Therma-Tek TMDS24-4-1 Service Manual

THERMA-TEK RANGE CORPORATION

“QUALITY AND STRENGTH”

GAS RESTAURANT RANGE

PARTS / SERVICE MANUAL

Models covered in this manual include:

TMDS24-4-1

(4 Open Top Burners, 1 Space Saver Oven)

TMDS36-6-1 (6 O T Burners, 1 Standard Oven)

TMDS48-8-2 (8 O T Burners, 2 Space Saver Ovens)

TMDS60-10-2 (10 O T Burners, 2 Standard Ovens)

TMDS60-6-24RGB-2

(6 O T Burners, Raised Grid/Broil, 2 Ovens)

TMDS72-12-2

(12 O T Burners, 2 Standard Ovens)

And models utilizing available options including:

Manual & Thermostatic Griddles, Hot Tops, Radiant & CharRock Broilers, Range Base Convection Ovens, and Storage

Cabinet Bases.

THERMA-TEK RANGE CORPORATION

115 ROTARY DRIVE – VALMONT IND. PARK

WEST HAZLETON, PA

TEL: 570-455-3000 FAX: 570-455-9491 WEB: WWW.THERMA-TEK.COM

INTRODUCTION

The Gas Restaurant Range Parts / Service manual contains Installation &

Operation Recommendations. It also includes Troubleshooting and

Technical Data such as Orifice Hood Sizing and Gas Pressure Requirements.

The material presented should be used in conjunction with the Owners

Manual, Professional Training, Service Experience, and Industry Standard

Practices.

