Page 1

Luminoskan Ascent

Luminoskan Ascent

User Manual

User Manual Rev. 2.1; Dec. 2003, Cat. no. 1507520

Page 2

2 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 3

Table of Contents

Symbols and Markings ................................................................ 7

1. Introduction ....................................................................... 9

2. Instrument Layout............................................................ 11

3. Installation ....................................................................... 19

4. Operation ......................................................................... 31

5. Maintenance..................................................................... 55

6. Troubleshooting Guide..................................................... 65

7. Frequently asked questions (FAQ) about the Luminoskan

Ascent.............................................................................. 69

8. Instrument Service...........................................................71

9. Disposal of the Instrument and Materials........................ 77

10. Ordering Information ....................................................... 79

11. Glossary and Abbreviations .............................................83

12. Literature.......................................................................... 85

13. Warranty Certificate......................................................... 87

14. Specifications................................................................... 89

15. Index................................................................................. 95

Appendix A. Brief User’s Guide ................................................. 99

Appendix B. Addresses............................................................ 101

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 3

Page 4

Contents

Symbols and Markings................................................................ 7

1. Introduction .......................................................................... 9

1.1 Intended use .................................................................................. 10

1.2 Method descriptions ..................................................................... 10

1.2.1 Luminometric measurement principle.................................. 10

2. Instrument Layout............................................................... 13

2.1 Front view ...................................................................................... 13

2.2 Rear view ....................................................................................... 14

2.3 Internal view .................................................................................. 15

2.4 Optical system............................................................................... 16

2.5 Control switches............................................................................ 16

2.6 Incubator........................................................................................ 17

2.7 Dispensers ..................................................................................... 17

2.8 Plate carrier.................................................................................... 18

3. Installation .......................................................................... 19

3.1 Upon delivery ................................................................................ 19

3.1.1 Unpacking............................................................................... 19

3.1.2 Checking delivery for completeness..................................... 20

3.1.3 Checking for damage during transport................................. 20

3.1.4 Environmental requirements and noise................................ 21

3.1.5 Things to avoid....................................................................... 21

3.1.6 Technical prerequisites.......................................................... 22

3.2 Releasing the transportation lock................................................. 22

3.3 Power and computer connections ............................................... 23

3.4 Installation of dispensers .............................................................. 25

3.5 Installation of the drop plate......................................................... 26

3.6 Plate adapters ................................................................................ 27

3.7 Adjusting the plate carrier............................................................. 29

3.8 Operational check.......................................................................... 30

4. Operation ............................................................................ 31

4.1 Switching on.................................................................................. 31

4.2 Loading the microplate ................................................................. 32

4.3 Luminometric measurement ........................................................ 33

4.3.1 Luminometric scaling............................................................. 34

4 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 5

4.4 Other functions...............................................................................35

4.4.1 Orbital shaking ........................................................................35

4.4.2 Incubator .................................................................................38

4.4.3 Dispensers...............................................................................38

4.4.4 Dispenser head height adjustment ........................................41

4.4.5 Chemical resistance of the dispenser ...................................43

4.5 Changing the measurement direction ..........................................46

4.6 Installing or removing the light shield ..........................................49

4.7 Installing the filters .........................................................................50

4.8 Shutdown .......................................................................................53

5. Maintenance........................................................................ 55

5.1 Routine cleaning of the instrument...............................................55

5.2 Cleaning the optical system ..........................................................56

5.2.1 Visual filter check ....................................................................56

5.3 Cleaning the plate carrier...............................................................57

5.4 Replacing the fuses........................................................................58

5.5 Routine maintenance of optional dispensers and main lens ......59

5.5.1 Basic maintenance..................................................................59

5.5.2 Extended maintenance...........................................................59

5.5.2.1 Weak detergent or 10% bleach ....................................................59

5.5.2.2 Weak acid and base in sequence..................................................60

5.5.2.3 Cleaning the main lens..................................................................60

5.6 Periodic maintenance ....................................................................61

5.6.1 Replacing the dispenser tubings............................................61

5.6.2 Replacing the dispensing tip ..................................................63

5.6.3 Replacing the dispenser syringe............................................64

6. Troubleshooting Guide ........................................................ 65

6.1 Troubleshooting.............................................................................65

6.2 Error messages ..............................................................................68

7. Frequently asked questions (FAQ) about the Luminoskan

Ascent ................................................................................. 69

8. Instrument Service .............................................................. 71

8.1 Service request protocol ...............................................................71

8.2 Decontamination procedure..........................................................71

8.3 Certificate of decontamination ......................................................73

8.4 Shipping the instrument (or items) ...............................................75

8.5 Service contracts............................................................................75

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 5

Page 6

9. Disposal of the Instrument and Materials........................... 77

9.1 Disposal of the instrument............................................................ 77

9.2 Disposal of materials..................................................................... 77

10. Ordering Information ....................................................... 79

10.1 Product code numbers ................................................................. 79

10.2 List of recommended spare parts ................................................ 82

10.3 Ordering filters............................................................................... 82

11. Glossary and Abbreviations ............................................. 83

12. Literature ......................................................................... 85

13. Warranty Certificate ........................................................ 87

13.1 Warranty limitations ...................................................................... 88

14. Specifications .................................................................. 89

14.1 General specifications................................................................... 89

14.2 Safety specifications ..................................................................... 91

14.3 In conformity with the requirements............................................ 92

14.4 Performance specifications........................................................... 93

15. Index ................................................................................ 95

Appendix A. Brief User’s Guide ................................................ 99

Appendix B. Addresses ........................................................... 101

6 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 7

Symbols and Markings

SYMBOLS USED IN THE LUMINOSKAN ASCENT

Power ON

Power OFF

Connection to the protective grounding system

WARNING MARKINGS USED ON THE INSTRUMENT

Caution: risk of electric shock.

Caution: risk of personal injury to the operator or a

safety hazard to the surrounding area. See the

WARNING MARKINGS USED IN THE DOCUMENTATION

accompanying documentation.

CE compliance mark

Caution: risk of electric shock.

Caution: risk of personal injury to the operator or a

safety hazard to the surrounding area.

Caution: risk of serious damage to the instrument, other

equipment or loss of performance or function in a

specific application.

Caution: biohazard risk.

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 7

Page 8

Luminoskan Ascent, Cat. no. 5300160 and 5300170 (with dispenser)

User Manual Rev. 2.1; Dec. 2003, Cat. no. 1507520

Copyright

1995 – 2003 Thermo Electron Corporation. All rights reserved. Printed in

Finland. Reproduction of the accompanying user documentation in whole

or in part is prohibited.

Patents

Luminoskan Ascent has national and international patents and patents

pending.

Trademarks (

and )

Ascent Software, Luminoskan, Luminoskan Ascent and Microtiter are

registered trademarks of Thermo Electron. BioBind and Microlite are

trademarks of Thermo Electron. Virkon is a registered trademark of Antec

International Ltd. All other trademarks, registered trademarks and

copyrights are property of their respective holders.

Disclaimer

Thermo Electron reserves the right to change its products and services at

any time to incorporate technological developments. This manual is

subject to change without prior notice. Although this manual has been

prepared with every precaution to ensure accuracy, Thermo Electron

assumes no liability for any errors or omissions, nor for any damages

resulting from the application or use of this information. This manual

supersedes all previous editions.

No liability for consequential damages

Thermo Electron shall not be liable for any damages whatsoever arising

out of the use or inability to use this product.

Contact information

P.O. Box 100, FIN-01621 Vantaa, Finland

Tel. +358-9-329 100, Fax +358-9-3291 0415

www.thermo.com

8 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 9

1. Introduction

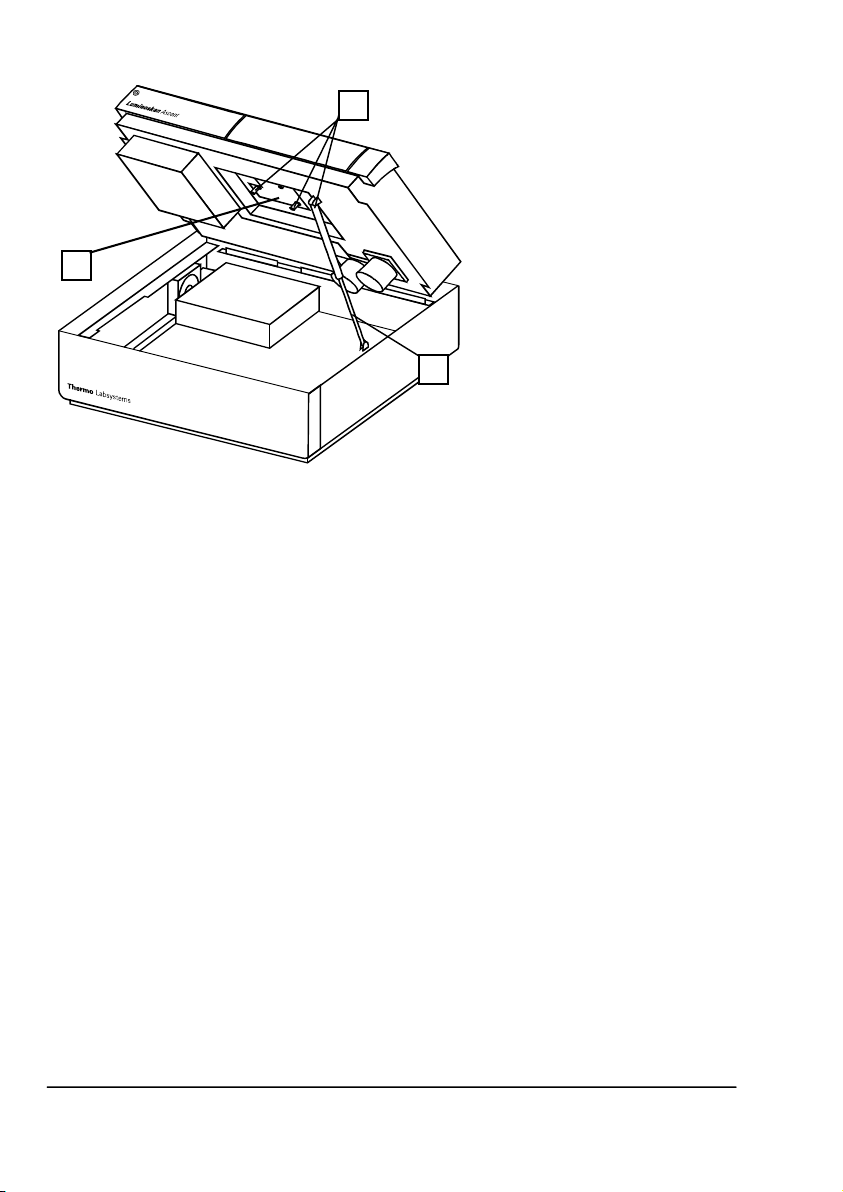

The Luminoskan Ascent (Fig. 1) designed and made by Thermo Electron is

a microplate luminometer which offers versatility and flexibility for even

the most demanding luminometric applications. The instrument covers the

full range of glow and flash luminometric applications.

