Thermo Fisher Scientific Amplitude Quick REFERENCE

QUICK REFERENCE

Amplitude™ Solution with the TaqPath™ COVID‑19

High‑Throughput Combo Kit—Module 2

Module 2—RNA extraction, real‑time RT‑PCR, and analysis of results

Pub. No. MAN0019430 Rev. B.0

Note: For safety and biohazard guidelines, see the “Safety” appendix in the Amplitude™ Solution with the TaqPath™ COVID‑19

High‑Throughput Combo Kit Instructions for Use (Pub. No. MAN0019428). Read the Safety Data Sheets (SDSs) and follow the handling

instructions. Wear appropriate protective eyewear, clothing, and gloves.

Module 2 required sample input, reagents, and consumables

Table 1 Check in—Required sample input

Required sample input

Hotel Input (Position 1, Figure 1 on page 3)

Sample extraction plates from Module 1 4 plates per run page 15

Table 2 Replenish reagents—Required reagents and consumables

Required reagents and consumables

Tecan™ Fluent™ 780 Automation Workstation (Position 2, Figure 1 on page 3)

TaqPath™ COVID-19 HT qPCR Assay 2 tubes per 6 runs

TaqPath™ COVID-19 Control 1 tube per 6 runs

TaqPath™ COVID-19 Module 2 Control Dilution Buer 1 tube per 6 runs

TaqPath™ HT Module 2 1-Step Multiplex Master Mix (No ROX) 2 bottles per 6 runs

MagMAX™ HT Water 1 bottle per 6 runs

1,000 µL Flexible Channel Arm™ (FCA) Disposable Tips Rack 3 racks per 18 runs

200 µL Flexible Channel Arm™ (FCA) Disposable Tips Rack 3 racks per 18 runs

150 µL MultiChannel Arm™ (MCA) Disposable Tips Rack 12 racks per 3 runs

2‑mL mixing tubes 2 per 6 runs

Usage

(Reload frequency)

Usage

(Reload frequency)

See

See

page 13

TaqPath™ HT Module 2 Empty Mixing Tubes (5‑mL) 6 per 6 runs

KingFisher™ Deep‑Well 96 Plate with Barcode

(PCR Reaction Mix working plate)

Multidrop™ Combi Reagent Dispenser × 3 (Positions 6-8, Figure 1 on page 3)

MagMAX™ HT Elution Solution (used with Combi 1) 1 bottle per 18 runs

80% Ethanol (Wash 2, used with Combi 3) 2 bottles per 18 runs

1 per 6 runs

For In Vitro Diagnostic Use. For Emergency Use Authorization Only | Rx Only

page 14MagMAX™ HT Wash Solution (Wash 1, used with Combi 2) 3 bottles per 18 runs

Table 3 Replenish consumables—Required consumables

Required consumables

Usage

(Reload frequency)

See

Tecan™ Fluent™ 780 Automation Workstation (Position 2, Figure 1 on page 3)

MicroAmp™ EnduraPlate™ Optical 384-Well Clear Reaction Plate with Barcode 6 plates per 6 runs page 13

RNA Elution Plate Stackers (Position 3, Figure 1 on page 3)

KingFisher™ Deep‑Well 96 Plate with Barcode (RNA elution plates) 40 plates per 10 runs

page 10

KingFisher™ 96 tip comb for DW magnets (for RNA elution plates) 40 tip combs per 10 runs

Wash Plate Stacker Carousel (Position 5, Figure 1 on page 3)

KingFisher™ Deep‑Well 96 Plates with Barcodes

(wash plates)

80 plates per 10 runs page 10

2 Amplitude

™

Solution with TaqPath™ COVID‑19 High‑Throughput Combo Kit—Module 2 Quick Reference

