Thermo Fisher Scientific CyberScan 6000 User Manual

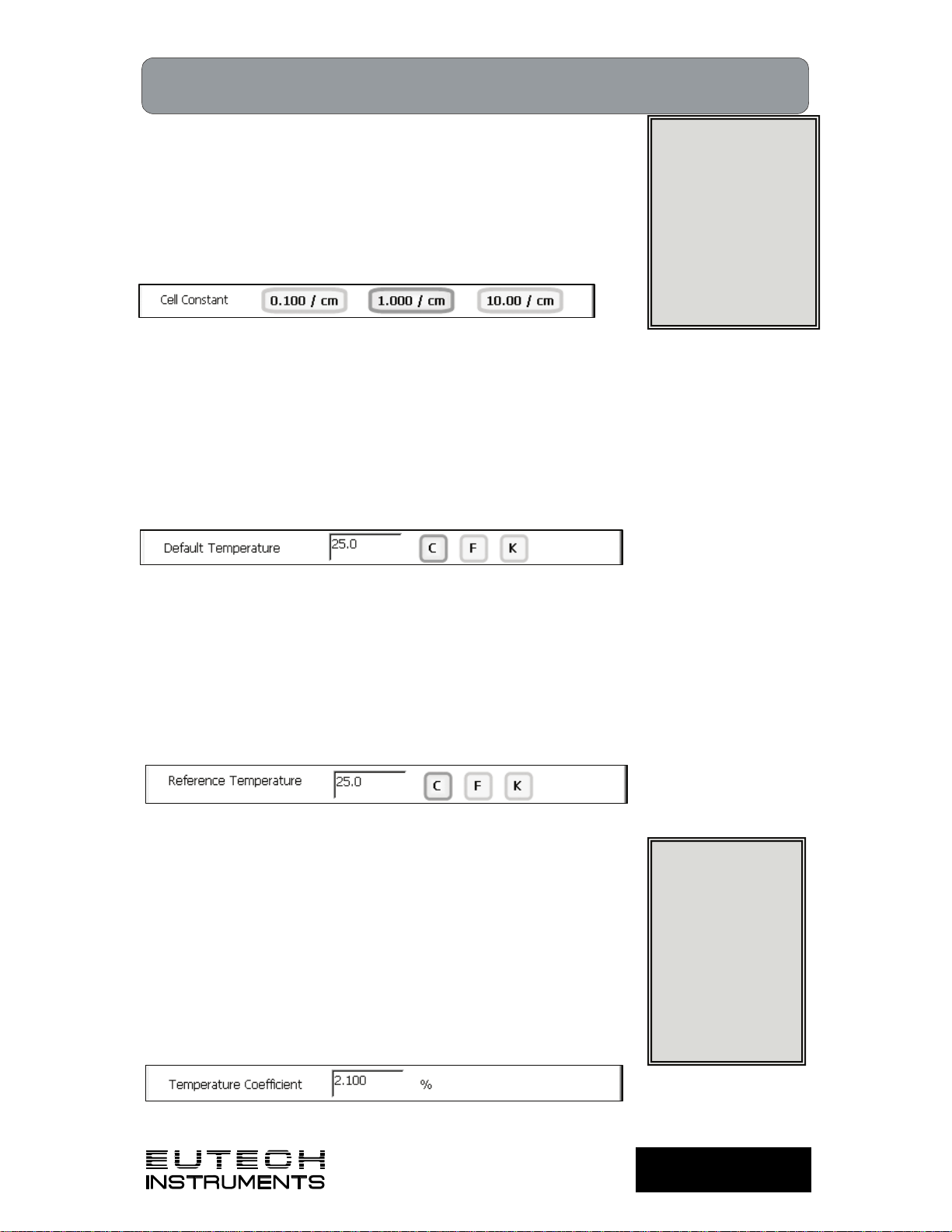

Conductivity Setup: Select Reference Temperature

gyM

y..

.

PC6000, CON6000, PC6500 and PCD6500 meters

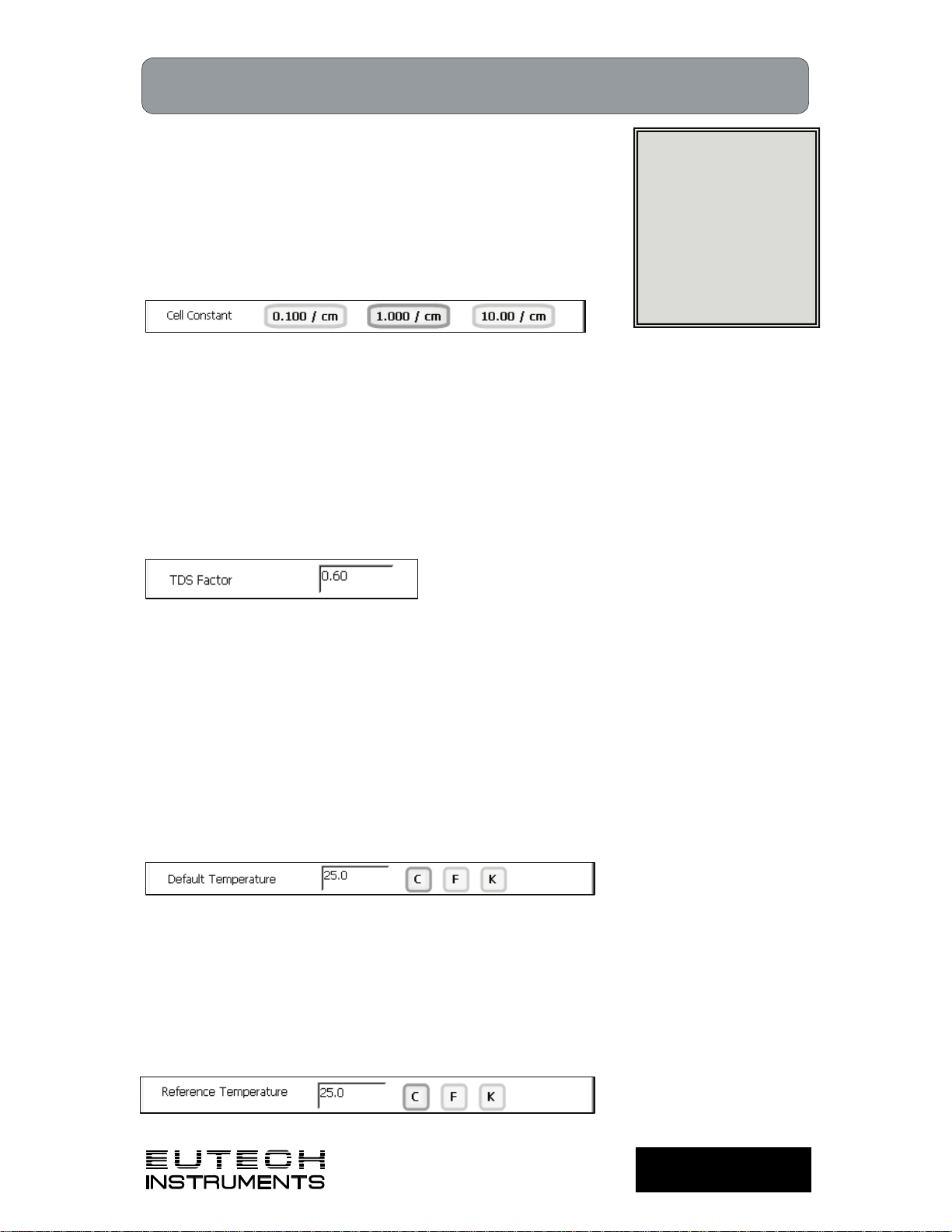

Set Default Temperature

Conductivity is a temperature dependent measurement. This option allows you to select a default

temperature that the meter will use along with the temperature coefficient to calculate a

temperature corrected conductivity measurement.

If an ATC probe is used any value entered as a default temperature will be overridden in favor of

the actual measured temperature of the solution provided to the meter by the ATC probe.

The default temperature can be set from -10°C to 110°C.

To set Default Temperature

1. Select temperature units by touching the appropriate unit button: C (Celsius), F

(Fahrenheit) or K (Kelvin).

2. Touch the Default Temperature box and use the numeric keypad to enter the desi red

default temperature (-10°C to 110°C).

3. Press Enter in the keypad to return to conductivity Setup screen.

Conductivity cells provided have a built-in Temperature sensor.

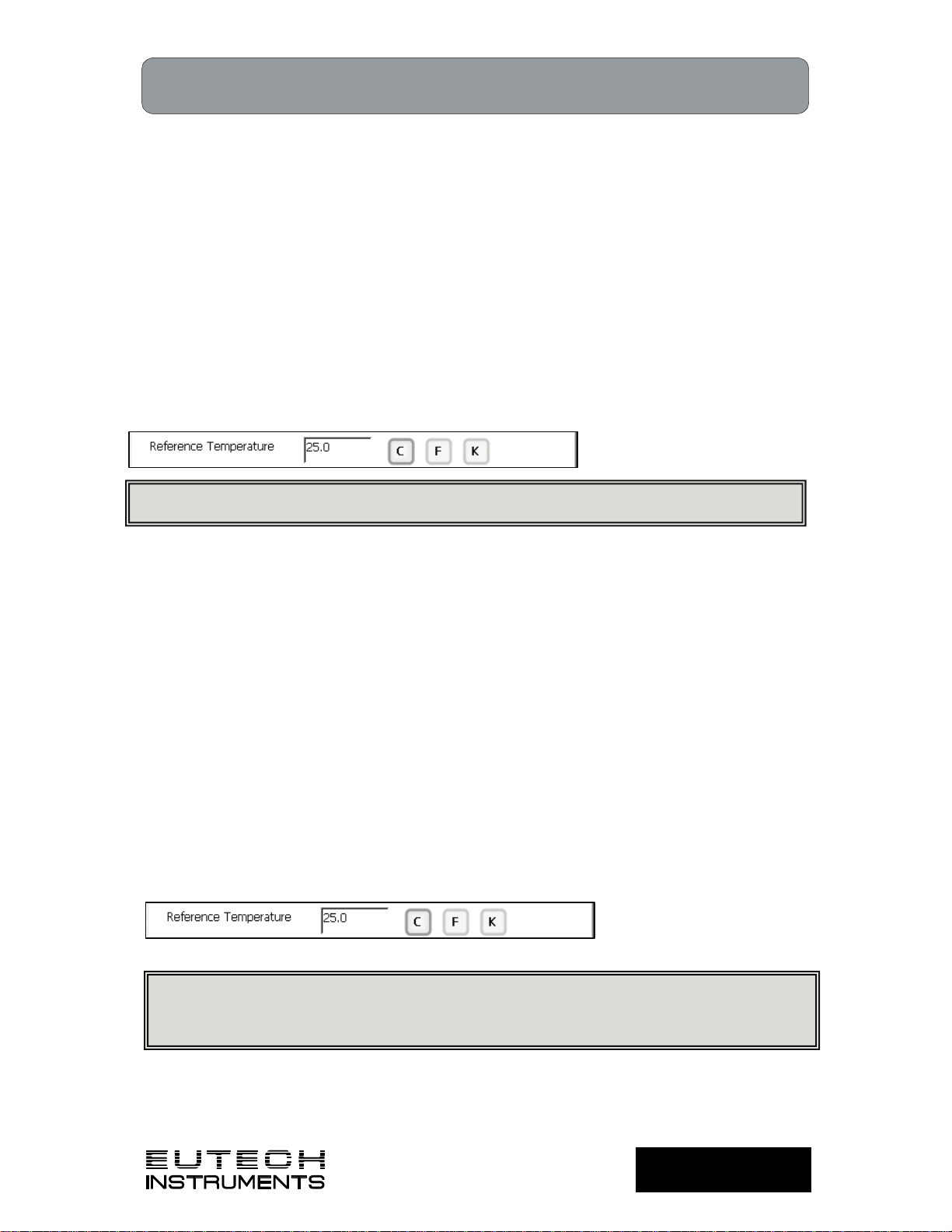

Set Reference Temperature

This setup option allows you to select the reference temperature to be used in the determination

of the conductivity of your sample. The reference temperature is the temperature to which the

conductivity readings would be normalized.

The reference temperature can be set from 15°C to 30°C.

To set Reference Temperature

1. Select temperature units by touching the appropriate unit button: C (Celsius), F

(Fahrenheit) or K (Kelvin).

2. Touch the Reference Temperature box and use the numeric keypad to enter the

desired default temperature (15°C to 30°C).

3. Press Enter in the keypad to return to conductivity Setup screen.

Note: The units of all temperature parameters must match. The meter will automatically

modify the temperature units of Default Temperature and Reference Temperature to match

the last choice made on any of these parameters.

Technolo

adeEas

86

Conductivity Setup: Set Alarm Limits

gyM

y..

.

