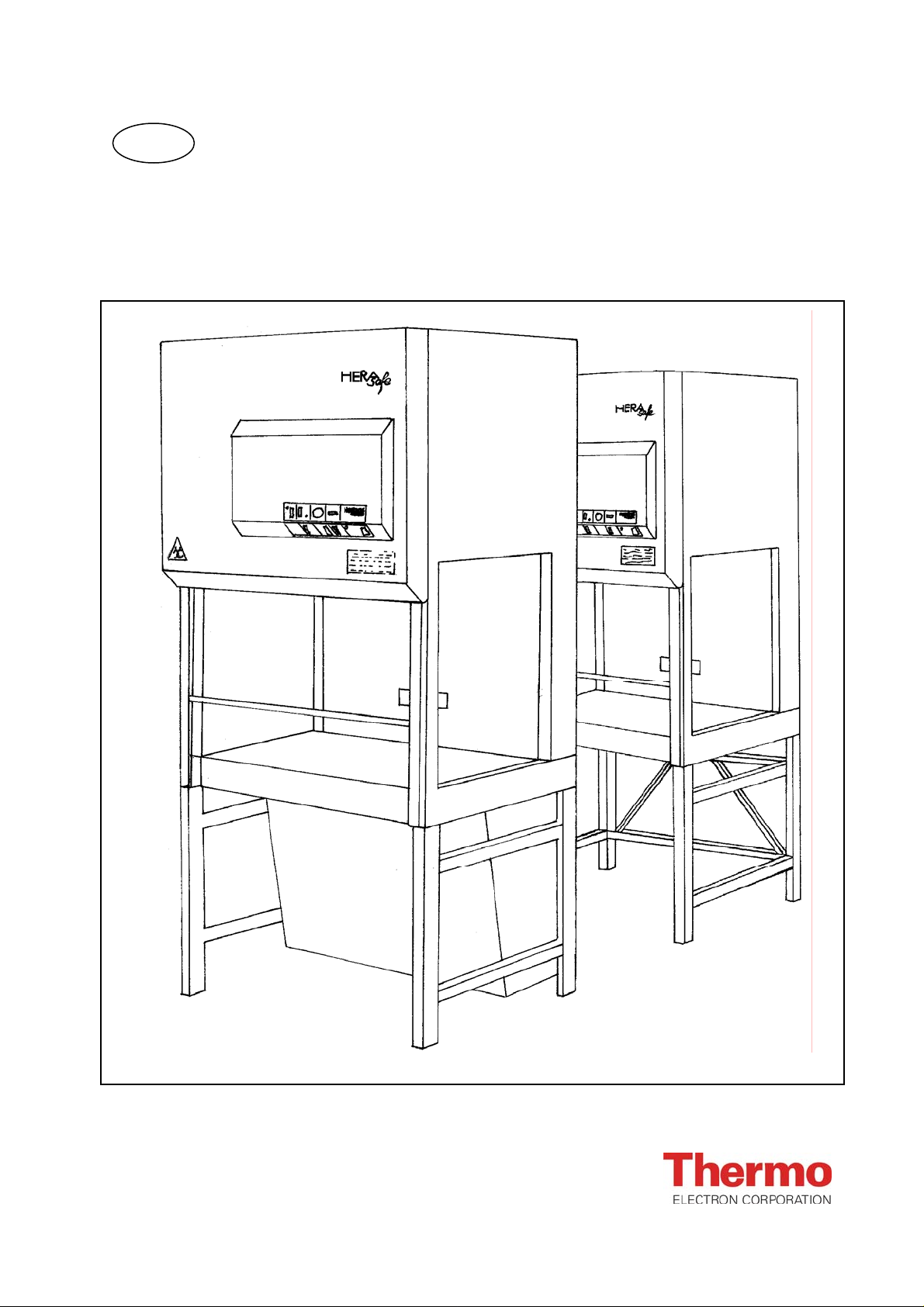

Thermo Safety Cabinet Class 2 User manual

GB

Class 2

Safety Cabinets

Operating instructions

Valid: 09.2005 / 50047299 C

These operating instructions apply to the following unit equipment levels:

Model Equipment

HS Units with intake protection pre-filters

HSP Units with HOSCH pre-filters

HSPC Units with activated charcoal pre-filters

HS. . . ./85 Units with increased interior height

Neither these instructions nor any part thereof may not be reproduced or distributed without the express written

approval of Thermo Electron LED GmbH.

