Page 1

Wellwash

Thermo Scientific Wellwash 4 Mk 2

User Manual

Rev. 2.4, Cat. no. 1507340

Page 2

Wellwash

Thermo Scientific Wellwash 4 Mk 2, Cat. no. 5160772 (115 V), 5160770 (230 V) or 5160771

(100 V)

User Manual Rev. 2.4; November 2008, Cat. no. 1507340

Copyright

Copyright 2008 Thermo Fisher Scientific. All rights reserved. Printed in

Finland. Reproduction of the accompanying user documentation in whole or in

part is prohibited.

Trademarks ( and )

Wellwash is a registered trademark of Thermo Fisher Scientific.

All other trademarks and registered trademarks are the property of their

respective holders.

Disclaimer

Thermo Fisher Scientific reserves the right to change its products and services at

any time to incorporate technological developments. This manual is subject to

change without prior notice as part of a continuous product development.

Although this manual has been prepared with every precaution to ensure

accuracy, Thermo Fisher Scientific assumes no liability for any errors or

omissions, or for any damages resulting from the application or use of this

information. This manual supersedes all previous editions.

No liability for consequential damages

Thermo Fisher Scientific shall not be liable for any damages whatsoever arising

out of the use or inability to use this product.

Contact information

Thermo Fisher Scientific Oy

P.O. Box 100, FI-01621 Vantaa, Finland

Tel. +358-9-329 100, Fax +358-9-3291 0415

www.thermo.com

Rev. 2.4, Cat. no. 1507340

Page 3

Table of Contents

Table of Contents

1 Safety Symbols and Markings .................................................................... 7

2 About the User Manual............................................................................ 8

3 Introduction to the Wellwash 4 Mk 2 .......................................................... 9

4 Functional Description ...........................................................................11

5 Installation..........................................................................................13

6 Operation ...........................................................................................26

7 Maintenance........................................................................................36

8 Troubleshooting ...................................................................................49

9 Technical Specifications .........................................................................55

10 Ordering Information.............................................................................57

11 Warranty Certificate .............................................................................58

12 Index .................................................................................................59

13 Glossary and Abbreviations .....................................................................63

Appendix A: Wellwash 4 Mk 2 Quick Reference Guide ....................................................64

Appendix B: Certificate of Decontamination ................................................................65

Appendix C: Wellwash 4 Mk 2 Feedback Form ..............................................................66

Appendix D: Addresses ...........................................................................................67

Notes .................................................................................................68

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 3

Page 4

Table of Contents

Table of Contents

1 Safety Symbols and Markings .................................................................... 7

2 About the User Manual............................................................................ 8

3 Introduction to the Wellwash 4 Mk 2 .......................................................... 9

3.1 Intended use ..........................................................................................9

3.2 Principle of operation ...............................................................................9

3.3 Advantages of using Wellwash 4 Mk 2 ............................................................9

4 Functional Description ...........................................................................11

4.1 Controls and indicators ........................................................................... 12

5 Installation..........................................................................................13

5.1 Installation check list ............................................................................. 13

5.2 What to do upon delivery......................................................................... 13

5.2.1 How to unpack.................................................................................... 13

5.2.2 Checking delivery for completeness .......................................................... 14

5.2.3 Checking for damage during transport ....................................................... 15

5.2.4 Environmental requirements ................................................................... 16

5.2.5 Things to avoid ................................................................................... 16

5.2.6 Technical prerequisites ......................................................................... 16

5.3 Installation procedure............................................................................. 17

5.3.1 How to install the pump unit and washer unit connections .............................. 19

5.3.2 Wash head height ................................................................................ 23

5.3.3 Mains supply cable ............................................................................... 24

5.3.4 Changing wash heads ............................................................................ 24

5.4 Operational check ................................................................................. 24

6 Operation ...........................................................................................26

6.1 Operational checklist.............................................................................. 26

6.2 Washing a microplate ............................................................................. 27

6.3 Priming procedure ................................................................................. 29

6.4 Adding wash reagent .............................................................................. 30

6.5 Program selection.................................................................................. 31

6.5.1 Two-way switch functions ...................................................................... 32

6.5.2 Rotary switch functions ......................................................................... 33

6.6 Resetting ............................................................................................ 35

6.7 Shutdown procedure............................................................................... 35

6.7.1 Daily shutdown procedure ...................................................................... 35

6.7.2 Long-period shutdown........................................................................... 35

6.8 Emergency situations .............................................................................. 35

7 Maintenance........................................................................................36

7.1 Regular and preventive maintenance .......................................................... 36

7.1.1 Service contracts ................................................................................. 36

7.1.2 Maintenance check list .......................................................................... 36

7.1.3 General ............................................................................................ 36

7.1.4 Immediate ......................................................................................... 37

7.1.5 Tubing.............................................................................................. 37

7.1.6 Reagent / waste bottles ........................................................................ 37

7.1.7 Liquid trap bottle ................................................................................ 38

7.1.8 Pinch valve ........................................................................................ 42

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 4

Page 5

Table of Contents

7.1.9 Unclogging tips ................................................................................... 42

7.1.10 Fuse replacement ................................................................................ 44

7.2 Disposal of materials .............................................................................. 46

7.3 Decontamination procedure...................................................................... 46

7.3.1 How to decontaminate the instrument ...................................................... 46

7.4 How to pack for service........................................................................... 47

7.4.1 Packing............................................................................................. 48

7.5 Disposal of the instrument ....................................................................... 48

8 Troubleshooting ...................................................................................49

8.1 Troubleshooting guide............................................................................. 49

8.2 Service request protocol .......................................................................... 52

8.3 Limitations, warnings and cautions ............................................................. 52

8.3.1 Liquid reservoir – IMPORTANT.................................................................. 52

8.3.2 Electrical .......................................................................................... 52

8.3.3 Mechanical and environmental ................................................................ 53

8.4 Defects and abnormal stresses .................................................................. 54

8.5 Before operation ................................................................................... 54

8.5.1 Installation ........................................................................................ 54

8.5.2 In operation ....................................................................................... 54

8.6 Cleanliness .......................................................................................... 54

9 Technical Specifications .........................................................................55

9.1 General specifications ............................................................................ 55

9.2 Safety specifications .............................................................................. 56

9.3 In conformity with the requirements ........................................................... 56

10 Ordering Information.............................................................................57

10.1 List of accessories.................................................................................. 57

10.2 List of recommended spare parts ............................................................... 57

11 Warranty Certificate .............................................................................58

11.1 Warranty limitations............................................................................... 58

12 Index .................................................................................................59

13 Glossary and Abbreviations .....................................................................63

13.1 Keywords for web pages .......................................................................... 63

13.2 Literature............................................................................................ 63

Appendix A: Wellwash 4 Mk 2 Quick Reference Guide ....................................................64

Appendix B: Certificate of Decontamination ................................................................65

Appendix C: Wellwash 4 Mk 2 Feedback Form ..............................................................66

Appendix D: Addresses ...........................................................................................67

Notes .................................................................................................68

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 5

Page 6

List of Figures

Fig. 4.1 Wellwash 4 Mk 2 microplate washer .................................................. 11

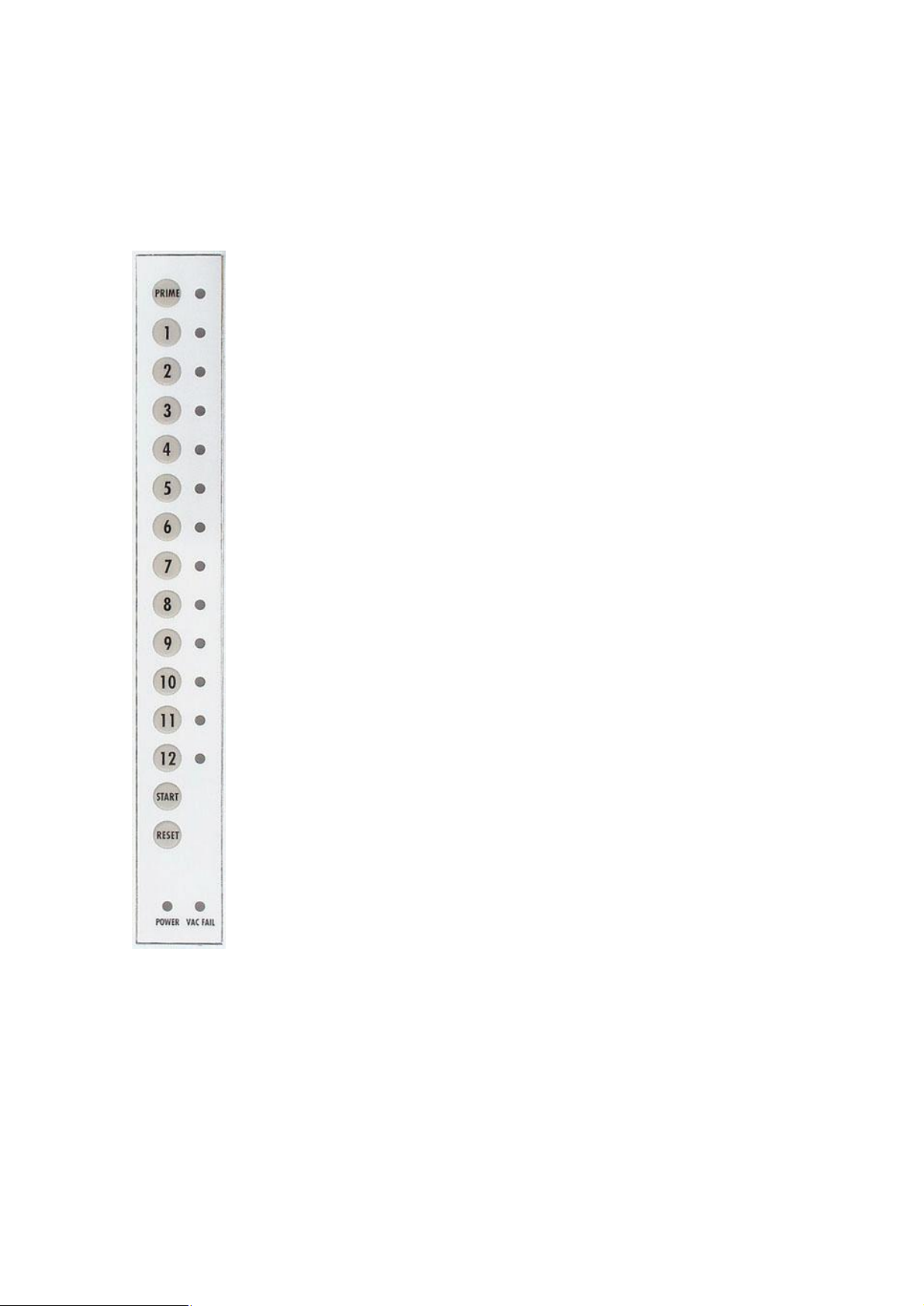

Fig. 4.2 Keypad..................................................................................... 12

