Page 1

gyM

sy...

Instruction Manual

(PH6000/PC6000/PH6500/CON6000/DO6000/PC6500/PCD6500)

CyberComm 6000

Data Acquisition Software

For CyberScan 6000 Series Meters

Tec hno lo

adeEa

68X090831 Rev. 0 Apr 06

Page 2

Page 3

Preface

This manual serves to explain the use of the CyberComm 6000 Data Acquisition

Software. The manual functions in two ways, firstly as a step by step guide to help

the user work with software application. Secondly, it serves as a handy reference

guide. It assumes that the user is familiar with setting up, calibrating & measuring

with CyberScan 6000 series meter.

The information presented in this manual is subject to change without notice as

improvements are made, and does not represent a commitment on part of Eutech

Instruments.

Eutech Instruments cannot accept any responsibility for damage or malfunction of the

unit due to improper use of the instrument.

Copyright ©2006 All rights reserved.

Eutech Instruments Pte Ltd.

Page 4

Page 5

Table of Contents

1. Getting Started ......................................................................................................1

1.1 Overview ................................................................................................................................ 1

1.2 Installing PC Communication Software.................................................................................. 2

1.3 Connecting to CyberScan 6000 Series Meter........................................................................ 6

1.3.1 RS232 Serial Port Connection....................................................................................... 6

1.3.2 Prepare the Meter for Communication .......................................................................... 6

1.4 Launching CyberComm ......................................................................................................... 8

1.5 Getting Familiar with CyberComm ....................................................................................... 11

1.5.1 Overview...................................................................................................................... 11

1.5.2 Menu bar...................................................................................................................... 11

1.5.3 Control tabs ................................................................................................................. 11

1.5.4 Workspace................................................................................................................... 12

1.6 Synchronizing Data ..............................................................................................................13

1.6.1 Data Import.................................................................................................................. 13

1.6.2 Data Export.................................................................................................................. 15

1.7 System Settings ................................................................................................................... 16

1.7.1 Time Stamp ................................................................................................................. 16

1.7.2 COM Port Configuration .............................................................................................. 16

2. Projects ................................................................................................................19

2.1 Overview .............................................................................................................................. 19

2.2 Adding a New Project........................................................................................................... 20

2.3 Loading a Project ................................................................................................................. 21

2.4 Editing a Project ................................................................................................................... 21

2.5 Deleting a Project ................................................................................................................. 21

3. Standardization ...................................................................................................23

3.1 About Standardization.......................................................................................................... 23

3.2 Select existing standardization data of the meter for measurement.................................... 24

3.3 Select existing standardization data of CyberComm for measurement............................... 26

3.4 New Standardization using an existing electrode ................................................................ 28

3.5 Add a new electrode to the project....................................................................................... 32

3.6 Remove an existing electrode from the project.................................................................... 33

3.7 Clear standardization from an electrode .............................................................................. 33

3.8 Compare Electrode Characteristics ..................................................................................... 34

3.9 Temperature Standardization............................................................................................... 36

4. Measurements .....................................................................................................37

4.1 About Measurement ............................................................................................................. 37

4.2 Measure Tab ........................................................................................................................ 37

4.2.1 Selecting a Single Channel ......................................................................................... 37

4.2.2 Selecting Multiple Channels ........................................................................................ 39

4.2.3 Refresh Temperature Reading.................................................................................... 41

4.2.4 Log measurement data................................................................................................ 41

4.2.5 Taking a Snap Shot of Graph ...................................................................................... 43

5. Reports.................................................................................................................44

5.1 About Reports ...................................................................................................................... 44

5.2 Graphic Sheet ...................................................................................................................... 45

5.3 View Graph........................................................................................................................... 47

5.4 Stored Data .......................................................................................................................... 49

5.5 Excel Sheet .......................................................................................................................... 50

5.6 Standardization (STD) Report.............................................................................................. 51

Page 6

6. Administrative Functions ...................................................................................57

6.1 Audit Log .............................................................................................................................. 58

6.1.1 View audit log file......................................................................................................... 58

6.1.2 Backup audit log file .................................................................................................... 59

6.1.3 Delete audit log file ...................................................................................................... 59

6.2 Unlocking Users ................................................................................................................... 60

Page 7

Instruction Manual CyberComm 6000

1. Getting Started

1.1 Overview

The Eutech Instruments’ CyberComm 6000 Data Acquisition software is a

Windows® based add-on application to CyberScan 6000 series meters. It enables

you to extend the use of CyberScan meter by seamlessly integrating the meter to a

personal computer and provides collaboration features for multi-user environment.

Key features of CyberComm:

User friendly interface to extend the CyberScan features

Easy synchronization of data between CyberScan & CyberComm

Unlimited number of data logging (depending on hard disk capacity)

Project base working environment lets users to organize their meter related

activities

Share standardization information among users and projects

Provides extensive audit track of CyberComm/CyberScan user activities

(accessible only for administrator)

Keep records of electrode configuration and buffer configuration

Provides graphical comparison of pH electrode properties

User configurable reports

Export data to Microsoft® Excel

Report printing

1

Page 8

Instruction Manual CyberComm 6000

1.2 Installing PC Communication Software

To install the PC Communication software:

1. Insert the PC Communication software installation CD into the CDROM drive of

your PC. The installation wizard should automatically start a shown in Figure 1 &

Figure 2 :.

Figure 1 : Preparing to install

2

Page 9

Instruction Manual CyberComm 6000

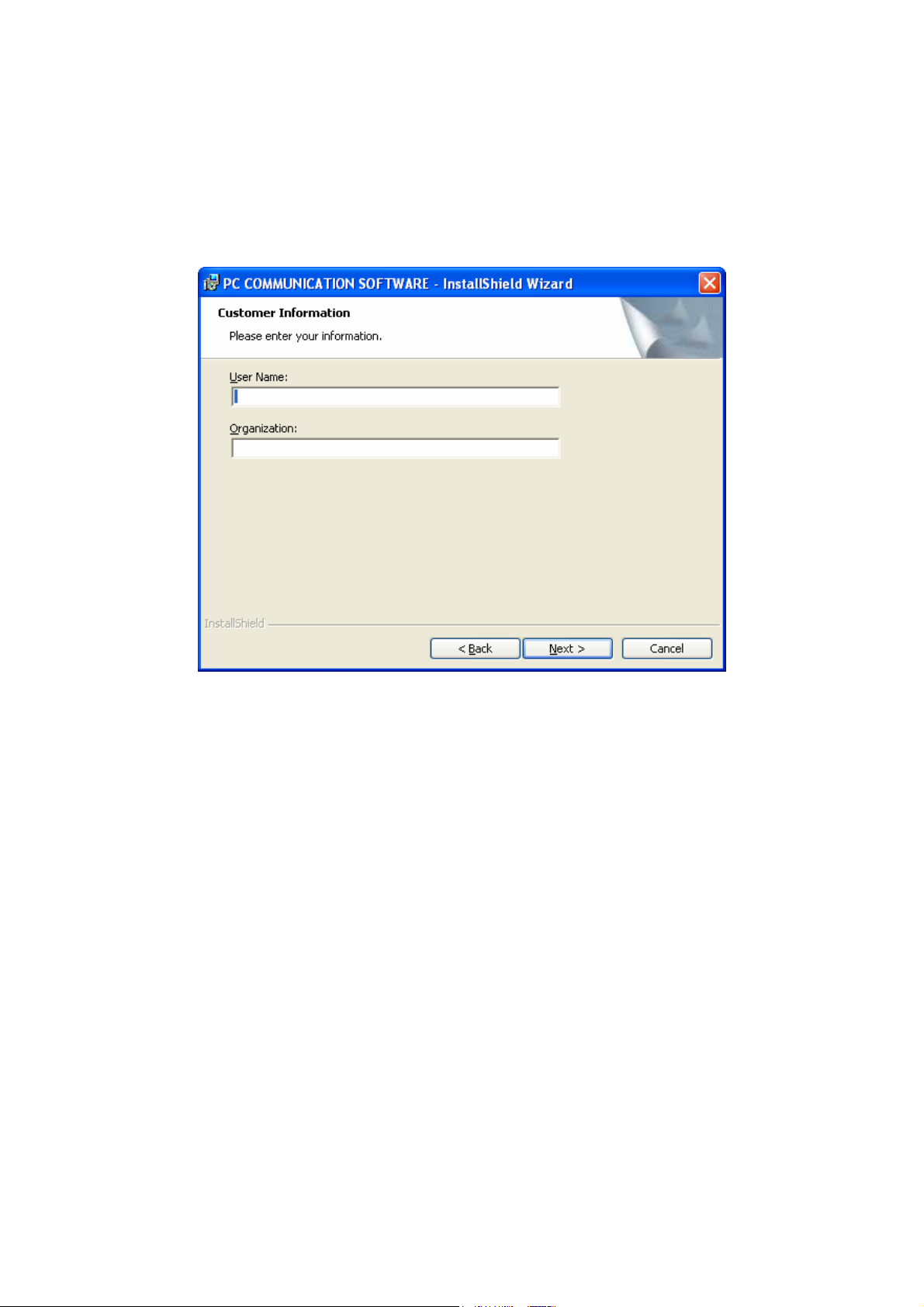

Figure 2 : Second screen of installation

2. In the second screen (Figure 2), click Next to continue.

3. You may optionally enter your name & your organization’s name in the next

screen (Figure 3). Click Next to continue.

