THERMADOR GAS COOKTOPS LP GAS CONVERSION KIT

SNLPKITF

LP GAS CONVERSION KIT

ENSEMBLE DE CONVERSION AU GAZ PL

KIT DE CONVERSIÓN DE GAS LP

Table of Contents..........................1

Models/Modèles/Modelos:

SGS

SGSL

SGSX

Table des matières ......................9

Índice ......................................... 17

Table of Contents

Questions?

1-800-735-4328

www.thermador.com

We look forward to hearing from you!

This Thermador Appliance is made by

BSH Home Appliances Corporation

1901 Main Street, Suite 600

Irvine, CA 92614

Safety .............................................................2

Pipe System Testing Requirements ......................2

Preparation ....................................................3

Installation Procedure ..................................3

Checklist ..........................................................3

Step 1 - Convert the Pressure Regulator .........3

Step 2 - Replace the Orifices and Venturis ......4

Step 3 - Convert Valves for LP Gas .................6

Test the Installation ......................................6

Test for Gas Leaks ................................................6

Check Manifold Gas Pressure ...............................6

Final Check ............................................................7

Service ...........................................................7

Before Calling Service .....................................7

BTU Ratings ..................................................8

THERMADOR® Support..............................25

Safety

Safety

IMPORTANT SAFETY INSTRUCTIONS

Read and save these instructions.

Please read these instructions in their entirety before

proceeding. It is important to save the p arts removed dur ing

the conversion process in case the appliance is later to be

converted back to using natural gas.

WARNING

This conversion kit shall be installed by a qualified

service agency in accordance with the

manufacturer’s instructions and all applicable codes

and requirements of the authority having jurisdiction.

If the information in these instructions is not followed

exactly, a fire, explosion or production of carbon

monoxide may result causing property damage,

personal injury or loss of life. The qualified service

agency is responsible for the proper installation of

this kit. The installation is not proper and complete

until the operation of the converted appliance is

checked as specified in the manufacturer’s

instructions supplied with the kit.

CAUTION

Pipe System Testing Requirements

The following requirements must be met when testing the

supply piping system:

a) The appliance and its individual shut-off valve must be

disconnected from the gas supply piping system at test

pressures in excess of 1/2 psig (3.5 kPa).

b) The appliance must be isolated from the gas supply

piping system by closing its individual manual shut-off

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than 1/2

psig (3.5 kPa).

IMPORTANT - Only a qualified service technician or

installer should make this conversion.

INST ALLER: Please leave these Installation Instructions

with this unit for the owner.

OWNER: Please retain these instructions for future

reference.

This kit is used to convert SGS, SGLS and SGSX Series

sealed ST AR burner cooktop s from natural gas oper ation to

propane (LP) gas operation. This kit cannot be used to

convert other Thermador Models or Series cooktops,

ranges or any other brand of gas appliances.

A pressure regulator is supplied with the cooktop.

Install this regulator to the cooktop. Also, make

certain the propane tank is equipped with its own

high pressure regulator . The maximum gas pre ssure

to this appliance is not to exceed 14" of water

column (3.5 kPA) from the propane tank regulator.

The minimum gas pressure to this appliance is not

to be less than 11" of water column (2.75 kPA).

For Massachusetts Installations:

1. Installation must be performed by a qualified or

licensed contractor, plumber, or gas fitter qualified or

licensed by the state, province, or region.

2. Shut-off valve must be a “T” handle gas cock.

3. Flexible gas connector must not be longer than 36’’

(91.5 cm).

2

Preparation

Qty Item

1 Installation Manual

1 Label sticker - “Unit Converted for Use with LP Gas’’

1 Foam Tape

Venturis

29mm

1 10.5 mm

2 12.5 mm

Orifices

2#74

2#91

1#117

Depending on the model (some are 4 burner models,

some are 5 burner) the kit may conta in more ven turis and

orifices than are necessary to complete your appliance

conversion.

7mm socket driver

(3” min. extension)

20mm socket

(and driver or ratchet)

flat blade screwdriver

Prep aration

CAUTION

TURN OFF GAS AND ELECTRICITY.

Before proceeding with the conversion, 1) shut off

the gas valve for the gas supply line to the cooktop,

2) remove the cooktop power cord from the

electrical outlet or turn off the breaker a t the b reaker

box, and 3) turn all control knobs to the “Off”position.

Installation Kit Contents

Inst allation Procedure

This conversion process adjusts the flow of gas to the

burners to accommodate an LP gas fuel source.

Checklist

Each of the following steps must be completed

correctly for the appliance to function properly.

Check off each step as it is finished.

__ Step 1 - Convert the pressure regulator to use LP gas.

__ Step 2 - Remove the Natural Gas (NG) venturis and

orifices and replace them with the LP gas venturis and

orifices supplied with this kit.

