Page 1

Model 48i

Instruction Manual

Gas Filter Correlation CO Analyzer

Part Number 101891-00

18Dec2010

Page 2

© 2007 Thermo Fisher Scientific Inc. All rights reserved.

Specifications, terms and pricing are subject to change. Not all products are available in all countries. Please

consult your local sales representative for details.

Thermo Fisher Scientific

Air Quality Instruments

27 Forge Parkway

Franklin, MA 02038

1-508-520-0430

www.thermo.com/aqi

Page 3

WEEE Compliance

This product is required to comply with the European Union’s Waste

Electrical & Electronic Equipment (WEEE) Directive 2002/96/EC. It is

marked with the following symbol:

Thermo Fisher Scientific has contracted with one or more

recycling/disposal companies in each EU Member State, and this product

should be disposed of or recycled through them. Further information on

Thermo Fisher Scientific’s compliance with these Directives, the recyclers

in your country, and information on Thermo Fisher Scientific products

which may assist the detection of substances subject to the RoHS Directive

are available at: www.thermo.com/WEEERoHS.

Thermo Fisher Scientific WEEE Compliance

Page 4

Page 5

Reference Method Designation

The Thermo Scientific Model 48i is designated by the United States

Environmental Protection Agency (USEPA) as a Reference Method for CO

as set forth in the U.S. Environmental Protection Agency regulations at

Title 40, Part 53 of the U.S. Code of Fereral Regulations.

Designated Reference Method Number: RFCA-0981-054

EPA Designation Date: September 23, 1981 (amended for Model 48i)

The Model 48i CO Analyzer meets EPA reference designation

requirements when operated with the following:

Range 0-1 to 100 ppm

Averaging Time 10 to 300 seconds

Temperature Range 20 to 35 °C

Line Voltage 90 to 110 Vac @50/60 Hertz

105 to 125 Vac @50/60 Hertz

210 to 250 Vac @50/60 Hertz

Pressure Compensation ON or OFF

Temperature Compensation ON or OFF

Flow Rate 0.5 to 2 L/min

RS-232/RS-485 Interface

With or without the following options:

Teflon Particulate Filter

Internal Zero/Span and Sample Valves

Internal Zero Air Scrubber

Rack Mounts

I/O Expansion Board

Thermo Fisher Scientific WEEE Compliance

Page 6

Page 7

About This Manual

This manual provides information about installing, operating, maintaining,

and servicing the Model 48i CO gas analyzer. It also contains important

alerts to ensure safe operation and prevent equipment damage. The manual

is organized into the following chapters and appendices to provide direct

access to specific operation and service information.

● Chapter 1 “Introduction” provides an overview of product features,

describes the principles of operation, and lists the specifications.

● Chapter 2 “Installation” describes how to unpack, setup, and startup

the analyzer.

● Chapter 3 “Operation” describes the front panel display, the front

panel pushbuttons, and the menu-driven firmware.

● Chapter 4 “Calibration” provides the procedures for calibrating the

analyzer and describes the required equipment.

● Chapter 5 “Preventive Maintenance” provides maintenance procedures

to ensure reliable and consistent instrument operation.

● Chapter 6 “Troubleshooting” presents guidelines for diagnosing

analyzer failures, isolating faults, and includes recommended actions for

restoring proper operation.

● Chapter 7 “Servicing” presents safety alerts for technicians working on

the analyzer, step-by-step instructions for repairing and replacing

components, and a replacement parts list. It also includes contact

information for product support and technical information.

● Chapter 8 “System Description” describes the function and location of

the system components, provides an overview of the firmware structure,

and includes a description of the system electronics and input/output

connections.

● Chapter 9 “Optional Equipment” describes the optional equipment

that can be used with this analyzer.

● Appendix A “Warranty” is a copy of the warranty statement.

● Appendix B “C-Link Protocol Commands” provides a description of

the C-Link protocol commands that can be used to remotely control an

analyzer using a host device such as a PC or datalogger.

Thermo Fisher Scientific Model 48i Instruction Manual i

Page 8

About This Manual

Safety

● Appendix C “MODBUS Protocol” provides a description of the

MODBUS Protocol Interface and is supported both over RS-232/485

(RTU protocol) as well as TCP/IP over Ethernet.

● Appendix D “Gesytec (Bayern-Hessen) Protocol” provides a

description of the Gesytec (Bayern-Hessen or BH) Protocol Interface

and is supported both over RS-232/485 as well as TCP/IP over

Ethernet.

Safety

Safety and Equipment

Damage Alerts

Review the following safety information carefully before using the analyzer.

This manual provides specific information on how to operate the analyzer,

however, if the analyzer is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be impaired.

This manual contains important information to alert you to potential safety

hazards and risks of equipment damage. Refer to the following types of

alerts you may see in this manual.

Safety and Equipment Damage Alert Descriptions

Alert Description

DANGER A hazard is present that could result in death or serious

WARNING A hazard or unsafe practice could result in serious

CAUTION A hazard or unsafe practice could result in minor to

personal injury if the warning is ignored.

personal injury if the warning is ignored.

moderate personal injury if the warning is ignored.

▲

▲

▲

Equipment Damage A hazard or unsafe practice could result in property

damage if the warning is ignored.

▲

Safety and Equipment Damage Alerts in this Manual

Alert Description

ii Model 48i Instruction Manual Thermo Fisher Scientific

WARNING The Model 48i is supplied with a three-wire grounded

If the equipment is operated in a manner not specified by

The service procedures in this manual are restricted to

power cord. Under no circumstances should this

grounding system be defeated.

the manufacturer, the protection provided by the

equipment may be impaired.

qualified service personnel only.

▲

▲

▲

Page 9

Alert Description

About This Manual

FCC Compliance

CAUTION If the LCD panel breaks, do not let the liquid crystal

Equipment Damage Do not attempt to lift the analyzer by the cover or other

Disconnect the serial cable before changing RS-232 and

Some internal components can be damaged by small

Do not use solvents or other cleaning products to clean

Do not remove the LCD panel or frame from the LCD

The LCD polarizing plate is very fragile, handle it

Do not wipe the LCD polarizing plate with a dry cloth, as

contact your skin or clothes. If the liquid crystal contacts

your skin or clothes, wash it off immediately using soap

and water.

external fittings.

RS-485 selection to prevent damage to any equipment

currently connected to the analyzer.

amounts of static electricity. A properly grounded

antistatic wrist strap must be worn while handling any

internal component.

the outside case.

module.

carefully.

it may easily scratch the plate.

▲

▲

▲

▲

▲

▲

▲

▲

FCC Compliance

Do not use alcohol, acetone, MEK or other ketone based

or aromatic solvent to clean the LCD module, but rather

use a soft cloth moistened with a naphtha cleaning

solvent.

Do not place the LCD module near organic solvents or

corrosive gases.

Do not shake or jolt the LCD module.

▲

▲

▲

Changes or modifications to this unit not expressly approved by the party

responsible for compliance could void the user’s authority to operate the

equipment.

Note This equipment has been tested and found to comply within the

limits for a Class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference, in

Thermo Fisher Scientific Model 48i Instruction Manual iii

Page 10

About This Manual

W

W

WEEE Symbol

which case the user will be required to correct the interference at his or her

own expense. ▲

EEE Symbol

here to Get Help

The following symbol and description identify the WEEE marking used on

the instrument and in the associated documentation.

Symbol Description

Marking of electrical and electronic equipment which applies to waste

electrical and electronic equipment falling under the Directive 2002/96/EC

(WEEE) and the equipment that has been put on the market after 13 August

2005.

▲

Service is available from exclusive distributors worldwide. Contact one of

the phone numbers below for product support and technical information

or visit us on the web at www.thermo.com/aqi.

1-866-282-0430 Toll Free

1-508-520-0430 International

iv Model 48i Instruction Manual Thermo Fisher Scientific

Page 11

Contents

Contents

Chapter 1

Chapter 2

Chapter 3

Introduction........................................................................................................ 1-1

Principle of Operation ........................................................................ 1-2

Specifications ...................................................................................... 1-3

Installation ......................................................................................................... 2-1

Lifting................................................................................................. 2-1

Unpacking and Inspection .................................................................. 2-1

Setup Procedure.................................................................................. 2-3

Connecting External Devices .............................................................. 2-5

Terminal Board PCB Assemblies...................................................... 2-5

I/O Terminal Board...................................................................... 2-5

D/O Terminal Board.................................................................... 2-7

25-Pin Terminal Board ................................................................. 2-8

Startup................................................................................................ 2-9

Operation............................................................................................................ 3-1

Display................................................................................................ 3-1

Pushbuttons........................................................................................ 3-2

Soft Keys.......................................................................................... 3-3

Alphanumeric Entry Screen ............................................................. 3-4

Firmware Overview............................................................................. 3-4

Power-Up Screen ............................................................................. 3-6

Run Screen....................................................................................... 3-6

Custom Run Screens..................................................................... 3-7

Main Menu...................................................................................... 3-8

Range Menu ....................................................................................... 3-8

Single Range Mode .......................................................................... 3-9

Dual Range Mode.......................................................................... 3-10

Auto Range Mode.......................................................................... 3-11

Gas Units....................................................................................... 3-13

CO Range...................................................................................... 3-14

Set Custom Ranges ........................................................................ 3-15

Custom Ranges........................................................................... 3-15

Averaging Time................................................................................. 3-16

Calibration Factors Menu ................................................................. 3-16

CO Background............................................................................. 3-17

CO Coefficient .............................................................................. 3-18

Background .............................................................................. 3-18

