Page 1

CTS™ Rotea™ Counterflow Centrifugation

System

USER GUIDE

Catalog Number A44769

Publication Number MAN0018908

Revision B.0

For Research Use or Manufacturing of Cell, Gene, or Tissue- Based

Products.

Page 2

Life Technologies Holdings Pte Ltd | Block 33 | Marsiling Industrial Estate Road 3 | #07-06, Singapore 739256

For descriptions of symbols on product labels or product documents, go to thermofisher.com/symbols-definition.

The information in this guide is subject to change without notice.

DISCLAIMER: TO THE EXTENT ALLOWED BY LAW, THERMO FISHER SCIENTIFIC INC. AND/OR ITS AFFILIATE(S) WILL NOT BE

LIABLE FOR SPECIAL, INCIDENTAL, INDIRECT, PUNITIVE, MULTIPLE, OR CONSEQUENTIAL DAMAGES IN CONNECTION WITH OR

ARISING FROM THIS DOCUMENT, INCLUDING YOUR USE OF IT.

The CTS™ Rotea™ Counterflow Centrifugation System is for use in further manufacturing applications only and not for fill and finish

applications. Drug manufacturers are responsible for ensuring the purity, potency, safety and identity of finished drug products and for

obtaining the appropriate regulatory approvals.

Revision history: Pub. No. MAN0018908

Revision Date Description

B.0 02 December 2020 Minor change to CTS™ Rotea™ Counterflow Centrifugation System

A.0 20 October 2020 New document. User guide for new workflow.

specific disclaimer statement.

Important Licensing Information: This product may be covered by one or more Limited Use Label Licenses. By use of this product,

you accept the terms and conditions of all applicable Limited Use Label Licenses.

TRADEMARKS: All trademarks are the property of Thermo Fisher Scientific and its subsidiaries unless otherwise specified.

©2020 Thermo Fisher Scientific Inc. All rights reserved.

Page 3

Contents

■

CHAPTER 1 Product information .................................................. 7

Product description ............................................................. 7

Features ....................................................................... 7

Contents ....................................................................... 7

System overview ................................................................ 8

Instrument description ....................................................... 8

Instrument dimensions ..................................................... 10

Working space ............................................................ 10

Instrument weight ......................................................... 10

Instrument properties ...................................................... 11

Push button controls ....................................................... 13

CTS™ Rotea™ Single-Use Kit schematic ...................................... 14

Wetted components ....................................................... 15

Allowed chemicals for wetted surfaces ....................................... 15

■

CHAPTER 2 Installation and setup ............................................... 16

Packaging contents ............................................................ 16

Instrument installation .......................................................... 16

Power instrument “On” ......................................................... 18

Power instrument “O” ......................................................... 19

Installation .................................................................... 20

First time setup ................................................................ 24

Download protocols ............................................................ 27

Create protocols ........................................................... 27

Load a protocol ........................................................... 27

Rotea™ GUI dashboard ..................................................... 31

User Management ......................................................... 32

Uninstall ...................................................................... 37

Logging ....................................................................... 38

™

Rotea™ Counterflow Centrifugation System User Guide

CTS

3

Page 4

Contents

■

CHAPTER 3 Basic instrument operation ........................................ 41

Open the door ................................................................. 41

Kit preparation, loading and removal ............................................. 43

Kit configuration ........................................................... 43

Pre-assembly of processing kit .............................................. 45

Connecting vessels, bags and reagents ...................................... 46

Bubble Trap ............................................................... 47

Kit installation ............................................................. 48

Initiate a protocol .......................................................... 54

Run a protocol ................................................................. 61

Rotea™ GUI navigation and instrument operation .............................. 61

Error messages ............................................................ 67

Kit removal .................................................................... 69

Aseptic disconnection of the kit components ...................................... 74

System settings ................................................................ 75

Instrument firmware ........................................................ 75

OPC-UA .................................................................. 80

Settings .................................................................. 81

Licenses .................................................................. 82

Calibration .................................................................... 83

■

CHAPTER 4 OPC-UA interface ................................................... 87

Introduction ................................................................... 87

Definitions .................................................................... 87

Scope of system ............................................................... 88

Instrument hardware configuration ........................................... 88

Single-Use Kit ............................................................. 88

Protocol file ............................................................... 89

Protocol metadata ......................................................... 89

MES interface ................................................................. 89

Background ............................................................... 89

Electronic communications ................................................. 90

Communications protocol .................................................. 90

MES – Commands and reports overview .......................................... 91

Enable OPC-UA ........................................................... 92

Log in to instrument ........................................................ 92

Load protocol ............................................................. 92

Load kit .................................................................. 93

Transfer metadata ......................................................... 93

Initialize protocol on to instrument ........................................... 93

Start/Stop/Pause/Resume protocol .......................................... 93

Instrument run status ....................................................... 94

4

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 5

MES batch history data ..................................................... 94

Alarm recovery tools ....................................................... 95

OPC-UA interface .............................................................. 96

Commands OPC-UA to Rotea™ application ................................... 96

Reports Rotea™ application to OPC-UA ...................................... 97

Use case sequence diagrams .................................................. 104

MES run a protocol ....................................................... 104

Protocol with parametric data .............................................. 105

MES drives Rotea in response to external systems ........................... 106

MES drives steps within protocol ........................................... 106

MES manage error recovery events with admin user .......................... 107

Use list file to load protocol ............................................... 108

■

CHAPTER 5 Maintenance ....................................................... 110

User maintenance schedule .................................................... 110

Instrument cleaning ........................................................... 110

Inspect casing ................................................................ 110

Open the door without power .................................................. 111

Power and fuses .............................................................. 112

Power supply ............................................................ 112

Fuses ................................................................... 112

Contents

■

CHAPTER 6 Troubleshooting ................................................... 113

■

CHAPTER 7 Compliance ........................................................ 115

■

CHAPTER 8 Safety instructions ................................................ 116

Labels ....................................................................... 116

Emergency procedures ........................................................ 116

Instrument emergency stop events ......................................... 116

Emergency shut down .................................................... 117

Restart after shut down ................................................... 117

Protocol recovery process ................................................. 118

Warnings and precautions ..................................................... 119

Warnings ................................................................ 119

Cautions ................................................................ 120

CTS™ Rotea™ Counterflow Centrifugation System User Guide

5

Page 6

Contents

■

APPENDIX A Safety .............................................................. 121

Symbols on this instrument .................................................... 121

Standard safety symbols .................................................. 122

Control and connection symbols ........................................... 122

Conformity symbols ...................................................... 122

Safety information for instruments not manufactured by Thermo Fisher Scientific ..... 124

Instrument safety ............................................................. 124

General ................................................................. 124

Physical injury ............................................................ 125

Electrical safety .......................................................... 125

Cleaning and decontamination ............................................. 126

Safety and electromagnetic compatibility (EMC) standards ......................... 126

Safety standards ......................................................... 126

EMC standards ........................................................... 127

Environmental design standards ............................................ 127

Chemical safety .............................................................. 128

Biological hazard safety ....................................................... 129

■

APPENDIX B Documentation and support .................................... 130

Customer and technical support ................................................ 130

Limited product warranty ...................................................... 130

6

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 7

1

IMPORTANT! Before using this product, read and understand the information in the “Safety” appendix

in this document.

Product description

The CTS™ Rotea™ Counterflow Centrifugation System is an automated, closed-flow benchtop

instrument that can perform a wide variety of cell processing steps across dierent cell types.

The CTS™ Rotea™ Single-Use Kit is specifically designed for a range of cell processing applications

such as separation, isolation, buer exchange, wash and concentrate. Each kit has 8 input/output

sterile weldable tubes, counterflow centrifuge and Carrier Frame for unparalleled setup flexibility.

The CTS™ Rotea™ Software is user-programmable and allows users to save, create, and modify

protocols depending on the application. The system's open design and integrated camera allows users

to visualize cells in real-time to more easily optimize protocols.

Product information

Features

CTS™ Rotea™ Counterflow Centrifugation System easily fits into existing workflows, from research to

commercial manufacturing.

•

Integrated camera provides real-time sample visualization

•

Patented technology that can process up to 20 L of starting volume to as little as 5 mL of output

volume

•

Gentle fluidized bed results in unmatched cell recovery and viability

•

Seamlessly transition from process development to GMP manufacturing on the same system.

Contents

Table 1 CTS™ Rotea™ Counterflow Centrifugation System (Cat. No. A44769)

Contents

CTS™ Rotea™ Centrifuge 1 ea

CTS™ Rotea™ Single-Use Kit Available separately

Protocol Development Application 1 ea

Amount

Dell™ 2-in-1 laptop for operation/programming 1 ea

CTS™ Rotea™ Counterflow Centrifugation System User Guide

7

Page 8

2

1

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Chapter 1 Product information

1

System overview

System overview

Instrument description

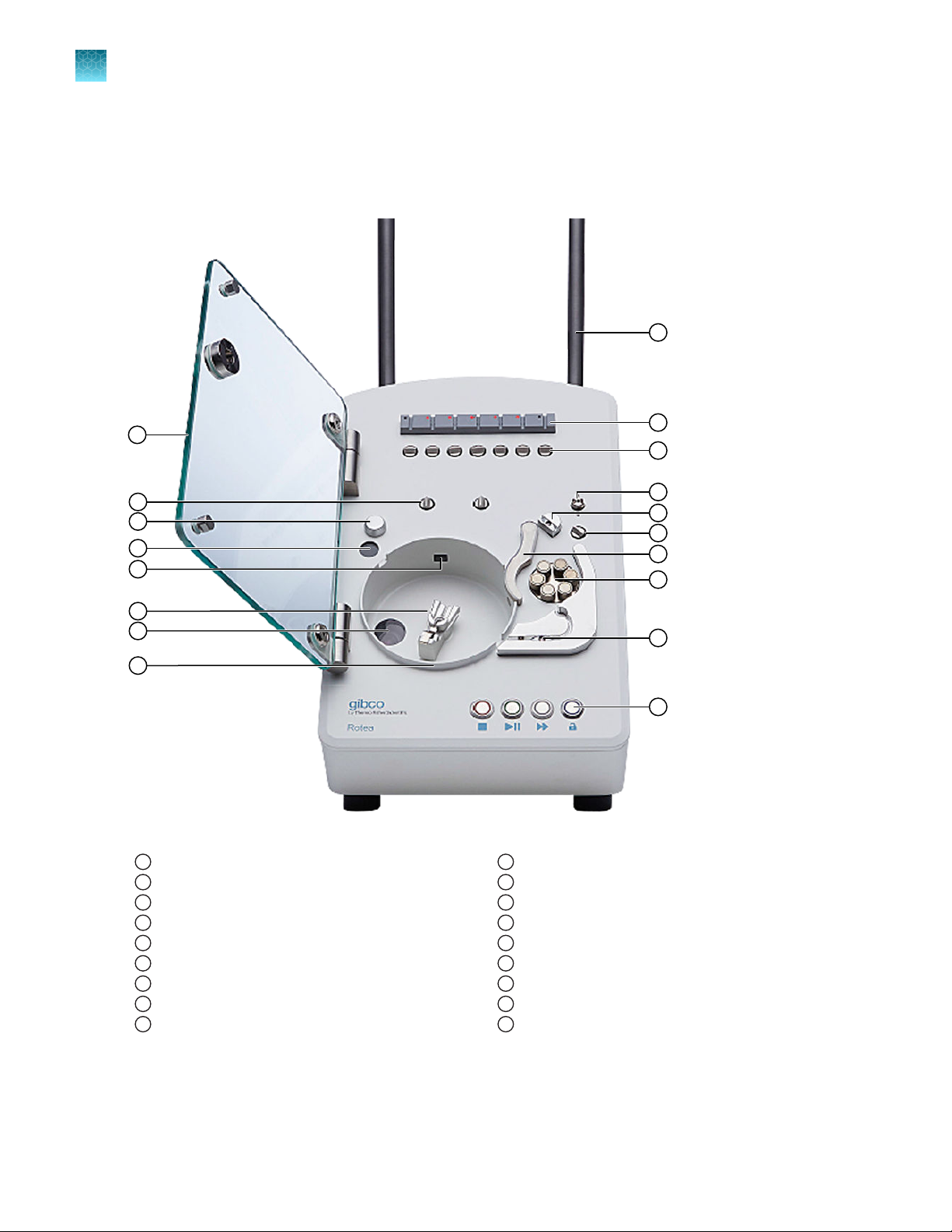

Figure 1 Instrument – Front View

Instrument Door

1

Pinch Valves (J & K)

2

Kit Location Button

3

2D Barcode Reader

4

CFC Chamber Detector

5

CFC Chamber Carrier

6

Camera

7

Moisture Sensor

8

Pushbutton Controls

9

8

Optical Density Sensor & Pressure Sensor (P1)

10

Peristaltic Pump

11

Pump Clamp Arm

12

Pinch Valve (H)

13

Kit Location Button & Pressure Sensor (P2)

14

Door Latch

15

Pinch Valves (A, B, C, D, E, F, & G)

16

Bubble Sensors

17

Hanger Posts

18

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 9

8

7

6

5111

1

432

Chapter 1 Product information

System overview

1

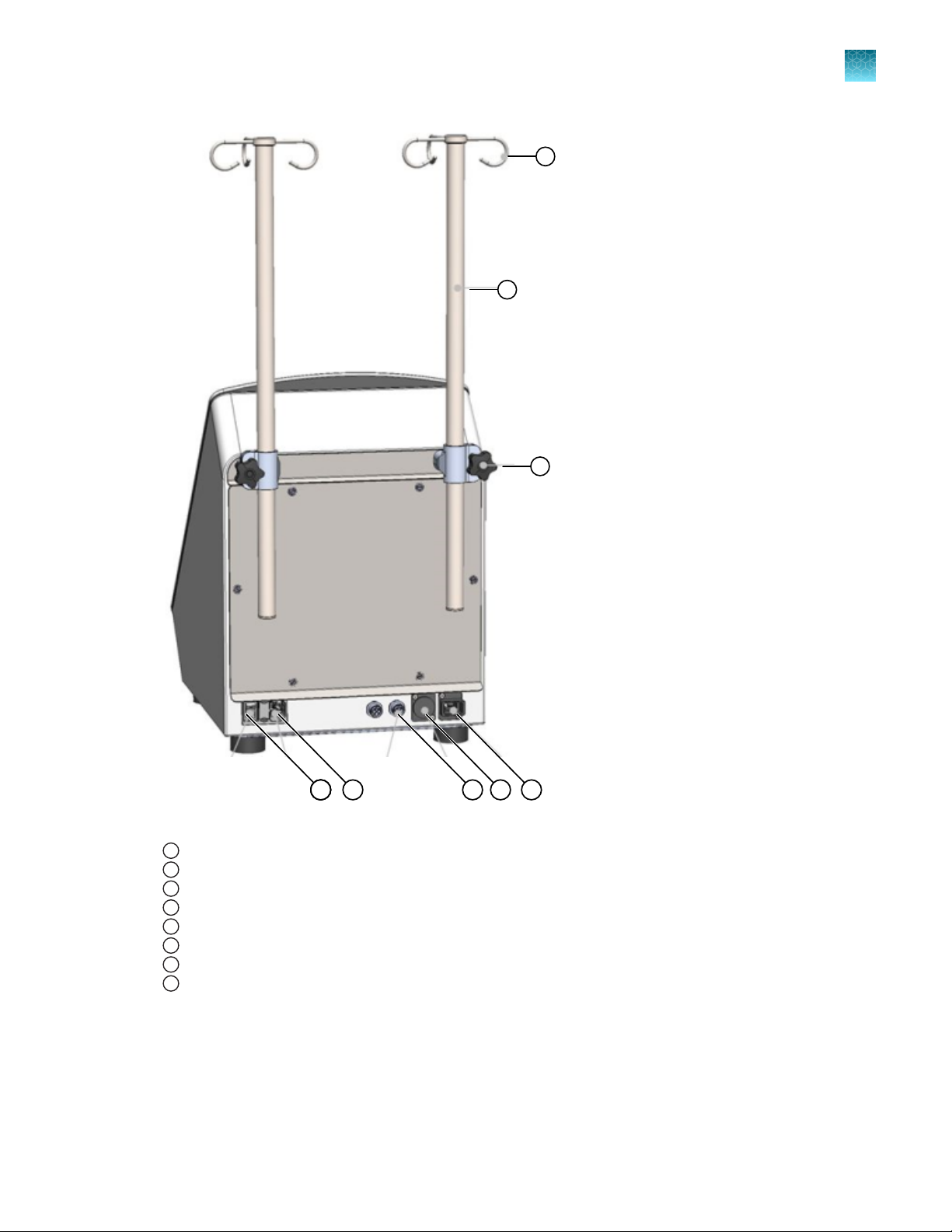

Figure 2 Instrument – Rear View

Power Switch

1

Mains Connector

2

CAN bus (2 o)