This version applies to operating instructions for series production safety workbenches.

These operating instructions may be expanded to include accessories.

Various sections of this manual may only be copied for the internal use of the operator, e.g., for person-

nel safety and accident prevention training. These sections are indicated in the contents.

Thermo Electron LED GmbH assumes no liability or responsibility for the suitability of the units for a particular purpose aside from those listed in the section dealing with the unit's areas of application.

We reserve the right to make changes to the content of these operating instructions at any time and without prior notification.

For all translations into foreign languages, the original German version of these operating instructions

is binding.

Published: 09.2005

Subject to fee.

Trademarks

HERAsafe ® and the term "Heraeus" are registered trademarks of Thermo Electron LED GmbH.

Any other trademarks mentioned are the exclusive property of the manufacturers in question.

© Thermo Electron LED GmbH, 63505 Langenselbold, Germany

2/27 50 047 299

Below is a list of the international Thermo marketing organizations.

Postal address Germany

Thermo Electron LED GmbH

D – 63505 Langenselbold

Robert-Bosch-Strasse 1

Enquiries from Germany

Phone

Sales 0800 1 536376

Service 0800 1 112110

Fax

Sales/Service 0800 1 112114

E-Mail

info.labequipment.de@thermo.com

Enquiries from Europe, Middle East

and Africa

Phone + 49(0) 6184 / 90-6940

Fax + 49(0) 6184 / 90-7474

E-Mail

info.labequipment.de@thermo.com

Enquiries from Asia Pacific

Postal address USA

Thermo Electron Corporation.

275 Aiken Road

Asheville, NC 28804

USA

Enquiries from North America

Phone + 1 800-879 7767

Fax + 1 828-658 0363

E-Mail

info.labequipment@thermo.com

Enquiries from Latin America

Phone + 1 828-658 2711

Fax + 1 828-645 9466

E-Mail

info.labequipment@thermo.com

Phone + 1 852-2711 3910

Fax + 1 852-2711 3858

E-Mail

info.labequipment@thermo.com

Internet: www.thermo.com

2a

WEEE Compliance:

This product is required to comply with the European Union`s Waste Electrical & Electronic

Equipment (WEEE) Directive 2002/96/EC. It is marked with the following symbol:

Thermo Electron has contracted with one or more recycling/disposal companies in each EU

Member State, and this product should be disposed of or recycled through them. Further

information on Thermo Electron`s compliance with these Directives, the recyclers in your

country, and information on Thermo Electron products wich may assist the detection of

substances subject to the RoHS Directive are available at www.thermo.com/WEEERoHS.

2b

CONTENTS

CONTENTS Page

GLOSSARY ................................ 2

CONTENTS ................................ 3

1. OVERVIEW ................................. 4

Control Panel ................................ 4

Explanation of Control Panel Elements ........ 5

Key to Symbols .............................. 5

2. NOTES CONCERNING ENVIRONNEMENTAL

SAFETY ....................................6

Disposal of Shipping Packing Material ......... 6

Disposal of Used Equipment .................. 6

Disposal of Used Filter Elements .............. 6

Energy Consumption ......................... 7

- Cirrculating air mode ....................... 7

- Exhaust mode .............................. 7

3. SAFETY NOTES ............................ 8

Stickers ...................................... 8

Abbreviated operating instructions ............ 8

Safety Notes ................................. 8

(SUMMARY EXCLUDED FROM COPYING PROHIBITION

WHEN USED FOR SAFETY INSTRUCTION)