Figure 3 : Customer information

4. By default, the program will be installed into ‘C:/Program Files/ PC

Communication/Cybercomm6000_620’ folder. Click Next to install the program in

this folder. Optionally, click Change to install into a different folder. (Figure 4)

3

Page 10

Instruction Manual CyberComm 6000

Figure 4 : Destination folder

5. In the next screen, click Install to begin the installation. (Figure 5)

Figure 5 : Ready to begin installation

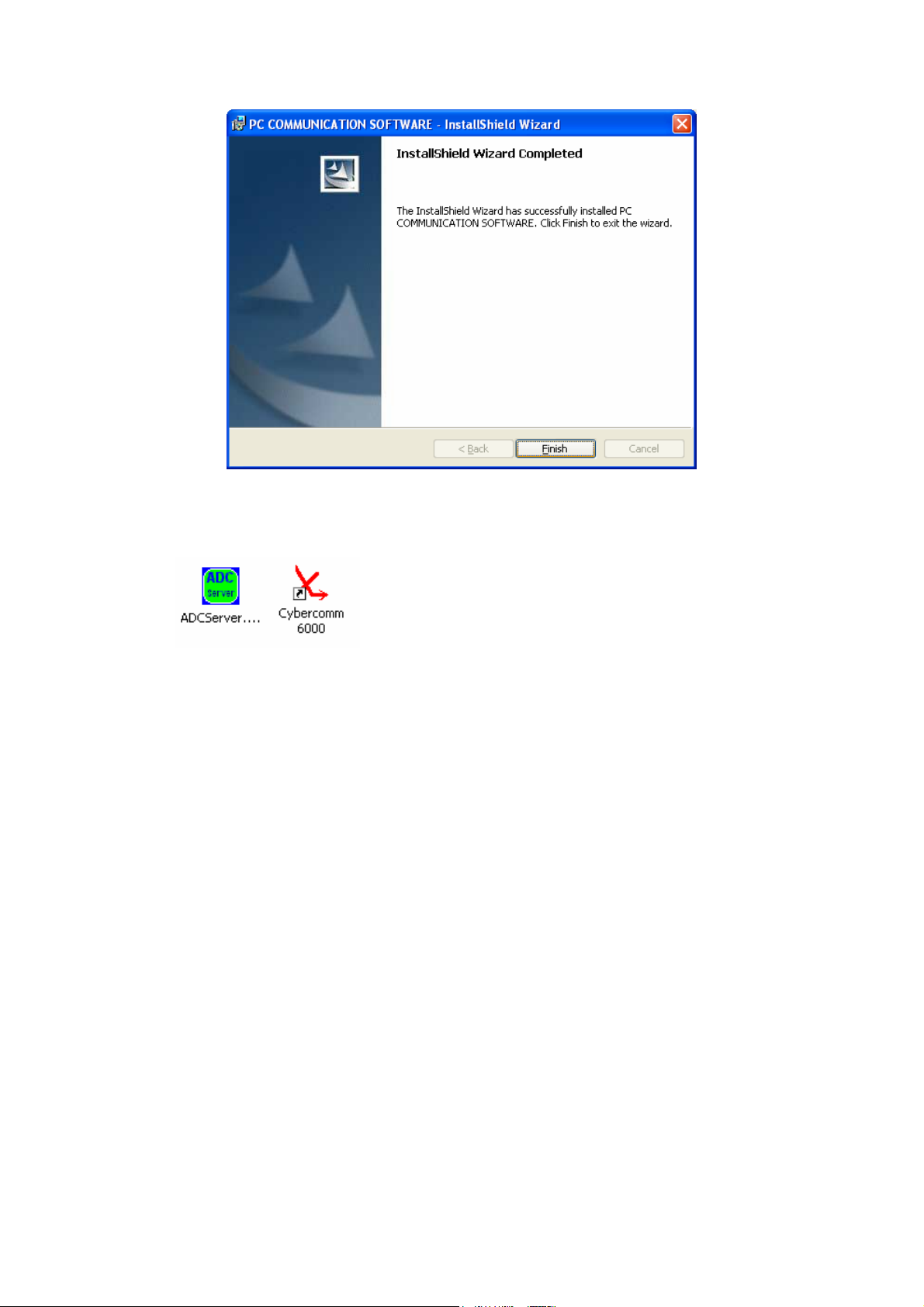

6. Once the installation successfully is completed, the following screen is shown.

(Figure 6). Click Finish to exit the wizard.

4

Page 11

Instruction Manual CyberComm 6000

Figure 6 : Installation completed

7. The following two icons are available in your Desktop after the installation.

5

Page 12

Instruction Manual CyberComm 6000

1.3 Connecting to CyberScan 6000 Series Meter

The Cybercomm 6000 Data Acquisition software is able to communicate with any

CyberScan 6000 series meter (PH6000 / PC6000 / PH6500 / CON6000 / DO6000 /

PC6500 / PCD6500) via RS232 serial port connection.

1.3.1 RS232 Serial Port Connection

1. Connect RS232 serial communication cable to RS232 port of the back panel of

CyberScan 6000 series meter.

2. Connect the other end of the cable to serial communication (COM) port of your

PC. If you use a serial communication port other than COM1, you need to specify

it in CyberComm configuration settings. Refer ‘COM Port Configuration’ in page

16.

1.3.2 Prepare the Meter for Communication

1. Make sure the required pH, DO, Conductivity probes are connected to the back

panel of the CyberScan 6000 series meter. (Refer the instruction manual of the

meter for more details)

2. Power on the meter. The CyberScan application starts automatically.

3. Tap Logoff button to exit form CyberScan application.

Note: The meter cannot be connected to the CyberComm software when

the CyberScan application is running. You need to exit the CyberScan

application before you can start communicating with CyberComm.

4. Start ADCServer. Double-tap on ‘ADCServer’ icon available in the

Desktop of the meter. The ADC Server application window appears.

(Figure 7)

6

Page 13

Instruction Manual CyberComm 6000

Figure 7 : ADC Server application window

Notes:

• The ADC Server is the communication interface between the meter

and the CyberComm 6000 software. Therefore, you need to run ADC

Server before you can start communicating with the CyberComm

6000.

• Do not close the ADC Server while the meter is communicating with

CyberComm software.

7

Page 14

Instruction Manual CyberComm 6000

1.4 Launching CyberComm

1. Make sure the ADC Server is running in the meter.

2. Double-click on CyberComm 6000 icon on the Desktop of your

PC. The CyberComm splash screen appears for few seconds and

then the application starts.

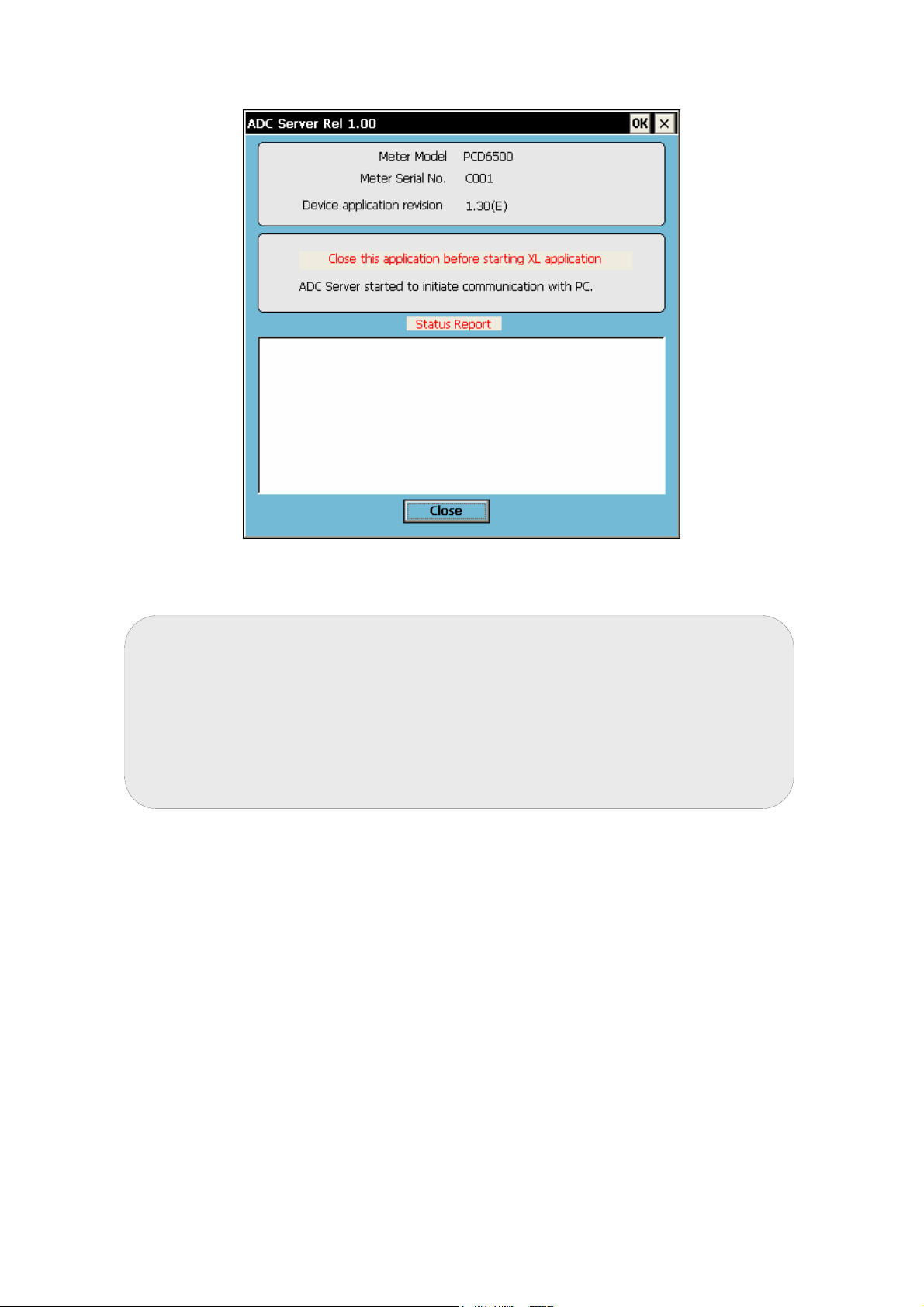

3. In the meter, the ADC Server recognizes the CyberComm

connection and starts sending user information, hardware calibration & user

database. The communication status information is shown in ADC Server window.

(Figure 8)