3

Ethernet (RJ-45)

4

USB-C

5

Bag Hooks

6

Hanger Post

7

Hanger Post Adjustment

8

CTS™ Rotea™ Counterflow Centrifugation System User Guide

9

Page 10

1

Chapter 1

System overview

Product information

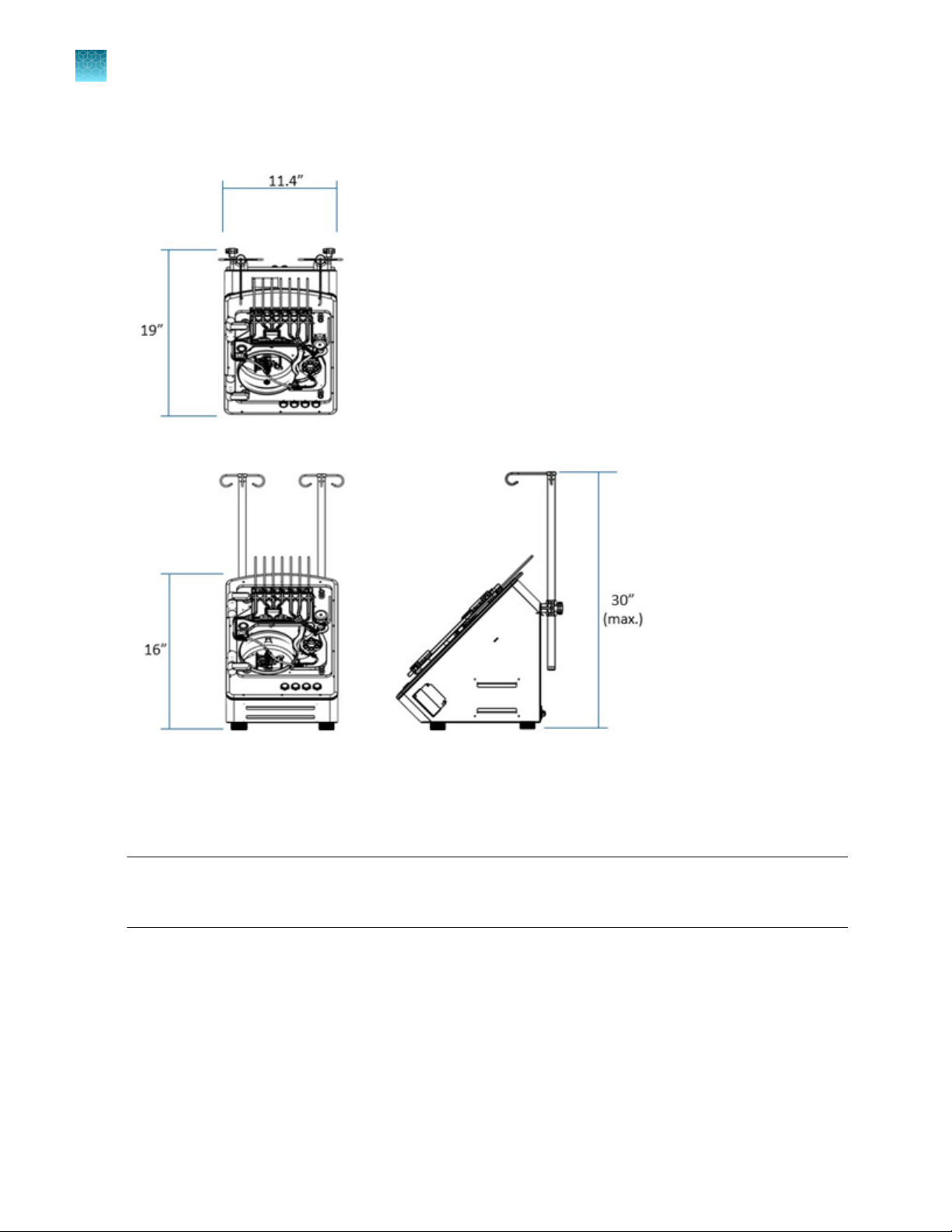

Instrument dimensions

Working space

The Rotea™ instrument is designed for bench top use and requires a working space of approximately

Height: 30” (76 cm), Width: 25” (63.5 cm), Depth: 20” (50.8 cm).

Note: The 2‑in‑1 laptop is connected via a USB-C cable and hence can be located in a range of

positions. The width dimension of 25” assumes that the laptop is located on the bench beside the

instrument.

Instrument weight

The Rotea™ instrument weighs 44 lbs (20 kg) with hanger posts installed.

10

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 11

Instrument properties

Chapter 1 Product information

System overview

1

Category

Electrical

Sound level

Environmental ranges

Property Value

Supply voltage 100–240 V AC ±10%, 50/60 Hz

Phases Single

Maximum Rated Input Current 5 A

Fuses 2 x 5 A

Maximum sound level 70 dBA (measured 1 m from instrument)

Typical sound level 65 dBA (measured 1 m from instrument)

Ambient temperature 15℃ to 30℃

Transport temperature 0℃ to 45℃

Storage temperature 15℃ to 30℃

Maximum relative humidity 80% (non-condensing)

Operating limits

Altitude (max.) 2000 m

Indoor use only —

Not intended for use in a wet

location

Intended for use in Pollution

degree 2 environment

Centrifuge speed 0 to 3000 × g (7000 rpm)

Flow rate Standard: 5 to 110 mL/min (LS19)

Hi-Flow: 30 to 160 mL/min (LS16 tube)

System pressure 100 kPa

Liquid temperature 4℃ to 38℃

Fluid density 1.0 to 1.1 g/mL

Minimum working volume Approx. 50 mL

Note: Smaller volumes of input material can be

diluted to enable processing

—

—

CTS™ Rotea™ Counterflow Centrifugation System User Guide

11

Page 12

Chapter 1 Product information

1

System overview

(continued)

Category

CAN bus connection

Property Value

Minimum concentrate recovery

volume

Centrifuge chamber volume 10 mL chamber containing up to 4 × 109 cells (cell

type and operating parameters dependent).

Note: Centrifuge chamber can be filled multiple

times to process larger batches.

Maximum bag weight per pole 4.4 lb (2 kg)

Output concentration Up to 300 × 106 cells/mL (cell type and operating

parameters dependent)

Purpose For connection and control of external devices

Connector TE Connectivity T4111402051-000 M12 Plug

Connections Pin 1 - VCC CAN - +5V out

Pin 2 - CAN-H - Dominant High

Pin 3 - CAN-L - Dominant Low

5 mL (subject to protocol optimization)

Pin 4 - GND - Ground

Pin 5 - GND - Shield, optional

12

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 13

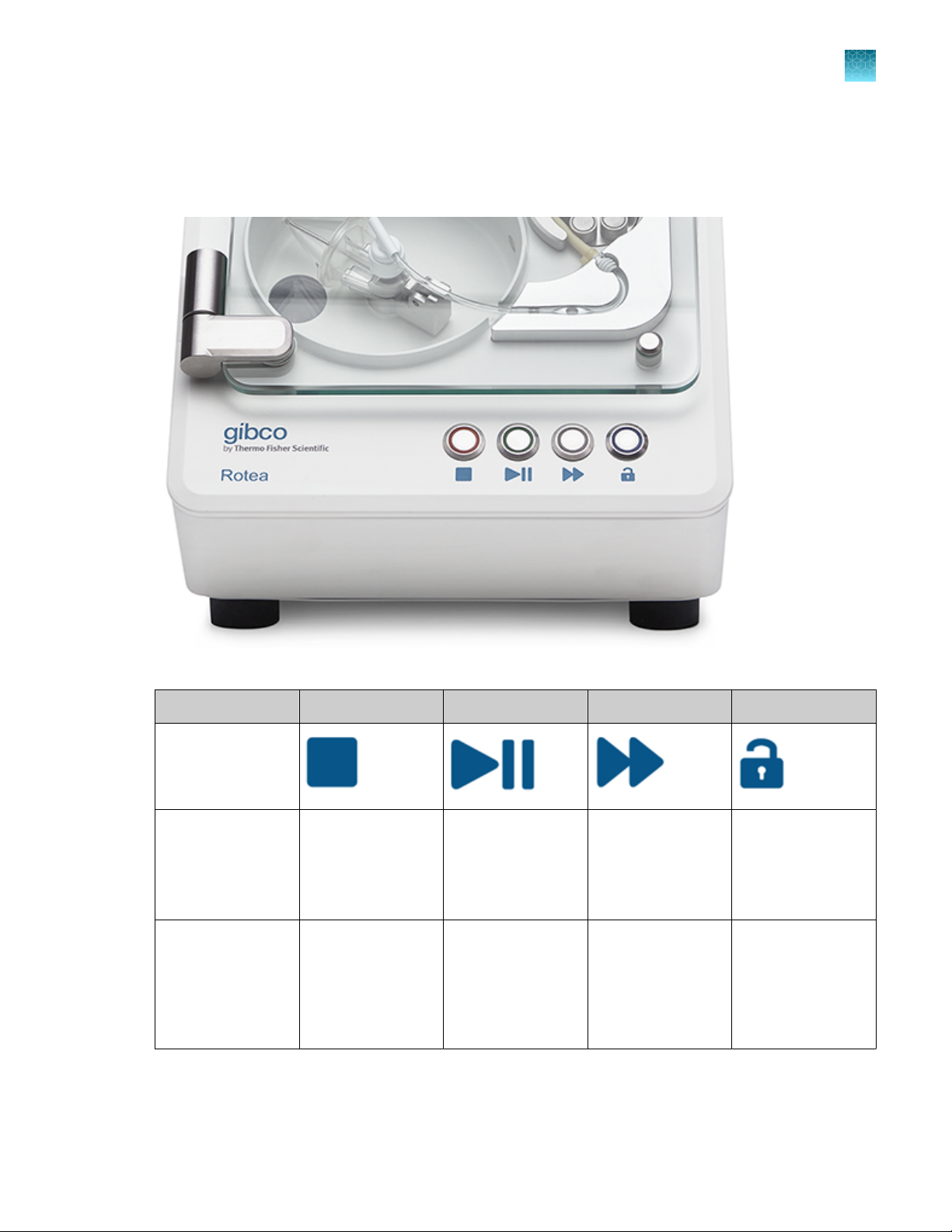

Push button controls

Once a protocol has been loaded and confirmed, the Rotea™ instrument can be operated almost

entirely from the push buttons on the front of the instrument.

Chapter 1 Product information

System overview

1

Figure 3 Instrument push button controls

Light

Push button

operation

Solid Push button to stop

Flashing Instrument has

STOP START/PAUSE ADVANCE DOOR UNLOCK

the instrument and

the current protocol

stopped due to

an alarm condition.

User intervention is

required.

Push button to start

the Protocol, pause

the current step in

the protocol or re-

start a paused step

Instrument is in a

paused condition.

Pressing allows

the instrument to

continue the current

step of the protocol.

Push button to

advance to the next

step in the protocol

Button can be

pushed, advancing

to the next step of

the protocol

Push button to

unlock the door

N/A

CTS™ Rotea™ Counterflow Centrifugation System User Guide

13

Page 14

6

3

5

1

2

4

7

8

9

10

11

12

Chapter 1 Product information

1

System overview

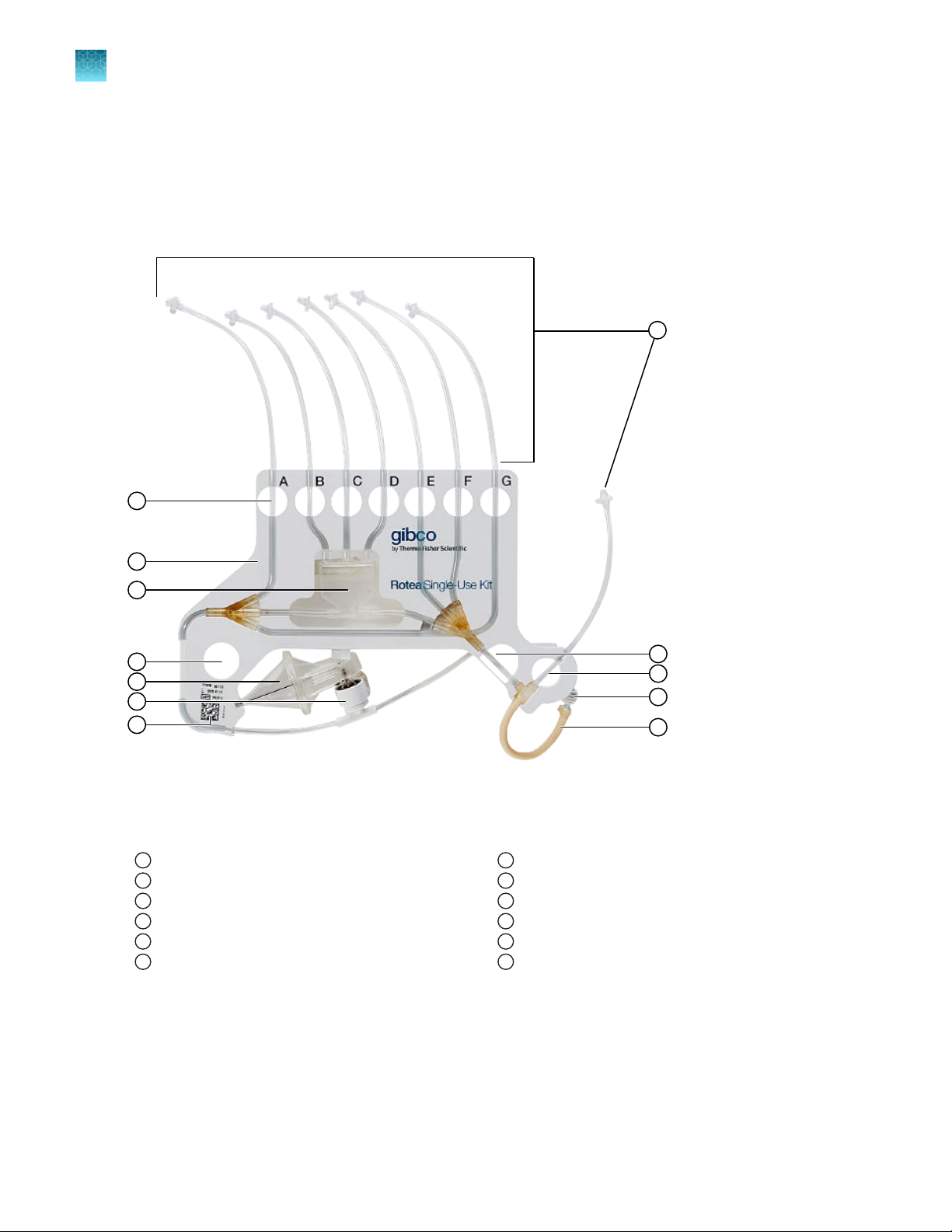

CTS™ Rotea™ Single-Use Kit schematic

The CTS™ Rotea™ Single-Use Kit enables users to configure kits to suit dierent protocols by adding

input and output vessels. Unused fluid lines are simply left sealed o.