Operating Instructions ....................... 10

Unit Log ..................................... 10

Test Chamber Power Sockets ................ 10

4. DEVICE DESCRIPTION ....................10

Application Area ............................. 10

Unit Construction ............................ 11

Operating Principle .......................... 12

Safety Equipment ........................... 13

- Power switch with key lock

(Function Selection Switch) ................ 13

- Air monitoring ............................. 13

- Fuel gas shutoff (option) ................... 13

- Front window monitoring ................... 13

- Front window - sealing ..................... 13

- UV lock (option) ........................... 14

- Lowered working bench (option/accessory) . 14

- Flow interrupter for connection to the

laboratory´s ventilation system (accessory) . 14

- Second exhaust filter element (accessory) .. 14

Connection to Laboratory Exhaust Systems .. 18

6. OPERATION ..............................19

Safety check, initial startup .................. 19

- Prior to Startup ............................ 19

Starting up the safety cabinet ................ 19

- Work / operating interruptions .............. 19

- UV disinfection mode ...................... 20

Working Guidelines ......................... 20

Problems ................................... 21

Taking the unit out of service ................ 21

7. MAINTENANCE ............................22

Routine Maintenance Tasks ................. 22

- Cleaning .................................. 22

Replacing Electrical Parts ................... 22

Filter Replacement .......................... 22

- General Information ....................... 22

- Circulation or exhaust filter replacement .... 23

- Intake screen replacement ................ 23

- Intake Protection Replacement (HS) ....... 23

- Prefilter replacement (HSP) ................ 23

Authorized Replacement Parts ............... 24

Authorized Accessories ...................... 24

8. TECHNICAL DATA .........................25

Geometry ................................... 25

Weights, Performance ....................... 26

Electrical Values ............................ 26

Technical ventilation ......................... 26

Filter Technology ............................ 27

Noise Generation ............................ 27

Illumination Strength ........................ 27

Ambient conditions .......................... 27

5. SETUP AND INSTALLATION ...............15

Transport ................................... 15

Setup Location .............................. 15

Room Ventilation ............................ 15

Setup ...................................... 16

Spacing ..................................... 16

Connections ................................. 16

- Power supply .............................. 16

- Fittings (accessory) ........................ 17

- Fuel gas shutoff connection / nnection to

external monitoring systems (Option) ....... 17

Sound Dampening ........................... 18

Version: 02.1999 50 047 299 c 3/27

1. OVERVIEW

The safety of this unit with respect to persons, the environment, and the material being processed depends to a great extent on the behavior of those working with the unit.

However, even safe operation cannot rule out risk, particularly with respect to the health of personnel.

This residual risk depends on the work being performed in each instance.

These operating instructions contain important information concerning your safety, the setup

and installation of the unit, as well as for its operation and maintenance !

Please read these instructions carefully before operating these units. Follow all instructions in

order to avoid problems that may result in damage, in particular, in damage to the user's health.

ALWAYS:

Wear protective gear in accordance with any applicable regulations and suited to the degree of risk in-

volved with the task at hand

(clothing, gloves, protective glasses ...).

Implement and follow appropriate hygienic measures.

Each person is responsible for his or her own personal safety and health.