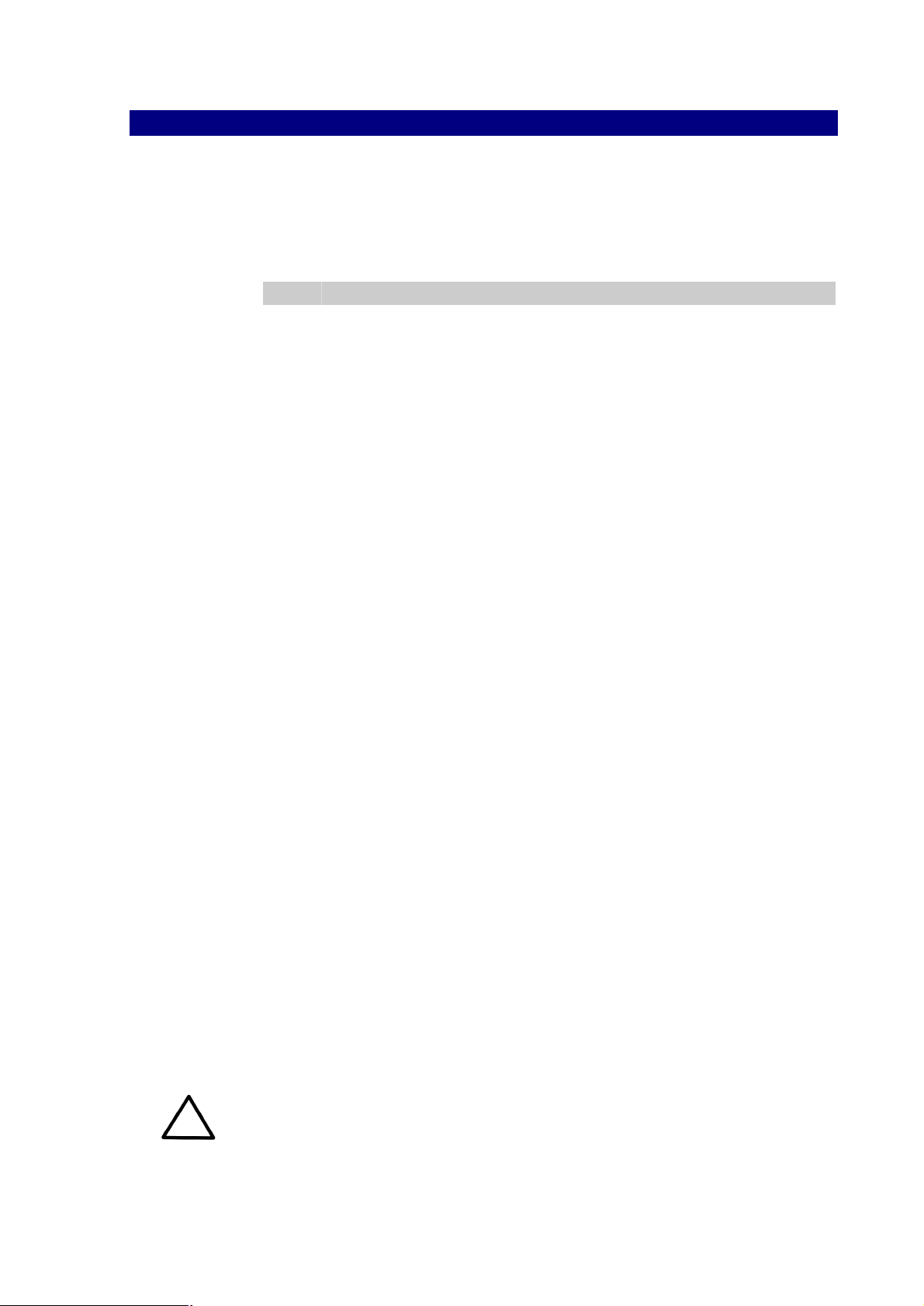

Fig. 5.1 Accessories included with the instrument. .......................................... 14

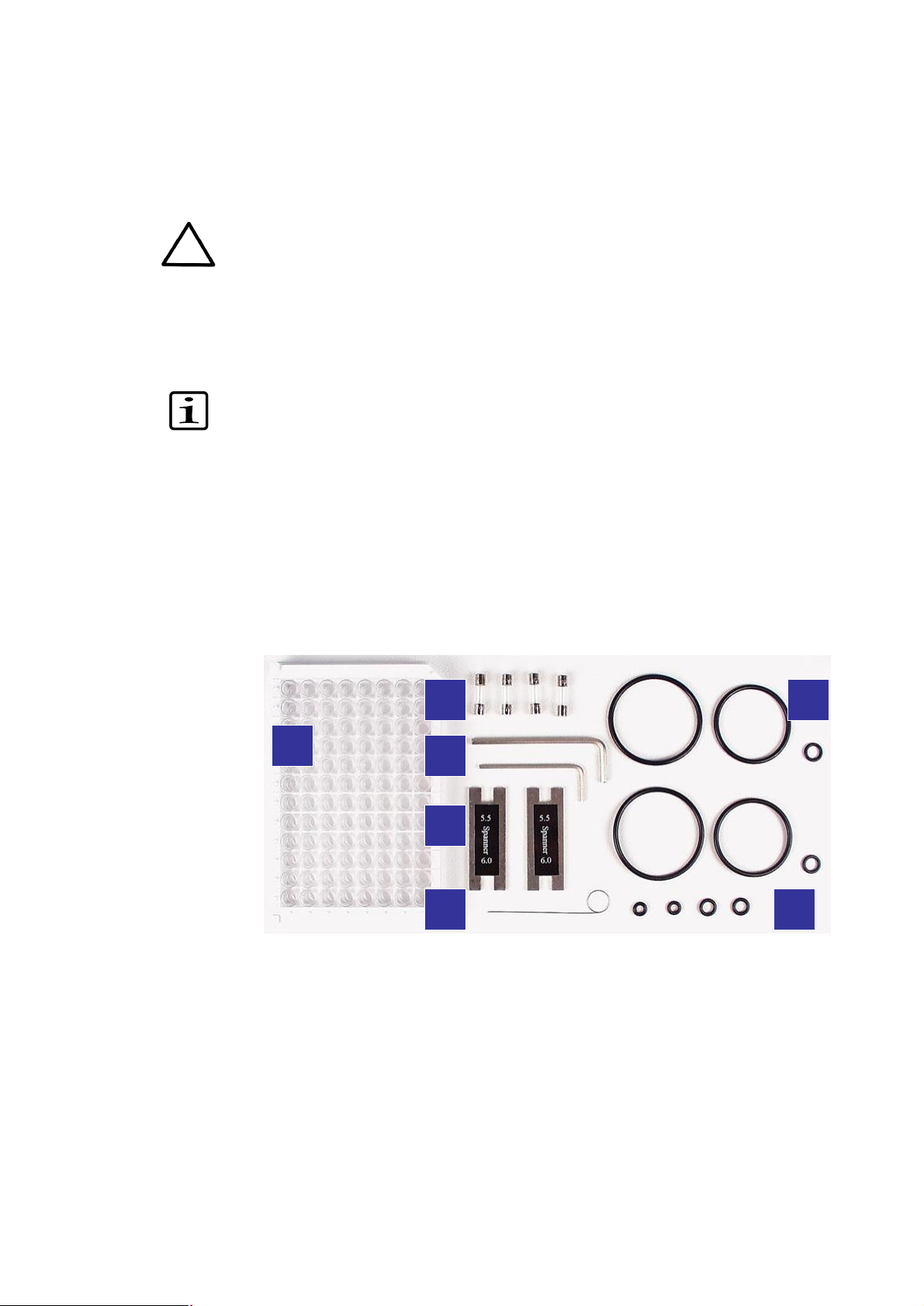

Fig. 5.2 Spare tubing .............................................................................. 15

Fig. 5.3 Wash arm assembly tubing ............................................................. 15

Fig. 5.4 Location of the frequency selector switch and the transit screws ............... 17

Fig. 5.5 Pinch valve holder ....................................................................... 18

Fig. 5.6 Installing the O rings to the wash head holders ..................................... 18

Fig. 5.7 Sliding the wash head between the holders ......................................... 19

