Page 1

EPD/HB/40521/000

ELECTRONIC PERSONAL

DOSEMETER

(EPD Mk2)

TECHNICAL HANDBOOK

DATE OF ISSUE: APRIL 2004 CHANGE REFERENCE: Thermo Electron Corp. Revision

© Thermo Electron Corporation. All rights reserved.

The information contained herein is the property of Thermo Electron Corporation and is supplied

without liability for errors or omissions. No part may be reproduced or used except as authorised

by contract or other written permission. The copyright and the forgoing restriction on reproduction

or use extend to all the media in which this information may be embodied.

EPD TECHNICAL HANDBOOK Page (iii)

ISSUE 5

Page 2

EPD/HB/40521/000

MANUFACTURERS DETAILS

Manufacturer's Address

Thermo Electron Corporation

Sopers Lane

Poole

Dorset

United Kingdom

BH17 7ER

Tel. (01202) 782779 International: + 44 1202 782779

(01202) 782374 International: + 44 1202 782374

(01202) 782780 International: + 44 1202 782780

Fax. (01202) 782335 International: + 44 1202 782335

USA Sales Office

Thermo Electron Corporation

105C Hembree Park Drive

Roswell

GA 30076

U.S.A.

Tel. 770 521 4502

Fax. 770 521 4535

Pages Issue Type Part ID File ID

All 5 ESERS EPD/HB/40521 HB40521_iss_5.doc

EPD TECHNICAL HANDBOOK Page (iv)

ISSUE STATE

ISSUE 5

Page 3

EPD/HB/40521/000

CONTENTS

GLOSSARY................................................................................................................................................................IX

CAUTIONS.................................................................................................................................................................XI

SECTION 1...................................................................................................................................................................1

INTRODUCTION........................................................................................................................................................1

1.1 GENERAL ..................................................................................................................................................1

1.2 EPD MAJOR CHARACTERISTICS.........................................................................................................1

1.3 BRIEF FUNCTIONAL DESCRIPTION........................................................................................................2

SECTION 2...................................................................................................................................................................5

GETTING STARTED..................................................................................................................................................5

2.1 SETTING-UP..............................................................................................................................................5

2.1.1 Unpacking The EPD......................................................................................................................6

2.1.2 The EPD Battery .............................................................................................................................6

2.1.3 Start-up Sequence................................ ..........................................................................................9

2.1.4 EPD Confidence Test..................................................................................................................10

2.1.5 Issuing an EPD..............................................................................................................................10

2.1.6 Wearing an EPD............................................................................................................................11

OPERATING INSTRUCTIONS ..............................................................................................................................13

Page

3.1 LCD DISPLAY AND BACKLIGHT .........................................................................................................13

3.2 AUDIBLE AND VISIBLE ALARMS.........................................................................................................16

3.2.1 Alarm features ................................................................................................................................16

3.2.2 Dose Alarms...................................................................................................................................20

3.2.3 Dose Rate Alarms.........................................................................................................................20

3.2.4 Over-Range Indication .................................................................................................................21

3.2.5 Alarm Muting...................................................................................................................................22

3.3 BUTTON OPERATION AND DISPLAY SELECTION..............................................................................23

3.4 LCD DISPLAY LOCK-ON FACILITY.................................................................................................... 24

3.5 DISPLAY OPTIONS AND BUTTON FUNCTIONS..................................................................................26

3.5.1 Displaying Hp (10) Dose, Dose Rate and User ID..............................................................26

3.5.2 Displaying Hp(0.07) Doses, Dose Rate and ADS User ID ...............................................27

3.5.3 Displaying Total Dose..................................................................................................................29

3.5.4 Starting/Stopping The Seconds Count Down Timer...........................................................29

3.5.5 Turning the EPD off ......................................................................................................................30

3.5.6 Displaying Peaks (Rate High)...................................................................................................31

3.5.7 EPD Confidence Test..................................................................................................................32

3.5.8 Clearing Dose Displays ...............................................................................................................34

3.5.9 Displaying/Setting Dose Alarm Thresholds...........................................................................34

3.5.10 Displaying/Setting Dose Rate Alarm On/Off Thresholds................................ .............36

3.5.11 Setting The Sounder ...............................................................................................................38

SECTION 4.................................................................................................................................................................43

TECHNICAL DESCRIPTION.................................................................................................................................43

4.1 GENERAL ................................................................................................................................................43

4.2.1 Electrical Characteristics............................................................................................................44

EPD TECHNICAL HANDBOOK Page (v)

ISSUE 5

Page 4

EPD/HB/40521/000

4.2.2 Battery Management....................................................................................................................44

4.3 MECHANICAL DESCRIPTION ................................................................................................................46

4.3.1 Mechanical Characteristics And Dimensions .......................................................................46

4.3.2 Brief Mechanical Description.....................................................................................................46

4.4 ENVIRONMENTAL DESCRIPTION .........................................................................................................48

4.4.1 Environmental Characteristics ..................................................................................................48

4.4.2 Brief Environmental Description ...............................................................................................48

4.5 INFRA-RED INTERFACE.......................................................................................................................... 49

4.5.1 Communicating With The EPD.................................................................................................49

4.6 EPD INTERNAL PROCESSING & FACILITIES..................................................................................... 51

4.6.1 Memory Characteristics: .............................................................................................................51

4.6.2 Alarm Characteristics:.................................................................................................................52

4.6.3 Default Display...............................................................................................................................52

4.6.4 User Identification.........................................................................................................................52

4.6.5 Dose and Dose Rate ....................................................................................................................53

Dose..................................................................................................................................................................53

Dose Rate................................ ........................................................................................................................53

4.6.6 Counts..............................................................................................................................................54

4.6.7 Dose Quality Flags.......................................................................................................................55

(i) Reset Count..............................................................................................................................................55

(ii) Shock Time Seconds...........................................................................................................................55

(iii) Dose Over -range...................................................................................................................................55

(iv) Dose Rate Over -range.........................................................................................................................55

(v) Counter Over -range ...............................................................................................................................55

(vi) Abuse Warning ......................................................................................................................................56

(vii) CRC Failure ...........................................................................................................................................56

4.6.8 Dose And Dose Rate Alarm Processing................................................................................56

4.6.9 EPD Operating Status .................................................................................................................57

EPD ‘Run’ and Off times................................ .............................................................................................57

EPD State.......................................................................................................................................................57

Alarms ..............................................................................................................................................................58

Faults................................................................................................................................................................58

4.6.10 Dose Profile ...............................................................................................................................59

4.6.11 Event History Store.................................................................................................................59

SECTION 5.................................................................................................................................................................61

EPD FAULTS AND RECOVERY ACTIONS........................................................................................................61

5.1 OVERVIEW ..............................................................................................................................................61

5.2 VISUAL AND AUDIBLE FAULT INDICATION................................................................................... 62

5.3 INTERNAL LOGGING OF FAULT CONDITIONS .................................................................................... 63

5.3.1 EPD Status Faults Record.........................................................................................................63

5.3.2 Event History store .......................................................................................................................63

5.4 BLANK LCD DISPLAY AND OTHER FAULTS..................................................................................... 65

5.5 INITIALISATION E RROR ( LCD ---- )...................................................................................................67

5.6 COMMUNICATIONS ERROR ( LCD ==== ).......................................................................................67

5.7 LCD DISPLAY ERROR CODES.............................................................................................................69

5.8 RECOVERY PROCEDURES .....................................................................................................................70

5.8.1 Logging Faults / Extracting Data ..............................................................................................70

5.8.2 Clearing faults ................................................................................................................................70

SECTION 6.................................................................................................................................................................77

MAINTENANCE........................................................................................................................................................77

6.1 CALIBRATION......................................................................................................................................... 77

ISSUE 5

EPD TECHNICAL HANDBOOK Page (vi)

Page 5

EPD/HB/40521/000

6.2 THE EPD BATTERY............................................................................................................................... 79

6.2.1 Replacement Batteries ................................................................................................................79

6.2.2 Battery Leakage............................................................................................................................79

6.2.3 Lithium Thionyl Chloride Battery Warning..............................................................................80

6.2.4 Replacing the EPD Battery ........................................................................................................81

6.3 EPD CLIP ASSEMBLY.......................................................................................................................... 82

6.3.1 Removing the EPD Lanyard Plate/Clip Assembly..............................................................83

6.3.2 Replacing The EPD Lanyard Plate/Clip Assembly................................ .............................84

6.4 CLEANING............................................................................................................................................... 85

6.4.1 General Cleaning...........................................................................................................................85

6.4.2 Radiological Cleaning................................ ...................................................................................85

6.4.3 Cleaning after a Battery Leakage.............................................................................................85

6.4.4 Periodic Cleaning ..........................................................................................................................86

APPENDIX A..............................................................................................................................................................87

RADIOLOGICAL SPECIFICATIONS..................................................................................................................87

APPENDIX B..............................................................................................................................................................89

ELECTROMAGNETIC COMPATIBILITY...........................................................................................................89

APPENDIX C..............................................................................................................................................................95

SUMMARY OF GENERAL PHYSICAL & FUNCTIONAL CHARACTERISTICS ....................................95

APPENDIX D..............................................................................................................................................................99

