CTS™ LV-MAX™ Lentiviral Production System

USER GUIDE

For xeno-free lentiviral vector production in suspension cells

for use with:

CTS™ Viral Production Cells

CTS™ LV-MAX™ Production Medium

CTS™ LV-MAX™ Transfection Kit

CTS™ Opti-MEM™ I

Publication Number MAN0018450

Revision B.0

For Research Use or Manufacturing of Cell, Gene, or Tissue-Based

Products. CAUTION: Not intended for direct administration into

humans or animals.

Life Technologies Corporation | 5781 Van Allen Way | Carlsbad, CA 92008

For descriptions of symbols on product labels or product documents, go to thermofisher.com/symbols-definition.

The information in this guide is subject to change without notice.

DISCLAIMER: TO THE EXTENT ALLOWED BY LAW, THERMO FISHER SCIENTIFIC INC. AND/OR ITS AFFILIATE(S) WILL NOT BE

LIABLE FOR SPECIAL, INCIDENTAL, INDIRECT, PUNITIVE, MULTIPLE, OR CONSEQUENTIAL DAMAGES IN CONNECTION WITH OR

ARISING FROM THIS DOCUMENT, INCLUDING YOUR USE OF IT.

Revision history: Pub. No. MAN0018450

Revision Date Description

B.0 5 January 2021 Update of reagent volumes in protocol.

A.0 28 March 2019 New document.

Important Licensing Information: These products may be covered by one or more Limited Use Label Licenses. By use of these

products, you accept the terms and conditions of all applicable Limited Use Label Licenses.

TRADEMARKS: All trademarks are the property of Thermo Fisher Scientific and its subsidiaries unless otherwise specified.

©2021 Thermo Fisher Scientific Inc. All rights reserved.

Contents

■

CHAPTER 1 Product information .................................................. 5

Product description ............................................................. 5

Required components ........................................................... 5

Required materials not supplied ................................................... 6

System components ............................................................. 8

Viral production cells ........................................................ 8

Growth medium ............................................................ 8

Transfection supplement .................................................... 8

Transfection reagent ......................................................... 8

Production enhancer ....................................................... 8

Opti-MEM ................................................................. 8

■

CHAPTER 2 Thaw and establish CTS™ Viral Production Cells .................. 9

Guidelines for handling cells ...................................................... 9

Required materials not supplied ................................................... 9

Thaw CTS™ Viral Production Cells ................................................ 10

Subculture CTS™ Viral Production Cells ........................................... 10

Required materials ......................................................... 10

Passage CTS™ Viral Production Cells ......................................... 11

Cryopreserve CTS™ Viral Production Cells ......................................... 12

Cryopreserve cells ......................................................... 12

■

CHAPTER 3 Produce lentiviral vector ............................................ 13

Procedural guidelines ........................................................... 13

Equipment guidelines .......................................................... 13

Required materials ............................................................. 14

Optimized transfection conditions ................................................ 14

Transfect CTS™ Viral Production Cells ............................................ 14

Transfect cells ............................................................. 16

Harvest the lentiviral vector ...................................................... 17

Titer the lentiviral vector ......................................................... 17

™

LV-MAX™ Lentiviral Production System User Guide

CTS

3

Contents

■

■

CHAPTER 4 Produce recombinant lentiviral vector in a 3-L stirred

tank bioreactor ..................................................................... 18

Procedural guidelines ........................................................... 18

Guidelines for scaling up reactions ............................................... 18

Required materials ............................................................. 18

Transfect CTS™ Viral Production Cells ............................................ 19

Transfect cells ............................................................. 20

CHAPTER 5 Titer lentiviral vector ................................................ 23

Titer using GFP expression ...................................................... 23

Procedural guidelines ...................................................... 23

Required materials not supplied ............................................. 23

Perform lentiviral vector titration ............................................. 24

Calculate the lentiviral titer .................................................. 25

Titer using antibiotic selection ................................................... 26

Procedural guidelines ...................................................... 26

Required materials not supplied ............................................. 26

Perform lentiviral vector titration ............................................. 26

Calculate the lentiviral titer .................................................. 28

■

APPENDIX A Scaling up tables .................................................. 30

Tables for scaling up preset and custom sized production volumes ................... 30

■

APPENDIX B Related products .................................................. 33

Related products .............................................................. 33

■

APPENDIX C Safety ............................................................... 34

Chemical safety ................................................................ 35

Biological hazard safety ......................................................... 36

■

APPENDIX D Documentation and support ...................................... 37

Customer and technical support ................................................. 37

Limited product warranty ........................................................ 37

4

CTS™ LV-MAX™ Lentiviral Production System User Guide

1

IMPORTANT! Before using this product, read and understand the information in the “Safety” appendix

in this document.

