Alpha COND 500

Controller/Transmitter

uS / mS / ºC

R

AQUAfast, Cahn, ionplus, KNIpHE, No Cal, ORION, perpHect, PerpHecT,

PerpHecTion, pHISA, pHuture, Pure Water, Sage, Sensing the Future, SensorLink,

ROSS, ROSS Ultra, Sure-Flow, Titrator PLUS and TURBO2 are registered

trademarks of Thermo Fisher.

1-888-pHAX-ION, A+, All in One, Aplus, AQUAsnap, AssuredAccuracy, AUTOBAR, AUTO-CAL, AUTO DISPENSER, Auto-ID, AUTO-LOG, AUTO-READ, AUTOSTIR, Auto-Test, BOD AutoEZ, Cable-Free, CERTI-CAL, CISA, DataCOLLECT,

DataPLUS, digital LogR, DirectCal, DuraProbe, Environmental Product Authority,

Extra Easy/Extra Value, FAST QC, GAP, GLPcal, GLPcheck, GLPdoc, ISEasy,

KAP, LabConnect, LogR, Low Maintenance Triode, Minimum Stir Requirement,

MSR, NISS, One-Touch, One-Touch Calibration, One-Touch Measurement,

Optimum Results, Orion Star, Pentrode, pHuture MMS, pHuture Pentrode, pHuture

Quatrode, pHuture Triode, Quatrode, QuiKcheK, rf link, ROSS Resolution, SAOB,

SMART AVERAGING, Smart CheK, SMART STABILITY, Stacked, Star Navigator

21, Stat Face, The Enhanced Lab, ThermaSense, Triode, T RIUMpH, Unbreakable

pH, Universal Access are trademarks of Thermo Fisher.

Guaranteed Success and The Technical Edge are service marks of Thermo Fisher.

1

Preface

This manual serves to explain the use of the Alpha COND 500 transmitter. It

functions in two ways, firstly as a step by step guide to help you to operate the

transmitter. Secondly, it serves as a handy reference guide. It is written to cover as

many anticipated applications of the transmitter as possible. If there are doubts in

the use of the transmitter, please do not hesitate to contact the nearest Authorized

Distributor.

Thermo Scientific will not accept any responsibilit y for damage or malfunction to th e

transmitter caused by improper use of the instrument.

The information presented in this manual is subject to change without notice as

improvements are made, and does not represent a commitment on the part of

Thermo Scientific.

