces relevés sont indiqués par

les icônes LOW, AVG et HIGH sur l'écran. Ces relevés ne sont pas liés aux lectures enregistrés mais sont

déterminés par la température lorsque l’appareil est allumé. Ces relevés sont supprimés après l’extinction de

l’appareil.

Codes d’affichage

OPEN CKT – Indique que le capteur fonctionne au-delà de sa température limite, que l'assemblage de la sonde a

été court-circuité à cause d’une section coupée ou cassée ou que le câble n’est pas inséré correctement dans le

connecteur du circuit imprimé. La cause la plus courante est un câble endommagé.

SHORT CKT – Indique que le capteur fonctionne en dessous de sa température limite ou que l'assemblage de la

sonde est en court-circuit à cause d’une section écrasée ou coupée. La cause la plus courante est un câble

endommagé.

NONE – Aucun relevé n’est enregistré en mémoire.

2 WIRE – Une connexion de sonde à 2 fils a été détectée.

3 WIRE – Une connexion de sonde à 3 fils a été détectée.

NO CAL – L’appareil ne dispose pas de données d’étal on nage stockées pour la sonde de température. Effectuez un

réglage/étalonnage avant utilisation.

10/2017, JK

Page 24

Types de sondes

Les TP7-D ou TP9-A peuvent utiliser des sondes à 2 ou 3 fils.

Des sondes de remplacement ThermoProbe sont disponibles dans différentes configurations. Les câbles sont

disponibles dans des longueurs allant jusqu’à 50 mètres ou 165 pieds. Des marquages en cuivre standards sont

disponibles en incréments de 5 pieds ou d’un mètre. Les capteurs sont disponibles avec 4 types de poids. Les

configurations des pièces d'assemblage de sonde sont présentées comme suit :

REMPLACER LA SONDE

NOTES :

1) Le remplacement de la sonde nécessite un nouvel étalonnage de l’appareil. Le remplacement ne devrait

être effectué que par du personnel expérimenté et que dans le cas où l’équipement d’étalonnage est

disponible.

2) Veuillez vous référer à IEC/EN 60079-19 (Atmosphères explosives - Section 19 : réparation, révision et

remise en état de l’appareil) lorsque vous effectuez la réparation

3) N’utilisez que des assemblages de sonde de remplacement obtenus auprès de ThermoProbe, Inc. ou de

l’un de ses distributeurs autorisés.

a) S

uivez tout d’abord les instructions de REMPLACER LES PILES a à c pour retirer les piles.

b) Sur le circuit imprimé, poussez les griffes du connecteur vers le bas et retirez les fils en notant la disposition des

codes de couleur des fils. Voir Figure 1.

Blanc – fil de capteur positif

Vert

Argent – fil de capteur négatif et fil de blindage

c) Séparez le couvercle et le circuit imprimé et retirez le nœud de décharge de traction de l’assemblage du câble.

d) Déroulez le câble et retirez le passe-câble en caoutchouc.

e) Insérez le nouveau câble dans le passe-câble en caoutchouc et tirez plusieurs centimètres de câble au-delà du

passe-câble.

f) Effectuez un simple nœud plat dans le câble au niveau du passe-câble comme décharge de traction et faites glisser

le nœud jusqu’au passe-câble.

g) Sur le circuit imprimé, poussez les griffes du connecteur vers le bas et insérez les nouveaux fils selon les codes de

couleur du connecteur. L’étiquette indique comment connecter une sonde à 2 et une sonde à 3 fils (celle-ci comporte

un fil vert). Voir Figure 1.

h) Réinstallez les piles et le couvercle et remettez en place l’assemblage du câble.

i) Effectuez un étalonnage (voir la procédure d’étalonnage).

Figure 1 : Connexion des fils de la sonde

– fil de compensation de câble (non utilisé sur les modèles à 2 fils)

10/2017, JK

Page 25

PROCÉDURE D’ÉTALONNAGE

Seul un personnel qualifié disposant d’un équipement approprié devrait avoir accès au mode d’étalonnage.

Dans le cas contraire, l’intégrité de l’étalonnage pourrait être compromise. Lisez les instructions suivantes

avec attention.

