Page 1

V250

TK 40839-1-MM (Rev. 2, 1/99)

©

Copyright

Printed in U.S.A.

1994 Thermo King Corp., Minneapolis, MN, U.S.A.

Page 2

The maintenance information in this manual covers unit models:

V250 10 (914500) Condenser 10 Plus (085067)

V250 20 Generic (085007) Condenser 10 Plus UK (085068)

V250 LOTEMP (715394) Kit - low temperature (715394)

Condenser 10 (085001) E1000 Evaporator (085031)

Evaporator - Thin Line (085003) E1000E Evaporator (085034)

V250 115/1/60 Standby (085009) V250/E1000E Evaporator (085041)

Evaporator (085005) V250 Converte (085066)

For further information, refer to…

V250 Parts Manual TK 40834

Diagnosing Thermo King Refrigeration Systems TK 5984

Tool Catalog TK 5955

V250 Operating Manual TK 40836

Installation Manual TK 41156

The information in this m anual is provided to as sist owners, operat ors and service peo ple in the proper upk eep

and maintenance of Thermo King units. For detailed descriptions of Thermo King engines, compressors, or

refrigeration systems , see the app ropria te Thermo King Over haul Man ual or Ref rigerat ion Syste ms Main tenanc e

Manual.

This manual is published for informational purposes only and the information so provided should not be considered

as all-inclusive or covering all c ont ing enc ie s. If fu rt her i nformation is required, T h er mo Ki ng C or por ation should be

consulted.

Sale of product shown in this manual is subject to Thermo King’s terms and conditions including, but not limited to,

the Thermo King Limited Express Warranty. Such terms and conditions are available upon request.

Thermo King’s warranty will not appl y to any equipm ent which has been “so r epaired or alter ed outside the manufacturer’s plants as, in the manufacturer’s judgment, to effect its stability.”

No warranties, express or implied, including warranties of fitness for a particular purpose or merchantability, or warr anties ar ising from c ourse o f dea ling or usage of trade, a re made rega rding the information , recommendations, and descriptions contained herein. Manufacturer is not responsible and will not be held

liable in contract or in tort (including negligence) for any special, indirect or consequential damages,

including injury or damage caused to vehicles, contents or persons, by reason of the installation of any

Thermo King product or its mechanical failure.

Page 3

Recover Refrigerant

At Thermo King, we recognize the need to pr eserve the

environment and limit the potential harm to the ozone

layer that can result from allowing refrigerant to escape

into the atmosphere.

We strictly adhere to a policy that promotes the recovery

and limits the loss of refrigerant into the atmosphere.

In addition, service personnel must be a ware of Federal

regulations concerning the use of refrigerants and the

certification of technicians. For additional informatio n on

regulations and technician certification programs, contact your local THERMO KING dealer.

R-404A R-134a

WARNING: Use ONLY Polyol Ester based refrigeration compressor oil (TK P/N 203-413) in

R-404A and R-134a units.

DO NOT use Polyol Ester based oil in standard Thermo King units.

DO NOT mix Polyol Ester and standard synthetic compressor oils.

Keep Polyol Ester compressor oil in tightly sealed containers. If Polyol Ester oil becomes

contaminated with moisture or standard oils, dispose of properly—DO NOT USE!

WARNING: When servicing Thermo King R-404A and R-134a units, use only those service

tools certified for and dedicated to R-404A or R-134a refrigerant and Polyol Ester

compressor oils. Residual non-HFC refrigerants or oils will contaminate R-404A and R-134a

systems.

Page 4

Table of Contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Maintenance Inspection Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unit Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Liquid Injection System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Oil Separator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Unit Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Unit Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Protection Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Optional Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Serial Number Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Unit Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Unit Protection Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Unit Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Bi-monthly Pre-Trip Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Starting the Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Adjusting the Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

After Start Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Loading Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Post Loading Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Bi-monthly Post Trip Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Electrical Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Unit Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Cab Control Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Selecting the Temperature Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Selecting the Setpoint Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Setpoint Differential Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Testing the Cab Control Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Display Diagnosis Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Thermostat Switch Sequence Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Defrost System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Engine Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Electric Standby Operation (Model 20) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Defrost Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

V250 Defrost System and P.C. Board Identification and Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

P.C. Board Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Troubleshooting the V250 Defrost System with P.C. Board P/N 41-776 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Troubleshooting the V250 Defrost System with P.C. Boards P/N 41-1619 and P/N 41-1812 . . . . . . . . . . . . . .44

Page 5

Table of Contents (continued)

Electrical Maintenance (continued)

P.C. Board P/N 41-776 Test Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

P.C. Board P/N 41-1812 and P/N 41-1619 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

M10 (V250/V-090) Cab Control Box Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Condenser Fan Pressure Switch (CFPS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

AC Components (Model 20) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Contactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Overload Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Electric Standby Circuits (Model 20 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

12 Volt System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Evaporator Heaters (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Refrigeration Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Refrigerant Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Charging the Refrigeration System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Checking the Refrigerant Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Checking Compressor Oil Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

High Pressure Cutout Switch (HPCO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Low Pressure Cutout Switch (LPCO). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Cleanup Procedure for Small Truck Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Refrigeration Service Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Condenser Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Drier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Receiver Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

High Pressure Cutout and Condenser Fan Pressure Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Hot Gas Solenoid Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Liquid Injection Solenoid Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Oil Separator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Liquid Injection Metering Orifice. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Testing the Liquid Injection Solenoid Valve and Metering Orifice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Check Valve Repair (Model 20 Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Evaporator Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Expansion Valve Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Low Pressure Cutout Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Suction Pressure Regulator Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Replacing Refrigerant Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Page 6

Table of Contents—(continued)

V-250 R-404A Conversion Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Structural Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Unit Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Evaporator Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Condenser Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Condenser Fan Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Unit Mounting Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Compressor and Clutch Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Clutch Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Clutch Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Shaft Seal Cover and Shaft Seal: Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Special Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

System Compressor and Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Checking the Oil Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Clutch Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Belt Tensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Engine/Compressor Belt and Pulleys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Electric Motor/Compressor Belt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Over-the-Road Mechanical Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Road Compressors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Electric Standby Mechanical Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Possible Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Remedy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Electric Standby Service Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

V250 Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

Wiring Diagrams and Schematic Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Page 7

Safety Precautions

GENERAL PRACTICES

1. ALWAYS WEAR GOGGLES OR SAFETY

GLASSES. Refrigerant liquid, refrigeration oil, and

battery acid can permanently damage the eyes (see First

Aid under Refrigeration Oil).

2. Never operate the unit with the compress or discharge

valve closed.

3. Keep your hands, clothing and tools clear of the fans

and belts when the unit is running. This sh ould also be

considered when opening and closing the compressor

service valves.

4. Make sure gauge manifold hoses are in good condition.

Never let them come in contact with a belt, fan motor

pulley, or any hot surface.

5. Never apply heat to a sealed refrigeration system or

container.

6. Fluorocarbon refrigerants, in the presence of an open

flame or electrical short, produce toxic gases that are

severe respiratory irritants capable of causing death.

REFRIGERANT

Although fluorocarbon refrigerants are classified as safe

refrigerants, certain precautions must be observed when

handling them or servicing a unit in which they are used.

When exposed to the atmosphere from the liquid state, fluorocarbon refrigerants evaporator rapidly, freezing anything

they contact.

First Aid

In the event of frost bite, the objectives of First Aid are to

protect the frozen area from further injury, to warm the

affected area rapidly and to maintain respiration.

• EYES: For contact with liquid, immediately flush eyes

with large amounts of water and get prompt medical

attention.

• SKIN: Flush area with large amounts of lukewarm

water. Do not apply heat. Remove contaminated clothing and shoes. Wrap burns with dry, sterile, bulky

dressing to protect from infection/injury. Get medical

attention. Wash contaminated clothing before reuse.

7. Make sure all mounting bo lts are tight an d are of correct length for their particular application.

8. Use extreme caution when drilling holes in the unit.

The holes may weaken structural components, and

holes drilled into electrical wiring can cause fire or

explosion.

9. Use caution when working around exposed coil fins.

The fins can cause painful lacerations.

10. Use caution when working with a refrigerant or refrigeration system in any closed or confined area with a

limited air supply (for example, a truck box or garage).

Refrigerant tends to displace air and can cause oxygen

depletion resulting in suffocation and possible death.

11. EPA Section 608 Certification is needed to work on

refrigeration systems.

• INHALATION: Move victim to fresh air an d use CPR

if necessary. Stay with victim until arrival of emergency medical personnel.

REFRIGERATION OIL

Avoid refrigeration oil contact with the eyes. Avoid prolonged or repeated contact of refrigeration oil with skin or

clothing. Wash thoroughly after handling refrigeration oil to

prevent irritation.

First Aid

In case of eye contact, immediately flush with plenty of

water for at least 15 minutes. Wash skin with soap and

water. CALL A PHYSICIAN.

i

Page 8

Safety Precautions (Rev 1/99)

ELECTRICAL HAZARDS

High Voltage

When servicing or repairing a refrigeration unit, the possibility of serious or even fatal injury from electrical shock

exists. Extreme care must be used when working with an

operating refrigeration unit. Lethal voltage potentials can

exist on connections in the high voltage tray of the control

box.

Precautions

1. When working on high v oltage circui ts on th e refrig eration unit, do not make any rapid moves. If a tool drops,

do not grab for it. People do not contact high voltage

wires on purpose. It occurs from an unplanned movement.

2. Use tools with insulated handles that are in good condition. Never hold metal tools in your hand if exposed,

energized conductors are within reach.

3. Treat all wires and connections as high voltage until a

meter and wiring diagram show otherwise.

4. Never work alone on high voltage circuits on the refrigeration unit, another person should always be standing

by in the event of an accident to shut off the refrigeration unit and to aid a victim.

5. Have electrically insulated gloves, cable cutters and

safety glasses available in the immediate vicinity in the

event of an accident.

First Aid

IMMEDIATE action must be initiated after a person has

received an electrical shock. Obtain immediate medical

assistance if available.

The source of shock must be immediately removed by

either shutting down the power or removing the victim from

the source. If it is not possible to shut off the power, the wire

should be cut with either an insulated instrument (e.g., a

wooden handled axe or cable cutters with heavy insulated

handles) or by a rescuer wearing electrically insulated

gloves and saf et y gl ass e s. Wh ic hev er me th od i s us ed do no t

look at the wire while it is being cut. The ensuing flash can

cause burns and blindness.

If the victim has to be removed from a live circuit, pull the

victim off with a non-conductive material. Use the victim’s

coat, a rope, wood, or loop your belt around the victim’s leg

or arm and pull the victim off. DO NOT TOUCH the victim.

You can receive a shock from current flowing through the

victim’s body. After separating the victim from power

source, check immediately for the presence of a pulse and

respiration. If a pulse is not present, start CPR (Car dio Pulmonary Resuscitation) and call for emergency medical

assistance. If a pulse is present, respiration may be restored

by using mouth-to-mouth resuscitation, but call for emergency medical assistance.

Low Voltage

Control circuits used in the refrigeration unit are lo w voltage (12 volts dc). This voltage potential is not considered

dangerous, but the large amount of current available (over

30 amperes) can cause severe burns if shorted or ground.

Do not wear jewelry, watch or rings. These items can short

out electrical circuits and cause severe burns to the wearer.

ii

Page 9

Specifications

General

Compressor Belt driven, multi cylind er, wobble plate type driven

by the truck engine (Model 10) and by the truck

engine or electric motor. (Model 20)

Engine Compressor Oil Charge 6 oz (177 ml) in compressor

Total system: 12 oz (355 ml)

Electric Standby Compressor Oil Charge 6 oz 177 ml) in each compressor

Total system: 24 oz (710 ml)

Compressor Oil Type Polyol Ester P/N 203-413

Defrost Method:

Truck Engine Operation Model 10 Hot gas

Model 20 Hot gas

Electric Standby Model 20 Hot gas

Defrost Timer: Initiation Interval Adjustable, 1 hour to 10 hours

Termination interval 45 minutes

R-134A REFRIGERATION SYSTEM

Refrigerant Charge and Type 5 lb (2.3 kg) R-134a

Defrost Termination Switch: Opens 52 F (11.1 C)

Closes 42 F (5.6 C)

Liquid Line Injection Switch: Opens 200 ± 5 F (93 ± 3 C)

Closes 230 ± 5 F (110 ± 3 C)

High Pressure Cutout Switch: Opens 350 + 25/-0 psi (2413 + 172/-0 kPa)

Closes 200 ± 20 psi (1379 ± 138 kPa)

Low Pressure Cutout: Opens 5 to 11 in. Hg vacuum (-17 to -34 kPa)

Closes 4 to 7 psi (28 to 48 kPa)

Condenser Fan Pressure Switch: Opens 130 ± 10 psi (896 ± 69 kPa)

Closes 180 ± 10 psi (1241 ± 69 kPa)

1

Page 10

Specifications (Rev 1/99)

R-404A REFRIGERATION SYSTEM

Refrigerant Charge and Type 5 lb (2.3 kg) R-404A

Defrost Termination Switch: Opens 52 F (11.1 C)

Closes 42 F (5.6 C)

Liquid Line Injection Switch: Opens 200 ± 5 F (93 ± 3 C)

Closes 230 ± 5 F (110 ± 3 C)

High Pressure Cutout Switch: Opens 470 ± 7 psi (3241 ± 48 kPa)

Closes 375 ± 38 psi (2585 ± 262 kPa)

Low Pressure Cutout: Opens 5 to 11 in. Hg vacuum (-17 to -34 kPa)

Closes 4 to 7 psi (28 to 48 kPa)

Condenser Fan Pressure Switch: Opens 130 ± 10 psi (896 ± 69 kPa)

Closes 180 ± 10 psi (1241 ± 69 kPa)