O

2

O

Coefficient................................................................................ 3-19

2

Thermo Fisher Scientific Model 48i Instruction Manual v

Page 12

Contents

Reset User Calibration Defaults ..................................................... 3-20

Calibration Menu ............................................................................. 3-20

Calibrate CO Background.............................................................. 3-21

Calibrate CO Coefficient ............................................................... 3-21

Zero/Span Check ........................................................................... 3-22

Next Time .................................................................................. 3-22

Period Hours............................................................................... 3-23

Total Duration Hour .................................................................. 3-23

Zero/Span/Purge Duration Minutes ........................................... 3-23

Zero/Span Averaging Time ......................................................... 3-24

Zero/Span Calibration Reset ....................................................... 3-24

Zero/Span Ratio.......................................................................... 3-24

Calibrate O

Calibrate O

Background ............................................................... 3-25

2

Coefficient................................................................. 3-25

2

Instrument Controls Menu ............................................................... 3-25

Datalogging Settings ...................................................................... 3-26

Select Srec/Lrec ........................................................................... 3-27

View Logged Data....................................................................... 3-27

Number of Records..................................................................... 3-27

Date and Time............................................................................ 3-28

Erase Log .................................................................................... 3-29

Select Content............................................................................. 3-29

Choose Field Data....................................................................... 3-29

Concentrations............................................................................ 3-30

Corrected Concentrations ........................................................... 3-30

Other Measurements................................................................... 3-31

Analog Inputs.............................................................................. 3-31

Commit Content ........................................................................ 3-32

Reset to Default Content ............................................................ 3-32

Configure Datalogging................................................................ 3-33

Logging Period Min.................................................................... 3-33

Memory Allocation Percent......................................................... 3-33

Data Treatment .......................................................................... 3-34

Flag Status Data .......................................................................... 3-34

Communication Settings................................................................ 3-35

Serial Settings.............................................................................. 3-35

Baud Rate ................................................................................... 3-35

Data Bits..................................................................................... 3-36

Parity .......................................................................................... 3-36

Stop Bits ..................................................................................... 3-36

RS-232/RS-485 Selection............................................................ 3-37

Instrument ID............................................................................. 3-37

Gesytec Serial No........................................................................ 3-38

Communication Protocol............................................................ 3-38

Streaming Data Configuration .................................................... 3-39

Streaming Data Interval .............................................................. 3-40

vi Model 48i Instruction Manual Thermo Fisher Scientific

Page 13

Contents

Add Labels .................................................................................. 3-40

Prepend Timestamp.................................................................... 3-40

Add Flags.................................................................................... 3-40

Choose Stream Data Item ........................................................... 3-41

Concentrations............................................................................ 3-41

Corrected Concentrations ........................................................... 3-41

Other Measurements................................................................... 3-42

Analog Inputs ............................................................................. 3-42

TCP/IP Settings.......................................................................... 3-43

Use DHCP ................................................................................. 3-43

IP Address................................................................................... 3-44

Netmask ..................................................................................... 3-44

Default Gateway ......................................................................... 3-44

Host Name ................................................................................. 3-45

Network Time Protocol Server.................................................... 3-45

I/O Configuration ......................................................................... 3-45

Output Relay Settings................................................................. 3-46

Logic State .................................................................................. 3-46

Instrument State ......................................................................... 3-47

Alarms......................................................................................... 3-47

Non-Alarm ................................................................................. 3-48

Digital Input Settings.................................................................. 3-48

Logic State .................................................................................. 3-49

Instrument Action....................................................................... 3-49

Analog Output Configuration (Select Channel).......................... 3-49

Allow Over/Under Range............................................................ 3-50

Analog Output Configuration (Select Action)............................. 3-50

Select Range................................................................................ 3-51

Minimum and Maximum Value ................................................. 3-51

Choose Signal to Output ............................................................ 3-52

Analog Input Configuration........................................................ 3-54

Descriptor................................................................................... 3-54

Units........................................................................................... 3-55

Decimal Places ............................................................................ 3-55

Number of Table Points ............................................................. 3-55

Table Point ................................................................................. 3-56

Volts ........................................................................................... 3-56

User Value .................................................................................. 3-57

Temperature Compensation .......................................................... 3-57

Pressure Compensation.................................................................. 3-58

O

Compensation .......................................................................... 3-58

2

Screen Contrast.............................................................................. 3-59

Service Mode ................................................................................. 3-59

Date/Time ..................................................................................... 3-60

Timezone....................................................................................... 3-60

Diagnostics Menu............................................................................. 3-61

Thermo Fisher Scientific Model 48i Instruction Manual vii

Page 14

Contents

Program Versions........................................................................... 3-61

Voltages ......................................................................................... 3-62

Motherboard Voltages................................................................. 3-62

Interface Board Voltages ............................................................. 3-62

I/O Board Voltages ..................................................................... 3-63

Temperatures ................................................................................. 3-63

Pressure.......................................................................................... 3-63

Flow............................................................................................... 3-64

Sample/Reference Ratio ................................................................. 3-64

AGC Intensity................................................................................ 3-64

Motor Speed .................................................................................. 3-65

O

Sensor Readings........................................................................ 3-65

2

Analog Input Readings................................................................... 3-65

Analog Input Voltages.................................................................... 3-66

Digital Inputs................................................................................. 3-66

Relay States .................................................................................... 3-66

Test Analog Outputs...................................................................... 3-67

Set Analog Outputs..................................................................... 3-67

Instrument Configuration.............................................................. 3-67

Contact Information ...................................................................... 3-68

Alarms Menu .................................................................................... 3-68

Internal Temperature ..................................................................... 3-69

Min and Max Internal Temperature Limits................................. 3-69

Bench Temperature........................................................................ 3-70

Min and Max Bench Temperature Limits ................................... 3-70

Pressure.......................................................................................... 3-70

Min and Max Pressure Limits ..................................................... 3-71

Sample Flow .................................................................................. 3-71

Min and Max Sample Flow Limits .............................................. 3-72

Bias Voltage ................................................................................... 3-72

Min and Max Bias Voltage Limits............................................... 3-72

AGC Intensity................................................................................ 3-73

Min and Max AGC Intensity Limits ........................................... 3-73

Motor Speed .................................................................................. 3-73

Zero and Span Check..................................................................... 3-74

Max Zero and Span Offset .......................................................... 3-74

Zero and Span Auto Calibration ....................................................3-74

Concentration................................................................................ 3-75

Min and Max Concentration Limits ........................................... 3-75

Min Trigger Concentration......................................................... 3-76

O

Concentration........................................................................... 3-76

2

Min and Max O

Concentration Limits ...................................... 3-76

2

Min Trigger ................................................................................ 3-77

External Alarms.............................................................................. 3-77

Service Menu .................................................................................... 3-78

Range Mode Select......................................................................... 3-78

viii Model 48i Instruction Manual Thermo Fisher Scientific

Page 15

Contents

Pressure Calibration ....................................................................... 3-79

Calibrate Pressure Zero ............................................................... 3-79

Calibrate Pressure Span............................................................... 3-80

Restore Default Pressure Calibration........................................... 3-80

Flow Calibration ............................................................................ 3-81

Calibrate Flow Zero .................................................................... 3-81

Calibrate Flow Span.................................................................... 3-81

Restore Default Flow Calibration................................................ 3-82

Initial Sample/Reference Ratio....................................................... 3-82

Multi-Point Calibration ................................................................. 3-83

Calibrate Point 1/2/3 .................................................................. 3-83

Coefficients................................................................................. 3-84

Default Coefficients .................................................................... 3-84

Preamp Board Calibration ............................................................. 3-84

Temperature Calibration................................................................ 3-85

Analog Output Calibration ............................................................ 3-85

Analog Output Calibrate Zero .................................................... 3-86

Analog Output Calibrate Full-Scale ............................................ 3-86

Analog Input Calibration ............................................................... 3-87

Analog Input Calibrate Zero ....................................................... 3-87

Analog Input Calibrate Full-Scale ............................................... 3-88

O

Correction Concentration......................................................... 3-88

2

Dilution Ratio................................................................................ 3-89

Setup Run Screens ......................................................................... 3-89

Edit Run Screen.......................................................................... 3-90

Edit Title .................................................................................... 3-90

Enabled....................................................................................... 3-90

Number of Items ........................................................................ 3-91

Select Run Screen Item ............................................................... 3-91

Concentrations............................................................................ 3-92

Corrected Concentrations ........................................................... 3-92

Other Measurements................................................................... 3-93

Analog Inputs ............................................................................. 3-93

Display Pixel Test .......................................................................... 3-93

Restore User Defaults..................................................................... 3-94

Password ........................................................................................... 3-94

Set Password .................................................................................. 3-95

Lock Instrument ............................................................................ 3-95

Lock/Unlock and Local/Remote Operation ................................ 3-95

Change Password ........................................................................... 3-96

Remove Password .......................................................................... 3-96

Unlock Instrument ........................................................................ 3-96

Chapter 4

Calibration.......................................................................................................... 4-1

Equipment Required........................................................................... 4-1

CO Concentration Standard............................................................ 4-1

Thermo Fisher Scientific Model 48i Instruction Manual ix

Page 16

Contents

Zero Air Generator........................................................................... 4-1

Compression ................................................................................. 4-2

Drying .......................................................................................... 4-2

Scrubbing...................................................................................... 4-2

Flow Meter(s) and Controller(s)....................................................... 4-2

Pressure Regulator for CO Standard Cylinder.................................. 4-2

Mixing Chamber.............................................................................. 4-3

Output Manifold ............................................................................. 4-3

