INSTALLATION INSTRUCTIONS

ENGINE PROTECTION SHUTDOWN KIT

For the Following Specs:

494170-1

•

494170-3

•

OWNER’S MANUAL Number 430429-080 (Rev - AA)

Revised March 13, 2000

IMPORTANT: Readtheseinstructionsbeforeinstalling,operating, or servicing this system.

THERMAL ARC INC., TROY, OHIO 45373-1085, U.S.A.

ARC WELDING SAFETY INSTRUCTIONS AND WARNINGS

Instruction 830001

ARC WELDING SAFETY INSTRUCTIONS AND WARNINGS

ARC WELDING can be hazardous.

PROTECT YOURSELF AND OTHERS FROM POSSIBLE SERIOUS INJURY OR DEATH. KEEP CHILDREN AWAY. PACEMAKER

WEARERSKEEPAWAY UNTILCONSULTINGYOUR DOCTOR.DONOT LOSETHESEINSTRUCTIONS. READOPERATING/INSTRUCTION MANUAL BEFORE INSTALLING, OPERATING OR SERVICING THIS EQUIPMENT.

Welding products and welding processes can cause serious injury or death, or damage to other equipment or property, if the operator does

not strictly observe all safety rules and take precautionary actions.

Safe practices have developed from past experience in the use of welding and cutting. These practices must be learned through study and

trainingbeforeusingthis equipment. Anyone not havingextensivetraining in welding and cuttingpracticesshould not attempt to weld.Certain

of the practices apply to equipment connected to power lines; other practices apply to engine driven equipment.

Safe practices are outlined in the American National Standard Z49.1 entitled:

other guides to what you should learn before operating this equipment are listed at the end of these safety precautions.

HAVE ALL INSTALLATION, OPERATION, MAINTENANCE, AND REPAIR WORK PERFORMED ONLY BY QUALIFIED PEOPLE.

ELECTRIC SHOCK can kill.

Touchingliveelectrical partscancause fatal shocks

or severe burns. The electrode and work circuit is

electricallylivewhenevertheoutputison. The input

power circuit and machine internal circuits are also

livewhen poweris on.In semiautomaticorautomatic

wire welding, the wire, wire reel, drive roll housing,

and all metal parts touching the welding wire are

electrically live. Incorrectly installed or improperly

grounded equipment is a hazard.

1. Do not touch live electrical parts.

2. Wear dry, hole-free insulating gloves and body protection.

3. Insulate yourselffromwork and ground using dryinsulatingmats

or covers.

4. Disconnect input power or stop engine before installing or servicing this equipment. Lock input power disconnect switch open,

or remove line fuses so power cannot be turned on accidentally.

5. Properly install and ground this equipment according to its

Owner’s Manual and national, state, and local codes.

SAFETY IN WELDING AND CUTTING. This publication and

6. Turn off all equipment when not in use. Disconnect power to

equipment if it will be left unattended or out of service.

7. Use fully insulated electrode holders. Never dip holder in water

to cool it or lay it down on the ground or the work surface.Donot

touch holders connected to two welding machines at the same

time or touch other people with the holder or electrode.

8. Do notuse worn, damaged,undersized,or poorlysplicedcables.

9. Do not wrap cables around your body.

10. Ground the workpiece to a good electrical (earth) ground.

11. Do not touch electrode while in contact with the work (ground)

circuit.

12. Useonlywell-maintained equipment.Repair orreplacedamaged

parts at once.

13. In confined spaces or damp locations, do not use a welder with

AC output unless it is equipped with a voltage reducer. Use

equipment with DC output.

14. Wear a safety harness to prevent falling if working above floor

level.

15. Keep all panels and covers securely in place.

ARC RAYS can burn eyes and skin;

NOISE can damage hearing.

Arc rays from the welding process produce intense

heat and strong ultraviolet rays that can burn eyes

and skin. Noise from some processes can damage

hearing.

Eye protection filter shade selector for welding or cutting (goggles or helmet), from AWS A6.2-73.

Welding or Cutting

Operation

Torch soldering

Torch brazing

Oxygen cutting

Light

Medium

Heavy

Gas welding

Light

Medium

Heavy

Shielded metal-arc welding

(stick) electrodes

Electrode Size

Metal Thickness

or Welding Current

—

—

Under 1 in., 25 mm

1 to 6 in., 25-150 mm

Over 6 in., 150 mm

Under 1/8 in., 3 mm

1/8 to 1/2 in., 3-12 mm

Over 1/2 in., 12 mm

Under 5/32 in., 4 mm

5/32 to 1/4 in., 4 to 6.4 mm

Over 1/4 in., 6.4 mm

Filter

Shade

No.

2

3or4

3or4

4or5

5or6

4or5

5or6

6or8

10

12

14

1. Wear a welding helmet fitted with a proper shade of filter (see

ANSI Z49.1 listed in Safety Standards) to protect your face and

eyes when welding or watching.

2. Wear approved safety glasses. Side shields recommended.

3. Use protective screens or barriers to protect others from flash

and glare; warn others not to watch the arc.

4. Wear protective clothing made from durable, flame-resistant

material (wool and leather) and foot protection.

