Page 1

Orbitrap Fusion Series

Hardware Manual

80011-97004 Revision B May 2016

Page 2

© 2016 Thermo Fisher Scientific Inc. All rights reserved.

Automatic Gain Control, EASY-ETD, EASY-IC, EASY-Max NG, Fusion, Lumos, and Orbitrap Fusion Lumos

are trademarks; Unity is a registered service mark; and Accela, Hypersil GOLD AQ, Orbitrap, Orbitrap

Fusion, Pierce, Thermo Scientific, Tribrid, and Xcalibur are registered trademarks of Thermo Fisher Scientific

Inc. in the United States. Fisher Scientific is a registered trademark of Fisher Scientific Co. in the United States.

The following are registered trademarks in the United States and other countries: COMBICON is a registered

trademark of Phoenix Contact GmbH & Co. Microsoft and Windows are registered trademarks of Microsoft

Corporation. Teflon is a registered trademark of E.I. du Pont de Nemours & Co.

The following are registered trademarks in the United States and possibly other countries: Liquinox is a

registered trademark of Alconox, Inc. MICRO-MESH is a registered trademark of Micro-Surface Finishing

Products, Inc. Nalgene is a registered trademark of Nalge Nunc International Corporation. Oerlikon Leybold

Vacuum is a registered trademark of OC Oerlikon Corporation AG. Rheodyne is a registered trademark of

IDEX Health & Science, LLC. SOGEVAC is a registered trademark of Oerlikon Leybold Vacuum. Tygon is a

registered trademark of the division of Saint-Gobain Performance Plastics Corporation. Upchurch Scientific is

a registered trademark of IDEX Health & Science LLC. Vespel is a registered trademark of E.I. du Pont de

Nemours & Co. Viton is a registered trademark of DuPont Performance Elastomers LLC.

Chemyx is a trademark of Chemyx Inc. MX Series II is a trademark of IDEX Health & Science, LLC.

All other trademarks are the property of Thermo Fisher Scientific Inc. and its subsidiaries.

Thermo Fisher Scientific Inc. provides this document to its customers with a product purchase to use in the

product operation. This document is copyright protected and any reproduction of the whole or any part of this

document is strictly prohibited, except with the written authorization of Thermo Fisher Scientific Inc.

The contents of this document are subject to change without notice. All technical information in this

document is for reference purposes only. System configurations and specifications in this document supersede

all previous information received by the purchaser.

This document is not part of any sales contract between Thermo Fisher Scientific Inc. and a purchaser. This

document shall in no way govern or modify any Terms and Conditions of Sale, which Terms and Conditions of

Sale shall govern all conflicting information between the two documents.

Release history: Rev A, July 2015; Rev B, May 2016

Software version: (Thermo) Foundation 3.0 and later, Xcalibur 3.0 and later, Tune 2.0 and later

For Research Use Only. Not for use in diagnostic procedures.

Page 3

Regulatory Compliance

Thermo Fisher Scientific performs complete testing and evaluation of its products to ensure full compliance with

applicable domestic and international regulations. When the system is delivered to you, it meets all pertinent

electromagnetic compatibility (EMC) and safety standards as described in the next section or sections by product name.

Changes that you make to your system may void compliance with one or more of these EMC and safety standards.

Changes to your system include replacing a part or adding components, options, or peripherals not specifically

authorized and qualified by Thermo Fisher Scientific. To ensure continued compliance with EMC and safety standards,

replacement parts and additional components, options, and peripherals must be ordered from Thermo Fisher Scientific

or one of its authorized representatives.

Regulatory compliance results for the following Thermo Scientific™ products:

• Orbitrap Fusion Lumos MS

• Orbitrap Fusion MS

Orbitrap Fusion Lumos MS

Low Voltage Directive 2006/95/EC

This device complies with Low Voltage Directive 2006/95/EC and the harmonized safety standard IEC/EN/CSA/

UL 61010-1, 3rd Edition.

EMC Directive 2004/108/EC

This device was tested by TÜV Rheinland of North America and complies with the following EMC standards:

47 CFR 15, Subpart B, Class A: 2015 EN 61000-3-2: 2006 + A1 + A2 EN 61000-4-5: 2006

CISPR 11: 2009 + A1 EN 61000-3-3: 2008 EN 61000-4-6: 2009

ICES-003: 2014 EN 61000-4-2: 2009 EN 61000-4-8: 20103

EN 55011: 2009 + A1 EN 61000-4-3: 2006 + A1 + A2 EN 61000-4-11: 2004

EN 61326-1: 2013 EN 61000-4-4: 2004 + A1

Page 4

Orbitrap Fusion MS

Low Voltage Directive 2006/95/EC

This device complies with Low Voltage Directive 2006/95/EC and the harmonized safety standard IEC/EN/CSA/

UL 61010-1, 3rd Edition.

EMC Directive 2004/108/EC

This device was tested by TÜV Rheinland of North America and complies with the following EMC standards:

47 CFR 15, Subpart B, Class A: 2012 EN 61326-1: 2013 EN 61000-4-4: 2004 + A1

CISPR 11: 2009 + A1 EN 61000-3-2: 2006 + A1 + A2 EN 61000-4-5: 2006

AS/NZS CISPR 22: 2009 + A1 EN 61000-3-3: 2008 EN 61000-4-6: 2009

ICES-003: 2012 EN 61000-4-2: 2009 EN 61000-4-8: 2010

EN 55011: 2009 + A1 EN 61000-4-3: 2006 + A1 + A2 EN 61000-4-11: 2004

FCC Compliance Statement

THIS DEVICE COMPLIES WITH PART 15 OF THE FCC RULES. OPERATION IS SUBJECT TO THE

FOLLOWING TWO CONDITIONS: (1) THIS DEVICE MAY NOT CAUSE HARMFUL INTERFERENCE,

AND (2) THIS DEVICE MUST ACCEPT ANY INTERFERENCE RECEIVED, INCLUDING

INTERFERENCE THAT MAY CAUSE UNDESIRED OPERATION.

CAUTION Read and understand the various precautionary notes, signs, and symbols contained inside

this manual pertaining to the safe use and operation of this product before using the device.

Notice on the Proper Use of

Thermo Scientific Instruments

In compliance with international regulations: This instrument must be used in the manner specified by Thermo Fisher

Scientific to ensure protections provided by the instrument are not impaired. Deviations from specified instructions on

the proper use of the instrument include changes to the system and part replacement. Accordingly, order replacement

parts from Thermo Fisher Scientific or one of its authorized representatives.

Page 5

WEEE Directive

2012/19/EU

Thermo Fisher Scientific is registered with B2B Compliance (B2Bcompliance.org.uk) in the UK and with the

European Recycling Platform (ERP-recycling.org) in all other countries of the European Union and in Norway.

If this product is located in Europe and you want to participate in the Thermo Fisher Scientific Business-to-Business

(B2B) Recycling Program, send an email request to weee.recycle@thermofisher.com with the following information:

• WEEE product class

• Name of the manufacturer or distributor (where you purchased the product)

• Number of product pieces, and the estimated total weight and volume

• Pick-up address and contact person (include contact information)

• Appropriate pick-up time

• Declaration of decontamination, stating that all hazardous fluids or material have been removed from the product

For additional information about the Restriction on Hazardous Substances (RoHS) Directive for the European Union,

search for RoHS on the Thermo Fisher Scientific European language websites.

IMPORTANT This recycling program is not for biological hazard products or for products that have been medically

contaminated. You must treat these types of products as biohazard waste and dispose of them in accordance with

your local regulations.

Page 6

Directive DEEE

2012/19/EU

Thermo Fisher Scientific s'est associé avec une ou plusieurs sociétés de recyclage dans chaque état membre de l’Union

Européenne et ce produit devrait être collecté ou recyclé par celle(s)-ci. Pour davantage d'informations, rendez-vous sur

la page www.thermoscientific.fr/rohs.

WEEE Direktive

2012/19/EU

Thermo Fisher Scientific hat Vereinbarungen mit Verwertungs-/Entsorgungsfirmen in allen EU-Mitgliedsstaaten

getroffen, damit dieses Produkt durch diese Firmen wiederverwertet oder entsorgt werden kann. Weitere Informationen

finden Sie unter www.thermoscientific.de/rohs.

Page 7

C

Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiii

Accessing Documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiii

Special Notices, Symbols, and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiv

Contacting Us . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Chapter 1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Orbitrap Fusion Series Mass Spectrometers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Overview of an LC/MS Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

LC/MS Functional Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electronic Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Controls and Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Power Entry Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Communications Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cooling Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 2 Scan Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Scan Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

MS Scan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2

MS

Scan and MSn Scan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

SIM Scan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Scan Rates for the Ion Trap Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Scan Mass-To-Charge Ratio Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Resolutions for the Orbitrap Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Data Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Ion Polarity Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 3 Vacuum System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Vacuum System Functional Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Schematic of the Internal Gas Supply Lines. . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Inlet Gases Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Helium Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Nitrogen Gas Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Vent Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Vacuum Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Thermo Scientific Orbitrap Fusion Series Hardware Manual vii

Page 8

Contents

Vacuum Gauges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Vacuum Pumps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Atmospheric Pressure Ionization Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

API Source Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Chapter 4 Ion Transmission and Mass Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Workflow for Mass Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Ion Optics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

MP00 Ion Optics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

MP0 Ion Optics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

MP1 Ion Optics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Curved Linear Trap. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Ion-Routing Multipole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

MP3 Ion Optics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

DC Offset Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Mass Analyzers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Quadrupole Mass Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Orbitrap Mass Analyzer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Linear Ion Trap Mass Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Ion Detection Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Chapter 5 Syringe Pump and Divert/Inject Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Syringe Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Divert/Inject Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Controlling the Divert/Inject Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Chapter 6 System Shutdown, Startup, and Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Shutting Down the System in an Emergency. . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Placing the Mass Spectrometer in Standby Mode . . . . . . . . . . . . . . . . . . . . . . . 50

Turning On the Mass Spectrometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Shutting Down the Mass Spectrometer Completely . . . . . . . . . . . . . . . . . . . . . 52

Starting the System after a Complete Shutdown . . . . . . . . . . . . . . . . . . . . . . . . 53

Starting the LC System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Starting the Data System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Starting the Mass Spectrometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Starting the Autosampler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Resetting the Mass Spectrometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Resetting Calibration Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Restarting the Data System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

