Page 1

Installation ManualInstallation Manual

Installation ManualInstallation ManualInstallation Manual

Installation Manual

TriPac Envidia

Auxiliary Heating and Cooling

Temperature Management System

TK 56459-19-IM (Rev. 0, 12/17)

Page 2

Page 3

Installation Manual

TriPac Envidia

Auxiliary Heating and Cooling

Temperature Management System

TK 56459-19-IM (Rev. 0, 12/17)

Copyright© 2017 Thermo King Corp., Minneapolis, MN, U.S.A. Printed in U.S.A.

1

Page 4

Introduction

This manual was written only to assist with the installation of the Thermo King TriPac Envidia Auxiliary Heating

and Cooling Systems onto a typical Cl ass 8 semi-tractor with sleeper. While it is not intended to be specific to a

particular vehicle, the information in this manual will provide the in stalle r with details to correc tly and safely install

each of the APU components.

Before beginning the installatio n, the in stalle r should confirm with the customer the location for each of the APU’s

component s by using the APU Installation Questionnaire. The customer should also be made aware that modifications to

existing equipment might be necessary to complete the installation.

Modifications may include:

• Tractor’s engine must be fitted with an upgraded alternator of 270 amps or more and with upgraded alternator

wiring of OEM approved design.

• APU condenser may be directly mounted to the outside of the sleeper.

• APU evaporator, power inverter and/or converter may be installed in existing storage spaces under the bunk or in

the toolbox areas.

• APU heating and A/C duct work may to be routed with vents installed in existing closets or storage compartments.

• OEM components on the chassis may need to be relocated to accommodate the installation of the APU battery box.

• OEM fuel tank may need to be changed to a smaller size to accommodate the installation of the APU battery box.

• For base level performance - tractor battery box must have four 12Vdc batteries connected to provide 12Vdc output.

• For optimum level performance - tractor batteries may be upgraded to Thermo King NXT 1150 CCA absorbed glass

mat (AGM) batteries.

Due to its complexity, y ou should not attempt this installation unless you:

• Are an experienced mechanic.

• Can safely lift 34 kilos (75 lbs.)

• In the U.S., EPA 608 certified and trained in the repair and maintenance of transport refrigeration systems.

• Have a basic understanding of electricity and electrical wiring.

• Have the necessary tools and equipment to complete the installation.

• Have a truck body designed and built to meet the requirements of this installation.

This manual is published for informational purposes only. Thermo King makes no representations warranties express or

implied, with respect to the information recommendations and descriptions contained herein. Information provided

should not be regarded as all-inclusive or co vering all co ntingencies. If further information is required, Thermo King

Corporation Service Department should be consulted. Thermo King’s warranty shall not apply to any equipment which

has been “so installed, maintained, repaired or altered as, in the manufacturer’s judgment, to affect its integrity.”

Manufacturer shall have no liability to any person or entity for any personal injury, property damage or any other

direct, indirect, special, or consequential damages whatsoever, arising out of the use of this manual or any

information, recomm e ndations or d e scriptions contained herein.

2

Page 5

Table of Contents

Introduction ................................................................................................................................................................ 2

Table of Contents ....................................................................................................................................................... 3

Tips for a Successful Installation................................................................................................................................ 5

Battery Box Dimensions ............................................................................................................................................. 9

Evaporator/Control Box Dimensions ....................................................................................................................... 11

Condenser with Receiver Drier Dimensions ............................................................................................................ 12

HMI Dimensions ...................................................................................................................................................... 13

1000 Watt Power Inverter Dimensions (Option) ...................................................................................................... 14

AC/DC Shore Power Converter Dimensions (Option) ............................................................................................. 15

D2/D4 Heater Dimensions (Option) ......................................................................................................................... 16

Required Tools and Additional Supplies .................................................................................................................. 18

Typical Component Locations ................................................................................................................................. 19

Tractor and APU Battery Recommendations ........................................................................................................... 20

Battery Box Installation ............................................................................................................................................ 22

Condenser and Receiver Drier Installation ............................................................................................................... 26

Evaporator/Control Box Installation ........................................................................................................................ 28

Fabricating Refrigeration Hoses ............................................................................................................................... 30

A/C Hose Installation ............................................................................................................................................... 34

A/C System Evacuation and Leak Check Procedures .............................................................................................. 36

D2/D4 Heater Installation (Heat Option) ................................................................................................................. 37

D2/D4 Heater Duct Installation (Heat Option) ......................................................................................................... 40

A/C Duct Installation ................................................................................................................................................ 42

Battery Box Harness Installation .............................................................................................................................. 44

Condenser Fan and Sensor Harness Installation ....................................................................................................... 46

Ignition Switch and Harness Installation .................................................................................................................. 47

HMI Installation ....................................................................................................................................................... 48

USB Service C om munication Cable .......................................................................................................................... 49

D2/D4 Heater Harness Installation (Heat Option) ................................................................................................... 50

Fuel Pickup Tube Installation (Heat Option) ........................................................................................................... 51

Heater Fuel Pump and Fuel Line Installation (Heat Option) .................................................................................... 55

Heater Fuel Pump Connections (Heat Option) ......................................................................................................... 57

Auxiliary AC Power Accessories (Option) .............................................................................................................. 58

Installing Battery Cables .......................................................................................................................................... 59

Priming the Heater Fuel Pump (Heat Option) .......................................................................................................... 61

3

Page 6

Heater Start-Up Procedure (Heat Option) ................................................................................................................ 62

A/C System Charging Procedure .............................................................................................................................. 66

Operation Checkout Procedures ............................................................................................................................... 67

Unit Setup ................................................................................................................................................................. 69

System Check List .................................................................................................................................................... 73

4

Page 7

Tips for a Successful In stallation

BEFORE BEGINNING THE INSTALLATION

• Read this manual t o understand where components are to be located and how they are to be installed.

• Review component location diagram and discuss with the customer where each component will be installed on his

tractor.

• Verify tools and special equipment required for the in stalla tion are available and in good working condition.

• Open all installation kits and inspect the contents before beginning installation.

• It is recommended that one person performs the installation of all the components outside the sleeper while a

second person installs all the components inside the sleeper. This will help minimize any damage to the sleeper’s

interior from grease, dirt, etc.

TRACTOR ALTERNATO R

•

Tractor’s engine must be fitted with an upgraded alternator of 270 amps or more and with upgraded alternator wiring of

OEM approved design.

TRACTOR’S BATTERIES

•

It is important not to allow the trac tor’s batteries to become discharged during the installation proc ess. A batte ry

charger should be connected to the batteries while the installation is in process or shut the tractor’s battery power

supply completely off using the OEM main battery disconnect switch, if available. See Tractor and APU Battery

Recommendations section in t his manual for more information.

APU BATTERIES

•

Thermo King NXT AGM batteries are shipped fully charged and ready to use. See Tractor and APU Battery

Recommend at io ns se ct io n in thi s ma nua l fo r mor e info r mati o n. .

APU BATTERY BOX INSTALLATION

IMPORTANT: DO NOT weld or dri l l h oles in the top or bottom flanges of the tractor’s frame. Seriou s structural

•

damage could occur to the frame! Consult your chassis manufacturer for further information.

• The battery box is designed to be mounted only to the existing truck frame rails. NO OTHER MOUNTING

LOCATION IS AC CEPTABLE!

• Safely relocate components on the chassis that interfere with the installation of the battery box.

• Check clearance around battery box before beginning t he installa tion.

• The use of a motorcycle/ATV lift or modified floor jack to raise battery box into position is recommended.

• Only the supplied spacer blocks and mounting claws must be used to install the battery box to the chassis frame rail.

• If diff erent mounting bol ts are u sed, they must be Grade 5 and of the correct length. DO NOT cut off excessive length

bolts.

• Verify the upper and lower battery box mounting bolts are square and flat with the chassis frame rail before

tightening.

• The mounting hardware securing the battery box to the tractor’s frame must be correctly positioned and torqued

using the fo ur-step tightening sequence described in this manual.

5

Page 8

Tips for a Successful Installation (continued)

A/C CONDENSER INSTALLATION

•

Keep all the A/C fittings capped and sealed until the installation of the refrigeration hoses. Refrigerant oil is

extremel y hygroscopi c and a system left open for more than 5 minutes may requir e extensive

evacuation/dehydration time to remove moisture.

• Verify all measurements before drilling any mountin g holes.

• Verify there is no interference with any OEM electrical wiring, internal supports, etc. before drilling mounting holes.

• Confirm the condenser location does not interfere with the service or operation of existing tractor components.

• Provide protection to the tractor’s interior and or exterior finish to prevent damage during the installation process.

• Use the stainless steel mounting hardware (supplied in the kit) to mount the condenser.

• Use the large fender washers (supplied in kit) inside the sleeper to provide additional support.

• All mounting holes must be sealed with silicone caulking to prevent Moisture or fumes from entering the sleeper.

A/C EVAPORATOR/C ONTROL BOX INSTALLATION

•

This installation requires a two-person or mechanically assisted lift.

• Keep all the A/C fittings capped and sealed until the installation of the refrigeration hoses. Refrigerant oil is

extremely hygroscopic and a system left open for more than 5 minutes may require extensive

evacuation/dehydration time to remove moisture.

• Determine the best location for the A/C Evaporator/Con trol Box inside the sleeper, typically under th e bunk and f lush

to the front bulkhead.

• Allow adequate clearance for attac hi ng the t wo air out le t t ub es.

• Verify there is no interference with any OEM electrical wiring, internal floor supports, etc. before drilling any mounting

holes in the tractor.

• The Evaporator/Control Box should be mounted directly onto the floor mat inside the sleeper. Use the supplied

template to properly locate the drain and mounting holes.

• Always install the drain valves (kazoos) into drain holes located on the bottom pan of the evaporator.

• The A/C vents should be located and installed to provide maximum air circulation in the sleeper such as: MEDIUM

(above lower bunk level) and HIG H (above up per bunk level). NOTE: Locating a ve nt LOW (floor level) is not

recommended. It will significantly reduce driver comfort and reduce maximum system run time.

• All mounting holes must be sealed with silicone caulk to prevent moisture or exhaust fume s from entering the

sleeper.

• All edges of access holes made in f iberglass and wood composite floors must be sealed correctly with fiberglass cloth

and resin.

6

Page 9

Tips for a Successful In stallation (continued)

D2/D4 HEATER INSTALLATION (Heat Option)

•

Determine the best location of the heater inside th e sleeper, typically un der the bunk. A llow clearance for dism antling

for service.

• Install heater so it will maintain a minimum distance of 2.00 inches (50.8 mm) from any heat sensitive or flammable

material.

• The heater must only be mounted on a flat horizo n tal sur face.

• Heater must be installed flush with the floor pan (i.e. sheet metal, fiberglass, etc.) to ensure proper sealing of the

mounting plate and gasket.

• All edges of access holes made in f iberglass and wood composite f loors must be sealed correctly with f iberglass cloth

and resin.

• Outside air intake and exhaust hoses must be installed correctly for the heater to operate safely.

• Exhaust hose should be mounted slightly downwards to help drain off condensation.

• Install exhaust hose so it will maintain a minimum distance of 2.00 inches (50.8 mm) from any heat sensitive or

flammable material.

• Inside air inlet and outlet ducts must be installed correctly for the heater to operate safely:

• Pulse type fuel pump outlet must be installed at a 15 to 35 degree angle up from horizontal to operate correctly.

• Fuel pickup tube must be installed correctly in the fuel tank or the heater will not operate.

• Fuel line from the pickup tube to the fuel pump to the heater should be routed at a continuous rise. Use a hose cutter

or sharp knife to cut plastic fuel lines. Do no t use a wire cutter as this will pinch the plastic fuel line closed.

• Do not route electrical wires, harness or battery cables together with fuel lines.

• BEFORE operating the heater, the fuel lines must be bled of air using the Heater Priming Harness (204-1144) or

damage to the fuel pump will result.

• The Diagnostic Code Reader (204-1143) must be used to setup and operate the heater in the run-in mode.

A/C HOSE CONNECTIONS AND ROUTING

• Keep all the A/C fittings capped and sealed

extremel y hygroscopi c and a system left open for more than 5 minutes may requir e extensive

evacuation/dehydration time to remove moisture.

until the installation of the refrigeration hoses. Refrigerant oil is

• Only cut refrigerant hoses with the corr ect hose cutting tool (204-677). NEVER USE A SAW!