5. Use approved ear plugs or ear muffs if noise level is high.

Welding or Cutting

Operation

Gas metal-arc welding (MIG)

Non-ferrous base metal

Ferrous base metal

Gastungstenarcwelding (TIG)

Atomic hydrogen welding

Carbon arc welding

Plasma arc welding

Carbon arc air gouging

Light

Heavy

Plasma arc cutting

Light

Medium

Heavy

Electrode Size

Metal Thickness

or Welding Current

All

All

All

All

All

All

Under 300 Amp

300 to 400 Amp

Over 400 Amp

May 8, 1996 2-1

Filter

Shade

No.

11

12

12

12

12

12

12

14

9

12

14

ARC WELDING SAFETY INSTRUCTIONS AND WARNINGS

Instruction 830001

FUMES AND GASES can be hazardous

to your health.

Weldingproducesfumesandgases.Breathingthese

fumes and gases can be hazardous to your health.

1. Keep your head out of the fumes. Do not breath the fumes.

2. If inside, ventilate the area and/or use exhaust at the arc to

remove welding fumes and gases.

3. If ventilation is poor, use an approved air-supplied respirator.

WELDING can cause fire or explosion.

Sparks and spatter fly off from the welding arc. The

flying sparks and hot metal, weld spatter, hot workpiece, and hot equipment cancausefiresand burns.

Accidental contact of electrode or welding wire to

metal objects can cause sparks, overheating, or fire.

1. Protect yourself and others from flying sparks and hot metal.

2. Do not weld where flying sparks can strike flammable material.

3. Remove all flammables within 35 ft (10.7 m) of the welding arc.

If this is not possible, tightly cover them with approved covers.

4. Be alert that welding sparks and hot materials from welding can

easily go through small cracks and openings to adjacent areas.

4. Read the Material Safety Data Sheets (MSDSs) and the manufacturer’s instruction for metals, consumables, coatings, and

cleaners.

5. Work in a confined space only if it is well ventilated, or while

wearing an air-supplied respirator. Shielding gases used for

welding can displace air causing injury or death. Be sure the

breathing air is safe.

6. Do not weld in locations near degreasing, cleaning, or spraying

operations. The heat and raysofthearccanreactwithvapors to

form highly toxic and irritating gases.

7. Do not weld on coated metals, such as galvanized, lead, or

cadmium plated steel, unless the coating is removed from the

weld area, the area is well ventilated, and if necessary, while

wearing an air-supplied respirator. The coatings and any metals

containing these elements can give off toxic fumes if welded.

5. Watch for fire, and keep a fire extinguisher nearby.

6. Be aware that welding on a ceiling, floor, bulkhead, or partition

can cause fire on the hidden side.

7. Do not weld on closed containers such as tanks or drums.

8. Connect work cable to the work as close to the welding area as

practical to prevent welding current from traveling long, possibly

unknown paths and causing electric shock and fire hazards.

9. Do not use welder to thaw frozen pipes.

10. Remove stick electrode from holder or cut off welding wire at

contact tip when not in use.

11. Wear oil-free protective garments such as leather gloves, heavy

shirt, cuffless trousers, high shoes, and a cap.

FLYING SPARKS AND HOT METAL can

cause injury.

Chipping and grinding cause flying metal. As welds

cool, they can throw off slag.

CYLINDERS can explode if damaged.

Shielding gas cylinderscontaingasunderhighpressure. If damaged, a cylinder can explode. Since gas

cylinders are normally part of the welding process,

be sure to treat them carefully.

1. Protectcompressed gascylindersfromexcessiveheat,mechanical shocks, and arcs.

2. Install and secure cylinders in an upright position by chaining

themtoastationarysupportorequipment cylinderracktoprevent

falling or tipping.

ENGINE EXHAUST GASES can kill.

Engines produce harmful exhaust gases.

1. Wear approved face shield or safety goggles. Side shields recommended.

2. Wear proper body protection to protect skin.

3. Keep cylindersawayfrom any welding orotherelectrical circuits.

4. Never allow a welding electrode to touch any cylinder.

5. Use only correct shielding gas cylinders, regulators, hoses, and

fittings designed for the specific application; maintain them and

associated parts in good condition.

6. Turn face away from valve outlet when opening cylinder valve.

7. Keep protective cap in place over valve except when cylinder is

in use or connected for use.

8. Read and follow instructionsoncompressedgas cylinders, associated equipment, and CGA publication P-1 listed in Safety

Standards.

ENGINES can be hazardous.

1. Use equipment outside in open, well-ventilated areas.

2. If used in a closed area, vent engine exhaust outside and away

from any building air intakes.

2-2 May 8, 1996

ARC WELDING SAFETY INSTRUCTIONS AND WARNINGS

Instruction 830001

ENGINE FUEL can cause fire or

explosion.

Engine fuel is highly flammable.

1. Stop engine before checking or adding fuel.

MOVING PARTS can cause injury.

Moving parts,suchasfans, rotors, and belts cancut

fingers and hands and catch loose clothing.

1. Keep all doors, panels, covers, and guards closed and securely

in place.

2. Stop engine before installing or connecting unit.

SPARKS can cause BATTERY GASES

TO EXPLODE; BATTERY ACID can

burn eyes and skin.

Batteriescontain acidandgenerateexplosivegases.

STEAM AND PRESSURIZED HOT

COOLANT can burn face, eyes, and

skin.

The coolantinthe radiator can beveryhot and under

pressure.

WARNING: This product, when used for welding or cutting, produces fumes or gases which contain chemicals known to the State

of California to cause birth defects and, in some cases, cancer. (California Health & Safety Code Sec. 25249.5 et seq.)

