Page 1

Operator’s Manual

V-Series Units with

Direct Smart Reefer

V-100, V-200, V-200s, V-300, V-500, V-600, V-800 and

Spectrum units

December 2018

Revision A

TTKK 6611665511--1188--OOPP--EENN

Page 2

Introduction

This manual is published for informational purposes only and the

information furnished herein should not be considered as all-inclusive or

meant to cover all contingencies. If more information is required, consult

your Thermo King Service Directory for the location and telephone number

of the local dealer.

TThheerrmmoo KKiinngg’’ss wwaarrrraannttyy sshhaallll nnoott aappppllyy ttoo aannyy eeqquuiippmmeenntt wwhhiicchh hhaass

bbeeeenn ““ssoo iinnssttaalllleedd,, mmaaiinnttaaiinneedd,, rreeppaaiirreedd oorr aalltteerreedd aass,, iinn tthhee

mmaannuuffaaccttuurreerr’’ss jjuuddggmmeenntt,, ttoo aaffffeecctt iittss iinntteeggrriittyy..””

MMaannuuffaaccttuurreerr sshhaallll hhaavvee nnoo lliiaabbiilliittyy ttoo aannyy ppeerrssoonn oorr eennttiittyy ffoorr aannyy

ppeerrssoonnaall iinnjjuurryy,, pprrooppeerrttyy ddaammaaggee oorr aannyy ootthheerr ddiirreecctt,, iinnddiirreecctt,, ssppeecciiaall,,

oorr ccoonnsseeqquueennttiiaall ddaammaaggeess wwhhaattssooeevveerr,, aarriissiinngg oouutt ooff tthhee uussee ooff tthhiiss

mmaannuuaall oorr aannyy iinnffoorrmmaattiioonn,, rreeccoommmmeennddaattiioonnss oorr ddeessccrriippttiioonnss

ccoonnttaaiinneedd hheerreeiinn.. TThhee pprroocceedduurreess ddeessccrriibbeedd hheerreeiinn sshhoouulldd oonnllyy bbee

uunnddeerrttaakkeenn bbyy ssuuiittaabbllyy qquuaalliiffiieedd ppeerrssoonnnneell.. FFaaiilluurree ttoo iimmpplleemmeenntt tthheessee

pprroocceedduurreess ccoorrrreeccttllyy mmaayy ccaauussee ddaammaaggee ttoo tthhee TThheerrmmoo KKiinngg uunniitt oorr

ootthheerr pprrooppeerrttyy oorr ppeerrssoonnaall iinnjjuurryy..

There is nothing complicated about operating and maintaining your Thermo

King unit, but a few minutes studying this manual will be time well spent.

Performing pre-trip checks and enroute inspections on a regular basis will

minimize operating problems. A regular maintenance program will also help

to keep your unit in top operating condition. If factory recommended

procedures are followed, you will find that you have purchased the most

efficient and dependable temperature control system available.

All service requirements, major and minor, should be handled by a Thermo

King dealer for four very important reasons:

• They are equipped with the factory recommended tools to perform all

service functions

• They have factory trained and certified technicians

• They have genuine Thermo King replacement parts

• The warranty on your new unit is valid only when the repair and

replacement of component parts is performed by an authorized Thermo

King dealer

Software License

The product includes software that is licensed under a non-exclusive, nonsublicensable, terminable and limited license to use the software as installed

2

TK 61651-18-OP-EN

Page 3

IInnttrroodduuccttiioonn

on the product for its intended purpose. Any removal, reproduction, reverse

engineering, or other unauthorized use of the software is strictly prohibited.

Hacking the product or installing unapproved software may void the

warranty. The owner or operator shall not reverse engineer, decompile, or

disassemble the software, except and only to the extent that such activity is

expressly permitted by applicable law notwithstanding this limitation. The

product may include third party software separately licensed as specified in

any documentation accompanying the product or in an about screen on a

mobile application or website that interfaces with the product.

Emergency Assistance

Thermo Assistance is a multi-lingual communication tool designed to put

you in direct contact with an authorized Thermo King dealer.

TThheerrmmoo AAssssiissttaannccee sshhoouulldd oonnllyy bbee ccoonnttaacctteedd ffoorr bbrreeaakkddoowwnn aanndd rreeppaaiirr

aassssiissttaannccee..

To use this system, you need the following information before you call:

(phone charges will apply)

• Contact Phone Number

• Type of TK Unit

• Thermostat Setting

• Present Load Temperature

• Probable Cause of Fault

• Warranty Details of the Unit

• Payment Details for the Repair

Leave your name and contact number and a Thermo Assistance Operator

will call you back. At this point you can give details of the service required

and the repair will be organized.

Please note that Thermo Assistance cannot guarantee payments and the

service is designed for the exclusive use of refrigerated transporters with

products manufactured by Thermo King Corporation.

TK 61651-18-OP-EN

3

Page 4

IInnttrroodduuccttiioonn

General Inquires and Unit Maintenance

For general inquiries please contact your local Thermo King dealer.

Go to www.europe.thermoking.com and select dealer locator for your local

Thermo King dealer.

Or refer to the Thermo King Service Directory for contact information.

4

TK 61651-18-OP-EN

Page 5

IInnttrroodduuccttiioonn

Customer Satisfaction Survey

Let your voice be heard!

Your feedback will help improve our manuals. The survey is accessible

through any internet-connected device with a web browser.

Scan the Quick Response (QR) code or click or type the web address http://

irco.az1.qualtrics.com/SE/?SID=SV_2octfSHoUJxsk6x to complete the

survey.

TK 61651-18-OP-EN

5

Page 6

Table of Contents

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Danger, Warning, Caution, and Notice . . . . . . . . . . . . . . . . . . . . . . . . 9

General Safety Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Automatic Start/Stop Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Battery Installation and Cable Routing . . . . . . . . . . . . . . . . . . . . . . . 11

Refrigerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Refrigerant Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

First Aid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Safety Decals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

High Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Condenser and Evaporator Fans. . . . . . . . . . . . . . . . . . . . . . . . . 18

Remote Start of the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Refrigerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Type Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Unit Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Standard Unit Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

System Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Compressor(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Condenser. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Evaporator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Electronic Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Unit Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Standby Operation (Models 20 and 50 Only) . . . . . . . . . . . . . . . . . 27

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6

TK 61651-18-OP-EN

Page 7

TTaabbllee ooff CCoonntteennttss

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Pharma . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

General Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Starting the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Engine Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Electric Standby Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Standard Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Single Temperature Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Multi-Temperature Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Entering Setpoint Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Single Temperature Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Multi-Temperature Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Compartment Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Initiating the Evaporator Manual Defrost Cycle . . . . . . . . . . . . . . . 37

Initiating the Condenser Manual Defrost Cycle (reverse cycle

units only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Manual Start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Auto Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Buzzers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Alarm Code Descriptions DSR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Clearing Alarm Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Viewing Information Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Hourmeter Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Loading and Inspection Procedures . . . . . . . . . . . . . . . . . . . . . . . . . 44

TK 61651-18-OP-EN

7

Page 8

TTaabbllee ooff CCoonntteennttss

Post-Start Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Loading Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Post Load Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Refrigeration System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Electrical Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Electric Motor (Model 50). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

TracKing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Inspection and Service Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Weekly Pre-Trip Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Weekly Pretrip Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Weekly Post-Trip Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Inspection and Service Schedules . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Service Record. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Warranty Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Serial Number Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Recover Refrigerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8

TK 61651-18-OP-EN

Page 9

Safety Precautions

Danger, Warning, Caution, and Notice

Thermo King® recommends that all service be performed by a Thermo King

dealer and to be aware of several general safety practices.

Safety advisories appear throughout this manual as required. Your personal

safety and the proper operation of this unit depend upon the strict

observance of these precautions.

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

could result in minor or moderate injury and unsafe practices.

Indicates a situation that could result in equipment or propertydamage only accidents.

TK 61651-18-OP-EN

9

Page 10

SSaaffeettyy PPrreeccaauuttiioonnss

General Safety Practices

DDAANNGGEERR

RRiisskk ooff IInnjjuurryy!!

Keep hands and loose clothing clear of fans and belts at all times when the

unit is operating with the doors open.

WWAARRNNIINNGG

RRiisskk ooff IInnjjuurryy!!