Figure 8 : ADC Server sending information

8

Page 15

Instruction Manual CyberComm 6000

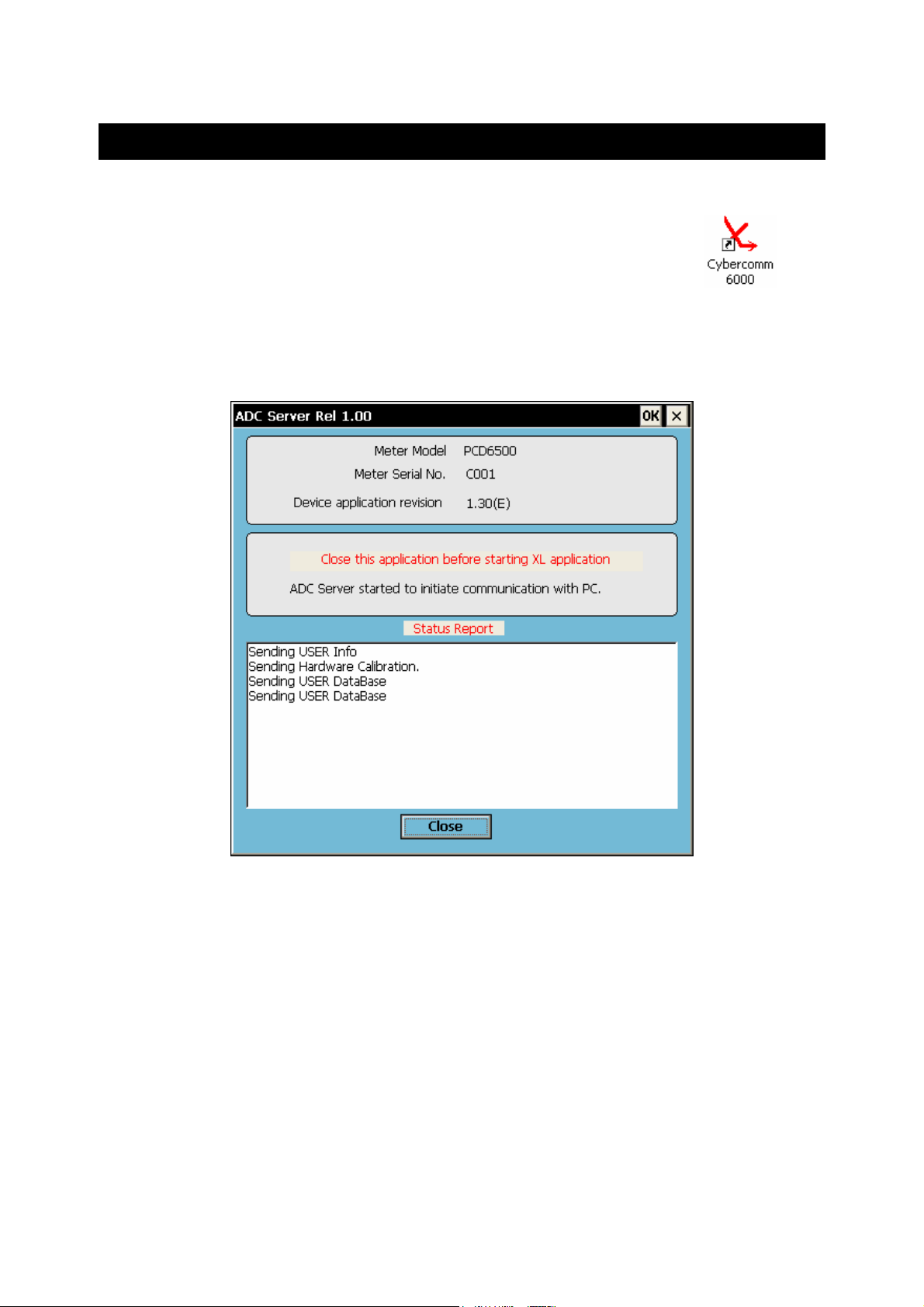

5. CyberComm establishes connection with the meter and synchronizes basic

information (user information, hardware calibration & user databases) with the

meter. (Figure 9)

Figure 9 : CyberComm synchronizes with meter

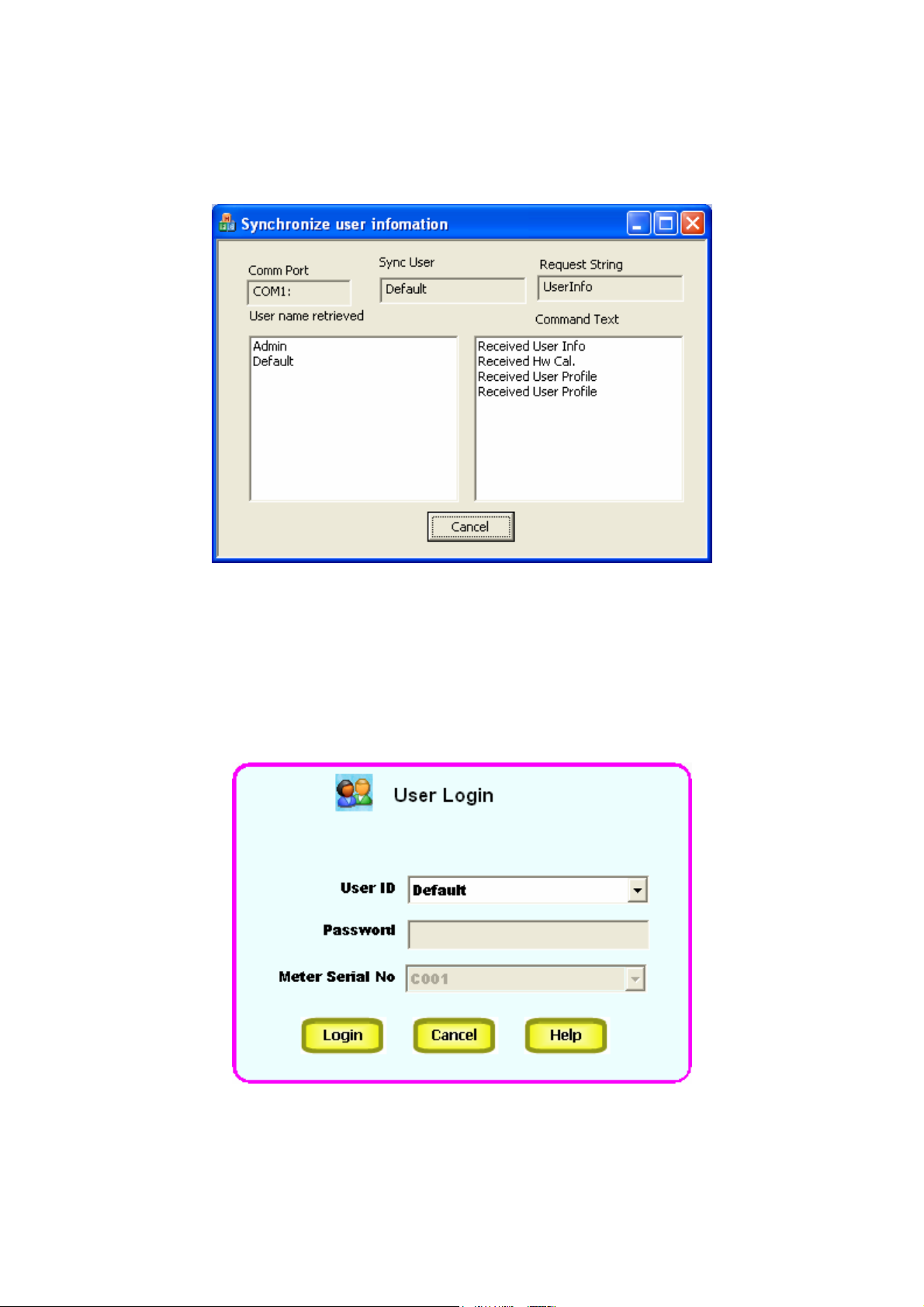

6. Once the synchronization is completed, the User Login screen appears. (Figure

10) CyberComm accepts all user IDs & passwords configured in the meter. The

user IDs available in the meter are listed in the User ID drop-down box. You can

proceed with the ‘Default’ user or select a specific user ID and enter password.

Click Login button to proceed

Figure 10 : User Login

9

Page 16

Instruction Manual CyberComm 6000

Note: If a user enters an invalid password for a particular user ID for

three consecutive attempts, CyberComm will ‘Lock’ the user profile and

the user will no longer be able to login to the system using that particular

user ID. This is a security feature. Only the ‘Admin’ user is able to unlock

such locked users. Refer ‘Unlocking Users’ in page 56.

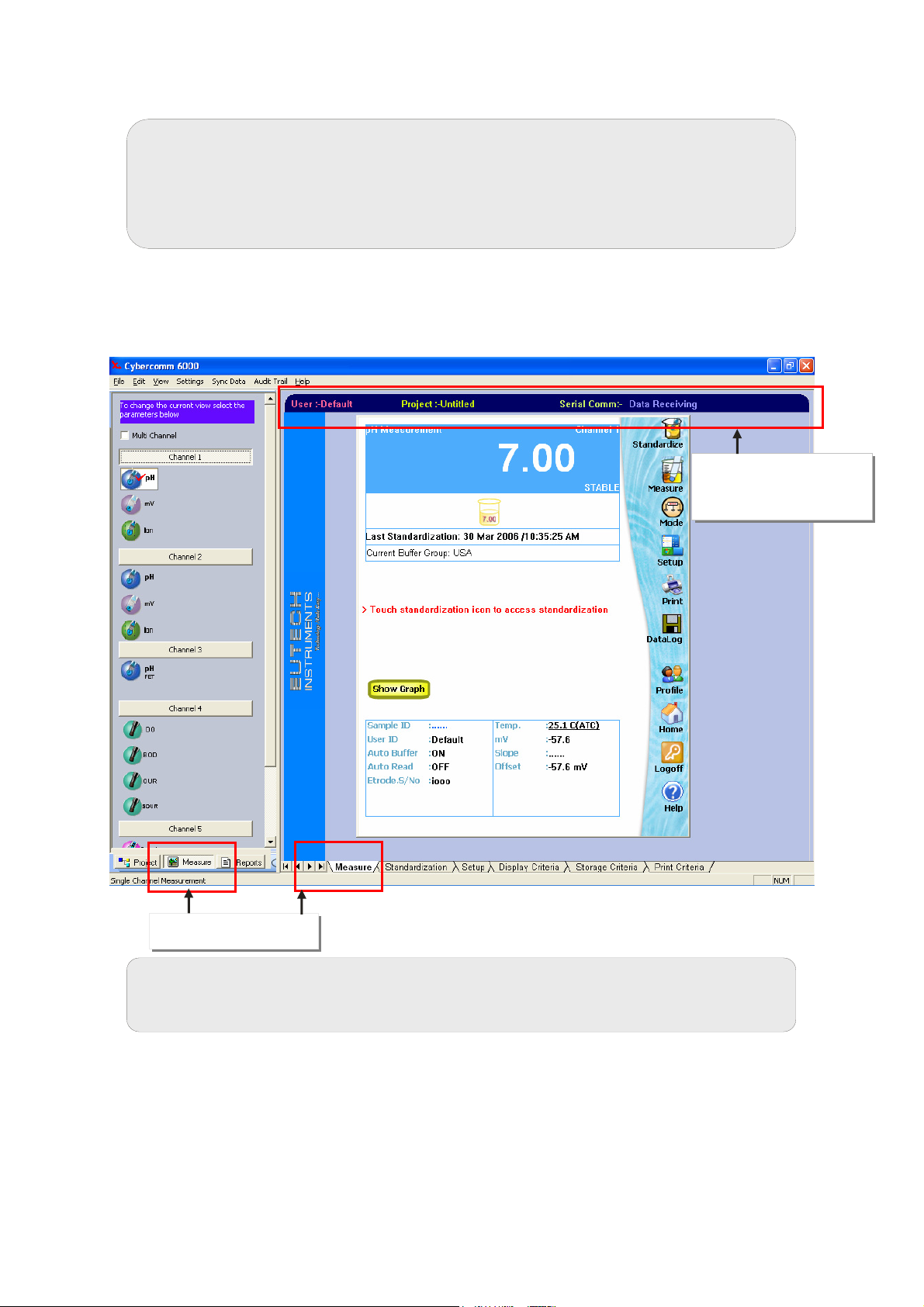

7. CyberComm goes to measurement mode in ‘Untitled’ project for the selected

user. (Figure 11). You are ready to work with the meter. You can proceed with

measurement using the meter.

Current user, project &

communication

information

Figure 11 : Measurement mode

Measurement mode

Note: All the activities you do with CyberComm are bound to your user

ID and project name.