Fig. 1. Luminoskan Ascent

Ascent Software controls all the reader functions and provides easy assay

optimization, flexible data handling and convenient report formatting. The

software for the Luminoskan Ascent is a dedicated software for

luminometric applications.

High sensitivity is one of the main benefits of the instrument. The

Luminoskan Ascent can also be equipped with filters for luminometric

applications.

Up to three reagent dispensers can be fitted on-board, making the reagent

addition simple and highly accurate. The ability of the instrument to

dispense and measure simultaneously enables the detection of flash

luminescence reactions and rapid kinetic applications. For assays requiring

temperature control, the instrument has an on-board incubator. Built-in

orbital shaking speeds up reaction times and ensures effective mixing.

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 9

Page 10

The robotic integration is simple and effective with the Luminoskan

Ascent. The plate carrier allows convenient access for the robotic arm and

Ascent Software is easy to integrate with robotic and HIS/LIMS systems.

The Luminoskan Ascent is also fully compatible with Thermo Electron

robotic plate handling devices, expanding the measurement capacity. For

further information, contact your local Thermo representative.

1.1 Intended use

1. The Luminoskan Ascent is a high-quality microplate luminometer

intended for laboratory research use by professional personnel. The

Luminoskan Ascent is used to measure luminescence from suitable 1to 384-well plates mentioned in this manual. It also has incubation,

shaking and reagent dispensing capabilities.

2. For verification of the entire system, it is recommended that Good

Laboratory Practices (GLP) be followed to guarantee reliable analyses.

3. Use for self-testing is excluded.

1.2 Method descriptions

1.2.1 Luminometric measurement principle

The filter slots 7 and 8 are reserved only for luminometric measurements.

Filter slot 7 is empty for measurement and filter slot 8 is blocked to enable

measurement of the PMT (photomultiplier tube) dark current. This feature

is important to obtain optimal sensitivity. The light path from the

measurement well to the first lens is protected by a light shield (Fig. 4.6a

and Fig. 4.6b). The light shield is required with 96- and 384-well plates to

avoid crosstalk in luminometric measurements. When plates are higher

than 15 mm, the light shield must be removed. If the 384-well plate has a

height of less than 15 mm, then an adapter must be used below the plate

to raise the plate to the proper height. This adapter for low 384-well plates

(Fig. 3.6:4) is included in the Luminoskan Ascent instrument and can also

be ordered separately.

10 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 11

Caution: A luminometric measurement without a light

shield may cause extra crosstalk.

Caution: The light shield must be removed with higher

plates.

Note: The emission filter slots 7 and 8 are reserved only for

luminometric measurements. Filter slot 7 is empty for

measurement and filter slot 8 is blocked to enable

measurement of the PMT (photomultiplier tube) dark

current.

DO NOT install any filters into slots 7 and 8.

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 11

Page 12

12 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 13

2. Instrument Layout

2.1 Front view

5

1

2

3

4

1 Instrument housing

2 Dispenser and optics cover

3 Instrument chassis

4 Measurement chamber door

5 Power, busy and error indicator

Fig. 2.1 Luminoskan Ascent front view

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 13

Page 14

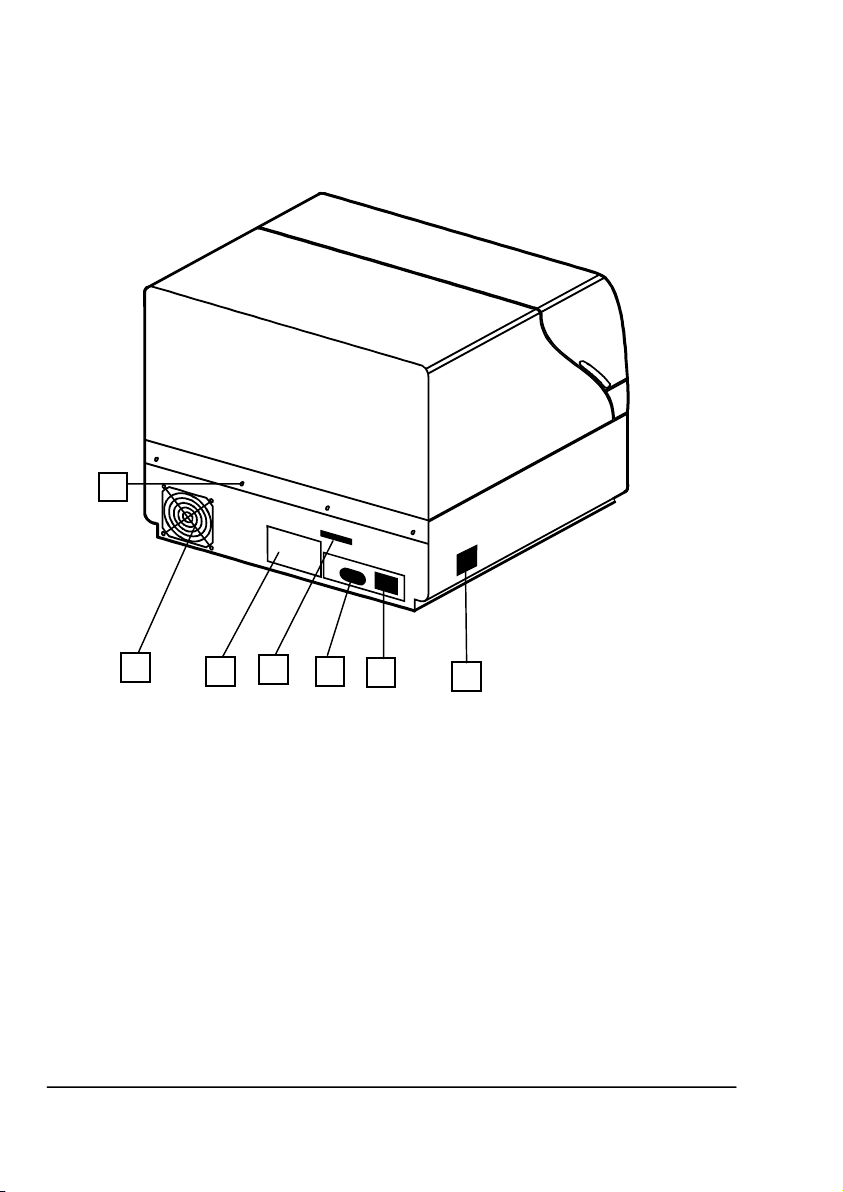

2.2 Rear view

6

7

5

4

3

1

2

1 Mains power supply socket

2 Power switch (ON/OFF)

3 Power fuses

4 Serial communication connector for the computer

5 Identification plate

6 Housing retaining screws

7 Cooling-air outlet

Fig. 2.2 Luminoskan Ascent rear view

14 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 15

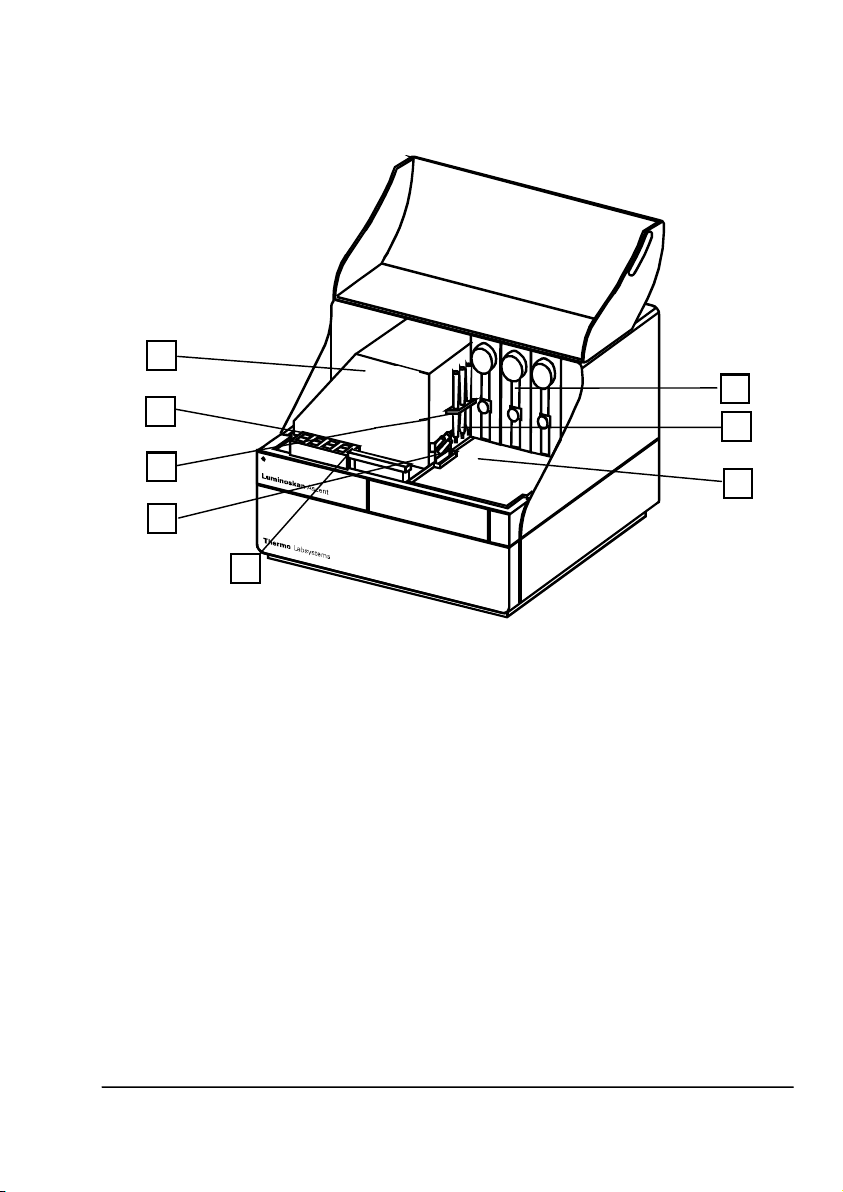

2.3 Internal view

1

7

2

3

5

6

4

8

1 Light cover for the optical unit

2 Dispensers (opt.)

3 Dispensing head (opt.)

4 Leakage tray (opt.)

5 Dispensing head holder (opt.)

6 Dummy plug

7 Control switches

8 Cover sensor

Fig. 2.3 Luminoskan Ascent internal view

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 15

Page 16

2.4 Optical system

2

3

5

4 1

1 In the Luminoskan Ascent the light beam is strictly limited by a light shield to

avoid crosstalk.

