Thermo Fisher Scientific COND 200 User Manual

Instruction Manual

Alpha COND 200

1/8 DIN Conductivity Controller Transmitter

μS / mS / ºC

68X276103 | Rev.3 | Apr 2008

PREFACE

This manual serves to explain the use of the Alpha COND 200

controller/transmitter. This manual functions in two ways: firstly as a step-by-step

guide to help you operate the meter; secondly as a handy reference guide.

This manual is written to cover as many anticipated applications of the Alpha

COND 200 controller/transmitter as possible. If there are doubts in the use of the

Alpha COND 200 controller/transmitter, do not hesitate to contact your nearest

αlpha Authorized Distributor.

The information presented in this manual is subjected to change without notice as

improvements are made, and does not represent a commitment on the part of

Thermo Scientific.

Thermo Scientific cannot accept any responsibility for damage or malfunction to

the unit caused by improper use of the instrument.

©

Copyright

2003 All rights reserved.

TABLE OF CONTENTS

1 INTRODUCTION 1

2 SAFETY INFORMATION 2

3 OVERVIEW 3

3.1 FRONT PANEL 3

3.2 BACK PANEL 4

3.3 WIRING 5

3.4 PANEL-MOUNTING THE CONTROLLER 6

3.5 INSTALLING SPLIT FERRITE CLAMPING 7

MEASUREMENT MODE 8

4 PASSWORD 9

5 CONDUCTIVITY CALIBRATION 11

6 TEMPERATURE CALIBRATION 13

7 SETUP MODE 14

7.1 GENERAL INFORMATION 14

7.2 SETUP MODE OVERVIEW 15

7.3 SET POINT 1 – P1.0 16

7.4 SET POINT 2 – P2.0 18

7.5 MEASUREMENT RANGE SELECTION – P3.0 20

7.6 CONFIGURE TEMPERATURE SETTINGS – P4.0 21

7.7 VIEWING CONDUCTIVITY CALIBRATION DATA – P5.0 22

7.8 VIEWING CONDUCTIVITY/ TEMPERATURE ELECTRODE DATA – P6.0 23

7.9 CONTROLLER RESET – P7.0 24

8 RELAYS 25

9 TRANSMITTER FUNCTION 25

10 SPECIFICATIONS 26

11 ACCESSORIES 27

12 GENERAL INFORMATION 30

1 INTRODUCTION

Thank you for purchasing a Alpha COND 200 ⅛ DIN Conductivity Controller. This

controller is part of a series of quality process controllers available from Eutech

Instruments. These sturdy, economical conductivity controllers are designed with

the features and reliability of a much more expensive instrument.

Your controller includes:

• Removable terminal blocks for easy connections;

• Two mounting brackets for easy panel mounting;

Some features of this controller are:

• Two set point, two SPDT relay operation

• Scrolling, 14-segment LED guides user easily through setup functions

• Reliable power supply from 85 to 260 V AC, 50/60 Hz or DC withstands

voltage fluctuations

• Push-button operation from the front panel

• Single-point calibration for each individual range

• Adjustable hysteresis band prevents rapid contact switching around set-point

• Selectable automatic or manual temperature compensation

• Two-level password protection

• Removable terminal strips for quick and easy connections

• Built-in memory backup retains setup even if power fails, and lets you

configure unit before installation

• Isolated 4-20 mA output for remote monitoring or hard copy recording

1

2 SAFETY INFORMATION

The Eutech Controller/Transmitter shall be installed and operated only in the

manner specified in the Instruction manual. Only skilled, trained or authorized

person should carry out installation, setup and operation of the instrument.

Before powering up the unit, make sure that power source it is connected to, is as

specified in the top label. Failure to do so may result in a permanent damage to the

unit.

The unit has live and exposed parts inside. If it has to be opened, make sure that

the power to the unit is off and disconnected.

The unit is Fuse protected. In the event the fuse has to be replaced, use only those

as specified in the manual.

The degree of protection against electric shock will be achieved only by

observance of the corresponding installation rules.

