Thermal Engineering 1702 Manual

CatCh the ‘cool’ alternative

HVAC/R Accessories, Vacuum Gauges, Compressor Tools,

Oil Pumps, Vacuum Pumps, Vacuum Accessories, Charging Scales,

Charging Cylinders, Hoses, Vocational Training Units

www.thermalengineeringcompany.com | 800 473-1754

2010 PRODUCT CATALOG

800 473-1754 | www.thermalengineeringcompany.com

1

INTRODUCTION

THERMAL ENGINEERING COMPANY

Founded over 40 years ago on the principles of innovation, quality, and service,

Thermal Engineering has developed a line of HVAC/R service tools that

continue to satisfy the needs of the HVAC/R professional. As a division of the

Airserco Manufacturing Company, we continue to adhere to the original founder’s

principals by developing quality products that meet the needs of the global HVAC/R

service market, and backing those products with a high level of customer service.

The full spectrum of Thermal Engineering’s product offering is presented in this

catalog. For your convenience, items have been indexed by product category along

with a handy product reference. We also encourage you to visit our web site at

www.thermalengineeringcompany.com for our most current product offerings, new

product introductions, technical information, and buying locations.

For 2010 we are pleased to introduce the following:

• TS-500 2-Valve Manifold, page 30

• TS-1000 The Sherman 4-Valve Test and Charging Manifold, page 30

• 4775 Handheld Digital Micron Gauge, page 16

• 4975 Scale / Vacuum Combo Unit, page 16

• DRSA-1600 Digital Refrigerant System Analyzer, page 28

• HLD-1201 Refrigerant Leak Detector, page 12

• GL-1000 Compressor Jumper, page 19

Thank you for your interest in our products and your continued support!

Sincerely,

Timothy Winings, President

2

www.thermalengineeringcompany.com | 800 473-1754

TABLE OF CONTENTS

Thermal Engineering Introduction ...............................................................................1

HVAC/R Accessories

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 10

Leak Detection

.............................................................................................11 - 14

Vacuum Gauges

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Thermometers

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Compressor Tools

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 - 19

Oil Pumps & Accessories

..................................................................................20 - 21

Vacuum Pumps

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22 - 23

Vacuum Pump Accessories

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Charging Cylinders & Accessories

.............................................................................25

Charging Scales

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Manifolds & Gauges

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27 - 29

Hoses

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 - 32

Fittings

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33 - 36

Vocational Training Units

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Index

.......................................................................................................38 - 43

Warranty

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Notes

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

800 473-1754 | www.thermalengineeringcompany.com

3

HVAC/R ACCESSORIES

CAP-CHECK OUTFIT MODEL 5101

Cap-Check Outfit provides both the Cap-Check and Chaser Kit in one compact case along

with an extended base that holds the Cap-Check. The Cap-Check can be operated with

one hand, allowing high pressures to be easily pumped. Carrying case has clips to hold

Cap-Check, Chaser Kit, hose, handle, and extended base.

CAP-CHECK CHASER KIT MODEL 1101

Chaser Kit is the only means available to clean partially plugged cap tubes, it must be

used with the Thermal Cap-Check since no other cap tube cleaning tool provides a rate

of oil flow large enough to remove partial restrictions even from the smallest cap tubes.

The Chaser Kit consists of 10 spools of lead alloy wire which can be used as a chaser for

the 10 most popular sizes of cap tubes (.028, .031, .036, .039, .042, .046, .050, .055, .064,

.070). In addition to the wire, a cap tube gauge, a set of sizing tools, and a combination

file/reamer are all included in a durable metal case.

CAP-CHECK MODEL 1003

Cap-Check is a portable, self contained hydraulic power unit with auxiliary equipment

especially adapted to cleaning refrigeration capillary tubes. A 0-5000 PSI gauge shows

pressure build-up if cap tube is restricted and also shows when chaser has passed

through the tube. A trigger operated gauge shutoff is provided so the gauge will not be

damaged if pressures greater than 5000 PSI are desired. A 30-inch high pressure hydraulic

hose with a 1/4-inch SAE male flare outlet connects the cap tube to the Cap-Check for

simple handling. An adapter is supplied to connect the cap tube directly to the hose outlet

without a flared fitting.