Product description

The CTS™ LV-MAX™ Lentiviral Production System is a lentiviral vector production system based on

transient transfection of high-density, suspension HEK293F cells adapted to a chemically defined,

serum-free and protein free medium. The system is available in both Research Use and Cell Therapy

Systems (CTS) options to enable a seamless transition from discovery to production.

The CTS™ LV-MAX™ Lentiviral Production System provides cells, production medium, supplement,

transfection reagent, and enhancer to produce high titer lentiviral vectors.

Product information

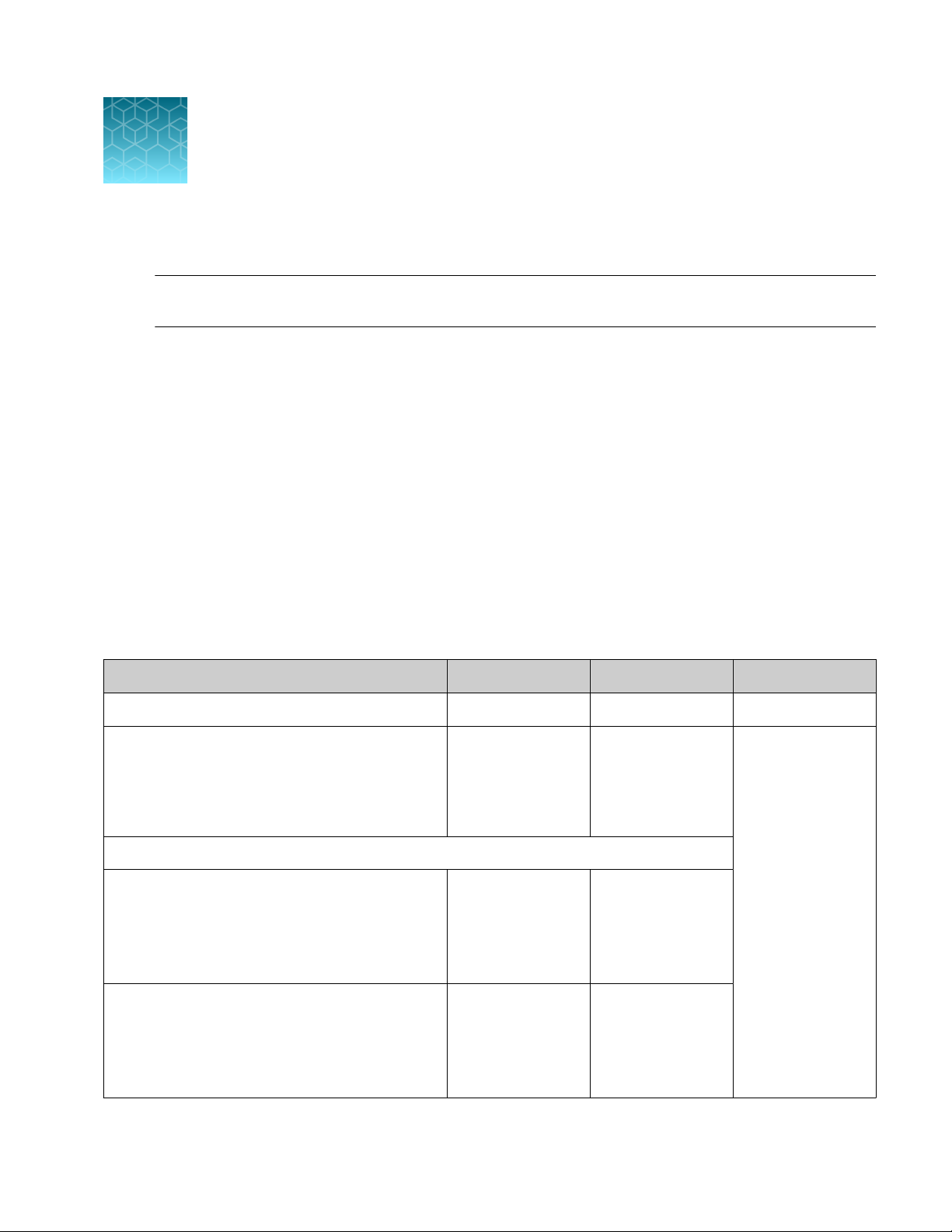

Required components

The workflows described in this document are for use with the components in the following table.