Figure 4 CTS™ Rotea™ Single-Use Kit

Valve Hole & Tube ID

1

Carrier Frame

2

Bubble Trap

3

Location Hole

4

CFC Chamber

5

Rotary Coupling

6

14

2D Barcode

7

Pump Tubing

8

Tube Retainer

9

Valve H Hole

10

Location Hole

11

Kit Tubing (Input and Output)

12

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 15

Wetted components

The materials used in the manufacturing of the CTS™ Rotea™ Single-Use Kit have been chosen for their

biological and chemical compatibility.

Component Description Material

Pump tubing

Kit tubing

Chapter 1 Product information

System overview

Pump tube Bioprene

1

CFC ChamberC

Rotary Coupling

Bubble Trap

0.160” OD, 0.116” ID

(4 mm OD, 3 mm ID)

Base Tritan MX711

Cone Tritan MX711

O-Rings EPDM, 70 DURO, FDA compliant

Cannular 316 SS

Cap Tritan MX711

Body Tritan MX711

Bush & Collar Ketron LSG Peek Classix, USP

Base Tritan MX711

Cap Tritan MX711

DEHP-FREE PVC

Class VI

Fittings

Triple Y Connector PVC

Barbed T-Connector Polyproylene

Allowed chemicals for wetted surfaces

Chemical

WFI 100% 5 minutes

Ethanol in water 50% 5 minutes

Culture media 100% 5 minutes

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Concentration Maximum exposure time

15

Page 16

2

Packaging contents

•

Rotea™ instrument

•

Hanger posts (2 o)

•

Mains plug IEC cables (USA/EUROPE/AUSTRALIA)

•

Pre-fitted mains fuses (2 x 5A)

•

USB-C (male) to USB-C (female)

•

Dell™ 2‑in‑1 laptop tablet (this will be in a separate carton)

Instrument installation

•

Remove outer packaging

•

Prepare bench space to receive Rotea™ instrument unit (see “Working space” on page 10) ensuring

that there is easy access to the “On/O” switch and mains IEC connector at the rear of the

instrument

Installation and setup

CAUTION! The Rotea

it is the user’s responsibility to ensure all safety hazards and functional risks are addressed including

adequately supporting the weight of the instrument and having sucient wheel span so that both the

trolley and instrument are stable.

•

Ensure that the bench is stable and level to within ±0.4" (10 mm)

•

Position the instrument on the bench with a minimum of 4" (10 m) between the rubber feet and the

edges of the bench

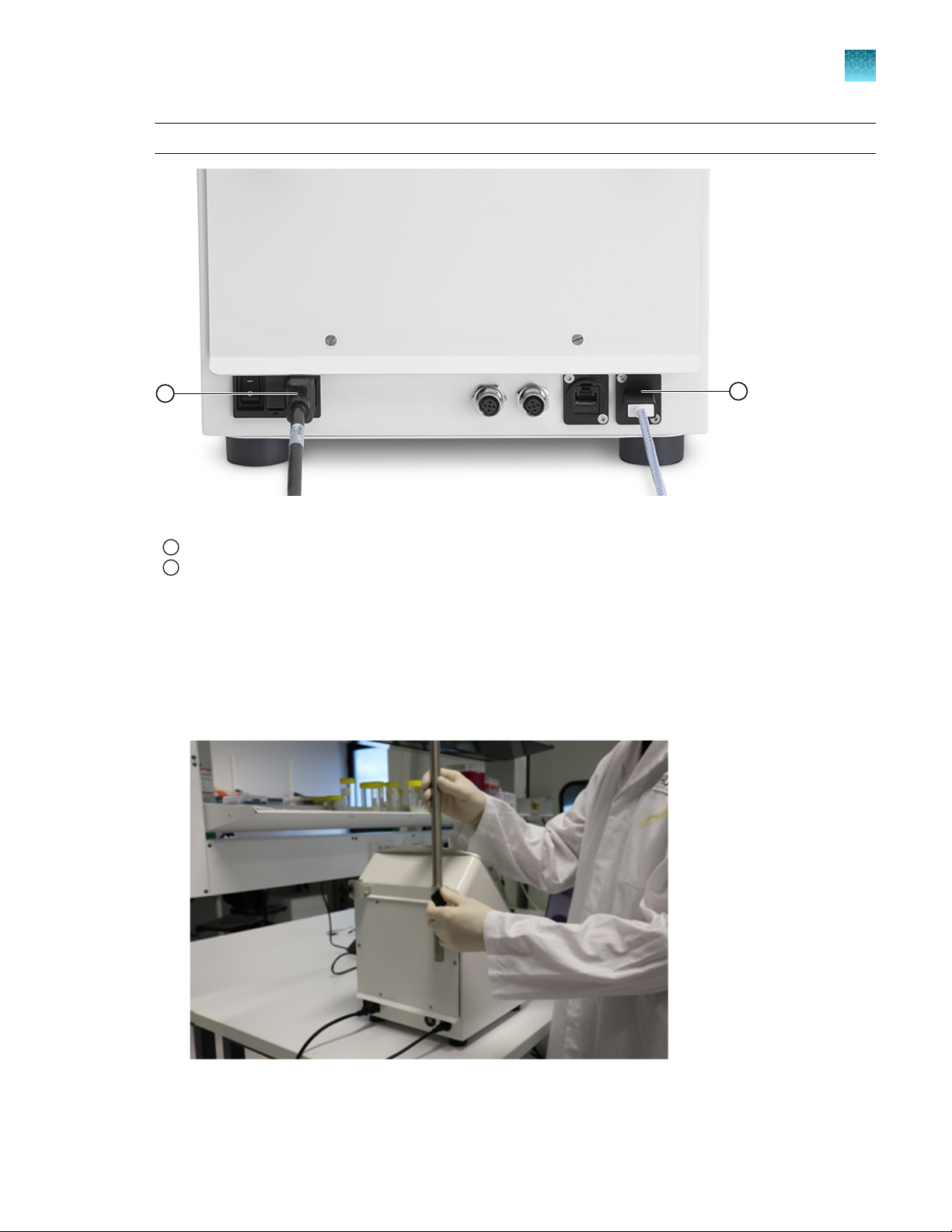

CAUTION! The Rotea

appropriate care and seek assistance if necessary when lifting or moving the instrument. Lift the

instrument, holding between the rubber feet on the bottom of the instrument.

CAUTION! Do not position the instrument is such a way that it would make it dicult to disconnect

the power cord from the power inlet.

CAUTION! If using an alternate mains cable, ensure it is rated for at least 10A.

™

instrument should be installed on a stable bench. If a mobile set up is used,

™

instrument weighs 40 lbs (18 kg) excluding hanger bag posts. Use

16

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 17

1

2

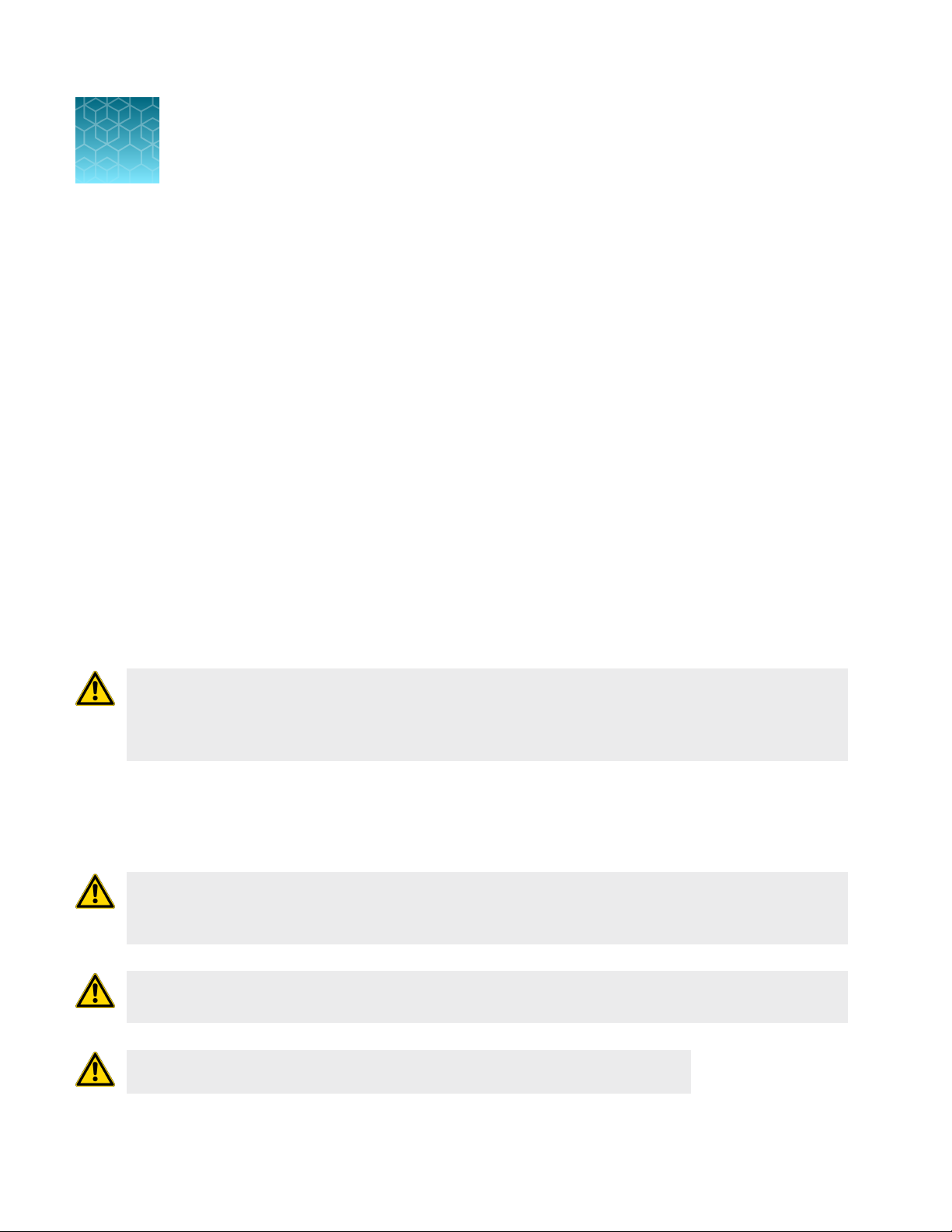

Chapter 2

Note: Suitable means of protective earthing are provided for this device

Installation and setup

Instrument installation

2

Figure 5 Back view of instrument

Mains IEC connector

1

USB-C port

2

1.

Connect mains IEC connector.

2.

Plug mains into power GPO

3.

Connect the laptop to USB-C port on the instrument using the USB-C cable.

4.

Insert 2 o bag hanger posts, adjust height to suit Kit and turn nut clockwise to secure in place.

5.

Adjust the instrument position on the bench where it is required.

CTS™ Rotea™ Counterflow Centrifugation System User Guide

17

Page 18

1

Chapter 2 Installation and setup

2

Power instrument “On”

Power instrument “On”

1.

Switch on using the mains IEC switch at the rear of the instrument.

2.

The instrument button lights will sequence as the instrument powers up. If the door is closed, the

instrument will automatically check if a Single-Use Kit is installed.

18

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 19

Power instrument “O”

1

Switch o the instrument using the mains IEC switch or mains power.

Chapter 2 Installation and setup

Power instrument “O”

2

CAUTION! There is no automatic recovery procedure. If a loss of power event has occurred see

“Restart after shut down” on page 117.