PC6000, CON6000, PC6500 and PCD6500 meters

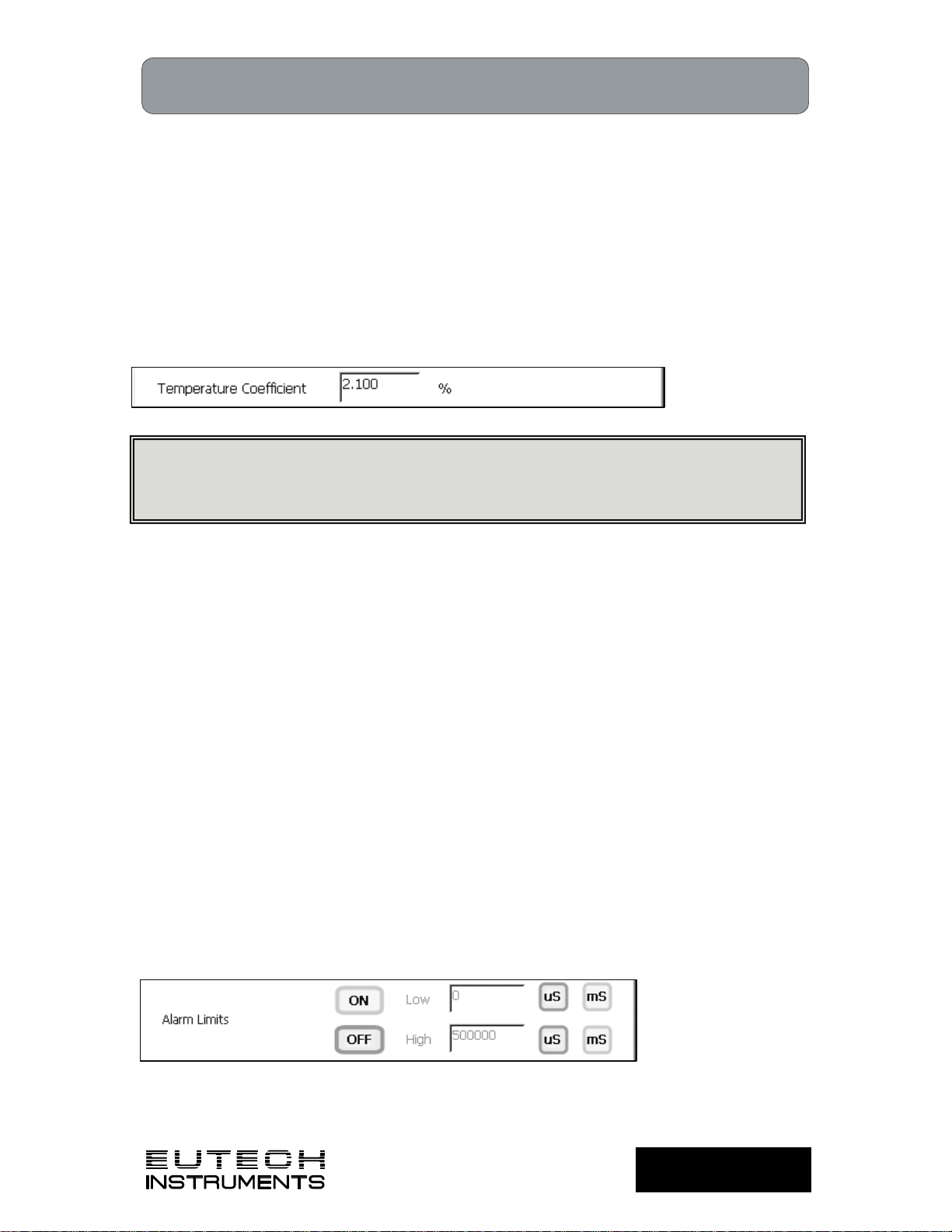

Set Temperature Coefficient

The temperature coefficient is a value that reflects the degree to which the sample’s conductivity

is effected by temperature changes. The meter will use the set temperature coefficient along with

the measured temperature provided by the ATC probe to calculate what the conductivity would be

at the selected reference temperature. If no ATC probe is being used, the meter will use the set

default temperature in the calculation.

The temperature coefficient can be set from 0 to 10.000%.

To set Temperature Coefficient

1. Touch the Temperature Coefficient box and use the numeric keypad to enter the

desired default temperature (0 to 10.000).

2. Press Enter in the keypad to return to conductivity Setup screen.

NOTE: The meter and probe with ATC will measure temperature even if the temperature

coefficient is set to 0.0%, however a temperature correction will not be applied to the

measurement.

Set Alarm Limits

This option allows you to set alarm limits for the conductivity measuring mode. If the conductivity

value of the measurement is outside of the boundaries set by the minimum and maximum limits,

audible and visual warnings will let you know that your sample measurement was outside of the

set limits.

The Alarm Limit can be set from 0.0 uS to 500000.00 uS.

To set Alarm Limits

1. Touch ON or OFF to set the status of the alarm of conductivity mode

2. Touch the Low box and use numeric keypad to enter the new limit values.

3. Touch Enter on the keypad to accept this limit and return to the conductivity Setup

screen.

4. Touch uS or mS to select conductivity units of low alarm value.

5. Touch the High box and use numeric keypad to enter the new limit values.

6. Touch Enter on the keypad to accept this limit and return to the conductivity Setup

screen.

7. Touch uS or mS to select conductivity units of high alarm value.

Technolo

adeEas

87

Conductivity Setup: Set Print Criteria

gyM

y..

.

PC6000, CON6000, PC6500 and PCD6500 meters

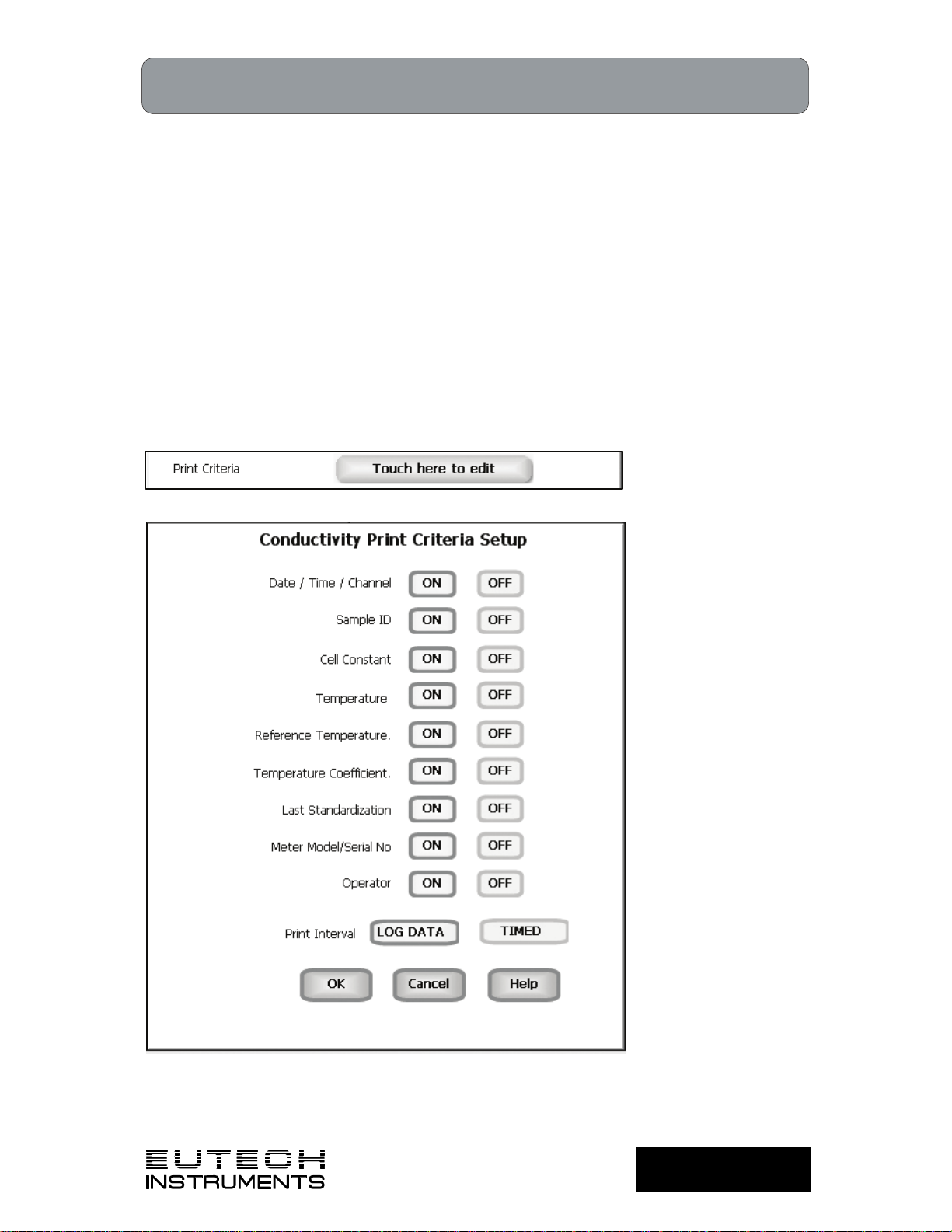

This screen allows you to select which criteria are printed with the measurement when you print

the data or send it to a computer. The status of the current print criteria is displayed on the

screen. The criteria option is active if ON appears to the right of the option. It is inactive if OFF

appears to the right of the option. Any active criteria will be printed on demand.

To set Print Criteria

1. Touch the Touch here to edit button next to the Print Criteria to access the Conductivity

Print Criteria Setup screen.

2. Touch ON or OFF to change the status of a criteria you want to modify.

3. Repeat step 2 for all the remaining criteria except Print Interval (or Print Option).

4. For Print Interval (or Print Option), select between Log Data and Timed. If “Log Data” is

selected, clicking on the “Print” button from the Measurement screen will send the logged

data to the printer. If “Timed” is selected, you can print data at an interval you select. This

data is buffered and is sent to the printer when the page is full.

5. Touch OK button to accept the changes of the entire group of print criteria and return to

the conductivity Setup screen.

Technolo

adeEas

88

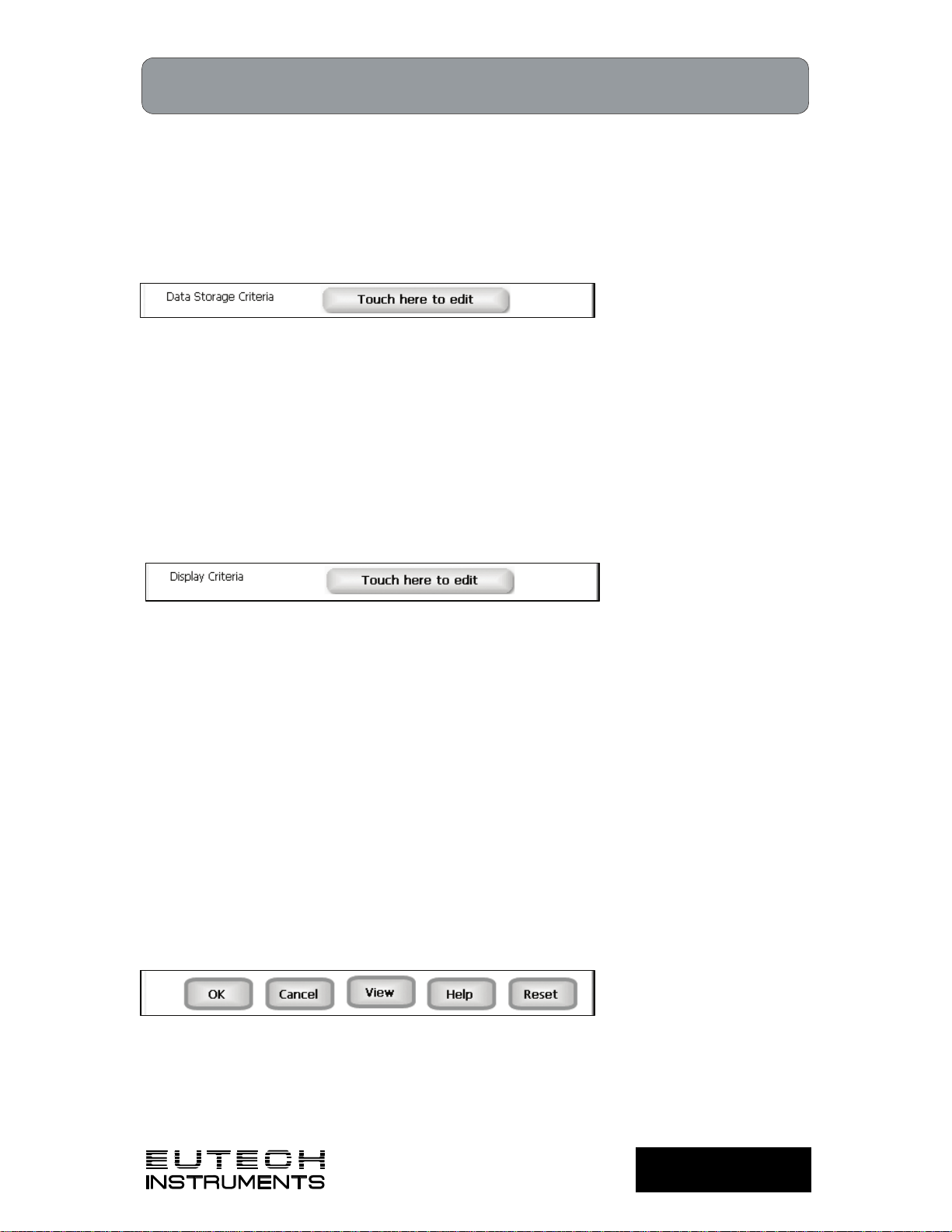

Conductivity Setup: Data Storage Criteria

gyM

y..

.