Pre-Calibration ................................................................................... 4-3

Calibration.......................................................................................... 4-3

Connect the Instrument................................................................... 4-3

Zero Adjust...................................................................................... 4-4

Span Adjust...................................................................................... 4-5

Calibration Frequency...................................................................... 4-6

Periodic Zero and Span Checks........................................................... 4-6

HI and LO Multi-Point Calibration ................................................... 4-7

Default Coefficients ......................................................................... 4-7

Cal Point 1, 2, and 3 Adjust............................................................. 4-7

References ........................................................................................... 4-9

Chapter 5

Chapter 6

Preventive Maintenance .................................................................................5-1

Safety Precautions ............................................................................... 5-1

Replacement Parts............................................................................... 5-2

Cleaning the Outside Case.................................................................. 5-2

Cleaning the Optics ............................................................................ 5-2

IR Source Replacement ....................................................................... 5-3

Fan Filter Inspection and Cleaning ..................................................... 5-3

Leak Test and Pump Check Out......................................................... 5-4

External Leaks.................................................................................. 5-4

Leaks Across the Optional Zero/Span and Sample Solenoid Valves.. 5-5

Pump Rebuilding................................................................................ 5-5

Disassembly .................................................................................. 5-5

Assembly with New Diaphragm and Valve.................................... 5-8

Troubleshooting.................................................................................................6-1

Safety Precautions ............................................................................... 6-1

Troubleshooting Guides...................................................................... 6-1

Board-Level Connection Diagrams ..................................................... 6-5

Connector Pin Descriptions................................................................ 6-7

Service Locations............................................................................... 6-20

Chapter 7

Servicing.............................................................................................................7-1

Safety Precautions ............................................................................... 7-3

Firmware Updates............................................................................... 7-4

Accessing the Service Mode................................................................. 7-4

x Model 48i Instruction Manual Thermo Fisher Scientific

Page 17

Contents

Replacement Parts List........................................................................ 7-4

Cable List............................................................................................ 7-6

External Device Connection Components .......................................... 7-6

Removing the Measurement Case Assembly and Lowering the Partition

Panel................................................................................................... 7-8

Fuse Replacement ............................................................................... 7-9

Fan/Filter Replacement..................................................................... 7-10

IR Source Replacement..................................................................... 7-11

Filter Wheel Replacement ................................................................. 7-12

Chopper Motor Replacement............................................................ 7-14

Optical Bench Replacement.............................................................. 7-15

Optical Switch Replacement ............................................................. 7-16

Bench Heater Assembly Replacement ............................................... 7-17

Detector/Preamplifier Assembly Replacement................................... 7-18

Preamp Board Calibration ................................................................ 7-20

Pump Replacement........................................................................... 7-20

Pressure Transducer Replacement ..................................................... 7-21

Pressure Transducer Calibration........................................................ 7-22

Flow Transducer Replacement .......................................................... 7-24

Flow Transducer Calibration ............................................................ 7-25

Capillary Cleaning or Replacement................................................... 7-26

Optional Zero/Span and Sample Solenoid Valve Replacement.......... 7-27

Analog Output Testing ..................................................................... 7-28

Analog Output Calibration ............................................................... 7-30

Analog Input Calibration .................................................................. 7-31

Calibrating the Input Channels to Zero Volts ................................ 7-31

Calibrating the Input Channels to Full-Scale ................................. 7-32

Ambient Temperature Calibration .................................................... 7-33

I/O Expansion Board (Optional) Replacement ................................. 7-34

Internal O

Sensor (Optional) Replacement...................................... 7-36

2

Digital Output Board Replacement .................................................. 7-36

Motherboard Replacement................................................................ 7-37

Measurement Interface Board Replacement ...................................... 7-38

Front Panel Board Replacement........................................................ 7-39

LCD Module Replacement............................................................... 7-40

Service Locations............................................................................... 7-41

Chapter 8

System Description ..........................................................................................8-1

Hardware ............................................................................................ 8-1

Optical Bench.................................................................................. 8-2

Band-pass Filter ............................................................................... 8-2

Bench Heater Board......................................................................... 8-2

Chopper Motor................................................................................ 8-2

Optical Pickup................................................................................. 8-3

Gas Filter Wheel .............................................................................. 8-3

Infrared Source ................................................................................ 8-3

Thermo Fisher Scientific Model 48i Instruction Manual xi

Page 18

Contents

Pre-amplifier Assembly with IR Detector ......................................... 8-3

Sample Flow Sensor ......................................................................... 8-3

Pressure Transducer ......................................................................... 8-3

Capillary .......................................................................................... 8-3

Pump ............................................................................................... 8-3

Purge Flow Switch (optional)........................................................... 8-3

Firmware............................................................................................. 8-3

Instrument Control.......................................................................... 8-4

Monitoring Signals........................................................................... 8-4

Output Communication .................................................................. 8-4

Electronics .......................................................................................... 8-5

Motherboard.................................................................................... 8-5

Measurement Interface Board .......................................................... 8-6

Measurement Interface Board Connectors..................................... 8-6

Flow Sensor Assembly ...................................................................... 8-6

Pressure Sensor Assembly ................................................................. 8-6

Bench Heater Board......................................................................... 8-7

Pre-amp Board Assembly ................................................................. 8-7

Digital Output Board....................................................................... 8-7

I/O Expansion Board (Optional) ..................................................... 8-7

Front Panel Connector Board .......................................................... 8-7

I/O Components................................................................................. 8-8

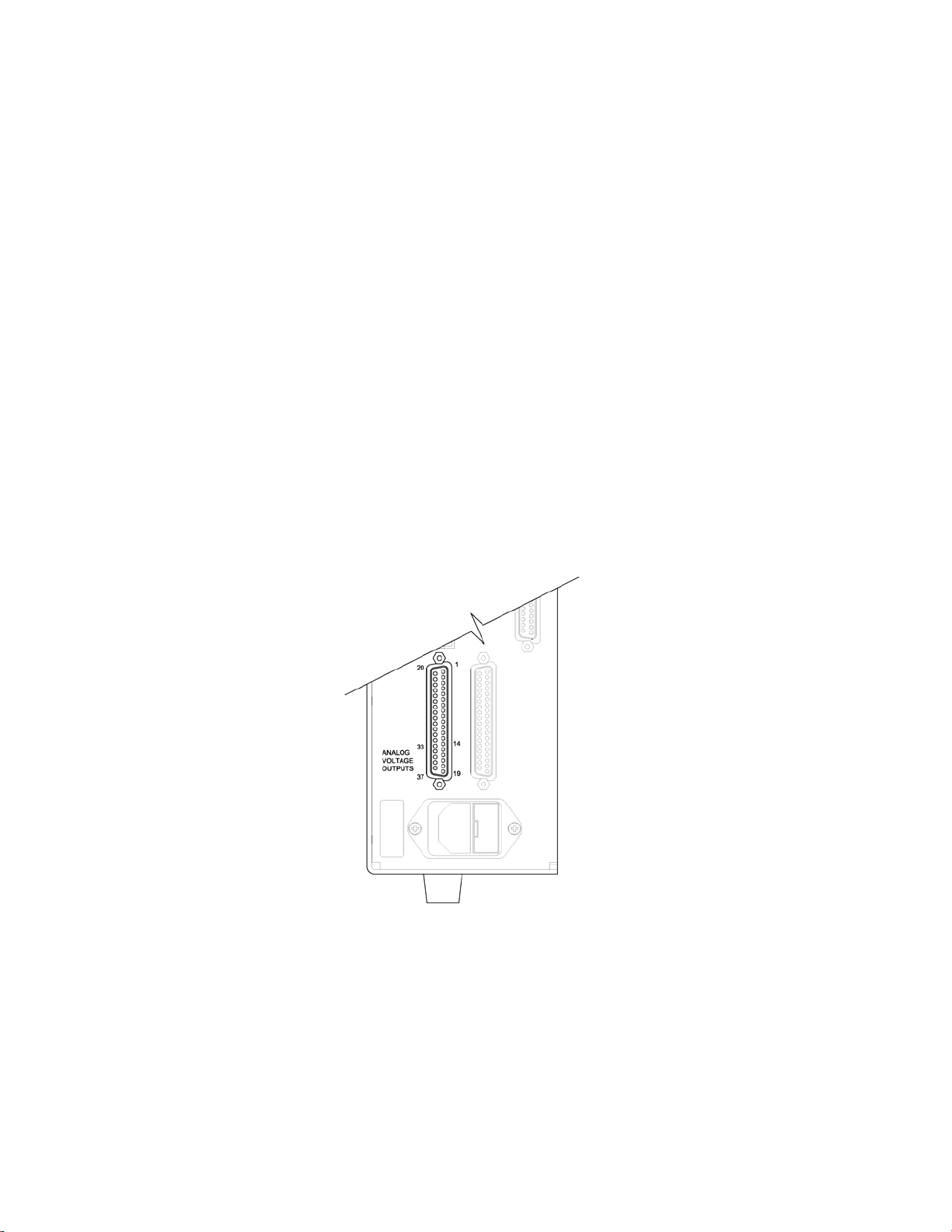

Analog Voltage Outputs................................................................... 8-8

Analog Current Outputs (Optional) ................................................ 8-8

Analog Voltage Inputs (Optional) .................................................... 8-9

Digital Relay Outputs ...................................................................... 8-9

Digital Inputs................................................................................... 8-9

Serial Ports ..................................................................................... 8-10

RS-232 Connection ....................................................................... 8-10

RS-485 Connection ....................................................................... 8-11

Ethernet Connection...................................................................... 8-11