• Always use the correct hose fitting tool (204-1045) when assembling refrigeration hose s .

Always lubricate hose fittings with Alkyl Benzene Refriger ant Oil (670404TKA) when assembling to refrigeration

•

hoses.

• Always install and lubricate O-rings with Alkyl Benzene Refrigerant Oil (670404TKA) when connecting

refrigeration hose fittings to component connection fittings.

• Refrigeration hoses should be installed onto components in such a way as to allow for vibration and movement of

the cab. THEY SHOULD NEVER BE STRETCHED TIGHT!

• All refrigeration connections should be tightened securel y using two wr enches.

• Always keep refr igeration hose s from rubbing or chafing agai nst sharp meta l objects, rotating components or hot

components.

7

Page 10

Tips for a Successful Installation (continued)

• Protective covers or sleeves (installer supplied) for the refrigeration hoses may be required depending on the

installation.

• Always install the condenser’s receiver drier so refrigerant flow is in the direction indicated by the arrow.

• Thermo King Evacuation Station (20 4-725) and Evacuation Station Operatio n and Field Application Instr uctio ns

(TK-40612) are recommended.

• The oil in the evacuation station vacuum pump should be changed after each use.

• The A/C system must be leak free. Check for leaks by using an electronic leak detector.

• The A/C system will be charged with 2.0 lbs. of R134a refrigerant. NOTE: Accuracy is important. Over or under

charge by 3 ounces will reduce cooling capacity.

ELECTRICAL WIRING AND HMI CONTROLLER INSTALLATION

•

Electrical wiring s hould be inst alled and rout ed in such a way as to allow for vibrat ion and movement o f

the cab. THEY SHOULD NEVER BE STRETCHED TIGHT!

• Always keep electrical wiring from rubbing or chafing against sharp metal objects, rotating components or hot objects.

• All electrical wiring should be neatly routed and secured with band wraps or clamps.

• Do note route or bundle 110Vac wires together with 12Vdc wires.

• Do not route electrical wires, harness or battery cables together with fuel lines.

• Excess length of battery cables should be cut off to reduce voltage drop.

• Superlube (203-524) or equivalent should be applied to a ll electric a l c onnections.

• All main power and ground accessory connections must be installed directly on top of the tractor’s battery terminal

posts and tightened securely. DO NOT INSTALL UNDER OEM BATTERY CABLES!

8

Page 11

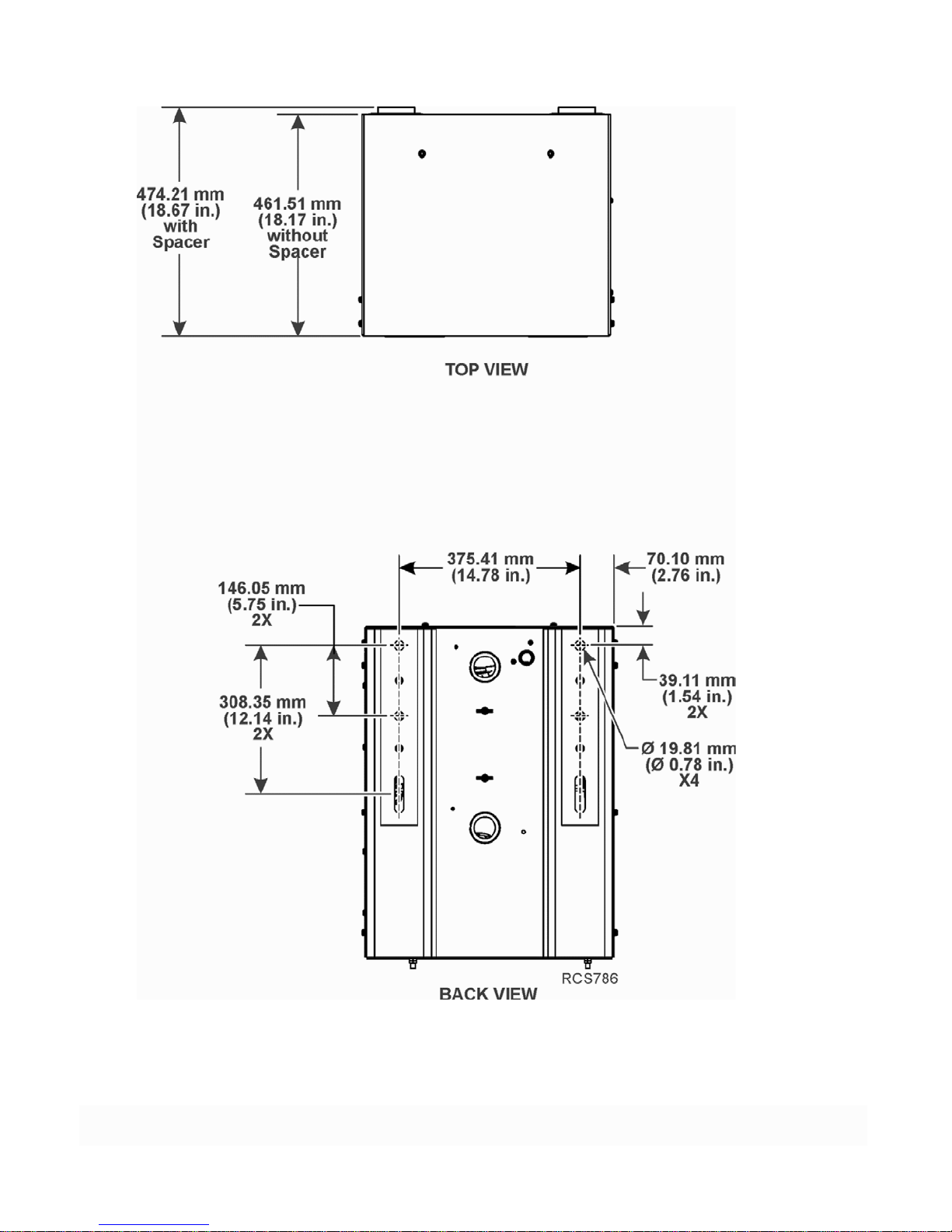

Battery Box Dimensions

Figure 1: Battery Box Dimensions

9

Page 12

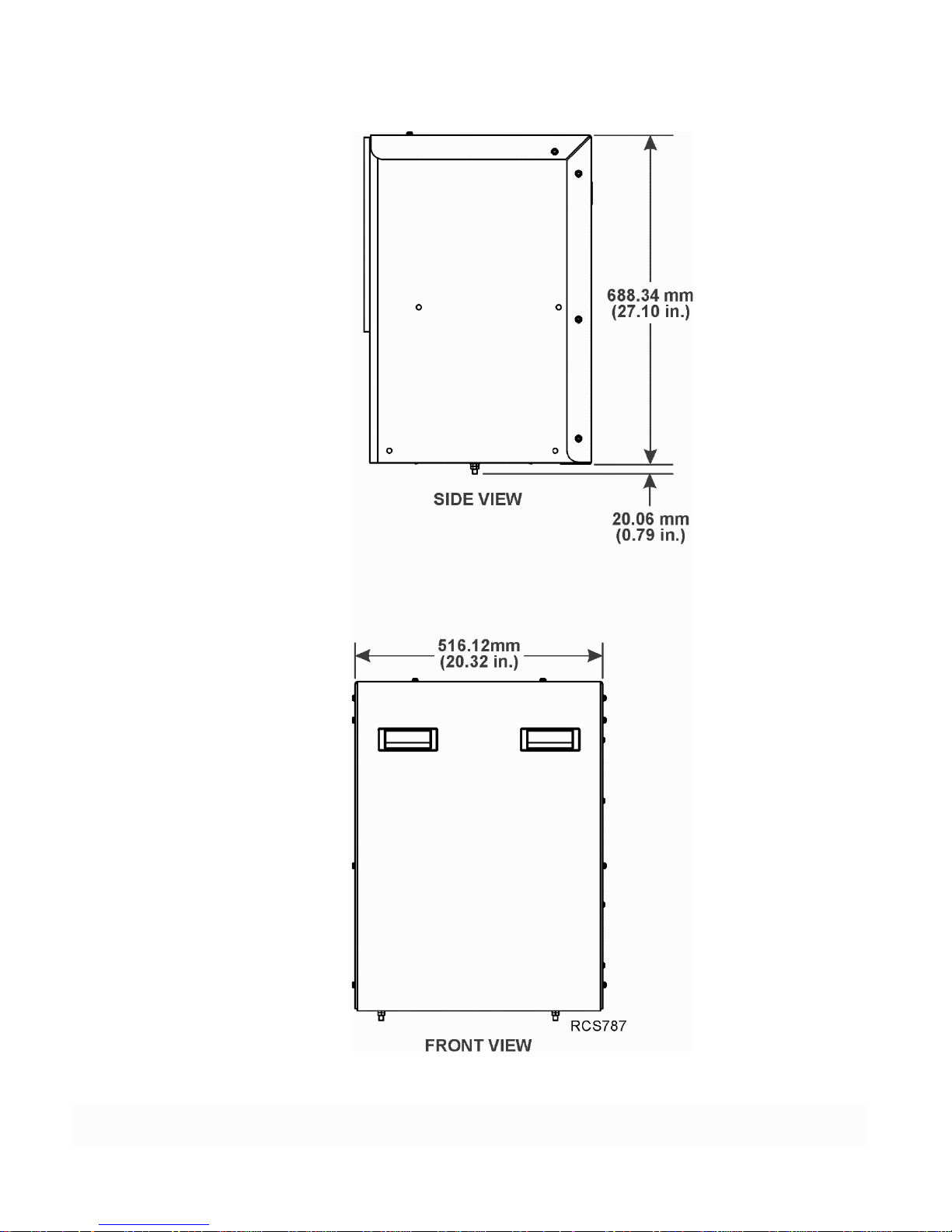

Battery Box Dimensions (continued)

Figure 2: Battery Box Dimensions (continued)