Un minimum de 2 points est nécessaire pour effectuer un réglage (ét al o nnage à 2 points). Des points

supplémentaires peuvent être acquis (étalonnage à 3 ou 4 points) pour calibrer une plage de températures

importante (ex. : -15 °C à 150 °C) ou si vous voulez utiliser des points spécifiques de votre plage. Il est

préférable d’inclure des points situés à l’extrémité inférieure et supérieure de la plage. Vous devez disposer

de l’équipement adéquat pour chaque point d’étalonnage.

N’essayez pas de calibrer l’instrument si l’indicateur de pile faible a été affiché. Dans ce cas, les nouvelles

valeurs d’étalonnage pourraient ne pas être stockées correctement en mémoire.

Référez-vous à l’API 7.2 ou à d’autres normes reconnues pour des recommandations de vérification

d’étalonnage de routine.

L’étalonnage ne doit être en aucun cas effectué dans un environnement considéré comme dangereux.

Équipement nécessaire :

Bain de glace ou autre bain à température basse avec un thermomètre de référence.

Bain tiède à chaud entre 20 °C (env. 68 °F) ou plus jusqu’à 90 °C (env. 194 °F) avec un thermomètre de

référence (voir Note)*.

Bain d’huile à haute température optionnel à environ 150 °C/300 °F et thermomètre de référence.

*Note pour un étalonnage limité : Si la plage de fonctionnement complète de l’instrument n’est pas nécessaire,

le réglage du point haut à 2 points peut être effectué à une température relativement proche de la température

habituelle du liquide mesuré et la précision sera conservée à l’intérieur de la plage limitée. Par exemple : Si le

produit liquide à mesurer est habituellement à moins de 38 °C (env. 100 °F), un « point haut » d’étalonnage

peut être établi à un point proche de cette température. La précision de la température au-delà de ce point

d’étalonnage ne peut pas être garantie.

Pour procéder à l’étalonnage, effectuez les étapes suivantes :

1. Entrez en mode étalonnage en allant à CALIBRAT dans le menu de sélection. Une fois ce mode

sélectionné, un mot de passe à 3 chiffres sera demandé à l’utilisateur. Les boutons « haut/bas » permettent

de modifier chaque chiffre. Une fois la valeur correcte définie, p assez au chiffre suivant en appuyant sur le

bouton « sélection ». Une fois le 3

mode d’étalonnage. Si un mot de passe incorrect est entré, FAIL (Échec) sera affiché et l’appareil

reviendra en mode température. Une fois en mode étalonnage, l’icône « CAL » clignotera sur l'écran. Le

mot de passe du mode étalonnage est : 112

e

chiffre défini, appuyez sur le bouton « sélection » pour entrer dans le

10/2017, JK

Page 26

2. Sélectionnez AD

JUST (Régler) dans le menu étalonnage et sélectionnez ensuite le nombre de points

d’étalonnage souhaités. Choisissez 2PT CAL, 3PT CAL ou 4PT CAL à l’aide du bouton de sélection.

NOTE : Si l’utilisateur n’est pas prêt à entrer en mode étalonnage, l’option EXIT (Quitter) peut

être choisie.

3. L’appareil est maintenant en mode réglage. ADD PT1 (Ajouter point 1) sera affiché. Utilisez les boutons

« haut/bas » pour sélectionner un point différent à régler ou CANCEL (Annuler). Si l’option CANCEL est

choisie, la procédure d’étalonnage est interrompue et les valeurs d’étalonnage précédentes sont réactivées.

ADD PT1 = le point de température le plus bas

ADD PT2 = le point de température plus élevé suivant

ADD PT3 = le point de température plus élevé suivant (uniquement utilisé dans les modes d’étalonnage à 3

ou 4 points)

ADD PT4 = le point de température le plus élevé (uniquement utilisé dans le mode d’étalonnage à 4 points)

ADJ DONE = pour enregistrer et quitter le mode étalonnage (tous les points réglés et valides)

CANCEL = quitter le mode d’étalonnage sans enregistrer

Choisissez le point à régler et appuyez sur le bouton de sélection pour commencer. La température actuelle

sera affichée et l’icône CAL et le nombre de points à régler commenceront à clignoter.

