Page 1

WHITE PAPER Bigfoot Spectral Cell Sorter

Bigfoo t Spectral

Cell Sorter

A new approach to

cell sorter safety

Introduction

Cell sorting continues to be a powerful contributor in the

quest to improve human health, allowing researchers

to make timely advancements in drug and vaccine

development, as illustrated by the newly released SARSCoV-2 sorting protocols [1]. However, cell sorting is also

known to produce aerosols that can expose the operator

to both known and unknown pathogens. When cell sorters

are run at high pressures, they can produce aerosols

with high particulate content as well as extremely small

particles. Such particles, especially those smaller than

2μm, are prone to deposition in both the upper airway and

the alveolar spaces in the lungs, with potential to harm the

operator [2]. Thishazard necessitates protective barriers

and containment apparatus to be incorporated into the

cell sor t e r.

In the early 2000s, manufacturers sought to address

these concerns by adding aerosol management systems

(AMSs), which continuously evacuate the sorting chamber

to remove aerosols. In the same period, the first attempt

was made to fit a cell sorter into a Class II biosafety cabinet

(BSC). Though less than ideal, it served to protect the

sort sample and to some extent the operator. Current

International Society for Advancement of Cytometry

(ISAC) safety regulations require that all cell sorters now

be equipped with an AMS [2]. These standards also

state that most types of cell samples and lab spaces

necessitate the sorter to be enclosed in a BSC. Despite

these regulations, AMSs and BSCs are frequently marketed

as optional accessories when purchasing a sorter and,

as such, frequently fall victim to funding shortfalls.

Several newer sorters include an AMS integrated with a

standard BSC, but they continue to resemble an ad hoc

solution with manual operation of air-handling controls and

poor access for service manipulation, which can lead to

inconsistent results and an unsafe environment.

The referenced ISAC regulations require periodic testing

of AMS and BSC systems. While the recently developed

Cyclex-D air sampler and 1 µm Dragon Green fluorescent

microspheres AMS testing method is an improvement over

previous procedures, the process remains cumbersome

and not clearly defined for many sorters. The literature

describes the testing using only one manufacturer’s

cell sorter, and while general guidelines are included to

modify the procedure for other vendors’ equipment, such

modifications are not always clear-cut and frequently

require burdensome manual overrides and manipulations.

An instrument designed with a well-integrated AMS

and BSC will likely solve most if not all of these

common concerns.

Page 2

BSC and AMS design reinterpreted

The Invitrogen™ Bigfoot Spectral Cell Sorter is designed

with an integrated BSC and AMS. Sample-related

subsystems are segregated inside the BSC for optimal

safety, sanitation, and performance. Sealed optical

windows surround the nozzle, defining the barrier between

the inside and outside of the BSC. This separation allows

lasers, excitation optics, and scatter objective lenses to

remain outside the BSC yet close to the interrogation point,

which maintains the superior performance of a jet-in-air

sorter. All other systems, such as detection, electronics,

and fluidics, are also outside the containment area. This

allows better service access and temperature regulation as

compared to othersorters.

The Bigfoot Spectral Cell Sorter BSC system has been

verified to meet personnel and product protection

standards for a Class II Type A2 biosafety cabinet per the

National Sanitation Foundation (NSF) International Standard

49, Section 3.8.2.3. Specifically, this means the BSC:

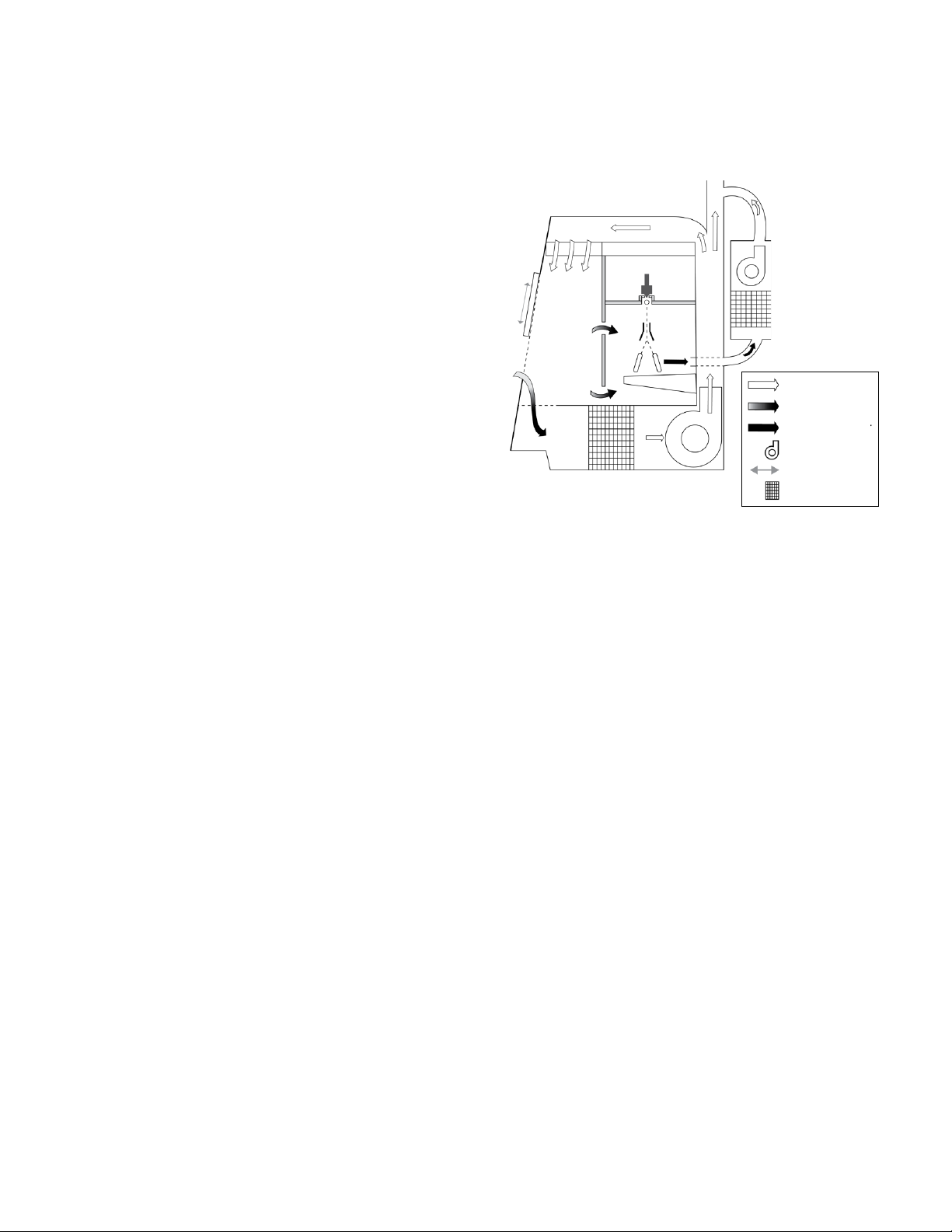

deliver uniform downflow air, and the remaining filtered air

is exhausted to the laboratory environment, or through an

external exhaust system connected to the optional cabinet

canopy connection (Figure 1).

HEPA-filtered air

Mixed air

Contaminated air

Fan

Adjustable sash

HEPA filter

• Maintains an average air velocity of 100 ft/min through

the work access opening

• Provides high-eciency particulate air (HEPA)–filtered

downflow air that is a mixed with the downflow and

inflow air

• Exhausts HEPA-filtered air into either the laboratory or,

via an optional canopy connection, through an external

exhaust system

• Holds all biologically contaminated ducts and plenums

under negative pressure

The AMS and BSC portions of the system can be operated,

and are monitored, independently. The system houses two

independent exhaust fans and two independent HEPA

filters; one fan and filter for the AMS, and one fan and

filter for the BSC. Pressure sensors independently monitor

containment in both the AMS and the BSC for redundant

biosafety containment.

Aerosols in the segregated sort chamber are entrained

in air that is ducted to a HEPA filter in the AMS. The door

to access the sort chamber is inside the greater BSC. In

the unlikely event hazardous aerosols leak out of the sort

chamber, the greater BSC oers a secondary biosafety

system to capture aerosols. As with all Class II Type A2

cabinets, a portion of the filtered air is recirculated to

Figure 1. Airflow diagram.

Recirculated and exhausted air is HEPA filtered to remove

99.97% of particles greater than 0.3 μm. Inflow air velocity

is regulated to a minimum of 100 ft/min through the work

access opening. During a sort, the AMS continuously

draws air from the sort chamber and through a HEPA

filter. If a clog is detected, software notifies the operator;

stops the sort, sample, and sheath; and automatically

increases the speed of the AMS fan to quickly purge

the sort chamber of aerosols prior to allowing the user

access to the aected area. All the while, the BSC portion

of the system continues operating independently to

maintaincontainment.

In contrast to standard BSCs, the Bigfoot Spectral

Cell Sorter’s integrated BSC filters the air before a

fan pressurizes it for recirculation or exhaust. Uniform

downflow air is established with a low-profile, three-stage

diuser. Therefore, all ducts under positive pressure

contain only filtered air, reducing the risk of leaks containing

aerosols. The fans and sensitive HEPA filters are located

below the work surfaces and to the rear of the instrument.

Thus, HEPA filters are protected from inadvertent damage

during daily operation, noise is kept to a minimum, and

vibrations are isolated from the optical path, which helps

to maintain the superior optical stability of the Bigfoot

Spectral Cell Sorter.

Page 3

User experience innovation

In addition to the eort invested in technical ingenuity,

significant resources were also devoted to user experience

innovations. Inside the laminar airflow barrier there is ample

deck space for sample racks and plates, as well as access

to a built-in sample vortex mixer, tube rack, and biohazard

bag. This makes it possible for the operator to complete

common tasks without breaching the safety barrier multiple

times during the normal workflow (Figure 2). Interior work

surfaces are made with nonporous, durable 304 stainless

steel for easy cleaning.