On/Off Status for MS Components Under Varying Power Conditions. . . . . . . 58

viii Orbitrap Fusion Series Hardware Manual Thermo Scientific

Page 9

Contents

Chapter 7 Daily Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Before Operating the Orbitrap Fusion Series System. . . . . . . . . . . . . . . . . . . . . 62

Checking the System Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Checking the Vacuum Pressure Levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Checking the Gas Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

After Operating the Orbitrap Fusion Series System . . . . . . . . . . . . . . . . . . . . . . 64

Flushing the Inlet Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Purging the Oil in the Forepump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Emptying the Solvent Waste Container. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Placing the System in Standby Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Chapter 8 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Maintenance Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Tools and Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Maintaining the API Source Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Maintaining the API Source Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Cleaning the Ion Sweep Cone, Spray Cone, and Ion Transfer Tube . . . . . . . 72

Removing the API Source Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Cleaning the RF Lens, Exit Lens, MP00 RF Lens, and Lens L0. . . . . . . . . . . 79

Reinstalling the API Source Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Maintaining the Forepump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Maintaining the Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Chapter 9 Replaceable Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Orbitrap Fusion Series Chemicals Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Calibration Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

MS Setup Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Performance Specification Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Single Mechanical Pump Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Dual Mechanical Pumps Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

API Source Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Miscellaneous Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

Thermo Scientific Orbitrap Fusion Series Hardware Manual ix

Page 10

Contents

x Orbitrap Fusion Series Hardware Manual Thermo Scientific

Page 11

F

Figures

Figure 1. Functional block diagram of the Orbitrap Fusion Series MS . . . . . . . . . . . . . . . . 5

Figure 2. Orbitrap Fusion Series front panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. Power entry module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 4. Communication connectors (left side of the MS) . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 5. Functional block diagram of the vacuum system . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 6. Schematic of the internal gas supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 7. Gas inlet ports (back of the mass spectrometer) . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 8. Placement of the three turbomolecular pumps . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 9. EASY-Max NG API source (H-ESI mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 10. API source interface (Orbitrap Fusion MS cross section) . . . . . . . . . . . . . . . . . . 24

Figure 11. Exit lens and RF lens (Orbitrap Fusion and Orbitrap Fusion Lumos

MSs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 12. Workflow for mass analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 13. Schematic of the Orbitrap Fusion Lumos Tribrid MS ion transmission

path (shown with the ETD source option) . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 14. MP00 RF lens (Orbitrap Fusion and Orbitrap Fusion Lumos MSs) . . . . . . . . . 30

Figure 15. Lens L0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Figure 16. Multipole MP0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 17. TK lens (both sides) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 18. Multipole MP1 (Orbitrap Fusion and Orbitrap Fusion Lumos MSs) . . . . . . . . 32

Figure 19. C-trap (Orbitrap Fusion and Orbitrap Fusion Lumos MSs) . . . . . . . . . . . . . . . 33

Figure 20. Ion-routing multipole (IRM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 21. Multipole MP3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 22. Quadrupole Q1 (side and end views, Orbitrap Fusion and Orbitrap Fusion

Lumos MSs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 23. Dual-split gate lens (both sides) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 24. Polarity of the RF and DC voltages applied to the Q1 rods . . . . . . . . . . . . . . . . 36

Figure 25. Schematic of the Orbitrap cell and an example stable ion trajectory . . . . . . . . . . 37

Figure 26. Electrodynamic squeezing of ions in the Orbitrap analyzer (r) versus the

increased field strength (z) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 27. Approximate shape of ion packets of different m/z after the voltages

stabilize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 28. Linear ion trap (LIT) (Orbitrap Fusion MS) . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 29. Assembly for the linear ion trap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 30. Visual representation of the LIT mass analyzer operation (low pressure

cell, Orbitrap Fusion MS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 31. Syringe pump setup (top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Thermo Scientific Orbitrap Fusion Series Hardware Manual xi

Page 12

Figures

Figure 32. Divert/inject valve positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 33. Divert/inject valve plumbed as a loop injector and as a divert valve . . . . . . . . . . 48

Figure 34. Modular divert/inject valve (front view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 35. Thermo Tune window (Orbitrap Fusion MS) . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 36. Direct Control dialog box (Instrument Setup window) . . . . . . . . . . . . . . . . . . . 51

Figure 37. Direct Control dialog box (Instrument Setup window) . . . . . . . . . . . . . . . . . . . 73

Figure 38. Ion sweep cone removed from the MS mount assembly (Orbitrap Fusion

MS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Figure 39. Ion transfer tube removal tool (Orbitrap Fusion MS) . . . . . . . . . . . . . . . . . . . . 75

Figure 40. Ion transfer removal tool (Orbitrap Fusion Lumos MS) . . . . . . . . . . . . . . . . . . . 75

Figure 41. Spray cone, O-ring, ion transfer tube, and ion sweep cone

(Orbitrap Fusion MS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Figure 42. API source interface removed from the vacuum manifold (Orbitrap Fusion

MS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Figure 43. Lens L0 removed from the back of the API source interface

(Orbitrap Fusion MS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Figure 44. MP00 RF lens assembly removed from the API source interface

(Orbitrap Fusion MS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Figure 45. RF lens removed from the API source interface cage (Orbitrap Fusion

MS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Figure 46. Exit lens removed from the API source interface (Orbitrap Fusion MS) . . . . . . 81

Figure 47. Alignment slot and thumbscrew locations on the MP00 RF lens

(Orbitrap Fusion MS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

xii Orbitrap Fusion Series Hardware Manual Thermo Scientific

Page 13

P

Preface

The Orbitrap Fusion Series Hardware Manual describes the modes of operation and hardware

components for the Thermo Scientific™ Orbitrap Fusion™ Series Tribrid ™ system. It also

provides the instrument’s cleaning and maintenance procedures.

This guide is intended for the following Thermo Scientific mass spectrometers (MSs):

• Orbitrap Fusion (also known as Fusion™) (requires one forepump)

• Orbitrap Fusion Lumos™ (also known as Lumos™) (requires two forepumps)

Contents

• Accessing Documentation

• Special Notices, Symbols, and Cautions

• Contacting Us

To suggest changes to the documentation or to the Help

Complete a brief survey about this document by clicking the button below.

Thank you in advance for your help.

Accessing Documentation

The Orbitrap Fusion Series MS includes complete documentation. For system requirements,

refer to the release notes on the software DVD.

To view the product manuals

From the Microsoft™ Windows™ taskbar, choose Start > All Programs > Thermo

Instruments > model x.x, and then open the applicable PDF file.

Thermo Scientific Orbitrap Fusion Series Hardware Manual xiii

Page 14

Preface

To view the Help

Do the following as applicable:

• Thermo Tune application: Click the Options icon, , and choose Tune H e l p .

• Thermo Xcalibur™ Method Editor: Choose an option from the Help menu (or press

the F1 key).

To view user documentation from the Thermo Fisher Scientific website

1. Go to thermofisher.com.

2. Point to Services & Support and click Manuals on the left.

3. In the Refine Your Search box, search by the product name.

4. From the results list, click the title to open the document in your web browser, save it, or

print it.

To return to the document list, click the browser Back button.

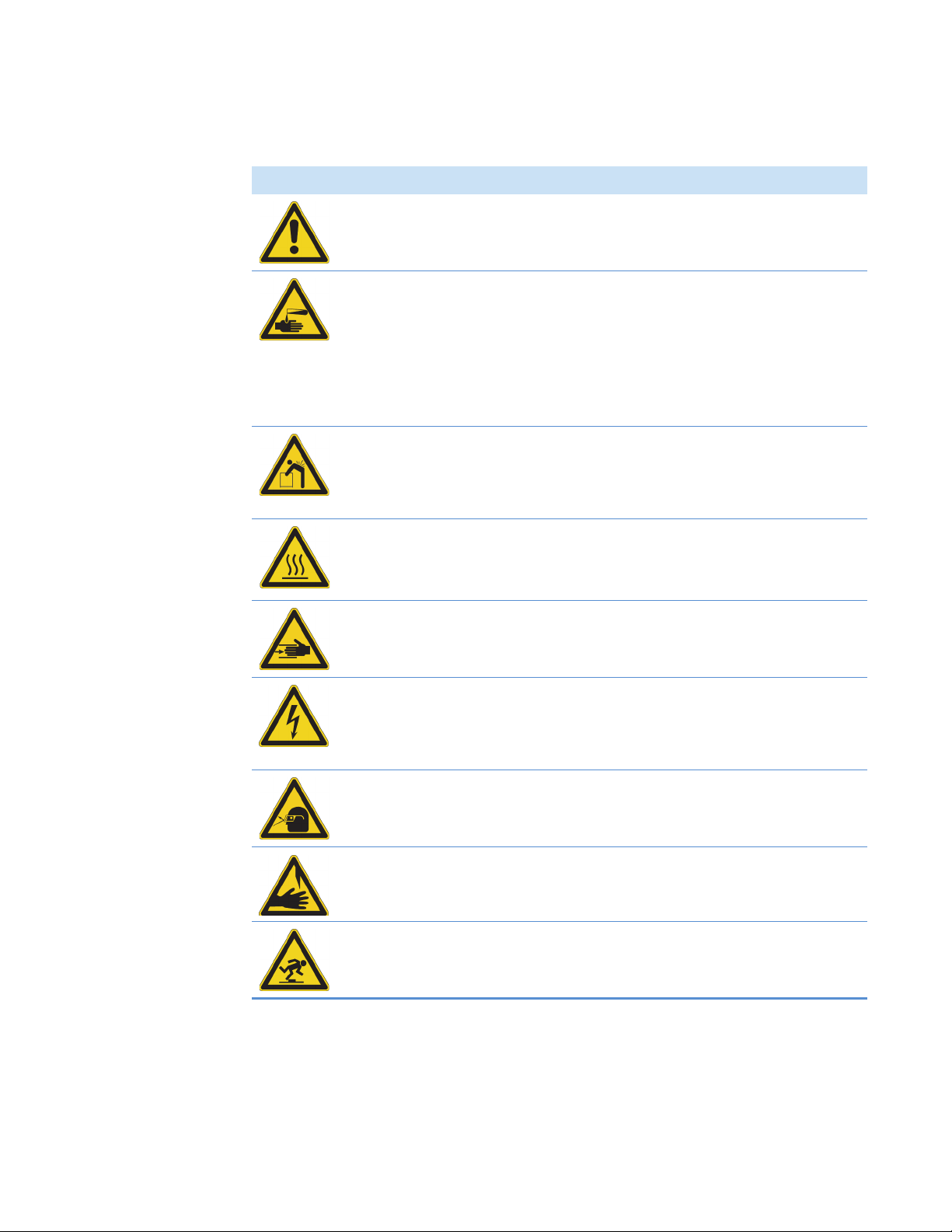

Special Notices, Symbols, and Cautions

Make sure you understand the special notices, symbols, and caution labels in this guide. Most

of the special notices and cautions appear in boxes; those pertaining to safety also have

corresponding symbols. Some symbols are also marked on the instrument itself and can

appear in color or in black and white. For complete definitions, see Ta bl e 1 .