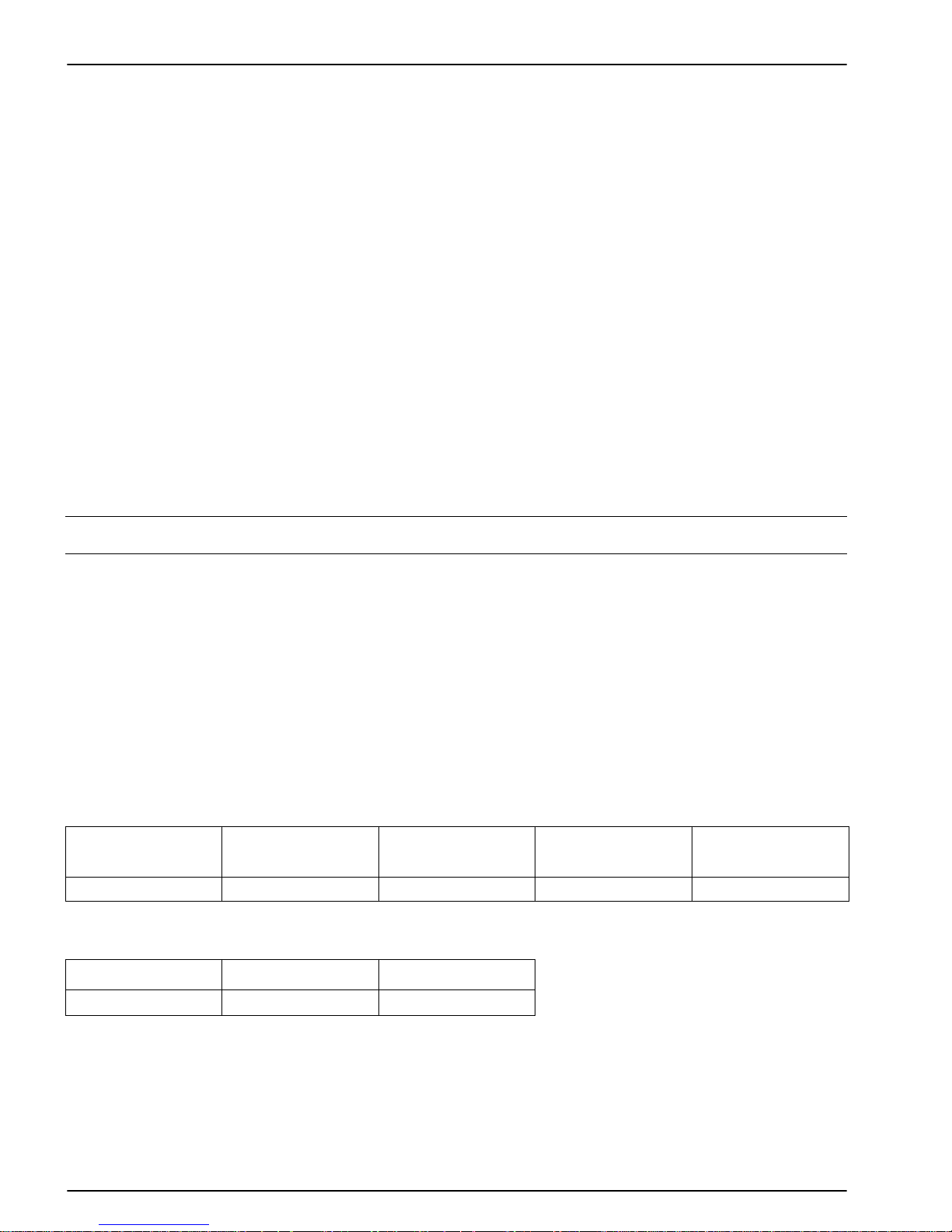

ELECTRICAL SYSTEM

Fuses

F1 Condenser Fan Fuse 15 amps

F2 Evaporator Fan Fuse 15 amps

F3 Power Fuse 10 amps

F4 Control Circuit Fuse 3 amps

Battery Circuit Breaker 40 amps

Transformer Fuse 4 amps (10 amps in 115/1/60 units)

F5 Defrost Circuit Fuse 1 amp

F7 Transformer Fuse 10 amps

Condenser and Evaporator Fan Motors

Voltage Horsepower

12 Vdc 0.17 0.12 1750-2000 6-9 amps

Hot Gas Solenoid and Liquid Injection Solenoid Coils

Voltage Current Resistance

Power Rating

in Kilowatts

rpm Full Load Current

12 Vdc 0.6-0.8 amps 15-19 ohms

2

Page 11

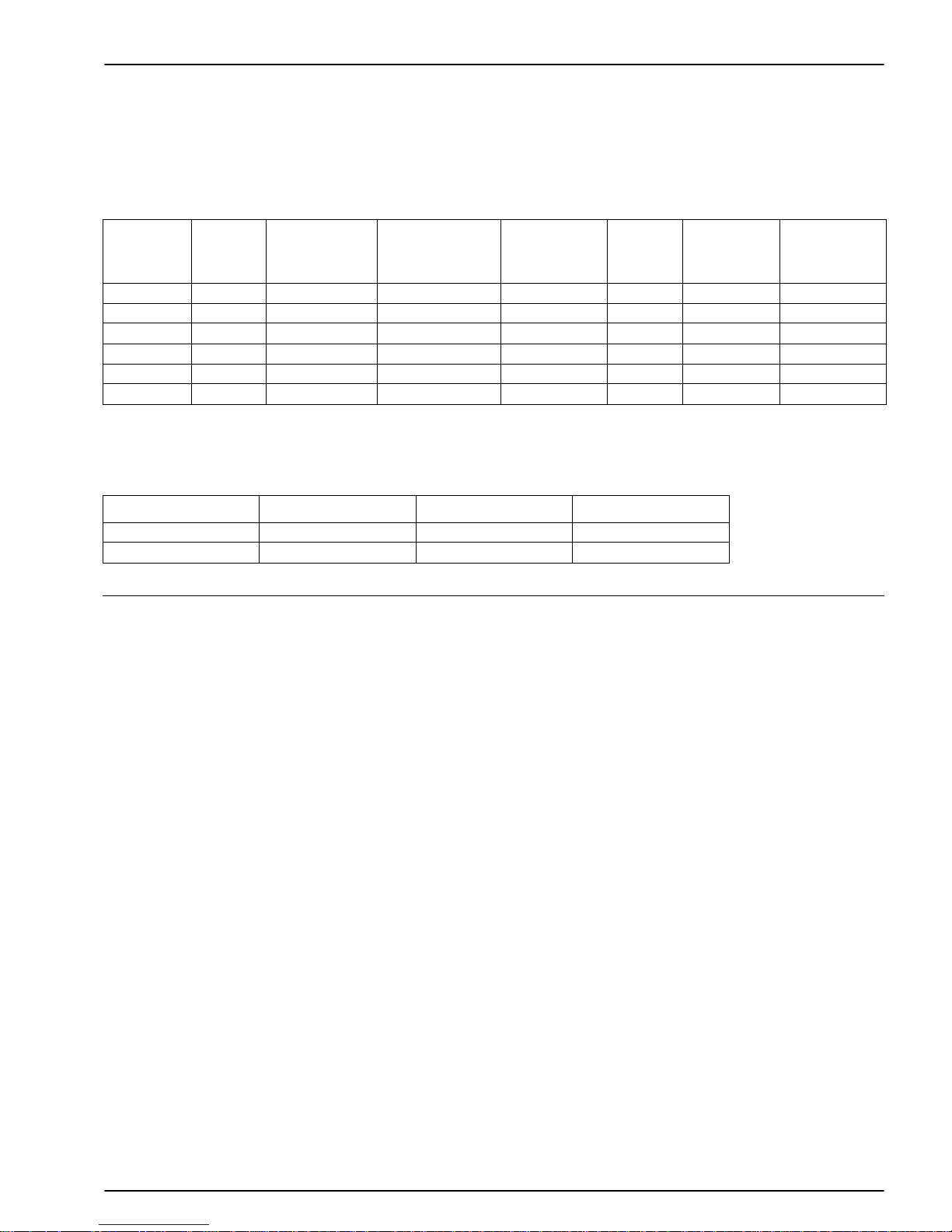

Electrical Standby Compressor Motors

Specifications (Rev 1/99)

Voltage Phase Frequency Horsepower Kilowatts

115 Vac 1 60 Hz 1.5 1.1 1750 15.0 16.0

230 Vac 1 60 Hz 2.0 1.5 1755 8.6 9.5

220 Vac 1 50 Hz 1.7 1.3 1460 10.0 11.0

230 Vac* 3 60 Hz 2.0 1.5 1695 6.8 3.5**

220 Vac* 3 50 Hz 1.6 1.2 1430 6.0 3.5**

400 Vac* 3 50 Hz 1.6 1.2 1405 3.2 3.5

* Motor can be wired for all three voltages.

**Overload relay monitors 1/2 motor windings on 220 and 230.

Optional Electri c Heaters

Voltage Power Rating Watts Current Resistance

230 Vac 1500 6.5 amps 35.3 ohms

400 Vac 1134 2.8 amps 141.1 ohms

BELT TENSION (Using Tool P/N 204-427)

Engine/Compressor 35

Electric Motor/Compressor 57

Field Reset

Full Load

rpm

Full Load

Current

(amps)

Overload

Relay Setting

(amps)

3

Page 12

4

Page 13

Maintenance Inspection Schedule

First Week Inspection and Maintenance

AFTER FIRST WEEK OF OPERATION:

• Check the belt tension

• Tighten the unit mounting bolts

• Check the refrigerant level

Bi-monthly Annually Inspect/Service These Items

ELECTRICAL

••

••

••

•

•

•

••

•

••

••

••

••

••

••

Check defrost initiation and termination.

Check thermostat cycle sequence.

Check operation of protection shutdown circuits.

Check thermostat and thermometer calibration in 32 F (0 C) ice-water bath.

Inspect wire harness for damaged wires or connections.

Inspect/replace DC fan motor brushes.

REFRIGERATION

Check refrigerant level.

Replace dehydrator.

STRUCTURAL

Visually inspect unit and refrigerant hoses for fluid leaks.

Visually inspect unit for damaged, loose or broken parts.

Clean defrost drains.

Inspect belts for condition and proper tension (belt tension tool P/N 204-427).

Clean entire unit including evaporator coil and condenser coil.

Check all unit mounting bolts, brackets, lines, hoses, etc.

5

Page 14

6

Page 15

Unit Description

The Thermo King V250 is a truck refrigeration system that

is designed for low and medium temperature applications

on medium-sized trucks. There are two basic models:

• Model 10: C o ol a nd de fr os t o n en gin e -dr iv e n c o mp re ssor operation.

• Model 20: Cool and defrost on both truck enginedriven and electric standby compressor operation.

The system consist of three separate assemblies: the condenser, the evaporator, and the compressor.

The condenser has a unique design that allows it to be

mounted horizontally or vertically, on the roof or on the

front of the truck box.

The evaporator is mounted inside the truck box. Funnel and

thin-line evaporators are available. The funnel evaporator

mounts on the ceiling or the front wall. The thin-line evaporator mounts on the front wall.

The electric standby compressor is connected in parallel

with the engine-driven compressor. The engine compressor

is driven by a belt from the engine. Th e standb y compres sor

is driven by a belt from the electric motor. Both compressors use the same refrigeration system circuit. Check valves

isolate one compressor from the other during operation.

Compressor operation is controlled by the thermostat,

which energizes the compressor clutch during engine operation or starts the electric motor and energizes the compressor clutch on electric standby operation. The refrigeration

system is protected by a high pressure cutout switch and a

low pressure cutout switch.

The control circuits operate on 12 volts dc supplied by the

truck battery for over-the-road operation. On standby operation, the power is rectified from an ac transformer.

The cab control box is mounted in the truck cab. It contai ns

the On-Off key, Manual Defrost key, thermometer, thermostat, and indicator lights.

Liquid Injection System

Condenser and Evaporator Configurations

The compressor is mounted on and driven by the truck

engine. Refrigeration hoses or lines are used to connect the

condenser, the evaporator and the compressor. Model 20

units have another compressor and an electric motor

mounted in the condenser section for electric standby

operation.

If the discharge gas leaving the engine driven compressor

reaches a temperature of 230 ± 5 F (110 ± 3 C), the liquid

injection switch closes, providing voltage to the liquid injection solenoid. The solenoid opens a valve, allowing liquid

refrigerant to flow from the liquid line near the receiver outlet valve to the metering orifice attached to the suction fitting at the compressor. As the refrigerant passes through the

metering orifice it expands and evaporates, cooling the suction gas entering the compressor. This cooling effect is

transferred to the dischar ge gas lea ving th e compresso r from

the adjacent cavity in the compressor head. When the discharge gas is cooled to 2 00 ± 5 F (9 3 ± 3 C), the liquid injection switch opens, the liquid injection solenoid v alve closes

and refrigerant no longer flows through the liquid injection

system.

7

Page 16

Unit Description (Rev 1/99)

Oil Separator

An oil separator is a standard feature. It separates compressor oil from refrigerant vapor and returns the oil to the compressor through the oil fill hole by using a special adapter.

The oil separator helps provide positive oil return at high

compressor speeds and low operating temperatures. This

feature enhances compressor lubrication and extends compressor life. Units built after November 1996 will be located

in the condenser section. Refer to photo on page 12 and

drawing on page 61.

UNIT OPERATION

These units shift between cool, null, and heat (optional) to

maintain the box temperature at the thermostat setpoint.

The operating modes are: cool, null, heat (optional), and

defrost.

Engine Operation

The thermostat controls the operation of the unit by energizing and de-energizing the power relay and the heat relay.

The thermostat places the unit in cool by energizing the

power relay. The thermostat places the unit in null by deenergizing all the relays. The thermostat places the unit in

heat by energizing the heat relay .

When the power relay is energized, power flows to energize

the fan relay and the compressor clutch through normally

closed contacts in ER2.

When the heat relay is energized, it closes contacts that

energize the fan relay, the water pump, and the water valve.

When the fan relay is energized, it closes contacts that energize the condenser and evaporator fans. The condenser fan

is also controlled by the condenser fan pressure switch.

This normally open switch monitors the compressor discharge pressure. When the discharg e pressure rises to 180 ±

10 psi (1241 ± 69 kPa), the switch closes and energizes the

condenser fan. When the discharge pressure drops to 130 ±

10 psi (896 ± 69 kPa), th e swit ch opens and de-ener gi zes the

condenser fan.