CTS™ Rotea™ Counterflow Centrifugation System User Guide

19

Page 20

Chapter 2 Installation and setup

2

Installation

Installation

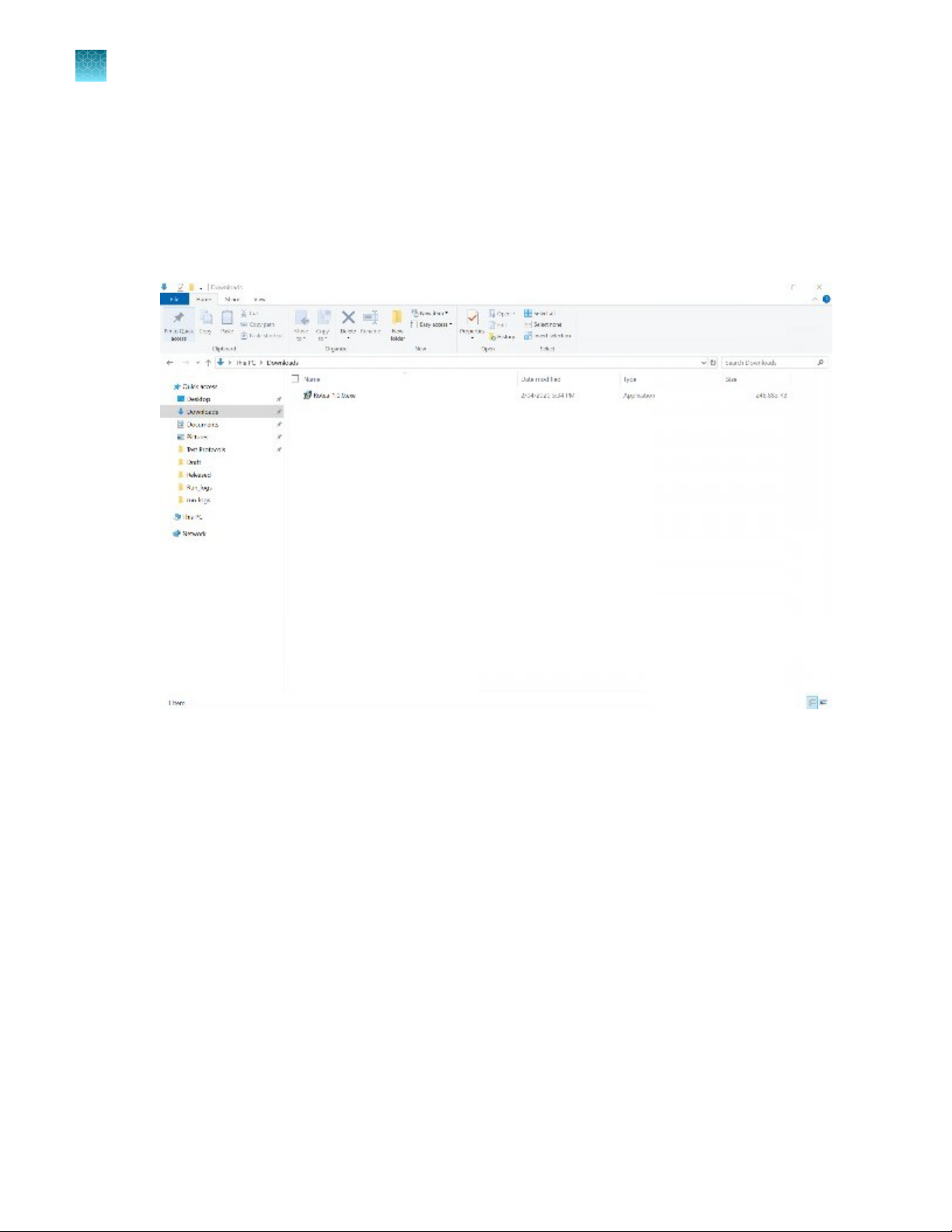

The Dell™ 2‑in‑1 laptop will be pre-installed with Windows™ OS. The latest CTS™ Rotea™ Graphical User

Interface (GUI) software will need to be installed onto the Dell™ 2‑in‑1 laptop provided. New releases of

the Rotea™ GUI software will be available for download from thermofisher.com.

1.

Download the Rotea-X.X.X.exe installer.

20

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 21

Chapter 2

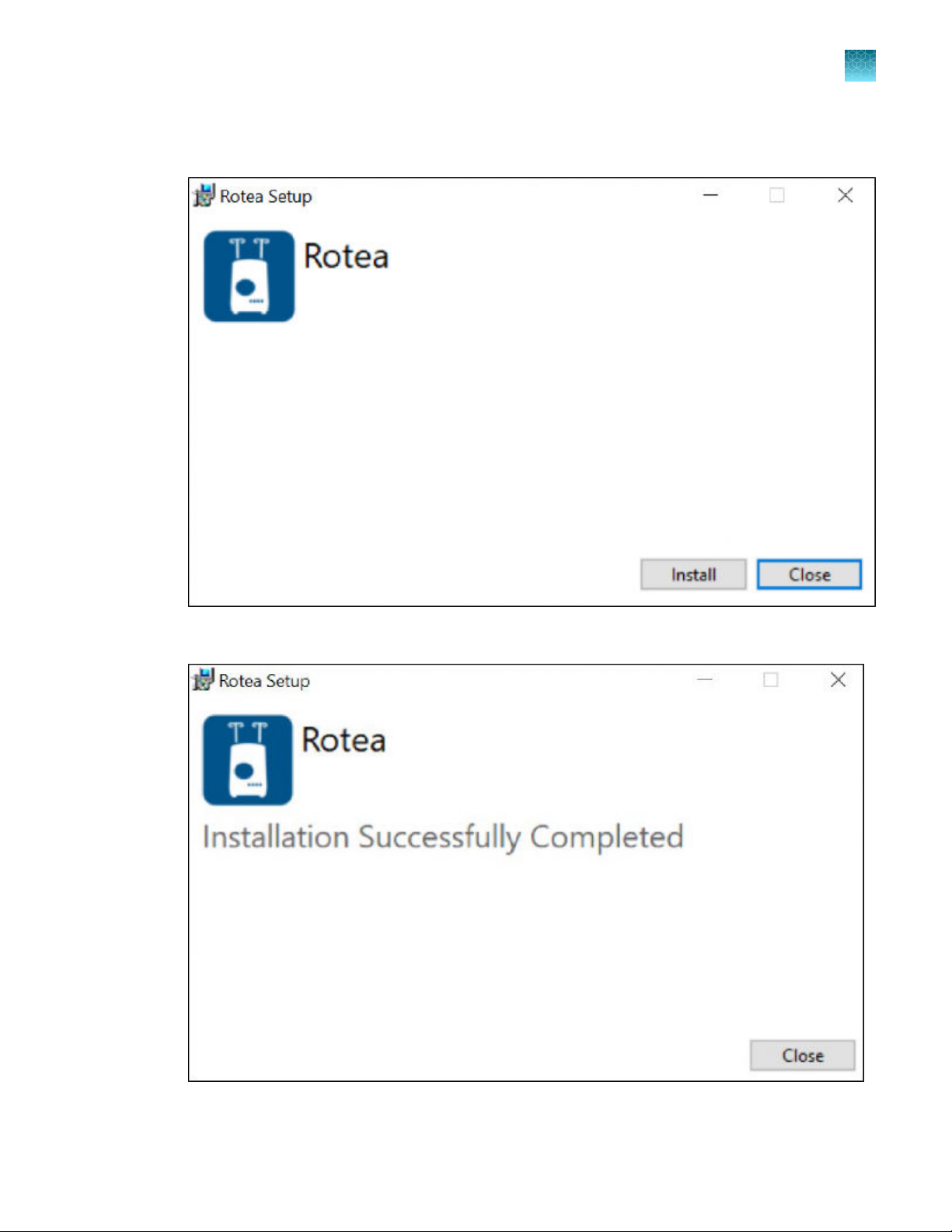

2.

Run the Rotea-X.X.X.exe installer. Click Install. The application will be installed in C:\Program

Files (x86)\Rotea\.

Installation and setup

Installation

2

3.

Click Close to finish the app installation.

4.

Power on the Rotea™ instrument (with the switch on the back) and plug it into the laptop.

CTS™ Rotea™ Counterflow Centrifugation System User Guide

21

Page 22

Chapter 2 Installation and setup

2

Installation

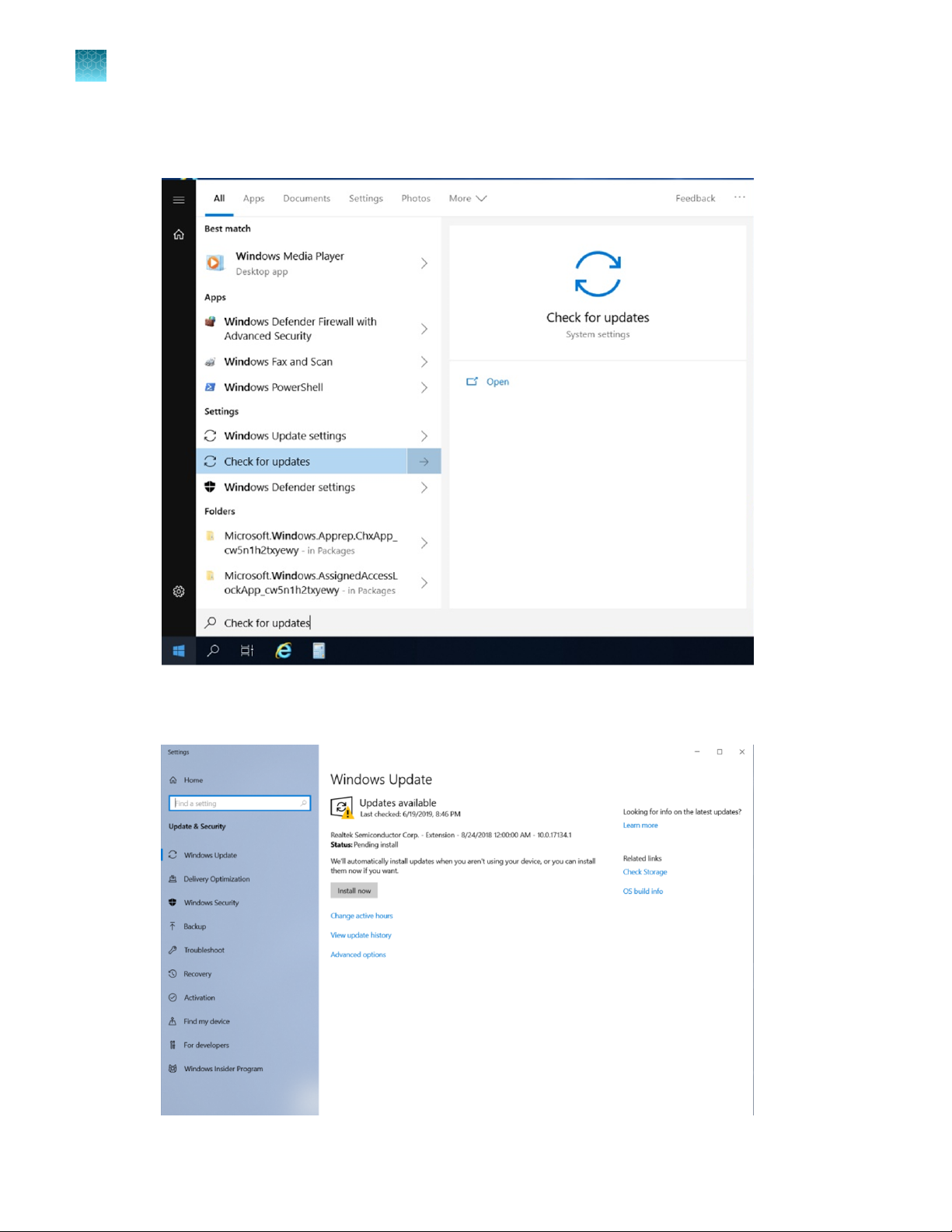

5.

The next step is to update Windows™ software. Make sure the laptop is connected to the local wifi

network. This can be done by opening the start menu and searching for Check for updates.

6.

Click Check for updates, Install now and restart the laptop as required. This process may need

to be repeated multiple times until Windows™ software is completely up to date.

22

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 23

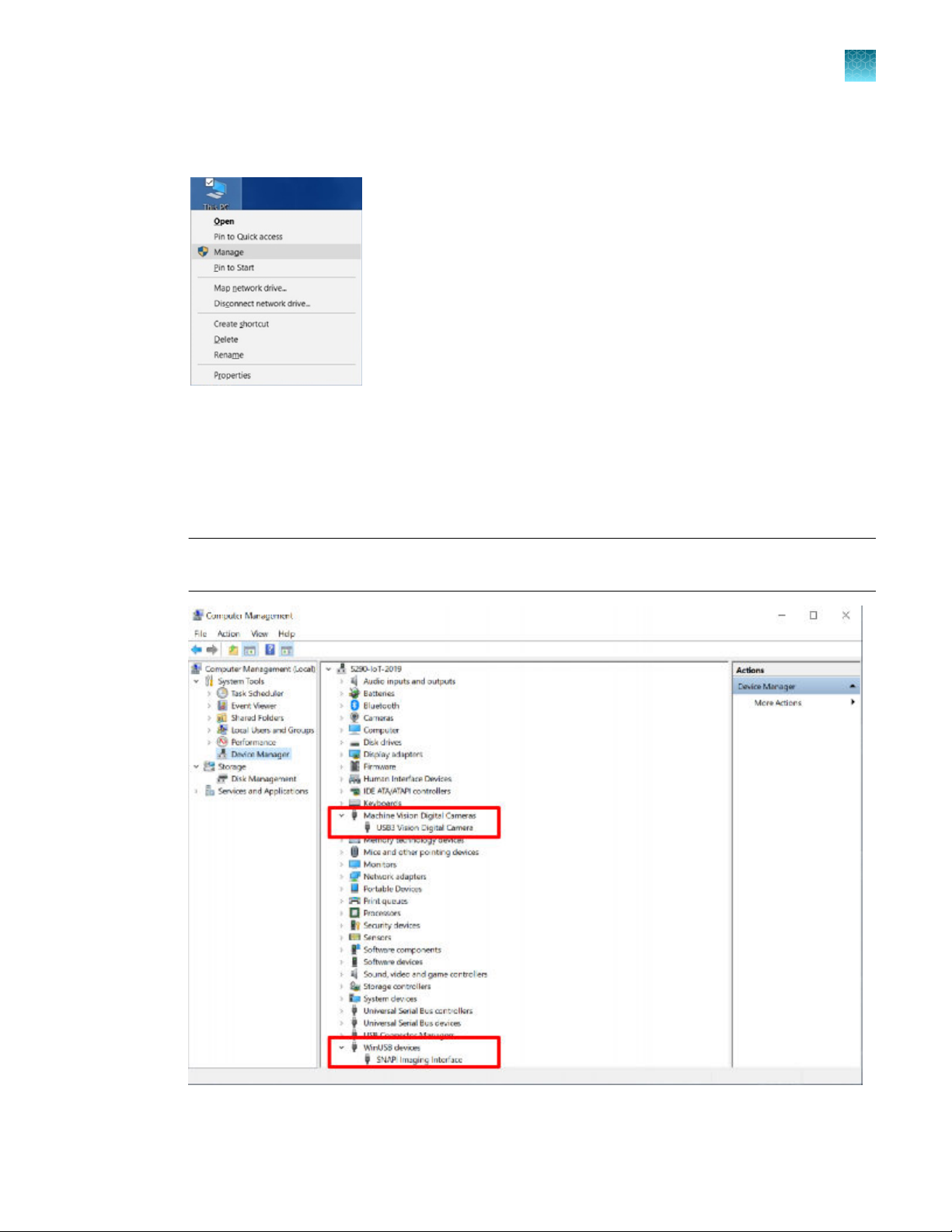

Chapter 2

7.

Check if Windows Update installed the required USB device drivers. Right click on This PC on the

desktop and open Manage.

8.

Ensure the USB devices are detected correctly. Check that the devices highlighted in figure can be

seen:

•

USB Vision Digital Camera

•

USB Serial Port (COM X)

•

SNAPI Imaging Interface

Installation and setup

Installation

2

Note: If these devices are missing ensure the USB cable is plugged in, the Rotea™ instrument is

powered and on, that there are no more Windows™ software updates to complete.

9.

The installation is now complete. Move onto setting up the application for the first time.

CTS™ Rotea™ Counterflow Centrifugation System User Guide

23

Page 24

Chapter 2 Installation and setup

2

First time setup

First time setup

1.

Push the power button on the laptop to start Windows™ software.

2.

Run the Rotea™ application from the desktop or start menu. The application has a single admin

user with Username: admin, Password: admin on a fresh installation.

