Page 1

Instruction Manual

EC620130 Series Combination pH Electrodes

Copyright © 2006 All rights reserved.

Eutech Instruments Pte Ltd

Version 1.1ML 68X068045 Rev 3 Jan 07

Blk 55, Ayer Rajah

Crescent, #04-16/24

Singapore 139949

+65 6778 6876

+65 67730836 fax

www.thermofisher.com

Page 2

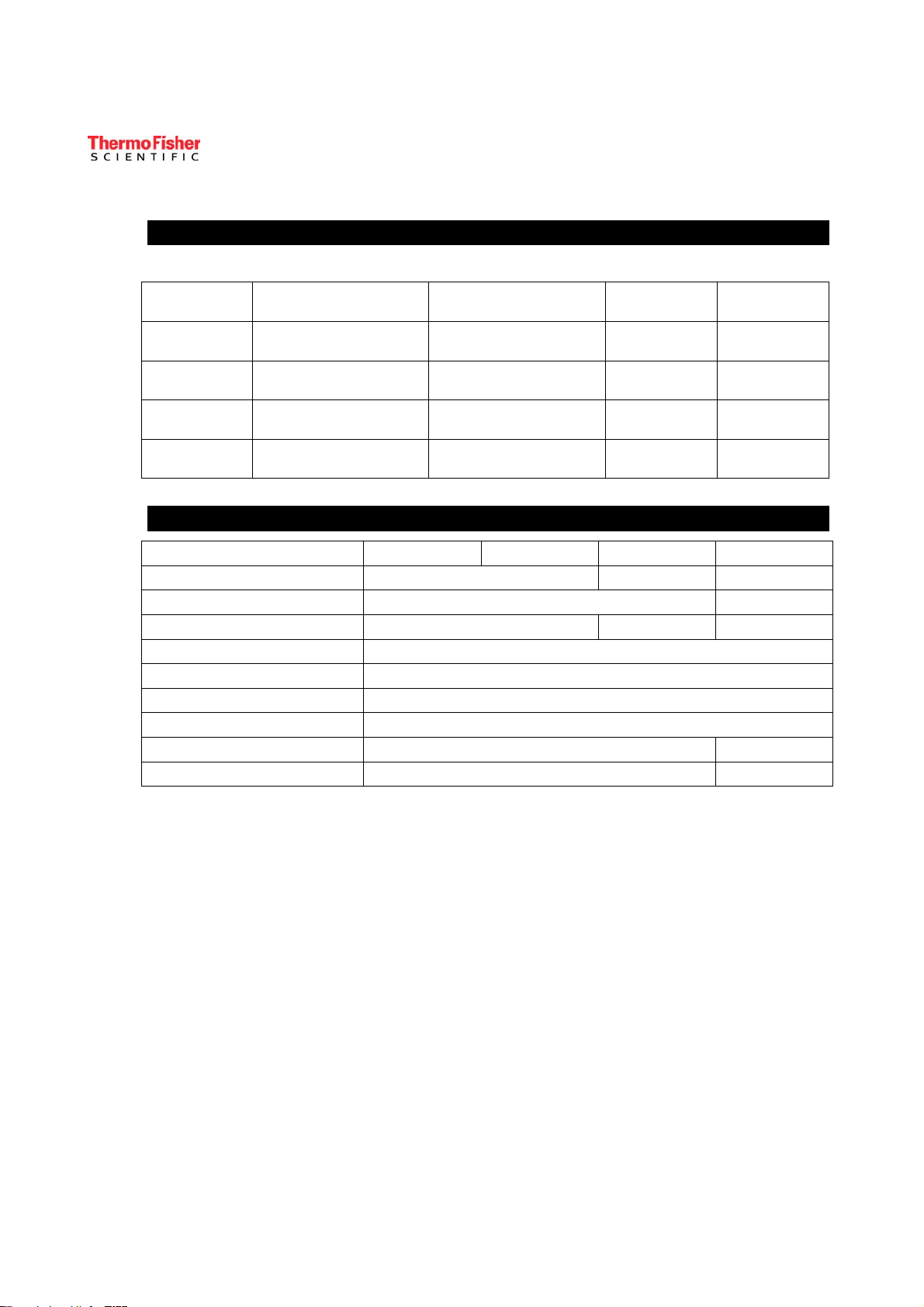

PRODUCT SPECIFICATIONS

EC620130 Series Combination pH Electrodes

Catalog No. Description Length/Diameter (mm) Connector

EC- 620-130

EC- 620-131

EC- 620-132

EC- 620-133

Glass body, refillable 160/12 BNC EC-636-430

Glass body, gel-filled 130/12 BNC N/A

Plastic body, gel-filled 120/12 BNC N/A

Glass body, gel-filled,

spear tip

70 mm overall length,

25/6 mm insertion

BNC N/A

Refilling

Solution

PERFORMANCE SPECIFICATIONS

Specification / Model EC-620-130 EC-620-131 EC-620-132 EC-620-133

Body Material Glass Plastic Glass

pH Range 0 to 14 pH 2 to 14 pH

Temperature range 0 to 80 °C 0 to 60 °C 0 to 50 °C

Slope (out of Box) 59 +/- 3 mV/pH at 25°C (95 to 105% slope)

Zero point pH 7

Offset (asymmetry potential) 0 mV +/- 25 mV

Reference Junction Double Junction

Junction Type Open pore Double Pore

Membrane Shape Cylindrical Spear Tip

Improved junction and reference design for precise, reliable, FAST readings

Better junction. EC620130 series electrodes use a single-pore capillary reference junction—about 200

times larger than typical ceramic junctions—that makes the electrodes almost impossible to clog, even

in difficult samples. The unique junction design provides increased electrolyte flow, resulting in greater

contact between sample and reference, and ensuring fast, stable readings.

Better reference design. Along with the capillary junction, our electrodes feature double junction

design for enhanced performance. A diffusion barrier separates the silver chloride reservoir from the

reference electrolyte, permitting use of silver-free electrolytes and preventing silver chloride loss from

temperature induced variations. End result: an extremely stable reference potential, providing long

electrode life.

EC-620-130 Unique fluid-gel electrolyte and innovative junction design produces a high flowrate and

improved contact between reference electrolyte and sample. The result is faster response time and very

accurate readings. The double-liquid-junction system further extends the diffusion barrier, greatly

