Page 1

Alpha pH/ORP 1000

Process Controller/Transmitter

Page 2

R

Afast, Cahn, ionplus, KNIpHE, No Cal, ORION, perpHect, PerpHecT, PerpHecTion,

AQU

pHISA, pHuture, Pure Water, Sage, Sensing the Future, SensorLink, ROSS, ROSS Ultra,

Sure-Flow, Titrator PLUS and TURBO2 are registered trademarks of Thermo Fisher.

1-888-pHAX-ION, A+, All in One, Aplus, AQUAsnap, AssuredAccuracy, AUTO-BAR, AUTOCAL, AUTO DISPENSER, Auto-ID, AUTO-LOG, AUTO-READ, AUTO-STIR, Auto-Test, BOD

AutoEZ, Cable-Free , CERTI -CAL, CI SA, Dat aCOLLECT , DataPLU S, dig ital Log R, Di rectCa l,

DuraProbe, Environmental Product Authority, Extra Easy/Extra Value, FAST QC, GAP,

GLPcal, GLPcheck, GLPdoc, ISEasy, KAP, LabConnect, LogR, Low Maintenance Triode,

Minimum Stir Requirement, MSR, NISS, One-Touch, One-Touch Calibration, One-Touch

Measurement, Optimum Results, Orion Star, Pentrode, pHuture MMS, pHuture Pentrode,

pHuture Quatrode, pHuture Triode, Quatrode, QuiKcheK, rf link, ROSS Resolution, SAOB,

SMART AVERAGING, Smart CheK, SMART STABILITY, Stacked, Star Navigator 21, Stat

Face, The Enhanced Lab, ThermaSense, Triode, TRIUMpH, Unbreakable pH, Universal

Access are trademarks of Thermo Fisher.

Guaranteed Success and The Technical Edge are service marks of Thermo Fisher.

Page 3

Preface

This manual serves to explain the use of the Alpha pH1000 pH/ORP process

controller/transmitter. The manual functions in two ways, firstly as a step by step guide to

help the user operate the instrument. Secondly, it serves as a handy ref erence guide. This

instruction manual is written to cover as many anticipated applications of the Alpha pH1000

pH/ORP process controller/transmitter. If you have doubts in the use of the instrument,

please do no t hesitate to co ntact the nearest Authorized Distributor.

Thermo Scientific will not accept any responsibility for damage or malfunction of the unit due

to improper use of the instrument.

The information presented in this manual is subject to change without notice as

improvements are made, and does not represent a commitment on part of Thermo Scien tific.

Copyright

All rights reserved

©

2009

Page 4

Safety Information

The Controller/ Transmitter shall be installed and operated only in the manner specified in this

Instruction ma nual. Only skilled, trained or authorized person should carry out installation, setup

and operation of the instrument.

Before powering up the unit, make sure that power source is connected to it as specified on the

top label. Failure to do so may result in permanent damage of the unit.

The unit has live and exposed parts inside. If it has to be opened, make sure that power to the

unit is off and disconnected.

The unit is Fuse protected. In the event the fuse has to be replaced, use only those as specified

in the manual.

Page 5

TABLE OF CONTENTS

1 INTRODUCTION ___________________________________________________ 1

1.1 Description of Unit............................................................................................1

1.2 Applications......................................................................................................1

2 ASSEMBLY AND INSTALLATIONS ____________________________________ 2

2.1 Measurement and Control System..... ..............................................................2

2.2 Unit Dimensions...............................................................................................2

3 ELECTRICAL CONNECTIONS ________________________________________ 3

3.1 Connection Diagram ........................................................................................3

3.2 Back Panel....................................................................................................... 5

4 OVERVIEW _______________________________________________________ 6

4.1 Keypad and Display .........................................................................................6

4.2 Function Groups...............................................................................................7

4.3 Control Concept...............................................................................................8

5 MEASUREMENT ___________________________________________________ 9

5.1 Display in Measurement mode..... .... ... ........................................ ... ... ...............9

5.2 Security Codes.................................................................................................9

6 CALIBRATION____________________________________________________ 11

6.1 pH Calibration ................................................................................................11

6.2 ORP – mV Calibration...... ... ........................................ ... ... .............................12

6.3 ORP – % Calibration......................................................................................13

7 ADVANCED SET UP MODE _________________________________________ 14

7.1 Electrode Offset (OFS) sub-function.......................................................... .... 14

7.2 Setting temperature (Set

7.3 Control Relay A/ Control Relay B (SP1/SP2) sub-function............................ 16

7.4 Controller (Cntr) sub-function.........................................................................18

7.5 Current Output (mg) sub-function .................................................................. 20

7.6 Configuration (ConF) sub-function.................................................................21

7.7 Calibration (CAL) sub-function....................................................................... 24

o

C) sub-function ...... ... ... ... ...................................... 14

8 ADVANCED SET UP MODE _________________________________________ 25

8.1 Auto mode (mode after switch-on)............ ... ... ........................................ ... ... . 25

8.2 Manual mode .................................................................................................25

9 TECHNICAL SPECIFICATIONS ______________________________________ 26

10 ACCESSORIES ___________________________________________________ 28

11 GENERAL INFORMATION __________________________________________ 29

11.1 Warranty.........................................................................................................29

11.2 Packaging ......................................................................................................29

11.3 Return of Goods.............................................................................................29

11.4 Guidelines for Returning Unit for Repair ........................................................29

12 APPENDICES ____________________________________________________ 30

12.1 Appendix 1 ..................................................................................................... 30

12.2 Appendix 2 ..................................................................................................... 31

12.3 Appendix 3 ..................................................................................................... 32

12.4 Appendix 4 ..................................................................................................... 33

Page 6

1 INTRODUCTION

1.1 Description of Unit

Thank you for purchasing the ¼ DIN Alpha pH1000 pH/ORP process controller/transmitter.

This unit is used for measuring either pH or ORP parameter one at a time, and the

operational mode is switchable from the menu. You can use this unit to measure pH or ORP

with limit control. This controller has many user-friendly and safety features which include:

• Menu-driven program that simplifies set-up

• Built-in non-volatile memory backup to ensure that calibration and other information

are not erased if power supply fails

• Press-button two-point calibration and electrode offset adjustment from the

keypad

• Automatic temperature compensation (ATC)

• Manual temperature compen sation setting without the ATC probe, with independent

setting for calibration and pr ocess temperature

• 0 to 2000 second time delay adjustment on all relays – minimise false alarms

• Separately adjustable high and low set point hysteresis (dead bands) prevent

chattering of relays around the set points

• Asymmetrical/symmetrical input for pH/ ORP operati o n

• Three control modes: limit, proportional pulse length or proportional pulse frequency

• Large dual display LCD for easy reading with clear multiple annunciators, alarm

status, operational and error messages

• Two switching contacts as set-point tr iggering relays

• A third rela y that can be be set up to perform either Alarm or Wash function

• When set to work as Alarm relay, alerts you when readings exceed set-point limits after

a set time buffer, and if the Pt100/Pt1000 wires are broken or disconnected during the

ATC function

• Programmable duration and frequency in the Wash mode

• Hold function freezes output current (0/4…20mA) and releases control relays

• LED indicators signal control activities to monitor controller status from a distance

• Protection against electromagnetic interference – galvanically isolated 0/4…20mA

output provides safety for datalo

• Choice of 7 buffers from USA or NIST standards

gging and control purposes

1.2 Applications

Use this controller in panel mounted enclosures for applications such as water treatment and

monitoring, galvanic-decontamination, chemical processing food processing, clean or waste

water control and neutralisation process.

1

Page 7

2 ASSEMBLY AND INSTALLATIONS

6

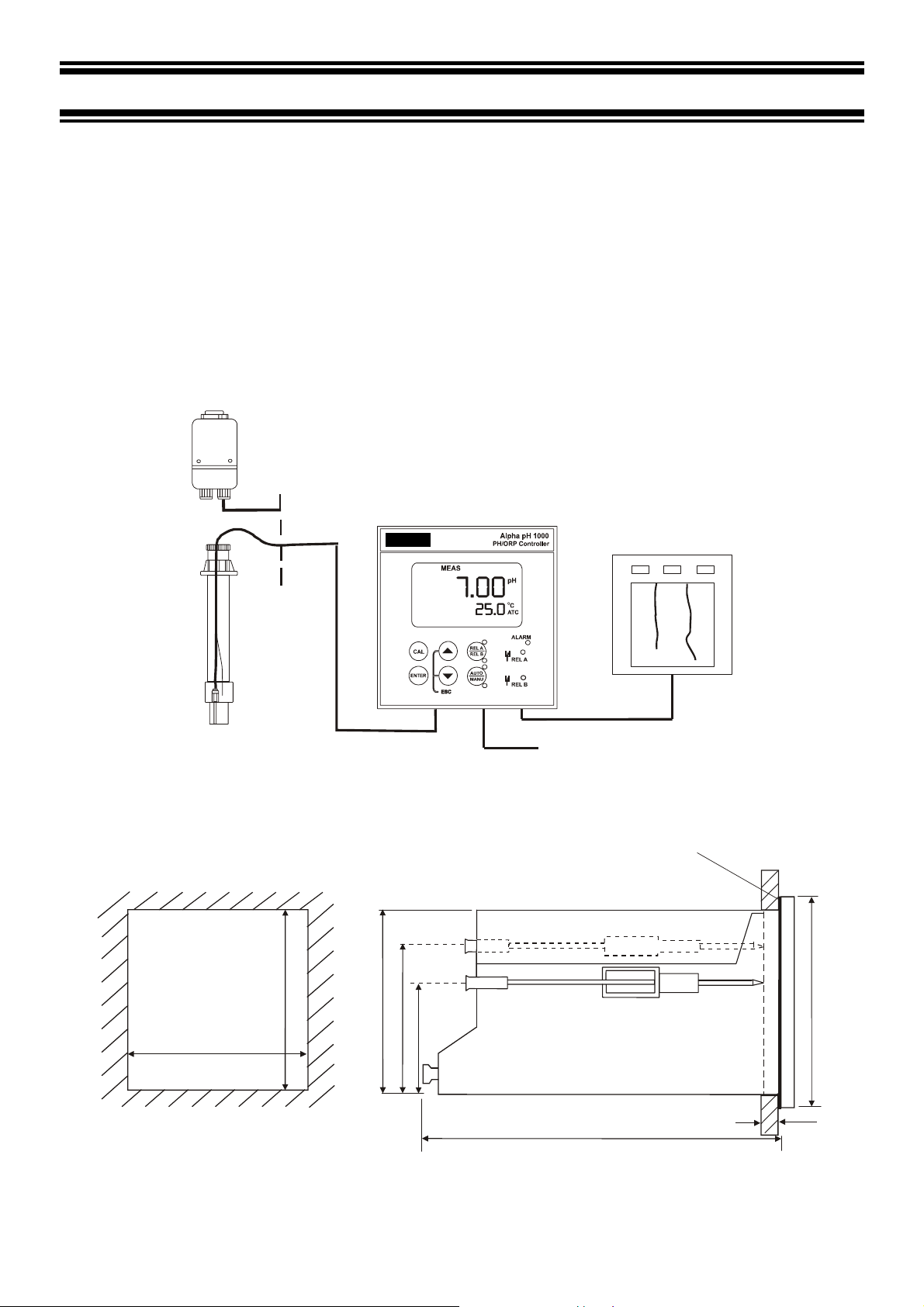

2.1 Measurement and Control System

A typical measurement system consists of:

• a pH/ORP process controller

• a pH/ORP combination electrode with integrated or separate temperature sensor Pt

100/1000,

• an immersion, flow or process assembly with or without a potential matching pin (PMP)

• a final control element such as pump or valve

• a recorder

• an appropriate pH or ORP measurement cable

Flow Assembly

PH Controller

Chart Recorder

Process Assembly

with Electrode

Measurement Cable

Power Mains

(220/110 VAC)

2.2 Unit Dimensions

Flat Gasket (1mm)

(To be Inserted By Customer)

Note: The Taped Corners Have to Be On Top

92 + 0.5

92

56

92 + 0.5

Mounting Cut-Out

The field-tested control panel housing is 96 x 96 mm; with protection class IP 54 (front).