10

Page 13

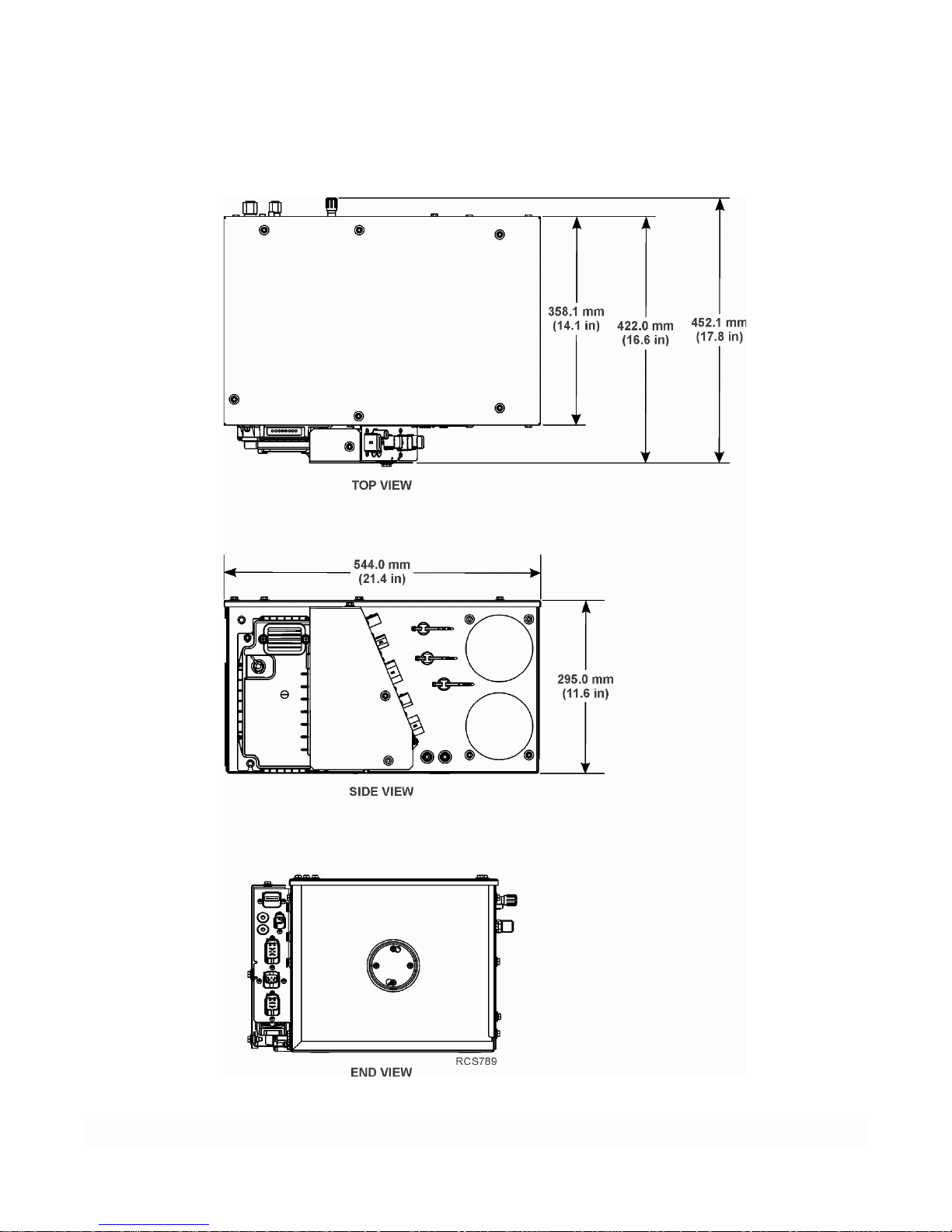

Evaporator/Control Box Dimensions

Figure 3: Evaporator/Control Box Dimensions

11

Page 14

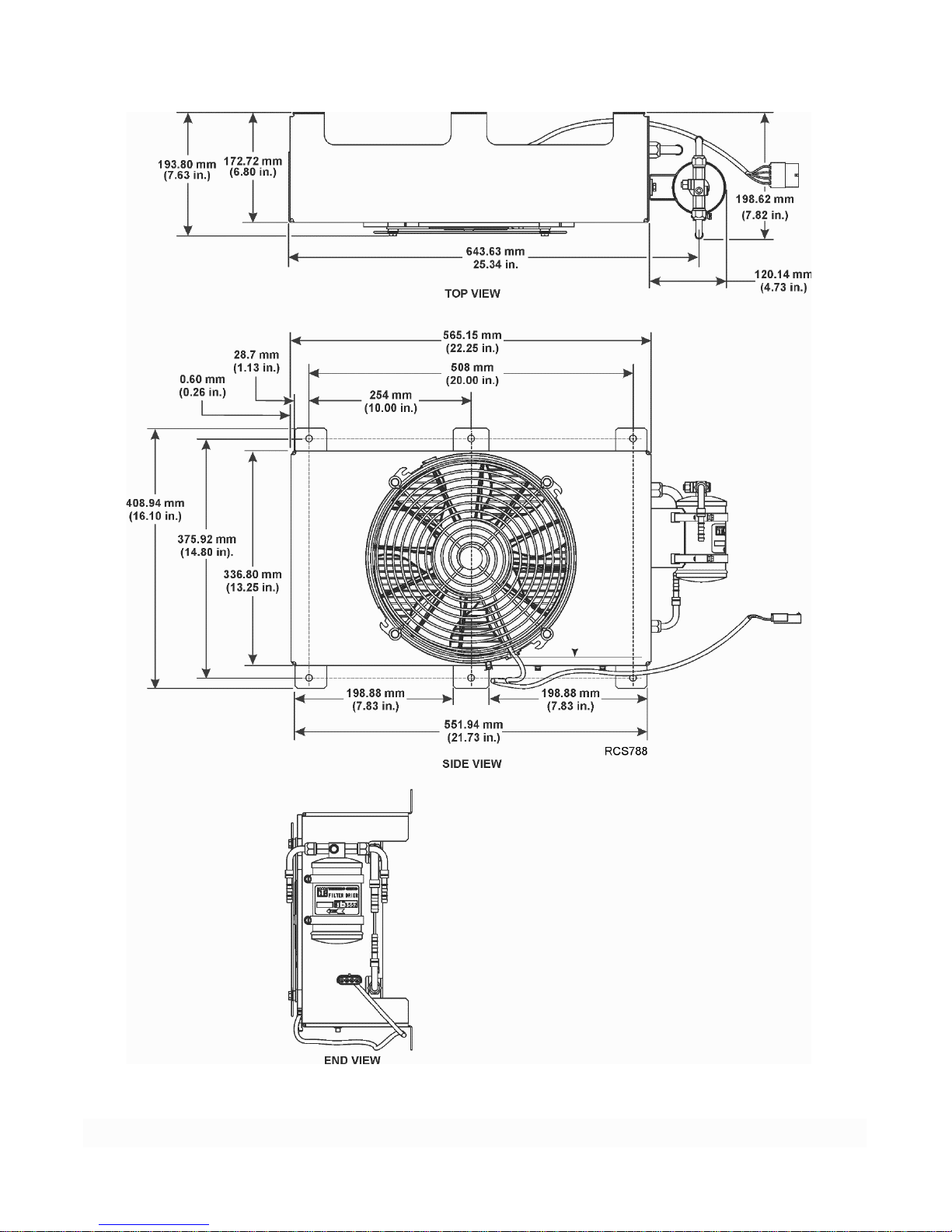

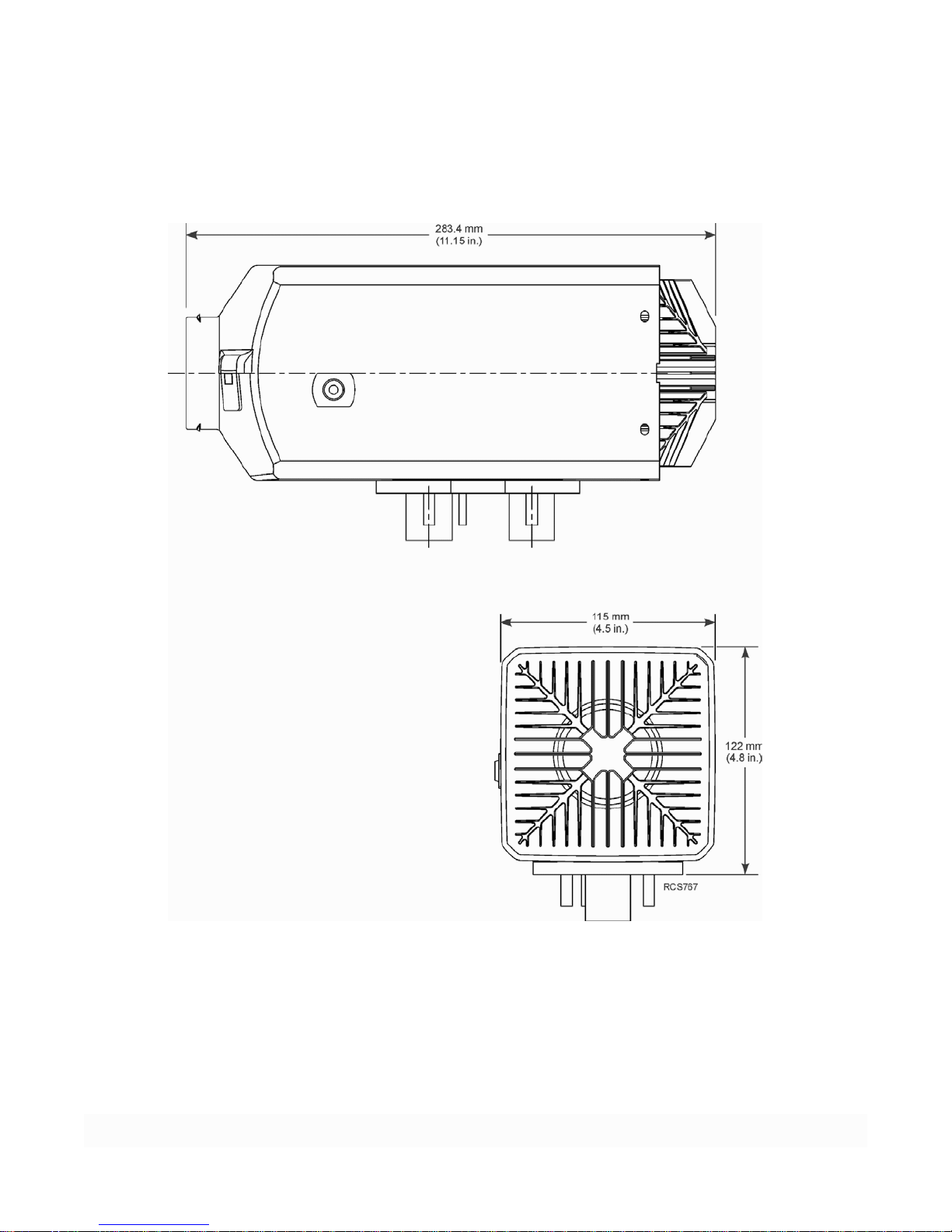

Condenser with Receiver Drier Dimensions

Figure 4: Condenser with Receiver Drier Dimensions

12

Page 15

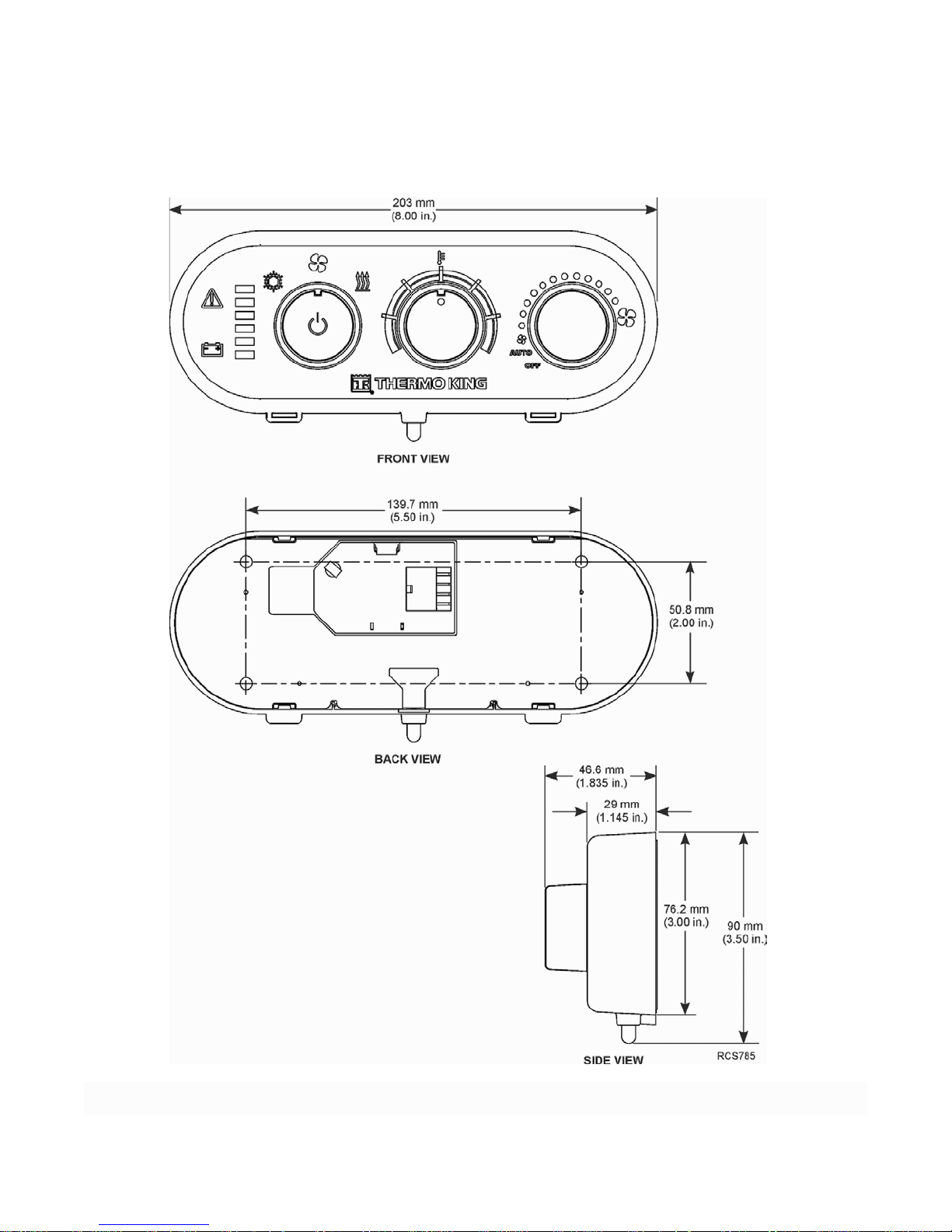

HMI Dimensions

Figure 5: HMI Dimensions

13

Page 16

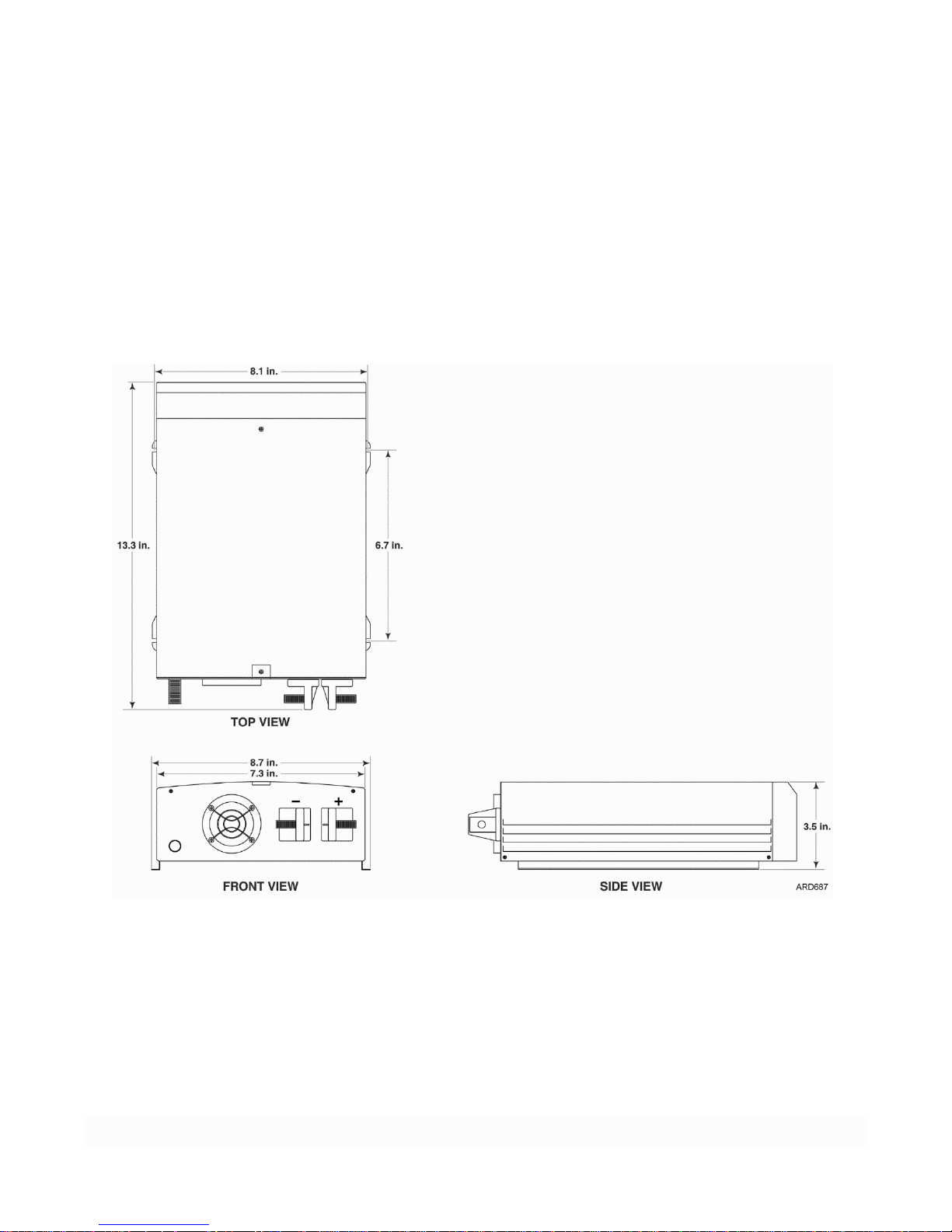

1000 Watt Power Inver ter Dimensions (Option)

Figure 6: 1000 Watt Power Inverter Dimensions

14

Page 17

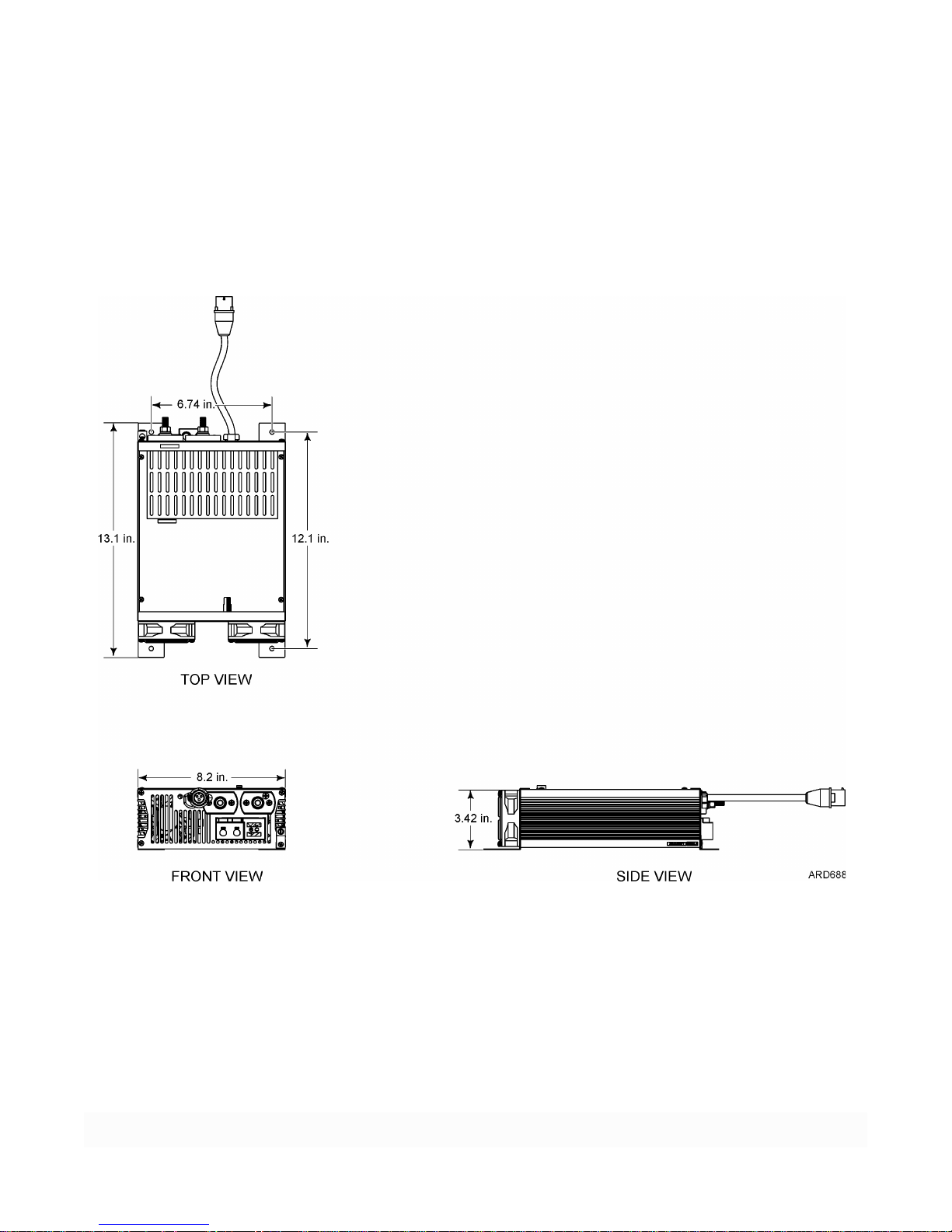

AC/DC Shore Power Converter Dimensions (Option)

Figure 7: AC/DC Shore Power Converter Dimensions

15

Page 18

D2/D4 Heater Dimensions (Option)

Figure 8: Heater Dimension

16

Page 19

BLANK PAGE

17

Page 20

Required Tools and Additional Supplies

Tools

1. Typical Mechanics Tools

2. Floor Jack or Motorcycle/ATV Lift

3. Drill Motor

4. Drill Bit Set

5. 7/8" dia. or 1" Step Reamer (for evaporator drain and controller holes)

6. Hole Saws

a. 1" dia. (for fuel tank pickup tube)

b. 2-1/2" dia. (for heater inlet/outlet louver)

c. 2" dia. (access hole for evaporator hoses and elec tric al wiring)

d. 3” dia. ( optiona l si ze acces s hole)

e. 4-1/4" dia. (mounting A/C louver s, r outing A/C d uc ts through and heater mounting hole)

7. Reciprocating Saw (return air opening)

8. 1/2" Wrench

9. Level

10. Tape Measure

