Thermo Fisher Scientific DO 600 User Manual

TechnologyMadeEasy...

68X415307 Rev. 6 Feb 2014

Integrated Instruction Manual

Part of Thermo Fisher Scientific

WP 600 Series Meters

pH 600 / 610 / 620, COND 600 / 610, DO 600,

PC 650, PD 650, CD 650, PCD 650

*IMPORTANT – PLEASE READ BEFORE YOU CONTINUE*

PLEASE USE THIS MANUAL IN THIS ORDER :

Step 1:

Use the first half of this manual “General Guide” and “Temperature” to set up and

calibrate your instrument (Pages 1 - 39).

Step 2:

Then go to the specific parameter guides (eg. pH, Conductivity, TDS etc) which are

relevant to the model you have purchased. (Pg 41 onwards).

CAUTION: Do not skip the general guide as your meter will not be configured to read

accurately if your set-up and calibrati ons ar e not don e acc or dingly.

Thank you for reading this page. Please proceed.

Table of Contents

GENERAL GUIDE .................................................................................. 1

1. Overview For All Meters ........................................................................................ 3

1.1 About the Meters ............................................................................................................................... 3

1.1.1 Display Overview .................................................................................................................... 3

1.1.2 Key Functions ......................................................................................................................... 3

1.2 Inserting Batteries ............................................................................................................................. 4

1.2.1 Inserting batteries for the first time ......................................................................................... 4

1.2.2 Changing batteries subsequently ........................................................................................... 4

1.3 Attaching the Belt .............................................................................................................................. 5

1.4 Connecting Peripherals ..................................................................................................................... 6

1.4.1 Probes (pH/Conductivity/DO) ................................................................................................. 6

1.4.2 Protective Rubber Boot .......................................................................................................... 7

2. System Setup Mode For All Meters ...................................................................... 8

2.1 About Setup Mode ............................................................................................................................ 8

2.2 Accessing Setup mode ..................................................................................................................... 8

2.3 Setup Selection: System Settings ..................................................................................................... 9

2.4 Accessing Setup mode when password protection enabled .......................................................... 15

2.5 Modifying Setup parameters ........................................................................................................... 16

3. Calibration Mode For All Meters ......................................................................... 17

3.1 About Calibration ............................................................................................................................. 17

3.2 About Conductivity/ Resistivity/ TDS/ Salinity Calibration ............................................................... 17

3.3 Preparing the Meter for Calibration ................................................................................................. 17

3.4 Accessing Calibration mode............................................................................................................ 19

3.4.1 Accessing Calibration mode when password protection enabled ........................................ 19

4. Measurement Mode For All Meters ..................................................................... 20

4.1 About Measurement Mode .............................................................................................................. 20

4.1.1 Accessing functions.............................................................................................................. 20

4.2 Taking Measurements ..................................................................................................................... 21

4.2.1 Prepare the meter for measurement .................................................................................... 21

4.2.2 Taking a reading ................................................................................................................... 21

4.2.3 Stable reading indicator ....................................................................................................... 22

4.2.4 Holding a reading ................................................................................................................. 22

4.3 Automatic Temperature Compensation (ATC) ................................................................................ 22

4.3.1 Manual Temperature Compensation (MTC) ........................................................................ 22

4.4 Alarm set point (For pH/conductivity/DO) ....................................................................................... 23

4.5 Calibration Due (CAL-DUE) Indicator (For pH/conductivity/DO) .................................................... 23

5. TRANSFERRING AND PRINTING DATA ............................................................. 23

5.1 CyberComm 600 Data Acquisition Software ................................................................................... 23

5.2 Working with Memory functions – Auto Data Logging .................................................................... 23

5.2.1 Logging data automatically in the meter’s memory .............................................................. 24

5.2.2 Storing a current measurement (In IrDA and LED print mode: Applicable to all modes) .... 24

5.2.3 Viewing stored data .............................................................................................................. 24

5.2.4 Transferring stored data to the Computer (CyberComm) through IrDA ............................... 25

5.2.5 Transferring stored data to a PC not equipped with infrared rece iv er. ................................ 26

5.2.6 Transferring stored data to a PC using an USB/ irDA Dongle. ............................................ 27

6. Technical Specifications ..................................................................................... 28

7. Accessories .......................................................................................................... 32

8. Warranty & Return Polic y .................................................................................... 33

8.1 Warranty ……. ................................................................................................................................. 33

8.2 Return of Goods .............................................................................................................................. 33

8.3 Guidelines for Returning Unit for Repair ......................................................................................... 34

TEMPERATURE ................................................................................... 35

1. Temperature Setup .............................................................................................. 37

2. Temperature Calibration ...................................................................................... 37

2.1 About Temperature Calibration ....................................................................................................... 37

2.2 Temperature Calibration for ATC mode .......................................................................................... 38

2.3 Temperature Calibration for MTC mode ......................................................................................... 39

3. Temperature Measurement ................................................................................. 39

pH.. ....................................................................................................... 41

1. pH Setup ............................................................................................................... 43

2. pH Calibration ....................................................................................................... 44

2.1 About pH Calibration ....................................................................................................................... 44

2.2 pH buffer group for calibration and auto-recognition ...................................................................... 45

2.2.1 pH Calibration points ............................................................................................................ 45

2.3 pH Calibration with a Standard Buffer ............................................................................................. 45

2.3.1 To start pH Calibration: ........................................................................................................ 45

2.4 pH Calibration with a User-defined Buffer ....................................................................................... 47

2.5 Calibration Report ........................................................................................................................... 48

2.5.1 To View Calibration Report: ................................................................................................. 48

2.6 Average Slope Indicator of pH Probe ............................................................................................. 49

3. pH Measurement Mode ........................................................................................ 49

3.1 Resolution of pH Reading ............................................................................................................... 49

3.2 Indicators in pH measurement screen ............................................................................................ 50

mV ........................................................................................................ 51

1. mV Setup Mode .................................................................................................... 53

2. mV Calibration Mode ........................................................................................... 53

2.1 mV Calibration with a Standard ORP Calibration Solution ............................................................. 53

2.2 Calibration Report ........................................................................................................................... 54

2.2.1 To View Calibration Report: ................................................................................................. 54

3. mV Measurement Mode ....................................................................................... 54

3.1 Indicators in mV measurement mode ............................................................................................. 54

ION ....................................................................................................... 57

1. Ion Setup ............................................................................................................... 59

2. Ion Calibration Mode ............................................................................................ 59

2.1 About Ion Calibration ....................................................................................................................... 59

2.2 Calibration Report ........................................................................................................................... 61

2.2.1 To View Calibration Report .................................................................................................. 61

3. Ion Measurement Mode ....................................................................................... 62

3.1 Changing unit of measurement ....................................................................................................... 62

3.2 Indicators in Ion measurement mode .............................................................................................. 62

CONDUCTIVITY ................................................................................... 63

1. Conductivity Setup .............................................................................................. 65

2. Conductivity Calibration Mode ........................................................................... 67

2.1 Conductivity Calibration mode ........................................................................................................ 67

2.1.1 Conductivity calibration points .............................................................................................. 67

2.2 Cell constant 67

2.3 Normalization Temperature (°C) ..................................................................................................... 67

2.4 Linear temperature Coefficient ........................................................................................................ 67

2.5 Pure Water Coefficient .................................................................................................................... 68

2.6 To begin Calibration ........................................................................................................................ 68

2.7 Manual Calibration .......................................................................................................................... 69

2.8 Automatic Calibration (For Conductivity Calibration) ...................................................................... 69

2.9 Calibration Report ........................................................................................................................... 71

2.9.1 To View Calibration Report: ................................................................................................. 71

3. Conductivity Measureme nt Mode ....................................................................... 71

3.1 Indicators in Conductivity measurement screen ............................................................................. 72

TDS ....................................................................................................... 73

1. TDS Setup ............................................................................................................. 75

2. TDS Calibration Mode .......................................................................................... 77

2.1 TDS Calibration Report ................................................................................................................... 78

2.1.1 To View Calibration Report: ................................................................................................. 78

3. TDS Measurement Mode ..................................................................................... 79

3.1 Indicators in TDS measurement mode ........................................................................................... 79

4. About TDS ............................................................................................................ 80

4.1 Calculating TDS Conversion Factor ................................................................................................ 80

4.2 Calculating Temperature Coefficients ............................................................................................. 80

SALINITY .............................................................................................. 81

1. Salinity Setup ....................................................................................................... 83

2. Salinity Calibration Mode .................................................................................... 84

2.1 Salinity Calibration Report ............................................................................................................... 86

2.1.1 To View salinity Report:........................................................................................................ 86

3. Salinity Measurement Mode ................................................................................ 87

3.1 Indicators in salinity measurement mode ........................................................................................ 87

RESISTIVITY ........................................................................................ 89

1. Resistivity Setup .................................................................................................. 91

2. Resistivity Calibration Mode ............................................................................... 93

2.1 Resistivity Calibration Report .......................................................................................................... 94

2.1.1 To View Calibration Report: ................................................................................................. 94

3. Resistivity Measurement Mode ........................................................................... 95

3.1 Indicators in Resistivity measurement mode .................................................................................. 95

DISSOLVED OXYGEN ......................................................................... 97

PAR T A - % Saturation Mode .............................................................. 99

1. O2 % - DO S aturation Setup ............................................................................... 99

2. DO Calibration in % Saturation Mode (with ATC) ............................................ 101

2.1 About DO(%) and DO (mg/L) Calibration ...................................................................................... 101

2.2 To calibrate 100% saturation ........................................................................................................ 101

2.3 To calibrate 0% saturation ............................................................................................................ 103

2.3.1 % DO Calibration Report .................................................................................................... 104

2.3.2 To View Calibration Report: ............................................................................................... 104

2.4 % Saturation Offset Adjustment .................................................................................................... 104

2.5 Set barometer pressure range and barometric pressure units ..................................................... 105

2.6 Pressure compensation ................................................................................................................ 105

3. Percentage Saturation (%) Measurement Mode .............................................. 105

3.1 Indicators in percentage saturation measurement mode .............................................................. 106

PART B – Concentration (mg/ L) (ppm ) Mode .................................. 107

1. O2 mg/L (ppm) – DO Concentration Setup ...................................................... 107

2. DO Calibration in mg/L mode or ppm Concentration mode ........................... 109

2.1 Concentration Calibration Report .................................................................................................. 110

2.1.1 To View Calibration Report: ............................................................................................... 110

2.2 Set Sa linity…. ................................................................................................................................ 110

2.2.1 Auto Salinity Compensation ............................................................................................... 111

3. Concentration in Measurement Mode .............................................................. 111

3.1 Indicators in concentration measurement screen ......................................................................... 111

3.2 Dissolved Oxygen Probe ............................................................................................................... 112

3.2.1 Dissolved Oxygen Principle ............................................................................................... 112

3.2.2 Probe Care ......................................................................................................................... 112

3.2.3 Membrane Housing Replacement ...................................................................................... 113

3.2.4 Membrane/O-ring Replacement (Optional Procedure) ...................................................... 115

3.2.5 Electrolyte Solution ............................................................................................................. 116

GENERAL GUIDE

This section is appli cable to all models of the

WP 600 Series Meters. Please do no t skip this

section.