External Accessory Connector ........................................................ 8-11

Chapter 9

Optional Equipment...........................................................................................9-1

Internal Zero/Span Assembly .............................................................. 9-1

Internal Oxygen (O

Internal O

Sensor Calibration ......................................................... 9-2

2

) Sensor............................................................... 9-1

2

Alternate Sensor Calibration ............................................................ 9-3

Internal Zero Air Scrubber .................................................................. 9-4

Filter Wheel Purge .............................................................................. 9-4

Calibration Note.............................................................................. 9-5

Teflon Particulate Filter ...................................................................... 9-5

I/O Expansion Board Assembly........................................................... 9-5

25-Pin Terminal Board Assembly..................................................... 9-5

Terminal Block and Cable Kits ........................................................... 9-5

Cables ................................................................................................. 9-6

xii Model 48i Instruction Manual Thermo Fisher Scientific

Page 19

Contents

Mounting Options.............................................................................. 9-7

Appendix A

Appendix B

Warranty.............................................................................................................A-1

C-Link Protocol Commands ............................................................................B-1

Instrument Identification Number......................................................B-1

Commands .........................................................................................B-2

Entering Units in PPB .....................................................................B-3

Convert Concentration Formats ......................................................B-3

Commands List................................................................................B-3

Measurements...................................................................................B-10

Alarms...............................................................................................B-14

Diagnostics .......................................................................................B-18

Datalogging ......................................................................................B-19

Calibration........................................................................................B-26

Keys/Display.....................................................................................B-33

Measurement Configuration .............................................................B-35

Hardware Configuration...................................................................B-38

Communications Configuration .......................................................B-40

I/O Configuration ............................................................................B-48

Record Layout Definition .................................................................B-53

Format Specifier for ASCII Responses............................................B-54

Format Specifier for Binary Responses ...........................................B-54

Format Specifier for Erec Layout.................................................... B-54

Text ............................................................................................B-55

Value String ................................................................................ B-55

Value Source............................................................................... B-55

Alarm Information......................................................................B-55

Translation Table........................................................................ B-56

Selection Table............................................................................B-56

Button Designator ......................................................................B-56

Examples..................................................................................... B-57

Appendix C

MODBUS Protocol ............................................................................................C-1

Serial Communication Parameters ......................................................C-1

TCP Communication Parameters .......................................................C-2

Application Data Unit Definition .......................................................C-2

Slave Address ...................................................................................C-2

MBAP Header .................................................................................C-2

Function Code.................................................................................C-3

Data.................................................................................................C-3

Error Check .....................................................................................C-3

Function Codes...................................................................................C-3

(0x01/0x02) Read Coils/Read Inputs ...............................................C-3

(0x03/0x04) Read Holding Registers/Read Input Registers..............C-5

Thermo Fisher Scientific Model 48i Instruction Manual xiii

Page 20

Contents

(0x05) Force (Write) Single Coil..................................................... C-7

MODBUS Parameters Supported ...................................................... C-8

Reading a Write Coil .................................................................... C-12

Appendix D

Gesytec (Bayern-Hessen) Protocol ..............................................................D-1

Serial Communication Parameters .....................................................D-1

TCP Communication Parameters ...................................................... D-2

Instrument Address ............................................................................ D-2

Abbreviations Used ............................................................................ D-2

Basic Command Structure ................................................................. D-2

Block Checksum Characters <BCC>..................................................D-3

Gesytec Commands ...........................................................................D-3

Instrument Control Command (ST)............................................... D-3

Data Sampling/Data Query Command (DA).................................. D-4

Measurements reported in response to DA command .....................D-7

Single Range Mode ...................................................................... D-7

Dual/Auto Range Mode............................................................... D-7

Operating and Error Status ............................................................. D-7

xiv Model 48i Instruction Manual Thermo Fisher Scientific

Page 21

Figures

Figure 1–1. Model 48i Flow Schematic ............................................................. 1-3

Figure 2–1. Remove the Packing Material ......................................................... 2-2

Figure 2–2. Removing the Shipping Screws ...................................................... 2-2

Figure 2–3. Model 48i Rear Panel...................................................................... 2-4

Figure 2–4. Atmospheric Dump Bypass Plumbing ............................................. 2-4

Figure 2–5. I/O Terminal Board Views ............................................................... 2-6

Figure 2–6. D/O Terminal Board Views.............................................................. 2-7

Figure 2–7. 25-Pin Terminal Board Views.......................................................... 2-8

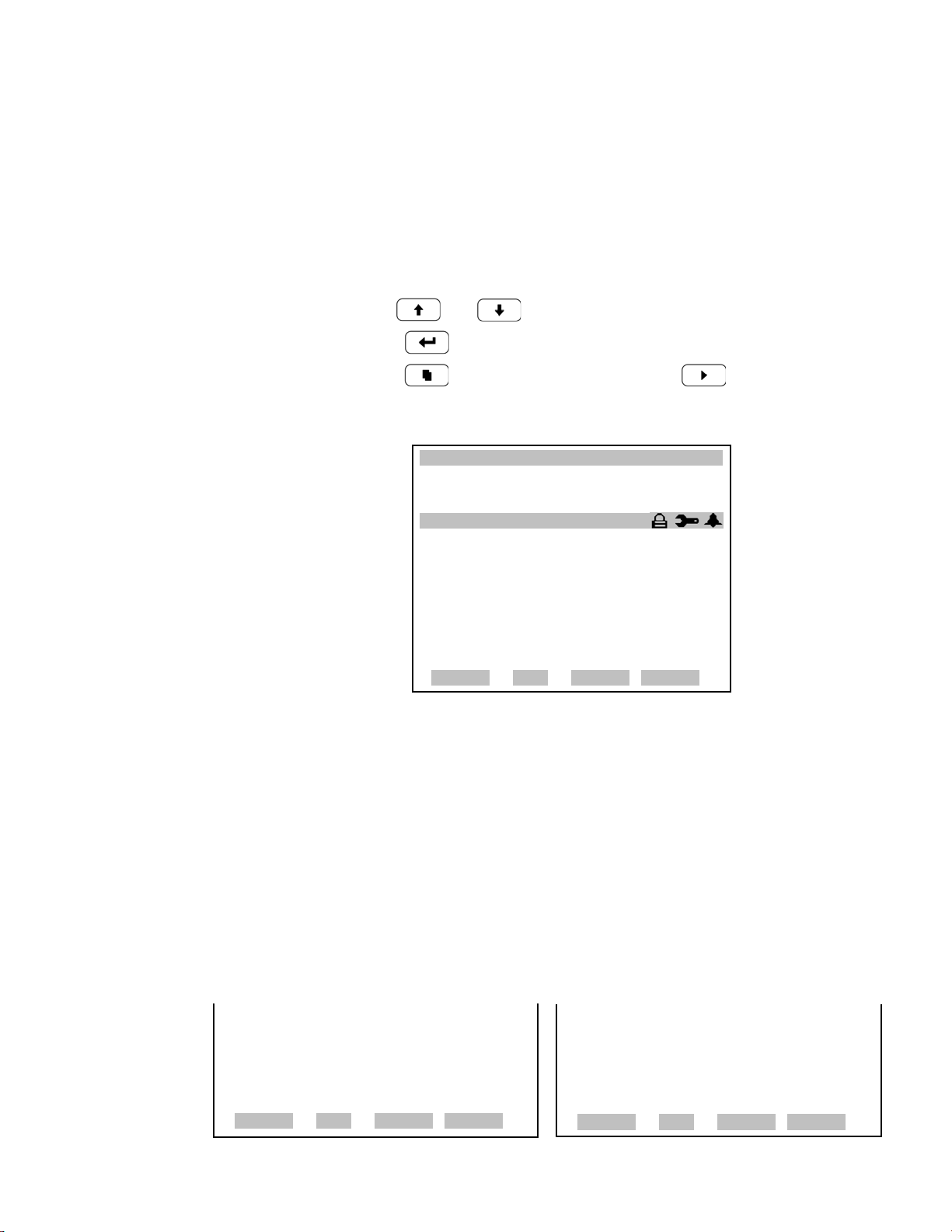

Figure 3–1. Front Panel Display.......................................................................... 3-2

Figure 3–2. Front Panel Pushbuttons.................................................................. 3-2