Electric Standby Operation

During electric standby operation, the thermostat controls

the operation of the unit by energizing and de-energizing the

power relay, the electric relays, and the heat contactor. The

thermostat places the unit in cool by energizing the power

relay and the electric relays.

The thermostat places the unit in null by de-energizing all

the relays and contactors. The thermostat places the unit in

heat by energizing the heat contactor.

When the power relay and the electric relays are energized,

they close contacts that energize the fan relay, the motor

contactor, and the electric standby compressor clutch.

When the heat contactor is energized, it energizes the electric evaporator heaters and the fan relay.

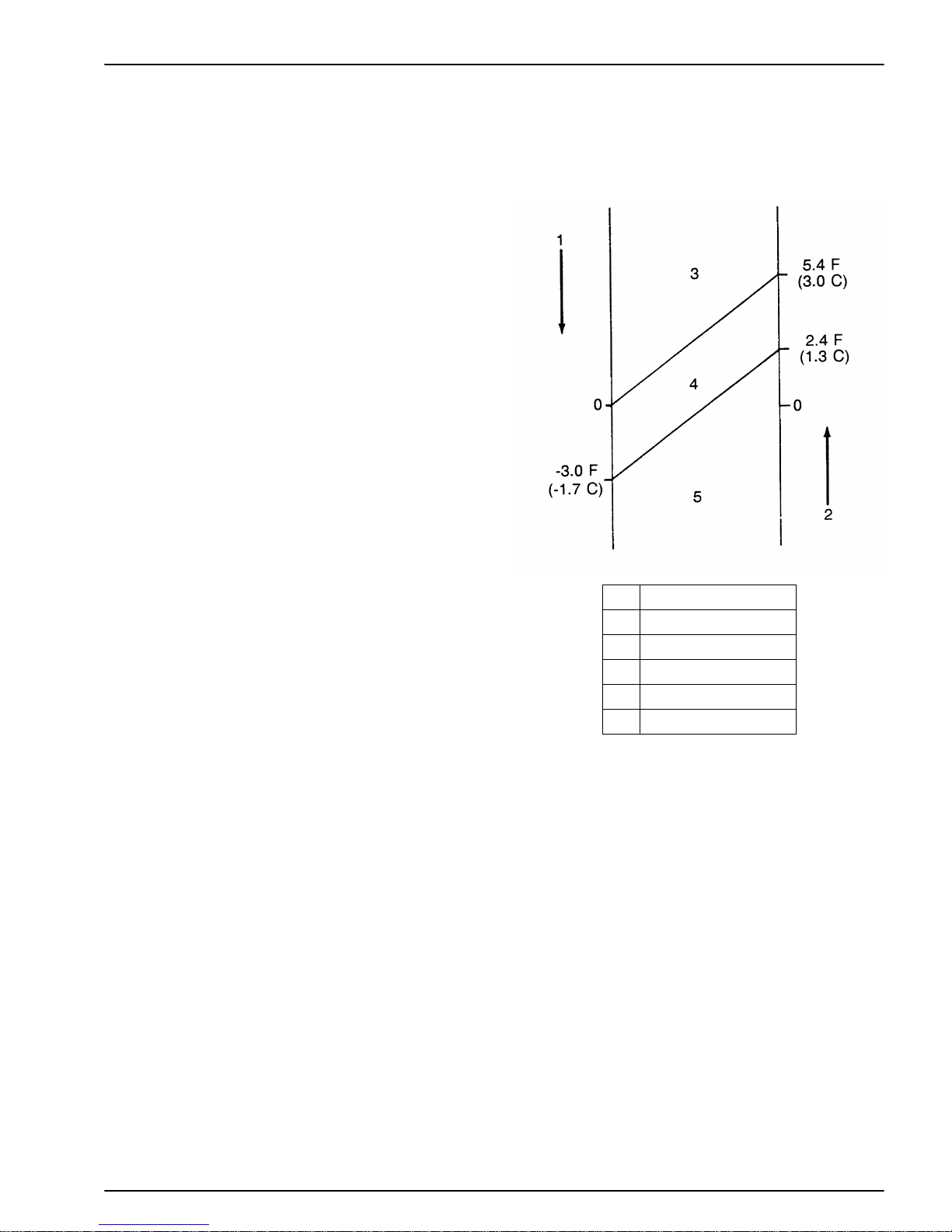

Cool

The thermostat shifts the unit to cool at temperatures more

than 5.4 F (3 C) above the thermostat setpoint. The thermostat keeps the unit running in cool until the temperature falls

to the thermostat setpoint.

During engine operation the engine compressor and the

evaporator fans operate while the unit is in co ol. During

electric operation, the electric motor, the electric standby

compressor, and the evaporator fans operate while the unit

is in cool.

Null

The thermostat shifts the unit from cool to null at the thermostat setpoint. The thermostat shifts the unit from null to

heat at 3 F (1.7 C) below the thermostat setpoint. The thermostat shifts the unit from heat to null at 2.4 F (1.3 C) above

the thermostat setpoint. The thermostat shifts the unit from

null to cool at 5.4 F (3 C) above the thermostat setpoint.

8

Page 17

Heat (Optional)

The thermostat shifts the unit to heat at temperatures more

than 3 F (1.7 C) below the thermostat setpoint. Th e therm ostat keeps the unit running in heat un til the temp erature ris es

to 2.4 F (1.3 C) above the thermostat setpoint. During

engine operation, the water pump and the evaporator fans

operate while the unit is in heat.

During electric operation, the evaporator heaters and the

evaporator fans operate while the unit is in heat.

Defrost

The defrost cycle can be initiated any time the evaporator

coil temperature is below 42 F (5.6 C). Defrost is initiated

automatically by the defrost timer, or manually by pressing

the Manual Defrost switch.

Unit Description (Rev 1/99)

AGA329

Initiating defrost energizes the defrost relay. This energizes

the hot gas solenoid to route hot gas to the evaporator, and

de-energizes the fan relay to stop the evaporator and condenser fans.

The unit runs in defrost until the evaporator coil temperature rises to 52 F (11.1 C), causing the defrost termination

switch to open. This de-energizes the defrost relay and terminates defrost. If the defrost termination switch does not

open in less than 45 minutes, the defrost timer will terminate the defrost cycle 45 minutes after is was started.

0Setpoint

1 Temperature Drop

2 Temperature Rise

3Cool

4Null

5 Heat (Optional)

(1) Shifts from Null to Cool if not previously in Heat

(2) Shifts from Null to Heat if not previously in Cool

Thermostat Algorithm

UNIT FEATURES

• Digital Thermometer

• Electronic Thermostat

• Defrost Timer

• Hot Gas Defrost

• Defrost Termination Switch

• Liquid Injection System

9

Page 18

Unit Description (Rev 1/99)

• Manual Defrost Key

• Suction Pressure Regulator

• Oil Separator

• Six Cylinder Compressor

• R-134a

Unit Features (continued)

• Standby Electric Motor and Six Cylinder Standby

Compressor (Model 20 only)

• Refrigerant Flow Controlled Between Compressors by

Discharge Check Valve (Model 20 only)

PROTECTION FEATURES

• Control Circuit Fuses

• Refrigerant High Pressure Cutout

• Refrigerant Low Pressure Cuto ut

• Heat, Truck Engine and Electric Standby Heater St rips

(Model 20)

• Paint, Special Color

• 24 V dc Converter

• R-404A Dealer Installed

SERIAL NUMBER LOCATIONS

Condenser: Roadside.

Evaporator: Roadside panel.

Compressor: Nameplate on compressor body.

Standby Motor: Nameplate on motor.

• Refrigerant High Pressure Relief Valve

• Power Cord Warning Light (in Cab Control Box)

• Overload Relay Protection for Electric Standby Motor

(Model 20 o nl y)

• Transformer Fuses (Model 20 only)

OPTIONAL FEATURES

• Electric Motors (Model 20 only)

115 Volt/1 Phase/60 Hz

220 Volt/1 Phase/50 Hz

230 Volt/1 Phase/60 Hz

220 Volt/3 Phase/50 Hz

230 Volt/3 Phase/60 Hz

400 Volt/3 Phase/50 Hz

• Heat, Truck Engine (Model 10)

10

Page 19

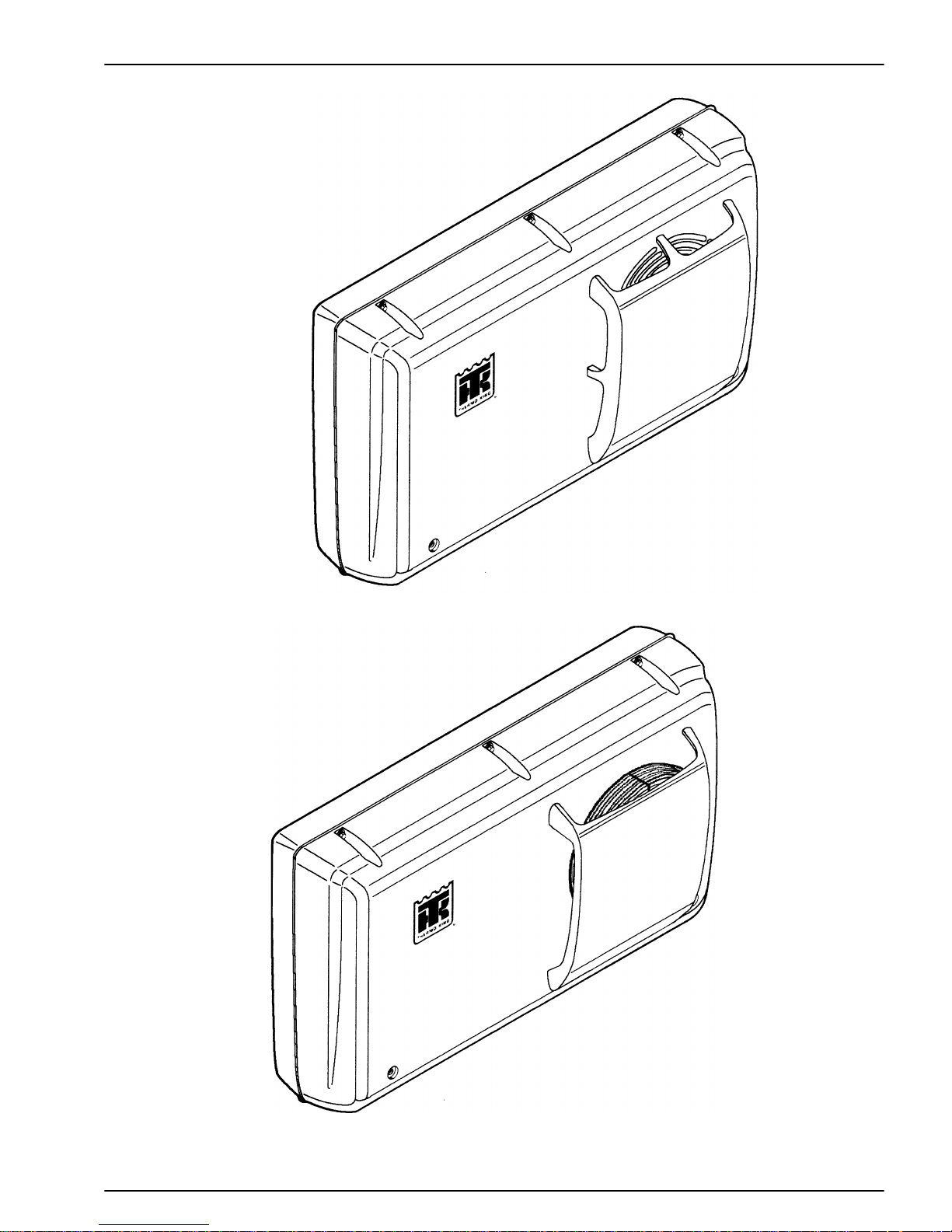

Unit Description (Rev 1/99)

AGA339

Vertical Mounted Condenser (Early Model)

AGA673

Vertical Mounted Condenser (Later Model)

11

Page 20

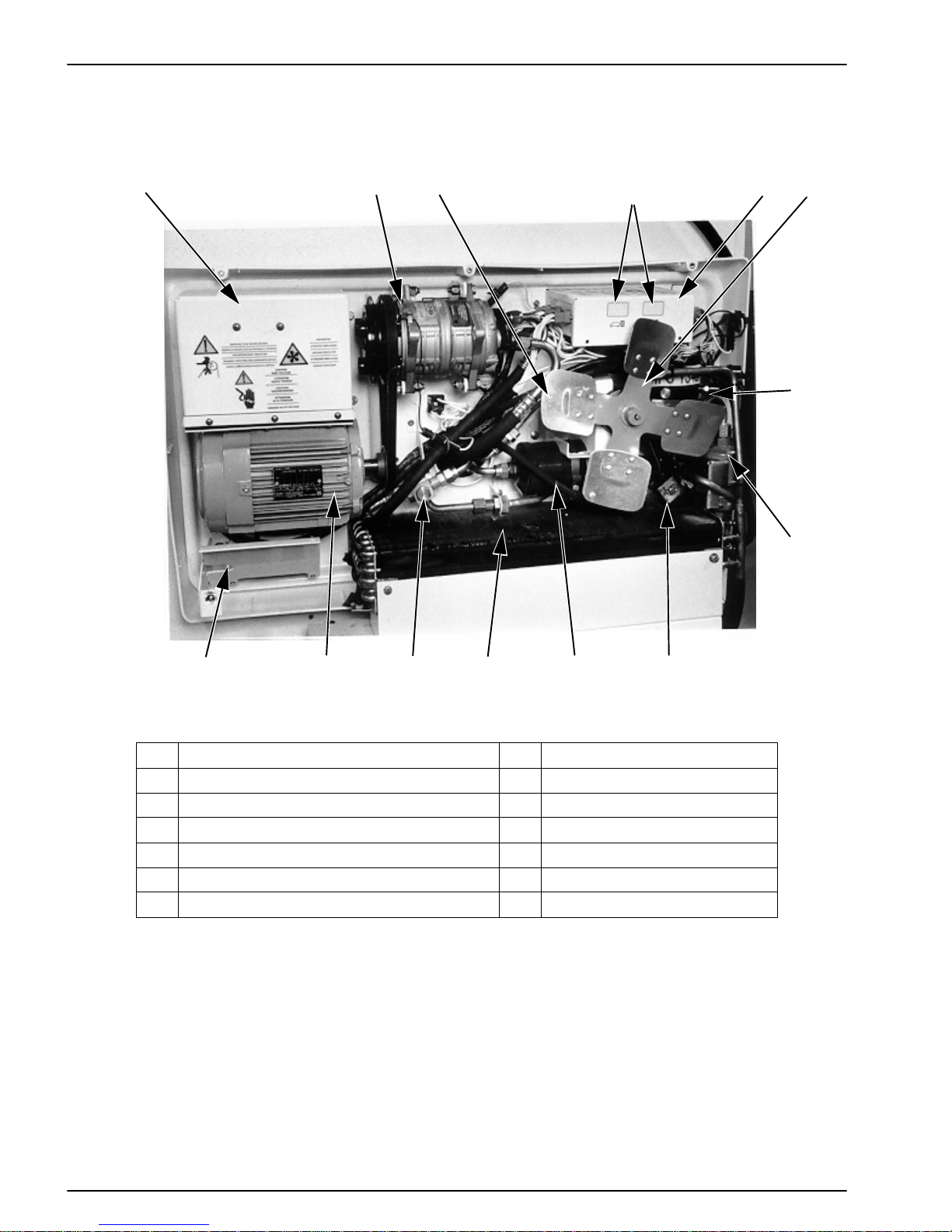

Unit Description (Rev 1/99)

