Thermo Fisher Scientific RES 1000 User Manual

Alpha RES 1000

Controller/Transmitter

Resistivity

.

AQUAfast, Cahn, ionplus, KNIpHE, No Cal, ORION, perpHect, PerpHecT, Per pHecTion, pHISA, pHuture,

Pure Water, Sage, Sensing the Future, SensorLink, ROSS, ROSS Ultra, Sure-F low, Titrator PLUS and

TURBO2 are registered trademarks of Thermo Fisher.

1-888-pHAX-ION, A+, All in One, Aplus, AQUAsnap, AssuredAccuracy, AUTO-BAR, AUTO-CAL, AUTO

DISPENSER, Auto-ID, AUTO-LOG, AUTO-READ, AUTO-STIR, Auto-Test, BOD AutoEZ, Cable-Free,

CERTI-CAL, CISA, DataCOLLECT, DataPLUS, digital LogR, DirectCal, DuraProbe, E nviro nmental Pro duct

Authority, Extra Easy/Extra Value, FAST QC, GAP, GLPcal, GLPcheck, GLPdoc, ISEasy, KAP,

LabConnect, LogR, Low Maintenance Triode, Minimum Stir Requirement, MSR, NISS, One-Touch, OneTouch Calibration, One-Touch Measurement, Optimum Results, Orion Star, Pentrode, pHuture MMS,

pHuture Pentrode, pHuture Quatrode, pHuture Triode, Quatrode, QuiKcheK, rf link, ROSS Resolution,

SAOB, SMART AVERAGING, Smart CheK, SMART STABILITY, Stacked, Star Navigator 21, Stat Face,

The Enhanced Lab, ThermaSense, Triode, TRIUMpH, Unbreakable pH, Universal Access are trademarks

of Thermo Fisher.

Guaranteed Success and The Technical Edge are service marks of Thermo Fisher.

Preface

This instruction manual serves to explain the use of the Alpha RES 1000 series Resistivity

controller/transmitter. The manual functions in two wa ys: firstly as a step by step guide to help the user

operate the instrument. Secondly, it serves as a handy reference guide. This instruction manual is writ ten

to cover as many anticipated ap plications of the Alpha RES 1000 Resi stivity controller/transmitter. If you

have doubts in the use of the ins trument, please do not hesita te to contact the nearest Thermo Scientific

Authorised Distributor.

The information presented in this m anual is subject to chan ge without notice as improve ments are made,

and does not represent a commitment on part of Thermo Fisher Scientific.

Thermo Fisher Scientific cannot accept any responsibility for damage or malfunction of the unit due t o

improper use of the instrument.

All rights reserved.

TABLE OF CONTENTS

1 INTRODUCTION.................................................................................................1

1.1 DESCRIPTION OF UNIT ....................................................................................1

1.2 APPLICATIONS................................................................................................1

2 ASSEMBLY AND INSTALLATION.....................................................................2

2.1 MEASUREMENT AND CONTROL SYSTEM............................................................2

2.2 UNIT DIMENSIONS ..........................................................................................2

3 ELECTRICAL CONNECTION.............................................................................3

3.1 CONNECTION DIAGRAM...................................................................................3

3.2 BACK PANEL..................................................................................................4

4 OVERVIEW.........................................................................................................5

4.1 KEYPAD AND DISPLAY.....................................................................................5

4.1.1 Keypad................................................................................................................... 5

4.1.2 Display ................................................................................................................... 5

4.2 FUNCTION GROUPS ........................................................................................6

4.3 CONTROL CONCEPT .......................................................................................7

5 MEASUREMENT ................................................................................................8

5.1 ISPLAY IN MEASUREMENT MODE ....................................................................8 D

5.1.1 Check electrode performance................................................................................ 8

5.1.2 Checking set points................................................................................................ 8