NOTES :

o L’étalonnage peut maintenant être effectué au centième de degré.

o Les boutons haut/bas peuvent être utilisés pour augmenter ou diminuer la valeur affichée.

o Maintenir les boutons haut/bas modifie la valeur par incréments de 0,1 degrés.

o Appuyer brièvement sur les boutons haut/bas pendant moins de 0,5 seconde modifie la valeur de

0,01 degré à chaque fois que vous appuyez.

o Les flèches de l’affichage clignoteront 3 fois pour indiquer que la température relevée est stable.

o Tous les points doivent être enregistrés avant de sélectionner ADJ DONE (Réglage terminé). Un

message DATA ERR (Erreur de données) s’affichera si tous les points n’ont pas été enregistrés

ou ne représentent pas des températures croissantes. (Par ex. : PT1 = 0C, PT2 = 50C, PT3 = 120C)

o En mode étalonnage, la température sera affichée en fonction de la courbe d’étalonnage

précédente.

o La fonction RESETCAL (Réinitialiser l’étalonnage) peut être utilisée pour réinitialiser l’appareil

à une courbe d’étalonnage d’usine (l’étalonnage/le réglage devra toujours être effectué).

o La fonction RESETCAL (réinitialiser à l’étalonnage d’usine) devrait être utilisée si la sonde est

remplacée par un ensemble à 2 fils au lieu d’un ensemble à 3 fils ou si l’étalonnage précédent a

provoqué un relevé largement hors tolérance.

4. Un

e fois la température stabilisée, vérifiez la température réelle dans le bain à l’aide d’un appareil de

référence et utilisez les boutons « haut/bas » pour régler l’appareil à la température réelle. Une fois que la

température sur l’appareil correspond à la température réelle, appuyez sur le bouton de sélection pour

enregistrer le paramètre. L’afficheur indiquera SAVE (Enregistrer) ou EXIT (Quitter). Si EXIT est

sélectionné, l’appareil reviendra au menu ADD PT1. Une fois SAVE sélectionné, l’afficheur passera au

prochain point de température en indiquant ADD PT…. Les boutons haut/bas peuvent être utilisés pour

sélectionner un point différent à régler ou choisissez CANCEL (Annuler). Si l’option CANCEL est

choisie, la procédure d’étalonnage est interrompue et les valeurs d’étalonnage précédentes sont réactivées.

o NOTE : Une fois SAVE sélectionné, l’affichage de la température reviendra au relevé précédent

jusqu’à ce que l’étalonnage soit terminé.

o NOTE : Si SAVE est sélectionné avant que la température ne soit stabilisée, l’afficheur indiquera

NOT STABLE (Non stable). Attendez que la température se stabilise avant d’enregistrer.

5. Déplacez la sonde dans le bain suivant et répétez l’étape 4. Après avoir enregistré le point de température le

plus élevé, READY (Prêt) clignotera à l'écran et les nouveaux paramètres d’étalonnage prendront effet. Les

boutons reviendront à leurs fonctions d’exploitation habituelles. Les paramètres d’étalonnage sont

enregistrés dans une mémoire flash lorsque l’appareil est éteint. L’appareil ne s’éteindra pas

automatiquement. Éteindre l’appareil manuellement enregistre les données d’étalonnage.

10/2017, JK

Page 27

INSTRUCTIONS DE SÉCURITÉ - TP7-D ET TP9 - A

RÉV. 102017

Ces instruments ThermoProbe sont destinés à être utilisés dans des zones dangereuses (potentiellement

inflammables ou explosives) et non dangereuses dans des conditions sèches à des températures ambiantes comprises

entre -20 et 40 °C.

Les instruments ne sont pas conçus pour être utilisés dans des installations extérieures permanentes et ne sont pas

conçus ou testés pour des conditions de givrage.

lorsque l’équipement peut être exposé à des contraintes extérieures excessives (par ex. : vibration, chaleur, impact,

L’utilisateur doit disposer d’une connaissance pratique des exigences de sécurité appropriées.

etc.).

a) L’utilisateur doit avoir une connaissance approfondie des produits à mesurer et doit connaître les précautions de

sécurité à adopter lors du travail avec les matériaux à mesurer.

b) Les défauts graves de l’instrument doivent être vérifiés ; vérifiez que l’instrument est complet (y compris le câble

de mise à la terre/masse), que les batteries sont opérationnelles, etc. Si nécessaire, vérifiez la précision des mesures.