12 4356

7

14

12

9101113

1. High Voltage Box 8. Oil Separator

2. Compressor 9. Liquid Injection Solenoi d

3. Hot Gas Solenoid (Behind Fan Blade ) 10. Drier

4. Hourmeters Location (Optional) 11. Condenser Coil

5. Low Voltage Box 12. Check Valve Assembly

6. Condenser Fan 13. Motor (Model 20 only)

7. Receiver Tank 14. 24 Volt Converter

Condenser Components—Front/Top View (Starting 1997)

8

AEA825

12

Page 21

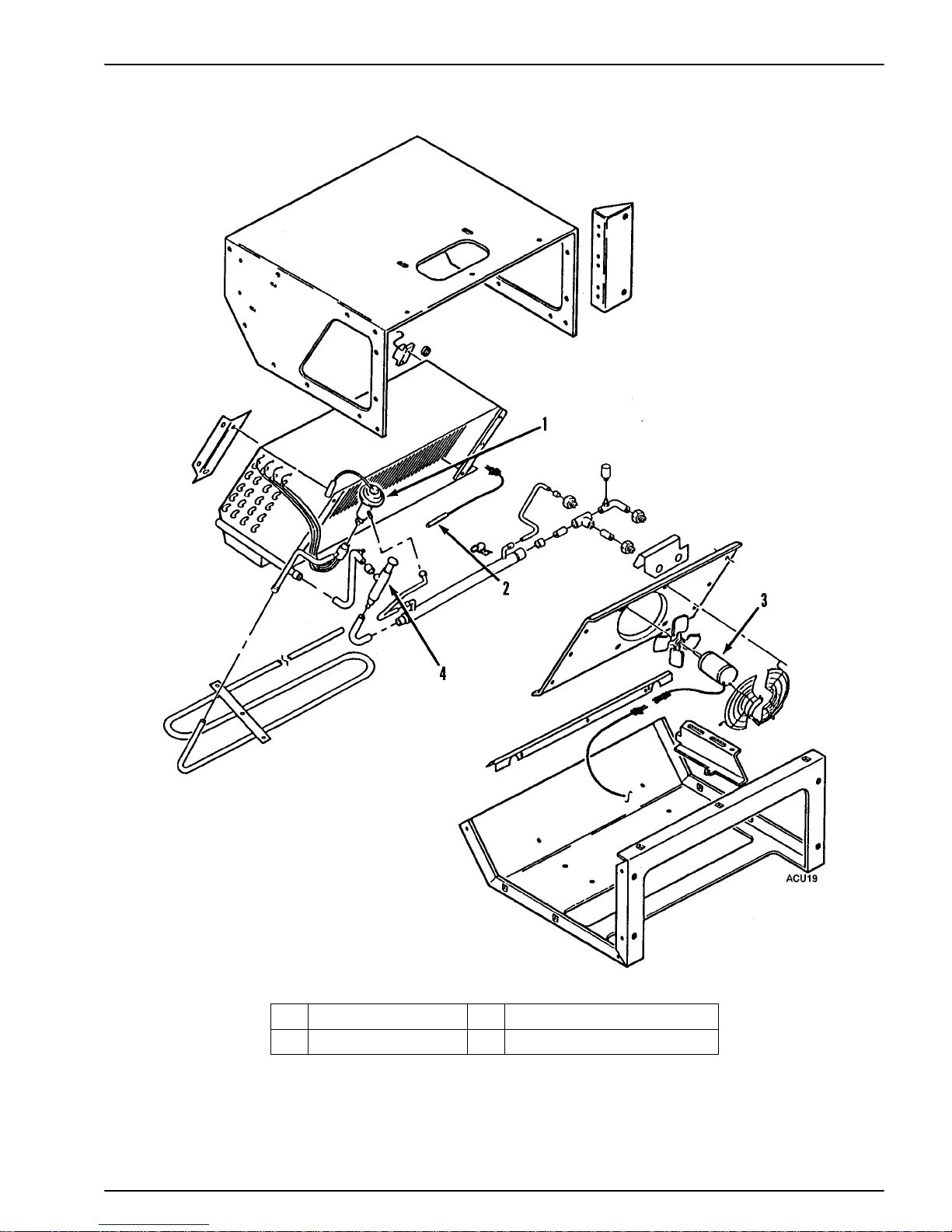

Unit Description (Rev 1/99)

1. Expansion Valve 3. Fan Motor

2. Thermostat Sensor 4. Suction Pressure Regulator

Funnel Evaporator

13

Page 22

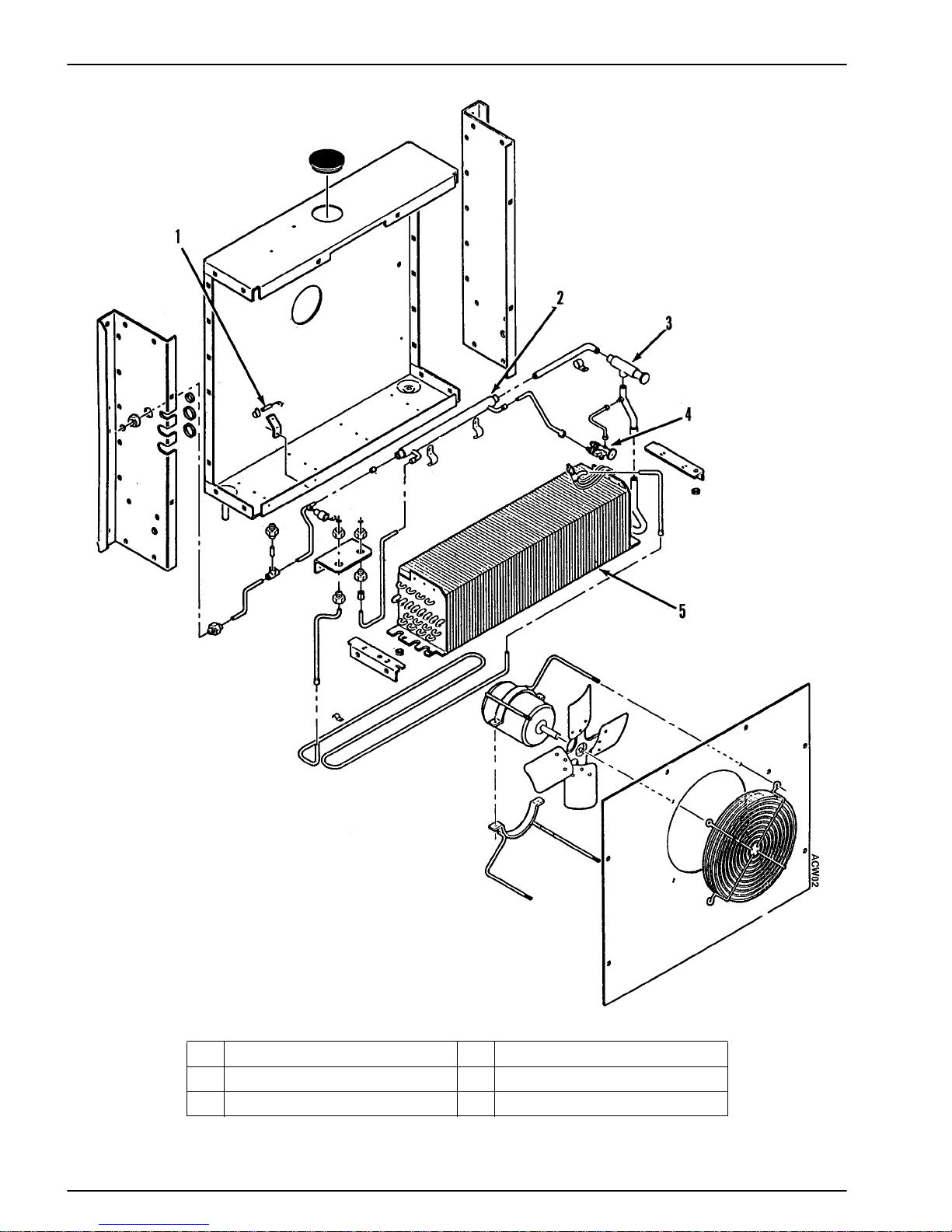

Unit Description (Rev 1/99)

1. Thermostat Sensor 4. Expansion Valve

2. Heat Exchanger 5. Evaporator Coil

3. Suction Pressure Regulator

Thin-Line Evaporator

14

Page 23

Unit Description (Rev 1/99)

1

AEA667

2

1. Relays 2. PC Board

Low Voltage Box—Pre-1996

15

Page 24

Unit Description (Rev 1/99)

9

8

7

1

6

5

4

3

AEA660

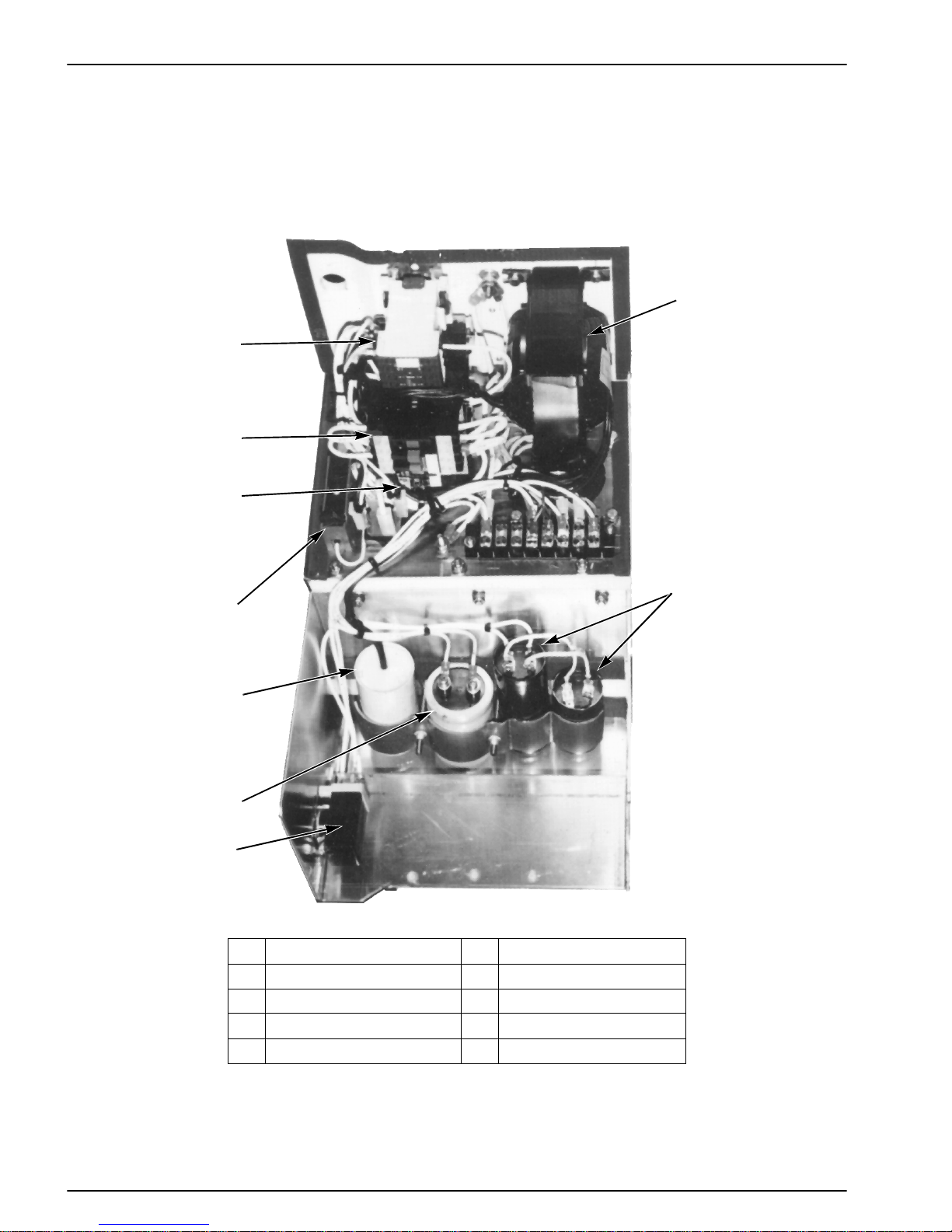

1. Transformer 6. Transformer Fuse

2. Motor Start Capacitors 7. Overload Relay

3. Motor Start Relay 8. Motor Contactor

4. DC Power Filter Capacitor 9. Heat Contactor (Optional)

5. Motor Run Capacitor

2

High Voltage Box—Pre-1997

16

Page 25

Unit Description (Rev 1/99)

