Thermo Fisher Scientific CON 400, CON410 User Manual

gyM

sy...

Instruction Manual

CON 400 and CON 410

Waterproof Hand-held Conductivity/TDS Meter

Technolo

adeEa

68X248904

Rev 4 May 06

Preface

This manual serves to explain the use of the Waterproof CON 400/410 hand-held meters. It

functions in two ways, firstly as a step by step guide to help you to operate the meter.

Secondly, it serves as a handy reference guide. It is written to cover as many anticipated

applications of the Waterproof CON 400/410 meters as possible. If there are doubts in the

use of the meter, please do not hesitate to contact the nearest Authorised Distributor.

Eutech Instruments/ Oakton Instruments cannot accept any responsibility for damage or

malfunction to the meter caused by improper use of the instrument.

The information presented in this manual is subject to change without notice as improvements

are made, and does not represent a commitment on the part of Eutech Instruments Pte Ltd/

Oakton Instruments.

Copyright © 1999

Eutech Instruments Pte Ltd/ Oakton Instruments

All rights reserved.

TABLE OF CONTENTS

1 INTRODUCTION ..............................................................................................1

2 DISPLAY AND KEYPAD FUNCTIONS............................................................. 2

2.1 DISPLAY .................................................................................................................... 2

2.2 KEYPAD .....................................................................................................................3

3 PREPARATION ................................................................................................ 4

3.1 INSERTING THE BATTERIES ......................................................................................... 4

3.2 CONDUCTIVITY ELECTRODE INFORMATION .................................................................. 5

3.3 CONNECTING THE PROBE TO THE METER ..................................................................... 6

4 CALIBRATION.................................................................................................. 7

4.1 IMPORTANT INFORMATION ON METER CALIBRATION ..................................................... 7

4.2 PREPARING THE METER FOR CALIBRATION.................................................................. 8

4.3 TEMPERATURE CALIBRATION ......................................................................................9

4.4 CONDUCTIVITY CALIBRATION .................................................................................... 10

4.5 TDS CALIBRATION ...................................................................................................12

4.5.1 Calibrating for TDS directly................................................................................ 12

4.5.2 Calibration with Conductivity Standard and TDS factor..................................... 13

5 MEASUREMENT ............................................................................................ 15

5.1 AUTOMATIC TEMPERATURE COMPENSATION ............................................................. 15

5.2 MANUAL TEMPERATURE COMPENSATION .................................................................. 16

5.2.1 Selecting Manual Temperature Compensation ................................................. 16

5.2.2 Setting a manual temperature compensation value .......................................... 17

5.3 TAKING MEASUREMENTS ..........................................................................................18

5.4 USING MANUAL RANGING FUNCTION......................................................................... 19

5.5 HOLD FUNCTION .....................................................................................................20

6 MEMORY AND DATA INPUT FUNCTIONS ................................................... 21

6.1 MEMORY INPUT........................................................................................................ 21

6.2 MEMORY RECALL..................................................................................................... 22