The Cap-Check is a Thermal Engineering innovation that has made cap tube cleaning possible and practical,

it is designed to pump a high rate of oil into the cap tube to build up pressures needed to open any plugged

cap tube, and will clean partially plugged cap tubes when used with the Thermal Chaser Kit.

CAP-CHECK

4

www.thermalengineeringcompany.com | 800 473-1754

HVAC/R ACCESSORIES

CAP-CHECK REPAIR KIT MODEL 1003RK

Complete Set of gaskets, “O” rings, springs, and balls for Model 1003 Cap-Check,

with instructions.

0-5000PSI GAUGE MODEL 1011

High pressure gauge for Model 1003 Cap-Check with a pressure range from 0-5000psi.

30-INCH HYDRAULIC HOSE (REPLACEMENT) MODEL 1012

30-inch high pressure hydraulic hose with a 1/4-inch SAE male flare outlet.

CAP-GAUGE MODEL 1102

Cap-Gage is a pocket knife type cap tube gauge with 10 stainless steel gauges to measure

the most popular sizes of cap tubes (.028, .031, .036, .039, .042, .046, .050, .055, .064, .070).

CARRYING CASE MODEL 1201

Store your Cap-Check in this heavy duty case that provides maximum protection from

wear and tear when not in use.

EXTENDED BASE MODEL 1301

This extension for the base of the Cap-Check provides better accessibility in certain situations.

A capillary tube is the most likely place a blockage in a system can occur and can cause a system to operate

very inefficiently. Therefore it is essential to have the proper tools on hand to fix this very common problem.

Below are accessories that we recommend for the Cap-Check and your service arsenal.

CAP-CHECK ACCESSORIES

CAP TUBING SIZES

PART NO SIZE

CT-31-100 .031 ID X 100 FT

CT-36-100 .036 ID X 100 FT

CT-42-100 .042 ID X 100 FT

CT-49-100 .049 ID X 100 FT

CT-54-100 .054 ID X 100 FT

CT-59-100 .059 ID X 100 FT

CT-64-100 .064 ID X 100 FT

CT-70-100 .070 ID X 100 FT

CAPILLARY TUBING

Thermal Engineering’s quality capillary tubing available in 100ft. coils.

800 473-1754 | www.thermalengineeringcompany.com

5

HVAC/R ACCESSORIES

Make on-the-spot readings with our easy-to-use HandyStat. Very useful for troubleshooting a system!

SYSTEM TESTER

HANDYSTAT MODEL HS-1

Save the steps, time and money to make system tests with a single tool.

FEATURES

Check out thermostat and control wiring output•

Operate individual system components for test purposes:•

Compressor, Fan, Heaters, Reversing Valves

Convenient momentary switch for quick ON-OFF activation

•

Connects to the control wiring at the point of service•

Great on Roof Top Units and Light Commercial Applications•

WARR ANTY: 12 MONTHS FROM DATE OF PURCHASE

WIRING CONNECTIONS FOR USE ON RESIDENTIAL HEAT PUMP SYSTEMS

WIRING CONNECTIONS FOR USE ON LIGHT COMMERCIAL HEAT PUMP SYSTEMS

WIRING CONNECTIONS FOR USE ON OIL OR GAS FURNACES WITH AIR CONDITIONING SYSTEMS

6

www.thermalengineeringcompany.com | 800 473-1754

HVAC/R ACCESSORIES

Many problems can arise from improper charging of any type of refrigeration system. Vizi-Vapr makes

it possible to correctly charge a system every time. Liquid refrigerant being charged is transformed into

a saturated vapor through a small orifice which thereafter can be viewed to ensure the system gets

charged properly.

VIZI-VAPR

VIZI-VAPR CHARGER MODEL 7701

The Vizi-Vapr eliminates the problem of slow vapor charging by removing the refrigerant

from the cylinder as a liquid and injecting it into the system as a saturated vapor.

Since the liquid refrigerant is removed from the cylinder by its own pressure, no heat is

removed from it and the cylinder does not get cold. Refrigerant blends must be removed

from their containers as liquid. Using the Vizi-Vapr, the blend can be charged into the

system as a saturated vapor without any composition change. Vizi-Vapr is adjustable

from 1/8hp up to 50hp. The operation is completely visible so there is little danger of

liquid entering the system.