Si des défauts sont trouvés, l’instrument ne doit pas être utilisé jusqu’à ce que des réparations aient été effectuées.

c) L’instrument, en particulier le câble et la sonde, doit être propre, pour des raisons de sécurité et de facilité

d’utilisation.

d) Les risques primaires et secondaires de l’endroit de mesure physique devraient être évalués.

e) La source d’alimentation doit être débranchée avant tout entretien.

f) L’échange de composants autres que les piles peut aller à l'encontre des certifications ATEX/IECEx ou d’a ut res

certifications et ne devrait être effectué que par ThermoProbe ou l’un de ses fournisseurs de services qualifié. Voir

également la section « Réparations autorisées ».

g) Pour réduire le risque d’incendie ou d’explosion, cet appareil doit être mis à la masse du réservoir selon les

clauses 6.3.2 e), IEC/EN 60079-14 b avant et durant l’introduction dans le réservoir et doit rester mis à la masse

jusqu’à ce que le capteur de la sonde soit entièrement retiré du réservoir.

h) L’appareil doit rester mis à la masse/terre à l’aide de la connexion fournie chaque fois qu’une atmosphère

dangereuse est potentiellement présente ainsi que dans les situations où une charge électrostatique peut se produire,

le déroulement/l’enroulement du câble du thermomètre ou le vidage ou le remplissage du réservoir.

comme

ATTENTION : Dans le cas où une partie quelconque de l’instrument deviendrait chargée électrostatiquement dans

un endroit potentiellement dangereux, suivez les directives de l’entreprise pour tester la présence de gaz dangereux

et les éliminer avant d’essayer de mettre l’instrument à la terre. Si cela s’avère impossible, attendez suffisamment

longtemps pour que l’instrument dissipe toute charge avant d’essayer de le mettre à la terre. En fonction de

l’atmosphère, cela pourrait prendre plusieurs heures.

Des moyens supplémentaires de protection devraient être utilisés

CONSEILS

Problèmes avec les substances et les environnements agressifs : soyez conscient des substances agressives et du fait

qu’une protection supplémentaire puisse être nécessaire.

La soude caustique et les substances hautement basiques et acides éroderont le clip et le fil de mise à la terre en

aluminium et en cuivre. L’ensemble capteur-câble comporte des surfaces externes en acier inoxydable et en

fluoropolymère. L’exposition à une chaleur excessive peut faire fondre les parties en plastique de l’instrument.

10/2017, JK

Page 28

APPROBATIONS DE SÉCURITÉ POUR TP7-D ET TP9-A :

AEx ia IIB T4 Ga

Les normes applicables sont : Agence ou désignation de sécurité

IEC 60079-0:Ed 6, IEC 60079-11:Ed 6 IECEx

EN 60079-0:2012 + A11 3013, EN60079-11 : 2012 Europe : ATEX

SÉCURITÉ INTRINSÈQUE

Un équipement à sécurité intrinsèque est défini comme « un équipement et un câblage incapables de libérer

suffisamment d’énergie électrique ou thermale dans des conditions normales ou anormales pour provoquer

l’inflammation d’un mélange atmosphérique dangereux dans sa concentration la plus facilement inflammable ».

(ISA-RP12.6) Ceci est réalisé en limitant la quantité d’énergie disponible pour l’équipement électrique dans la zone

dangereuse à un niveau inférieur à celui qui enflammera les gaz.

Pour qu’un incendie ou une explosion se produise, un carburant, de l’oxygène et une source d’inflammation doivent

être présents. Un système à sécurité intrinsèque suppose que le carburant et l’oxygène sont présents dans

l’atmosphère, mais le système est conçu de façon à ce que l’énergie électrique ou thermique d’une boucle

d'instrument particulière ne soit jamais suffisante pour provoquer l’inflammation.

PILES

ATTENTION :

Les piles doivent être changées dans une zone sans risques.

Les piles doivent être du type correct approuvé.