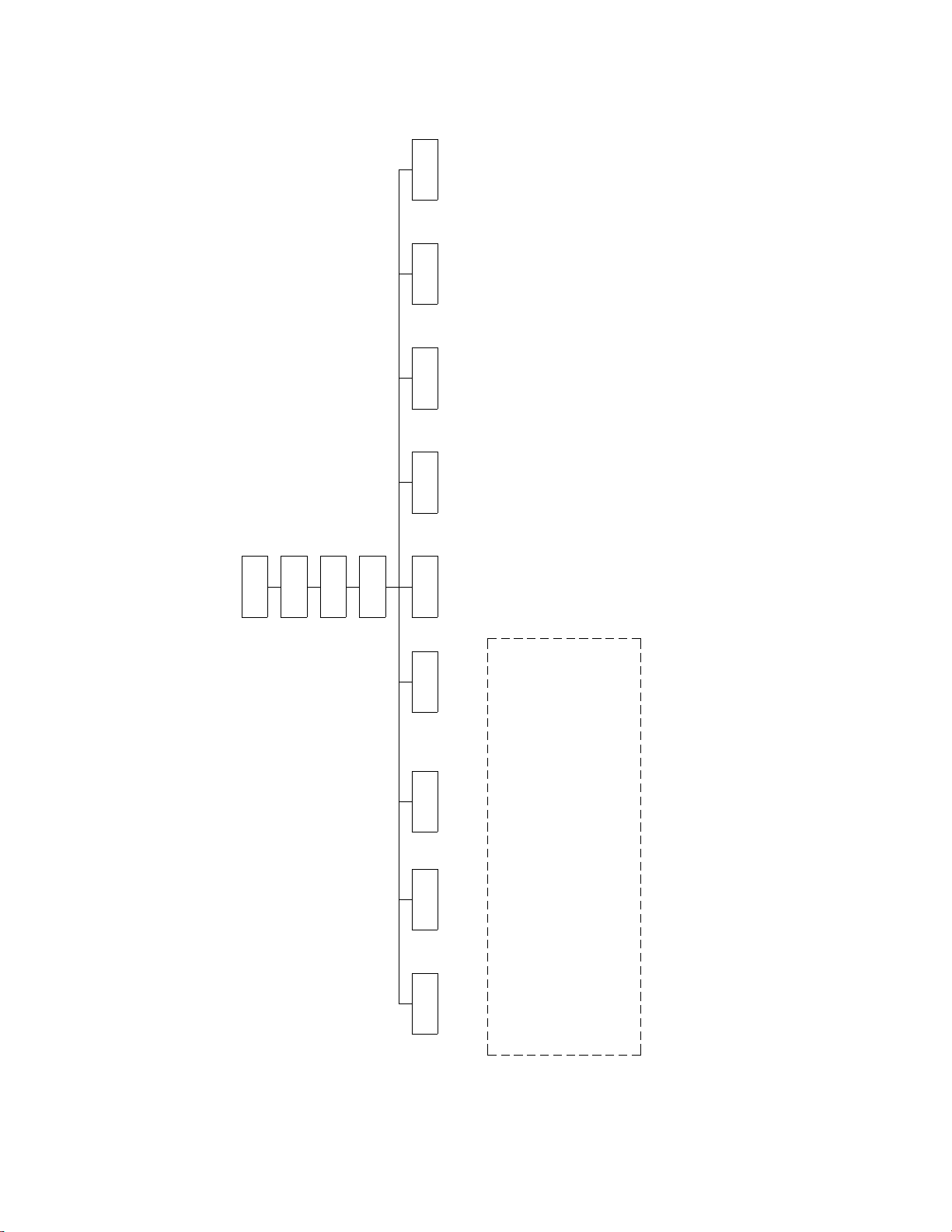

Figure 3–3. Flowchart of Menu-Driven Firmware.............................................. 3-5

Figure 3–4. Pin-Out of Rear Panel Connector in Single Range Mode ............... 3-9

Figure 3–5. Pin-Out of Rear Panel Connector in Dual Range Mode................ 3-10

Figure 3–6. Analog Output in Auto Range Mode............................................. 3-12

Figure 3–7. Pin-Out of Rear Connector in Auto Range Mode.......................... 3-12

Figure 4–1. Calibration Flow Schematic ............................................................ 4-4

Figure 5–1. Inspecting and Cleaning the Fan..................................................... 5-4

Figure 5–2. Rebuilding the Pump (New Technology)......................................... 5-7

Figure 5–3. Rebuilding the Pump........................................................................ 5-9

Figure 6–1. Board-Level Connection Diagram - Common Electronics............... 6-5

Figure 6–2. Board-Level Connection Diagram - Measurement System ............ 6-6

Figure 7–1. Properly Grounded Antistatic Wrist Strap ...................................... 7-4

Figure 7–2. Component Layout........................................................................... 7-7

Figure 7–3. Removing the Measurement Case Assembly and Lowering the

Partition Panel ...................................................................................................... 7-8

Figure 7–4. Replacing the Fan .......................................................................... 7-11

Figure 7–5. Replacing the IR Source ................................................................ 7-12

Figure 7–6. Removing the Motor...................................................................... 7-13

Figure 7–7. Replacing the Optical Bench ......................................................... 7-16

Figure 7–8. Replacing the Optical Switch (Inverted View) .............................. 7-17

Figure 7–9. Replacing the Detector/Preamplifier Assembly ........................... 7-19

Figure 7–10. Replacing the Pump..................................................................... 7-21

Figure 7–11. Replacing the Pressure Transducer............................................. 7-22

Figure 7–12. Replacing the Flow Transducer................................................... 7-25

Figure 7–13. Cleaning or Replacing the Capillary............................................ 7-27

Figure 7–14. Rear Panel Analog Input and Output Pins................................... 7-29

Thermo Fisher Scientific Model 48i Instruction Manual xv

Page 22

Figures

Figure 7–15. Replacing the I/O Expansion Board (Optional)............................ 7-35

Figure 7–16. Rear Panel Board Connectors...................................................... 7-35

Figure 7–17. Replacing the Measurement Interface Board.............................7-39

Figure 7–18. Replacing the Front Panel Board and the LCD Module............... 7-40

Figure 8–1. Hardware Components .................................................................... 8-2

Figure 9–1. Flow Diagram, Internal O

Sensor ...................................................9-2

2

Figure 9–2. Purge Housing Assembly ................................................................. 9-4

Figure 9–3. Rack Mount Option Assembly .........................................................9-8

Figure 9–4. Bench Mounting............................................................................... 9-9

Figure 9–5. EIA Rack Mounting ........................................................................9-10

Figure 9–6. Retrofit Rack Mounting..................................................................9-11

Figure B–1. Flags Field......................................................................................B-13

xvi Model 48i Instruction Manual Thermo Fisher Scientific

Page 23

Tables

Table 1–1. Model 48i Specifications ................................................................. 1-3

Table 1–2. Model 48i Optional Internal Oxygen Sensor Specifications ........... 1-4

Table 2–1. I/O Terminal Board Pin Descriptions ................................................ 2-6

Table 2–2. D/O Terminal Board Pin Descriptions............................................... 2-7

Table 2–3. 25-Pin Terminal Board Pin Descriptions........................................... 2-8

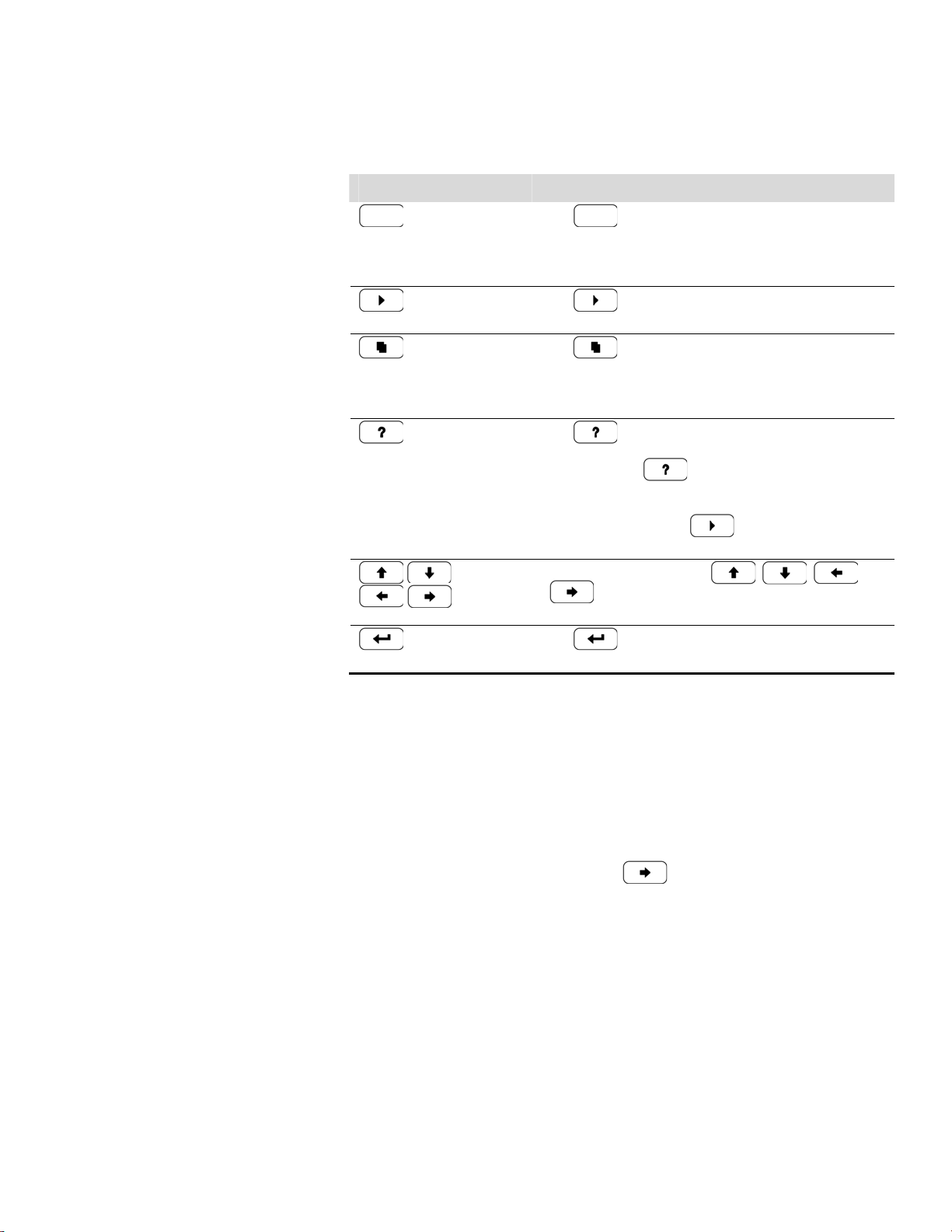

Table 3–1. Front Panel Pushbuttons................................................................... 3-3