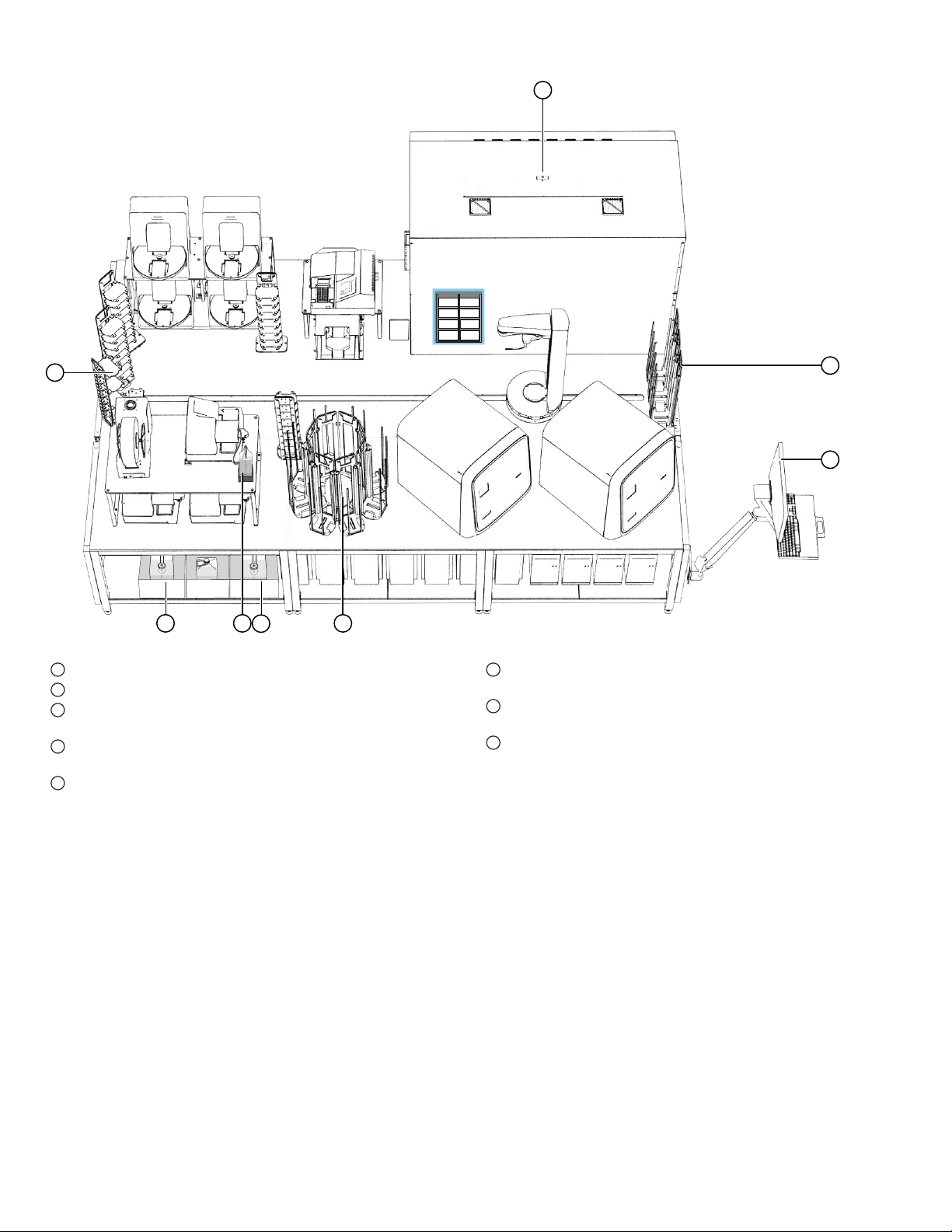

Locations for loading Module 2 incoming samples, reagents, and consumables

2

3

1

4

5

8 7

6

Figure 1 Locations for loading Module 2 incoming samples, reagents, and consumables

Hotel Input for Module 1 sample extraction plates

1

Tecan™ Fluent™ 780 Automation Workstation

2

RNA Elution Plate Stacker × 4—Used to hold prepared RNA

3

elution plates

Module 2 computer station—Used to replenish required materials

4

in the Momentum™ Workflow Scheduler Software

Wash Plate Stacker Carousel—Used to hold wash plates

5

Wash 2 (80% Ethanol) carboy (reagent dispensed by Multidrop

6

Combi Reagent Dispenser 3)