__ Step 3 - Adjust the unit valves to LP settings.

Step 1 - Convert the Pressure Regulator

Locate the pressure regulator on the bottom right end of

the cooktop.

Note: The arrow on the back of the regulator must

point in the direction of the gas flow to the

cooktop.

Tools Required

.

3

Installation Procedure

spring

gasket

plastic

button stem

Natural

Gas

LP

Gas

bottom of cooktop

ignitor

venturi

Remove the hexagon shaped cap from the regulator

making sure not to dislodge the gasket on the cap or the

spring inside the regulator.

.

Grasp the plastic button stem (stem) firmly and pull it

forcefully from the metal cap. The stem snaps snugly into

an indent in the cap and may require a strong pull to

remove.

After removing the stem from the cap, rot a te the stem 1 80°

so the button end of the stem is away from the cap and the

letters “LP” on the stem are upside down when the cap is

set flat on its head. Snap the stem back in place in this

position inserting it into the indent in the metal cap.The

stem should snap into place.

Step 2 - Replace the Orifices and

Venturis

1. Remove the grates and burner caps.

2. Remove the venturis using a 20 mm socket.

3. Set the NG (natural gas) venturis aside and save for

later use if needed.

Note: Do not remove the ignitor from the unit.

4. Remove the orifices.

Note: The orifices require a 7 mm socket driver for

removal/replacement. The driver will need to be

inserted approximately 2 1/2” (64 mm) into the

burner cavity to reach the orifice.

Important - Attach the metallic sticker (included with this

conversion kit) to the bottom of the appliance as shown,

placing it near the appliance data plate (shows model

number and information about the appliance). This sticker

provides notice that the appliance has been converted for

use with LP gas

.

Hint: To reduce the chance of the orifice being dropped

from the socket driver, add a piece of foam tape or

adhesive tape inside the socket.

a) Trim a small piece of the foam tape provided with

this kit (about 1/4” x 1/2”; 6mm x 12mm).

b) Fit this so the tape wraps against one side of the

socket so it stays in place.

c) When pressing the socket driver onto the orifice,

the tape will fit to the orifice and help prevent the

orifice from falling out of the socket during

extraction.

Save the NG orifices in case there is need later to restore

the appliance to use natural gas again.

4

Installation Procedure

LP Orifices

4-Burner Models

5-Burner Models

LP Venturis

4-Burner Models

5-Burner Models

4. Identify the correct placement of the LP gas orifices as

layed out on the orifice package card.

The orifice sizes are shown in the white circles

corresponding to each burner as shown in the image

above. These numbers are engraved on the top of each

orifice. It is very important install the correct orifice size for

each burner.

5. Insert each of the LP gas orifices provided with this kit

into the socket (using the small piece of foam tape to

assure a tight fit).

a) Check to be sure the small piece of foam tape use d

earlier is fitted to wrap against one side of the

socket.

b) When pressing the socket driver onto the orifice,

the tape will help the orifice fit more snugly inside

the socket. This will help prevent the orifice from

falling out of the socket during insertion.

3. Identify the correct placement of the LP gas venturis as

layed out on the venturi package card (see image

below).

The venturi sizes are shown in the white circles

corresponding to each burner as shown in the image

above. These numbers are engraved on the top of each

venturi. It is very important install the correct venturi size for

each burner.

4. Insert each of the LP gas venturis provided with this kit.

Tighten snugly.