7 ADVANCED SETUP FUNCTIONS ................................................................. 23

7.1 ADVANCED SETUP MODE OVERVIEW....................................................................... 25

7.2 P 1.0: MEMORY CLEAR (CLR).................................................................................. 27

7.3 P2.0: VIEWING CALIBRATION DATA ............................................................................ 28

7.4 P3.0: VIEWING PROBE DATA ..................................................................................... 29

7.5 P4.0: UNIT CONFIGURATION ..................................................................................... 30

7.5.1 P4.1: READY indicator and auto endpoint function ........................................... 30

7.5.2 P4.2 Selecting °C or °F...................................................................................... 31

7.5.3 P4.3 Selecting Automatic or Manual Temperature Compensation................... 32

7.5.4 P4.4 Setting the TDS factor .............................................................................. 33

7.6 P5.0 TEMPERATURE................................................................................................ 34

7.6.1 P5.1 Adjusting the temperature coefficient ....................................................... 34

7.6.2 P5.2 Adjusting the normalization temperature.................................................. 35

7.7 P6.0 SELECTING THE CELL CONSTANT ...................................................................... 36

7.8 P7.0: SETTING THE REAL-TIME CLOCK....................................................................... 37

7.9 P8.0: RESETTING TO FACTORY DEFAULT SETTINGS....................................................39

8 PROBE CARE AND MAINTENANCE............................................................. 40

9 TROUBLE SHOOTING GUIDE....................................................................... 41

10 ERROR MESSAGES.................................................................................. 42

11 SPECIFICATIONS ...................................................................................... 43

12 ACCESSORIES .......................................................................................... 44

CALIBRATION SOLUTIONS ................................................................................. 44

13 ADDENDUM 1: CALIBRATION TIPS ........................................................45

14 ADDENDUM 2: CALCULATING TDS CONVERSION FACTORS.............. 46

14.1 “PREPARING YOUR OWN TDS CALIBRATION STANDARDS”........................................... 46

15 ADDENDUM 3: CALCULATING TEMPERATURE COEFFICIENTS .......... 47

16 ADDENDUM 4: METER FACTORY DEFAULT SETTINGS .......................48

17 WARRANTY ...............................................................................................49

18 RETURN OF ITEMS ................................................................................... 50

Instruction Manual CON 400/410

1 INTRODUCTION

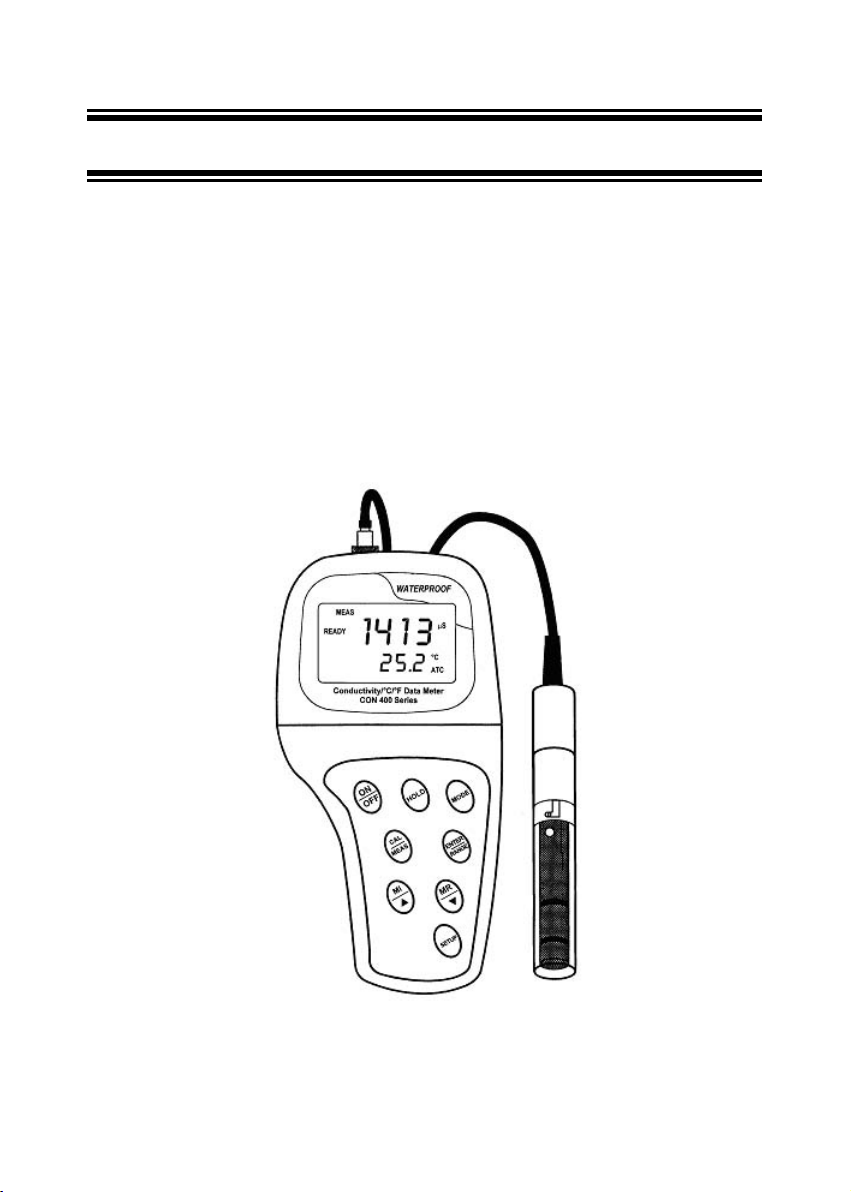

Thank you for selecting the CON 400/410 waterproof portable meter. This meter is a

microprocessor-based instrument that is designed to be user-friendly and allow one-hand

operation. It has a built-in real time clock, expanded memory, and many other user-friendly

features, all of which are accessible through the membrane keypad. It is completely

WATERPROOF --- and it FLOATS! You have one of the following models:

• CON 400 meter: reads conductivity and temperature.

• CON 410 meter: reads conductivity, TDS and temperature.

Your meter includes 4 ‘AAA’ batteries and a conductivity electrode (cell constant K = 1.0) with

built-in temperature sensor. Please read this manual thoroughly before operating your meter.

