Page 1

INSTRUCTIONS FOR USE

MagMAX™ Viral/Pathogen II Nucleic Acid Isolation Kit,

High‑Throughput

Magnetic bead technology‑based nucleic acid purif ication for high‑throughput workf lows

REF.

A50884

Pub. No. MAN0019941 Rev. A.0

WARNING! Read the Safety Data Sheets (SDSs) and follow the handling instructions. W

clothing, and gloves. Safety Data Sheets (SDSs) are available from thermofisher.com/support.

ear appropriate protective eyewear,

Intended use

Applied Biosyst

of viral nucleic acid from human respiratory specimens. The magnetic bead technology‑based nucleic acid purification reagents have

been validated for the following workflows:

• Automated, high‑throughput workflows—for isolation and purification of RNA from nasal and nasopharyngeal specimens

• Manual and semi‑automated workflows—for isolation and purification of RNA and DNA from nasopharyngeal specimens

The MagMAX™ Viral/Pathogen II Nucleic Acid Isolation Kit, High‑Throughput is intended for use by qualified and trained clinical laboratory

personnel specifically instructed and trained in the techniques of magnetic bead purification, either manual or automated, and in vitro

diagnostic procedures. The MagMAX™ Viral/Pathogen II Nucleic Acid Isolation Kit, High‑Throughput is intended for use in a qualified

laboratory environment according to the sample type.

ems™ MagMAX™ Viral/Pathogen II Nucleic Acid Isolation Kit, High‑Throughput is intended for the isolation and purification

Product information

MagMAX™ Viral/Pathogen II Nucleic Acid Isolation Kit, High‑Throughput (REF. A50884) is specifically designed to recover nucleic acid

from viral particles contained in viral transport media (VTM). The kit utilizes MagMAX™ magnetic-bead technology, ensuring reproducible

recovery of high-quality RNA.

MagMAX™ Viral/Pathogen II Nucleic Acid Isolation Kit, High‑Throughput is intended for in vitro diagnostic use and includes the following

features:

• Automated, high‑throughput workflow using the Amplitude™ Platform to allow for up to 8,000 samples to be processed in a 24‑hour

period

• No requirement for carrier RNA

• Elution volume of 50 µL

Note: Protocol options also support a manual workflow or a semi‑automated workflow, accommodating sample volume inputs from

200 to 400 μL of VTM. Semi‑automated workflows using the KingFisher™ Flex Magnetic Particle Processor with 96 Deep-Well Head allow

for 96 nasopharyngeal swab specimens to be processed in <30 minutes.

For product information on manual or semi‑automated protocols, see the MagMAX™ Viral/Pathogen II Nucleic Acid Isolation Kit

Instructions For Use (Pub. No. MAN0019746).

Contents and storage

MagMAX™ Viral/Pathogen II Nucleic Acid Isolation Kit, High‑Throughput (REF. A50884) is compatible with the Amplitude™ Platform. The

reagents are supplied in 2 distinct modules that are designed to align with Amplitude™ Platform Module 1 and Module 2:

• MagMAX™ MVPII HT Module 1 Sample Prep (Cat. No. A50770)

• MagMAX™ MVPII HT Module 2 Sample Prep (Cat. No. A50771)

The MagMAX™ Viral/Pathogen II Nucleic Acid Isolation Kit, High‑Throughput contains sucient reagents for 20,000 reactions.

For In Vitro Diagnostic Use.