Component

CTS™ Viral Production Cells (1 X 107 cells/mL) A3152801 1 × 1 mL Liquid nitrogen

CTS™ LV-MAX™ Production Medium

One of the following CTS™ LV-MAX™ Transfection Kit:

CTS™ LV-MAX™ Transfection Kit:

•

CTS™ LV-MAX™ Supplement

•

CTS™ LV-MAX™ Transfection Reagent

•

CTS™ LV-MAX™ Enhancer

CTS™ LV-MAX™ Transfection Kit:

•

CTS™ LV-MAX™ Supplement

•

CTS™ LV-MAX™ Transfection Reagent

•

CTS™ LV-MAX™ Enhancer

Cat. No. Amount Storage

•

A4124001

•

A4124004

•

A4124002

•

A4124003

A4132601 1 L Production Kit

A4132602 10 L Production Kit

•

•

•

•

•

•

•

•

•

•

1 L

6 × 1 L

10 L

20 L

50 mL

6 mL

40 mL

500 mL

60 mL

400 mL

•

2°C to 8°C

•

Protected from

light

[1]

CTS™ LV-MAX™ Lentiviral Production System User Guide

5

Chapter 1 Product information

1

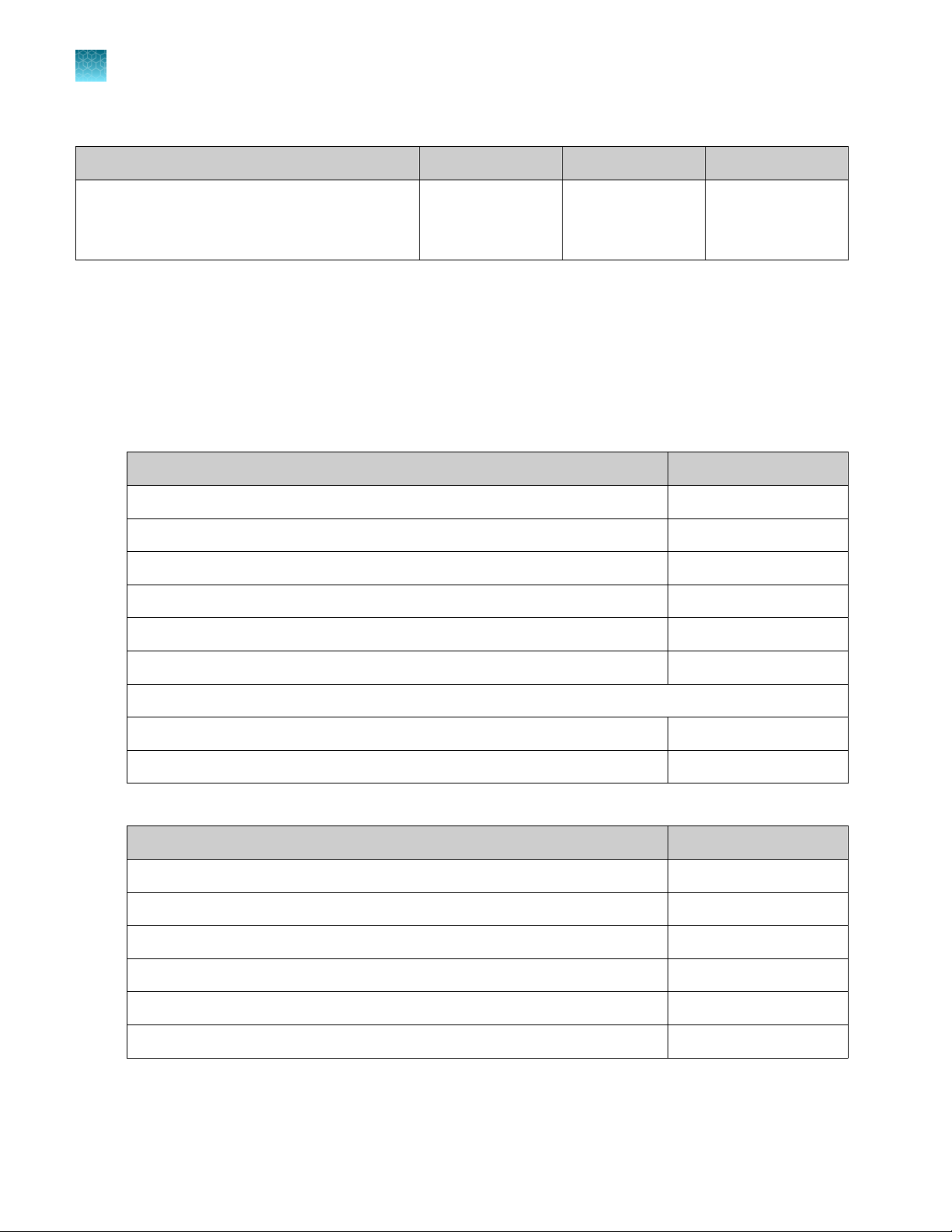

Required materials not supplied

(continued)

Component Cat. No. Amount Storage

•

A4124801

CTS™ Opti-MEM™ I

[1]

Store the frozen cells in liquid nitrogen until ready to use. Do not store the cells at −80°C.

•

A4124802

Required materials not supplied

Unless otherwise indicated, all materials are available through thermofisher.com. "MLS" indicates that

the material is available from fisherscientific.com or another major laboratory supplier.

Table 1 Materials required for lentiviral vector production (all methods)

Item Source

CO2 resistant orbital shaker 88881101

•

•

100 mL

500 mL

•

2°C to 8°C

•

Protected from

light

125-mL shaker flasks for Viral Production Cells MLS

Adjustable micropipettors MLS

Laboratory mixer (Vortex mixer or equivalent) MLS