24

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 25

Chapter 2 Installation and setup

First time setup

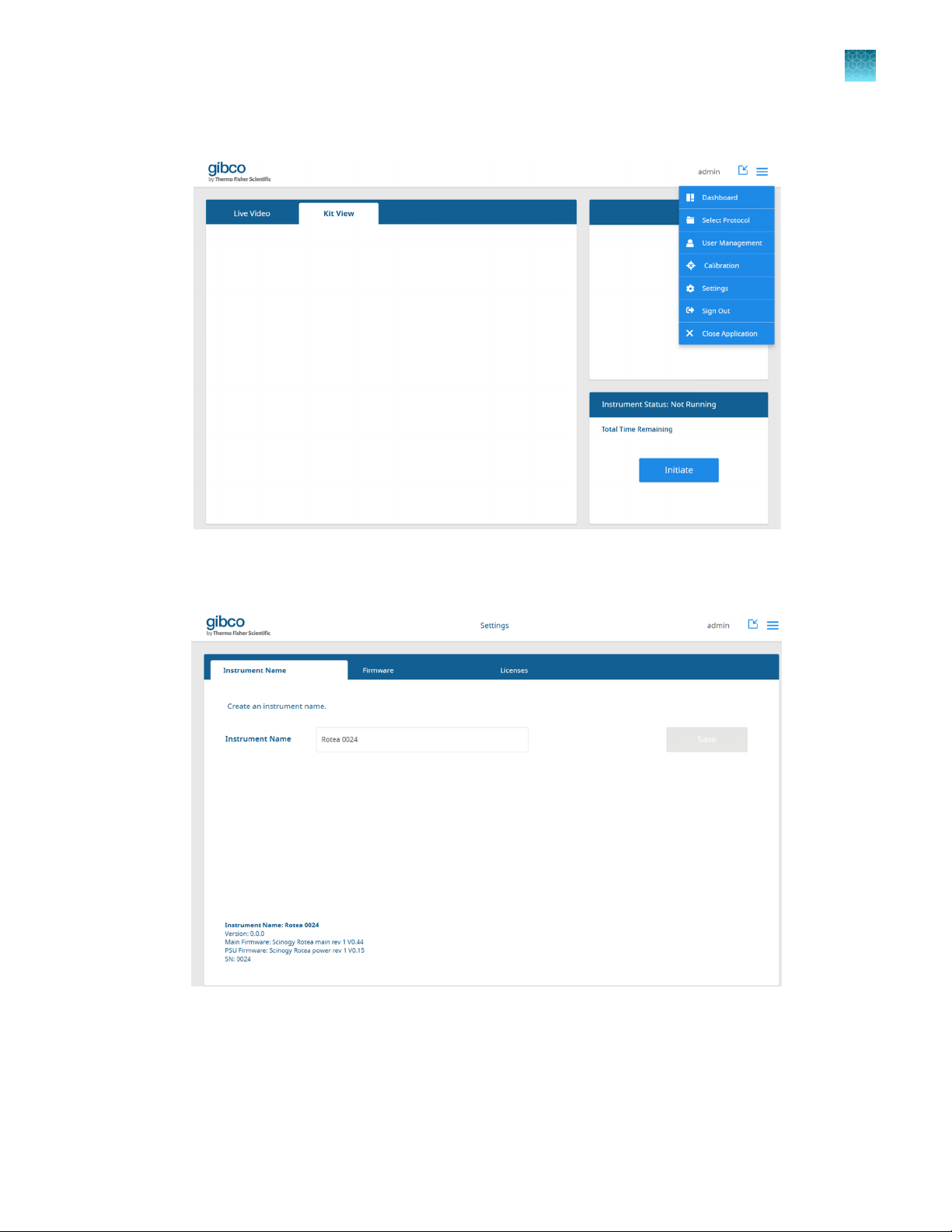

3.

The main navigation menu in the top right corner is used to get to all areas of the applications.

2

4.

Click the Settings in the navigation menu to set the instrument name. Edit the instrument name if

required.

CTS™ Rotea™ Counterflow Centrifugation System User Guide

25

Page 26

2

Chapter 2

First time setup

5.

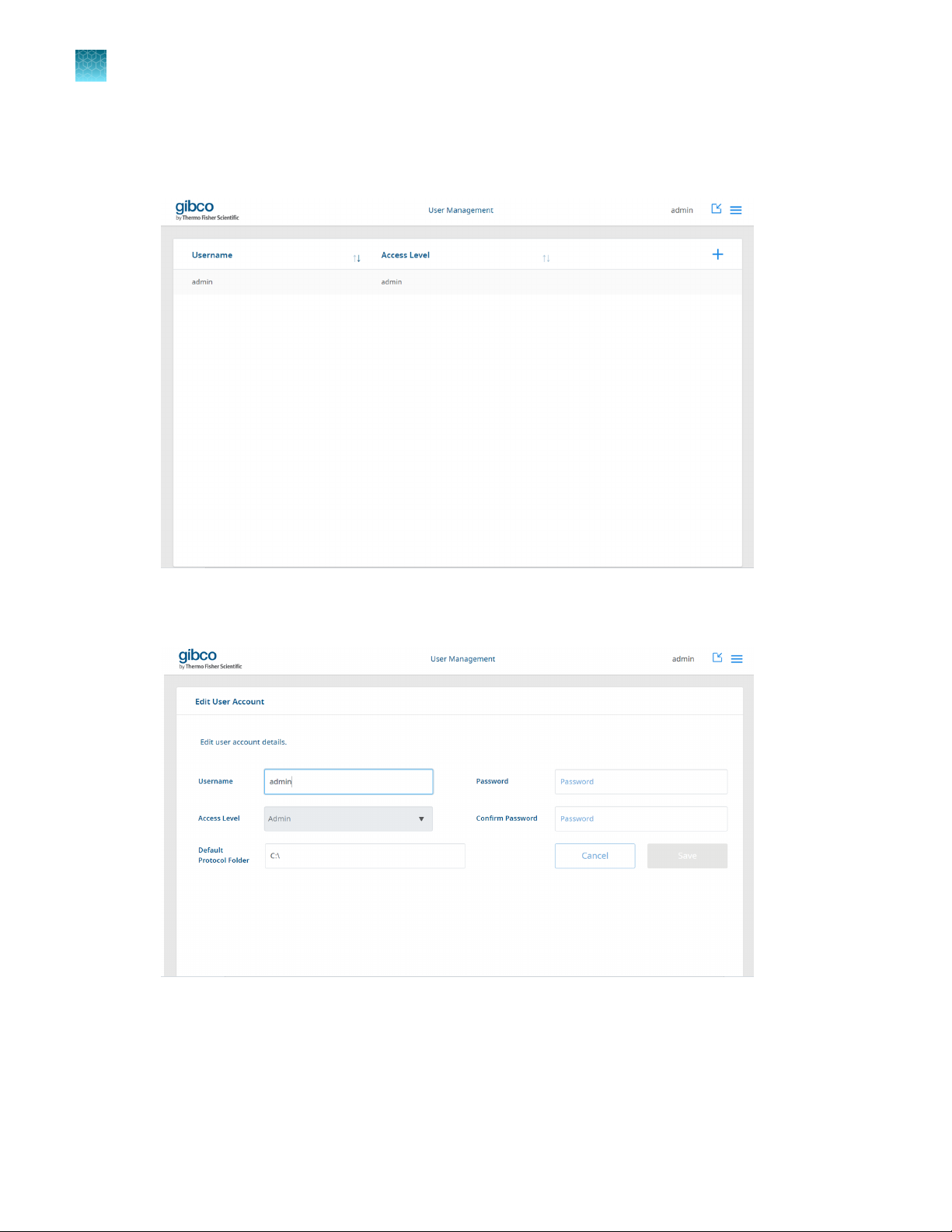

Installation and setup

Click User Management in the navigation menu to change the admin username/password. This

page shows all the users configured for in the application. Click the admin user to change the

account details. New users can be added with the + button.

6.

Change the admin user account username, password and the default directory for this user to find

protocols. Click Save for any changes.

7.

The configuration is now complete.

26

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 27

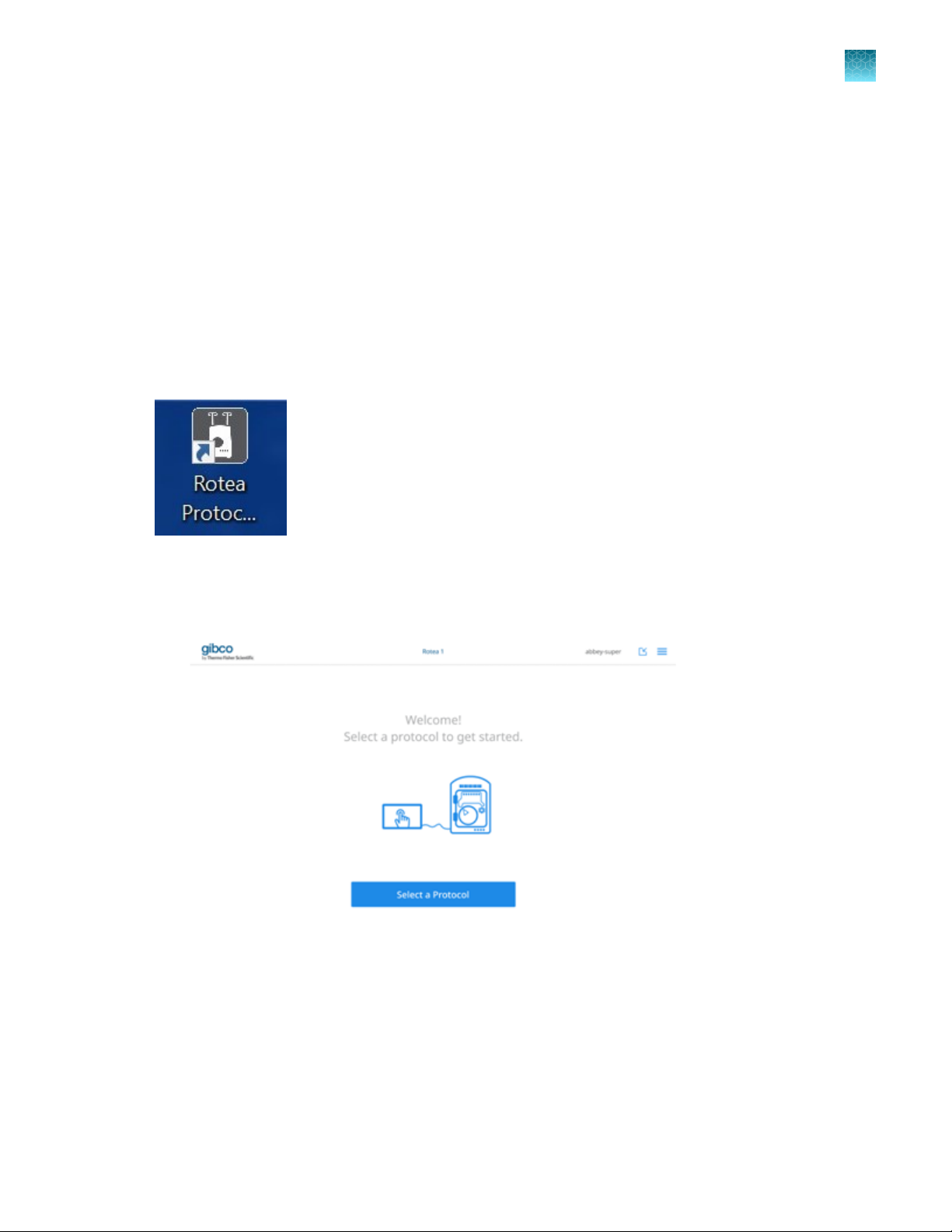

Download protocols

Create protocols

Protocols comprise a series of individual steps that are to be perfomed by the instrument. Triggers are

used to define when the instrument will move to the next step. A range of existing protocols can be

downloaded from the Thermo Fisher Scientific portal.

Users can also modify existing protocols or create entirely new protocols using the Rotea Protocol

App that can be installed on any Windows™ PC, laptop or tablet.

Protocols can be saved for future retrieval using the GUI.

The Rotea Protocol App can be accessed at any time by clicking on the icon on the desktop.

Chapter 2 Installation and setup

Download protocols

2

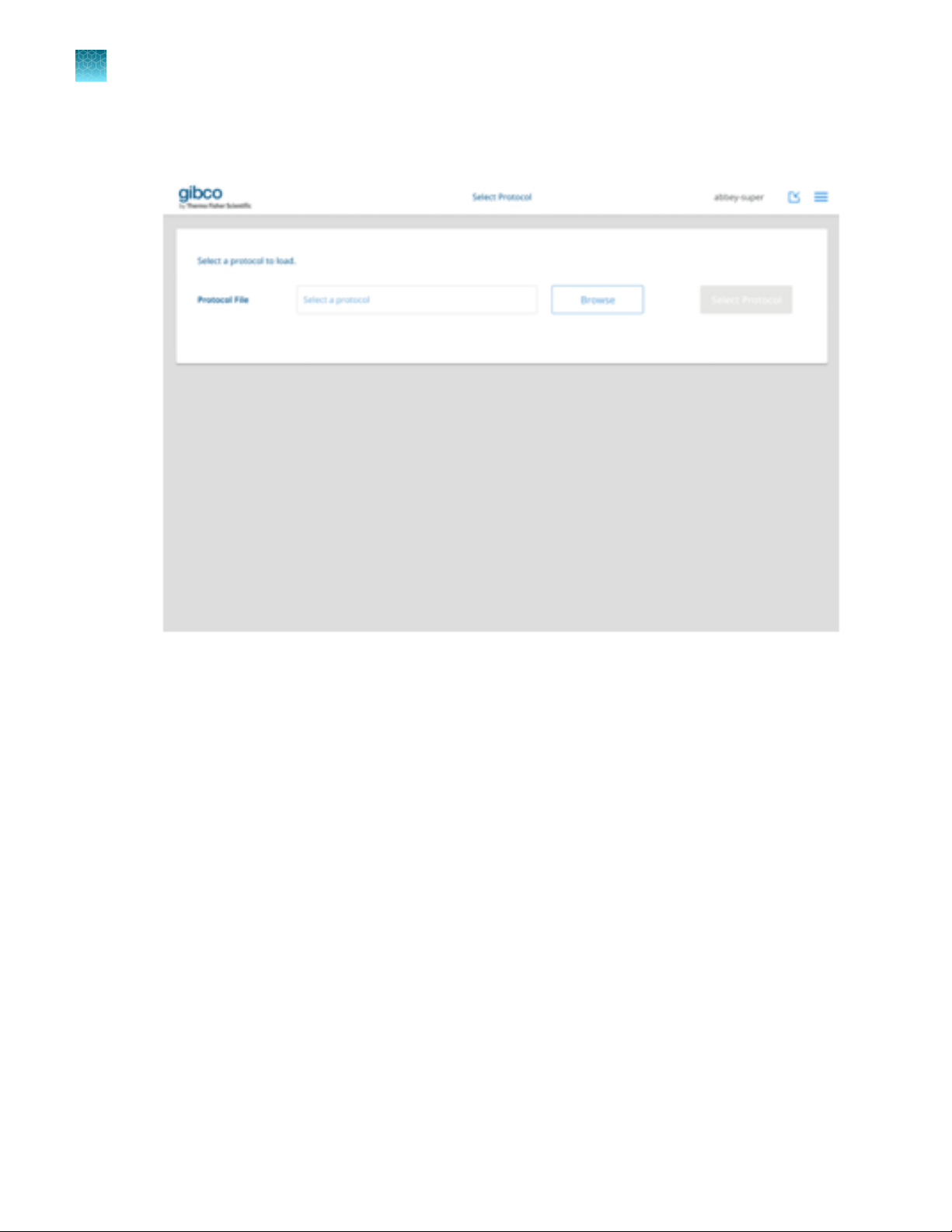

Load a protocol

1.