Page 2

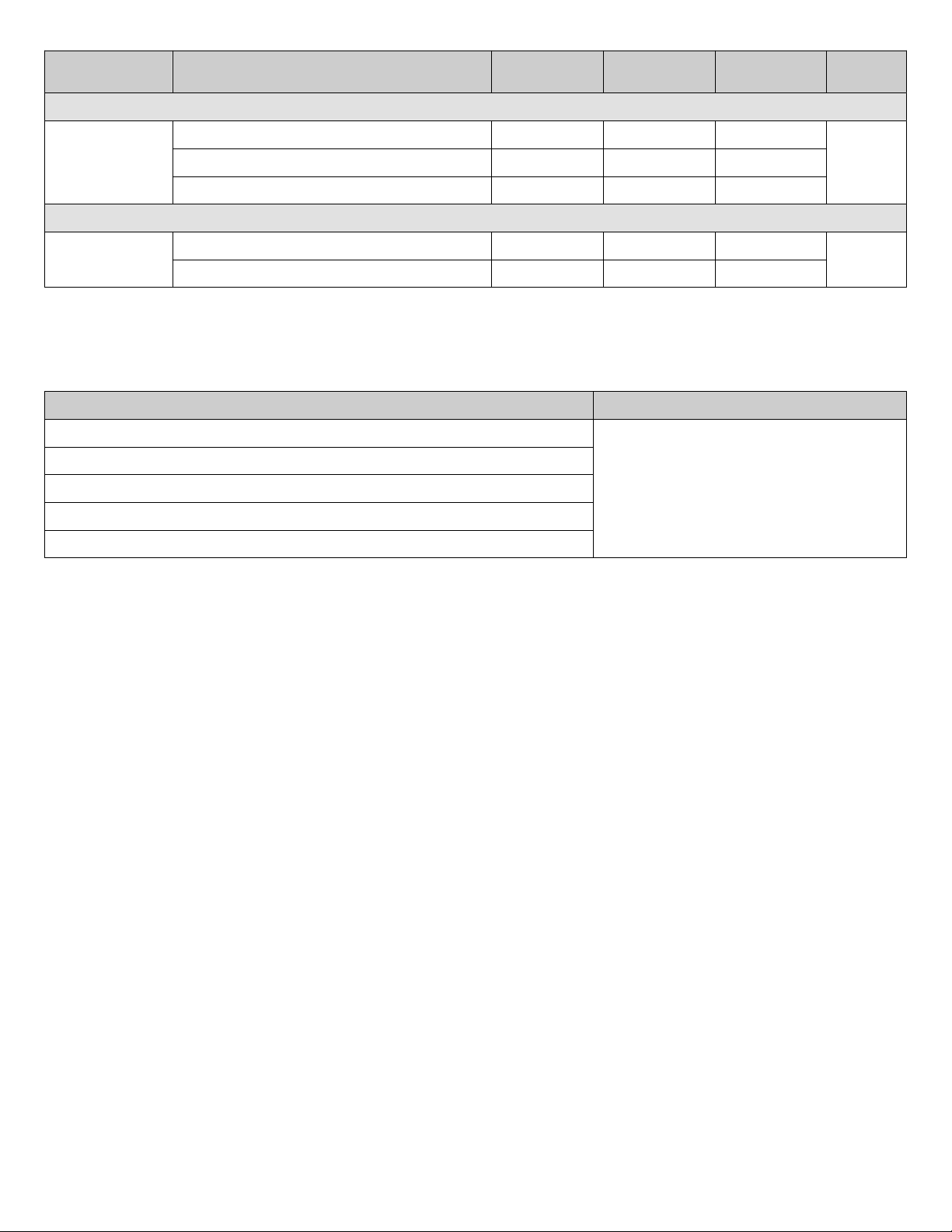

Table 1 MagMAX™ Viral/Pathogen II Nucleic Acid Isolation Kit, High‑Throughput (REF. A50884)

Amplitude

Platform Module

MagMAX™ MVPII HT Module 1 Sample Prep (Cat. No. A50770)

Module 1

MagMAX™ MVPII HT Module 2 Sample Prep (Cat. No. A50771)

™

MagMAX™ MVPII HT Binding Solution B32430F4 3 800 mL

MagMAX™ MVPII HT Binding Beads 109‑00‑502F4 3 30 mL

MagMAX™ MVPII HT Proteinase K EO2180F4 3 20 mL

Component REF. Quantity Amount Storage

15°C to

25°C

Module 2

MagMAX™ MVPII HT Wash Solution B32440F4 3 1,500 mL

MagMAX™ MVPII HT Elution Solution B29880F9 1 700 mL

15°C to

25°C

Required materials not supplied

Unless otherwise indicated, all materials are available through thermofisher.com. "MLS" indicates that the material is available from

fisherscientific.com or another major laboratory supplier.

Item

Amplitude™ Platform Module 1 and Module 2 equipment

80% Ethanol

Silicone oil

Amplitude™ High‑Throughput Consumable Package 3 Plastics

(Optional) Extraction control, if required for your assay

[1]

See also “Module 1 Required samples, reagents, and consumables” on page 4 and “Module 2 Required sample input, reagents, and consumables” on page 8.

See the user guide for the Amplitude™ Platform

(Pub. No. MAN0019842)

Source

[1]

Product limitations

• The system performance was established using nasal and nasopharyngeal swab samples only. Specimen types other than nasal and

nasopharyngeal swab should not be tested with this kit.

• Samples must be collected, transported, and stored using appropriate procedures and conditions. Improper collection, transport, or

storage of specimens may hinder the ability of the assay to detect the target sequences.

• Chemical inactivation and other known clinically relevant interfering substances and techniques can lead to inappropriate primary

samples and interfere with test results.

• The Amplitude™ Platform workflow must be performed according to the specified methods described in the user guide for the

system.

• The quality of the biological samples is essential for the quality of the results generated with this kit.

• False-negative results may arise from:

– Improper sample collection

– Degradation of the SARS-CoV-2 RNA during shipping/storage

– Specimen collection after SARS-CoV-2 RNA can no longer be found in the specimen matrix

– Using unauthorized extraction or assay reagents

– Failure to follow instructions for use

• False-positive results may arise from:

– Cross contamination during specimen handling or preparation

– Cross contamination between patient samples

– Specimen mix-up

– RNA contamination during product handling

2 MagMAX

™

Viral/Pathogen II Nucleic Acid Isolation Kit, High‑Throughput Instructions for Use

Page 3

Warnings and precautions

The reagents should only be used in a qualified laboratory environment according to the sample type by qualified and trained sta to

avoid cross-contamination and the risk of erroneous results. For information about operator roles and requirements, see the user guide for

your system.

• Before using this product, read and understand the information provided in this guide and the user guide for your system.

• Read and understand the Safety Data Sheets (SDSs) provided by the chemical manufacturer before you store, handle, or work with

any chemicals or hazardous materials. To obtain SDSs, see the "Documentation and Support" section in this document.

• Samples and controls should always be treated as if infectious and/or biohazardous in accordance with safe laboratory procedures.

• Follow necessary precautions when handling specimens. Use personal protective equipment (PPE) consistent with current guidelines

for the handling of potentially infectious samples.

• Always use pipette tips with aerosol barriers. Tips that are used must be sterile and free from DNases and RNases.

• Do not eat, drink, smoke, or apply cosmetic products in the work areas.

• Modifications to assay reagents, assay protocol, or instrumentation are not permitted.

• Reagents must be stored and handled as specified in “Contents and storage” on page 1.

• Do not use system consumables or reagents after the indicated expiry date.

• Dispose of waste in compliance with local, state, and federal regulations.

Sample collection, transport, and storage

CAUTION! Handle all samples and controls as if they are capable of transmitting infectious agents.

• Patient samples must be collected according to appropriate laboratory guidelines. The Amplitude™ Platform can be used with patient

samples collected via nasopharyngeal or nasal swab.

• Store samples at 2–8°C for up to 72 hours after collection. If a delay in testing is expected, store samples at ≤-70°C.