EPD FAULT LOG FORM.........................................................................................................................................99

EPD TECHNICAL HANDBOOK Page (vii)

ISSUE 5

Page 6

Page 7

EPD/HB/40521/000

GLOSSARY

/h Per hour

°C Degrees Celsius

ADS Approved Dosimetry Service (or System)

CRC Cyclic Redundancy Check. Error checking code.

dB(A) Decibels - ‘A’ weighted scale (sound intensity)

DC Direct Current

DDE Deep Dose Equivalent (alternative nomenclature for Hp(10))

Dose The accumulated dose to which alarm thresholds apply, intended for

tactical dose monitoring (eg. per day, per week, per shift etc)

Double-press Pressing the button twice in quick succession

EEPROM Electrically Erasable Programmable Read Only Memory

EPD Electronic Personal Dosemeter

EPDS Electronic Personal Dosimetry System

eV Electron Volt

Gy Gray, SI unit of dose

HEX Hexadecimal

H10 EPD LCD nomenclature for personal dose (Hp(10))

H07 EPD LCD nomenclature for personal dose (Hp(0.07))

H10/h EPD LCD nomenclature for dose rate (Hp(0.07)/h)

H07/h EPD LCD nomenclature for dose rate (Hp(10)/h)

Hp(10) Personal dose equivalent at a depth of 10mm of tissue (‘penetrating’,

‘deep’ or ‘whole body’ dose).

Hp(0.07) Personal dose equivalent at a depth of 0.07 mm of tissue (‘superficial’,

‘shallow’ or ‘skin’ dose).

Hp(10)/h Hp(10) dose rate

(0.07)/h Hp(0.07) dose rate

Hp

ICRU International Commission on Radiation Units

ID Identification

IR Infra-red

IrDA Infra-red Data Association

keV Kilo Electron Volt

LCD Liquid Crystal Display

LED Light Emitting Diode

Long Press Pressing and holding the button

LTC Lithium Thionyl Chloride (Sulphurous Oxychloride, SOCl2)

MeV Mega Electron Volt

m metre/milli

mm millimetre

nm nanometre

NRPB National Radiological Protection Board - the statutory authority for

radiological protection in the UK

PCB Printed Circuit Board

EPD TECHNICAL HANDBOOK Page (ix)

ISSUE 5

Page 8

EPD/HB/40521/000

Glossary (continued)

SDE Shallow Dose Equivalent (alternative nomenclature for Hp(0.07))

ppm Parts per million

RAM Random Access Memory

rem A unit of dose equivalent, equal to 10mSv

RFI Radio Frequency Interference

Short-press A short press and release of the button

Sv Sievert, SI unit of dose equivalent

T Tesla

TLD Thermoluminescent Dosemeter

Total Dose Intended to be a secure record of the total accumulated dose received

since Dosemeter issue - alarms do not apply to total dose.

User ID A numeric code of up to 12 digits that may be written to the EPD to

define the current user or wearer. By convention a value of

FFFFFFFFFFFF is written to EPDs not currently issued to a wearer.

User Name A character string of up to 22 characters that may be written to the EPD

and used as a second or supplementary Wearer Identity

( Supplementary to user ID ).

Wearer ID Alternative terminology for the User ID.

Wearer Name Alternative terminology for the User Name.

EPD TECHNICAL HANDBOOK Page (x)

ISSUE 5

Page 9

EPD/HB/40521/000

WARNINGS

Radioactive Contamination

DURING OPERATIONAL USE THE EPD MAY BECOME EXPOSED TO RADIOACTIVE

CONTAMINATION. THE EPD MUST BE SUBJECT TO ALL RELEVANT

DECONTAMINATION PROCEDURES LAID DOWN BY THE RADIOLOGICAL PROTECTION

AUTHORITY.

Lithium Thionyl Chloride Batteries

LITHIUM THIONYL CHLORIDE* (LTC) BATTERIES ARE POTENTIALLY DANGEROUS.

THEY MAY LEAK TOXIC SUBSTANCES THAT CAN BE HARMFUL. READ AND TAKE

NOTE OF THE MANUFACTURERS WARNINGS ON THE BATTERY CASE . READ ALSO

THE DETAILED LTC BATTERY WARNINGS IN THIS HANDBOOK.

* Sulphurous Oxychloride, SOCL2

Cautions

EPD batteries

Batteries are susceptible to fire and abuse. Some manufacturers provide batteries with a

safety vent, which allows a controlled release of electrolyte if fire and abuse conditions prevail.

If the EPD has been damaged in a manner that could affect the battery, care must be exercised

during battery removal. The battery may have vented into the EPD case and caused the EPD

to become pressurised.

Take care when removing the EPD battery cap, the battery cap may spring free with

unexpected force.

EPD TECHNICAL HANDBOOK Page (xi)

EPD Battery Cap

ISSUE 5

Page 10

EPD/HB/40521/000

EPD TECHNICAL HANDBOOK Page (xii)

ISSUE 5

Page 11

EPD/HB/40521/000

SECTION 1

INTRODUCTION

This handbook is for the Thermo Electron Electronic Personal Dosemeter (EPD) EPD Mk2. The EPD Mk2 is lighter and slimmer than the original Thermo Electron

EPD and has new micro-circuitry, case design and software. The EPD Mk2 also has

a number of enhanced dosimetry features and user functions. To simplify

nomenclature the term EPD has been used throughout this handbook. The term EPD

should be read to signify the EPD Mk2.

1.1 General

The EPD is a personal radiation monitor that detects and measures beta and gamma

radiation. Radiation that is detected by the EPD is processed to give an indication of

penetrating dose, superficial dose and the dose rates. This information is displayed

to the user via an LCD display on the top of the EPD.

The EPD contains three silicon diode detectors. Each detector feeds a chain of

dedicated amplifiers and counter circuits to measure soft gamma, hard gamma and

beta rad iation. The outputs from each detector chain are processed to calculate and

display penetrating and superficial dose and dose rate. Other functions include:

EEPROM storage of detected radiation, annunciation of alarm conditions (LED and

sounder), Infra-red (IR) communication and a user interface comprising an LCD

display and button. Each of the above functions is described in detail in this

handbook.

1.2 EPD Major Characteristics

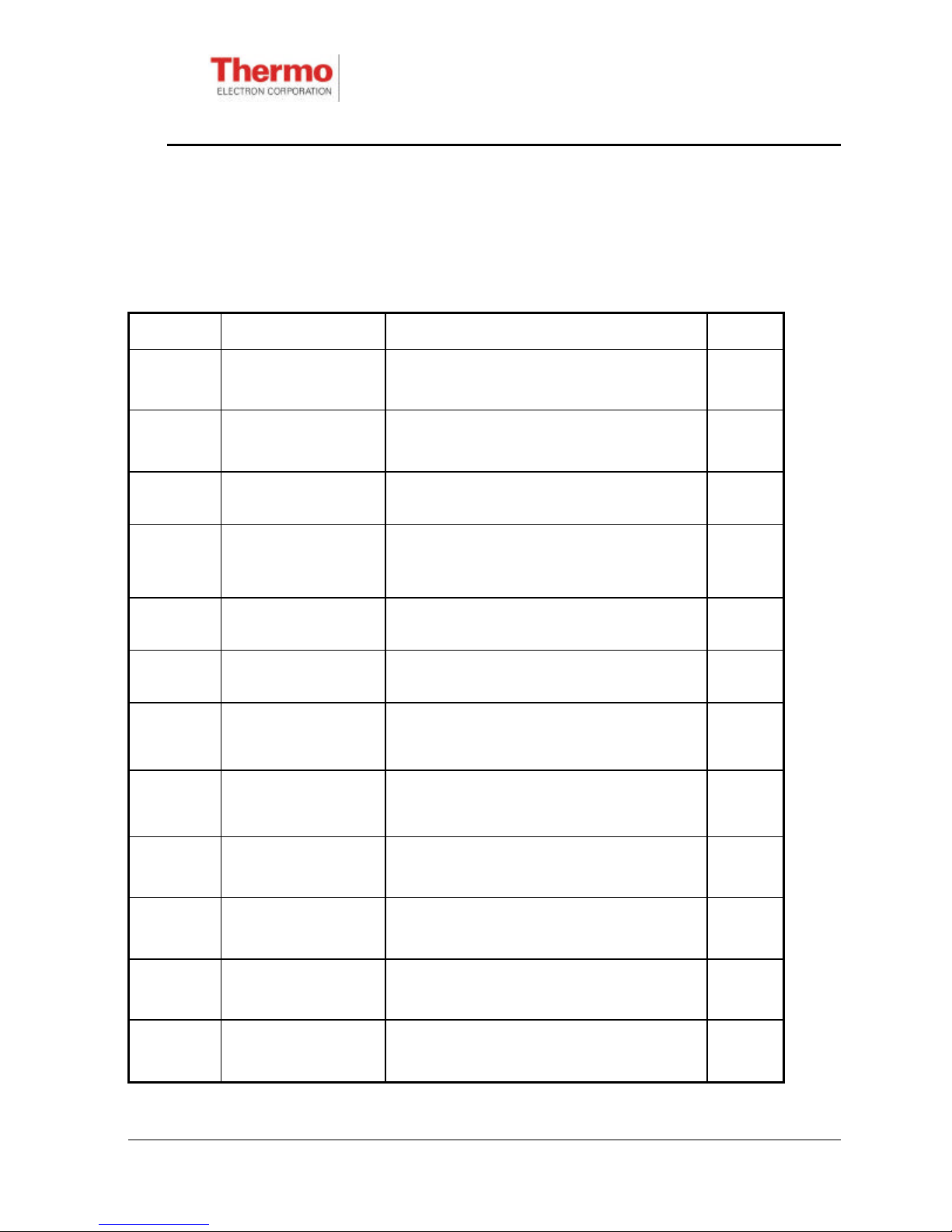

Major Characteristics relating to the EPD are listed in Table 1.1.