32

max. 45

max. 175

9

2

Page 8

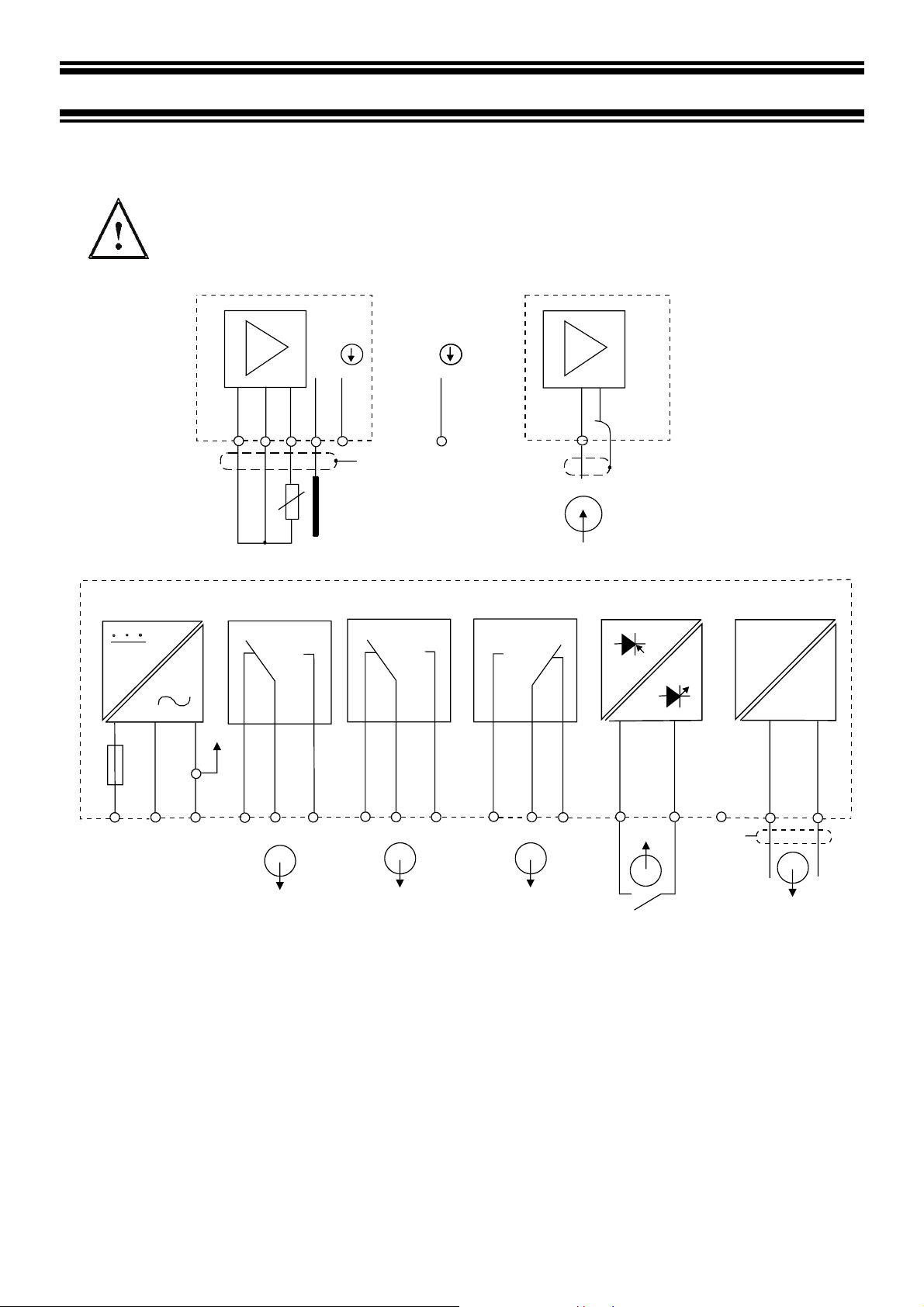

3 ELECTRICAL CONNECTIONS

3.1 Connection Diagram

ENSURE electrical mains is disconnected before proceeding.

S/

V

S/S/

pH

AC:

Power Mains

2

1

NL

PE

18 19 20

Pt 100

3

Relay A

4

21 22

PE/S

Potential Matching Pin (PMP)

Relay B

6

5

78 9

Signal Input pH/ORP

Alarm

10

11

BNC

12 13

14

PE/S

151715

Signal OutputHold Input

pH

-

mA

+

16

*)indicated contact positions are for currentless conditions

3

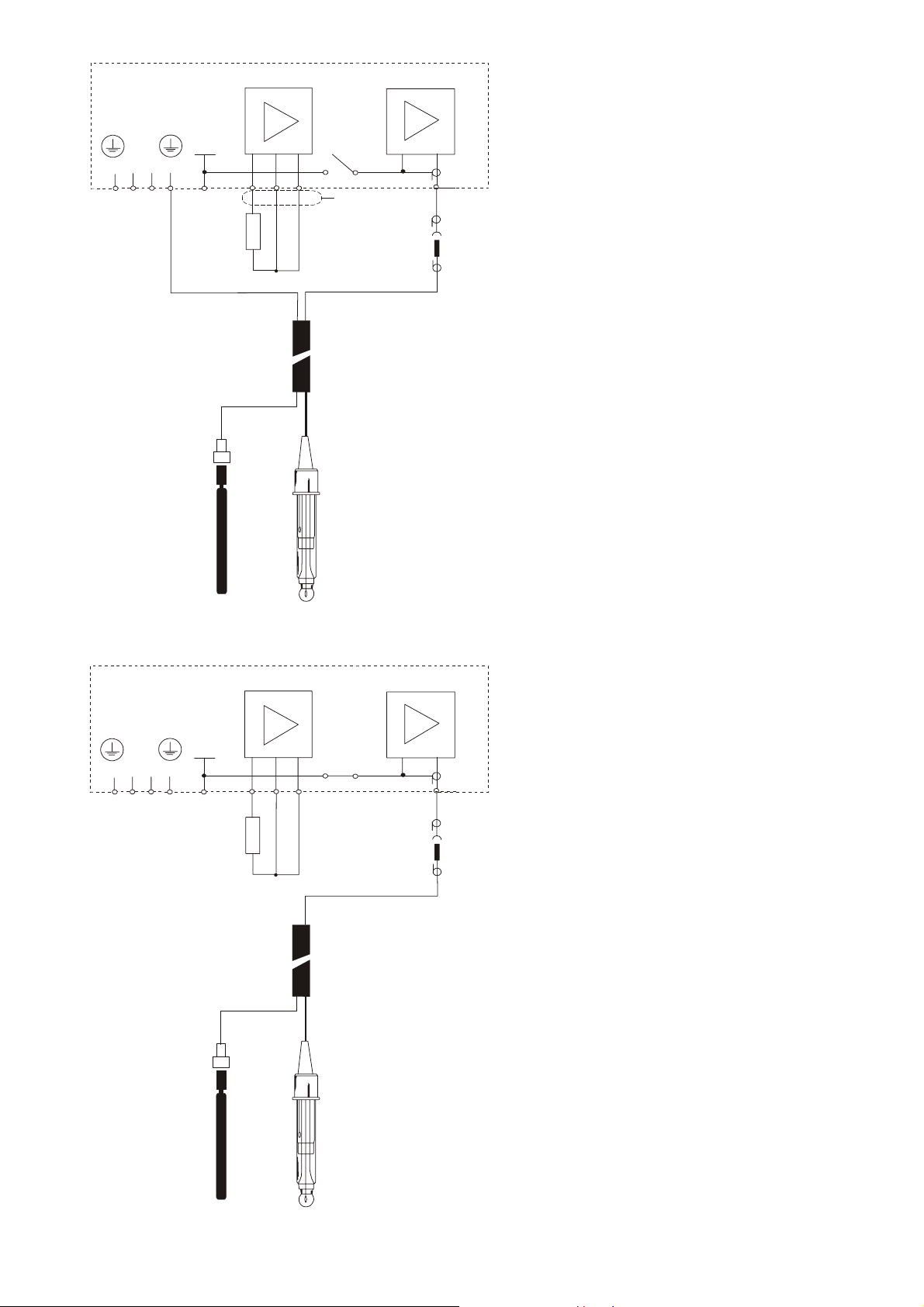

Page 9

NLS

PE

22

1

3

2

Potential

Matching Pin (PMP)

NLS

PE

22

1

3

2

Potential

Matching Pin (PMP)

0 / PA

21

0 / P A

21

20

20

Temp.

19 18

Temp.