5.2 ECURITY CODES...........................................................................................8 S

5.2.1 How to enter and change parameters in Calibration mode.................................... 8

5.2.2 How to enter and change parameters in Advanced Setup mode .......................... 9

6 CALIBRATION MODE......................................................................................10

6.1 RESISTIVITY CALIBRATION.............................................................................10

7 ADVANCED SET-UP MODE............................................................................10

7.1 TEMPERATURE COEFFICIENT SUB-FUNCTION...................................................11

7.1.1 Selecting Pure-water or Linear Temperature Coefficient..................................... 11

7.2 EMPERATURE CALIBRATION (ATC MODE ONLY)..............................................12 T

7.2.1 Setting manual temperature compensation ......................................................... 12

7.3 ONTROL RELAY A/CONTROL RELAY B (SP1/SP2) SUB-FUNCTION ..................13 C

7.3.1 Entering the Set point 1 (Set point 2) sub-function .............................................. 13

7.3.2 Selecting the set point values .............................................................................. 13

7.3.3 Choosing High or Low set points ......................................................................... 13

7.3.4 Selecting a hysteresis (dead band) value (0.000 to 0.200 m

Setting an on-delay time lag................................................................................. 14

7.3.5

7.3.6 Setting an off-delay time lag................................................................................. 15

Ω

or 0.00 to 2.00 m

Ω

)1 3

7.4 ONTROLLER (CNTR) SUB-FUNCTION .............................................................15 C

7.4.1 Entering the Controller sub-function..................................................................... 15

7.4.2 Choosing the controller type (limit or proportional) .............................................. 15

7.4.3 Choosing break/make contact relay type............................................................. 16

7.4.4 Selecting proportional range value Xp................................................................. 16

7.4.5 Maximum Pulse Length (tPL) or Maximum Frequency (FPF).............................. 17

7.5 MEASUREMENT RANGE SUB-FUNCTION...........................................................17

7.5.1 Entering the Measuring Range sub-function........................................................ 17

7.5.2 Selecting Measuring Range sub-function ............................................................ 17

7.5.3 Measurement Range available in the Controller.................................................. 18

7.5.4 Current Output (rng) sub-function........................................................................ 18

7.5.5 Choosing the output type..................................................................................... 18

7.5.6 Selecting Resistivity value at 0(4)mA................................................................... 18

7.5.7 Selecting Resistivity value at 20mA..................................................................... 19

7.6 ONFIGURATION (CONF) SUB-FUNCTION ........................................................19 C

7.6.1 Entering Configuration sub-function..................................................................... 19

7.6.2 Selecting Filter Function and the Alarm or Wash Function.................................. 19

7.6.3 Selecting the alarm time lag (if the relay 3 is set to Alarm).................................. 20

7.6.4 Selecting steady or pulse contact for the alarm relay (if the relay 3 is set to Alarm)20

7.6.5 Wash Contact (if the relay 3 is set to Wash)........................................................ 20

7.6.6 Input Line Resistance Adjust................................................................................ 21

7.6.7 Reverting to factory default settings..................................................................... 21

7.7 ALIBRATION (CAL) SUB-FUNCTION ...............................................................21 C

7.7.1 Entering Calibration mode from Advanced Set-up mode..................................... 21

8 AUTO/MANUAL MODE....................................................................................22

8.1 AUTO MODE (MODE AFTER SWITCH-ON)...........................................................22

8.2 MANUAL MODE.............................................................................................22

9 TECHNICAL SPECIFICATIONS....................................................................... 23

10 GENERAL INFORMATION...........................................................................24

10.1 PACKAGING .................................................................................................24

10.2 RETURN OF GOODS......................................................................................24

10.3 GUIDELINES FOR RETURNING UNIT FOR REPAIR ..............................................24

11 APPENDICES...............................................................................................25

APPENDIX 1 – JUMPER POSITIONS.............................................................................25

APPENDIX 2 – CONDUCTIVITY / RESISTIVITY OF VARIOUS AQUEOUS SOLUTIONS AT 25OC26

APPENDIX 3 - SIMPLE EXPLANATION ON THE FUNCTION OF HYSTERESIS ........................26

APPENDIX 4 – PURE WATER CURVE...........................................................................27

Operating Instructions Alpha RES 1000

1 Introduction

1.1 Description of Unit

Thank you for purchasing the Alpha ¼ DIN Alph a RES 1000 Resistivity process controllers. This unit is

used for measuring the Resistivity of a solution in meg a-ohms. You c an use this unit t o me asure Resis tivity

with limit control. This controller has many user-friendly and safety features which include:

