Page 1

Instruction Sheet

ECDOGEN-S / ECDOTPII-S

Submersible Galvanic Dissolved Oxygen Sensor

Copyright © 2006 All rights reserved.

Eutech Instruments Pte Ltd

Blk 55, Ayer Rajah

Crescent, #04-16/24

Singapore 139949

+65 6778 6876

+65 67730836 fax

www.thermofisher.com

Page 2

HOW DISSOLVED OXYGEN SENSORS WORK

Your Dissolved Oxygen (DO) Probe is a galvanic electrochemistry device; i.e. it does not require power

from your meter or controller to generate its signal. The Sensorex DO Probe will provide a millivolt signal

proportional to the concentration of oxygen in the water. DO probes do not measure oxygen directly.

They measure the partial pressure of oxygen in the water, which is directly proportional to the percent

saturation of oxygen in the water. The concentration (mg/L or ppm) can be calculated based upon the

oxygen solubility, temperature, salinity, and total atmospheric pressure. Your Dissolved Oxygen Probe

consists of a cathode, anode, and an electrolyte separated from your process fluid by an oxygen

permeable membrane. The oxygen passing through the membrane reacts with the cathode, giving up

electrons, which produce an electrical current. A Pt 100 RTD temperature sensor is also included.

Electrical Connections

First connect the sensor to the DO instrument as follows:

DO + Red

DO - Yellow

TC+ Red, White

TC – Black

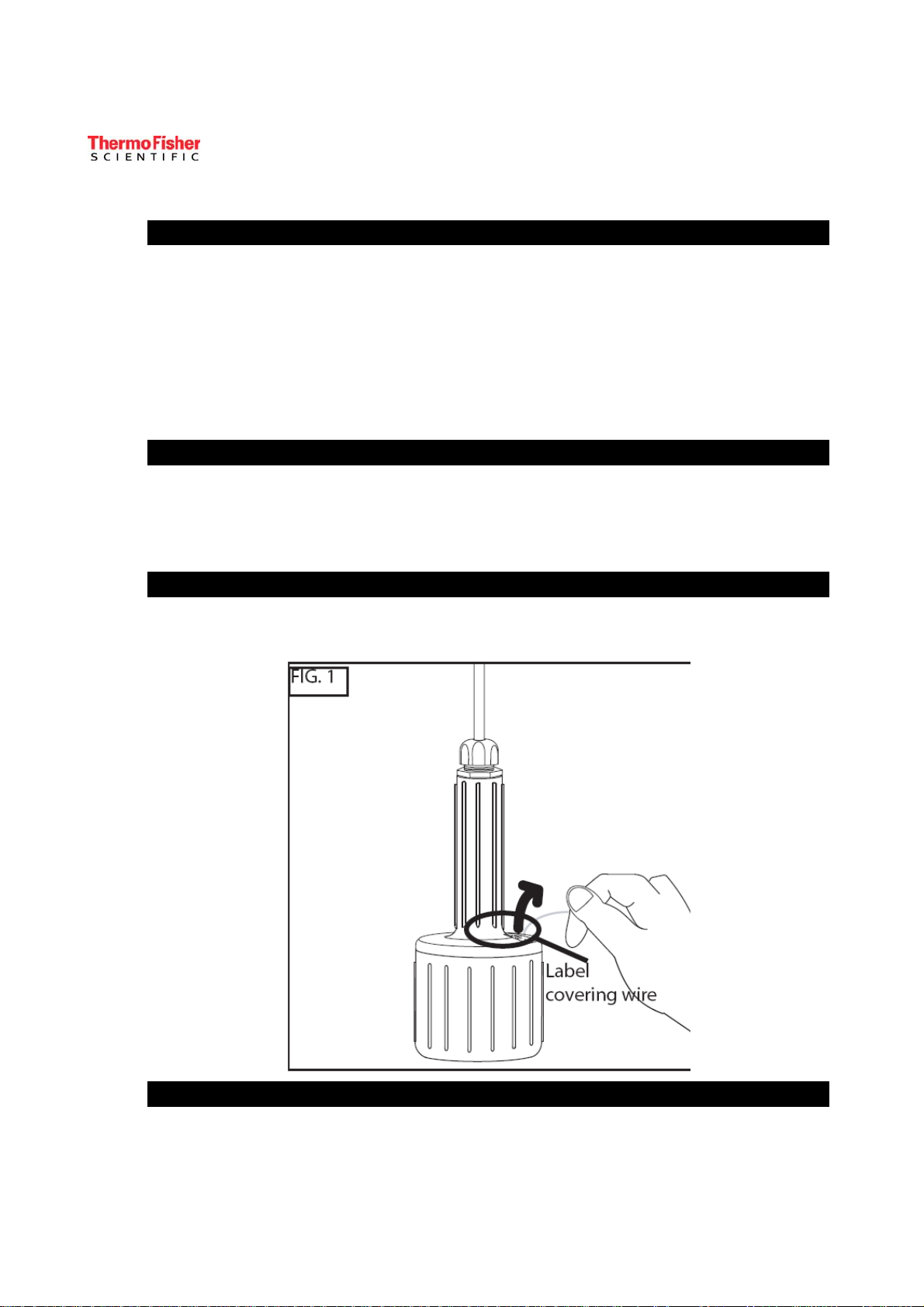

GETTING YOUR DO SENSOR READY TO USE

Remove clear wire and label from vent hole on top of DO sensor as shown in FIG 1. Discard these parts

after removing.