11. Utility Knife

12. Caulk Gun

13. Digital Meter (204-1079)

14. Refrigerant Leak Detector (204-712)

15. Hose Fitting Tool (204-1045)

16. Hose Cutting Tool (204-677)

17. Heater Priming Harness (204-1144)

18. Shop Vacuum

19. R-134a Gauge Manifold with automotive connectors

20. Vacuum Pump (204-713)

21. Micron Gauge (204-720)

22. Accurate Refrigerant Scale

23. AGM Battery Tester (204-1959)

24. Heavy Duty AGM Battery Charger (204-1923)

25. Laptop Computer (IBM Compatible) with Microsoft Internet Explorer 10.0 or higher installed.

26. USB Adapter Cable (204-2000)

Supplies (as required)

1. RTV Silicone sealant

2. Sealer Tape (203-391)

3. Alkyl Benzene Refrigerant Oil (670404TKA for lubricating hose fittings and O-rings)

4. Refrigerant 134a

5. Return air wall louver (approximately 11” x 10”)

6. Mounting Clamps #24 and #32 (to secure cables and hoses)

7. Band Wraps (assorted sizes and lengths)

8. Upholstery cleaner

9. Cardboard or blankets (to protect truck interior)

10. Fiberglass repair Kit (only used for fiberglass and wood composite floor)

18

Page 21

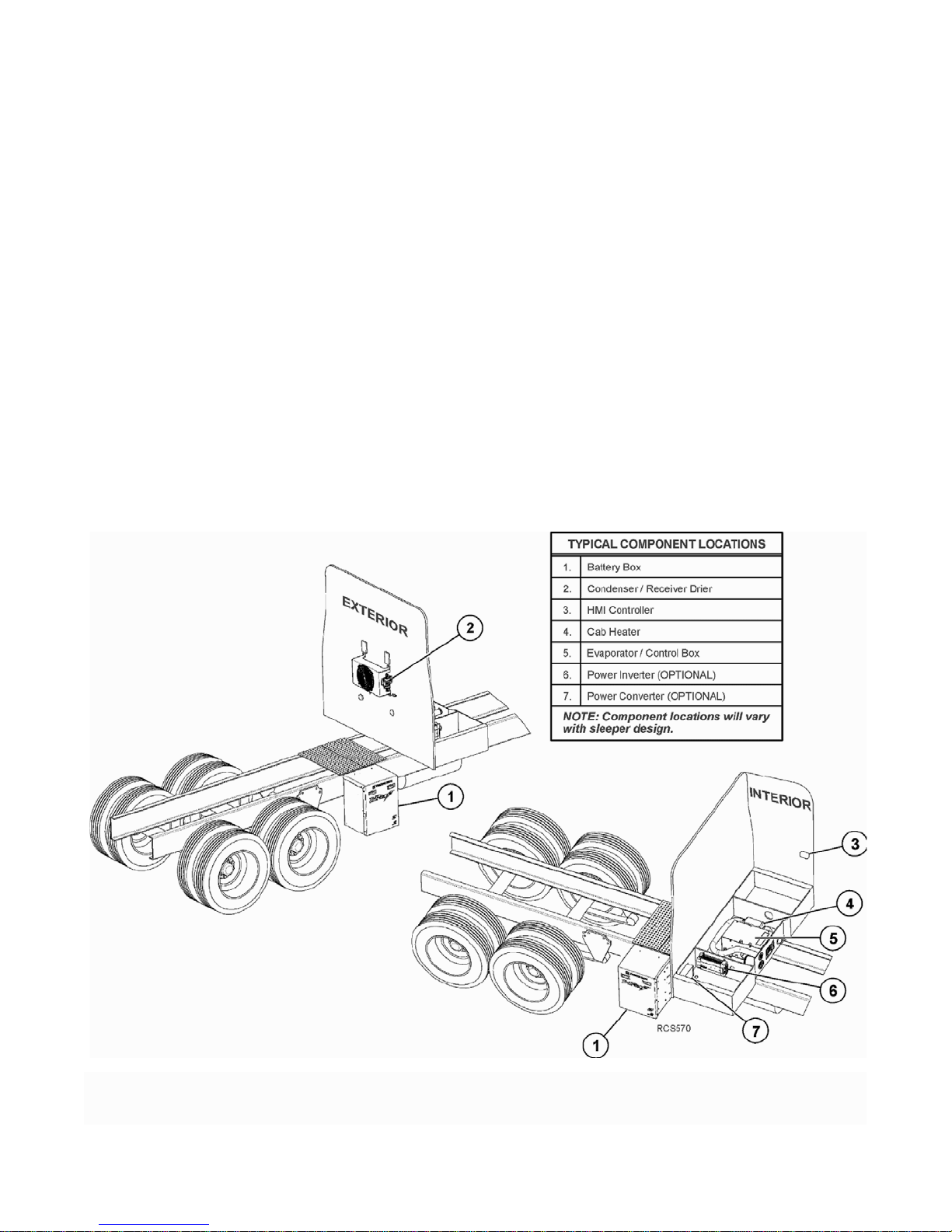

Typical Component Locations

Figure 9: Typical Component Locations

19

Page 22

Tractor and APU Battery Recommendations

Tractor’s Batteries

The tractor’s batteries should not be allowed to become discharged during the APU installation process. Always

connect a battery charger to the tractor’s batteries before beginning the installation.