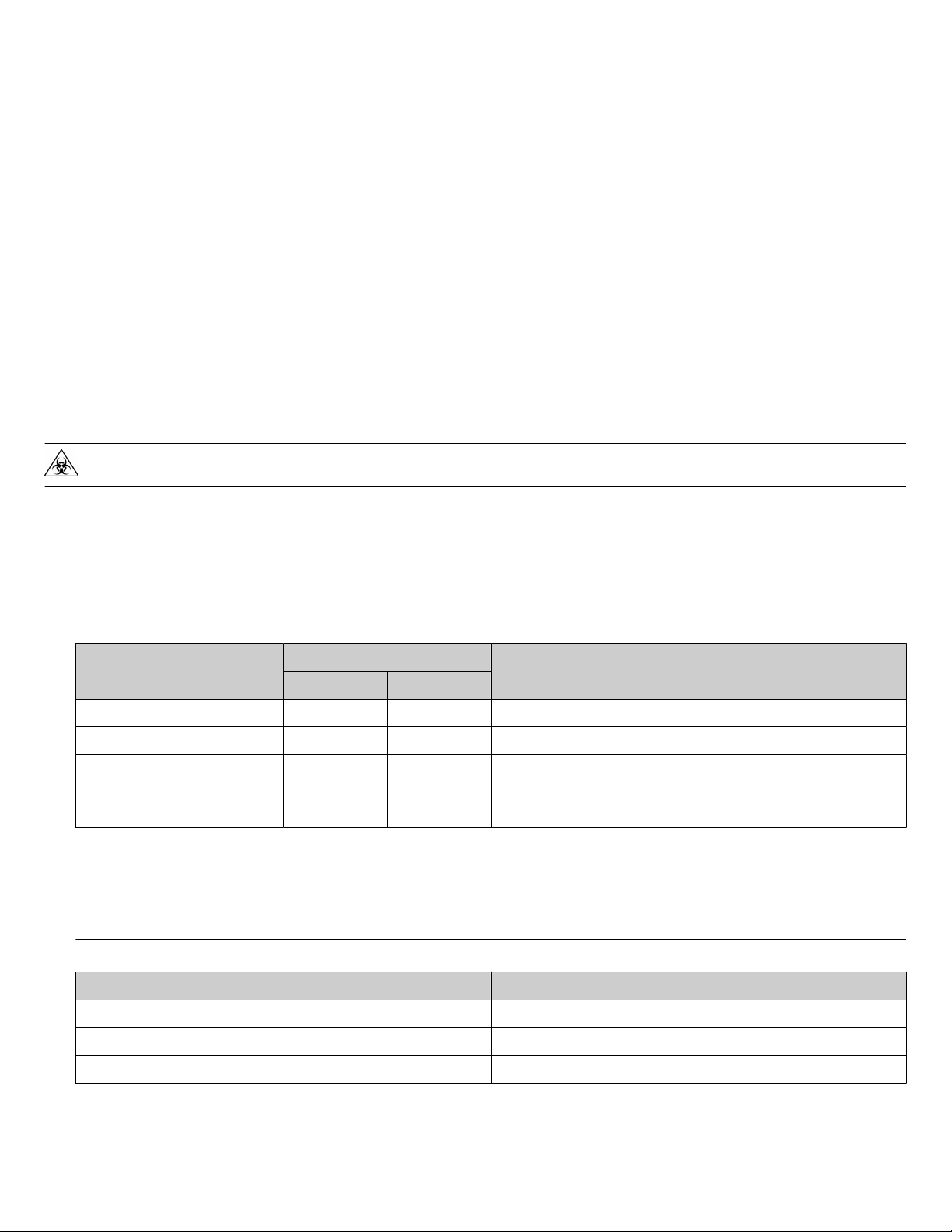

Guidelines for sample tubes

• Only use sample tubes meeting the specifications listed in the table below:

Tube runner type

13 mm, 32‑position 12 mm 14 mm 140 mm Skirted, internal conical only

16 mm, 26‑position 15 mm 17 mm 140 mm Skirted, internal conical only

17 mm, 24‑position 16 mm 18 mm 140 mm

Tube diameter range

Minimum Maximum

IMPORTANT!

For each Module 1 run, all 376 sample tubes must be within the same diameter range. Individual tube heights can vary, but should

·

not exceed 140 mm.

For each Module 1 run, all 376 sample tubes must be loaded in the same type of tube runner. Tube runner types cannot be mixed

·

within a run.

• Ensure that you have the minimum volume of sample required for the sample tube size.

Maximum tube

height

Tube bottom type

Non‑skirted, external conical

or

Skirted, internal conical

Sample tube size

12–14 mm 0.5 mL

15–17 mm 1 mL

16–18 mm 1 mL

• All sample tubes must be barcoded with a unique ID. For sample tube barcode requirements, see the user guide for your system.

Note: The Amplitude™ Platform does not perform sample accessioning. If required, perform sample accessioning according to

guidelines established by your laboratory prior to processing the samples on Module 1. After testing, the results can be ported into

your laboratory system.

MagMAX™ Viral/Pathogen II Nucleic Acid Isolation Kit, High‑Throughput Instructions for Use 3

Minimum volume required

Page 4

• For sample collection devices containing swabs, the swabs must be removed from sample tube before loading into the tube runners.

Alternatively, the sample can be transferred to a fresh, barcoded sample tube that is then loaded into an appropriate runner type.

• The Amplitude™ Platform cannot run fewer than 376 samples at a time. If you have fewer than 376 sample tubes, you must include

additional empty, barcoded tubes to fill any empty positions in the tube runners.

Guidelines for sample inactivation

Follow the sample inactivation guidelines and requirements established by your laboratory and local regulatory bodies. If your laboratory

inactivates samples, do so before you begin the Module 1 workflow.

Chemical inactivation is not recommended and may interfere with test results.

In‑use reagent stability

Table 2 In-use reagent stability

Reagent

MagMAX™ MVPII HT Binding Solution Store capped at 15°C to 25°C long‑term.

MagMAX™ MVPII HT Binding Beads Store capped at 15°C to 25°C long‑term.

Binding Bead Mix (prepared by customer)

MagMAX™ MVPII HT Proteinase K

Purified sample nucleic acid

Once the MagMAX™ MVPII HT Binding Solution and MagMAX™ MVPII HT Binding Beads

are combined, the mix is stable for 24 hours after preparation. Store capped at 15°C to

25°C.

Once placed in the Tecan™ Fluent™ 1080 Automation Workstation reagent carrier (15°C to

25°C), the reagent has long‑term stability.

Once extracted, purified sample nucleic acid is stable at 4°C for 48 hours.

For long term storage, store according to the guidelines established by your laboratory.