Item Characteristic

Power One AA battery, either a standard Alkaline (1.5 V) battery or

Weight 95 gms (including LTC battery and clip).

Dimensions 86 x 62 x 18.5 mm (excluding clip).

Alarm sounder 98 - 101 dB.

EPD TECHNICAL HANDBOOK Page 1

Table 1.1 - EPD Major Characteristics

high energy Lithium Thionyl Chloride (LTC) (3.6 V).

ISSUE 5

Page 12

EPD/HB/40521/000

The new EPD also has the following major features:

♦ Improved immunity to radio frequency interference (RFI).

♦ Display Backlight.

♦ EPD communication via an infra-red interface up to a range of approximately

1 metre.

♦ Improved dose profile facility.

♦ Real-time dose chirp (adjustable).

♦ Password protected dose store for ADS functions.

♦ Extended systems integration facilities.

♦ Count down timer and alarm.

Appendix C is a summary of the general physical & functional characteristics of the EPD.

1.3 Brief Functional Description

The EPD is a highly sophisticated device sensitive to gamma and X -rays (photons),

and beta radiation (energetic electrons) in the following energy range:

gamma, X-rays : 15 keV to 10 MeV

Beta radiation: 250 keV to 1.5 MeV (mean energy)

A full list of radiological characteristics and specifications can be found in Appendix A

to this Handbook.

Radiation detected by the three silicon diode detectors is combined to give the

following dose equivalents (as defined by ICRU Document 47):

(i) Hp(10) personal dose equivalent at a depth of 10mm of tissue (‘penetrating’,

‘deep’ or ‘whole body’ dose).

(ii) Hp(0.07) personal dose equivalent at a depth of 0.07 mm of tissue

(‘superficial’, ‘shallow’ or ‘skin’ dose).

The EPD calculates both the accumulated dose and the dose rate for Hp(10) and

Hp(0.07). These, and other data, are stored in an internal store (EEPROM) within the

EPD. A button in the EPD case allows the user to retrieve this data from store, select

a range of displays, acknowledge alarms and perform user control functions. Data is

EPD TECHNICAL HANDBOOK Page 2

ISSUE 5

Page 13

EPD/HB/40521/000

displayed to the user on a LCD display on the top of the EPD (see Figure 2.1). To

minimise the loss of data from battery or other failure, data is saved to secure

memory within the EPD every 15 minutes.

Data is written to and read from the EPD via an integral infra-red communications

interface. The Thermo Electron supplied EasyEPD2 program reads and writes data

to the EPD via the Infra-red communications link and displays the data in a PC

window. Thermo Electron also produces a range of Access Control Systems for use

with the EPD.

Dose is accumulated separately in the EPD in three stores: Dose, Total Dose and

ADS Dose . The use of several stores allows dose to be recorded over differing

periods, for example the Dose store may be used for each job or task performed (

and reset after each ), whilst the Total Dose records the total or aggregate dose from

all the jobs or tasks performed. ADS Dose is a password -protected dose store

intended for ‘legal dosimetry’ applications. Note that audible alarms are given if either

the accumulated dose or dose rates exceed programmable threshold levels. Dose

alarms are raised against the Dose store only.

The EPD is a sealed unit and is splash-proof. The unit will withstand short periods of

immersion in water but is not designed for prolonged immersion under pressure.

General maintenance is confined to:

♦ Removing/replacing the EPD battery,

♦ Removing/replacing the EPD clip assembly,

♦ Clearing fault conditions (where possible),

♦ Checking the functionality and calibration of the EPD,

♦ Keeping the unit clean.

Note:

1. This manual deals with Sieverts (Sv) throughout. To convert to rem multiply all

values by 100.

EPD TECHNICAL HANDBOOK Page 3

ISSUE 5

Page 14

EPD/HB/40521/000

This page is intentionally blank

EPD TECHNICAL HANDBOOK Page 4

ISSUE 5

Page 15

EPD/HB/40521/000

SECTION 2

GETTING STARTED

This section describes the general procedures that must be carried out to ensure that

the EPD is set-up correctly and is functionally operational.

2.1 Setting-up

The EPD requires very little setting-up. Setting-up is primarily confined to:

1. Unpacking the EPD,

2. Inserting the battery,

3. Checking the initialisation sequence,

4. Checking the default settings,

5. Performing a confidence test.

A general view of the EPD is shown in Figure 2.1. External features are described in

Table 2.1.

EPD TECHNICAL HANDBOOK Page 5

Figure 2.1 - External View Of The EPD

ISSUE 5

Page 16

EPD/HB/40521/000

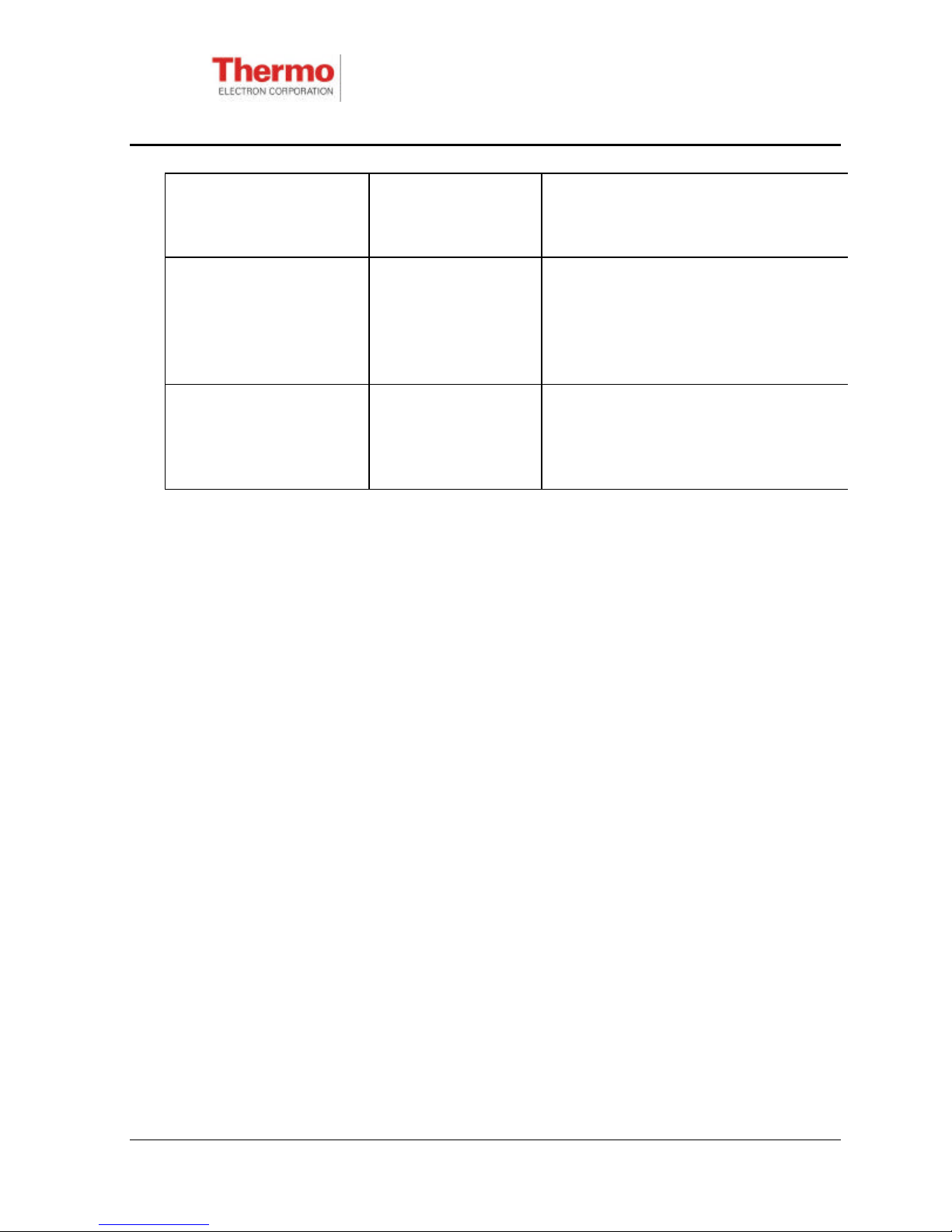

Feature Description

Battery Compartment Houses an Alkaline AA battery (1.5 V) or a Lithium

Thionyl Chloride (LTC) AA battery (3.6 V).