An alternative method is to shut the tractor’s battery power completely off using the OEM main battery discon nect

switch if available.

For base level performance - tractor battery box must have four 12Vdc batteries connected in parallel to provide 12Vdc

output.

For optimum level performance - Thermo King recommends the tractor batteries be upgraded to Thermo King NXT

1150 CCA absorbed glass mat (AGM) batteries.

NXT AGM Batteries Charge Maintenance

Thermo King NXT AGM batteries are shipped fully charged. Fully charged NXT AGM batteries that are kept in stock

should not require charging for 2 ye ars if ke pt be l ow 77 F (25 C ). NX T AGM batt e ries should be ch a rged w hen th e open

circuit voltage (OCV) falls below 12.50 volts.

To charge the NXT AGM battery, use the following guidelin e s:

1. Verif y the output vo ltage of y our batter y charger is capable of maintaining 14.1 to 14.7 chargin g voltage. The

recommended charging voltage range for the NXT AGM battery is 14.1 to 14.7 volts. Voltages are to be

measured at the battery terminals with the battery connected to the charger.

IMPORTANT: Never exceed 15 volts when charging the NXT AGM battery. Exceeding 15 volts will cause pressure

relief valves to open and out-gas hydrogen and oxygen from inside the battery. This will shorten the life of the

battery and could lead to premature battery failure.

2. Battery chargers with the batte ry type output setting should be set to AGM type battery. Do not set the output

type to gel cell or maintenance free settings.

3. Determine if your battery charger is an automatic or manual charger. Manual battery chargers must be closely

monitored during the charge period and for this reason an automatic battery charger is preferred over a manual

charger.

a. Automatic battery chargers either charge up to a preset voltage and shut off, or charge to a present

voltage and then switch to a trickle charge mode. Either one of these battery chargers is acceptable:

however, the automatic charger that shuts off may not fully charge the battery.

b. Manual battery chargers will have manual controls for setting the charge amperage rate. The charge

amperage rate will remain the same until the battery charger is manually shut off.

NOTE: When using a manual battery charger, set the charger to charge at 10 or 20 amps and limit the charging

time based on the batteries state of charge (SOC). Use the chart below as a general guide to determine the amount of

time necessary to charge the battery. DO NOT overcharge the battery.

20

Page 23

Tractor and APU Battery Recommendations

12.84 Volts

100%

0 Hours

0 Hours

12.50 Volts

75%

2 Hours

1 Hour

12.20 Volts

50%

4 Hours

2 Hours

11.88 Volts

25%

6 Hours

3 Hours

(continued)

Determining Maximum Charge Time Using a Manual Charger

Voltmeter Reading State of Charge Time @ 10 Amps Time @ 20 Amps

WARNING: Overcharging can damage the battery and possibly cause a fire or explosion. Follow the battery

charger’s recommendations for monitoring batteries while charging. Batteries should be monitored while charging

for signs of internal problems. Signs of internal problems include bulging cases, extreme gassing, pungent smell,

and extreme heat. If you notice any of these signs turn the charger off and allow the battery to stabilize before

handling or testing.

Cleaning a Battery

Use a damp cloth to clean the top of the battery to eliminate conductive paths created by dirt and dried or wet

electrolyte, and to prevent corrosion. Use a battery terminal-cleaning tool that has nonco nductive (plastic or r ubber)

cover to clean the battery terminals when corrosion is present. Replace any battery cables (or cable terminals) that are

frayed, corroded, swelled, or damaged to the extent that they cannot be cleaned.

Battery Hold Down Hardware

Batteries are subjected to extreme shock loads and vibration. It is very important to make sure each battery is secured

by the proper mounting hardware. Failure to secure each battery correctly can result in premature battery failure. Using

a torque wrench, torque the hold down nuts in two step increments:

• STEP 1 - Torque ea ch ho ld down nut to 60 in-lbs. (6.8 N•m)

• STEP 2 - Torque each hold down nut to 120 to 144 in-lbs. (13.5 to 16.3 N•m)

Battery Cable Mo un tin g

On threaded stud type batteries, use only stainless steel nuts to fasten the cable to the battery. Torque the nut to 150 to

200 in-lbs. (17 to 22 .5 N•m).

On SAE post type batteries, use o nly stainless steel battery clamp bolts. Torque the nut to 60 in-lbs. (7 N•m).

21

Page 24

Battery Box Installation

Special Tools Required

Modified Floor Jack or Motorcycle/ATV Lift

½” Drive Torque Wrench

STANDARD INSTALLATION METHOD - MOUNTING CLAWS

WARNING: Installer supplie d lifting eyebolts must be forged stee l, 1/2"(12mm) diameter.

WARNING: Use only locking lif ting hooks to attach to the lifting eyeb olts.

WARNING: DO NOT connect any of the TriPac ENVIDIA battery cables to any b atteries at this time.

NOTE: DO NOT OIL THE BOLT THREADS!

1. Remove the cover from the battery box to access and remove hardware that secures box to the shipping crate.

2. It is recommended that a modified floor jack or motorcycle/ATV lift be used to install the battery box.

Protection suc h as c ar db o ard, sho p ra gs, etc. sho uld be us ed und e r t he bo x to pr eve nt d amage d uri ng

installation.

a. Install lifting eyebolts, wa shers and nuts securely into the two holes at the top of the battery box.

b. Using locking lifting hooks, raise the battery box and place onto the lift then remove lifting eyebolts,

washers and nuts.

3. Using a lift, carefully raise the battery box into position. Install the 3/4" bolts and washers through the

mounting claws and the rear of the b attery box.

4. Loosely install the retainers and locking nuts inside the battery box.

NOTE: Mounting bolt threads must extend into the battery box.

IMPORTANT: The following steps are critical and must be followed to ensure the safe installation of the battery box

to the tractor’s frame.

5. With battery box still supported by a lift:

a. Push battery box up tight to tractor’ s frame .

b. Adjust height of box so top and bottom mounting claws and bolts are positioned flat on frame.

c. Review (Detail A) - Lightly tighten mounting hardware only enough to remove excess p lay.

6. Using a torque wrench, torque mounting bolts in four step increments starting with top bolts, then bottom

bolts.

a. STEP 1 - Torque top then bottom mounting bolts to 25 ft-lb. (33.9 N•m). IMPORTANT: STOP and

verify all mounting claws and bolts remained flat on frame (Detail A). If they are not, loosen bolts,

adjust as necessary and retighten again to 25 ft-lb. (33.9 N•m).

b. STEP 2- After first step is s uccessfully completed, tor que top, then bottom bolts to 50 ft-lb. (67.8

N•m).

c. STEP 3- Next, torque top, and then bottom bolts to 100 ft-lb. (135.6 N•m).

d. STEP 4 - Finally, recheck all bolts to confirm they are at 100 ft-lb. (135.6 N•m)

7. Remove the support lift and visuall y inspect installation for the follo wi ng:

a. Mounting claws and bolts are correctly installed. They should be square and flat on the frame (Detail

A).

b. If any mounting claws and bolts are improperly installed on the frame (i/e. they r e semble Details B

& C) - adjust as nec essary.

c. Damaged, deformed or cracked components during installation - must be replace immediately.

WARNING: DO NOT connect any of the TriPac Envidia battery cables to any batteries at this time.

22

Page 25

Battery Box Installation (continued)

STANDARD INSTALLATION METHOD - MOUNTING CLAWS

WARNING: DO NOT connect any of the TriPac Envidia battery cables to any batteries at this time.

NOTE: Mounting bolt threads must extend into the battery box.

Figure 10: Standard Installation Method – Mounting Claws

23

Page 26

Battery Box Installation (continued)

Special Tools Required

Modified Floor Jack or Motorcycle/ATV Lift

Large Drill (appropriate size to drill holes in frame rails)

25/32" or (20 mm) Drill Bit

1/2” or 3/4" Drive Torque Wrench

Direct Mount Bolt Kit (800461)

OPTIONAL INSTALLATI O N METHOD - DIRECT MOUNT

WARNING: Installer supplie d lifting eyebolts must be forged steel, 1/2" (12 mm) diameter.

WARNING: Use only locking lif ting hooks to attach to the lifting eyeb olts.

WARNING: DO NOT connect any of the TriPac ENVIDIA battery cables to any b atteries at this time.

NOTE: DO NOT OIL THE BOLT THREADS!

1. Remove the cover from the battery box to access and remove hardware that secures box to the shipping crate.

2. It is recommended that a modified floor jack or motorcycle/ATV lift be u sed to install the battery box.

Protection such as cardboard, shop rags, etc. should be used under the box to prevent damage during

installation.

a. Install the lifting eyebolts, washers and nuts securely into the two holes at the top of the battery box.

b. Using lock i ng lifting hooks, rai s e the battery box and pl ace onto the l ift then remove the lifting eyebolts,

washers and nuts.

c. The upper batteries must be removed.

NOTE: If the 1 1/2"or 2 ½” spacer options are being used refer to the installation instructions included with the

option kit.

3. DETAIL A - Before installing the battery box to the tractor’s frame, insert the 3/4 x 3.00" long bolts and

washers through the slotted holes at the rear of the battery box.

a. From inside the battery box, install the washers and locking nuts int o the inner frame channe l. Hand

tighten hard war e

b. Position the bolts at the bottom of the slots and tighten to 200 ft-lb. (270 N•m).

4. DETAIL B - IMPORTANT: Observe the positioning of existing OEM fasteners on the tractor’s frame. The

four fasteners used in this Direct -Mount Option need to be located on the tractor’s frame no higher and no

lower than any existin g OEM faste ners.

a. Measure and mark the lo cation of the four mounting holes on the tractor’s frame. Drill four 25/32" (20

mm) holes in the frame.

5. Using the lift, carefully raise the battery box into position and align t he b a tte ry box mounting ho les wit h the

holes in the tractor’s frame.

a. From the backside of the tractor’s frame, insert bolts and washers through the holes in the frame and then

into the battery box.

b. From inside the battery box, instal l the washers and locking nuts into the inner frame channel. Hand

tighten hardware.

6. With the battery box still supp orted by a lift and level with the tractor’s frame, use a torque wrench and torque

the four frame mounting bolts in three step increments as described below:

a. STEP 1 - Torque top then bottom bolts to 50 ft-lb. (68 N•m).

b. STEP 2 - Torque top then bottom bolts to 100 ft-lb. (135 N•m).

c. STEP 3 - Torque top then bottom bolts to 200 ft-lb. (270 N•m).

DO NOT OVER-TORQUE THE MOUNTING BOLTS!

7. Remove the support lift.

24

Page 27

Battery Box Installation (continued)

OPTIONAL INSTALLATI O N METHOD - DIRECT MOUNT

WARNING: DO NOT connect any of the TriPac ENVIDIA b attery cables to any batteries at this time.