VIZI-VAPR REPAIR KIT MODEL 7701RK

Complete set of gaskets, “O” rings, and back-up rings required for repairing the 7701 Vizi-Vapr.

800 473-1754 | www.thermalengineeringcompany.com

7

HVAC/R ACCESSORIES

Quick and easy process of pressurizing a refrigerant supply cylinder to move any refrigerant to another

vessel.

CYLINDER HEATER MODEL 3054

A quick, convenient, easy-to-use means to pressurize refrigerant supply cylinders to

move any refrigerant to another vessel or charging dispenser, the 3054 Cylinder Heater is

designed to fit 30Ib. and 50Ib. containers. It also can be used on 125Ib. cylinders and fits

the refrigerant cylinders in many recovery units. The device consists of a 6 x 28 flexible

silicone rubber heating element with extra-Iong Velcro straps, built-in molded thermostat,

and power cord. The heater draws 200 watts at 120 VAC and has a 135° preset thermostat.

Model 3054-230V

230 Volt model available for European market.

CYLINDER HEATER MODEL 4054M

The 4054M Refrigerant Cylinder Heater is designed to automatically maintain any desired pressure within a range of 80 to 250

PSIG. Pre-set at 160 PSIG, the unit can be easily adjusted in the field. The heating element also incorporates a 135° pre-set

thermostat as a safety backup to the pressure control.

Fits 125/145 Ib. refrigerant supply cylinders.

Accurate and adjustable pressure control

•

Safe and easy-to-use•

Complete, including valve and charge hose•

Energy-efficient•

The 4054M includes three basic components:

1. The control manifold, which adapts directly to the cylinder’s liquid valve and includes a visual refrigerant indicator,

pressure gauge, quarter-turn ball valve, heavy-duty 6ft. charging hose, adjustable pressure switch with power

supply cord and female connector for accepting the heating element.

2. A 350 watt, 120 VAC heating element with built-in safety thermostat and power cord that plugs into the

control manifold. The 12 x 28 heating element is secured with Velcro straps.

3. A special insulating cover that includes a Velcro seam and fits over the entire cylinder to improve efficiency.

HEATERS

8

www.thermalengineeringcompany.com | 800 473-1754

HVAC/R ACCESSORIES

Reference points on a variety of topics and scales to make even the most technically demanding jobs

a breeze.

ROOM AIR CONDITIONER CALCULATOR MODEL 5100

Used to determine size of air conditioner unit with allowances for:

Exposed and unexposed walls

•

Exposed and unexposed windows•

Roof and ceiling insulation•

Heat gain from number of people•

Location•

This calculator selects amount of capacity needed in a cooling load of 5000-24000 BTUs

per hour, and indicates the size of unit required in BTU ratings. The calculator not only

simplifies the job of specifying window air conditioners, but also eliminates misapplication

and paper work. An ideal service and sales tool for the estimator and service engineer, the

calculator is imprinted with full directions.

AIR DUCT CALCULATOR MODEL 5125

This ingenious, pocket-size Air Duct Calculator uses only three slides to give all of the

information needed when figuring the sizes of air ducts. Convenient tables printed on

the back of the calculator supply additional data in a handy, easy-to-use form. The few

words of instruction needed to understand and use the different slides are printed on the

calculator face, where they cannot be lost or mislaid.

Used to determine:

Size of air ducts by the equal pressure loss method

•

Size of round ducts vs. rectangular ducts•

Weight per foot of round ducts by U.S.S. gauge•

Weight per foot of rectangular ducts by U.S.S. gauge•

Recommended duct velocities•

Friction loss of 1-1/2 radius elbows•

Gauge of metal for size of ducts•

HUMIDITY CALCULATOR MODEL 5150

Designed for determining the percent of relative humidity when using any standard sling

psychrometer, this calculator eliminates the use of psychrometric charts from 60° to 100°F.

The reverse side of the calculator has a chart of recommended humidities according to

industry application and temperature.

CALCULATORS

800 473-1754 | www.thermalengineeringcompany.com

9

HVAC/R ACCESSORIES

TROUBLESHOOTING CALCULATOR MODEL 5175

This calculator simplifies the job of diagnosing cooling system troubles. Ideally suited to the needs of

the expert as well as of the needs of the trainee, it provides immediate reference, from COMPLAINT to

POSSIBLE CAUSE to REPAIR.