TABLE OF CONTENTS: PAGE

Model Number Identification………………………………………..3

Gas Restaurant Range Standard Features……………………………3

Gas Restaurant Range Standard Features (continued)…….…….…..4

Rating Plate Location………………………………………………..5

Identifying the Age of Equipment by Warranty Number……………5

Gas Specifications…………………………………………………..6

Lighting Standing Pilots…………………………………………….7

Shut Down -Nightly and Complete…………………………………8

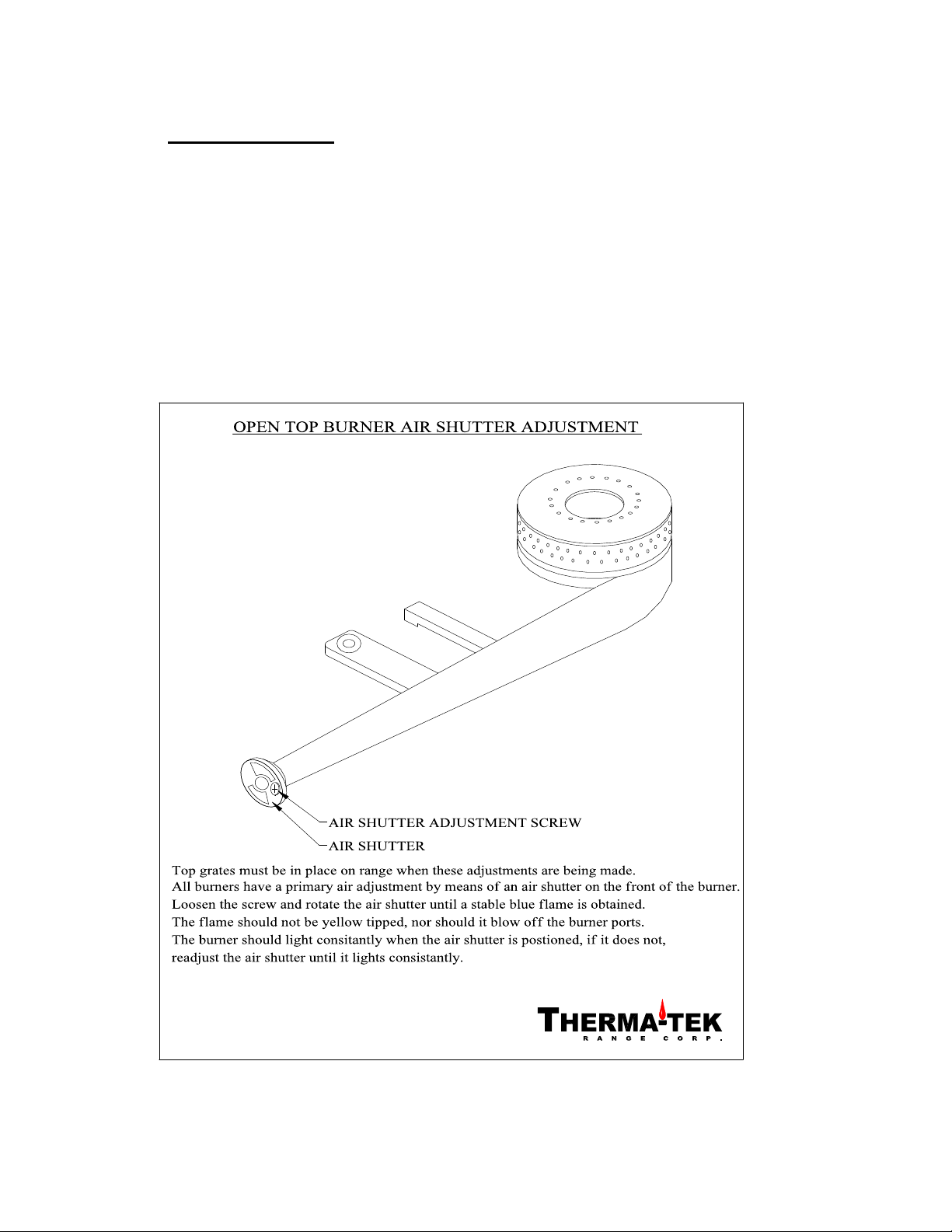

Open Top Burner Air Adjustment………………………………..…8

Setting the Bypass Flame on Thermostatic Griddles……….……….9

Calibration Check and Thermostat Recalibration…………….……..9

Oven Pilot Safety System…………………………………………..10

Trouble Shooting the Pilot Burner………………………………….10

Control Tips – Thermocouple / Safety…………………………11- 14

Parts – Exploded View and Detail List………………………...15- 26

Notes……………………………………………………………….27

2

Model Number Identification

EXAMPLE: TMDS60-10-2N

T (Therma) M (Medium) D (Duty) S (Standard Aluminized Oven)

24, 36, 48, 60, 72 (The Width of the Unit)

-4, -6, -8, -10, -12 (The Number of Open Burners)

Optional

-HT (Hot Top), -_ _G (Manual Griddle), -__TG (Thermostatic Griddle),

GP (Grooved Plate), - RB (Radiant Broiler), - CRB (Char-Rock Broiler),

- 0 (Storage Cabinet Base), - C (Range Base Convection Oven)

The Final Character N or L (NATURAL or LP Gas).

Gas Restaurant Range Standard Features

• Gas Restaurant Ranges consist of a welded frame construction.

• Fully stainless steel exterior.

• 6” (152.5 mm) adjustable legs.

• Gas pressure regulator provided.

• One year limited parts and labor warranty.

Open Top Burners

• Cast iron lift off burner heads for easy cleaning.

• Rated at 30,000 BTU’s (8.79 kW).

• Top grate supports located every 12” assuring structural integrity.

• Spill-proof pilot ignition system.

• Individual 12” (305 mm) x 12” (305 mm) cast iron top grates.

• Burner is controlled by a brass valve with infinite adjustment.

3

Griddles

• 5/8” thick, highly polished steel plate.

• Spatula width grease trough.

• One heavy-duty, steel tube burner per 12” section; at 20,000 BTU/hr.

• Each 12” section is controlled by a valve.

• Each 24” section is controlled by a thermostat.

• Manual valve control is standard. Thermostat control is available.

• Large capacity grease container.

Radiant Broilers

• One heavy-duty cast-iron H-Type burner per 12” section; 30,000 BTU/hr.

• Heavy cast-iron radiant with multiple heat sinks - (2) per burner.

• Heavy-duty cast-iron cooking grates.

• Single piece precision brass valves with infinite heat control.

• Easy to remove drip pans

Char-Rock Broilers

• One heavy-duty cast-iron H-Type burner per 12” section; 30,000 BTU/hr.

• High quality lava rocks on cast iron supports provide maximum heat.

• Burners protected by heat shield to prevent blockage of ports and pilot.