- 1 -

Instruction Manual CON 400/410

2 DISPLAY AND KEYPAD FUNCTIONS

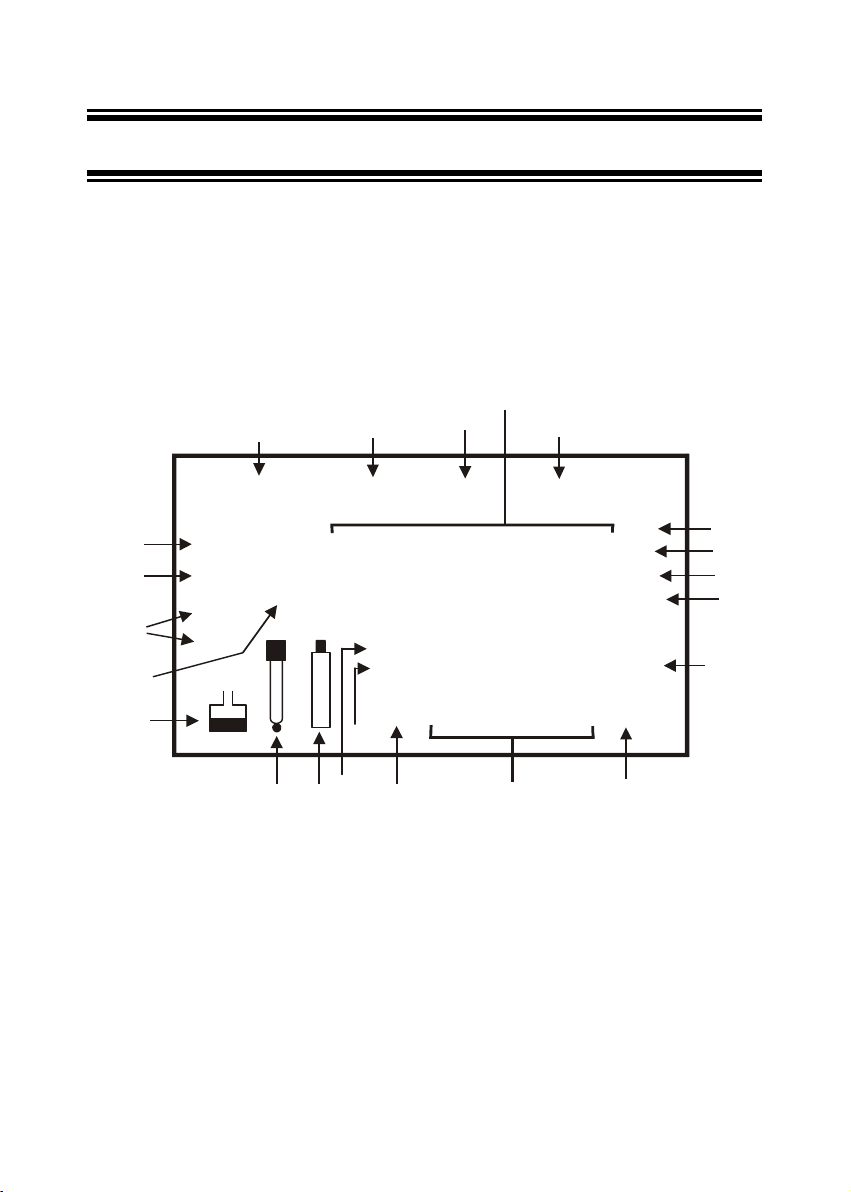

2.1 Display

The LCD has a primary and secondary display.

• The primary display shows the measured conductivity or TDS reading.

• The secondary display shows the measured temperature.

The display also shows error messages, keypad functions and program functions.

See Figure 1.

Primary Display

12

3

4

SETUP MEAS CAL MEM

5

6

7

9

19

20

18

17

READY

HOLD

ON

OFF

K =

-8.8.8.8

MEM

ERR

mS

μ

S

ppt

ppm

°C °F

8

-1.8.8.8

16

1. SETup mode indicator 8. parts per million indicator (CON

2. MEASurement mode indicator 9. Temperature indicator 16. Calibration solution indicator

3. CALibration indicator 10. Automatic Temperature

4. MEMory recall mode indicator 11. Clock indicator 18. ON / OFF indicator

5. millisiemens indicator 12. ERRor indicator 19. HOLD indicator

6. microsiemens indicator 13. MEMory location indicator 20. READY indicator

7. parts per thousand indicator

(CON 410 meter only)

AM PM

12

131415

Figure 1: Full LCD Screen

410 meter only)

Compensation indicator

14. Low battery indicator

Secondary Display

ATC

1011

15. Probe indicator

17. Cell constant indicator

- 2 -

Instruction Manual CON 400/410

2.2 Keypad

The large membrane keypad makes the instrument easy to use. Each button, when pressed,

has a corresponding graphic indicator on the LCD. See Figure 2. Some buttons have several

functions depending on its mode of operation.

Key Function

ON/OFF Powers on and shuts off the meter. When you switch on the meter, the meter starts up

HOLD Freezes the measured reading. To activate, press HOLD while in measurement mode.

MODE Selects the measurement parameter.

CAL/MEAS Toggles between Calibration and Measurement mode.

ENTER /

RANGE

MI/S and

MR/T

SETUP Takes you into the SETUP mode. This mode lets you customise meter preference and

in the mode that you last switched off from. For example, if you shut the meter off in

TDS measurement mode (only in CON 410 meter), the meter will be in TDS

measurement mode when you switch the meter on.

To release, press HOLD again.

~ CON 400 meter: Toggles between conductivity and time.

~ CON 410 meter: Toggles between conductivity, TDS and time.

NOTE: Temperature calibration is available from conductivity calibration mode; see

page 9 for directions.

ENTER function: Press to confirm values in Calibration mode and to confirm selections

in SETUP mode.

RANGE function: Press to enter manual ranging function.

The MEAS indicator blinks while in manual ranging function.

In Measurement mode:

Press MI/S (memory input) to store values with its corresponding temperature values in

the memory. Press MR/T (memory recall) to retrieve data from memory.

In Calibration mode:

Press to scroll through calibration values.

In SETUP mode:

Press to scroll through the setup subgroup programmes.

defaults, and view calibration, electrode offset data and select cell constant.

Figure 2 - Keypad

- 3 -

Instruction Manual CON 400/410

3 PREPARATION

3.1 Inserting the Batteries

Four AAA batteries are included with your meter.