PC6000, CON6000, PC6500 and PCD6500 meters

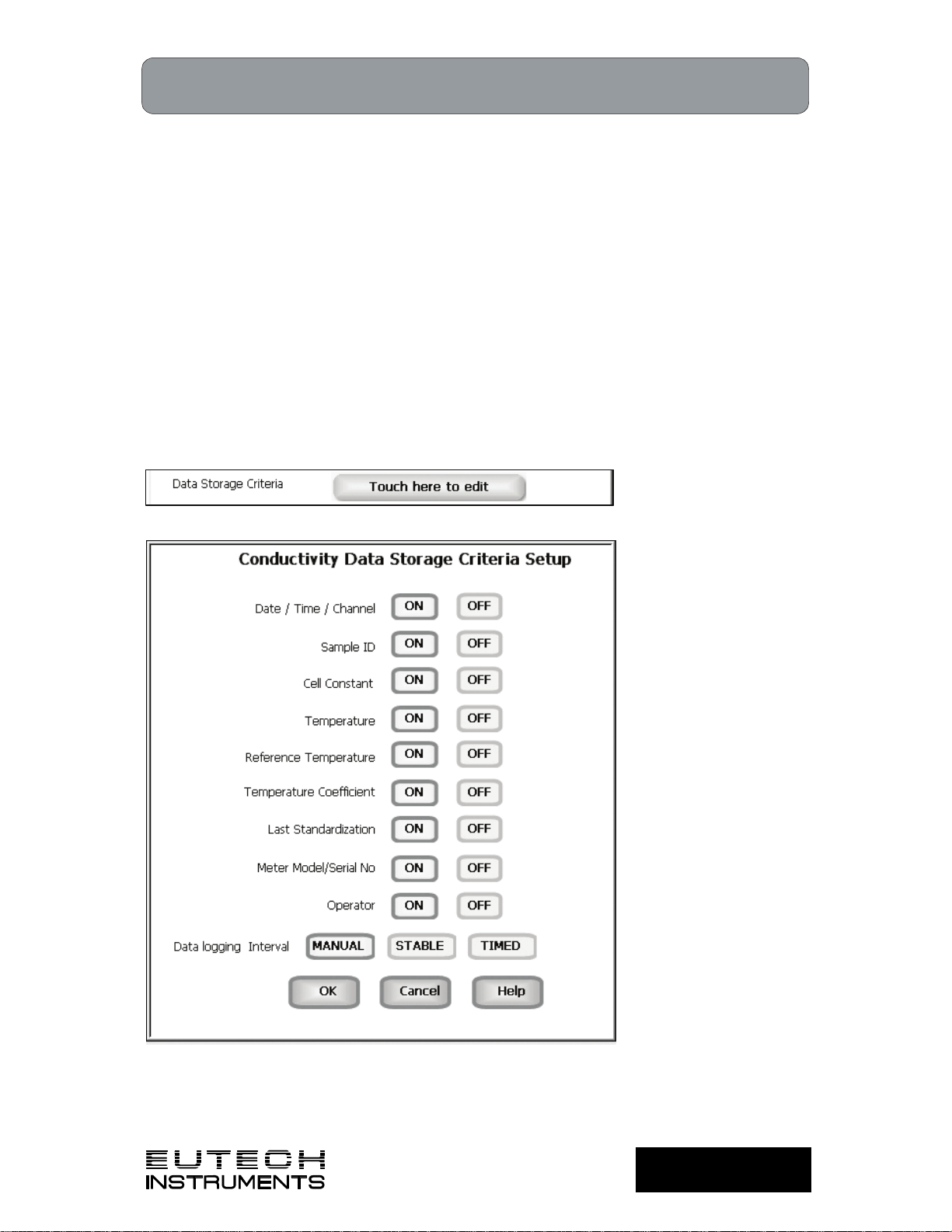

This screen allows you to select which criteria are stored in the data logger with the measurement

when you store the data .The status of the current data storage criteria is displayed on the

screen. The criteria option is active if ON appears to the right of the option. It is inactive if OFF

appears to the right of the option. Any active criteria will be stored on demand.

To set Data Storage Criteria

1. Touch the Touch here to edit button next to the Data Storage Criteria to access the

Conductivity Data Storage Criteria Setup screen.

2. Touch ON or OFF to change the status of a criteria you want to modify.

3. Repeat step 2 for all the remaining criteria except Data logging Interval (Data storage

Interval).

4. For Data logging Interval (Data storage Interval), touch MANUAL to log conductivity data

only when the Log Data button is pushed, touch STABLE to automatically log

conductivity data when conductivity reading is stable, or touch TIMED to set a specific

timed interval in seconds to log conductivity data.

5. Touch OK button to accept the changes of the entire group of data storage criteria and

return to the conductivity Setup screen.

Technolo

adeEas

89

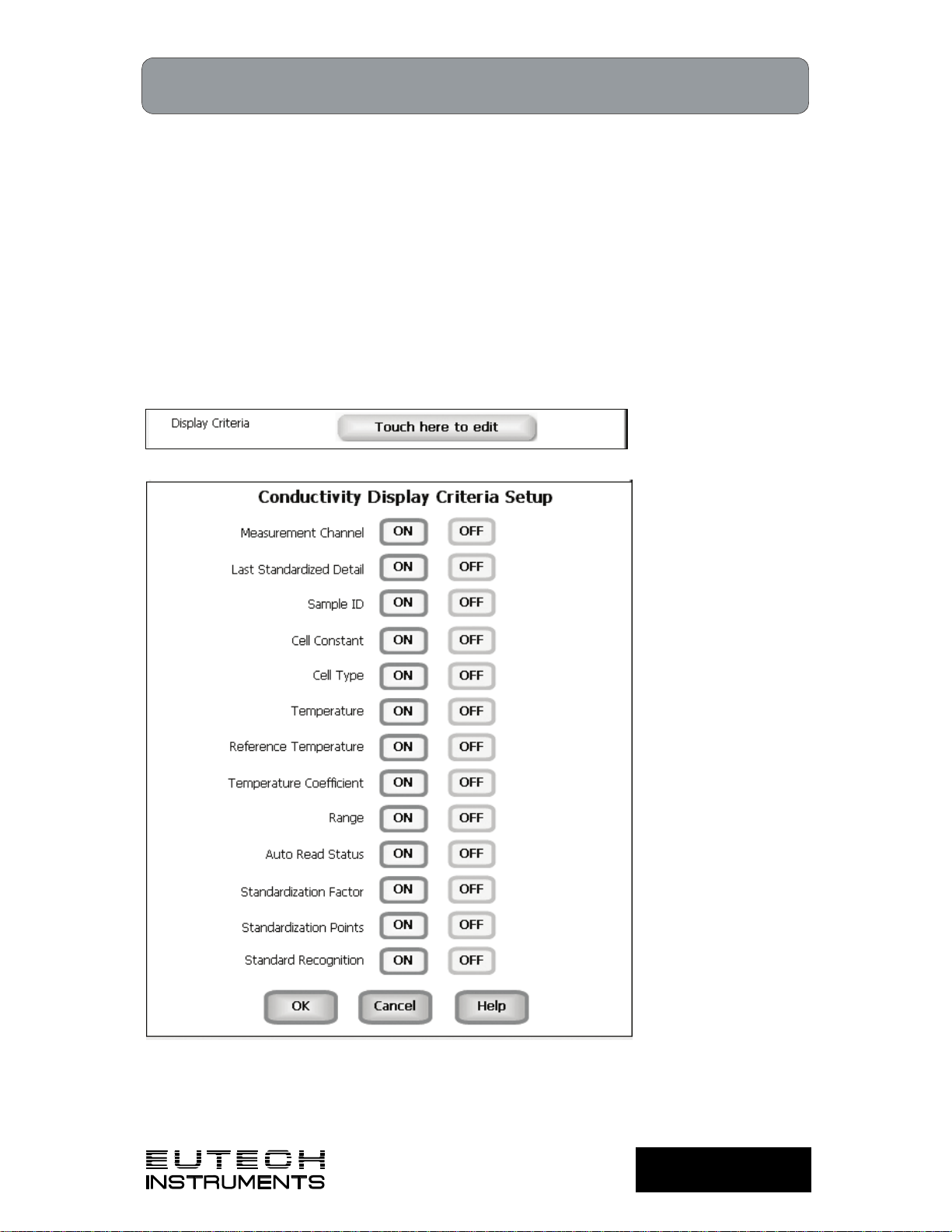

Conductivity Setup: Set Display Criteria

gyM

y..

.

PC6000, CON6000, PC6500 and PCD6500 meters

This screen allows you to choose what information you would like to be displayed on the

conductivity Measure screen, particularly the information contained in the data box at the bottom

of the Measurement screen. The status of the current display criteria is displayed on the screen.

The criteria option is active if ON appears to the right of the option. It is inactive if OFF appears to

the right of the option.

To set Display Criteria

1. Touch the Touch here to edit button next to the Display Criteria to access the

Conductivity Display Criteria Setup screen.

2. Touch ON or OFF to change the status of a criteria you want to modify.

3. Repeat step 2 for all the remaining criteria.

4. Touch the OK button to accept the changes of the entire group of display criteria and

return to the conductivity Setup screen.

Technolo

adeEas

90

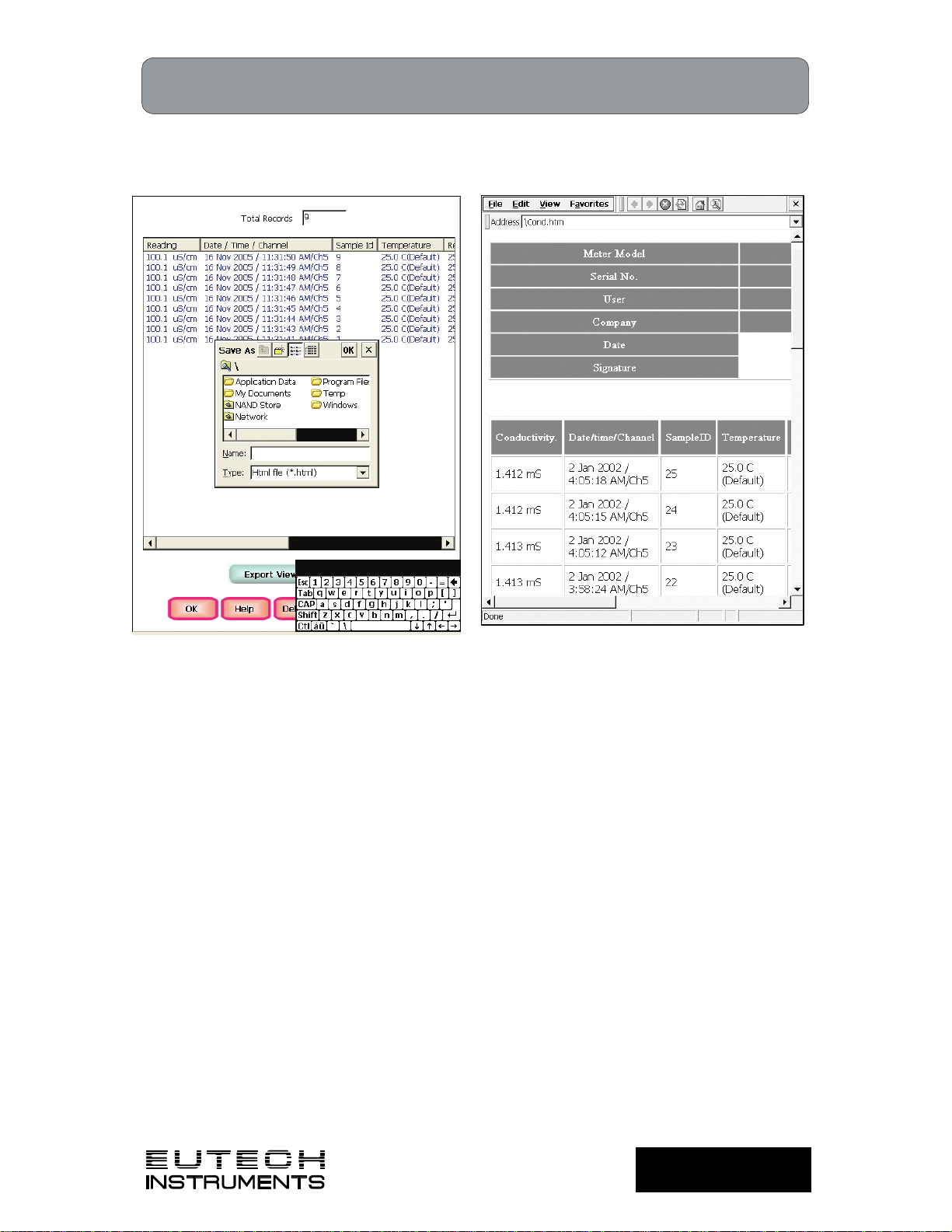

Conductivity Setup: View Stored Data

gyM

y..

.

PC6000, CON6000, PC6500 and PCD6500 meters

The PC6000, CON6000, PC6500 and PCD6500 have a memory capacity to store up to 1000

data points. The View Stored Data screen allows you to sort and look at specific data points

stored in the meter based on the meters memory capacity. The stored data can be sorted by any

of the parameters available in the screen header.

The meter stores conductivity data under the following parameters:

Reading Temperature Coefficient

Date / Time / Channel Cell Type

Sample Id Last Standardizations

Temperature Meter Model / Serial No

Reference Temperature Operator

To View Stored Data

1. Touch the View button in the conductivity Setup screen.

You can only log 1000 data points at a time. To clear space for new data points, you have to

delete the same number of old data points as you want to add new data points.

Function buttons on View Stored

Data Screen

Touch OK to go back to the Conductivity

Setup screen from the View Stored Data

screen.

When you touch the Help button, information

about the current screen appears. This

information includes step-by-step instructions

for operating the meter from the current

screen and possible applications information

for that screen.

Touch Delete to delete a selected data point

from the list. To delete a data point, first

touch the data point you want to delete then

touch the Delete button.

Touch Delete All to delete all the data point

in the memory.

Touch Print to print all the data points in the

memory.

See next page for Export View and Header

(or Export View) explanation.

Technolo

adeEas

91

Conductivity Setup: View Stored Data

gyM

y..

.

PC6000, CON6000, PC6500 and PCD6500 meters

Touch Export View and Header (or Export View) to save your data in HTML format. The file

can be stored in either the Nand flash, SD Card or any of the other available locations as shown

in the window. After having selected the path, touch the alphanumeric keypad to name your file.

Touch the alphanumeric keypad to name

your file.