Les piles doivent être mises en place avec la polarité correcte : assurez-vous que l’extrémité (+) de la

batterie est alignée avec le symbole (+) inscrit en relief sur le boîtier de la pile.

Les nouvelles piles ne doivent pas être mélangées avec d’anciennes piles.

Les piles ne doivent pas être mélangées avec des piles d’autres modèles ou fabricants.

Les piles ne doivent pas être mises en place avec une polarité inversée qui ferai t qu ’u ne pi le pourrai t en

charger une autre.

Les piles CERTIFIÉES pour le TP9-A et le TP7-D sont les suivantes :

Fabricant Type Référence

Duracell AA (LR6) alcaline MN1500

Panasonic AA (LR6) alcaline LR6XWA

GP (Gold Peak) AA (LR6) alcaline GP15A

10/2017, JK

Page 29

РУКОВОДСТВО ПОЛЬЗОВАТЕЛЯ. МОДЕЛИ TP7-D И TP9-A

ВВЕДЕНИЕ

В настоящем руководстве описаны основные функции цифрового портативного термометра моделей TP7-D

и TP9-A, а также приведены инструкции по его эксплуатации и по технике безопасности при работе с ним.

ЗАМЕНА БАТАРЕЙ

При низком заряде батарей на дисплее отображается соответствующий значок.

О чрезмерно низком заряде свидетельствует отсутствие фоновой подсветки и мигание значка низкого

заряда на дисплее.

После появления значка низкого заряда необходимо как можно скорее заменить батареи в безопасном месте.

Это обеспечит работу фоновой подсветки и позволит избежать возможных неисправностей в работе

прибора. Недопустимо выполнять тарировку прибора, если на дисплее отображается индикатор низкого

заряда.

ПРЕДУПРЕЖДЕНИЕ.

Замена батарей должна производиться в безопасном месте.

Используйте батареи только разрешенного типа.

При установке батарей необходимо соблюдать правильную полярность, то есть полюс батареи,

обозначенный символом «+», должен совпадать с символом «+» на в батарейном отсеке.

Не допускается устанавливать батареи так, чтобы их полярность друг относительна друга была

обратной; при

Недопустимо устанавливать новую батарею вместе со старой. Не допускается одновременное

использование батарей разных моделей или производителей.

a) Прибор должен быть выключенным и находиться в безопасном месте.

b) С помощью крестовой отвертки 2-го размера открутите 3 винта (модель TP7-D) или 2 винта (модель TP9-

A), удерживающие переднюю крышку

c) С помощью крестовой отвертки 1-го размера открутите шуруп, удерживающий крышку батарейного

отсека. Снимите крышку батарейного отсека, переместите одну батарею по направлению к пружинному

контакту и извлеките ее из отсека, после чего извлеките вторую батарею.

d) Установите две новые батареи, при этом полюс каждой батареи, обозначенный символом «+», должен

совпадать с символом

e) Поместите на прежнее место удерживающее устройство и установите крышку на батарейный отсек.

Ниже указаны ОФИЦИАЛЬНО ОДОБРЕННЫЕ батареи для моделей TP9-A и TP7-D.

Производитель Тип Артикул

«Дюраселл» AA (LR6) Щелочная MN1500

«Панасоник» AA (LR6) Щелочная LR6XWA

«Джи-пи» («Голд пик») AA (LR6) Щелочная GP15A

такой схеме одна батарея заряжается от другой.

прибора.

«+» в батарейном отсеке.

РЕМОНТ УПОЛНОМОЧЕННЫМИ ЛИЦАМИ

Все работы по обслуживанию, не описанные в настоящем руководстве, рекомендуется поручать

специалистам компании «Термопроб Инк.» или уполномоченным дистрибьюторам.

На сайте www.thermoprobe.net размещено видео по правильному применению данного прибора. Стандарты

по измерениям описаны в главе 7.2 сборника стандартов Американского института нефти (API).

Октябрь 2017 г., JK

Page 30

р

ИНТЕРФЕЙС ПОЛЬЗОВАТЕЛЯ

Кнопка питания и выбора

Кнопки «вверх» и

«вниз»

Значки для

показаний из

памяти прибора

Кнопки «вверх» и «вниз»

Стрелки для индикации

повышения и понижения

Индикаторы для

точек тарировки

Индикатор низкого

за

яда батарей

Кнопка питания:

При однократном нажатии кнопки питания происходит включение прибора. (Примечание. Прибор

автоматически отключается через 20 минут после последнего нажатия данной кнопки.)