19 18

pH

s

Measuring Cable

pH Combination

Electrode

pH

Measuring Cable

pH Combination

Electrode

BNC

BNC

Symmetrical high-impedanc e

connections

Asymmetrical connect ions

4

Page 10

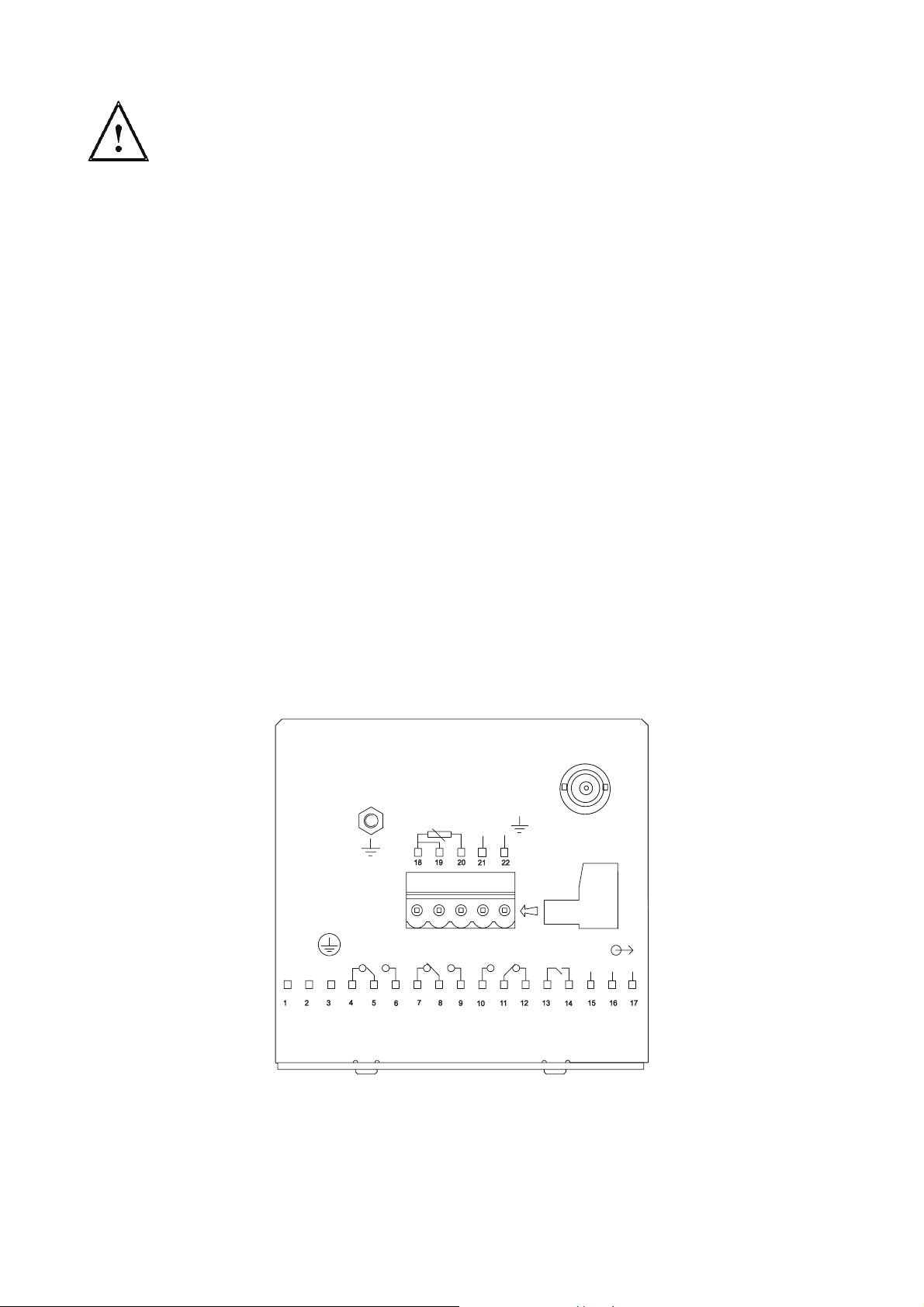

3.2 Back Panel

A

ENSURE electrical mains is disconnected before proceeding.

The back panel consists of two connectors. The first connector is the 17-way PCB edge

connector and the other is the 5-way connector.

Connection for the 17-way screw terminals (from left to right):

1. AC mains live wire 10. Alarm/Wash relay working position (NO)

2. AC mains neutral wire 11. Alarm/Wash relay common

3. AC mains protective earth wire 12. Alarm/Wash relay resting position (NC)

4. Low set relay resting position (NC) 13. Hold function switch terminal 1

5. Low set relay common 14. Hold function switch terminal 2

6. Low set relay working position (NO) 15. No connection

7. High set relay resting position (NC) 16. 4 - 20 mA for -ve connection

8. High set relay common 17. 4 - 20 mA for +ve connection

9. High set relay working position (NO)

Connections for the 5-way screw terminals:

18. Pt100/Pt1000 lead 1 terminal

19. Pt100/Pt1000 sense lead terminal

20. Pt100/Pt1000 lead 2 terminal

Note: If using a two-wire RTD, short terminal 19 to terminal 18.

Pt 100/Pt 1000 is selectable via an internal jumper. Factory default is Pt100. See Appendix

1 for directions on switching the R TD type.

21. pH/ORP (potential matching pin)

22. pH/ORP (shield)

pH/mV

FUSE 250V AC

(F)

100mA

L

N

PE

RELAY A

Pt100/

Pt1000

RELAYB

0V/

S/

PAL

LARM / WASH

HOLD

+

-

NC

Important: The Alarm relay functions as an “Active Low” device i.e. it switches OFF under

Alarm condition. Therefore, the Alarm display device should be connected to the ‘NC’

contacts of the relay (11 and 12). In the Wash mode, the relay works on a positive mode.

Therefore, the Wash device should be connected to contacts 10 and 11.

5

Page 11

4 OVERVIEW

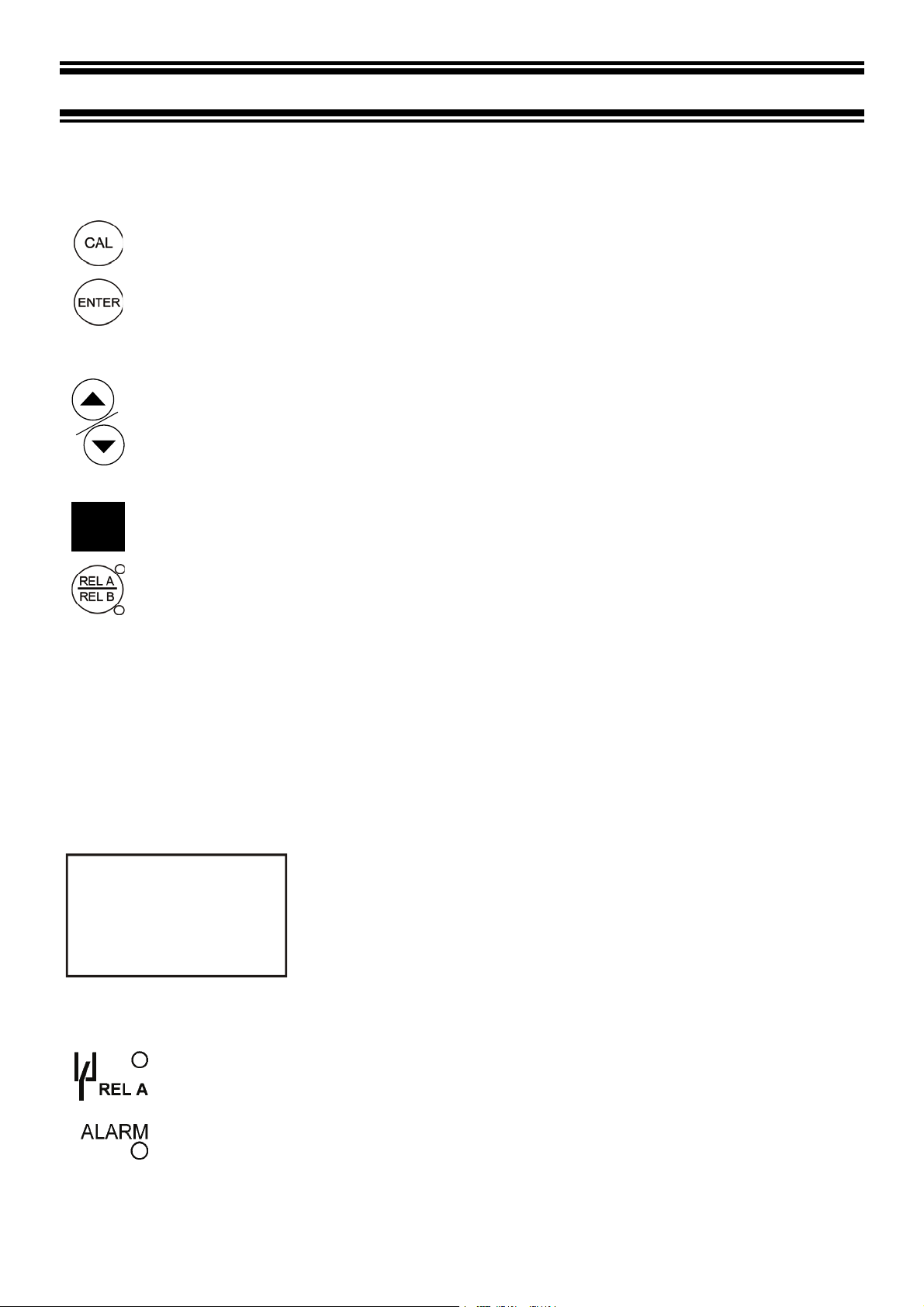

4.1 Keypad and Display

4.1.1 Keypad

• Perform rapid 2-point ca l ibration

• Allows entry to Set up mode

• Select individual functions within the function group of Set up mode

• Store input data in the Set up mode

• Start calibration in the calibration mode

• Select various function groups in the Set up mode.

• Set parameters and numerical values in sub functions of Set up mode

If pressed continuously, the setting speed increases

• Return to the Measurement mode when both keys are pressed together

• Return to the Measurement mode when both keys are pressed together

• Switch beween AUTO and MANUAL relay operation mode

• Display limit set-point values for the switch contacts in AUTO relay operation

mode

• Switch between RELAY A and RELAY B in MANUAL relay operation mode

4.1.2 Display

The LCD display features two numerical displays that show status messages and measured

values for easy, quick reference. The display provides short-text information for setting

parameters and configuration.

• MEAS: Measurement mode

• SETUP: Set-up mode of function groups

• CAL: Calibration mode of pH/ORP and temperature

• READY: Comes on after a succe ssful calibrat ion

• HOLD: Relay position and current output are frozen

• ATC: Comes on in the ATC mode. Disappears in the

Manual temperature Compensation mode.

• “ATC” flashes if the temperature probe is faulty in its ATC

mode

• ERR: Error or alarm indicator

READY

HOLD

7.00

ERR

25.0

• Display for RELAY A/B. Green LED indicates measured value within limit

CONMEAS CALSET UP

pH

°C

AT C

while RED LED indicates measured value outside limit.

• Alarm display if limit value overshoot or the ATC probe fails;with ERR

annunciator appears on the display. Wash display if cleaning cycle is on.

