Thermo Fisher Scientific SAIVI User Manual

USER GUIDE

SAIVI™ Alexa Fluor™ 647 Antibody/Protein Labeling Kit

Catalog Number S30044

Pub. No. MAN0019834 Rev. A.0

WARNING! Read the Safety Data Sheets (SDSs) and follow the handling instructions. Wear appropriate protective eyewear,

clothing, and gloves. Safety Data Sheets (SDSs) are available from thermofisher.com/support.

Product description

The SAIVI™ Alexa Fluor™ 647 Antibody/Protein 1 mg-Labeling Kit provides a convenient means to label proteins with Alexa Fluor™ 647

near-IR emitting dye (Figure 1). The kit is designed for labeling and purifying 1 mg of protein per reaction, and has been optimized using 1

mg of IgG per conjugation reaction. Comparable amounts of other proteins (>20 kDa) can also be labeled. For labeling smaller amounts of

proteins (20–100 μg), we recommend the Alexa Fluor™ 647 Microscale Protein Labeling Kit (Cat. No. A30009).

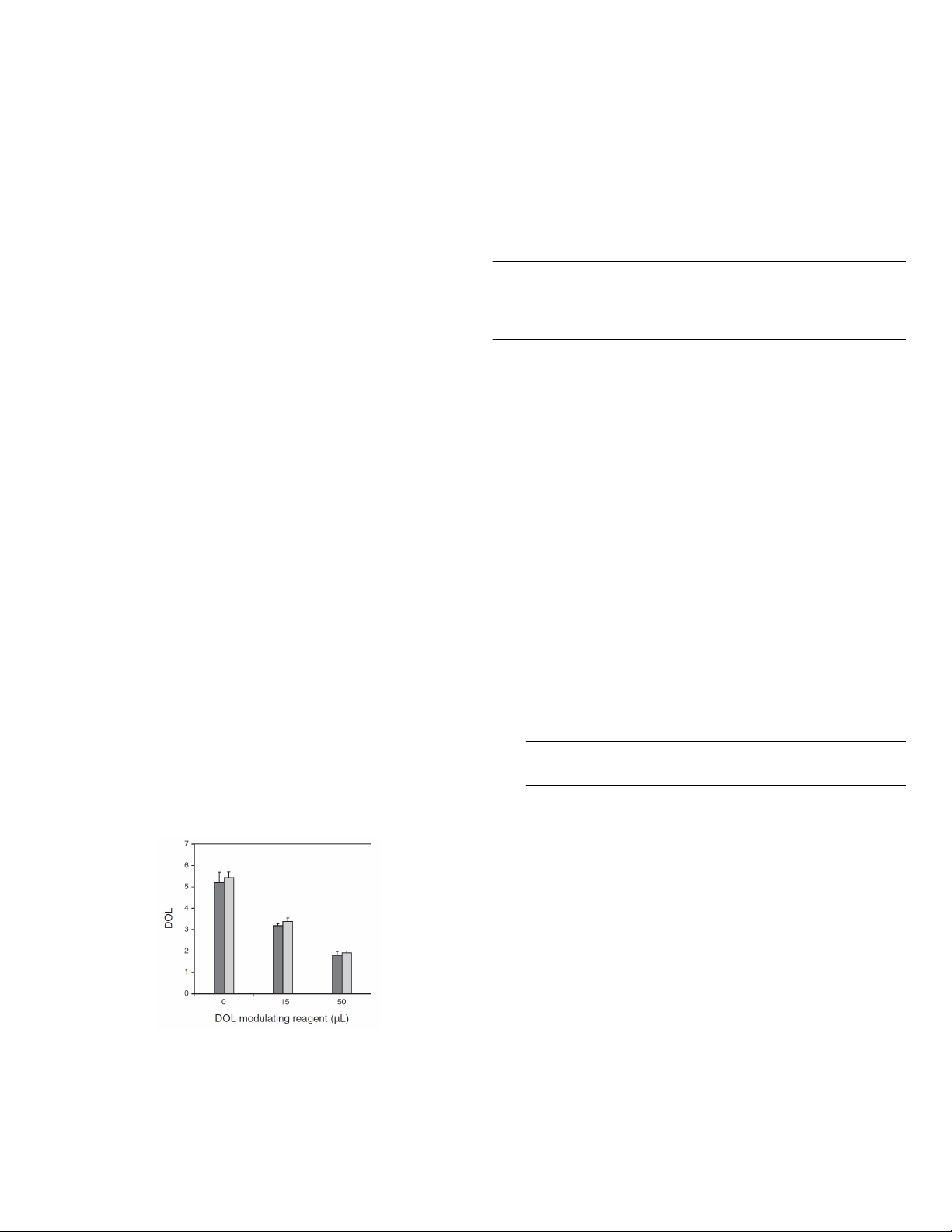

To conveniently control the average number of fluorescent dye molecules that become covalently attached to each protein molecule

(the degree of labeling, or DOL), this kit includes a DOL modulating reagent and instructions for decreasing the DOL from its intrinsic

highest value by adding specific amounts of DOL modulating reagent to the labeling reaction. Using this method, you can quickly and

reproducibly obtain protein preparations with varying ratios of dye to protein without significantly altering the labeling conditions or the

purification procedure (Figure 1), allowing more ecient optimization in applications such as in vivo imaging, where the DOL of a protein

can have significant eects on factors such as signal-to-background, biodistribution, and blood clearance.

Contents and storage

Material Amount Storage

Alexa Fluor™ 647 Reactive Dye (Component A) 3 vials (each containing a magnetic

Sodium bicarbonate (MW=84) (Component B) 84 mg

Purification columns (Component C)

DOL modulating reagent, lyophilized solid

(Component D)

Collection tubes 6 tubes

Number of labelings: Each vial of reactive dye contains the appropriate amount of dye to label approximately 1 mg of IgG (MW ~145,000) as 0.5 mL of

IgG solution at 2 mg/mL.

[1]

The kit can be stored under the conditions listed. For optimal storage conditions of individual components, refer to the labels on the vials or bags. Note that the reactive dye