Click on the Select a Protocol button

CTS™ Rotea™ Counterflow Centrifugation System User Guide

27

Page 28

Chapter 2 Installation and setup

2

Download protocols

2.

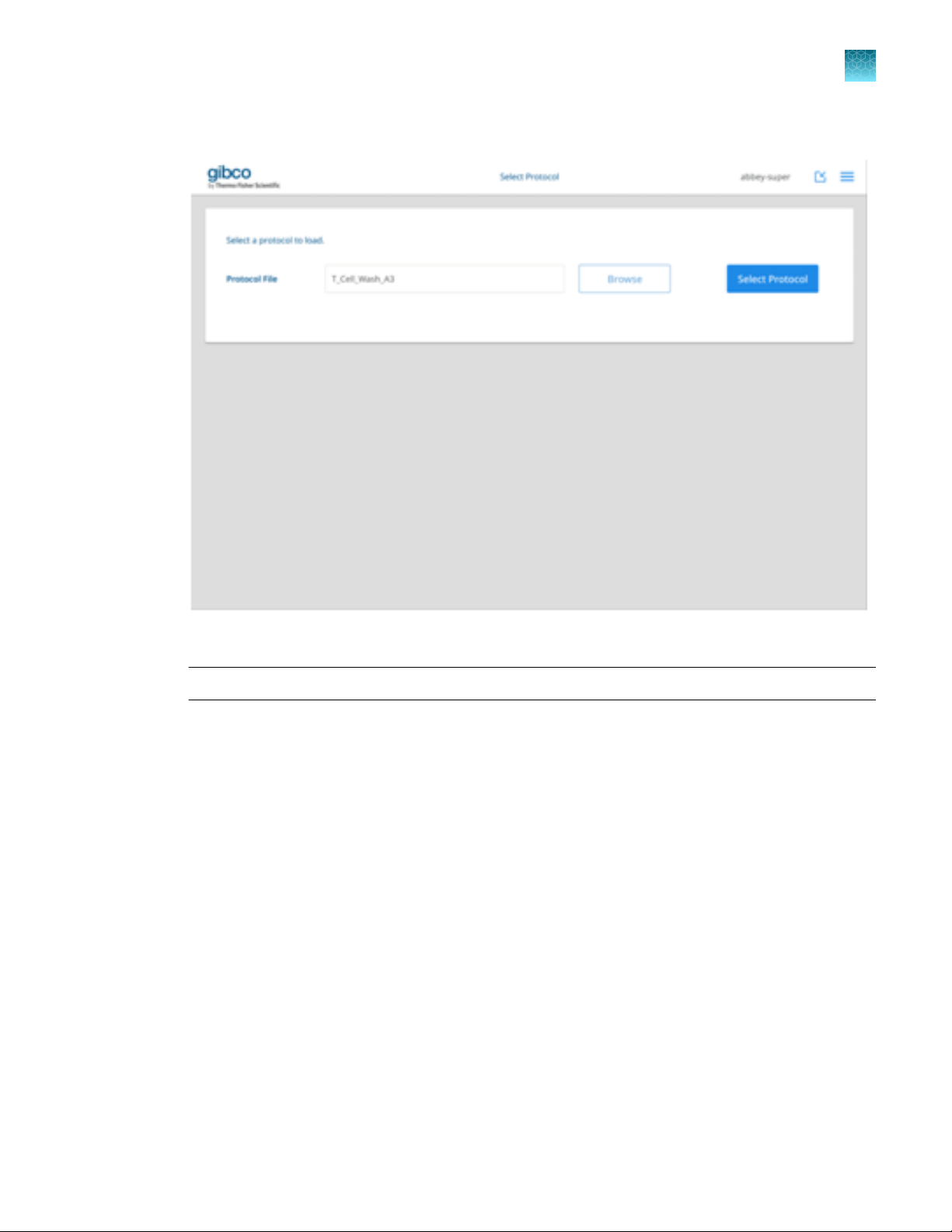

Click Browse or Select a Protocol to browse for a protocol stored locally or on any connected

devices.

28

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 29

Chapter 2 Installation and setup

Download protocols

3.

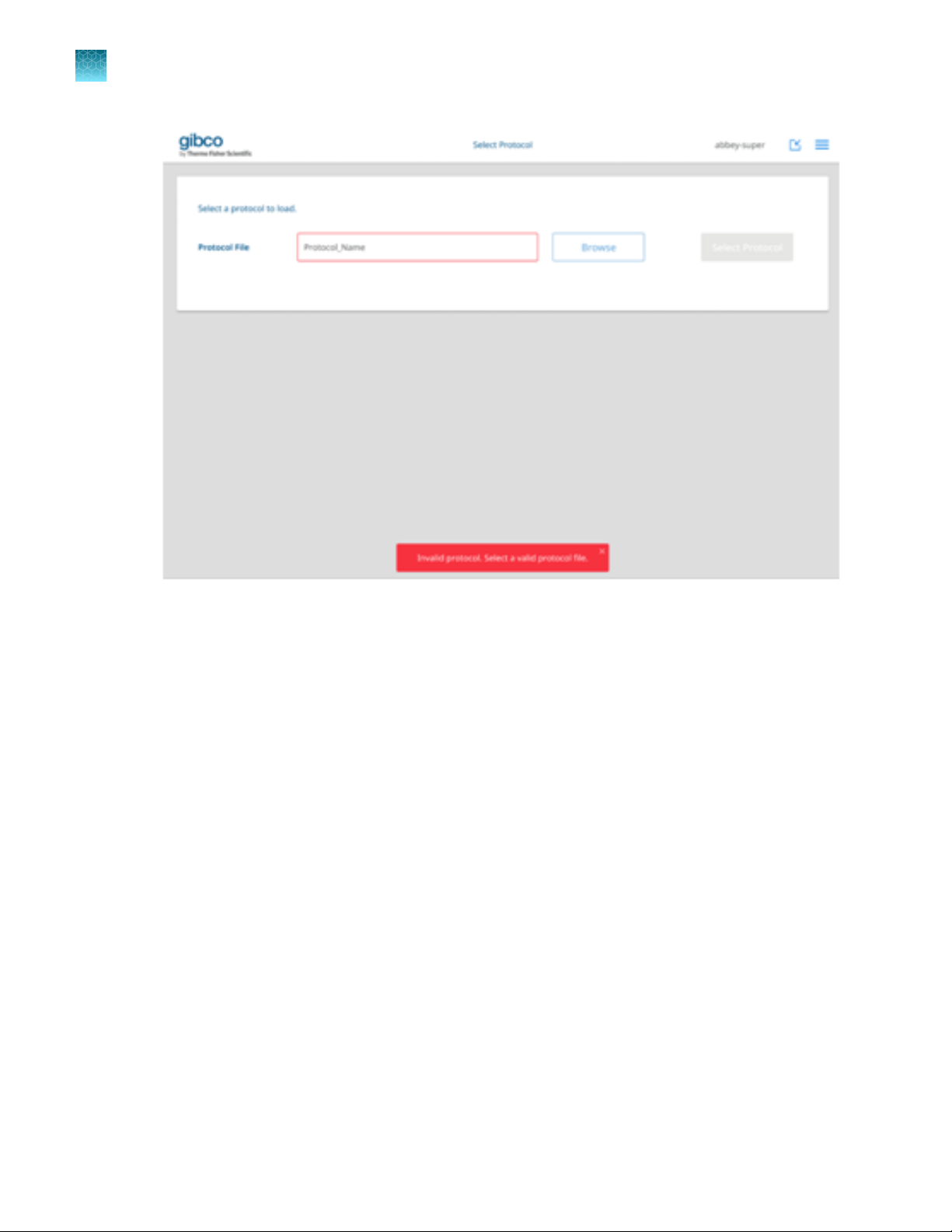

Double click the required protocol to display the filename in the Protocol File text box.

2

4.

Click on Select Protocol.

Note: If an invalid protocol is selected, a warning box will be displayed.

CTS™ Rotea™ Counterflow Centrifugation System User Guide

29

Page 30

Chapter 2 Installation and setup

2

Download protocols

30

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 31

Rotea™ GUI dashboard

1 2 3 4 5 6

10 9

8

7

The Rotea™ GUI dashboard is the primary means of navigation around the Rotea™ GUI and operation

of the Rotea™ instrument. It can be operated using the laptop touch screen only or with the keyboard

attached.

Chapter 2 Installation and setup

Download protocols

2

Live video of the spinning centrifuge chamber

1

Kit View for the current step

2

Instrument name

3

Protocol name and list of adjacent steps (current step in bold)

4

Username

5

Minimize screen

6

Dropdown menu

7

Shortcut to Step List

8

Manual speed adjustment (buttons or keyed values)

9

Resettable timer

10

CTS™ Rotea™ Counterflow Centrifugation System User Guide

31

Page 32

Chapter 2 Installation and setup

2

Download protocols

User Management

1.

Select User Management from the dropdown menu.

32

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 33

2.

Click on the + icon to add a new user.

Chapter 2 Installation and setup

Download protocols

2

3.

Type in new Username and Password.

CTS™ Rotea™ Counterflow Centrifugation System User Guide

33

Page 34

Chapter 2 Installation and setup

2

Download protocols

4.

Confirm new password.

5.

Select Access Level from dropdown list.

6.

Select default folder for saving protocols.

7.

Click Add Account to save new user settings.

8.

Edit user account details including setting Access Level.

34

9.

Click Save or Cancel.

Note: Edits to Access Level can only be performed by a user with admin rights.

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 35

10.

Select to delete a user.

Chapter 2 Installation and setup

Download protocols

2

11.

Click Confirm or Cancel.

CTS™ Rotea™ Counterflow Centrifugation System User Guide

35

Page 36

Chapter 2 Installation and setup

2

Download protocols

12.

Users without admin rights can edit their profile by selecting Profile from the dropdown menu.

13.

Edit user profile fields.

14.

Click Save or Cancel.

36

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 37

Uninstall

1.

Open the Add or remove programs utility by searching for it in the start menu.

Chapter 2 Installation and setup

Uninstall

2

CTS™ Rotea™ Counterflow Centrifugation System User Guide

37

Page 38

Chapter 2 Installation and setup

2

Logging

2.

Search and remove the Rotea™ application.

3.

Wait for the uninstall to complete and the Rotea™ application will be removed. The user

database and log files will not be deleted when the application is uninstalled. If the user

wants to permanently delete them, they need to be deleted manually by removing the

C:\ProgramData\Rotea directory.

Logging

The application saves several logs. The main logs of interest to the user are the run logs which contain a

run history of each run performed by the laptop.

The run log files are saved in: C:\ProgramData\Rotea\logs\run_logs.

The service logs are saved in: C:\ProgramData\Rotea\logs\service and may be required for

warranty claims and to help resolve application issues.

Note: The ProgramData directory is a hidden directory, typing C:\ProgramData\Rotea in the

address bar will take you to the directory.

38

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 39

Chapter 2 Installation and setup

You can also add notes to the run log.

• Click Add Log Comment in the dropdown menu during a protocol run.

Logging

2

CTS™ Rotea™ Counterflow Centrifugation System User Guide

39

Page 40

Chapter 2 Installation and setup

2

Logging

• Write comment in the comment box and click Add Comment.

40

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 41

3

Open the door

The instrument door is automatically locked by the instrument and can only be opened when the:

•

Instrument is powered up

•

Blue door unlock button is illuminated

•

Instrument is not currently running a protocol

•

Centrifuge carrier and peristaltic pump are stationary

Basic instrument operation

1.

Press

pushbutton when it is illuminated to unlock the door.

2.

Open the door and raise until past vertical.

Note: Soft close hinges prevent the door from opening or closing abruptly.

CTS™ Rotea™ Counterflow Centrifugation System User Guide

41

Page 42

Chapter 3 Basic instrument operation

3

Open the door

Note: An emergency maintenance access method can be used to open the door should this be

required e.g. in the case of power loss – (See “Open the door without power” on page 111).

When the unlock button is pressed, the safety circuit is disabled to prevent the pump or centrifuge from

operating and triggers the following:

•

Pinch valves retract

•

Pump clamp is released

•

Door is unlocked and partially opens

Note: If there is a Single-Use Kit installed on the instrument, unlocking the door will release the valves

that are clamping the tubes of the kit closed. Any fluids in bags or vessels attached to the kit will be free

to flow. Close all manual tube clamps before opening the door.

42

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 43

Kit preparation, loading and removal

Kit configuration

Once a protocol has been selected to run on the instrument, the Kit View on the Rotea™ GUI

dashboard will display a schematic of the CTS™ Rotea™ Single-Use Kit with bag connections.

Chapter 3 Basic instrument operation

Kit preparation, loading and removal

3

Figure 6 Instrument with CTS™ Rotea™ Single-Use Kit

CTS™ Rotea™ Counterflow Centrifugation System User Guide

43

Page 44

Chapter 3 Basic instrument operation

3

Kit preparation, loading and removal

Figure 7 Rotea™ GUI showing Kit View

CAUTION! The Single-Use Kit has been designed exclusively for use with the Rotea

and includes several features to enable fast, error-free loading by the user. It is the responsibility of

the user to ensure correct assembly and loading of the Single-Use Kit prior to initiating an instrument

protocol.

™

instrument

CAUTION! Only use kits supplied by Thermo Fisher Scientific or its agents.

CAUTION! Inspect each Single-Use Kit for any damage or imperfections that may result in incorrect

operation. Do not use kit if any such defect is found.

44

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 45

Pre-assembly of processing kit

1.

Peel open the sealed pouch and remove the Single-Use Kit.

Chapter 3 Basic instrument operation

Kit preparation, loading and removal

3

2.

Release the CFC Chamber from the Carrier Frame if still retained.

CTS™ Rotea™ Counterflow Centrifugation System User Guide

45

Page 46

Chapter 3 Basic instrument operation

3

Kit preparation, loading and removal

Connecting vessels, bags and reagents

The instrument has been specifically designed for single use, functionally closed processing. The CTS

Rotea™ Single-Use Kit uses DEHP-Free PVC 0.160” OD tubing to enable sterile welding to compatible

bags using devices that service the blood banking industry such as the TSCD II Sterile Tubing Welder

(TerumoBCT). See the instructions provided by instrument providers for completion of sterile welding.