6

Page 12

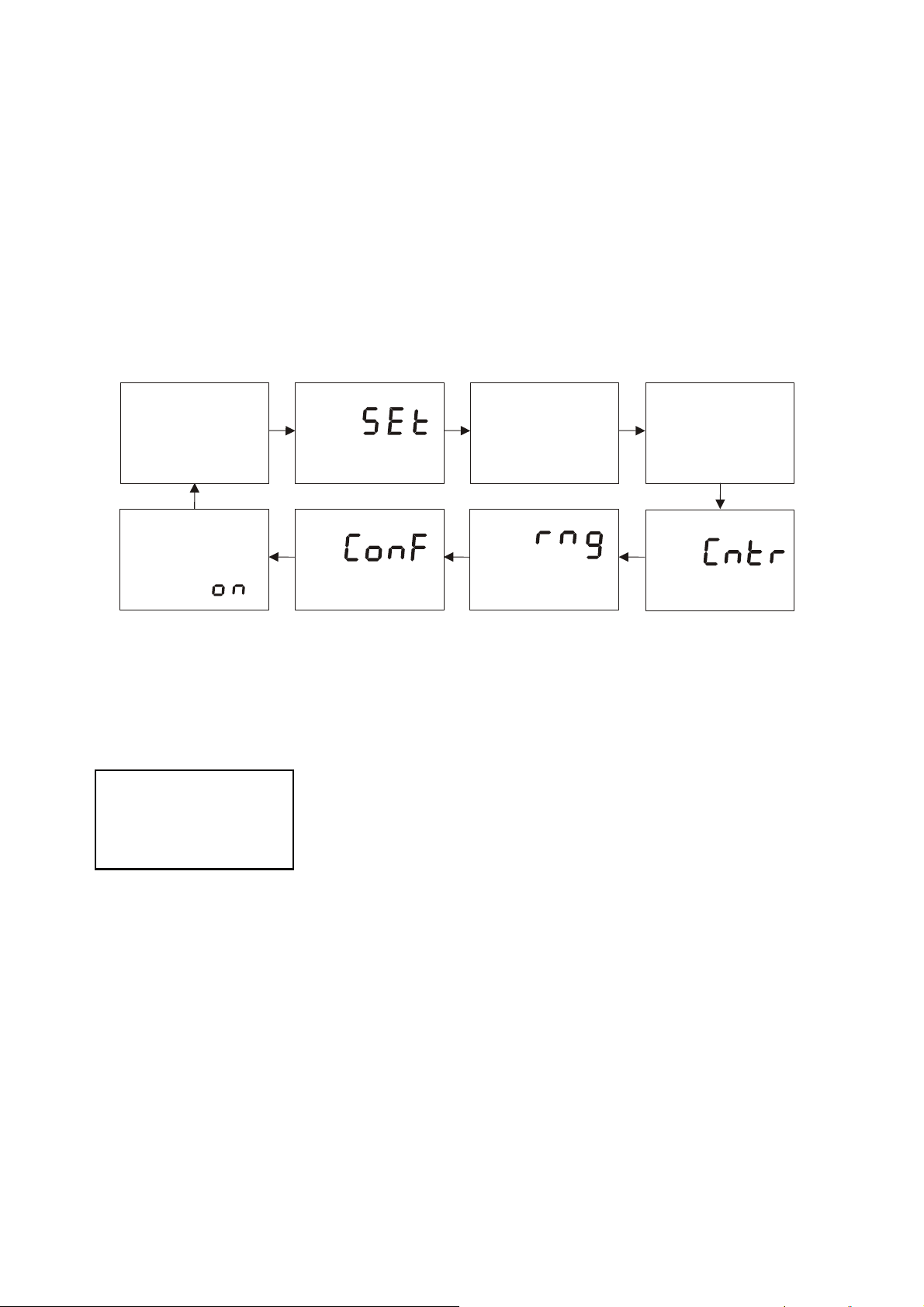

4.2 Function Groups

The main function and sub-function groups are or ganis ed in a matrix format for configuration and

selection of parameters. The main function groups are:

1) Offset adjustment (OFS)

2) Temperature Measurement / compensation settings (Set

3) Control relay 1 configuration (SP1)

4) Control relay 2 configuration (SP2)

5) Control type (Cntr)

6) Current output (mg)

7) Configuration (ConF)

8) Calibration (CAL pH)

o

C)

SETUP

HOLD

SETUP

HOLD

OFS

Cal

SETUP

HOLD

SETUP

HOLD

SETUP

HOLD

°

C

SETUP

HOLD

Sp1 Sp2

SETUP

HOLD

SETUP

HOLD

C

The set-up parameters can be viewed or changed by entering a security code. See section 5.2

for security code information.

4.2.1 How to view operating parameters without access to change them:

SETUP

HOLD

000

S.Cd

a) Press the Enter key. The display will prompt the user to

enter a security code (S.Cd). Leave the security code at

“000” (do not enter a security code).

b) Press ENTER key again. This allows you to only view (not

change) any sub-functions’ settings.

Press the ▲ or ▼ key to scroll through the sub-functions.

c)

d)

Press the ENTER key at a particular sub-function to view in detail.

e)

Press the ENTER key to return to the sub-function menu.

Press the ▲ or ▼ keys simultaneously (as an Escape key) at any time to return to the

f)

Measurement mode.

Note: To simplify operations, the controller will not display parameters that are not relevant to a

particular subfunction. For example, if the user set the controller for limit control, it will not display

pulse length/frequency settings.

7

Page 13

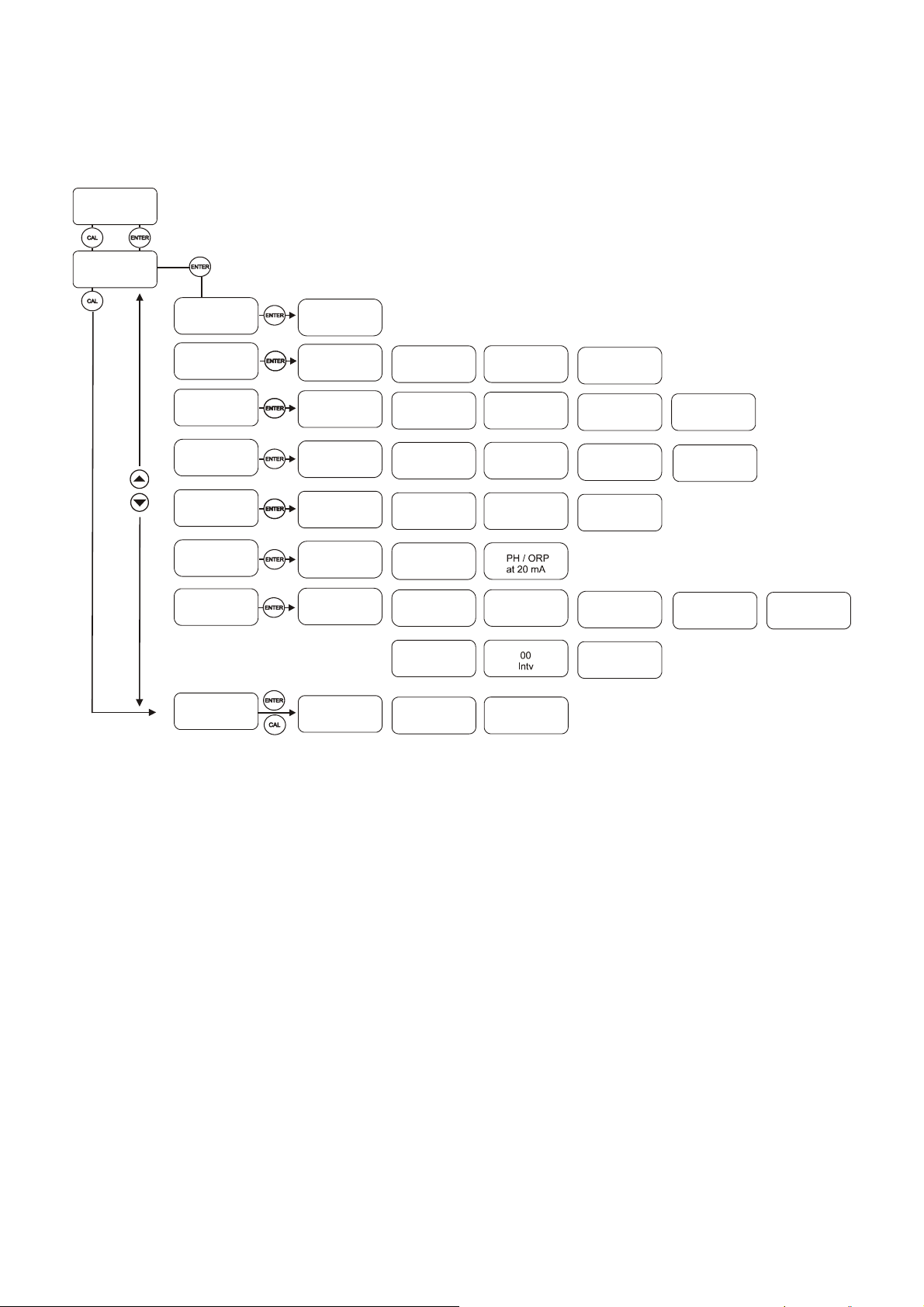

4.3 Control Concept

The main function and sub-function groups are organised in a matrix format as shown below.

These functions can be accessed via the front keypad for configuration and selection of

parameters.

MEASURE

CODE

OFFSET

O

SET C

SET-POINT 1

SET-POINT 2

CONTROLLER

MEASUREMENT

RANGE

CONFIGURATION

CALIBRATION

Set Offset

Switch On/Off ATC

Set value 1

Set value 2

Controller type

Current output

0.20 / 4.0 mA

pH/ ORP Symm.

/ Asymmetrical

Calibrate

1st value

Process temp.

(MTC)

MIN / MAX Function

MIN / MAX Function

N.O. / N.C.

Contact

pH / ORP

at 0/4 mA

Alr

Cln

Calibrate

2nd value

Calib. temp.

(MTC)

Hysteresis 1

Hysteresis 2

Proportional

range XP

Alarm delay

Display zero point

and slope

Calibrate Pt100

Pick-up delay

contact 1

Pick-up delay

contact 2

Cycle time bzw.

Max. Frequency

Alarm contact

cont./wiper contact

1000

Dur

Dropout delay

contact 1

Dropout delay

contact 2

Electrode type

Glass/Antimony

Reset to factory

default settings

The controller offers two levels of password protection: (1) for direct access to calibration

function and (2) for setting or editing specific controller parameters or functions in the SETUP

mode to suit individual requirements.

Note: The passwords are not user-defined and have been set by factory. It is very important to

keep these passwords strictly confidential to avoid unauthorised tampering of the system at

all times.

Note: If the user reads parameters only, the controller automatically reverts to Measurement mode

if no key is pressed for 30 seconds.

8

Page 14

5 MEASUREMENT

5.1 Display in Measurement mode

When the controller is initially powered on, it automatically enters into the Measurement mode

after the large dual LCD displays al l segments briefly.

The upper display shows the measured pH or ORP value, while lower display shows either

temperature value if controller is set for pH measurement or “OrP” if it is set for ORP

measurement.

Annunciators at right side of display indi cate whether cont roller is set for pH or mV

measurement. If the controller is set for OR P % measurement, neither the pH or mV indicator

displays.

Similarly annunciators or icons at top or left side of display show current status of controller, e.g.

“MEAS”, “SETUP”, “CAL”, “READY”, e tc. In addition, error messages also guide user in time of

any faulty conditions as indicated by “ERR” or icons flashing.

5.1.1 Check electrode performance

To read current electrode slope and offset values withou t changing them:

1) Press the CAL key followed by the ENTER key without adjusting the security code (leave

code at “000”). The upper display shows electrode slope. The lower display reading shows

the pH reading at 0 mV.

Note: If security code is changed to a value other than “000”, press the ENTER key to return to

Measurement mode, without displaying electrode information.

2) Press the ENTER key a second time to return to Measurement mode.

5.1.2 Checking set points

To read current set point values without changing them:

1) Press the RELAY Selection (Rel A/Rel B) key. The upper display shows the set point for

Relay A; the lower display shows “SP1”.