Figure 11: Optional Installation Method – Direct Mount

25

Page 28

Condenser and Receiver Drier Installation

Special Tools Required

Hose Fitting Tool (204-1045)

Alkyl Benzene Refrigerant Oil (670404TKA)

Torque Wrench

Fitting Size

Torque Specifications

#6 (3/8”)

11-13 ft-lb (15-17 N•m)

Figure 12: Refrigeration hose I.D. and sizes shown

Sub-Assembly

IMPORTANT: Keep all the A/C fittings capped and sealed until the installa tion of the refrigeration hoses. Refrigerant

oil is extremely hygroscopic and a system left open for more than 5 minutes may require extensive evacuation /

dehydration time to remove moisture.

NOTE: Read and understand Fabricating Refrigeration Hoses on page 30 for proper hose fabrication requirements.

Always use two wrenches while tightening refrigeration fittings.

Hose Cutting Tool (204-677)

Place the condenser coil onto a workbench and subassemble the following components:

• Loosely install the Ambient Temp Sensor

clamp to the receiver drier bracket.

• Install the receiver drier bracket onto the

condenser c oil housing with the Ambient Temp

Sensor clamp to the back. Use supplied 1/4-20

mounting hardware and tighten securely.

• Attach the two large hose clamps to the

bracket.

• Install the receiver drier to the bracket with the

hose clamps and tighten s ecurely. Use arrow to

verify correct direction of refrigerant flow.

• Fabricate and install a #4 hose (5.00 in. long)

with two 90 degree fittings onto the INLET

fitting of the drier and the bottom OUTLET

fitting on the co ndenser coil . Tighten fi ttings to

the torque specs shown.

#8 (1/2”) 15-20 ft-lb (20-27 N•m)

26

Page 29

Condenser and Receiver Drier Installation

Special Tools Required

Template – Condenser Assembly

Tape Measure

Level

Drill Motor

3/8” Drill Bit

Caulk Gun and RTV Silicone Sealant

(continued)

Installation

CAUTION: Before drilling any holes in the trac tor, check for interference with internal wires, supports or interior

panels. Avoid drilling into any interior support members as this could void the tractor’s OEM warranty.

IMPORTANT: Use a backup wrench whenever tightening refrigerant hose fittings.

Locate an area on the exterior of the sleeper to install the condenser assembly that does not interfere with the operation

of existing truck components. The condenser air inlets and fan outlet airflow must not be restricted. Obstr uctions must

not cause recirculation of condenser out air.

If possible, mount the condenser below the bunk level. This allows easier access to 3/8” bolts with large fender washers

inside the sleeper without disturbing interior panels.

1. Measure and mark the exterior center line of the sleeper.

2. Position the supplied template onto the exterior of the sleeper maki ng sure it is level and centered. Ma r k and

drill the 3/8” mounting holes and r emove the template.

3. Apply a bead of RTV silicone around each of the six mounting holes.

4. Install the condenser assembly with the supplied 3/8” stainless mounting hardware.

5. Assure all six mounting tabs a r e in contact with truck body. Use spacers as required.

6. Tighten hardware securely.

27

Page 30

Evaporator/Control Box Installation

Special Tools Required

Template – Evaporator/Control Box

Drill Motor

1/4” Drill Bit

7/8” Step Reamer

2” dia. Hole Saw (standard installation)

3” dia Hole Saw (optional installation)

Reciprocating Saw

Caulk Gun and RTV Silicone Sealant

Sealing Tape (203-391)

Fiberglass C loth a nd Re sin Ki t (if re qu ired)

Figure 13: Evaporator Template shown

PREFERRED LOCATION - FLUSH WITH FRONT BULK HEAD

IMPORTANT: Keep all the A/C fittings capped and sealed until the installa tion of the refrigeration hoses.

Refrigerant oil is extremely hygroscopic and a system left open for more than 5 minutes may require extensive

evacuation/dehydration time to remove moisture.

Maximum cooling is obtained when evaporator inlet is installed flush with the bulkhead. This allows the hot air from

the sleeper to be drawn directly into the return air inlet filter, through the evaporator coil and out the discharge air vents.

Template

The supplied template represent the amount of area needed to accommodate the Evaporator/Control Box and it also

provides the locations for the mounting feet, drain holes and the two 2" access holes. One hole on each side of the

Evaporator/Control Box. If there is not enough room for the hole near the Controller, an optional larger hole can be cut

near the refrigeration hoses. The controller harnesses will wrap around the end of the Evaporator/Control Box.

IMPORTANT ACCESS HOLE INFORMATION:

• The actual location of the 2” access holes will be determined by your particular sleeper construction, including

OEM internal floor supports, electr ic a l wiring, etc.

• Before drilling any holes, check for interference with internal wires, supports or interior panels. Avoid drilling

into the truck’s support membe rs.

• Floors made from fiberglass covered wood construction require the edges of the access holes be completely

sealed with fiberglass and epoxy resin.

• An optional single 3” hole on the refrigerant line side may be used if mounting location does not permit a hole

on the controller side of the Evaporator/Control Box.

28

Page 31

Evaporator/Control Box Installation (continued)

Figure 14: Preferred Location Shown - Flush with Front Bulkhead

NOTE: It is not necessary to remove the Evaporator/Control Box cover to complete a system installation.

NOTE: This installation requires a two -person or mechanically assisted lift.

1. Position template with RETURN AIR flush with bulkhead. Mark location of the 7/8” evaporator drain holes

and 2” access holes. Remove the template:

a. Drill a 1/4” pilot hole for drain holes followed by a 7/8” step reamer.

b. Drill the 2” access holes. The holes may also be located outside the template area as shown.

2. Cut and install a piece of split loo m (or similar) around the inside edge of the 2” access holes to provide

protection for hoses and wiring.

3. Install ret ur n air fil ter s upport to front of Evaporator/Control Box.

4. Set evaporator in place and determine where return air opening needs to be located on bulkhead. Leave

clearance for filter removal.

5. Mark return air opening (11.00 in. x 10.00 in.).

a. Cut opening in bulkhead.

b. A return air grille (installer supplied) can be installed to the bulkhead if desired.

6. Install the defrost drain tubes to the base of the evaporator before mounting to the floor.

7. Loosely install the three mounting tabs onto the evaporator.

8. Secure the evaporator to the floor with TEK screws.

9. Tighten the mounting ta b bolts.

10. From underneath the sleeper:

a. Seal around drain tube access holes with sealing putty or silicone sealant.

b. Apply silicone sealant around the three evaporator mounting screws.

c. Seal any unused holes, cracks, or visible air gaps that might be found.

29

Page 32

Fabricating Refrigeration Hoses

Assembly Materials Checklist

Hose Cutting Tools (204-677)

Nipple Assembly

Alkyl Benzene refrigerant oil (670404TKA)

4.

Nipple with internal O-ring

Figure 15: TK 2000 Components shown

TK 2000 Assembly System

The TK 2000 System is designed for assembly with Multi-Refrigerant hose only.

Hose Fitting Tool (204-1045)

TK 2000 Multi-Refrigerant Hose

Appropriately Sized Clips and Cage

NOTE: The two black O-rings on the nipple assembly are of a specific rubber compound and size. They should not

be removed or replaced.

1. Hose

2. Cage

3. Clips

30

Page 33

Fabricating Refrigeration Hoses (continued)

Cut the Hose

1. Cut the hose to proper length with an appropriate cutting tool. Hand -held hose cutter (204-677) has been

specially designed for cutting all non-wire reinforced hose, such as TK 2000 Multi-Refrigerant hose. Be sure the

cut is made square to the hose length.

Slip on Two Clamps

2. Install one or two proper- size clips, depending on hose size, onto the cut end of the hose. Orientation of the clips

does not affect the performance of the connection. However, for ease of assembly, both clips should have the

same orientation.

CAUTION: Failure to slide the clips over the hose at this time will require the clips to be stretched over the

hose or fitting later. This

may permanently damage the clip.

31

Page 34

Fabricating Refrigeration Hoses (continued)

Oil the Nipple

3. Lubricate the nipple with a generous amount of the Alkyl Benzene refrigerant oil (670404TKA). This MUST be done to

lower the force of nipple insertion.

4. Insert the nipple into the hose. To ensure that the nipple is full y inserted, check the gap between the cut end of the

hose and the shoulder o n the nippl e. Care should be taken to avoid kinking or othe r damage to the hose during

nipple insertion.

NOTE: Be sure to wipe excess oil from the nipple and hose

.

Snap on the Cage

5. Snap the cage into the groove on the nipple. The arms should extend over the hose length. When the cage has been

carefully installed in the cage grove, the cage will be able to rotate in the grove. This step must be performed to

ensure:

a. The clips will be located over the O-ring on the nipp le .

b. The connection will be compatible with the connection’s pressure rating.

Slide the Clips

6. Slide the clips over the cage arms and into the channels on each arm.

Close the Clips

7. Use the fitting tool (204-1045 or 204-1128) to close the clips. The pliers should be positioned squarely on the

clip connection points and should remain square during the closi ng of the clip

NOTE: For easiest assembly, the clasp should be closed between the cage arms.

.

32

Page 35

Fabricating Refrigeration Hoses (continued)

Correct

Incorrect

Nose of the pliers should be firmly seated under the assembly bump and lock latch.

If the pliers are not kept square during closing the clip, the clasp may have an offset. Use the piers to correct the clasp

alignment.

CAUTION: TK 2000 Speedy Clip System components should not be reused. Failure to follow these instructions and/or the

use of TK 2000 Speedy Clip System hose with fittings supplied by other manufactures could result in sudden or

unintended escape of refrigerant gases. Personal injury and/or violations of EPA regulations may occur as a

consequence.

NOTE: Thermo King recommends adherence to all guidelines, including EPA guidelines concerning the service of

refrigerant sy st ems.

33

Page 36

A/C Hose Installation

Special Tools Required

Hose Fitting Tool (204-1045)

Hose Cutting Tool (204-677)

Alkyl Benzene refrigerant oil (670404TKA).

Torque Wrench

Installation

IMPORTANT: Keep all the A/C fittings capped and sealed until the installa tion of the refrigeration hoses.

Refrigerant oil is extremely hygroscopic and a system left open for more than 5 minutes may require extensive

evacuation/dehydration time to remove moisture.

NOTE: The Evaporator/Control Box system has a Nitrogen holding charge of 5 PSI. This holding charge can safely

be vented into the atmosphere.

NOTE: Read and understand Fabricating Refrigeration Hoses section for proper hose fabrication requirements.

IMPORTANT: Always use two wrenches while tightening refrigeration fittings.

Condenser Coil to Evaporator/Control Box (Discharge Line)

1. Fabricate a #6 hose with a 90 degree fitting and connect to the fitting on the condenser coil inlet (top

connection). Tighten the fitting to 15-20 ft-lb (20-27 N•m). Use a backup wrench.

2. Route the ho s e up throu gh the 2” access hole in the tractor floor near the Evaporator/Control Box air

conditioning fittings.

3. Cut the hose to length, install a 90 degree fitting with service por t a nd a tta c h it to the large fitting o n the

Evaporator/Control Box. Tighten the fitting to 15 to 20 ft-lb (20 to 27 N•m). Use a backup wrench.

Receiver Drier to Evaporator/Control Box (Liquid Line)

4. Fabricate a #4 hose with a 90 degree fitting and attach onto the receiver liquid line outlet fitting on the

receiver drier. Tighten the fitting to 11 to 13 ft-lb (15 to 17 N•m). Use a backup wrench.

5. Route the hose up through the 2” access hole in the tractor floor near the Evaporator/Control Box air

conditioning fittings.

6. Cut the hose to length, install a 90 degree fitting and attach onto the small fitting on the Evaporator/Control

Box. Tighten the fitting to 11 to 13 ft-lb (15 to 17 N•m).

7. Secure all hoses adequately with clamps or band wraps.

34

Page 37

A/C Hose Installation (continued)

#4 Liquid Line from Drier Outlet

#6 Discharge Line from Condenser

Figure 16:A/C Hose I.D. and routing sh o wn

35

Page 38

A/C System Evacuation and L eak Check Procedures

Special Tools Required

Vacuum Pump (204-713 or equivalent)

Micron Gauge (204-720)

Refrigerant Leak Detector (204-712)

Gauge Set with R134a Adapters

System Evacuation Procedures

IMPORTANT: Always use recommended vacuum equipment. Before each use, check that there are no leaks in the

vacuum equipment e it he r in the pump itself or in the ho se s. The oil in the evacuation sta t ion vacuum pump sho ul d

be changed after each use.