Export view in HTML format

Technolo

adeEas

92

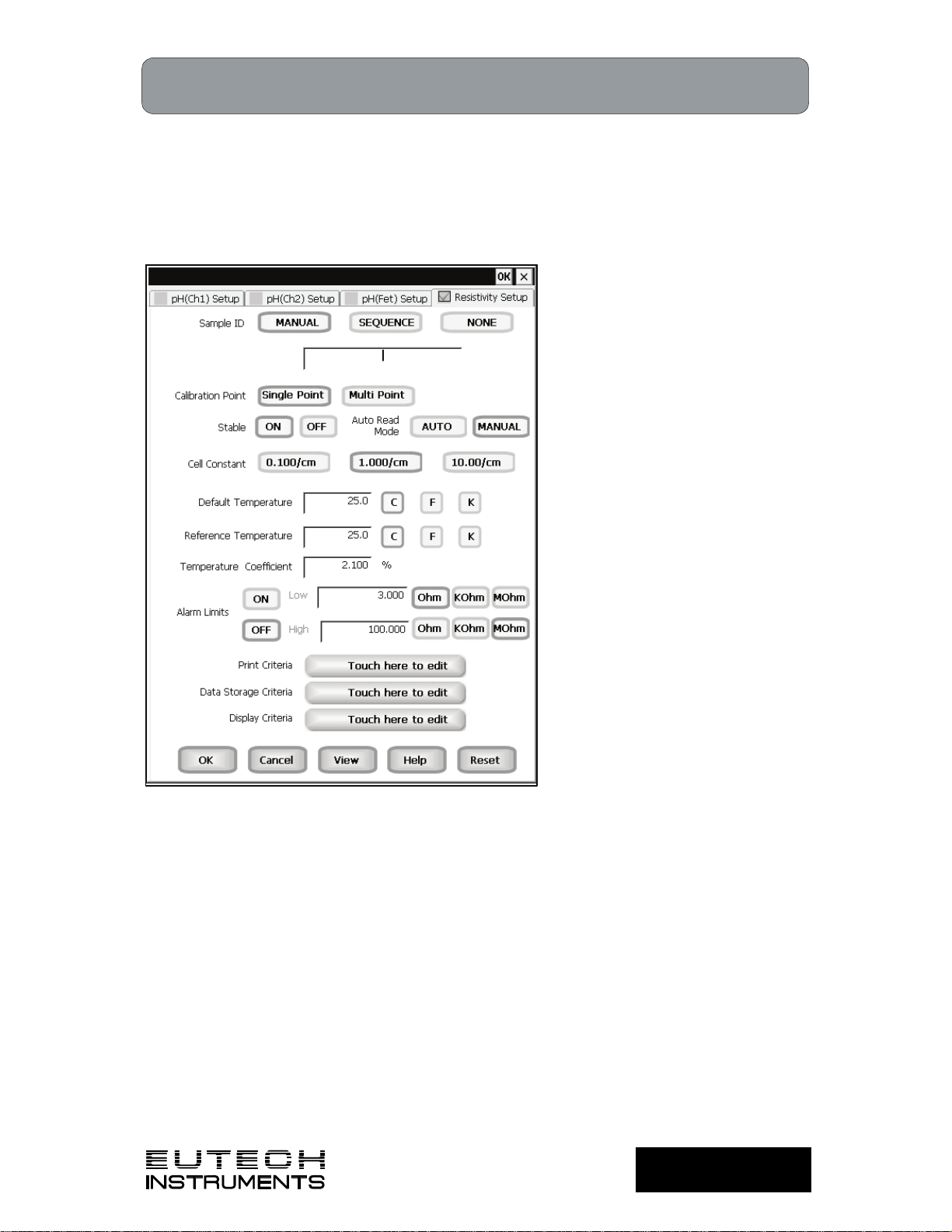

Resistivity Setup: Resistivity Setup Screen

gyM

y..

.

PC6000, CON6000, PC6500 and PCD6500 meters

Available in PC6000, CON6000, PC6500 and PCD6500 meters, the resistivity Setup screen

present many options to control the operating parameters of the meter. The meter is factory set

with regard to these options, and is ready for use under most circumstances (see ‘Appendix:

6000 Series Meters Factory Default Settings’ section for default settings). The operating

parameters of the resistivity mode can be set and controlled from the resistivity setup screen. The

resistivity Setup section will guide you through the various options available in the resistivity setup

mode.

Example: - PCD6500 Resistivity Setup screen

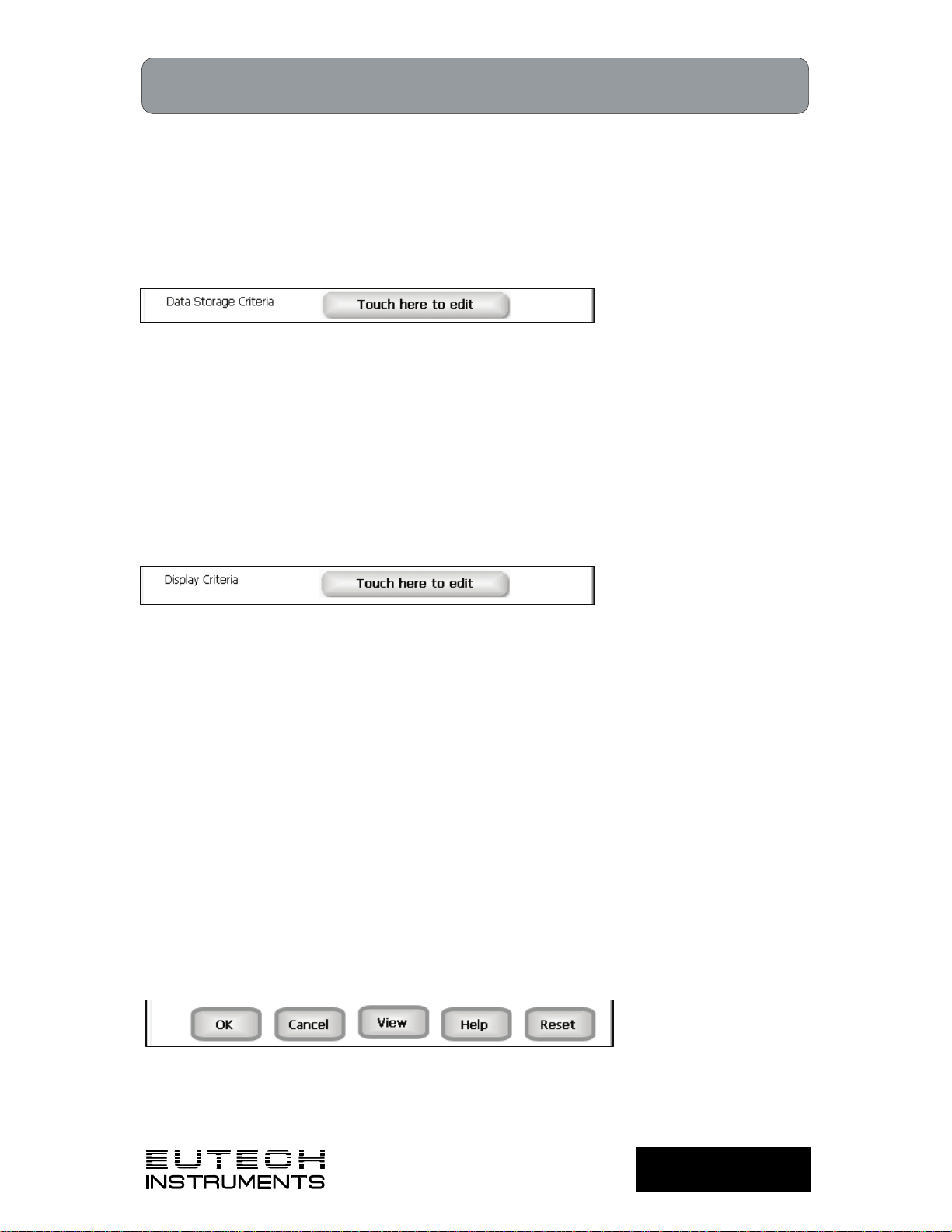

Function Buttons on Resistivity Setup Screen

Touch OK to confirm resistivity Setup and return to the resistivity Measure screen.

Touch Cancel to exit and return to the resistivity Measure screen without confirming resistivity

Setup.

Touch View to view all resistivity data points stored in memory. See ‘Resistivity Setup: View

Stored Data’ section for details.

When you touch the Help button, information about the current screen appears. This information

includes step-by-step instructions for operating the meter from the current screen and possible

applications information for that screen.

Touch Reset to reset all resistivity Setup Criteria to the factory default.

Technolo

adeEas

93

Resistivity Setup: Access Resistivity Setup

gyM

y..

.

PC6000, CON6000, PC6500 and PCD6500 meters

To access the Setup screen:

1. Make sure you are in the resistivity Measure screen.

2. Touch the Setup button to access the resistivity Setup screen.

If you were in quadruple, triple or dual display mode, you have access to the Setup mode for

each channel displayed. Touch the Setup Channel buttons at the top of the screen to toggle

back and forth between the setup screens for each channel. To change Re sistivity parameters,

select the Resistivity Setup button.

If you were in single display mode, you will access the Setup mode for the single channel

displayed only.

Technolo

adeEas

94

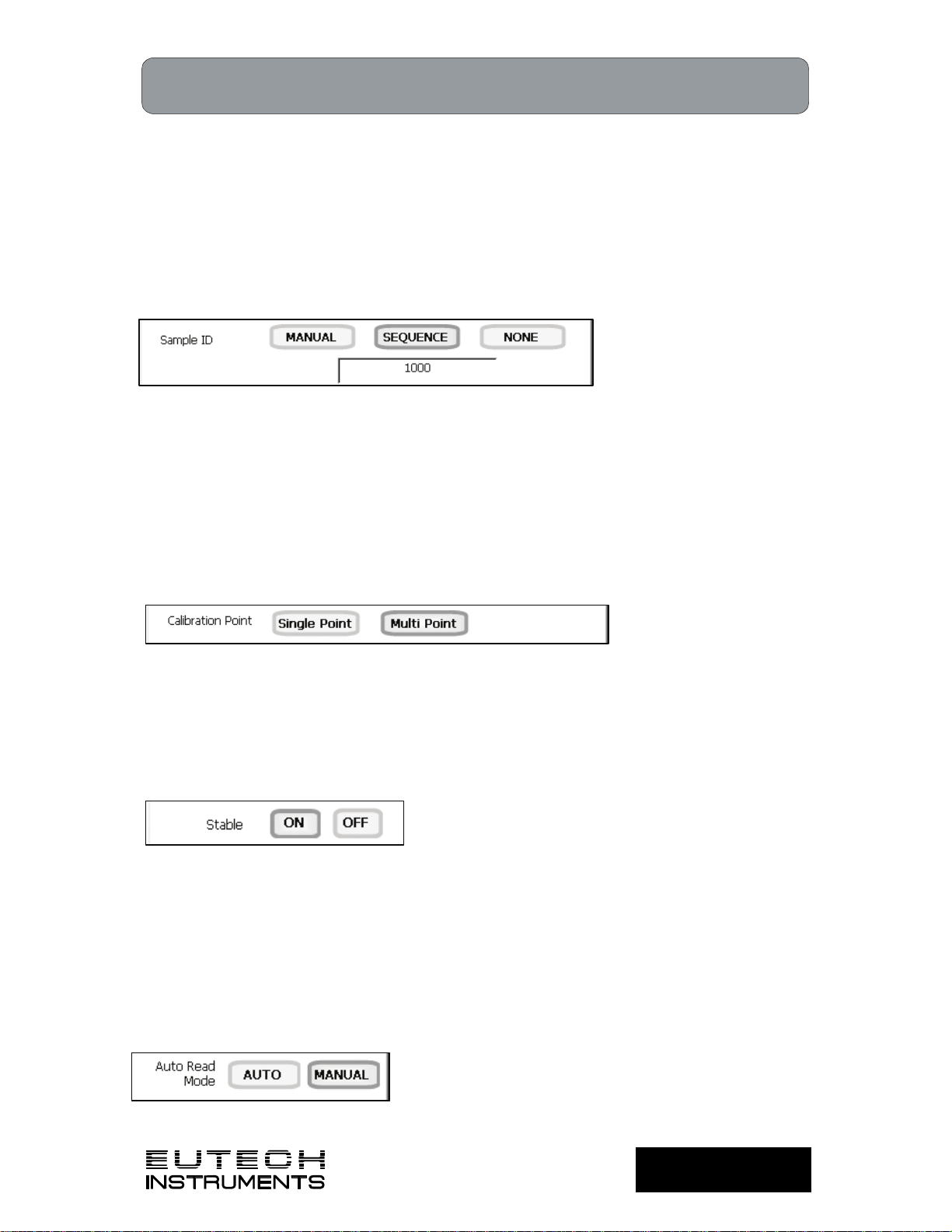

Resistivity Setup

gyM

y..

.

PC6000, CON6000, PC6500 and PCD6500 meters

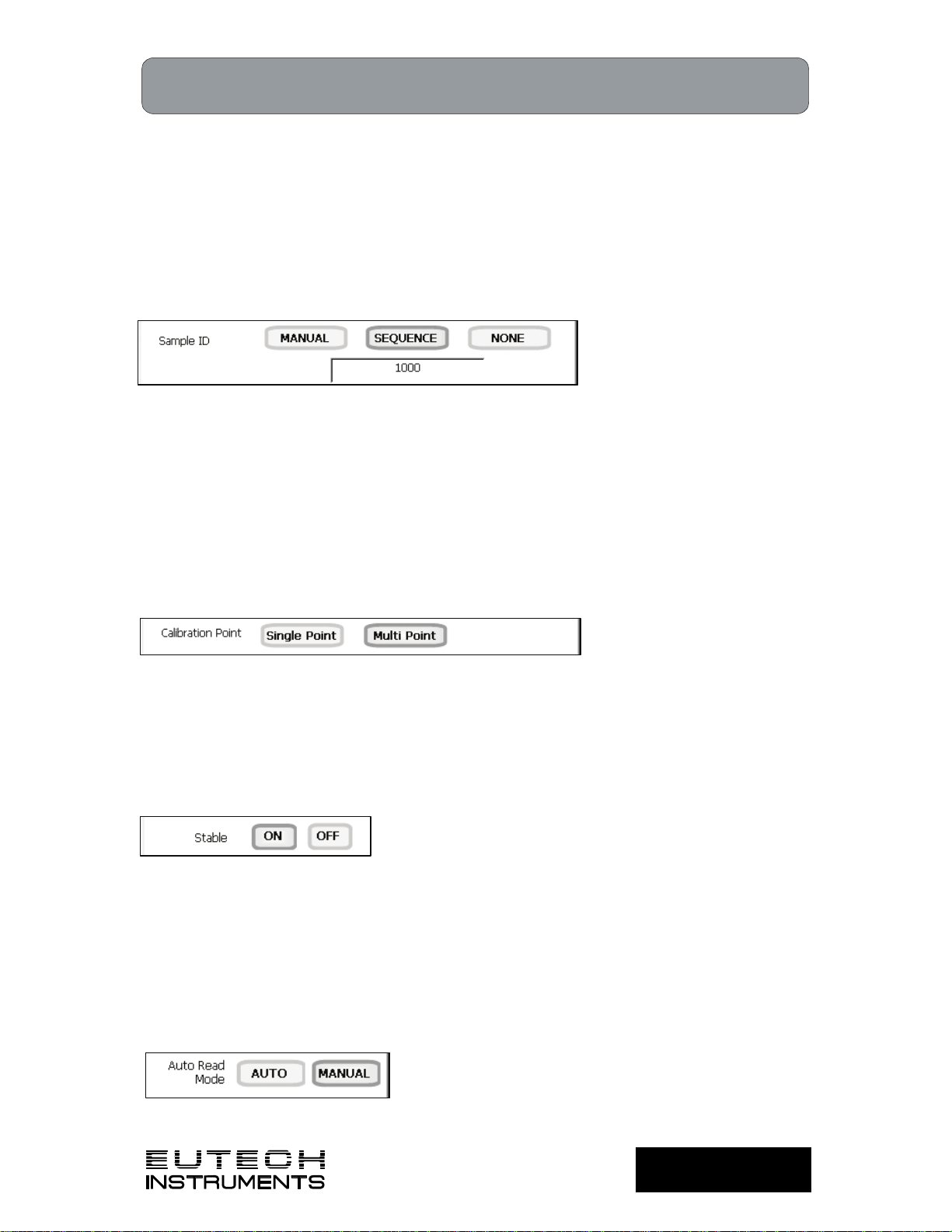

To Set Sample ID#

A sample ID is required if you wish to log data or activate a timed printing. Whenever this option

is active, each time you touch Log Data on the resistivity Measure screen, the resistivity value

along with date/time/channel and the sample ID will be sent to data storage.