2) After two seconds the upper display shows the set-p oint val ue f or R ela y B; th e lowe r di sp la y

shows “SP2”.

3) After an additional two seconds, the controller returns to its Measurement mode.

5.2 Security Codes

This controller has two levels of security protection with separate security codes. The first level

allows entry into the Calibration mode: security code = 11; the second allows entry into the

SETUP mode: security code = 22.

The security codes protect the controller from unauthorised tampering of its current setting. The

parameters cannot be changed unless the security code is entered.

9

Page 15

5.2.1 How to enter and change para meters in Calibration mode

1) Press the CAL key. The upper display shows “000” and the

SETUP

HOLD

000

display shows “C A L Or P ”.

4) Press ENTER key again to begin calibration. Refer to Section 6 for full details on calibration.

5) Press the ▲ and ▼ keys simultaneously (escape) to return to the Measurement mode.

NOTE: To view (not change) the SETUP parameters, press the ENTER key when the security

code reads “000”.

5.2.1.1 Clearing the Cali bration security code from the display

The calibration security code automatically resets from “11” to “000” after you return to

Measurement mode, so you do not need to clear the security code from the display.

5.2.2 How to enter and change parameters in Advanced Setup mode

1) Press the ENTER key once. The upper display shows “000” and the lower display shows

“S.Cd” to prompt you to enter the Advanced Setup security code.

2) Press the ▲ or ▼ key to scroll the display to Setup security code “22”.

3) Press the ENTER key.

4) If configured for pH control, the upper display re ads “OFS”.

5) If configured for ORP control, the upper disp lay reads “SP1”.

NOTE: Pressing the ENTER key at a value other than “22” causes the controller to revert to the

Measurement mode.

6) You are now in the Advanced Setup mode. See Section 7 for complete instructions. To

return to Measurement mode, press the ▲ and ▼ keys simultaneously (escape).

NOTE: If you want to view (not change) set up parameters, press the ENTER key when the

security code reads “000”.

5.2.2.1 Clearing the Advanced Setup security code from the display

After you have entered the security code and returned to the Measurement mode, the security

code “22” still appears on the display whenever you press the ENTER key. To conceal the

security code, you must manually reset the code. To clear the Advanced Setup security code

from the display:

1) Press the ENTER key in the Measurement mode.

2) Set to any security code (not 11 or 22) and complete by pressing ENTER.

NOTE: When you enter the Calibration mode with code “11” or Advanced Setup mode with

security code “22”, the unit automatically enters into the HOLD mode until you return back to

Measurement mode. The HOLD annunciator is displayed at the upper left of the display. While on

HOLD, the current output is frozen and set point relays are deactivated.

lower display shows “C.Cd” to prompt the user to enter the

Calibration security code.

2) Press the ▲ or ▼ key to scroll upper display to Calibration

security code “11”.

3) Press the ENTER key. If configured for pH control, the

display shows “CAL pH”. If configured for ORP control, the

10

Page 16

6 CALIBRATION

You can reach the Calibration mode directly from the Measurement mode by pressing the CAL

key and entering the Calibration security code. You can also reach the Calibration mode from

the Advanced Setup mode.

6.1 pH Calibration

This unit features 7 preset buffer values (1.01, 4.01, 6.86, 7.00, 9.00, 9.18 and 10.01) for

fast auto calibration. When you calibrate this instrument, you need a standar d pH buffer

solution that matches one of these values.

SETUP

HOLD

CAL

pH

pH

HOLD

6.96

7.00

SETUP

HOLD

CAL

4.02

4.00

CAL

READY

HOLD

the ENTER key, the electrode and CAL indicator will flash. The controller adjusts the

reading to the buffer.

7) After calibrating to a second buffer value, this controller will automatically display slope in the

upper displa y and zero point in the lo wer display. You can view the values for zero point and

slope without calibration --- see sec tion 5.1.2 for instruction The zero poi nt and slope are redetermined after each calibration.

59.0

7.00

pH

pH

pH

mV

pH

1) Enter Calibration mode. While in the Measurement

mode, press the CAL key and scroll to Calibration code

“11”. Press the ENTER key again. The upper and lower

display reads “CAL pH”.

NOTE: If the display reads “CAL OrP”, see section 7.6.2 for

procedures on how to switch from ORP to pH readings.

2) Press the ENTER key again to begin calibration. The

“CAL” indicator appears at the top of display and the

buffer indicator appears in the bottom left corner of the

display. The upper display shows your present

uncalibrated reading. The lower display indicates one of

the two buffer values used for the first point calibration.

It would either be 7.00 or 6.86.

3) Press the ▲ or ▼ key to scroll the lower display to the

buffer value that matches your buffer solution.

4) Make sure the electrode is in the buffer solution. In

ATC, you must also immerse the temperature probe in

the buffer solution. Likewise for symmetrical mode, you

must also immerse the potential matching pin in the

buffer.

5) Press the ENTER key to confirm the buffer value and

start the calibration of its first point. The electrode

indicator and CAL indicator both flash. The controller

automatic al ly adjusts the read ing to match the buf fer

value.

6) The lower display will now show its next lower ‘pH’

buffer. Use ▲ and ▼ keys to select its second buffer

from one of the 5 preset values. Remove the electrode

from the first buffer, wash and then immerse into the

second buffer. Once the upper display stabilises press

11

Page 17

8) Press the ENTER key. If you entered the calibra tion mode using the CAL key, the

controller will return to the Measurement mode. If you entered the calibration mode from the

Advanced Set-up mode, the controller will return to the sub-function menu.

Note: If there is a calibration error, the controller displays “ERR”. If this happens, press both the ▲

and ▼ keys (escape) to restart the calibration beginning from step 1.

Note: When calibrating with manual temperature compensation, the controller automatically

changes from the preset process temperature to the calibration temperature. After leaving the

Calibration mode, the controller switches back to process temperature (for setting the calibration

temperature and the process temperature, see section 7.2.3).

6.2 ORP – mV Calibration

This mode allows one-poin t calibration.

1) Enter Calibration mode. While in the

Measurement mode, press the CAL key and

scroll to Calibration code “11”. Press the

SETUP

HOLD

SETUP

HOLD

CAL

226

C

ENTER key again. The upper and lower display

reads “CAL OrP”.

NOTE: If the display reads “CAL pH”, see section

7.6.2 for procedures on how to switch from pH to

ORP mV readings.

2) Place sensor in the ORP solution.

3) Press the ENTER key to begin calibration. The

“CAL” indicator appears on the display. The

upper display shows the current mV output of

the electrode without any offset adjustment.

4) Press the ▲ and ▼ keys to match the mV

value to your exact reading.

5) To confirm, press the EN TER key. The

controller calculates the correction factor and

returns to the Measurement mode.

12

Page 18

6.3 ORP – % Calibration

The ORP % mode allows you to calibrate at two points: a low concentration sample (20%) and a

high concentration sample (80%).

To calibrate the controller for ORP %:

1) Enter Calibration mode. While in the Measurement

SETUP

HOLD

SETUP

HOLD

CAL

80

C.1

SETUP

HOLD

20

C.2

indicator flashes and the controller adjusts its display to the 20% relative value and exits to

Measurement mode.

Note: If there is a calibration error, the controller displays “ERR”, and it will not automatically return

to Measurement mode. If this happens, press the ▲ and ▼ keys simultaneously (escape) to

restart the calibration beginning from step 1.

Note: If you stop calibration after entering the first value, or if calibration is defective, the controller

will use its original calibration data.

mode, press the CAL key and scroll to Calibration

code “11”. Press the ENTER key again. The upper

and lower display reads “CAL OrP”.

NOTE: If the display reads “CAL pH”, see section 7.6.2

for procedures on how to switch from pH to ORP mV

readings.

2) Press the ENTER key to begin calibration. The

“CAL” indicator appears on the display. The upper

display sh ows “80”. The low er display shows “C1”

(=calibrated value 80%).

3) Place sensor in the high concentration sample

(relative value of 80%).

4) Press the ENTER key to confirm the value. The

electrode indicator and CAL indicator flash. The unit

automatically adjusts its reading to match the

solution value.

5) The display will now show ‘20’ and ‘C2’. Remove the

electrode from the first standard, wash it well and

then immerse it in the 20% standard. When the

display stabilises, press the ENTER key. The ‘CAL’

13

Page 19

7 ADVANCED SET UP MODE

7.1 Electrode Offset (OFS) sub-function

You can perform electrode offset only in the pH mode. Th is mode allows you to change the

offset parameter to make reading corrections without removing the electrode from the control

system. You can make adjustments of up to ±120 mV.

The controller will add or subtract the value from the measured pH and display the correct val ue .

However, if you need to offset the value beyond the average offset you would expect in yo ur

application type, consider a full calibration or even electrode replacement.

1) Pull a sample from the system. Record the controller’s pH reading at the time you take the

sample.

2) Measure the pH of your sample using a calibrated pH tester, hand-held meter, or bench

meter. Record the correct pH value.

3) Enter Advanced set-up mode. Press the ENTER key and scroll to Advanced Set-up

security code “22”. Press the ENTER key again.

4) Press the ▲ or ▼ key to scroll until the upper display shows OFS.

5) Press the ENTER key. The SETUP annunciator appears at the top of the display. The lower

display shows the current measured pH value. The upper display shows the current offset

value.

6) Press the ▲ or ▼ key until the pH value coincides with the correct pH value noted in Ste p

2. As the ▲ and ▼ keys are pressed to adjust the pH value, you will see that the ‘offset’

value in its upper display also changes.

7) Press the ENTER key to enter the offset value.

Note: The offset value is reset during full calibration. See Section 6 for full calibration instructions.

Note: The offset parameter is blanked out during ORP operation.

7.2 Setting temperature (Set °C) sub-function

7.2.1 Selecting automatic or manual temperature compensation

SETUP

HOLD

SETUP

HOLD

SETUP

HOLD

Set

1) Enter Advanced Set-up mode. Press the ENTER key and scroll

to Advance Set-up security code “22”. Press the ENTER key

again.

2) Press ▲ and ▼ keys to scroll until display shows “Set °C”.

3) Press ENTER key. The lower display shows “Atc”; upper display

shows “on” or “oFF” depending on whether or not ATC is selected.

4) Press ▲ and ▼ keys to toggle between ATC on and off.

5) Proceed with additional Advanced Set-up procedures (press

ENTER again) or return to Measurement mode by pressing ▲ and

▼ keys (escape) simultaneously.

14

Page 20

7.2.2 Temperature calibration (ATC mode only)

SETUP

HOLD

SETUP

HOLD

0.0

25.0

°C

ATC

1) Select “ATC on” as described above in Section 7.2.1.

2) Press ENTER key. The upper display indicates current

temperatu re offset. The curr ent measured temperature is

shown in the lower display.

3) Compare the current measured temperature on the controller

display to a thermometer known to be accurate. Note down

the correct temperature value.

4) Press ▲ and ▼ keys to scroll the lower display to match the

correct value. Upper display will now show the offset value.