Model

pH 600 Temperature (with ATC), pH (-2.00 to 20.00 measuring range).

pH 610 Temperature (wi th ATC), pH (expandable resolution to 0.001).

pH 620 Temperature (with ATC), pH (expandable resolution to 0.001)

COND 600 Temperature (with ATC), Conductivity, TDS.

COND 610 Temperature (with ATC), Conductivity, TDS, Salinity,

DO 600 Temperature (with ATC), Dissolved Oxygen (% & ppm).

PC 650 Temperature (with ATC), pH, mV, Ion, Conductivity, TDS,

PD 650 Temperature (with ATC), pH, mV, Ion, Dissolved Oxygen (% &

CD 650 Temperature (with ATC), Conductivity, TDS, Salinity,

PCD 650 Temperature (with ATC), pH, mV, Ion, Conductivity, TDS,

Parameters

and Ion.

Resistivity.

Salinity, Resistivity.

ppm).

Resistivity, Dissolved Oxygen (% & ppm).

Salinity, Resistivity, Dissolved Oxygen (% & ppm).

1

2

1. Overview For All Meters

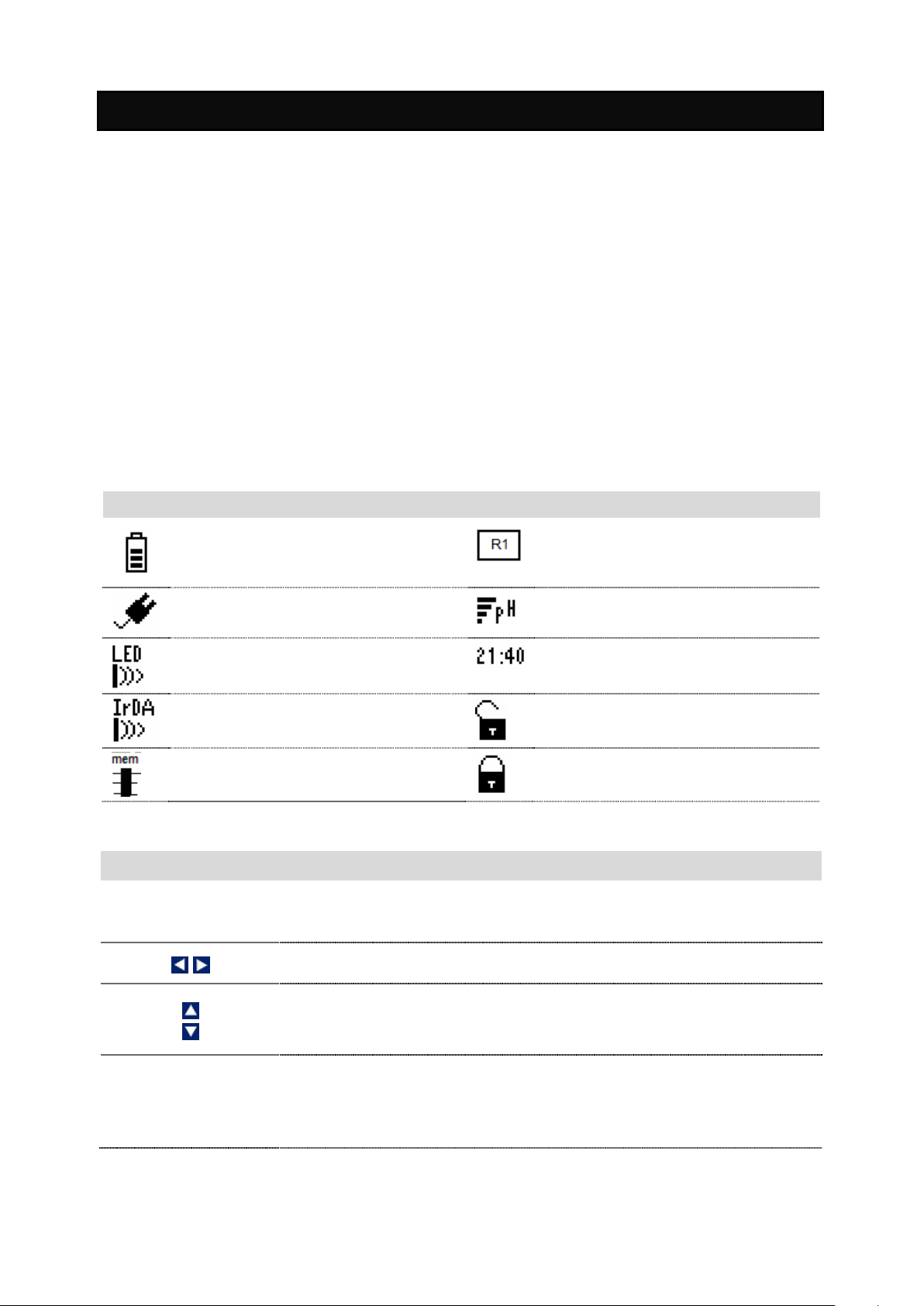

Indicators Used in Header Area

1.1 About the Meters

SPECIAL FEATURES

• Displays and measures up to 4 parameters simultaneously

• Automatic temperature compensation

• Built in memory backup to save calibration and 500 sets of measured data

• Data logging feature date-and-time stamp to meet Good Laboratory Practice (GLP)

• Data transmission through IrDA or RS232 through LED

• User-selectable ‘CAL-DUE’ and set point alarm functions

• Power source and Battery level indicator

• Designed to work either from mains power or battery and automatically detect and switch to

mains if available

• Waterproof casing

• User-configurable password protection for calibration & setup data

• Intuitive on-screen messages appear to assist user

1.1.1 Display Overview

Power Source & Battery Level

Power Source: DC Adapter

Data Transmission mode: LED

Data Transmission mode: Infrared

Data Logging Mode: Internal

Memory

1.1.2 Key Functions

Key Function

Selects the function shown (in the display) just above the

key. (For ON key, press and hold for 3 seconds.

Navigates to next avai l able f uncti o ns

Conductivity range of the probe

Average slope of the pH probe

Current Time in 24 Hour format

Password Protection: Disabled

Password Protection: Enabled

3

Increment/decrement values in Setup & Calibration modes.

Navigates to sub groups in Setup selection screen.

In Setup mode, confirms selection or modified values

In Calibration mode, confirms calibration points or modified

values

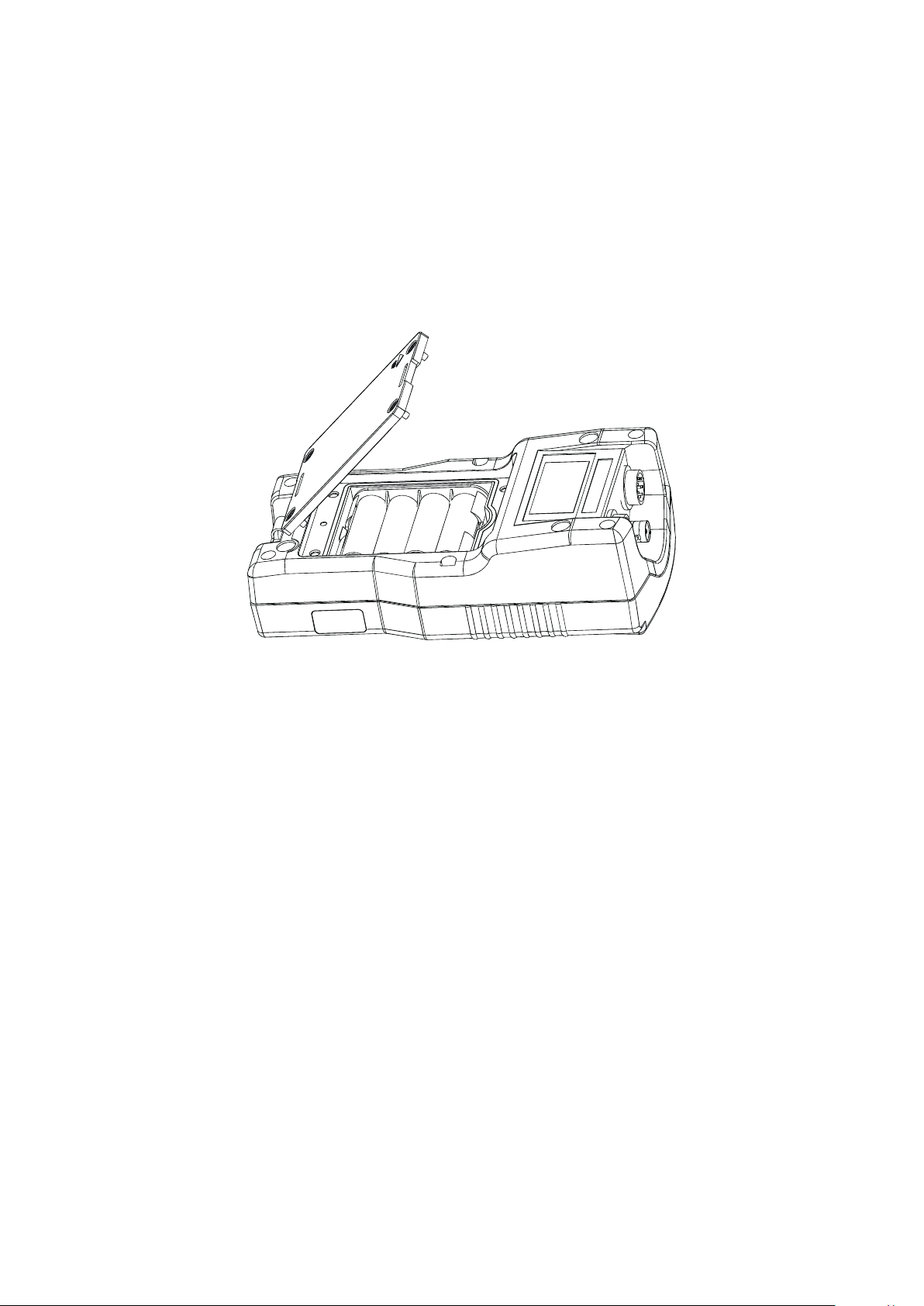

1.2 Inserting Batteries

NOTE: Please ensure that the gasket is in place otherwise the instrument will

not be waterproof.