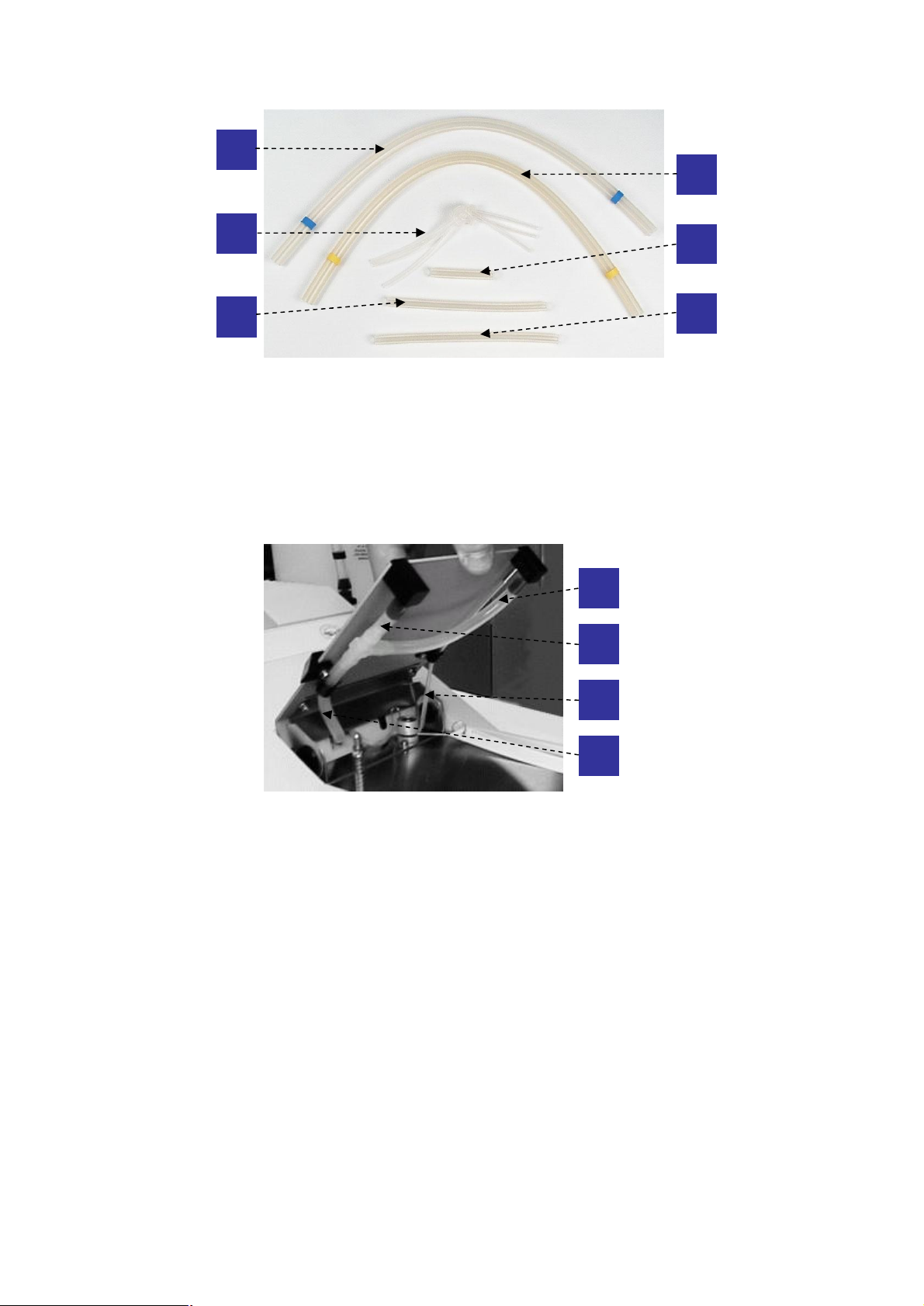

Fig. 5.8 Pump unit with tubes installed ........................................................ 19

Fig. 5.9 Liquid level sensor system.............................................................. 20

Fig. 5.10 Removing the plastic caps .............................................................. 21

Fig. 5.11 Connection of pump and washer units................................................ 21

Fig. 5.12 Opening and closing the bottle ........................................................ 22

Fig. 5.13 Correct position of the plate carrier ................................................. 22

Fig. 5.14 Loosening the locknut with spanners ................................................. 23

Fig. 5.15 Changing the wash head ................................................................ 24

Fig. 5.16 Placing the microplate with 12-way and 8-way wash head ........................ 25

Fig. 6.1 Releasing the pressure from the wash bottle........................................ 30

Fig. 6.2 Preprogrammed card: three washes with a 12-way wash head ................... 31

Fig. 6.3 Programmable switch card ............................................................. 32

Fig. 7.1 Liquid level sensor and liquid trap bottle cover .................................... 38

Fig. 7.2 Opening the liquid trap bottle cover ................................................. 39

Fig. 7.3 Pulling the thick tube out of the liquid trap bottle ................................ 40

Fig. 7.4 Pulling the thin tube out of the liquid trap bottle ................................. 40

Fig. 7.5 Opening the liquid trap bottle......................................................... 41

Fig. 7.6 Unpinching the tube ..................................................................... 42

Fig. 7.7 De-clogging the wash head ............................................................. 43

Fig. 7.8 Opening the fuse holder of the washer unit ......................................... 44

Fig. 7.9 Washer unit fuse and fuse holder ..................................................... 44

Fig. 7.10 Opening the fuse holder of the pump unit........................................... 45

Fig. 7.11 Pump unit fuse holder opened ......................................................... 45

List of Figures and List of Tables

List of Tables

Table 5.1 Installation check list ................................................................... 13

Table 5.2 Silicon tubing color-codes .............................................................. 19

Table 6.1 Operational checklist ................................................................... 26

Table 6.2 Number of washes after a soak period ............................................... 33

Table 6.3 Aspiration after the final wash........................................................ 33

Table 6.4 Soak period (in minutes)................................................................ 33

Table 6.5 Pause (in seconds) between each washing cycle .................................... 34

Table 6.6 Number of washes before soaking..................................................... 34

Table 6.7 Washing volume (in µl).................................................................. 34

Table 7.1 Maintenance check list.................................................................. 36

Table 8.1 Troubleshooting list..................................................................... 50

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 6

Page 7

1 Safety Symbols and Markings

IVD

These symbols are intended to draw your attention to particularly important

information and alert you to the presence of hazards as indicated.

Safety symbols and markings used on the Wellwash 4 Mk 2

Power ON

Power OFF

SN

REF Catalog number

Serial number

Date of manufacture

Chapter 1: Safety Symbols and Markings

Consult Instructions for Use

In Vitro Diagnostic Medical Device

WEEE symbol This product is required to comply with the European Union’s Waste

Electrical & Electronic Equipment (WEEE) Directive 2002/96/EC.

Warning markings used in the documentation

Warning: Risk of electric shock.

Warning: Biohazard risk.

Warning: Risk of injury to the user(s).

Caution: Risk of damage to the instrument, other equipment or loss of

performance or function in a specific application.

Other markings used in the documentation

Note: Marks a tip, important information that is useful in the optimum

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 7

operation of the system, or an item of interest.

Page 8

2 About the User Manual

This User Manual has been written for the actual user (e.g., laboratory

technician) and provides information on the Thermo Scientific Wellwash 4 Mk 2

microplate strip washer, including installation and operating instructions.

Read the manual in its entirety prior to operating the instrument.

This User Manual has been designed to give you the information you need to:

Review safety precautions

Install the Wellwash 4 Mk 2

Carry out washing procedures

Perform basic maintenance procedures

Troubleshoot the instrument performance

Maintain the instrument

This User Manual also describes features and specifications of the Wellwash

4 Mk 2 hardware and on-board software.

Chapter 2: About the User Manual

Chapter 6 explains the operating procedures.

The user should be familiar with the contents of Chapter 7 on maintenance

procedures that may be performed by the user.

For warranty and ordering information, refer to Chapters 10 Ordering Information

and 11 Warranty .

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 8

Page 9

3 Introduction to the Wellwash 4 Mk 2

The Wellwash 4 Mk 2 is a semiautomatic microplate washer, comprising pump

and washer units. The instrument is supplied with both 8- and 12-way wash

heads, four program cards and an accessory pack.

Your local Thermo Fisher Scientific representative can arrange instrument

training at the commissioning of the instrument for extra charge, if required.

3.1 Intended use

The Wellwash 4 Mk 2 is a microplate washer for 96-well plates. It can be used in

research or routine-test laboratories by trained personnel to wash Microtiter

microplates and strips in 96-well plate format that meet the SBS standards.

For verification of the entire system, it is recommended that Good Laboratory

Practices (GLP) be followed to guarantee reliable analyses.

Use for self-testing is excluded.

If the assay performance is essential for the analysis, the test result has to be

ensured with internal quality controls or with an alternative test.

Chapter 3: Introduction to the Wellwash 4 Mk 2

3.2 Principle of operation

The instrument provides the following wash functions initiated through the

keypad and control switches or a preprogrammed wash card:

1. Liquid dispensing into wells (microplate or microstrip)

2. Liquid aspiration from wells (microplate or microstrip)

With their unique and proven design, the coaxial wash heads of the Wellwash

4 Mk 2 ensure excellent washing efficiency and low residual volumes of less than

5 µl. For clean delivery of washing buffer, the inner dispensing tubes are made of

stainless steel. A continuous vacuum in the outer tube prevents cross

contamination and ensures complete liquid removal.

For fast and accurate selection of routine protocols, the Wellwash 4 Mk 2 comes

with four standard program cards (1 to 4 washing cycles) as well as a

programmable card. This switch card permits a quick selection of all wash

parameters, including soak times and final wash protocols.

The quick release bottle caps of the Wellwash 4 Mk 2 ensure easy buffer changes.

An additional rinse bottle can be connected, making it easier to purge wash

buffer from the wash head or change to a different wash buffer. Automatic pump

shutdown reduces wear and noise levels. If unused for 30 seconds, the wash

pump of the Wellwash 4 Mk 2 automatically switches off.