Table 1 . Notices, symbols, labels, and their meanings (Sheet 1 of 2)

Notice, symbol, or label Meaning

IMPORTANT Highlights information necessary to prevent damage to

software, loss of data, or invalid test results; or might contain

information that is critical for optimal performance of the

product.

Note Highlights information of general interest.

Tip

Highlights helpful information that can make a task easier.

xiv Orbitrap Fusion Series Hardware Manual Thermo Scientific

Page 15

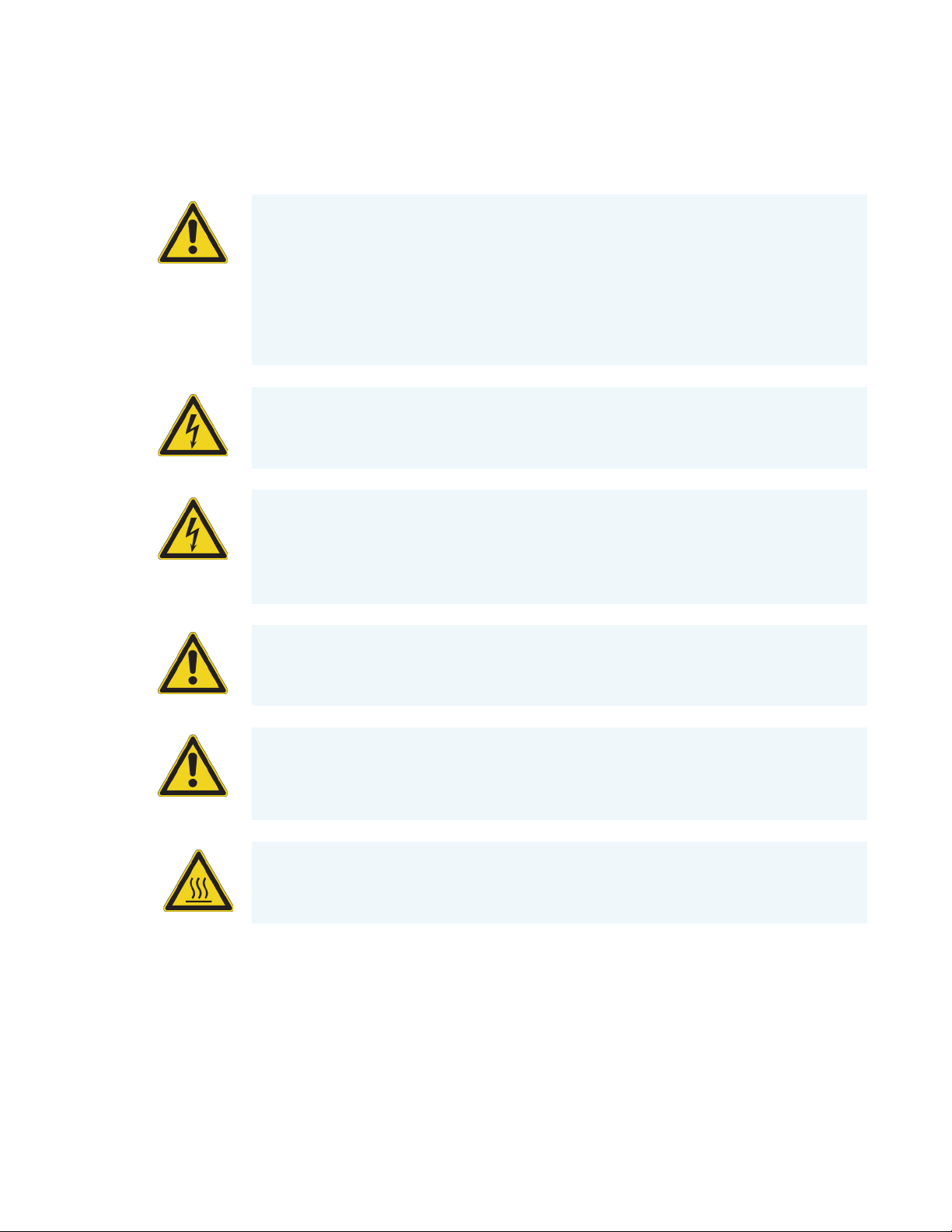

Table 1 . Notices, symbols, labels, and their meanings (Sheet 2 of 2)

Notice, symbol, or label Meaning

Caution: Read the cautionary information associated with this

task.

Chemical hazard: Observe safe laboratory practices and

procedures when handling chemicals. Only work with volatile

chemicals under a fume or exhaust hood. Wear gloves and other

protective equipment, as appropriate, when handling toxic,

carcinogenic, mutagenic, corrosive, or irritant chemicals. Use

approved containers and proper procedures to dispose of waste

oil and when handling wetted parts of the instrument.

Heavy object: The Orbitrap Fusion Series MS, excluding its

workbench, weighs over 227 kg (500 lb). Never try to detach

and move the instrument from its workbench; you can suffer

personal injury or damage the instrument.

Preface

Hot surface: Before touching the API source assembly, allow

heated components to cool.

Pinch point: Keep hands away from the specified areas.

Risk of electric shock: This instrument uses voltages that can

cause electric shock and personal injury. Before servicing the

instrument, shut it down and disconnect it from line power.

While operating the instrument, keep covers on.

Risk of eye injury: Eye injury can occur from splattered

chemicals, airborne particles, or sharp objects. Wear safety

glasses when handling chemicals or servicing the instrument.

Sharp object: Avoid handling the tip of the syringe needle.

Trip obstacle: Be aware of cords, hoses, or other objects located

on the floor.

Thermo Scientific Orbitrap Fusion Series Hardware Manual xv

Page 16

Preface

Read and understand the following cautions that are specific to the shutdown of the mass

spectrometry system or to the removal of parts for cleaning.

CAUTION If you must turn off the mass spectrometer in an emergency, turn off the

main power switch located on the right-side power panel. This switch turns off all

power to the mass spectrometer, including the forepump, without harming components

within the system. However, do not use this method as part of the standard shutdown

procedure. Instead, see “Shutting Down the Mass Spectrometer Completely” on page 52.

To turn off the LC, autosampler, and data system computer in an emergency, use their

respective on/off switch or button.

CAUTION To avoid an electrical shock, be sure to follow the instructions in “Shutting

Down the Mass Spectrometer Completely” on page 52.

CAUTION Do not turn the instrument on if you suspect that it has incurred any kind of

electrical damage. Instead, disconnect the power supply cord and contact Thermo Fisher

Scientific technical support for a product evaluation. Do not attempt to use the

instrument until it has been evaluated. (Electrical damage might have occurred if the

system shows visible signs of damage, or has been transported under severe stress.)

CAUTION Do not disconnect the power supply cord at the mass spectrometer while the

other end is still plugged into the electrical outlet.

CAUTION Do not place any objects (for example, the syringe pump or other containers

with liquids) on top of the instrument, unless instructed to in the documentation.

Leaking liquids might contact the electronic components and cause an electrical short

circuit.

CAUTION Hot surface. Allow heated components to cool to room temperature

(approximately 20 minutes) before servicing them.

xvi Orbitrap Fusion Series Hardware Manual Thermo Scientific

Page 17

Contacting Us

Preface

There are several ways to contact Thermo Fisher Scientific for the information you need. You

can use your smartphone to scan a QR code, which opens your email application or browser.

Contact us Customer Service and Sales Technical Support

(U.S.) 1 (800) 532-4752 (U.S.) 1 (800) 532-4752

(U.S.) 1 (561) 688-8731 (U.S.) 1 (561) 688-8736

us.customer-support.analyze

@thermofisher.com

To find global contact information or customize your request

us.techsupport.analyze

@thermofisher.com

1. Go to thermofisher.com.

2. Click Contact Us and then select the type of support you need.

3. At the prompt, type the product name.

4. Use the phone number or complete the online form.

To find product support, knowledge bases, and resources

Go to thermofisher.com/us/en/home/technical-resources.

To find product information

Go to thermofisher.com/us/en/home/brands/thermo-scientific.

Note To provide feedback for this document:

• Send an email message to Technical Publications (techpubs-lcms@thermofisher.com).

• Complete a survey at surveymonkey.com/s/PQM6P62.

Thermo Scientific Orbitrap Fusion Series Hardware Manual xvii

Page 18

Preface

xviii Orbitrap Fusion Series Hardware Manual Thermo Scientific

Page 19

1

Introduction

The Orbitrap Fusion Series Tribrid mass spectrometer is part of the Thermo Scientific family

of mass spectrometers. The Orbitrap Fusion Series system consists of the mass spectrometer, a

syringe pump, a divert/inject valve, and the Thermo Xcalibur™ data system.

Note The “Glossary” defines some of the terms used in this manual.

Contents

• Overview of an LC/MS Analysis

• LC/MS Functional Block Diagram

• Electronic Assemblies

• Controls and Indicators

• Cooling Fans

Orbitrap Fusion Series Mass Spectrometers

The Orbitrap Fusion Series includes the Orbitrap Fusion MS and Orbitrap Fusion Lumos

MS. For descriptions of the various hardware components, see Chapter 3, “Vacuum System,”

Chapter 4, “Ion Transmission and Mass Analysis,” and Chapter 5, “Syringe Pump and

Divert/Inject Valve.”