Lab personnel in biohazardous environments must

work eciently and make use of techniques that reduce

interactions with hazards in order to maximize safety. The

Bigfoot Spectral Cell Sorter includes four major innovations

to help operators limit hazardous contact:

• The sample loader holds multiple controls or samples,

which reduces the need for the operator to enter and

exit the BSC continuously for sample loading

Figure 3. The sort collector accommodates numerous sort tubes.

• The sort collection rack accommodates numerous sort

tubes to collect multiple sorts from dierent runs or

one long run, which reduces the need for the operator

to enter and exit the BSC to unload sorted samples

(Figure 3)

• Plates can be sorted in less than 20 sec; therefore,

the time the operator interacts with the biohazardous

environment is reduced

• The internal control panel limits the need for the

operator to reach in and out of the BSC to operate

the system (Figure 4)

Figure 4. The internal control panel limits the need for the operator to

reach in and out of the BSC.

Figure 2. Adjustable sash in the up position for sampleaccess.

Page 4

Low noise

Due to the integrated design, the Bigfoot Spectral Cell

Sorter is far more compact compared to other models

currently available. The smaller containment area and

thoughtful fan placement have resulted in a system that

produces less noise during operation. Therefore, the

Bigfoot Spectral Cell Sorter can be more comfortably

housed near other laboratory instrumentation and

operators, which is a valuable consideration for spacelimited facilities. Furthermore, by minimizing materials

use, integrated containment reduces the overall cost of

the system so that safety is not compromised due to

limitedfunding.

Conclusion

We have reinterpreted BSC design by enclosing only

potentially pathogen-exposed components and leaving

the rest of the instrument accessible to operators and

service personnel. The recent SARS-CoV-2 crisis has

focused global attention on the importance of biosafety,

which should prompt scientific laboratories to reevaluate

existing biosafety measures, reinforce old procedures,

and implement improvements. Biosafety is increasingly

critical in sorting facilities and is mandated as a condition

of obtaining some grants and funding [4]. The softwareguided containment testing protocol simplifies and

streamlines mandated safety assessments. The Bigfoot

Spectral Cell Sorter provides containment and operator

protections that meet the need for modern cell sorter safety

without sacrificing performance or laboratory space.

Persistent containment

Unlike traditional biosafety cabinets applied to flow

cytometry applications, the sliding sash on the Bigfoot

Spectral Cell Sorter allows improved operator access to

the instrument while still maintaining aerosol containment.

When the sash is in the up position, the operator has safe

access to the sample area (similar to traditional cabinets).

Uniquely, when interaction with the nozzle is necessary, the

operator slides the sash down to access a BSC-contained

upper opening for ergonomic interaction. Upon opening

the nozzle door, the nozzle automatically moves forward

where it can be easily cleaned or changed (Figure 5).

The BSC maintains personnel safety protections for total

system operation regardless of the sash position.

Seamless laboratory integration

The previously referenced ISAC standard was used to

develop an integrated airflow-and-containment software

wizard that guides personnel through the recommended

protocols for periodic AMS testing and yearly BSC

certification. This integrated software has been developed

specifically to run the instrument and the BSC together,

which helps the operator seamlessly follow all biosafety

precautions while running the Bigfoot Spectral Cell Sorter.

Figure 5. Adjustable sash in the down position for nozzleaccess.

References

1. Perfet to, Stephen P. and Ben Fontes. New SARS-CoV-2 Sorting Protocols Released.

ISAC, 26 March 2020, https://isac-net.org/news/497501/NEW-SARS-CoV-2SORTING-PROTOCOLS-RELEASED.htm.

2. Holmes K, Fontes B, Hogarth P, Kunz R, Monard S, Pletcher C, Wadley R, Schmid I,

Perfetto S. International Society for the Advancement of Cytometr y Cell Sorter Biosafety

Standards Cytometry A. May;85(5):434–53. doi: 10.1002/cyto.a.2245 4. Epub 2014

Mar 13. PubMed PMID: 24634405; PubMed Central PMCID: PMC4117398.

3. The NFS Joint Committee on Biosafety Cabinetry. NSF/ANSI 49 - 2018 Biosafety

Cabinetry: Design, Construction, Performance, and Field Certification. NSF

International/American Standards Institute 2019;3.8.2:5–6.

4. Oce of Biotechnology Activities.NIH Guidelines for Research Involving Recombinant

and Synthetic Nucleic Acid Molecules.O ce of Biotechnology Activities;

2013. [Online: the most current version can be found athttp://osp.od.nih.gov/

oce-biotechnology-activities/biosafety/nih-guidelines.]

Find out more at thermofisher.com/bigfoot

For Research Use Only. Not for use in diagnostic procedures. © 20 21 Thermo Fisher Scientific Inc. All right s reserved. All trademarks

are the property of Thermo Fisher Scientific and its subsidiaries unless otherwise specified. COL014843 0321

Loading...

Loading...