Copyright © 2009

All rights reserved

2

TABLE OF CONTENTS

INTRODUCTION ................................................................................... 4

1

2 PREPARATION .................................................................................... 5

2.1 POWER SUPPLY REQUIREMENTS (SL2 POSITION) ........................................... 6

2.2 CONNECTING THE ELECTRODE AND TEMPERATURE SENSOR (SL1 POSITION) .... 6

3 INSTALLATION .................................................................................... 8

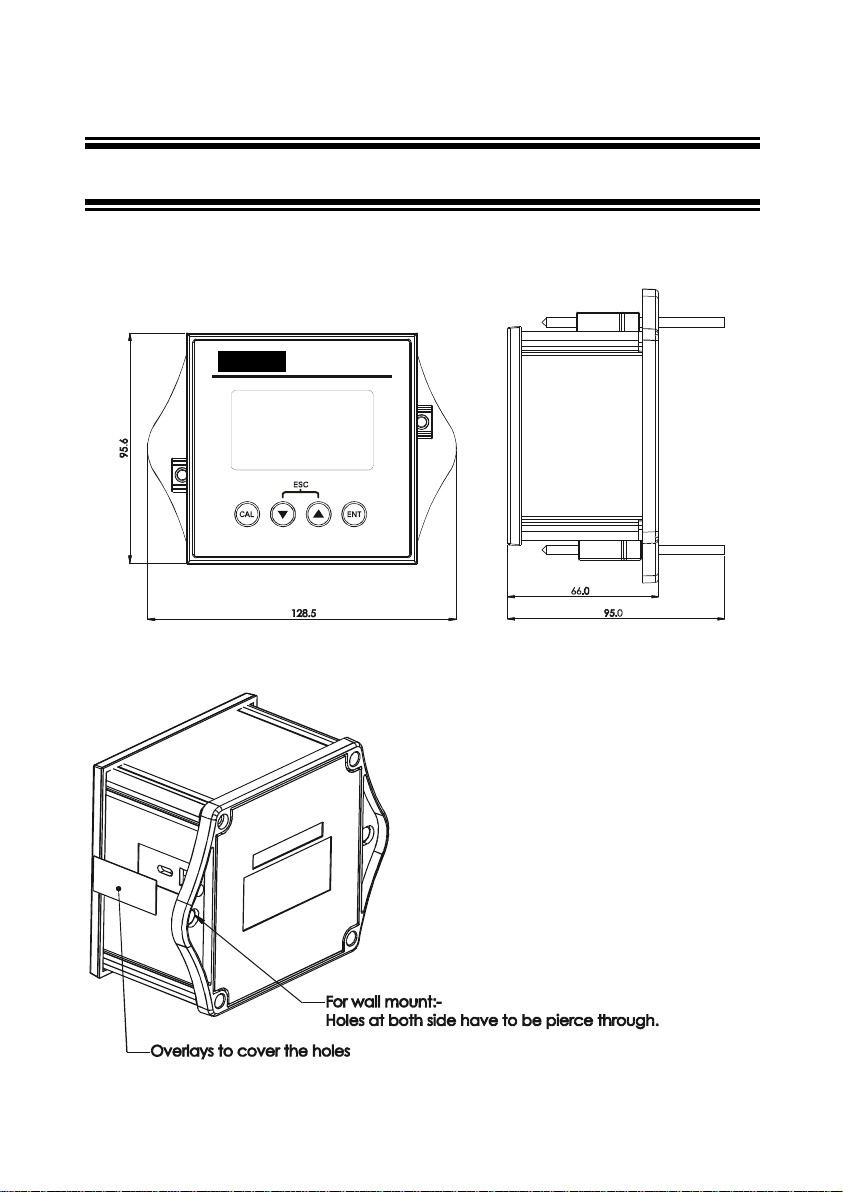

3.1 MECHANICAL DIMENSIONS ............................................................................ 8

3.2 WALL MOUNT .............................................................................................. 8

3.3 PANEL MOUNT ............................................................................................ 9

4 DISPLAY AND KEYPAD FUNCTIONS .............................................. 10

4.1 DISPLAY ................................................................................................... 10

4.2 KEYPAD .................................................................................................... 11

5 CALIBRATION .................................................................................... 12

5.1 IMPORTANT INFORMATION ON TRANSMITTER CALIBRATION ............................. 12

5.2 TEMPERATURE CALIBRATION ...................................................................... 14

5.3 CONDUCTIVITY CALIBRATION ...................................................................... 15

6 ADVANCED SETUP FUNCTIONS ..................................................... 16

6.1 RANGE AND ZOOMING SELECTION SETTING .................................................. 16

6.2 TEMPERATURE COMPENSATION SETTING ..................................................... 18

6.3 HOLD CURRENT SETTING .......................................................................... 21

6.4 OUT-OF-RANGE CURRENT SETTING ............................................................ 21

6.5 TEMPERATURE COEFFICIENT AND NORMALIZATION TEMPERATURE SETTING .... 22

6.6 CELL CONSTANT SETTING .......................................................................... 23

6.7 LINE RESISTANCE SETTING ......................................................................... 23

6.8 VIEWING CALIBRATION POINT...................................................................... 24

6.9 VIEWING THE ELECTRODE DATA .................................................................. 24

6.10 RESET FUNCTION ...................................................................................... 25

7 FACTORY DEFAULT SETTINGS ...................................................... 26

8 TROUBLE SHOOTING GUIDE ........................................................... 27

9 SPECIFICATIONS .............................................................................. 28

10 ACCESSORIES .................................................................................. 29

11 WARRANTY ........................................................................................ 30

12 RETURN OF ITEMS ............................................................................ 30

3

A

A

1 INTRODUCTION

Thank you for selecting an Alpha COND 500 2-Wire Transmitter. This isolated

output 4-20mA transmitter is a sturdy microprocessor-based instrument that

measures conductivity and temperature and transmits its output via the 2-wire

power supply loop.

This transmitter has many user-friendly features – all of which are completely

accessible through the water-resistant membrane keypad. Your transmitter includes

an instruction manual and a warranty card.