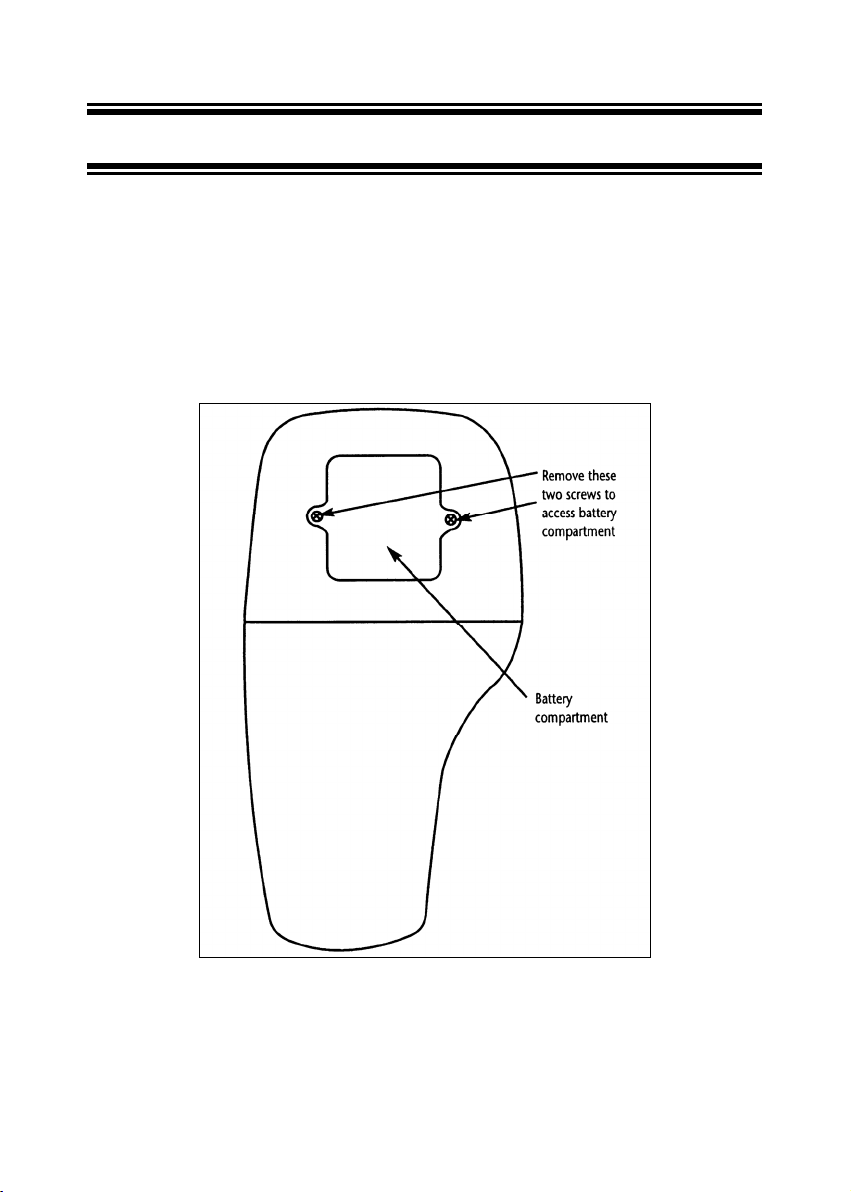

1. Use a Philips screwdriver to remove the two screws holding the battery cover. See Figure

3 below.

2. Remove battery cover to expose batteries.

3. Insert batteries. Follow the diagram inside the cover for correct polarity.

4. Replace the battery cover into its original position using the two screws removed earlier.

Figure 3 - Back panel of meter showing meter compartment

- 4 -

Instruction Manual CON 400/410

3.2 Conductivity Electrode Information

The CON400/410 meter uses a conductivity / TDS cell with a

sturdy 6-pin connector.

Your meter includes a conductivity probe (Part No: EC-

CONSEN91W / 35608-50) Ultem / Stainless Steel cells with a cell

constant of K = 1.0. This conductivity / TDS cell features a built-in

temperature sensor for Automatic Temperature Compensation

(ATC). It has a specially designed housing that provides fast

temperature response and reduces air bubble entrapment, which

makes it easy to obtain accurate, stable readings.

Wetted parts include:

1. Polyetherimide (Ultem™)

2. Polybutylterphalate (Valox™)

3. Stainless Steel (SS 304)

NOTE: We recommend that you do not submerge the probe above

the protective yellow cap for prolonged periods. The protective

yellow cap can be removed for cleaning, but must be attached at

all times during calibration or measurement.

See Section 8 on page 40 for “Probe Care and Maintenance”

information.

1

Figure 4 - Conductivity probe

(EC-CONSEN91W/ 35608-50)

1

Valox and Ultem are trademark names of General Electric Co.