CALIBRATION

The simplest method to calibrate your DO sensor is in air, since air is saturated with oxygen. You may also

bubble oxygen or air. The sensor is pre-calibrated at the factory (see Specifications Section for calibration

range). If you want a 2-point calibration, a saturated solution of sodium sulfite (Na2SO3) is suggested.

17g Sodium sulfite in 125mL DI water is more than enough. Sodium sulfite will not reach a true zero

output but it should reach less than 1 mV (see Specifications Section for range).

www.thermofisher.com

Page 3

MEMBRANE TYPE

Two types of membrane materials are offered for DO sensors, either PTFE or HDPE. Teflon offers excellent

durability and moderate speed of response. HDPE offers fast response but less mechanical strength. The

PTFE membrane also has less membrane permeability error with temperature as compared to HDPE.

Spare membranes are available is 5 or 25 counts, or in maintenance kits.

MOUNTING YOUR DO SENSOR

Submersion mounting of the sensor is recommended. To prevent air bubbles from becoming trapped on

the membrane and producing falsely high DO readings, it is recommended that the sensor be mounted

with the membrane pointing slightly upward (not horizontal) as shown in FIG. 2.

SENSOR RE-CONDITIONING

1. Unscrew the lower body from the upper body(FIG. 3)

2. Safely dispose of the electrolyte that is a special molarity, reagent grade Sodium Chloride

solution (salt water) as shown in FIG. 4

3. Using the Membrane Tool, unscrew the Membrane Lock in the lower body as shown in FIG. 5

4. Remove and dispose of the membrane and its O-Ring as show in FIG 6

5. Using a toothbrush, dishwashing powder and clean water, clean the cathode, anode, and plastic

between them. Rinse all components thoroughly. Household Ammonia may be used to clean

the silver anode overnight If Ammonium Hydroxide is used, expose it for no more than 3

minutes (it is very strong). See FIG. 7.

6. Install a new O-Ring into the lower body membrane cavity then a new membrane into the lower

body. Using the Membrane Tool, screw the Membrane Lock on top of the membrane as shown

in FIG. 8.

7. Inspect the membrane for wrinkles--replace if it is wrinkled.

8. Pour some water into the lower body and look for leakage around the membrane--replace it if

there is leakage. If no leakage, dispose of the water.

www.thermofisher.com

Page 4

9. Fill the lower body to its rim with fresh Electrolyte as shown in FIG. 9.

10. Inspect the large O-Ring between the upper and lower body. Replace it if it appears

deteriorated. See FIG. 10.

11. Screw the lower body onto the upper body. Excess Electrolyte will squirt out of a small pressure

balance hole atop the upper body. If no electrolyte squirts out, clear the hole of its blockage

before installing the lower body.

www.thermofisher.com

Page 5

SENSOR STORAGE

If long-term storage of probes is required, empty electrolyte out of probe leaving only a little solution on

the membrane to keep it wet. Leaving a full volume of electrolyte in DO probe long-term without use will

deplete the probes’ anode. See section “Sensor RE-CONDITIONING ” for steps on how to open and close

probe housing.

SENSOR SPECIFICATIONS

Output at 100% saturation

PTFE membrane 24-42 mV

HDPE membrane 36-54 mV

Output at 0% saturation

PTFE membrane <1mV <1mV

HDPE membrane <1mV <1mV

Temperature Range

Max 50 °C

Min 0 °C

Accuracy +2% when measuring temp equal cal temp.

Response Time

PTFE membrane 2 minutes to reach 90% of final reading

HDPE membrane 1 minute to reach 95% of final reading

Water Flow Rate Min 2 inch/second across membrane

Wetted Materials

Body Delrin

Membrane Teflon, HDPE

Wiring

DO + Red

DO – Yellow

TC + Red, White

TC – Black

Teflon and Delrin are registered trademarks of E.I. DuPont.

www.thermofisher.com

Page 6

WARRANTY

This electrode is supplied with a six-month warranty against significant deviations in material and

workmanship.

Exclusions

The warranty on your instrument shall not apply to defects resulting from:

Improper or inadequate maintenance by customer

Unauthorised modification or misuse

Operation outside of the environment specifications of the products

RETURN POLICY

Please obtain authorisation from our Customer Service Department or authorised distributor before

returning items for any reason. A “Return Goods Authorisation” (RGA) form is available through our

authorised distributor. Please include data regarding the reason the items are to be returned. Items

must be carefully packed to prevent damage in shipment and insured against possible damage or loss.

Eutech Instruments/ Oakton Instruments will not be held responsible for damage resulting from careless

or insufficient packing. A restocking charge will be made on all unauthorised returns.

NOTE: Eutech Instruments Pte Ltd reserves the right to make improvements in design, construction, and

appearance of products without notice.

As of the date of preparation of this document, the foregoing information is believed to be accurate.

However, no warranty or representation with respect to such information is intended or given.

www.thermofisher.com

Loading...

Loading...