3.3 Advantages of using Wellwash 4 Mk 2

The Wellwash 4 Mk 2 provides several advantages relating mainly to the principle

of operation in that it has:

Unique coaxial wash heads for trouble-free washing and low residual

volumes

8- and 12-way interchangeable wash heads

Easy to program

Excellent washing performance

Quick release wash/waste bottle caps

Automatic pump shutdown

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 9

Page 10

Effective liquid management

Chapter 3: Introduction to the Wellwash 4 Mk 2

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 10

Page 11

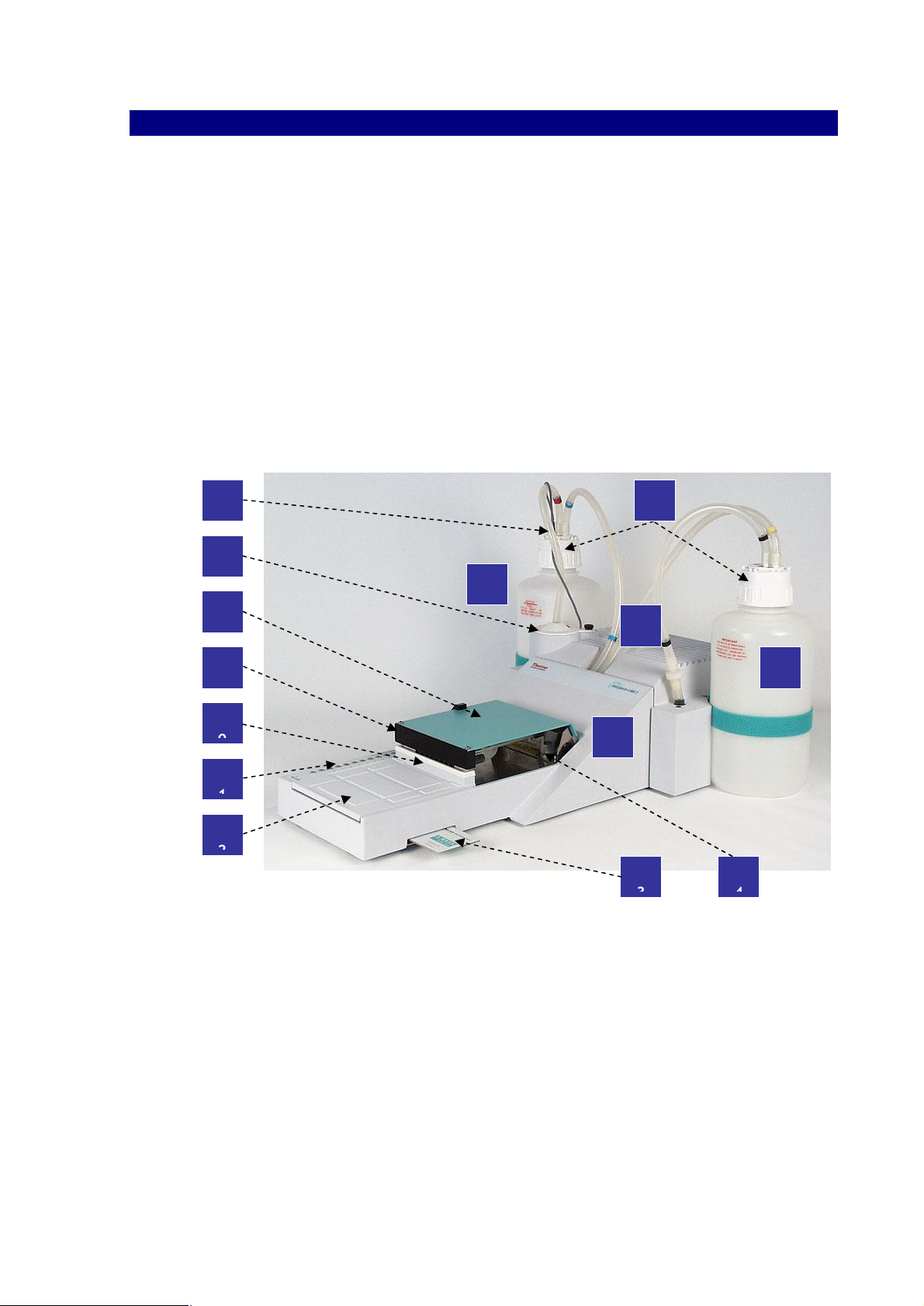

4 Functional Description

The Wellwash 4 Mk 2 is designed to wash wells in an 8 x 12 microplate. It

comprises a pump unit and a washer unit (Fig. 4.1), which are connected by

power, air and liquid lines.

The pump unit consists of a double-headed vacuum pump with high-density

polythene reagent and waste bottles and a liquid trap. The main power ON/OFF

switch is at the rear of the pump unit. The frequency selector switch is located

on the bottom side of the pump model Cat. no. 5190771 near the transport

locking screws.

The keypad is located on the left-hand side of the washer unit and the

microprocessor and associated control electronics are housed under the keypad.

The wash head is located above the plate carrier slideway, which can be either

8- or 12-way. The plate carrier moves the microplate accurately beneath the

wash head and incorporates a priming reservoir at its leading edge. The plate

carrier is indexed forward by means of a magnetic coupling to the drive system

housed inside the washer.

Chapter 4: Functional Description

5 6

7

3

8

9

1

1

1

1. Pump unit 8. Wash arm assembly

2. Washer unit 9. Wash head and wash head holders

3. Waste bottle 10. Priming reservoir

4. Wash bottle 11. Keypad

5. Bottle caps 12. Plate carrier

6. Liquid level sensor 13. Program card

7. Liquid trap bottle 14. Pinch valve

Fig. 4.1 Wellwash 4 Mk 2 microplate washer

2

1

1

4

1

The pump creates pressure to the wash bottle (Fig. 4.1, item 4) allowing the

wash liquid to be dispensed through the pinch valve (Fig. 4.1, item 14) into the

microplate wells and a vacuum to the waste bottle (Fig. 4.1, item 3) to aspirate

the used wash liquid into the waste bottle.

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 11

Page 12

4.1 Controls and indicators

Here is a description of the controls and indicators on the Wellwash 4 Mk 2.

POWER ON/OFF switch

This two-position switch at the rear of the pump unit controls the electrical

power to both the pump and washer units.

PRIME push button

A momentary action switch that starts the PRIME function. An audible tone will

sound when pressed to confirm operation.

PRIME indicator

This yellow LED (light-emitting diode) located to the right of the PRIME button

flashes to indicate that the PRIME function is required and, when continuously

ON, indicates that the washer is primed and ready for use. The indicator will turn

off after a while, but the instrument remains ready for use.

ROW SELECT (1 – 12) push buttons

These are momentary action switches that select the last row to be washed in

any chosen program sequence. An audible tone will sound when pressed to

confirm operation.

Chapter 4: Functional Description

Fig. 4.2 Keypad

ROW SELECT indicators

These yellow LEDs located to the right of the ROW SELECT push buttons, when

illuminated, indicate the rows selected for washing.

START push button

This momentary action switch initiates the wash cycle. An audible tone will

sound when pressed to confirm operation.

RESET push button

When pressed, the RESET button will reset the washer to its pre-programmed

state. An audible tone will sound when pressed to confirm operation.

POWER indicator

This green LED is located at the bottom left of the keypad and, when

illuminated, indicates that the POWER switch is ON.

VAC FAIL indicator

A yellow LED which, when flashing, indicates that the waste bottle is full or that

there is a vacuum failure.

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 12

Page 13

5 Installation

5.1 Installation check list

The section on installation will contain an outline of the points mentioned in the

check list below.

Table 5.1 Installation check list

Tick Item

Unpack the Wellwash 4 Mk 2 instrument carefully. Refer to 5.2.1. Keep the

original packaging and packing material for future transportation.

Check the delivery for completeness. Refer to 5.2.2.

Check for damage during transport. Refer to 5.2.3.

Place the instrument on a normal laboratory bench taking into account both

the environmental and technical prerequisites. Refer to 5.2.4 and 5.2.6.

Leave sufficient clearance on both sides and at the rear of the unit.

Install the instrument:

Remove the transit screws. Refer to 5.3, step 1.

Check the voltage and frequency of the electrical supply. Refer to 5.3,

step 2.

Remove the pinch valve holder. Refer to 5.3, step 4.

Install the wash head. Refer to 5.3, steps 5 and 6.

Connect the tubing and the liquid level sensor cord to the pump unit. Refer

to 5.3.1, steps 1 to 5.

Connect the washer unit to the pump unit. Refer to 5.3.1, steps 6 and 7.

Fill the wash bottle and tighten both bottle caps. Refer to 5.3.1, steps 8

and 9.

Slide the plate carrier to its place. Refer to 5.3.1, step 10.

Connect the mains supply cable (cord) to the mains input socket. Refer

to 5.3.2.

Carry out the operational check. Refer to 5.4.

Chapter 5: Installation

5.2 What to do upon delivery

5.2.1 How to unpack

Move the unpacked instrument to its site of operation. Unpack the Wellwash

4 Mk 2 instrument and accessories carefully with the arrows on the transport

package pointing upwards. The following notes and instructions are sent with the

instrument and are immediately available when you open the package:

the Warranty Certificate card

the packing instructions/packing list

the Transportation discrepancy report

the User Manual

Caution: DO NOT touch or loosen any screws or parts other than those specially

designated in the instructions. Doing so might cause misalignment and

Fig. 4.1 shows the pump and washer units in their entirety.

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 13

will invalidate the instrument warranty.

Page 14

Lift out the washer and pump units, removing the shaped packing pieces from

around the washer, and place them on a flat level surface.