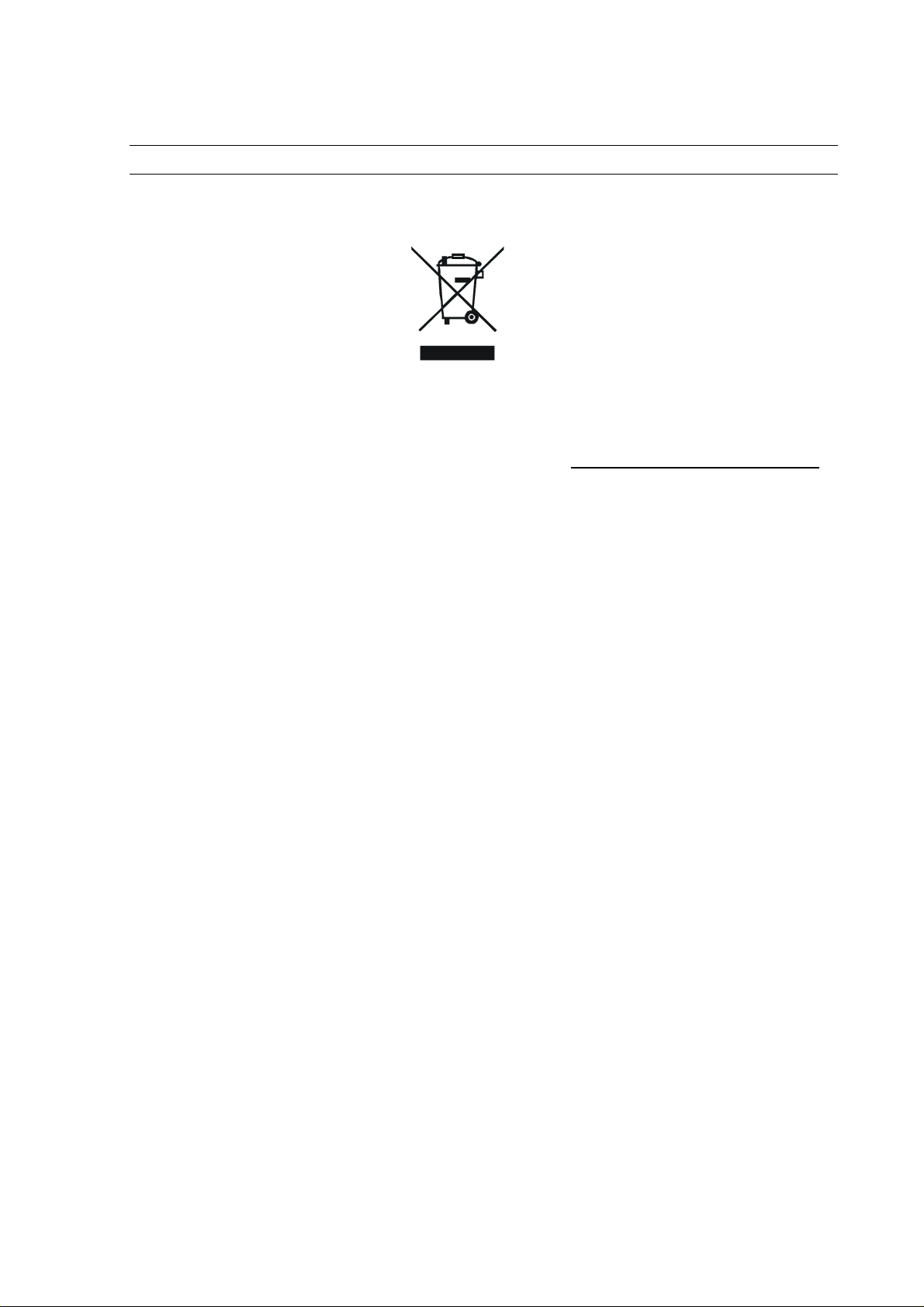

Control Panel

All switches necessary for operation together with all optical and acoustic signaling elements indicating

operation and faults are located on the control panel:

Figure 1/1: Control panel

12 13 14 15

UV

1 2

UV

h

Made in Germany

6 5 48 791011

3

4/27 50 047 299 c Version: 02.1999

1. OVERVIEW

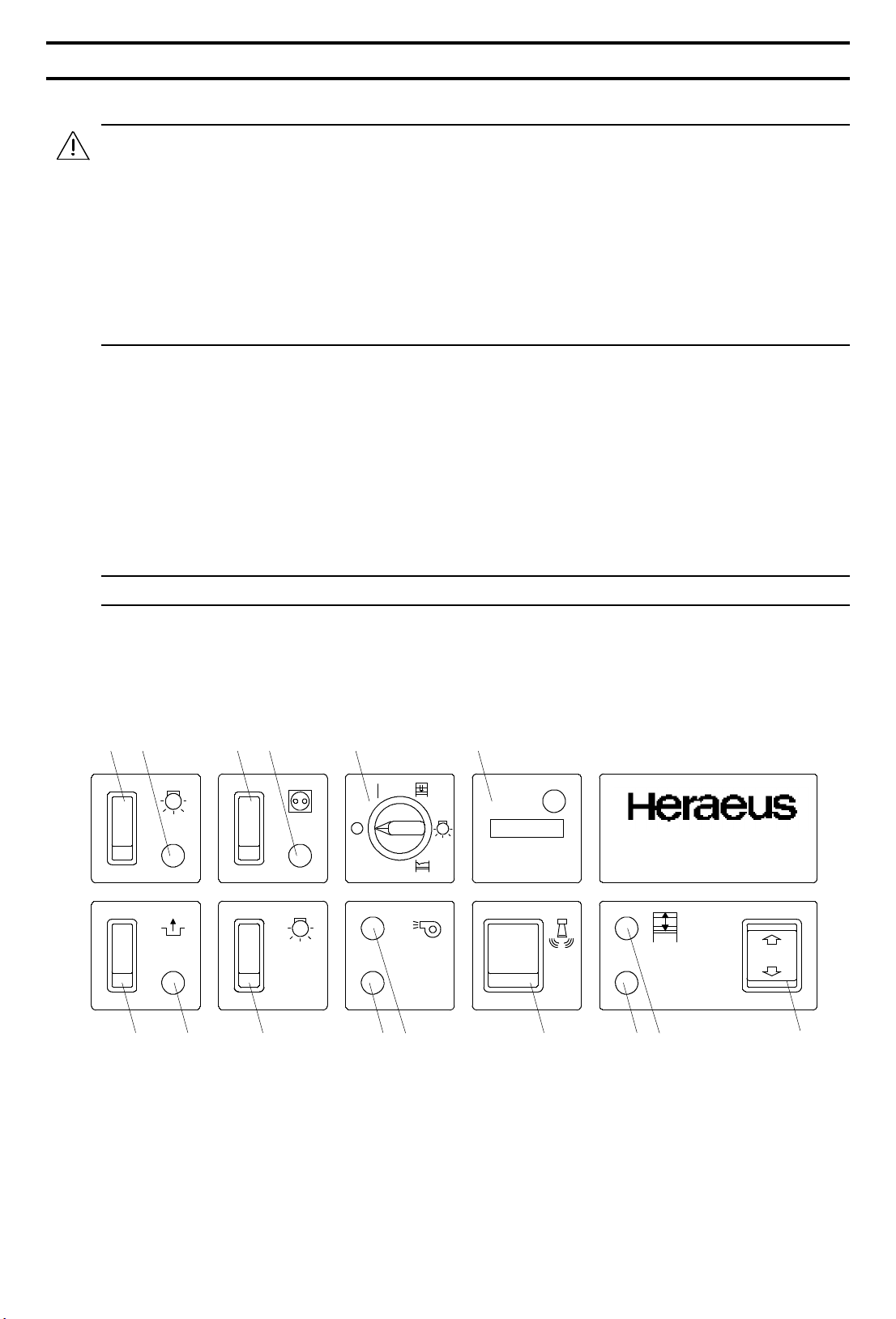

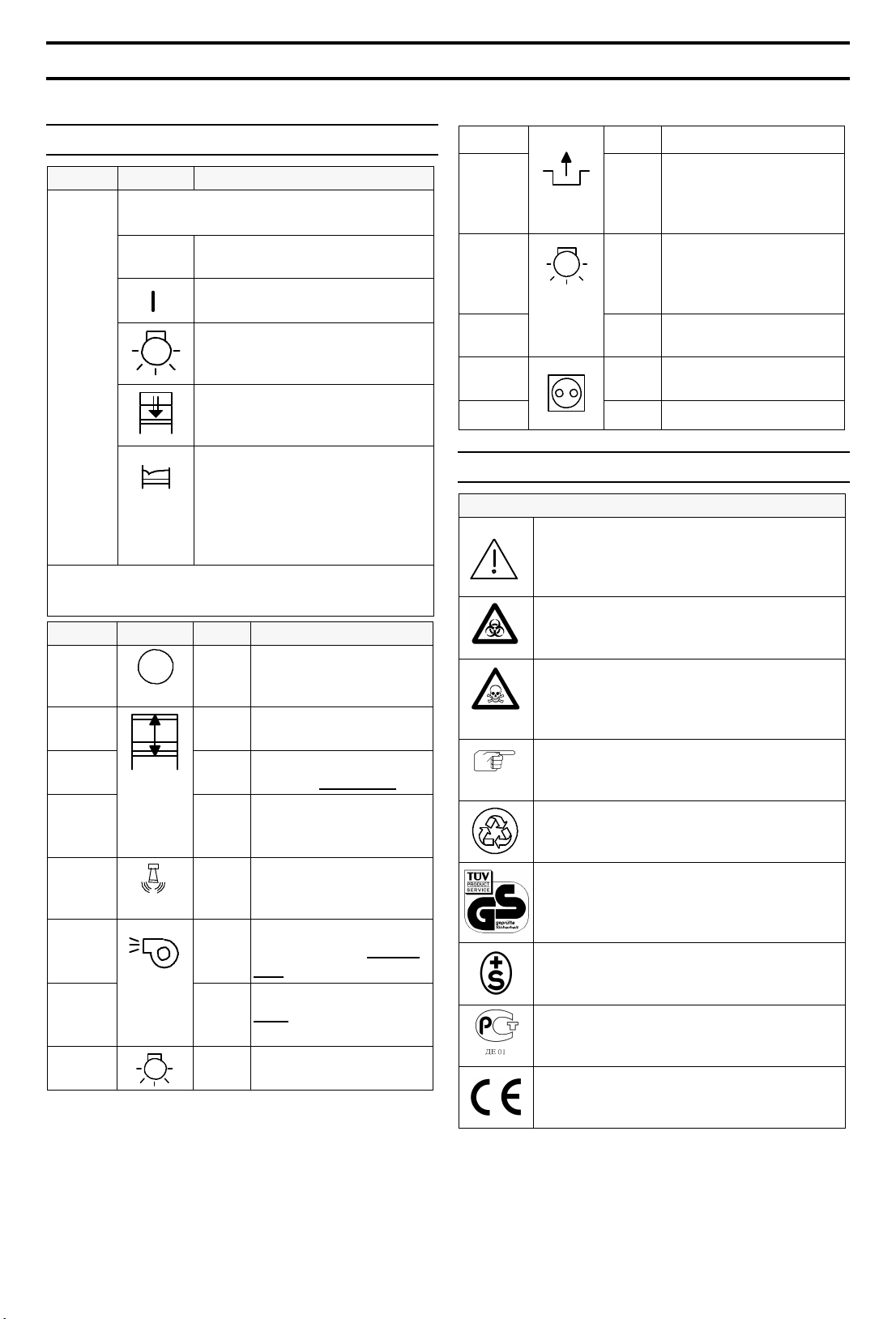

Explanation of Control Panel Elements

Item No. Symbol Message / Comment

Power switch / Function selection

switch with key lock:

Unit OFF

O

Unit ON:

1

UV

Note: The key can be removed and held by the responsible operator,

regardless of the switch position, in order to prevent accidental or

unauthorized switch use.

Item No. Symbol Signal Message / Comment

2

3

4

5

6

7

8

9

Operation / Normal setting

Unit ON:

Operation with UV surface sterilization irradiator (option)

Unit ON:

Close front window (in addition

to command key)

Unit ON:

Ventilation OFF, power outlets

and interior lighting ready

It is not possible to work

safely with pathogenic material.

h

White Window in operating

Red View port not in opera-

Green Ventilation system ope-

Red Ventilation system

Hours of operation

counter, e.g., for machine log maintenance.