1

9

8

7

6

AEA826

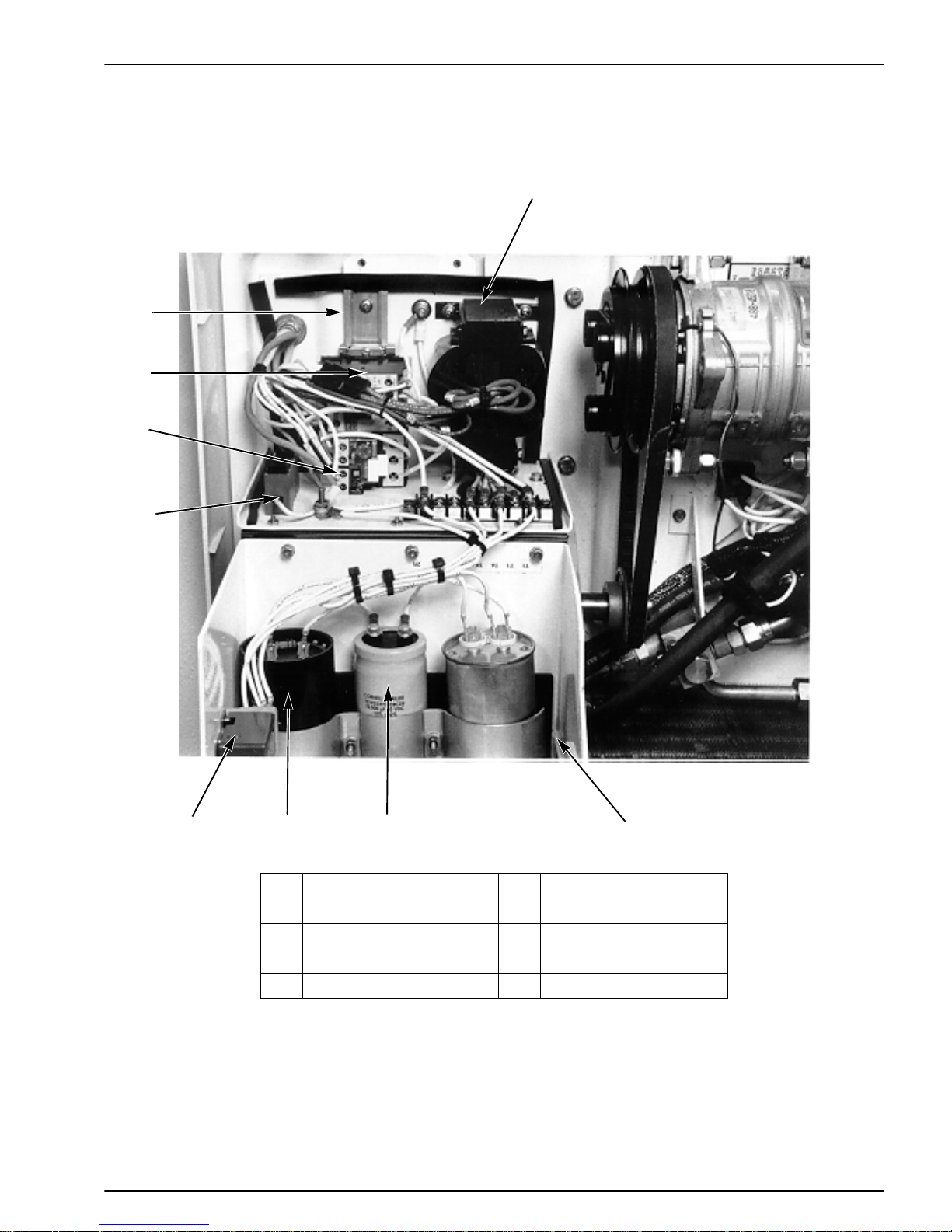

2345

1. Transformer 6. Transformer Fuse

2. Motor Start Capacitors 7. Overload Relay

3. DC Power Filter Capacitor 8. Motor Contactor

4. Motor Run Capacitor 9. Heat Contactor (Optional)

5. Motor Start Relay

High Voltage Box—Starting 1997

17

Page 26

Unit Description (Rev 1/99)

1

2

3

8

4

5

7

6

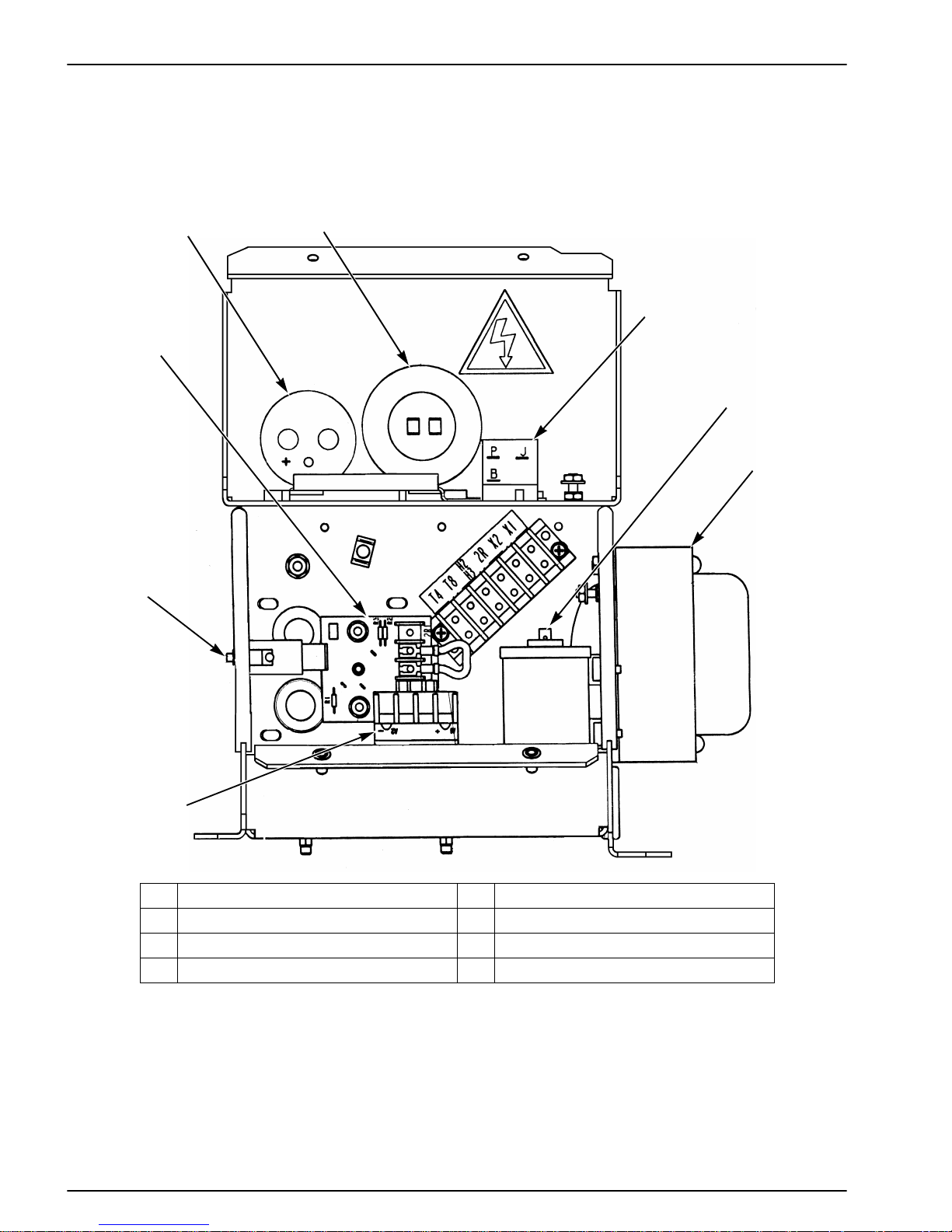

1. D.C. Power Filter Capacitor 5. Transformer

2. Motor Starting Capacitor 6. Motor Contactor

3. Motor Start Relay 7. Fuse and Fuseholder

4. Motor Run Capacitor 8. Motor Protector

High Voltage Box - Typical for Single Phase P97

AGA340

18

Page 27

Unit Description (Rev 1/99)

1

2

3

5

4

AGA345

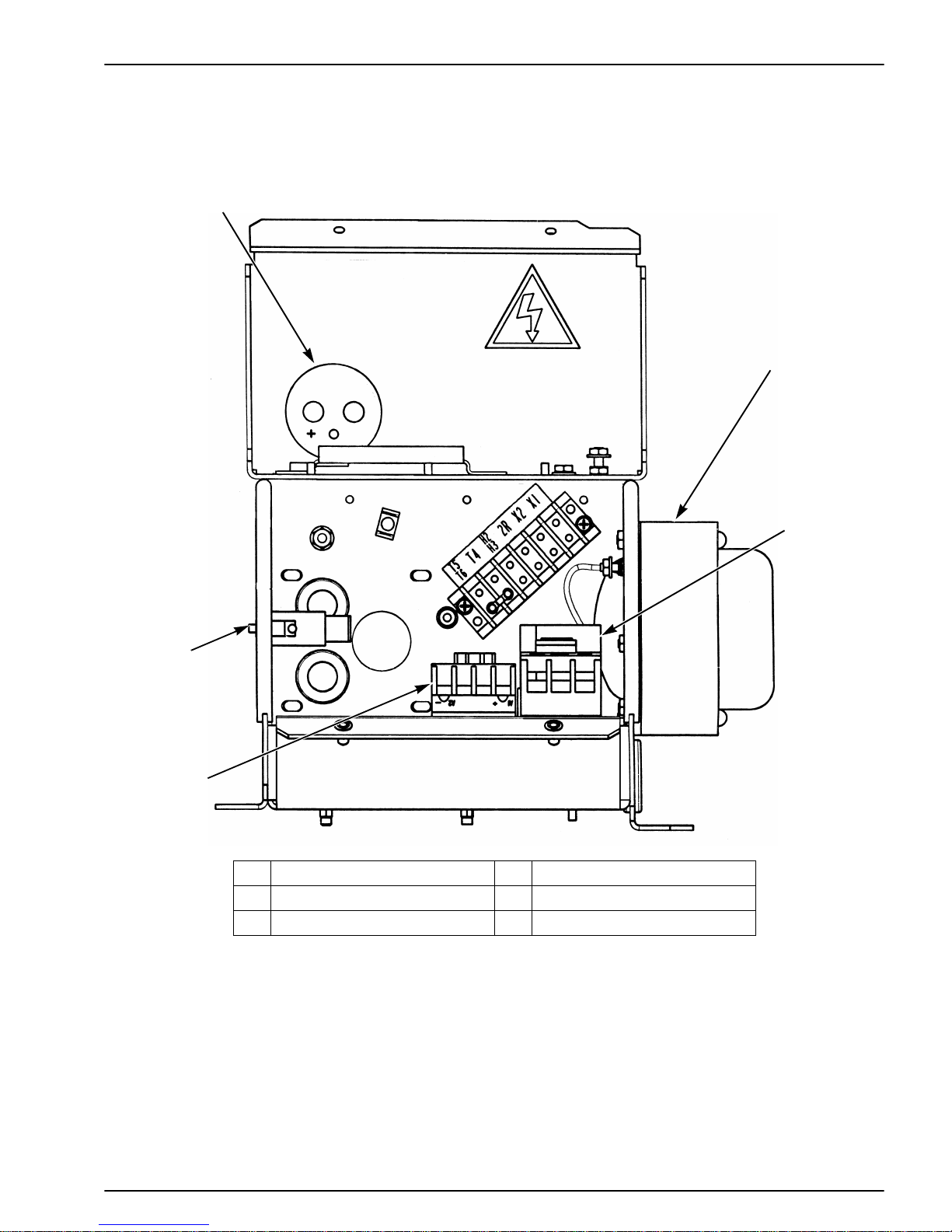

1. D.C. Power Filter Capacitor 4. Motor Contactor

2. Transformer 5. Fuse and Fuse Holder

3. Overload Relay

High Voltage Box - Typical fo r 3 Phase P97

19

Page 28

Unit Description (Rev 1/99)