Table 3–2. Default Analog Outputs in Single Range Mode............................... 3-9

Table 3–3. Default Analog Outputs in Dual Range Mode ............................... 3-11

Table 3–4. Default Analog Outputs in Auto Range Mode ............................... 3-13

Table 3–5. Available Operating Ranges........................................................... 3-14

Table 3–6. Analog Output Zero to Full-Scale Table......................................... 3-52

Table 3–7. Signal Type Group Choices............................................................. 3-53

Table 6–1. Troubleshooting - General Guide ..................................................... 6-2

Table 6–2. Troubleshooting - Alarm Messages ................................................. 6-3

Table 6–3. Motherboard Connector Pin Descriptions........................................ 6-7

Table 6–4. Measurement Interface Board Connector Pin Descriptions .......... 6-12

Table 6–5. Front Panel Board Connector Pin Diagram..................................... 6-14

Table 6–6. I/O Expansion Board (Optional) Connector Pin Descriptions ......... 6-16

Table 6–7. Digital Output Board Connector Pin Descriptions.......................... 6-17

Table 6–8. Pre-amp Board Connector Pin Descriptions ................................... 6-19

Table 7–1. Model 48i Replacement Parts.......................................................... 7-4

Table 7–2. Model 48i Cables.............................................................................. 7-6

Table 7–3. External Device Connection Components ........................................ 7-6

Table 7–4. Analog Output Channels and Rear Panel Pin Connections............ 7-30

Table 7–5. Analog Input Channels and Rear Panel Pin Connections............... 7-30

Table 8–1. RS-232 DB9 Connector Pin Configuration...................................... 8-10

Table 8–2. RS-485 DB9 Connector Pin Configuration...................................... 8-11

Table 9–1. Cable Options.................................................................................... 9-6

Table 9–2. Color Codes for 25-Pin and 37-Pin Cables ....................................... 9-6

Table 9–3. Mounting Options ............................................................................. 9-7

Table B–1. Command Response Error Descriptions ..........................................B-3

Table B–2. C-Link Protocol Commands ..............................................................B-3

Table B–3. Averaging Times ............................................................................B-10

Table B–4. Alarm Trigger Values .....................................................................B-18

Table B–5. Record Output Formats ..................................................................B-23

Thermo Fisher Scientific Model 48i Instruction Manual xvii

Page 24

Tables

Table B–6. Stream Time Values .......................................................................B-26

Table B–7. Standard Ranges ............................................................................B-35

Table B–8. Contrast Levels...............................................................................B-39

Table B–9. Reply Termination Formats ............................................................B-44

Table B–10. Allow Mode Command Values ....................................................B-46

Table B–11. Power Up Mode Values................................................................B-47

Table B–12. Set Layout Ack Values..................................................................B-47

Table B–13. Analog Current Output Range Values..........................................B-48

Table B–14. Analog Voltage Output Range Values .........................................B-49

Table B–15. Default Analog Output Channel Assignments.............................B-51

Table C–1. Read Coils for 48i.............................................................................C-8

Table C–2. Read Registers for 48i....................................................................C-10

Table C–3. Write Coils for 48i..........................................................................C-12

Table D–1. Operating Status for Model 48i...................................................... D-7

Table D–2. Error Status for Model 48i .............................................................. D-8

xviii Model 48i Instruction Manual Thermo Fisher Scientific

Page 25

Chapter 1

Introduction

The Model 48i CO Analyzer measures CO concentration using Gas Filter

Correlation (GFC). The Model 48i combines proven detection technology,

easy to use menu-driven firmware, and advanced diagnostics to offer

unsurpassed flexibility and reliability. The Model 48i has the following

features:

● 320 x 240 graphics display

● Menu-driven firmware

● Field programmable ranges

● User-selectable single/dual/auto range modes

● Multiple user-defined analog outputs

● Analog input options

● High sensitivity

● Fast response time

● Linearity through all ranges

● Highly specific to CO

● Self-aligning optics

● Automatic temperature and pressure compensation

● User-selectable digital input/output capabilities

● Standard communications features include RS232/485 and Ethernet

● C-Link, MODBUS, Gesytec (Bayern-Hessen), streaming data, and

NTP (Network Time Protocol) protocols. Simultaneous connections

from different locations over Ethernet.

For details of the analyzer’s principle of operation and product

specifications, see the following topics:

● “Principle of Operation” on page 1-2

● “Specifications” on page 1-3

Thermo Fisher Scientific Model 48i Instruction Manual 1-1

Page 26

Introduction

Principle of Operation

Thermo Fisher Scientific is pleased to supply this CO analyzer. We are

committed to the manufacture of instruments exhibiting high standards of

quality, performance, and workmanship. Service personnel are available for

assistance with any questions or problems that may arise in the use of this

analyzer. For more information on servicing, see the “Servicing” chapter

starting on page 7-1.

Principle of

Operation

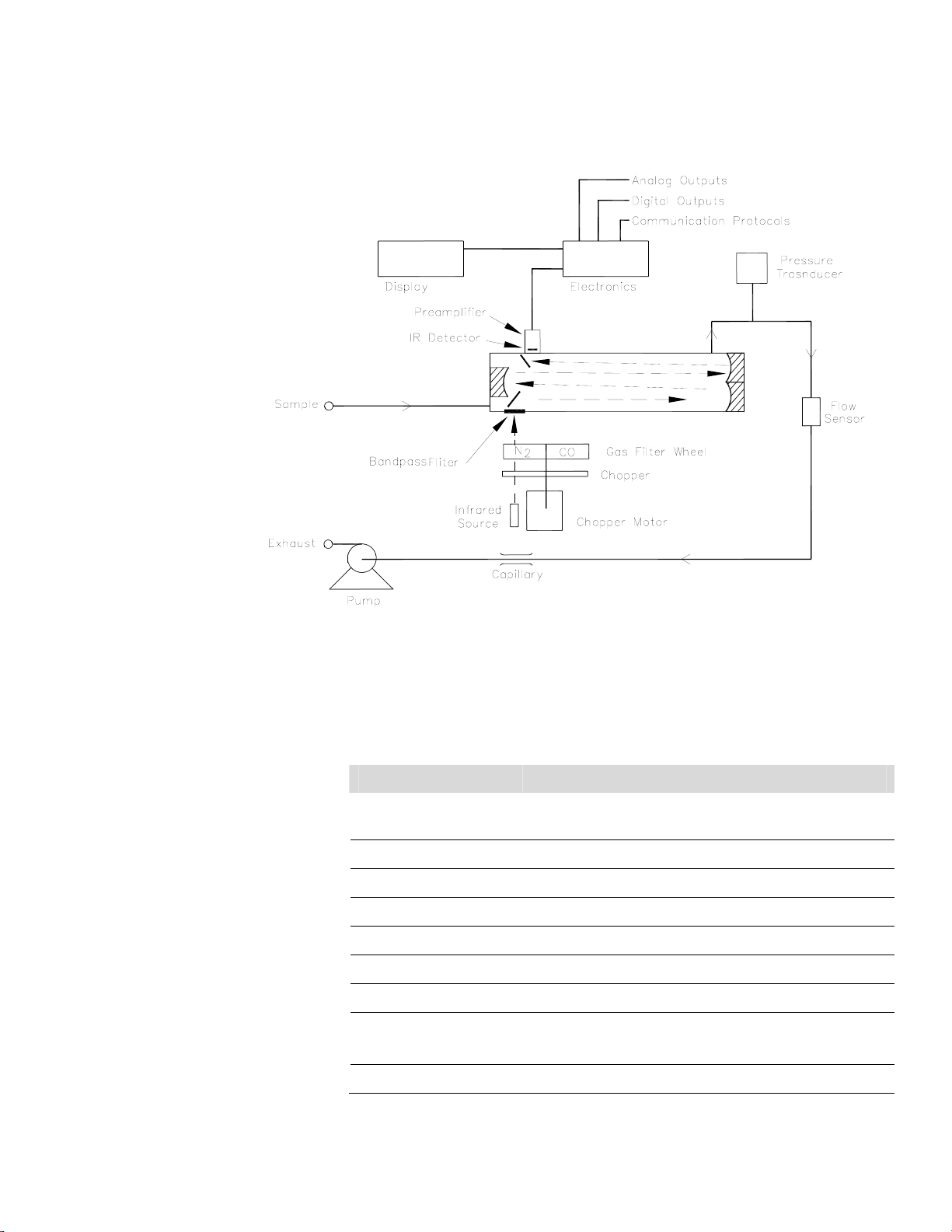

The Model 48i operates on the principle that carbon monoxide (CO)

absorbs infrared radiation at a wavelength of 4.6 microns. Because infrared

absorption is a non-linear measurement technique, it is necessary to

transform the basic analyzer signal into a linear output. The Model 48i uses

an internally stored calibration curve to accurately linearize the instrument

output over any range up to a concentration of 10,000 ppm.

The sample is drawn into the Model 48i through the sample bulkhead, as

shown in Figure 1–1. The sample flows through the optical bench.

Radiation from an infrared source is chopped and then passed through a

gas filter alternating between CO and N2. The radiation then passes

through a narrow bandpass interference filter and enters the optical bench

where absorption by the sample gas occurs. The infrared radiation then

exits the optical bench and falls on an infrared detector.