(Component A) may be stored frozen at ≤−20°C or at 2–8°C. Do not freeze the purification columns (Component C).

[2]

The resin in each column is supplied in a 0.1 N NaCl/0.05% sodium azide solution.

[2]

Equipment required but not supplied

• Benchtop centrifuge capable of 1,000 × g

Labeling protocol

Prepare the proteins

• For optimal labeling eciency, the purified protein must be in

a buer free of ammonium ions or primary amines.

• The presence of significant concentrations of proteins other

than the intended labeling target in the solution (e.g., BSA

or gelatin carrier in antibody preparations) will likely result in

poor labeling, due to competition eects.

stir bar)

3 each

1 vial

• Store at 2–6°C

protected from light.

• Do not freeze.

• If the protein is in or has been lyophilized from an unsuitable

buer (e.g., Tris or glycine), the buer should be replaced

with phosphate-buered saline (PBS) by dialysis or another

method. Impure proteins (e.g., antibodies in crude serum

or proteins stabilized with bovine serum albumin (BSA) or

gelatin) will not label well.

• The presence of low concentrations of sodium azide (≤3 mM)

or thimerosal (≤1 mM) will not interfere with the conjugation

reaction.

For tips on optimizing the procedure for other proteins or for

antibody solutions at lower concentrations, see “Optimize the kit

for use with other proteins and/or concentrations” on page 3 or

“Optimization and troubleshooting” on page 3.

[1]

When stored properly, kit

components are stable

for at least 3 months.

Stability

For Research Use Only. Not for use in diagnostic procedures.

Labeling reaction

1. Prepare a 1 M solution of sodium bicarbonate by adding 1

mL of deionized water (dH2O) to the provided vial of sodium

bicarbonate (Component B). Vortex or pipet up and down

until fully dissolved. The bicarbonate solution, which will

have a pH ~8.3, can be stored at 4°C for up to 2 weeks.

2. Prepare a solution of DOL modulating reagent. Briefly

centrifuge the DOL modulating reagent (Component D) to

collect any solid at the bottom of the vial. Add 330 µL of

sterile deionized water, cap the tube tightly, and vortex.

3. Prepare 0.5 mL of a ~2 mg/mL protein solution by diluting

it with an appropriate buer and add sodium bicarbonates

as directed here, depending on the nature of the starting

protein sample.