To lift the instrument, put your fingers under the bottom on both sides and lift it

with your back straight. The net weight of the instrument is 10 kg (22 lbs.).

Caution: When unpacking the instrument, it is recommended that two people lift

the instrument together, taking proper precautions to avoid injury.

Retain the original packaging and packing material for future transportation. The

packaging is designed to assure safe transport and minimize transit damage. Use

of alternative packaging materials may invalidate the warranty. Also, retain all

instrument-related documentation provided by the manufacturer for future use.

Note: Before use remember to remove the transit screws at the bottom of the

instrument and save them in the adjoining screw holes (marked with the

text "Transit screw storage"). Remove and save the pinch valve holder

until needed for future transportation of the instrument.

5.2.2 Checking delivery for completeness

Check the enclosed packing list against order. In case of any deviations, contact

your local Thermo Fisher Scientific representative or Thermo Fisher Scientific Oy.

Chapter 5: Installation

The instrument is supplied with both 8- and 12-way wash heads, four program

cards, the user manual, the mains supply cable and an accessory pack. The

content of the accessory pack is shown in Fig. 5.1 and Fig. 5.2. Store the

accessories in their bags until you need them.

2

1

3

4

5

1. Combiplate

2. 4 spare fuses (see Section 7.1.10 Fuse replacement)

3. 2 Allen keys (see Section 5.3 Installation procedure, step 1)

4. 2 spanners (see Section 5.3.2 Wash head height)

5. De-clogging tool (see Section 7.1.9 Unclogging tips)

6. 6 spare O rings for the bottle caps

7. 4 spare O rings (see Section 5.3 Installation procedure, step 5)

Fig. 5.1 Accessories included with the instrument.

7

6

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 14

Page 15

1

Chapter 5: Installation

2

3

5

1. Waste liquid spare tube

2. Reagent liquid spare tube

3. Pinch valve spare tubes (item 3 in Fig. 5.3) (see Section 7.1.8 Pinch valve)

4. Wash arm assembly spare tube (item 2 in Fig. 5.3)

5. Wash arm assembly spare tube (item 4 in Fig. 5.3)

6. Wash arm assembly spare tube (item 1 in Fig. 5.3)

Fig. 5.2 Spare tubing

1

2

4

6

Fig. 5.3 Wash arm assembly tubing

5.2.3 Checking for damage during transport

Visually inspect the transport package, the instrument and the accessories for

any possible transport damage.

If the carton has been damaged in transit, it is particularly important that you

retain it for inspection by the carrier in case there has also been damage to the

instrument.

Neither the manufacturer nor its agents can be held responsible for any damage

incurred in transit, but the manufacturer will make every effort to help obtain

restitution from the carrier. Upon receipt of the carrier's inspection report,

arrangements will be made for repair or replacement.

Visually check all interconnections in the basic instrument. Check that there are

no loose parts inside the instrument.

If any parts are damaged, contact your local Thermo Fisher Scientific

representative or Thermo Fisher Scientific Oy.

3

4

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 15

Page 16

5.2.4 Environmental requirements

When you set up your Wellwash 4 Mk 2, avoid sites of operation with excess dust,

vibrations, strong magnetic fields, direct sunlight, draft, excessive moisture or

large temperature fluctuations.

Make sure the working area is flat, dry, clean and vibration-proof and leave

additional room for accessories, cables, wash bottles, etc.

Leave sufficient space (at least 10 cm) on both sides and at the back of the

unit to allow adequate air circulation.

Make sure the ambient air is clean and free of corrosive vapors, smoke and

dust.

Make sure the ambient temperature range is between +5°C (41 F) and +40°C

(104 F), preferably between +15°C (59 F) and +25°C (77 F).

Make sure relative humidity is between 10% and 90% (non-condensing).

Note: The use of the instrument in strong, direct sunlight or next to radiators

The Wellwash 4 Mk 2 does not produce operating noise at a level that would be

harmful. No sound level measurements are required after installation.

and other heat sources may markedly increase the temperature prevailing

at the instrument. This should be taken into account when deciding

where the instrument should be located and operated.

Chapter 5: Installation

Warning: DO NOT operate the instrument in an environment where potentially

damaging liquids or gases are present.

5.2.5 Things to avoid

DO NOT smoke, eat or drink while using the Wellwash 4 Mk 2. Wash your hands

thoroughly after handling test fluids. Observe normal laboratory procedures for

handling potentially dangerous samples. Use proper protective clothing. Use

disposable gloves. Be sure the working area is well ventilated.

Never spill fluids in or on the equipment.

Only use the instrument for its intended purpose. Refer to Section 3.1.

5.2.6 Technical prerequisites

The washer and pump units require no special site preparations. A normal

laboratory bench close to a mains supply socket is quite suitable. The net weight

of the instrument is 10 kg (22 lbs.).

Check that the voltage label on the rear panel of the pump unit conforms to the

supply voltage used in the laboratory. The instrument operates at voltages of 100

– 120 Vac, 220 – 240 Vac and the frequency range 50/60 Hz (see Section 5.3, step

2).

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 16

Page 17

5.3 Installation procedure

Any suitably skilled person using standard tools may carry out the following

procedure.

1. Rest the pump unit on its side and remove the transit screws (the Allen cap

head type is painted red) using the key supplied (Fig. 5.1, item 5). Relocate

them in the retaining holes provided (Fig. 5.4).

Note: When relocating this instrument or returning it for repair, it is essential

2. Ensure that the pump mains switch is in the OFF position. After checking that

the electrical supply conforms to that specified on the voltage label on the

rear panel of the unit, slide the frequency selector switch (in the pump

model Cat. no. 5160771) to the 50 Hz or 60 Hz position depending on the

mains supply voltage frequency (Fig. 5.4). (Other pump models do not

include a frequency selector.)

Chapter 5: Installation

that the transit screws are refitted. Failure to do so could invalidate the

warranty.

2

1

3

1. Location of the frequency selector switch

2. Retaining holes for the transit screws

3. Transit screws during transportation

Fig. 5.4 Location of the frequency selector switch and the transit screws

3. Turn the pump unit back to its normal position.

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 17

Page 18

Chapter 5: Installation

Pinch valve holder

4. Lift the wash arm assembly (the stainless steel cover). Remove the pinch

valve holder (Fig. 5.5) before use. Store the wire holder for future use.

Fig. 5.5 Pinch valve holder

Note: The wash heads are packed separately. Install them before use.

5. Install first the four (4) small O-rings to the wash head holders, two (2) on

both sides (Fig. 5.6).

Fig. 5.6 Installing the O rings to the wash head holders

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 18

Page 19

6. Slide the wash head between the holders (Fig. 5.7).

Note: The wash heads will only fit into the end slots when the raised flange on

the wash head is facing the front.

Fig. 5.7 Sliding the wash head between the holders

5.3.1 How to install the pump unit and washer unit connections

Chapter 5: Installation

Fig. 5.8 Pump unit with tubes installed

1. The wash bottle with the black connections is located on the right-hand side

of the pump unit and the waste bottle to the left. All the tubing and

connections are color coded to ensure correct connection (Table 5.2).

Table 5.2 Silicon tubing color-codes

Black

Yellow

Red

Blue

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 19

Pressure feed from the pump to the wash bottle

Pressuring wash reagent from the wash bottle to the washer

unit

Vacuum feed from the pump to the waste bottle

Waste feed from the washer unit to the waste bottle

Page 20

Chapter 5: Installation

2. Connect the pressure feed from the pump on the right to the wash bottle

using the black-coded tube.

3. Connect the vacuum feed tube (red) from the pump to the waste bottle

(Fig. 5.9, item 2).

4. Connect the liquid level sensor cord from the liquid trap bottle to the waste

bottle. Make sure the black connector is firmly in place (Fig. 5.9, item 1).

Caution: The liquid level sensor does not function if the connector is not properly

inserted: the black connector has to be pushed down all the way. The

waste bottle may otherwise overfill and cause the liquid trap bottle to

start filling. If at that point the liquid trap bottle is not emptied, the

overflowing waste liquid can enter the pump unit and damage it.

1

1. Liquid level sensor connector

2. Vacuum feed tube

3. Liquid trap bottle cover

Fig. 5.9 Liquid level sensor system

2

3

5. Check that the tubes are properly connected to the pinch valve under the

wash arm assembly on the washer unit (Fig. 4.1, item 14). The thin tube

going through the valve should not be pinched by the edges of the valve.

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 20

Page 21

Chapter 5: Installation

6. Remove the three (3) black plastic caps from the hose connectors and the

pump control at the rear of the washer unit (Fig. 5.10).

Fig. 5.10 Removing the plastic caps

7. Slide the two units together until the locating dowel and electrical

connectors are firmly engaged (Fig. 5.11).

1

2

3a

1. Silicone tube (waste, blue color code)

2. Manifold pipes (PRESSURE for reagent tube/yellow, VACUUM for waste tube/blue)

3. Locating pin (a) and friction bush (b)

4. Silicone tube (wash, yellow color code)

5. Signal connectors (with text PUMP CONTROL)

6. Silicone tube (pressure, black color code)

7. Pump pressure adjustment screw (do not touch –for authorized service personnel

only!)

Fig. 5.11 Connection of pump and washer units

4

5

6

7

3b

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 21

Page 22

Chapter 5: Installation

Cap ring

Plug

8. Open the wash bottle (Fig. 4.1, item 4) by rotating the cap ring, while the

white plug remains stationary. Lift the cap ring and open the plug. Fill the

wash bottle up to the shoulder with wash reagent and reconnect ensuring

that the plug mates correctly with the bottle insert (Fig. 5.12) and that the

cap ring is tightly screwed down.

Fig. 5.12 Opening and closing the bottle

9. Tighten the cap on the waste bottle.

10. Lift the wash head and slide the plate carrier onto the stainless steel

slideway so that the reservoir is under the wash head (Fig. 5.13).