Power up your meter using either:

1. Four ‘AA’ size 1.5 V alkaline batteries (supplied) or,

2. 9V DC power adapter (Optional in some models).

1.2.1 Inserting batteries for the first time

1. Use a Phillips screw driver to remove the four screws holding the battery

cover.

2. Insert the batteries in the right direction.

3. Replace the battery cover and screws. Note the ▲UP symbol marked on the

cover.

4. Press the ON (F4) key. Hold the key down until the display appears.

5. Set the system date & time before you start operating the meter for the first

time.

1.2.2 Changing batteries subsequently

1. Connect the adapter before changing the batteries.

2. If DC adapter is not available, switch off the meter and change the

batteries within 30 seconds to avoid resetting the clock. This prevents the

system time from resetting automatically.

4

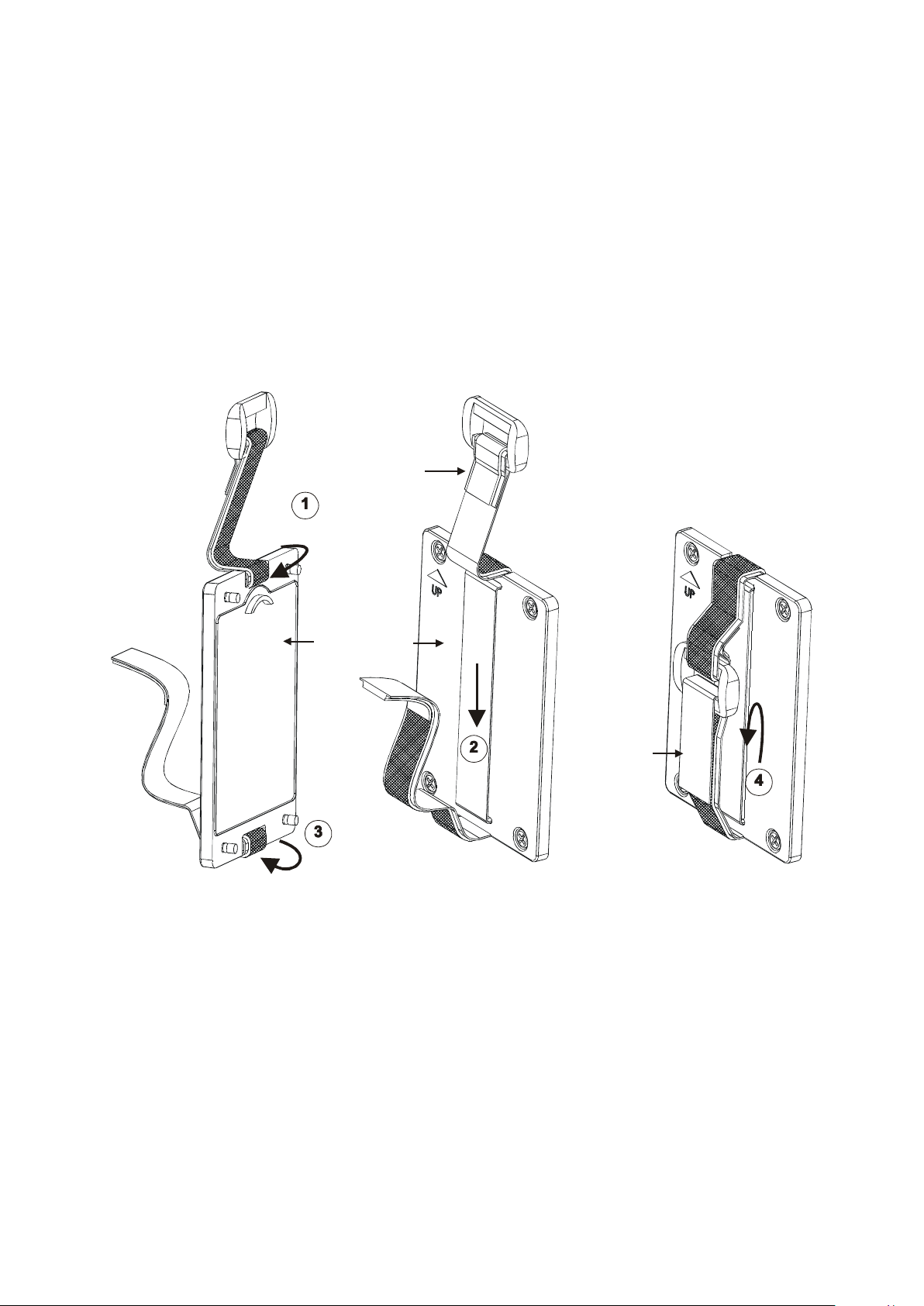

1.3 Attaching the Belt

Note the correct side

of the belt

Battery Cover

Hook & Loop

fastener

To attach the safety belt:

1. Use a Phillips screw driver to remove the four screws holding the battery

cover.

2. Insert the safety belt through the two slots as indicated below.

3. Screw the battery cover back on. Note the ▲UP symbol marked on the

cover.

4. Insert your palm between the belt and the body of the meter and adjust the

hook & loop fastener.

5

1.4 Connecting Peripheral s

pH Probe (BNC)

Conductivity Probe

DO Probe with built

1.4.1 Probes (pH/Conductivity/DO) Attach the probes with correct type of connectors as indicated.

with built in

temperature sensor

(8-pin Connector)

Use this socket for

the standalone

temperature probe

in the pH only

models.

Use the electrode properly for best results:

1. Keep the protective plastic electrode guard in

tact during measurement and calibration. DO

NOT REMOVE IT.

in temperature

sensor (6-pin

Connector)

6

2. Always immerse the electrode beyond upper

steel band as shown.

3. Be sure to remove the protective electrode

storage bottle or rubber cap of the pH electrode

before calibration or meas ur e me nt.

NOTE: If the electrode has been stored dry, wet the electrode in clean water

for 10 minutes before calibrating or taking readings to saturate the pH electrode

surface and to minimize drift.

1.4.2 Protective Rubber Boot The rubber boot protects the meter when used in the field. For bench top

applications, lift up the stand at the back of the rubber boot.

PLEASE SET UP THE SYSTEM BEFORE YOU BEGIN USING

THE METER. USE THE FOLLOWING OVERVIEW FOR

SETUP MODE:

7

2. System Setup Mode For All Meters

Note: If the meter is password protected, you will be prompted to enter a

2.1 About Setup Mode

The setup mode lets you configure various parameters & settings of the meter.

You can choose to password-protect your settings, so that other users who may

use the meter will not be able to change the settings.

Setup mode consists of the following sub-groups:

System – General settings of the meter

pH / mV / Ion / Conductivity / TDS / Salinity / Resistivity / O2 mg/L

(ppm) / O2 (%) – The pH / mV / Ion / Conductivity / TDS / Salinity /

Resistivity / O2 mg/L (ppm) / O2 (%) Setup screen presents many options to

control the operating parameters of their respective mode (Please refer to

individual parameter sections for more information).

Temperature - Temperature measurement & calibration related settings.