• For protein samples already in a volume of appropriate

buer, add 1/10 volume of 1 M sodium bicarbonate to

the ~500 µL of protein sample (at 2 mg/mL).

• For protein samples lyophilized from an appropriate

buer, prepare a 2 mg/mL solution of the protein by

adding a sucient volume of 0.1 M sodium bicarbonate

buer. (Prepare 0.1 M sodium bicarbonate buer by

diluting the 1 M solution from step 1 10-fold with

deionized water.)

Purify the labeled proteins

Thermo Scientific™ Zeba™ Dye and Biotin Removal Spin Columns

contain a ready-to-use resin that is uniquely designed for rapid

removal of non-conjugated fluorescent dyes with exceptional

protein recovery. The purification resin is designed to separate

free dye from proteins with MW >20 kDa. For smaller proteins,

gel filtration media of a suitable molecular weight cuto should

be selected. Labeled peptides may be separated from free dye

by TLC or HPLC. Removal of free dye after a labeling reaction is

essential for the accurate determination of dye to protein ratios.

For optimal protein recovery and dye removal, ensure that the

appropriate amount of sample and buer conditions are used.

IMPORTANT! Protein conjugates that are between 20–50 kDa

require a more alkaline buer system to elute and will retain on the

column if the buer system is not changed. See procedure below

for purifying 20–50 kDa conjugates.

Procedural guidelines

• Do not reuse the purification resin.

• Limit DMF and other organic solvents to ≤10% of solvent

volume loaded onto the column.

• If labeling a 20-50 kDa protein, refer to “Purify 20-50 kDa

conjugates” on page 2 to ensure conjugate recovery.

4. If desired, add an appropriate volume of DOL modulating

reagent solution to the protein vial and mix gently but

thoroughly. To decrease the DOL by ~40%, add 15 µL of

the DOL modulating reagent solution prepared in step 2.

To decrease the DOL by ~70%, add 50 µL of the DOL

modulating reagent solution.

5. Transfer the protein solution to a vial of Alexa Fluor™ 647

reactive dye. This vial contains a magnetic stir bar. Gently

pipette the solution up and down to fully dissolve the

dye (excess agitation of the solution can result in protein

denaturation.

6. Stir the solution for ~1 hour at room temperature, protected

from light. You can perform labeling at lower temperatures,

if necessary; labeling overnight on ice usually yields results

similar to those achieved by labeling for 1 hour at room

temperature. DOL control using the DOL modulating reagent

works similarly at either temperature.

Prepare the spin column

1. Twist to remove the bottom plug of the column, then loosen

the cap. Do not remove the cap.

2. Place the column in a collection tube, then centrifuge the

column-tube assembly at 1,000 × g for 2 minutes to remove

the storage buer. Discard the flowthrough.

3. If using a fixed-angle rotor, place a mark facing away from

the rotor center. For all subsequent centrifugation steps,

place the column in the centrifuge with the mark facing away

from the rotor center.

IMPORTANT!

centrifugation can result in reduced small molecule removal.

4. If desired, the resin storage buer can be exchanged using

a buer of choice. To exchange, add 2 mL of equilibration

buer to the column, then centrifuge at 1,000 × g for 2

minutes. Discard the flowthrough.

Improper orientation of the column during

Purify 20-50 kDa conjugates

If purifying a 20–50 kDa protein, a buer exchange is required to

ensure conjugate recovery.

1. Following storage buer removal, apply 500 µL of 0.2 M, pH

9.4 bicarbonate buer to the column (Cat. No. 28382).

Figure 1 Modulation of the degree of labeling achieved

using the DOL modulating reagent. Observed labeling is

60% and 30% of the unmodulated value using 15 μL or 50

μL DOL modulating reagent, respectively. Labeling results

obtained at room temperature for 60 minutes or on ice for

20 hours are essentially identical.

2 SAIVI

2. Centrifuge the column-tube assembly at 1,000 × g for 2

minutes.

3. For optimal conjugate recovery, repeat steps 1 and 2 two

more times for a total of 3 column washes to ensure

equilibration.

™

Alexa Fluor™ 647 Antibody/Protein Labeling Kit User Guide

Loading...

Loading...