NOTE: Considerations About Welding And The Effects Of Low Frequency Electric And Magnetic Fields

The following is a quotation from the General Conclusions Section of the U.S. Congress, Office of Technology Assessment,

of Power Frequency Electric& Magnetic Fields — Background Paper, OTA-BP-E-63 (Washington, DC: U.S. Government Printing Office, May

1989): “... there is now a very large volume of scientific findings based on experiments at the cellular level and from studies with animals and

people which clearly establish that low frequency magnetic fields can interact with, and produce changes in, biological systems. While most of

this work is of very high quality, the results are complex. Current scientific understanding does not yet allow us to interpret the evidence in a

single coherent framework. Even more frustrating, it does not yet allow us to draw definite conclusions about questions of possible risk or to

offer clear science-based advice on strategies to minimize or avoid potential risks.”

To reduce magnetic fields in the workplace, use the following procedures:

1. Keep cables close together by twisting or taping them.

2. Arrange cables to one side and away from the operator.

2. Do not addfuelwhile smokingorif unitisnear anysparksor open

flames.

3. Allow engine to cool before fueling. If possible, check and add

fuel to cold engine before beginning job.

4. Do not overfill tank — allow room for fuel to expand.

5. Do not spillfuel.Iffuelisspilled,clean up before starting engine.

3. Have only qualified people remove guards or covers for mainte-

nance and troubleshooting as necessary.

4. To prevent accidentalstartingduring servicing, disconnectnega-

tive (-) battery cable from battery.

5. Keep hands, hair, loose clothing, and tools away from moving

parts.

6. Reinstall panels or guards and close doors when servicing is

finished and before starting engine.

1. Always wear a face shield when working on a battery.

2. Stop engine before disconnecting or connecting battery cables.

3. Do not allow tools to cause sparks when working on a battery.

4. Do not use welder to charge batteries or jump start vehicles.

5. Observe correct polarity (+ and –) on batteries.

1. Do not remove radiator cap when engine is hot. Allow engine to

cool.

2. Wear gloves and put a rag over cap area when removing cap.

3. Allow pressure to escape before completely removing cap.

Biological Effects

3. Do not coil or drape cables around the body.

4. Keep welding power source and cables as far away from body as

practical.

About Pacemakers:

The above procedures are among those also normally recommended for pacemaker wearers. Consult your doctor for complete information.

PRINCIPAL SAFETY STANDARDS

Safety inWeldingandCutting,ANSI Standard Z49.1, from American

Welding Society, 550 N.W. LeJeune Rd., Miami, FL 33126.

SafetyandHealthStandards, OSHA 29 CFR1910,fromSuperintendent of Documents, U.S. Government Printing Office, Washington,

D.C. 20402.

Recommended Safe Practices for the Preparation for Welding and

CuttingofContainersThatHaveHeldHazardousSubstances,American Welding Society Standard AWS F4.1, from American Welding

Society, 550 N.W. LeJeune Rd., Miami, FL 33126.

National Electrical Code, NFPA Standard 70, from National Fire

Protection Association, Batterymarch Park, Quincy, MA 02269.

Safe Handling of Compressed Gases in Cylinders, CGA Pamphlet

P-1, from Compressed Gas Association, 1235 Jefferson DavisHighway, Suite 501, Arlington, VA 22202.

Code forSafetyin Welding and Cutting,CSAStandard W117.2, from

Canadian Standards Association, Standards Sales, 178 Rexdale

Boulevard, Rexdale, Ontario, Canada M9W 1R3.

Safe Practices for Occupation and Educational Eye and Face Protection, ANSI Standard Z87.1, from American National Standards

Institute, 1430 Broadway, New York, NY 10018.

Cutting and Welding Processes, NFPA Standard 51B, from National

Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

May 8, 1996 2-3

ARC WELDING SAFETY INSTRUCTIONS AND WARNINGS

Instruction 830001

This page intentionally left blank.

2-4 May 8, 1996

430429-080

INSTALLATION INSTRUCTIONS

for

ENGINE PROTECTION

SHUTDOWN KIT

494170-1, -3

See back of this manual prior to starting installation for information for Optional Linkage Setup.

The following instructions are for the installation of this engine protection shutdown kit on either a 3- or

4-cylinder Perkins diesel engine. These engines are used by Thermal Arc on Model MA-4030D, MA-4535D,

or MA-5040D welders.

READ THESE INSTRUCTIONS THOROUGHLY BEFORE BEGINNING

INSTALLATION.

Figure 1 Fuel Control System As Standard On Engine

1. Remove cable support bracket (1) from injection pump (2).

2. Remove throttlecable (3) fromfuel shutoff (5)and speed controlarms (6). Retain cable stops (4) for later

use.

3. Remove tension springs from fuel shutoff (5) and speed control arms (6); discard.

4. Remove fuel shutoff arm (5) from injection pump. Retain nut and lockwasher (7).

March 13, 2000 Revised Page 1

430429-080

5. Remove pivot (8) from fuel shutoff arm and attach arm to the fuel shutoff linkage (pulley) supplied in kit.

Mount using the same hardware that attached the pivot to the arm. Align the pulley center hole and arm slot.

Put the screw into the short side of the arm. The arm should be parallel to the face of the pulley (see Figure

2).

Figure 2

6. Test fit fuel shutoff pulley on the shutoff valve to be sure it seats properly on the valve shaft shoulders.

The flat part of thepulley should face away from theengine fan. (Ifit does not seat properly, the shutoff valve

will not function correctly.)