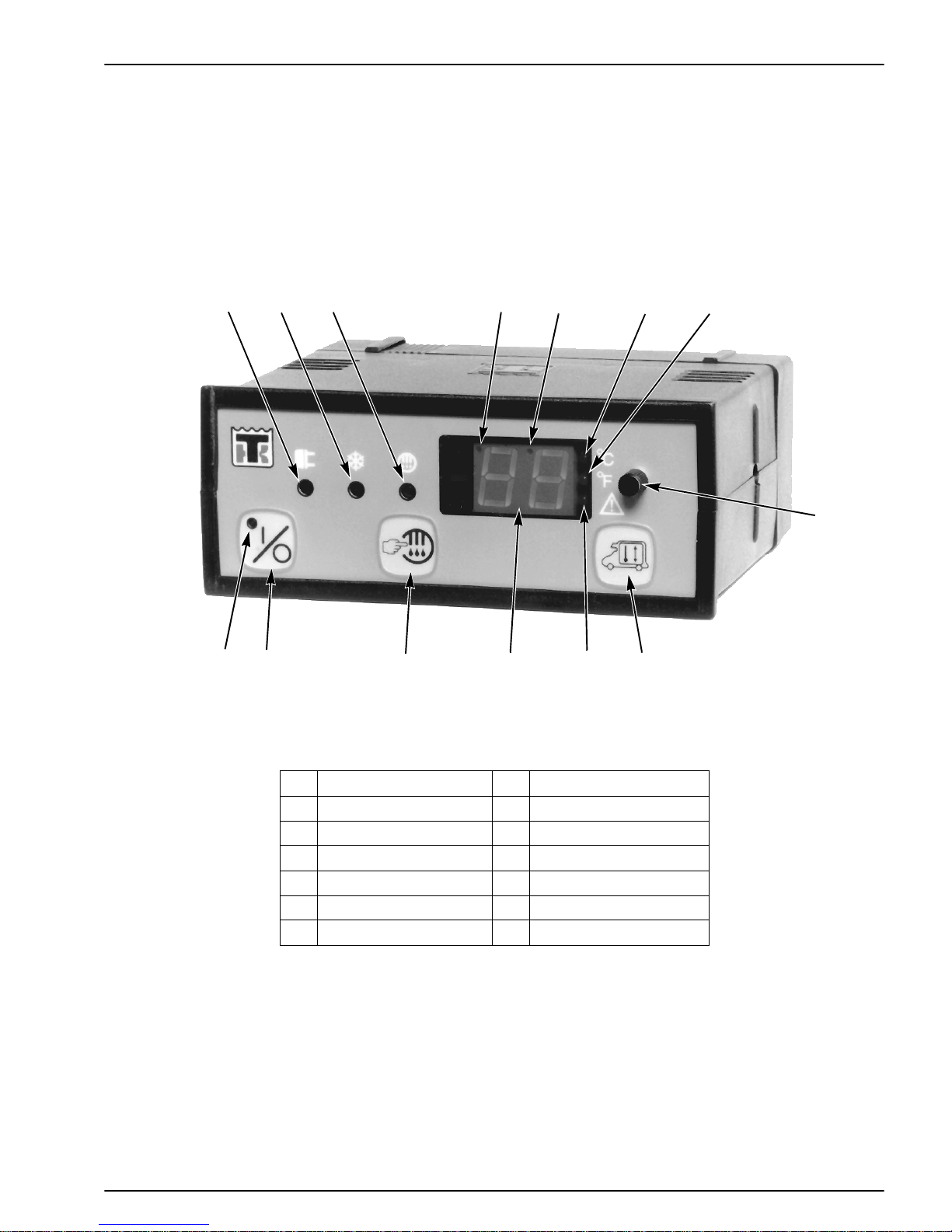

123 4 5 6 7

91011121314

1. Power Cord Indicator 8. Thermostat Dial

2. Running Indicator 9. Setpoint Key

3. Defrost Indicator 10. AC Overload Indicator

4. Heat Indicator 11. Digital Display

5. Cool Indicator 12. Manual Defrost Key

6. Celsius Indicator 13. On-Off Key

7. Fahrenheit Indicator 14. On Indicator

Cab Control Box—M10 Pre-1997

8

AEA661

20

Page 29

Unit Description (Rev 1/99)

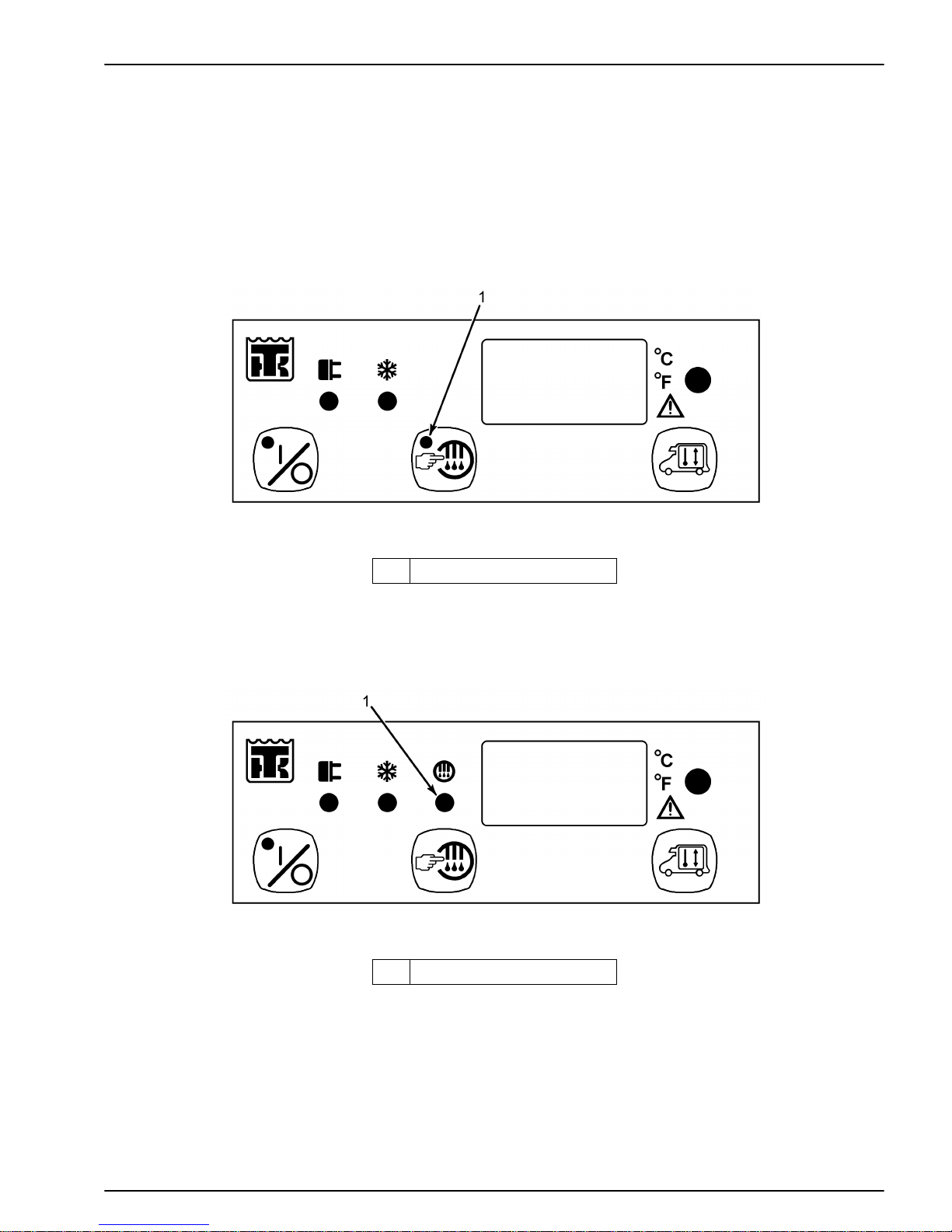

NOTE: The M13 and M10 cab boxes a re identified by th e position of the d efrost indicator li ght. On the M13 cab box the

defrost indicator light is po sitioned on the def rost key. On the M10 cab box t he defrost indica tor light is pos itioned left of

the digital display. Refer to the following illustrations. Refer to Service Bulletin 177.

AEA835

1. Defrost Indicator Light

M13 Cab Box—TK No. 45-1780

1. Defrost Indicator Light

M10 Cab Box—TK No. 45-1705

AEA836

21

Page 30

22

Page 31

Operating Instructions

UNIT CONTROLS

Cab Control Box

1. ON-OFF KEY. Press this key to turn the unit ON and

OFF.

2. ON INDICATOR. When this light is on, it indicates

that the unit is turned ON. When this light is off, it

indicates that the unit is turned OFF.

3. POWER CORD INDICAT OR. When this light is on, it

indicates that the unit is connected to an electric

standby power source.

4. RUNNING INDICATOR. When this light is on, it

indicates that the unit is running.

5. MANUAL DEFROST KEY. Press this key to start a

defrost cycle. The unit will not defrost unless the

defrost termination switch is closed (evaporator coil

temperature below 42 F [5.6 C]).

6. DEFROST INDICATOR. When this light is on, it indicates that the unit is in defrost.

7. DIGITAL DISPLAY. This display is active only when

the unit is turned on. The thermometer reading (return

air sensor temperature) normally appears on the display. Pressing the setpoint key causes the thermostat

setpoint to appear on the di splay for 10 t o 15 seconds.

12. AC OVERLOAD INDICATOR. When this light is on,

it indicates that the overload relay has opened. This

indicator must be reset by pressing the On-Off Key

after allowing time for the overload relay to cool.

13. SETPOINT KEY. Press this key to make the thermostat setpoint appear on the digital display. The thermostat setpoint will remain on the display for 10 to 15

seconds after the key is released. This gives the operator time to adjust the thermostat setpoint.

14. THERMOSTAT DIAL. Turn this dial to adjust the

thermostat setpoint.

NOTE: The Thermostat Dial will change the thermostat setpoint without pressing the Setpoint Key.

Low Voltage Box

1. DEFROST TIMER. The defrost timer is built-in to the

PC board. It can automatically initiat e or terminate a

defrost cycle if necessary. The initiation interval is

adjustable from 1 hour to 10 hours. The termination

interval is set at 45 minutes. Refer to the Electrical

Maintenance section for more information about the

defrost timer.

2. CONTROL RELAYS. Six control relays are located

on the PC board. These relays are used to control the

operation of the unit.

8. HEAT INDICATOR. When this light is on, it indicates

that the unit is running in heat.

9. COOL INDICATOR. When this light is on, it indicates

that the unit is running in cool.

10. CELSIUS INDICATOR. When t his light is on, it indicates that the temperature is being displayed in degrees

Celsius.

11. FAHRENHEIT INDICATOR. Wh en this light is o n, it

indicates that the temperature is being displayed in

degrees Fahrenheit.

3. ENGINE HOURMETER (Optional). This hourmeter

records the amount of time the unit runs on engine

operation.

4. ELECTRIC HOURMETER (Model 20) (Optional).

This hourmeter records the amo unt o f time the un it runs

on electric standby operation.

High Voltage Box (Model 20)

1. MOTOR CONTACTOR. The motor contactor is used

to control the operation of the electric motor that drives

the electric standby compressor .

23

Page 32

Operating Instructions (Rev 1/99)

2. HEATER CONTACTOR (Optional). The heater contactor is used to control the operation of the optional

electric evaporator heaters.

Other Controls

1. DEFROST TERMINATION SWITCH. This temperature sensitive switch is located on the evaporator coil.

It closes to enable defrost when the evaporator coil

temperature falls below 42 F (5.6 C).

The switch opens to terminate, or disable, defrost when

the evaporator coil temperature rises to 52 F (11.1 C).

2. CONDENSER FAN PRESSURE SWITCH. This pressure sensitive switch is located on the receiver tank.

When the pressure in the receiver tank rises above 180

psi (1241 kPa), the switch closes to energized the condenser fan. When the pressure in the receiver tank falls

below 130 psi (896 kPa), the switch opens to de-energize the condenser fan.

3. LIQUID INJECTION SWITCH. This temperature sensitive switch is located on the discharge fitting of the

truck engine compressor. When the discharge temperature rises above 230 F (110 C), the switch closes to

open the liquid injection solenoid. When the disch arge

temperature falls below 200 F (93 C), the switch opens

to close the liquid injection solenoid.

4. SUCTION PRESSURE REGULATOR VALVE. This

valve is located in the suction line in the evaporator. It

limits the suction pressure at the comp ressor. The normal pressure setting for this valve is 18 to 20 psi (124 to

138 kPa).

UNIT PROTECTION DEVICES

1. PC BOARD FUSES. Five fuses are located on the PC

board in the low voltage box.

F1 This 15 amp fuse protects the circuit to the con-

denser fan m otor.

F2 This 15 amp fuse protects the circuit to the evapo-

rator fan motor.

F3 This 10 amp fuse protects the circuit to the power

relay and the heat relay.

F4 This 3 amp fuse protects the circuit from the trans-

former output to the cab control box.

F5 Defros t Circ uit Fuse. 1 Amp

F6 A 40 amp fuse protects the battery circuit.

F7 A 10 amp fuse protects transformer motor circuit

for 115V/1 Ph/60 Hz, 230V,1 Ph/60 Hz, and 230V/

1 Ph/50 Hz. A 4 amp fuse protects the transformer

motor circuit for 230V and 400V at 3 Ph, 50 units

and 230V, 3 Ph, 60 Hz units.

2. CIRCUIT BR EAKER. A 40 a mp circuit breaker or 40

amp fuse protects the circuit from the vehicle battery to

the unit.

3. HIGH PRESSURE CUTOUT SWITCH. This pressure

sensitive switch is located on the receiver tank. If the

pressure in the receiver tank rises above 350 psi (2413

kPa) for R-134a systems or 470 psi (3241 kPa) for R404A systems, the switch opens the circuit to the

power relay, which stops the unit.

NOTE: This operation is for units with printed circuit

board manufactured prior to 3-25-96 (s ee “P.C. Bo ar d

P/N 41-776 (First Version)” on page 38).

When the HPCO opens on models using printed ciruit

board manufactured between 3-26-96 and 5-21-96,

see “P.C. Board P/N 41-1619 (Second Version)” on

page 39 or after 5-21-96 (see “P.C. Board P/N 411812 (Third Version)” on page 40) the HPCO will

cycle the compressor clutch only.

4. LOW PRESSURE CUTOUT SW ITCH. This p ressure

sensitive switch is located on the suction line in the

evaporator. If the pressure in the suction line falls

24

Page 33

Operating Instructions (Rev 1/99)

below 5 to 11 in. Hg of vacuum (-17 to -37 kPa), the

switch opens the circuit to the power relay, which stops

the unit.

NOTE: This operation is for units with printed circuit

board manufactured p rior to 3-25-96 (see “P.C. Board

P/N 41-776 (First Vers ion)” on page 38).

When the LPCO opens on models using printed cirucit board manufactured between 3-26-96 and 5-21 -96,

see “P.C. Board P/N 41-1619 (Second Version)” on

page 39 or after 5-21-96 (see “P.C. Board P/N 411812 (Third Version)” on page 40) the HPCO will

cycle the compressor clutch only.

5. FUSE PLUG. The fuse plug is located on the receiver

tank. It opens to relieve the pressure in the refrigeration system if the pressure becomes excessive. If the

fuse plug has opened, it must be replaced. It cannot be

reused.

6. OVERLOAD RELAY (Model 20). This auto reset

relay protects the electric motor that drives the electric

standby compressor. The overload relay opens the circuit to the cab control box, which de-energizes the

motor contactor and the electric motor if the motor

overloads for any reason (e.g., low line voltage or

improper power supply) during electric standby operation. When the overload relay opens, it illuminates the

AC overload indicator.