удержании кнопки питания на дисплее отобразится слово «OFF» (выкл.) и прибор выключится.

При нажатии и

Октябрь 2017 г., JK

Page 31

МЕНЮ выбора:

С помощью кнопок «вверх» и «вниз»

LOG (журнал): сохраняет до четырех показаний текущей стабильной температуры.

C-F (Ц — Ф): экран выбора между отображением температуры по Цельсию или по Фаренгейту.

DECIMAL (десятичные разряды): выбор количества разрядов отображаемого значения: с десятыми (0,1)

или с сотыми (0,01) долями.

MEMORY (память) — с помощью кнопок «вверх» и «вниз» можно

С значение температуры.

Среднее значение температуры.

Наибольшее значение температуры.

С 1-го по 10-е сохраненные показания (внесенные в журнал).

(Чтобы удалить сохраненные показания, используйте команду CLR LOG (очистка журнала).)

CALIBRAT (тарировка): вход в режим тарировки (корректировки).

(Требуется пароль из 3 цифр: 112). См. раздел «Порядок тарировки»

можно выбрать следующие элементы:

просмотреть:

Фоновая подсветка

Прибор оснащен фотоэлементом, который включает фоновую подсветку при эксплуатации в условиях

слабого освещения.

Внесение показаний температуры в журнал

В журнал может быть внесено значение только стабильной температуры. После стабилизации показаний

температуры стрелки на дисплее мигнут 3 раза.

Для внесения значения температуры в журнал один раз нажмите кнопку «вниз», чтобы на экране

отобразилось слово LOG (журнал). Чтобы сохранить значение температуры, один раз нажмите кнопку

выбора. Факт сохранения значения подтверждается надписью

помощью данной процедуры можно сохранить до 10 значений температуры.

LOG 1-10 (журнал 1–10) на дисплее. С

Октябрь 2017 г., JK

Page 32

Для доступа к сохраненным в журнале значениям используется меню «MEMORY» (память). Сохраненные

значения температуры отображаются со значком «LOG» (журнал) и цифрой (1, 2, 3, 4, 5, 6, 7, 8, 9 или 0) в

соответствии с порядком сохранения значения в журнале. Для перемещения между сохраненными

значениями используются стрелки «вверх» и «вниз». Для возврата к экрану отображения температуры

нажмите кнопку EXIT (выйти

Значения, внесенные в журнал, сохраняются даже после выключения прибора. Чтобы удалить из журнала

сохраненные значения, перейдите в раздел «Memory» (Память) в меню прибора и выберите команду CLR

LOG (очистка журнала). Новые показания могут быть сняты только после удаления сохраненных значений.

).

USB-накопитель

На плате устройства предусмотрен разъем микро-USB для доступа к данным тарировки и журнала.

Предупреждение. Доступ к плате устройства разрешен только при нахождении в безопасной зоне.

Самое низкое, среднее и самое высокое значения температуры

Для просмотра самого низкого, среднего и самого высокого значений температуры используется меню

«MEMORY» (память). Соответствующие значения отмечаются значками «LOW» (самое низкое), «AVG»

(среднее) и «HIGH» (самое высокое) на дисплее прибора. Данные значения определяются на основании

измеряемой температуры в течение сеанса работы прибора, они не связаны с сохраненными в журнале

значениями. После выключения прибора данные

значения удаляются.

Коды, отображаемые на дисплее

OPEN CKT (разомкнутый контур) — означает, что датчик работает при температуре, превышающей

допустимый верхний предел, что контур узла термощупа разомкнут в результате обрыва или неисправности

участка цепи либо что кабель неправильно подсоединен к клемме монтажной платы. Наиболее

распространенной причиной является повреждение кабеля.

SHORT CKT (короткое замыкание) — означает, что датчик работает при температуре ниже

минимума либо что в контуре узла термощупа произошло короткое замыкание вследствие поломки или

обрыва участка цепи. Наиболее распространенной причиной является повреждение кабеля.