7. On models MA-4030D and MA-4535D (3-cylinder engine), the fuel line may need to be removed from

the filter at the fan end of the injection pump in order to complete Steps 8 to 12. (See Note, Step 13.) On

some older 3-cylinder engines, itmay be necessary touse a file to remove awebof material located between

the stop post and the shutoff valve post. File web down until it is flush with pump body. Refer to Figure 3.

8. Place torsion spring supplied in kit over shutoff valve post withstraight leg down and positionedbetween

the valve post and the stop post.

9.With flat part of pulley facing away from the

engine fan, place the pulley onto the shutoff

valve screw and insert onto valve shaft shoulder. Be sure the pulley seats properly as it did

in Step 6.

10. Replace nut and lockwasher and secure

on valve screw.

11. Rotate torsion spring counterclockwise

untiltheverticalarm of the spring locks into the

large hole in the end of the fuel shutoff arm.

12. Check pulley operation.Ifthe pulley does

notreturn when rotated andreleased, then the

pulley and/or spring may not beinstalledproperly. Recheck assembly positioning. (Refer to

Figure 3 for installation sequence.)

13. Reinstall fuel line removed in Step 7.

Assure clearance between pulley and fuel line

after installation. Fuel line may require some

slight reforming. (Disregard this step for MA-

Figure 3

Page 2 March 13, 2000 Revised

5040D.)

430429-080

NOTE: If fuel lines are removed, bleeding of fuel system may be required after reinstallation.

14. Remove speed control arm (6). Retain nut and lockwasher (9).

15. Remove pivot (10) from speed control arm. Retain lock and flat washer; discard screw.

16. Put small pivot (supplied) in place on the bottom side of the speed control arm where larger pivot was

removed. Mount using pivot hardware and #6 screw in kit.

17. Remount speed control arm, using nut and lockwasher, assuring slot aligns on shoulder of shaft.

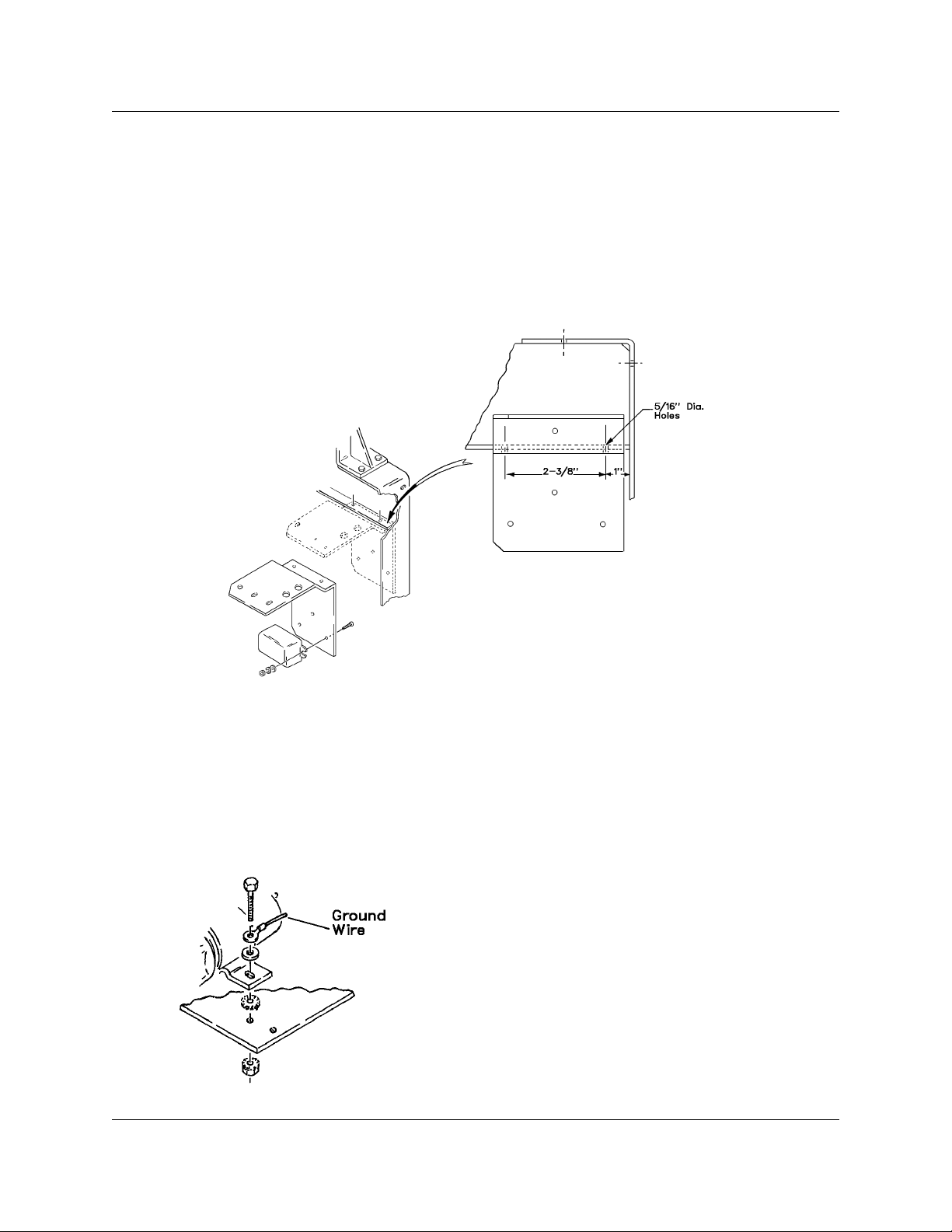

18. Using the supplied bracket as a template, drill two 5/16" diameter holes in the lifting yoke located as

shown in Figure 4. Mount the relay to the inside of this bracket using two #6 screws, flat and lockwashers,

and nuts supplied.