You can offset temperature up to ± 5 °C.

5) Press ENTER key to confirm your selection.

6) Continue with additional Advanced Set-up procedures, or

return to the Measurement mode by pressing ▲ and ▼ keys

(escape) simultaneously.

7.2.3 Setting manual temperature compensation

Note: This option is not available when the controller is set for

SETUP

HOLD

SETUP

25.0

HOLD

SETUP

25.0

HOLD

5) Press ▲ and ▼ keys to adjust the calibration temperature value, between -9.9 and 125°C.

6) Press ENTER key to confirm.

7) Continue with additional Advanced Set-up procedures, or return to Measurement mode by

pressing ▲ and ▼ (escape) simultaneously.

ATC operation.

For manual temperature compensation, two different

temperatures: process and calibration, can be input

independently. This allows calibration at a temperature other than

the process temperature. Example: setting a calibration

temperature of 25

solutions at 25

1) Select “ATC oFF” as described above in section 7.2.1

2) Press ENTER key. Upper display shows current process

temperature and lower display shows “P.°C” to indicate

process temperature.

3) Press ▲ and ▼ keys to adjust the process temperature

value, between -9.9 and 125°C.

4) After setting the process temperature value, press ENTER

key. Upper displ ay shows current calibration temperature and

lower display shows “C.°C”.

o

o

C allows calibration using standard buffer

C, even if the process temperature is different.

15

Page 21

7.3 Control Rel ay A/ Control Relay B (SP1/SP2) sub-function

The SP1 option sets operating parameters for Relay A; the SP2 option sets operating

parameters for relay B. Since these groups have the same set-up parameters, they are

described together.

7.3.1 Entering Set point 1 (Set point 2) sub-function

1)

SETUP

HOLD

SETUP

HOLD

Sp1

pH

4.00

Sp1

SETUP

HOLD

Sp1

7.3.3 Choosing High or Low set points

Select a low set point to activate controller when the pH/ORP valu e goes below the low set

point; select a high set poin t to activate controller when the value overshoots the high set point.

Using both SP1 and SP2, y ou can select lo/lo, lo/ hi, hi/lo, or hi/hi se t points.

1) Follow directions in 7.3.1 to enter Control Relay mode.

2) Press ENTER key. Scroll with the ▲ or ▼ keys until upper display shows Lo or Hi (for low

or high set poi n t ) an d the lower displ a y shows SP1 (SP2).

3) Press the ▲ or ▼ keys to select low (lo) or high (hi) set point for SP1 (SP2).

4) Press ENTER key to confirm your selection.

5) Proceed to 7.3.4 step 3, or return Measurement mode by pressing the ▲ and ▼ keys

simultaneously (escape).

7.3.4 Selecting a hysteresis (dead band) value

Hysteresis prevents rapid contact switching if your value is fluctuating near the set point. It does

this by overshooting the set point value to a specified hysteresis value. You can set the

hysteresis value from 0.1 to 1.0 pH, 10 to 100mV or 1 to 10%.

Example: You hav e set your high set point at pH 9.0 and your hysteresis limit value at pH 0.5. If

your measured value overshoots the high set point pH 9.0, the controller’s relay activates, which

in turn activates an external device such as a pump or valve. The actions of the external device

will cause the solut ion’s pH to drop. When t he pH drops to 8.

will switch off.

Enter Advanced Set-up mode. Press the ENTER key an d

scroll to Advanced Set-up security code “22”. Press the ENTER

key again.

2) Press ▲ or ▼ key to scroll until upper display shows SP1

(SP2).

7.3.2 Selecting set point values

This lets you choose the value that will cause your controller to

activate (i.e. pH 9.0).

1) Follow directions in 7.3.1 to enter Control Relay mode. If you

are in this mode, skip to step 2.

2) Press ENTER key. The upper display shows current set point

value and lower display shows SP1 (SP2).

3) Press ▲ or ▼ key to enter value for Set point 1 (Set point 2).

Your controller will activate at the value you selec t.

4) Press ENTER key to confirm your selection.

5) Proceed to 7.3.3 step 3, or return to Measurement mode by

pressing the ▲ and ▼ keys simultaneously (escape).

5 pH, the relay and hence the pump

16

Page 22

1) Follow directions in 7.3.1 to enter Control Relay mode.

s

SETUP

0.50

HOLD

Hy

4) Press the ENTER key to confirm your selection.

5) Proceed to 7.3.5 step 3, or return to Measurement mode by pressing the ▲ and ▼ keys

simultaneously (escape).

NOTE: Please refer to Appendix 3 for a graphical representation of the Hysteresis.

7.3.5 Setting an on-delay time lag

You can set a time delay for each relay, w hich stops the relay from switchi n g on the moment the

set point is exceeded. This controller lets you set a 0 to 2000 second time delay before the relay

activates.

SETUP

HOLD

4) Press the ENTER key to confirm your selection.

5) Proceed to 7.3.6 step 3, or return to Measurement mode by pressing the ▲ and ▼ keys

simultaneously (escape).

7.3.6 Setting an off-delay time lag

You can set a time delay for each relay, w hich stops the relay from switching off the moment the

value reached the set point and hysteresis. This controller lets you set a 0 to 2000 second time

delay before your relay deactivates.

SETUP

HOLD

of seconds (0 to 2000) you select.

4) Press the ENTER key to confirm your selection.

5) Continue with Advanced Set-up mode procedures, or return to Measurement mode by

pressing the ▲ and ▼ keys simultaneously (escape).

0

0

2) Press the ENTER key. Scroll with the ▲ or ▼ key until the

pH

upper display shows the hysteresis (dead band) value an d the

lower display shows “HYS”.

3) Press the ▲ or ▼ keys to enter your hysteresis value for Set

point 1 (Set point 2). Your controller will activate at the value

you select.

1) Follow directions in 7.3.1 to enter Control Relay mode.

2) Press the ENTER key. Scroll with the ▲ or ▼ key until the

upper display shows “on delay” time and the lower di splay

shows “On.d”.

3) Press the ▲ or ▼ key to enter on-delay time for Set point 1

(Set point 2). The controller will delay activation for the number

of seconds (0 to 2000) you select.

1) Follow directions in 7 .3.1 to enter Control Relay mode.

2) Press the ENTER key. Scroll with the ▲ or

upper

shows “OF.d”.

3) Press the ▲ or ▼ key to enter on-delay time for Set point 1

(Set point 2) Your controller will delay activation for the number

display shows “off delay” t ime and the lower displ ay

▼ key until the

17

Page 23

7.4 Controller (Cntr) sub-funct ion

You can set the c ontroller’s parameters in this sub-func tion.

7.4.1 Entering Controller sub-function

1) Enter Advanced Set-up mode. Press the ENTER key and scroll to Advanced set-up

security code “22”. Press the ENTER key again.

2) Press the ▲ or ▼ key to scroll until upper display shows “Cntr”.

SETUP

HOLD

SETUP

HOLD

7.4.2 Choosing the cont ro ller type (limit or proprotional)

This mode lets you choose your controller type: limit control, pulse length fre quency proportional

control, or control off.

- Use limit control with pumps or values for fast response.

- Use pulse frequency proportional control to operate your pumps smoothly.

- Use pulse length proportional control for precise control of proportioning

valves.

- Use control off to operate controller as a monitor only or to keep relays from

switching.

1) Follow directions in 7.4.1 to enter Controller mode.

2) Press the ENTER key. The upper display shows the current controller type and the lower

display shows “tyP”.

3) Press the ▲ or ▼ key to select your controller type.

- L.Ct = limit value pickup (on/off control).

- oFF = controller off.

- PLC = pulse length control.

- PFC = pulse frequency control.

4) Press the ENTER key to confirm your selection.

5) Proceed to 7.4.3 step 3, or return to Measurement mode by pressing the ▲ and ▼ keys

simultaneously (escape).

7.4.3 Choosing break/m ake co ntact relay type

Note: If the controller type “oFF” is set, the parameters listed in 7.4.3, 7.4.4 and 7.4.5 are

blanked out. This mode lets you determine the re lay state under Non-Alarm condition – dEEN

(de-energised) or EN (energised).

SETUP

HOLD

SETUP

HOLD

Plc

SETUP

HOLD

Pfc

18

Page 24

SETUP

HOLD

SETUP

HOLD

Note: If the controller type “oFF” or “L.Ct” is set, the paramet ers listed in 7.4. 4 and 7.4.5 are

blanked out.

This mode lets you set a band as a percentage of its full scale value. You can select this range

from 10 to 200%, and the lower display shows “PrP”.

SETUP

HOLD

5) Proceed to 7.4.5 step 3, or return to Measurement mode by pressing the ▲ and ▼ keys

simultaneously (escape).

7.4.5 Maximum Pulse Length (tPL) or Maximum Frequency (FPF)

Note: If the controller type “oFF” or “L.Ct” is set, the paramet ers listed in 7.4. 4 and 7.4.5 are

blanked out.

This mode lets you set the maximum pulse length or the maximum frequency at which the relay

will operate.

SETUP

HOLD

SETUP

HOLD

100

10.0

60

F.Pf

3) Press the ▲ or ▼ key to choose the period duration or maximum frequency, depending on

your mode.

4) Press the ENTER key to confirm your selection and to return to Advanced Set-up mode, or

return to Measurement mode by pressing the ▲ and ▼ keys simultaneously (escape).

NOTE: The alarm contact is always of the f ail-safe type: in the event of power failure the

alarm is triggered.

1) Follow directions in 7.4.1 to enter Controller mode.

2) Press the ENTER key. Scroll until the lower display shows

“rEL” and the upper display shows the current sele ction (deenergised = dEEN or energised = EN).

3) Press the ▲ or ▼ key to choose de-energised or energised

relay state.

4) Press the ENTER key to confirm your selection.

5) Proceed to 7.4.4 step 3, or return to Measurement mode by

pressing the ▲ and ▼ keys simultaneously (escape).

7.4.4 Selecting proportional range value Xp

1) Follow directions in 7.4.1 to enter Controller mode.

2) Press the ENTER key. Scroll until the upper display shows

the proportional range (a number from 10 to 200%), and the

lower display shows “PrP”.

3) Press the ▲ or ▼ key to choose the proportional range

value Xp.

4) Press the ENTER key to confirm your selection.

1) Follow directions in 7 .4.1 to enter Controller mode.

2) Press the ENTER key. Scroll until the lower display shows

“t.PL” or “F.PF”.

- In PLC (pulse length) mode: The lower display shows “t.PL”

to indicate pulse length. The upper displ ay show s your

current pulse length. You can select any value from 0.5 to 20

seconds.

- In PFC (pulse frequency) mode: The lower display shows

F.PF to indicate pulse frequency. The upper display shows

your current maximum pulse rate. You can select any value

from 60 to 120 pulses per minute. When the measured value

exceeds the Proportional Band in 7.4.4, the controller will

the relay at this rate.

pulse

19

Page 25

7.5 Current Output (rng) sub-function

This sub-function lets you set the controller current output

SETUP

HOLD

SETUP

4-20

HOLD

SETUP

HOLD

SETUP

HOLD

pH mode, ORP parameters are blocked out. If you are in the ORP mode, pH parameters are

blocked out.