Equipment and reagents to determine cell density and viability MLS

LV-MAX™ Lentiviral Packaging Mix A43237

For cryopreservation:

DMSO MLS

Cryovials MLS

Table 2 Additional materials required for lentiviral vector production in a 96-deep well block

Item

3 mm orbital shaker MLS

2-mL sterile 96-deep well block MLS

2-mL sterile 96-deep well block (V bottom) MLS

96-well round bottom plate MLS

Source

Multi-channel micropipettors MLS

PureLink™ Air Porous Tape 12262010

6

CTS™ LV-MAX™ Lentiviral Production System User Guide

Chapter 1 Product information

Required materials not supplied

Table 3 Additional materials required for lentiviral vector production in a 50-mL conical tube

Item Source

Nunc 50-mL conical tube 339653

Corning™ Mini Bioreactor Centrifuge Tube 07-202-150

50-mL conical tube holder MLS

Nalgene™ Single-Use PETG Erlenmeyer Flasks with Plain Bottom: Sterile

125 mL 4115-0125

250 mL 4115-0250

1 L 4115-1000

Table 4 Additional materials required for lentiviral vector production in a shaker flask

Item Source

Nalgene™ Single-Use PETG Erlenmeyer Flasks with Plain Bottom: Sterile

1

125 mL 4115-0125

250 mL 4115-0250

1 L 4115-1000

2 L 4115-2000

CTS™ LV-MAX™ Lentiviral Production System User Guide

7

Chapter 1

1

System components

Product information

System components

The following section provides descriptions of the components in the CTS™ LV-MAX™ Lentiviral

Production System.

Viral production cells

CTS™ Viral Production Cells are derived from the HEK293F cell line, and are adapted to suspension

culture in CTS™ LV-MAX™ Production Medium. These cells can be thawed directly into CTS™ LV-MAX

Production Medium.