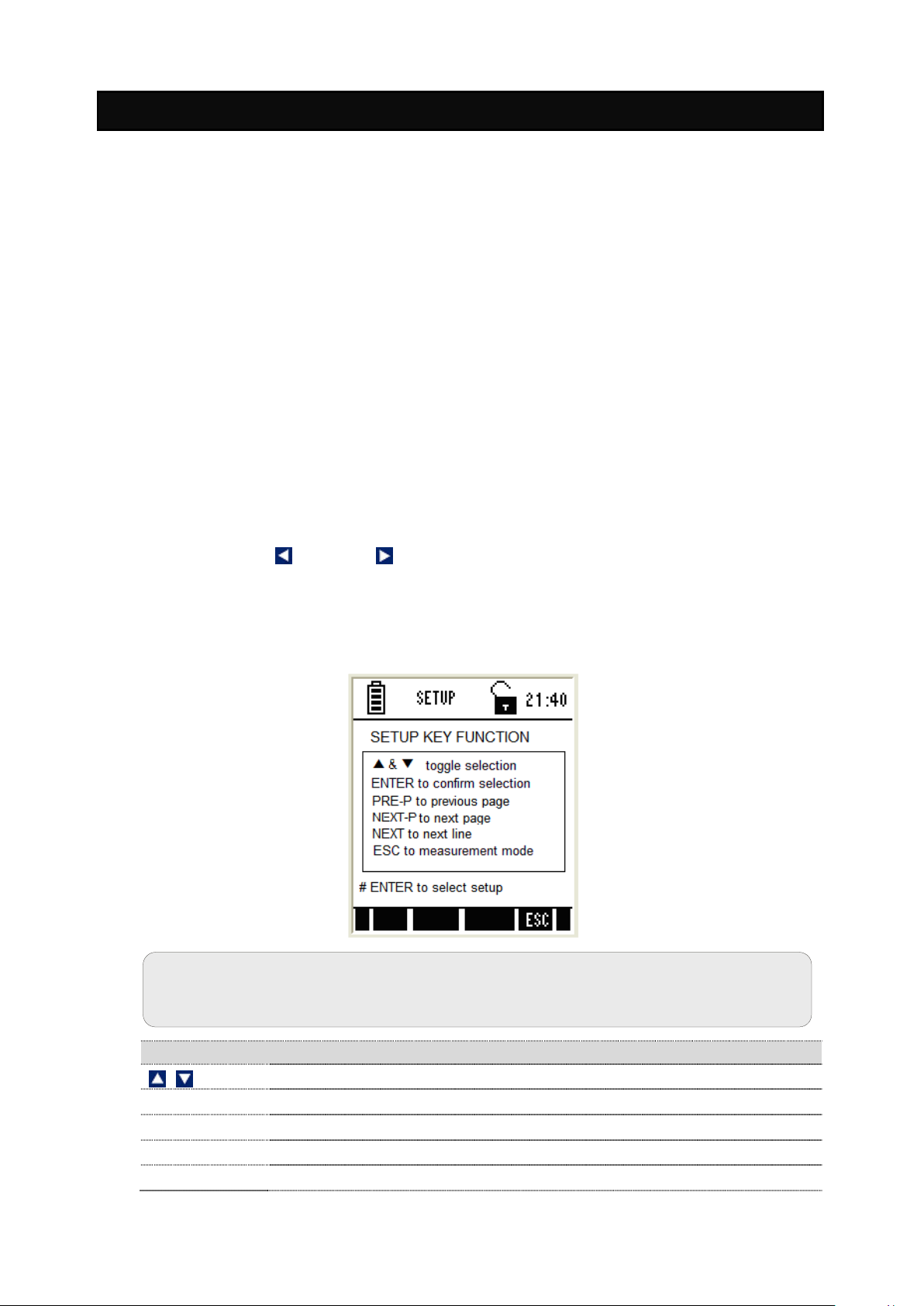

2.2 Accessing Setup mode

1. Switch the meter on. The meter goes to measurement mode.

2. Press left or right arrow key on the keypad to navigate to other

available functions until you see SETP function in the LCD.

3. Press SETP (F1) and Setup Key Function screen appears. This page

describes the key functions for configuring various param eters and settings

of the meter.

password before accessing Setup Key Function screen.

Function Keys available in setup key function screen:

To select individual setup

ENTER

NEXT-P

NEXT

ESC

To select or confirm the selection.

To navigate to next page.

To go to next parameter without saving the changed parameter.

To go back to measurement mode.

8

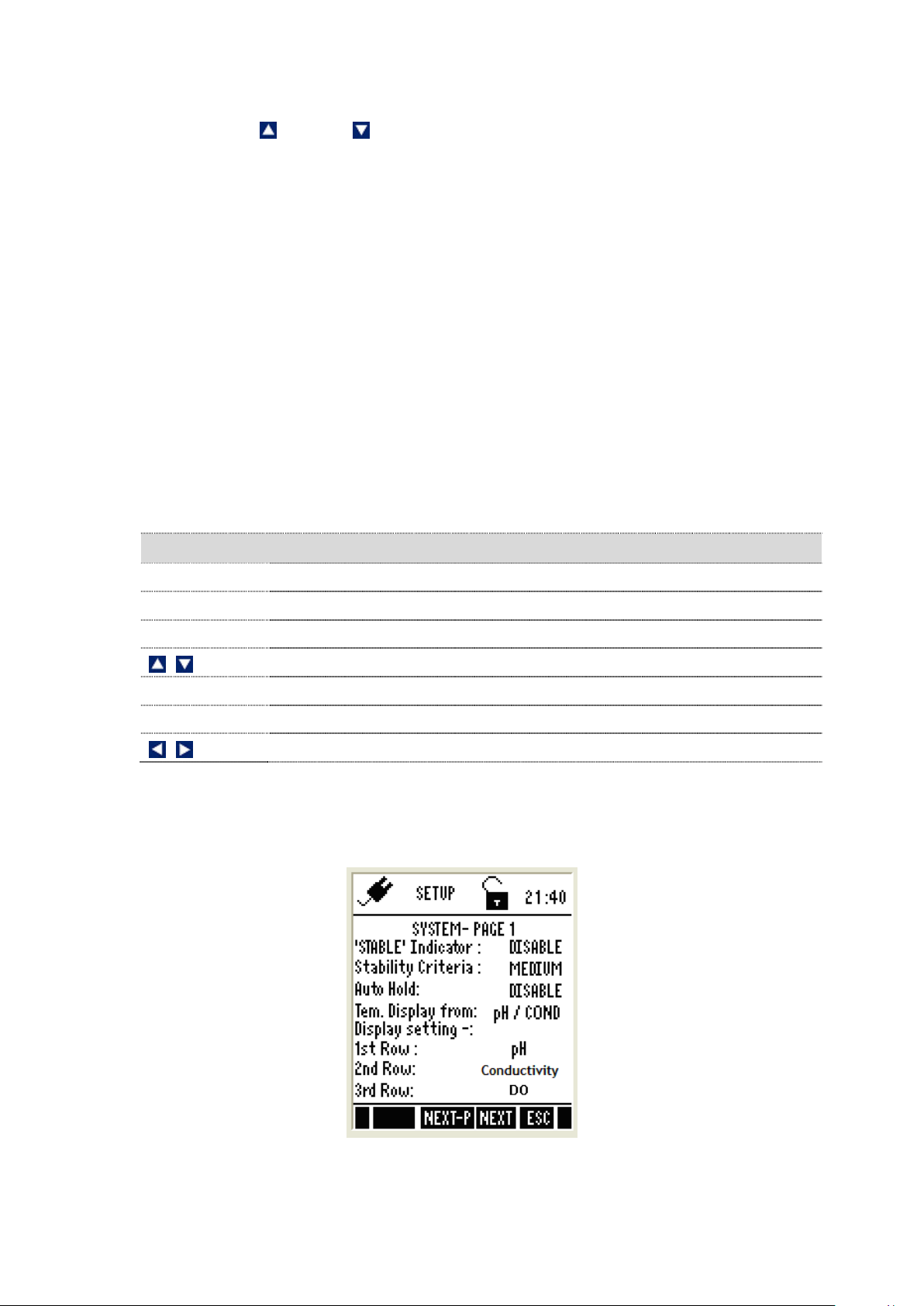

1. Press ENTER key to select Setup Selection screen.

2. Press up or down arrow key to go to required setup sub-group.

3. Press ENTER key to select the currently shown sub-group.

Figure 1: Setup Selection Screen

Function keys available in setup selection screen:

(F1)

(F2)

(F3)

ENTER

ESC (F4)

(Not functional)

(Not functional)

(Not functional)

Goes to required setup sub-groups

Selects the current sub-group

Goes to measurement mode from where you entered setup

(Not functional)

2.3 Setup Selection: System Setti ngs

System Settings Page 1 – General Settings

Figure 2: System Settings Page 1 – General Settings

9

System setup sub-group allows you to configure general settings of the meter.

Note: In order to activate the RESPONSE TIME function, you have to first

The settings are displayed in 6 pages. Press NEXT-P (F2) and PREV-P (F1) to

navigate through these pages.

Parameter Description Factory Default

STABLE

Indicator

Stability

Criteria

Auto Hold

ENABLE - The meter displays ‘Stable’ indicator in the

measurement screen as per the ‘STABLE CRITERIA’

defined below.

DISABLE – ‘Stable’ indicator does not appear.

SLOW – The reading is stabilized slowly and exhibits

good repeatability

MEDIUM – Reading stability is averaged between

slow & fast stability

FAST – Reading is stabilized quickly at the cost of

repeatability.

(This parameter has no effect if ‘STABLE’ parameter

is disabled)

ENABLE - The meter holds the reading in the

measurement screen, if the reading is ‘Stable’ for 5

seconds.

If this is enabled, ‘Response time’ appears in the

measurement screen, indicating the average response

time of the probe.

DISABLE – The reading is not held

(This parameter has no effect if ‘STABLE’ parameter

is disabled. The response time may not work if the

system time has not been set as described previously.

ENABLE

FAST

DISABLE

Tem. Display

from

Allows you to select temperature from pH/COND/DO

probes to display in multi measurement screen.

For PCD 650-pH/COND->DO

Display

setting:-

Allows you to select multi modes that you would like to

be displayed on the 1st and 2

nd

row of the

measurement screen after calibration.

st

1

Row : pH / Ion / mV / Conductivity / Salinity /

Resitivity / TDS / O

nd

2

Row : pH / Ion / mV / Con d uctivity / Salinity /

Resitivity / TDS / O

rd

3

Row : pH / Ion / mV / Conductivity / Salinity /

Resitivity / TDS / O

mg/L (ppm) / O2 (%)

2

mg/L (ppm) / O2 (%)

2

mg/L (ppm) / O2 (%)

2

activate the STABLE and AUTO HOLD functions.

-

-

10

System Settings Page 2 – Date & Time

Year

Sets the current year

2006

Month

Sets the current month

Jan

Date

Sets the current date

01

Hour

Sets the hour (24 Hours) for the current time

00

Minute

Sets the minute for the current time

00

Second

Sets the second for the current time

00

Figure 3 : System Settings Page 2 – Date & Time

This page allows you to set the date & time of the meter.

Parameter Description Factory Default

System Settings Page 3 – Auto-Off & Backlight

Figure 4 : System Settings Page 3 – Auto-Off & Backlight

This page allows you to set auto-off and back li ght related parameters.

Parameter Description Factory Default

Auto OFF

ENABLE – Turns the meter off automatically if no key is

pressed for the time period specified in ‘ON TIME’ below.

However, this will happen only if you are using the battery,

NOT when the meter is plugged into an AC power source

or when it is printing data.

ENABLE

11

DISABLE – Meter does not turn off automatically.