™

46

Figure 8 TSCD II Sterile Tubing Welder (TerumoBCT)

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 47

Bubble Trap

1 2

To manage air in the system, the CTS™ Rotea™ Single-Use Kit includes a small bubble trap with a

capacity of approximately 5 mL.

Chapter 3 Basic instrument operation

Kit preparation, loading and removal

3

Figure 9 CTS™ Rotea™ Single-Use Kit and close-up of Bubble Trap

CTS™ Rotea™ Single-Use Kit

1

Close-up of Bubble Trap

2

CAUTION! Once the Bubble Trap volume is consumed, any additional air in the system will now

be able to enter the CFC Chamber and ultimately cause an over-pressure fault, shutting down the

instrument.

CAUTION! Protocols created for the Rotea

™

instrument must include a suitable priming sequence

to ensure air in fluid supply lines and the Bubble Trap is replaced with fluid prior to commencing

processing.

Note: If the length of tubing from the product supply bag has a volume greater than the Bubble Trap,

then air can enter the circuit. It is therefore preferred that the length of tubing for each connection (1/8”

ID assumed) is less than 12” (or 300 mm). In some cases where the supply vessel is large, e.g. remote

bioreactor, additional process strategies can be included to re-fill the supply tube when needed.

CTS™ Rotea™ Counterflow Centrifugation System User Guide

47

Page 48

Chapter 3 Basic instrument operation

3

Kit preparation, loading and removal

Kit installation

1.

Ensure door is open and any previous Single-Use Kit has been removed.

2.

Hang input / output bags on hanger hooks.

Note: The product input bag can be suspended using one of the side cut-outs on the bag to help

ensure that all product drains from the bag.

48

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 49

Chapter 3 Basic instrument operation

Kit preparation, loading and removal

3.

Place the Carrier Frame over the two Single-Use Kit location buttons on the instrument.

3

4.

Install the CFC Chamber into the CFC Chamber Carrier.

a.

Load CFC Chamber into the CFC Chamber Carrier.

b.

Push CFC Chamber down into CFC Chamber Carrier to depress latch.

CTS™ Rotea™ Counterflow Centrifugation System User Guide

49

Page 50

Chapter 3 Basic instrument operation

3

Kit preparation, loading and removal

c.

Slide CFC Chamber away from axis of rotation until the latch clicks.

5.

Insert tubes A, B, C, D, E, F & G into the corresponding slot in the Bubble Detector Strip and push

downwards with fingers to fully engage each tube in the slot.

50

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 51

Chapter 3 Basic instrument operation

Kit preparation, loading and removal

6.

Stretch the pump tubing around the Peristaltic Pump rollers and insert the Tube Retainer into the

Sensor Block to hold it in place.

3

Pump tube barbed connector correctly placed in the Sensor Block.

CTS™ Rotea™ Counterflow Centrifugation System User Guide

51

Page 52

Chapter 3 Basic instrument operation

3

Kit preparation, loading and removal

7.

Insert tubing in Sensor Block channel.

52

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 53

1

2

Chapter 3 Basic instrument operation

Kit preparation, loading and removal

Correct: Pressure Sensor tubing in

1

Incorrect: Pressure Sensor tubing out

2

CAUTION! The instrument cannot detect if the pump tubing or Tube Retainer have been correctly

positioned. Check prior to closing the door.

3

CAUTION! The tube will sit slightly proud of the channel in the region of the Pressure Sensor so that

the tube is compressed into the required shape when the door is closed. If not correctly located in the

channel, the tubing may be crushed when the door is closed.

CTS™ Rotea™ Counterflow Centrifugation System User Guide

53

Page 54

Chapter 3 Basic instrument operation

3

Kit preparation, loading and removal

Initiate a protocol

1.

Click Initiate to commence running the protocol.

54

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 55

2.

Close the door.

Chapter 3 Basic instrument operation

Kit preparation, loading and removal

3

Note: Soft close hinges prevent the door from dropping suddenly.

CTS™ Rotea™ Counterflow Centrifugation System User Guide

55

Page 56

Chapter 3 Basic instrument operation

3

Kit preparation, loading and removal

3.

Push the door downwards to compress the Single-Use Kit tubing onto Pressor Sensors and other

control features.

4.

(auto): Closing the door initiates the following automatic system checks. The status of each system

check is displayed on the Rotea™ GUI with indicating correct installation of the Single-Use Kit.

56

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 57

Chapter 3 Basic instrument operation

Kit preparation, loading and removal

5.

Errors detected during the automatic system check are identified with a and will require the user

to identify and rectify the source of the error.

3

CTS™ Rotea™ Counterflow Centrifugation System User Guide

57

Page 58

Chapter 3 Basic instrument operation

3

Kit preparation, loading and removal

6.

Manually confirm that the Single-Use Kit configuration matches the image and that manual clamps

have been opened.

7.

Click Confirm to continue.

CAUTION! Manual clamps are provided for use on input and output lines on the Single-

Use Kit to prevent fluid movement until the instrument Pinch Valves are engaged. However,

manual clamps also represent a significant process hazard if left in the closed state. Whilst

the instrument should detect this failure mode as an over-pressure fault, it will stop the

process potentially compromising the batch. Release all manual clamps prior to starting the

automatic sequence.

If required by the selected protocol:

8.

Enter data inputs.

58

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 59

9.

Click Confirm or Cancel.

Chapter 3 Basic instrument operation

Kit preparation, loading and removal

3

CTS™ Rotea™ Counterflow Centrifugation System User Guide

59

Page 60

Chapter 3 Basic instrument operation

3

Kit preparation, loading and removal

10.

The protocol is automatically sent to the instrument and the Rotea™ GUI dashboard is displayed for

the new protocol.

60

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 61

Run a protocol

Rotea™ GUI navigation and instrument operation

1.

Press the Start button on the instrument to start the protocol.

2.

Change the Rotea™ GUI dashboard view as required by clicking on the tabs.

Chapter 3 Basic instrument operation

Run a protocol

3

CTS™ Rotea™ Counterflow Centrifugation System User Guide

61

Page 62

Chapter 3 Basic instrument operation

3

Run a protocol

3.

The live video will automatically turn on when the centrifuge speed exceeds 500 × g. The live video

can be manually turned on at any operating speed by clicking on the Turn on video toggle.

62

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 63

Chapter 3 Basic instrument operation

Run a protocol

4.

The instrument will automatically progress through each step in the protocol until the protocol is

complete, pre-defined user intervention is required or an error occurs.

3

CTS™ Rotea™ Counterflow Centrifugation System User Guide

63

Page 64

Chapter 3 Basic instrument operation

3

Run a protocol

5.

Depending on user access rights, the user can make in-process adjustments to the following

parameters using the control buttons:

•

Reset Step Time Remaining

•

Increase/reduce Pump flow rate

•

Increase/reduce Centrifuge g-force

6.

Switch to the Step List to see a summary of all steps in the protocol.

64

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 65

Chapter 3 Basic instrument operation

7.

Return to the dashboard by clicking on or using the dropdown menu.

Run a protocol

3

CTS™ Rotea™ Counterflow Centrifugation System User Guide

65

Page 66

Chapter 3 Basic instrument operation

3

Run a protocol

Value volumes and pressure sensor values

When in Kit View, click on the Details to display the current net volume that has passed through each

valve and the current pressure of P1 and P2.

66

When the valve volume is positive, more liquid has been pumped out through a valve than has been

pumped in, increasing the volume in the attached bag. A negative value means more liquid has been

pumped in through a valve than has been pumped out, reducing the bag volume.

The example, shows that the net valve volumes are as follows:

1. + 105.2 mL has been pumped out through valve A

2. - 76.0 mL has been pumped in through valve B

3. - 54.6 mL has been pumped in through valve D

4. + 24.9 mL has been pumped out through valve G

5. A small volume of + 0.3 mL has been pumped out through valves E & F which occurred during the

Prime Pressure step.

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 67

Note:

The valve volumes are not the same as the volume that has entered or left a bag. In the example

·

shown, the input bag (cells in culture) is a dual port bag connected to both valve D and G. To

calculate the volume change in or out of the input bag, add the valve volumes for valves D and G e.g.

- 54.6 + 24.9 = - 29.7mL (out of the input bag)

The valve volume is the volume displaced by the pump and hence does not account for volume

·

retained in the Single-Use Kit during priming. For example, the net volume for valve A would overestimate the volume that has been delivered to the waste bag by the volume of the CFC Chamber

plus the kit tubing.

Note: The Pressor Sensors, P1 and P2, are at a low negative pressure meaning there is a slight

vacuum in the system. These will fluctuate during processing depending on the flow rate and pump

direction. A rapidly increasing Pressure Sensor value would indicate a flow restriction or blockage.

Error messages

Chapter 3 Basic instrument operation

Run a protocol

3

Alarm or

message

Safety system

error

Protocol is

Malformed

Door lock error Yes — Trigger instrument stop state Door lock error

Critical

alarm

Yes — Cut power to pump and

Yes — GUI error message after loading

Warning Instrument response GUI message

centrifuge, trigger instrument

stop state

protocol will appear

Safety system error

Protocol run has stopped.

Press the stop button on

the instrument, close manual

clamps and open and close

the instrument door to reset.

Restart the protocol or select

a protocol step to start from. If

error persists, abort the run.

Protocol is Malformed error

Note: Check pump calibration

number to ensure protocol flow

rates are within range.

Protocol run has stopped.

Open and close the door, then

restart the protocol. If error

persists, abort the run.

Pump error Yes — Trigger instrument stop state Pump error

Protocol run has stopped.

Press the stop button to clear

the error, then restart the

protocol or select a step to

start from. If error persists,

abort the run.

CTS™ Rotea™ Counterflow Centrifugation System User Guide

67

Page 68

Chapter 3 Basic instrument operation

3

Run a protocol

(continued)

Alarm or

message

Centrifuge error Yes — Trigger instrument stop state Centrifuge error

Valve error Yes — Trigger instrument stop state Valve error

Out of balance

condition

Critical

alarm

Yes — Trigger instrument stop state Instrument out of balance

Warning Instrument response GUI message

Protocol run has stopped.

Press the stop button on

the insturment, close manual

clamps and open and close

the instrument door to reset.

Restart the protocol or select

a protocol step to start from. If

error persists, abort the run.

Protocol run has stopped.

Press the stop button on

the instrument, close manual

clamps and open and close

the instrument door to reset.

Restart the protocol or select

a protocol step to start from. If

error persists, abort the run.

Protocol run has stopped.

Press the stop button to clear

the error, then restart the

protocol or select a step to

start from. If error persists,

abort the run.

Moisture in bowl Yes — Trigger instrument stop state Centrifuge leak detected

Protocol run has stopped.

Press the stop button to

clear the error or temporarily

override the moisture sensor if

safe to do so. If error persists,

abort the run.

68

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 69

(continued)

Chapter 3 Basic instrument operation

Kit removal

3

Alarm or

message

Over-pressure

condition

Communication

error

Kit removal

CAUTION! Seal all fluid lines using a tube sealer or manual clamps prior to unlocking the door to

prevent fluid movement when the instrument pinch valves are released.

Critical

alarm

Yes — Trigger instrument stop state Blockage detected

— Yes Instrument continues running

Warning Instrument response GUI message

Protocol run has stopped.

Ensure manual clamps are

open and bags are connected

correctly. Press the stop button

to relieve pressure to Bag X.

Restart the protocol or select a

protocol step to start from.

Communication error

protocol, GUI indicates error

until communications are

restored

Ensure that the cable between

the laptop interface and

instrument is connected.

1.

Press pushbutton when it is illuminated to unlock the door.

CTS™ Rotea™ Counterflow Centrifugation System User Guide

69

Page 70

Chapter 3 Basic instrument operation

3

Kit removal

2.

Open the door and raise until past vertical.

70

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 71

Chapter 3 Basic instrument operation

Kit removal

3.

Remove the CFC Chamber from the CFC Chamber Carrier by lifting the lever and rotating the CFC

Chamber back towards the latch.

3

CTS™ Rotea™ Counterflow Centrifugation System User Guide

71

Page 72

Chapter 3 Basic instrument operation

3

Kit removal

4.

Lift CFC Chamber clear of the Centrifuge Carrier.

72

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 73

5.

Remove the tubing from the Sensor Block and Peristaltic Pump.

Chapter 3 Basic instrument operation

Kit removal

3

CTS™ Rotea™ Counterflow Centrifugation System User Guide

73

Page 74

Chapter 3 Basic instrument operation

3

Aseptic disconnection of the kit components

6.

Gently raise the Carrier Frame drawing out the tubes from the Bubble Sensor.

Aseptic disconnection of the kit components

If not done prior to Single-Use Kit removal from the instrument:

•

Create sterile seal and disconnect finished product from the Single-Use Kit.

•

Create sterile seal and disconnect any bags or subassemblies to be disposed of separately or

manually clamp tube connections to bags if preferred.

•

Dispose of used Single-Use Kit in accordance with approved procedures.

Note: The Single-Use Kit tube materials are suitable for RF sealing using a SEBRA or Terumo Tube

Sealer or equivalent. Please consult the tube sealer supplier’s manual for instructions on creating a

sterile disconnection.

74

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 75

System settings

Instrument firmware

1.

Select Settings from the drop down menu.

Chapter 3 Basic instrument operation

System settings

3

CTS™ Rotea™ Counterflow Centrifugation System User Guide

75

Page 76

Chapter 3 Basic instrument operation

3

System settings

2.

Click on the Firmware tab.

3.

Select the latest firmware.

4.

Click Update.

76

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 77

5.

The selected firmware will be automatically updated.

Chapter 3 Basic instrument operation

System settings

3

CTS™ Rotea™ Counterflow Centrifugation System User Guide

77

Page 78

Chapter 3 Basic instrument operation

3

System settings

6.

The system will automatically reboot.

7.

Once firmware has updated successfully, click Done.

78

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 79

Chapter 3 Basic instrument operation

8.

If firmware has not been updated click Done and restart the firmware update.

System settings

3

CTS™ Rotea™ Counterflow Centrifugation System User Guide

79

Page 80

Chapter 3 Basic instrument operation

3

System settings

OPC-UA

An Open Platform Communications - United Architecture (OPC-UA) interface is provided that enables

admin users to connect Rotea™ instrument to a Supervisory Control and Data Acquisition (SCADA)

system to send protocols, start a protocol and monitor run progress, see Chapter 4, “OPC-UA

interface”.

80

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 81

Settings

Admin users have the ability to update the instrument settings via the Rotea Settings tab.

Chapter 3 Basic instrument operation

System settings

3

CTS™ Rotea™ Counterflow Centrifugation System User Guide

81

Page 82

Chapter 3 Basic instrument operation

3

System settings

Licenses

All relevant software licenses are listed in the Licenses tab. The detail for each license can be displayed

by clicking on the v arrows.

82

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 83

Calibration

1.

Select Calibration ( ) from the drop down menu.

Chapter 3 Basic instrument operation

Calibration

3

CTS™ Rotea™ Counterflow Centrifugation System User Guide

83

Page 84

Chapter 3 Basic instrument operation

3

Calibration

2.