You can manually enter an alphanumeric identification number of 10 characters for any sample or

you can have the meter sequentially number your samples beginning at the number of your

choice. You can also choose to deactivate the sample ID.

The resistivity Sample ID# is set the same way as previously described in Conductivity Setup.

See ‘Conductivity Setup: Set Sample ID#’ section for instructions.

To Set Calibration Point(s)

This option also allows you to choose single-point or multi-point standardardization. Use the

single-point standardization option if you are measuring samples that close in value. Use the

multi-point standardization option if you are measuring a wide range of samples. If a single point

calibration is selected, there will be only one calibration factor for the entire range of operation. In

the multi point mode, there will be one for each of the 4 ranges.

To select Calibration Point(s)

1. Touch Single Point or Multi Point to choose the method of standardization.

To Select Stable Indicator

This setup option lets you turn ON or OFF the stability indicator. When this function is turned on,

the STABLE appears when the resistivity reading is stable.

To select Stable indicator

1. Touch ON or OFF to turn stable indicator on or off.

To Select Auto Read Mode

You can use this meter when the Auto Read function is active or when it is inactive. When the

Auto Read function is active, the meter will lock onto a reading when the meter recognizes it as

stable. The meter will not deviate from this reading until Measure is touched. If the Auto Read

function is inactive, then the meter will continuously monitor any resistivity fluctuations.

To select Auto Read Mode

1. Touch MANUAL or AUTO to choose the desired read mode

Technolo

adeEas

95

Resistivity Setup

gyM

y..

.

PC6000, CON6000, PC6500 and PCD6500 meters

To Select Cell Constant

This setup option allows you to select the appropriate cell constant

of the cell that you are using. There are three cell constants to choose

from. Each is used for a different range of resistivity.

The Resistivity Cell Constant is set the same way as previously

described in Conductivity Setup. See ‘Conductivity Setup: Stable

Indicator/Auto Read Mode/Cell Constant’ section for instructions.

To Set Default Temperature

Resistivity is a temperature dependent measurement. This option allows you to select a default

temperature that the meter will use along with the temperature coefficient to calculate a

temperature corrected resistivity measurement. If an ATC probe is used, any value entered as a

default temperature will be overridden in favor of the actual measured temperature of the solution

the ATC probe provides to the meter. The default temperature can be set from -10°C to 110°C.

The Resistivity Default Temperature is set the same way as previously described in Conductivity

Setup. See ‘Conductivity Setup: Select Reference Temperature’ section for inst ructions.

When you change

cell constants your

calibration factor will

automatically reset

to default values. It

is recommended

that you standardize

your meter to

establish a new

calibration factor.

To Set Reference Temperature

This setup option lets you select the reference temperature to be used in the determination of the

resistivity of your sample. The reference temperature is the temperature to which the resistivity

readings would be normalized. The reference temperature can be set from 15°C to 30°C.

The Resistivity Reference Temperature is set the same way as previously described in

Conductivity Setup. See ‘Conductivity Setup: Select Reference Temperature’ section for

instructions.

To Set Temperature Coefficient

The temperature coefficient is a value that reflects the degree to which

the sample’s resistivity is effected by temperature changes. The meter

will use the set temperature coefficient along with the measured

temperature provided by the ATC probe to calculate what the resistivity

would be at the selected reference temperature. If no ATC probe is

being used, the meter will use the set default temperature in the

calculation. The temperature coefficient can be set from 0 to 10.000%.

The Resistivity Temperature Coefficient is set the same way as

previously described in section ‘Conductivity Setup: Set Alarm

Limits’.

NOTE: The meter

and probe with

ATC will measure

temperature even

if the temperature

coefficient is set

to 0.0%, however

a temperature

correction will not

be applied to the

measurement.

Technolo

adeEas

96

Resistivity Setup

gyM

y..

.

PC6000, CON6000, PC6500 and PCD6500 meters

To Set Alarm Limits

This option allows you to set alarm limits for the resistivity measuring mode. If the resistivity value

of the measurement is outside of the boundaries set by the minimum and maximum limits,

audible and visual warnings will let you know that your sample measurement was outside of the

set limits.

The Alarm Limit can be set from 3.000 Ohm to 100.000 M Ohm.

To set Alarm Limits

1. Touch ON or OFF to set the status of the alarm of resistivity mode

2. Touch the Low box and use numeric keypad to enter the new limit values.

3. Touch Enter on the keypad to accept this limit and return to the resistivity Setup screen.

4. Touch Ohm, KOhm or MOhm to select resistivity units of low alarm value.

5. Touch the High box and use numeric keypad to enter the new limit values.

6. Touch Enter on the keypad to accept this limit and return to the resistivity Setup screen.

7. Touch Ohm, KOhm or MOhm to select resistivity units of high alarm value.

To Set Print Criteria

This screen allows you to select which criteria are printed with the measurement when you print

the data or send it to a computer. The status of the current print criteria is displayed on the

screen. The criteria option is active if ON appears to the right of the option. It is inactive if OFF

appears to the right of the option. Any active criteria will be printed on demand.

The Resistivity Print Criteria is set the same way as previously described in Conductivity Setup.

See ‘Conductivity Setup: Set Print Criteria’ section for instruction s.

Technolo

adeEas

97

Resistivity Setup

gyM

y..

.

PC6000, CON6000, PC6500 and PCD6500 meters

To Set Data Storage Criteria

This screen allows you to select which criteria are stored in the data logger with the measurement

when you store the data. The status of the current data storage criteria is displayed on the

screen. The criteria option is active if ON appears to the right of the option. It is inactive if OFF

appears to the right of the option. Any active criteria will be stored on demand.

The Resistivity Data Storage Criteria is set the same way as previously described in Conductivity

Setup. See ‘Conductivity Setup: Data Storage Criteria’ section for instructions.

To Set Display Criteria

This screen allows you to choose what information you would like to be displayed on the

resistivity Measure screen, particularly the information contained in the data box at the bottom of

the Measurement screen. The status of the current display criteria is displayed on the screen.

The criteria option is active if ON appears to the right of the option. It is inactive if OFF appears to

the right of the option.

The Resistivity Display Criteria is set the same way as previously described in Conductivity

Setup. See ‘Conductivity Setup: Set Display Criteria’ section for instructions.

To View Stored Data

The PC6000, CON6000, PC6500 and PCD6500 have a memory capacity to store up to 1000

data points. The View Stored Data screen allows you to sort and look at specific data points

stored in the meter based on the meters memory capacity. The stored data can be sorted by any

of the parameters available in the screen header.

The meter stores resistivity data under the following parameters:

Reading Temperature Coefficient

Date / Time / Channel Cell Type

Sample Id Last Standardizations

Temperature Meter Model / Serial No

Reference Temperature Operator

Viewing Stored Resistivity Data is done the same way as previously described in Conductivity

Setup. See ‘Conductivity Setup: View Stored Data’ section for instructions.

Technolo

adeEas

98

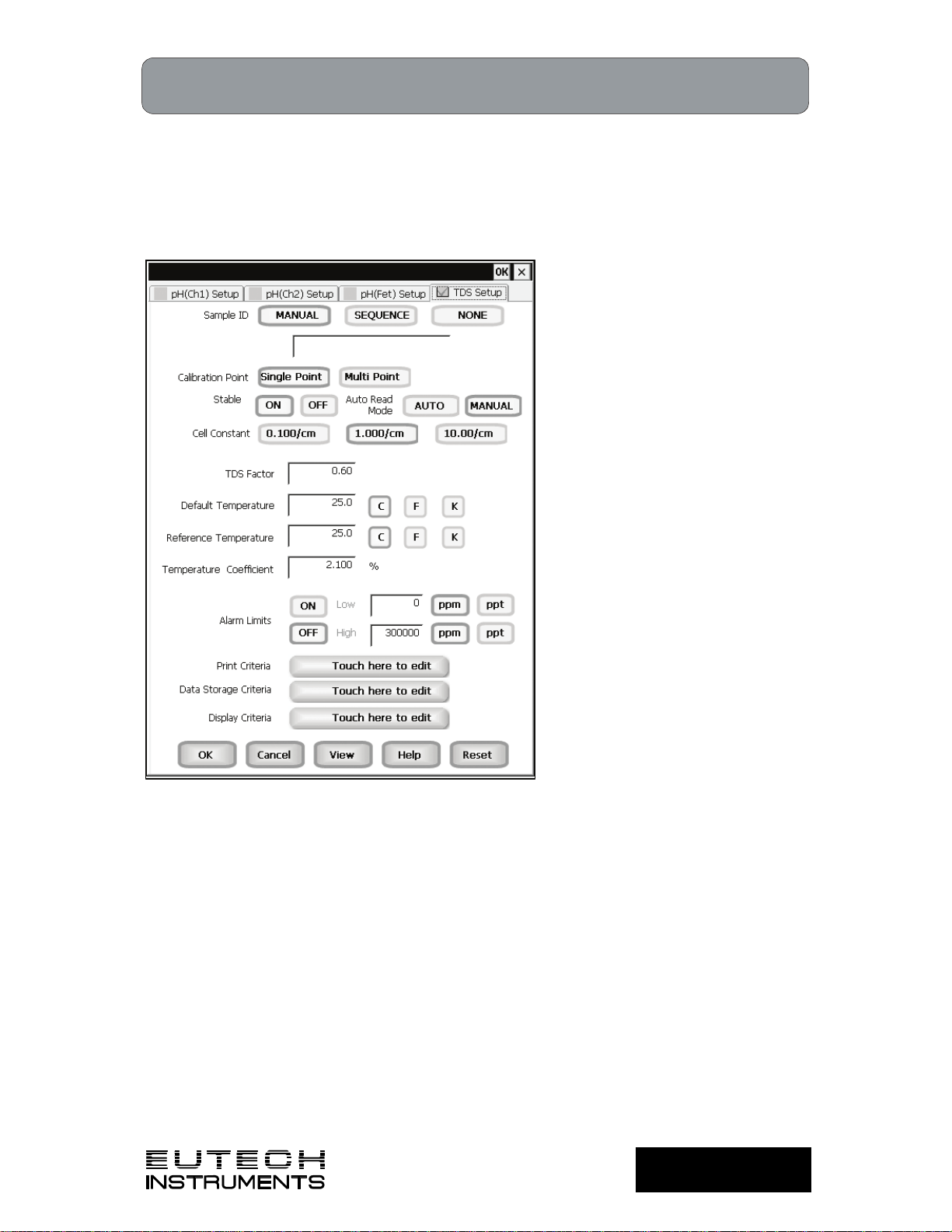

TDS Setup: TDS Setup Screen

gyM

y..

.

PC6000, CON6000, PC6500 and PCD6500 meters

Available in PC6000, CON6000, PC6500 and PCD6500 meters, the TDS Setup screen present

many options to control the operating parameters of the meter. The meter is factory set with

regard to these options, and is ready for use under most circumstances (see ‘Appendix: 6 000

Series Meters Factory Default Settings’ section for default settings). The operating parameters

of the TDS mode can be set and controlled from the TDS setup screen. The TDS Setup section

will guide you through the various options available in the TDS setup mode.

Example: - PCD6500 TDS Setup screen

Function Buttons on TDS Setup Screen

Touch OK to confirm TDS Setup and return to the TDS Measure screen.

Touch Cancel to exit and return to the TDS Measure screen without confirming TDS Setup.

Touch View to view all TDS data points stored in memory. See ‘TDS Setup: View Stored Data’

section for details.

When you touch the Help button, information about the current screen appears. This information

includes step-by-step instructions for operating the meter from the current screen and possible

applications information for that screen.

Touch Reset to reset all TDS Setup Criteria to the factory default.

Technolo

adeEas

99

TDS Setup: Access TDS Setup

gyM

y..

.

PC6000, CON6000, PC6500 and PCD6500 meters

To access the Setup screen:

1. Make sure you are in the TDS Measure screen.

2. Touch the Setup button to access the TDS Setup screen.

If you were in quadruple, triple or dual display mode, you have access to the Setup mode for

each channel displayed. Touch the Setup Channel buttons at the top of the screen to toggle

back and forth between the setup screens for each channel. To change TDS pa rameters, select

the TDS Setup button.