Infra-red Interface Infra-red communications interface to the EPD.

Button User interface for EPD control, alarm acknowledgement

and LCD display selection.

Soun der Provides an audible indication of an EPD alarm.

Beta Window Allows beta particles to pass through the case to the

Beta detector.

LCD Display Displays EPD parameters and/or functionality as

selected by the button.

Alarm LED Provides a visual indication of an EPD alarm.

Clip Assembly Provides a means of attaching the EPD to clothing, or

for attaching a lanyard as an alternative means of

wearing the EPD.

Table 2.1 - EPD External Features

2.1.1 Unpacking The EPD

There are no special unpacking instructions. Depending on customer requirements

the EPD may, or may not, be shipped with a battery and/or a clip assembly.

Alternatively, the EPD may be shipped with just a lanyard plate and lanyard (see

Section 6.3). The battery, if supplied, may be a LTC or Alkaline type.

2.1.2 The EPD Battery

LITHIUM THIONYL CHLORIDE* (LTC) BATTERIES ARE POTENTIALLY

DANGEROUS. THEY MAY LEAK TOXIC SUBSTANCES THAT CAN BE

HARMFUL. READ AND TAKE NOTE OF THE MANUFACTURER’S WARNINGS

ON THE BATTERY CASE. READ ALSO THE DETAILED LTC BATTERY

WARNINGS ON PAGE 6.2 OF THIS HANDBOOK.

WARNING

* Sulphurous Oxychloride, SOCl2)

EPD TECHNICAL HANDBOOK Page 6

ISSUE 5

Page 17

EPD/HB/40521/000

General Precautions and Instructions

Always fit new undamaged batteries of the correct type (see section 6.2). A time

interval of at least 10 seconds must elapse between removal and replacement of the

EPD battery (this allows the internal circuits of the EPD to power-down).

The EPD is fitted with either a security-type (tamper-proof) battery cap or a coinrelease battery cap, depending on customer requirements (see Figure 2.2). The

security -type battery cap restricts unauthorised removal of the cap and requires a

special tool. The coin type battery cap should be rotated using a small coin circa 20

mm diameter and 2 mm thick.

Figure 2.2 - Battery Cap Types and Special Tool

The battery cap also provides the return path for the EPD’s power supply.

Therefore, during fitment of either type of battery cap the EPD will begin its start-up

sequence (see Section 2.1.3). If the battery cap is not fitted cleanly and contact is

temporarily broken, the software initialisation process may not be successful. Under

these circumstances it is essential that the battery cap is removed and that a time

interval of at least 10 seconds elapses before any attempt is made to refit the battery

cap.

Inserting/Replacing The EPD Battery

Caution:

Take care when removing the EPD battery cap, the cap may spring free with

unexpected force.

ISSUE 5

EPD TECHNICAL HANDBOOK Page 7

Page 18

EPD/HB/40521/000

To set up the EPD for operational use the battery must be inserted/replaced in

accordance with the following procedure:

(i) Read and observe the General Precautions and Instructions at the beginning

of this section. If necessary remove the battery cap from the case as

described in (ii) and (iii) below.

(ii) If the battery cap is of the security type, locate the two pips of the special tool

into the two conical recesses in the battery cap. If the battery cap is of the

coin type, locate the coin in the groove in the battery cap.

(iii) Maintain steady pressure on the special tool or coin so as to keep it fully

engaged in the battery cap and rotate the battery cap through approximately

85° in a counter-clockwise direction (to remove cap, see Figure 2.3). If a

battery is already fitted, the cap will normally release from the case under the

action of the battery cap compression spring.

Note: Do not attempt to rotate the cap beyond the design point

(approximately 85 degrees) or beyond the point where the

resistance of the end-stop is felt.

(iv) Remove the existing battery (if fitted). Insert a new (or replacement) battery

into the battery compartment as shown in Figure 2.4.

Note: The battery must be inserted anode (+) first.

EPD TECHNICAL HANDBOOK Page 8

Figure 2.3 - Battery Cap Removal

ISSUE 5

Page 19

EPD/HB/40521/000

Figure 2.4 - Inserting The EPD Battery

(v) To fit the battery cap, first locate it against the special tool or coin, as

appropriate) and align the battery cap tangs with the recesses in the EPD

body. Push the battery cap into the battery compartment opening, ensuring

that:

a) the body of the battery cap, which houses the (-) electrode contact

plate, is fully engaged within the battery compartment,

b) the cap sits flush with the body of the EPD.

(vi) Using the special tool or coin, as required, maintain pressure on the battery

cap (against its compression spring), and rotate the battery cap in a clockwise

direction, through approximately 85°, to its end-stop. Rotate the cap slowly to

the point where the resistance of the end stop is felt. Avoid use of excessive

force.

2.1.3 Start-up Sequence

When a battery is inserted into the EPD, fitment of the battery cap will automatically

initiate the start-up sequence. The start-up sequence is as follows:

1. ‘8888’ is shown on the display for approximately three seconds;

2. internal software initialisation, which checks the state of the EPD (such as

the internal bus, internal memory, each detector amplifier and counter

chain, etc.);

EPD TECHNICAL HANDBOOK Page 9

ISSUE 5

Page 20

EPD/HB/40521/000

3. confidence test sequence, see section 2.1.4 below.

If the confidence tests pass, the EPD default display will appear. The EPD default

display is preset at the factory to show Hp(10) (the penetrating or deep dose) or to

another default display as specified by the customer.

If a fault code is displayed, or the start-up sequence repeats, try a fresh battery. If

problems persist, refer to section 5.

2.1.4 EPD Confidence Test

The EPD has an built-in confidence test facility. This runs automatically at startup

following battery change. When enabled, this test can als o be run at any time during

operational use as a check that the EPD is functioning correctly. The confidence test

is selected by scrolling through the EPD LCD displays to the CONFIDENCE TEST

menu (see Section 3.5.7). Throughout the confidence test the heart-beat (activity)

indicator flashes once per second. The confidence test can be stopped at any time

by pressing the button.

The confidence test sequence is as follows. This test sequence is automatic and

should be visually confirmed as each step initiated:

1. All segments of the display are activated for approximately 5 seconds. This

allows the user to check that all segments are functional (see Figure 3.2).

2. The alarm will sound and the LED will flash for approximately 2 seconds. This

indicates that the sounder and LED are functional.

3. The all-segment display will disappear. The alarm will continue to sound and

the LED will continue to flash, at an increased rate, for approximately 6

seconds. This indicates that all LCD segments can be turned off, and that the

tone frequencies are functional.

4. The all-segment display will reappear for approximately 5 seconds and the

LED will slow flash.

5. The all-segment display will disappear and the default display will appear. This

indicates that the confidence test has been successfully completed and that

the EPD is ready for operational use.

2.1.5 Issuing an EPD

In order to issue an EPD (i.e. assign it to a person) the EPD should be configured

with a numerical User ID and optionally with a User Name. There is a similar, but

ISSUE 5

EPD TECHNICAL HANDBOOK Page 10

Page 21

EPD/HB/40521/000

separate, configuration for Approved Dosimetry Service (ADS). The User Name and

numerical ID can only be configured via the IR communications link.

Controlled and ADS User IDs can be viewed via the EPD’s LCD display. Detailed

instructions to display User IDs are given in Section 3.5.

2.1.6 Wearing an EPD

The EPD should be worn under the direction of the health physicist. For most

operating conditions it is recommended that the EPD be worn on the outside of any

protective clothing (see Figure 2.5). Note that the button should be facing outwards.

Wearing the EPD on the outside of protective clothing has the major advantage that

the user can read the EPD’s LCD display and operate the button as required.

Typically, the EPD should be worn on the chest or the waist. The type of outer

protective clothing will determine how the EPD is attached (i.e. the EPD clip or

lanyard). For example, if the protective clothing has no breast pocket (or the use of a

belt is prohibited) the lanyard may be the most practical method of wearing the EPD.

Note: The lanyard cannot be fitted without first removing the lanyard plate (see

Section 6.3.1).

When the EPD is worn on the outside of protective clothing, to minimise the risk of

contamination of the EPD, consideration should be given to wearing the EPD in a

suitably -sealed plastic bag.

EPD TECHNICAL HANDBOOK Page 11

Figure 2.5 - Wearing An EPD

ISSUE 5

Page 22

EPD/HB/40521/000

WARNING

DURING OPERATIONAL USE THE EPD MAY BECOME EXPOSED TO

RADIOACTIVE CONTAMINATION. THE EPD MUST BE SUBJECT TO ALL

RELEVANT DECONTAMINATION PROCEDURES LAID DOWN BY THE

RADIOLOGICAL PROTECT ION AUTHORITY.

EPD TECHNICAL HANDBOOK Page 12

ISSUE 5

Page 23

EPD/HB/40521/000

SECTION 3

OPERATING INSTRUCTIONS

This section explains the essential functions performed by the EPD and describes

operating instructions that will allow the user to display data, acknowledge alarms

and operate the EPD.