7. TRANSFORMER FUSE (Model 20). This fuse is

located in the high voltage box. The 115 volt, single

phase, 60 Hz unit has a 10 amp f use. Al l oth er uni ts use

a 4 amp fuse.

inspection is not a substitute for regularly scheduled maintenance inspections, it is an important part of t he preventive

maintenance program designed to head off operating problems before they happen.

1. LEAKS. Inspect for refrigerant leaks and worn refrigerant lines.

2. BELTS. Inspect for cracks, wear and proper tensions.

3. ELECTRICAL INSPECTION. The electrical connections should be securely fastened. Wires and terminals

should be free of corrosion, cracks or moisture.

4. DEFROST DRAINS. Check the defrost drain hoses

and fittings to make sure that they are open so condensate can run out during defrost. Check the bottom end

of each drain hose to make sure that it is not plugged or

crushed.

5. STRUCTURAL INSPECTION. Visually check for

physical damage.

6. REFRIGERANT CHARGE. Check the receiver tank

sight glass for the proper charge level.

Starting the Unit

Model 10 Units

1. Start the truck engine.

2. Press the On-Off key in the cab control box to turn the

unit ON.

3. Adjust the thermostat to the proper setting.

Model 20 Units

UNIT OPERATION

Bi-monthly Pre-Trip Checks

The following bi-monthly pre-trip inspection should be

completed before loading the truck. While the bi-monthly

Engine Operation

1. Start the truck engine.

2. Press the On-Off Key in the cab control box to turn the

unit ON.

25

Page 34

Operating Instructions (Rev 1/99)

3. Adjust the thermostat to the proper setting.

NOTE: The power cord indicator will come on if the

unit is connected to an electric standby power supply.

Electric Standby Operation

1. Connect the electric standby power supply to the unit’s

power receptacle. Make sure that the power supply has

the proper voltage and phasing.

2. Press the On-Off Key in the cab control box to turn the

unit ON.

3. Adjust the thermostat to the proper setting.

NOTE: The power cord indicator will come on while

the unit is connected to an electric standby power

supply.

Adjusting the Thermostat

The thermometer reading (return air sensor temperature)

normally appears on the digital display while the unit is

turned ON. Pressing the Setpoint Key causes the thermostat

setpoint to appear on the di splay for 10 to 15 seconds.

1. Press the Setpoint Key to display the setpoint. The setpoint will appear on the display for 10 to 15 seconds.

2. PRECOOLING. With the thermostat set at the correct

temperature, allow the unit to run for one-half to one

hour (longer if possible) before loading the truck. Precooling will remove residual body heat and moisture

from the box interior and provide a good test of the

refrigeration system.

3. DEFROST. When the unit has finished pre-cooling the

truck interior (the evaporator temperature has dropped

below 42 F (5.6 C), initiate a defrost cycle with the

Manual Defrost switch. The defrost cycle should end

automatically.

Loading Procedure

1. Make sure that the unit is OFF before opening the doors

to minimize frost accumulation on the evaporator coil

and heat gain in the truck. (The unit may be running

when the truck is being loaded from a warehouse with

door seals.)

2. Spot check and record the load temperature while loading. Especially note any off-temperature product.

3. Load the product so there is adequate space for air circulation completely around the load. DO NOT block

the evaporator inlet or outlet.

2. Turn the Thermostat Dial to adjust the setpoint to the

proper setting while the setpoint is being displayed.

3. After the thermometer reading appears on the display,

press the Setpoint Key to check the setpoint.

NOTE: The Thermostat Dial will change the setpoint

without pressing the Setpoint Key. Do not turn the

Thermostat Dial without checking the setpoint.

After Start Inspection

1. THERMOSTAT. Adjust the thermostat setting above

and below the box temperature to check the thermostat

operation (see Operating Modes).

4. Products should be precooled before loading. Thermo

King units are designed to maintain loads at the temperature at which they are loaded. Transport refrigeration

units are not designed to pull hot loads down t o te mp erature.

Post Loading Procedure

1. Make sure that all the doors are closed and locked.

2. Adjust the thermostat to the desired temperature setpoint.

3. Start the unit.

26

Page 35

4. One-half hour after loading, def rost the uni t by momentarily pressing the Manual Defrost switch. If the coil

temperature has dropped below 42 F (5.6 C), the unit

will defrost. The defrost cycle should stop automatically.

Bi-monthly Post Trip Checks

1. Wash the unit.

2. Check for leaks.

3. Check for loose or missing hardware.

4. Check for physical damage to the unit.

Operating Instructions (Rev 1/99)

27

Page 36

28

Page 37

Electrical Maintenance

UNIT WIRING

Periodically inspect the unit wiring and the wire harnesses

for loose, chafed or broken wires to protect against unit malfunctions due to open or short circuits.

CAB CONTROL BOX

Selecting the Temperature Scale

The temperature readings can be displayed in eith er the Celsius scale or the Fahrenheit scale. Dip switch 3, located

inside the cab control box, is used to select which scale is

displayed. In dicator lights next to the digital display show

which scale has been selected. Place dip switch 3 in the ON

position to display temperatures in degrees Celsius.

Place dip switch 3 in the OFF position to display temperatures in degrees Fahrenheit. To change the temperature

scale selection:

1. Remove the cover from the back of the cab control box.

2. Place dip switch 3 in the proper position.

ON for Celsius

OFF for Fahr e nheit

3. Replace the cover.

Selecting the Setpoint Range

The setpoint range can be set at either -26 to 86 F (-32 to 30

C) or -8 to 86 F (-22 to 30 C). Dip switches 1 and 2, located

inside the cab control box, are used to select the setpoint

range. Place dip switches 1 and 2 in the ON position for a

setpoint range of -26 to 86 F (-32 to 30 C). Place dip

switches 1 and 2 in the OFF positio n for a setpo int range of

-8 to 86 F (-22 to 30 C). To change the setpoint range selec-

tion:

1. Remove the cover from the back of the cab contro l box.

2. Place dip switches 1 and 2 in the proper position.

ON for a setpoint range of -26 to 86 F (-32 to 30 C).

OFF for a setpoint range of -8 to 86 F (-22 to 30 C).

3. Replace the cover.

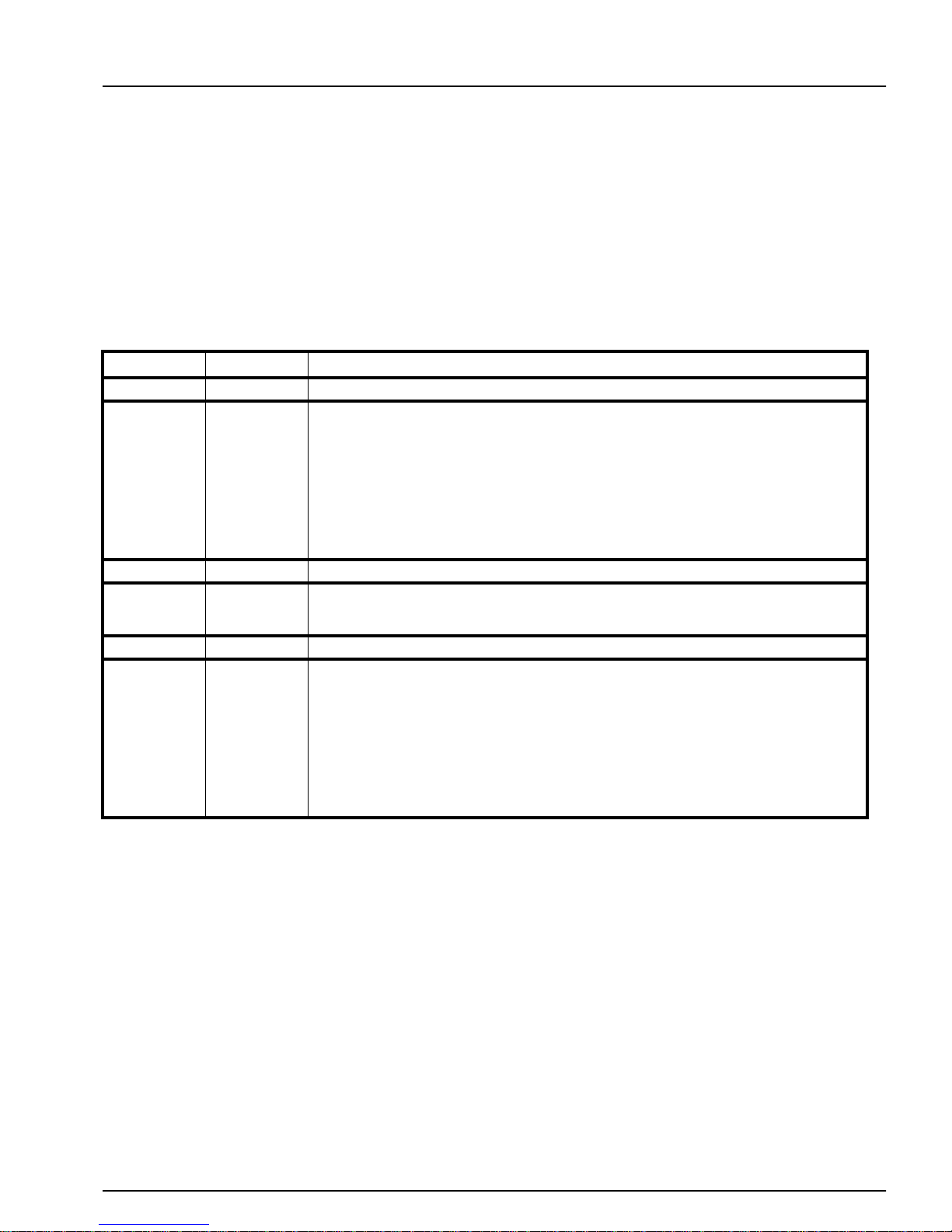

1. Dip Switches

Back of Cab Control Box with Cover Removed

29

Page 38

Electrical Maintenance (Rev 1/99)

NOTE: Do not run a R-1 34a un i t t o -2 6 F (-3 2 C). R-404A

units may be operated at -24 F (-32 C).

Setpoint Differential Adjustment

Adjust the thermostat setpoint differential to 4 F (2 C).

1. Remove the cab control box from its bracket.

2. Remove the cover from th e back o f the cab contro l bo x.

3. Turn the adjusting potentiometer to the 12 o’clock position.

4. Replace the cover and place the cab contro l box back in

its bracket.

1. 1 Amp Fuse

2. 12/24 Volt Jumper

3. Main Harness Plug

4. Dip Switches

5. Sensor Plug

6. Setpoint Differential Potentiometer Set to 12 o’cl oc k pos it ion

Adjust Setpoint Differential

30

Page 39

Electrical Maintenance (Rev 1/99)

Testing the Cab Control Box

The cab control box contains the thermometer and the thermostat. The thermometer and the thermostat share the same

digital display and use the same sensor. The thermometer

displays the sensor temperature. The thermostat compares

the sensor temperature with the setpoint to determine the

unit’s operating mode. The sensor is normally located in the

evaporator return airflow.

Thermometer

The range for the thermometer is -40 to 99 F (-40 to 38 C).

Normally the thermometer reading appears on the digital

display. Pressing the Setpoint key causes the thermostat

setpoint to appear on the digital display for 10 to 15

seconds.

Thermostat

The setpoint range for the thermostat is -26 to 86 F (-32 to

30 C) or -8 to 86 F (-22 to 30 C). The thermostat setpoint

appears on the digital display when the Setpoint key is

pressed. Turning the thermostat dial changes the setpoint.

The thermostat controls the operation of the unit by controlling the power relay, the heat relay, and the electric relays.

Initial Digital Display Test

1. Turn the un it ON. Note what ap pears o n the digital dis play. This is the temperature display.

a. Normal Display (-40 to 199 F [-40 to 38 C])

b. Blank Display

c. Erratic Display

2. Press the Setpoint key and note what appears on the

digital display. This is the setpoint display.

a. Normal Display (-26 to 8 6 F [-32 to 30 C])

b. Blank Display

c. Erratic Display

d. No Change

3. Refer to the Display Diagnosis Chart to see what to

check next.

Check Power—Engine Operation

1. Make sure that the condenser cover is on the unit.

2. Remove the cover from the back of the cab contro l box.

Temperature

Display

3. Start the truck engine and turn the unit ON.

Display Diagnosis Chart

Setpoint Display

Normal Display Blank Display Erratic Display No Change

Normal Display

Blank Display Check Sensor Check Power Check Power Check Power

Erratic Display Check Sensor Check Power Check Power Check Power

No Problem Faulty Cab

Control Box

Faulty Cab

Control Box

Faulty Cab

Control Box

31

Page 40

Electrical Maintenance (Rev 1/99)

Steps 4 and 5 refer to Wiring Diagram 5D44456 and Schematic Diagram 5D44455.

4. Check the voltage between the 2R3 circuit (pin 3) and

the CH circuit (pin 9) in the connector on the back of

the cab control box. Battery voltage (12 volts).

5. If battery voltage is not present, check the wiring and

connectors in the circuit to the vehicle accessory terminal 2R3 and SW2 on the PC board. Make sure that the

vehicle accessory terminal has power.

Steps 6 and 7 refer to Wiring Diagram 5D46190 and Schematic Diagram 5D46179.

6. Check the voltage between the ACD circuit (pin 3) and

the CH circuit (pin 9) in the connector on the back or

the cab control box. Battery voltage (12 volts).

7. If the battery voltage is not present, check the wiring

and connectors in the circuit to the vehicle accessory

terminal, ACD. Make sure that the vehicle accessory

has power.

Check Power—Electric Standby Operation

proper output voltages (X3-X4) and make sure that the

electric standby power supply is turned ON.

Steps 6 and 7 refer to Wiring Diagram 5D46190 and Schematic Diagram 5D46179.

6. Check the voltage between 2R1 (pin 2) and the CH circuit (pin 9) in the connector on the back of the cab control box. Transformer output voltage (12 volts) should

be present.

7. If voltage is not present, check the wiring, connectors

and components to the transformer (L1, L3; 2R2, 2R2;

and F7) fuse. Check the transformer for the proper output voltages (X3-X4) and make sure that the electric

power standby is ON.