increasing electrode life in aggressive samples. It also performs well in liquids with low ion concentration

and in partly aqueous samples.

EC-620-131, -132, -133 Solid polymer-gel electrolyte offers the advantages of the EC620130 series

system in a maintenance-free version. Polymer gel provides a more stable matrix than other gelled

electrode reference systems, providing reliable results in very dirty, ion-weak or protein samples—even

www.thermofisher.com

Page 3

at low pH or in the presence of organic solvents. -133 offers a rugged spear tip is ideal for semi-solids or

soft foods.

GETTING STARTED

Each electrode has a unique serial number and is quality checked before it leaves the factory.

Electrodes are shipped with an electrode storage bottle containing electrode storage solution. This

storage solution will occasionally creep out and appear as dry white crystal residue on the electrode.

However, this will have no long-term effect on the electrode and can be simply rinsed off with clean

water.

Proper removal and insertion of the storage bottle is very important. Improper use can result in a

pressure build up either inside the electrode or the bottle resulting in electrolyte leakage through the fill

hole or the cap of the storage bottle. Proper use of the electrode storage bottle is shown in Figure 1.

EC-620-130 is a refillable electrode and will include a bottle of Skylite electrolyte solution along with a

separate syringe and nozzle for electrolyte refilling process. New electrodes are shipped filled with their

filling holes closed, so electrolyte refilling of a new electrode is generally not required. It is recommended

that the Skylite electrolyte (EC-636-430) be added using the syringe and nozzle provided when the

electrolyte level in the reference cavity (outer annular space) is lower than ¼ inch below the cap. Simply

open the fill hole at the top of the electrode by rotating the cap ring. Mount the nozzle to the syringe and

fill it with the Skylite electrolyte solution (The tip hole of the Skylite bottle can be enlarged by trimming

the tip so as to accommodate the diameter size of the nozzle during electrolyte collection into the

syringe). Insert the syringe’s nozzle into the fill hole of the electrode and gently inject the electrolyte into

the electrode. If the electrolyte level is not visible, the electrode may be filled to a capacity just beneath

the fill hole.