Raise/lower front window key

position, Operation

ting position, OPERATI-

ON NOT SAFE

Acoustic warning signal

response button

rating properly, Opera-

tion

, OPERATION

fault

NOT SAFE

Test chamber light ON /

OFF switch

10

11

12

UV

13

14

15

Key to Symbols

Warnings / Notes / Quality marks

Chapters and sections within the operating instructions that are relevant to safety

matters are indicated by this symbol.

Biohazard warning !

On the unit, this symbol warns personnel

against accidental use.

Toxic material warning !

- cytostatic agents On the unit, this symbol warns personnel

against accidental use.

Note providing information on optimum

utilization of the unit.

Note concerning regulated disposal /

reclamation of raw materials.

Symbol indicated safety tested in accord.

with DIN 12950, Part 10/10.1991 and DIN

12 980. Applies to tested device versions

with standard equipment.

Swiss safety certification seal, awarded by

the Eidgenössische Starkstrominspektorat

GOST R conformity certification for devices exported to the Russian Federation

EU symbol confirming conformity with all

relevant European guidelines (nameplate)

Yellow Release active

Release key (option,

e.g., release error message system, magnetic

valve, etc.)

Started timed UV operation timer key

(approx. 60 min) (option)

Yellow UV irradiator ON (opti-

on)

sockets ON / OFF

switch

white sockets ON

Version: 02.1999 50 047 299 c 5/27

2. NOTES CONCERNING ENVIRONMENTAL SAFETY

Disposal of Shipping Packing Material

The packaging is designed to protect the unit against

shipping damage. Aside from the purely technical aspects of shipping, the packaging materials have been

selected with environmental and disposal concerns in

mind, and are recyclable.

The corrugated cardboard employed is made primarily from recycled paper.

Plastic molded parts (Styrofoam) are free of CFCs.

Wood frames and pallets are made of recycled

wood and are untreated.

The polyethylene foil (PE) is made from partially re-

cycled material.

The strapping is made of polypropylene (PP).

Returning the packaging material to the material

circuit saves on raw materials and reduces waste. In

general, packaging material can be returned to your

dealer.

If you will be disposing of the packaging material

yourself, please contact your local government for

the name of the nearest recycling center.

Disposal of Used Equipment

Prior to their proper disposal, any equipment employed for microbiological work must be thoroughly

disinfected and cleaned. An appropriate confirmation

of this is to be included with the equipment being disposed of.

Used equipment contains valuable materials. You

should not simply take an old unit to the nearest

dump or land fill, but should contact your local government department with respect to the required

disinfection/cleaning procedures and the possibility of

recycling some or all device components and materials.

Disposal of Used Filter Elements

The service life of the filter elements depends primarily on the type of work being performed, the cleanliness of the environment in the are in which the unit is

located, and the device construction.

If the filters must be replaced during operation, the

type and extent of possible contamination must be

considered. Depending on the type and degree of

usage, adequate safety measures for the proper disposal of used filters must be in place prior to replacement.

Only you, as the operator can determine the type

and degree of possible environmental stress, possibly

by also referring to the unit handbook.

In cases of microbiological contamination, the filter

elements must undergo suitable decontamination

measures (sterilization or, at least, disinfection) in order to make them non-hazardous. The proper performance of the selected method is to be confirmed in

writing, and this document is to accompany the filter

elements being disposed of.

The most widely accepted procedure for this is total

room disinfection with formaldehyde vapor, followed

by neutralization with ammonia vapor. Follow all

applicable federal, state, and local ordinances when

carrying out this process (in Germany: TRGS 522).

As a rule, the filters are passivated after this disinfection procedure. There is practically no risk of

contamination with filters employed for safety class 1

and 2 work. For filters employed for safety class 3

work, an additional sterilization step by means of autoclaving the broken up filter material may represent

an additional, practical measure.