You may perform any of the following activities:

Create a new project (See page 19)

Import setup data from the meter (See page 13)

Import standardization (calibration) data from the meter (See page 13)

Import logged data from the meter (See page 13)

10

Page 17

Instruction Manual CyberComm 6000

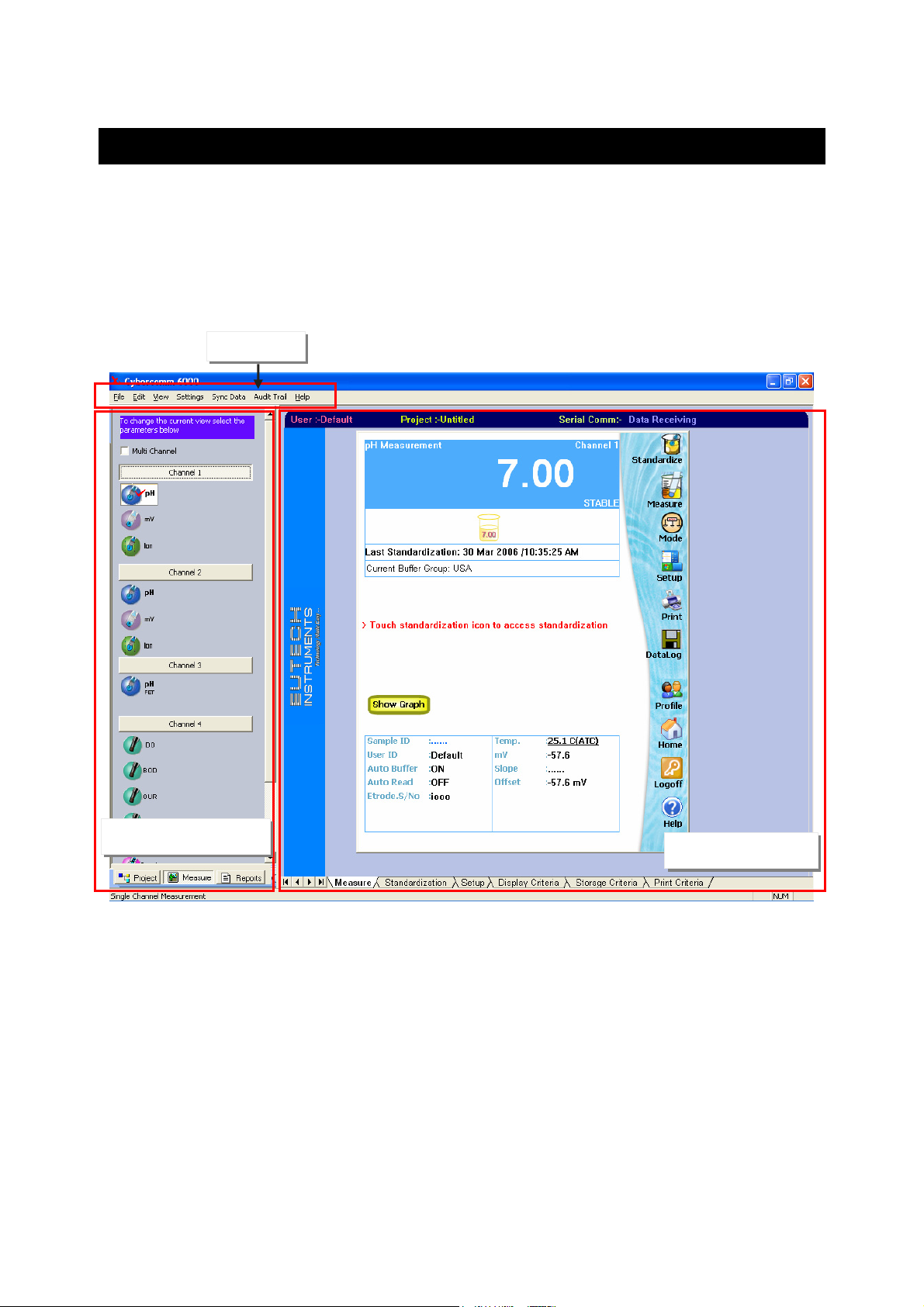

1.5 Getting Familiar with CyberComm

1.5.1 Overview

The user interface of CyberComm 6000 has the following main sections.

Menu bar

Control tabs

Workspace

Menu bar

Control tabs

Figure 12 : Menu bar, Control tabs & Workspace

1.5.2 Menu bar

Menu bar has menus and sub-menus to perform common tasks

1.5.3 Control tabs

Control tabs consist of three tabs:

Project: Project related activities are carried out in this tab. Read more about

projects (page 19)

Measure: Meter related activities are carried out in this tab. You can select

multiple channels and measuring parameters form the left-pane. The rightpane (workspace) displays 6 tabs (Measure, Standardization, Setup, Display

11

Workspace

Page 18

Instruction Manual CyberComm 6000

Criteria, Storage Criteria and Print Criteria) for the selected channel (or

channels) and a parameters. The functions and features available in your

CyberScan 6000 series meter are accessible from the measure tab.

Report: This tab provide access to various reports, graphs, view stored data &

printing reports

1.5.4 Workspace

Workspace is the main display and working area of the CyberComm. What is

displayed in workspace depends on the selections in the control tab.

12

Page 19

Instruction Manual CyberComm 6000

1.6 Synchronizing Data

CyberComm 6000 allows you to synchronize data between the PC & the CyberScan

6000 series meter. This involves import (from meter to CyberComm) & export (from

CyberComm to meter)

1.6.1 Data Import

The following data can be transferred from the meter to CyberComm.

User information & hardware calibration (Automatically synchronized each

time the meter is connected to CyberComm)

Setup data

Standardization data

Logged data

User information & hardware calibration data are synchronized automatically each

time the meter is connected to CyberComm. However, setup, standardization &

logged data of the meter have to be synchronized with user intervention as described

below.

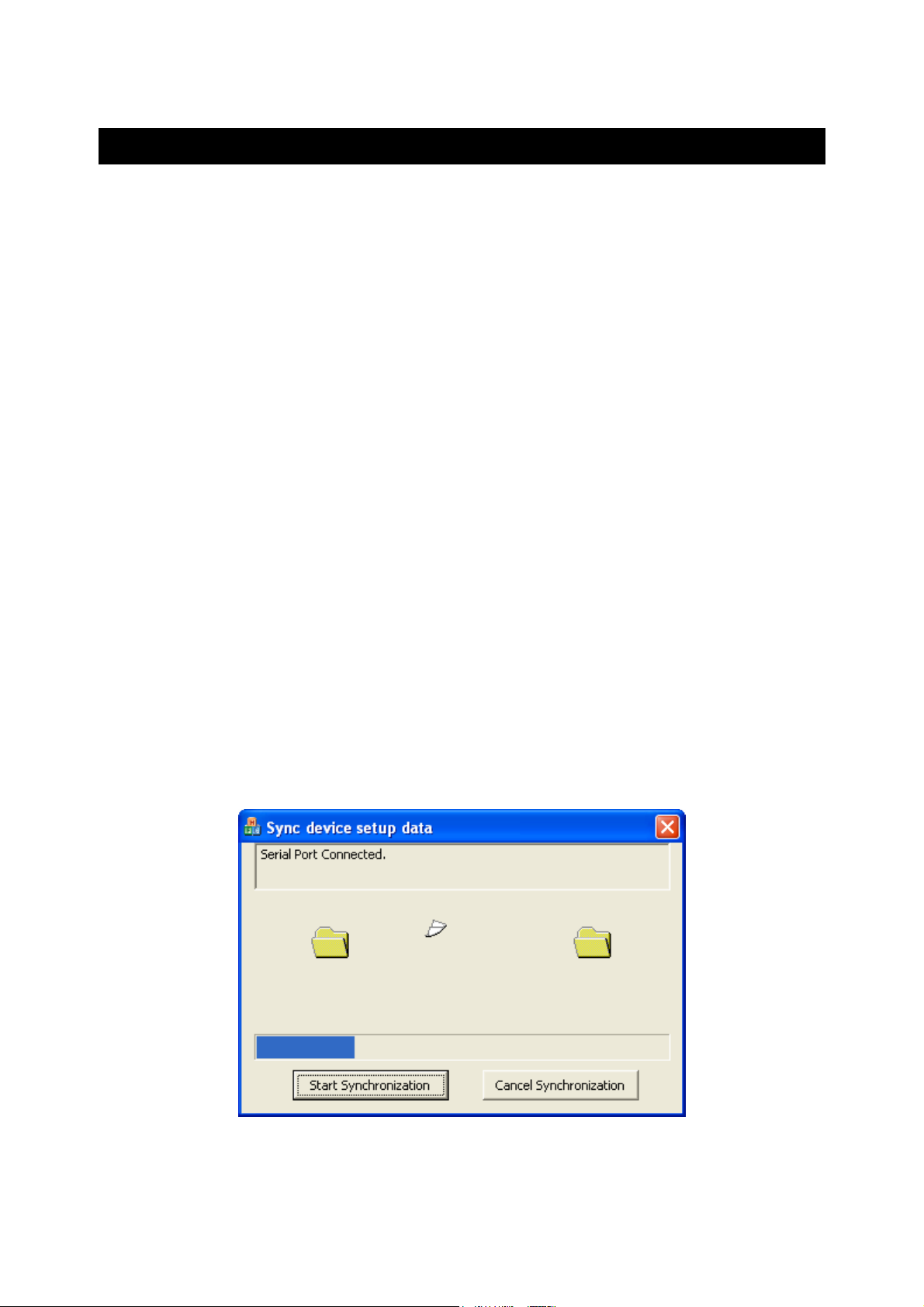

To import Device Data:

1. Click on Project button to switch to Project tab.

2. In the menu bar, click Sync Data and then click on any of the following sub

menus :