Stability information

Perform a Module 1 run

Module 1 overview

Module 1 operation is controlled by the Tecan™ FluentControl™ Software, via the Tecan™ Fluent™ 1080 Automation Workstation

touchscreen. For more information, see the user guide for the Amplitude™ Platform (Pub. No. MAN0019842).

During Module 1 operation:

• Technicians load prepared sample tube runners, reagents, and consumables on the Tecan™ Fluent™ 1080 Automation Workstation

deck and start runs.

• The instrument prepares 4 sample extraction plates containing the following components:

– 200 µL of sample from the sample tubes

– MagMAX™ MVPII HT Proteinase K

– Extraction control and assay control as required by the assay that is used in combination with MagMAX™ Viral/Pathogen II

Nucleic Acid Isolation Kit, High‑Throughput

– Binding Bead Mix

– Silicone oil

• The Tecan™ Fluent™ 1080 Automation Workstation scans the barcodes on sample tubes and sample extraction plates, then registers

the information with the SampleManager LIMS™ Software for sample tracking.

Module 1 Required samples, reagents, and consumables

For a complete list of required samples, reagents, and consumables, see the user guide for the Amplitude™ Platform

(Pub. No. MAN0019842).

Required samples, reagents, and consumables

Sample input

Barcoded sample tubes in sample carrier racks 376 samples per run

4 MagMAX

™

Viral/Pathogen II Nucleic Acid Isolation Kit, High‑Throughput Instructions for Use

Usage

(Reload frequency)

Page 5

Required samples, reagents, and consumables

Consumables

KingFisher™ Deep‑Well 96 Plate with Barcode (sample extraction plates) 4 plates per run

1,000 µL Flexible Channel Arm™ (FCA) Disposable Tips Rack 15 racks per 3 runs

200 µL Flexible Channel Arm™ (FCA) Disposable Tips Rack 3 racks per 6 runs

Nunc™ Microplate Lids 12 lids per 3 runs

Axygen™ Multi Well Low Profile Reagent Reservoir

(for MagMAX™ MVPII HT

Proteinase K/extraction control)

Axygen™ Single Well High Profile Reagent Reservoir (for Binding Bead Mix) 1 reservoir per 6 runs

Axygen™ Single Well High Profile Reagent Reservoir (for silicone oil) 1 reservoir per 6 runs

Reagents

MagMAX™ MVPII HT Binding Beads 1 bottle per 6 runs

MagMAX™ MVPII HT Binding Solution 1 bottle per 6 runs

[1]

Usage

(Reload frequency)

1 reservoir per 6 runs

Extraction control

MagMAX™ MVPII HT Proteinase K 1 bottle per 6 runs

HT Water for Dilution 1 bottle per 6 runs

Silicone oil 1 bottle per 6 runs

Samples and controls

Positive control and negative control samples as applicable

[1]

See “In‑use reagent stability” on page 4.

as recommended by the assay

supplier

Before you begin

Follow the procedure as described in the user guide for the Amplitude™ Platform (Pub. No. MAN0019842), starting with powering the

system on through preparing the Tecan™ Fluent™ 1080 Automation Workstation.

Thaw extraction control

Every six runs, thaw the appropriate quantity of control according to the recommendations of the assay supplier.

Prepare the Binding Bead Mix

Every six runs, prepare the Binding Bead Mix.

IMPORTANT! Use the Binding Bead Mix within 24 hours of preparation.

MagMAX™ Viral/Pathogen II Nucleic Acid Isolation Kit, High‑Throughput Instructions for Use 5

Page 6

1. Vortex one bottle of MagMAX™ MVPII HT Binding Beads for a minimum of 15 seconds to ensure that the bead mixture is

homogeneous.

2. Combine the appropriate volumes of MagMAX™ MVPII HT Binding Beads and MagMAX™ MVPII HT Binding Solution for the required

number of runs.

• For fewer than 6 runs, combine the appropriate volumes in a sterile, secondary mixing container that can be closed.

• For 6 runs, pour all of the MagMAX™ MVPII HT Binding Beads directly into the bottle of MagMAX™ MVPII HT Binding Solution.

Number of runs MagMAX™ MVPII HT Binding Beads

[1]

MagMAX™ MVPII HT Binding Solution

1 5.2 mL 133 mL

2 10.3 mL 266 mL

3 15.4 mL 399 mL

4 20.5 mL 532 mL

5 25.6 mL 665 mL

6 30 mL (entire volume) 800 mL (entire volume)

[1]

Fill volume 30 mL.

[2]

Fill volume 800 mL.

IMPORTANT! Keep the bottle of MagMAX

™

MVPII HT Binding Beads and the bottle of MagMAX™ MVPII HT Binding Solution to

scan when prompted by the Tecan™ Fluent™ 1080 Automation Workstation touchscreen.

3. Mix well by inversion, then store the Binding Bead Mix at room temperature until ready to use.

4. Perform the following procedures as described in the user guide for the Amplitude™ Platform (Pub. No. MAN0019842).

a. View the SampleManager Module 1 Load Indicator

b. Start the method on the Tecan™ Fluent™ 1080 Automation Workstation

Load the Tecan™ Fluent™ 1080 Automation Workstation deck

[2]

IMPORTANT! Start the method on the Tecan

™

Fluent™ 1080 Automation Workstation, then load reagents and consumables in the correct

deck positions when prompted by the instrument touchscreen. Failure to do so can result in reduced throughput.

The following procedure describes the process for loading consumables and reagents for the MagMAX™ Viral/Pathogen II Nucleic

Acid Isolation Kit, High‑Throughput only. For a complete list of materials that are loaded in the instrument, see the user guide for the

Amplitude™ Platform (Pub. No. MAN0019842).

