QUICK REFERENCE

Amplitude™ Solution with the TaqPath™ COVID‑19

High‑Throughput Combo Kit—Module 1

Module 1—Sample and reagent transfer to deep‑well plates for RNA extraction

Pub. No. MAN0019429 Rev. B.0

Note: For safety and biohazard guidelines, see the “Safety” appendix in the Amplitude™ Solution with the TaqPath™ COVID‑19

High‑Throughput Combo Kit Instructions for Use (Pub. No. MAN0019428). Read the Safety Data Sheets (SDSs) and follow the handling

instructions. Wear appropriate protective eyewear, clothing, and gloves.

Required samples, reagents, and consumables

For information about the location of the required materials in the deck layout, see “Load the Tecan™ Fluent™ 1080 Automation

Workstation deck” on page 6.

Required samples, reagents, and consumables

Sample input

Barcoded sample tubes in sample carrier racks 376 samples per run page 8

Tips and Plates

KingFisher™ Deep‑Well 96 Plate with Barcode (sample extraction plates) 4 plates per run

1,000 µL Flexible Channel Arm™ (FCA) Disposable Tips Rack 15 racks per 3 runs

200 µL Flexible Channel Arm™ (FCA) Disposable Tips Rack 3 racks per 6 runs

Axygen™ Multi Well Low Profile Reagent Reservoir

(for MagMAX™ HT

Proteinase K/TaqPath™ COVID-19

Module 1

MS2 Phage Control)

Axygen™ Single Well High Profile Reagent Reservoir (for Binding Bead Mix) 1 reservoir per 6 runs

Axygen™ Single Well High Profile Reagent Reservoir (for silicone oil) 1 reservoir per 6 runs

Reagents

MagMAX™ HT Binding Beads 1 bottle per 6 runs

MagMAX™ HT Binding Solution 1 bottle per 6 runs

TaqPath™ COVID-19 Module 1 MS2 Phage Control 2 bottles per 6 runs

Usage

(Reload frequency)

1 reservoir per 6 runs

See

page 6

page 4

MagMAX™ HT Proteinase K 1 bottle per 6 runs

MagMAX™ HT Water 1 bottle per 6 runs

Silicone oil 1 bottle per 6 runs

For In Vitro Diagnostic Use. For Emergency Use Authorization Only | Rx Only

page 6

Workflow

Prepare and load the sample tube runners, ensure that you have all of the required materials, then prepare the Tecan™ Fluent™ 1080

Automation Workstation.

Every 6 runs, ensure that you prepare reagents before they need to be reloaded.

Before each run, confirm that it is time to load Module 1.

To start a run, select the appropriate method for your sample tube size.

Every run, follow the instrument touchscreen prompts to load the reagents and consumables as required.

Module 1 workflow (approximately 1 hour)

Before you begin

Prepare Module 1 reagents

• Thaw TaqPath™ COVID-19 Module 1 MS2 Phage Control (page 4)

• Prepare the Binding Bead Mix (page 4)

View the SampleManager Module 1 Load Indicator

Start the method on the Tecan™ Fluent™ 1080 Automation Workstation

Load the Tecan™ Fluent™ 1080 Automation Workstation deck

• Every run—Binding Bead Mix, Silicone Oil, and KingFisher™ Deep‑Well 96 Plates with Barcodes

• Every 3 runs—1,000 µL FCA Disposable Tips

• Every 6 runs—All reagents and consumables

Load the tube runners in the Tecan™ Fluent™ 1080 Automation Workstation

Every run, load the tube runners containing the sample tubes when prompted by the instrument touchscreen.

Monitor the Module 1 run

During each run, monitor the run progress on the instrument touchscreen.

Transfer sample extraction plates from Module 1 to Module 2

After a run is complete, immediately transfer the 4 Sample Extraction Plates to Module 2.

Unload the tube runners

After transferring the Sample Extraction Plates to Module 2, unload the tube runners when prompted by the instrument touchscreen.

Prepare the Tecan™ Fluent™ 1080 Automation Workstation for the next shift or to be idle

At the end of each shift, empty tip waste and perform daily Tecan™ Fluent™ 1080 Automation Workstation system care.

Before you begin

At the beginning of each shift, complete the following tasks:

• Prepare tube runners (page 3)

• Load sample tubes into tube runners (page 3)

• Ensure that you have all of the required materials to complete the desired number of runs.