The CO gas filter acts to produce a reference beam, which cannot be

further attenuated by CO in the sample cell. The N2 side of the filter wheel

is transparent to the infrared radiation and therefore produces a

measurement beam, which can be absorbed by CO in the cell. The

chopped detector signal is modulated by the alternation between the two

gas filters with an amplitude related to the concentration of CO in the

sample cell. Other gases do not cause modulation of the detector signal

since they absorb the reference and measure beams equally. Thus, the GFC

system responds specifically to CO.

The Model 48i outputs the CO concentration to the front panel display,

the analog outputs, and also makes the data available over the serial or

Ethernet connection.

1-2 Model 48i Instruction Manual Thermo Fisher Scientific

Page 27

Introduction

Specifications

Specifications

Figure 1–1. Model 48i Flow Schematic

Table 1–1 lists the specifications for the Model 48i.

Table 1–1. Model 48i Specifications

Preset ranges 0-1, 2, 5, 10, 20, 50, 100, 200, 500, 1000, 2000, 5000, 10000

(ppm or mg/m

Custom ranges 0-1 to 10000 (ppm or mg/m

Zero noise 0.02 ppm RMS (30 second averaging time)

Lower detectable limit 0.04 ppm

Zero drift (24 hour) <0.1 ppm

Span drift ±1% full-scale

Response time 60 seconds (30 second averaging time)

Linearity ±1% full-scale ≤ 1000 ppm

±2.5% full-scale > 1000 ppm

3

)

3

)

Sample flow rate 1.0 L/min

Thermo Fisher Scientific Model 48i Instruction Manual 1-3

Page 28

Introduction

Specifications

Operating temperature 20–

Power requirements

30 °C (may be safely operated over the range of 0–45 °C)*

100 VAC @ 50/60 Hz

115 VAC @ 50/60 Hz

220–240 VAC @ 50/60 Hz

275 watts

Physical dimensions 16.75” (W) X 8.62” (H) X 23” (D)

Weight Approximately 49 lbs.

Analog outputs 6 voltage outputs; 0–100 mV, 1, 5, 10 V (user selectable), 5% of

full-scale over/under range (user selectable), 12 bit resolution,

measurement output user selectable per channel

Digital outputs 1 power fail relay Form C, 10 digital relays Form A, user

selectable alarm output, relay logic, 100 mA @ 200 VDC

Digital inputs 16 digital inputs, user select programmable, TTL level, pulled

high

Serial Ports 1 RS-232 or RS-485 with two connectors, baud rate 1200–

115200, data bits, parity, and stop bits, protocols: C-Link,

MODBUS, Gesytec (Bayern-Hessen), and streaming data (all

user selectable)

Ethernet connection RJ45 connector for 10Mbs Ethernet connection, static or

dynamic TCP/IP addressing

*In non-condensing environments. Performance specifications based on operation with 20–30 °C range.

Table 1–2. Model 48i Optional Internal Oxygen Sensor Specifications

Technology Paramagnetic (Pm)

Range 0-100% O

2

Accuracy (Intrinsic error) <±0.1% O2

Linearity <±0.1% O2

Repeatability <±0.1% O2

Zero Drift <±0.2% O2 per month (excludes up to 0.1% O2 in the first 24

hours of operation)

Response Time (T10-T90) <2.5 seconds

Weight Approximately 2 lbs. (in addition to standard instrument)

1-4 Model 48i Instruction Manual Thermo Fisher Scientific

Page 29

Chapter 2

Installation

Installation of the Model 48i includes lifting the instrument, unpacking

and inspection, connecting sample, zero, span, and exhaust lines, and

attaching the analog and/or digital outputs to a recording device. The

installation should always be followed by instrument calibration as

described in the “Calibration” chapter of this manual.

Installing the Model 48i includes the following recommendations and

procedures:

● “Lifting” on page 2-1

Lifting

Unpacking and

Inspection

● “Unpacking and Inspection” on page 2-1

● “Setup Procedure” on page 2-3

● “Connecting External Devices” on page 2-5

● “Startup” on page 2-9

When lifting the instrument, use procedure appropriate to lifting a heavy

object, such as bending at the knees while keeping your back straight and

upright. Grasp the instrument at the bottom in the front and at the rear of

the unit. Although one person can lift the unit, it is desirable to have two

persons lifting, one by grasping the bottom in the front and the other by

grasping the bottom in the rear.

Equipment Damage Do not attempt to lift the instrument by the cover or

other external fittings.

The Model 48i is shipped complete in one container. If there is obvious

damage to the shipping container when you receive the instrument, notify

the carrier immediately and hold for inspection. The carrier is responsible

for any damage incurred during shipment.

▲

Use the following procedure to unpack and inspect the instrument.

1. Remove the instrument from the shipping container and set it on a

table or bench that allows easy access to both the front and rear.

Thermo Fisher Scientific Model 48i Instruction Manual 2-1

Page 30

Installation

Unpacking and Inspection

2. Remove the cover to expose the internal components.

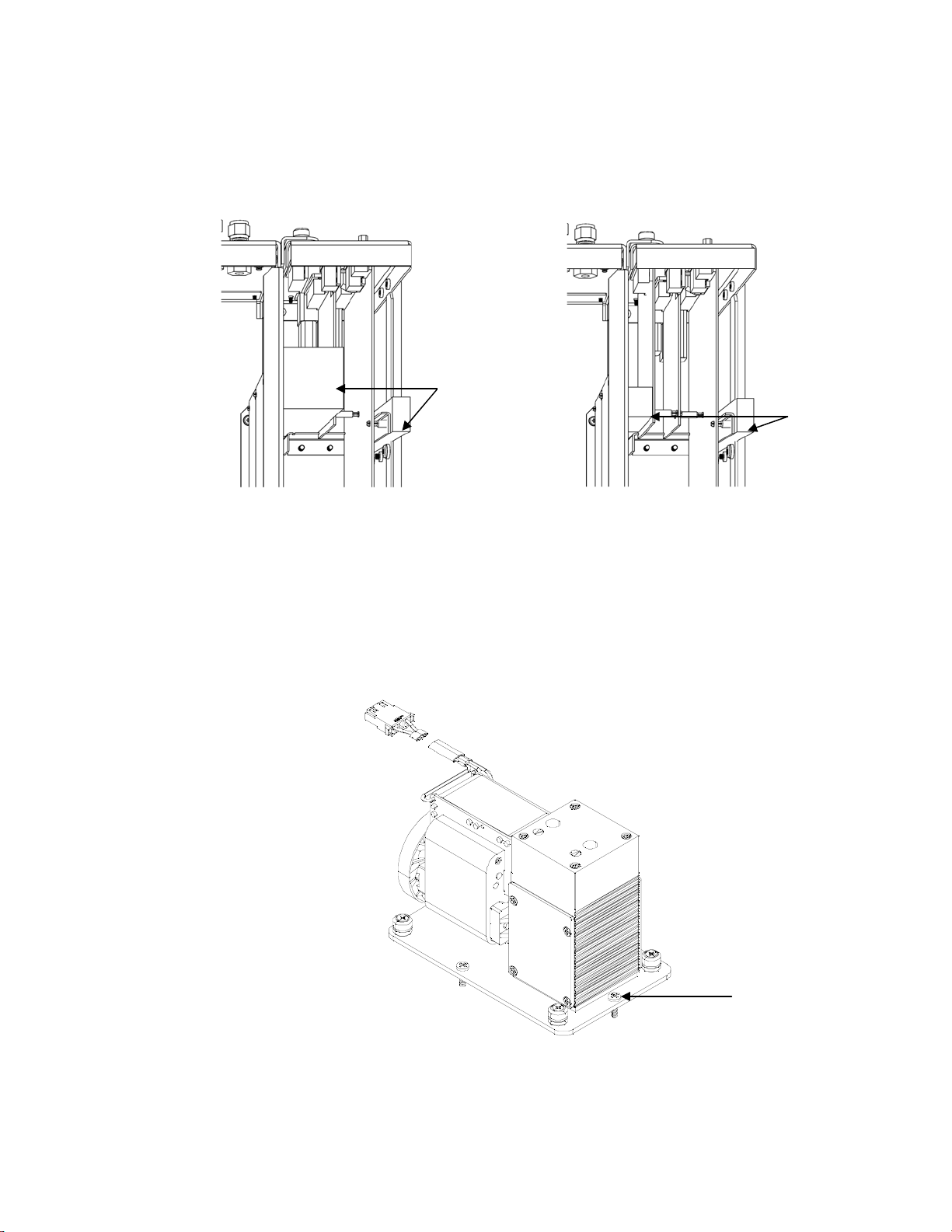

3. Remove the packing material (Figure 2–1).

Remove Packing

(2 pieces)

Remove Packing

(2 pieces)

Units without Optional I/O Board Units with Optional I/O Board

Figure 2–1. Remove the Packing Material

4. Remove the three shipping screws (Figure 2–2).

Shipping Screws (3)

Figure 2–2. Removing the Shipping Screws

2-2 Model 48i Instruction Manual Thermo Fisher Scientific

Page 31

Installation

Setup Procedure

5. Check for possible damage during shipment.

6. Check that all connectors and circuit boards are firmly attached.

7. Re-install the cover.

8. Remove any protective plastic material from the case exterior.

Setup Procedure

Use the following procedure to setup the instrument:

1. Connect the sample line to the SAMPLE bulkhead on the rear panel

(Figure 2–3). Ensure that the sample line is not contaminated by dirty,

wet, or incompatible materials. All tubing should be constructed of

Teflon®, 316 stainless steel, borosilicate glass, or similar tubing with an

OD of 1/4-inch and a minimum ID of 1/8-inch. The length of the

tubing should be less than 10 feet.