Cell line characteristics:

•

Transformed via culture with sheared human adenovirus 5 DNA

•

Expresses E1A adenoviral gene

•

Lacks the SV40 large T antigen

•

Cell doubling time of ~26 hours

•

Achieves maximum cell densities of ~1 × 107 cells/mL in shaker flask cultures

•

High lentiviral production capabilities between cell passages 5–20

Growth medium

CTS™ LV-MAX™ Production Medium is a complete, chemically defined, animal origin-free, serum-free,

protein-free formulation, developed for growth and transfection of CTS™ Viral Production Cells. This

medium is ready-to-use and does not require the addition of supplements.

Transfection supplement

CTS™ LV-MAX™ Supplement is a chemically defined, animal origin-free, serum-free, protein-free

formulation designed to control cell growth during transfection and increase lentiviral vector production

without compromising cell viability.

™

Transfection reagent

CTS™ LV-MAX™ Transfection Reagent is uniquely designed for high eciency co-transfection of multiple

plasmids into CTS™ Viral Production Cells, with low toxicity.

Production enhancer

CTS™ LV-MAX™ Enhancer is a chemically defined, animal origin-free, serum-free, protein-free

formulation that is designed to boost lentiviral vector production in CTS™ Viral Production Cells.

Opti-MEM

CTS™ Opti-MEM™ I is a xeno-free formulation for use with transfection reagent to facilitate complexation

in viral vector production. It is an improved Minimal Essential Medium (MEM) containing insulin,

transferrin, hypoxanthine, thymidine, and trace elements.

8

CTS™ LV-MAX™ Lentiviral Production System User Guide

Thaw and establish CTS™ Viral

2

Guidelines for handling cells

IMPORTANT! Store the frozen cells in liquid nitrogen until ready to use. Do not store the cells at

–80°C.

•

Avoid subjecting cells to short-term, extreme temperature changes.

•

After storing cells in liquid nitrogen following receipt on dry ice, allow the cells to remain in liquid

nitrogen for 3–4 days before thawing.

•

For all cell manipulations, mix cells by gentle swirling and avoid vigorous shaking/pipetting.

•

For routine cell culture maintenance, subculture cells every 3–4 days when they reach 3.5–5.5 × 10

cells/mL (see “Subculture CTS™ Viral Production Cells” on page 10). Do not subculture cells that

have not reached early log phase growth of ≥3.5 × 106 cells/mL.

Production Cells

6

Required materials not supplied

•

CTS™ Viral Production Cells

•

125-mL Erlenmeyer Flask (e.g., Nalgene™ Single-Use PETG Erlenmeyer Flasks with Plain Bottom:

Sterile for culturing Viral Production Cells, Cat. No. 4115-0125)

•

Orbital shaker (e.g., MaxQ™ HP Tabletop Orbital Shaker, Cat. No. SHKE416HP)

•

Temperature and CO2 controlled incubator (e.g., Large-Capacity Reach-In CO2 Incubator, Cat. No.

3950)

•

Reagents and equipment to determine cell viability (e.g., hemocytometer with trypan blue or cell

counter)

CTS™ LV-MAX™ Lentiviral Production System User Guide

9

Chapter 2

2

Thaw CTS™ Viral Production Cells

Thaw and establish CTS™ Viral Production Cells

Thaw CTS™ Viral Production Cells

1.

Remove the vial of cells from liquid nitrogen and swirl in a 37°C water bath for 1 to 2 minutes to

thaw the cells rapidly until only a small amount of ice remains.

Note: Do not submerge the vial in the water.

2.

Just before the cells are completely thawed, decontaminate the vial by wiping it with 70% ethanol

before opening it in a laminar flow hood.

3.

Use a 2-mL or 5-mL pipette, to transfer the entire contents of the cryovial into a 125-mL

polycarbonate, disposable, sterile, vent-cap Erlenmeyer shaker flask containing 30 mL of CTS

LV-MAX™ Production Medium pre-warmed to 37°C.

4.

Incubate the cells in a 37°C incubator with ≥80% relative humidity, and 8% CO2 on an orbital

shaker platform.

Note: Set the shake speed to 125±5 rpm for shakers with a 19 mm shaking diameter, 120±5 rpm

for shakers with a 25 mm shaking diameter and 95±5 rpm for shakers with a 50 mm shaking

diameter.

™

5.

Culture cells for 3–4 days post-thaw and then determine viable cell density and percent viability.