ON Time

Print Mode

Note: The above settings may not work if the system time has not been

set as described previously.

Back Light

(permanently

ON)

Back Light

ON with (Key

press)

ON time with

(Key press)

After the last key is pressed, no. of minutes the meter

should wait before automatically shuts down the meter.

Maximum range: 30 min

(This parameter has not editable if ‘AUTO OFF’ parameter

is disabled)

ENABLE – Sets the back light always on.

DISABLE – Sets the backlight always off.

ENABLE – The back light of the LCD is automatically on

when any key is pressed.

DISABLE – Does not turn on the back light automatically.

Sets the meter to wait for specified number of minutes

before automatically turning off the back light after the last

key is pressed.

(This parameter is not editable when ‘BACK LIGHT (Key

press)’ is disabled)

(This parameter has no effect if ‘BACK LIGHT (Always)’

parameter is set to ON)

10 min

DISABLE

DISABLE

1 min

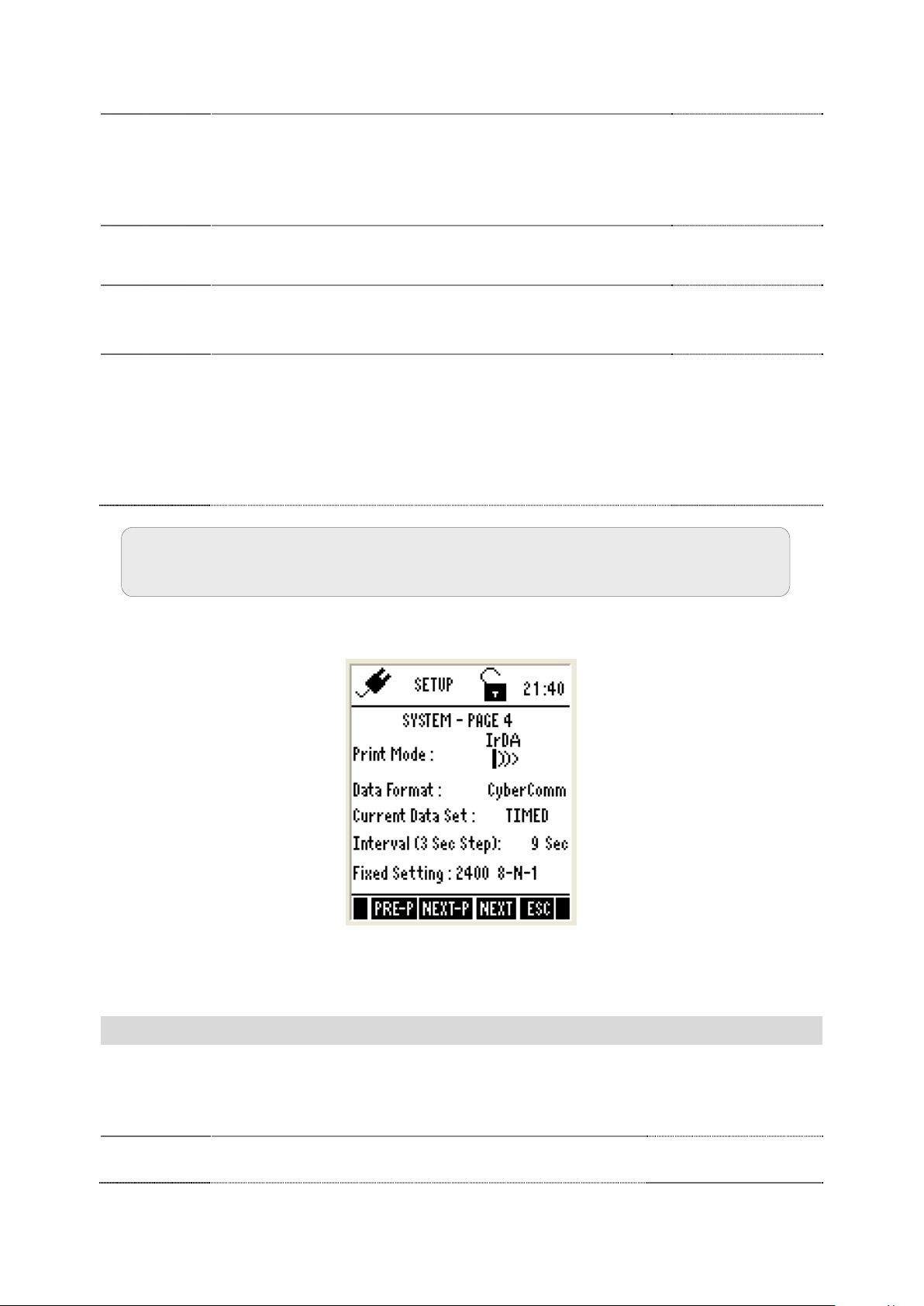

System Settings Page 4 – Wireless Serial Data Communication

Figure 5: System Settings Page 4 – Wireless Serial Data Communication

This allows you to set wireless serial data communication related parameters.

Parameter Description Factory Default

IrDA – Sets serial data communication protocol to IrDA

LED – Sets serial data communication protocol to

RS232C

MEM- Logs data to meter’s memory.

Data Format

CyberComm – Select this format if you use

CyberComm Data Acquisition Software (DAS)

12

IrDA

CyberComm

TEXT – Select this format if you use any other method

(such as Windows® Hyperterminal)

Current Data

Interval

This parameter is used when downloading data from

the meter through IrDA

TIMED

9 Sec

2400 8-N-1

Set

(3 Sec Step)

Fixed Setting

TIMED – Prints measurement data continuously at the

interval specified in ‘INTERVAL’ parameter below.

SINGLE – Prints only the currently measured reading

This parameter applies when PRIN key is pressed from

measurement mode to send the currently measured

readings to the computer.

Time interval at which the meter should send currently

measured data to the printer/CyberComm/PCD

Acceptable range : 3 sec to 600 sec (in 3 sec steps)

(This parameter is applicable when ‘CURRENT DATA

SET’ is set to ‘TIMED’ and this is not editable when

‘CURRENT DATA SET’ is set to ‘SINGLE’)

Indicates serial communication settings in the format of

‘Baud rate, Data bits-Parity bits-Stop bits’. This

parameter is not editable.

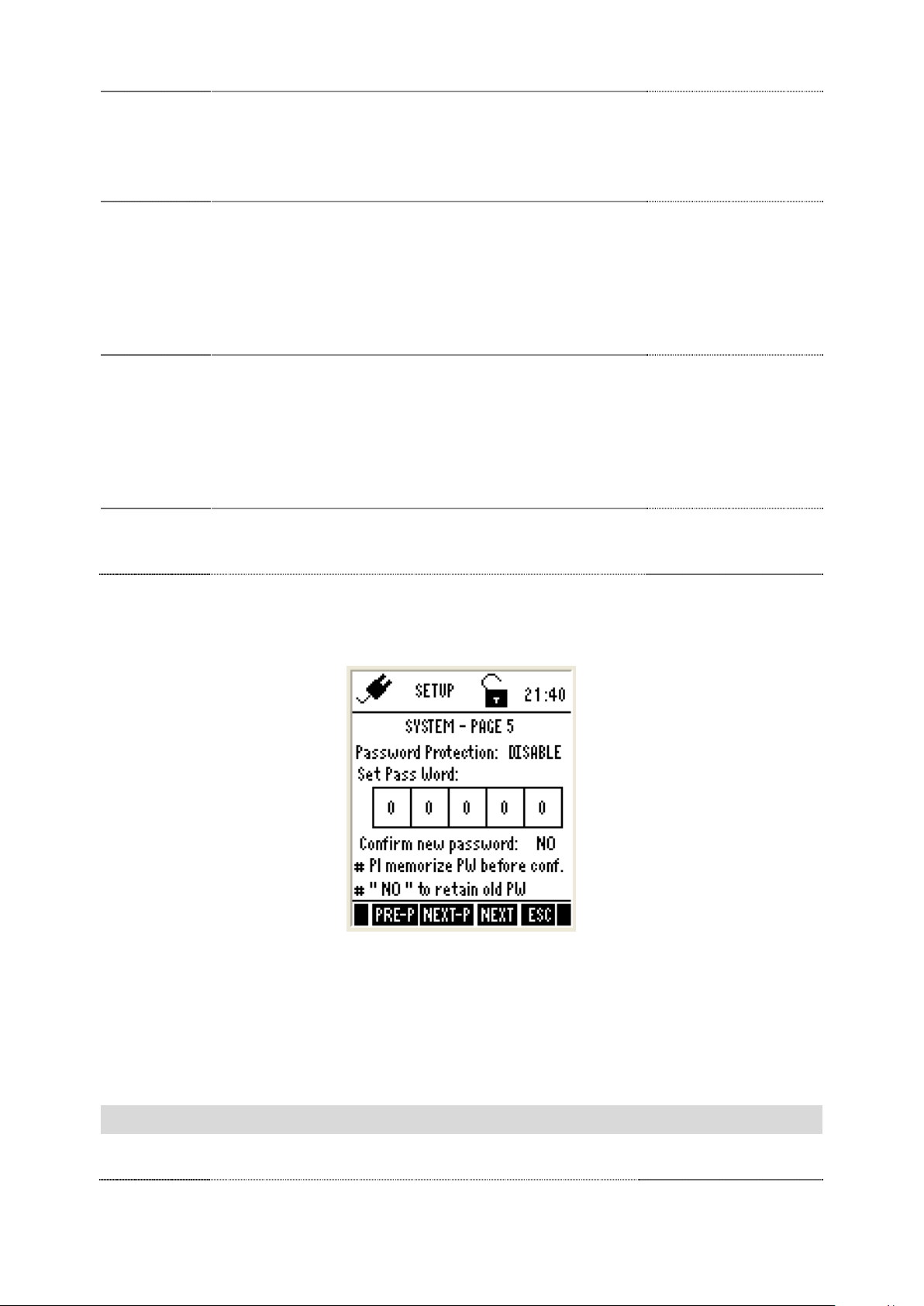

System Settings Page 5 – Password Protection

This allows you to enable password protection for the setup mode & calibration

mode:

Figure 6: System Settings Page 5 – Password Protection

When you enable password protection, the meter prompts you to enter the password

whenever you try to access the Setup or Calibration mode. The meter does not allow

you to edit setup parameters or perform a new calibration unless you enter the

correct password. If an incorrect password is entered for 3 consecutive times, the

meter goes to measurement mode.