5

5. Replace burner caps and grates.

Test the Installation

a. Hollow Stem

b. Solid Stem

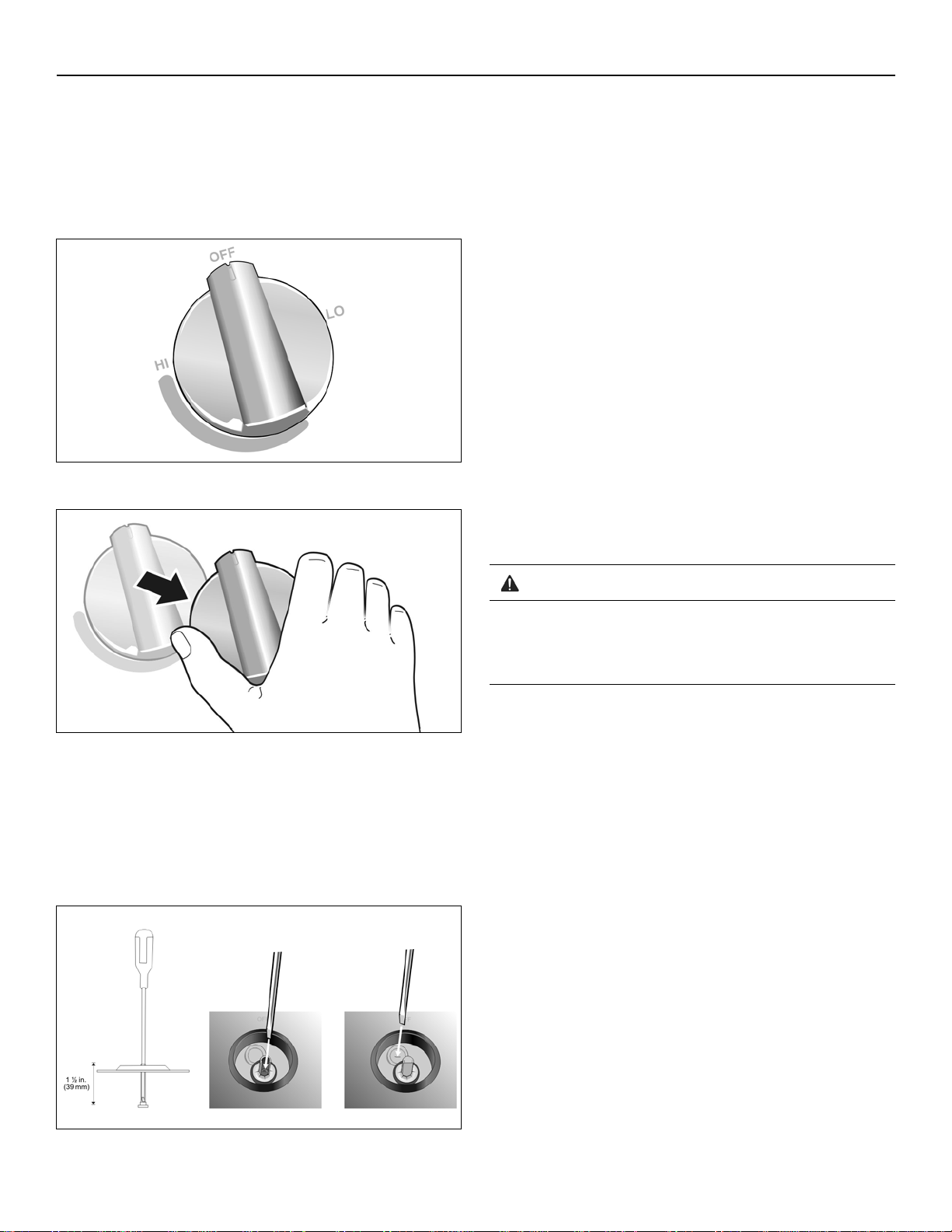

Step 3 - Convert Valves for LP Gas

The bypass jet on each valve must be adjusted. Your

cooktop may come with either hollow or solid valve shafts.

Determine the bypass screw location accordingly.

1. Turn all knobs to the “Off” position.

2. Remove knobs.

a) Hollow stem valve - insert a long, thin flat blade

screwdriver in the hollow stem of the valve. The

adjustment screw is approximately 1 1/2” (39 mm)

from the top of the stem. The screwdriver slides

through a thin rubber barrier in the stem (helps

prevent damage in the case of a spill on the unit

surface).

b) Solid stem valve - insert a long, thin flat blade

screwdriver through the seal in the area shown.

3. Engage the tip of the screwdriver into the adjustment

screw by slowly turning the screwdriver and feeling for

the blade to engage the screw . Then turn the screw

clockwise about 70 degrees (less than 1/4 turn) until it

“bottoms out” (does not turn any furthe r). The s cre w

does not take much pressure to turn. Stop when the

screw does not easily turn any further. Repeat for each

valve until all have been adjusted correctly.

4. Replace the knobs

Test the Installation

Test for Gas Leaks

Your appliance will have either a) hollow stem valves, or b)

solid stem valves. The location of the adjustment screw is

determined by which type of valve your appliance has.

3. Locate the correct point of insertion for the long, thin

flat blade screwdriver to adjust the bypass jet (see the

following illustration).

WARNING

NEVER TEST FOR GAS LEAKS USING A FLAME.

If any leaks are detected, do not proceed past this

step until all leaks have been eliminated.

Leak testing is to be conducted by the installer according to

the instructions given in this section.

Turn on gas. Apply a non-corrosive leak detection fluid to

all joints and fittings in the gas connection between the

shutoff valve and the cooktop. Include gas fittings and

joints in the cooktop if connections may have been

disturbed during installation. Bubbles appearing around

fittings and connections indicate a leak. An electronic Gas

Leak Detector can also be used.

If a leak appears, turn off the supply line gas shutoff valve

and tighten the leaking connections. Retest for leaks by

turning on the supply line gas shutoff valve. When the leak

check is complete (no bubbles appear), the test is

complete. Wipe off all detection fluid residue.

Check Manifold Gas Pressure

During any pressure testing of the gas supply piping

system at test pressures greater than 14" of water column

pressure (approximately ½" psig,

3.5 kP A

) it is necessary to

6