Do not apply heat to a closed cooling system. Before applying heat to a

cooling system, drain it. Then flush it with water and drain the water.

Antifreeze contains water and ethylene glycol. The ethylene glycol is

flammable and can ignite if the antifreeze is heated enough to boil off the

water.

WWAARRNNIINNGG

RRiisskk ooff IInnjjuurryy!!

Temperatures above 120 degrees F (50 degrees C) can cause serious burns.

Use an infrared thermometer or other temperature measuring device

before touching any potentially hot surfaces.

CCAAUUTTIIOONN

SShhaarrpp EEddggeess!!

Exposed coil fins can cause lacerations. Service work on the evaporator or

condenser coils is best left to a certified Thermo King technician.

10

TK 61651-18-OP-EN

Page 11

SSaaffeettyy PPrreeccaauuttiioonnss

Automatic Start/Stop Operation

CCAAUUTTIIOONN

RRiisskk ooff IInnjjuurryy!!

The unit can start and run automatically any time the unit is turned on. Turn

the Microprocessor On/Off switch Off before doing inspections or working

on any part of the unit. Please note that only Qualified and Certified

personnel should attempt to service your Thermo King unit.

Battery Installation and Cable Routing

WWAARRNNIINNGG

HHaazzaarrdd ooff EExxpplloossiioonn!!

An improperly installed battery could result in a fire, explosion, or injury. A

Thermo King approved battery must be installed and properly secured to

the battery tray.

WWAARRNNIINNGG

HHaazzaarrdd ooff EExxpplloossiioonn!!

Improperly installed battery cables could result in a fire, explosion, or

injury. Battery cables must be installed, routed, and secured properly to

prevent them from rubbing, chaffing, or making contact with hot, sharp, or

rotating components.

TK 61651-18-OP-EN

11

Page 12

SSaaffeettyy PPrreeccaauuttiioonnss

WWAARRNNIINNGG

FFiirree HHaazzaarrdd!!

Do not attach fuel lines to battery cables or electrical harnesses. This has

the potential to cause a fire and could cause serious injury or death.

WWAARRNNIINNGG

PPeerrssoonnaall PPrrootteeccttiivvee EEqquuiippmmeenntt ((PPPPEE)) RReeqquuiirreedd!!

A battery can be dangerous. A battery contains a flammable gas that can

ignite or explode. A battery stores enough electricity to burn you if it

discharges quickly. A battery contains battery acid that can burn you.

Always wear goggles or safety glasses and personal protective equipment

when working with a battery. If you get battery acid on you, immediately

flush it with water and get medical attention.

WWAARRNNIINNGG

HHaazzaarrdd ooff EExxpplloossiioonn!!

Always cover battery terminals to prevent them from making contact with

metal components during battery installation. Battery terminals grounding

against metal could cause the battery to explode.

CCAAUUTTIIOONN

HHaazzaarrddoouuss SSeerrvviiccee PPrroocceedduurreess!!

Set all unit electrical controls to the OFF position before connecting battery

cables to the battery to prevent unit from starting unexpectedly and causing

personal injury.

NNOOTTIICCEE

EEqquuiippmmeenntt DDaammaaggee!!

Do not connect other manufacturer’s equipment or accessories to the unit

unless approved by Thermo King. Failure to do so can result in severe

damage to equipment and void the warranty.

12

TK 61651-18-OP-EN

Page 13

SSaaffeettyy PPrreeccaauuttiioonnss

Refrigerant

Although fluorocarbon refrigerants are classified as safe, use caution when

working with refrigerants or in areas where they are being used.

DDAANNGGEERR

HHaazzaarrddoouuss GGaasseess!!

Refrigerant in the presence of an open flame, spark, or electrical short

produces toxic gases that are severe respiratory irritants which can cause

serious injury or possible death.

DDAANNGGEERR

RReeffrriiggeerraanntt VVaappoorr HHaazzaarrdd!!

Do not inhale refrigerant. Use caution when working with refrigerant or a

refrigeration system in any confined area with a limited air supply.

Refrigerant displaces air and can cause oxygen depletion, resulting in

suffocation and possible death.

WWAARRNNIINNGG

PPeerrssoonnaall PPrrootteeccttiivvee EEqquuiippmmeenntt ((PPPPEE)) RReeqquuiirreedd!!

Refrigerant in a liquid state evaporates rapidly when exposed to the

atmosphere, freezing anything it contacts. Wear butyl lined gloves and

other clothing and eye wear when handling refrigerant to help prevent

frostbite.

TK 61651-18-OP-EN

13

Page 14

SSaaffeettyy PPrreeccaauuttiioonnss

Refrigerant Oil

Observe the following precautions when working with or around refrigerant

oil:

WWAARRNNIINNGG

PPeerrssoonnaall PPrrootteeccttiivvee EEqquuiippmmeenntt ((PPPPEE)) RReeqquuiirreedd!!

Protect your eyes from contact with refrigerant oil. The oil can cause serious

eye injuries. Protect skin and clothing from prolonged or repeated contact

with refrigerant oil. To prevent irritation, wash your hands and clothing

thoroughly after handling the oil. Rubber gloves are recommended.

First Aid

RREEFFRRIIGGEERRAANNTT

• EEyyeess:: For contact with liquid, immediately flush eyes with large amounts

of water and get prompt medical attention.

• SSkkiinn:: Flush area with large amounts of warm water. Do not apply heat.

Remove contaminated clothing and shoes. Wrap burns with dry, sterile,

bulky dressing to protect from infection. Get prompt medical attention.

Wash contaminated clothing before reuse.

• IInnhhaallaattiioonn:: Move victim to fresh air and use Cardio Pulmonary

Resuscitation (CPR) or mouth-to-mouth resuscitation to restore

breathing, if necessary. Stay with victim until emergency personnel

arrive.

• FFrroosstt BBiittee:: In the event of frost bite , the objectives of First Aid are to

protect the frozen area from further injury, warm the affected area

rapidly, and to maintain respiration.

RREEFFRRIIGGEERRAANNTT OOIILL

• EEyyeess:: Immediately flush with large amounts of water for at least 15

minutes. Get prompt medical attention.

• SSkkiinn:: Remove contaminated clothing. Wash thoroughly with soap and

water. Get medical attention if irritation persists.

14

TK 61651-18-OP-EN

Page 15

SSaaffeettyy PPrreeccaauuttiioonnss

• IInnhhaallaattiioonn:: Move victim to fresh air and use Cardio Pulmonary

Resuscitation (CPR) or mouth-to-mouth resuscitation to restore

breathing, if necessary. Stay with victim until emergency personnel

arrive.

• IInnggeessttiioonn:: Do not induce vomiting. Immediately contact local poison

control center or physician.

EENNGGIINNEE CCOOOOLLAANNTT

• EEyyeess:: Immediately flush with large amounts of water for at least 15

minutes. Get prompt medical attention.

• SSkkiinn:: Remove contaminated clothing. Wash thoroughly with soap and

water. Get medical attention if irritation persists.

• IInnggeessttiioonn:: Do not induce vomiting. Immediately contact local poison

control center or physician.

BBAATTTTEERRYY AACCIIDD

• EEyyeess:: Immediately flush with large amounts of water for at least 15

minutes. Get prompt medical attention. Wash skin with soap and water.

EELLEECCTTRRIICCAALL SSHHOOCCKK

Take IMMEDIATE action after a person has received an electrical shock. Get

quick medical assistance, if possible.

The source of the shock must be quickly stopped, by either shutting off the

power or removing the victim. If the power cannot be shut off, the wire

should be cut with an non-conductive tool, such as a wood-handle axe or

thickly insulated cable cutters. Rescuers should wear insulated gloves and

safety glasses, and avoid looking at wires being cut. The ensuing flash can

cause burns and blindness.

If the victim must be removed from a live circuit, pull the victim away with a

non-conductive material. Use wood, rope, a belt or coat to pull or push the

victim away from the current. DO NOT TOUCH the victim. You will receive a

shock from current flowing through the victim’s body. After separating the

victim from power source, immediately check for signs of a pulse and

respiration. If no pulse is present, start Cardio Pulmonary Resuscitation

(CPR). If a pulse is present, respiration might be restored by using mouth-tomouth resuscitation. Call for emergency medical assistance.