FEATURES

19 major ‘Complaint’ sections•

32-part ‘Trouble Shooting’ Index•

127 ‘Possible Cause’ items•

All items keyed to ‘Repair’ window•

CAPILLARY TUBE AND TROUBLESHOOTING CALCULATOR MODEL 5180

TWO SLIDE CHARTS IN ONE

This is a dual-purpose slide chart. One side is a new, scientific approach for selecting

readily available standard capillary tubing sizes to replace the hard-to-get sizes that original

manufacturers often recommend. The other side is a trouble shooting calculator that

simplifies the job of diagnosing cooling system trouble where the capillary tube is suspect.

On-the-fly calculations can be made very easily to help troubleshoot a system, saving you valuable time!

CALCULATORS

REFRIGERATION CALCULATOR MODEL 5300

A time-saving and easy-to-use calculator to supply technical refrigeration data:

Hermetic terminal colors

•

Thermostatic control settings•

Pressure control settings•

Head and back pressures•

Hermetic motor diagrams•

Temperature pressure chart•

The calculator graphically shows vital refrigeration data and provides service information not available in

any other form.

10

www.thermalengineeringcompany.com | 800 473-1754

HVAC/R ACCESSORIES

REVIEW OF VACUUM FOR SERVICE ENGINEERS MODEL 5225

The story of how vacuum is used as a tool to dehydrate and degas a refrigeration

system. This text is the only publication that clearly and non-technically explains vacuum

fundamentals for the service man or engineer.

Illustrated with charts, photographs, and diagrams, this authoritative handbook describes

and explores vacuum terms, properties, uses, activities, advantages, limitations, and

techniques.

FEATURES

Covers key service-related topics•

Vital for processing engineer, serviceman•

What vacuum means•

How a pump works•

Sizing high vacuum pumps and lines•

Vacuum gauges procedure for dehydration, degassing, leak detection•

BOOKS

“TheHardWay”

...tolearnaboutvacuums.

“TheEasyWay”

Take“TheEasyWay”with

“ReviewofVacuumforServiceEngineers”

by

Saunders&Williams

800 473-1754 | www.thermalengineeringcompany.com

11

LEAK DETECTION PRODUCTS

REFRIGERANT LEAK DETECTOR MODEL HLD-1101

The Thermal Engineering HLD-1101 refrigerant leak detector is the perfect tool for the

service technician requiring a fast, easy to use, and economical tool for the maintenance

and repair of HVAC and refrigeration Systems.

The HLD-1101 utilizes a newly developed semi-conductor sensor which is extremely

sensitive to a variety of generally used refrigerants and the microprocessor control

provides advanced digital signal processing.

FEATURES

Heated Semiconductor•

High-Low Leak Sensitivity Selector•

7 LED Tricolored Visual Leak Level Indicator•

Audible Alarm•

Ambient Concentration Reset•

15-1/2-inch (40cm) Flexible Stainless Probe•

Detection of R-134A, R-404A, R-410A, R-407C, R-22, R-502, and R-600A Refrigerant Gas•

Sensitivity as Small 6g/year•

In accordance with SAE J1627, CE Design•

Low Battery Indication•

Reference Leak Source included•

Carrying case included•

Operating Temperature: 0˚ to 40˚C (32˚ to 104˚F)•

Size: 216mm x 66mm x 56mm•

8.5-inches x 2.6-inches x 2.2-inches

Weight: Approximately 1lb. (with battery)

•

Power Source: (4) AA Size Alkaline Batteries (included)•

Battery Life: Approximately 40 hours•

Often finding a leak is the hardest task for a technician. This tools will help make the process as easy

as possible.

LEAK DETECTION SENSITIVITY

SENSITIVITY HI LO

R-22, R-134A 0.21 OZ (6G) /YEAR 1.05 OZ (30G) /YEAR

R-404A, R-407C, R-410A 0.28 OZ (8G) /YEAR 1.41 OZ (40G) /YEAR

LEAK DETECTION

12

www.thermalengineeringcompany.com | 800 473-1754

LEAK DETECTION PRODUCTS

REFRIGERANT LEAK DETECTOR MODEL HLD-1201

Building on their successful line of leak detection products, Thermal Engineering introduces the

HLD-1201 refrigerant leak detector. This durable hand held detector has increased sensitivity

of up to 3 grams/0.105 ounces per year and a pump for faster response time. Utilizing newly

developed semi-conductor gas sensing technology, the HLD-1201 is ideal for diagnosing leaks

on air-conditioning and cooling systems utilizing a wide variety of common refrigerants.