Check Sensor

A good sensor should have a resistance of 805 to 825 ohms

at a temperature of 32 F (0 C). To check a sensor:

1. Disconnect the sensor wires form the back of the cab

control box and connect the sensor wires to an accurate

ohmmeter.

1. Make sure that the condenser cover is on the unit.

2. Remove the cover from the back of the cab contro l box.

3. Connect the unit to an appropriate electric standby

power supply and turn the unit ON.

Steps 4 and 5 refer to Wiring Diagram 5D44456 and Schematic Diagram 5D44455

4. Check the voltage between the 2R2 circuit (pin 2) and

the CH circuit (pin 9) in the connector on the back of

the cab control box. Transformer output voltage (12

volts) should be present.

5. If voltage is not present, check the wiring, connectors,

and components in the circuit to the transformer (L1,

L3; 2R2, 2R 1; F5 fuse). Check the t ransforme r for the

2. Remove the sensor from the evaporator and place the

sensor in an ice water bath at 32 F (0 C). Use a reliable

thermometer to confirm the temperature of the ice

water bath. Make sure that the sensor is in the ice water

bath long enough (a few mi nute s) for th e temperatu re to

saturate the sensor.

3. Check the resistance of the sensor. It should be 805 to

825 ohms. If not, check the sensor wires to make sure

that they are not damaged. If the sensor wires are not

damaged, the sensor is defective.

4. If the sensor is not defective, reconnect the sensor wires

to the back of the cab control box and check the thermometer display. If th e thermometer display is not normal, attach a new sensor to the cab control box and

recheck the thermometer display. If thermometer display is still not normal, the cab control box is defective.

32

Page 41

Electrical Maintenance (Rev 1/99)

Faulty Cab Control Box

Before replacing the cab control box make sure that another

problem, such as a l oose wire connection or a bad ground, is

not causing the cab control box to malfunction.

Thermometer Calibration Test

1. Place the sensor in an ice-water bath for a few minutes

and allow the sensor temperature to stabilize.

2. Check the thermometer reading. It should be 32 ± 2 F

(0 ± 1 C).

3. If the thermometer reading is out of calibration, replace

the sensor and repeat the test.

4. If the thermometer reading is still out of calibration, the

cab control box is defective.

Thermostat Switch Sequence Test

This test should be performed during scheduled preventive

maintenance operations. Make sure that the thermometer is

calibrated before performing this test.

NOTE: Press the Setpoint key to display the thermostat

setpoint.

3. Continue to slowly turn the thermostat dial up to raise

the thermostat setpoint about 2 F (1 C) every 5

seconds. When the thermostat setpoint is approximately 3.6 F (2 C) above the thermometer reading, the

Heat Indicator and the Running Indicator should both

come on, the heat relay should energize, and the unit

should shift to heat.

4. Slowly turn the thermostat dial d own to lower the thermostat setpoint about 2 F (1 C) every 5 seconds. When

the thermostat setpoint is equal to the thermometer

reading, the Heat Indicator and the Running Indicator

should both go off, the heat relay should de-energize,

and the unit should shift to null.

5. Continue to slowly turn the thermostat dial down to

lower the thermostat setpoint about 2 F (1 C) every 5

seconds. When the thermostat setpoint is ap proximately

3.6 F (2 C) below the thermometer reading, the Cool

Indicator and the Running Indicator should both come

on, the power relay should ener gize, an d the unit s hould

shift to cool.

If the indicator lights do not come on and go off properly,

and if the unit does not shift operating modes properly, the

cab control box is probably defective.

Engine Operation Test

1. Start the unit on engine operation and set the thermostat

at least 6.3 F (3.5 C) below the thermometer reading.

The Cool Indicator and the Running Indicator should

be on, the Heat In dica to r sho u ld be off, t he po we r rela y

should be energized, the heat relay should be de-energized, and the unit should be running in cool.

2. Slowly turn the thermostat dial up to raise the thermostat setpoint about 2 F (1 C) every 5 seconds. When the

thermostat setpoint is approximately equal to the thermometer reading, the Cool Indicator and the Running

Indicator should both go of f, the pow er relay shou ld deenergize, and the unit should shift to null.

If the indicator lights come on and go off properly, but the

unit does not shift operating modes properly, make sure that

the power relay, the heat relay , the associated wiring and the

wire connections are not defective before assuming that the

cab control box is defective. Specifically:

1. The thermostat energizes the power relay by energizing

pin 6 in the connector on the back of the cab control

box.

2. The thermostat energizes the heat relay by grounding

pin 10 in the connector on the back of the cab control

box.

Therefore, the cab control box is no t def ective if it energizes

pin 6 and grounds pin 10 properly.

33

Page 42

Electrical Maintenance (Rev 1/99)

Electric Standby Operation Test

1. Start the unit on standby operation and set the thermostat at least 6.3 F (3.5 C) below the thermometer reading. The Cool Indicator and the Running Indicator

should both be on, the Heat Indicator should be off, the

electric relays should be energized, the heat contactor

should be de-energized, and the unit should be running

in cool.

2. Slowly turn the thermostat dial up to raise the thermostat setpoint about 2 F (1 C) every 5 seconds. When

the thermostat setpoint is approximately equal to the

thermometer reading, the Cool Indicator and the Running Indicator should both go off, the electric relays

should de-energize, and the unit should shift to null.

3. Continue to slowly turn the thermostat dial up to raise

the thermostat setpoint about 2 F (1 C) every 5 seconds. When the thermostat setpoint is approximately

3.6 F (2 C) above the thermometer reading, the Heat

Indicator and the Running Indicator should both come

on, the heat contactor should energize, and the unit

should shift to heat (optional).

4. Slowly turn the thermostat dial dow n to lower th e thermostat setpoint about 2 F (1 C) ev ery 5 seco nds. Wh en

the thermostat setpoint is equal to the thermometer

reading, the Heat Indicator and the Running Indicator

should both go off, the heat contacto r should de-energize, and the unit should shift to null.

5. Continue to slowly turn the thermostat dial down to

lower the thermostat setpoint about 2 F (1 C) every 5

seconds. When the thermostat setpoint is approximately

3.6 F (2 C) below the thermometer r eading, the Cool

Indictor and the Running Indicator should both come

on, the electric relays should energize, and the unit

should shift to cool.

If the indicator lights do not come on and go off properly,

and if the unit does not shift operating modes properly, the

cab control box is probably defective.

If the indicator lights come on and go off properly, but the

unit does not shift operating modes properly, make sure that

the electric relays, the heat contactor, the associated wiring

and the wire connections are not defective before assuming

that the cab control box is defective. Specifically:

1. The thermostat energizes the electric relays by energizing pin 1 in the connector on the back of the cab control

box.

2. The thermostat energizes the heat contactor by grounding pin 10 in the connector on the back of the cab control box.

Therefore, the cab control box is no t def ective if it energizes

the pin 1 and grounds pin 10 properly.

DEFROST SYSTEM

Engine Operation

A defrost cycle can be initiated by pressing the manual

defrost key or by the defrost ti mer when the defr ost term ination switch is closed. Starting a defrost cycle energizes the

defrost relay which energizes the hot gas solenoid and deenergizes the fan relays. Energizing the hot gas solenoid

diverts hot gas into the evaporator coil to melt the frost and

ice. De-energizing the fan relay stops the evaporator and

condenser fans.

The defrost termination switch de-energizes the defrost

relay when the evaporator temperature rises above 52 F

(11.1 C).

To check the defrost cycle, run the unit in cool to drop the

evaporator coil to a temperature below 42 F (5.6 C). Press

the manual defrost key. The unit should shift from the cool

to defrost. If the unit continues to cool, double check the

evaporator coil temperature, and refer to Testing the Defrost

System.

34

Page 43

Electrical Maintenance (Rev 1/99)

NOTE: It takes more time to complete a defrost cycle in

low ambient temperatures (below 35 F [2 C]) than it does

in high ambient temperatures (above 70 F [21 C]). Therefore, consider the ambient temperature before deciding

that a unit is not defrosting proper ly.

Electric Standby Operation (Model 20)

Defrost operates essentially the same on electric standby as

it does on engine operation.

Defrost Components

Defrost Timer

The defrost timer is built-in to the PC b oard in the low voltage box. It initiates and, if necessary, terminates the defrost

cycle.

The initiation interval for the defrost timer is adjustable. It

can be set at intervals ranging from 1 hour to 10 hours. The

initiation interval begins when the defrost termination

switch closes. Every time the defrost termination switch

opens, the timer resets to zero.

(5.6 C), completing the defrost circuit to ground (CH) and

preparing the electrical system for the defrost cycle.

When the unit does shift into a defrost cycle, the evaporator

fan stops, and heat from the hot refrigerant gas melts the

frost from the evaporator coil. The switch opens and terminates the defrost cycle when the evaporator coil temperature

rises to 52 F (11.1 C).

Installation

The proper polarity must be observed when installing the

defrost termination switch. The wire from the switch is negative and must be attached to the chassis ground of the unit.

This chassis ground wire cannot be attached to either of the

switch moun ting scre ws or an im proper g round m ay result.

The 12 wire from the unit attaches to the screw terminal that

is mounted solidly on the switch. If the polarity is rever sed

on the device, it will conduct continuously and act like a

switch that is stuck closed.

At the initiation of the defrost cycle, a 45 minute ti mer is

activated. If the defrost termination switch does not open

and terminate the defrost cycle, the timer will terminate the

defrost cycle 45 minutes after it started.

Manual Defrost Key

A Manual Defrost key is located in the cab control box.

Pressing the Manual Defrost key initiat es the defrost cycle

if the defrost termination switch is closed.

Defrost Termination Switch

The electronic defrost termination switch uses solid state

components to control the defrost circuit. The switch is

mounted in the evaporator and controls the defrost cycle in

response to the evaporator coil temperature. The switch is

closed when the evaporator coil temperature is below 42 F

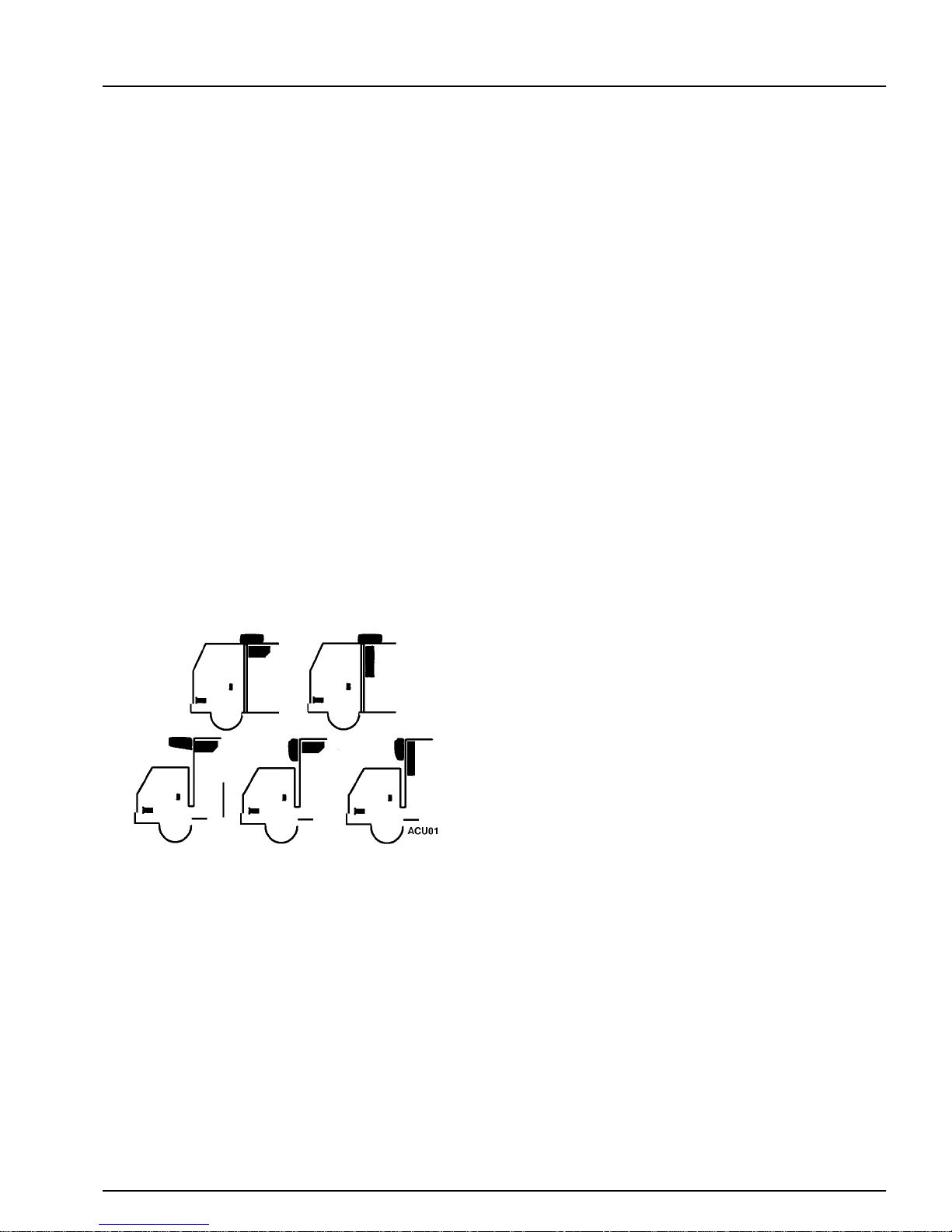

1. Defrost Termination Switch 3. Screw Terminal

2. 12 Wire 4. Ground Wire

Defrost Termination Switch

35

Page 44

Electrical Maintenance (Rev 1/99)

Defrost Termination Switch Bench Test

1. Connect a test light between the screw terminal on the

switch and the positive battery terminal.

NOTE: Attempting to test th e electronic defrost termination switch with an ohmmeter is generally not

satisfactory because of the low voltage available at the

meter leads.

2. Connect the ground wire of the switch to the negative

battery terminal.

3. Raise the temperature of the defrost termination switch