Figure 4

19. Attach bracket to underside of lifting yoke with 1/4-20 bolts, toothed washer, and nuts supplied. Place

toothed lockwasher under one bolt head to assure good electrical grounding.

20. Install solenoid on top side of bracket. Adjust position so that solenoid is pointing towards fuel shutoff

pulley. Secure with 1/4-20 screws, toothed washer and nuts supplied. Place one toothed washer between

bracket and solenoid base to assure good electrical grounding. (Refer to Figure 5).

21. Attach tension spring supplied in kit to solenoid plunger

using two 1/4-28 nuts supplied. Center spring on screw.

22. Making sure cable lays in groove of pulley, connect cable

from shutoff pulley to tension spring, slipping loop over hook of

spring. Linkage length adjustment may be required. Small adjustment for fine tuning can be accomplished by adjusting the

nuts on the solenoid plunger.

Larger length adjustments will be required on the MA-4030D

and MA-4535D, and can be made by adjusting the cable length

prior to installing. Loosen the nuts on the clamp holdingthe loop

in the cable and pull more cable through — approximate length

Figure 5

from flat pulley face to end of cable loop is 6 inches.

March 13, 2000 Revised Page 3

430429-080

Figure 6

23. Adjust so that cable is tight without flexingthe tension spring when solenoid plunger isextended. When

properly adjusted, the tension spring should flex approximately 1/8 inch when plunger is fully compressed.

Cut off excess cable length.

24. Remove throttle cable from old bracket. Retain clamp (11); discard bracket.

25. Place one cable stop (removed earlier) on throttle cable.

26. Thread cable through hole in small pivot on the speed control arm.

27. Place second cable stop (removed earlier) onto cable. Adjust cable stops so the valve can be fully

pushed open and closed. Cut off any excess cable length. (Refer to Figure 7 for proper installation.)

28. Install clamp from throttle cable on bottom side of new bracket in small hole in front (beside solenoid

mounting holes) using #10 screw and nut (supplied) and secure throttle cable in place.

29. Drain approximately 4 to 6 quarts of coolant

from radiator. This may be done from the drain

cock on the engine block on the right-hand side

while facing thecontrol panel. Funnelcoolant into

a container and save for reuse.

NOTE: The kit is supplied with two temperature switches. The finer thread one

(3/8) is for the 3-cylinder engine. The

coarser thread one (1/2) is for the 4-cylinder engine.

30. On the 3-152 engine (Model MA-4030D or

MA-4535D), remove the 3/8 pipe plug located on

the left side of the water pump (when facing front

of engine) and install the water temperature

switch. Connect per connection diagram. Use the

#209 wire with two ring tongue terminals. Discard

the other.

31. On the 4-236 engine (Model MA-5040D),

remove the 1/2 pipe plug located on the top right

of the water pump (when facing front of engine)

and install the watertemperature switch. Connect

Figure 7

Page 4 March 13, 2000 Revised

per connection diagram. Use the #209 wire with

one quick connect terminal. Discard the other.

430429-080

32. Refill radiator with coolant drained in Step 29.

33. Remove the 1/4- and 3/8-inch hole plugs located in the lower right-hand corner of the control panel.

Mount the “Murphy” magnetic switch to the control panel using the nut supplied with the switch.

34. Attach fuseholder to bracket (hole closest to lifting yoke).

35. Install new “Operation and Maintenance” label over existing label located on inside surface of left-hand

door. Wire the engine protection shutdown system per Connection Diagram, using the wires and wire ties

supplied in kit.

36. Referring to the Owner’s Manual connection diagram, disconnect #25 black wire from the alternator

light and connect the proper end of diode assembly 490597-2 (the one with quick-connect receptacles on

each end) to the light and the other end to #25 black wire, using the terminal coupler supplied. Be sure that

you do

the right direction as indicated by the Connection Diagram.

hose to fuel lines with wire tie if necessary.

not disconnect the resistor on the alternator light (if so equipped) and that the diode is connected in

37. Attach diode assembly (with ring terminals) to the solenoid.See Connection Diagram for orientation.

38. Ground wire attaches to solenoid mounting screw as shown in Figure 5.

39. Assure that PCV hose is clear from cable linkage during operation (4-cylinder engine). Tie down PCV

March 13, 2000 Revised Page 5

430429-080

Figure 8 Engine Protection Shutdown Device Kit

494170-1 (Properly Installed)