• Menu-driven program that simplifies set-up

• Two ranges of Resistivity measurements-software selectable (Section 7.5.3).

• Built-in memory backup to ensure that calibration data and other information are not erased if

power supply fails

• Automatic temperature compensation (ATC) with Pt100 or Pt 1000

• Manual temperature compensation with independent setting for calibration and process

temperature

• Temperature coefficient variable between 0.00 to 10.00 % per

curve stored in memory. Reference temperature at 25

• 0 to 1999 second time delay adjustment on all relays – minimise false alarms

• Separately adjustable high and low set point hysteresis (dead bands) prevent chattering of relays

around the set points.

• Three control modes: limit, proportional pulse length or proportional pulse frequency.

• Large dual display LCD for easy reading with clear multiple annunciators, alarm status and

operational message annunciators

• Two switching contacts as set-point triggering relays and an alarm output relay

• Separate alarm relay alerts you when set points have exceeded the limits and if the Pt100/Pt10 00

wires are broken or disconnected during the ATC function

• Hold function freezes output current (0/4...20mA) and releases control relays

• LED indicators signal control activities to monitor controller status from a distance

Selectable Filter function stabilises rapid measurement changes.

• Protection against electromagnetic interference - galvan ically isolated 0/4.. 20mA output provides

safety for data logging and control purposes

1.2 Applications

Use this controller in panel mounted enclosures for applications in Pure water and R.O. Systems.

o

o

C. Separate pure water compensation

C.