6 MagMAX

™

Viral/Pathogen II Nucleic Acid Isolation Kit, High‑Throughput Instructions for Use

Page 7

1. Open the Tecan™ Fluent™ 1080 Automation Workstation access door.

2. Follow the touchscreen prompts to fill the empty deck. The consumables and reagents are refilled every 1, 3, and 6 runs as indicated

in the following table:

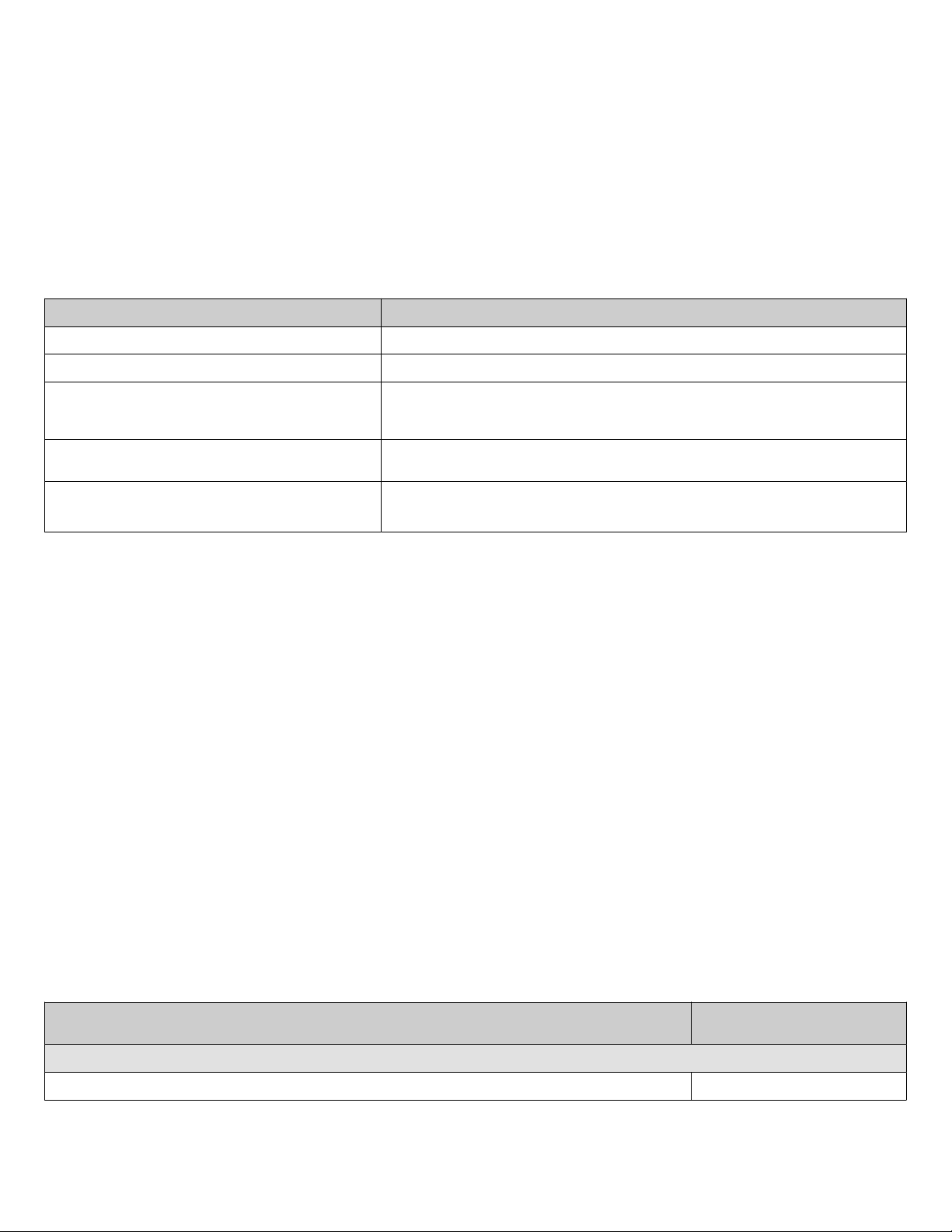

Load the empty deck

Add new Binding Bead Mix trough

Fill Binding Bead Mix trough X X X

Add new silicone oil trough

Fill silicone oil trough X X X

Add new MagMAX™ MVPII HT Proteinase K/extraction control mixing trough

Load MagMAX™ MVPII HT Proteinase K in reagent carrier (see Figure 1)

Load extraction control × 2 in reagent carrier (see Figure 1)

Load KingFisher™ Deep‑Well 96 Plates with Barcodes × 4 X X X

[1]

Axygen™ Single Well High Profile Reagent Reservoir

[2]

Axygen™ Multi Well Low Profile Reagent Reservoir

[1]

[1]

[2]

Every run Every 3 runs Every 6 runs

Reload frequency

a. (Every 6 runs) In the Load reagents and mixing trough screen, follow the prompts to replace both the used Binding Bead Mix

trough and the silicone oil trough with a new Axygen™ Single Well High Profile Reagent Reservoir.

b. (Every 6 runs) In the Load reagents and mixing trough screen, follow the prompts to scan the barcodes on the bottles of

MagMAX™ MVPII HT Binding Beads and MagMAX™ MVPII HT Binding Solution that were used to prepare the Binding Bead

Mix.

c. (Every run) In the Load reagents and mixing trough screen, follow the prompts to gently invert the bottle of Binding Bead

Mix 10 times to ensure that the mixture is homogenous, then pour the Binding Bead Mix to the trough fill line.

X

X

X

X

X

WARNING! Improper or overly vigorous mixing of the Binding Bead Mix can lead to invalid results or failure to

inactivate the SARS‑CoV‑2 virus during the Module 1 process. Minimize foaming during the mixing process.

CAUTION! Ensure that you add the Binding Bead Mix to the correct trough. Adding the reagent to the incorrect

trough can lead to invalid results.

d. (Every run) In the Load reagents and mixing trough screen, follow the prompts to pour the silicone oil to the trough fill line.

CAUTION! Ensure that you add the silicone oil to the correct trough. Adding the reagent to the incorrect trough can

lead to invalid results.

e. (Every 6 runs) Follow the prompts to replace the used MagMAX™ MVPII HT Proteinase K/extraction control mixing trough with

a new Axygen™ Multi Well Low Profile Reagent Reservoir.

f. (Every 6 runs) Follow the prompts to scan the reagents, then load the reagent carrier.