NOTE: EC-620-130 has a faster electrolyte flow rate as compared to other conventional refillable electrodes.

Therefore a fast drop in the level of its electrolyte will be observed and this should not be construed as a sign of

an electrode problem.

Mount the EC620130 series open-pore electrodes onto a suitable electrode holder and connect the

electrode to the meter. For EC-620-130 refillable electrodes, the fill hole should be in the open position

when in use. If necessary, rotate the cap ring to open the fill hole.

Immerse the electrode in pH 4 or pH 7 buffer for 5 to 10 minutes to condition the glass pH bulb.

ELECTRODE OPERATION

1) The level of electrolyte in the outer cavity should be kept above the level of the solution being

measured to prevent reverse electrolyte flow. The electrode needs only be immersed far enough to cover

both the glass pH sensing bulb and reference junction to obtain accurate readings.

2) If the electrode has not been hydrated (placed in solution for more than one hour), allow the

electrode to soak in a buffer (preferably pH 4) as needed prior to standardization or measurement. This

will help to optimize and re-establish the thin hydration layer on the sensing bulb that is critical to

accurate pH measurement.

3) Rinse the electrode with deionized or distilled water between samples. Note: wiping the sensing bulb

is not recommended as the thin hydration layer of the sensing bulb could be affected and electrical

charges may be produced.

4) Moving or touching the electrode cable may result in unstable readings due to the high impedance

(resistance) of the pH glass membrane.

www.thermofisher.com

Page 4

5) To eliminate temperature errors associated with the electrode, manual or automatic temperature

compensation (ATC) should be used for best accuracy. Since pH changes with temperature, the sample

temperature should always be noted with pH readings, for example, “pH 8.43 @ 23.2 °C”.

CALIBRATION/STANDARDIZATION

New EC620130 series pH electrodes are factory-tested to have an efficiency or “slope” of > 95%. The

theoretical pH response is 100% (59.16 mV/pH unit) and therefore the millivolt difference between pH

4.00 and pH 7.00 certified calibration standards at 25ºC should be 177.48 mV. A 95% slope means that a

new accumet electrode will have a response of at least 168.61 mV between these values. As electrodes

naturally age, this efficiency deteriorates. Periodic calibration against known standards is necessary to

ensure the electrode’s efficiency. Most pH meters have features to display the current electrode slope,

protection that warn users of a low slope (usually 90%) and/or features that prevents erroneous

calibrations.

After completing calibration with the meter, the measured pH reading of each calibration buffer can be

compared to the pH value indicated for each buffer at the actual temperature. A chart with pH at various

temperatures is usually found on the calibration standard packaging or label. Using one-point

standardization, proper response is indicated if the reading is within ± 0.05 pH units from the

standardization point within 30 seconds when using certified pH buffers . Multiple-point standardization

is recommended for more precise measurements. To provide a linear response in the area of interest, use

two calibration standards that bracket the expected sample pH.

STORAGE

Storing electrodes in distilled or deionized water is NOT recommended as it will deplete the hydration

layer of refillable electrodes, and decrease the life of non-refillable electrodes. The electrode storage

bottle containing storage solution can be used for short or long term storage. For refillable electrodes,

the electrolyte level in the outer cavity should be kept above the level of the solution being measured.

Ensure that the fill hole is closed when not in use.

TROUBLESHOOTING

SYMPTOM / CAUSE (REMEDY)

• No response, all buffers or samples read the same pH—usually pH 7.00 or 0 mV / Broken

sensing bulb or wiring problem (replace electrode), probe not connected to input (verify correct

channel selection when using multiple-channel meters), probe is not in contact with sample

(remove electrode storage bottle or rubber bulb guard), meter automatically has frozen reading

(verify that the ‘Hold’ feature or ‘Auto Read’ feature is set to ‘Off’ when using meters with this

feature).