Please read this manual thoroughly before operating your transmitter.

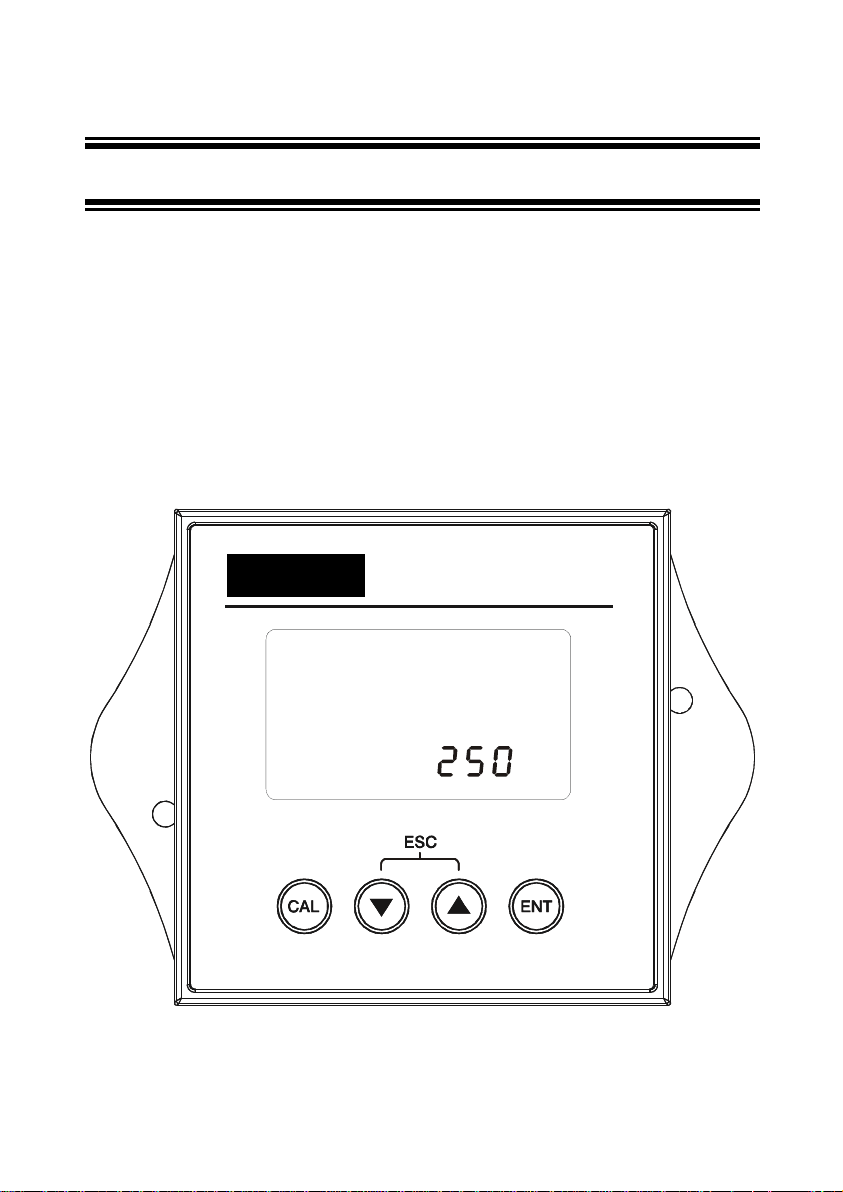

lpha COND 500

A

MEAS

MEAS

READY

READY

1413

1413

2-wire Conductivity Transmitter

2-wire Conductivity Transmitter

4

μ

S

μ

S

°C

°C

.

.