NOTE: While the system is being ev acuated, continue the installation with D2/D4 Heater if applicable.

1. Connect gauge manifold to suction and discharge service ports at the Evaporator/Control Box.

2. Connect service line of the gauge manifold to vacuum pump and micron gauge.

3. Open gauge manifold and vacuum p ump valves and gauge manifold hand valves.

4. Start vacuum pump and evacuate until system reaches 500 microns.

5. Once syste m reaches 500 microns, continue e vacuation for one additional hour.

6. Close vacuum pump isolation valve, switch off pump. Chec k that the gauge reading for the system does not

exceed 2000 microns in the following five minutes. If vacuum level exceeds 2000 microns before five

minutes, and continues to rise, proceed to the Leak Check Procedures section. If it stops in a vacuum

continue to evacuate for an additional 30 minutes.

7. If vacuum level remains below 2000 microns for 5 mi nutes the system is leak free and ready to be filled with

refrigerant.

8. Close mani fold hand valves and remove evacua tion equipment.

Leak Check Procedure

1. Add vapor R-134a to the unit until bottle pressure is reached.

2. Thoroughly leak check the system with an electronic leak detector.

3. If leak(s) are found, recover leak check charge.

4. Repair any leaks and re-evacuate system.

36

Page 39

D2/D4 Heater Installation (Heat Optio n)

Special Tools Required

Drill Motor

Utility Knife

Center Punch

4-1/4” dia. Hole Saw

Fiberglass Cloth and Resin Kit (if required)

Figure 17: Marking and Cutting the Hole.

Heater Location

IMPORTANT: Correct installa tion of this heater is necessary to ensure safe and proper operation.

BEFORE installing the heater, thoroug hly re ad and understand the heater manufacturer’s manual included with

the heater.

The location for mounting the heater will vary depending on the type of tractor. Typically, the heater is mounted inside

the sleeper, under the bunk in a storage compartment. However, the heater may be mounted anywhere inside the tractor

provided you adhere to the following conditions:

• Install heater so it will maintain a mini mum distance of 2.00 inches (50.8 mm) from any heat sensitive or

flammable material.

• Combustion air intake, exhaus t a nd fuel inlet must be located outside the tra c tor.

• Install exhaust hose so it will maintain a minimum d istance of 2.00 inches (50.8 mm) fr om any hea t sensitive

or flammable material.

• Heater must be mounted on flat horizontal surface providing an air tight seal between heater and tractor.

• All floor matting, carpet, insulation, etc. must be removed to allow the heater to be mounted directly to the

bare floor.

• Heater harness may be repos itio ned to ei the r side of the heat er.

• Floors made of fiberglass covered wood construction require the edges of the access hole be sealed with

fiberglass and epoxy resin.

Drilling Hole in Floor

1. Position the heater’s metal

mounting plate onto the

floor mat.

2. Use a utility knife to cut the

floor mat around the outside

edges of the plate. Remove

floor mat to access the bare

floor.

3. With the mounting plate in

position, center punch the

four outer holes. Re move

the mounting plate and

mark an “X” c onnecting the

four center punched o ut er

holes.

4. Center punch the center of

the “X” and drill a 4-1/4”

hole with a hole saw.

37

Page 40

D2/D4 Heater Installation (continued)

Figure 18: Heater Subassembly and Installation.

Heater Subassembly

Turn the heater upside down and att ach the following co mponents:

1. Snap the air outlet hood onto the end of the heater.

2. Place the mounting plate onto the heater studs. Mounting hardware will be installed later.

3. Attach the short rubber hose and clamps onto the fuel inlet connection located at the base of the heater.

4. Insert the plastic fuel line all the way into the rubber hose until it bottoms o ut to prevent air gaps. Tighten both

hose clamps securely.

5. Attach the exhaust hose and metal clamp onto the fitting located under the OUTLET end of the heater. Turn

metal clamp to the center and tighten securely.

6. Insert the plastic air intake tube through the beveled opening of the small plastic mounting plate. Install the

plastic plate and tube onto studs located under the INLET end of the heater.

7. Install lock washers and nuts onto each of the mounting studs and tighten hardware securely.

8. Install gasket to mounting plat e .

9. The heater has two service data nameplates. Remove one a nd reinstall it onto the top of the heater so that it is

visible when the heater is installed.

Heater Installation

10. Position the heater over t he access hole with intake and exhaust hose and fuel line exiting t he tractor. Attach

the heater to the floor with TEK screws and tighten securely.

NOTE: Tighten TEK screws sufficiently to ensure a positive seal be tween mounting plate and mounting surface. Do

not over tighten!

38

Page 41

D2/D4 Heater Installation (continued)

Figure 19: Exhaust and Combustion Air Intake Routing

Exhaust and Combustion Air Intake Routing

IMPORTANT: Correct installa tion of this heater is necessary to ensure safe and proper operation.

BEFORE installing the heater, thoroughly read and understand the heater manufacturer’ s manual included with

the heater.

DANGER: The correct installation of the exhaust and combustion air intake hoses is extremely important to prevent

carbon monoxide poisoning or asphyxiation.

EXTREME CARE MUST BE TAKEN TO:

• Route the exhaust outlet hose and combustion air intake tube so they cannot be plugged by d ir t, water or snow.

• Ensure the exhaust outlet and air inlet d o not face into the tractor’s slip stream to prevent “ram air” effect.

• Keep exhaust outlet and air intake hoses a minimum of 12” apart.

• Install exhaust hose so it will mai ntain a minimum distance of 2.00 inches (50.8 mm) from any heat sensitive

or flammable material.

• The exhaust hose should be mounted slightly downwards to help drain off condensation.

• Install the protective cap onto the end of the exhaust hose.

• Route the exhaust hose to an open area to the rear or side of the tractor so fumes cannot build up and enter the

cab or the combustion air inlet tube to the heater.

• DO NOT mount the exhaust hose to the tra c tor’s frame. It must be installed to the cab to a llow for movement.

Installation

DANGER: The exhaust hose outlet must exit at least 3 feet from the A/C evaporator drains located under the tractor

to prevent carbon monoxide poisoning or asphyxiation.

ALWAYS VERIFY the two water valves (kaz oos) ar e inst al led on to t h e evapor at or dr ain tube s and are secured with

hose.

1. Route the ex haust hose to an open area to the rear or side of the tractor positioned slightly downwards to help

drain off condensation and secure with clamps .

a. Drill a 1/8” hole in exhaust hose if necessary to allow for water dra inage.

b. Exhaust hos e can be shortened to a minimum of 8” if required.

2. Attach metal end cap to exhaust hose.

3. Position air intake tube

facing towards the rear of

the tractor where it can

pick up clean, fresh,

moisture free air.

4. From underneath the

sleeper:

a. Apply silicone

sealant around

ONLY the four

heater mount in g

screws.

b. DO NOT apply

any sealant

around the access

hole!

39

Page 42

D2/D4 Heater Duct Installation (Heat Opti o n)

Special Tools Required

Drill Motor

2-1/2” Hole Saw (for installing discharge return air vents)

3” dia. Hole Saw (for routing ducts through compartment walls if required)

Duct Locations

CAUTION:

• USE SUPPLIED HEATER DUCT H OSE ONLY! D o not use existing v ehicle ducts or o utlets.

Ducts and outlets must be capable of withstanding a minimum of 300F (148.9C) operating

temperatures.

• Adjustable air vent must alway s b e insta lle d so it cannot blow hot air directly at liv ing creatures (people,

animals) or objects sensitive to temperature.

• Do not position outlet so that it will blow hot air directly at operator o r at thermostat.

• Position air outlet so that it cannot be obstructed.

• Use the supplied protective air intake grille on the air inlet side of the he ater to prevent objects from being

sucked in.

• Do not overtighten duct clamps.

• DO NOT lay or bundle the heater ducts with A/C ducts. They should not touch each other.

• Ensure provisions are mad e for proper air return v entilation.

The heater is equipped with a Return Inlet and Discharge Outlet for attaching the flexible heater duct hoses.

IMPORTANT: A return air duct to the heater should be provided for best heating efficiency.

• Return Inlet must be provided to return air to the heater. It is typically mounted at the base of the bunk

directly opposite the discharge outlet ve nt.

• Discharge Outlet should be located at floor level to provide maximum heating comfort in the sleeper. It is

typically installed at the base of the bunk on one end.

• Heater ducts should be installed and routed with smooth bends and no kinks to provide maximum airflow.

Installation

40

Page 43

D2/D4 Heater Duct Installation (continued)

Figure 20: Discharge and Return Air Duct Installation

Discharge Air

1. Find an appropriate locatio n f or the floor level discharge air vent and drill a 2-1/2” hole using the correct

hole saw.

a. Unsnap rotating outer louver assembly from the mounting base.

b. Install the base into 2-1/2” hole and secure with supplied screws.

c. Reinstall rotating outer louver assembly back into the mounting base ring. Verify that it rotates freely.

2. Attach one end of the heater duct to the dischar ge outlet hood on the heater and secure with supplied clamp.

3. Route the heater duct to the floor level discharge air vent, cut as needed, attach to the end of the plastic louver

vent and secure with sup plied hose c lamp.

Return Air

4. If a return air duct is not used, the protective grille must be installed onto the heater inlet.

5. Find an appropriate locatio n f or the floor level return air grille and drill a 2-1/2” hole usi ng the correct hole

saw.

a. Install the return air grille into the 2 -1/2” hole and secure with supplied screws.

6. Attach one end of the return air duct to the air inlet hood on the heater and secure with supplied clamp.

a. Route the return air duct to the return air grille, cut as needed, attach to the end of the plastic

louver vent and secure with supplied hose clamp.

41

Page 44

A/C Duct Instal lation

Special Tools Required

Drill Motor

vents and routing ducts through compartment walls)

A/C Vent Locations

The evaporator is equipped with two air discharge outlets to a tta c h the supplied flexible air ducts. The ducts will be

attached to plastic air vents that should be located and installed to provide maximum air circulation in the sleeper.

Suggested locations of the ai r vents:

• MEDIUM (above lower bunk level)

• HIGH (above upper bu nk level)

A/C air ducts and vents are typically routed and installed through closets or storage compartments. Route air ducts as

directly as possible with fewest number bends. Stretch out air ducts and cut off loose excess duct material. Verify all

duct connections are leak free.

In some applications one of the Envidia air ducts may be connected to the truck OEM ducts. If this is done, a backflow

damper must be installed in the duct near the truck’s under bunk OEM A/C unit. A back flow damper kit is provided

along with installation instructions.

NOTE: When connecting to OEM duct work a backflow damper must be installed. This will prevent air from back

flowing into the OEM HVAC ho using . Reduced maximum system runtime will result if damper is not installed.

NOTE: The A/C air duct adapter plate can be installed on either side of the Evaporator/Control Box. Optional

adapters will allow one duct on each side.

IMPORTANT: Ex t reme care shou l d always be taken when drilling holes in the various types of material found in

sleepers such as plastic, steel, a luminum, and upholstery.

Installation

4-1/4” dia. Hole Saw (for installing plastic A/C louver

1. Install the hose adapters into each air discharge outlet plate.

2. Find appropriate locations for the A/C vent(s) inside the sleeper and drill 4-1/4” diameter hole(s).

3. Attach the flexible air duct onto hose adapter(s) and secure with a supplied hose clamp.

4. Route the flexible air duct thro ugh the A/C ve nt hole. Cut excess duc t as needed .

5. Unsnap rotating outer louver assembly from the mounting base.

6. Attach to flexible air duct to the end of the hose adapter with band wraps.

7. Push the hose adapter back into 4-1/4” mounting hole and secure with supplied screws.

8. Reinstall rotating outer louver assembly back into the hose adapter and verify that it rotates freely.

9. Verify flexible ducts are installed and routed with smooth bends and no kinks to provide maximum airflow.

10. Secure flexible ducts with large band wraps to prevent excess movement.

42

Page 45

A/C Duct Instal lation (continued)

Figure 21: A/C Duct locations

FLUSH MOUNTED EVAPORATOR

43

Page 46

Battery Box Harness Ins tallation

Figure 22: Battery Box Harness Connections

From Envidia

Through

Controller

IMPORTANT: Before making any electrical connections, confirm the battery cables in the TriPac Envidia battery

box and truck battery box are not connected to the batteries.