2 Mirror

3 An optional filter in the filter wheel

4 The photomultiplier tube (PMT) detects the light.

5 Light shield

Fig. 2.4 Principle of the optical system

2.5 Control switches

The control switch box (Fig. 2.3:7) contains three rocker switches for

priming and emptying dispenser tubings, one rocker switch for driving the

plate carrier in or out, and a sensor (Fig. 2.3:8) to monitor that the

dispenser cover is in the closed position in luminometric measurements.

The priming control switches are only functional when the plate carrier is

located outside the instrument.

16 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 17

2.6 Incubator

The incubator contains two heating element plates in the measurement

chamber, one heating element plate under the microplate and another

above it. The incubator only heats, but does not cool.

2.7 Dispensers

The optional dispensers, 1 to 3 dispensers from left to right, are located

inside the instrument housing under the dispenser cover, as seen in

Fig. 2.3. The dispensers consist of modular digital pumps with valves,

syringes, tubing and dispensing heads. The dispensing heads have three

alternative dispensing positions, one of these dispenses into the well in the

measurement position.

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 17

Page 18

2.8 Plate carrier

p

A1 corner of the

micro

late

2

1 Positioning lever

2 Adjustable stoppers

3 Waste strip holder (opt., 4 wells) for the tip priming during the measurement

session

4 Plate carrier door

3

1

4

Fig. 2.8 Plate carrier

18 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 19

3. Installation

3.1 Upon delivery

3.1.1 Unpacking

The Luminoskan Ascent

Move the unpacked instrument to its site of operation. To prevent

condensation, the instrument should be left in its protective plastic

wrapping until the ambient temperature has been reached. Unpack the

Luminoskan Ascent instrument and accessories carefully with the arrows

on the transport package pointing upwards. Open the top of the package

and lift the Luminoskan Ascent

(Fig. 3.1). The following notes and instructions are sent with the instrument

and are immediately available when you open the package:

• the packing instructions

• the packing list

• the Thermo Electron Warranty Certificate card

• the performance test reports

• the User Manual.

Caution: DO NOT touch or loosen any screws or parts other

than those specifically designated in the instructions. Doing so

might cause misalignment and will void the instrument

warranty.

Caution: The Luminoskan Ascent

(46 lbs.) without dispensers and should be lifted with care. It is

recommended that two persons lift the instrument together,

taking the proper precautions to avoid injury.

is packed in a specially designed shipping carton.

out of the shipping carton

weighs approximately 21 kg

Retain the original packing materials and shipping carton for future

transportation. Also retain all the documentation provided with the

instrument.

If you relocate your instrument or ship it for service, remember to:

1. Empty the dispenser(s) and remove the tube assembly.

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 19

Page 20

2. Remove any loose items from the plate carrier, for example, adapters,

plates and priming vessels.

3. Remove the power cable as well as the serial cable.

4. Replace the transportation lock.

For further information, see Section 8.4 Shipping the instrument (or items).

Intended lifting

area

Fig. 3.1 Luminoskan Ascent

3.1.2 Checking delivery for completeness

Check the enclosed packing list against order. If any parts are missing,

contact your local Thermo representative or Thermo Electron Oy.

3.1.3 Checking for damage during transport

Visually inspect the transport package, the instrument and the accessories

for any possible transport damage.

If the carton has been damaged in transit, it is particularly important that

you retain it for inspection by the carrier in case there has also been

damage to the instrument.

20 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 21

Visually check all interconnections in the basic instrument. Check that

there are no loose parts inside the instrument.

If any parts are damaged, contact your local Thermo representative or

Thermo Electron Oy.

3.1.4 Environmental requirements and noise

When you set up your Luminoskan Ascent, avoid sites of operation with

excess dust, vibrations, strong magnetic fields, direct sunlight, draft,

excessive moisture or large temperature fluctuations.

• Make sure the working area is flat, dry, clean and vibration-proof and

leave additional room for cables, connections, controlling computer,

printer, etc.

• Make sure the ambient air is clean and free of corrosive vapors, smoke

and dust.

• Make sure the ambient temperature range is between +10°C (50°F)

and +40°C (104°F).

• Make sure relative humidity is between 10% and 90% (noncondensing).

Leave sufficient space (at least 10 cm) at both sides of the instrument and

at the back of the unit to allow adequate air circulation. Make space for the

controlling computer on one side of the Luminoskan Ascent.

The Luminoskan Ascent does not produce operating noise at a level which

could be harmful. No sound level measurements are needed after

installation.

Warning: DO NOT operate the instrument in an environment

where potentially damaging liquids or gases are present.

3.1.5 Things to avoid

DO NOT smoke, eat or drink while using the Luminoskan Ascent. Wash

your hands thoroughly after handling test fluids. Observe normal

laboratory procedures for handling potentially dangerous samples. Use

proper protective clothing. Use disposable gloves. Be sure the working

area is well-ventilated.

Never spill fluids in or on the equipment.

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 21

Page 22

3.1.6 Technical prerequisites

Place the instrument on a normal laboratory bench close to the mains

power supply socket. The net weight of the unit is approx. 21 kg (46 lbs.).

The instrument operates at voltages of 100 – 240 Vac. The frequency range

is 50/60 Hz.

3.2 Releasing the transportation lock

2

3

4

1

1 Cover retaining screws, 4 pieces

2 Dispenser and optics cover

3 Rear of the cover

4 Point to where cover lifted

Fig. 3.2a Removing the instrument cover

1. Remove the four cover retaining screws (Fig. 3.2a:1).

2. Open the dispenser and optics cover (Fig. 3.2a:2).

3. Lift the rear of the cover at first about 3 cm (Fig. 3.2a:3).

4. Lift the cover aside (Fig. 3.2a:4).

5. Undo the two screws (Fig. 3.2b:1) at the right rear corner of the

measurement chamber.

6. Turn the locking piece upside down (Fig. 3.2b:2).

22 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 23

7. Fit the locking piece back with the fitting screws (Fig. 3.2b:3).

8. Refit the cover by first fixing the front corners.

1 2

3

1 Connected locking piece with two screws

2 Disconnected locking piece turned upside down

3 Reconnected locking piece

Fig. 3.2b Removing the transportation lock

Caution: If the locking piece is not fitted into its place, light

may enter the measurement chamber and affect the results.

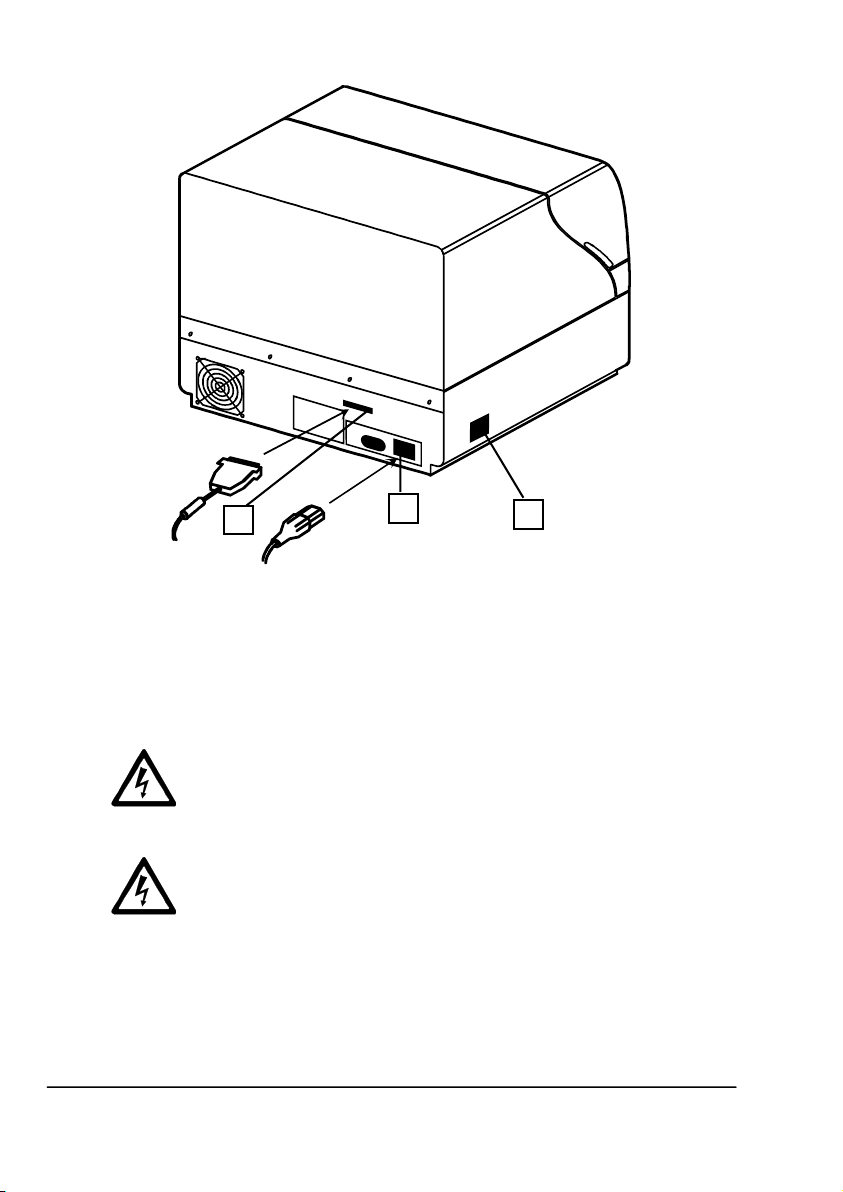

3.3 Power and computer connections

1. Ensure that the power switch (Fig. 3.3:1) is in the OFF position.

2. Connect the mains supply cable to the mains power supply socket

(Fig. 3.3:2). The instrument box contains two different mains supply

cables with North American and European types of plugs. Select the

correct type used in your laboratory. If any other type of mains supply

cable is needed, use only cables certified by the local authorities.