1) Follow directions in 7.5.1 to enter Current Output mode.

2) Press the ENTER key. Scroll with the ▲ or ▼ keys until the upp e r display shows a pH or

ORP value and the lower display shows “r.0(4)”.

3) Press the ▲ or ▼ key to select pH or ORP value to be equivalent to 0(4) mA.

4) Press the ENTER key to confirm your selection.

5) Press the ENTER key to return to Advanced Set-up mode, or return to Measurement mode

by pressing the ▲ and ▼ keys simultaneously (escape).

7.5

.4 Selecting pH/ORP value at 20mA

This parameter lets you choose a pH or ORP value at which th e c ontroller output will be 20 mA.

NOTE: If you are in the pH mode, ORP parameters are blocked out. If you are in the ORP mode,

pH parameters are blocked out.

1) Follow directions in 7.5.1 to enter Current Output mode.

2) Press the ENTER key. Scroll with the ▲ or ▼ keys until the upp e r display shows a pH or

ORP value and the lower display shows “r.20”.

3) Press the ▲ or ▼ key to select pH or ORP value to be equivalent to 20 mA.

4) Press the ENTER key to confirm your selection.

5) Press the ENTER key to return to Advanced Set-up mode, or return to Measurement mode

by pressing the ▲ and ▼ keys simultaneously (escape).

14

pH

0

pH

range of this unit.

7.5.1 Entering current output sub-function

1) Enter Advanced Set-up mode. Press the ENTER key

and scroll to Advanced Set-up security code “22”. Press

the ENTER key again.

2) Press the ▲ or ▼ key to scroll until the upper display

shows “rng”.

7.5.2 Choosing the output type

This parameter lets you choose between 0-20 mA or 4-20

mA output.

1) Follow directions in 7 .5.1 to enter Current Output

mode.

2) Press the ENTER key. Scroll with the ▲ or ▼ key until

the upper display shows the output type (0-20 or 4-20),

and the lower display shows “out”.

3) Press the ▲ or ▼ key to select your output type: 0-20 or

4-20 mA.

4) Press the ENTER key to confirm your selection.

5) Proceed to 7.5.3 step 3, or return to Measurement mode

by pressing the ▲ and ▼ keys simultaneously (escape).

7.5.3 Selecting pH/ORP value at 0(4)mA

This parameter lets you choose a pH or ORP valu e at which

the controller output will be 0(4) mA. NOTE: If you are in the

20

Page 26

7.6 Configuration (ConF) sub-function

This group of parameters lets you configure the controller to suit your requirements.

7.6.1 Entering the Configuration s ub-f u nction

1) Enter Advanced Set-up mode. Press the ENTER key and scroll to Advanced Set-up

security code “22”. Press the ENTER key again.

2) Press the ▲ or ▼ key to scroll until the upper dis play shows “ConF ”.

SETUP

HOLD

SETUP

HOLD

Ph

Sy

SETUP

HOLD

Ph

Asy ASy

7.6.2 Selecting pH, ORP% or ORP mV measurement

This parameter group lets you select pH, mV, or % readings , and input type symmetrical or

asymmetrical. Symmetrical mode is used in conjunction with a potential matching pin – in an

electrically noisy environment.

Please refer to section 3, page 6 for a graphical representation.

1) Follow directions in 7.6.1 to enter Configuration mode.

2) Press the ENTER key. Scroll with the ▲ or ▼ key until the upper display shows the control

type (pH, ORP mV or ORP %) and the lower display shows symmetrical (SY) or

asymmetrical (ASY) input type. Choose ORP without the mV indicator for ORP% readings.

3) Proceed to 7.6.3, or return to Measurement mode by pressing the ▲ and ▼ keys

simultaneously (escape).

SETUP

HOLD

Sy

SETUP

HOLD

ASy

SETUP

HOLD

SETUP

HOLD

mV

Sy

mV

21

Page 27

7.6.3 Selecting Alarm or Wash function

This function allows you to use the Alarm relay as Wash contact. The Wash contact is used in

combination with automatic cleaning systems. During the wash cycle, the analogue output is set

on hold.

SETUP

HOLD

SETUP

HOLD

7.6.4 Selecting the alarm time lag if relay 3 has been set to Alarm mode

This parameter group lets you select a period of time before the alarm activates when your set

point has been overshot. You can select from 0 to 2000 seconds.

SETUP

HOLD

5) Proceed to 7.6.4 step 3, or return to Measurement mode by pressing the ▲ and ▼ keys

simultaneously (escape).

7.6.5 Selecting steady or pulse contact for the alarm relay

This parameter group lets you select whether the alarm contact wil l operate as a steady contac t

or a fleeting (single pulse) contact. Pulse contact closing time is 1 second.

SETUP

HOLD

30

Al.c

SETUP

HOLD

Al.c

1) Follow direction in 7.6.1 to enter Configuration mode.

2) Press the ENTER key until upper display shows “Alr” or

“CLn”.

3) Press the ▲ or ▼ key to choose the desired function.

4) Press the ENTER key to confirm your selection.

1) Follow directions in 7.6.1 to enter Configuration mode.

2) Press the ENTER key. Scroll with the ▲ or ▼ key until the

upper display shows a numerical value (in seconds) and the

lower display shows “AL.d”.

3) Press the ▲ or ▼ key to select how long of an alarm delay

(0 to 2000 seconds) you want.

4) Press the ENTER key to confirm your selection.

1) Follow directions in 7.6.1 to enter Configuration mode.

2) Press the ENTER key. Scroll with the ▲ and ▼ keys until the

upper display shows “Stdy” or “FLEt” and lower display shows

“AL.C.”.

- AL.C = alarm contact

- StdY = steady contact

- FLEt = fleeting (single pulse) contact

3) Press

4) Press the ENTER key to confirm your selection.

5) Proceed to 7.6.5 step 3, or return to Measurement mode by

pressing the ▲ and ▼ keys simultaneously (escape).

the ▲ or ▼ key to select steady or pulse contact.

22

Page 28

7.6.6 Configuring the Wash contact if re lay 3 has been set to the Wash mode

SETUP

HOLD

SETUP

HOLD

SETUP

HOLD

7.6.7 Selecting pH sensor type

Note: This parameter is blocked out in ORP mode. Proceed to 7.6.6.

Note: After each changeover, the factory calibration data for zero point and slope are

overwritten. Be sure to re cali brate (see section 6).

This parameter group lets you configure the controller for glass or antimony electrodes. Use an

antimony electrode for systems with hydrofluoric acid content.

SETUP

HOLD

10.0

10

Glas

El

SETUP

HOLD

El

1) Follow direction in 7.6.1 to enter Configuration mode.

2) Press the ENTER key until upper display shows “Alr” or

“CLn”.

3) Press the ▲ or ▼ key to select the “CLn” function. Press the

ENTER key.

4) Press the ▲ or ▼ key to select the wash cycle (int. 0.1 to

199.9 hours) and press ENTER.

5) Press the ▲ or ▼ key to select the wash duration (1 to 1999

seconds) and press ENTER.

Note: During wash cycle, the controller is set to HOLD. For safety

reasons, the HOLD function starts 5 seconds before the start of

wash cycle and will continue for 10 seconds after the wash cycle is

completed.

1) Follow directions in 7.6.1 to enter Configuration mode.

2) Press the ENTER key. Scroll with the ▲ or ▼ key until the

upper display shows “GLAS” or “AnTY” and lower display

shows “EL”.

- EL = electrode

- GLAS = glass

- AnTY = antimony

3) Press the ▲ or ▼ key to select glass or antimony.

4) Press the ENTER key to confirm your selection.

5)

Proceed to 7.6.6 step 3, or ret

pressing the ▲ and ▼ keys simultaneously (escape).

urn to Measurement mode by

23

Page 29

7.6.8 Reverting to factory default settings

Use this parameter to reset all settings to factory default.

1) Follow directions in 7.6.1 to enter Configuration mode.

2) Press the ENTER key until the upper display shows “no”,

“FCt” or “CAL”, and the lower display shows “deF” (default).

3) Press the ▲ or ▼ key to select “no” for using the old values,

“FCt” to reset all settings to factory defaults or “CAL” to reset

calibration values only to the factory default values.

WARNING: Changing from “no” to “FCt” or “CAL” and pressing the

ENTER key resets all settings or the calibration values

respectively to factory defaults .

4) Press the ENTER key to confirm your selection and to return

to Advanced Set-up mode, or return to Measurement mode by

pressing the ▲ and ▼ keys simultaneously (escape).

SETUP

HOLD

SETUP

HOLD

SETUP

HOLD

Cal

7.7 Calibration (CAL) sub-function

The calibration procedure in Advanced Set-up mode is identical to the procedure in the

Calibration mode. The only di fference is that the controller will revert back to Set-up mode

(instead of Measurement mode) after calibrat ion is completed.

7.7.1 Entering the Calibration mode from Advanced Set-up mode

1) Enter Advanced Set-up mode. Press the ENTER key and scroll to Advanced Set-up

security code “22”. Press the ENTER key again.

2) Press the ▲ or ▼ key to scroll until the upper dis play shows “CAL”.

3) See Sect i on 6 for complete calibratio n procedures.

24

Page 30

8 AUTO/MANUAL MODE

Regardless of the mode, you can control devices connected to Relay A or Relay B from the front

panel of this controller. In Automatic mode, the controller’s set point values act ivate the relays. In

Manual mode, you have manual control of the relays so you can prime the pump or check pump

status without operating the entire system.

8.1 Auto mode (mode after switch-on)

In this mode, the controller set-point values activate the relays. To view the set-point values:

1) Press the RELAY SELECTION (Rel A/Rel B) key. The upper display shows your set-point

value for Relay A; the lower display show s “SP1”.

2) After two seconds the upper display shows your set-point value for Relay B; the lower

display shows “SP2”.

3) After an additional two seconds the controller will return to Measurement mode.

8.2 Manual mode

In this mode, you can manually turn on and off the control devices connected to Relay A or

Relay B or both.

1) Press the RELAY CON T ROL (auto/manu) key. The upper display shows “000”; the lower

display shows “S.Cd” to prompt you to enter the Advanced Set-up code.

2) Press the ▲ or ▼ key to scroll the upper display until it reads “22”.

3) Press the ENTER key. The manual ind ica tor by the RELAY CONTROL key lights up.

Note: Pressing ENTER key at a value other than “22” will ca use the controller to revert to

Measurement mode, and the relays will remain in automatic mode.

4) Press the RELAY SELECTIO N key to select either Relay A or Relay B. The LED next to the

currently selected relay (A or B) will light.

The manual control options now available will depend on the control type (limit, pulse frequency,

or pulse length) you selected set in section 7.4.2.

- If you selected Limit control: Upper display reads the current measured value. Lower

display shows “oFF” or “on” depending on the relay status of the currently selected relay.

- If you selected Pulse length control: Upper display reads the current measured value.

Lower display shows the current pulse duration.

- If you selected Pulse frequency control: Upper display reads the current measured value.