FEATURES

•

Heated semiconductor gas sensor

• High low leak sensitivity selector, 3 levels of sensitivity

• Bright LED display

• Ambient concentration reset

• Includes durable carrying case and reference source

• Optional DC adapter 3.3V 0.5A

SPECIFICATIONS

•

Alarm method: Buzzer, Tri-color LED Bar Indicator

• Power usage: (4) AAA size (6V DC) Alkaline batteries

• Snake tube length: 15.5 inches (40cm)

• Dimensions / Weight: 173mm x 66mm x 56mm (400 grams)

6.8-inches x 2.6-inches x 2.2-inches (14.1 oz)

• Accessories: Aklaline batteries (4 pieces), user manual, leak check bottle, carrying case

• Battery Life: 7 hours normal usage

• Auto Power off: 10 minutes

• Disable Auto Power off: Press and hold (HI) button then power on the meter

LEAK DETECTION

LEAK DETECTION SENSITIVITY

SENSITIVITY HI MEDIUM LO

R-22, R-134A 0.105 OZ (3G) /YEAR 0.529 OZ (15G) /YEAR 1.05 OZ (30G) /YEAR

R-404A, R-407C, R-410A 0.141 OZ (4G) /YEAR 0.705 OZ (20G) /YEAR 1.41 OZ (40G) /YEAR

800 473-1754 | www.thermalengineeringcompany.com

13

LEAK DETECTION PRODUCTS

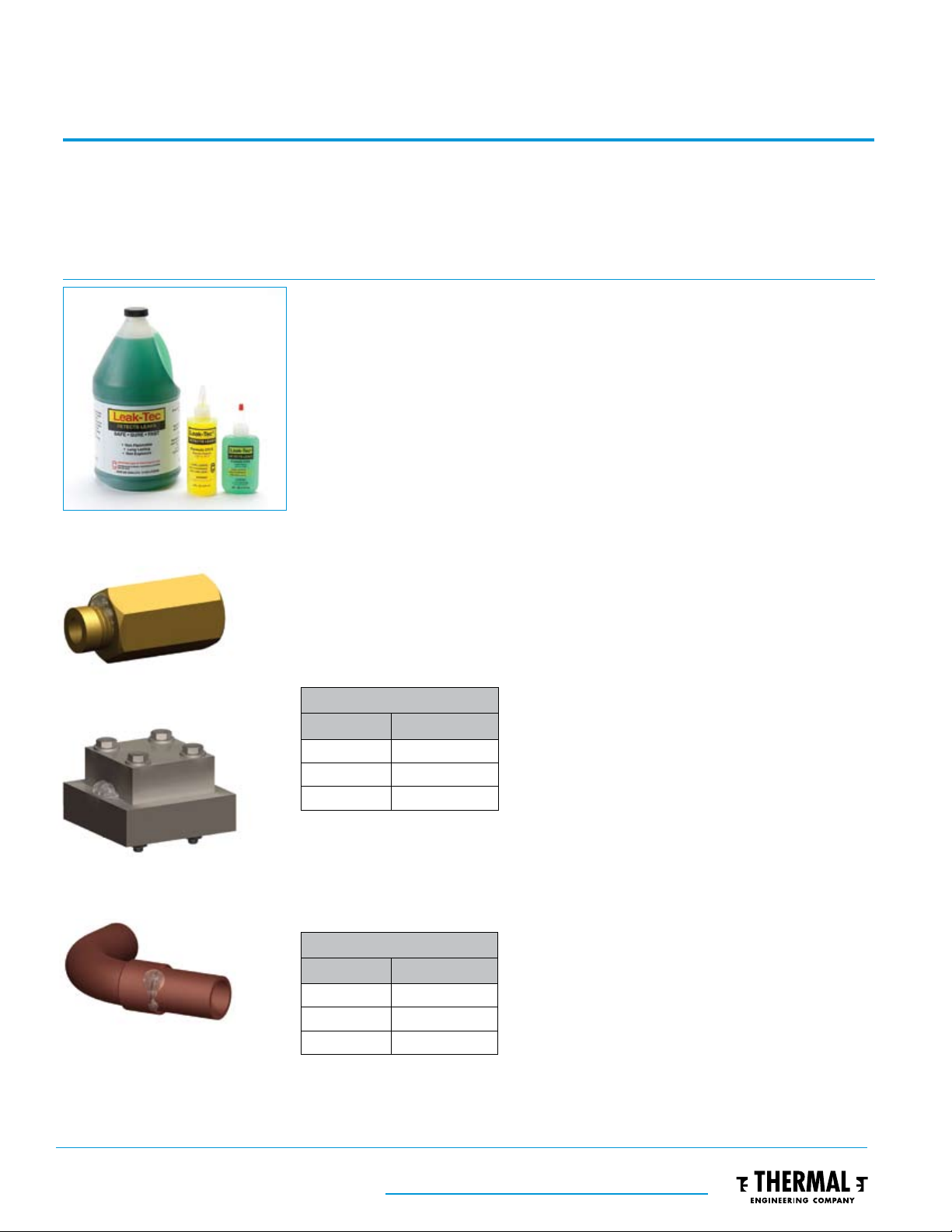

LEAK-TEC MODEL 4014

FEATURES

Fast, quickly finds and pinpoints the smallest of leaks•

Safe, does not affect metal or rubber and is nonflammable•

Economical, a few drops do the job•

Convenient, unbreakable dispenser bottle•

Stocked in 4oz. and 8oz. squeeze bottles, and 1 gallon jugs•

Leak-Tec is a non-toxic, nonflammable liquid that produces a white foam of live bubbles at

the point of leakage. The high viscosity enables the liquid to cling to surfaces long enough

to pinpoint leaks as small as .05oz. per year. The liquid spreads quickly and penetrates oil

and grease films common on metal surfaces. Used in small amounts, the mass of bubbles

will continue to foam as long as pressure is maintained on the equipment being tested.

Leak-Tec is stocked in 4oz., 8oz. and 1 gallon containers in two different formulas to fit most