3. Connect the instrument to a correctly installed line power outlet that

has a protective conductor also called ground or earth.

4. Connect the serial cable to the serial connector (Fig. 3.3:3) and secure it

with the locking screws. Connect the other end similarly to the

controlling computer.

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 23

Page 24

3

2

1

1 Power switch (ON/OFF)

2 Mains power supply socket

3 Serial connector

Fig. 3.3 Power and computer connections

Warning: Always make sure the power switch on the

instrument is in the OFF position and remove the mains

power supply cable from the back of the instrument prior

to any installation or relocation of the instrument.

Warning: Never operate your instrument from a power

outlet that has no ground connection.

24 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 25

3.4 Installation of dispensers

The optional dispensers 1 to 3 are installed in number order from left to

right. The complete dispensing assemblies are packed with the

accessories.

hole of the valve. Ensure that the aspirate tubing is finger-tight. If

necessary, turn the fitting another quarter to half turn using a 7.9 mm (5/16

in.) wrench. The aspirate tubing is used to fill the syringe with reagent.

When using the dispensers, make sure that the aspiration tube end is

completely submerged in the reservoir and there is a sufficient volume of

the reagent in the reservoir (for all primings and the actual dispensing).

Fit the complete dispensing tube assembly (Fig. 3.4:2) into the right hole of

the valve and tighten it finger-tight. Then turn the fitting another quarter to

half turn using a 7.9 mm (5/16 in.) wrench. The dispensing tube is used to

dispense reagent from the syringe into a microplate. Place the dispensing

heads in the dispensing head holder on the left-hand side of the

dispensers.

First push the plunger manually upwards into the upper position before

tightening the plunger lock screw (Fig. 3.4:5). Ensure that the plunger lock

screw is sufficiently tightened. Note that the plunger can be extremely

firm.

1

The aspirate tubing (Fig. 3.4:1) is factory installed into the left

1

Instructions concerning the pump are reproduced from CAVRO XP3000 Modular Digital

Pump Operators Manual made by Cavro Scientific Instruments, Inc., USA, 1994.

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 25

Page 26

1

2

3

4

5

1 Aspirate tube assembly (incl. tubing and end weight)

2 Complete dispensing tube assembly

3 3-port valve

4 Dispensing syringe (1.0 ml) and plunger

5 Plunger lock screw

Fig. 3.4 Automatic dispenser unit

3.5 Installation of the drop plate

The instrument is supplied with a special drop plate (Fig. 3.5a). The drop

plate is used to protect the instrument from damage caused by accidental

dispensing without any microplate. If the user forgets to place a microplate

onto the plate carrier but has the drop plate in place, the reagent will be

dispensed into the drop plate, not inside the instrument. The drop plate is

placed like an adapter into the plate carrier (Fig. 3.5b) and the microplate is

placed onto the drop plate. The holding capacity of the drop plate is 19 ml

of liquid.

Note: The drop plate cannot be used for bottom reading.

26 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 27

Fig. 3.5a Drop plate

Fig. 3.5b Drop plate placed into the plate carrier

3.6 Plate adapters

Reading certain plate types with the Luminoskan Ascent instrument

requires special plate adapters (Fig. 3.6). These plate adapters are required

for the following reasons:

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 27

Page 28

1. Raising the 384-well plate with a height of less than 15 mm to the

proper height for luminometric measurement.

2. If the 384-well plate height is less than 13.5 mm, an adapter must be

used to raise the plate for dispensing.

3. Positioning of other sample vessel types than microplates (for

example, Petri dishes or Terasaki plates) onto the plate carrier for

measurement and dispensing.

4. Supporting flexible PCR plates and tubes on the plate carrier for

measurement and dispensing.

When using any adapter, measure the height of the plate and the adapter

together and ensure that this value is correctly entered into the Ascent

Software plate template parameter file. Refer to the Ascent Software

User’s Guide for further information.

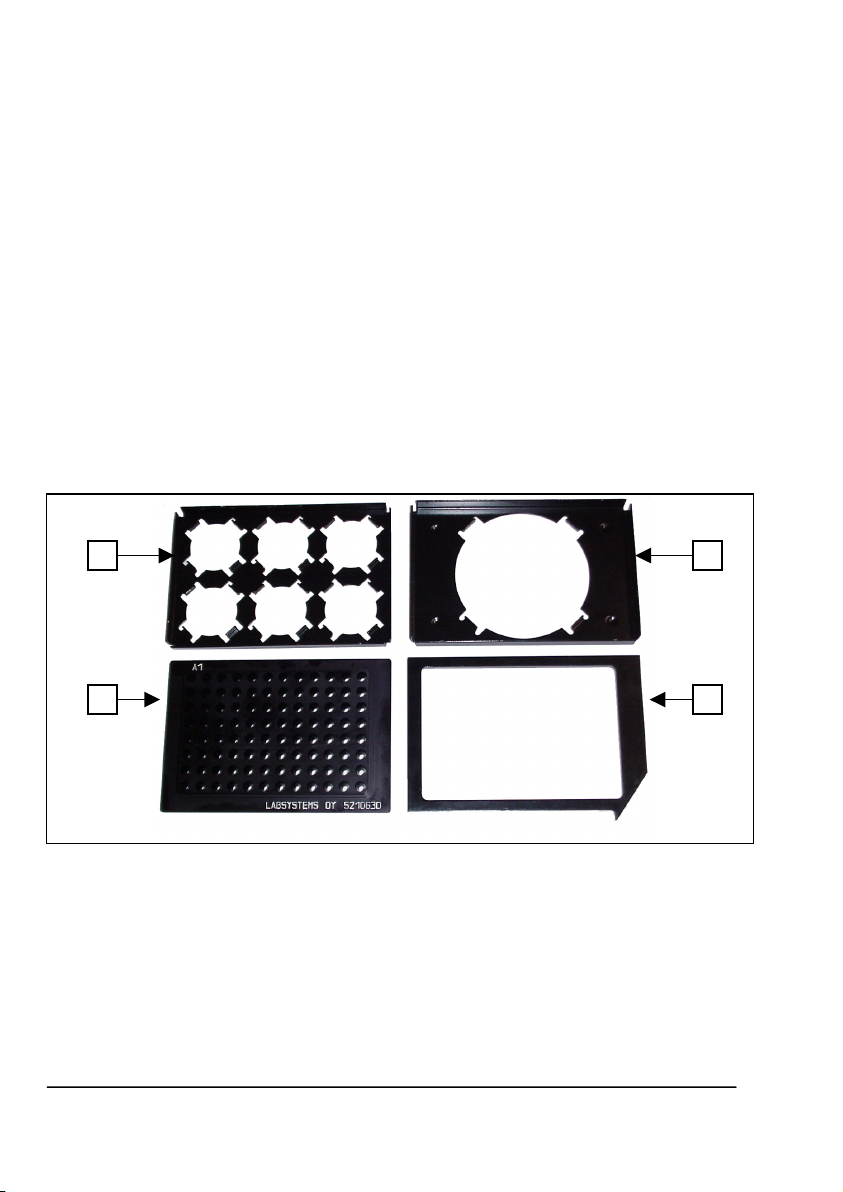

1

2

1 Adapter for Petri dish, 6 x 40 mm

2 Adapter for 96-well PCR plates

3 Adapter for Petri dish, 93 mm

4 Adapter for low 384-well plates

Fig. 3.6 Example of plate adapters

28 Luminoskan Ascent

3

4

User Manual Rev. 2.1, Cat. no. 1507520

Page 29

Note: If the orientation of the plate adapter is important, the correct

orientation is printed on the adapter or the adapter has been

designed in such a way that only one orientation is possible.

When the adapter is needed, place it into the plate carrier. Then place the

sample vessel(s) on the corresponding adapter or a drop plate, select the

correct plate template (marked “with adapter”) from Ascent Software and

run the instrument normally.

Note: Always remember to remove the plate adapter before

using the instrument with any other plate types.

3.7 Adjusting the plate carrier

The plate carrier of the Luminoskan Ascent has been designed for plates

with different footprints and to be robot compatible. The plate carrier has

two adjusting knobs with two different orientations. These knobs have

been set for standard plate types at the factory. The setting is also valid for

the robotic 384-adapter but readjustment of the knobs will be needed with

the plate types requiring special adapters (see Section 3.6). Fig. 3.7 shows

how the knobs should be adjusted for special plate adapters. Both knobs

should be rotated 90° clockwise after which all special adapters fit into the

plate carrier.

Rotate two knobs

90° clockwise

Fig. 3.7 Two plate carrier knobs rotated 90

°

clockwise for special plate

adapters

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 29

Page 30

3.8 Operational check

Switch the instrument ON. The instrument automatically performs a

complete set of initialization tests or adjustments.

When the initialization tests and adjustments have been completed

successfully, the indicator LED turns from yellow to green.

If anything fails in the initialization tests or adjustments, the indicator LED

will turn red. In this case, switch the instrument OFF and ON again. If this

failure is repeated, contact authorized technical service.

The instrument is ready for operation.

The instrument also performs different kinds of additional runtime

hardware tests before each measurement run, like automatic blanking.

Because of the relative nature of luminometry, we recommend you use

known samples or controls to verify proper instrument operation.

30 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 31

4. Operation

The Luminoskan Ascent is fully computer-controlled. Thermo Electron

Ascent Software controls the reader functions and provides complete data

handling and report formatting. For further details on how to use the

software, refer to the Ascent Software User’s Guide.

Warning: DO NOT use any other software than Thermo

Electron software designed for this instrument. Use only valid

combinations of the PC software and the instrument’s internal

EEPROM.

Warning: The Luminoskan Ascent instrument does not verify

the logic flow of the received commands.