MagMAX™ HT Elution Solution (reagent dispensed by Multidrop

7

Combi Reagent Dispenser 1)

Wash 1 (MagMAX™ HT Wash Solution) carboy (reagent dispensed

8

by Multidrop™ Combi Reagent Dispenser 2)

™

™

Amplitude™ Solution with TaqPath™ COVID‑19 High‑Throughput Combo Kit—Module 2 Quick Reference 3

Module 2 workflow

If Module 2 was just powered on, or is oine, complete the following tasks:

• Initialize each QuantStudio™ 7 Flex Real-Time PCR System (page 5)

• Initialize the Tecan™ Fluent™ 780 Automation Workstation (page 6)

• Open the Momentum™ Software (page 6)

Before you begin each shift, ensure that you have all of the required materials, then prepare the following instruments for use, as

required:

• Inspect the Tecan™ Fluent™ 780 Automation Workstation and A25 Refrigerated Circulator (page 7)

• Engage and prime each Multidrop™ Combi Reagent Dispenser if idle (page 7)

Every 6 runs, ensure that you thaw the Module 2 reagents before they need to be reloaded.

Every 10 runs, prepare 40 RNA Elution Plates before they need to be reloaded. Each run uses 4 plates.

Module 2 workflow ( approximately 2 hours 15 minutes)

Initialize Module 2 if oine

Before you begin—Module 2

Thaw Module 2 reagents

Prepare the RNA elution plates

Reload Module 2 consumables

As needed, replenish consumables in the Momentum™ Software, then reload in the correct location.

• Every 6 uns—RT‑PCR Plates

• Every 10 runs—Wash Plates and RNA Elution Plates

Bring all Module 2 devices online (page 15)

Before every run, ensure that all of the Module 2 devices are online.

Reload Module 2 reagents

As needed, replenish reagents in Momentum™ Software, then reload in the correct location.

• Every 3 runs—150 µL MCA Disposable Tips

• Every 6 runs—RT‑PCR reagents and consumables

• Every 18 runs—200 µL FCA Disposable Tips, 1,000 µL FCA Disposable Tips, and Multidrop™ Combi Reagent Dispenser

reagents

Check in Module 1 sample extraction plates and start a run

To start a run, load the Sample Extraction Plates, then check in using the Momentum™ Software.

Monitor the Module 2 run

During each run, monitor the run progress in the Momentum™ Software.

Unload outgoing RNA elution plates from the Hotel Output

After a run is complete, unload the outgoing RNA Elution plates when prompted in the Momentum™ Software.

Prepare Module 2 for the next shift or to be idle

After every shift, empty system waste and perform regular maintenance as needed.

4 Amplitude

™

Solution with TaqPath™ COVID‑19 High‑Throughput Combo Kit—Module 2 Quick Reference

Module 2 workflow ( approximately 2 hours 15 minutes)

Review results (automated workflow)

Review results, including any sample error messages.

Initialize Module 2 if oine

If Module 2 was just powered on or is oine you must complete the following tasks using the Module 2 computer station:

1. Initialize each QuantStudio™ 7 Flex Real-Time PCR System (page 5)

2. Initialize the Tecan™ Fluent™ 780 Automation Workstation (page 6)

3. Open the Momentum™ Software (page 6)

All of the computers are accessed using the Module 2 computer station. To switch the desktop display to a dierent computer, use the

following keyboard shortcuts:

Desktop to display Shortcut

Momentum™ Software computer, also runs the following software:

• BioTek® Liquid Handling Control Software 2.2

• FILLit™ Software 2.0 for Multidrop™ Combi Reagent Dispensers

• BindIt™ Software 4.0 for KingFisher™ Purification Systems

QuantStudio™ 7 Flex Real-Time PCR System 1 computer Ctrl Ctrl 2

QuantStudio™ 7 Flex Real-Time PCR System 2 computer Ctrl Ctrl 3

Ctrl Ctrl 1

Tecan™ Fluent™ 780 Automation Workstation computer Ctrl Ctrl 4

Note: To use a shortcut, press Ctrl twice in a row, then press the indicated number.