Cell viability should be ≥90% 3–4 days post-thaw, with viable cell density typically >1 × 106 viable

cells/mL; if viability is not >90%, incubate cells for up to an additional 3 days to reach optimal

density. Subculture cells when the viable cell density reaches 1–3 × 106 viable cells/mL.

Subculture CTS™ Viral Production Cells

CTS™ Viral Production Cells are capable of achieving high cell densities; therefore, it is important that

cells attain a minimum density of 3.5–5.5 × 106 viable cells/mL at the time of subculturing.

Required materials

•

CTS™ Viral Production Cells cultured in CTS™ LV-MAX™ Production Medium

•

CTS™ LV-MAX™ Production Medium, pre-warmed to 37°C

•

CTS™ Opti-MEM™ I

•

Disposable, sterile Erlenmeyer flasks

•

Orbital shaker (e.g., MaxQ™ HP Tabletop Orbital Shaker, Cat. No. SHKE416HP)

•

Temperature and CO2 controlled incubator (e.g., Large-Capacity Reach-In CO2 Incubator, Cat. No.

3950)

•

Reagents and equipment to determine cell viability (e.g., hemocytometer with trypan blue or cell

counter)

10

CTS™ LV-MAX™ Lentiviral Production System User Guide

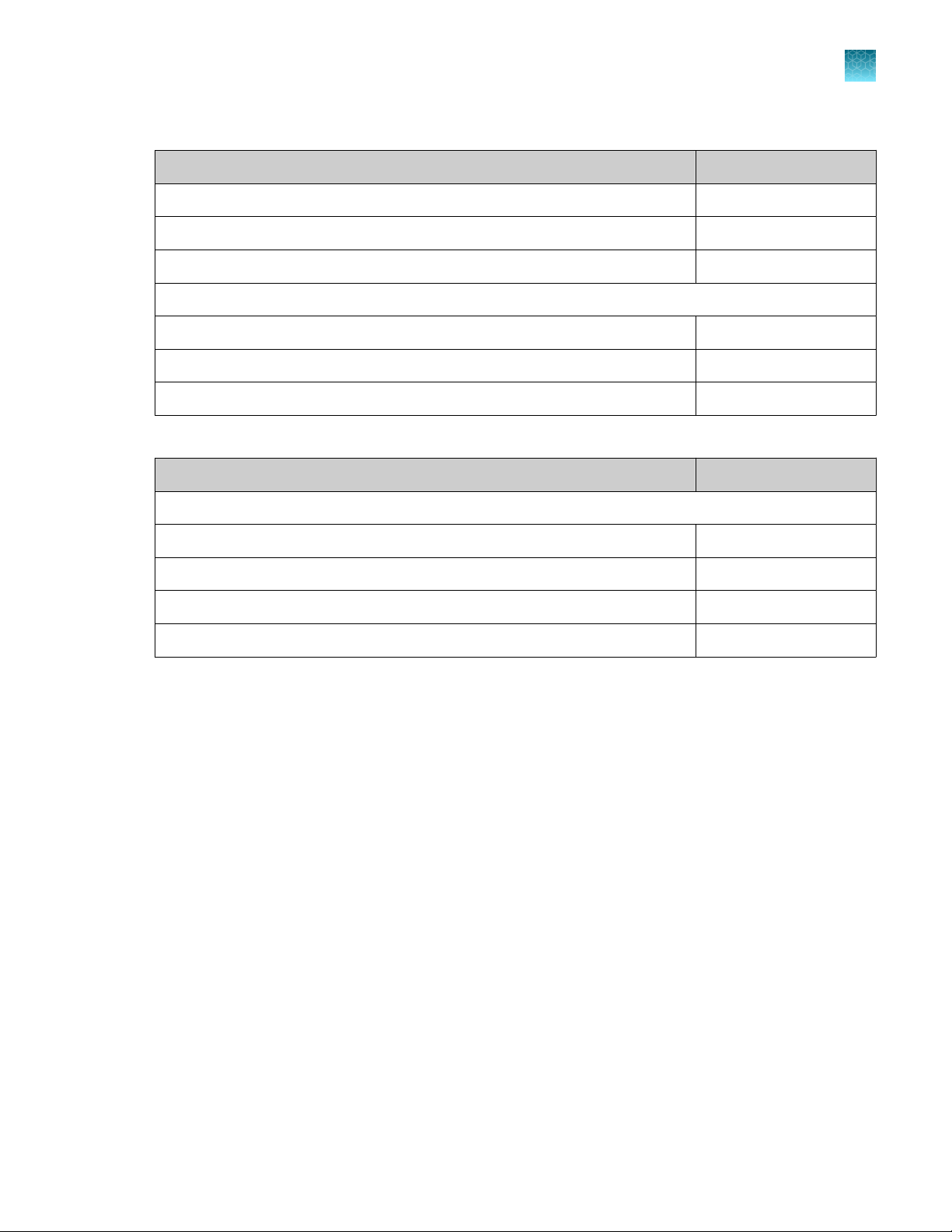

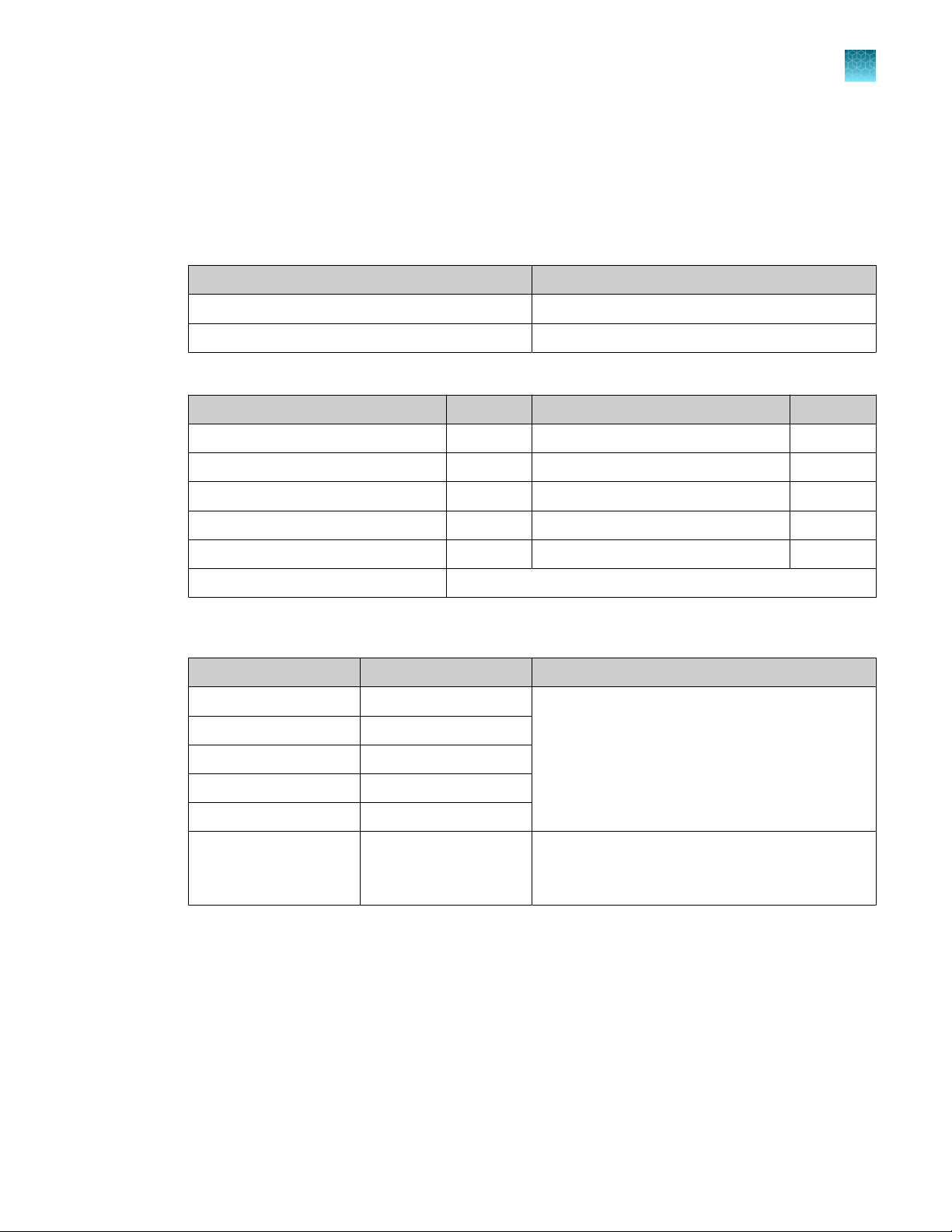

Passage CTS™ Viral Production Cells

1.