Page 6 March 13, 2000 Revised

430429-080

Parts List for Figure 9

Quantity

Item Part per Application

No. No. Description Assembly Code

494170-1 . Kit - Engine Protection 1 A

494170-3 . Kit - Engine Protection 1 B

1 493799 . Solenoid - 20 Lb. Pull 1 All

2 493804 . Bracket - Mounting 1 A

493804-1 . Bracket - Mounting 1 B

3 402658 . Fuseholder 1 All

4 16DA-4252-6 . Fuse - 8 Amp, MDL, Slow Blow 4 All

5 400562-46 . Spring - Torsion 1 All

6 493814 . Linkage - Fuel Shutoff 1 All

7 400562-45 . Spring - Tension 1 All

8 W-11280-3 . Nut - 1/4-28, Hex, ST. (For Sol. Plunger) 2 All

9 402119-6 . Screw - 1/4-20 x 1, HHCS, ST. 4 All

10 50MS-732-0 . Nut - 1/4-20, Hex, Keps, ST. 4 All

11 403091-2 . Plug - Hole, Plastic (Optional Use) 1 All

12 W-11112-1 . Screw - #10-24 x 1/2, Rd. Hd. ST. 1 All

13 50MS-732-5 . Nut - #10-24, Hex, Keps, ST. 1 All

14 490597-1 . Diode - Assembly 1 All

— 406224 . Switch - Water Temp. (Mts. On 3-Cylinder

Engine) 1 All

— 494169 . Switch - Water Temp. (Mts. On 4-Cylinder

Engine) 1 All

15 404473 . Switch - Magnetic 1 All

— 493825 . Label - Maintenance (Mts. Inside Door) 1 All

16 493816 . Pivot - Throttle 1 All

17 490597-2 . Diode - Assembly 1 All

18 400778 . Terminal - Coupler, Ins. 1 All

19 W-11242-5 . Washer - 1/4, FL, ST. 2 All

20 W-11263-4 . Washer - LK, IET, 1/4 2 All

21 W-11110-1 . Screw - #6-32 x 1/4, Rd. Hd. ST. 1 All

22 403056-8 . Relay - 12 V DC 1 All

23 W-11110-4 . Screw - #6-32 x 1/2 Rd. Hd. ST. 2 All

24 W-11254-1 . Washer - #6, LK, ST. 2 All

25 W-11245-2 . Washer - #6, FL, Brs. 2 All

26 W-11287-2 . Nut - #6-32, Hex, SCR, ST. 2 All

— W-11287-9 . Nut - #8-36, UNF 1 All

— Not Illustrated

March 13, 2000 Revised Page 7

430429-080

INSTALLATION OF THE ENGINE PROTECTION SHUTDOWN KIT WHEN

THE IDLE DEVICE KIT (493820) IS ALREADY INSTALLED

These instructions are for the installation of a engine protection shutdown kit (494170-1) on either a 3- or

4-cylinder Perkins diesel engine when an automatic idle kit (493820) is already installed.

Figure 9 Engine Protection Shutdown

and Idle Device Kit (Properly Installed)

1. Remove cable support bracket and throttle cable from injection pump and fuel shutoff arm.

2.Remove throttle cable and “FuelShutoff”label from control panel. Discard thethrottlecable and the cable

support bracket. Install plastic hole plug supplied in hole in control panel.

3. Refer to ENGINE PROTECTION SHUTDOWN KIT, Steps 4 through 13. Install relays “back to back” on

bracket.

4. Install solenoidon top side of bracket. Adjust the position so that the solenoid is pointing towards the fuel

shutoff pulley. Attach using the hardware holding the speed control solenoid in place. Ground leads and

hardware to be attached per Figure 9, View A.

5. Refer to ENGINE PROTECTION SHUTDOWN KIT, Steps 21 through 23.

6. Refer to ENGINE PROTECTION SHUTDOWN KIT, Steps 29 through 39. (Additional fuseholder mounts

in available hole next to speed control solenoid fuseholder.)

Page 8 March 13, 2000 Revised

430429-080

OPTIONAL ENGINE PROTECTION LINKAGE FOR 3.152 PERKINS ENGINES

These instructions need to be followed when installing the optional rigid linkage specifically designed for

the Perkins 3.152 powered units only (Mega-Arc 4030D or the Mega-Arc 4535D). This linkageis optional for

use,and may provide an easierinstallationthanthe standard flexible linkage also includedwiththis kit. Either

linkage will give adequate service and the choiceof which to use is up to theinstaller. In either case, the rigid

linkage assembly will work only with the 3.152 engines and if installing a kit on a 4.236 engine (Mega-Arc

5040D) you must use the flexible cable linkage.

Follow the directions in the original instruction sheet, Steps 1 through 4, disregard Steps 5 through 13,

perform Steps 14 through 21, then use the following addendum instructions and photo to properly install the

rigid linkage parts.

1/4 HEX SCREW

FLAT WASHER

KEPS LOCK NUT

LOWER

LINKAGE

COTTER PIN

#8 HEX SCREW

LOCK WASHER

BRASS FLAT WASHER

UPPER

LINKAGE

Remount fuel shutoff arm removed in Step4 (from original instructions), using nut and lockwasher . Assure

the slot of the arm is aligned with the shoulder of the shaft. Attach upper linkage (with formed offset) from

this kit to the free end of the tension spring on solenoid. Spring should lie on top of the linkage and a flat

washer should beplaced against theloop end of spring.Assemble with 1/4-20x 1/2 screw and with the Keps

lock nut against flat washer.

Place lower linkage pivot pin into hole on the speed control arm. Assemble two halves of linkage using hex

head #8 screws, lockwashers, and brass flat washers. Lower linkage should be below the upper linkage.

Screwsshouldpositionapproximatelyhalfwayinthelengthofslotforinitialsetting. Secure pivot pintocontrol

arm placing 3/64-diameter cotter pin into hole in pivot. Bend cotter pin around pivot to assure clearance of

other components.