Thermo Scientific Orbitrap Fusion Series Hardware Manual 1

Page 20

1

Introduction

Orbitrap Fusion Series Mass Spectrometers

Orbitrap Fusion MS

The Orbitrap Fusion is a mass spectrometer that contains three mass analyzers and includes

an external syringe pump, a divert/inject valve, and the Thermo Scientific EASY-Max NG™

API source. The instrument requires one forepump.

Orbitrap Fusion Lumos MS

The Orbitrap Fusion Lumos is a mass spectrometer that contains three mass analyzers and

includes an external syringe pump, a divert/inject valve, and the EASY-Max NG API source.

The instrument requires two forepumps.

2 Orbitrap Fusion Series Hardware Manual Thermo Scientific

Page 21

Overview of an LC/MS Analysis

In a typical LC/MS analysis, the liquid chromatograph (LC) portion of the system separates a

mixture into its chemical components. The LC pump produces a solvent stream (the mobile

phase) that passes through an LC column (containing the stationary phase) under high

pressure. An autosampler introduces a measured quantity of sample into this solvent stream.

As the solvent stream passes through the LC column, the sample separates into its chemical

components. The rate at which the components of the sample elute from the column depends

on their relative affinities to the mobile phase and the solid particles that make up the column

packing.

As the separated chemical components exit the LC column, they pass through a sample

transfer line and enter the mass spectrometer for ionization and analysis. As the mass

spectrometer analyzes the ionized components and determines each mass-to-charge ratio

(m/z) and relative intensity, it sends a data stream to the data system computer. In addition to

supplying information about the mass-to-charge ratios of ionized compounds, the mass

spectrometer can also supply structural and quantitative information by performing MS

experiments.

1

Introduction

Overview of an LC/MS Analysis

n

When the system setup includes a syringe pump and divert/inject valve, there are four

additional ways to introduce a sample into the mass spectrometer, as described in Ta bl e 2.

Table 2 . Methods of sample introduction into the mass spectrometer

Method Description

Direct infusion Connect the syringe pump directly to the atmospheric

pressure ionization (API) source of the mass spectrometer.

High-flow infusion Use a union Tee to combine the flow from the syringe pump

with the flow from an LC pump.

Automated loop injection Connect a sample loop, an LC pump, and the syringe pump

to the divert/inject valve. After you connect the plumbing,

specify the flow rate at which the syringe pump fills the

sample loop. After the loop is filled, the data system triggers

an injection.

Manual loop injection Connect a sample loop, a needle port fitting, and an LC

pump to the divert/inject valve. After you fill the sample loop

with sample, switch the position of the divert/inject valve,

which places the contents of the sample loop in the path of

the solvent flow produced by the LC pump.

The Orbitrap Fusion Series MS consists of an API source, ion optics, three mass analyzers,

and an ion detection system. The ion optics, mass analyzers, ion detection system, and part of

the API source are enclosed in a vacuum manifold.

Thermo Scientific Orbitrap Fusion Series Hardware Manual 3

Page 22

1

Introduction

LC/MS Functional Block Diagram

Ionization of the sample takes place in the API source. The specific method used to ionize the

sample is referred to as the ionization technique. The ion optics transmit the ions produced in

the API source into the user-specified mass analyzer, where the mass-to-charge ratios (of the

ions produced in the API source) are determined. The polarity of the electric potentials

applied to the API source and ion optics determines whether positively charged ions or

negatively charged ions are transmitted to the designated mass analyzer. You can set up data

acquisition methods for the mass spectrometer to analyze positively or negatively charged ions

or to switch between these polarity modes during a single run.

Certain lenses in the API source and ion optics act as gates to start and stop the transmission

of ions from the API source to a mass analyzer. An Automatic Gain Control™ (AGC) process

controls the function of these lenses and sets them to transmit the optimum number of ions to

the mass analyzer.

The data system serves as the user interface to the mass spectrometer, autosampler, LC pump,

and syringe pump. Refer to the Xcalibur Help for more information about the Orbitrap

Fusion Series data processing and instrument control application.

Each sequence of loading a mass analyzer with ions followed by mass analysis of the ions is

called a scan. The mass spectrometer uses several different scan mode and scan type

combinations to load, fragment, and detect ions. The ability to vary not only the ionization

and ion polarity modes, but the scan mode and scan type, provides greater flexibility in the

instrumentation for solving complex analytical problems.

For information about the H-ESI, APCI, and APPI techniques, refer to the Ion Max NG and

EASY-Max NG Ion Sources User Guide. For information about the nanoelectrospray ionization

(nanoESI or NSI) technique, refer to the manual that came with your NSI source.

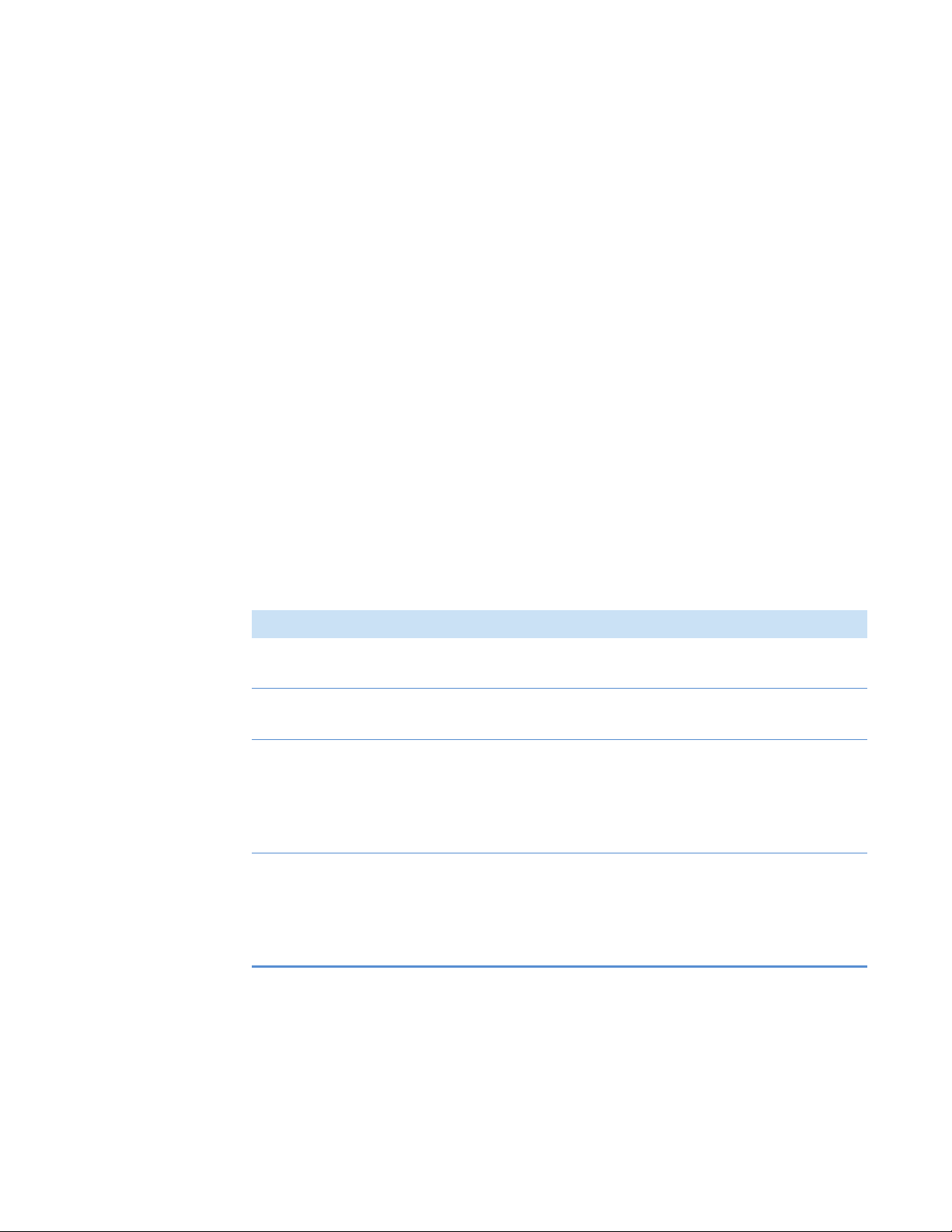

LC/MS Functional Block Diagram

Figure 1 shows a functional block diagram of the Orbitrap Fusion Series system with

hyperlinks to the applicable sections. A sample transfer line connects the LC to the mass

spectrometer. The LC instrument or modules are usually installed on the left side of the mass

spectrometer. A dedicated holder that sits on top of the mass spectrometer contains the

syringe pump and divert/inject valve.

In a typical analysis by LC/MS, a sample is injected onto an LC column. The sample then

separates into its various components. The components elute from the LC column and pass

into the mass spectrometer for analysis.

4 Orbitrap Fusion Series Hardware Manual Thermo Scientific

Page 23

Figure 1. Functional block diagram of the Orbitrap Fusion Series MS

Ion

optics

Mass

analyzers

Ion

detection

system

Instrument

control

electronic

assemblies

Vacuum

system

Printer

Computer

Monitor

Mass spectrometer Data systemInlet

Autosampler

(optional)

LC pump

(optional)

Syringe pump

Divert/inject

valve

API

source

1

Introduction

Electronic Assemblies

Electronic Assemblies

Controls and Indicators

The electronic assemblies that control the operation of the mass spectrometer are distributed

among various printed circuit boards (PCBs) and other modules, in the embedded computer,

and on or around the vacuum manifold of the mass spectrometer. You cannot service the

electronic assemblies.

Note If you need assistance, contact your local Thermo Fisher Scientific field service

engineer.