Filters treated in this manner can be viewed as domestic waste and can be disposed of accordingly.

The filters can be disassembled for the separate disposal of the filter medium (residual waste) and the

aluminum frames. The modalities of the appropriate

disposal methods may need to be separately worked

out within the context of overall waste management.

For the remainder, all applicable federal, state, and

local ordinances must be adhered to (in Germany:

BImSchG, AbFG ...)

Contaminated filter elements are always to

be treated in the same manner as any other

infectious waste generated by the laboratory.

- CAUTION -

Thermo warns against irresponsible surrender of

possibly dangerous filter waste to persons without the

necessary hazardous waste transport certificates and

permits for the disposal of hazardous waste material.

As the originator, you are responsible for this

waste material.

Noncompliance with the regulated procedures for

waste disposal may make you liable for subsequent

damages.

6/27 50 047 299

2. NOTES CONCERNING ENVIRONMENTAL SAFETY

Should you encounter problems in disinfecting - and

thus in neutralizing - the filter elements in question,

please contact us for assistance.

Our Service Department will be happy to present you

with an appropriate offer.

If, aside from the microbiological contamination, the filter elements are expected to

also contain other contaminants (e.g., chemical, toxic, radioactive ...), appropriate

steps must be taken to deal with these prior to disposal of the elements.

Particularly in the case of filter waste that may contain cytostatic agents, it must be treated as hazardous material and be disposed of accordingly.

Energy Consumption

The unit has been designed for continuous operation in order to minimize the risk of contamination.

The ability of the filters to retain materials is only

guaranteed when the unit is operating, that is, when

air is flowing across the filter elements.

Once work in the test chamber has been completed,

the front window can be sealed. The unit then operates in a power-saver mode and is practically si-

lent.

Since the front window is completely sealed in this

mode, it is practically impossible for aerosol materials

in the test chamber to be dispersed into the surrounding atmosphere.

In this operating mode and depending on the ambient

temperature in the setup area, the safety cabinet's interior temperature may increase by up to 10 °C in

this operating mode.

You should therefore never shut the ventilation system off, immediately after completing your work,

so that any untrapped material can still be captured. We recommend waiting approx. 20 minutes of

run-out or reduced continuous operation.

If work is to be interrupted for any length of time,

always turn the test chamber lights out in order to

reduce the unit's energy consumption.

Depending on the agents being processed and their

release in the test chamber, you can also completely

shut down the unit, if it is sealed.

Circulating air mode:

To prevent unnecessary increases in the energy required to heat the laboratory area, we recommend

operating the unit in the circulating air mode. As a

rule, laboratories with a safety classification of L 1

and L 2 do not need to implement any additional

measures to do this.

For laboratories with a safety classification of L 3, a

second exhaust filter (AEF accessory) can provide

additional safety against failure. The required accessory part (AEF) can be retrofitted (HS models

only). After installing the additional filter, the entire

system must be readjusted and re-verified. These

are simple procedures.

The second, supplemental exhaust filter can also

increase the safety level of laboratories handling

cytostatic agents.

The installation of a second, in-line exhaust filter is

not required for series HSP units. The standard prefiltration step performs the same function.

Exhaust mode:

In order to increase safety in case of the failure of

the unit's exhaust filter system, the unit can be connected to the in-house exhaust system by means of

the recommended accessory parts. The air removed from the overall system must be air conditioned before being returned to the working area.

Please note that the unit's safety suffers when replacement air is fed into the work area. This tends

to be the case, particularly where the unit is set up

in a small room.

With respect to energy consumption, this mode is

less economical than the circulating air mode.

All applicable federal, state, and local environmental ordinances must be observed to operate the unit

in the exhaust mode (in Germany: BImSchG).

The adapters required to connect the unit to an inhouse exhaust system are available as optional accessories.

If necessary, surface disinfection of the test chamber

should be performed. Follow the instructions concerning disinfection in the "MAINTENANCE" chapter.

50 047 299 7/27

Loading...

Loading...