2

3 OVERVIEW

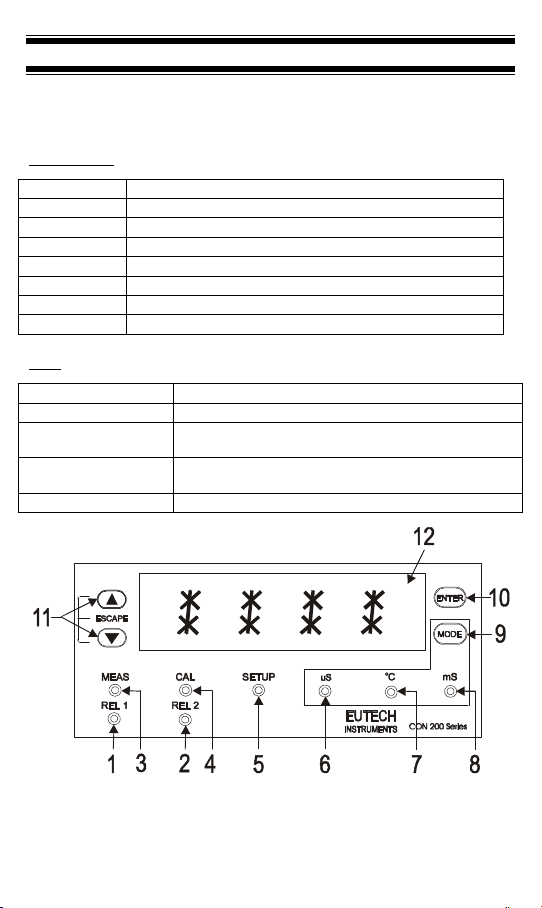

3.1 Front Panel

The front panel consists of a 4-digit LED display, 8 LED annunciators and 4 keys.

Annunciators

1. REL 1 Displayed when Relay 1 is activated

2. REL 2 Displayed when Relay 2 is activated

3. MEAS Displayed in measurement mode

4. CAL Displayed in calibration mode

5. SETUP Displayed in setup mode

6. µS Displayed when measurement range in micro-Siemens / cm

7. oC Unit of the displayed parameter (temperature)

8. mS Displayed when measurement range in milli-Siemens / cm

Keys

9. MODE

10. ENTER

11. ▲(increment)

11. ▼(decrement)

12. LED Display 14 segment LED display

Toggle between Conductivity and temperature display

Confirm changes or to enter into further levels of sub-menu

Use during calibration and setup modes to increment values.

Press

▲/▼keys together to escape to Measurement mode

Use during calibration and setup modes to decrease values.

Press

▲/▼keys together to escape to Measurement mode

8.8.8.8.

3

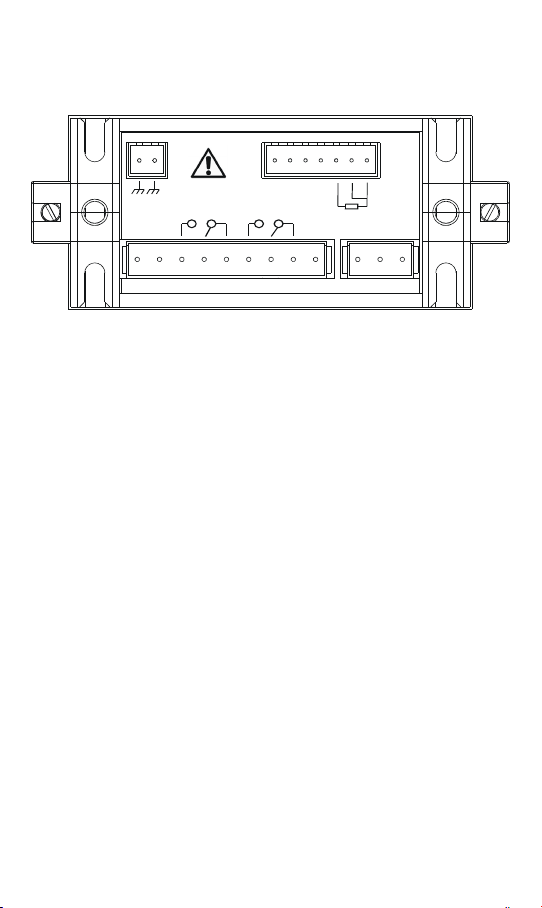

3.2 Back Panel

The back panel consists of three different connectors that can be used with

removable terminal blocks (included):

153514

13

1820 1921

A

A

m

m

0

0

2

2

-

-

4

4

+

-

12 11 10 9

Caution

RELAY1

8177166

RELAY2

C

N

N

C

N

O

C

-

NC NC N L

E

D

N

N

S

I

N

O

N

G

C

E

S

+

PT100

24

1. VAC live wire

2. VAC neutral wire

3. unused

4. unused

5. Relay 2 deactivated position (normally closed)

6. Relay 2 center pole

7. Relay 2 activated position (normally open)

8. Relay 1 deactivated position (normally closed)

9. Relay 1 center pole

10. Relay 1 activated position (normally open)

11. 4-20 mA connection, negative

12. 4-20 mA connection, positive

Pt 100 connection: sense (jumper to terminal 14 if using 2-wire RTD)

13.