The instrument is equipped with a power switch (ON/OFF) and a threecolor LED indicator. When the instrument is switched ON, the color

indicates the state of the instrument:

Green The instrument is ready and waiting for a command.

Orange The instrument is busy, executing a command.

Red The instrument has found an error, the error message is sent

to the computer and the computer has not acknowledged it.

4.1 Switching on

When switched on, the instrument performs the initialization tests. When

all the initialization tests and adjustments have been performed

successfully, the indicator LED turns green and the instrument is ready to

receive computer commands. The recommended warm-up time is

15 minutes, but the instrument will perform commands immediately after

the initialization period.

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 31

Page 32

4.2 Loading the microplate

The microplate is loaded onto the plate carrier of the instrument for

measurement. The plate carrier is able to handle microplates of different

sizes, therefore the free space in the plate carrier is clearly larger than the

standard 96-well plate. The positioning lever (Fig. 4.2:1) in the plate carrier

(Fig. 4.2) will automatically position the plate correctly into the upper left

corner of the carrier when the plate is driven in.

A1 corner of the

microplate

Positioning lever

Fig. 4.2 Plate carrier

32 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 33

4.3 Luminometric measurement

Luminometric reading is optimized for 96- and 384-well plates and top

reading. To obtain the best sensitivity and the lowest crosstalk, a light

shield (Fig. 4.6a) between the optics and the plate must be used. In

luminometric measurements the dispenser cover must be closed.

Reading 1- to 48-well plates as well as bottom reading can cause increase

in background signal and effect sensitivity in luminometric measurements,

because the light shield cannot be used and most of these plates are

transparent, which enables light leakage from one well to another.

A measurement function has several phases:

1. The anode voltage of the PMT is set according to the selected value of

the software.

2. The filter slot 8 (= block) is held in place until the plate door is closed.

The empty position/selected filter is then driven to the measurement

positions. The filter slot 8 is also used for the blanking procedure to

compensate for the possible PMT drift.

3. In the blanking procedure the instrument reads the PMT dark signal. If

the bottom value drifts, the results are compensated. To obtain the

most accurate results, the measurement time of the dark must be as

long as the measurement time of the sample. The measurement time of

the dark is divided into two parts. The first half is measured before the

sample measurement and the second half after the sample

measurement. The time used for the instrument blanking procedure

can be selected from Ascent Software (refer to the Overview part of the

Ascent Software User’s Guide).

Note: Ensure that there are no items preventing the closure of

the plate carrier door when measurement is started. DO NOT

open the plate carrier door during measurement.

Note: DO NOT install any filters into the filter wheel positions

7 and 8.

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 33

Page 34

4.3.1 Luminometric scaling

The measured results are expressed as Relative Light Units (RLU). Scaling

is a way to convert readings to show desired values.

1. Prepare a scaling reference solution and a blank solution and pipette

several wells of blanks and the known concentration.

2. Measure the wells using the correct filter or an open slot.

3. Calculate the average values of the measured reference values and

blank values. The blank values should be very small compared to the

reference values.

4. Calculate the scaling factor using calculated average values:

Factor = Known reference / (Measured reference - Measured blank)

Example

• The known concentration is 500 pmol/well.

• The calculated average of the measured reference wells is

1825 RLU.

• The calculated average of the measured blank wells is 0.2 RLU.

• Factor = 500 / (1825 - 0.2) = 0.274

• After scaling the measured result is: 0.274 x 1825 RLU =

500 pmol/well.

You can find the scaling entry in Ascent Software. The menu selection is

Setup|Filters. Select the corresponding filter or None and key in the

scaling factor. The measured results are expressed as Relative Light Units

(RLU).

34 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 35

4.4 Other functions

4.4.1 Orbital shaking

The track movement system can perform the shaking action. The speed is

adjustable from 60 to 1200 rpm (revolutions per minute) and the diameter

of the orbital movement is adjustable from 1 to 50 mm.

Some combinations of speed and diameter would cause too high g-forces

inside the well area resulting in spills inside the measurement chamber.

Therefore, only certain combinations are available.

The following tables (Table 4.4.1a – Table 4.4.1e) show the recommended

and the not recommended but available and unavailable speed and

diameter combinations with different plate types. These tables are based

on the liquid used being of low viscosity like water and the volumes being

appropriate (the wells are not full). The gray area in the tables show the

recommended (Recommended), the black area the not recommended

(Possible), and the white area the prevented speed and diameter

combinations (Not allowed).

Table 4.4.1a

1200

1140

1080

1020

960

900

840

780

720

660

600

540

480

Speed (rpm)

420

360

300

240

180

120

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 35

Shaking speeds for 48- (or more) well plates

Rec omm ended Not a llowed

60

0

1 3 5 7 9 111315171921232527 2931333537394143454749

Diameter (mm)

Page 36

Table 4.4.1b

1200

1140

1080

1020

960

900

840

780

720

660

600

540

480

Speed (rpm)

420

360

300

240

180

120

60

0

1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 41 43 45 47 49

Shaking speeds for 24-well plates

Recommended Possible Not allowed

Diameter (mm)

Table 4.4.1c

1200

1140

1080

1020

960

900

840

780

720

660

600

540

480

Speed (rpm)

420

360

300

240

180

120

60

0

135791113151719212325272931333537394143454749

Shaking speeds for 12-well plates

Diameter (mm)

36 Luminoskan Ascent

Rec ommended Possible Not allowed

User Manual Rev. 2.1, Cat. no. 1507520

Page 37

Table 4.4.1d

1200

1140

1080

1020

960

900

840

780

720

660

600

540

480

Speed (rpm)

420

360

300

240

180

120

60

0

1 3 5 7 9 111315171921232527293133353739 4143454749

Shaking speeds for 6-well plates

Recommended Possible Not allowed

Diameter (mm)

Table 4.4.1e

1200

1140

1080

1020

960

900

840

780

720

660

600

540

480

Speed (rpm)

420

360

300

240

180

120

60

0

1 3 5 7 9 11 131517192123 252729 3133353739414345 4749

Shaking speeds for 95 mm Petri dish

Recommended Possible Not allowed

Diameter (mm)

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 37

Page 38

4.4.2 Incubator

The incubator contains two heating element plates in the measurement

chamber, one heating element plate under the microplate and another

above it. Both heating element plates are temperature-controlled. The

upper plate is slightly warmer than the lower plate to avoid condensation

on the plate lid. The measurement chamber is large to adopt different plate

formats and therefore extensive evaporation may cause some variations in

the temperatures between the wells. Consequently, when using

incubations with extended periods of time in the instrument, a plate lid is

recommended.

If the incubation period is long without any other important functions, the

Luminoskan Ascent automatically changes the place of the plate within the

measurement chamber to minimize temperature differences between the

wells.

4.4.3 Dispensers

The optional dispensers, 1 to 3 dispensers numbered from left to right, are

located inside the instrument housing under the dispenser cover

(Fig. 2.1:2). The dispensing heads have three alternative dispensing

positions, one of these dispenses into the well in the measurement

position (M). The positions are optimized for a 96-well plate (Fig. 4.4.3a).

When the dispensers are not in use, the dispensing heads may be stored

in the dispensing head holder, but the tip holes to the measurement

chamber must be closed with dummy plugs.

Note: Ensure that the tip position in the instrument

corresponds to that defined in Ascent Software.

38 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 39

1

2 2

1

Y

M

X

1 M position: Dispensing head directed in the measurement well position.

Dispensing into the well during the measurement step is possible with this

position.

2 Y position: Dispensing head directed in the well next to the measurement

position in the Y direction. When this position is used for dispensing, an extra

plate movement is carried out before the measurement step causing minor

time delays.

3 X position: Dispensing head directed in the well next to the measurement

position in the X direction. When this position is used for dispensing, an extra

plate movement is carried out before the measurement step causing minor

time delays.

3

3

Fig. 4.4.3a Dispenser tip positioning optimized for a 96-well plate

Before inserting the dispensing head into a dispensing position, prime the

syringe and tubing to an external priming vessel. The instrument has no

internal priming vessel for priming the syringe and tubing. You can find

the priming instructions in the Ascent Software User’s Guide. The

minimum priming volume needed is 700 µl and the recommended volume

is 2700 µl.

The Luminoskan Ascent also has control switches for priming the

dispenser tubing. With these switches, priming can be carried out

alternatively by using an external priming vessel or by using an empty

microplate on the plate carrier as a priming vessel or a drop plate. When

priming is performed with the dispensing heads installed into the M, X or

Y positions, place the empty priming vessel into the plate carrier. Initiate

priming by pressing the corresponding switch when the plate carrier is

located outside the unit. Priming is carried out as long as the

corresponding switch is pressed.

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 39

Page 40

Note: The priming control switches are functional only when

the plate carrier is located outside the instrument. DO NOT use

priming vessels higher than the actual plate intended to be

used in the assay. Notice the dispensing height adjustment.

Priming with Ascent Software must always be performed with

the dispensing heads removed from the M, X or Y dispensing

positions.

Note: Never use liquids that can cause any precipitation,

clotting or contain any mechanical particles with the automatic

dispensers.

The instrument has a Prime Tip feature. If this function is selected in the

Dispense or Dispense And Measure steps in Ascent Software, the

dispenser dispenses about 5 µl reagent into the tip priming vessels every

time the instrument fills the syringe. This makes the volume of the first well

equal to that of the others. We recommend you use the tip priming feature

when the dispensing volumes are small, for example, 5 – 20 µl. Notice that

the Execute by command causes the syringe to fill.

A1 corner of the

microplate

Fig. 4.4.3b Tip priming vessel (1) is a piece of a breakable strip

40 Luminoskan Ascent

1

User Manual Rev. 2.1, Cat. no. 1507520

Page 41

The recommended tip priming vessel consists of four wells of a breakable

96-well plate strip (Fig. 4.4.3b). There is a holder for the tip priming vessel

in the right rear corner of the plate carrier. The four-well piece of a strip

should be exchanged after about 300 tip primings.

You may need to adjust the dispenser speed. The default setting is for a

water-based liquid. You can find the adjustments and selections in Ascent

Software.

When dispensing is started, the liquid volume in the well should be less

than half of the total well volume (for example, the volume should be less

than 200 µl in a typical 96-well plate).