1

Operating Instructions Alpha RES 1000

A

A

p

p

2 Assembly and Installation

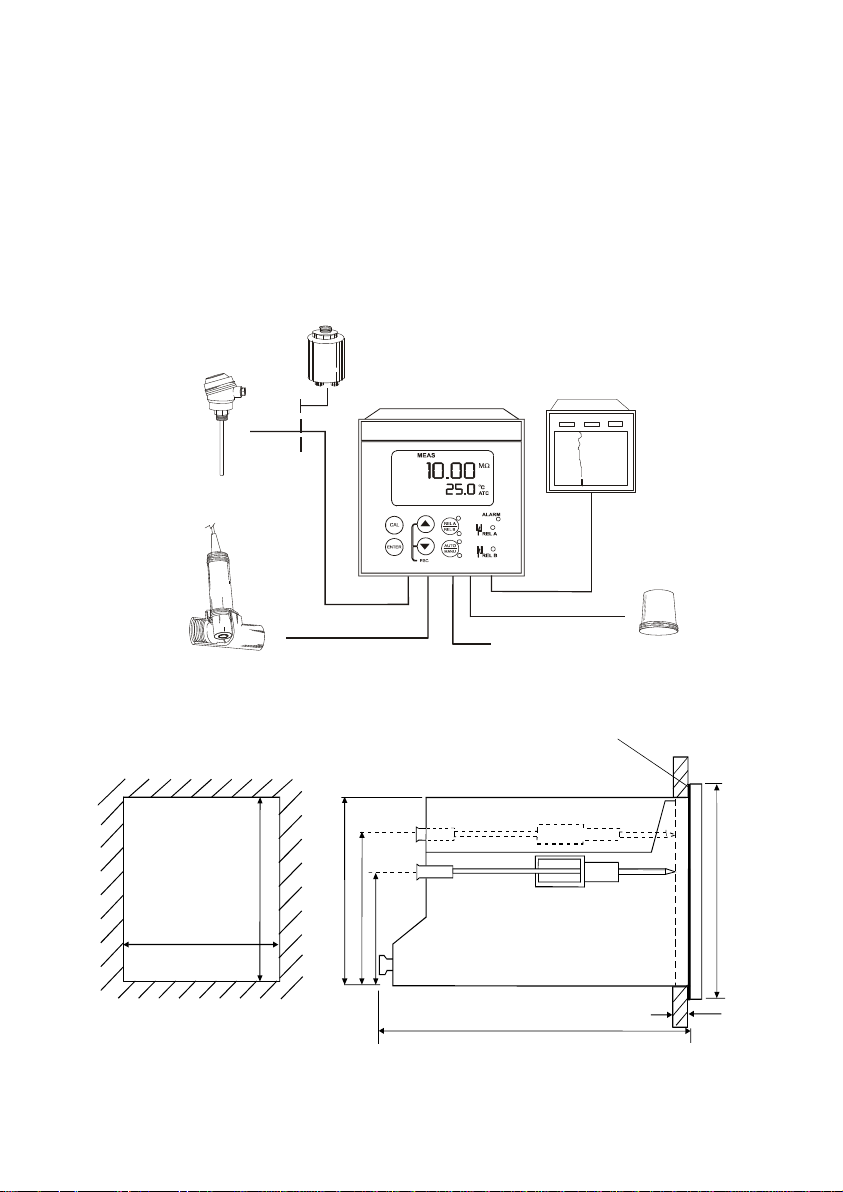

2.1 Measurement and Control System

A typical measurement system consists of:

• an Alpha RES 1000 process controller

• a suitable Resistivity electrode with the appropriate Cell constant a nd integrated temperature sensor Pt

1000 or Pt 100,

• an immersion, flow or process assembly

• a final control element such as pump or valve and

• a chart recorder

Flow Assembly

to Dosing Pumps

Pt100/Pt1000

Temperature Sensor

Process Assembly

with Electrode

2.2 Unit Dimensions

92+ 0.5

92+ 0.5

Mounting Cut-Out

The field-tested control panel housing is 96 x 96 mm; with protection class IP 54 (front).

92

56

Chart Recorder

rollerAlpha RES 1000 Cont

lpha RES 1000

larm / Siren

System

Power Mains

(220/110 VAC)

Flat Gasket (1mm)

(TobeInsertedByCustomer)