1

2

3

1. Wash head

2. Priming reservoir

3. Plate carrier

Fig. 5.13 Correct position of the plate carrier

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 22

Page 23

5.3.2 Wash head height

To accommodate the differences in size and volume capacity of manufacturers’

microplates, the height of the wash head is adjustable. This means that a

positive meniscus can always be obtained without an unnecessary waste of wash

reagent.

The wash head is factory-set at a nominal height to suit the most commonly used

microplates. Should adjustment be required follow these instructions:

1. Make sure the wash bottle is empty to facilitate the adjustment. Start a

simple wash routine and wait until the wash arm assembly starts to slide

backwards. Turn OFF the instrument from the power switch at the back of

the pump unit. The wash head is now in the raised position.

2. A stainless steel head lift rod is located on the left-hand side of the washer

unit immediately above the keypad. There is a domed nut at the top of the

rod with a locknut underneath.

3. Perform the adjustment using the two spanners 5.5/6.0 supplied with the

instrument.

Chapter 5: Installation

Fig. 5.14 Loosening the locknut with spanners

4. Loosen the locknut (Fig. 5.14) by keeping the 6.0-spanner stationary while

turning the 5.5-spanner clockwise.

5. Adjust the height by rotating the domed nut, clockwise to lower the wash

head and anticlockwise to raise the wash head.

6. Set the tips of the wash head to approx. 1.5 mm to 2.0 mm above the height

of a microplate on the plate carrier, when the wash head is in the raised

position.

7. Lock the domed nut into position with the locknut. When locking the domed

nut into position, keep it still with the spanner 6.0 and only rotate the

locknut anticlockwise using the spanner 5.5.

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 23

Page 24

5.3.3 Mains supply cable

Warning: Never operate your instrument from a power outlet that has no ground

1. Ensure that the mains switch at the rear of the pump unit is in the OFF

position.

2. Connect the mains supply cable (cord) to the mains input socket at the rear

of the pump unit. If you need to use any other type of mains supply cable

than supplied, use only cables certified by the local authorities.

3. Connect the instrument to a correctly installed line power outlet that has a

protective conductor that is grounded (earthed).

5.3.4 Changing wash heads

You can change the wash head to either 8-way or 12-way. Lift the head assembly

(Fig. 4.1, item 8), grasp the wash head (Fig. 4.1, item 9) at both ends and slide it

down in the direction of the tips until it clears the end caps. Check that the two

O rings in each end cap are in position and undamaged. To install the alternative

wash head, slide it upwards onto the slots making sure that it is fully engaged

(Fig. 5.7).

Chapter 5: Installation

connection. Never use a mains supply cable (cord) other than the Thermo

Scientific mains supply cable designed for your region.

Fig. 5.15 Changing the wash head

Note: The wash heads will only fit into the end slots when the raised flange on

Remember to check the program card accordingly (8-way or 12-way).

5.4 Operational check

The following procedure should be completed to confirm the correct functioning

of the washer prior to normal use.

1. Check that the wash head is correctly located by means of its guide slots in

the head assembly (Fig. 5.7). The operational check is performed faster with

the 12-way wash head.

2. Add approximately 2 to 3 dl of distilled aqua to the wash bottle and make

sure that both bottle caps are firmly tightened.

3. Switch ON the mains power supply by depressing the POWER ON switch

positioned on the rear panel of the pump unit.

The POWER indicator on the keypad (Fig. 4.2) will be illuminated and a

countdown sequence will begin on the row indicators. The row 12 indicator

will illuminate first followed by row 11, row 10, row 9, and so on, at onesecond intervals until the PRIME indicator is reached. The pressure

the wash head is facing the front.

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 24

Page 25

Chapter 5: Installation

generation takes 10 seconds. The PRIME indicator continues flashing to

prompt the user to prime the system.

4. Select the preprogrammed wash card for 1 wash and for the 12-way wash

head. Plug it into the slot on the right-hand side of the washer unit (Fig. 4.1,

item 13).

5. Lift the wash head and slide the plate carrier onto the stainless steel

slideway so that the reservoir is under the wash head (Fig. 5.13).

6. The instrument should now be primed. Press the PRIME button to initiate the

sequence. The wash head will lift and the pinch valve will open for one

second allowing wash fluid to flow into the priming reservoir. The wash head

will then lower itself to empty the prime reservoir. The PRIME indicator will

turn off when the priming is complete.

If no further key entry is made within ten (10) seconds of priming, the pump

will automatically switch OFF. The instrument will then enter its idle state,

waiting for instructions from the keypad and program card.

7. Place a microplate onto the plate carrier. When using a 12-way wash head,

the well A1 of the microplate should be positioned in the top left-hand

corner. When using an 8-way wash head, the well A1 should be positioned in

the top right-hand corner. See Fig. 5.16.

A1 A1

Fig. 5.16 Placing the microplate with 12-way and 8-way wash head

8. Select the row number of the last row to be washed on the keypad (e.g.,

when button 4 is pressed, rows 1 to 4 will be washed).

Note: When the 12-way program card is installed, buttons 9 to 12 are

inoperative.

9. Press the START button to set the washing cycle into operation. The plate

carrier will be drawn into the washer, filling and aspirating each row

according to the sequence selected on the program card. At the end of a

sequence, rows will be left substantially dry and the plate carrier will stop

with the priming reservoir under the wash head.

10. The instrument is performing properly, if the wells are dry. If they are not,

check that both bottle caps are firmly closed

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 25

Page 26

6 Operation

key Perform

6.1 Operational checklist

Table 6.1 Operational checklist

Tick Item

Chapter 6: Operation

Fill the wash bottle with appropriate washing reagent.

Select the program card and insert it.

When using the programmable switch card, check the settings.

Switch the instrument ON.

Prime the instrument.

Place a microplate onto the plate carrier.

Select the row number of the last row to be washed.

Start the wash sequence.

When the wash sequence has finished, remove the microplate.

Shut down the instrument.

The following symbols are used in the flowchart below:

Press the key.

action

Indicates the actions you should take.

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 26

Page 27

6.2 Washing a microplate

Fill the wash

Turn the

Remove the

Place the

Position the

Plug the

program card

1 –

Turn the

Ensure that the instrument is switched OFF.

Chapter 6: Operation

bottle and

empty the

waste bottle

into the slot

plate carrier

for priming

instrument

ON

PRIME

microplate

onto the

plate carrier

Open the wash bottle cap (Fig. 6.1) very carefully to release any

residual pressure. Let the hissing sound end prior to opening the cap all

the way. Fill the wash bottle with appropriate washing reagent and

tighten the bottle cap firmly (see Fig. 5.12).

Select either one of the preprogrammed wash cards or the

programmable switch card (see Section 6.5).

Before inserting any program card, ensure that it is clean and dry.

Wiping the surfaces with a soft dry cloth will suffice. If any liquid is

present on the card, a malfunction of the program may occur.

Position the plate carrier on its slideway with the priming reservoir to

the rear under the wash head (see Fig. 5.13).

The POWER indicator on the keypad (Fig. 4.2) illuminates and a

countdown sequence will begin on the row indicator LEDs.

The PRIME indicator flashes until you prime the system (Section 6.3).

The priming function is complete when the PRIME indicator turns OFF.

If no further key entry is made within fifteen seconds of priming, then

the pump will automatically switch OFF. The instrument will then enter

the idle state, waiting for instructions from the keypad and program

card.

Check that the correct wash head (8-way or 12-way) is fitted.

Check that the plate is placed properly onto the plate carrier (Fig.

5.16).

12

START

microplate

from the

plate carrier

instrument

OFF

Select the row number of the last row to be washed. If no row is

selected, the whole plate will be washed.

The instrument performs the wash sequence.

After pressing the START button, there may be a delay of up to 15

seconds before the run begins to allow the reagent and waste bottles to

reach the working pressure.

The plate carrier will advance into the washer aspirating and filling

selected rows in the sequence determined by the program card fitted.

On completion of the protocol, the plate carrier will come to rest with

the wash head lowered into the priming reservoir.

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 27

Page 28

Chapter 6: Operation

Warning: If the instrument is used in a manner not specified by the manufacturer,

the protection provided by the instrument may be impaired. See Section

9.1 General specifications.

Caution: Handle the microplate with care to avoid any contamination of the

instrument and the subsequent specimens. The contamination of the

specimen will lead to incorrect results.

If the contents of the microplate does spill, however, follow the

decontamination procedure presented in Section 7.3. Also, follow the

system supplier's instructions in regard to the reagent kit and specimen

handling in the event of contamination.

Warning: Never open the wash bottle, detach any of the tubing or press the black

top of the pinch valve without first releasing the pressure by slightly

opening the bottle cap. Let the hissing sound end prior to opening the cap

all the way.

Warning: If you are using a washing reagent that is either volatile or splashes

easily, keep yourself at a safe distance from the instrument while it is

operating to avoid exposure. Place the instrument into a fume hood.

Warning: When washing microplates with samples of human or animal origin, keep

yourself at a safe distance from the instrument while it is operating to

avoid exposure. Place the instrument into a fume hood.

Note: If the pump fails to start or if the bottle caps are loose, an audible

warning will be heard and the VAC FAIL indicator will illuminate. This

condition will clear once the pump has started. If the VAC FAIL indicator

does not clear after the pump has started, the RESET key must be

depressed. Also, check that the waste bottle is not full.

Note: The priming procedure must be repeated whenever the POWER switch has

been engaged or if there has been an interruption of the power supply.

Caution: Make sure that sufficient reagent is present in the wash bottle to

complete the required protocol. See Fluid consumption in Section 9.1

General specifications.