Parameter Description Factory Default

Password

Protection

ENABLE – Sets password protection for the setup &

calibration mode. If this is enable you need to specify

13

DISABLE

a 5-digit password in the ‘SET PASSW ORD’

parameter below

Set Pass

Clear logged Data Memory: NO

Display Contrast: 12

Factory Reset: NO

DISABLE – Disable password protection of the meter

88888

NO

Word

Confirm New

Password

Specify your 5-digit password here. Use (Up) &

(Down) key to select a number and then press ENTER

key to confirm and move to the next digit.

Do not set your password to ‘00000’ as this is

reserved for ‘read-only’ password.

(This parameter is not editable when ‘PASSWORD

PROTECT’ is disabled)

YES – Select this if you have made changes to the

password and you wish to confirm the changes.

NO – Select this if you wish to ignore the changes

made to the password and to store the default

password.

1. Please memorize the password that you have entered after enabling the

password protection. Without it, you can’t disable the password protection or

reset the meter to factory defaults. However, if the user forgets his

password, he can contact the nearest distributor or Eutech

Instruments/Oakton Instruments to request for meter password. This

would be unique to each instrument and would be tied to the serial number of

the unit.

2. Default password ‘88888’ is valid only if it is not changed with new password.

3. You can enter ‘00000’ ( r ead-only password) if you wish to view the setup

parameters. You are not allowed to modify any parameter when you enter

‘read-only password’.

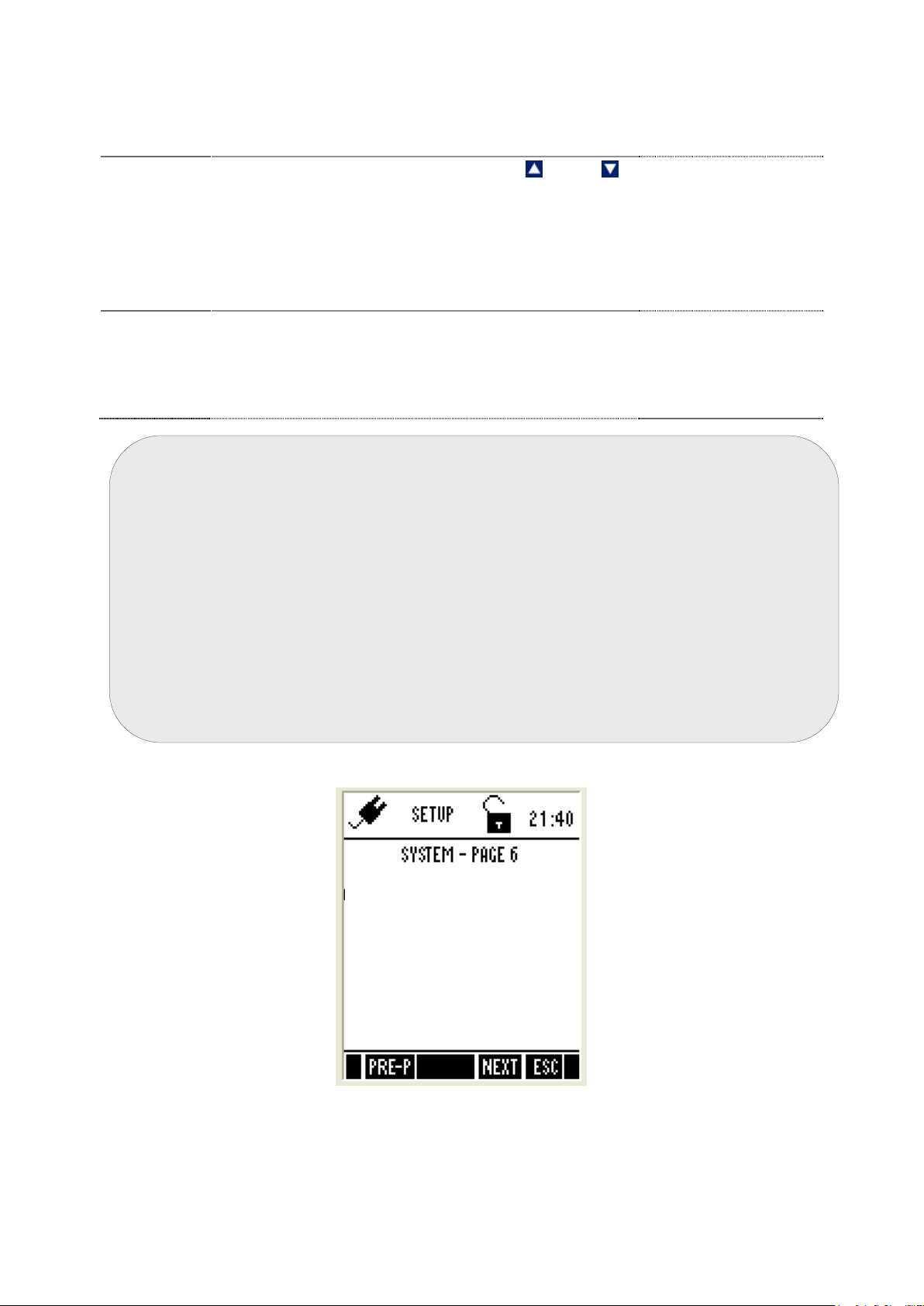

System Settings Page 6 – Data Memory & Factory Settings

Figure 7: System Settings Pag e 6 – Data Memory, Display Contrast & Factory Settings

This allows you to clear the memory, display contrast an d reset the meter to factory

defaults.

14

Note: You can enter ‘00000’ (read-only password) if you wish to view the

Parameter Description Factory Default

Clear logged

Data Memory

Display

Contrast

Factory Reset

YES – Select this to clear all the stored data from the

meter’s memory

NO – Select this if you do not wish to clear the stored

data from the meter’s memory

Adjust display contrast from 1 - 25 12

Press ENTER if you wish to reset the meter to its

factory default settings. This includes:

Deleting your calibration data

Resetting setup parameters to factory defaults

(except date & time)

Deleting your stored data in the memory

Press ESC if you do not wish to reset the meter.