WARNING! Any Tecan

Software, not the Tecan™ Fluent™ 780 Automation Workstation touchscreen.

™

Fluent™ 780 Automation Workstation error messages should be managed through the Momentum

™

Initialize each QuantStudio™ 7 Flex Real-Time PCR System

Each QuantStudio™ 7 Flex Real-Time PCR System must be initialized if Module 2 was just powered on or if the system is oine.

CAUTION! Do not independently operate the instruments via the instrument controls.

1. On the Module 2 computer station, use the Ctrl Ctrl 2 shortcut to open the QuantStudio™ 7 Flex Real-Time PCR System 1 computer

desktop.

2. On the QuantStudio™ 7 Flex Real-Time PCR System 1 desktop, double‑click the QuantStudio™ Real‑Time PCR Software icon.

3. In the QuantStudio™ Real‑Time PCR Software, in the Run pane, click Instrument Console.

4. In the My Instruments pane, confirm that the QuantStudio™ 7 Flex Real-Time PCR System status is READY.

5. Minimize the QuantStudio™ Real‑Time PCR Software window.

IMPORTANT!

6. On the QuantStudio™ 7 Flex Real-Time PCR System 1 desktop, double‑click the shortcut to open the QuantStudio™ server.

The QuantStudio™ server dialog box opens, indicating that the server is communicating with the Momentum™ Software.

7. Use the Ctrl Ctrl 3 shortcut to switch to the QuantStudio™ 7 Flex Real-Time PCR System 2 computer desktop.

8. Repeat step 2 to step 6 for the QuantStudio™ 7 Flex Real-Time PCR System 2.

Amplitude™ Solution with TaqPath™ COVID‑19 High‑Throughput Combo Kit—Module 2 Quick Reference 5

Do not close the QuantStudio™ Real‑Time PCR Software, only minimize it.

Initialize the Tecan™ Fluent™ 780 Automation Workstation

The Tecan™ Fluent™ 780 Automation Workstation must be initialized if Module 2 was just powered on or if the system is oine.

1. On the Module 2 computer station, use the Ctrl Ctrl 4 shortcut to open the Tecan™ Fluent™ 780 Automation Workstation computer

desktop.

2. On the Tecan™ Fluent™ 780 Automation Workstation computer desktop, double‑click the Tecan™ server icon.

The Tecan™ server automatically starts the Tecan™ FluentControl™ Software.

3. Use the Ctrl Ctrl 1 shortcut to switch back to the Momentum™ Workflow Scheduler Software computer desktop view.

Open the Momentum™ Software

If the system was just powered on, complete the following tasks before opening the Momentum™ Software:

• Initialize each QuantStudio™ 7 Flex Real-Time PCR System (page 5)

• Initialize the Tecan™ Fluent™ 780 Automation Workstation (page 6)

1. On the Module 2 computer station, use the Ctrl Ctrl 1 shortcut to open the Momentum™ Software computer desktop.

2. Double‑click the Momentum™ Software icon to open the software.

3. In the Momentum Security dialog box, enter the username and password, then click Login.

IMPORTANT!

If you forget your password or get locked out of the software, contact your laboratory administrator.

4. In the Momentum™ Software home screen, in the Monitor menu pane, click Work Manager Dashboard.

Before you begin—Module 2

At the beginning of each shift, complete the following tasks, if needed:

Task

Ensure that you have all of the required

materials to complete the desired number

of runs (see “Module 2 required sample

input, reagents, and consumables” on

page 1).

Inspect the Tecan™ Fluent™ 780

Automation Workstation and A25

Refrigerated Circulator (page 7)

Engage and prime each Multidrop™ Combi

Reagent Dispenser if idle (page 7)

[1]

The technician is responsible for monitoring the time the instrument is idle.