This section describes the following controls and indicators for the Orbitrap Fusion Series

MS:

• LEDs

• Power Entry Module

• Communications Panel

Thermo Scientific Orbitrap Fusion Series Hardware Manual 5

Page 24

1

Introduction

Controls and Indicators

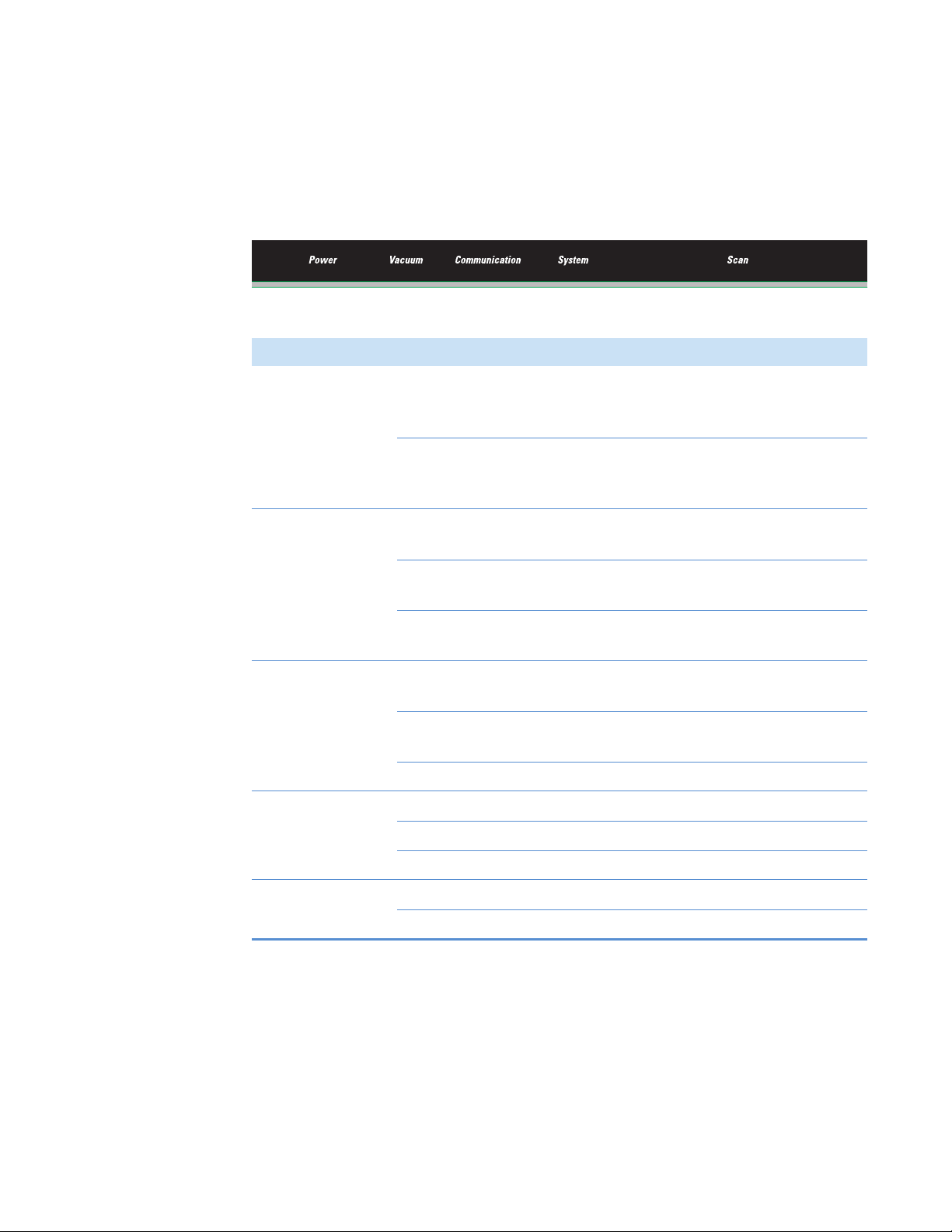

LEDs

Figure 2 shows the LEDs on the front panel with their descriptions listed in Ta b le 3 .

Figure 2. Orbitrap Fusion Series front panel LEDs

Table 3 . LEDs for the Orbitrap Fusion Series MS

LED State Description

Power Green The mass spectrometer is receiving power.

(The electronics service switch is in the Operating

Mode position.)

Off The mass spectrometer is not receiving power.

(The electronics service switch is in the Service

Mode position.)

Vacuum Green The vacuum is within the allowable operating

range.

Yellow The system bakeout is in progress or the vacuum

is outside the allowable operating range.

Off The mass spectrometer is either off or in the

process of starting up.

Communication Green The mass spectrometer and data system are

communicating.

Yellow The mass spectrometer and data system are trying

to establish a communication link.

Off The mass spectrometer is off.

System Green The mass spectrometer is on.

Yellow The mass spectrometer is in standby mode.

Off The mass spectrometer is off.

Scan Flashing blue The mass spectrometer is on and scanning.

Off The mass spectrometer is not scanning.

6 Orbitrap Fusion Series Hardware Manual Thermo Scientific

Page 25

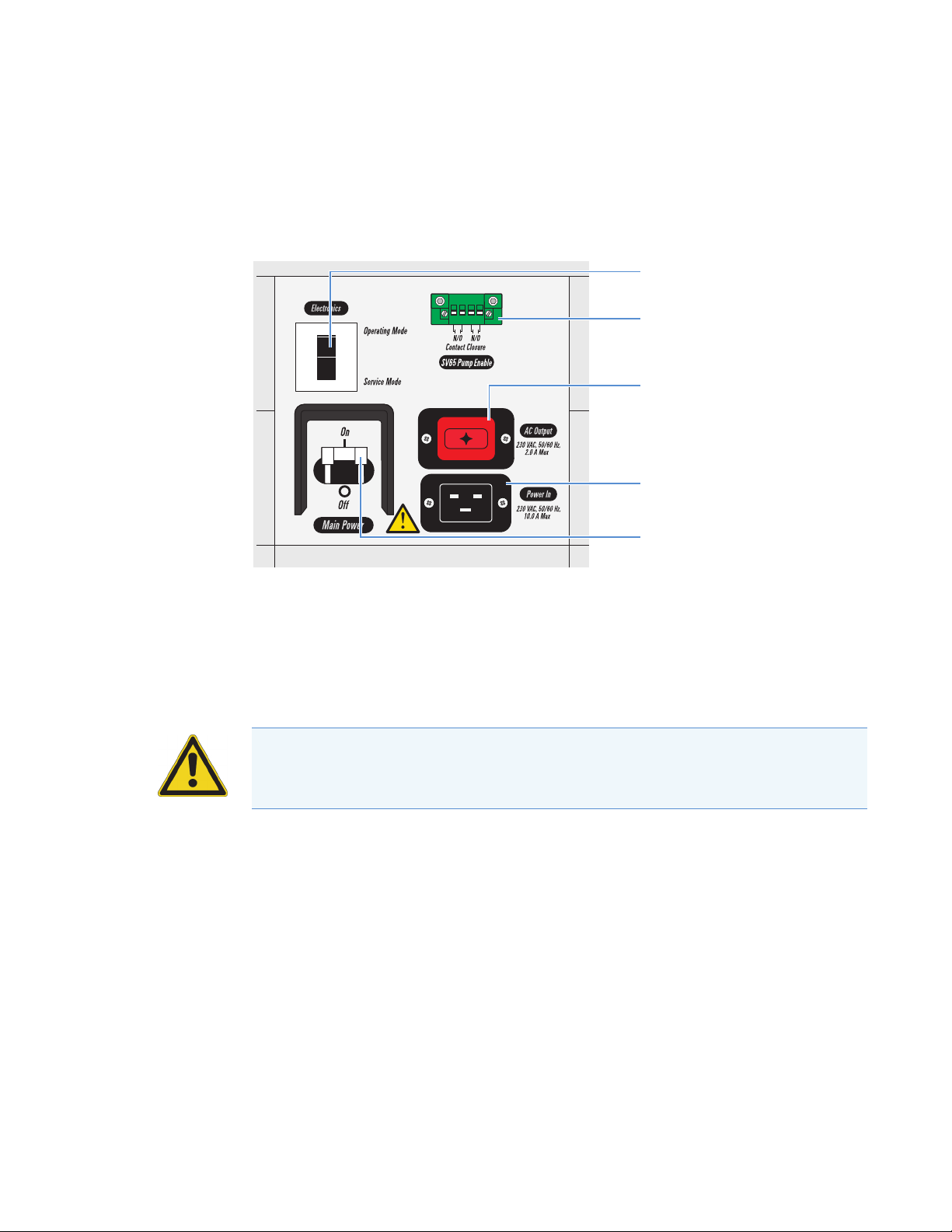

Power Entry Module

Power In receptacle

(230 Vac)

Main Power switch

Electronics service switch

SV65 Pump Enable connector

(forepump on/off control)

AC Output receptacle

(reserved for future use)

The mass spectrometer receives line power at 230 Vac ±10%, 15 A, 50/60 Hz through the

right-side power entry module (Figure 3).

Figure 3. Power entry module

1

Introduction

Controls and Indicators

Main Power Switch

In the Off position, the Main Power (circuit breaker) switch removes all power to the mass

spectrometer, including the external forepump or forepumps. In the On position, the mass

spectrometer receives power. In the standard operational mode, the switch stays in the On

position.

CAUTION To shut off all power to the mass spectrometer in an emergency, place the main

power circuit breaker switch (labeled Main Power) in the Off (down) position. Do not use

the electronics service switch.

Electronics Service Switch

The electronics service switch is a circuit breaker. In the Service Mode (down) position, the

switch removes power to all components of the mass spectrometer except for the fans and

vacuum system. This setting allows you to service nonvacuum system components with the

vacuum system still operating. In the Operating Mode (up) position, all components of the

mass spectrometer have power.

SV65 Pump Enable Connector

The mass spectrometer turns the forepump or forepumps on and off by using the relay control

cable that connects to the SV65 Pump Enable connector.

Thermo Scientific Orbitrap Fusion Series Hardware Manual 7

Page 26

1

Peripheral Control connector

Analog Input connector

USB ports

Ethernet port

Reset button

Introduction

Controls and Indicators

Communications Panel

The communications panel, which is located on the left side of the mass spectrometer,

provides a system Reset button, a contact closure interface (Peripheral Control), an analog

input connector, USB ports for the external syringe pump and divert/inject valve, and a

Gigabit Ethernet connection port for the data system computer.

When you briefly press the reset button, the embedded processing system and digital circuitry

reset and the system software reloads from the data system. For information about resetting

the mass spectrometer, see “Resetting the Mass Spectrometer” on page 55.

Figure 4 shows the communication connectors, and Ta b le 4 lists the pin-out descriptions for

these connectors.