3.1 LCD Display and Backlight

A custom-designed LCD display on the top of the EPD provides a visual interface for

viewing dose and other EPD data. The EPD display is illustrated in Figure 3.2, which

shows all segments in the on state. All segments are activated in this way

temporarily during the start-up sequence, and during user initiated Confidence Test,

(see Section 3.5.7). On completion of the start-up sequence or Confidence Test the

default display will appear.

The default display is preset at the factory to show Hp(10) (the penetrating or deep

dose), or another default display as specified by the customer. The default display

can also be changed by the customer after delivery, to any display shown in Figure

3.4. Default settings and other display controls are changed using a suitable IR

communications link and software (e.g. EasyEPD2). For example, the display can

be configured to display values in either Sieverts or rems.

The EPD is provided with many different displays in order to provide a powerful

‘stand-alone’ facility for users not having direct access to communications software

such as EasyEPD2. However for many users the sheer number of displays

available may lead to confusion and Thermo Electron has therefore provided a

facility for unwanted or unnecessary displays to be disabled.

Backlight Operation

The EPD is equipped with a display backlight to enable the display to be read in the

dark. The following points should be noted:

♦ The backlight will only function if it is enabled over the IR communications link.

♦ The backlight only operates for a short period after the button is pressed. This

is to conserve battery life.

♦ When the backlight is enabled but currently off, the first short press of the button

serves only to activate the backlight and does not cause a change of display

selection. This may cause confusion in bright day-time conditions when the

EPD TECHNICAL HANDBOOK Page 13

ISSUE 5

Page 24

EPD/HB/40521/000

backlight effect is not apparent and the user may assume that a button press

operation has somehow been ‘lost’.

♦ The backlight activation causes a temporary alarm muting effect, see section

3.2.5.

EPD TECHNICAL HANDBOOK Page 14

ISSUE 5

Page 25

EPD/HB/40521/000

EPD TECHNICAL HANDBOOK Page 15

ISSUE 5

Page 26

EPD/HB/40521/000

Figure 3.2 - LCD Display Segments

3.2 Audible And Visible Alarms

3.2.1 Alarm features

Overview

The EPD contains a sounder and alarm LED (see

Figure 3.1), which are activated together when

certain alarm conditions occur. Alarms are also

indicated in various ways on the LCD. Under

alarm conditions the LED illuminates red and the

sounder sounds at 4 kHz or 2 kHz with an intensity

of between 98 to 101 dBA (4 kHz Loud) at 20 cm.

It is possible to disable the sounder and/or LED so that only one or neither will

activate, but alarm flags on the LCD remain until the condition is normalised. The

alarm sounder can be configured for quieter operation, for example, for office or

hospital environments.

Alarms are acknowledged by pressing the button (long press). This action will

extinguish the alarm LED and mute the sounder. It is possible to disable the mute

function, via the EPD IR communications link (see section 3.2.5).

Note that certain operations and events will automatically mute the audible alarm for

a short period, because of the high electrical current required. These are as follows.

The period of interruption to the sound output is also given:

Operation or event. Typical mute period.

Figure 3.1 - Alarm LED

And Sounder

Communication over the IrDA link 1 second or more, depending upon the

Communications over the

teledosimetry link.

Backlight activated (from the button). Default display timeout ( typically 10

Battery test ( typically every 15

minutes ).

EPD TECHNICAL HANDBOOK Page 16

application.

Less than a second.

seconds ), during which the backlight is on.

Less than 1 second.

ISSUE 5

Page 27

EPD/HB/40521/000

Alarm Configuration

The EPD is able to initiate alarms for a number of different operational conditions.

The nature of any alarm is shown on the LCD display by an alarm flag (see Figure

3.2) or, in the case of an over-range alarm, by a flashing LCD display. Faults are

shown as a letter ‘F’ followed by 3 digits.

There are a number of options that can be set for each alarm, for example, tone,

frequency and volume. The various options are defined in Tables 3.1 and 3.2. The

sounder, LED and mute facilities can only be configured via the IR communications

link. The configurations can be set independently for each alarm event recognised by

the EPD ( see Table 3.3 ).

Note that alarm duration is se t in increments of 4 seconds. Assuming an alarm is not

acknowledged then following this period the alarm is replaced by a single beep every

30 seconds. This feature avoids wasting battery power. The timeout can be disabled

if desired and the alarm output is not then so curtailed.

Alarm Feature Configuration

Alarm Sound

Options

Off

Volume Loud*/Quiet Continuous Single Tone

LED Enabled/Disabled Continuous Dual Tone Slow

Sound Enabled/Disabled Continuous Dual Tone Fast

Tone High*/Low frequency Intermittent Single Tone Slow

User Silence

Enabled/Disabled Intermittent Single Tone Fast

(Mute)

Alarm Sound Options (table 3.2) Intermittent Double Beep Slow

Duration Continuous (0) or up

Intermittent Double Beep Fast

to 17 minutes

Table 3.1 - Alarm Configuration Options

Table 3.2 - Alarm Sounds

EPD TECHNICAL HANDBOOK Page 17

ISSUE 5

Page 28

EPD/HB/40521/000

Note: High Frequency = 4 kHz (approximately)

Low Frequency = 2 kHz (approximately)

* To obtain the loudest alarm output it is necessary to configure the

alarm to Loud and High frequency.

The different alarm events identified by the EPD are listed in Table 3.3. This table

also shows the default alarm configurations set by Thermo Electron at manufacture.

The following alarms are regenerated after a reset (e.g. battery change):

• Over Range Alarm

• Dose Alarms

• Return Alarm

• Battery Alarm ( after 1 minute )

• Dose Rate Alarm ( if the condition persists )

Alarm Priorities

It is possible for more than one alarm condition to prevail at any one time. In this

event the sounder output is determined by the highest priority prevailing alarm.

Alarms are prioritised as defined in Table 3.3, Priority 1 being the highest priority.

An active alarm can be superseded by the following events:

• A higher priority alarm is activated ( the new alarm starts ).

• The user mutes alarms with a long button press ( all mute-able alarms are

muted ).

• Alarms are cleared via the communications links.

• A self-cancelling condition de-activates the alarm ( e.g. falling dose -rate ).

Care should be taken if the alarm configurations are altered from the defaults set by

Thermo Electron and the following points should be noted:

1. The alarm priorities are fixed and cannot be altered by the user.

2. If the Alarm Type is OFF, or both LED and Sounder are disabled, then the alarm

type is effectively removed from the list.

3. If the LED (or sounder) only is disabled then the LED (or sounder) output for an

active lower priority alarm will be masked ( not output ).

4. A short duration high priority alarm can curtail the output of a long duration low

priority alarm.

EPD TECHNICAL HANDBOOK Page 18

ISSUE 5

Page 29

EPD/HB/40521/000

In general therefore the higher priority alarms should not be configured with

either a short duration, or with LED or sounder disabled, unless the lower

priority alarms are also configured this way.

Priority Alarm/Event Alarm Tone Frequency Volume

1 EPD Failure Alarm. Intermittent Single Slow Tone

__ __ __ __

2 Over-range Alarm. Continuous Dual Fast Tone

_-_-_-_-_-_

3 Hp (10) Dose Alarm

(2)

4 Hp (0.07) Dose

Alarm

5 Hp (10) Dose Alarm

(1)

6 Hp (10)/h Dose Rate

Alarm (2)

7 Hp (0.07)/h Dose

Rate Alarm

8 Hp (10)/h Dose Rate

Alarm (1)

Continuous Single Tone

____________

Continuous Single Tone

____________

Continuous Single Tone

____________

Continuous Single Tone

____________

Intermittent Single Fast Tone

_ _ _ _ _ _

Intermittent Single Fast Tone

_ _ _ _ _ _

High Loud

High/Low Loud

High Loud

High Loud

High Loud

High Loud

High Loud

High Loud

9 Battery Alarm Intermittent Single Slow Tone

10 Return Alarm Intermittent Single Slow Tone

11 Count Down Alarm Continuous Single Tone

12 Abuse Alarm Intermittent Single Slow Tone

EPD TECHNICAL HANDBOOK Page 19

__ __ __ __

__ __ __ __

____________

__ __ __ __

Table 3.3 - Default Alarm Tones

ISSUE 5

Low Quiet

Low Quiet

High Loud

Low Quiet

Page 30

EPD/HB/40521/000

3.2.2 Dose Alarms

Dose alarms are checked and updated every second, except at low dose rates

where this period increases to a maximum of 14 seconds. Alarms can be adjusted

or inhibited via the IR communications link.

Dose alarms are calculated against a preset alarm threshold set in the EPD. When

the dose equals or exceeds the dose threshold the LED will illuminate, the sounder

will activate and the appropriate alarm flag on the LCD will be displayed. Note that it

is dose and not total dose that is compared with the threshold.

The alarm may be muted by pressing and holding the button, unless alarm mute (user

silence) is inhibited.

The four most significant digits of the alarm thresholds can be viewed on the EPD

LCD and changed using the function button (see Section 3.5.8).

3.2.3 Dose Rate Alarms

Dose rate alarms are checked and updated every second, except at low dose rates

where this period increases to a maximum of 14 seconds. Alarms can be adjusted

or inhibited via the IR communications link.

