Page 1

TThheerrm

moo

PPrroobbee,,

IInncc..

RECOMMENDED OPERATION

To properly use this instrument the operator

should be familiar with API 7 and the

International Safety Guide For Oil Tankers and

Terminals.

SPOOL-LOCK

To avoid unwanted dispatch or tangling of

the cable, a threaded spool-lock is located on

the case where the ground wire is attached.

When using the instrument simply turn the

screw out so that the cable spool can freely

spin.

AUTO-SHUTOFF

The TP7 is equipped for automatic shut off after

approximately 2 minutes. Battery life is

extended since the unit cannot be left on

unattended.

LOW BATTERY ALERT

LO - Battery Voltage Low

When the TP7 is switched on, it will

immediately check the status of the battery. A

low battery situation will result with a flashing of

“LO” to the display for a few seconds before the

temperature reading is available. The battery

needs to be replaced soon after the warning is

observed, this is especially important if the unit

will be used in low light situations where the

backlight will be illuminated.

BATTERY REPLACEMENT

PROCEDURE

PERFORM BATTERY REPLACEMENT ONLY IN

AN AREA KNOWN TO BE NONHAZARDOUS.

APPROVED BATTERIES. See Identification plate

for approved batteries.

Remove the three-faceplate screws; turn the

unit upside down allowing the faceplatecircuit board module to fall into your hand.

The battery is then readily accessible for

manual replacement.

TP7 USER MAINTENANCE

DISPLAY CHECK

When the instrument is first turned on, the display

will briefly show all possible character segments.

This will look like: 888.8. If any segments fail to

show, the instrument should not be used and it is

likely that the glass display is cracked.

ERROR CODES

Two error codes have been established to

provide the user information in case a

maintenance situation has occurred.

E1 - Short Circuit or Under Range

E2 - Open Circuit or Over Range

“E1” When this happens, one of two

situations has exists. In most cases, the probe

circuit has been shorted; usually meaning the

cable has been smashed at some point.

Secondly, “E1” represents a below range

reading. The temperature being gauged is

below the measurable specified range.

“E2” When this occurs, there are also two

possible situations. The first and most likely is

that the probe circuit has a discontinuity. This

may occur as a result of a cut cable, bad

termination at the circuit board or damaged

sensor. Check the cable terminal making sure

the wires are correctly inserted into the

connector on the board. Secondly, “E2”

represents an over range reading, meaning the

temperature at the sensor has risen above the

measurable specified limit of the unit.

°F/°C DISPLAY UNITS

The TP7 may display the temperature reading

in Fahrenheit or Celsius units. To change the

readout from one unit to the other remove the

switch plate and slide the circuit board through

the top. The selector is located above the

battery and the letters F and C can be seen on

the surface of the board. Place the selector

shunt on the center and upper pin for °F and

center and lower pin for °C. See illustration on

next page. There is no need for recalibration if

the there is a change in the temperature units.