Figure 4. Communication connectors (left side of the MS)

8 Orbitrap Fusion Series Hardware Manual Thermo Scientific

Page 27

1

Introduction

Controls and Indicators

Table 4 . Pin-out descriptions for the communication connectors (Sheet 1 of 2)

Pin Name Description

– Reset Resets the instrument to a power-up state.

Note Use this button only if the instrument does not

respond to the control program on the data system

computer or if you need to restart the instrument

without turning off the electronics service switch.

Peripheral Control

1Ground Earth ground

2 5V Provides a 5 Vdc, 500 mA output (with pin 1).

4 Start In Receives the start signal from the contact closure

connection of a connected external device.

To activate this signal, the external device must pull the

signal either low (below 0.75 Vdc) or high (above

2.4 Vdc), depending on the polarity, for at least

100 ms by using a relay, an open-collector driver, or a

similar device that connects between pins 4 and 1.

Note In the Instrument Configuration window, set

the contact closure signal to “High-to-low edge” or

“Low-to-high edge,” whichever matches the setting

for the connected external device.

5 Ready Out Provides a relay-driven programmable output signal to

the connected external device. The relay opens when a

method starts and closes when the method finishes.

Output: Maximum 24 Vdc, 3 A

6 Injection Hold Provides a relay-driven programmable output signal to

the connected external device, such as a fraction

collector.

Output: Maximum 24 Vdc, 3 A

8 RO/IH Common (return) connection for the Ready Out and

Injection Hold pins

Thermo Scientific Orbitrap Fusion Series Hardware Manual 9

Page 28

1

Introduction

Cooling Fans

Table 4 . Pin-out descriptions for the communication connectors (Sheet 2 of 2)

Pin Name Description

Analog Input

The two analog channels connect to two separate 12-bit analog-to-digital converters (ADC)

for on-demand conversion of the input voltage. The conversion rate depends on the mass

spectrometer rate.

1 Chassis Earth ground (for pins 3 and 4)

Cooling Fans

3, 4 2V Max:

+ (positive, pin 3) and

(Channel 2) Provides a connection for an external

device, such as an LC instrument.

– (negative, pin 4)

Input: 0–2 Vdc (voltage clamps at 5 Vdc)

5 Chassis Earth ground (for pins 7 and 8)

7, 8 10V Max:

+ (positive, pin 7) and

(Channel 1) Provides a connection for an external

device, such as an LC instrument.

– (negative, pin 8)

Input: 0–10 Vdc (voltage clamps at 15 Vdc)

Other connectors

– USB (2 ports) Provides a connection for the syringe pump and

divert/inject valve.

– Ethernet 1000 Base T Provides a connection for the Ethernet switch.

Over 20 fans, including those in the power supply subassemblies, provide internal cooling for

the Orbitrap Fusion Series MS. Cooling air enters through the three main air intake fans on

the right side of the mass spectrometer. Exhaust air exits the instrument from the left side

ventilation slots.

The only user-serviceable part is the right-side air filter in front of the air intake fans. For the

recommended maintenance schedule, see Chapter 8, “Maintenance.”

CAUTION To ensure safety and proper cooling, always operate the mass spectrometer with

its covers in place. This is also necessary to comply with product safety and

electromagnetic interference regulations.

10 Orbitrap Fusion Series Hardware Manual Thermo Scientific

Page 29

2

Scan Parameters

This chapter describes some of the scan parameter settings that you set in the Orbitrap Fusion

Series Tune application.

Contents

• Scan Types

• Scan Rates for the Ion Trap Detector

• Scan Mass-To-Charge Ratio Ranges

• Resolutions for the Orbitrap Detector

• Data Types

• Ion Polarity Modes

Scan Types

The following scan types are available:

• MS Scan

2

• MS

• SIM Scan

Scan and MSn Scan

MS Scan

The full-scan MS (or MS1) scan type corresponds to a single stage of mass analysis—that is, a

scan power of n =1.

With the single-stage full scan, the ions formed in the API source are stored in the ion-routing

multipole (IRM). The mass spectrometer then transfers these ions to either the Orbitrap™ or

linear ion trap (LIT) to produce a full mass spectrum of the observable ions in the specified

mass range at a specific time point in the analysis.

Thermo Scientific Orbitrap Fusion Series Hardware Manual 11

Page 30

2

Scan Parameters

Scan Rates for the Ion Trap Detector

Single-stage full-scan analysis is a useful tool for qualitative and quantitative analysis. Use

single-stage full-scan experiments to determine the molecular weight and intensity of

compounds present in the mass spectrum.

MS2 Scan and MSn Scan

An MS2 Scan selects the MS/MS mass analysis. An MSn Scan typically involves 2 to 10 stages

of mass analysis (scan power of n =2 to n = 10). Each stage of mass analysis where n >1

includes an ion selection step. As you raise the scan power, you can obtain more structural

information that can be useful in structure elucidation of compounds of interest. The

Orbitrap Fusion Series MS has several advanced features that make its MS

extremely powerful.

In an MS/MS scan, precursor ions fragment into product ions. The MS/MS scan type

experiment can use a full-scan or a defined scan range.

• First stage of mass analysis—You can set either the Quadrupole or the Ion Trap to select

the ions for MS/MS analysis. The mass spectrometer then transfers the selected ions to

the IRM for HCD or to the linear ion trap (LIT) for CID or ETD.

n

capabilities

• Second stage of mass analysis—The mass spectrometer transfers the product ions to either

the Orbitrap or the LIT for detection.

In the n

th

stage of mass analysis, subsequent stages of product ion selection occur in the LIT.

SIM Scan

The selected ion monitoring (SIM) scan type is a single-stage (scan power of n =1) technique

that monitors a particular ion or set of ions. In a SIM scan, the mass spectrometer selects ions

in the defined mass-to-charge ratio range, and ejects all other ions by using either the

quadrupole or the LIT analyzer. The Orbitrap or the LIT then detects the selected ions to

produce a SIM mass spectrum.

Scan Rates for the Ion Trap Detector

With the Orbitrap Fusion Series MS, you can use five scan rates: Turbo, Rapid, Normal,

Enhanced, and Zoom. For information about these scan rates, refer to the Tune Help.

Ta bl e 5 lists the scan rates and their peak widths (resolutions) for the Orbitrap Fusion Series

MS. For additional information about the scan rates, refer to the data system Help.

12 Orbitrap Fusion Series Hardware Manual Thermo Scientific

Page 31

Table 5 . Ion trap scan rates and peak widths

Scan rate Parameter Value

2

Scan Parameters

Scan Mass-To-Charge Ratio Ranges

Tu r b oa

Scan rate (Da/sec): 125 000

Peak width (FWHM

Rapid (default) Scan rate (Da/sec): 66 666

Peak width (FWHM): 0.6

Normal Scan rate (Da/sec): 33 333

Peak width (FWHM): 0.5

Enhanced Scan rate (Da/sec): 10 000

Peak width (FWHM): 0.35

Zoom Scan rate (Da/sec): 2222

Peak width (FWHM): 0.3

a

The isotopes are partially unresolved. The actual observed peak widths are isotope-abundant dependent.

b

Defined as the peak width at half height.

Scan Mass-To-Charge Ratio Ranges

The Orbitrap Fusion Series MS has two mass-to-charge ratio (m/z) range modes:

b

):

3

•Normal: m/z 50–2000

•High: m/z 100–4000 (ion trap detector type) or m/z 100–6000 (Orbitrap detector type)

with the precursor ion selection up to m/z 4000

Resolutions for the Orbitrap Detector

When you specify the Orbitrap mass analyzer as the detector type, you can choose from seven

resolution levels:

•15000

•30000

•50000

•60000

• 120 000

• 240 000

• 500 000

Thermo Scientific Orbitrap Fusion Series Hardware Manual 13

Page 32

2

Scan Parameters

Data Types

Data Types

With the Orbitrap Fusion Series MS, you can acquire and display mass spectral data (intensity

versus mass-to-charge ratio) in one of two data types:

•Profile data

With profile data, you can see the inherent shape of the peaks in the mass spectrum. The

mass spectrum divides each atomic mass unit into several sampling intervals. The

intensity of the ion current is determined at each sampling interval. The intensity at each

sampling interval is displayed with the intensities connected by a continuous line.

• Centroid data

With centroid data, you can see the mass spectrum as a bar graph. This scan data type

sums the intensities of each set of sampling intervals. This sum is displayed versus the

integral center of mass of the many sampling intervals. Centroid data requires about

one-tenth the computer disk space of what is required for profile data.

Ion Polarity Modes

The Orbitrap Fusion Series MS can operate in either positive or negative ion polarity mode.

The mass spectrometer controls whether positive ions or negative ions are transmitted to the

mass analyzer for mass analysis by changing the polarity of the voltage potentials applied to

the API source, ion optics, and ion detection system. The ion optics are located between the

API source and the mass analyzer. For a schematic of the ion transmission path, see Figure 13.

14 Orbitrap Fusion Series Hardware Manual Thermo Scientific

Page 33

3

Vacuum System

This chapter describes the principal components of the vacuum system for the

Orbitrap Fusion Series mass spectrometer.