The dose rate alarms can be made to work with hysteresis, i.e. the alarm 'off'

threshold is lower than the alarm 'on' threshold. The alarm 'off' threshold can be set in

the EPD over the same range as can the alarm 'on' threshold. As the dose rate rises

above the alarm 'on' threshold the LED will flash and the sounder is activated (see

Figure 3.3). The alarm may be muted by pressing and holding the button, unless

alarm mute (user silence) is disabled. The alarm will self-cancel when the dose rate

falls below the alarm 'off' threshold.

EPD TECHNICAL HANDBOOK Page 20

ISSUE 5

Page 31

EPD/HB/40521/000

Figure 3.3 - Dose Rate Alarm Example

The four most significant digits of the alarm ‘Off’ and the alarm 'On' thresholds can be

viewed on the EPD LCD and, if user has authority to modify the thresholds, changed

using the function button (see Section 3.5.9).

3.2.4 Over-Range Indication

If a dose rate exceeds 1Sv/h, or if a dose store increments above 1.0Sv, an overrange alarm will occur. The sounder (if enabled) will sound and the LED will flash (if

enabled). The over-range alarm will also cause the LCD display to flash every

second.

Notes:

1. The over-range alarm condition is latched and the LCD will continue to flash

even after a temporary dose -rate over-range condition has cleared. The overrange conditions are recorded in the EPD EEPROM and must be cleared

over the IR communications link before the display will stop flashing.

2. The over-range alarm can be muted ( if enabled ). The EPD will not recur

after muting should over-range conditions re-occur (e.g. in the case of a

second dose-rate over-range alarm ), until the latched condition has been

cleared over the IR communications link. However the LCD will continue to

flash.

3. Th e ADS dose over-range alarm only operates if the unit is ADS issued.

EPD TECHNICAL HANDBOOK Page 21

ISSUE 5

Page 32

EPD/HB/40521/000

3.2.5 Alarm Muting

Alarm conditions cause the sounder to be activated and the alarm LED to illuminate,

subject to these facilities being enabled for the alarm. The appropriate LCD alarm

flag is always activated. The user can silence ( mute ) the alarm by pressing and

holding the button, provided mute is enabled on the alarm. This will also extinguish

the Alarm LED. However the LCD alarm flag remains set until such time as the

alarm condition is cleared.

Dose rate alarms are self muting when the dose rate falls below the alarm ‘off’

threshold level. Similarly dose alarms are self muting if the dose is cleared or the

thresholds suitably increased over the IR communications link.

Note that if the display backlight is enabled a short press of the button turns the back -

light on and temporarily silences any active alarm. This is because the EPD unit

battery cannot supply sufficient current for both backlight and sounder together. After

the display timeout period the backlight is automatically turned off and the sounder

re-enabled. Thus a short press may appear to mute the alarm and confuse the user

under such conditions. It is necessary therefore for the user to remember that a long

press is required to mute the alarm.

EPD TECHNICAL HANDBOOK Page 22

ISSUE 5

Page 33

EPD/HB/40521/000

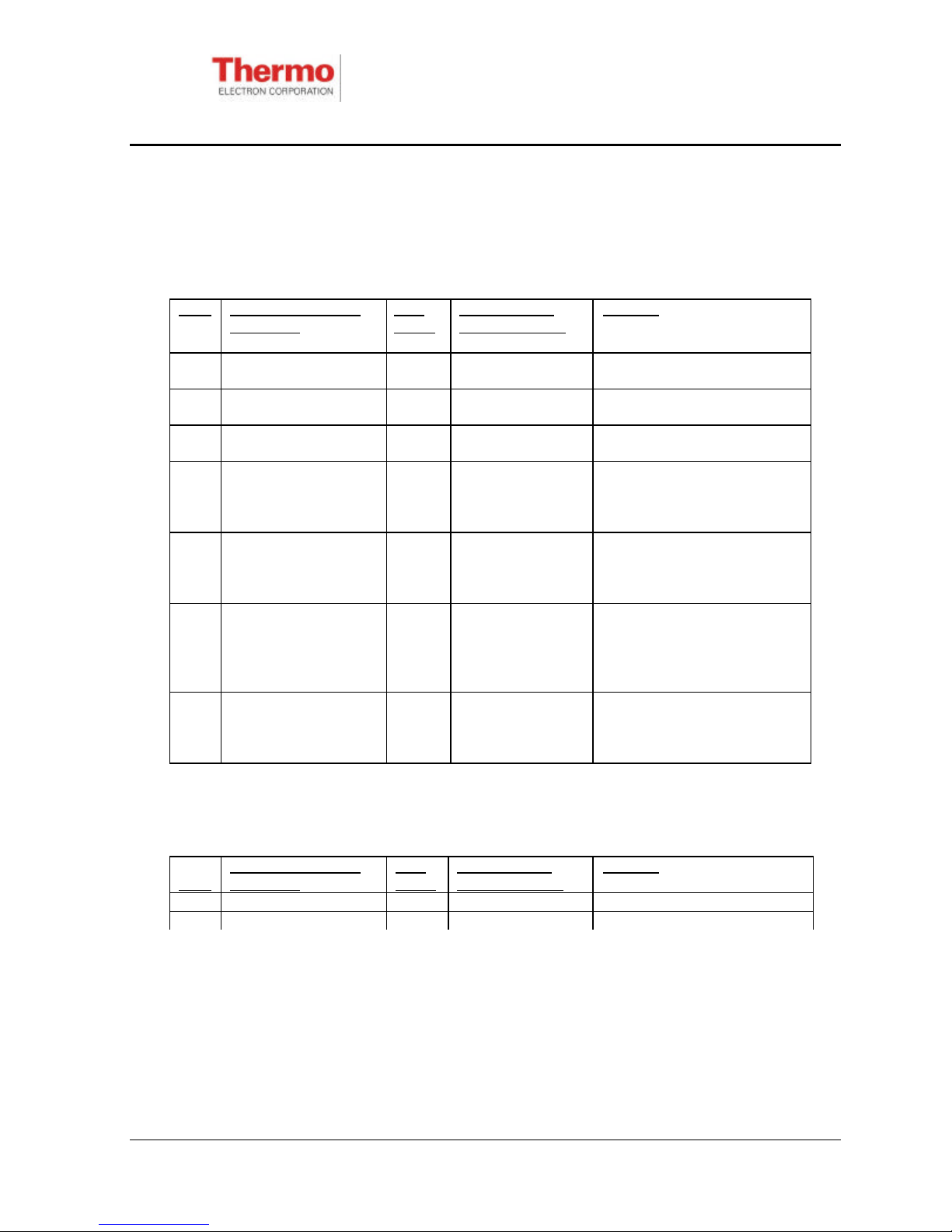

3.3 Button Operation and Display Selection

The EPD will display a range of data to the user. The data displayed is selected by

use of the button. The full range of displays is arranged on a two dimensional grid,

as shown in Figure 3.4. There are a number of menus, each having a top-level

display. Menus are changed by holding down the button (Long Press). This

navigates the user down the left hand side of Figure 3.4. Once the desired menu has

been reached the button must be released. Then, by a series of short presses, the

user can navigate across Figure 3.4 until the desired display within the current menu

has been reached.

Any displays that are disabled are removed from the sequence. Some displays are

usefully disabled if their retention might confuse the wearers of the EPD. Other

displays should be disabled if their retention might cause an operational risk, for

example, the ability to zero dose or adjust alarm thresholds. Such display

configuration is easily done using the EasyEPD2 software package. A batch write

facility is available in EasyEPD2 to enable the speedy configuration of a number of

EPD units.

Some displays allow the user to change the status or operation of the EPD. For

example, the user can start, stop and reset the countdown timer. In general, these

operations are activated by “double-pressing” the button. To prevent unwanted user

intervention (e.g. to prevent the user resetting count-down timer) the EPD can be

configured to disable any (or all) of the displays shown in Figure 3.4. Display

configuration changes can only be carried out via the IR communications link.

EPD TECHNICAL HANDBOOK Page 23

ISSUE 5

Page 34

EPD/HB/40521/000

3.4 LCD Display Lock-on Facility

Any new display selected using the button remains visible for a set period of time,

(Thermo Electron default time-out is 10 seconds), before returning to the default

display. Some display selections (marked * in Figure 3.4) can be ‘locked -on’, i.e. the

return to the default display is suspended. This facility is especially useful when

displaying dose-rate or when using the count down alarm. If a lock-on facility is

available it must be accepted quickly - when a colon (:) appears just before the

selected display times-out. The colon will only appear for approximately two

seconds. To accept the lock -on facility, press the button when the colon appears. If

the lock-on facility is not required, allow the selected display to time-out. To deselect

the lock-on facility press the button. The display will move on to the next display

selection but will thereafter revert to the default display after time -out.

The seconds count -down timer lock-on facility operates in a slightly different manner

to that described abo ve. In this instance the lock-on facility is available when the

colon disappears. This only occurs for the count -down timer display and, again, is

just before the display times out. To accept the lock -on facility, press the button when

the colon disappears. If the lock-on facility is not required, allow the selected display

to time-out.