If you were in single display mode, you will access the Setup mode for the single channel

displayed only.

Technolo

adeEas

100

TDS Setup

gyM

y..

.

PC6000, CON6000, PC6500 and PCD6500 meters

To Set Sample ID#

A sample ID is required if you wish to log data or activate a timed printing. Whenever this option

is active, each time you touch Log Data on the TDS Measure screen, the TDS value along with

date/time/channel and the sample ID will be sent to data storage.

You can manually enter an alphanumeric identification number of 10 characters for any sample or

you can have the meter sequentially number your samples beginning at the number of your

choice. You can also choose to deactivate the sample ID.

The TDS Sample ID# is set the same way as previously described in Conductivity Setup. See

‘Conductivity Setup: Set Sample ID#’ section for instructions.

To Set Calibration Point(s)

This option also allows you to choose single-point or multi-point standardardizat ion.

Use the single-point standardization option if you are measuring samples that close in value. Use

the multi-point standardization option if you are measuring a wide range of samples. If a single

point calibration is selected, there will be only one calibration factor for the entire range of

operation. In the multi point mode, there will be one for each of the 4 ranges.

To select Calibration Point(s)

1. Touch Single Point or Multi Point to choose the method of standardization.

To Select Stable Indicator

This setup option lets you turn ON or OFF the stability indicator. When this function is turned on,

the STABLE appears when the TDS reading is stable.

To select Stable indicator

1. Touch ON or OFF to turn stable indicator on or off.

To Select Auto Read Mode

You can use this meter when the Auto Read function is active or when it is inactive. When the

Auto Read function is active, the meter will lock onto a reading when the meter recognizes it as

stable. The meter will not deviate from this reading until Measure is touched. If the Auto Read

function is inactive, then the meter will continuously monitor any TDS fluctuations.

To select Auto Read Mode

1. Touch MANUAL or AUTO to choose the desired read mode.

Technolo

adeEas

101

TDS Setup

gyM

y..

.

PC6000, CON6000, PC6500 and PCD6500 meters

To Select Cell Constant

This setup option allows you to select the appropriate cell constant of

the cell that you are using. There are three cell constants to choose

from. Each is used for a different range of TDS.

The TDS Cell Constant is set the same way as previously described

in Conductivity Setup. See ‘Conductivity Setup: Stable

Indicator/Auto Read Mode/Cell Constant’ section for instructions.

To Set TDS Factor

A TDS conversion factor is needed when a solution does not have a similar ionic content to

natural water or salt water. The TDS conversion factor automatically adjusts the reading.

The TDS conversion factor can be set from 0.40 to 1.00.

To set TDS Factor

1. Touch the TDS Factor box and use the numeric keypad to enter the desired default

temperature (0.40 to 1.00).

2. Press Enter in the keypad to return to TDS Setup screen.

To Set Default Temperature

When you change

cell constants your

calibration factor will

automatically reset to

default values. It is

recommended that

you standardize your

meter to establish a

new calibration factor.

TDS is a temperature dependent measurement. This option allows you to select a default

temperature that the meter will use along with the temperature coefficient to calculate a

temperature corrected TDS measurement. If an ATC probe is used any value entered as a

default temperature will be overridden in favor of the actual measured temperature of the solution

provided to the meter by the ATC probe.

The default temperature can be set from -10°C to 110°C.

The TDS Default Temperature is set the same way as previously described in Conductivity Setup.

See ‘Conductivity Setup: Select Reference Temperature’ section f o r inst ructions.

To Set Reference Temperature

This setup option allows you to select the reference temperature to be used in the determination

of the TDS of your sample. The reference temperature is the temperature to which the TDS

readings would be normalized.

The reference temperature can be set from 15°C to 30°C.

The TDS Reference Temperature is set the same way as previously described in Conductivity

Setup. See ‘Conductivity Setup: Select Reference Temperature’ section for inst ructions.

Technolo

adeEas

102

TDS Setup

gyM

y..

.

PC6000, CON6000, PC6500 and PCD6500 meters

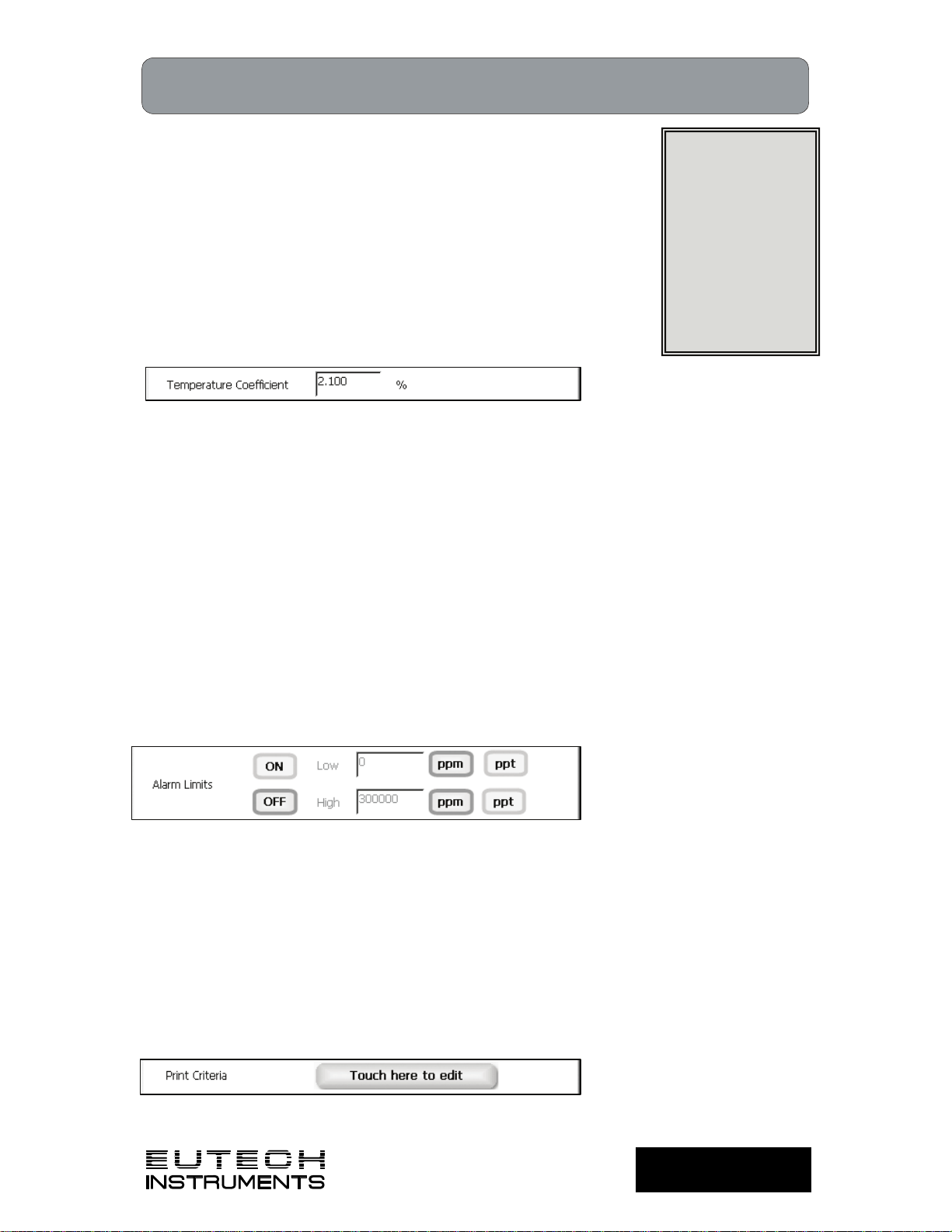

To Set Temperature Coefficient

The temperature coefficient is a value that reflects the degree to

which the sample’s TDS is affected by temperature changes. The

meter will use the set temperature coefficient along with the

measured temperature provided by the ATC probe to calculate what

the TDS would be at the selected reference temperature. If no ATC

probe is being used, the meter will use the set default temperature

in the calculation.

The temperature coefficient can be set from 0 to 10.000%.

The TDS Temperature Coefficient is set the same way as previously

described in ‘Conductivity Setup: Set Alarm Limits’ section.

To Set Alarm Limits

This option allows you to set alarm limits for the TDS measuring mode. If the TDS value of the

measurement is outside of the boundaries set by the minimum and maximum limits, audible and

visual warnings will let you know that your sample measurement was outside of the set limits.

The Alarm Limit can be set from 0.00 to 500.00 ppt (depending upon TDS factor).

To set Alarm Limits

NOTE: The meter

and probe with

ATC will measure

temperature even

if the temperature

coefficient is set

to 0.0%, however

a temperature

correction will not

be applied to the

measurement.

1. Touch ON or OFF to set the status of the alarm of TDS mode

2. Touch the Low box and use numeric keypad to enter the new limit values.

3. Touch Enter on the keypad to accept this limit and return to the TDS Setup screen.

4. Touch PPM or PPT to select TDS units of low alarm value.

5. Touch the High box and use numeric keypad to enter the new limit values.

6. Touch Enter on the keypad to accept this limit and return to the TDS Setup screen.

7. Touch PPM or PPT to select TDS units of high alarm value.

To Set Print Criteria

This screen allows you to select which criteria are printed with the measurement when you print

the data or send it to a computer. The status of the current print criteria is displayed on the

screen. The criteria option is active if ON appears to the right of the option. It is inactive if OFF

appears to the right of the option. Any active criteria will be printed on demand.

The TDS Print Criteria is set the same way as previously described in Conductivity Setup. See

‘Conductivity Setup: Set Print Criteria’ section for instructions.

Technolo

adeEas

103

TDS Setup

gyM

y..

.

PC6000, CON6000, PC6500 and PCD6500 meters

To Set Data Storage Criteria

This screen allows you to select which criteria are stored in the data logger with the measurement

when you store the data .The status of the current data storage criteria is displayed on the

screen. The criteria option is active if ON appears to the right of the option. It is inactive if OFF

appears to the right of the option. Any active criteria will be stored on demand.

The TDS Data Storage Criteria is set the same way as previously described in Conductivity

Setup. See ‘Conductivity Setup: Data Storage Criteria’ section for instructions.

To Set Display Criteria

This screen allows you to choose what information you would like to be displayed on the TDS

Measure screen, particularly the information contained in the data box at the bottom of the

Measurement screen. The status of the current display criteria is displayed on the screen. The

criteria option is active if ON appears to the right of the option. It is inactive if OFF appears to the

right of the option.

The TDS Display Criteria is set the same way as previously described in Conductivity Setup. See

‘Conductivity Setup: Set Display Criteria’ section for instructions.

To View Stored Data

The PC6000, CON6000, PC6500 and PCD6500 have a memory capacity to store up to 1000

data points. The View Stored Data screen allows you to sort and look at specific data points

stored in the meter based on the meters memory capacity. The stored data can be sorted by any

of the parameters available in the screen header.

The meter stores TDS data under the following parameters:

Reading Temperature Coefficient

Date / Time / Channel Cell Type

Sample Id Last Standardizations

Temperature Meter Model / Serial No

Reference Temperature Operator

Viewing Stored TDS Data is done the same way as previously described in Conductivity Setup.

See ‘Conductivity Setup: View Stored Data’ section for instructions.

Technolo

adeEas

104

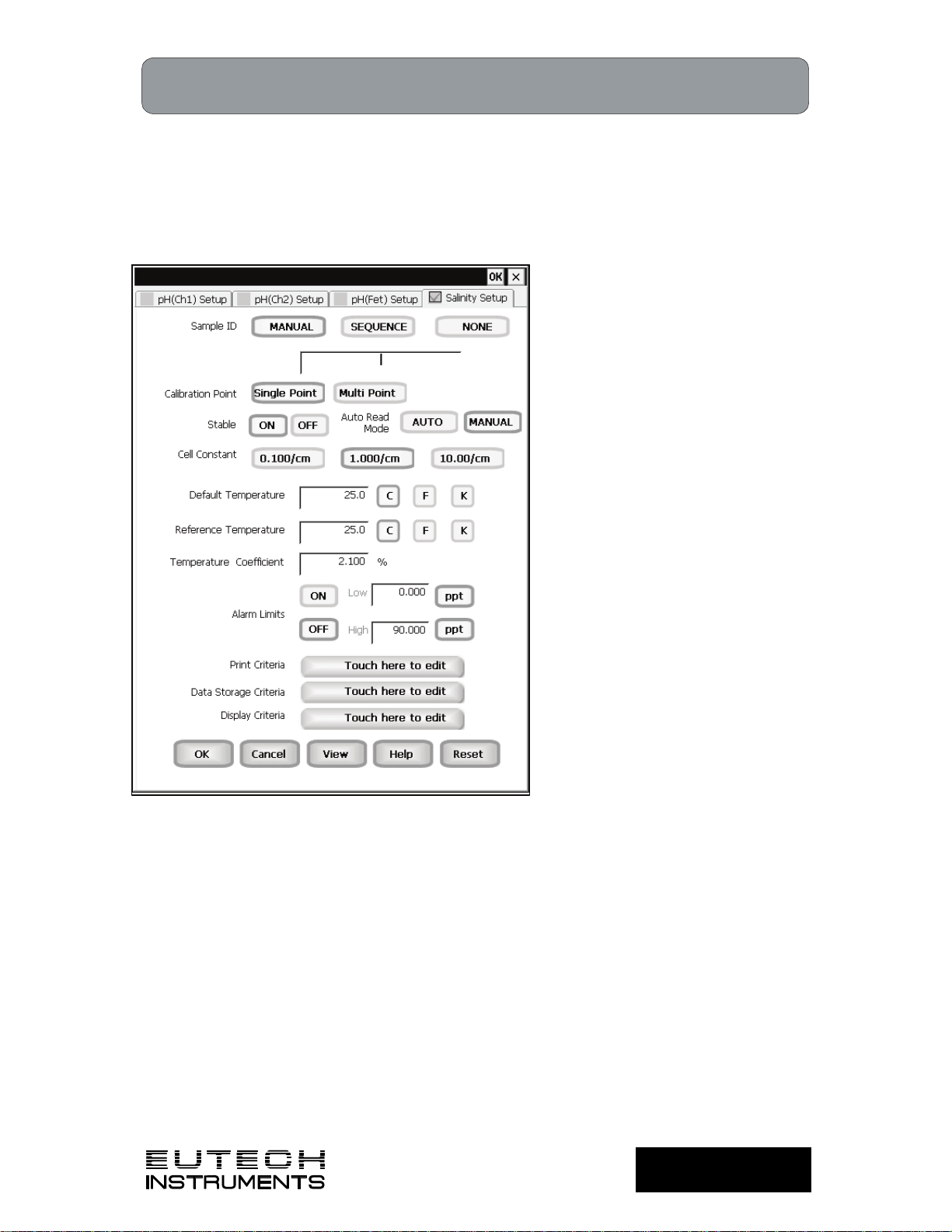

Salinity Setup: Salinity Setup Screen

gyM

y..