4.4.4 Dispenser head height adjustment

Plate height 13.5 – 15.0 mm,

e.g., 96-well plate

Plate height 15.1 – 18.0 mm,

e.g., 48-well plate

Plate height 18.1 – 21.0 mm,

e.g., 24- to 6-well plates

No adjustment collars

One adjustment collar

Two adjustment collars

Fig. 4.4.4a Dispenser head height

The correct dispenser head height (Fig. 4.4.4a) is very important to avoid

contaminating neighboring wells. The correct tip height is also important

to prevent damaging the tip or the plate.

Note: Ensure that the dispenser tips are always correctly

inserted sufficiently deep into their slots.

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 41

Page 42

The plate height is one of the template parameters in Ascent Software and

it is defined as the height of the uncovered well from the bottom of the

plate, not the inside height of the well. The selected dispenser head height,

the used plate and the template selected in Ascent Software must match

to avoid problems. To see the heights of plates in Ascent Software, select

Setup and edit Plate Templates.

Some 384-well plates are lower than the standard 96-well plates. If the

plate height is less than 13.5 mm, an adapter must be used to raise the

plate. Measure the height of the plate and the adapter together and enter

this value to the plate template.

Caution: Plate manufacturers may change the dimensions of

plates without any prior notice or change in order numbers.

Check the dimensions when you start using plates from a new

box.

The dispenser head height is adjusted with red adjustment collars by

moving them from either side of the fixed stopper collar (Fig. 4.4.4b).

1

2

1 Dispenser head tube

2 Red adjustment collars

Fig. 4.4.4b Changing the position of the red adjustment collars

1. Remove the dispenser head tube (Fig. 4.4.4b:1) from the brass tube

lock.

2. The red adjustment collars (Fig. 4.4.4b:2) should be moved from one

side of the fixed collar to the other to select the correct dispenser head

height.

3. Fit the dispenser head tube back into place.

42 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 43

4.4.5 Chemical resistance of the dispenser 1

The following table (Table 4.4.5) is intended to provide guidelines for

compatibility with materials used in the fluid path of the dispensers.

Compatibility information is based on charts provided by the material

manufacturer. Cavro recommends that each laboratory determines

compatibility for their respective applications.

Caution: Failure to determine compatibility of chemicals used

in individual applications with the XP 3000, may result in

damage to the dispenser and/or test results.

Plastic materials used in dispensers:

Polysulfone: Cross Flow Manifold Assembly in the aspirate syringe

Teflon (PTFE, TFE, FEP): tubing; valve plug, and seal

Kel F: valve body

Polypropylene: fittings for tubing, and dispensing tip

Note: Also take into account the chemical resistance of

microplates.

Classification in the table:

– No data available

0 No effect – excellent

1 Minor effect – good

2 Moderate effect – fair

3 Severe effect – not recommended

1

Instructions concerning the pump are reproduced from CAVRO XP 3000 Modular Digital

Pump Operators Manual made by Cavro Scientific Instruments, Inc., USA.

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 43

Page 44

Table 4.4.5 Compatibility chart of materials suitable with the dispenser

Solvent Polysulfone Teflon Kel F Polypropylene

Acetaldehyde – 0 0 0

Acetates – – 0 0

Acetic Acid 0 0 0 0

Acetic Anhydride – – 0 –

Acetone 3 0 0 0

Acetyl Bromide – 0 – –

Ammonia 0 0 – 0

Ammonium Acetate – 0 – –

Ammonium Hydroxide – 0 0 0

Ammonium Phosphate – – 0 0

Ammonium Sulfate – – 0 0

Amyl Acetate – 0 – 3

Aniline – 0 0 0

Benzene 3 0 3 *

Benzyl Alcohol – 0 0 0

Boric Acid – 0 0 0

Bromide – 0 0 *

Butyl Alcohol 2 0 0 1

Butyl Acetate 3 0 – *

Carbon Sulfide – 0 – *

Carbon Tetrachloride 0 0 1 3

Chloroacetic Acid – 0 0 –

Chlorine – 0 1 3

Chlorobenzene 3 – – 3

Chloroform 3 0 – 3

Chromic Acid 3 0 0 –

Cresol – 0 – *

Cyclohexane 0 0 – 3

Dimethyl Sulfoxide (DMSO) 0 0 0 0

Ethers – 0 – **

Ethyl Acetate 3 0 – 0

Ethyl Alcohol 0 0 – 0

Ethyl Chromide – 0 1 3

Continued

44 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 45

Cont.

Solvent Polysulfone Teflon Kel F Polypropylene

Formaldehyde 0 0 0 0

Formic Acid – 0 0 0

Freon 2 0 2 0

Gasoline 2 0 0 3

Glycerine 0 0 0 0

Hydrochloric Acid 0 0 0 0

Hydrochloric Acid (conc.) 0 0 0 0

Hydrofluoric Acid 2 0 0 *

Hydrogen Peroxide – 0 0 0

Hydrogen Peroxide (conc.) – 0 0 0

Hydrogen Sulfide – 0 0 0

Kerosene 2 0 0 0

Methyl Ethyl Ketone (MEK) 3 0 – 0

Methyl Alcohol 0 0 – 0

Methylene Chloride 3 0 0 3

Naphtha 0 0 1 0

Nitric Acid 0 0 0 0

Nitric Acid (conc.) 3 0 0 –

Nitrobenzene – 0 – **

Phenol – 0 – 0

Pyridine 3 0 – –

Silver Nitrate – 0 – 0

Soap Solutions – 0 – 0

Stearic Acid – 0 – *

Sulfuric Acid 0 0 0 0

Sulfuric Acid (conc.) 3 0 0 –

Sulfurous Acid – 0 0 0

Tannic Acid – 0 0 0

Tannin Extracts – – – –

Tartaric Acid – 0 – –

Toluene 3 0 1 **

Trichloroethylene 3 0 3 3

Turpentine 2 0 0 **

Water 0 0 0 0

Xylene 3 0 0 *

* Polypropylene – satisfactory to 22°C (72°F), ** Polypropylene – satisfactory to 49°C (120°F)

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 45

Page 46

4.5 Changing the measurement direction

The measurement direction can be changed by moving the whole optical

unit from above the measurement chamber to below the measurement

chamber, or vice versa.

1. Switch off the instrument and disconnect the mains power supply

cable (Fig. 3.3:2). There are anode voltages inside the mains power

supply box and the optical unit if the power is on.

2. Remove the instrument cover as described in Section 3.2 Releasing

the transportation lock.

3. Undo the four finger nuts (Fig. 4.5a:2) to release the light cover

(Fig. 4.5a:1).

4. Remove the light cover.

1

2

2

1 Light cover

2 Finger nuts, 4 pieces

Fig. 4.5a Removing the light cover of the optical unit

5. Undo the six screws, three screws on each side of the instrument

(Fig. 4.5b:1), fixing the measurement chamber to the chassis.

46 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 47

6. Lift the measurement chamber into the upper position from the

handle (Fig. 4.5b:2). There are hinges in the rear and a gas spring

(Fig. 4.5c:3) holds the chamber in the upper position.

Caution: The measurement chamber is very heavy. DO NOT leave

your fingers between the measurement chamber and the bottom

case.

7. Remove the three short finger nuts holding the cover (Fig. 4.5c:2).

Then remove the cover plate (Fig. 4.5c:1) from the opposite position

of the optical unit under the measurement chamber.

4

3

2

1

1 Six screws, three screws on each side of the instrument

2 Handle

3 Flat cable

4 Long finger nuts, 3 pieces

Fig. 4.5b Removing the optical unit

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 47

Page 48

1

2

3

1 Cover plate

2 Short finger nuts, 3 pieces

3 Gas spring

Fig. 4.5c Cover plate

8. Lower the measurement chamber back into the down position from

the handle.

9. Unplug the flat cable (Fig. 4.5b:3) from the optical unit. DO NOT

remove any other parts from the optical unit.

10. Undo the three long finger nuts (Fig. 4.5b:4) and remove the optical

unit.

11. Lift the measurement chamber into the upper position from the

handle.

12. Place the optical unit into the position where you removed the cover

plate (Fig. 4.5c:1). Fix it with the long finger nuts and plug in the cable

connectors and the flat cable. No adjustments are needed.

13. Lower the measurement chamber back into the down position.

14. Place the cover plate instead of the removed optical unit and fix it

with the short finger nuts.

15. Fit the six screws back to hold the measurement chamber and replace

the instrument cover. The unfitted cover may increase stray light and

harm the measurement.

16. To change the measurement direction, the optical unit and the cover

plate are interchangeable.

48 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 49

4.6 Installing or removing the light shield

Light shield

Positioning

guide

Fig. 4.6a Installing the light shield

1. Switch off the instrument and disconnect the mains power supply cable

(Fig. 3.3:2).

2. Remove the instrument cover as described in Section 3.2 Releasing the

transportation lock.

3. Undo the four finger nuts (Fig. 4.5a:2) and remove the light cover

(Fig. 4.5a:1).

4. Undo the three long finger nuts (Fig. 4.5b:4) and remove the optical unit

or, if the optical unit is below the measurement chamber, remove the

cover plate (Fig. 4.5c:1).

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 49

Page 50

5. When removing the light shield, use your little finger to lift the light

shield up. When installing the light shield, ensure that the positioning

guide is placed towards the front of the instrument against the

corresponding guide in the holder (Fig. 4.6a and Fig. 4.6b). If the light

shield is not positioned correctly, the optical unit does not slot down

into its correct place but stays swinging.

Caution: Mispositioning of the light shield will cause

discrepancies in the measurement results or may cause the

instrument not to work.

Positioning

guide

Fig. 4.6b Top view of the light shield

6. Fit the optical unit, light cover and the instrument cover back into

their places.

4.7 Installing the filters

1. Switch off the instrument and disconnect the mains power supply

cable (Fig. 3.3).

2. Remove the instrument covers as described in Section 3.2 Releasing

the transportation lock points 1 – 4.

3. If the optical unit is above the measurement chamber, undo the four

finger nuts (Fig. 4.5a:2) and remove the light cover (Fig. 4.5a:1). You

can find more detailed instructions in Section 4.5 Changing the

measurement direction.

4. If the optical unit is below the measurement chamber, undo the six

screws (Fig. 4.5b:1) fixing the measurement chamber to the chassis.

50 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 51

Lift the measurement chamber into the upper position. There are

hinges in the rear and a gas spring (Fig. 4.5c:3) holds the chamber in

the upper position.