TC

TC

2 PREPARATION

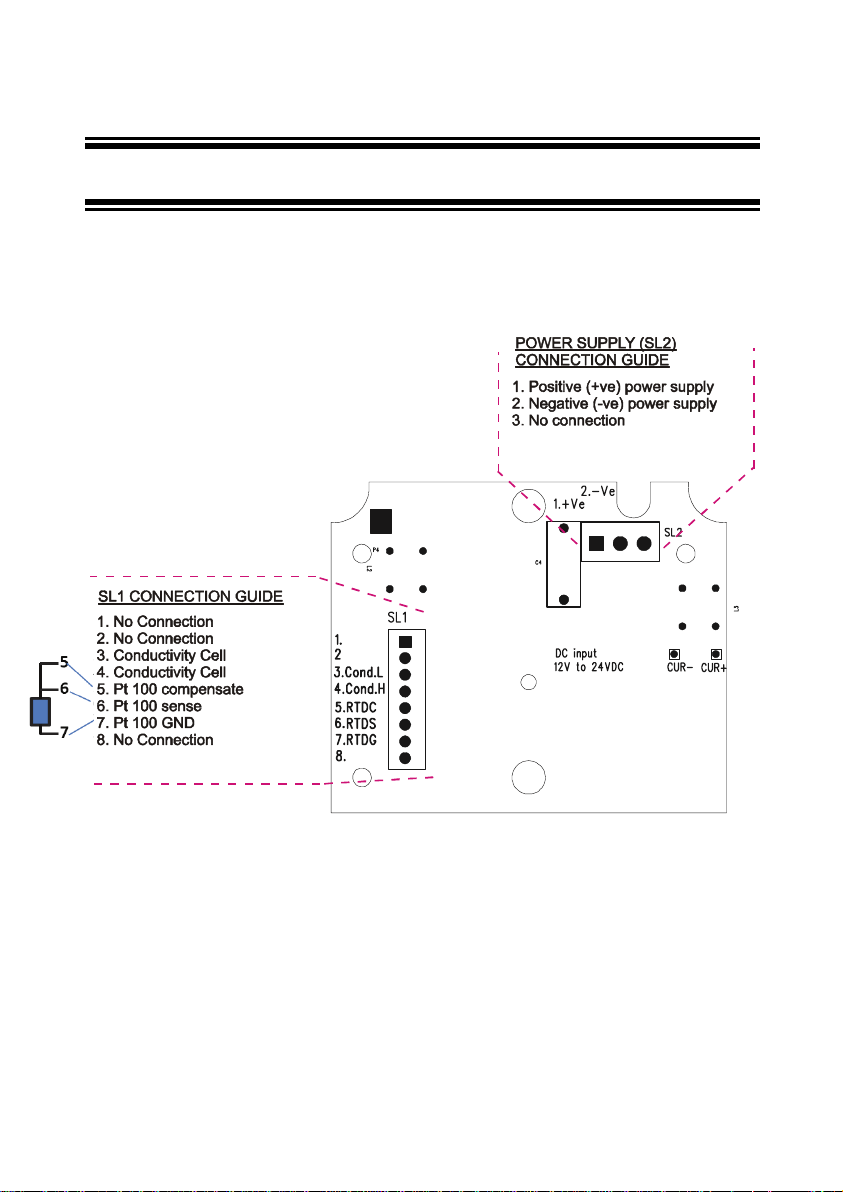

Remove screws from the four corners at the back of the Transmitter, and remove

back cover.

Connectors should be exposed as follows:

NC

NC

NC

Figure 1 – Connection Guide

All wiring is done on 2 detachable connectors: –

1. 9-pin connector (located on SL1 position) for Conductivity electrode and

temperature sensor; &

2. 3-pin connector (located on SL2 position) for power supply.

Using a suitable screwdriver, loosen screws from top of connector.

When inserting the wires, always hold connector with top screws facing up.