Note: Before removing the reagent bottle cap, gently tap the reagent bottle on the bench to ensure the liquid is collected at the

bottom of the container.

CAUTION!

system then the reagent may run out mid‑run, resulting in lower throughput, inaccurate results, or loss of sample.

MagMAX™ MVPII HT Proteinase K 1 bottle

HT Water for Dilution (for Negative Control) 1 bottle

Only scan, then load new, full bottles of reagents. If a reagent is not at full volume when it is loaded in the

Reagent Amount

Extraction control 2 bottles

MagMAX™ Viral/Pathogen II Nucleic Acid Isolation Kit, High‑Throughput Instructions for Use 7

Page 8

1

2

3

3

Figure 1 Module 1 reagent carrier positions

MagMAX™ MVPII HT Proteinase K

1

HT Water for Dilution

2

Extraction control × 2

3

g. (Every run) In the Load deepwell extraction plates screen, follow the prompts to load 4 × KingFisher™ Deep‑Well 96 Plate

with Barcode.

Perform Module 1 run—After all of the reagents and consumables are reloaded, follow the touchscreen prompts to load the

tube runners, then complete the remaining procedures for Module 1 as described in the user guide for the Amplitude™ Platform

(Pub. No. MAN0019842).

During a Module 1 run, the Tecan™ Fluent™ 1080 Automation Workstation performs the following steps:

1. Picks up equal parts of MagMAX™ MVPII HT Proteinase K and extraction control, then mixes them in the MagMAX™ MVPII HT

Proteinase K/extraction control mixing trough.

2. Transfers 200 µL of each sample to a well in a KingFisher™ Deep‑Well 96 Plate with Barcode.

3. Transfers 275 µL of Binding Bead Mix and 10 µL of MagMAX™ MVPII HT Proteinase K/extraction control mix to every well in four

KingFisher™ Deep‑Well 96 Plates with Barcodes.

4. Adds 200 µL of silicone oil to every well in the four KingFisher™ Deep‑Well 96 Plates with Barcodes.

Perform a Module 2 run

Module 2 overview

Module 2 operation is controlled via the Momentum™ Workflow Scheduler Software on the Module 2 computer station. For more

information, see the user guide for the Amplitude™ Platform (Pub. No. MAN0019842).

During Module 2 operation, the following tasks are performed:

• Technicians transfer extraction plates from Module 1 to Module 2, replenish reagents and consumables, and unload the outgoing

nucleic acid elution plates.

• The 4 sample extraction plates are processed, with an output of 4 nucleic acid elution plates that contain 50 μL of purified sample

nucleic acid per well.

Module 2 Required sample input, reagents, and consumables

The following tables list the required sample input, reagents, and consumables for automated nucleic acid extraction based on the action

being completed in the Momentum™ Software: Check in, Replenish reagents, or Replenish consumables.

Note: The Check in process also requires assay-specific reagents and consumables. For more information, see the user guide for the

Amplitude™ Platform (Pub. No. MAN0019842)

For a complete list of required samples, reagents, and consumables, see the user guide for the Amplitude™ Platform

(Pub. No. MAN0019842).

8 MagMAX

™

Viral/Pathogen II Nucleic Acid Isolation Kit, High‑Throughput Instructions for Use

Page 9

Table 3 Check in—Required sample input

Required sample input

Hotel Input (Position 1)

Sample extraction plates from Module 1 4 plates per run

Usage

(Reload frequency)

Table 4 Replenish reagents—Required reagents

Required reagents

Multidrop™ Combi Reagent Dispenser × 3 (Positions 6-8)

MagMAX™ MVPII HT Elution Solution (used with Combi 1) 1 bottle per 18 runs

MagMAX™ MVPII HT Wash Solution (Wash 1, used with Combi 2) 3 bottles per 18 runs

80% Ethanol (Wash 2, used with Combi 3) 2 bottles per 18 runs

Usage

(Reload frequency)

Table 5 Replenish consumables—Required consumables

Required consumables

Tecan™ Fluent™ 780 Automation Workstation (Position 2)

MicroAmp™ EnduraPlate™ Optical 384-Well Clear Reaction Plate with Barcode 6 plates per 6 runs

RNA Elution Plate Stackers (Position 3)

Usage

(Reload frequency)

KingFisher™ Deep‑Well 96 Plate with Barcode (nucleic acid elution plates) 40 plates per 10 runs

KingFisher™ 96 tip comb for DW magnets (for nucleic acid elution plates) 40 tip combs per 10 runs

Wash Plate Stacker Carousel (Position 5)

KingFisher™ Deep‑Well 96 Plates with Barcodes

(wash plates)

80 plates per 10 runs

Before you begin

Follow the procedure as described in the user guide for the Amplitude™ Platform (Pub. No. MAN0019842).

Refill the Multidrop™ Combi Reagent Dispenser reagents

1. Follow the procedure to replenish the Multidrop™ Combi Reagent Dispenser reagents in the Momentum™ Software as described in

the user guide for the Amplitude™ Platform (Pub. No. MAN0019842).

2. Refill the reagents.

CAUTION! Ensure that you pour the MagMAX

carboy.

Reagent Description

MagMAX™ MVPII HT Elution Solution

Remove the tubing bundle weight from the used MagMAX™ MVPII HT Elution Solution bottle,

then place in the new MagMAX™ MVPII HT Elution Solution bottle. Wrap the bottle top with

Parafilm™ film to prevent evaporation.

™

MVPII HT Wash Solution (Wash 1) and 80% Ethanol (Wash 2) in the correct

MagMAX™ MVPII HT Wash Solution (Wash 1)

80% Ethanol (Wash 2)

MagMAX™ Viral/Pathogen II Nucleic Acid Isolation Kit, High‑Throughput Instructions for Use 9

Remove the Wash 1 carboy lid, then pour 3 bottles of MagMAX™ MVPII HT Wash Solution into

the Wash 1 carboy. Tightly close the carboy lid.

Remove the Wash 2 carboy lid, then pour 2 bottles of 80% Ethanol into the Wash 2 carboy.