NONE (отсутствует) — означает, что в памяти прибора отсутствуют сохраненные показания температуры.

2 WIRE (двухпроводной) — означает, что подключен двухпроводной термощуп.

3 WIRE (трехпроводной) — означает, что подключен трехпроводной термощуп.

NO CAL (нет данных по тарировке) — означает, что в системе нет сохраненных данных о тарировке

соответствующего термощупа. Перед использованием прибора

необходимо провести его тарировку (корректировку).

допустимого

Октябрь 2017 г., JK

Page 33

Типы термощупов

Для моделей TP7-D и TP9-A могут использоваться как двухпроводные, так и трехпроводные термощупы.

Сменные узлы термощупов «Термопроб» предлагаются в нескольких вариантах конфигурации. Длина их

кабеля может достигать 50 м. Предусмотрена стандартная латунная маркировка, нанесенная через

интервалы, равные 1 м. Датчики предлагаются в четырех вариантах массы. Предусмотрены следующие

конфигурации узла термощупа:

ЗАМЕНА УЗЛА ТЕРМОЩУПА

ПРИМЕЧАНИЯ.

1) После замены узла термощупа необходимо провести повторную тарировку прибора. Замена узла

термощупа должна производиться только опытным персоналом и при наличии тарировочного

оборудования.

2) При производстве работ по ремонту необходимо руководствоваться стандартом IEC/EN 60079-19

( «Взрывоопасные среды. Часть 19. Ремонт, проверка и восстановление электрооборудования)».

3) Допускается использование только сменных узлов термощупа, приобретенных у компании

ThermoProbe, Inc. или у ее уполномоченных дистрибьюторов.

a) Прежде всего, извлеките из устройства элементы питания, выполнив этапы a–c инструкции по ЗАМЕНЕ

БАТАРЕЙ.

b) На монтажной

провода по его расцветке. См. рис. 1.

Белый — положительный провод датчика.

Зеленый — компенсационный провод (отсутствует в двухпроводных моделях).

Серебристый — отрицательный экранированный провод датчика.

c) Убрав крышку и монтажную плату, развяжите узел для снятия натяжения, выполненный в кабельном

узле.

d) Размотайте кабель, удалив его из узла, и вытяните его из резиновой втулки.

e) Вставьте новый провод через резиновую втулку и вытяните несколько сантиметров провода с обратной

стороны втулки.

f) Завяжите простой узел

пока узел не достигнет втулки.

g) На монтажной плате нажмите на рычажки зажима клеммы и вставьте выводы нового провода согласно

расцветке. На ярлыке указывается, как соединять двухпроводной и трехпроводной (с зеленым проводом)

термощупы. См. рис. 1.

h) Поместите батареи на прежнее

i) Проведите тарировку прибора (см. порядок тарировки).

плате нажмите на зажимы клемм и извлеките провода, запомнив местоположение каждого

на кабеле у втулки, предназначенный для снятия натяжения, и протяните кабель,

место, установите крышку и скрутите кабельный узел.

Октябрь 2017 г., JK

Page 34

Рис. 1. Присоединение проводов узла термощупа

ПОРЯДОК ТАРИРОВКИ

Режим тарировки должен использоваться только квалифицированным персоналом с применением

надлежащего оборудования, иначе возможны ошибки тарировки. Внимательно изучите

приведенную ниже инструкцию.

Для осуществления корректировки требуется как минимум 2 точки (двухточечная тарировка).

Также могут использоваться дополнительные точки (трехточечная или четырехточечная тарировка),

если тарировка выполняется в широком диапазоне температур (например, от –20 °C до 150 °C) или

при необходимости обеспечить точное соответствие определенным точкам в заданном диапазоне. В

такую тарировку должны быть включены начальная и конечная точки диапазона. Для каждой точки

тарировки необходимо использовать надлежащее оборудование.

Недопустимо выполнять тарировку прибора, если на дисплее отображается индикатор низкого

заряда, поскольку это может привести к тому, что в памяти

тарировки.

Рекомендации по проверке штатной тарировки приведены в API 7.2 и иных признанных стандартах.

Недопустимо проведение тарировки в среде, которая считается опасной.