• Prepare the Tecan™ Fluent™ 1080 Automation Workstation (page 4)

2 Amplitude

™

Solution with TaqPath™ COVID‑19 High‑Throughput Combo Kit—Module 1 Quick Reference

Prepare tube runners

3

1

2

2

1

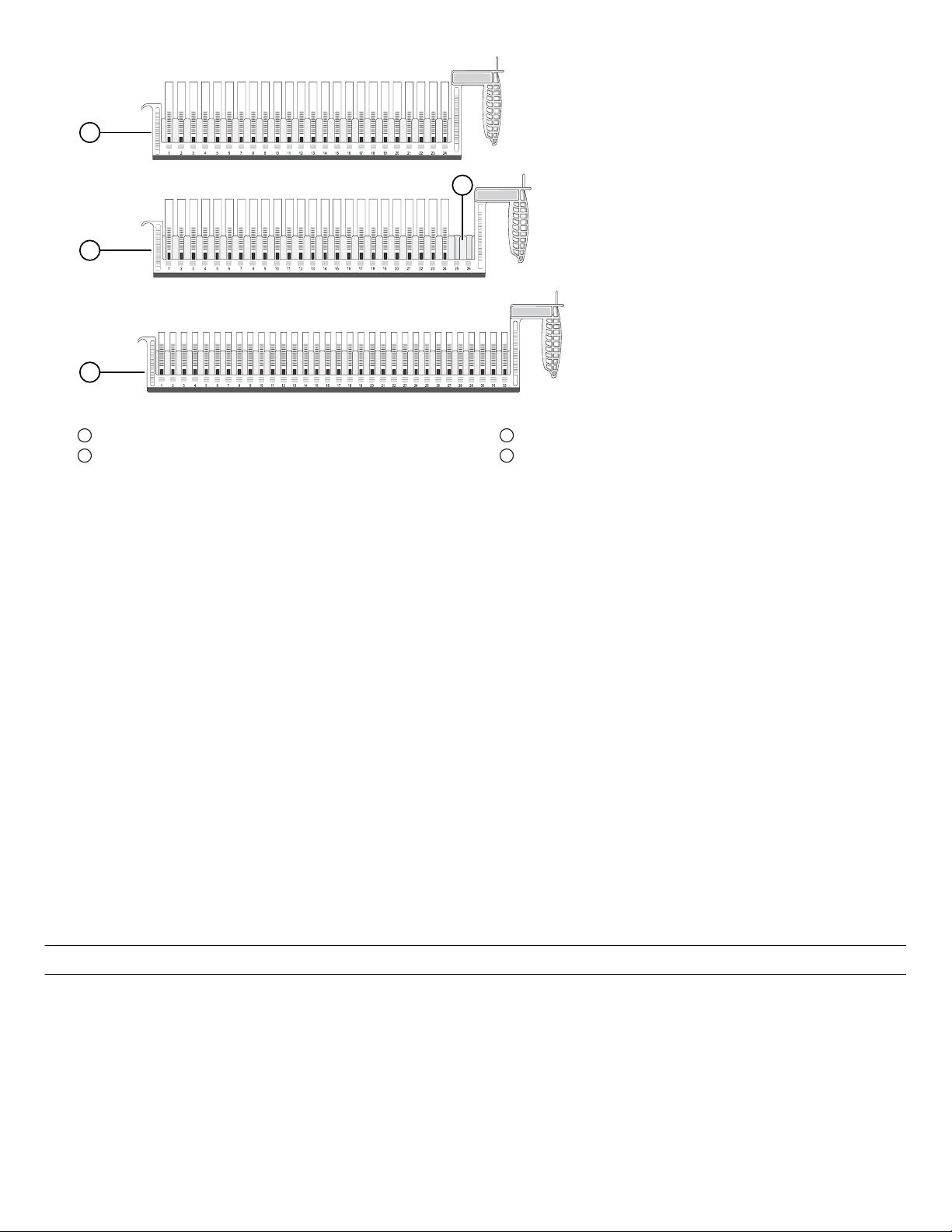

Note: The number of required tube runners and the control positions depend on the size of the sample tubes.