Caution: If you use the programmable switch card, ensure that the 8 WAY –

12 WAY switch is in the correct position (for either the 8-way or the

12-way wash head).

Caution: If removable-well microplates are being used, make sure that there are

no missing wells in the rows to be washed and that all the wells are at

the same level.

Note If you press the RESET button on the keypad at any stage, this will stop

the immediate washing sequence and reset the system to its preprogrammed state.

Caution: DO NOT smoke, eat or drink while using the Wellwash 4 Mk 2. Wash your

hands thoroughly after handling test plates. Observe normal laboratory

procedures for handling potentially dangerous plates. Use proper

protective clothing. Use disposable gloves. Ensure that the working area

is well ventilated.

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 28

Page 29

Caution: Never spill fluids in or on the equipment. Prevent any liquid from

Caution: Immediately wipe away spilled liquids from outer surfaces to prevent

Caution: Keep the instrument free of dust and other foreign matter. Clean the

6.3 Priming procedure

Position the plate carrier on its slideway with the priming reservoir to the rear

under the wash head (see Fig. 5.13). Press the PRIME button. The wash head will

lift and the pinch valve will open for one second allowing wash fluid to flow into

the priming reservoir. The wash head will then lower itself to empty the priming

reservoir. The priming function is complete when the PRIME indicator turns OFF.

If no further key entry is made within ten seconds of priming, the pump will

automatically switch OFF. The instrument will then enter the idle state, waiting

for instructions from the keypad and program card.

Chapter 6: Operation

entering the instrument.

damage and wipe over with a mild detergent.

plate carrier and the plate carrier slideway and keep them dry to prevent

jamming.

If the pump fails to start or if the bottle caps are loose, an audible warning will

be heard and the VAC FAIL indicator will illuminate. This condition will clear

once the pump has started. If the VAC FAIL indicator does not clear after the

pump has started, the RESET key must be depressed. Check also that the waste

bottle is not full.

Note: The priming procedure must be repeated whenever the POWER switch has

been operated or if there has been an interruption of the power supply.

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 29

Page 30

6.4 Adding wash reagent

To add wash reagent, first release the pressure from the wash bottle by carefully

opening the bottle cap (see Fig. 6.1). Let the hissing sound end prior to opening

the cap all the way.

Chapter 6: Operation

Fig. 6.1 Releasing the pressure from the wash bottle

Also, when you are changing the used reagent and you wish to rinse and clean

the tubing, first release the pressure from the tubing and the wash bottle by

slightly opening the wash bottle cap.

Close the wash bottle tightly (Fig. 5.12).

The waste bottle needs to be emptied when the wash bottle is filled.

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 30

Page 31

6.5 Program selection

Choose an appropriate card for the wash routine. Plug the card into the slot

located at the base to the right of the washer unit.

Note: Before inserting any program card, ensure that it is clean and dry. Wiping

Note 1: If a run is started without a program card or any row selection, the

Note 2: If a run is started with the rows selected but with no program card

Note 3: If a run is started without any rows selected but with a program card

The preprogrammed wash cards will dispense and aspirate the plate row by row

for the number of times indicated on the card. There are four cards which can be

inserted either side up to perform the wash routine indicated on the side facing

up.

Chapter 6: Operation

the surfaces with a soft dry cloth will suffice. If any liquid is present on

the card, a malfunction of the program may occur.

instrument will signal an error by sounding the audible warning device

3 times.

inserted, the instrument aspirates the rows selected and returns to its

idle state with the wash head lowered into the priming reservoir.

fitted, the instrument will aspirate all the rows in accordance with the

card configuration, i.e., 8-way or 12-way wash head.

Fig. 6.2 Preprogrammed card: three washes with an 8-way wash head

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 31

Page 32

Chapter 6: Operation

Contained on the programmable switch card are four (4) rotary type and nine (9)

two-way type switches each marked with their function. The setting of these

switches controls the function of the washer, enabling a wide variety of protocols

to be performed.

Fig. 6.3 Programmable switch card

6.5.1 Two-way switch functions

SINGLE

Make sure that this switch is always set to

single wash head.

8 WAY

Use with an 8-way wash head.

PLATE

All selected rows are washed once, the

instrument waits during the PAUSE setting,

and the following wash cycle is started.

STEPOFF

The plate carrier will only pass over the

selected rows. With this selection, the

plate processing times are kept to a

minimum.

WASHLO

The wash head fills the well while rising

from the bottom of the well.

WET

The plate will remain filled after washing.

Use this setting with soak period.

F WET

The plate will remain filled after the final

wash.

Switch settings

—

12 WAY

Use with a 12-way wash head.

STRIP

Each row is washed the set number of

times (WASHES). The PAUSE setting is

between each row.

STEPOVR

The plate carrier will pass over all the

rows, not washing the rows not selected.

With this selection, the time used for each

plate remains constant.

WASHHI

The wash head fills the well from the

raised position.

DRY

The plate will be aspirated after washing.

F DRY

The plate will be aspirated after the final

wash.

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 32

Page 33

Chapter 6: Operation

F1 OFF – FINAL X1 and F2 OFF – FINAL X2

Table 6.2 Number of washes after a soak period

Settings Number of

washes

F1 OFF F2 OFF 0

FINAL X1 F2 OFF 1

F1 OFF FINAL X2 2

FINAL X1 FINAL X2 3

PLATE – STRIP and WET – DRY

Table 6.3 Aspiration after the final wash

Settings

PLATE WET No aspiration (wells filled)

PLATE DRY All rows aspirated after the final wash

STRIP WET No aspiration (wells filled)

STRIP DRY Each row aspirated after its final wash

6.5.2 Rotary switch functions

SOAK

Set the soak period (Table 6.4), which commences after all the presoak wash

routines (WASHES) are complete. Make sure you have selected WET.

Table 6.4 Soak period (in minutes)

Setting

Soak time (minutes) 0 0.5 1.0 1.5 2.0 2.5 3.0 3.5

Setting 8 9 A B C D E F

Soak time (minutes) 4.0 4.5 5.0 6.0 7.0 8.0 9.0 10.0

0 1 2 3 4 5 6 7

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 33

Page 34

Chapter 6: Operation

PAUSE

Set the pause between each wash cycle (Table 6.5). During the strip wash mode,

the pause is between each row. During the plate wash mode, the pause is

between each pass over the plate.

Note: The times currently available are subject to approval and may be altered

to suit individual customer requirements.

Table 6.5 Pause (in seconds) between each washing cycle

Setting

Strip wash mode

(seconds)

Plate wash mode

(seconds)

Setting 8 9 A B C D E F

Strip wash mode

(seconds)

Plate wash mode

(seconds)

0 1 2 3 4 5 6 7

0 1 2 3 4 5 6 7

0 5 10 15 20 25 30 40

8 9 10 15 20 30 45 60

50 60 75 85 105 120 180 240

WASHES

Set the number of washes to be performed before a soak period (Table 6.6).

Table 6.6 Number of washes before soaking

Setting

Number of washes 0*) 1 2 3 4 5 6 7

Setting 8 9 A B C D E F

Number of washes 8 9 10 11 12 13 14 15

*) No wash, only aspirate

0 1 2 3 4 5 6 7

VOLUME

Set the volume dispensed during washing (Table 6.7).

Table 6.7 Washing volume (in µl)

Setting

Washing volume (µl) 0 50 100 150 200 250 300 350

Setting 8 9 A B C D E F

Washing volume (µl) 400 450 500 550 600 650 700 750

0 1 2 3 4 5 6 7

Note: The dispense volume is less than the wash volume to avoid overfilling the

wells.

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 34

Page 35

6.6 Resetting

If you press the RESET button on the keypad at any stage, this will stop the

immediate washing sequence and reset the system to its pre-programmed state.

6.7 Shutdown procedure

Warning: Remove any microplate still on the plate carrier. Dispose of all

microplates and strips as biohazardous waste.

The wash reagents may contain buffer salts, which can crystallize when the

washer is not in use. This may cause clogging of the wash/aspirate tips. To avoid

this, the following procedures should be followed.

6.7.1 Daily shutdown procedure

When the last wash cycle of the day is complete, switch the power OFF through

the switch at the rear of the pump unit. Fill the priming reservoir of the plate

carrier with distilled water and lower the wash head tips into the priming

reservoir. Do not detach the tubes unless you first open the wash bottle cap

slightly to release the pressure.

Chapter 6: Operation

Wipe the instrument surfaces with a soft cloth or tissue paper moistened with

deionized distilled aqua, a mild detergent (SDS, sodium dodecyl sulfate) or soap

solution.

If you have spilt infectious agents on the instrument, disinfect with 70% alcohol

or other disinfectant. See the Wellwash 4 Mk 2 User Manual, Section 7.3.

Last of all, put the dust cover on.

6.7.2 Long-period shutdown

If the washer is not likely to be used for a long period, you should flush the

system through with distilled water prior to carrying out the DAILY shutdown

procedure. Empty and clean the waste bottle and check that the liquid trap is

dry.

When the washer is to be used after a prolonged shutdown, you should prime the

system (Section 6.3) at least four (4) times prior to carrying out any wash

function.

6.8 Emergency situations

In case there is any abnormal situation during operation, such as fluids spilling

inside the instrument, follow these steps:

1. Switch OFF the instrument.

2. Unplug the instrument from the mains.

3. Perform appropriate corrective actions. However, do not touch the interior

of the instrument.

4. Contact authorized technical service or your local Thermo Fisher Scientific

representative.

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 35

Page 36

7 Maintenance

7.1 Regular and preventive maintenance

7.1.1 Service contracts

It is strongly recommended that this instrument be regularly maintained and

serviced every twelve (12) months on a contract basis by trained service

engineers of the manufacturer. This will ensure that the product is properly

maintained and that it gives trouble-free service. For more details, contact

Thermo Fisher Scientific's service department.