5

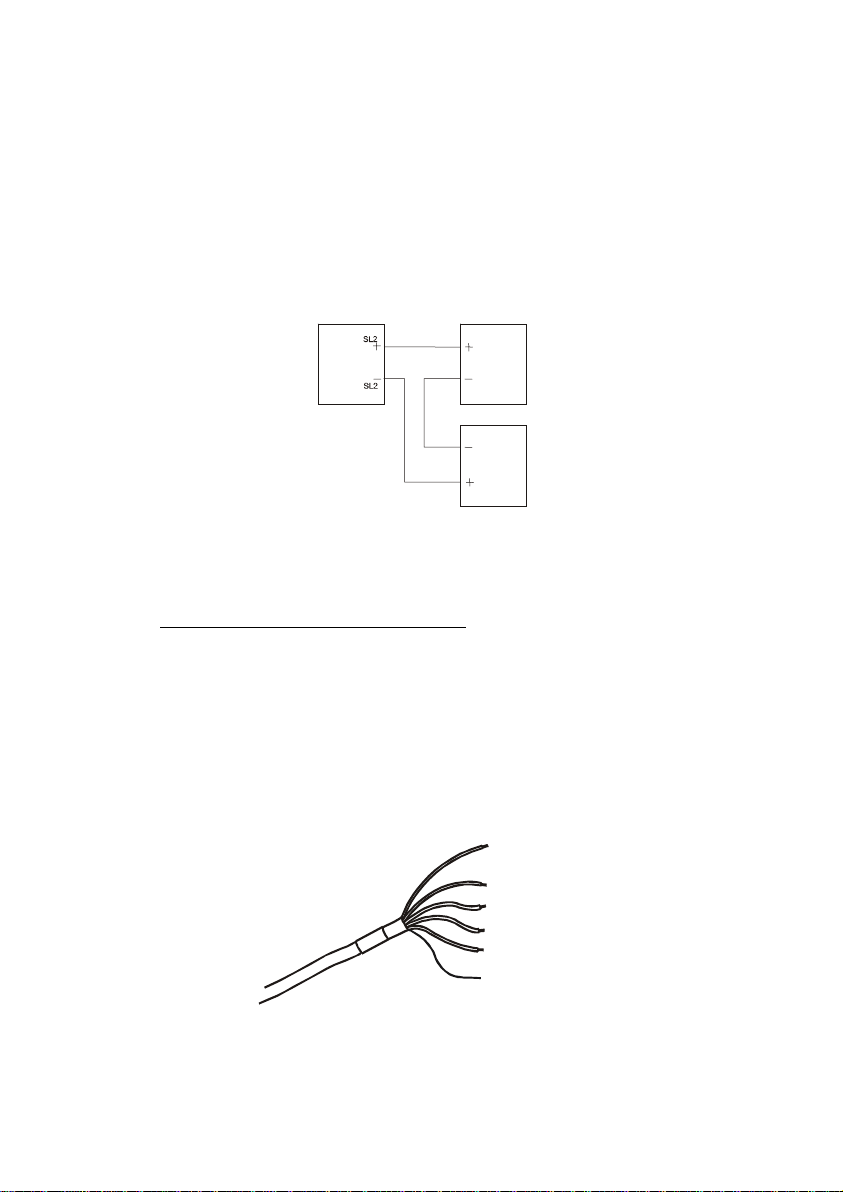

2.1 Power Supply Requirements (SL2 Position)

The Alpha COND 500 transmitter requires a 12 to 24V DC power supply. Other

Transmitters and/or a chart recorder may be connected in the loop.

1. Insert positive loop wire from power supply to pin 1, tighten screw.

2. Insert negative loop wire to pin 2, tighten screw. This wire may be linked to

a chart recorder or to negative terminal of power supply.

Alpha

COND 500

1

2

Power

Supply

Chart

Recorder

2.2 Connecting the Electrode and Temperature Sensor (SL1

Position)

2.2.1 To connect the Conductivity electrode:

The Alpha COND 500 transmitter accepts any industrial electrodes for conductivity

measurements and they are usually offered with bare wires.

1. Insert the electrode’s conductivity wire Low into pin 3 of SL1 connector.

Tighten the screw.

2. Insert the electrode’s conductivity wire High into pin 4 of SL1 connect or.

Tighten the screw.

Pt 100 Input wire

Pt 100 Sense wire

Pt 100 Return wire

Conductivity wire High

Conductivity wire Low

Shield wire

To Electrode

6

2.2.2 To connect ATC temperature sensor:

For Automatic Temperature Compensated (ATC) Conductivity readings, an in-built

temperature sensor is usually integrated in the industrial conductivity electrodes.

Otherwise, a separate 100Ω Pt RTD temperature probe can be used.

3 wire temperature sensor

1. Insert the Pt100 input wire to pin 5 of SL1 connector. Tighten the screw.

2. Insert the Pt100 sense wire to pin 6 of SL1 connector. Tighten the screw.

3. Insert the Pt100 return wire and the shield wire to pin 7 of SL1 connector.

Tighten the screw.

2 wire temperature sensor

1. Take a small length of wire and short pins 5 and 6 of SL1 connector. Insert

Pt 100 sense wire into pin 6 of SL1 connector and tighten the screws.