- 5 -

Instruction Manual CON 400/410

3.3 Connecting the probe to the meter

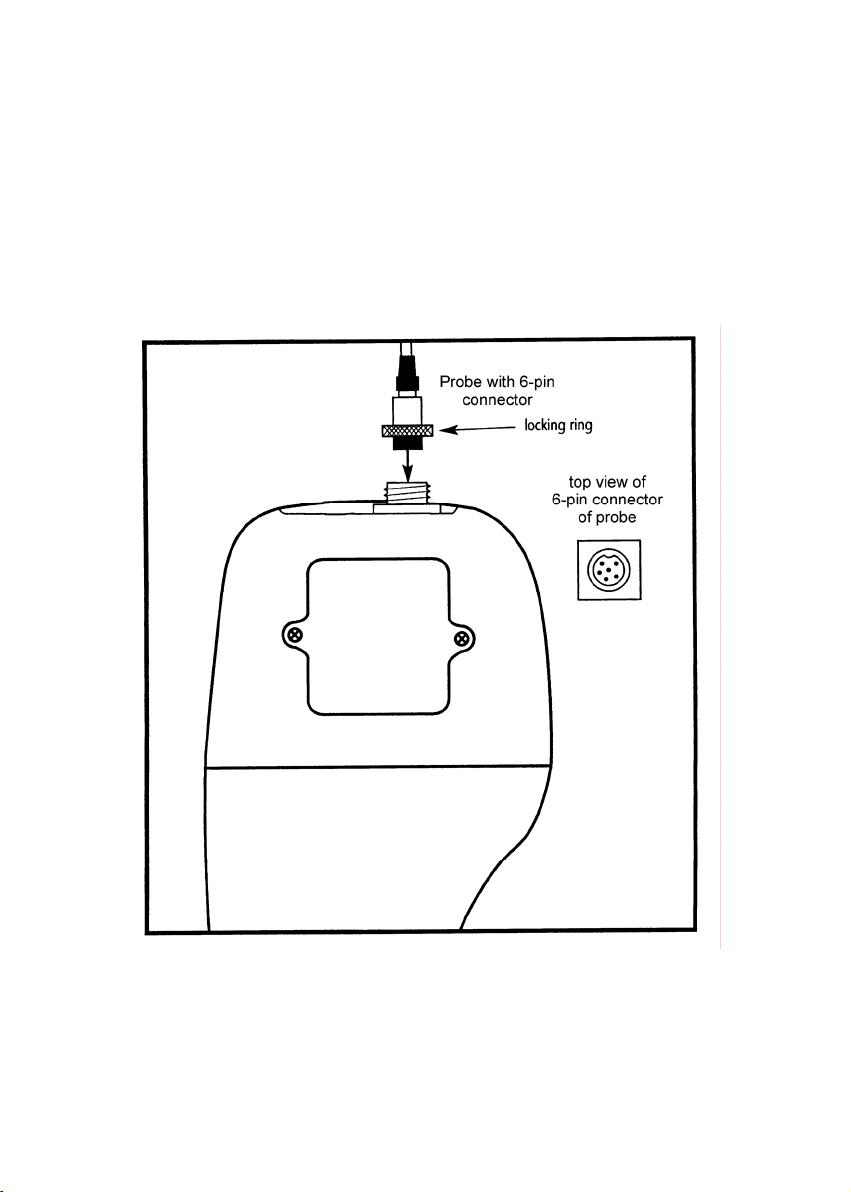

1. Line up the notch and 6 pins on the meter with the holes in the 6-pin connector. Push

down and turn the locking ring clockwise to lock into place. See figure below.

2. To remove probe, turn the locking ring counterclockwise on the probe connector. Pull

probe away from the meter.

CAUTION: Do not pull on the probe cord or the probe wires might disconnect.

NOTE: Keep connectors clean. Do not touch connector with soiled hands.

Figure 5 - Connection for Conductivity probe (6-pin connector)

- 6 -

Instruction Manual CON 400/410

4 CALIBRATION

4.1 Important Information on Meter Calibration

Your meter has five measuring ranges. You can calibrate one point in each of the measuring

ranges (up to five points). If you are measuring values in more than one range, make sure to

calibrate each of the ranges you are measuring.

To view current calibration points, see SETUP section Program 2.0 on page 28.

The following table lists the corresponding conductivity and TDS ranges. You should calibrate

each range using a solution that falls between the values in the “recommended calibration

solution range” column.

Conductivity

Measuring

Range

0.00 Æ 19.99 μS 6.00 to 17.00 μS 0.00 Æ 9.99 ppm 3.00 to 8.50 ppm

0.0 Æ 199.9 μS 60.0 to 170.0 μS 10.0 Æ 99.9 ppm 30.0 to 85.0 ppm

0 Æ 1999 μS 600 to 1700 μS 100 Æ 999 ppm 300 to 850 ppm

0.00 Æ 19.99 mS 6.00 to 17.00 mS 1.00 Æ 9.99 ppt 3.00 to 8.50 ppt

0.0 Æ 199.9 mS 60.0 to 170.0 mS 10.0 Æ 200 ppt 30.0 to 170 ppt

When you recalibrate your meter, old calibrations are replaced on a range by range basis. For

example, if you previously calibrated your conductivity meter at 1413 μS in the 0 to 1999 μS

range and you recalibrate at 1500 μS (also in the 0 to 1999 μS range), the meter will replace

the old calibration data (1413 μS) in that range. The meter will retain all calibration data in

other ranges.

To completely recalibrate your meter, or when you use a replacement probe, it is best to clear

all calibration data in memory. To erase all the old conductivity and TDS calibration data

completely from memory, see SETUP section Program 8.0 on page 39.

For information on how to calibrate your meter:

• See section 4.3 for Temperature Calibration.

• See section 4.4 for Conductivity

• See section 4.5 for TDS Calibration (CON 410 meter only).

• See Addendum 1 for more calibration tips.

Recommended

Calibration Solution

Range

TDS Measuring

Range

Recommended

Calibration Solution

Range

- 7 -

Instruction Manual CON 400/410

4.2 Preparing the Meter for Calibration

Before starting calibration, make sure you are in the correct measurement mode. When you

switch on the meter, the meter begins with the units you shut it off in.

For best results, select a standard value close to the sample value you are measuring.

Alternatively use a calibration solution value that is approximately 2/3 the full-scale value of

the measurement range you plan to use. For example, in the 0 to 1999 μS conductivity range,

use a 1413 μS solution for calibration.

Do not reuse calibration solutions after calibration. Contaminants in the solution can affect the

calibration, and eventually the accuracy of the measurements. Use fresh calibration solution

each time you calibrate your meter.

NOTE: Your meter is factory set to a temperature coefficient of 2.1% per °C. For most

applications this will provide good results. See Program P5.1 on page 34 to set the

temperature coefficient to different value. See Addendum 3, “Calculating Temperature

Coefficients” to determine the appropriate temperature coefficient for your solution.