.

PC6000, CON6000, PC6500 and PCD6500 meters

Available in the PC6000, CON6000, PC6500 and PCD6500 meters, the salinity Setup screen

present many options to control the operating parameters of the meter. The meter is factory set

with regard to these options, and is ready for use under most circumstances (see ‘Appendix:

6000 Series Meters Factory Default Settings’ section for default settings). The operating

parameters of the salinity mode can be set and controlled from the salinity setup screen. The

salinity Setup section will guide you through the various options available in the salinity setup

mode.

Example: - PCD6500 Salinity Setup screen

Function Buttons on Salinity Setup Screen

Touch OK to confirm salinity Setup and return to the salinity Measure screen.

Touch Cancel to exit and return to the salinity Measure screen without confirming salinity Setup.

Touch View to view all salinity data points stored in memory. See ‘Salinity Setup: View Stored

Data’ section for details.

When you touch the Help button, information about the current screen appears. This information

includes step-by-step instructions for operating the meter from the current screen and possible

applications information for that screen.

Touch Reset to reset all salinity Setup Criteria to the factory default.

Technolo

adeEas

105

Salinity Setup: Access Salinity Setup

gyM

y..

.

PC6000, CON6000, PC6500 and PCD6500 meters

To access the Setup screen:

1. Make sure you are in the salinity Measure screen.

2. Touch the Setup button to access the salinity Setup screen.

If you were in quadruple, triple or dual display mode, you have access to the Setup mode for

each channel displayed. Touch the Setup Channel buttons at the top of the screen to toggle

back and forth between the setup screens for each channel. To change Salinity parameters,

select the Salinity Setup button.

If you were in single display mode, you will access the Setup mode for the single channel

displayed only.

Technolo

adeEas

106

Salinity Setup

gyM

y..

.

PC6000, CON6000, PC6500 and PCD6500 meters

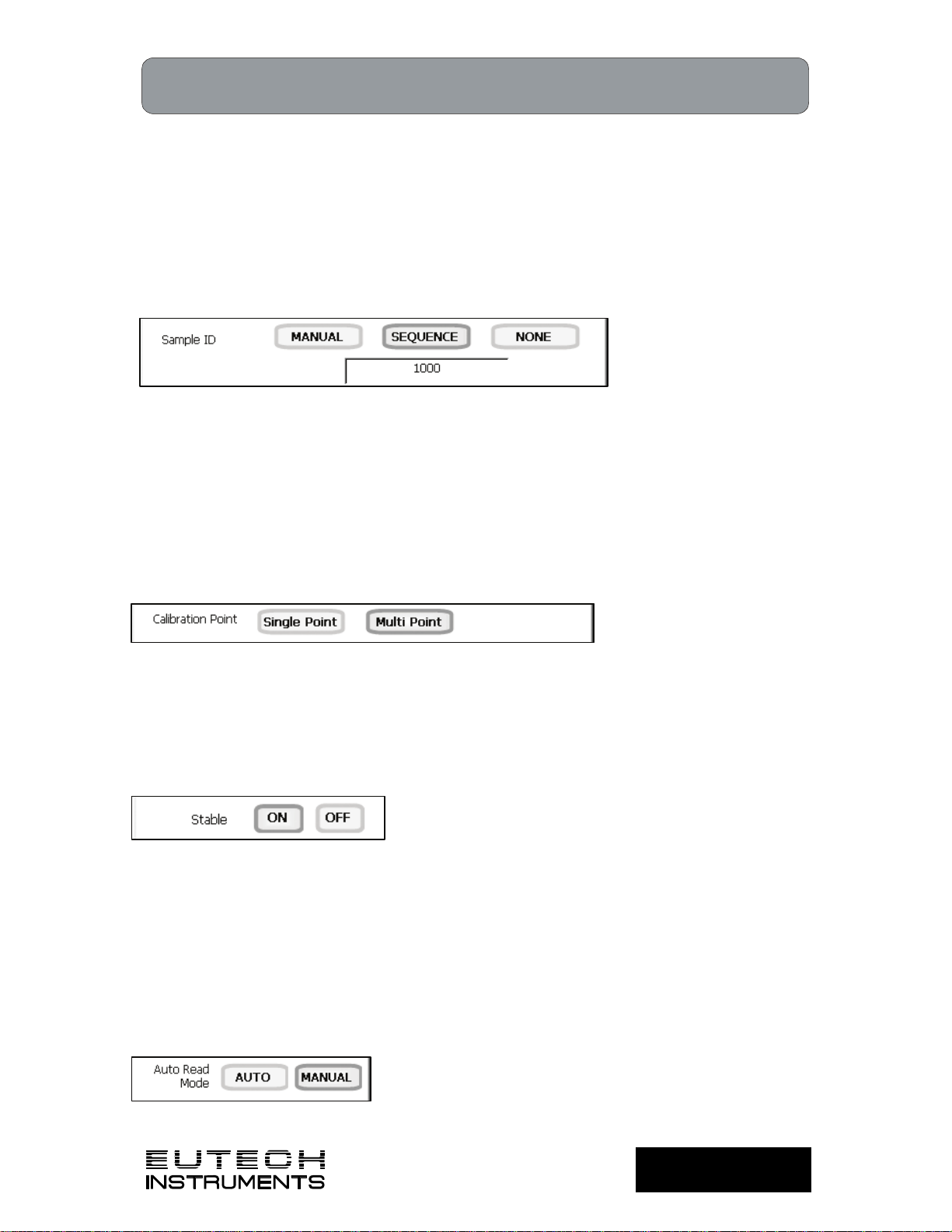

To Set Sample ID#

A sample ID is required if you wish to log data or activate a timed printing. Whenever this option

is active, each time you touch Log Data on the salinity Measure screen, the salinity value along

with date/time/channel and the sample ID will be sent to data storage.

You can manually enter an alphanumeric identification number of 10 characters for any sample or

you can have the meter sequentially number your samples beginning at the number of your

choice. You can also choose to deactivate the sample ID.

The Salinity Sample ID# is set the same way as previously described in Conductivity Setup. See

‘Conductivity Setup: Set Sample ID#’ section for instructions.

To Set Calibration Point(s)

This option also allows you to choose single-point or multi-point standardardization. Use the

single-point standardization option if you are measuring samples that close in value. Use the

multi-point standardization option if you are measuring a wide range of samples. If a single point

calibration is selected, there will be only one calibration factor for the entire range of operation. In

the multi point mode, there will be one for each of the 4 ranges.

To select Calibration Point(s)

1. Touch Single Point or Multi Point to choose the method of standardization.

To Select Stable Indicator

This setup option lets you turn ON or OFF the stability indicator. When this function is turned on,

the STABLE appears when the salinity reading is stable.

To select Stable indicator

1. Touch ON or OFF to turn stable indicator on or off.

To Select Auto Read Mode

You can use this meter when the Auto Read function is active or when it is inactive. When the

Auto Read function is active, the meter will lock onto a reading when the meter recognizes it as

stable. The meter will not deviate from this reading until Measure is touched. If the Auto Read

function is inactive, then the meter will continuously monitor any Salinity fluctuations.

To select Auto Read Mode

1. Touch MANUAL or AUTO to choose the desired read mode.

Technolo

adeEas

107

Salinity Setup

gyM

y..

.

PC6000, CON6000, PC6500 and PCD6500 meters

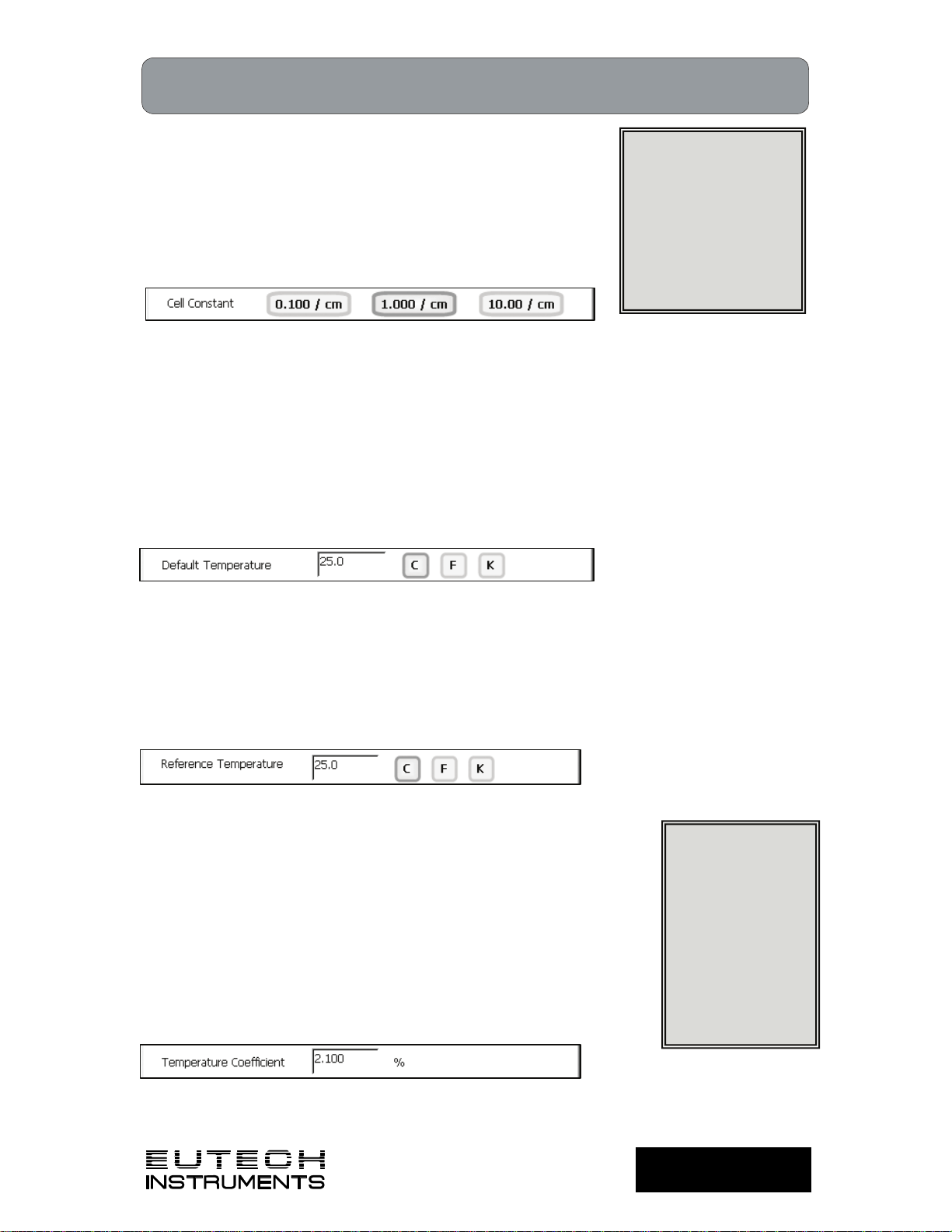

To Select Cell Constant

This setup option allows you to select the appropriate cell constant

of the cell that you are using. There are three cell constants to

choose from. Each is used for a different range of salinity.

The Salinity Cell Constant is set the same way as previously

described in Conductivity Setup. See ‘Conductivity Setup: Stable

Indicator/Auto Read Mode/Cell Constant’ section for instructions.

To Set Default Temperature

Salinity is a temperature dependent measurement. This option allows you to select a default

temperature that the meter will use along with the temperature coefficient to calculate a

temperature corrected salinity measurement. If an ATC probe is used any value entered as a

default temperature will be overridden in favor of the actual measured temperature of the solution

provided to the meter by the ATC probe.

The default temperature can be set from -10°C to 110°C.

The Salinity Default Temperature is set the same way as previously described in Conductivity

Setup. See ‘Conductivity Setup: Select Reference Temperature’ section for inst ructions.

When you change cell

constants your

calibration factor will

automatically reset to

default values. It is

recommended that

you standardize your

meter to establish a

new calibration factor.

To Set Reference Temperature

This setup option allows you to select the reference temperature to be used in the determination

of the salinity of your sample. The reference temperature can be set from 15°C to 30°C.

The Salinity Reference Temperature is set the same way as previously described in Conductivity

Setup. See ‘Conductivity Setup: Select Reference Temperature’ section for inst ructions.

To Set Temperature Coefficient

The temperature coefficient is a value that reflects the degree to which

the sample’s salinity is affected by temperature changes. The meter will

use the set temperature coefficient along with the measured temperature

provided by the ATC probe to calculate what the salinity would be at the

selected reference temperature. If no ATC probe is being used, the

meter will use the set default temperature in the calculation.

The temperature coefficient can be set from 0 to 10.000%.

The Salinity Temperature Coefficient is set the same way as previously

described in section ‘Conductivity Setup: Set Alarm Limits’.

NOTE: The meter

and probe with

ATC will measure

temperature even

if the temperature

coefficient is set

to 0.0%, however

a temperature

correction will not

be applied to the

measurement.

Technolo

adeEas

108

Salinity Setup

gyM

y..

.