Lower display shows the current pulse frequency.

5) Press the ▲ or ▼ key to change the Relay on/off status, pulse length, or pulse frequency.

LED indicators at the right of controller will change between Red and Green to indicate Relay

status.

Note: If you wish to manually chang e the sta tus of both relays, press t he RELAY SELECTION

key at this point and repeat step 5 for the second relay. This first rela y will remai n under manual

control while you set the second relay.

6) Press the RELAY CONTROL key to return to Measurement mode. Relays are now back

under automatic control.

25

Page 31

9 TECHNICAL SPECIFICATIONS

pH Range 0.00 to 14.00 pH

Resolution

Relative Accuracy

mV Range 0 to 100.0% / -1000 to +1000 mV

Resolution

Relative Accuracy

Temperature - 9.9 to + 125.0 oC

Resolution

Relative Accuracy

Sensor Pt 100 /Pt 1000 (jumper selectable)

Temperature Compensation Auto / manual (reference at 25.0 oC)

Set-point and Controller Functions

Controller characteristics proporational controller

Adjustabl e period with pulse length controller 0.5 t o 20 sec.

Adjustable period with pulse frequency controller 60 to 120 pulses/min

Pickup / Dropout delay 0 to 2000 sec.

Switching pH hysteresis 0.1 to 1 pH

Switching ORP hysteresis 1 to 10.0% / 10 to 100 mV

Contact outputs, controller 2 potential-free change-over contacts

Switching voltage / current / power max. 250 VAC / max. 3A / max. 600 VA

Alarm Functions

Function (switchable) Latching / pulse

Wash cycle 0.1 to 199.9 hrs

Wash duration 1 to 1999 s

Pickup delay 0 to 2000 s

Switching voltage / current / power max. 250 VAC / max. 3A / max. 600 VA

Electrical Data and Connections

Power Requirements 110 / 220 VAC (jumper selectable)

Frequency 48 to 62 Hz

Power Consumption max. 7 VA

Signal Output / Load 4 to 20 mA, galvanically isolated

Load Max. 600 Ω

pH / ORP input BNC, screw terminals

Connection terminal Terminal blocks 5-pole / 17-pole, removable

Mains fuse / fine wire fuse slow-blow 250 V / 100 mA

EMC Specifications

Emissions According to EN 50081-1

Susceptibility According to EN 50082-1

Environmental Conditions (For Indoor Use)

Altitude Up to 2000 m

Maximum Relative Humidity

Power Supply

Transient Overvoltages Category II

Pollution Degree Category II

Ambient temp. operating range -10 to +50 oC

0.01 pH

± 0.01 pH

0.1% / 1mV

± 1 mV

0.1

± 0.5

limit controller Function (switchable)

pulse length/ frequency controller

80% up to 31

at 40

Mains suppl y voltage fl uctuations not

exceeding +10% of the nominal voltage

o

C

o

C

o

o

C

C decreasing linearly to 50%

26

Page 32

Mechanical Specifications

Dimensions (control panel housing - L x H x W) 175 x 96 x 96 mm

Weights (control panel housing) max. 0.7 kg

Material ABS with polycarbonate (front housing)

Insulation (Front / Housing) IP 54 / IP 40

27

Page 33

10 ACCESSORIES

Replacement Unit

Product Description Thermo Scientific

Code no.

Alpha-pH1000 pH/ORP Controller/Transmitter with 0/4-20

mA output and 110VAC Setting

Alpha-pH1000 pH/ORP Controller/Transmitter with 0/4-20

mA output and 220VAC Setting

TSPHCTP1001 ECPHCTP1001

TSPHCTP1002 ECPHCTP1002

Assembly Accessories

Product Description Code no.

pH Combination Electrode with Pt 100 RTD and PMP EC100GTSO05B

pH Combination Electrode with HF resistant glass (w/o ATC & PMP) ECARTSOHF05B

pH Combination Electrode with PMP (w/o ATC) ECARGTSO05B

Eutech

Code no.

pH Combination Electrode with high temperature resistance (110 oC) and

high pressure resistance (9 bar) (w/o ATC & PMP)

pH Combination Electrode (w/o ATC & PMP) ECARTSO05B

ORP Gold Electrode with PMP but w/o ATC ECHTAUTSO05B

ORP Platinum Electrode with PMP but w/o ATC ECHTPTTSO05B

ECARHTTSO05B

Note: Above pH/ORP electrodes withstand up to 6 bar pressure except ECARHTTSO05B.

These electrodes have integral 5m measuring cable terminating with a BNC connector.

Please contact your authorised distributor or dealer for the prices of extension

measuring cables and other accessories like tee joints, electrode assembly, and

calibration solutions.

28

Page 34

11 GENERAL INFORMATION

11.1 Warranty

Thermo Scientific warrants this product to be free fr om sig nificant deviations in material and

workmanship for a period of one year from the date of purchase. If repair is necessary and has

not been the result of abuse or misuse within the warranty period, please return by freight prepaid and amendment will be made without any charge. Our Customer Service Dept. will

determine if product problem is due to devia tions or customer abuse. Out of warranty products

will be repaired on a charge basis.

11.2 Packaging

The instrument is packaged in a corrugated box with a warranty card, instruction manual and the

following accessories:

- 17-way and 5-way (right-angled) terminal block [1 unit each]

- side threaded rod with catch [2 units]

- receptacle cable lug [1 unit]

- rubber gasket [1 unit]

11.3 Return of Goods

Authorisation must be obtained from our Customer Service Dept. to issue a RMA ( Return of

Material Authorisation) number before returning items for any reason. When applying for

authorisation, please include data requir ing the reason of return. Items must be carefully packed

to prevent damage in shipment and insured against possible damage or loss. Thermo Scientific

will not be responsible for any damage resulting from careless or insufficient packing.

Warning: Shipping damage as a result of inadequate packaging is the user/distributor’s

responsibility, whoever applicable. Please follow the guidelines below before

shipment.

11.4 Guidelines for Returning Unit for Repair

Use the original packaging material, if possible when shipping the unit for repair. Otherwise wrap

it with bubble pack and use a corrugated box for better protection. Include a brief description of

any faults suspected for the convenience of Customer Service Dept., if possible.

29

Page 35

12 APPENDICES

12.1 Appendix 1

Before opening the unit, ENSURE that the power c able is physically separated from the

power supply.

Jumper Positions - Internal to the cont r oller

JP 1 Selects the input voltage 220 VAC.

JP 2 Selects the input voltage 110 VAC.

JP 3 Solder bridge selects between Pt100 and Pt1000.

Fuse Note that there is a fuse (slow-blow 100mA) internal to the

controller. Replace fuse with the recommended type only.

30

Page 36

12.2 Appendix 2

The following table shows the various pH values at different temperature of the solution during

calibration.

Temperature (oC) pH 1.00 pH 4.01 pH 6.86 pH 7.00 pH 9.00 pH 9.18 pH 10.01

0 0.96 4.01 6.98 7.12 9.33 9.47 10.32

5 0.99 4.01 6.95 7.09 9.24 9.38 10.25

10 0.99 4.00 6.92 7.06 9.16 9.32 10.18

15 0.99 4.00 6.90 7.04 9.11 9.27 10.12

20 1.00 4.00 6.88 7.02 9.05 9.22 10.06

25 1.01 4.01 6.86 7.00 9.00 9.18 10.01

30 1.01 4.01 6.85 6.99 8.95 9.14 9.97

35 1.01 4.02 6.84 6.98 8.91 9.10 9.93

40 1.01 4.03 6.84 6.97 8.88 9.07 9.89

45 1.01 4.04 6.83 6.97 8.85 9.04 9.86

50 1.01 4.06 6.83 6.97 8.82 9.01 9.83

55 1.01 4.08 6.83 6.97 8.79 8.99 9.81

60 1.02 4.10 6.84 6.98 8.76 8.96 9.79

70 1.02 4.12 6.85 6.99 8.72 8.92 9.76

80 1.02 4.16 6.86 7.00 8.68 8.89 9.74

90 1.02 4.20 6.88 7.02 8.65 8.85 9.73

31

Page 37

12.3 Appendix 3

Simple Explanation on the Function of Hysteresis

S P 1 S e t t o L O

S P 2 S e t t o H I

4 . 0 4 . 5 9 . 5 1 0 . 0

S P 1

F O R W A R D D I R E C T I O N

R E V E R S E D I R E C T I O N

R E L A Y O N

R E L A Y O F F

7.0

S P 2

H Y S T E R E S I S B A N D

( D E F A U L T = 0 . 5 p H )

The controller relay activates when the set-point is reached. In the reverse direction, it does not

de-activate when the value reaches the set-point. In stead, it continues to be active till the value

reaches the amount set by the Hysteres is band.

32

Page 38

12.4 Appendix 4

General Instructions Concerning C ontroller Setting

MIN function MAX function

-Xw

Xp

Prop. band Prop. band

SP 1

100% Yh

50%

0%

SP 2

Xp

+Xw

Control characteristic of P-Controller as proportional controller

MIN function MAX function

100% Yh

50%

-Xw

Xp = 0

0%

SP 2SP 1

Xp = 0

Control characteristic of P-Controllers as limit value switch

Characteristics of Pulse Length and Pulse Frequency

Relay

Pulse Le ngth T

tON

ON

OFF

tOFF

Controller signal of Pulse len gth controller

Time [s]

+Xw

33

Page 39

The output relay of the pulse length controller is clock-timed. The switching period T re mains

constant. Depending on the divergence from the limit value, the switch-on time t

is increased

ON

or decreased in accordance with the proportional range Xp.

The following applies:

t

+ t

ON

greater div e rgence → greater t

Xp exceeded → t

= T (Const.)

OFF

ON

= T (relay remains picked up)

ON

Relay

Pulse Length T

tON

ON

tOFF

OFF

Tim e [s]

Controller signal of Pulse Frequency Controllers

The output relay of the pulse frequency controller is clock-timed. The pulse duration t

constant at 250mS.

Depending on the divergence from the limit value, the frequency (

1

/T) is increased or decreased

in accordance with the proportional range Xp.

The following applies:

t

= Const. (250 msec.)

ON

greater div e rgence → greater f (greater frequency)

Xp exceeded → max. frequency

remains

ON

34

Page 40

Page 41

Page 42

Water Analysis Instruments

North America

166 Cummings Center

Beverly, MA 01915 USA

Toll Free: 1-800-225-1480

Tel: 1-978-232-6000

Dom. Fax: 1-978-232-6015

Int’l Fax: 978-232-6031

Europe

P.O. Box 254, 3860 AG Nijkerk

Wallerstraat 125K, 3862 CN Nijkerk,

Netherlands

Tel: (31) 033-2463887

Fax: (31) 033-2460832

Asia Pacific

Blk 55, Ayer Rajah Crescent

#04-16/24, Singapore 139949

Tel: 65-6778-6876

Fax: 65-6773-0836

www.thermo.com/process

© 2009 Thermo Fisher Scientific Inc.

All rights reserved. Thermo Fisher Scientific Inc.

68X216801 Rev 3

Loading...

Loading...