NOTE: The factory default value for normalization temperature is 25 °C. If you need to

normalize to a value other than 25 °C, see Program P5.2 on page 35.

- 8 -

Instruction Manual CON 400/410

μSμ

4.3 Temperature Calibration

Your probe features a built-in temperature sensor. The

temperature sensor is factory calibrated. Calibrate your

sensor only if you suspect temperature errors that may

have occurred over a long period of time or if you have a

replacement probe.

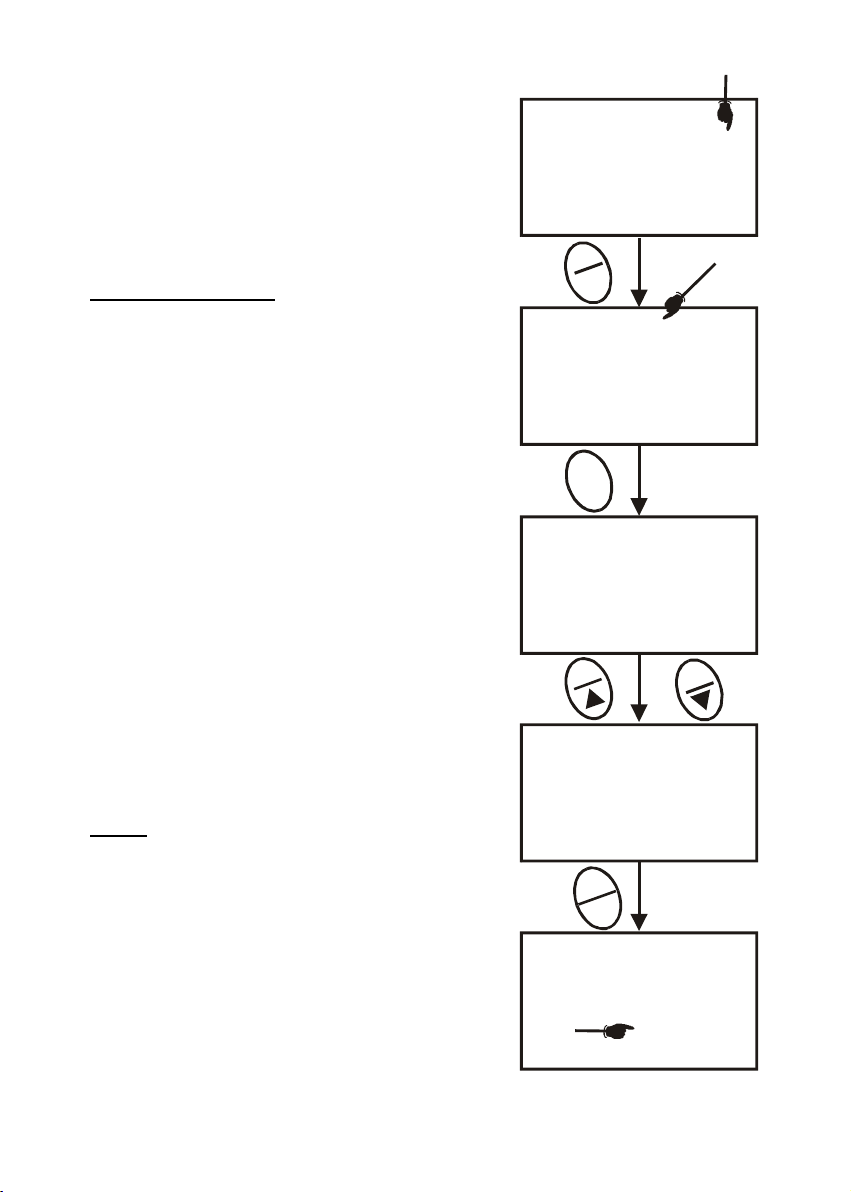

Temperature Calibration

1. Make sure the cell is attached to the 6-pin connector.

The ATC annunciator will appear at the right-hand

side of the LCD*.

2. Switch the meter on. Press the MODE key to select

conductivity or TDS mode.

3. Press the CAL/MEAS key to enter conductivity or

TDS calibration mode. The CAL indicator appears

above the primary display.

4. While in conductivity or TDS calibration mode, press

the MODE key to enter temperature calibration

mode. The primary display shows the current

temperature reading and the secondary display

shows the factory default temperature value.

5. Dip the cell into a solution of known temperature (i.e.

A temperature bath). Allow time for the built-in

temperature sensor to stabilise.

6. Scroll with the MI/S or MR/T keys to set the correct

temperature value (i.e. the temperature of the

temperature bath). You can adjust the reading in

increments of 0.1 °C.

7. Once you have selected the correct temperature,

press the ENTER key.

* If the ATC indicator does not light up, see Program P4.3

to switch it on.

NOTES:

• You can offset the temperature reading up to ±5°C from

the original reading (default reading).

• To exit this program without confirming the temperature

calibration value, DO NOT press ENTER. Press

CAL/MEAS instead.

• If the ATC indicator does not light, see Program P4.3,

on page 32 to switch it on.

• Since temperature readings affect the accuracy of the

conductivity/TDS measurements, it is strongly

recommended to carry out a conductivity/TDS

calibration after a temperature calibration is done.