AASSPPHHYYXXIIAATTIIOONN

Move victim to fresh air and use Cardio Pulmonary Resuscitation (CPR) or

mouth-to-mouth resuscitation to restore breathing, if necessary. Stay with

victim until emergency personnel arrive.

TK 61651-18-OP-EN

15

Page 16

SSaaffeettyy PPrreeccaauuttiioonnss

Safety Decals

Service

The Service decal is located in an appropriate location internally. This decal

gives you the information to access/download your unit operator manual,

but also the safety icons associated with your unit. These safety icons are

directly associated with the information within this chapter. You can see the

explanations for these icons starting from the beginning of this chapter.

NNoottee:: This decal only contains symbols of warning for the service of the unit.

Figure 1. Service Decal

16

TK 61651-18-OP-EN

Page 17

SSaaffeettyy PPrreeccaauuttiioonnss

Operation

The Operation decal is located in an appropriate position near your in-cab

controller (HMI). This decal gives you the information to access/download

your unit operator manual and other supporting documentation and in many

supported languages.

Figure 2. Operation Decal

High Voltage

• In the control box.

TK 61651-18-OP-EN

17

Page 18

SSaaffeettyy PPrreeccaauuttiioonnss

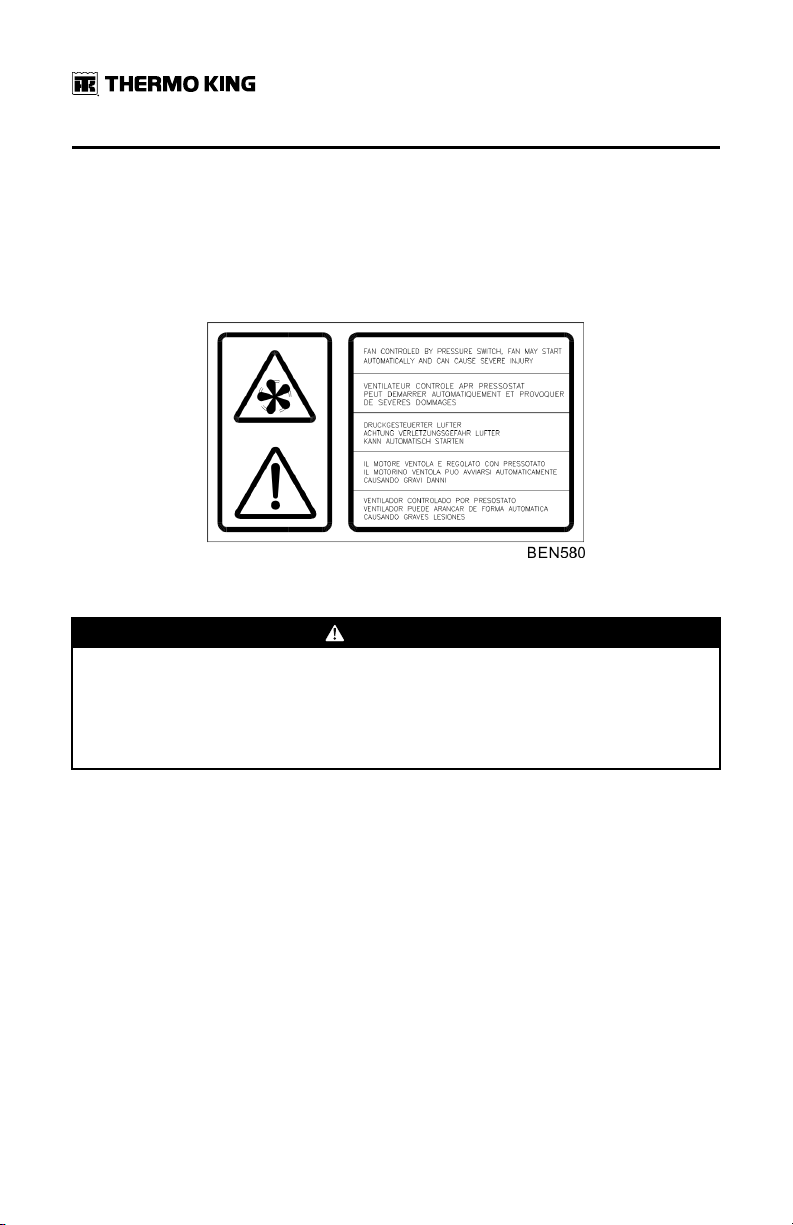

Condenser and Evaporator Fans

Be aware of the warning nameplates () in the following locations:

• On belt guard

• On rear of evaporator housing

Figure 3. Fan Warning

Remote Start of the Unit

CCAAUUTTIIOONN

RRiisskk ooff IInnjjuurryy!!

The unit can start and run automatically any time the unit is turned on. Turn

the Microprocessor On/Off switch Off before doing inspections or working

on any part of the unit. Please note that only Qualified and Certified

personnel should attempt to service your Thermo King unit.

Decals located behind service door.

18

TK 61651-18-OP-EN

Page 19

SSaaffeettyy PPrreeccaauuttiioonnss

Figure 4. Unit Auto-start Warning

Refrigerant

Refrigerant Decal is located adjacent to the service ports for charging or

recovering the gas, as per the F-Gas regulation.

F Gas decal indicates that this equipment Contains fluorinated greenhouse

gases.

TK 61651-18-OP-EN

19

Page 20

SSaaffeettyy PPrreeccaauuttiioonnss

Type Certification

UNECE R10 decal sample.

20

TK 61651-18-OP-EN

Page 21

Unit Description

Thermo King Vehicle Powered Truck Units are two-piece units comprised of

a condenser and evaporator designed for fresh, frozen, and deep frozen

applications on small trucks and vans.

A belt driven compressor running off the vehicle’s engine operates the

refrigeration system during mobile operation. Electric Standby models have

a second compressor located inside the condenser. This compressor is belt

driven off an electric motor when connected to an AC power source during

stationary operation.

The user friendly Direct Smart Reefer (DSR) controller makes operating your

unit simple, while its modular design allows for ease of service.

V-Series Units Include:

• VV--110000,, VV--220000,, VV--330000,, VV--550000,, VV--660000,, VV--880000:: for fresh temperature

applications above 0°C.

• VV--110000,, VV--220000,, VV--330000,, VV--550000,, VV--660000,, VV--880000 MMAAXX:: for frozen temperature

applications below 0°C and down to -32°C.

There are four basic models:

• MMooddeell 1100:: Cool and Defrost with only vehicle powered engine driven

compressor operation.

• MMooddeell 2200:: Cool and Defrost with both vehicle powered engine driven

compressor operation and electric standby compressor operation.

• MMooddeell 3300:: Hot gas heat, Cool, and Defrost with only vehicle powered

engine driven compressor operation.

• MMooddeell 5500:: Hot gas heat, Cool, and Defrost on both vehicle powered

engine driven operation and electric standby compressor operation.

Two add-on heat options are available:

• Coolant Heat (Models 10 and 20 only).

• Coolant and Electric Heat (Model 20 only).

TK 61651-18-OP-EN

21

Page 22

UUnniitt DDeessccrriippttiioonn

Standard Unit Features

• CCoonnddeennsseerr - Lightweight design of aluminium construction, easy to

service with automotive grade polypropylene cover.

• EEvvaappoorraattoorr - Ultra slim design, aluminum construction automotive

grade polypropylene cover.

• CCoonnttrroollss - User friendly Direct Smart Reefer (DSR) In-Cab controller.

• RReeffrriiggeerraanntt - R-134a, R-452A or R-404a (depending on unit model).

Options

• Electric Standby

• Hot Gas, Electric or Coolant Heating

• Door Switch Kit

• Discharge Muffler Kit

• Snow Covers

• Refrigeration Hose / Harness Covers

• Roof Top Mounting Kit

• Electric Standby Plug (115 Vac, 230 Vac 1 phase, 230 Vac 3 phase)

NNoottee:: Some options are available factory installed or as a retro-fit option to

suit individual customer needs.

System Components

The system consists of four main components: compressor, condenser,

evaporator, and In-cab control panel (HMI).

Compressor(s)

All vehicle-powered systems utilize an engine driven compressor, either a

swash plate or reciprocating depending on your particular model. Electric

standby models also have an electric motor that operates a second

compressor located inside the condenser.