Caution: The measurement chamber is very heavy. DO NOT

leave your fingers between the measurement chamber and

the bottom case.

5. Unplug the flat cable (Fig. 4.5b:3) from the optical unit. Undo the three

long finger nuts (Fig. 4.5b:4) and remove the optical unit and place it

on a table.

6. The filter wheel (Fig. 4.7a:2) can be removed by undoing the fitting

screw (Fig. 4.7a:1). DO NOT touch the filter surfaces.

7. Select the first free filter slot. DO NOT install any filters into the filter

wheel positions 7 and 8.

1

2

1 Fitting screw(s) holding the filter wheel in place

2 Filter wheel

Fig. 4.7a Filter wheels in the optical unit

8. Undo the fitting screws (Fig. 4.7b:1).

9. Remove the spring wheel (Fig. 4.7b:2).

10. Remove the spacer collar (Fig. 4.7b:3).

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 51

Page 52

11. Remove the dummy filter or previously installed filter used

(Fig. 4.7b:4). Install a new filter so that the small arrow on the filter rim

points away from the filter wheel. The arrow shows the direction of

the light flow. DO NOT install any filters into the filter wheel positions

7 and 8.

12. Fit the spacer collar, spring wheel and the fitting screws. Fit the filter

wheel back into place.

4

3

13. Replace the optical unit and connect the flat cable. Lower the

measurement chamber and replace the instrument cover.

2

Fig. 4.7b Filters in a filter wheel

1

1 Fitting screw(s)

2 Spring wheel

3 Spacer collar

4 Dummy filter or previous filter used

52 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 53

4.8 Shutdown

• Remove any microplates left on the plate carrier or breakable strips

from the tip priming vessel. Dispose of all microplates and strips as

biohazardous waste.

• Flush the pump(s) out thoroughly with distilled water. Empty all the

tubings.

• Place the dispensing tips into the tip holder (Fig. 2.3:5).

• Switch off the Luminoskan Ascent by pressing the power switch on the

left-hand side of the instrument into the OFF position.

• Wipe the plate carrier surface and the external surfaces of the

instrument with a soft cloth or tissue paper moistened with distilled

water or a mild detergent solution.

• Push the plate carrier manually in.

• If you have spilt infectious agents on the plate carrier, disinfect with

70% pure ethanol in distilled water or some other disinfectant. See

Section 8.2 Decontamination procedure.

• If you are not using the Luminoskan Ascent for an extended period of

time, always clean the external surfaces of the instrument.

• Finally put the dust cover on.

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 53

Page 54

54 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 55

5. Maintenance

Note: Follow normal laboratory safety procedures with regard

to biohazardous, infectious, radiologic or toxic materials when

maintaining the instrument.

5.1 Routine cleaning of the instrument

For reliable operation keep the instrument free of dust and spills of liquids.

We recommend that you clean the case of the instrument periodically. A

soft cloth dampened in mild detergent is sufficient. We recommend that

you service the instrument at least yearly.

If you believe liquid has entered the luminometer, switch the instrument

off and contact your local Thermo representative or Thermo Electron or for

technical service (see Sections 8.1 Service request protocol and 8.4

Shipping the instrument (or items). If any surfaces have been

contaminated with biohazardous material, a sterilizing solution must be

used.

The prescribed decontamination procedure (see Section 8.2

Decontamination procedure), or similar routine, must be performed before

returning the instrument to the supplier for service or repair. All

instruments must be accompanied by a completed and signed Certificate

of Decontamination securely attached to the exterior of the packaging (see

Section 8.3 Certificate of Decontamination).

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 55

Page 56

5.2 Cleaning the optical system

Filter wheel

Main lens

Fig. 5.2 Cleaning the optical unit

1. Switch off the instrument and disconnect the mains power supply

cable. Locate the optical unit and remove it according to the

instructions in Sections 3.2 Releasing the transportation lock and 4.5

Changing the measurement direction.

2. Clean the main lens (Fig. 5.2), the possible filters and the light shield

(Fig. 4.6a) with a cloth dampened with 96% pure ethanol and

afterwards with a lint-free cloth or a lens tissue.

DO NOT use any other liquids to clean the optical unit.

Avoid any harsh treatment.

3. Replace all the removed parts and reconnect the instrument to the

mains power supply.

5.2.1 Visual filter check

The useful life of a filter depends on environmental factors, such as dust,

humidity and temperature. Filters have a one year warranty.

Carry out the visual check in the following way:

Visually check the filter(s) by holding it (them) against an even light source.

If the color of the filter is even, then the filter is suitable for use. On the

56 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 57

other hand, if the filter appears to be mottled or discolored, discard the

filter since it is either damaged or defective.

The best alternative is to measure the filters with a spectrophotometer.

5.3 Cleaning the plate carrier

2

1 Plate carrier

2 A1 corner of the microplate

1

Fig. 5.3 Plate carrier

Clean the plate carrier (Fig. 5.3) with a cloth dampened with distilled water.

In case of any spills of infectious agents, clean the plate carrier with

disposable towels dampened with a disinfectant solution containing 2%

glutaraldehyde. Always use disposable gloves. Place the disposable

towels and gloves in a biohazardous waste container.

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 57

Page 58

5.4 Replacing the fuses

1. Switch off the instrument and disconnect the mains power supply cable

(Fig. 5.4:1). Locate the fuse holders (Fig. 5.4:2) at the rear of the

instrument.

2. Open the fuse holder to expose the fuse (Fig. 5.4:3) using a

screwdriver.

3. Replace the faulty fuse with the spare provided with the accessories or

with the same certified type.

4. Reconnect the instrument to the mains power supply. If the fuse blows

again, contact your local Thermo representative for technical service.

1

1 Mains power supply

2 Fuse holder

3

2

Fig. 5.4 Replacing the fuses

3 Fuse

58 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 59

5.5 Routine maintenance of optional dispensers and

main lens 1

To obtain optimum performance and maximum useful life from the

dispensers, it is important that the recommended cleaning maintenance

instructions are followed.

Luminometry is a very sensitive detection technology. Therefore, take

special care to avoid any contamination of any parts of the dispenser

tubings and follow all GLP (Good Laboratory Practice) recommendations.

5.5.1 Basic maintenance

1. The basic maintenance procedure should be performed regularly to

ensure proper dispenser operation.

2. Rinse the dispenser tubings out thoroughly with distilled water after

each use.

3. DO NOT allow the dispensers to run dry for more than a few cycles.

4. Inspect the dispensers for leaks and rectify any problems immediately.

5. Wipe up all spills on and around the dispensers immediately.

5.5.2 Extended maintenance

Clean the fluid path thoroughly using one of the procedures outlined

below. There are three ways that the dispensers may be cleaned:

• Weak detergent

• 10% bleach

• Weak acid and base

5.5.2.1 Weak detergent or 10% bleach

Remove the dispensing heads from the dispensing positions and DO NOT

let any cleaning fluids enter the measurement chamber. Use external

containers.

1. Prime the dispensers with a weak detergent or 10% bleach solution and

leave it in the dispensers with the syringes full for 30 minutes.

1

Instructions concerning the pump are reproduced from CAVRO XP 3000 Modular Digital

Pump Operators Manual made by Cavro Scientific Instruments, Inc., USA.

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 59

Page 60

2. After the 30-minute period, remove the aspirate tubing from the

detergent or bleach solution and remove all the fluid from the syringes

and tubing into a waste container.

3. Flush the dispenser a minimum of 10 cycles with distilled water.

5.5.2.2 Weak acid and base in sequence

Remove the dispensing heads from the dispensing positions and DO NOT

let any cleaning fluids enter the measurement chamber. Use external

containers.

1. Prime the dispensers with 0.1 M NaOH and leave the solution in the

dispensers for 10 minutes with the syringes full.

Note: DO NOT spill any 0.1 M NaOH onto any instrument

surfaces to avoid damage of the instrument. If needed, use

suitable protection covering.

2. Flush the dispensers with distilled water.

3. Prime the dispensers with 0.1 M HCl and leave the solution in the

dispensers for 10 minutes with the syringes full.

4. After the 10-minute period, remove the aspirate tubing from the 0.1 M

HCl solution and remove all the fluid from the syringes and tubing into

a waste container.

5. Flush the dispensers a minimum of 10 cycles with distilled water.

5.5.2.3 Cleaning the main lens

It is recommended that you check the main lens of the optical unit weekly.

1. Remove the optical unit if it is above the measurement chamber, or the

cover plate if the optical unit is below the measurement chamber, as

described in Section 4.5 Changing the measurement direction.

2. If needed, clean the main lens according to the instructions in Sections

5.2 Cleaning the optical system.

60 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 61

5.6 Periodic maintenance

There are three parts which require periodic maintenance: tubing; syringe

seals, and valves. If they become worn out, the symptoms are:

• Poor precision and accuracy

• A variable or moving air gap

• Leakage

• Drops and spills

The frequency of replacement will depend on the duty cycle, fluids used

and instrument maintenance.

If any of these symptoms occur and it is not obvious which component is

causing the problem, the easiest and most economical way is to replace

one component at a time in the following order: (1) dispensing or aspirate

tubings and/or dispensing tip, and (2) syringe.

5.6.1 Replacing the dispenser tubings

1. To remove either the dispensing tube or the aspirate tube assembly

from the valve, gently loosen the fittings either manually or using a

7.9 mm (5/16 in.) wrench. Unscrew the fittings and remove the tubing.

2. We recommend you replace the complete assemblies always when

replacement is necessary. Alternatively, only some parts of the

assemblies can also be replaced. If only the dispensing tubing is

changed, first remove the complete dispensing tube assembly from

the dispenser unit.

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 61

Page 62

7

6

4

5

3

2

1

1 Dispensing head tube

2 Dispensing tip

3 Silicone tubing

4 Internal dispenser head tube

5 Brass tube holder

6 Brass locking ring

7 Dispensing tubing

Fig. 5.6.1 Structure of the complete dispensing tube assembly

3. Remove the dispensing head tube (Fig. 5.6.1:1) from the brass tube

holder (Fig. 5.6.1:5).

4. Loosen the brass locking ring (Fig. 5.6.1:6).

5. Remove the dispensing tip (Fig. 5.6.1:2) and the connecting piece of

silicone tubing (Fig. 5.6.1:3).