To fine tune linkage length, fully compress solenoid plunger, making sure the plunger is bottomed in the

solenoid. Adjust linkage lengthusing the #8 hexscrews or the 1/4nuts on the solenoidplunger shaft, or both.

Length is correct when the fuel shutdown arm is against the stop closest to the solenoid and the tension

spring is stretched 1/16 to 1/8 inch with the solenoidplunger bottomed out. Tighten fully the #8 hex screw to

assure linkage length won’t change as solenoid cycles.

Disregard Steps 22 and 23, and then continue with Step 24 through the end to finish installation

March 13, 2000 Revised Page 9

430429-080

PARTS LIST FOR OPTIONAL ENGINE PROTECTION LINKAGE KIT

Item Part Description Qty Application

No Number per Code

Assy

1 50MS-732-1 NUT, 1/4 -20, HEX, KEPS 1 All

2 W-11242-5 WASHER, 1/4, FLAT, STEEL 1 All

3 W-11254-2 WASHER, #8, LOCK, STD 2 All

4 W-11245-15 WASHER, #8, FLAT, BRASS 2 All

5 402812-2 SCREW, #8-32 X 3/8, HEX, STEEL 2 All

6 402119-2 SCREW, 1/4-20 X 1/2, HEX, STEEL 1 All

7 800081-1 PIN, COTTER, 3/64 1 All

8 800079 LINKAGE, UPPER 1 All

9 800080 LINKAGE, LOWER 1 All

Page 10 March 13, 2000 Revised

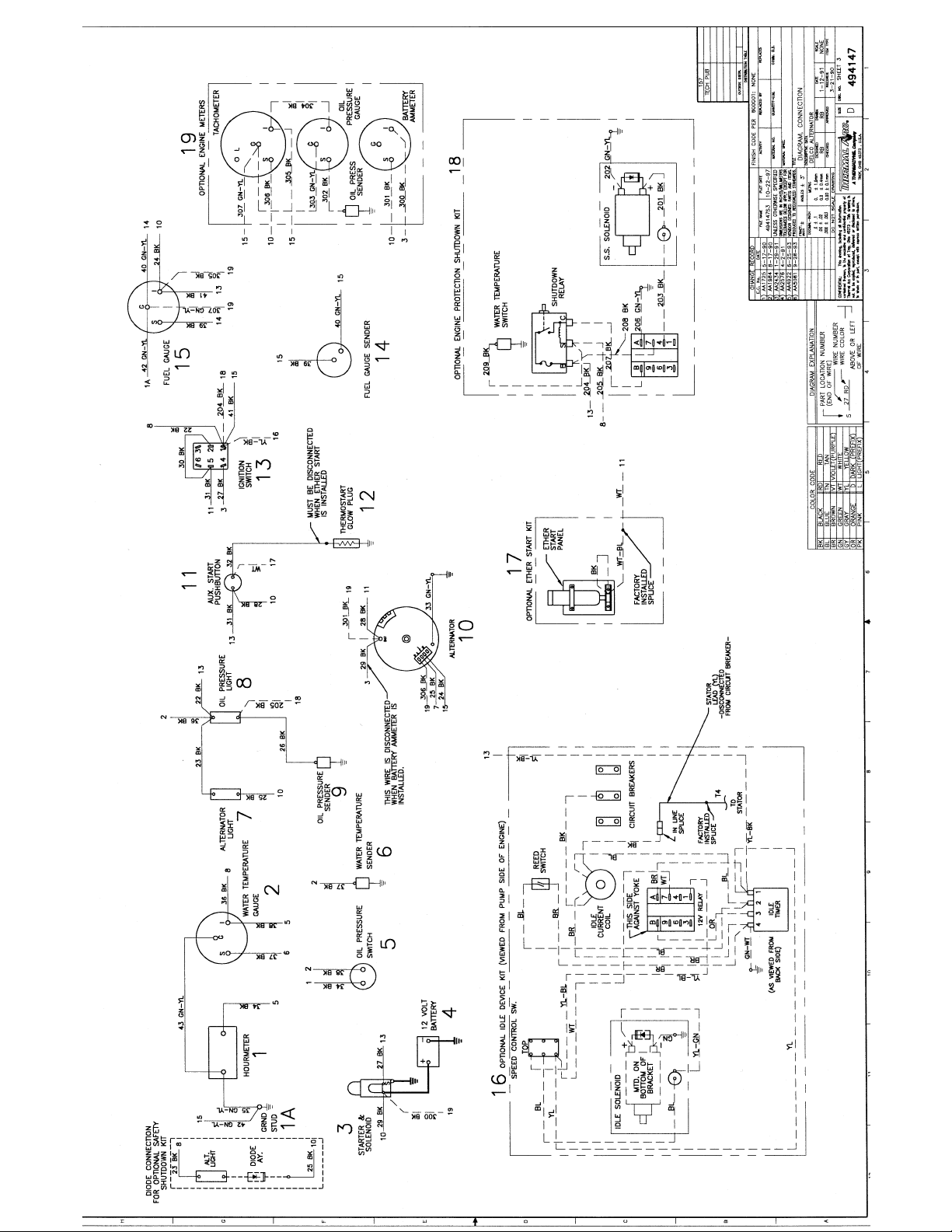

DIAGRAMS

430429-080

INSTRUCTION

SHEET

494170-1

494170-3

UNIT

SPEC MODEL

S-6298C MA-4030D 494148

S-6495A MA-4535D

S-6429B MA-5040D 494147

S-6298D MA-4030D 494148

S-6495A MA-4535D

S-6429C MA-5040D 494147

S-6298E MA-4030D 800045

CONNECTION

DIAGRAM

Sheet 3

494148A

Sheet 3

Sheet 3

Sheet 3

494148A

Sheet 3

Sheet 3

Sheet 3

March 13, 2000 Revised

S-6429D MA-5040D 800044Sheet 3

STATEMENT OF WARRANTY

LIMITED WARRANTY:ThermalArc®, Inc., AThermadyneCompany,warrantsthat its products will be free ofdefectsinworkmanship