EPD TECHNICAL HANDBOOK Page 24

ISSUE 5

Page 35

EPD/HB/40521/000

Top-Level Display

Sub-Displays

Button Operation: Long- Next Menu or Mute Alarm

Menu

0

Blank

1

H10 Doses

2

H07 Doses

3

Total Doses

4

Countdown

Timer

5

Power Saving

6

Peaks

(Rate High)

7

Test

8

Clear

9

Dose Alarm

Thresholds

10

Dose Rate

Alarm ON

Thresholds

(Rate On)

11

Dose Rate

Alarm Off

Thresholds

(Rate Off)

12

Sound

Settings

Display:0

HP10

HP07

t0t

5EC5

0n

OFF

r Hi

tE5t

CLr

d AL

r on

roFF

bEEP

1 2 3 4

Button Operation: Short- Next display or lock-on

H10 Dose

H07 Dose

Total H10

Dose*

Count-down

Times

MM:SS

Peak H10

Dose Rate

H10 and H07

Dose Clear

Clr?

1st H10

Dose Alarm

1st H10

Dose Rate

Alarm

ON

1st H10

Dose Rate

Alarm

Off

Button Bleep

Enable/

Disable

H10 Dose

Rate *

H07 Dose

Rate

Total H07

Dose*

Reset

rSt

Peak H07

Dose Rate

2nd H10

Dose Alarm

2nd H10

Dose

Rate Alarm

ON

2nd H10

Dose Rate

Alarm

Off

Chirp Dose

Adjustment

User ID digits

5,6,7,8

ADS User ID

digits 1,2,3,4

H07

Dose Alarm

H07 Dose

Rate Alarm

ON

H07 Dose

Rate Alarm

Off

Internal

Counters

Display* * = Lock-on

User ID digits

1,2,3,4

ADS User ID

digits 5,6,7,8

5

User ID digits

9,10,11,12

ADS User ID

digits 9,10,11,12

EPD TECHNICAL HANDBOOK Page 25

Figure 3.4 - LCD Display Selections

ISSUE 5

Page 36

EPD/HB/40521/000

3.5 Display Options and Button Functions

The following sections describe typical displays that a user may see within each of

the menus shown in Figure 3.4. This description assumes that all displays are

enabled. The user may have access to any (or none) of the displays, depending on

how the EPD has been configured. To call up a top-level display, press and hold the

button until the relevant top-level display appears. Any sub -displays are selected

either by short-pressing, or double-pressing, the button within the display default

time-out.

3.5.1 Displaying Hp (10) Dose, Dose Rate and User ID.

To display Hp(10) doses, press

and hold the button until this toplevel display appears:

Three sub-displays are available (in the following sub-display order):

♦ Hp (10) Dose

♦ Hp (10)/h Dose Rate

♦ User ID Digits

Hp (10) Dose Display

Short-press the button to display the

current dose. This dose parameter is

used for tactical dose monitoring (e.g.

per task etc.).

Display Range: 0µSv to >16Sv (auto

ranging)

Note: Over-range (> 1.0 Sv) is indicated with a flashing LCD display.

Hp(10)/h Dose Rate Display

Short-press the button again to display

the current Hp(10)/h dose rate. Only

the first two significant figures of the

dose rate are displayed, the actual

reading is rounded down.

EPD TECHNICAL HANDBOOK Page 26

ISSUE 5

Page 37

EPD/HB/40521/000

Display Range: 0µSv/h to >4Sv/h (auto ranging)

Note: Over-range (> 1.0 Sv/h) is indicated with a flashing LCD display. This

condition is latched to warn the user that the dose value may be inaccurate.

User ID Digits

Short-press the button again to display the user identity number (User ID). This is a

12-digit number that is shown on three separate displays - the High 4 digits, the

Middle 4 digits and the Low 4 digits. Short -press the button to display each of the

remaining User ID digit displays. The User ID cannot be changed using the button.

By convention a non-issued EPD is given a User ID = FFFFFFFFFFFF. Typically, a

User ID will have fewer than 12 digits, but it must be an integer between 1 and

999999999999. For example, a User ID = 9012 will be shown on the LCD display

as follows:

(First Display) (Second Display) (Third Display)

In systems using 8 or fewer digits for the User ID it is usual to disable and thereby

remove the unused displays ( e.g. the first and second display in the above example).

3.5.2 Displaying Hp(0.07) Doses, Dose Rate and ADS User ID

To display Hp(0.07) doses, press

and hold the button until this toplevel display appears:

Three sub-displays are available (in the following sub-display order):

♦ Hp(0.07) Dose

♦ Hp(0.07)/h Dose Rate

♦ ADS User ID Digits

Hp(0.07) Dose Display

Short-press the button to display the

current dose. This dose parameter

EPD TECHNICAL HANDBOOK Page 27

ISSUE 5

Page 38

EPD/HB/40521/000

is used for tactical dose monitoring (e.g. per task etc.).

Display Range: 0µSv to >16Sv (auto ranging).

Note: Over-range (> 1.0 Sv) is indicated with a flashing LCD display.

Hp(0.07)/h Dose Rate Display

Short-press the button again to display

the current Hp(0.07)/h dose rate. Only

the first two significant figures of the

dose rate are displayed, the actual

reading is rounded down

Display Range: 0µSv/h to >4.0Sv/h (auto ranging).

Note: Over-range (> 1.0 Sv/h) is indicated with a flashing LCD display. This

condition is latched to warn the user that the dose value may be inaccurate.

ADS User ID Digits

An additional User ID is provided, called Approved Dosimetry Service (ADS) User

ID. This is password-protected and is used by ADS systems for “permanent” issue

EPDs. The ADS User ID may be displayed in a similar fashion to the User ID.

Short-press the button again to display each of the remaining ADS User ID digit

displays. A non-issued EPD may have an ADS User ID = FFFFFFFFFFFF.

Typically, an ADS User ID will have fewer than 12 digits, but it must be an integer

between 1 and 999999999999. For example, an ADS User ID = 3324 will be shown

on the LCD display as follows:

(First Display) (Second Display) (Third Display)

In systems using 8 or fewer digits for the ADS User ID it is usual to disable and

thereby remove the unused displays ( e.g. the first and second display in the above

example).

EPD TECHNICAL HANDBOOK Page 28

ISSUE 5

Page 39

EPD/HB/40521/000

3.5.3 Displaying Total Dose

To display total dose, press and

hold the button until this top -level

display appears:

Two sub-displays are available (in the following sub-display order):

♦ Hp(10) Total Dose

♦ Hp(0.07) Total Dose

Hp(10) Total Dose

Short-press the button to display

the total Hp(10) dose.

Display Range: Hp(10) 0µSv to >16Sv

(auto ranging).

Hp(0.07) Total Dose

Short-press the button again to

display the total Hp(0.07) dose.

Display Range: Hp(0.07) 0µSv to >16Sv (auto ranging).

Each display represents a record of the total dose received by the EPD over multiple

tasks (e.g. per day, per week etc.).

3.5.4 Starting/Stopping The Seconds Count Down Timer

To start/stop the seconds countdown timer, press and hold the

button until this top-level display

appears.

Two sub-displays are available (in the following sub-display order):

EPD TECHNICAL HANDBOOK Page 29

ISSUE 5

Page 40

EPD/HB/40521/000

♦ Count-down Time MM:SS

♦ Reset (rSt)

The count-down timer is a useful facility for activities where actions need to be

completed within known time periods. The User may start, stop and reset the count

down timer using the button. When the timer expires the appropriate alarm is

sounded. The count down time period is pre-set and can only be adjusted via the IR

communications link.

Count-Down Time

Short-press the button to display the

‘Count-Down Time’ (which indicates the

count down time period, or the remaining

count down time available).

Double-press the button to start the digits counting down to zero. The display is in

units of minutes and seconds. The maximum count down time available is 99

minutes, 59 seconds.

The count down function continues when the display reverts to the default display

after the display timeout period. However it is useful to ‘lock on’ to this display as

described in section 3.4.

Stopping the Timer

To stop the timer double-press the button again. The digits will stop decreasing.

Reset

Short-press the button to select the

display shown opposite. Double press

the button and the display will flash.

Double-press the button again to confirm the reset (the display will show the reset

time at its reset value). The timer may now be started as described above.

3.5.5 Turning the EPD off

EPD TECHNICAL HANDBOOK Page 30

ISSUE 5

Page 41

EPD/HB/40521/000

To turn the unit off, press and hold the

button until the word ‘On’ appears:

Only one sub-display is available:

♦ On/Off

This function enables the EPD to be placed in sleep or OFF mode. In OFF mode

power consumption is reduced considerably and the EPD stops measuring

radiation.

Assuming that the display shows On, double-press the button. The display will

change to “OFF” (flashing). Double-press the button again to confirm the request.

The display will change to the word “OFF” (not flashing), confirming that the unit is in

OFF mode and not measuring radiation.

To return to operating mode press and hold the button. The display will revert to the

default display.

Note: ON/OFF control via the button may be inhibited by the appropriate setting of

the EPD internal configuration via the IR communications link.

3.5.6 Displaying Peaks (Rate High)

To display peaks (high rate),

press and hold the button until

this top -level display appears:

Two sub-displays are available (in the following sub-display order):

♦ Peak Hp(10)/h Dose Rate

♦ Peak Hp(0.07)/h Dose Rate

These displays show the highest dose rate that the EPD has measured since the

peaks were last cleared. The peak dose rates measured are recorded for

penetrating and superficial dose rates, together with the times at which these rates

occurred (to a resolution of 1 second).