Input Target Volume.

3.

Input Actual Volume from calibration test run.

4.

Select Kit Type from the drop down list.

5.

Click Calibrate.

84

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 85

6.

Click Save or Cancel.

Chapter 3 Basic instrument operation

Calibration

3

CTS™ Rotea™ Counterflow Centrifugation System User Guide

85

Page 86

Chapter 3 Basic instrument operation

3

Calibration

7.

Click Done if calibration is successful.

8.

If calibration was not successful, click Done and restart the calibration process.

86

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 87

4

Introduction

There are applications for the CTS™ Rotea™ Counterflow Centrifugation System where a Supervisory

Control and Data Acquisition (SCADA) system will supervise the operation. This supervision will include

items like sending a protocol to the Rotea™ instrument, starting a protocol and monitoring of run

progress.

Each CTS™ Rotea™ Counterflow Centrifugation System includes a dedicated Dell™ 2‑in‑1 laptop with

software applications to program and operate the instrument. An open data communication interface is

also included to interface with SCADA systems.

One SCADA system is the Emerson DeltaV. DeltaV is technically a Process Control System (PCS), but it

incorporates all the functionality of a SCADA system, and those are the functions that will be primarily

used with the Rotea™ instrument.

OPC-UA interface

Definitions

Abbreviation

GUI Graphical User Interface

DeltaV A Process Control System (PCS made by Emerson

ERP Enterprise Resource Planning

MES Manufacturing Execution System

PCS Process Control System

PLC Programmable Logic Controller

Protocol A series of equipment instructions

Run The execution (running) of a protocol, from beginning to end

SCADA Supervisory Control and Data Acquisition

OPC-UA Open Platform Communications - United Architecture, a machine to

Definition

machine communication protocol for industrial automation

CTS™ Rotea™ Counterflow Centrifugation System User Guide

87

Page 88

4

Chapter 4

Scope of system

OPC-UA interface

Scope of system

CTS™ Rotea™ Counterflow Centrifugation System is a stand alone instrument with an operational

configuration comprising:

• The instrument hardware

• Firmware and software

• Dell™ 2‑in‑1 laptop

• The installed CTS™ Rotea™ Single-Use Kit and attached tubing and bags/vessels

• The protocol file

• In-process data that is supplied as protocol metadata before the protocol commences

Instrument hardware configuration

The Rotea™ instrument's embedded control has been designed to enable integration of functional

components that are external to the base instrument and hence would vary the configuration from the

standard:

• External components may be externally powered

• Communications from the Rotea™ instrument's embedded control to external components is

through a CAN-BUS interface

• External devices may be individual devices already defined in the Rotea™ instrument's embedded

schema such as a pump, centrifuge, push button, bubble sensor or valve

• External devices may be newly defined with a set of device specific commands and status reports

• External devices may also comprise a series of components managed by a self-contained control

that responds to purpose designed messages from the Rotea™ instrument's embedded through the

CAN-BUS

Single-Use Kit

The Single-Use Kit defines:

• The fluidic connections between instrument components such as the pump and valves

• The size of the pump tubing for each pump

• Optionally the volume capacity of each attached bag/vessel

• Optionally the priming volume for each valve line

• Optionally the required minimum volume for each reagent supply to be attached

The Single-Use Kit is identified by:

• A barcode read from a label attached to the kit

• The kit identification includes a unique number, batch identification number and kit type specifier.

The kit type specifier is used for verification of kit type to the protocol requirements.

The scope of a Single-Use Kit may extend beyond the base instrument to include attached devices

such as external mixers and pumps, or simply the tubing or other features that facilitate connection to

external systems such as bio-reactors or electroporation systems that are not managed by the Rotea

instrument's control.

88

™

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 89

Protocol file

• Protocol files for the Rotea™ instrument will be stored and transmitted in JSON format.

• The JSON format provides an extensible structure to support future devices and software

functions.

• The Rotea™ instrument's embedded control supports one only protocol file.

• The protocol file is re-written to the instrument each time the protocol is run.

Protocol metadata

Protocol metadata entries provide the means to adjust fixed, qualified protocols to respond to process

conditions.

• Metadata is supplied at the time the protocol is transferred to the instrument

• The metadata populates variables that are needed to complete the protocol definition

• This is managed by the IAL as part of the protocol transfer actions

Chapter 4

OPC-UA interface

MES interface

4

MES interface

A Manufacturing Execution System (MES) interface is provided to enable processing by the Rotea

instrument within a qualified clinical cGMP environment.

Background

The CTS™ Rotea™ Counterflow Centrifugation System is for research use or manufacture of cell, gene or

tissue-based products.

For use in a qualified manufacturing processes, the instrument, Single-Use Kit and protocol must be

qualified and maintained fit for purpose for the application.

When a qualified process is run, a record is required to verify that the process was performed in the

formally defined way. If any variation to the process operations occur, then such events need to be

documented and formally reviewed before the product can be released.

An MES interface is a communication system that links the CTS™ Rotea™ Counterflow Centrifugation

System to a formally qualified electronic batch management system and associated data capture and

record management functions.

The MES system is responsible for formal identification of users, their level of training, recording of

equipment, consumables and events associated with each processing run.

The CTS™ Rotea™ Graphical User Interface (GUI) does not support this formal data capture activity.

If an automated electronic interface is part of the implementation plan for CTS™ Rotea™ Counterflow

Centrifugation System, then the MES interface provides that tool.

™

CTS™ Rotea™ Counterflow Centrifugation System User Guide

89

Page 90

Chapter 4 OPC-UA interface

4

MES interface

Electronic communications

It is assumed the MES applications will be located externally to the CTS™ Rotea™ Counterflow

Centrifugation System.

Communications by any MES system to the instrument will be through the CTS™ Rotea™ GUI installed

on the Dell™ 2‑in‑1 laptop attached to the instrument. View the structure diagram, see “MES run a

protocol” on page 104.

Figure 10 System components

Communications protocol

The MES interface to the Rotea™ instrument application will be through an implementation of OPC-UA.

When enabled in the Rotea™ GUI, an OPC-UA server will run on the laptop allowing an MES OPC-UA

client to connect to it.

The commands and reports available to OPC-UA client are outlined (see “MES – Commands and

reports overview” on page 91) with details (see “OPC-UA interface” on page 96).

90

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 91

MES – Commands and reports overview

Chapter 4

MES – Commands and reports overview

OPC-UA interface

4

Figure 11 Run protocol workflow

For more use cases, See “Use case sequence diagrams” on page 104.

CTS™ Rotea™ Counterflow Centrifugation System User Guide

91

Page 92

Chapter 4

4

MES – Commands and reports overview

OPC-UA interface

Enable OPC-UA

The OPC-UA interface is not enabled by default. The enable button is available to an administrator

under the Settings: OPC-UA Setup tab. The OPC-UA server only supports one OPC-UA client

connecting to it. The Rotea™ application uses a Unified Automation OPC-UA stack which supports

a number of configurable parameters, including: encryption level, security level, certificate configuration,

valid certificates, end point addresses, server names, server url, etc. The full list of parameters can

be found at the following link. http://documentation.unified-automation.com/uasdkcpp/1.7.0/html/

L2ServerSdkServerConfig.html#server_config_xml_file

The Rotea™ application configuration file is available on the laptop under:

C:\Program Files (x86)\Rotea\opcua\opcua_server_config.xml

The user can modify the configuration file to suit their needs. The configuration file is loaded when the

laptop is started if the OPC-UA server is enabled or when the OPC-UA server is enabled under the

OPC-UA Setup tab.

Log in to instrument

The MES can login to the Rotea™ GUI at any time, it does so by changing the SetGuiUserLevel node.

Full details of the SetGuiUserLevel values, see “OPC-UA interface” on page 96.

Load protocol

A protocol can be loaded three ways:

1. SetLocalProtocolFilePath – Sets the file path on the laptop of where to load the protocol file.

2. SetProtocolFileContents – Supply the protocol file contents to transfer to Rotea™ GUIRotea™ and

the instrument.

3. SetProtocolFileByLookupTableId – Select a protocol based on the id in a lookup table. The user

must generate a YAML file called OPCUAProtocolList.yaml with the ids and filenames in it.

This is an example OPCUAProtocolList.yaml file with 2 files in it:

The user must set the directory where the OPCUAProtocolList.yaml file can be found. This is done

on the OPC-UA settings page.

Note: The YAML file can be modified in any text editor. Freeware program NotePad++ is used in the

illustration.

92

Confirmation of protocol loading can be obtained from the ProtocolName and ProtocolChecksum

reports. ProtocolCheckSum can be used to verify integrity of protocol file transfer from uncontrolled

repositories.

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 93

The protocol checksum is an hexidecimal number with 32 characters.

Example: e152abb59e4949980731c5bbf7194b

It can be saved and compared as a string.

The ProtocolState report should now report ProtocolSelected.

Load kit

The instrument verification process needs the instrument door to be closed and a valid kit to be

detected. The kit ID is read by the instrument when the door is closed.

The DoorState is reported Closed, and the KitID string is supported by KitState report that checks the

kit type against that required for the protocol. If the kit ID is valid and aligned to the protocol then the

KitState is reported as valid.

Transfer metadata

Protocols can be defined with metadata or parameters that allow a qualified recipe to respond to

changing input materials and output targets.

Chapter 4

MES – Commands and reports overview

OPC-UA interface

4

Refer to the sequence diagram, see “MES drives Rotea in response to external systems” on page 106.

After the protocol information is loaded the instrument will set ParameterName1 through

ParameterName20 to the names of the variables that need to set in the protocol metadata.

The MES can check ParameterValid1 to ParameterValid20 to determine the status of metadata

definition for the protocol. This will advise if that parameter is in use, if it has been set, and if the

setting is valid.

To set the value, use SetParameter1 through SetParameter20 and supply an Int32 value.

Initialize protocol on to instrument

Once the protocol has been specified, kit loaded and any metadata defined within acceptable ranges,

set the SetProtocolState to SendProtocolToRotea.

The protocol definition is sent to the instrument and ProtocolState will report ProtocolReadyToStart.

Start/Stop/Pause/Resume protocol

• The MES can Start, Stop and Pause/Resume the instrument with SetProtocolState variable.

• The ProtocolState will report ProtocolRunning.

• These actions are available through the buttons on the instrument when enabled.

• The MES can disable Start, Pause and Advance functions with the SetSkipButtonEnable and

SetPlayPauseButtonEnable. When the buttons are enabled they will follow the configuration in the

protocol file, if they are disabled the buttons on the instrument are disabled.

CTS™ Rotea™ Counterflow Centrifugation System User Guide

93

Page 94

Chapter 4 OPC-UA interface

4

MES – Commands and reports overview

• When the instrument completes the protocol or is stopped for any other reason, the instrument

state will be reported as InstrumentReady. This provides the option for the protocol to be restarted using StartatStep or other administrator actions from the InstrumentReady state.

• When a user with administrator authority is logged in via the MES or without MES supervision, the

Pause and Advance instrument buttons become active independent of protocol settings.

Instrument run status

The instrument status can be monitored on the Rotea™ GUIor via the exposed OPC-UA variables.

• The ProtocolState will report ProtocolRunning or ProtocolPaused.

• The ProtocolStepNumber reports the current step.

• WaitingUserAck reports if the instrument is waiting for verification to proceed to the next step or

repeat the current step. The MES uses SetProtocolState to RunProtocol to repeat the same step,

or SkipToNextStep in response to this state.

MES batch history data

• The Rotea™ Run Manager captures the run history data into a unique file each time the protocol is

run.

• Run history contains details of the process conditions throughout the run.

94

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 95

Alarm recovery tools

• Alarm reset commands; these may include active instrument reactions such as opening valves for a

controlled period to release pressure.

• Several options for product recovery are available through MES commands:

– Re-start the protocol at a specified step. The protocol can contain dedicated blocks of code

independent of the main process.

– Download a new protocol and start it at a specified step

– Start running the settings of a single step in the existing protocol.

• The MES can also log in a qualified user with administrative privileges to run the instrument from

the Rotea™ GUI as a manual intervention.

– All actions are recorded in the history files and instrument status is reported to the MES

– To return to MES managed operations, the administrator user logs out of the MES. The MES

then logs in as ViewUser again. (The instrument can be running the protocol while users/MES

log in and log out.)

Chapter 4 OPC-UA interface

MES – Commands and reports overview

4

Figure 12 OPC-UA enabled administrator to perform recovery

CTS™ Rotea™ Counterflow Centrifugation System User Guide

95

Page 96

Chapter 4 OPC-UA interface

4

OPC-UA interface

OPC-UA interface

Commands OPC-UA to Rotea™ application

Table 2 OPC-UA command list

Variable Type Values/Description

RescanKit Boolean Force a kit rescan:

SetGuiUserLevel Enum • GUIManagedLogin – Application login

• True – The instrument will rescan the kit

barcode.

• False – No action.

is managed by the GUI, OPC-UA

commands are ignored in this mode.

• ViewUser – The MES has control of the

Rotea™ instrument and GUI just displays

the instrument status.

• AdminUser – The GUI is logged in as

an administrator and has control the

Rotea™ instrument, OPC-UA commands

are ignored in this mode.

Note: When OPC-UA enabled, a

SetGuiUserLevel command from the OPC-UA

server will over-ride the current instrument login state.

SetLocalProtocolFilePath String Set the file name path of the protocol on the

laptop to be loaded to the Rotea™ instrument.

SetPlayPauseButtonEnable Enum Enable the Play/Pause button on the Rotea

instrument.

• Disabled

• AsPerProtocol

• Enabled

SetProtocolFileContents String Send the protocol file contents to the laptop to

be loaded to the Rotea™ instrument.

SetProtocolFileByLookupTableId UInt32 Id of the protocol file in the OPC-UA look

up table. The lookup table is defined in

™

OPCUAProtocolList.yaml

SetParameter1 through SetParameter20 Int32 The Metadata parameter data for the protocol.

The associated name of the parameter can be

found in variables ParameterName1 through

ParameterName20 after the protocol has been

loaded.

96

CTS™ Rotea™ Counterflow Centrifugation System User Guide

Page 97

Chapter 4 OPC-UA interface

OPC-UA interface

Table 2 OPC-UA command list (continued)

Variable Type Values/Description

SetProtocolState Enum • StopProtocol – Stop the protocol.

• SendProtocolToRotea – Load the

protocol to the Rotea™ instrument.

• RunProtocol – Start the protocol, same

as pressing the Start button on the

instrument.

• PauseProtocol – Pause the protocol

• RecoveryRunProtocolFromStep – Start

a protocol from the step specified in

SetRecoveryStepNumber.

• RecoveryRunProtocolFromStep – Start

a protocol from the step specified in

SetRecoveryStepNumber.

• RecoveryRunProtocolSingleStep – Start

a protocol and run a single step number

SetRecoveryStepNumber.

• SkipToNextStep - advances the protocol

to the next step by ending this step.

4

SetRecoveryStepNumber UInt32 The recovery step number to start from. Used

SetSkipButtonEnable Enum Enable the advance button on the Rotea