Contents

• Vacuum System Functional Block Diagram

• Schematic of the Internal Gas Supply Lines

• Inlet Gases Hardware

• Vacuum Manifold

• Vacuum Gauges

• Vacu um Pu mps

• Atmospheric Pressure Ionization Source

• API Source Interface

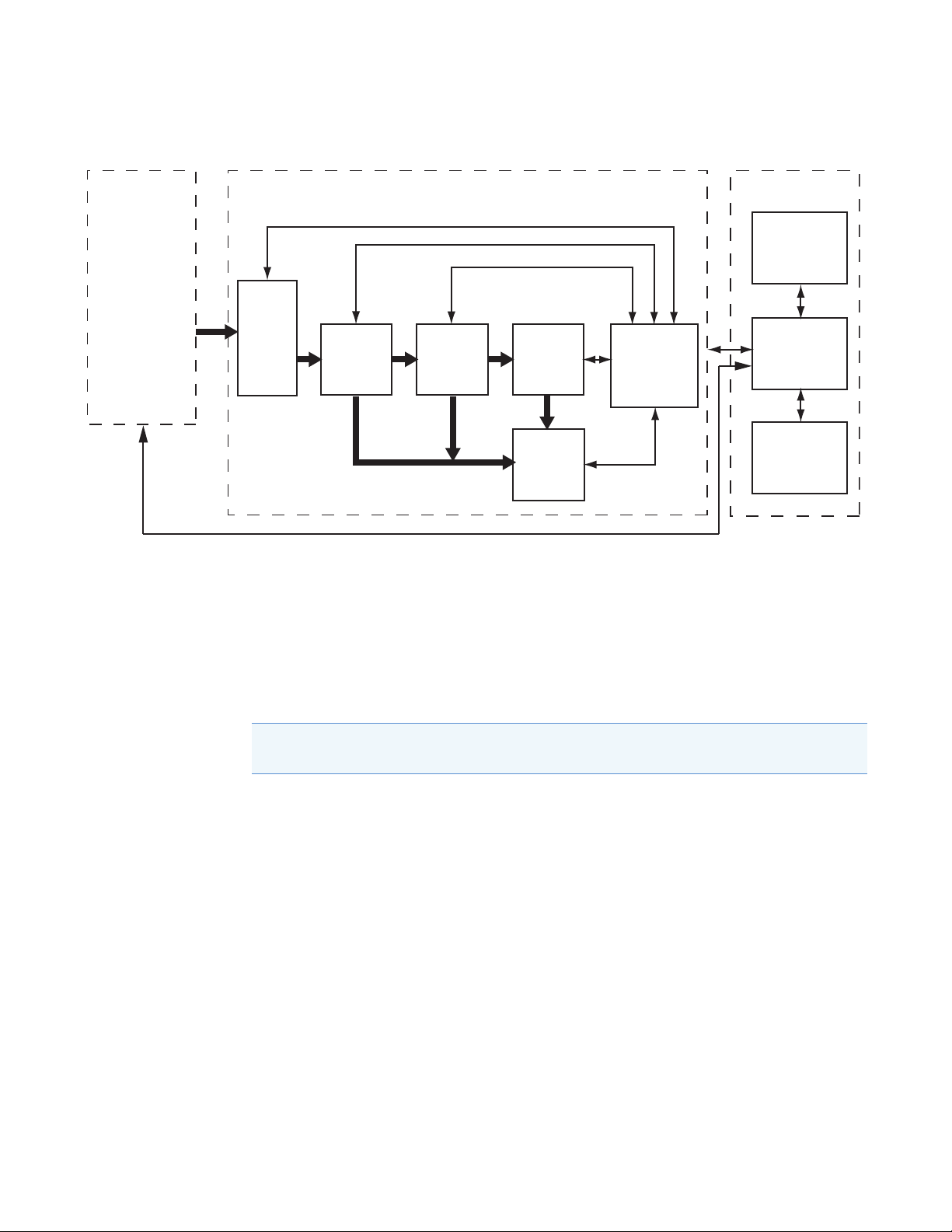

Vacuum System Functional Block Diagram

The vacuum system evacuates the region around the API source interface, ion optics, mass

analyzers, and ion detection system. Figure 5 shows a functional block diagram of the vacuum

system with hyperlinks to the applicable sections.

Thermo Scientific Orbitrap Fusion Series Hardware Manual 15

Page 34

3

Nitrogen gas

port

Sweep gas

valve

Sheath gas

valve

Aux gas

valve

Sample

inlet

device

Sample tube

API source

region

RF lens

region

MP00

RF lens

region

MP0

ion guide

region

Quadrupole / MP1 / IRM / C-trap region

Linear ion trap /

MP3 region

Damping gas

restrictor

Helium gas

port

Collision gas

restrictor

Collision gas

port

Orbitrap

region

UHV

pressure

gauge

Vent

valve

Triple-inlet

turbomolecular pump

Foreline

Forepump(s)

Exhaust

Source pressure

gauge

Collision

pressure gauge

Turbomolecular pump

Turbomolecular pump

Ion gauge

Nitrogen gas

Vacuum System

Vacuum System Functional Block Diagram

Figure 5. Functional block diagram of the vacuum system

16 Orbitrap Fusion Series Hardware Manual Thermo Scientific

Page 35

Schematic of the Internal Gas Supply Lines

Helium open

split inlet

Gas

block

Reagent

ion source

API

source

Ion-routing

multipole

Vent valve

Source PCB

Regulator

UHP nitrogen

gas inlet

UHP helium

gas inlet

HP nitrogen

gas inlet

Linear

ion trap

(Back of the MS)

Figure 6 shows a schematic drawing of the gas lines in the Orbitrap Fusion Series MS where

“Reagent ion source” represents the optional EASY-ETD™ or EASY-IC™ ion source.

Figure 6. Schematic of the internal gas supplies

3

Vacuum System

Schematic of the Internal Gas Supply Lines

Thermo Scientific Orbitrap Fusion Series Hardware Manual 17

Page 36

3

UHP nitrogen gas inlet

HP nitrogen gas inlet

UHP helium gas inlet

(Orbitrap Fusion MS)

(Orbitrap Fusion Lumos MS)

UHP nitrogen gas inlet

HP nitrogen gas inlet

UHP helium gas inlet

Vacuum System

Inlet Gases Hardware

Inlet Gases Hardware

The inlet gas hardware controls the flow of the helium damping gas; the nitrogen sheath gas,

auxiliary gas, sweep gas, and collision gas; and the nitrogen venting gas into the mass

spectrometer. Figure 7 shows the gas inlets on the back of the mass spectrometer.

• Helium Regulator

• Nitrogen Gas Valves

• Ven t Val ve

Figure 7. Gas inlet ports (back of the mass spectrometer)

18 Orbitrap Fusion Series Hardware Manual Thermo Scientific

Page 37

Helium Regulator

The helium (damping) regulator controls the flow of helium into the LIT analyzer cavity.

Helium (275 70 kPa [40 10 psi], 99.999% ultra high purity [UHP]) enters the mass

spectrometer through a 1/8 in. port on the back of the mass spectrometer. The mass

spectrometer regulates the flow of helium and delivers it to the ion trap.

Helium in the ion trap cavity dampens ionic motion and improves the performance of the

mass spectrometer. See “Helium Damping Gas” on page 41.

Nitrogen Gas Valves

The valves for the sheath, auxiliary, and sweep gases control the flow of dry nitrogen gas into

the API source (Figure 5). Sheath gas is the inner-coaxial nitrogen gas that helps nebulize the

sample solution into a fine mist as the solution exits the API spray insert nozzle. Auxiliary gas

is the outer-coaxial nitrogen gas that helps the sheath gas in the nebulization and evaporation

of the sample solution by focusing the vapor plume and lowering the humidity in the API

source. Sweep gas is the off-axis nitrogen gas that flows out from behind the optional ion

sweep cone to aid in solvent declustering and adduct reduction. The optional ion sweep cone

has an inlet for the sweep gas.

3

Vacuum System

Inlet Gases Hardware

The data system controls the valves that regulate the nitrogen pressure (see “Checking the Gas

Supplies” on page 63). You can set the gas flow rates on the Ion Source pane in the Tune

application.

High-purity (HP, 99%) and ultra-high-purity (UHP, 99.999%) dry nitrogen enter the back of

the mass spectrometer through two ports:

• 1/4 in. port for the HP nitrogen gas, which functions as the sheath, auxiliary, and sweep

gases

• 1/8 in. port for the UHP nitrogen gas, which functions as the higher energy

collision-induced dissociation (HCD) collision gas and the venting gas. For instruments

with the electron transfer dissociation (ETD) option, the UHP nitrogen gas also

functions as the ETD make-up gas and reagent carrier gas.

For a list of guidelines for the operating parameters, refer to the section “LC Flow Rate

Ranges” in Chapter 1 of the Orbitrap Fusion Series Getting Started Guide.

Thermo Scientific Orbitrap Fusion Series Hardware Manual 19

Page 38

3

Vacuum System

Vacuum Manifold

Vent Valve

The solenoid-operated vent valve allows the vacuum manifold to be vented with UHP

nitrogen. The vent valve on the vacuum manifold is closed when the solenoid is energized.

The vacuum manifold vents when the mass spectrometer no longer receives external power, as

with a power failure or when you turn off the main power switch. Power is briefly provided to

the vent valve after losing external power to protect against the accidental loss of power. When

power to the vent valve solenoid shuts off for more than a very brief period of time, the vent

valve opens and the manifold vents nitrogen gas.

IMPORTANT After venting the mass spectrometer, remember to turn off the UHP

nitrogen gas supply.

Vacuum Manifold

The vacuum manifold (Figure 8) encloses the API source interface, ion optics, mass analyzers,

and ion detection system assemblies. The vacuum manifold is a thick-walled, aluminum

chamber with multiple removable top cover plates, and various electrical feedthroughs and gas

inlets.

Ta bl e 6 lists the seven vacuum regions, the pumps that evacuate them, and the chamber

pressures. The block diagram in Figure 5 shows the vacuum regions.

Table 6 . Vacuum regions, evacuation devices, and typical pressures

Region Components Evacuated by Pressure

Orbitrap Fusion Orbitrap Fusion Lumos

1API source N/A Atmosphere

2 RF lens Forepump or forepumps Less than 2 Torr Less than 3 Torr

3 MP00 ion optics Triple-inlet turbomolecular pump

50 mTorr 100 mTorr

(first inlet [molecular drag])

4 MP0 ion optics Triple-inlet turbomolecular pump

1 . 5 m To r r 3 m To r r

(second inlet [interstage])

5 Quadrupole mass

analyzer, MP1 ion optics,

Triple-inlet turbomolecular pump

(third inlet [high vacuum])

5×10

–5

Tor r

IRM, C-trap

–5

6 LIT mass analyzer and

MP3 ion optics

Single-inlet turbomolecular

vacuum pump

8×10

7 Orbitrap mass analyzer Single-inlet turbomolecular pump 2 × 10

Tor r 2 × 1 0–5 Tor r

–10

To r r

20 Orbitrap Fusion Series Hardware Manual Thermo Scientific

Page 39

Vacuum Gauges

The Orbitrap Fusion Series MS contains three types of vacuum gauges that measure the

pressure in specific regions of the vacuum manifold. In the Tune application, you can observe

the readback values for the vacuum gauges on the By Function page in the Status pane (under

Source and FT Vacuum).

3

Vacuum System

Vacuum Gauges

• Convection pressure gauge—Measures pressure down to a fraction of a milliTorr (mT).