2. Insert Pt 100 return wire and the shield wire to pin 7 of SL1 connector.

Tighten the screw.

IMPORTANT: It is necessary to connect the SHIELD wire to the pin 7 as stat ed

above to eliminate possible oscillation of the conductivity and/or temperature

reading due to electrical noise or interference.

Ensure that no bare wires are exposed and all screws are tightened for p rop er

contact.

7

3 INSTALLATION

3.1 Mechanical Dimensions

Alpha COND 500

2-wire Conductivity Transmitter

3.2 Wall Mount

8

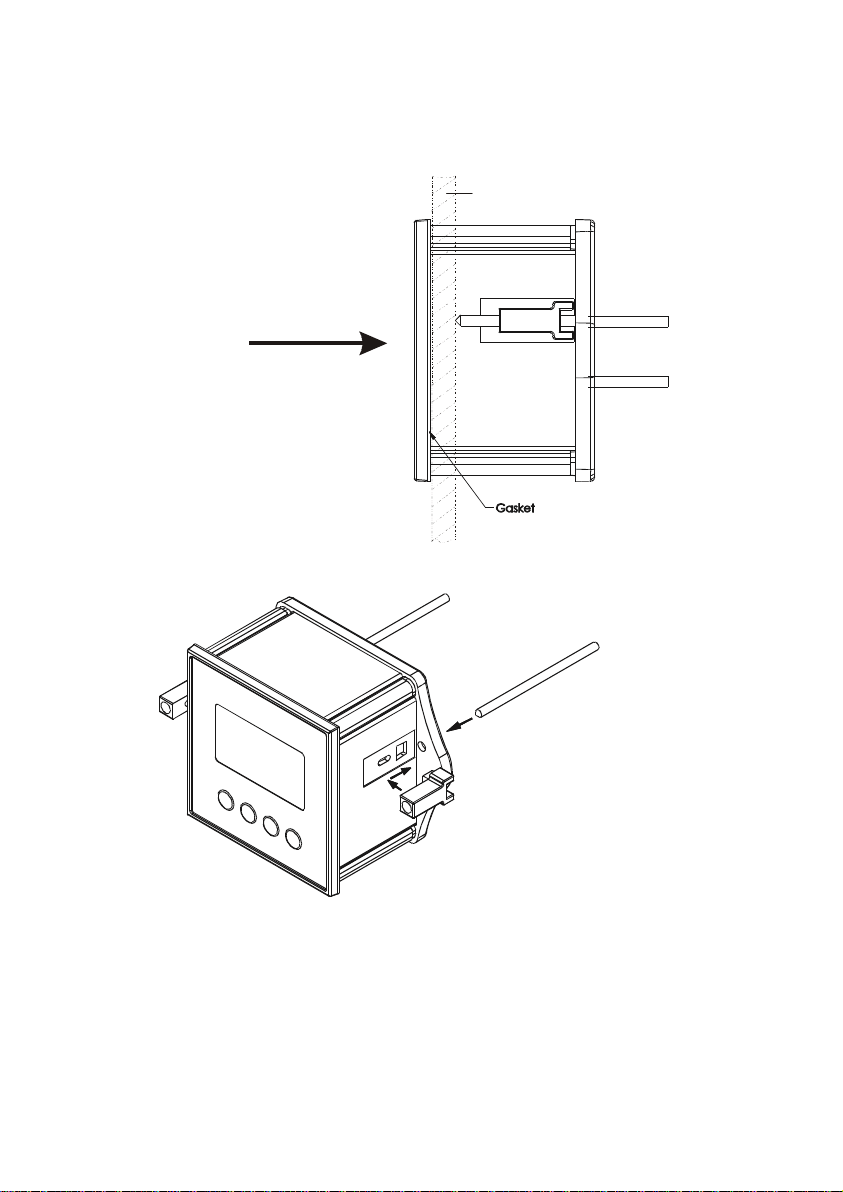

3.3 Panel Mount

1. Prepare panel cut-out of

92.0 mm by 92.0 mm

2. Remove back cover of

transmitter and slide it

through panel cut-out

Panel (side)

4. Thread rods through

lugs until transmitter

is held in place against

panel

3. Attach lugs to either

side of transmitter

9

Loading...

Loading...