PC6000, CON6000, PC6500 and PCD6500 meters

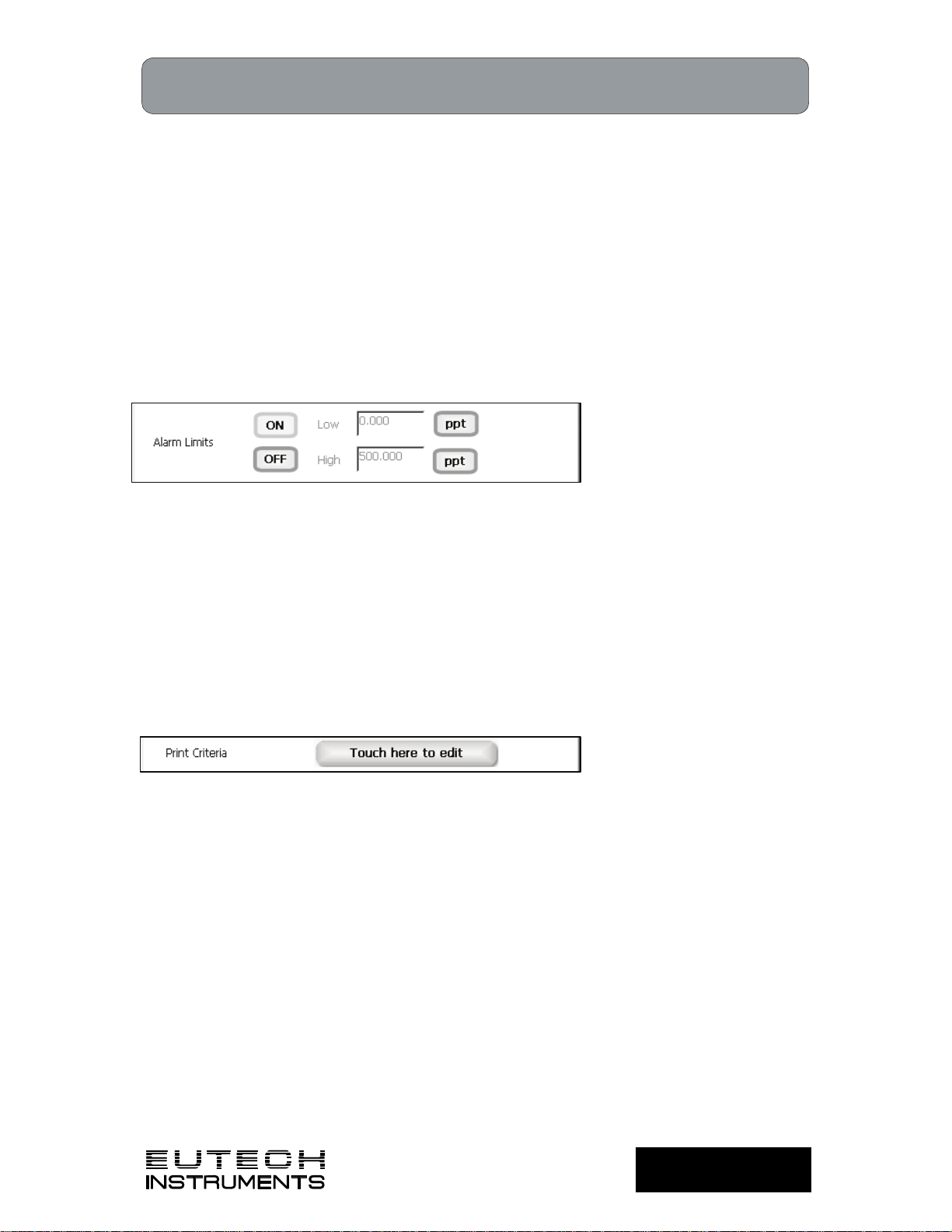

To Set Alarm Limits

This option allows you to set alarm limits for the salinity measuring mode. If the salinity value of

the measurement is outside of the boundaries set by the minimum and maximum limits, audible

and visual warnings will let you know that your sample measurement was outside of the set

limits.

The Alarm Limit can be set from 0 to 90.000 ppt.

To set Alarm Limits

1. Touch ON or OFF to set the status of the alarm of salinity mode

2. Touch the Low box and use numeric keypad to enter the new limit values.

3. Touch Enter on the keypad to accept this limit and return to the salinity Setup screen.

4. Touch the High box and use numeric keypad to enter the new limit values.

5. Touch Enter on the keypad to accept this limit and return to the salinity Setup screen.

To Set Print Criteria

This screen allows you to select which criteria are printed with the measurement when you print

the data. The status of the current print criteria is displayed on the screen. The criteria option is

active if ON appears to the right of the option. It is inactive if OFF appears to the right of the

option. Any active criteria will be printed on demand.

The Salinity Print Criteria is set the same way as previously described in Conductivity Setup.

See ‘Conductivity Setup: Set Print Criteria’ section for instruction s.

Technolo

adeEas

109

Salinity Setup

gyM

y..

.

PC6000, CON6000, PC6500 and PCD6500 meters

To Set Data Storage Criteria

This screen allows you to select which criteria are stored in the data logger with the measurement

when you store the data. The status of the current data storage criteria is displayed on the

screen. The criteria option is active if ON appears to the right of the option. It is inactive if OFF

appears to the right of the option. Any active criteria will be stored on demand.

The Salinity Data Storage Criteria is set the same way as previously described in Conductivity

Setup. See ‘Conductivity Setup: Data Storage Criteria’ section for instructions.

To Set Display Criteria

This screen allows you to choose what information you would like to be displayed on the salinity

Measure screen, particularly the information contained in the data box at the bottom of the

Measurement screen. The status of the current display criteria is displayed on the screen. The

criteria option is active if ON appears to the right of the option. It is inactive if OFF appears to the

right of the option.

The Salinity Display Criteria is set the same way as previously described in Conductivity Setup.

See ‘Conductivity Setup: Set Display Criteria’ section for instructions.

To View Stored Data

The PC6000, CON6000, PC6500 and PCD6500 have a memory capacity to store up to 1000

data points. The View Stored Data screen allows you to sort and look at specific data points

stored in the meter based on the meters memory capacity. The stored data can be sorted by any

of the parameters available in the screen header.

The meter stores salinity data under the following parameters:

Reading Temperature Coefficient

Date / Time / Channel Cell Type

Sample Id Last Standardizations

Temperature Meter Model / Serial No

Reference Temperature Operator

Viewing Stored Salinity Data is done the same way as previously described in Conductivity

Setup. See ‘Conductivity Setup: View Stored Data’ section for instructions.

Technolo

adeEas

110

pH Operation: About pH Measurement

gyM

y..

.

PH6000, PC6000, PH6500, PC6500 and PCD6500 meters

For the PH6000, PC6000, PH6500, PC6500 and PCD6500 meters, in the pH measurement

mode, you will able to measure the pH of a wide variety of samples. Before measuring pH, you

will need to standardize the meter using buffers with known pH values. It is good practice to

standardize the meter frequently using a minimum of two buffers. Using two buffers allows the

meter to calculate and display an actual slope for the electrode, and therefore produce more

accurate measurements. If there is no standardization in the memory of the meter or if only one

buffer has been used to standardize the meter, the slope value will appear as “......”.

You can standardize your meter using automatic or manual buffer recognition. With the Automatic

buffer recognition activated (ON), the meter will automatically recognize the buffers from the

chosen buffer group and flash the current buffer. When the reading is stable, you must confirm

the buffer.

In the Manual buffer recognition mode, you must enter the buffer value during the standardization

procedure. The meter will flash the manually entered buffer you must confirm the buffer when the

reading is stable. During the standardization procedure, you may accept the buffer value before

the meter recognizes it as stable by touching confirm.

See ‘pH Setup: Select Auto Read Mode’ section to select desired buffer recognition.

Remember to setup your pH measuring mode parameters. Refer to the pH Setup se ction for

instructions. Connect the electrodes you will be using to the meter.

Touch the Channel 1, 2, or 3 buttons (single pH channel screen) to access the

standardization screen. Standardization is not available from multiple display modes.

pH measure screen without standardization

Technolo

adeEas

111

pH Operation: Standardizing

gyM

y..

.

g

PH6000, PC6000, PH6500, PC6500 and PCD6500 meters

To Standardize the meter with Auto Buffer Recognition

1. Make sure Auto Buffer Recognition is selected in the Setup screen.

2. Immerse your rinsed electrode(s) and temperature probe in a buffer solution from the

selected buffer group that you chose during the pH setup process and stir gently. The

selected buffer group appears on the standardization screen.

3. Touch Standardize on the Channel 1, 2 or 3 pH measure screen to access the

standardization screen.

4. Touch Clear if necessary to delete all previous standardization values. If the screen says

“Not standardized” proceed to step 5.

5. The screen will flash a beaker icon of the buffer solution you have selected. When the

reading is stable, STABLE appears on the screen.

6. Touch Confirm to standardize buffer. The meter will return to the pH measure screen.

7. Touch Standardize on the pH measure screen to access the standardization screen.

Repeat process to standardize with up to 5 buffers.

The efficiency of the electrode is reported as the slope. When doing a multi-point standardization,

the slopes of the individual segment are calculated by the meter. The slope that appears on the

screen is the slope applicable to that zone (in which the measurement is currently being made).

For optimal results, the meter should be standardized at a minimum of every 8 hours. For more

accurate measurements, the meter should be standardized more frequently.

If there is no previous standardization, there is no need to click the Clear button. If your

meter already has a calibration in memory, click Clear if you need to clear the previous

calibration values.

pH calibration screen with Auto Buffer

Reco

nition

Once the meter is calibrated, the pH Measure

screen shows the buffers that have been

standardized and last standardization time/date

Technolo

adeEas

112

pH Operation: Standardizing

gyM

y..

.

p

PH6000, PC6000, PH6500, PC6500 and PCD6500 meters

To standardize the meter with Manual Buffer Recognition

The Manual mode requires a minimum two-point calibration. When you press the Enter key after

the first calibration point, a message appears: “Minimum 2 buffers need to be standardized to

apply the standardization in measurement’.

1. Make sure Manual Buffer Recognition is selected in the Setup screen.

2. Immerse your rinsed electrode(s) and temperature probe in a buffer solution from the

selected buffer group that you chose during the pH setup process and stir gently. The

selected buffer group appears on the standardization screen.

3. Touch Standardize on the Channel 1, 2, or 3 pH measure screen to access the

standardization screen.

4. Touch Clear if necessary to delete all previous standardization values. If the screen says

“Not standardized” proceed to step 5.

5. The screen will flash each beaker icon once, then a numberic keypad will appea r. Using

the displayed keypad input the value of the buffer that you are using to standardize the

meter and then touch Enter. The meter now shows the buffer value in the flashing

beaker.

6. When the reading is stable, STABLE appears on the screen. Touch Confirm to

standardize the buffer. The meter will then return to the pH measure screen.

7. Touch Standardize on the pH measure screen to access the standardization screen.

Repeat process to standardize with up to 5 buffers.

If there is no previous standardization, there is no need to click the Clear button. If your

meter already has a calibration in the memory, use the Clear button if you need to clear the

revious calibration values.

pH calibration screen with Manual

Buffer Recognition

Once meter is calibrated, pH Measure screen

shows standardized buffers and last

standardization time/date

Technolo

adeEas

113

pH Operation: Temperature Standardization

gyM

y..

.

PH6000, PC6000, PH6500, PC6500 and PCD6500 meters

To Standardize Temperature of the Meter

1. Touch Standardize on the pH measure screen to access the standardized screen.

2. Immerse your ATC probe into a solution of known temperature, such as a temperature

bath, for a few minutes while temperature stabilizes.

3. Make sure ATC probe is attached to meter.

4. Touch Temp Std to access temperature standardization

5. The Temperature Standardization screen appears. Check the current temperature

displayed with that of the solution of known temperature. Touch the Standardization

Temperature box and use numeric keypad to enter the current temperature. Press Enter

to confirm value.

6. Touch OK to confirm Standardization Temperature and return to the pH Measure screen.

Touch Reset to reset and enter a new standardization temperature. Touch Cancel to

cancel temperature standardization and return to the pH Standardization screen.

Note: The meter will not allow entered value to exceed ±5° of the ATC probe value. If entered

value exceeds ±5° an error window will appear and you will have to re-enter value or cancel

out of the temperature screen. This might indicate that you have a problem with the ATC

probe.

Technolo

adeEas

114

pH Operation: pH Measurements

gyM

y..

.

PH6000, PC6000, PH6500, PC6500 and PCD6500 meters

The measure screen provides readout of

the current sample measurement. You

can use this meter when the Auto Read

function is active or when it is inactive.

When the auto read function is active,

the meter will lock onto a reading when

the meter recognizes it as stable. The

meter will not deviate from this reading

until the Measure button is touched.

If the Auto Read mode is inactive, then

the meter will continuously monitor the

pH of the sample and the measure

display screen will indicate any

fluctuation in the sample pH. Regardless

of the status of the Auto Read mode,

STABLE will flash as the meter

recognizes the measurement as stable.

Once the meter is standardized, you are

ready to take pH measurements of your

sample.

pH Measure screen with Auto Read OFF

To Measure pH of a Sample with Auto Read ON

1. Immerse the rinsed electrode(s) in the sample and stir gently.

2. Touch Measure to begin measuring your sample. The meter will accept the reading and

display STABLE* when the measurement meets the selected stability criteria.

OR

To Measure pH of a Sample with Auto Read OFF

1. Immerse the rinsed electrode(s) in the sample and stir gently.

2. Record the reading once the measurement has become stable. STABLE* will appear

once the meter recognizes that the measurement is stable.

* Please note that STABLE will only appear if you have completed a successful two point calibration.

NOTES: You can access other functions of the meter with the remaining buttons on the measure

screen.

• Touching Setup will access the pH Setup screen.

• Touching Measure will initiate a new measurement of a sample with Auto Read ON.

• At anytime, you can touch Mode to access another mode of operation.

Technolo

adeEas

115

Loading...

Loading...