Note Gas must be delivered to the instrument free of particulates. It may

be necessary to use the Teflon particulate filter as described in “Teflon

Particulate Filter” on page 9-5. ▲

Note Gas must be delivered to the instrument at atmospheric pressure. It

may be necessary to use an atmospheric bypass plumbing arrangement as

shown in Figure 2–4 if gas pressure is greater than atmospheric pressure. ▲

2. Connect the EXHAUST bulkhead to a suitable vent. The exhaust line

should be 1/4-inch OD with a minimum ID of 1/8-inch. The length of

the exhaust line should be less than 10 feet. Verify that there is no

restriction in this line.

3. If the optional zero/span solenoid valves are installed, connect a source

of CO-free air to the ZERO bulkhead, and connect a source of CO

span gas to the SPAN bulkhead.

4. Connect a suitable recording device to the rear panel connector. For

detailed information about connecting to the instrument, refer to:

“Connecting External Devices” on page 2-5

Instrument Controls > “I/O Configuration” on page 3-45

“External Device Connection Components” on page 7-6

Thermo Fisher Scientific Model 48i Instruction Manual 2-3

Page 32

Installation

Setup Procedure

“Terminal Block and Cable Kits” on page 9-5

For detailed information about troubleshooting a connection, refer to

“Analog Output Testing” on page 7-28.

5. Plug the instrument into an outlet of the appropriate voltage and

frequency.

WARNING The Model 48i is supplied with a three-wire grounding cord.

Under no circumstances should this grounding system be defeated. ▲

SAMPLE

Figure 2–3. Model 48i Rear Panel

Instrument Bulkhead

Vent to Exhaust Line at

Atmospheric Pressure

Input Gas Line

Figure 2–4. Atmospheric Dump Bypass Plumbing

2-4 Model 48i Instruction Manual Thermo Fisher Scientific

Page 33

Installation

Connecting External Devices

Connecting

External Devices

Terminal Board PCB

Assemblies

Several components are available for connecting external devices to iSeries

instruments.

These connection options include:

● Individual terminal board PCB assemblies

● Terminal block and cable kits (optional)

● Individual cables (optional)

For detailed information on the optional connection components, refer to

the “Optional Equipment” chapter. For associated part numbers, refer to

“External Device Connection Components” on page 7-6.

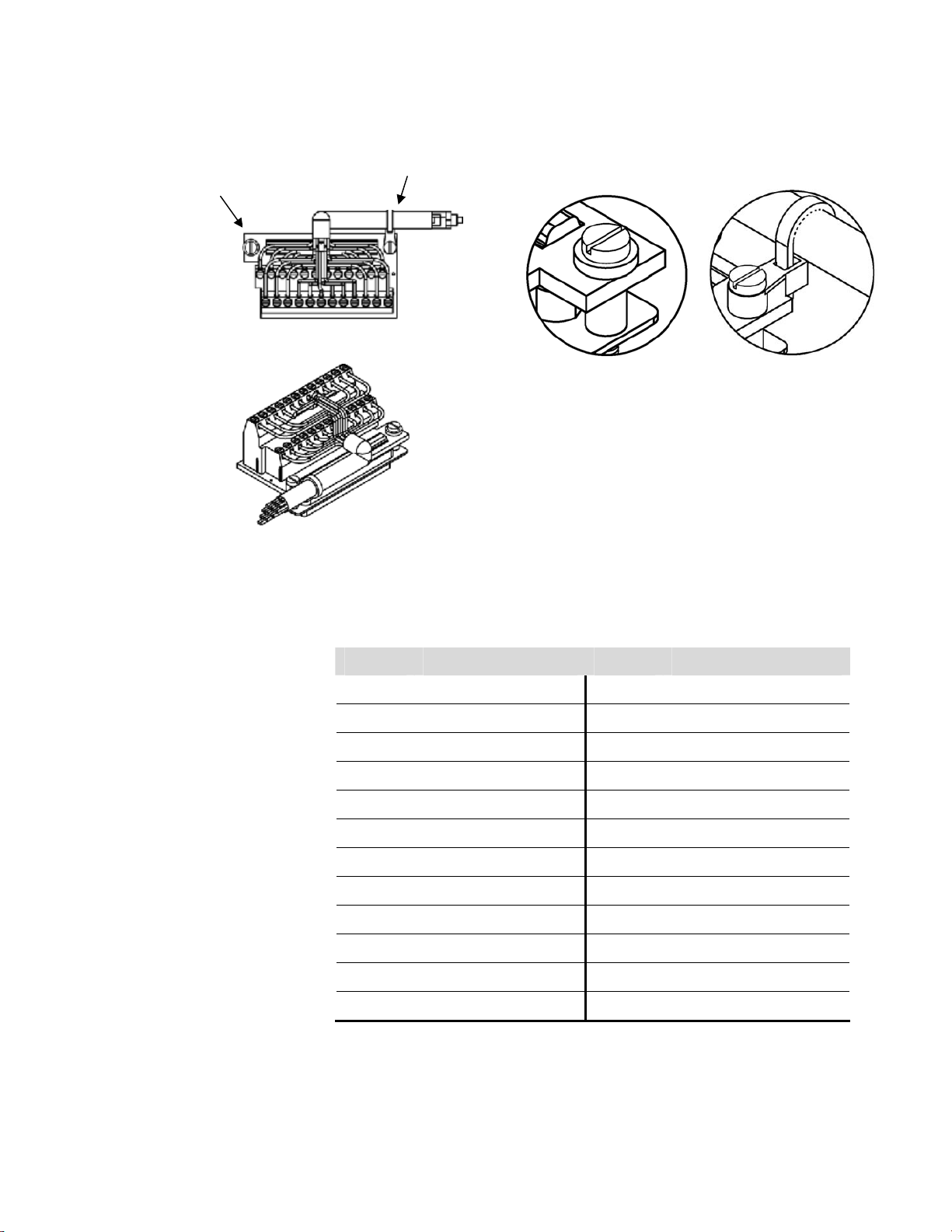

The terminal board PCB assemblies are circuit boards with a D-Sub

connector on one side and a series of screw terminals on the other side.

This assembly provide a convenient mechanism for connecting wires from

a data system to the analyzer’s I/O connectors.

The following terminal board PCB assemblies are available for iSeries

instruments:

● I/O terminal board PCB assembly, 37 pin (standard)

I/O Terminal Board

● D/O terminal board PCB assembly, 37 pin (standard)

● 25-pin terminal board PCB assembly, (included with optional I/O

Expansion Board)

Figure 2–5 shows the recommended method for attaching the cable to the

terminal board using the included tie-down and spacer. Table 2–1

identifies the connector pins and associated signals.

Note Not all of the I/O available in the instrument is brought out on the

supplied terminal board. If more I/O is desired, an alternative means of

connection is required. See optional “Terminal Block and Cable Kits”.

▲

Thermo Fisher Scientific Model 48i Instruction Manual 2-5

Page 34

Installation

Connecting External Devices

See Detail “A”

See Detail “B”

Component Side Viewed from Top of Board

Assembled Connector

Figure 2–5. I/O Terminal Board Views

Table 2–1. I/O Terminal Board Pin Descriptions

Screw Signal Description Screw Signal Description

1 Analog1 13 Power_Fail_NC

2 Analog ground 14 Power_Fail_COM

3 Analog2 15 Power_Fail_NO

4 Analog ground 16 TTL_Input1

Detail “A”

Detail “B”

5 Analog3 17 TTL_Input2

6 Analog ground 18 TTL_Input3

7 Analog4 19 TTL_Input4

8 Analog ground 20 Digital ground

9 Analog5 21 TTL_Input5

10 Analog ground 22 TTL_Input6

11 Analog6 23 TTL_Input7

12 Analog ground 24 Digital ground

2-6 Model 48i Instruction Manual Thermo Fisher Scientific

Page 35

Installation

Connecting External Devices

D/O Terminal Board

See Detail “A”

Component Side Viewed from Top of Board

Figure 2–6 shows the recommended method for attaching the cable to the

terminal board using the included tie-down and spacer. Table 2–2

identifies the connector pins and associated signals.

See Detail “B”

Detail “A” Detail “B”

Assembled Connector

Figure 2–6. D/O Terminal Board Views

Table 2–2. D/O Terminal Board Pin Descriptions

Screw Signal Description Screw Signal Description

1 Relay1_ContactA 13 Relay7_ContactA

2 Relay1_ContactB 14 Relay7_ContactB

3 Relay2_ContactA 15 Relay8_ContactA

4 Relay2_ContactB 16 Relay8_ContactB

5 Relay3_ContactA 17 Relay9_ContactA

6 Relay3_ContactB 18 Relay9_ContactB

7 Relay4_ContactA 19 Relay10_ContactA

8 Relay4_ContactB 20 Relay10_ContactB

9 Relay5_ContactA 21 Solenoid_Drive_Output1

10 Relay5_ContactB 22 +24V

11 Relay6_ContactA 23 Solenoid_Drive_Output2

12 Relay6_ContactB 24 +24V

Thermo Fisher Scientific Model 48i Instruction Manual 2-7

Page 36

Installation

Connecting External Devices

25-Pin Terminal Board

See Detail “A”

Component Side Viewed from Top of Board

The 25-pin terminal board is included with the optional I/O Expansion

Board.

See Detail “B”

Detail “A” Detail “B”

Assembled Connector

Figure 2–7. 25-Pin Terminal Board Views

Table 2–3. 25-Pin Terminal Board Pin Descriptions

Screw Signal Description Screw Signal Description

1 IOut1 13 Analog_In1

2 GND_ISO 14 Analog_In2

3 IOut2 15 Analog_In3