- 9 -

MEAS

1413

L

A

C

S

A

E

M

1413

E

D

O

M

22.3

I

M

22.0

R

E

T

N

E

E

G

N

A

R

MEAS

READY

1425

Figure 10 - Temperature

Calibration

22.3

CAL

22.3

CAL

22.3

CAL

22.3

22.0

°C

ATC

S

°C

ATC

°C

ATC

R

M

°C

ATC

μ

S

°C

ATC

Instruction Manual CON 400/410

4.4 Conductivity Calibration

The CON 400 and CON 410 meters are capable of up

to 5-point conductivity calibration at one point per

conductivity range (0.00 - 19.99 μS; 0.0 - 199.9 μS; 0 -

1999 μS; 0.00 - 19.99 mS; 0.0 - 199.9 mS).

All new calibration data will over-ride existing stored

calibration data for each measuring range calibrated.

Calibrating for Conductivity:

1. If necessary, press the MODE key to select

conductivity mode.

2. Rinse the probe thoroughly with de-ionized (DI)

water or a rinse solution, then rinse with a small

amount of calibration standard.

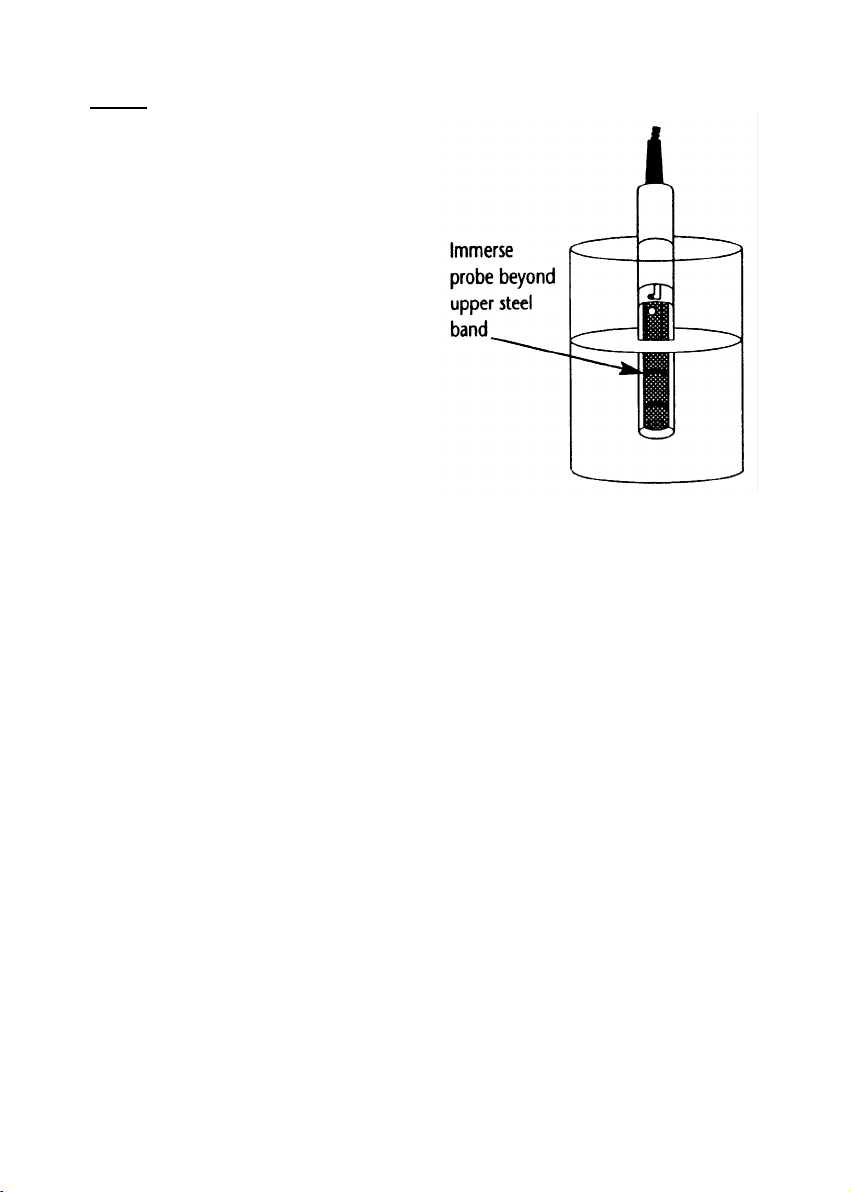

3. With the yellow probe guard attached, dip the

probe into the calibration standard. Immerse the

probe tip beyond the upper steel band. Stir the

probe gently to create a homogeneous sample.

Allow time for the reading to stabilise.

See Figure 7.

4. Press CAL/MEAS to enter conductivity

calibration mode. The CAL indicator will appear

in the upper right corner of the display.

5. Press the MI/S or MR/T key to change the

value on the primary display to match the value

of the calibration standard referenced to your

normalisation temperature (usually 25°C).

6. Press ENTER to confirm calibration value. The

meter returns to the MEAS (measurement) mode.

7. Repeat steps 1 to 6 for other measuring ranges.

See figure 6.

Figure 6 - Conductivity Calibration

- 10 -

Instruction Manual CON 400/410

NOTES:

When entering calibration mode, the meter

displays the factory default value. If the meter

was previously calibrated, the display may

seem to “jump” to the factory default value

when switching from measurement to

calibration mode. This is expected.

To exit from Conductivity calibration

mode without confirming calibration, DO

NOT press the ENTER key in step 6. Press

CAL/MEAS instead. This will retain the

meter’s old calibration data in the measuring

range of the calibration.

You can offset the conductivity reading up to

±40% from factory default value. If your

measured value differs by more than ±40%,

clean or replace probe if needed.