Peak Hp(10)/h Dose Rate

EPD TECHNICAL HANDBOOK Page 31

ISSUE 5

Page 42

EPD/HB/40521/000

Short-press the button to display the

Peak Hp(10)/h Dose Rate:

Peak Hp(0.07)/h Dose Rate

Short-press the button again to

display Peak Hp(0.07)/h Dose

Rate:

Note: Peaks can only be cleared via the IR communications link.

3.5.7 EPD Confidence Test

To perform the EPD confidence test,

press and hold the button until this

top-level display appears:

Only one sub-display is available:

♦ Test

This test can be run at any time during operational use as a confidence check that

the EPD is functioning correctly. Throughout the confidence test the heart-beat

(activity) indicator flashes once per second. The confidence test can be stopped at

any time by pressing the button.

Note: During the EPD confidence test a brief detector test is performed, during

which dose accumulation is momentarily inhibited.

Double-press the button. The EPD will commence its confidence test routine, as

follows:

1. The all-segment display is displayed for approximately 5 seconds. This

allows the user to check that all segments are functional (see Figure 3.2).

2. The alarm will sound and the LED will flash for approximately 2 seconds. This

indicates that the sounder and LED are functional.

3. The all-segment display will disappear. The alarm will continue to sound and

the LED will continue to flash, at an increased rate, for approximately 6

EPD TECHNICAL HANDBOOK Page 32

ISSUE 5

Page 43

EPD/HB/40521/000

seconds. This indicates that the LCD segments can be turned off, and that

the tone frequencies are functional.

4. The all-segment display will reappear for approximately 5 seconds and the

LED will slow flash.

5. The all-segment display will disappear and the default display will appear.

This indicates that the confidence test has been successfully completed and

that the EPD is ready for operational use.

Upon completion of the confidence test, the unit reverts to the default display. If the

confidence test is unsuccessful a letter ‘F’ followed by three digits is displayed. Note

the failure codes and refer to Section 5 (Failure Modes and Fault Diagnosis).

EPD TECHNICAL HANDBOOK Page 33

ISSUE 5

Page 44

EPD/HB/40521/000

3.5.8 Clearing Dose Displays

To clear dose displays, press and

hold the button until this top-level

display appears:

Only one sub-display is available

♦ Clr?

This mode is used to clear the Hp(10) and Hp(0.07) doses.

Note: The total doses are not cleared.

Press the button once to select the

display shown opposite.

Double-press the button again and the display will flash. Double-press the button

again to confirm the request. The display will change to 0000 and return to the

default display. The Hp(10) and Hp(0.07) doses have now been cleared.

3.5.9 Displaying/Setting Dose Alarm Thresholds

To display and/or set dose

alarm thresholds, press and

hold the button until this toplevel display appears:

Three sub-displays are available (in the following sub-display order):

♦ 1st Hp(10) Dose Alarm

♦ 2nd Hp(10) Dose Alarm

♦ Hp(0.07) Dose Alarm

The EPD can be used as a ‘personal alarming’ dosemeter, with alarm thresholds for

accumulated dose alarms. This mode displays the current settings for the dose

alarm thresholds. The alarm threshold can be modified by the user, if required, but

only when the default setting is set to ‘adjustable’. The user is barred from modifying

the threshold if the default is set to ‘not adjustable’. These default settings can only

be set via the IR communications link.

EPD TECHNICAL HANDBOOK Page 34

ISSUE 5

Page 45

EPD/HB/40521/000

There are two Hp(10) alarm thresholds and a single Hp(0.07) alarm threshold that

can be displayed and modified. The 2nd Hp(10) dose alarm has the higher priority

and should always be set to a higher value than the 1st Hp(10) alarm. The

accumulated dose alarm thresholds can be set using the button as follows:

1st & 2nd Hp(10), Hp(0.07): 10µSv, 50µSv, 100µSv, 500µSv, 1mSv, 5mSv,

10mSv, 50mSv, 100mSv, 500mSv, 1.0Sv.

Example of 1st Hp(10) Dose alarm

threshold display set at a default

value of 500 µSv:

Other values for the dose alarm thresholds may be set via the IR communications

link.

Changing The Dose Alarm Thresholds

To change the 1st Hp(10) dose

alarm threshold select the display

above and double-press the button.

The display will change to the

following with the digits flashing:

Alarm Set Limits: 10µSv to 1Sv.

Pressing the button will increase the alarm threshold in the following steps: 10µSv,

50µSv, 100µSv, 500µSv, 1mSv, 5mSv, 10mSv, 50mSv, 100mSv, 500mSv, 1.0Sv.

When the required threshold is reached double-press the button to confirm the value

and the flashing display will stop.

If you start to change the threshold and change your mind this option can be aborted,

as follows:

Short-press the button until the

following is displayed (letters

flashing). Double-press the button to

confirm that you wish to escape and

return to the previous alarm

threshold.

If the “ESC” screen is displayed and the button is not pressed, after default time -out

the display will return to the dose alarm threshold that was being set-up. Again, if the

button is not pressed, the display will return to the default screen after a further timeout period.

EPD TECHNICAL HANDBOOK Page 35

ISSUE 5

Page 46

EPD/HB/40521/000

3.5.10 Displaying/Setting Dose Rate Alarm On/Off Thresholds

To display and/or set dose rate

alarm ON thresholds, press and

hold the button until this top-level

display appears:

Three sub-displays are available (in the following sub-display order):

♦ 1st Hp(10)/h Dose Rate Alarm ON

♦ 2nd Hp(10)/h Dose Rate Alarm ON

♦ Hp(0.07)/h Dose Rate Alarm ON

To display and/or set dose rate

alarm OFF thresholds, press the

button until this display appears:

Three sub-displays are available:

♦ 1st Hp(10)/h Dose Rate Alarm OFF

♦ 2nd Hp(10)/h Dose Rate Alarm OFF

♦ Hp(0.07)/h Dose Rate Alarm OFF

The EPD can perform the role of a ‘personal alarming’ EPD with alarm thresholds for

dose rate. There are two Hp(10)/h dose rate alarms and a single Hp(0.07)/h dose

rate alarm that can de displayed. The 2nd Hp(10)/h dose alarm has the higher priority

and should always be set to a higher value than the 1st Hp(10)/h alarm. The alarm

thresholds can be modified by the user, if required, but only when the EPD default

setting is set to ‘adjustable’. The user is barred from modifying the thres holds if the

EPD default is set to ‘not adjustable’. These default settings can only be set via the

IR communications link.

The dose rate alarm thresholds can be set using the button as follows:

10µSv/h, 50µSv/h, 100µSv/h, 500µSv/h, 1mSv/h, 5mSv/h, 10mSv/h,

50mSv/h, 100mSv/h, 500mSv/h, 1.0Sv/h

EPD TECHNICAL HANDBOOK Page 36

ISSUE 5

Page 47

EPD/HB/40521/000

Other values for the dose rate alarm thresholds may be set via the IR

communications link.

Note: To avoid false alarms due to counting statistics it is recommended that the

Hp(0.07)/h dose rate alarm is not set to less than 100µSv/h

Example 1st Hp(10)/h dose rate on

alarm threshold display set at a default

value of 500 µSv/h:

'On' and 'Off' alarm thresholds allow hysteresis for dose rate alarms, see section

3.5.1. If hysteresis is not to be used the ‘On’ and ‘Off’ thresholds should be set to the

same value.

Changing the Dose Rate Alarm Thresholds (ON and OFF):

To change the 1st

on alarm threshold, for example,

select the above display and double press the button. The display will

change to the following and the digits

will flash:

Alarm Set Limits: 10µSv/h to 1Sv/h

Pressing the button will increase the alarm threshold in the following steps: 10 µSv/h,

50µSv/h, 100µSv/h, 500µSv/h, 1mSv/h, 5mSv/h, 10mSv/h, 50mSv/h, 100mSv/h,

500mSv/h, 1.0Sv/h. When the required threshold is reached double -pressing the

button to confirm the value and the flashing display will stop.

(10)/h dose rate

H

p

If you start to change the threshold and change your mind this option can be aborted,

as follows:

Short-press the button until the

following is displayed (letters

flashing). Double -press the button to

confirm that you wish to escape and

return to the previous alarm threshold.

If the ‘ESC’ screen is displayed and the button is not pressed, after default time-out

the display will return to dose alarm threshold that was being set-up. Again, if the

button is not pressed, the display will return to the top level default screen after a

further time out period.

EPD TECHNICAL HANDBOOK Page 37

ISSUE 5

Page 48

EPD/HB/40521/000

Notes:

1. The ‘On’ threshold must always be greater than or equal to the ‘Off’ threshold.

2. If an attempt is made to set the ‘On’ threshold below the ‘Off’ threshold the

‘Off’ threshold will be set automatically to the same value as the ‘On’ threshold.

3. If an attempt is made to set the ‘Off’ threshold above the ‘On’ threshold the

‘Off’ threshold will be set automatically to the same value as the ‘On’ threshold.