Import Setup Data

Import STD Data, or

Import Logged Data

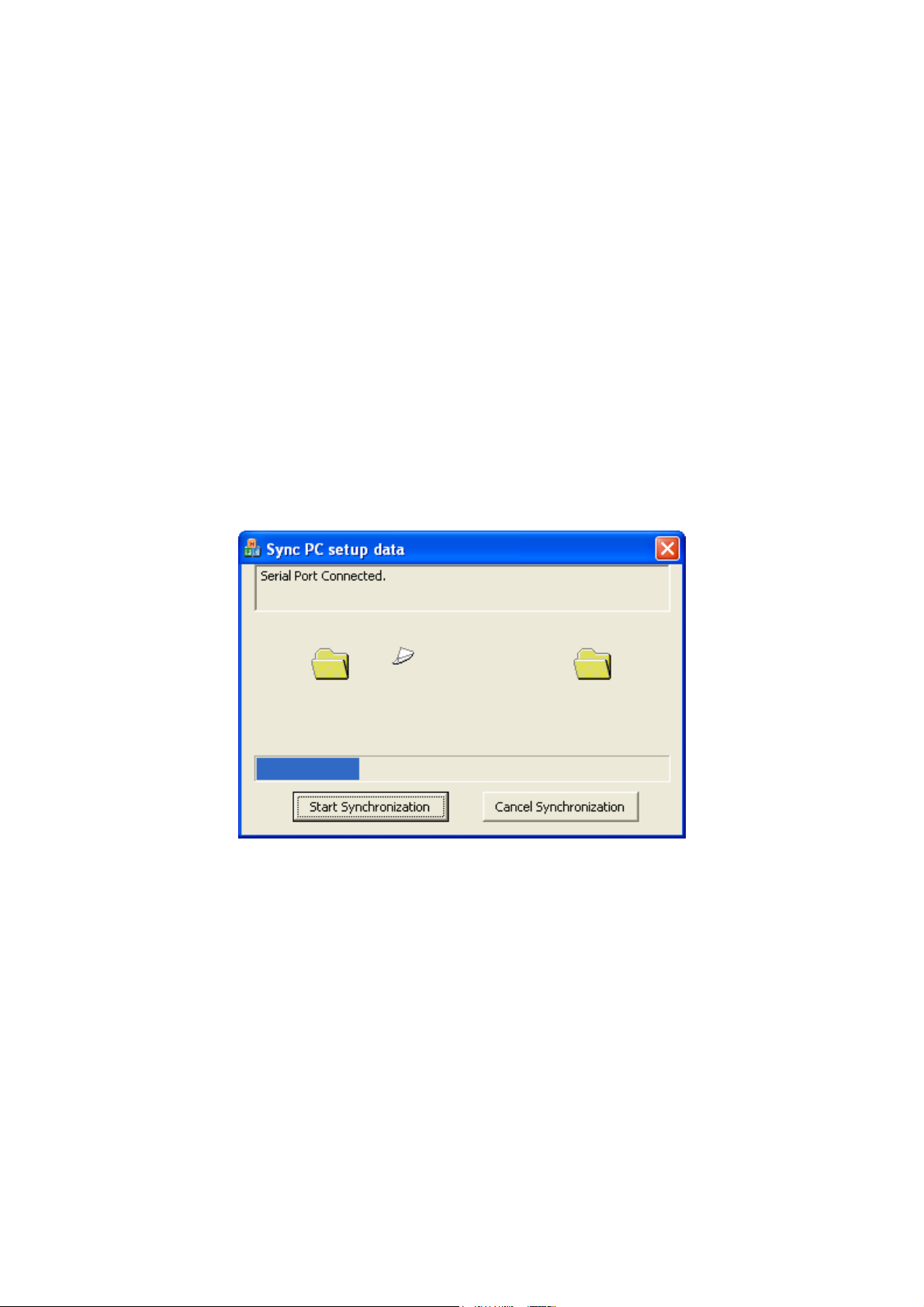

3. Sync Device Data dialog appears (Figure 13). Click Start Synchronization. The

progress bar shows the status of data synchronization.

Figure 13 : Synchronizing device data

13

Page 20

Instruction Manual CyberComm 6000

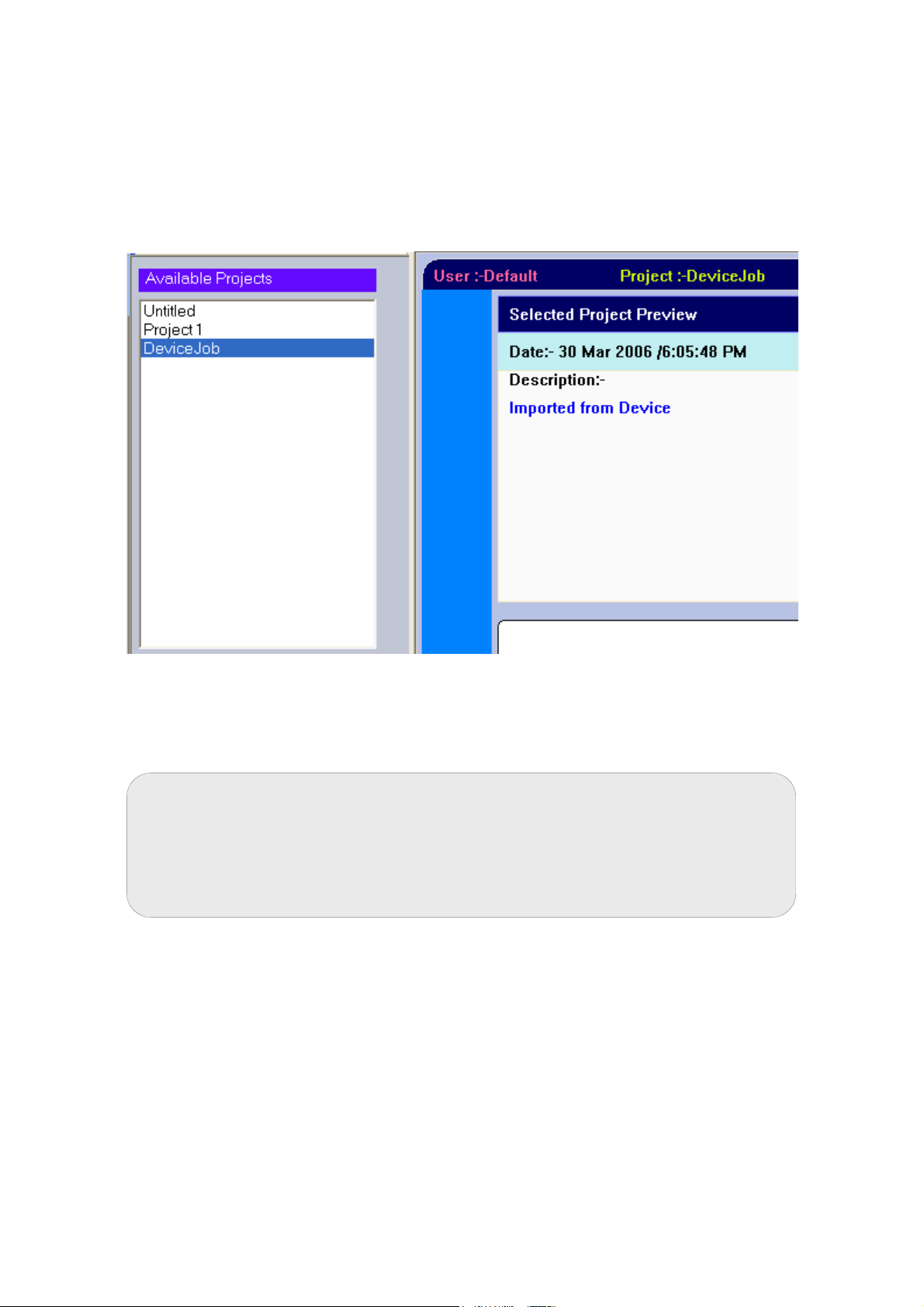

4. When the synchronization (import) is completed, system creates a new project

named ‘DeviceJob’ and attaches the imported device data to that project. (Figure

14). If there is ‘DeviceJob’ already available in the project list, then the imported

data is automatically copied to it.

Figure 14 : DeviceJob

5. Repeat step 2 & 3 selecting rest of the two sub menus to import all the device

data.

Note: The imported standardization data is available for other projects

you may create for the same CyberScan meter. Other users who use the

same CyberScan meter can access the standardization data you

imported from the meter. Thus, users do not need to calibrate the meter

for each project they create.

14

Page 21

Instruction Manual CyberComm 6000

1.6.2 Data Export

The following data can be transferred from CyberComm to the meter.

Setup data

Standardization data

When you export setup and standardization data, only the data of the current project

is transferred to the meter.

To export data:

1. Click on Project button to switch to Project tab.

2. In the menu bar, click Sync Data and then click on any of the following sub

menus :

Export Setup Data, or

Export STD Data

3. Sync Device Data dialog appears (Figure 15). Click Start Synchronization. The

progress bar shows the status of data synchronization.

Figure 15 : Synchronizing CyberComm data

4. When the data export is competed, the dialog box closes automatically and the

selected data (setup or standardization) of the current project copied to the meter,

replacing previously stored data of the meter (if any).

15

Page 22

Instruction Manual CyberComm 6000

1.7 System Settings

1.7.1 Time Stamp

Time stamps are used in audit logs, data logs and standardization records. By default,

CyberComm uses the system date/time of the PC (host computer) for all time stamps.

You can change this setting if you wish to use date/time of the device (CyberScan

meter) for all time stamps of CyberComm.

To change:

1. On the menu bar, click Settings menu and then click System Setting sub menu.

The System Setup dialog appears (Figure 16Figure 50).

2. In Time stamp source group, select the required option.

Figure 16 : System Setup

1.7.2 COM Port Configuration

CyberComm communicates with CyberScan meter through serial communication port

of the PC. By default, CyberComm tries to connect to COM1 port at a baud rate of

115200 bits per second. If you connect CyberScan meter to your PC using a

communication port other than COM1, CyberComm fails to communicate with the

meter. To rectify this, you need to specify the correct COM port in CyberComm.

To change COM port configuration:

1. On the menu bar, click Settings menu and then click COM Port configuration

sub menu. The following dialog appears. (Figure 17). Selected COM port and

baud rate are shown in the dialog box.

16

Page 23

Instruction Manual CyberComm 6000

(a) (b)

Figure 17 : COM Port Configuration

If CyberComm is already connected to the selected COM port, the ‘COM Port

Status’ field shows ‘COM Port is OK’ and the two drop-down boxes are readonly. [Figure 17 (a)]. To change COM port configuration, click Disconnect

button.

If the CyberComm is not connected to the selected COM port, the ‘COM Port

Status’ field shows ‘COM Port Failed’. [Figure 17 (b)]

2. Select the correct COM port from the COM Port drop-down box.

3. Click Connect button to connect to the selected COM port.

Note: If you are using a USB-to-Serial conversion cable to connect the

meter to USB port of the PC, you may need to check the Device

Manager of your PC to see what the exact port number is.

Right-click on My Computer icon. Click on Properties pop-up menu to

open System Properties. Click Hardware tab and then click Device

Manager. See the applicable COM port name under ‘Ports (COM & LPT)

as shown in Figure 18.

17

Page 24

Instruction Manual CyberComm 6000

Figure 18 : Device Manger

18

Page 25

Instruction Manual CyberComm 6000

r

2. Projects

2.1 Overview

CyberComm 6000 is a project based application. What ever activities you do with

CyberComm is bound to a project. When CyberComm starts working with a

CyberScan meter for the first time, it begins with a default project called ‘Untitled’.

You can proceed with the ‘Untitled’ project or you can create new projects of your

own. Figure 19 shows relationship between a CyberScan meter, user profile &

projects.

CyberScan 6000 Series Mete

(With unique Serial Number)

User 1

Project A

Setup data

Standardization Date

Reports

Stored Data

User 2 User 3 User N

Project B

Setup data

Standardization Date

Reports

Stored Data

Figure 19 : Meter-User-Project hierarchy

Project C

Setup data

Standardization Date

Reports

Stored Data

Setup data

Standardization Date

Reports

Stored Data

Project Z

A particular CyberScan meter can have multiple users working with it. Each user can

have his-own projects. Each project has a separate database to store its setup,

standardization, reports and stored data which cannot be accessed by other uses.

Notes:

• Users have access to standardization (calibration) information of

other users of the same meter. This allows sharing the same

meter with multiple users without having to calibrate individually.