22

TK 61651-18-OP-EN

Page 23

UUnniitt DDeessccrriippttiioonn

Figure 5. Compressors

1. Swash Plate

2. Reciprocating

Condenser

The condenser is located on the roof of the vehicle or on the front of the

cargo box. The cover can easily be removed to access the fuses or service

the unit.

Figure 6. Condenser

Evaporator

The evaporator is mounted on the ceiling inside the cargo box. The cover

can easily be removed for service.

Figure 7. Evaporator

TK 61651-18-OP-EN

23

Page 24

UUnniitt DDeessccrriippttiioonn

Electronic Control System

The Electronic Control System is composed of an Electronic Control Module

(located inside the condenser unit) and the HMI. This HMI allows the truck

driver to operate the Thermo King refrigeration unit.

Figure 8. HMI

Description

The Electronic Control System has the following characteristics:

• Auto Start

• Soft Start

• Active Display

• Lit Keypad

• Total Hourmeter

• Vehicle Compressor Hourmeter

• Electric Standby Compressor Hourmeter

• Low Battery Voltage Alarm

• Buzzer

• Unit Control without HMI

• Manual or Automatic Defrost

• Maintenance Warning

• Return Air Temperature Sensor

• Setpoint Temperature Reading

• Electric Power Warning

• Independent connection/disconnection of compartments in multitemperature units

24

TK 61651-18-OP-EN

Page 25

UUnniitt DDeessccrriippttiioonn

AAuuttoo SSttaarrtt:: Should the unit stop due to a failure in the power supply,

whether during on-the-road or electric standby operation, it will start up

again as soon as the power supply is re-established.

SSoofftt SSttaarrtt:: All operation modes remain inactive for a few seconds after an

Auto Start.

AAccttiivvee DDiissppllaayy:: The HMI display is always active and backlit except when

the unit is disconnected (no power) or when the unit is connected but has

been manually switched off from the HMI (when there is no active alarm).

LLiitt KKeeyyppaadd:: The HMI keys are always lit except when the unit is

disconnected (no power) or when the unit is connected but has been

manually switched off from the HMI (when there is no active alarm). The On/

Off key is always lit except when the unit is disconnected (no power), and

thus indicates the presence of power in the unit.

TToottaall HHoouurrmmeetteerr:: Total number of hours the unit is in operation.

VVeehhiiccllee CCoommpprreessssoorr HHoouurrmmeetteerr:: Number of hours the unit has been

operating on-the-road.

EElleeccttrriicc SSttaannddbbyy CCoommpprreessssoorr HHoouurrmmeetteerr:: Number of hours the unit has

been operating in electric standby.

LLooww BBaatttteerryy VVoollttaaggee AAllaarrmm:: Disconnects the unit when the battery voltage

falls below 10.5V in 12VDC systems or below 21V in 24VDC systems.

BBuuzzzzeerr:: It is energised when the vehicle battery and the electric power

supply are connected at the same time. It is also energised if the doors are

opened while the refrigeration unit is running.

UUnniitt CCoonnttrrooll wwiitthhoouutt HHMMII:: The unit can also be operated by the Electronic

Control System without the HMI, under conditions selected by the HMI

before it is disconnected.

MMaannuuaall oorr AAuuttoommaattiicc DDeeffrroosstt:: It is possible to choose between manual or

automatic defrost.

MMaaiinntteennaannccee WWaarrnniinngg:: On-screen warning of the need to carry out

maintenance on the unit.

RReettuurrnn AAiirr TTeemmppeerraattuurree SSeennssoorr:: On-screen reading of the temperature in

the load compartment. In bi-temperature units, the temperature in both

compartments can be read on the same screen.

SSeettppooiinntt TTeemmppeerraattuurree RReeaaddiinngg:: On-Screen Setpoint Temperature

Reading. In bi-temperature units, the setpoint temperature of both

compartments can be read on the same screen.

EElleeccttrriicc PPoowweerr WWaarrnniinngg:: On-screen warning that the unit is connected to an

electric power supply.

TK 61651-18-OP-EN

25

Page 26

UUnniitt DDeessccrriippttiioonn

Unit Controls

WWAARRNNIINNGG

RRiisskk ooff IInnjjuurryy!!

Never operate the unit unless you completely understand the controls;

otherwise serious injury may occur.

Figure 9. In-cab Control Panel (HMI) Display, Keys, Symbols

1. Display It is always active and backlit except when the unit is disconnected

2. On/Off Key This key is used to start/stop the unit. It is always lit except when the

3. Select Key Selects prompt screens and information screens.

4. Up Key Is used to increase the setpoint temperature.

5. Down Key Is used to reduce the setpoint temperature.

6. Enter Key

7. Buzzer It is energised when the vehicle battery and the electric power supply

8. Cool Symbol (Thermometer with an arrow pointing downward). The unit is cooling.

9. Heat Symbol (Thermometer with an arrow pointing upward). The unit is heating.

10. °C/°F Symbol Indicates whether the on-screen temperature reading is in degrees

11. Alarm Symbol Indicates that there is an alarm in the system.

26

(no power) or when the unit is connected but has been manually

switched off from the HMI. It normally displays the return air

temperature (of both load compartments in bi-temperature units).

unit is disconnected (no power), and thus acts as an indicator of the

presence of power in the unit.

Is used to enter a new command such as manual defrost, etc.

are connected simultaneously. It is also energized if the doors are

opened while the refrigeration unit is running.

Celsius (C) or degrees Fahrenheit (F).

TK 61651-18-OP-EN

Page 27

UUnniitt DDeessccrriippttiioonn

12. Maintenance

Symbol

13. Defrost

Symbol

14. Electrical

Symbol

15. Condenser

Defrost Symbol

16. Combined

Compartment

Symbol

Warns of the need to carry out maintenance to the unit.

Indicates the unit is in Defrost Mode.

Indicates that the unit is in Electric Standby.

Indicates the condenser unit is in defrost mode (turns on at the same

time as defrost symbol 13).

Indicates that the bi-temperature unit is working as a single

temperature unit.

Standby Operation (Models 20 and 50 Only)

WWAARRNNIINNGG

HHaazzaarrddoouuss VVoollttaaggee!!

A certified electrician should verify that the proper standby power

requirements are being supplied before connecting to a new power source.

These units may be operated in electric standby mode by connecting the

proper voltage power cable to the unit’s power receptacle mounted on the

vehicle. Standby operation is used while the vehicle is stationary with the

engine shut off.

Figure 10. Standby Power Receptacle

TK 61651-18-OP-EN

27

Page 28

UUnniitt DDeessccrriippttiioonn

Electrical System

The unit’s controls and refrigeration components operate on 12 Vdc.

Electric Standby units have a standby motor that operates on 115 or 230 Vac

when connected to a remote power source. A transformer in the condenser

unit converts the 115 or 230 Vac to 12 Vdc to operate the unit’s controls and

refrigeration components.

Fuses

The electrical components are protected by various fuses.

MMaaiinn PPoowweerr FFuussee - The main power fuse is located in the vehicle’s engine

compartment and is connected directly to the vehicle’s battery.

This 60 amp in-line fuse is non-serviceable and must only be replaced by an

authorized Thermo King Dealer.

IIggnniittiioonn PPoowweerr FFuussee - The ignition power fuse is connected to the vehicle’s

fused ignition system. Depending on the vehicle, the location of the fuse

panel could be located inside the cab or under the hood of the vehicle.

UUnniitt CCoommppoonneenntt FFuusseess - These fuses are located in the condenser unit.

Remove the condenser cover to access them. Depending on your model,

some fuses may not be used. Refer to ()Refer to (“Electrical Control

System,” p. 46).

Figure 11. Fuse Location (condenser cover removed)

28

TK 61651-18-OP-EN

Page 29

UUnniitt DDeessccrriippttiioonn

Pharma

Single and Multi-temperatures temperature Units qualified for

pharmaceutical applications under Thermo King protocol are configured

with specific Pharma configuration file and parameters loaded during

commissioning by your local dealer. Evaporators fans have to run during the

Null Cycle.