NO

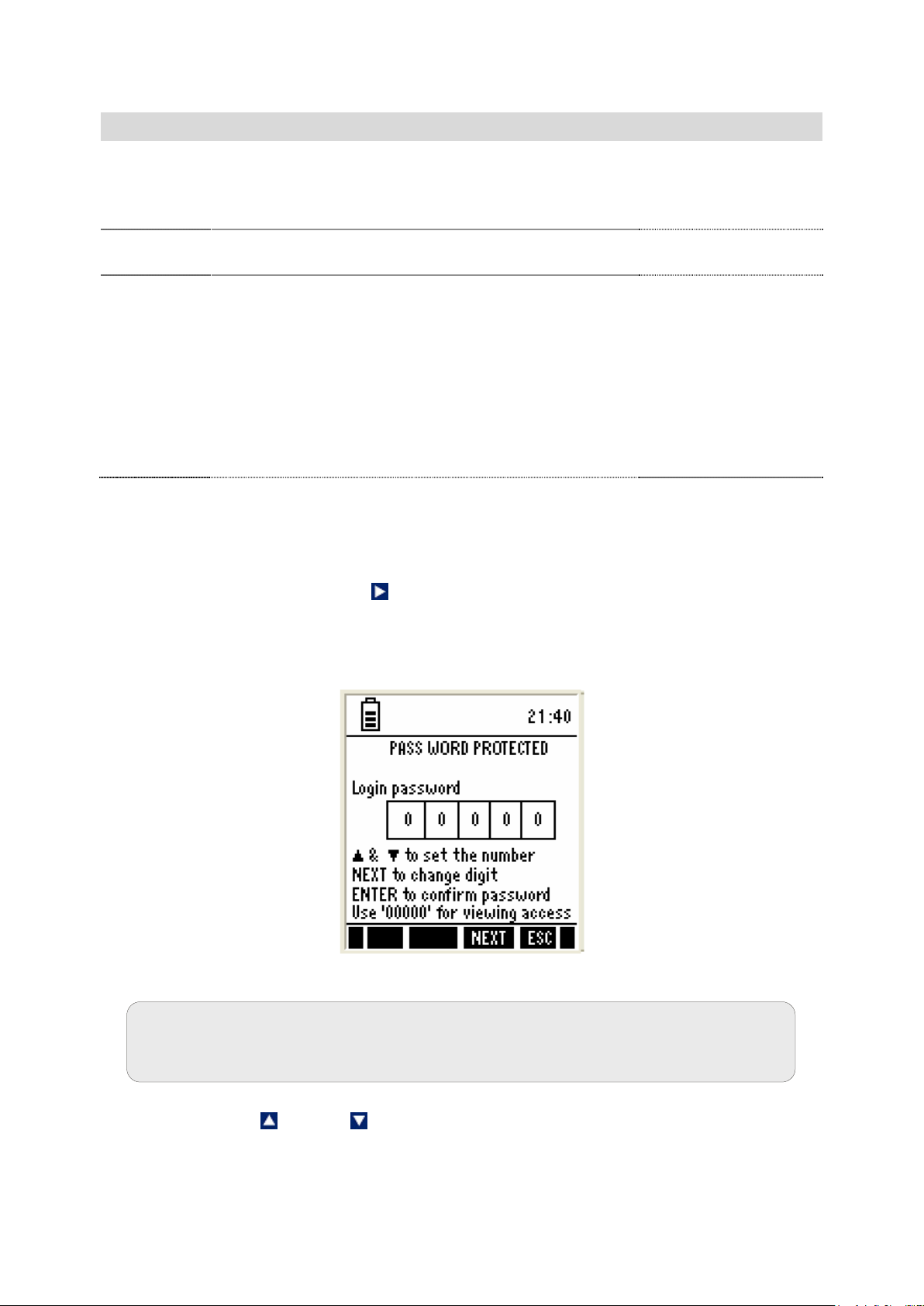

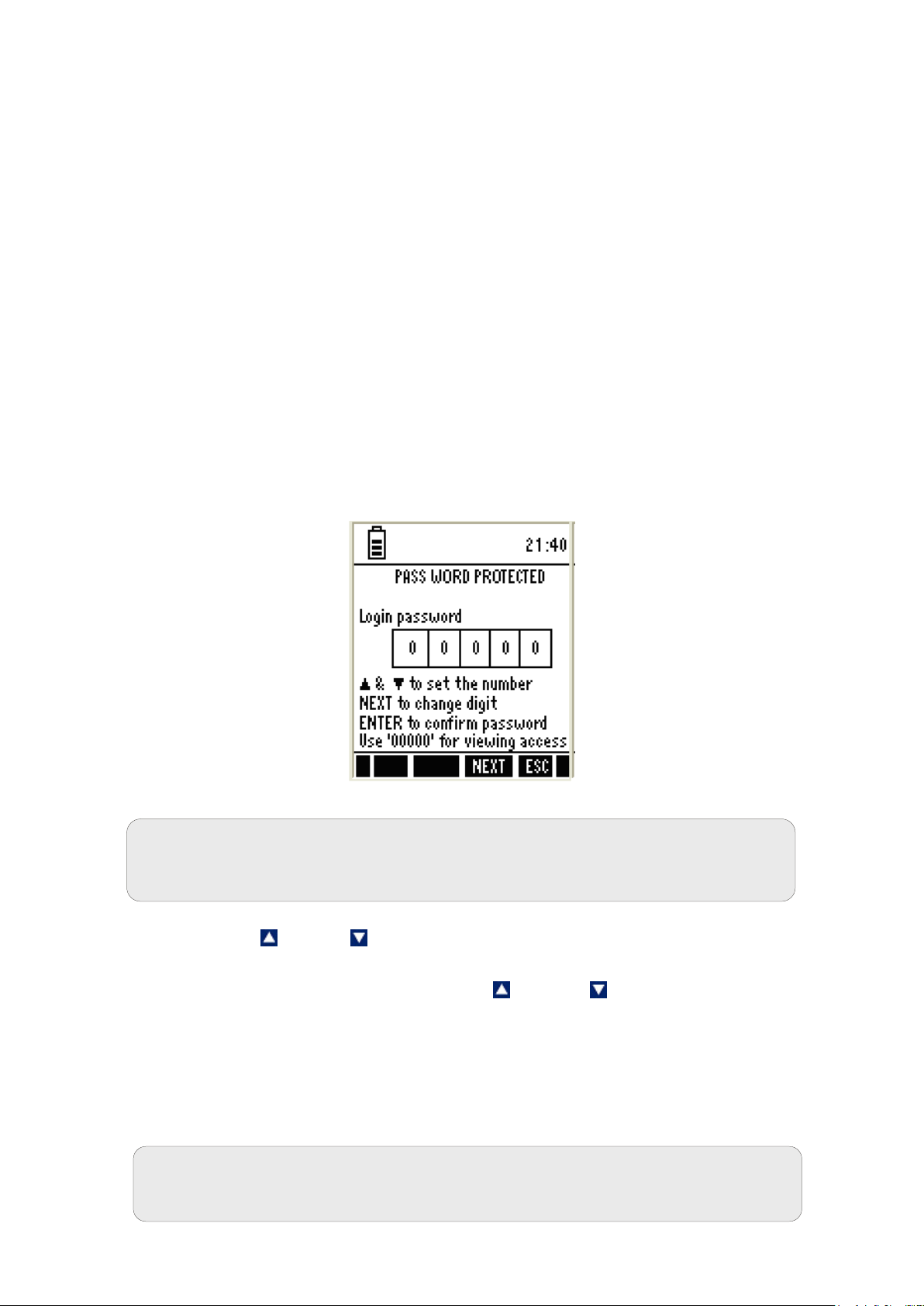

2.4 Accessing Setup mode when password protection enabled

1. Switch the meter on. The meter goes to measurement mode.

2. Press right arrow key to navigate to other functions on the right-side of

LCD.

3. Press SETP (F 1) to go to Setup mode. Login password screen appears. The

meter expects the 5-digit password specified in system setup.

Figure 8: Login Password

setup parameters. You are not allowed to modify any parameter when

you enter ‘read-only password’.

1. Press up & down arrow keys to enter the first digit of the password and

then press NEXT (F3) key to move to the next digit.

15

2. The next digit is selected. Press up & down arrow keys to enter the

Note: If you enter an incorrect password, the screen shows “Try Again”. If

second digit of the password. Enter all 5-digits.

3. Press ENTER key to confirm the password.

an incorrect password is entered three consecutive times, the meter goes

into measurement mode. If you forget the password, there is no way to

access the system setting and calibration. Please contact your authorised

dealer for assistance.

1. When the correct password is entered, the Setup Key Function Screen

appears.

2. Press Enter key to launch Setup Selection Screen. Press up or down

arrow key to go to required setup sub-group.

3. Press ENTER key to select the sub-group.

2.5 Modifying Setup parameter s

1. Press NEXT (F3) key to select individual setup parameters sequentially.

2. Press (Up) or (Down) arrow key to change the value of a selected

parameter.

3. Once you have changed a value:

• Press ENTER key to save the change, or

• Press NEXT (F3) key to go to the next parameter without saving the

changed parameter.

4. Press NEXT-P (F2) or PRE-P (F1) to navigate to next or previous page.

5. Press ESC (F4) to exit from setup mode.

(Refer to Page 9 for current function keys settings)

16

3. Calibration Mode For All Meters

3.1 About Calibration

The 600 series meters are factory calibrated and allows you to measure

pH/mV/ion/conductivity/resistivity/TDS/salinity/DO(%)/DO(mg/L) respective to

the model(s) you have purchased. Calibrate to all measurement ranges to

ensure the highest accuracy in any given m easurement range. This should be

done before you make measurements for the first time and also each time a

new electrode is attached to the meter or when you suspect that the

meter/electrode is out o f calibr ation.

3.2 About Conductivity/ Resist ivity/ TDS/ Salinity Calibration

Before measuring conductivity, resistivity, TDS or salinity, you will need to

calibrate the meter with known conductivity, resistivity, TDS or salinity values.

The meter is capable of performing either automatic or manual calibration.

In the automatic calibration mode, the meter automatically detects and verifies

the appropriate known calibration standards solutions being calibrated before

accepting these particular calibration standards as one of its calibration values

in a specific measurement range. This automatic calibration mode frees you

from cumbersome calibration procedure.

The meter can perform a single- or multi-point calibration. You will need to set

your meter to single- or multi-point calibration in the Setup mode for

conductivity, resistivity, TDS or salinity.

Refer to the setup section for the particular mode you will be measuring. Instead

of calibrating for TDS directly using TDS calibration standard solutions, you can

have TDS calibration by using the conductivity calibration method and enter the

appropriate TDS conver si on fac tor int o the m eter .

For more information regarding TDS Conversion Factor determination, please

go to the ‘Appendix’ of this manual.

3.3 Preparing the Meter for Calibration

Before starting calibration, make sure the meter is in the appropriate

measurement mode.

For pH

Connect the pH probe to the BNC connector of the meter.

Be sure to remove the protective electrode storage bottle or rubber cap of the

electrode before calibration or measurement. If the electrode has been stored

dry, wet the electrode in clean water for 10 minutes before calibrating or taking

readings to saturate the pH electrode surface and m inimize drift.

Wash your electrode in clean water after use, and store in electrode storage

solution. If storage solution is not available, use pH 4.01 or 7.00 buffer solution.

Do not reuse buffer solutions after calibration. Contaminants in the solution can

affect the calibration, and eventually the accuracy of the measurements.

17

It is recommended that you perform at least a 2-Point Calibration using

standard buffers that adequately cover the expected measurement range, prior

to measurement.

For Ion

Connect the ISE to the BNC connector of the meter.

Remove plastic protective cap of ISE. Briefly rinse the electrode with clean

water to remove any residues. Rinse ISE before and after each calibration or

sample measurement to avoid cross-contamination. Ensure that you use new or

fresh standard solutions during calibration. Do not reuse Ion standard solution

as it may be contaminated and affect the calibration and accuracy of

measurements.

For Conductivity

Connect the conductivity probe with built-in temperature sensor into the 8-pin

connector of the meter.

For best results, select a standard value close to the sample value you are

measuring. Alternatively use a calibration solution value that is approximately

2/3 the full-scale value of the measurement range you plan to use. For example,

in the 0 to 2000 µS conductivity range, use a 1413 µS solution for calibration.

Perform calibration for all measurement ranges to ensure the highest accuracy

throughout all measurement range.

If you are measuring in solutions with Conductivity lower than 100 µS/cm or

TDS lower than 50 ppm, calibrate the meter at least once a week to ensure

accuracy. If you are measuring in the mid ranges and you wash the electrode in

de-ionized water and store it dry, calibrate the meter once a month. If you take

measurements at extreme temperatures, calibrate at least once a week.

Ensure that you use new conductivity standard solutions or sachets during

calibration. Do not reuse standard solutions as it may be contaminated and

affect the calibration and accuracy of measurements. Use fresh calibration

solution each time you calibrate your meter. Keep solutions in a dry and cool

environment if possible.

For DO(%) and DO (mg/L) Calibration

Before starting calibration, make sure you are in the correct measurement mode

and in the correct calibration sequence. The temperature and the %

Saturation calibration must be done first before attempting to do the mg/L

(ppm) Concentration calibration.

Rinse the probe well in the de-ionized (DI) water or rinse solution and wipe the

probe carefully taking care of the membrane.