NOTE: Excessive communication harness length should be doubled up and secured with band wraps. DO NOT

CUT THE WIRE H ARNESS!

NOTE: Always check the male pins for straightness before attempting to mate connectors. If any resista nc e is f e lt

when mating the connector: recheck the male pin alignment. Exercise care when mating the connections to circuit

boards.

From TriPac ENVIDIA Battery Box

1. From the TriPac Envidia Battery Box route the Base Controller Communication harness and white (8 AWG)

power wires through the floor access hole. Route to the Evaporator/Control Box Connector Panel.

2. The Battery Box communication harness plugs into the 12-pin, (J8) connector on the Connector Panel.

3. Remove the Interconnect Harness cover plate.

4. Insert grommets into the two hol e s i n the Con ne c to r P a ne l .

5. Route the Ba se Co ntroller power wires through the holes in the Connector P a nel to the Base Controller.

6. Cut cables to length. Terminate with ¼” terminal lugs.

7. Connect the #2 power terminal lug to the stud marked +2. Co nnect the CH-0 1 ground te rminal lug to the stud

marked CH. Tighten the nuts to 1 8 in-lbs. (2.0 N•m).

IMPORTANT: Make sure the two terminal lugs are not touching each other!

8. Reinstall the Interconnect Harness cover plate.

9. Route the RED and BLA CK (2 AWG) cables from the TriPac ENVIDIA battery box to the truck battery box.

Do not connect at this time.

Battery Box

Connector Panel to

44

Page 47

Battery Box Harness Ins tallation (continued)

Figure 23: Battery Box harness connections

From Evaporator/Control Box

10. From the Evaporator/Control Box route the RED and BLACK (4 AWG) Co mpressor Drive Module power

cables through the floor access hole with the refrigerant lines. Route cables to the back of the TriPac Envidia

Battery Box. NOTE: These cables are pre-connected to the Compressor Drive Module inside the

Evaporator/Control Box.

11. Route the posi t ive cable (RED) through the upper hole in the back of the battery box to the F10 (150 amp) fuse

in the holder.

12. Cut cable to length and install terminal with 1/4” hole.

13. Connect to F10 fuse holder terminal. Torque nut to 120 in-lb (13.5 N•m).

14. Route the negat ive (BLACK) cable through the lower hole in the back of the battery box to the chassis ground

stud.

15. Cut cable to length and install terminal with 3/8 ” ho le .

16. Secure to existing cables.

17. Connect to chassis ground stud.

45

Page 48

Condenser Fan and Sensor Harness Installation

Figure 24: Condenser and Sensor Harness Connections

IMPORTANT: Before making any electrical connections, confirm the battery cables in the TriPac Envidia battery

box and truck battery box are not connected to the batteries.

NOTE: Excessive harnesses lengths should be doubled up and secured with band wraps. DO NOT CUT THE WIRE

HARNESSES!

NOTE: Always check the male pins for straightness before attempting to mate connectors. If any resista nc e is f e lt

when mating the connector: recheck the male pin alignment. Exercise care when mating the connections to

Connector Panel.

Evaporator/Control Box

1. Locate the Condenser Fan and Sensor harness supplied loose in the installation kit.

2. Locate the Connector Panel located outside the Evaporator/Control Box.

3. Connect the 6-pin connector to the Condenser (J6) connector.

4. Route the harness down through the 2” access hole in the tractor floor and out to the condenser fan.

Condenser Assembly

5. Connect the 4-pin connector to the matting connector from the condenser fan.

6. Attach the Ambient Air Sensor to the inside of the receiver drier bracket with the supplied clamp and

mounting hardware.

NOTE: Always install the sen sor to the inside of the drier bra cket for best temperature readings and to pro te c t it

from damage.

7. Secure all harness adeq uately with insulated cla mp s or band wrap s.

46

Page 49

Ignition Switch and Harness Installation

Figure 25: Ignition Switch Harness Connections

IMPORTANT: Th e Ignition Sense h arness wire must be connec t ed to the ON or RUN position of t h e tractor’s

ignition system. This will prev e nt the HVAC system from operating and allow battery charging when the tractor’s

engine is running.

Locate the Ignition Sense harness supplied loose in the installation kit.

1. Connect the 2-pin connector to the I gnition (J10) connector on the Evaporator/Control Box connector panel.

2. Route the harness towards the tr a c tor’s ignition switch.

3. Connect the end with the diode and fuse to the ON or RUN position of the tractor’s ignition switch.

4. Secure the harness adequately with band wraps.

NOTE: On some truck models the ignition switch acts only as a selector device connected to an ignition module. There

may not be system power available at the switch. The TriPac Envidia sys tem may not function correctly. In this case

locate the truck ignition module and connect to the ON or RUN outpu

t.

47

Page 50

HMI Installation

Special Tools Required

Level

Drill Motor

Drill Bits

Figure 26: HMI Controller Installation

HMI Controller Location

Choose a location inside the tractor’s sleeper for the HMI controller that is easily accessible and visible from

the driver’s bunk

Installation

Locate the HMI Controller Harness with the 8-pin conne c tors on each end supplied loose in the installation kit. The

connectors are not the same. Connect the white end to the HMI.

1. Route the harness to the Evaporator/Control Box.

2. Connect the black 8-pin connector to the HMI (J7) connector on the Evaporator/Control Box connector panel.

3. From the Evaporator/Control Box , route th e harness behind the in terior walls (if applicable) to the location chosen

to install the HMI controller.

4. Unsnap the r ear mounti ng base from the controller and route the harness connector through the access hole.

a. Positio n and le vel the mo un ting base a nd i ns ta l l s e c ur e l y.

5. Push the white connector firmly into the plug on the rear of the controller.

6. Snap the controller back onto the mounting base.

7. Secure harness.

48

Page 51

USB Service Communi catio n C ab l e

Figure 27: USB Cable Connection

The USB Service Communication Cable will allow installation and service technicians to ea sily access the

communication application.

1. On the Base Controller, remove the cover over the USB Communication Port.

2. Plug the USB Mini-B connector into the communicatio n port.

3. Route the cable to a protected area that is accessible without raising the bunk. Recommend inside truck tool

box door.

4. Secure communication cable to other harnesses or cab structure.

49

Page 52

D2/D4 Heater Harness Installation (Heat Option)

Figure 28: D2/D4 Heater Harness Connection

Locate the Heater Harness supplied loose in the installation kit. Remove the two small plastic bags attached to the

harness cont aining the fuel pump electrical connector components and the in-line fuse assembly. Retain these for

installation later.

1. Connect the 14-pin connector (with the locking tab) to the mating connector on the heater.

a. Use a large bladed screwdriver to pull the locking tab out (to unlock) from the connector body.

b. Connect the two connectors together.

c. Push locking tab back in (to lock) the connector body.

2. Connect the 10-pin connector to the Heater (J9) connector o n t he Evaporator/Control Box connector panel.

3. Route the fuel pump harness out of the sleeper through the 2” access hole. It will be assembled and connected

to the fuel pump in a later step.

NOTE: The Diagnostic Connector near the heater is only used for diagnostic purposes.

50

Page 53

Heater Fuel Pickup Tube Installation (Heat Option)

Special Tools Required

Tape Measure

Tubing Cutter

Direct Tank Installation – No Drilling

OEM Fuel Tank Fittings

DANGER: Use caution when working in or around the area of the diesel fuel tank. Diesel fuel vapors are potentially

explosive. Do not smoke while working near the diesel fuel tank.

NOTE: Some fuel tanks may have auxiliary fuel connections or 1/4" NPT connections factory installed . These

fitting eliminate the need to drill into the f ue l tank to install the heater’s fuel pickup tube.

• OEM Fuel Connections - Route and connect the heater’s fue l sup ply line to one of these fittings.

• OEM 1/4" NPT Fitting - See following installation instructions.

Important Installation Tips

• Remove the protective cap from the e nd of the pickup tube prior to installatio n.

• Do not apply any type of sealant material to the fuel pickup tube assembly. Doing so will result in plu gged fuel

lines.

Installation

NOTE: The tank mounted fuel pump bracket cannot be used on direct tank installations. The supplied

remote mounted L-bracket must be used.

1. Remove the nut, washers and b us hing assembly from the fuel pic kup tube as shown. The nut, washers and

bushing assembly will not be used.

2. Remove the 1/4" NPT fitting from fuel pickup tube and install it into the fuel tank’s 1/4" NPT fitting securely.

3. Measure the fuel tank diameter and cut the pickup tube 3” shorter.

4. Install the pickup tube with the fer rule nut into the tank.

a. Position the pickup tube as needed to facilitate fuel line connections and tighten ferrule nut securely.

5. Install the supplied warning n ameplate onto the fuel tank in a visible area near the fuel cap.

51

Page 54

Heater Fuel Pickup Tube Installation (continued)

Figure 29: Fuel Pickup Tube Installation – No Drilling

Direct Tank Installation – No Drilling

52

Page 55

Heater Fuel Pickup Tube Installation (continued)

Special Tools Required

Tape Measure

Drill Motor

¼” Drill Bit

1” Hole Saw

Tubing Cutter

Alternative Instal la t ion – Drilling hole in Fuel Tank

Installing the Fuel Pickup Tube

DANGER: Use caution when working in or around the area of the diesel fuel tank. Diesel fuel vapors are potentially

explosive. Do not smoke while working near the diesel fuel tank.

DANGER: Before drilling into a fuel tank, drain all fuel from the tank. Use nitrogen or an inert gas to purge the

diesel fuel vapors from the tank. Keep the diesel tank filled with inert gas while drilli ng.

DANGER: Use extreme ca ution when drilling into a diesel fuel tank . Sparks from an electric drill or drill bit could

cause an explosion.

Important Installation Tips

• Check for i nt ernal baffles inside the fuel tank BEFORE drilling any holes.

• Remove protective caps from ends of pic kup tube prior to installation.

• Do not apply any type of sealant material to the fuel pickup tube assembly. Doing so will result i n plugged f uel

lines.

• The ferrule nut and 1/4" NPT fitting must be tightened securely into the bushing before installing the pickup

tube into the tank. Failure to tighten the fittings will allow the bushing and washer assembly to slide down the

pickup tube and drop into the fuel tank.

Installation

1. Measur e a nd ma rk the mo u nt i n g h o l es o n t he fu e l ta n k as sho wn.

2. Drill (2) 0.25" outer holes first followed by the 1.00" center hole.

a. Thoroughly cle an a nd flus h the tank t o remove any chips.

3. Measure the fuel tank diameter and cut the pickup tube 3” shorter.

a. With the pickup tube positioned at the correct height, place a wrench on the flats of the bushing and

tighten the 1/4" NPT fitting and the ferrule nut securely.

4. Remove the large nut, metal cupped washer and rubber washer from the bushing assembly.

a. Insert the fuel pickup tube (with the reinforcing washer) into the tank using the slot created by the two

0.25" holes.

b. Lift the pickup tube and bushing into positio n through the 1.00" ho le.

c. Hold the pickup tube in place and reinstall the rubber washer, metal cupped washer, fuel pump

bracket and large nut ont o the bushing. Hand tighten the large nut.

d. Position the pickup tube as needed to facilitate fuel line connections.

e. Place a wrench on the flats of the bushing and tighten the large nut securely.

5. Install the supplied warning nameplate onto the fuel tank in a visible area near the fuel cap.

53

Page 56

Heater Fuel Pickup Tube Installation (continued)

IMPORTANT: The ferrule nut and 1/4" NPT fitting must be tightened securely into the bushing before

Figure 30: Fuel Pickup Tube Installation – Drilling Hole in Tank

Alternative Installation – Drilling hole in Fuel Ta nk

installing the pickup tube into the tank.

54

Page 57

Heater Fuel Pump and Fuel Line Installation

Special Tools Required

Utility Knife

Hose Cutting Tool (204-677)

(Heat Option)

Tank Mounted Fuel Pump

1. Install the fuel pump and rubber clamp onto t he tank mounted bracket securel y.

2. Attach a fuel line hose from the fuel pick-up supply to the inlet end of the fuel pump and secure with supplied

hose clamps.

3. Attach the short rubb er hose connection to the outlet end of the fuel pump and secure with supplied hose

clamps.

4. Route the plastic fuel line (installed earlier on the heater) to the fuel pump and cut to length. Insert the fuel line