Note: The Ta

ed CornersHaveto BeOnTo

96

32

max. 175

max. 45

2

Operating Instructions Alpha RES 1000

3 Electrical Connection

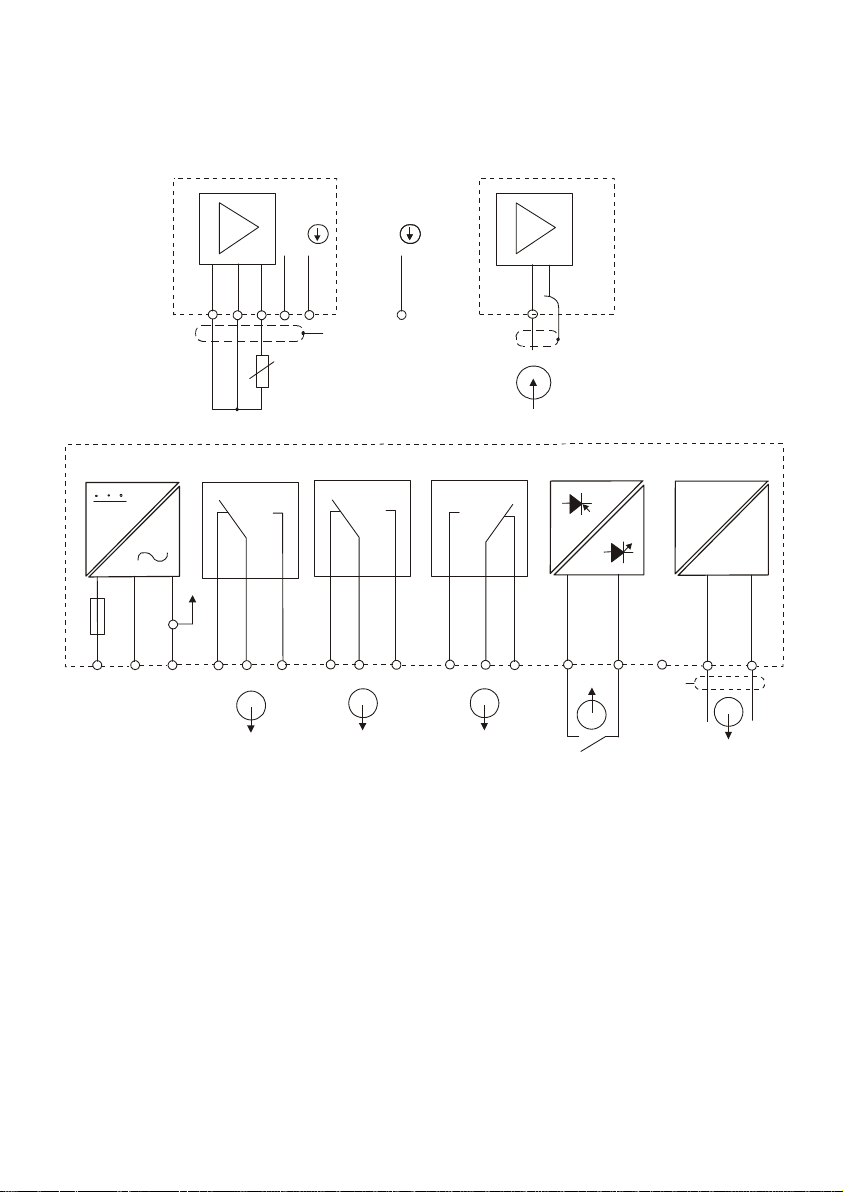

3.1 Connection Diagram

Res.

S/

V

S/S/

Power Mains

2

1

18 19 20

Pt100/Pt1000

36

PEAC: NL

4

Relay 1

5

21 22

PE/S

Relay 2

78 9

Signal Input Resistivi

Alarm

10

11

12 13

* ) indicated contact positions are for currentless or no er

ty

151715

14

PE/S

ror conditions

Signal Outputput Hold In

Res.