applications. Additional formulas and container sizes are also available as special order.

SPECIFICATIONS

No.4014 Formula 372E

Application: compressed air and stable gases

Sensitivity: 1 x 10

-5

std. cc of air per sec.

Temperature Range: +35°F to +160°F

SPECIFICATIONS

No.4015 Formula 372G

Application: Refrigerants, low temp,

Sensitivity: 1 x 10

-4

std. cc of air per sec.

Temperature Range: -35°F to +180°F

OTHER SIZES AVAILABLE AND SPECIAL FORMULAS AVAIL ABLE.

AVAILABLE SIZES

PART NO CONTAINER

4015 4 OZ

4015-8OZ 8 OZ

4015-G GALLON

AVAILABLE SIZES

PART NO CONTAINER

4014 4 OZ

4014-8OZ 8 OZ

4014-G GALLON

MACHINE SURFACE CONNECTIONS

SOLD ERE D O R WELDE D

CONNECTIONS

THREAD CONNECTIONS

14

www.thermalengineeringcompany.com | 800 473-1754

LEAK DETECTION PRODUCTS

ULTRASONIC LEAK DETECTOR TYPE VPE MODEL 9997

FEATURES

Detects any type of refrigerant gas•

Battery-powered for cordless operation•

Does not require tracer gases•

Detects vacuum and pressure leaks•

Headset and padded carrying case included•

Adjustable sensitivity•

The VPE Leak Detector represents state-of-the-art technology for pin-pointing leaks in air

conditioning/refrigeration systems. Able to detect both vacuum and pressure leaks, the

VPE overcomes the disadvantages inherent in other types of leak detectors. No ultraviolet

dyes or tracer gases are necessary, and the VPE can detect any gas, even in a gas-

saturated environment. The VPE offers both visual and sound identification via the LED

display and the included headset. Lightweight and easy to use, the VPE is a tool every

technician should have.

SPECIFICATIONS

Nominal sensitivity: -80db / V / uBar

Frequency response: 38 to 42 kHz

Display: 10-bar element graph audio output

Power: 9V cell

Battery life: 15 hrs. continuous

Headset: dynamic 32 ohm

Size: 4.56 x 2.40 x .866

Weight: 1/2Ib.

Housing: durable PVC/aluminum

PART NO CONTAINER

9997 PVC

Loading...

Loading...