• Heavy-duty cast-iron cooking grates.

• Single piece precision brass valves with infinite heat control.

• Easy to remove drip pans.

Range Base Convection Oven

• 1/3 Hp convection oven motor

• Three oven racks

• Three rack guide positions

• 6 Ft. - 120 volt cord and plug.

4

RATING PLATE LOCATION

The Rating Plate (sticker) on all Gas Restaurant Range Models

is located on the backside of the lower front panel. It flips down to

expose the Rating Plate and Operating Instructions.

On double oven models, the Rating Plate is behind the lower front panel

of the right oven.

WARRANTY SERIAL NUMBER

THERMA-TEK SERIAL NUMBER & DATE CODE

Date of manufacture is a date code and is part of the serial number.

(a) (c)

Example: 09J00001A

(b) (d)

(a) Year Code

: Use the last two digits of the year.

07 = 2007

08 = 2008

09 = 2009

(b) Month Code

: A=Jan, B=Feb, C=Mar, D=Apr, E=May, F=Jun,

G=Jul, H=Aug, I=Sep J=Oct, K=Nov, L=Dec

(c) 5 Digit Serial Number

: This number is reset to zero on the

new year.

(d) Engineering Digit

: “A” is used for new release. Anytime a

design element is changed that would affect service, this digit

would be changed to “B”. Each time a change is made, the

letter is changed going down through the alphabet.