Perform at the beginning of the day. Perform at the beginning of every shift.

Engage and prime all 3 instruments after powering

on or at the beginning of the day.

Prime the Wash 1 Multidrop™ Combi Reagent

Dispenser if idle for >3 hours.

1 shift per day 3 shifts per day

[1]

Frequency

Engage and prime all 3 instruments after powering

on.

Prime the Wash 1 Multidrop™ Combi Reagent

Dispenser if idle for >3 hours.

[1]

Refresh run count

Under continuous operation, RT‑PCR reagents and consumables need to be replenished every 6 runs in the Tecan™ Fluent™ 780

Automation Workstation. If RT‑PCR reagents and consumables are replenished before the completion of the 6th run, you must perform

the following processes:

• Execute the Refresh Run Count process to reset the run counter to zero and force the Tecan™ Fluent™ 780 Automation Workstation

to dilute the positive control in the next run.

• After the Refresh Run Count process is complete, barcode scan and replenish RT‑PCR reagents and consumables, 150 µL MCA

Disposable Tips, 200 µL FCA Disposable Tips, and 1,000 µL FCA Disposable Tips.

6 Amplitude

™

Solution with TaqPath™ COVID‑19 High‑Throughput Combo Kit—Module 2 Quick Reference

1. In the Momentum™ Software Work Manager Dashboard, click Refresh Run Count, then click OK in the dialog box to begin the

process.

2. Barcode scan and replenish all reagents and consumables on the Tecan™ Fluent™ 780 Automation Workstation deck, including the

following:

• RT‑PCR reagents and consumables

• 150 µL MCA Disposable Tips

• 200 µL FCA Disposable Tips

• 1,000 µL FCA Disposable Tips

3. Ensure that there are 6 RT‑PCR plates present in the hotel on the Tecan™ Fluent™ 780 Automation Workstation deck, then check in

the plates as described in “Replenish consumables in the Momentum™ Software” on page 9.

Inspect the Tecan™ Fluent™ 780 Automation Workstation and A25 Refrigerated Circulator

1. Ensure that the Tecan™ Fluent™ 780 Automation Workstation is powered on and initialized (see “Initialize the Tecan™ Fluent™ 780

Automation Workstation” on page 6).

2. On the Tecan™ Fluent™ 780 Automation Workstation, inspect the RGA gripper fingers for misalignment and damage. If misaligned or

damaged, contact Support.

3. Under the Tecan™ Fluent™ 780 Automation Workstation table, check the tip waste level, then empty if needed.

4. Visually inspect the Tecan™ Fluent™ 780 Automation Workstation chiller tubing and clamps to ensure they are secure and that there

are no leaks.

5. Ensure that the A25 Refrigerated Circulator is powered on and set to 9°C.

WARNING! Failure to set the A25 Refrigerated Circulator to 9°C can result in inaccurate results.

Engage and prime each Multidrop™ Combi Reagent Dispenser if idle

If idle, use this procedure to engage and prime each Multidrop™ Combi Reagent Dispenser (Combi1-Combi3).

Note: The technician is responsible for monitoring the time the instruments are idle.

IMPORTANT! Wash 1 forms bubbles in the Multidrop

must always prime the Wash 1 Multidrop™ Combi Reagent Dispenser (Combi2) if idle for >3 hours.

1. On the Module 2 computer station, use the Ctrl Ctrl 1 shortcut to open the Momentum™ Software computer desktop.

2. In the Momentum™ Software Work Manager Dashboard, confirm that the system is oine.

3. If the system is online, click Device Tasks, then click next to each Multidrop™ Combi Reagent Dispenser (Combi1–Combi3) to

take them oine.

™

Combi long standard tube dispensing cassette tubes if left idle for >3 hours. You

Amplitude™ Solution with TaqPath™ COVID‑19 High‑Throughput Combo Kit—Module 2 Quick Reference 7

Loading...

Loading...