ThermoKing recommends to run the unit with the recommended Setpoints

below:

Table 1. Single Temperature units:

Temperature Range

Temperature between +15°

C and +25°C

Temperature between 15°C

and 25°C

Table 2. Multi-Temperature units:

Temperature Range

Temperature between +15°

C and +25°C

Temperature between 15°C

and 25°C

Recommended

Setpoint

+20°C

+5°C +/- 2°C of setpoint

Recommended

Setpoint

+20°C

+6°C +/- 2°C of setpoint

Max Deviation Setpoint

+1/- 2°C of setpoint

Max Deviation Setpoint

+/- 2°C of setpoint

Efficient loading practices and operating procedures have to be followed to

ensure optimum air circulation and temperature management.

TK 61651-18-OP-EN

29

Page 30

Operating Instructions

General Operation

In truck-driven units, temperature control is based on two values: The setting

(Setpoint) of the electronic thermostat and the evaporator return

temperature. The difference between these two temperatures will determine

the mode of operation: cool, heat, or null.

• CCooooll:: When the temperature in the load compartment is higher than the

setpoint, the unit runs in cool mode to reduce the evaporator return

temperature.

• HHeeaatt:: When the temperature in the load compartment is lower than the

setpoint, the unit changes to heat mode to raise the evaporator return

temperature.

• NNuullll:: Once the Setpoint Temperature has been reached, and while the

temperature remains between XºC/F above or below the setpoint, there is

no demand for transfer of heat or cold, and the unit runs in null mode.

• DDeeffrroosstt:: After a scheduled period of time in cool mode, between 1 and 8

hours, the unit runs in this fourth mode of operation to eliminate ice that

has accumulated in the evaporator or condenser coil. Defrost can be

initiated automatically or manually.

Factory setting for X is 3ºC (5ºF). During unit installation, this value can be

adjusted by between 1 and 5ºC (2 and 9ºF) in increments of 1ºC/F.

UUnniittss wwiitthh RR--113344aa rreeffrriiggeerraanntt:: Temperatures can be controlled from -20ºC

to +22ºC (-4ºF to +71ºF).

30

TK 61651-18-OP-EN

Page 31

OOppeerraattiinngg IInnssttrruuccttiioonnss

UUnniittss wwiitthh RR--440044AA //RR--445522AA rreeffrriiggeerraanntt:: Temperatures can be controlled

from -32ºC to +22ºC (-26ºF to +71ºF).

Address:

Sant Josep, 140-142 P.I. “El Pla”,

Sant Feliu de Llobregat,

Barcelona, Spain.

YYeeaarr ooff mmaannuuffaaccttuurree:: Reference Serial Plate.

Installation and commissioning are to be carried out by an authorised

Thermo King Dealer in accordance with Thermo King procedures and

drawings. Exceptions to this with the written authorisation of the

manufacturer only.

Starting the Unit

Engine Operation

1. Start the vehicle.

2. Press the On/Off Key located in the HMI. The HMI display will be

activated.

3. Check the setpoint, and adjust if necessary.

Electric Standby Operation

1. Connect the external power supply to the electric power receptacle.

Verify the power supply is of the correct voltage and phase for the unit.

WWAARRNNIINNGG

HHaazzaarrddoouuss VVoollttaaggee!!

In case of outdoor conditions, ensure that the connection is made under

safe conditions.

2. Press the On/Off Key located in the HMI. The HMI display will be

activated. The electric symbol will appear on the screen.

3. Check the setpoint, and adjust if necessary.

TK 61651-18-OP-EN

31

Page 32

OOppeerraattiinngg IInnssttrruuccttiioonnss

NNootteess::

1. Regular monitoring of the unit is recommended, the frequency of

this monitoring will depend on the type of cargo.

2. The operating mode, whether engine-driven or electric standby, is

selected automatically. When the unit is connected to an electric

power source, engine-driven operation is automatically blocked.

If the truck engine is started up while the power cable is still

connected to the electrical power source, the unit will continue to

operate in electric standby mode and the buzzer will be activated.

Standard Display

This is the display that appears when the On/Off key is pressed and the unit

started. It normally displays the return air temperature (of both load

compartments in bi-temperature units) and the current operating mode with

the appropriate symbol.

Should there be an alarm, the alarm symbol will also appear on screen.

Single Temperature Units

The example below shows 10.8ºC temperature, cool mode, and standby

operation.

Multi-Temperature Units

The example below shows -10ºC temperature and cool mode in the main

compartment, and 2ºC temperature and heat mode in the remote

compartment. Unit running in on-the-road mode.

32

TK 61651-18-OP-EN

Page 33

OOppeerraattiinngg IInnssttrruuccttiioonnss

Entering Setpoint Temperature

The Setpoint Temperature can be quickly and easily changed.

Single Temperature Units

1. Press and release the Select key twice (three times for reverse cycle

units), and the current Setpoint Temperature and the letters SP will

appear on screen.

2. Press the Up or Down arrow keys to select the desired Setpoint

Temperature. Each time either of these buttons is pressed and released,

the Setpoint Temperature will change one degree.

3. Press and release the Enter key to set the setpoint or press and release

the Select key to set the setpoint and return to the Standard Display.

IImmppoorrttaanntt:: If the Select key or the Enter key is not pressed within 20

seconds to select the new Setpoint Temperature, the unit will

continue to run at the original Setpoint Temperature.

Multi-Temperature Units

NNoottee:: Since software MSK 544.03, Thermo King has introduced a Zone

Priority function which allows Spectrum units to provide cooling or

heating priority for a specific zone to satisfy setpoint as soon as

possible. Contact your local dealer for detailed information.

TK 61651-18-OP-EN

33

Page 34

OOppeerraattiinngg IInnssttrruuccttiioonnss

1. MMaaiinn LLooaadd CCoommppaarrttmmeenntt:: Press and release the SELECT key twice, and

the current Setpoint Temperature in the main compartment and the

letters SP will appear on screen.

2. Press the UP or DOWN arrow keys to select the desired Setpoint

Temperature. Each time either of these buttons is pressed and released,

the Setpoint Temperature will change one degree.

3. Press and release the ENTER key to set the setpoint or press and release

the SELECT key to set the setpoint and to change to the RReemmoottee

CCoommppaarrttmmeenntt Setpoint Temperature Setting Screen.

IImmppoorrttaanntt:: If the Select key or the Enter key is not pressed within 20

seconds to select the new Setpoint Temperature, the unit will

continue to run at the original Setpoint Temperature.

4. RReemmoottee LLooaadd CCoommppaarrttmmeenntt:: The present Setpoint Temperature in the

remote compartment and the letters SP2 will appear on screen.

5. Press the UP or DOWN arrow keys to select the desired Setpoint

Temperature. Each time either of these buttons is pressed and released,

the Setpoint Temperature will change one degree.

6. Press and release the Enter key to set the set point value or press and

release the SELECTION key to set the set point and move to the CCSSEE

((CCoommppaarrttmmeenntt SSeelleeccttiioonn)) screen.

IImmppoorrttaanntt:: If the Select key or the Enter key is not pressed within 20

seconds to select the new Setpoint Temperature, the unit will

continue to run at the original Setpoint Temperature.

34

TK 61651-18-OP-EN

Page 35

OOppeerraattiinngg IInnssttrruuccttiioonnss

Compartment Selection

1. Press the key UP or DOWN to change option between the four different

options available:

• 11--22:: This is the standard multi-temperature setting where both

compartments (zones) are active.

– The screen shows the temperature in both compartments (zones).

• CC11:: Compartment 1 is active while Compartment 2 is disabled.

– Only the temperature for compartment 1 appears on the screen,

while no reading is shown for compartment 2.

TK 61651-18-OP-EN

35

Page 36

OOppeerraattiinngg IInnssttrruuccttiioonnss

• CC22:: Compartment 2 is active while Compartment 1 is disabled.

– Only the temperature for compartment 2 appears on the screen,

while no reading is shown for compartment 1.

• 11--11:: Compartments 1 and 2 are combined to operate as a single-

temperature unit; only the temperature for Compartment 1 is

displayed.

36

TK 61651-18-OP-EN

Page 37

OOppeerraattiinngg IInnssttrruuccttiioonnss

– The screen shown as that of a single-temperature unit but with

the triangle symbol activated to indicate that it is actually a bitemperature unit operating as a single-temperature unit.