• Slow response with excessive crystallization inside probe / electrolyte flow clogged from

supersaturated electrolyte (“flush & fill” by remove the filling solution through the fill hole with a

syringe or by shaking it upside down. Repeatedly flush and rinse the reference cavity with clean,

60-80°C water to dissolve crystals until removed. Replace filling solution and re-hydrate

electrode in storage solution or pH 4 buffer, (ensure fill hole is in open position). To prevent this

in the future, ensure that the fill hole is closed when electrode is not in use.

• Dried salt deposits present / electrolyte residue deposited on electrode surface –often with

new electrodes or periods of non-use. Simply dissolve the deposits in warm tap water followed

by a brief soak in pH 4 buffer.

• Slow Response, Noisy, unstable, or erratic readings / sensing bulb dry or dirty (clean

electrode with mild detergent & warm water and re-hydrate electrode) , temperature may be

changing rapidly or electrode may be thermally shocked (allow electrode to reach sample

temperature), sample may be non-aqueous (take 30 second readings and soak in pH buffer for

one minute between measurements)

www.thermofisher.com

Page 5

REPLACEMENTS & ACCESSORIES

Catalog No. Description

EC-BU-1BT

EC-BU-4BT

EC-BU-7BT

EC-BU-9BT

EC-BU-10BT

EC-BU-12BT

EC-DPC-BT

ECRE006

EC-BU-4BTC1LIT

EC-BU-7BTC1LIT

EC-BU-10BTC1LIT

EC-BU-4BS

EC-BU-7BS

EC-BU-10BS

EC-RIN-WT

pH 1.68 Buffer Solution, 480 mL

pH 4.01 Buffer Solution, 480 mL

pH 7.00 Buffer Solution, 480 mL

pH 9.00 Buffer Solution, 480 mL

pH 10.01 Buffer Solution, 480 mL

pH 12.45 Buffer Solution, 480 mL

Protein Cleaning Solution for pH electrode

Storage Solution for pH electrode

pH 4.01 Buffer Solution (Red), 1 L

pH 7.00 Buffer Solution (Yellow), 1 L

pH 10.01 Buffer Solution (Blue), 1 L

pH 4.01 Buffer Sachets, (NIST traceable)

pH 7.00 Buffer Sachets, (NIST traceable)

pH 10.01 Buffer Sachets, (NIST traceable)

pH Deionized Water Rinse Sachets (NIST traceable)

Detachment of storage bottl e for measurement

Attachment of storage bottle for storing elect rode

Step 1 Step 2 Step 2Step 1

(for covering filling hole)

Ring

Storage bottle c a p, with

rubber gasket

Storage bottle

(with solution inside)

Step 1: K eep the ring close.

Unscrew the stora ge bottle cap and remove the bottle.

Next, remove the cap with the rubber gasket.

Step 2: Rotate the ring and open the filling hole.

Start your measurement.

Step 1: Keep the fil l hole open.

Mount the cap with the rubber gasket.

Next, attach the storage bottle, electrode close to the base of the bottle.

Screw the storage bottle onto the cap tightly.

Step 2: Rotate the ring to close the filling hole.

Store your electrode.

Figure 1: Proper attachment and detachment of storage bottle to prevent electrolyte leakage

WARRANTY

This electrode is supplied with a six-month warranty against significant deviations in material and

workmanship.

Exclusions

The warranty on your instrument shall not apply to defects resulting from:

Improper or inadequate maintenance by customer

Unauthorised modification or misuse

Operation outside of the environment specifications of the products

www.thermofisher.com

Page 6

RETURN POLICY

Please obtain authorisation from our Customer Service Department or authorised distributor before

returning items for any reason. A “Return Goods Authorisation” (RGA) form is available through our

authorised distributor. Please include data regarding the reason the items are to be returned. Items

must be carefully packed to prevent damage in shipment and insured against possible damage or loss.

Eutech Instruments/ Oakton Instruments will not be held responsible for damage resulting from careless

or insufficient packing. A restocking charge will be made on all unauthorised returns.

NOTE: Eutech Instruments Pte Ltd reserves the right to make improvements in design, construction, and

appearance of products without notice.

As of the date of preparation of this document, the foregoing information is believed to be accurate.

However, no warranty or representation with respect to such information is intended or given.

www.thermofisher.com

Loading...

Loading...