-

mA

+

16

3

Operating Instructions Alpha RES 1000

/

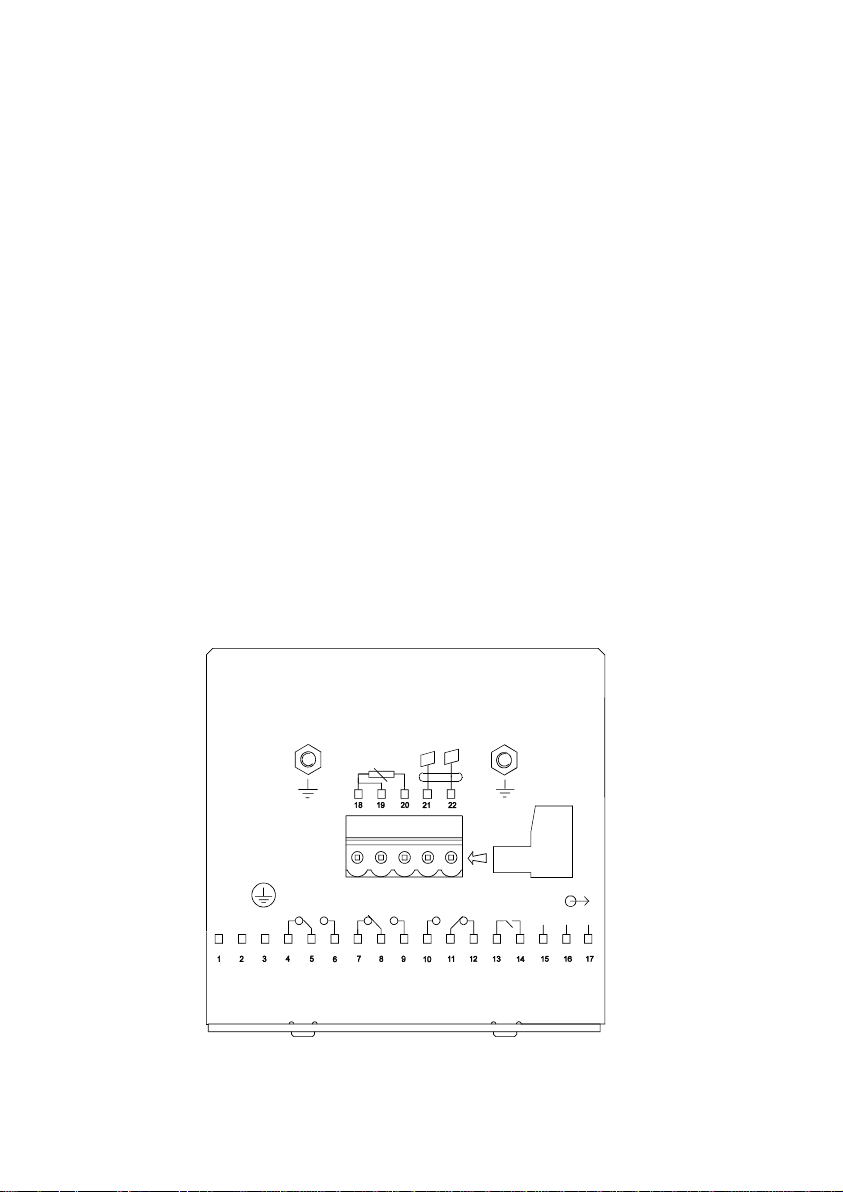

3.2 Back Panel

The back panel consists of two connectors. The first connector is the 17-way PCB edge connector and the

other is the 5-way connector.

Connection for the 17-way screw terminals (from left to right):

1. AC mains live wire 10. Alarm/Wash relay resting position (NO)

2. AC mains neutral wire 11. Alarm/Wash relay common

3. AC mains protective earth wire 12. Alarm/Wash relay working position (NC)

4. Relay 1 relay resting position (NC) 13. Hold function switch terminal 1

5. Relay 1 relay common 14. Hold function switch terminal 2

6. Relay 1 relay working position (NO) 15. No connection

7. Relay 2 relay resting position (NC) 16. 0/4 - 20 mA for -ve connection

8. Relay 2 relay common 17. 0/4 - 20 mA for +ve connection

9. Relay 2 relay working position (NO)

Connections for the 5-way screw terminals:

18. Pt1000/Pt100 lead 1 terminal (red)

19. Pt1000/Pt100 sense lead terminal (short 18 & 19 if using a two-wire system)

20. Pt1000/Pt100 lead 2 terminal (green)

21. Resistivity lead 1 (black)

22. Resistivity lead 2 (white)

*cable wire colours stated above are applicable to EC-CS10 series. For other electrodes, please check

electrode specifications.

IMPORTANT: The

Alarm relay functions

as an “Active Low”

device i.e. it switches

OFF under Alarm

condition. Therefore

the Alarm display

device should be

connected to the ‘NC’

contacts of the relay. If

the relay is configured

as “wash”, then it

+

works in the ‘Active

High’ mode. Therefore

the wash pump has to

be connected across

its “NO” contacts.

FUSE 250VAC

100 mA

(F)

LNPE

RELAY1

Pt100

Pt1000

RELAY2

cell

ALARM

J2

HOLD

-

NC

4

Loading...

Loading...