2. Press and release the ENTER key to select an option or press and release

the SELECTION key to select an option and return to the standard screen.

IImmppoorrttaanntt:: If the Select key or the Enter key is not pressed within 20

seconds to select the new Setpoint Temperature, the unit will

continue to run at the original Setpoint Temperature.

Initiating the Evaporator Manual Defrost Cycle

IImmppoorrttaanntt:: Before initiating a manual defrost, ensure that the unit is not

already in a defrost cycle. When the unit is in a defrost cycle the

defrost symbol appears on screen.

1. Press and release the Select key once, and the letters dEF will appear

(flashing) on screen along with the present defrost condition OFF.

2. To activate manual defrost, press the Enter key and then the Up or Down

key and the defrost condition will change to On.

TK 61651-18-OP-EN

37

Page 38

OOppeerraattiinngg IInnssttrruuccttiioonnss

3. Press the Select key twice to return to the Standard Display (three times

in bi-temperature units and in reverse cycle units), where the letters dEF

and the DEFROST symbol will appear when the defrost cycle starts (the

load compartment temperature must be lower than 0ºC).

NNoottee:: The letters dEF will remain on screen for a while after returning to cool

mode.

Initiating the Condenser Manual Defrost Cycle (reverse cycle units only)

IImmppoorrttaanntt:: Before initiating a manual defrost, ensure that the unit is not

already in a defrost cycle. When the unit is in a defrost cycle the

defrost symbol appears on screen.

1. Press and release the Select key twice, and the letters dFC will appear

(flashing) on screen along with the present defrost condition OFF.

38

TK 61651-18-OP-EN

Page 39

OOppeerraattiinngg IInnssttrruuccttiioonnss

2. To activate manual defrost, press the Enter key and then the Up or Down

key and the defrost condition will change to On.

3. Press the Select key twice to return to the Standard Display where the

letters dFC and the DEFROST symbol will appear when the defrost cycle

starts (the outside ambient temperature must be lower than 0ºC).

TK 61651-18-OP-EN

39

Page 40

OOppeerraattiinngg IInnssttrruuccttiioonnss

Alarms

When the unit is not operating properly, the microprocessor records the

alarm code, alerts the operator by displaying the Alarm symbol and,

depending on the type of alarm, shuts the unit down.

TThheerree aarree tthhrreeee aallaarrmm ccaatteeggoorriieess::

Manual Start

The alarm stops the unit, and only the Alarm symbol appears on screen.

Once the alarm condition has been rectified, the On/Off key must be pressed

to start up again.

Press and release the Select key to display the current alarm code on screen.

If there is more than one active alarm, all the alarm codes on the unit can be

viewed in sequence by pressing and releasing the Select key.

Auto Start

The alarm stops the unit, the Alarm symbol appears on screen and the unit

starts up automatically once the alarm condition has been rectified.

Should a PP11EE alarm occur (return air temperature read error alarm code)

appear, — will appear on screen together with the alarm symbol, instead of

the return air temperature reading.

40

TK 61651-18-OP-EN

Page 41

OOppeerraattiinngg IInnssttrruuccttiioonnss

If it is a multi-temperature unit, the — will appear on the screen together with

the alarm symbol, instead of the main compartment return air temperature

reading.

In multi-temperature units, should a PP22EE - return air temperature read error

in the remote compartment alarm code - appear, — will also appear on

screen together with the alarm symbol, instead of the remote compartment

return air temperature reading.

Press and release the Select key to display the current alarm code on screen.

If there is more than one active alarm, all the alarm codes on the unit can be

viewed in sequence by pressing and releasing the Select key.

Buzzers

The buzzers are energized when the vehicle battery and the electrical supply

are connected simultaneously (the unit continues running in Standby mode).

The buzzers are also energized if the doors open, if this option is selected.

TK 61651-18-OP-EN

41

Page 42

OOppeerraattiinngg IInnssttrruuccttiioonnss

Alarm Code Descriptions DSR

Alarm Description

Manual Start

OL Electric Motor Overload (Electric standby models only) - The

bAt Low Battery Voltage - Check vehicle battery.

Auto Start

HP High Pressure Alarm - The system has detected excessively high

LP Low Pressure Alarm - The system has detected excessively low suction

PSE High Pressure Sensor Failure - The high pressure sensor has become

dr1, dr2 Cargo Doors Are Open (Units with door switch option only) - Doors

tCO Control Module Overheating

SOF Software Failure

P1E Faulty Cargo Box Return Air Temperature Sensor - Faulty or

P2E

C Communications Failure

electric motor overload relay has tripped due to excessive current draw.

If the problem persists when the unit is restarted, contact your Thermo

King Dealer.

discharge pressure.

If the problem persists when the unit is restarted, contact your Thermo

King Dealer.

pressure.

If the problem persists when the unit is restarted, contact your Thermo

King Dealer.

faulty or disconnected.

Contact your Thermo King Dealer.

are open, faulty door switches, or improper door switch configuration.

Contact your Thermo King Dealer.

If the problem persists when the unit is restarted, contact your Thermo

King Dealer.

Contact your Thermo King Dealer.

disconnected return air temperature sensor.

Contact your Thermo King Dealer.

Remote Cargo Box Return Air Temperature Reading Error (open

circuit or short-circuit)

Contact your Thermo King Dealer.

Contact your Thermo King Dealer.

42

TK 61651-18-OP-EN

Page 43

OOppeerraattiinngg IInnssttrruuccttiioonnss

Clearing Alarm Codes

The alarm condition in the unit must first be corrected. See important note

below. After resolving the alarm condition, press and release the Select key

to remove existing Alarm codes. The Standard Display will appear once the

Alarm codes have been cleared.

TToo CClleeaarr AAllaarrmm CCooddeess::

• Correct the cause of the alarm code.

• Press the Select key to remove the alarm code.

• If more than one alarm code is present, press the Select key to clear each

alarm code individually.

IImmppoorrttaanntt:: Continually clearing alarm codes without resolving the problem

will result in damage to the unit and compressor.

Viewing Information Screens

Main Menu

From the Standard Display use the Select key to display:

1. Alarms (if any active).

2. Evaporator Manual Defrost.

3. Condenser Manual Defrost (reverse cycle units only).

4. Temperature Setpoint.

Hourmeter Menu

From the Standard Display press the Select key for three seconds to open

the Hourmeter Menu, then use the Select key to display:

NNoottee:: For units with firmware version 380.03 and earlier: The unit of

measurement is tens of hours (e.g., 150 = 1500 hours). For units with

firmware version 380.06 and later: The unit of measurement is hours.

1. HHCC:: Hours remaining to maintenance notice.

2. ttHH:: The total amount of time the unit has been switched on protecting the

load.

3. CCCC:: Engine driven compressor operating hours.

4. EECC:: Electric standby compressor operating hours.

5. Return to Main Menu.

TK 61651-18-OP-EN

43

Page 44

Loading and Inspection Procedures

This chapter describes pre-loading inspections, loading procedures, postloading procedures, post-loading inspections and enroute inspections.

Thermo King refrigeration units are designed to maintain the required

product load temperature during transit. Follow these recommended loading

and enroute procedures to help minimize temperature related problems.

Post-Start Inspection

TThheerrmmoossttaatt:: Adjust the thermostat setting to above and below the

compartment temperature to check thermostat operation (see Operating

Modes).

PPrree--ccoooolliinngg:: With the thermostat set at the desired temperature, run the

unit for half-an-hour to one hour (or longer if possible) before loading the

truck. Pre-cooling eliminates residual heat and acts as a good test of the

refrigeration system.

DDeeffrroosstt:: When the unit has finished pre-cooling the truck interior - the

evaporator temperature should have dropped below 2ºC (35.6ºF) - initiate a

defrost cycle with the manual defrost switch. The defrost cycle should stop

automatically.

Loading Procedure

1. To minimise frost accumulation in the evaporator coil and a heat

increase inside the load compartment, ensure that the unit is OFF before

opening the doors (The unit may continue to run when the truck is being

loaded in a warehouse with the doors closed).

2. Carefully check and record the load temperature when loading the truck.

Note whether any products are out of temperature range.