The instrument uses two convection gauges:

– Source pressure gauge—Measures the pressure in the RF lens and API ion transfer

tube region in the vacuum manifold and the foreline, which connects the triple-inlet

turbomolecular pump and the forepump or forepumps.

– Collision pressure gauge—Measures the pressure in the IRM.

• Ion gauge—Measures the pressure in the multipole MP3 and LIT region of the vacuum

manifold.

The ion gauge produces energetic electrons that cause the ionization of molecules in the

ion gauge. A collector attracts positive ions formed in the ion gauge. The collector current

is related to the pressure in the vacuum manifold. The ion gauge is also involved in

vacuum protection.

Vacuum Pumps

• Ultra high vacuum (UHV) pressure gauge—A compact cold cathode (inverted

magnetron) gauge measures the pressure in the Orbitrap region of the vacuum manifold.

The Orbitrap Fusion Series MS requires one or two external forepumps and three internal

turbomolecular pumps to provide the vacuum pressures for the seven vacuum regions

(Figure 5).

The forepumps create the vacuum necessary for the proper operation of the turbomolecular

pumps. They also evacuate the ion transfer tube region of the vacuum manifold.

The forepumps’ detachable power supply cords plug into separate, single-phase 230 Vac wall

outlets and the relay control cable connects to the mass spectrometer’s SV65 Pump Enable

connector (Figure 3) so that the mass spectrometer can remotely turn the forepumps on and

off. The Main Power switch controls the SV65 Pump Enable connector, not the electronics

service switch.

Thermo Scientific Orbitrap Fusion Series Hardware Manual 21

Page 40

3

Triple-inlet turbomolecular

pump (main)

Triple-inlet turbomolecular

pump (UHV)

Turbomolecular

pump (ion trap)

Vacuum System

Vacuum Pumps

As shown in Figure 8, there are three turbomolecular pumps: two triple-inlet pumps that

control the vacuum for multiple vacuum regions and one single-inlet pump that controls the

LIT vacuum region. The turbomolecular pumps also send status information, such as their

temperatures or rotational speeds, to the data system computer.

The Main Power switch turns off the turbomolecular pumps. The electronics service switch

has no effect on these pumps. Power to the turbomolecular pumps automatically shuts off if

the temperatures on the turbomolecular pumps becomes too high.

Figure 8. Placement of the three turbomolecular pumps

22 Orbitrap Fusion Series Hardware Manual Thermo Scientific

Page 41

Atmospheric Pressure Ionization Source

ESI spray insert

API source housing

Locking lever (locked position)

Sample inlet

The atmospheric pressure ionization (API) source forms gas phase sample ions from sample

molecules that are contained in solution. The API source also serves as the interface between

the LC and the mass spectrometer. You can configure the EASY-Max NG API source, which

is provided with the mass spectrometer, for the following ionization techniques:

heated-electrospray (H-ESI), atmospheric pressure chemical ionization (APCI), and

atmospheric pressure photoionization (APPI).

The Orbitrap Fusion Series MS has a front, built-in drain that routes the solvent waste from

the API source to the solvent waste container connected to the back drain/waste port. For

information about the solvent waste connection, refer to the Orbitrap Fusion Series Getting

Connected Guide.

For information about the API source, refer to Chapter 2 in the Orbitrap Fusion Series Getting

Started Guide. For instructions on how to install the spray insert, refer to the Ion Max NG and

EASY-Max NG Ion Sources User Guide.

Figure 9. EASY-Max NG API source (H-ESI mode)

3

Vacuum System

Atmospheric Pressure Ionization Source

Thermo Scientific Orbitrap Fusion Series Hardware Manual 23

Page 42

3

Ion transfer tube (not shown)

RF lensVent prevent ball

Ion sweep cone

Heater block

Exit lens

Lens L0

Spray cone (directly

behind the sweep

cone)

Release latch

Vacuum System

API Source Interface

API Source Interface

The API source interface for the Orbitrap Fusion Series MS consists of the components of the

API source that are held under vacuum (except for the atmospheric pressure side of the ion

sweep cone) in a vacuum chamber that the forepump evacuates to a pressure of approximately

1.5 Torr for the Orbitrap Fusion MS and 2.7 Torr for the Orbitrap Fusion Lumos MS. The

API source interface includes an ion sweep cone, an ion transfer tube, two cartridge heaters, a

heater block, a sensor, a vent prevent ball, the RF lens, the exit lens, and lens L0 (Figure 10).

Figure 10. API source interface (Orbitrap Fusion MS cross section)

24 Orbitrap Fusion Series Hardware Manual Thermo Scientific

The ion sweep cone is a metal cone over the ion transfer tube. The ion sweep cone channels

the sweep gas toward the entrance of the ion transfer tube, acts as a physical barrier that

protects the entrance of the ion transfer tube, and increases source robustness. The net result

is a significant increase in the number of samples to analyze without a loss of signal intensity.

In addition, keeping the ion transfer tube entrance as clean as possible reduces the need for

frequent maintenance. Install the ion sweep cone to improve ruggedness when analyzing

complex matrices such as plasma or nonvolatile salt buffers. Remove the ion sweep cone

before performing NSI experiments.

The ion transfer tube is a metal, cylindrical tube that assists in desolvating ions produced by

the API spray insert while transferring them into the vacuum system.

The heater block contains two heater cartridges, surrounds the ion transfer tube, and heats the

tube to temperatures up to 400 °C (752 °F). A thermocouple measures the temperature of the

heater block. Typical temperatures of the ion transfer tube are 270 °C (518 °F) for H-ESI and

250 °C (482 °F) for APCI, but these temperatures vary with the flow rate and the mobile

phase composition. A decreasing pressure gradient draws ions into the ion transfer tube in the

Page 43

3

Exit lens

RF lens

Orbitrap Fusion MS

Orbitrap Fusion Lumos MS

Vacuum System

API Source Interface

atmospheric pressure region and transports them to the API source interface region of the

vacuum manifold. The mass spectrometer applies the same electrical potential (positive for

positive ions and negative for negative ions) to the ion transfer tube and the RF lens, which

assists in transporting the ions from the tube to the RF lens. When you remove the ion

transfer tube (after it has cooled to room temperature), the vent prevent ball drops into place

to stop air from entering the vacuum manifold. Therefore, you can remove the ion transfer

tube for cleaning or replacement without venting the system.

Ions from the ion transfer tube pass through the RF lens and then the exit lens (Figure 11).

The RF lens is an ion transmission device consisting of progressively spaced, stainless-steel

electrodes. The RF lens differs slightly between the Orbitrap Fusion Lumos MS and the

Orbitrap Fusion MS. The mass spectrometer applies an RF voltage to the electrodes, and

adjacent electrodes have voltages of opposite phase. As the RF amplitude increases, ions of

progressively higher mass-to-charge ratios pass through to the exit lens and move toward the

MP00 RF lens. The exit lens acts as a vacuum baffle between the higher pressure API source

interface region and the lower pressure MP00 RF lens region of the vacuum manifold. The

RF lens and exit lens mount to the API source interface cage.

Figure 11. Exit lens and RF lens (Orbitrap Fusion and Orbitrap Fusion Lumos MSs)

Thermo Scientific Orbitrap Fusion Series Hardware Manual 25

Page 44

3

Vacuum System

API Source Interface

26 Orbitrap Fusion Series Hardware Manual Thermo Scientific

Page 45

4

Ion Transmission and Mass Analysis

This chapter provides a workflow chart that shows the paths for mass analysis through the

Orbitrap Fusion Series mass spectrometer. It also provides descriptions of the ion optics

elements, the three mass analyzers, and the ion detection system.

Contents

• Workflow for Mass Analysis

• Ion Optics

• Mass Analyzers

• Ion Detection Systems

Workflow for Mass Analysis

Figure 12 shows the possible mass analysis paths through the Orbitrap Fusion Series MS.

Thermo Scientific Orbitrap Fusion Series Hardware Manual 27

Page 46

4

Ion-routing multipole

activation (optional)

Further

processing?

Send to linear

ion trap?

Ion-routing

multipole

activation?

Ion-routing multipole

C-trap

LIT high-pressure

trap

Yes

No

Further

processing?

Yes

LIT low-pressure

analysis

Yes

No

Send to linear

ion trap?

No

CID activation

(optional)

Orbitrap

analysis

Q1 isolation

(optional)

Ions pass through C-trap

to ion-routing multipole.

High-pressure cell

isolation

Ions exit the

API source.

Yes

No

Yes

No

Ion Transmission and Mass Analysis

Workflow for Mass Analysis

Figure 12. Workflow for mass analysis

28 Orbitrap Fusion Series Hardware Manual Thermo Scientific

Page 47

Ion Optics

Dual-pressure linear

ion trap (LIT)

Conversion

dynode

Lens TL1

MP3

Lenses L3-1 and L3-2

Ion-routing multipole

C-trap, trap lens

C-trap

C-trap, gate lens

Ultra-high field Orbitrap

mass analyzer

Orbitrap

transfer lens

MP1

Split gate

Lens L2

Q1 quadrupole

mass analyzer

Lenses TK1

and TK2

MP0 (90 degrees)

Lens L0

MP00 RF lens

Exit lens or reagent ion

source

1

(shown)

RF lens

EASY-ETD or -IC

ion source

(Drawing is not to scale)

High capacity ion

transfer tube

4

Ion Transmission and Mass Analysis

Ion Optics

Figure 13 shows a schematic of the ion transmission path through the Orbitrap Fusion Series

MS with hyperlinks to the applicable sections.

Figure 13. Schematic of the Orbitrap Fusion Lumos Tribrid MS ion transmission path (shown with the ETD source option

1

)

1

For the Orbitrap Fusion Series MS with the Internal Calibration (IC) or ETD configuration, the ETD/IC source heater interface replaces the

exit lens.

Thermo Scientific Orbitrap Fusion Series Hardware Manual 29

Page 48

4

Orbitrap Fusion MS Orbitrap Fusion Lumos MS

Ion Transmission and Mass Analysis

Ion Optics

The ion optics focus and accelerate the gas-phase sample ions into the designated mass

analyzer, where they are isolated and ejected according to their mass-to-charge ratios. This

section describes the following:

• MP00 Ion Optics

• MP0 Ion Optics

• MP1 Ion Optics