1. Ensure that you have the correct tube runners for your tube size.

Sample tube size Tube runner type Number of tube runners used per run

12–14 mm 13 mm, 32‑position 12

15–17 mm 16 mm, 26‑position 16

16–18 mm 17 mm, 24‑position 16

2. Place plug inserts in position 1 (Negative Control) and position 2 (Positive Control) in four tube runners.

Note: We recommend labeling the tube runners that contain plugs in the control positions so that they are easily identifiable

when loading them on the Tecan™ Fluent™ Automation WorkstationTecan™ Fluent™ 1080 Automation Workstation deck. Control tube

runners must be loaded at specific grid positions on the deck (see “Load the tube runners in the Tecan™ Fluent™ 1080 Automation

Workstation” on page 8).

Figure 1 Plug insert positions in control tube runners

17 mm, 24‑position control tube runner (16–18 mm tubes)—Plugs

1

in positions 1 and 2

16 mm, 26‑position control tube runner (15–17 mm tubes)—Plugs

2

in positions 1, 2, 25, and 26

13 mm, 32‑position control tube runner (12–14 mm tubes)—Plugs

3

in positions 1 and 2

3. Place plug inserts in positions 25 and 26 in all 16 of the 26‑position (15-17 mm tubes) tube runners (including the control tube

runners).

The plug inserts block positions 25 and 26 of the 26‑position (15-17 mm tubes) to prevent insertion of sample tubes.

Figure 2 Plug insert positions in 16 mm, 26‑position tube runners (15–17 mm tubes)

16 mm, 26‑position control tube runner (15–17 mm tubes)—Plugs

1

in positions 1, 2, 25, and 26

16 mm, 26‑position tube runner (15–17 mm tubes)—Plugs in

2

positions 25 and 26

Load sample tubes into tube runners

CAUTION!

the BSL‑2 biological safety cabinet until they are all ready to be loaded into the Tecan™ Fluent™ 1080 Automation Workstation (see

“Load the tube runners in the Tecan™ Fluent™ 1080 Automation Workstation” on page 8).

Handle all samples and controls as if they are capable of transmitting infectious agents. Keep the tube runners in

Before you begin, prepare the tube runners (for more information, see “Prepare tube runners” on page 3).

1. In a BSL‑2 biological safety cabinet, uncap the sample tubes, then discard the caps.

Note: New caps are put on the sample tubes after the Module 1 run is complete.

2. Place the uncapped sample tube into the open positions in the prepared tube runners.

IMPORTANT!

Amplitude™ Solution with TaqPath™ COVID‑19 High‑Throughput Combo Kit—Module 1 Quick Reference 3

Do not place tubes in positions that have a plug insert (see “Prepare tube runners” on page 3).

3. Ensure that the barcode on each sample tube is aligned facing left and that it is visible in the scanning window of the tube runner.

4

2

1

3

Figure 3 Tube runners with sample tube barcodes facing left and visible in the scanning window

17 mm, 24‑position tube runner (16–18 mm tubes)

1

16 mm, 26‑position tube runner (15–17 mm tubes); includes plug

2

inserts in positions 25 and 26

Plug inserts in positions 25 and 26

3

13 mm, 32‑position tube runner (12–14 mm tubes)

4

Prepare the Tecan™ Fluent™ 1080 Automation Workstation

1. Ensure that the Tecan™ Fluent™ 1080 Automation Workstation and computer are powered on.

2. On the Tecan™ Fluent™ 1080 Automation Workstation computer desktop, double‑click the Tecan™ FluentControl™ Software to open.

3. On the Tecan™ Fluent™ 1080 Automation Workstation touchscreen, select a user profile, enter the password, then touch OK.

4. Inspect the RGA gripper fingers for misalignment and damage.

• Ensure that RGA gripper finger screws are not loose. If needed, tighten with the T20 wrench.

• If the RGA gripper fingers are damaged, contact Support.

5. Check the tip waste level, then empty if needed.

Prepare Module 1 reagents

Thaw TaqPath™ COVID-19 Module 1 MS2 Phage Control

Every six runs, thaw 2 bottles of the TaqPath™ COVID-19 Module 1 MS2 Phage Control at room temperature (15°C to 30°C) for up to one

hour.

Prepare the Binding Bead Mix

Every six runs, prepare the Binding Bead Mix.

IMPORTANT!

Use the Binding Bead Mix within 24 hours of preparation.

4 Amplitude

™

Solution with TaqPath™ COVID‑19 High‑Throughput Combo Kit—Module 1 Quick Reference

Loading...

Loading...