• Also, a particular user can share standardization data between his

own projects

DeviceJob

DeviceJob is a special project created by the system when you import device data

from the meter.

19

Page 26

Instruction Manual CyberComm 6000

2.2 Adding a New Project

To add a new project:

1. Click button to switch to

Project control tab. The available

projects and project related buttons are

displayed in the Project tab (Figure 20)

2. Click Add New Project. New project

dialog box appears.

3. Specify Project Name of your choice

(mandatory) & Description (optional).

System automatically adds the system

date/time and your user ID. (Figure 21)

4. Click OK.

5. The new project is added to Available

Projects list.

Figure 20 : Project Tab

Figure 21 : Adding a New Project

20

Page 27

Instruction Manual CyberComm 6000

2.3 Loading a Project

When you select an existing project from the Available Projects list, the upper area

of the workspace shows the Project Preview which includes project description and

date created. However, the project data are not loaded to the workspace. Before you

can work with a project, you need to load it to the workspace.

To load a project:

1. Select the project from the Available Projects list.

2. Click Load Selected Project. The project details are loaded into the lower area of

the workspace. The title bar shows the name of the loaded project (Figure 22)

Figure 22: Title bar

2.4 Editing a Project

System allows you to edit the description of the project as long as it is not loaded into

workspace.

To edit a project:

1. Make sure the project is not currently loaded in the workspace.

Hint: If the project you wish to edit is currently loaded in the workspace, load

another project.

2. Click Edit Project. Project properties dialog box appears. Only the description

field is editable. Edit the description.

3. Click OK.

2.5 Deleting a Project

System allows you to delete a project as long as it is not loaded into workspace.

To delete a project:

1. Make sure the project is not currently loaded in the workspace.

Hint: If the project you wish to edit is currently loaded in the workspace, load

another project.

2. Click Delete Project. System shows a confirmation message.

3. Click Yes. The Project is permanently deleted.

21

Page 28

Instruction Manual CyberComm 6000

22

Page 29

Instruction Manual CyberComm 6000

3. Standardization

3.1 About Standardization

It is recommended that you standardize CyberComm before you make any

measurements. CyberComm provides you flexibility in Standardization. You can

either perform a fresh standardization or import existing standardization data from the

CyberScan meter or re-use standardization data of other users who have already

performed standardization in the CyberComm. At any time, you can switch your

standardization without losing the previous standardization data.

In CyberComm, standardization is available when you are in single-channel mode.

Note: If you wish to use existing standardization data of the meter, you

need to import standardization data from the meter. You will see

‘DeviceJob’ under Projects tab once you synchronized data. See page

12 for more details on importing standardization data.

Available options in standardization:

Select existing standardization data of the meter and proceed with

measurement

Select existing standardization data of CyberComm and proceed with

measurement

New standardization using an existing electrode

Temperature standardization

Additional options:

Add a new electrode to the project

Remove an existing electrode from the project

Clear standardization from an electrode

Compare electrode characteristics

23

Page 30

Instruction Manual CyberComm 6000

3.2 Select existing standardization data of the meter for

measurement

Follow the steps below, if you wish to use standardization data, available in the

CyberScan meter. Note that you need to synchronize standardization data of the

meter or any other user has already synchronized standardization data with the meter,

before you can use the data. See page 13 for more details on importing

standardization data.

To begin:

1. Make sure Multi-channel check box is not selected in the Measure control tab.

2. Select the channel and its parameter that you intend to standardize.

3. Click Setup tab and set appropriate standardization options.

For pH standardization, click on Setup tab and select the Buffer Group.

For conductivity standardization, click on Setup tab and select appropriate

Standard Recognition.

For DO standardization, click on Setup tab and select appropriate

Standardization mode.

4. Click on Standardization tab in the workspace.

5. Electrode Configuration Dialog appears. (Figure 23)

6. in User drop-down box, select :

You user ID: if you have already synchronized standardization data with

the meter and you wish to use that info

Any other user ID: if any other user has already synchronized

standardization data with the meter and you wish to use that info.

7. The Project Name (Job Name) drop-down box lists all the available projects for

the selected user. Select DeviceJob from the list

8. The Electrode Serial No drop-down box lists available electrode list for the

selected project (in this case it is ‘DeviceElectrode’)

9. Select ‘DeviceElectrode’. Existing Standardization grid shows standardization

data for the selected channel, selected parameter, for the selected

standardization buffer/range and for the selected electrode. Depending on the

selected channel/parameter, it also shows related information such as

standardization date, slope, offset, buffer expiry date etc.

Note: If the selected electrode of the project does not have a matching

standardization data for the selected channel/parameter/buffer/range, the

Existing Standardization grid does not show any data.

10. If you wish to use the standardization data shown in the grid for your

measurement, click Load Selected Standardization button.

11. The Electrode Configuration Dialog exists. CyberComm copies the selected

electrode to the current project. The selected standardization data is loaded to the

selected channel/parameter and the CyberComm is ready for measurement using

the selected standardization.

24

Page 31

Instruction Manual CyberComm 6000

Figure 23 : Selecting standardization available in the meter

25

Page 32

Instruction Manual CyberComm 6000

3.3 Select existing standardization data of CyberComm for

measurement

Follow the steps below, if you wish to use standardization data, available in the

CyberComm. This includes standardization done by you previously for the same

meter and for the same channel/parameter or standardization done by other users for

the same meter and same channel/parameter.

To begin:

1. Make sure Multi-channel check box is not selected in the Measure control tab.

2. Select the channel and its parameter that you intend to standardize.

3. Click Setup tab and set appropriate standardization options.

For pH standardization, click on Setup tab and select the Buffer Group.

For conductivity standardization, click on Setup tab and select appropriate

Standard Recognition.

For DO standardization, click on Setup tab and select appropriate

Standardization mode.

4. Click on Standardization tab in the workspace.

5. Electrode Configuration Dialog appears. (Figure 24)

6. in User drop-down box, select :

You user ID: if you have already performed standardization with this

project or any other project and you wish to use that info

Any other user ID: if any other user has already performed

standardization and you wish to use that info.

7. The Project Name (Job Name) drop-down box lists all the available projects for

the selected user. Select required project from the list

8. The Electrode Serial No drop-down box lists available electrode list for the

selected project.

9. Select required electrode’. Existing Standardization grid shows standardization

data for the selected channel, selected parameter, for the selected

standardization buffer/range and for the selected electrode. Depending on the

selected channel/parameter, it also shows related information such as

standardization date, slope, offset, buffer expiry date etc.

Note: If the selected electrode of the project does not have a matching

standardization data for the selected channel/parameter/buffer/range, the

Existing Standardization grid does not show any data.

10. If you wish to use the standardization data shown in the grid for your

measurement, click Load Selected Standardization button.

11. The Electrode Configuration Dialog exists. If you have selected standardization

data from another project, CyberComm copies the selected electrode to the

current project. The selected standardization data is loaded to the selected

channel/parameter and the CyberComm is ready for measurement using the

selected standardization.

26

Page 33

Instruction Manual CyberComm 6000

Figure 24 : Selecting existing standardization available in CyberComm

27

Page 34

Instruction Manual CyberComm 6000

3.4 New Standardization using an existing electrode

Follow the steps below, if you wish to perform a fresh standardization using an

existing electrode. It is assumed that the electrode data has been already added to

CyberComm.

Prepare you standard buffer solutions in beakers. Make sure the electrode is

attached to the meter and it is ready for standardization.

To begin:

1. Make sure Multi-channel check box is not selected in the Measure control tab.

2. Select the channel and its parameter that you intend to standardize.

3. Click Setup tab and set appropriate standardization options.

For pH standardization, click on Setup tab and select the Buffer Group.

For conductivity standardization, click on Setup tab and select appropriate

Standard Recognition.

For DO standardization, click on Setup tab and select appropriate

Standardization mode.

4. Click on Standardization tab in the workspace.

5. Electrode Configuration Dialog appears. (Figure 25)

6. Make sure your user name and your current project name are selected in User &

Project Name (Job Name) drop-down box.

7. From Electrode Serial No drop-down box lists select the electrode you wish to

use for standardization. (Existing Standardization grid shows standardization

data for the selected channel, selected parameter, for the selected

standardization buffer/range and for the selected electrode)

Note: If the selected electrode of the project does not have a matching

standardization data for the selected channel/parameter/buffer/range, the

Existing Standardization grid does not show any data.

Notes:

• You need to add buffer information to the system before you can use

a new buffer for the standardization.

• You can add only one buffer at a time. Once standardization is

completed, you need to come back to this screen if you wish to add a

second buffer.

8. To add a new buffer, click Add New Buffer button. Calibration standard

solution info screen appears. (Figure 26)

9. Enter Batch No. & Expiry Date of the buffer solution. This info will be used for

identification purposes.

28

Page 35

Instruction Manual CyberComm 6000

Note: Optionally, you may select an existing batch number from the list,

if you wish to re-use an exiting buffer.

10. Click OK to confirm the details of the new buffer. The added information is

displayed in the lower grid until you proceed with standardization.

11. To proceed with standardization for the selected electrode using the new buffer,

click OK button.

Figure 25 : New standardization using an existing electrode

29

Page 36

Instruction Manual CyberComm 6000

Figure 26 : Adding a new buffer

12. The Electrode Configuration Dialog closes. Standardization process begins for

the selected channel/electrode using the selected buffer. (Figure 27)

13. If you wish to abort the standardization due to any reason, click Cancel. To

confirm the standardization, click Confirm.

14. Once you confirm, you may proceed with standardization with another buffer by

clicking on Standardization tab or proceed with measurement by clicking

Measure tab.

30

Page 37

Instruction Manual CyberComm 6000

Figure 27 : Standardization in progress

31

Page 38

Instruction Manual CyberComm 6000

3.5 Add a new electrode to the project

You need to add electrode serial number into CyberComm before you can perform a

standardization using that electrode. The serial number uniquely identifies the

electrode. CyberComm does not allow duplicating electrode serial number.

To add a new electrode:

1. Make sure Multi-channel check box is not selected in the Measure control tab.

2. Select the channel and its parameter.

3. Click on Standardization tab in the workspace.

4. Electrode Configuration Dialog appears.

5. Click Add new electrode button. A dialog box appears (Figure 28)

6. Enter serial number of the new electrode. Click OK.

7. The newly added electrode serial number appears in the Electrode Serial No list.

Standardization data is empty for this electrode as no standardization is done yet.

You may select this electrode and perform standardization at any time.

Figure 28 : Adding a new electrode

32

Page 39

Instruction Manual CyberComm 6000

3.6 Remove an existing electrode from the project

You can delete an existing electrode from CyberComm if you are no longer using it.

The electrode and its standardization data is permanently removed from CyberComm.