6. Remove the internal dispenser head tube (Fig. 5.6.1:4), the brass tube

holder and the brass locking ring.

7. Insert the new dispensing tubing into the brass tube holder/locking

ring and the internal dispenser head tube.

8. Connect the dispensing tip with the connecting piece of silicone

tubing into the new dispensing tubing.

62 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 63

9. Fit the dispensing tip and tubing into the dispenser head tube. When

you push the dispensing tubing gently towards the tip, the internal

dispenser head tube should be visible about 1 mm. This can be

adjusted through the length of the connecting piece of silicone tubing.

10. First screw the brass tube holder onto the dispenser head tube.

Gently tighten the tubing and ensure that the tube end stays in the

silicone tubing. Then tighten the brass locking ring.

11. To fit a new tubing, insert the fitting into the valve and tighten it

finger-tight. Using a 7.9 mm (5/16 in.) wrench, turn the fitting another

quarter to half turn.

5.6.2 Replacing the dispensing tip

3

1

2

1 Dispensing head tube

2 Dispensing tip

3 Brass tube holder

Fig. 5.6.2 Replacing the dispensing tip

1. Remove the dispensing head tube (Fig. 5.6.2:1) from the brass tube

holder (Fig. 5.6.2:3).

2. Replace the dispensing tip (Fig. 5.6.2:2) connected with a small piece of

silicone tubing in the dispensing tube.

3. Replace the dispensing head tube.

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 63

Page 64

5.6.3 Replacing the dispenser syringe

1

4

2 3

1 Aspirate and complete dispensing tube assemblies

2 Plunger lock screw

3 Plunger holder arm

4 Dispenser syringe (1.0 ml) and plunger

Fig. 5.6.3 Replacing the dispenser syringe

1

1. Remove the liquid from the dispenser syringe (Fig. 5.6.3:4) and from

the tubings.

2. Switch off the power from the instrument.

3. Push the plunger manually into the upper position.

4. Loosen the plunger lock screw (Fig. 5.6.3:2) approximately three full

turns.

5. Pull the plunger holder arm (Fig. 5.6.3:3) firmly down.

6. Unscrew the syringe from the valve.

7. To fit the new dispenser syringe, screw the syringe into the valve, pull

the syringe plunger down to the plunger holder arm and screw it into

place. Make sure the plunger lock screw is securely tightened.

64 Luminoskan Ascent

User Manual Rev. 2.1, Cat. no. 1507520

Page 65

6. Troubleshooting Guide

Note: DO NOT use the instrument if it appears that it does

not function properly.

6.1 Troubleshooting

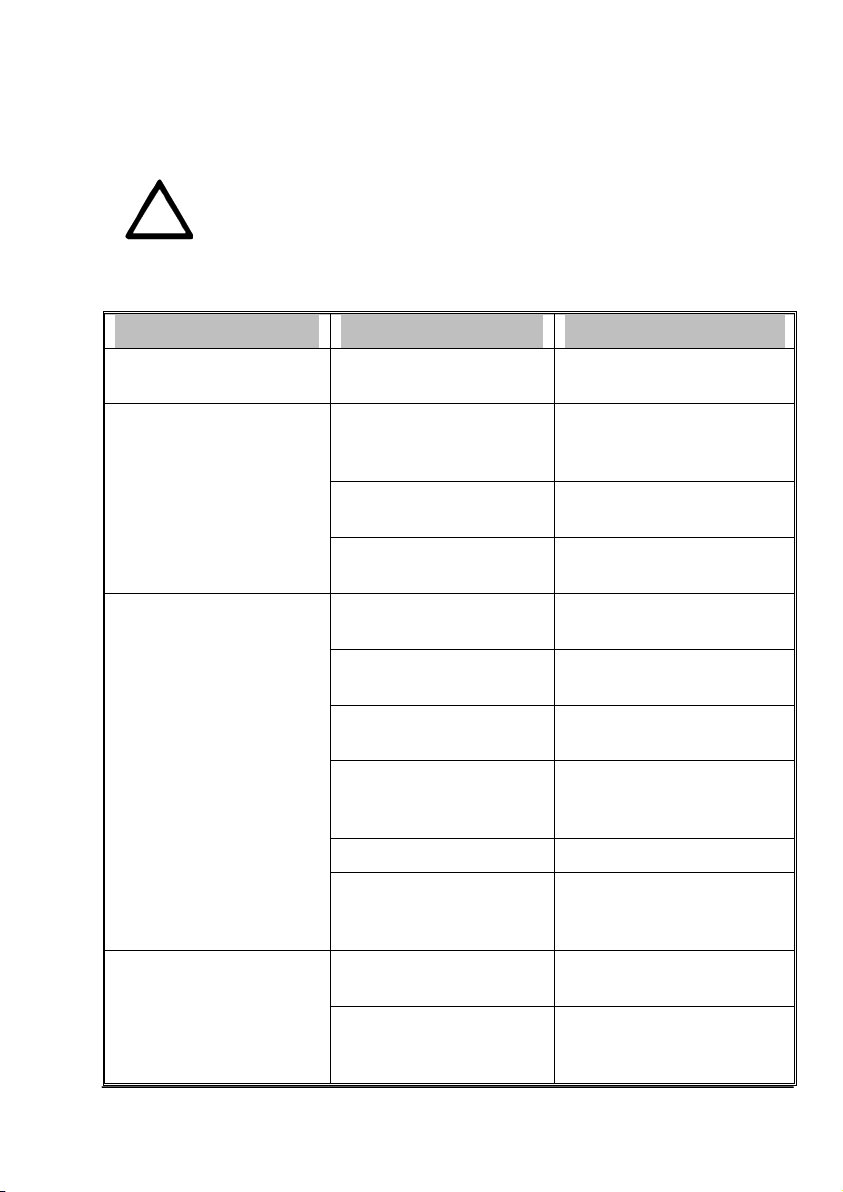

Problem Cause Action

Instrument does not

turn on correctly

No connection between

instrument and PC

Too high background

No power connection Check the power cable

and the fuses

Incorrect software type Check that the software is

installed for the correct

instrument model

Loose serial cable

connections

Software in simulation

mode

No liquid in the well Always use some liquid in

Unclean plate Use a disposable plate

Contaminated reagents Replace the reagents

Microplate material Check if the plate

Contaminated tubing Replace/clean the tubing

Phosphorescence from

the plastic

Check the cable

connections

Switch the connection to

the instrument

the blank wells

only once

used

manufacturer or material

has changed

Use only plastics

designed for luminometry

without phosphorescence

Too low/high signal

Luminoskan Ascent User Manual Rev. 2.1, Cat. no. 1507520 65

Changed scaling factor Check the scaling factor

used

Microplate material Check if the plate

manufacturer or material

has changed Continued

Page 66

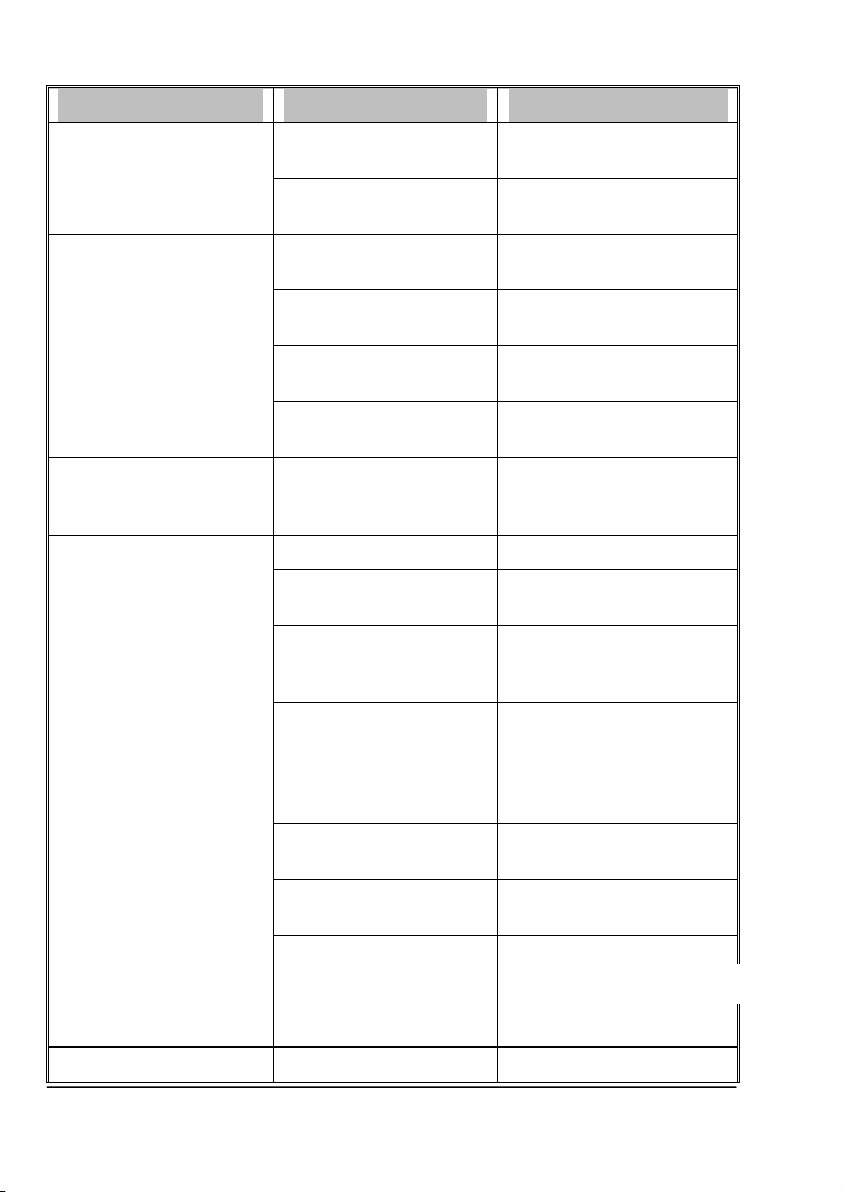

Problem Cause Action

Cont.

Even, low signal level

for the whole plate

Bottom reading of nontransparent plate

Bottom reading when

drop plate in its place

Too large deviation

Unclean plate Use a disposable plate

between replicates

Dust or dirt in the wells Keep the plates protected

Foaming in the sample Use a lower dispensing or

Use correct pipetting