Page 2

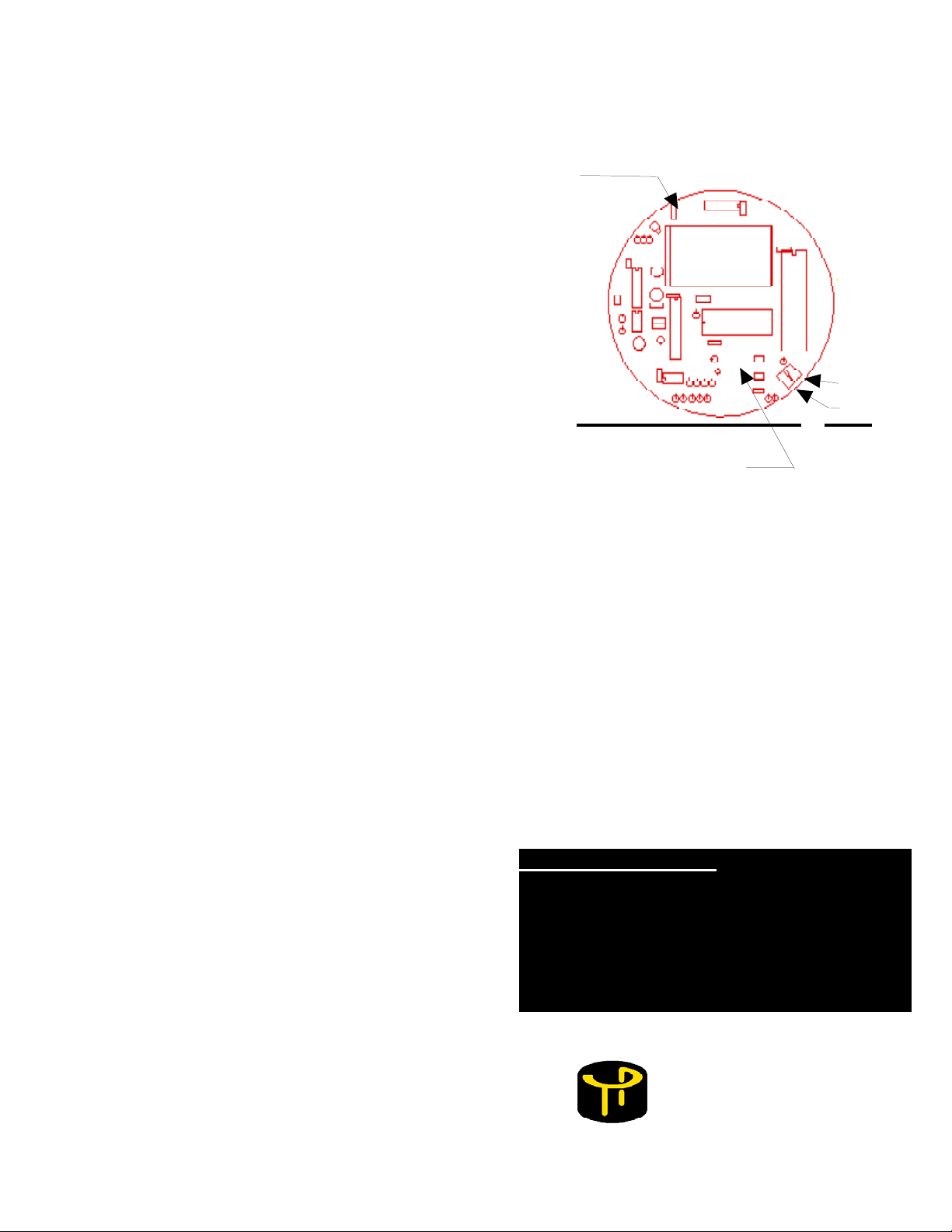

REPLACING THE PROBE ASSEMBLY

When attaching a new probe assembly to circuit, it is necessary

to pay attention to the polarity of the probe.

Black Wire (shielding with shrink wrap) = (-)

White Wire (signal lead) = (+)

Polarity markings are located on the circuit board in front of the

finger connector. See illustration.

Reversed wires will inhibit proper probe grounding and may

cause false readings.

If a probe assembly is replaced with one of the same length, the

calibration will be within + 0.2 °F at 32 °F and within +0.6 °F

at 200 °F. It is recommended that a recalibration be performed

to make the instrument as accurate as possible.

CALIBRATION

The TP7 design allows extended calibration periods. If

accuracy is not within specifications check cable integrity and

inspect the circuit board for possible corrosion, particularly near

the cable terminals. Calibration adjustments will not properly

correct these problems.

To verify/calibrate the instrument to the best possible accuracy

over a wide range, the following items are necessary:

-A certified thermometer.

-A circulated refrigerated bath, with a temperature near:

32.0 °F/ 0.0 °C (Bath 1)

-A circulated hot bath with a temperature:

190-200 °F /88-93°C (Bath 2)

-Small flat head adjustment screwdriver or similar tool.

1. Remove the 3 faceplate screws and lift assembly from housing.

2. Using the illustration (to the right) find the adjustment trims.

3. Adjust the ZERO with the probe assembly in Bath 1.

4. Adjust the SPAN with the probe assembly in Bath 2.

5. Repeat several times or until no adjustment is necessary.

FACEPLATE-CIRCUIT BOARD MODULE

F / C

SELECTOR

(Other Side of

Board)

- +

95.8F

SPAN

ZERO

PROBE WIRE

TERMINALS

( Other Side)

AUTHORIZED REPAIR:

It is recommend that service done beyond

the scope of this article be presented to

ThermoProbe Inc. or one of its distributors.

Any servicing by unauthorized parties may

void the Intrinsic Safety and the warranty.

TThheerrmmo

112-A Jetport Drive

Pearl, MS 39208 USA

Voice: +1 601-939-1831

Fax: +1 601-355-1831

www.thermoprobe.net

o

PPrroobbee,, IInncc.

.

Loading...

Loading...