ormaterial.Should any failuretoconform to this warrantyappear within the timeperiodapplicable to theThermalArcproducts as stated

below, Thermal Arc shall, upon notification thereof and substantiation that the product has been stored, installed, operated, and

maintained in accordancewithThermal Arc’s specifications,instructions,recommendations and recognized standard industry practice,

and not subject to misuse, repair, neglect, alteration, or accident, correct such defects by suitable repair or replacement, at Thermal

Arc’s sole option, of any components or parts of the product determined by Thermal Arc to be defective.

THERMAL ARC MAKES NO OTHER WARRANTY, EXPRESS OR IMPLIED. THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF

ALL OTHERS, INCLUDING, BUT NOT LIMITED TO ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY

PARTICULAR PURPOSE.

LIMITATION OF LIABILITY: Thermal Arc shall not under any circumstancesbe liable for special or consequential damages, such as,

but not limited to, damage or loss of purchased or replacement goods, or claims of customers of distributor (hereinafter “Purchaser”)

for service interruption.TheremediesofthePurchaserset forth herein are exclusive and the liability of Thermal Arc with respect to any

contract, or anything done in connection therewith such as the performance or breach thereof, or from the manufacture, sale, delivery,

resale, or use of any goods covered by or furnished by Thermal Arc whether arising out of contract, negligence, strike tort, or under

any warranty, or otherwise, shall not, except as expressly provided herein, exceed the price of the goods upon which such liability is

based. No employee, agent, or representative of Thermal Arc is authorized to change this warranty in any way or grant any other

warranty.

PURCHASER’SRIGHTS UNDERTHISWARRANTYAREVOID IFREPLACEMENT PARTSOR ACCESSORIESARE USEDWHICH

IN THERMAL ARC’S SOLE JUDGMENT MAY IMPAIR THE SAFETY OR PERFORMANCE OF ANY THERMAL ARC PRODUCT.

PURCHASER’S RIGHTS UNDER THIS WARRANTY ARE VOID IF THE PRODUCT IS SOLD TO PURCHASER BY

NON-AUTHORIZED PERSONS.

Except with regards to the products listed below, this warranty shall remain effective three (3) years from the date Thermal Arc’s

authorized distributor delivers the product to Purchaser, but in no event more than (4) years from the date Thermal Arc delivers the

product to the authorized distributor.

Shorter warranty periods apply to the products listed below. On these products, the warranty is effective for the time stated below

beginning on the date that the authorized distributor delivers the products to the Purchaser. Notwithstanding the foregoing, in no event

shall the warranty period extend more than the time stated plus one year from the date Thermal Arc delivered the product to the

authorized distributor.

ALL OTHER P-WEE, PRO-LITE

POWER SUPPLIES POWER SUPPLIES PRO-PLUS, PRO-WAVE LABOR

MAIN POWER MAGNETICS (STATIC & ROTATING) 3 YEARS 2 YEARS 1 YEAR

ORIGINAL MAIN POWER RECTIFIER 3 YEARS 2 YEARS 1 YEAR

CONTROL PC BOARD 3 YEARS 2 YEARS 1 YEAR

ALLOTHERCIRCUITSANDCOMPONENTSINCLUDING 1 YEAR 1 YEAR 1 YEAR

BUT NOT LIMITED TO, CONTACTORS, RELAYS,

SOLENOID, PUMPS, POWER SWITCHING SEMI-CONDUCTORS

ENGINES: ENGINES ARE NOT WARRANTED BY THERMAL ARC, ALTHOUGH MOST ARE WARRANTED BY THE ENGINE

MANUFACTURER. SEE THE ENGINE MANUFACTURES WARRANTY FOR DETAILS

CONSOLES, CONTROL EQUIPMENT, HEAT 1 YEAR 1 YEAR 1 YEAR

EXCHANGES, AND ACCESSORY EQUIPMENT

TORCH AND LEADS 180 DAYS 180 DAYS 180 DAYS

REPAIR/REPLACEMENT PARTS 90 DAYS 90 DAYS 90 DAYS

Warranty repairsorreplacementclaimsunder this limited warranty mustbesubmittedto Thermal Arc by anauthorizedThermalArc®repair

facility within thirty (30) days of the repair. No transportation costs of any kind will be paid under this warranty. Transportation charges to

sendproductsto anauthorizedwarranty repairfacility shallbe the responsibilityof thecustomer.All returnedgoodsshall beatthe customer’s

risk and expense. This warranty supersedes all previous Thermal Arc warranties.

.

Thermal Arc®is a Registered Trademark of Thermadyne Industries Inc.

Thermal Arc Inc. Effective January 4, 1999

Troy, Ohio 45373 830538

Loading...

Loading...