Calibrate the meter in all the modes to ensure the highest accuracy throughout

the DO measurement range. In % Saturation, the meter is able to perform either

a one point calibration or a 2 point calibration. For one point calibration, it is

recommended that you perform a 100% Saturation calibration in saturated air. If

you opt for 2 point calibration, you can calibrate for 100% Saturation in

saturated air and 0% Saturation using a zero oxygen solution.

18

All new calibration values will automatically override the existing data. It is

Note: You can enter ‘00000’ (read-only password) if you wish to view the

calibration when you enter ‘read-only password’.

Note: If you enter an incorrect password, the screen shows ‘Try again’. If

to measurement mode.

recommended to calibrate the meter periodically and or if it is suspected to be

inaccurate.

Always rinse the probe with either DI water or rinse solution before and after

each calibration/sample measurement. When calibrating in air, make sure that

any water droplets from the probe’s membrane are removed.

3.4 Accessing Calibration mode

From measurement mode, press CAL (F2) key. The meter goes to

corresponding calibration mode, based on the selected measurement mode. If

the meter is password protected, you will be prompted to enter password.

3.4.1 Accessing Calibration mode when password protection enabled

1. Make sure you are in measurement mode. If required, press MODE (F3) to

switch to the measurement mode for which you wish to perform calibration.

2. Press CAL (F2) to go to calibration mode. Login Password screen appears

(Figure 9). The meter expects the 5-digit password specified in system

setup.

Figure 9 : Login Password

calibration report of the last calibration. You are not allowed to perform

1. Press up & down arrow keys to enter the first digit of the password and

then press NEXT (F3) key to move to the next digit.

2. The next digit is selected. Press up & down arrow keys to enter the

second digit of the passw or d.

3. Similarly enter all 5-digits.

4. Press ENTER key to confirm the password.

5. When the correct password is entered, the ‘Calibration – Rinse Electrode’

screen will appear.

an incorrect password is entered for 3 consecutive times, the meter goes

19

4. Measurement Mo de For All Meters

1st function group

2nd function group

3rd function group

4.1 About Measurement Mode

The following is the full range of measurement modes in the WP 600 series

meters:

Temperature measurement mode

pH measurement mode

mV measurement mode

Ion measurement mod e

Conductiv i ty measure men t mod e

TDS measurement mode

Salinity measurement mode

Resistivity measurement mode

O2 % - DO percentage satur ation measurement mode

O2 mg/L (ppm) - DO concentration mode

Only the PCD 650 model is equipped with all of them.

The meter automatically goes to the mode that was used before it was turned

off the last time. Press MODE (F3) key to select your required measurement

mode.

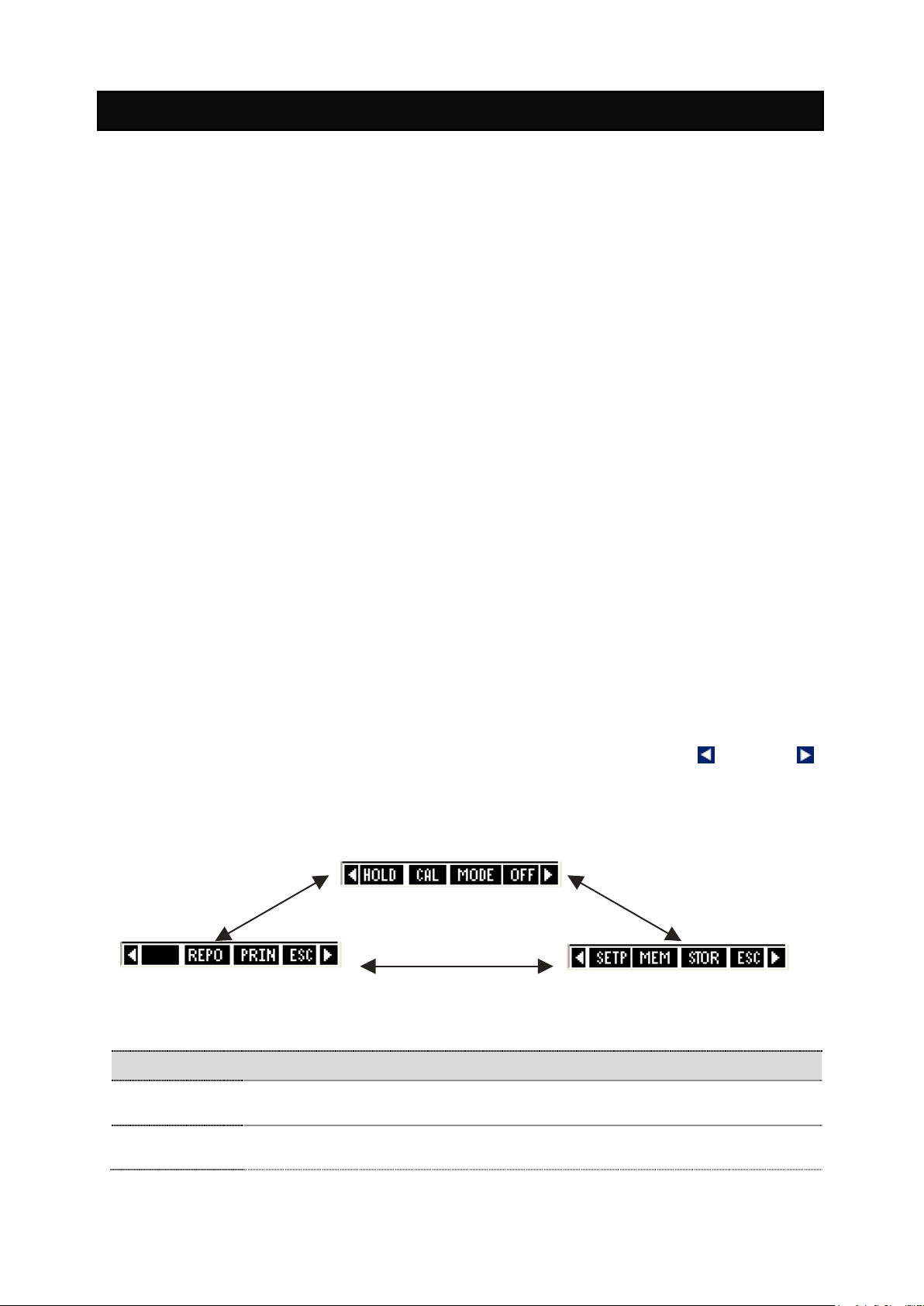

4.1.1 Accessing functions There are many functions available in the measurement mode. Use the 4

Function keys (F1, F2, F3 & F4) to access them. The f irst group of functions

appear when you enter the measurement mode. Press the left or right

arrow key to navi gate to the 2nd and 3rd function groups.

Function Keys available in measurement screen (1st Group):

HOLD (F1)

CAL (F2)

20

Holds the current reading in the display. The ‘HOLD’ indicator starts

blinking. Press HOLD key again to release the reading

Goes to corresponding calibration mode (based on the selected

measurement mode)

MODE (F3)

Switches between measurement modes

ENTER

MEM (F2)

ESC (F4)

OFF (F4)

Function Keys available in measurement screen (2nd Group):

SETP (F1)

STOR (F3)

ESC (F4)

Function Keys available in measurement screen (3rd Group):

REPO(F2)

PRIN (F3)

ENTER

Power off the meter (press and hold this key for 3 seconds)

Switches between functions groups available in measurement mode

(Not functional)

(Not functional)

Goes to setup mode

Shows stored data in the memory

Stores the currently displayed reading in the memory

Shows 1st Group of functions

Shows corresponding calibration report (based on selected measurement

mode)

Sends the currently displayed reading to the computer through IrDA. (This

key has to be pressed to establish communication with CyberComm PCD

application through IrDA). If data logging mode has been selected in

System Setup then it sends data automatically to meter’s memory.

Shows 1st Group of functions

Switches between functions groups available in measurement mode

(Not functional)

(Not functional)

Note: If you press a function key that is not relevant to measurement mode (for

example ENTER, , ) the meter shows ‘Invalid key!’ message in the footer

area of the screen as shown here.

Figure 10 : Invalid Key Prompt

4.2 Taking Measurements

4.2.1 Prepare the meter for measurement

Perform a calibration test if you change to a new probe and connect the probe

to the meter before measuring .

4.2.2 Taking a reading

1. Press ON (F4) key to switch the meter on. Hold for 3 seconds.

2. Press MODE (F3) to select your required mode.

3. Dip the appropriate probe into the sample solution.

4. The LCD shows a ‘Stable’ indicator if this feature was enabled during the

setup. Note the reading.

21

4.2.3 Stable reading indicator

Note: The factory default value for normalization temperature is 25°C.

You can configure the meter so that LCD displays a ‘Stable’ indicator when the

reading does not vary for 2 consecutive seconds. The amount of variations

allowed can be set at ‘Slow’, ‘Medium’ or ‘Fast’.

4.2.4 Holding a reading In some situations, you may want to freeze (hold) the measured reading in the

LCD for a delayed observation. You can hold a reading in two different ways:

Manual Hold – Allows you to hold the reading by pressing HOLD (F1) key at

any time you want. When you hold a reading, the ‘HOLD’ indicator starts

flashing. The readings (including temperature reading) will be held until you

press any other key again.

Auto-Hold –The meter automatically holds the reading if it is ‘Stable’ for 5

consecutive seconds. This feature needs to be enabled in the setup. Press

HOLD (F1) key to release the reading.

4.3 Automatic Temperature Compe ns a ti on (ATC)

Connect an appropriate probe to the meter and select ‘ATC mode’ in the

temperature setup for the pH/ conductivity/ DO reading to be automatically

compensated for temperature variations.

If you select ‘ATC’ without connecting a probe to the meter, the LCD will show

the word ‘UNDER’ for temperature reading.

Figure 11: Under Range

4.3.1 Manual Temperature Compensation (MTC) If an ATC probe is not available, you can choose to manually compensate for

the temperature. This is suitable when the temperature of your sample is

sufficiently stable. Select ‘MTC mode’ in the temperature setup. Press CAL

(F2) and then press NEXT key. Press TEMP (F1) to go to temperature

calibration. Enter the temperature value of your sample.

22

Loading...

Loading...