To delete an existing electrode:

1. Make sure Multi-channel check box is not selected in the Measure control tab.

2. Select the channel and its parameter

3. Click on Standardization tab in the workspace.

4. Electrode Configuration Dialog appears.

5. From Electrode Serial No list, select the electrode you intend to delete.

6. Click Delete Electrode button. CyberComm shows a warning message.

7. Click OK to confirm. The electrode and its standardization data is permanently

removed from CyberComm. Standardization selected for measurement of the

current channel/parameter is also removed. You need to select standardization for

the current channel/parameter.

3.7 Clear standardization from an electrode

CyberComm allows you to remove an existing standardization data from an electrode.

This helps you to remove the current standardization from the electrode until you

perform a fresh standardization at a later time.

To clear standardization from an electrode:

1. Make sure Multi-channel check box is not selected in the Measure control tab.

2. Select the channel and its parameter

3. Click on Standardization tab in the workspace.

4. Electrode Configuration Dialog appears.

5. From Electrode Serial No list, select the electrode for which you intend to clear

standardization.

6. Click Clear Standardization button. CyberComm shows a warning message.

7. Click OK to confirm. The standardization data is permanently removed from the

electrode. Standardization selected for measurement of the current

channel/parameter is also removed. You need to select standardization for the

current channel/parameter.

33

Page 40

Instruction Manual CyberComm 6000

3.8 Compare Electrode Characteristics

CyberComm allows you to graphically compare pH electrode characteristics. You

need to add electrode serial number and perform standardization for each electrode

before you can compare them.

To compare electrodes:

1. Make sure Multi-channel check box is not selected in the Measure control tab.

2. Select the channel and its parameter

3. Click on Standardization tab in the workspace.

4. Electrode Configuration Dialog appears.

5. Click Compare Electrode button. The Electrode Comparison Graph screen

appears. (Figure 29) The graph shows electrode output characteristics against pH

values for each pH electrode in your project. Calibrated points are marked with

special symbols along the graph. The legend shows the serial number of each pH

electrode and corresponding symbols used in the graph to identify them.

Figure 29 : Electrode Comparison

6. You can select/unselect electrode form the graph. Click Select/Unselect button.

Electrode Selection Dialog appears. (Figure 30)

34

Page 41

Instruction Manual CyberComm 6000

7. A check box is available against each electrode serial number. Check to select or

uncheck to deselect electrode for graph. Click OK to conform your selection.

Figure 30 : Electrode selection for graph

Note: You can compare pH electrodes available in other projects with

the electrodes of your current project. You need to add them to your

current project before you can compare them.

35

Page 42

Instruction Manual CyberComm 6000

3.9 Temperature Standardization

CyberComm allows you to specify standardization temperature if you wish to perform

standardization at a specific temperature other than the temperature reading shown

by the meter.

To specify standardization temperature:

1. Make sure Multi-channel check box is not selected in the Measure control tab.

2. Select the channel and its parameter

3. Click on Standardization tab in the workspace.

4. Electrode Configuration Dialog appears.

5. Click Temperature Standardization button. A dialog box appears. (Figure 31)

6. Enter the temperature that you wish to perform standardization for the selected

channel/parameter.

7. Click OK to confirm. You can proceed with standardizing the selected

channel/parameter.

Note: You can reset the standardization temperature back to the actual

reading of the meter. Click Standardization Temperature button and

then click Reset.

Figure 31 : Standardization Temperature

36

Page 43

Instruction Manual CyberComm 6000

4. Measurements

4.1 About Measurement

CyberComm lets you carry out measurements just as if you were using your

CyberScan meter by providing the same look and feel screens & buttons. In addition,

CyberComm enables you to quickly access and switch between single-channel,

multi-channel, standardization, setup, display criteria, storage criteria and print criteria

screens.

With CyberComm, you can keep records of multiple electrodes & standardization and

switch between them whenever you need.

It is important to standardize the CyberScan meter/electrode or import existing

standardization data from the meter, before you start making any measurement.

4.2 Measure Tab

In Measure tab, you do your measurements, calibrations (standardizations), setting

up channel parameters, configure display, storage & print criteria.

Click to switch to Measure control tab.

The measure tab lets you:

Select between single-channel & multi-channel

Select channels and their measuring parameters

4.2.1 Selecting a Single Channel

You can view single channel measurement screen, configure a single channel, setup

display, storage & print criteria of a single channel by just selecting the channel and

its parameter from the Measure tab.

To select a single channel:

1. Make sure that the Multi Channel check box is not selected in the Measure

control tab.

2. Click on the channel button you want to select. (Click on the channel button again

if you wish to unselect.)

Example:

3. Click on the parameter icon of which you wish to measure/standardize/setup.

Example:

37

Page 44

Instruction Manual CyberComm 6000

4. The right-pane (workspace) displays the measuring screen of the selected

parameter of the channel. (Figure 32). This screen is the same as the

measurement screen of CyberScan meter.

5. Click any of the tabs shown in the bottom of the workspace to switch to other

screens (such as standardization, setup etc) of the selected parameter. (Figure

33).

Figure 32 : Single channel measurement screen

Figure 33 : Channel related tabs

38

Page 45

Instruction Manual CyberComm 6000

You may perform any of the following activities for the selected channel/parameter:

Carry out measurements

Take a snap shot of a graph (Refer page 43)

Perform a fresh standardization or switch to a different standardization

Setup channel/parameter (Refer CyberScan instruction manual)

Configure display criteria (Refer CyberScan instruction manual)

Configure storage criteria (Refer CyberScan instruction manual)

Configure print criteria (Refer CyberScan instruction manual)

4.2.2 Selecting Multiple Channels

You can view multiple channel measurement screens, configure channel/parameter,

setup display, storage & print criteria of multiple channels by just selecting channels

and its parameter from the Measure tab.

To select multiple channels:

1. In the Measure control tab, click on the Multi Channel check box to select it.

2. Click on the first channel you want to select. Click on the channel button again if

you wish to unselect.

Example:

3. Click on the parameter icon of your interest in the selected channel.

Example:

4. Repeat step 2 & 3 for other channels you wish to select.

5. The right-pane (workspace) displays the measuring screen of the selected

parameters of each of the channels. (Figure 34).

6. Click any of the tabs shown in the bottom of the workspace to switch to other

screens of the selected channel/parameters (Figure 33).

Note: Standardization is available only in single-channel mode.

You may perform any of the following activities for the selected channels/parameters:

Carry out measurements

Log measurement data (Refer page 41)

Setup channel/parameter (Refer CyberScan instruction manual)

Configure display criteria (Refer CyberScan instruction manual)

Configure storage criteria (Refer CyberScan instruction manual)

Configure print criteria (Refer CyberScan instruction manual)

39

Page 46

Instruction Manual CyberComm 6000

Figure 34 : Multi-channel measurement screen

40

Page 47

Instruction Manual CyberComm 6000

4.2.3 Refresh Temperature Reading

‘Refresh temperature’ is applicable only for ATC (Automatic Temperature

Compensation).

In some rare situations where you may notice that the temperature reading appears

in CyberComm is not accurate, click Settings menu in the menu bar and click

Refresh Temperature submenu. CyberComm reloads its temperature curve

information and the ATC temperature is refreshed.

Note: ATC mode is enabled when you connect a temperature probe to

the meter. The measurement screen indicates the ATC mode by

displaying ‘(ATC)’ next to the Temperature (‘Temp’) field of the channel

(Figure 34). When there is no temperature probe is connected to the

meter, or the temperature probe is faulty, the measurement screen

indicates ‘(Default)’ next to the temperature field of the channel.

4.2.4 Log measurement data

You can enable logging data of a single or multiple channels. When logging is

enabled, the readings are automatically stored in your PC. CyberComm allows you to

create extensive reports based on this stored data.

To enable data logging (Timed data logging):

7. Select channel & parameter you wish to log, from the Measure control tab.

8. Click on Measure tab in the workspace

9. Click on Sample ID field. A dialog appears (Figure 35)

10. Click Start Data Log button. Click OK to begin data logging.

11. A red square starts blinking next the Sample ID field, indicating the data logging is

in progress.

To disable data logging:

12. Click on Sample ID field.

13. A message appears asking whether you wish to stop data logging. Click OK

button to confirm.

14. A red square (next the Sample ID field) stops blinking, indicating the data logging

is stooped.

41

Page 48

Instruction Manual CyberComm 6000

Figure 35 : Enable data logging

42

Page 49

Instruction Manual CyberComm 6000

4.2.5 Taking a Snap Shot of Graph

In single-channel measurement mode, you can choose to view variations of the

measurement in a graphical manner by clicking on Show Graph button (Figure 36).

The graph plots the variations of the measured parameter continuously. You can take

a ‘snap shot’ of the graph any time and save it for further analysis. These saved snap

graphs can be viewed in Reports control tab.

To take a snap shot:

1. Select channel & parameter, from the Measure control tab.

2. Click on Measure tab in the workspace.

3. Click Show Graph button. The graph starts plotting the variations of the

measured parameter.

4. When you wish to take snap shot of the graph, click Snap Graph button.

CyberComm saves the snap shot with a time stamp and then it shows you a

confirmation message.

5. To view saved snap shots, click Reports control tab and then click View Graph.

Figure 36 : Taking Snap shot of graph

43

Page 50

Instruction Manual CyberComm 6000

5. Reports

5.1 About Reports

CyberComm provides extensive reporting features. This includes creating graphical

charts using stored data, exporting stored data into Microsoft Excel or HTML, View

past readings and current readings on a graph and creating customized

standardization reports.

To access the reports, click tab.

Options available in the Reports tab:

Graphic sheet

View Graph

Stored Data

Excel Sheet

Standardization Report

44

Page 51

Instruction Manual CyberComm 6000

5.2 Graphic Sheet

The Graphic Sheet allows you to create a customized graphical chart (Pie chart or

Histogram) for a set of available data in CyberComm. The chart is created for a

selected parameter (mode) of a channel of your choice. Data selection criteria allow

you to select data by date, range or sequence. You can create as many charts as

you wish, save them and print.

To add a new Graphic Sheet:

1. Go to Reports control tab.

2. Click Add Report. The New Report Object dialog appears. (Figure 37)

3. Select the report type (Pie chart or Histogram) from the Select Report Type dropdown box.

4. From Select Channel drop-down box, select the channel number for which you

wish to create graphical report.

5. From Select Mode drop-down box, select the parameter (mode) for which you

wish to create graphical report.

6. In Interval field, specify data interval for the report.

7. In Title field, specify a title for the graphical report. This will be printed at the top of

the report. (Check any limitation on number of characters?)

Figure 37 : Adding a new Graphic sheet

45

Page 52

Instruction Manual CyberComm 6000

8. In Data Selection options, select your choice of data:

o All: Selects all the available data in CyberComm for the selected

channel/parameter.

o Range: Allows you limit the data selection for a particular data range. If you

select this option you can specify your upper & lower boundaries in Low

Range & High Range fields. (E.g. Select data range between pH1 to

pH14)

o Forward Sequence: Allows you to pick data from the very first sample

logged in CyberComm. In Data Count field, specify how many sample

readings you wish to use in the graph from the very first sample.

o Reverse Sequence: Allows you to pick data from the last sample recorded

in CyberComm. In Data Count field, specify how many sample readings

you wish to use in the graph from last sample backward.

o By Date: Selects available data for a given date range. (Provided that the

data is available for the specified date range for the selected

channel/parameter in the system). In From & To fields, specify the date

range.