7.1.2 Maintenance check list

The check list below contains a recommended maintenance schedule .

Table 7.1 Maintenance check list

Item

Chapter 7: Maintenance

7.1.3 General

As required

Daily

Weekly

Monthly

Wipe the case of the instrument.

Cover the instrument with the dust cover after use.

Clean the instrument and the keyboard with a cloth

dampened with mild detergent, followed by deionized

distilled aqua. See Sections 7.1.3 and 7.1.4

Check the condition of the tubing and the wash and

waste bottles. See Sections 7.1.5 and 7.1.6

Check the pinch valve. See Section 7.1.8.

Unclog the wash head tips. See Section 7.1.9.

Change the fuses when blown. See Section 7.1.10.

Decontaminate the instrument if any biohazardous

material has been spilled on it or when shipping it to

service. See Section 7.3.

Perform the operational check regularly. See

Section 5.4.

Arrange for the yearly servicing of the instrument

(Section 7.1.1 above).

Routine and service procedures must be performed by the user to prevent

unnecessary wear or hazards and are described below at the frequency with

which they should be applied.

Yearly

For reliable daily operation, keep the instrument free of dust and spills from

liquids. It is also advisable to cover the instrument with the dust cover supplied

when not in use. In the event of any damage, contact your local Thermo Fisher

Scientific representative for service.

Abrasive cleaning agents are not recommended, because they are likely to

damage the paint finish.

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 36

Page 37

Chapter 7: Maintenance

It is recommended that you clean the case of the instrument periodically to

maintain its good appearance. A soft cloth dampened in a warm, mild detergent

solution will be sufficient.

Caution: Painted surfaces can be cleaned with most laboratory detergents. Dilute

the cleaning agent as recommended by the manufacturer. DO NOT expose

painted surfaces to concentrated acids or alcohols for prolonged periods

of time as damage may occur.

Clean the keypad with a mild laboratory detergent.

Plastic covers and surfaces can be cleaned with a mild laboratory detergent or

alcohol.

Warning: If any surfaces have been contaminated with biohazardous material, a

mild sterilizing solution should be used. See Section 7.3.

Warning: If, for any reason, you need to move the instrument, release first the

pressure from the tubing by slightly opening the bottle cap. Let the

hissing sound end and then detach the yellow and blue coded tubes from

the instrument.

7.1.4 Immediate

Although the Wellwash 4 Mk 2 is constructed from high-quality materials, you

must immediately wipe away spilled saline solutions, solvents, acids or alkaline

solutions from outer surfaces to prevent damage and wipe with deionized

distilled aqua.

Spillages of liquid on the carrier slideway should be wiped off promptly, as this

may cause the plate carrier to drag during operation.

Caution: DO NOT use any solutions containing hypochlorite, such as bleach, on any

7.1.5 Tubing

Inspect the condition of the tubing regularly. When you notice that a tube is

becoming harder and it is no longer clear, it should be replaced. Only use tubing

supplied by Thermo Fisher Scientific Oy. The instrument is supplied with spare

tubes (Fig. 5.2). See Chapter 10 Ordering Information.

Warning: Never detach a tube without first releasing the pressure by slightly

of the stainless steel surfaces, as this may cause permanent damage to

the finish.

opening the bottle cap. Let the hissing sound end prior to detaching any

of the tubes.

7.1.6 Reagent / waste bottles

Due to the nature of the materials used for the manufacture of our reservoir

bottles, our suppliers have recommended that they be replaced after two years

of use. This replacement policy must be more frequent if the bottles are stored

or used in direct sunlight for long periods of time.

Thermo Fisher Scientific Oy is aware of a potential risk of leakage in the pressure

bottles when they have been subjected to long periods of UV radiation. Although

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 37

Page 38

this occurrence is very rare, our customers are urged to follow this piece of

advice.

Bottles are available from Thermo Fisher Scientific Oy for the Wellwash 4 Mk 2

(Cat. no. WW934/1). Spare O rings for the bottle plugs are included in the spare

parts bag delivered with the instrument (see Fig. 5.1, item 6). See Chapter 10

Ordering Information.

Ensure that the waste bottle is emptied regularly and at least every time the

wash bottle is filled. Do not let the liquid level exceed the level mark on the

bottle.

The waste bottle is fitted with a liquid level sensor. The sensor prevents the use

of the instrument after the waste bottle is filled to the mark.

7.1.7 Liquid trap bottle

The liquid trap bottle prevents liquid from entering the pump and it should be

kept dry at all times. Liquid should enter the liquid trap bottle only if the liquid

level sensor is not properly connected (Fig. 7.1, item 1) and the waste bottle

overflows. If that happens, follow immediately the steps below:

1. Switch OFF the instrument and make sure there is no pressure in the wash

bottle by opening the wash bottle cap slightly.

Chapter 7: Maintenance

2. Open the black screw on the cap of the liquid trap bottle cover (Fig. 7.1,

item 2).

1

2

1. Liquid level sensor

2. Liquid trap bottle cover screw

Fig. 7.1 Liquid level sensor and liquid trap bottle cover

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 38

Page 39

Chapter 7: Maintenance

3. Release the cover by slightly lifting the tube and slide the cover then

upwards along the tube (Fig. 7.2)

Fig. 7.2 Opening the liquid trap bottle cover

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 39

Page 40

Chapter 7: Maintenance

Mark on the thin tube

4. Pull the thick vacuum tube (with the 90° angle) out of the liquid trap bottle.

Fig. 7.3 Pulling the thick tube out of the liquid trap bottle

5. Pull the thin tube out of the liquid trap bottle.

Fig. 7.4 Pulling the thin tube out of the liquid trap bottle

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 40

Page 41

Chapter 7: Maintenance

6. Let the red-coded tube remain connected to the bottle cap and take the

bottle out, unscrew the liquid trap bottle cap and empty the bottle.

Fig. 7.5 Opening the liquid trap bottle

7. Close the bottle. Make sure the end of the red-coded tube is about 2 cm

deeper inside the bottle than the thin tube will be. Put the bottle back to its

place, but don't push it yet all the way down.

8. Insert the thin tube back through the liquid trap bottle cap so that the mark

on the tube (Fig. 7.4, item 1) is at the level of the cap.

9. Push the bottle all the way down. Push the thick vacuum tube as far as it

goes. Its end should now be approximately at the same level as the redcoded tube's end.

10. Slide the cover back down and screw the black screw back on. You can pull

the red-coded tube slightly out to make sure the cover is tightly on.

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 41

Page 42

7.1.8 Pinch valve

Occasionally the tube passing through the pinch valve becomes permanently

closed, i.e., it will not return to its normal shape when the valve opens while in

use. This tends to occur after extended periods of non-operation.

Release the pressure in the tubing by opening the wash bottle cap slightly. To

unpinch, locate the valve under the wash arm assembly. Press the black top of

the valve to release the tube, and pull the tube gently through the pinch valve a

few millimeters; the valve will now pinch into a new position. See Fig. 7.6.

Warning: Never press the black top of the pinch valve without first releasing the

Chapter 7: Maintenance

pressure by slightly opening the wash bottle cap. Let the hissing sound

end prior to pushing the valve top.

Fig. 7.6 Unpinching the tube

If the washer is run now, the liquid will flow normally.

It may be necessary to replace the tube after extended periods of use due to

fatigue. Use the spare tubes supplied with the instrument (Fig. 5.2, item 3).

1. Switch OFF the instrument and make sure there is no pressure in the wash

bottle by opening the wash bottle cap slightly.

2. Press the black top of the valve to release the tube and slide the tube gently

out of the pinch valve through the slit on the side.

3. Disconnect the tube from both ends and replace with a new one.

4. Press the black top of the valve and slide the new tube back into the valve

through the slit. Make sure the tube is properly in place through the valve

and is not pinched especially on the rear side of the valve.

7.1.9 Unclogging tips

The dispense/aspirate tips of the wash head may become clogged with salt

deposits. To clear them, switch OFF the washer, lift up the wash arm assembly

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 42

Page 43

Chapter 7: Maintenance

and unclog the tips using the small de-clogging tool provided (see Fig. 7.7). Push

the de-clogging tool into the thin metal tube.

Fig. 7.7 De-clogging the wash head

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 43

Page 44

Fuse holder

7.1.10 Fuse replacement

1. Switch OFF the washer and disconnect the mains supply cable.

2. Slide the washer and pump units open, and disconnect the pressure and

vacuum tubing from the washer unit.

Warning: Never disconnect the pressure tubing without first releasing the pressure

3. Locate the fuse holders at the rear of the washer and pump units.

4. On the washer unit, use a screwdriver to remove the fuse holder cap. Turn

the screwdriver counterclockwise about 45° to release it and then pull it out

(Fig. 7.8).

Chapter 7: Maintenance

by slightly opening the wash bottle cap. Let the hissing sound end prior to

disconnecting the tubing.

Fig. 7.8 Opening the fuse holder of the washer unit

5. Remove the faulty fuse and discard it.

Fig. 7.9 Washer unit fuse and fuse holder

Thermo Scientific Wellwash® 4 Mk 2 User Manual Rev. 2.4, Cat. no. 1507340 44

Page 45

Chapter 7: Maintenance

Fuse holder

Used fuse

Spare fuse

6. Ensure that the replacement has the same rating as appears on the rating

label on the rear panel of the washer unit. Only use fuses specified by

Thermo Fisher Scientific Oy.

7. Insert the new fuse to the fuse holder and push the holder into its place.

Turn the holder clockwise about 45° with the screwdriver.

8. On the pump unit, use the screwdriver to gently pry the fuse folder open.

Fig. 7.10 Opening the fuse holder of the pump unit

9. There are two fuses inside the holder. The outer one is a spare fuse and the

inner one is the one in use.