Figure 7 - Proper Immersion of

the conductivity probe

The minimum offset reading allowable is

limited to 10% of full scale reading of the

range you are working in. The maximum offset reading allowed is the range full scale reading

Eutech Instruments/ Oakton Instruments offers a wide selection of high-quality calibration

standards. See page 44 for more information.

- 11 -

Instruction Manual CON 400/410

4.5 TDS Calibration

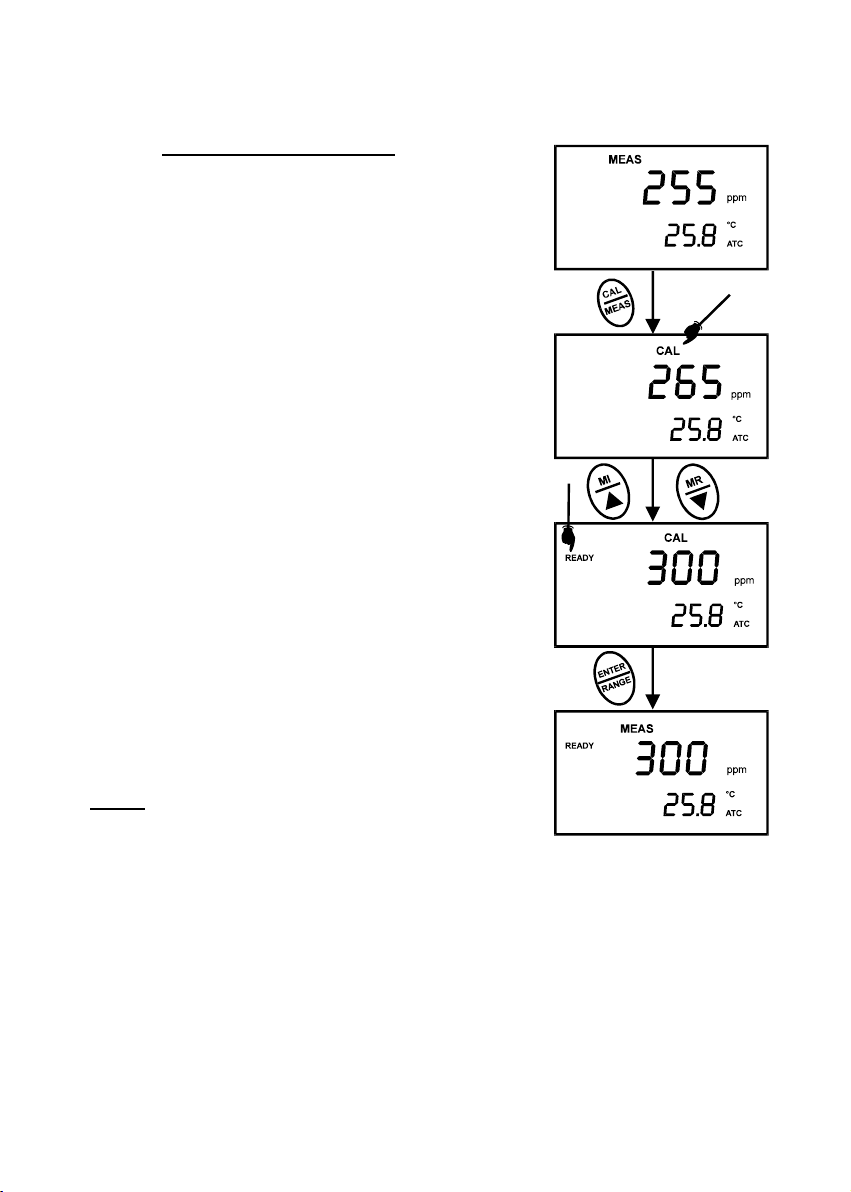

4.5.1 Calibrating for TDS directly

For CON 410 meter only

The factory default setting for the TDS conversion factor is

0.50. If your solution has a different TDS factor, you can

improve calibration accuracy by setting the TDS factor prior to

calibration. See page 33 for directions.

1. If necessary, press the MODE key to select TDS mode.

2. Rinse the probe thoroughly with DI water or a rinse

solution, then rinse with a small amount of calibration

standard.

3. With the yellow probe guard attached, dip the probe into

the calibration standard. Immerse the probe tip beyond

the upper steel band. Stir the probe gently to create a

homogeneous sample. Allow time for the reading to

stabilise.

4. Press CAL/MEAS to enter TDS calibration mode. The

CAL indicator will appear in the upper right corner of the

display.

5. Press the MI/S or MR/T to change the value on the

primary display to match the value of the calibration

standard referenced to your normalisation temperature

(usually 25°C).

6. Press ENTER to confirm the calibration value. The meter

returns to the MEAS (measurement) mode.

7. Repeat steps 1 to 6 for other measuring ranges.

NOTES

To exit from TDS Calibration mode without confirming

calibration, DO NOT press the ENTER key in step 6. Press

CAL/MEAS instead. This will retain the meter’s old calibration

data in the measuring range of the calibration.

You can offset the TDS reading up to ±40% from the default

setting. If your measured value differs by more than ±40%,

clean or replace probe as needed.

The minimum offset reading allowable is limited to 10% of full scale reading of the range you

are working in. The maximum offset reading allowed is the range full scale reading

Eutech Instruments/ Oakton Instruments offer a wide selection of high-quality calibration

standards. See page 44 for more information.

Figure 8 - TDS Calibration

- 12 -

Loading...

Loading...