9. Click OK to conform your selections. The system generates the graphical report

based on the selections you made. (Figure 38). The new graphical report is added

to Available Reports list. System notifies you if there is no sufficient or matching

data available in the CyberComm for the selected channel/parameter or data

selection criteria.

Figure 38 : Pie Chart & Histogram

10. Select a report name from Available Reports list and click Print button to print.

46

Page 53

Instruction Manual CyberComm 6000

5.3 View Graph

The View Graph is an extension to the ‘Show graph’ feature available in CyberScan

meter for single channel measurement mode. Use this to view graphs (snap graphs)

which have been previously captured at measurement screen or view current

measurement graphs of a selected channel.

To view graph:

1. To see current measurement graph:

Make sure you are in single-channel mode. (Multi-channel check box

should be unchecked)

From Measure tab, select the channel and its parameter you wish to view.

Click Show Graph button in the measurement screen. The graph starts

plotting data.

Note: In order to view the graph of the currently selected channel, you

have to click Show Graph button in the measurement screen.

2. Click on Reports tab.

3. Click View Graph button. The plotted graph is shown. (Figure 39)

47

Page 54

Instruction Manual CyberComm 6000

p

Figure 39 : View Graph

4. Click Zoom In or Zoom Out button to zoom in or out the graph.

5. Click on the graph and drag it horizontally or vertically to pan the graph. Panning

is useful if you wish to see a graph which has been plotted for a long period of

time or covering wide variations of data values.

6. Click Save button, if you wish to save the graph. A dialog appears. (Figure 40)

7. Enter a suitable name and click OK. The graph is saved. The new graph is added

to Available Reports list. You may view graphs in this list by double-clicking on a

name.

Saved Graphs

Saved Sna

Graphs

Figure 40 : Saving a graph

8. The ‘snap shot’ graphs saved from the measurement screen (using Snap Graph

button) are listed in the Available Reports list. You can double-click on a snap

graph to view.

Note: Refer ‘Taking a Snap Shot of Graph’ in page 43 for more details

on snap graphs.

48

Page 55

Instruction Manual CyberComm 6000

5.4 Stored Data

This feature allows you to view data stored in your project. You can view data per

channel/parameter. Additionally, you can delete selected records and export the data

to HTML file.

To view stored data:

1. Go to Reports control tab.

2. Click on Stored Data button.

3. In Available Reports list, click on a channel and double-click on parameter you

wish to view stored data.

4. The workspace shows the stored data in a tabular format.

5. Click Refresh button, if you need to refresh the screen with latest data. This is

useful if automatic data logging is enabled.

To delete a single data record:

1. Select it by clicking on the record

2. Click Delete button

3. System shows you a confirmation message. Click OK to confirm deletion.

To delete all the records:

1. Click Delete All button

2. System shows you a confirmation message. Click OK to confirm deletion.

3. All data stored for the currently selected channel/parameter is permanently

deleted.

To export data into HTML file:

1. Click HTML Export button.

2. File Save As dialog opens. Specify a name. You can save the HTML file in any

location in your PC.

3. Click Save.

To print stored data:

1. Select a channel & parameter of which you wish to print data from Available

Reports list

2. Click Print button to print.

49

Page 56

Instruction Manual CyberComm 6000

5.5 Excel Sheet

CyberComm allows you to export stored data in to a scaled down version of

Microsoft® Excel format. The exported file is saved as .cyc file format and can be

opened from Microsoft® Excel application. Most functions available in Excel such as

formatting, plotting graphs & printing are also applicable for this file format.

Note: Exporting to Excel feature is not available if Microsoft® Excel

application has not been installed in your PC.

To Export to Excel:

1. Go to Reports control tab.

2. Click Excel Sheet button.

3. Click Launch Excel Application button in the workspace. Parameter selection

for Excel View dialog appears.

4. In Parameter selection for Excel View dialog, select the channel & parameter

for which you wish to select stored data.

5. Click OK.

6. The Microsoft® Excel application opens and data is exported to Excel spread

sheet. You may work with the file as you would work with any other excel file

(such as save the file, generate charts or print etc.)

Figure 41 : Exporting to Excel

50

Page 57

Instruction Manual CyberComm 6000

5.6 Standardization (STD) Report

CyberComm allows you to create customized & detailed reports on standardization

data. You can select multiple channels and their parameters to be included in the

report, format data, insert any additional text, insert user information and define the

paper sizes, save & print.

Note: Standardization report is a single page document. You may create

multiple pages and save them as individual reports.

Follow the steps below to create & format a report:

Select standardization data:

The first step is to select standardization data for the report.

1. Go to Reports control tab.

2. Click STD Reports button.

3. Click Select button in the workspace. A dialog box appears. (Figure 42)

Figure 42 : Selecting standardization data

4. Make sure ‘STD Report’ is selected in the Select Report Type drop-down box.

From the tree view on the left-pane, click on channel and parameter to expand the

tree. Double-click on parameter of which you wish to select standardization data.

(For pH, double-click on Buffer group.)

51

Page 58

Instruction Manual CyberComm 6000

5. The right-pane displays standardization data available for the selected

parameter/buffer group. You can unselect any of the standardization data by

clicking on the check box against the data to de-select it.

6. Click OK to add the selected data to the report. The selected standardization

data is added as a block of data. (Figure 43) You may format the look and feel of

this block, if required.

Figure 43 : Standardization data added as a block

7. You may add standardization data of another channel/parameter to the same

report. Click on Select button and make your selection again and click OK. The

newly added set of data is added to report as a separate block.

8. Optionally, you may select a block of data and press Delete keyboard button to

delete a block, if you wish to remove them.

52

Page 59

Instruction Manual CyberComm 6000

Format data:

You may format a block of data to modify its appearance by removing one or more

columns, change font types and colors o r modify column widths.

1. Right-click on block of data which you wish to format. A dialog box appears

(Figure 44)

2. The following formatting options are available:

Click on Column Name check box to unselect it, if you wish to

remove a column from the report.

Change column width of a data column

Click button to change font properties of a particular column

Click Data Font button to change font properties of all the data

columns

Click Header Font button to change font properties of the header

row.

3. Click OK to conform the formatting changes. The formatting is applied to the

selected block of data.

Figure 44 : Formatting data

53

Page 60

Instruction Manual CyberComm 6000

Insert additional text:

You may add any additional text to the report such as a Title, page number or footer

note etc.

1. Click Select button. A dialog box appears (Figure 42).

2. In Select Report Type drop-down box, select ‘Text’ and click OK.

3. A text filed is added to the report. (Figure 45).

Double-click on the text field to edit it.

Right-click on the text field to change its font properties

Drag it to move the text field to any place on the report

Figure 45 : Adding an addition text field

Insert user information:

You may add user related information to the report. This includes user name, project

name, date created and meter serial number.

1. Click Select button. A dialog box appears (Figure 42)

2. In Select Report Type drop-down box, select ‘User Info’ and click OK

3. A user info filed is added to the report. (Figure 46).

You are not allowed to edit the user info

Drag it to move the user info field to any place on the report

Figure 46 : Adding user information

54

Page 61

Instruction Manual CyberComm 6000

Setup paper size:

You may modify the paper size of the report, add a custom paper size, change paper

orientation or modify margin of the report to suit your printing requirements.

1. Click Paper button. A dialog appears. (Figure 47)

2. From Paper drop-down box, select an existing paper size or define a custom

size.

3. Change orientation or margins.

4. Click OK to confirm the changes.

Figure 47 : Setup paper size

Save a report:

Once you customize and format the report, you can save it for future reference or

print it later.

1. Click Save button. A dialog box appears. (Figure 48)

2. Specify a name for the report. Click OK. The new report is added to Available

Reports list.

Figure 48 : Saving STD report

55

Page 62

Instruction Manual CyberComm 6000

Adding a new report:

To add a new page, click New Page button. A blank page appears. You may add

standardization data, format and save.

Printing a report:

Select a report name from Available Reports list and click Print button to print.

56

Page 63

Instruction Manual CyberComm 6000

6. Administrative Functions

CyberComm provides special functions exclusively for administrator. CyberScan

meter is shipped with a default ‘Admin’ user account which has the administrator

privileges. You need to log into CyberComm using the ‘Admin’ user account to

perform the following administrative functions:

View audit log file

Backup audit log file

Delete audit log file

Unlock users

57

Page 64

Instruction Manual CyberComm 6000

6.1 Audit Log

CyberComm maintains an audit log to record all the user activities carried out in

CyberComm application.

6.1.1 View audit log file

1. On the menu bar, click Audit Trial menu and then click View Application log file

sub menu.

2. Audit Trial dialog appears. (Figure 49)

3. By default the entire audit log records are shown. To view logged activities of a

specific time period, select Date From & Date To and click Refresh button.

4. Click Print button to print the audit log file.

Figure 49 : Audit Log

58

Page 65

Instruction Manual CyberComm 6000

6.1.2 Backup audit log file

CyberComm allows you to back up the audit log file in case if you wish to keep a

back up. When backed up the audit logs are exported to a text file.

1. Click Export button. The Save As dialog appears.

2. Select a folder and specify a name for the file.

3. Click Save button. The audit log file is exported to a text file.

6.1.3 Delete audit log file

Deleting the audit log file is not recommended. However, if you wish to delete the

audit log file due to special reasons, it is recommended that you make a backup

before you deleting.

1. Back up the audit log file as described in the above section.

2. Click Delete button. System shows you a confirmation dialog box.

3. Click OK to confirm deleting.

59

Page 66

Instruction Manual CyberComm 6000

6.2 Unlocking Users

If a user enters an invalid password for three consecutive attempts while logging in to

CyberComm application, the user will be ‘locked’ by CyberComm and will not allow

the user to login again. This is a security feature. Only the administrator can unlock

these users.

To unlock a specific locked user:

1. On the menu bar, click Settings menu and then click Unlock User sub menu.

The Unlock User dialog appears (Figure 50).

2. All the ‘locked’ users currently available in the system are listed in the dialog.

Select the user you wish to unlock and then click Unlock.

3. The dialog closes and the selected user is unlocked.

Figure 50 : Unlocking a user

To unlock all locked users:

1. On the menu bar, click Settings menu and then click Unlock all locked user sub

menu.

2. System unlocks all locked users and shows a notification message (Figure 51).

Figure 51 : All users unlocked

60

Page 67

Page 68

For more information on Eutech Instruments’ products, contact your nearest

distributor or visit our website listed below:

Eutech Instruments Pte Ltd.

Blk 55, Ayer Rajah Crescent,

#04-16/24 Singapore 139949

Tel: (65) 6778 6876

Fax: (65) 6773 0836

E-mail: marketing@eutechinst.com

Web-site: www.eutechinst.com

Distributed by:

Loading...

Loading...