Tightly close the carboy lid.

Page 10

3. On each Multidrop™ Combi Reagent Dispenser keypad, press and hold PRIME for the duration listed in the following table.

IMPORTANT! Ensure that you prime each Multidrop

™

Combi Reagent Dispenser for the duration listed. Failure to adequately prime

the instruments can aect performance.

Multidrop™ Combi Reagent Dispenser

Combi 1 (dispenses MagMAX™ MVPII HT Elution Solution) 5 seconds

Combi 2 (dispenses Wash 1)

Combi 3 (dispenses Wash 2)

Prime duration

20 seconds

WARNING! Ensure that the liquid runs steadily from all of the cassette dispensing tips by the end of the recommended

prime duration. Failure to do so can aect performance.

™

Perform Module 2 run—Follow the remaining procedures for Module 2 as described in the user guide for the Amplitude

(Pub. No. MAN0019842). The workflow processes 200‑μL sample input volumes.

During a Module 2 run, instruments perform the following steps:

1. Multidrop™ Combi Reagent Dispenser dispenses Wash 1, Wash 2, and Elution solutions into wash and elution plates.

2. Four KingFisher™ Presto Purification Systems extract RNA from extraction plates, then wash the sample using the Wash 1 and

Wash 2 solutions.

3. The sample RNA is eluted in 50 μL of MagMAX™ MVPII HT Elution Solution.

4. The Spinnaker™ Microplate Robot wastes the used wash and extraction plates and conveys the elution plates to instrument systems

that carry out the assay. For more information, see the user guide for the Amplitude™ Platform (Pub. No. MAN0019842).

Platform

Appendix A Amplitude™ Platform system components

Component

Instruments

Tecan™ Fluent™ 1080 Automation Workstation (base unit) Tecan Switzerland | Seestrasse 103 | 8708 Maennedorf | Switzerland

Tecan™ Fluent™ 780 Automation Workstation (base unit) Tecan Switzerland | Seestrasse 103 | 8708 Maennedorf | Switzerland

Thermo Fisher Scientific Spinnaker™ Microplate Robot with

BenchTrak

Spinnaker™ Microplate Robot Mini‑Hub Control Puck Thermo CRS Ltd. | 5250 Mainway | Burlington, Ontario L7L 5Z1 | Canada

Applied Biosystems™ QuantStudio™ 7 Flex Real-Time PCR

System (× 2)

Thermo Scientific™ Multidrop™ Combi Reagent Dispenser (× 3)

ALPS 3000 Automated Microplate Heat Sealer

Thermo Scientific™ KingFisher™ Presto Purification System (× 4)

Agilent™ Microplate Centrifuge

BioTek® ELx405™ Select Microplate Washer BioTek Instruments, Inc. | 100 Tigan Street | Winooski, Vermont 05404 USA

Thermo CRS Ltd. | 5250 Mainway | Burlington, Ontario L7L 5Z1 | Canada

Life Technologies Holdings Pte Ltd | Block 33 | Marsiling Industrial Estate Road 3 |

#07-06, Singapore 739256

Life Technologies Holdings Pte Ltd | Block 33 | Marsiling Industrial Estate Road 3 |

#07-06, Singapore 739256

ABgene™ UK Ltd | Units 4-7 Suolk Drive | Fairwood Industrial Park | Ashford | Kent |

TN23 4FD | UK

Life Technologies Holdings Pte Ltd | Block 33 | Marsiling Industrial Estate Road 3 |

#07-06, Singapore 739256

Agilent Technologies Singapore (International) Pte Ltd | 1 Yishun Avenue 7 |

Singapore 768923

Manufacturer

Thermo Scientific™ Arctic™ A25 Refrigerated Circulator (115V or

230V)

Lab Automation Robotic Testing Platform Thermo CRS Ltd. | 5250 Mainway | Burlington, Ontario L7L 5Z1 | Canada

10 MagMAX

Thermo Fisher Scientific (Asheville) LLC | 275 Aiken Road | Asheville, North Carolina

28804 USA

™

Viral/Pathogen II Nucleic Acid Isolation Kit, High‑Throughput Instructions for Use

Page 11

Component Manufacturer

Software

Tecan™ FluentControl™ Software v2.8 Tecan Switzerland | Seestrasse 103 | 8708 Maennedorf | Switzerland

SampleManager LIMS™ Software Version 12.2 SP1

Momentum™ Workflow Scheduler Software 6.0.1 Thermo CRS Ltd. | 5250 Mainway | Burlington, Ontario L7L 5Z1 | Canada

COVID‑19 Interpretive Software Driver v1.1.0

BioTek® Liquid Handling Control Software 2.22 BioTek Instruments, Inc. | 100 Tigan Street | Winooski, Vermont 05404 USA

FILLit™ Software 2.0.1

BindIt™ Software 4.0

QuantStudio™ Real‑Time PCR Software v1.7.1

[1]

The operator does not interact directly with the COVID‑19 Interpretive Software Driver, FILLit™ Software, or BindIt™ Software.

[1]

[1]

[1]

Thermo Electron Ltd. | 1 St. George's Court, Hanover Business Park | Altrincham,

Cheshire WA14 5TP | United Kingdom

Life Technologies Corporation | 6055 Sunol Blvd | Pleasanton, California 94566 USA

Thermo Fisher Scientific Oy | Ratastie 2 | FI-01620 Vantaa | Finland

Life Technologies Holdings Pte Ltd | Block 33 | Marsiling Industrial Estate Road 3 |

#07-06, Singapore 739256

Life Technologies Holdings Pte Ltd | Block 33 | Marsiling Industrial Estate Road 3 |

#07-06, Singapore 739256

Appendix B Safety

WARNING! GENERAL SAFETY. Using this product in a manner not specified in the user documentation may result in personal

injury or damage to the instrument or device. Ensure that anyone using this product has received instructions in general safety

practices for laboratories and the safety information provided in this document.

Before using an instrument or device, read and understand the safety information provided in the user documentation provided

·

by the manufacturer of the instrument or device.