Use the viable cell density to calculate the volume of cell suspension required to seed a new shake

flask according to the recommended seeding densities in Table 5 and the recommended culture

volumes in Table 7.

Table 5 Recommended seeding densities for routine cell culture maintenance

Sub-culture timing Recommended seeding density

For cells ready 3 days post-subculture 0.5 × 106 viable cells/mL

For cells ready 4 days post-subculture 0.3 × 106 viable cells/mL

™

Table 6 Recommended Vi-CELL

XR Cell Counting Settings

Chapter 2

Thaw and establish CTS™ Viral Production Cells

Subculture CTS™ Viral Production Cells

2

Parameter

Minimum diameter 5 Cell brightness (%) 85

Maximum diameter 50 Cell sharpness 100

Number of images 50 Viable cell spot brightness (%) 65

Aspirate cycles 3 Viable cell spot area (%) 5

Trypan blue mixing cycles 3 Minimum circularity 0

Decluster degree Medium

Value Parameter Value

Table 7 Recommended volumes for routine cell culture maintenance in vented, non-baed

flasks

Flask size

125 mL 30–35 mL

250 mL 60–70 mL

500 mL 120–140 mL

1 L 240–280 mL

2 L 480–560 mL

2.8–3 L 720–840 mL

[1]

If using volumes outside of the recommended range, it is critical to ensure that all cell growth (i.e., doubling times), health (i.e.,

cell diameter, viability), and expression levels remain consistent with control conditions. Cell performance is decreased if cell

health is compromised.

Culture volume

[1]

Parameter

125±5 rpm (19 mm shaking diameter)

120±5 rpm (25 mm shaking diameter)

95±5 rpm (50 mm shaking diameter)

90±5 rpm

85±5 rpm

80±5 rpm

2.

Transfer the calculated volume of cells to fresh, pre-warmed CTS™ LV-MAX™ Production Medium in

a shake flask.

CTS™ LV-MAX™ Lentiviral Production System User Guide

11

Chapter 2 Thaw and establish CTS™ Viral Production Cells

2

Cryopreserve CTS™ Viral Production Cells

3.

Incubate flasks in a 37°C incubator with ≥80% relative humidity, and 8% CO2 on an orbital shaker

platform until cultures reach a density of 3.5–5.5 × 106 viable cells/mL.

Note: Cells subcultured at densities outside of the early log-phase growth window may show

longer doubling times and lower titers over time. Modify the initial seeding density to attain the

target cell density of 3.5–5.5 × 106 viable cells/mL at the time of subculturing.

4.

Repeat Steps 1–3 to maintain or expand cells for transfection.

Cryopreserve CTS™ Viral Production Cells

CTS™ Viral Production Cells can be frozen directly in CTS™ LV-MAX™ Production Medium with 10%

DMSO. Alternatively, conditioned cryopreservation medium consisting of 45% fresh CTS™ LV-MAX

Production Medium, 45% conditioned CTS™ LV-MAX™ Production Medium, and 10% DMSO can be

used.

Cryopreserve cells

1.

Centrifuge cells that have attained a viable cell density of 3.5−5.5 × 106 viable cells/mL and cell

viability at 300 × g for 5 minutes. Discard the supernatant without disturbing the cell pellet.

2.

Add ice cold CTS™ LV-MAX™ Production Medium with 10% DMSO to the cell pellet, then

resuspend the cell pellet by gentle pipetting.

3.

Dilute the cells to a final density of 1 × 107 viable cells/mL in 1 mL total volume of 90% fresh CTS

LV-MAX™ Production Medium with 10% DMSO.

4.

Freeze the cells in an automated or manual controlled-rate freezing apparatus following standard

procedures.

For ideal cryopreservation, the freeze rate should decrease by 1°C per minute.

5.

Transfer the frozen vials to liquid nitrogen for long-term storage.

™

™

12

CTS™ LV-MAX™ Lentiviral Production System User Guide

Loading...

Loading...