3. Load the product in such a way that there is sufficient space for the air to

circulate throughout the load. DO NOT block the evaporator inlet or

outlet.

4. Product should be pre-cooled before loading. Thermo King units are

designed to maintain the load at the temperature at which it is loaded.

Transport refrigeration units are not designed to reduce the load

temperature.

Post Load Procedure

1. Verify all doors are closed and locked.

44

TK 61651-18-OP-EN

Page 45

LLooaaddiinngg aanndd IInnssppeeccttiioonn PPrroocceedduurreess

2. Adjust the thermostat to the desired temperature setpoint.

3. Start the unit.

4. Half an hour after loading the truck, defrost the unit for a moment by

pressing the Manual Defrost switch. If the coil temperature drops to

below 2ºC (35.6ºF), the unit will defrost. The defrost cycle should stop

automatically.

TK 61651-18-OP-EN

45

Page 46

Specifications

Refrigeration System

Contact your Thermo King dealer for refrigeration system service or

maintenance.

Compressor

V-100/

V-200s

Compressor Model QP08N QP13 QP15 QP16 QP21

Displacement (cc) 82 131 146.7 163 215

Number of cylinders

6 6 6 6 10

V-200 V-300 V-500/

V-600

V-800

Electrical Control System

12 Vdc 24 Vdc

Fuses

Common Fuses

Fuse 3: Evaporator Fan Motor (EFM1) 15 amps 10 amps

Fuse 4: Evaporator Fan Motor (EFM2) 15 amps 10 amps

Fuse 5: Roadside (Engine) Compressor Clutch

(CCL1), Liquid Injection Switch (LIS), Liquid

Injection Valve (LIV), EVAP1 Defrost Hot Gas

Solenoid Valve (PS1), Compressor Motor Contactor

(CMC), Heat Pilot Solenoid (PS5)

Fuse 14: Vehicle Ignition Switch 5 amps 5 amps

Fuse 30: Condenser Fan Motor (CFM) (located in

CF1 wire near terminal strip in condenser section)

20 amps 10 amps

16 amps 10 amps

V-100/V-200s

Fuse 6: Condenser Fan 1/2 2 amps 2 amps

Fuse 21: Battery Power Supply (located in 2 wire

near battery)

46

30 amps 30 amps

TK 61651-18-OP-EN

Page 47

SSppeecciiffiiccaattiioonnss

V-200/V-300 and Spectrum

Fuse 6: Condenser Fan 1/2 2 amps 2 amps

Fuse 8: (Spectrum Only) EVAP2 Liquid Solenoid

Valve (PS2), EVAP1 Liquid Solenoid Valve (PS3),

EVAP2 Defrost Hot Gas Solenoid Valve (PS4), Drain

Heaters 3 and 4 (HT3, HT4)

Fuse 9: (Spectrum Only) Evaporator Fan 3 15 amps 10 amps

Fuse 10: (Spectrum Only) Evaporator Fan 4 15 amps 10 amps

Fuse 11: Drain Heaters (H1 and H2) 2 amps 2 amps

Fuse 20: Transformer AC Power Supply (located at

compressor motor contactor in condenser section)

Fuse 21: Battery Power Supply (located in 2 wire

near battery)

V-500/V-600 and Spectrum

Fuse 6: Condenser Fan 1/2 10 amps 7.5 amps

Fuse 8: (Spectrum Only) EVAP2 Liquid Solenoid

Valve (PS2), EVAP1 Liquid Solenoid Valve (PS3),

EVAP2 Defrost Hot Gas Solenoid Valve (PS4), Drain

Heaters 3 and 4 (HT3, HT4)

Fuse 9: (Spectrum Only) Evaporator Fan 3 15 amps 10 amps

Fuse 10: (Spectrum Only) Evaporator Fan 4 15 amps 10 amps

Fuse 11: Drain Heaters (H1 and H2) 2 amps 2 amps

Fuse 17: Drain Heaters (H3 and H4) 2 amps 2 amps

Fuse 20: Transformer AC Power Supply (located at

compressor motor contactor in condenser section)

Fuse 21: Battery Power Supply (located in 2 wire

near battery)

Fuse 31: Condenser Fan Motor 2 (CFM2) (located in

CF2 wire near terminal strip in condenser section)

20 amps 10 amps

4 amps 4 amps

40 amps 40 amps

20 amps 10 amps

4 amps 4 amps

50 amps

(Single Temp)

16 amps 10 amps

60 amps (MultiTemp)

TK 61651-18-OP-EN

47

Page 48

SSppeecciiffiiccaattiioonnss

V-800 and Spectrum

Fuse 6: Drain Heaters 1/2 2 amps 2 amps

Fuse 8: (Spectrum Only) EVAP2 Liquid Solenoid

Valve (PS2), EVAP1 Liquid Solenoid Valve (PS3),

EVAP2 Defrost Hot Gas Solenoid Valve (PS4), Drain

Heaters 3 and 4 (HT3, HT4)

Fuse 9: (Spectrum Only) Evaporator Fan 3 15 amps 10 amps

Fuse 10: (Spectrum Only) Evaporator Fan 4 15 amps 10 amps*

Fuse 11: Drain Heaters (H3 and H4) 2 amps 2 amps

Fuse 15: TracKing 5 amps 5 amps

Fuse 16: TracKing 5 amps 5 amps

Fuse 17: TracKing 5 amps 5 amps

Fuse 20: Transformer AC Power Supply (located at

compressor motor contactor in condenser section)

Fuse 21: Battery Power Supply (located in 2 wire

near battery)

Fuse 31: Condenser Fan Motor 2 (CFM2) (located in

CF2 wire near terminal strip in condenser section)

Note: * 15 A in Spectrum Versions with Double Evaporator Fan 4

Condenser Fan Motor (All except V-800)

Voltage 13 Vdc 26 Vdc

Full Load Current 10 Amps 4.7 Amps

Power Rating 130 W 122 W

RPM with Full Load 2,800 2,800

20 amps 10 amps

2 x 2 amps 2 x 2 amps

2 x 30 amps 2 x 30 amps

16 amps 10 amps

Condenser Fan Motor (V-800)

Voltage 13 Vdc 26 Vdc

Full Load Current 11 Amps 9 Amps

Power Rating 145 W 230 W

RPM with Full Load

48

2,670 2,900

TK 61651-18-OP-EN

Page 49

SSppeecciiffiiccaattiioonnss

Evaporator Fan Motors (Each)

Voltage 13 Vdc 26 Vdc

Full Load Current 7.5 Amps 4 Amps

Power Rating 97.5 W 104 W

RPM with Full Load 2,800 2,800

Transformer

Power 500 VA

Frequency 50/60 Hz

Primary Inputs 115-208-230 Vac

Secondary Nominal Voltage 11.7 Vac (21.4 Amps)

TK 61651-18-OP-EN

49

Page 50

SSppeecciiffiiccaattiioonnss

Electric Motor (Model 50)

AC Electric Compressor Motors and Overload Relays

Voltage/

Phase/

Frequency

V-100/V-200s

230/1/50 2.0 1.5 1750 5.4 5.5

V-200/V-300

230/1/50 2.0 1.5 1750 8.6 8.6

230/1/60 2.0 1.5 1750 9 9

230/3/60 2.4 1.8 1750 6.9 6.9

400/3/50 2.4 1.8 1750 4 4

400/3/60

V-500/V-600

115/1/60 1.5 1.1 1710 14 14

208/1/60 2.0 1.5 1740 9.5 9.5

230/1/60

208/3/60 2.4 1.8 1730 7.2 7.2

230/3/60 2.4 1.8 1750 6.9 7

V-800 (ES600+2xES150)

230/3/50 2.4 1.8 1750 66.6/9.6

230/3/60 2.4 1.8 1750 19.9/11.5

Horse-

power

2.4 1.8 1750 4 4

2.0 1.5 1750 9 9

Kilowatts

RPM

Full Load

(amps)

amps

amps

Overload

Relay

Setting

(amps)

9.6

11.5

TracKing

Platform ARM Cortex-A8, 300MHz, 256MB RAM, 4GB Flash, Linux

GSM/GPRS 3G, Sierra HL8548

GPS u-blox NEO-7M

50

TK 61651-18-OP-EN

Page 51

SSppeecciiffiiccaattiioonnss

Bluetooth Version 4.0 Bluetooth Classic /Bluetooth Low Energy (BLE)

Serial Ports 2 External Serial Ports for TracKing extensions or Third-

Input Power 12V Nominal

Backup Battery Single cell Li-Ion 3.7V Nominal, > 2Ah

Environmental Storage

Temperature

Party Connect

-40 to +85 C

TK 61651-18-OP-EN

51

Page 52

Warranty

Please contact your nearest Thermo King dealer for terms of the Thermo

King North American Trailer Unit Limited Warranty.