Before handling chemicals, read and understand all applicable Safety Data Sheets (SDSs) and use appropriate personal

·

protective equipment (gloves, gowns, eye protection, and so on). To obtain SDSs, see the “Documentation and Support”

section in this document.

Biological hazard safety

WARNING! BIOHAZARD. Biological samples such as tissues, body fluids, infectious agents, and blood of humans and other

animals have the potential to transmit infectious diseases. Conduct all work in properly equipped facilities with the appropriate

safety equipment (for example, physical containment devices). Safety equipment can also include items for personal protection,

such as gloves, coats, gowns, shoe covers, boots, respirators, face shields, safety glasses, or goggles. Individuals should be

trained according to applicable regulatory and company/ institution requirements before working with potentially biohazardous

materials. Follow all applicable local, state/provincial, and/or national regulations. The following references provide general

guidelines when handling biological samples in laboratory environment.

World Health Organization, Laboratory Biosafety Manual, 3rd Edition, WHO/CDS/CSR/LYO/2004.11; found at:

·

www.who.int/csr/resources/publications/biosafety/Biosafety7.pdf

U.S. Department of Health and Human Services, Biosafety in Microbiological and Biomedical Laboratories (BMBL), 5th Edition,

·

HHS Publication No. (CDC) 21-1112, Revised December 2009; found at:

https://www.cdc.gov/labs/pdf/CDC-BiosafetymicrobiologicalBiomedicalLaboratories-2009-P.pdf

WARNING! Potential Biohazard. If you use the kit with the automated nucleic extraction workflow, the surface of the

KingFisher™ purification system may be considered a biohazard. Use appropriate decontamination methods when working with

biohazards.

MagMAX™ Viral/Pathogen II Nucleic Acid Isolation Kit, High‑Throughput Instructions for Use 11

Page 12

Chemical safety

WARNING! GENERAL CHEMICAL HANDLING. To minimize hazards, ensure laboratory personnel read and practice the

general safety guidelines for chemical usage, storage, and waste provided below. Consult the relevant SDS for specific precautions

and instructions:

Read and understand the Safety Data Sheets (SDSs) provided by the chemical manufacturer before you store, handle, or work

·

with any chemicals or hazardous materials. To obtain SDSs, see the "Documentation and Support" section in this document.

Minimize contact with chemicals. Wear appropriate personal protective equipment when handling chemicals (for example,

·

safety glasses, gloves, or protective clothing).

Minimize the inhalation of chemicals. Do not leave chemical containers open. Use only with sucient ventilation (for example,

·

fume hood).

Check regularly for chemical leaks or spills. If a leak or spill occurs, follow the manufacturer cleanup procedures as

·

recommended in the SDS.

Handle chemical wastes in a fume hood.

·

Ensure use of primary and secondary waste containers. (A primary waste container holds the immediate waste. A secondary

·

container contains spills or leaks from the primary container. Both containers must be compatible with the waste material and

meet federal, state, and local requirements for container storage.)

After emptying a waste container, seal it with the cap provided.

·

Characterize (by analysis if needed) the waste generated by the particular applications, reagents, and substrates used in your

·

laboratory.

Ensure that the waste is stored, transferred, transported, and disposed of according to all local, state/provincial, and/or national

·

regulations.

IMPORTANT! Radioactive or biohazardous materials may require special handling, and disposal limitations may apply.

·

Appendix C Documentation and support

Customer and technical support

Visit thermofisher.com/support for the latest service and support information.

• Worldwide contact telephone numbers

• Product support information

– Product FAQs

– Software, patches, and updates

– Training for many applications and instruments

• Order and web support

• Product documentation

– User guides, manuals, and protocols

– Certificates of Analysis

– Safety Data Sheets (SDSs; also known as MSDSs)

Note: For SDSs for reagents and chemicals from other manufacturers, contact the manufacturer.

Limited product warranty

Life Technologies Corporation and/or its aliate(s) warrant their products as set forth in the Life Technologies' General Terms and

Conditions of Sale at www.thermofisher.com/us/en/home/global/terms-and-conditions.html. If you have any questions, please

contact Life Technologies at www.thermofisher.com/support.

12 MagMAX

™

Viral/Pathogen II Nucleic Acid Isolation Kit, High‑Throughput Instructions for Use

Page 13

Thermo Fisher Scientific Baltics UAB | V.A. Graiciuno 8, LT-02241 | Vilnius, Lithuania

For descriptions of symbols on product labels or product documents, go to thermofisher.com/symbols-definition.

The customer is responsible for compliance with regulatory requirements that pertain to their procedures and uses of the instrument.

The information in this guide is subject to change without notice.

DISCLAIMER: TO THE EXTENT ALLOWED BY LAW, THERMO FISHER SCIENTIFIC INC. AND/OR ITS AFFILIATE(S) WILL NOT BE LIABLE FOR SPECIAL, INCIDENTAL, INDIRECT,

PUNITIVE, MULTIPLE, OR CONSEQUENTIAL DAMAGES IN CONNECTION WITH OR ARISING FROM THIS DOCUMENT, INCLUDING YOUR USE OF IT.

Revision history: Pub. No. MAN0019941

Revision Date Description

A.0 28 January 2021 New MagMAX™ Viral/Pathogen II Nucleic Acid Isolation Kit, High‑Throughput Instructions for Use.

Important Licensing Information: These products may be covered by one or more Limited Use Label Licenses. By use of these products, you accept the terms and conditions of all

applicable Limited Use Label Licenses.

©2021 Thermo Fisher Scientific Inc. All rights reserved. All trademarks are the property of Thermo Fisher Scientific and its subsidiaries unless otherwise specified. Agilent is a

trademark of Agilent Technologies, Inc.. Axygen is a trademark of Axygen, Inc.. Biotek is a registered trademark and ELx405 is a trademark of BioTek Instruments, Inc.. Parafilm is a

trademark of Bemis Company, Inc.. Tecan, Fluent, FluentControl, and Flexible Channel Arm are trademarks of Tecan Group, Ltd.

thermofisher.com/support | thermofisher.com/askaquestion

thermofisher.com

28 January 2021

Loading...

Loading...