14. Pt 100 connection: input

15. Pt 100 connection: ground

16. Conductivity positive terminal

17. Conductivity negative terminal

18. unused

19. unused

20. VAC protective ground wire

21. VAC protective ground wire

1

4

3.3 Wiring

Caution: Ensure electrical mains are disconnected before proceeding.

1. Connect the power supply to the three-pin terminal block

• VAC live wire = 1

• VAC neutral wire = 2

• VAC protective ground wire = 20 OR 21

Alpha COND 200 controller accepts voltages from 85 to 260 VAC, 50/60 Hz or DC.

2. Connect the Pt 100 leads to terminals 13 to 15 of the seven-pin terminal block.

Either wire can be connected to either terminal. Terminals 13 and 14 must be

shunted unless using a 3-wire RTD.

NOTE: CON 200 is factory set for Automatic temperature compensation. MTC can

be selected in Program P4.0.

3. Power on the controller. The display automatically shows the Conductivity

reading, the µS and ‘MEAS’ annunciators lights.

NOTE: In the event Pt 100 is not connected or the connection is broken in the ATC

mode, the display flashes ‘OR’ to alert you.

5

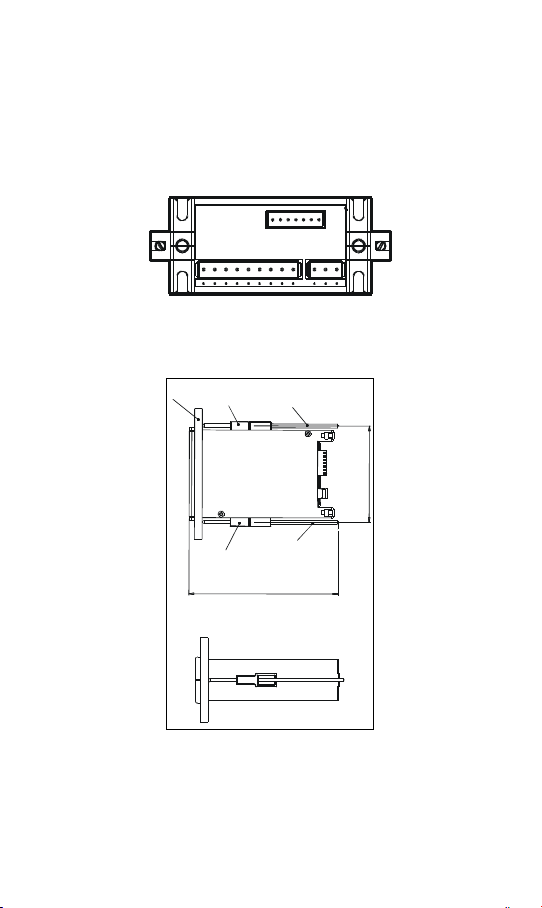

3.4 Panel-mounting the controller

a

d

The supplied mounting hardware allows surface mounting to all panels and

protective enclosures. Mounting cut-out size is 91 x 45 mm.

To attach the mounting to the controller:

1. Align the catch to the side of the controller, and insert threaded rods through

catch.

2. Screw the threaded-rod through the catch in a clock-wise direction. Tighten

until the catch holds the controller firmly against the back of the panel or

protective housing. Repeat on the other side.

h

c

t

a

C

h

c

t

a

C

2

0

.

TOP VIEW

e

d

a

e

r

h

T

0

0

1

.

x

o

r

p

p

a

d

o

r

d

e

d

a

e

r

h

T

1

5

4

.

x

p

o

p

a

r

p

l

l

a

W

SIDE VIEW

6

3.5 Installing Split Ferrite Clamping

The power cable (L, N & E) need to be connected to the instrument with two turns

through Split Ferrite (Wurth Electronika) clamp which is supplied as an accessory

with the instrument.

7

Loading...

Loading...