Please also refer to TK 61654-18-WA Thermo King EMEA Unit Limited

Warranty for Vehicle Powered Truck Units.

52

TK 61651-18-OP-EN

Page 53

Inspection and Service Intervals

Weekly Pre-Trip Checks

1. Visually inspect belt.

2. Listen for unusual noises, vibrations, etc.

3. Visually inspect unit for fluid leaks (coolant, oil, refrigerant).

4. Visually inspect unit for damaged, loose or broken parts (including air

ducts and bulkheads, if so equipped).

5. In the event of excess of dirt or obstruction clean the unit, including

condenser and evaporator coils.

Weekly Pretrip Inspection

The following Weekly Pretrip Inspection should be completed before starting

the unit and loading the truck. While the weekly inspection in not a substitute

for regularly scheduled maintenance inspections, it is important part of the

preventive maintenance program designed to head off operating problems

before they happen.

LLeeaakkss:: Inspect for refrigerant leaks and worn refrigerant lines.

BBaatttteerryy:: Terminals should be properly tightened and show no signs of

corrosion.

BBeellttss:: Inspect for cracks, wear, and proper belt tension.

MMoouunnttiinngg BBoollttss:: Verify bolts are properly tightened.

EElleeccttrriiccaall:: Electrical connections should be securely fastened. Wires and

terminals should be free of corrosion, cracks, or moisture.

SSttrruuccttuurraall:: Visually check for physical damage.

CCooiillss:: The condenser and evaporator coils (evaporator coils in bitemperature units) should be clean and free of debris.

• Washing with clean water should be sufficient. The use of cleaning

agents or detergents is strongly discouraged due to the possibility of

degradation of the construction. If using a power washer, the nozzle

pressure should not exceed 600 psi (41 bar). For the best results, spray

the coil perpendicular to the face of the coil. The spray nozzle should be

kept between 1 inch and 3 inches (25 to 75 millimetres) from the coil

surface. If necessary to use a chemical cleaner or detergent use a cleaner

that does not contain any hydrofluoric acids and is between 7 and 8 on

the pH scale. Ensure dilution instructions provided by the detergent

supplier are followed. In case of doubt about the compatibility of the

TK 61651-18-OP-EN

53

Page 54

IInnssppeeccttiioonn aanndd SSeerrvviiccee IInntteerrvvaallss

detergent with the type of materials listed above, always ask the supplier

a written confirmation of the compatibility. Should a chemical cleaner be

required, it is MANDATORY that all components are thoroughly rinsed

with water even if the instructions of the cleaner specify that it is a “no

rinse” cleaner. Failure to comply with above mentioned guidelines will

lead to a shortened life of the equipment to an indeterminable degree.

The repeated transportation of meat and fish waste can cause extensive

corrosion to the evaporator coils and evaporator section tubing over time

due to ammonia formation and can reduce the lifespan of the coils.

Appropriate additional measures should be taken to protect the coils

against the aggressive corrosion that can result from transportation of

such products.

LLooaadd CCoommppaarrttmmeenntt:: Inspect the interior and exterior of the truck for any

damage. Any damage to the walls or insulation should be repaired.

DDeeffrroosstt DDrraaiinnss:: Check the defrost drain hoses and fittings to ensure they are

not blocked.

DDoooorrss:: Verify doors and weather seals are in good condition and seal

hermetically.

SSiigghhtt ggllaassss:: Check that the refrigerant charge sight glass on the running

unit is totally full (the cargo compartment temperature must be

approximately 0ºC).

Weekly Post-Trip Checks

NNOOTTIICCEE

EEqquuiippmmeenntt DDaammaaggee!!

Do not use pressurised water.

1. Clean the outside cover of the unit. Use a damp cloth and neutral

detergents. Do not use harsh cleaning products or solvents.

2. Check for leaks.

3. Check for loose or missing hardware.

4. Check for physical damage to the unit.

Inspection and Service Schedules

To ensure that your Thermo King unit operates reliably and economically

over its full life, and to avoid limiting its warranty cover, the appropriate

inspection and service schedule must be followed. Inspection and Service

intervals are determined by the number of unit operating hours and by the

54

TK 61651-18-OP-EN

Page 55

IInnssppeeccttiioonn aanndd SSeerrvviiccee IInntteerrvvaallss

age of the unit. Examples are shown in the table below. Your Dealer will

prepare a schedule to suit your specific needs.

Operating

Hours

per Year

Inspection 6 months/ 500 hours

Inspection 12 months/ 1000 hours

Inspection 18 months/ 1500 hours 12 months/ 2000 hours

Full

Service

1000 2000 3000

6 months/ 1000 hours 4 months/ 1000 hours

(+ warranty

Inspection)

8 months/ 2000 hours

(+ warranty

Inspection)

24 months/ 2000 hours 18 months/ 3000 hours 12 months/ 3000 hours

(+ warranty

Inspection)

(continue as above) (continue as above) (continue as above)

Service Record

Each inspection and service performed should be recorded on the Service

Record Sheet found at the back of this manual.

Warranty Inspection

The unit must be presented at the buyers expense at an authorised Thermo

King dealer or service provider for an inspection. The inspection will verify

that the unit has been correctly maintained and any upgrades or repairs

deemed necessary will be carried out. Subject to a satisfactory inspection,

the second twelve months warranty cover will be authorised. This is

illustrated in the table above.

Preventive Maintenance

Refer to the previous page for checks that should be carried out daily/weekly

on the unit. Please work with your Dealer in order to create a maintenance

schedule which fits your needs.

TK 61651-18-OP-EN

55

Page 56

Serial Number Locations

1. CCOONNDDEENNSSEERR:: Nameplate located on the front inside edge of condenser

frame (Cover needs to be removed).

2. SSTTAANNDDBBYY CCOOMMPPRREESSSSOORR:: 20 and 50 Models only. Nameplate located

on standby compressor body. Standby compressor is located inside the

Condenser.

3. EENNGGIINNEE DDRRIIVVEENN CCOOMMPPRREESSSSOORR:: Nameplate located on compressor

body. Engine driven compressor is located in the vehicle’s engine

compartment.

Figure 12. Condenser and Standby Compressor Serial Number Locations

Figure 13. Engine Driven Compressor Serial Number Location

56

TK 61651-18-OP-EN

Page 57

Recover Refrigerant

At Thermo King®, we recognize the need to preserve the environment and

limit the potential harm to the ozone layer that can result from allowing

refrigerant to escape into the atmosphere.

We strictly adhere to a policy that promotes the recovery and limits the loss

of refrigerant into the atmosphere.

In addition, service personnel must be aware of Federal regulations

concerning the use of refrigerants and the certification of technicians. For

additional information on regulations and technician certification programs,

contact your local THERMO KING dealer.

TK 61651-18-OP-EN

57

Page 58

NNootteess

58

TK 61651-18-OP-EN

Page 59

NNootteess

TK 61651-18-OP-EN

59

Page 60

Ingersoll Rand (NYSE: IR) advances the quality of life by creating comfortable,

sustainable and efficient environments. Our people and our family of brands —

including Club Car

®

, Ingersoll Rand®, Thermo King®and Trane®—work together

to enhance the quality and comfort of air in homes and buildings; transport and

protect food and perishables; and increase industrial productivity and efficiency.

We are a global business committed to a world of sustainable progress and

enduring results.

ingersollrand.com

Ingersoll Rand has a policy of continuous product and product data improvements and reserves the

right to change design and specifications without notice.

We are committed to using environmentally conscious print practices.

TK 61651-18-OP-EN 03 Dec 2018

Supersedes TK 51916-18-OP-EN (January 2016) ©2018 Ingersoll Rand

Loading...

Loading...