5

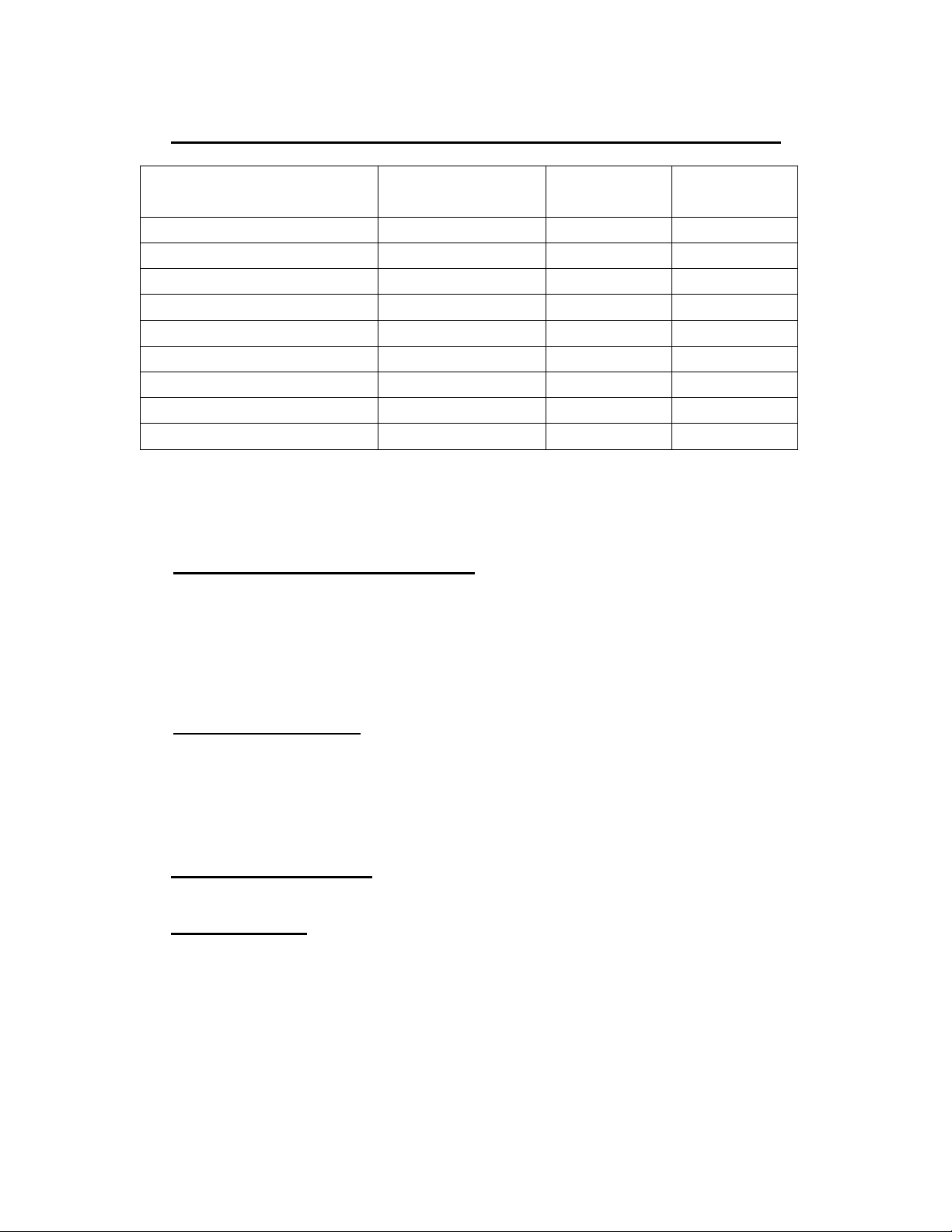

RESTAURANT RANGE GAS SPECIFICATIONS

BURNER TYPE

BTU / kW

NAT Hood

Orifice #

PRO Hood

Orifice #

Open Top

30,000 / 8.79

40

53

Griddle

20,000 / 5.86

48

55

Raised Griddle / Broiler

15.000 / 4.39

51

57

Hot Top

20,000 / 5.86

48

55

Char-Rock Broiler

30,000 / 8.79

39

52

Radiant Broiler

30,000 / 8.79

39

52

Standard Oven

35,000 / 10.25

36

51

Convection Oven Base

35,000 / 10.25

37

52

Space Saver Oven

27,000 / 7.9

42

53

PRESSURE REGULATOR

A Pressure Regulator is provided with every Gas Restaurant

Range and must be installed prior to start up.

GAS PRESSURE

Natural 5.0” Water Column / 12.45 mbar

Liquefied Propane 10.0” Water Column / 24.90 mbar

MANIFOLD SIZE

¾” N.P.T. on all Restaurant Ranges.

LOCATION

Gas manifold inlet is left facing, inboard 1

13/16”.

6

SHUTDOWN

Nightly shutdown:

Turn burner valves or thermostats to off position. Pilots will remain lit.

• Complete shutdown:

Turn burner valves or thermostats to off position. Turn main gas supply

to range off.

8

OVEN / GRIDDLE THERMOSTAT OPERATION

When An Oven or Griddle reaches the temperature at which the dial was set,

the control cuts down the flow of gas to the amount required to maintain that

temperature. This minimum burner flame is called the bypass flame. The

control must provide enough bypass gas to keep the entire burner lighted.

If not, the bypass must be set carefully and accurately as follows:

Setting the Bypass Flame

1. With the pilot lighted, turn the thermostat dial to “Full On”.

2. After 5 minutes, turn the dial clockwise to the point slightly beyond

the first mark on the dial.

3. Carefully remove the dial.

4. With a straight-bladed screw driver, turn the bypass adjustment screw

counter-clockwise to increase the flame, clockwise to decrease the

flame, until there is a minimum flame (approximately 1/8” high) on

the entire burner. This flame should be stable without lifting.

With a good bypass established, we can check the thermostat’s calibration.

An accurate pyrometer or other reliable test instrument is required.

Checking Calibration

1. Set the thermostat dial to 400° F mark. That’s 240 C.

2. To allow the temperature to stabilize, the control must cycle at least

three times (min. 15 minutes) before taking a meter reading.

3. Continue to check temperature at 5 minute intervals until two

successive readings are within 5 degrees of each other. If readings are

not within 20 degrees of the dial setting, calibration is required.

Calibrating the Control

1. With the dial insert removed, hold the dial firmly.

2. With a straight bladed screwdriver, push and hold the calibration

screw located down the center of the stem. Do not turn the screw

.

3. While holding the calibration screw firmly, turn the dial to the set

point matching the actual temperature shown on your test instrument.

Remove the screwdriver. Replace the dial insert.

4. Set the temperature at 400° (240° C). After 15 minutes, check

temperature. It should be within 20 degrees of the dial setting.

5. A control exhibiting 50 or more degrees “out” should be replaced.

9

Loading...

Loading...