Page 1

For Thermador ProfessionaP PRO-GRAN DTM

Gas Ranges

Pour toutes cuisinieres a gaz Thermador Professional ®

PRO-GRAND TM

ModeLs

PG30

PG36

PG48

A= _>J=,=ic==3=, =..

Page 2

Please Read Entire Instructions

Before Proceeding

mMPORTANT:

mNSTALLER:

OWNER:

Save these instructions for the Local Gas Inspector's use.

Please leave these Installation Instructions with this unit for the owner.

Please retain these instructions for future reference.

Disconnect power before installing. Before

turning power ON, be sure that all controls

are in the OFF position.

IMPORTANT

LocaJ codes vary. Installation, gas

connections and grounding must

comply with all applicable codes.

For Massachusetts Instamaations:

,

Installation must be performed by a qualified

or licensed contractor, plumber or gas fitter

qualified or licensed by the state, province or

region where this appliance is being in-

stalled.

.

Shut-off valve must be a "T" handle gas

cock.

3.

Flexible gas connector must not be longer

than 36 inches.

,_ WARNtNG

If the information in this manual is not

followed exactly, a fire or explosion may

result causing property damage, personal

injury or death.

m Do not store or use gasoline or other flam-

mable vapors and liquids in the vicinity of this

or any other appliance.

WHAT TO DO _F YOU SMELL GAS

[] Do not try to light any appliance.

[] Do not touch any electrical switch.

[] Do not use any phone in your building.

[] Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

[] If you cannot reach your gas supplier, call the

fire department.

Installation and service must be performed by

a qualified installer, service agency or the gas

supplier.

m All Ranges can tip

m Injury to Persons

could result

m lnstaHAnti-Tip Device

m See _nstaHation

Instructions

TO REDUCE THE RiSK OF TIPPING OF THE

APPMANCE, IT MUST BE SECURED BY A

PROPERLY INSTALU=D ANTI-TIP DEVICE.

VERIFY THAT TH_=ANTi-TIP D_=WC_=IS _=NGAG _=D

PER INSTALLATION INSTRUCTIONS. (NOTE:

ANTi-TIP DEVICE IS REQUIRED ON ALL 30" AND

36" RANGES)

Note: This Range is NOT designed for installa-

tion in manufactured (mobile) homes orfor instal-

lation in Recreational Park Trailers.

Do Not install this range outdoors.

Page 3

Contents

Important Installation Information ................. 1

Step 1: Ventilation Requirements ................ 2

Step 2: Cabinet Preparation ................. 3 - 7

Step 3: Unpacking, Moving

and Placing the Range ......................... 8 - 9

Step 4: Installing AntioTip Device ...... 10 - 11

Step 5: Gas Requirements and Hookup .... 12

Step 6: Electrical Requirements,

Connection and Grounding ....................... 13

Step 7: Backguard Installation .................. 14

Step 8: Door Removal and Installation ...... 15

Step 9: Burner Test and Adjustment.. 16 - 17

Installer Checklist ...................................... 18

To Clean and Protect Exterior Surfaces .... 18

Page 4

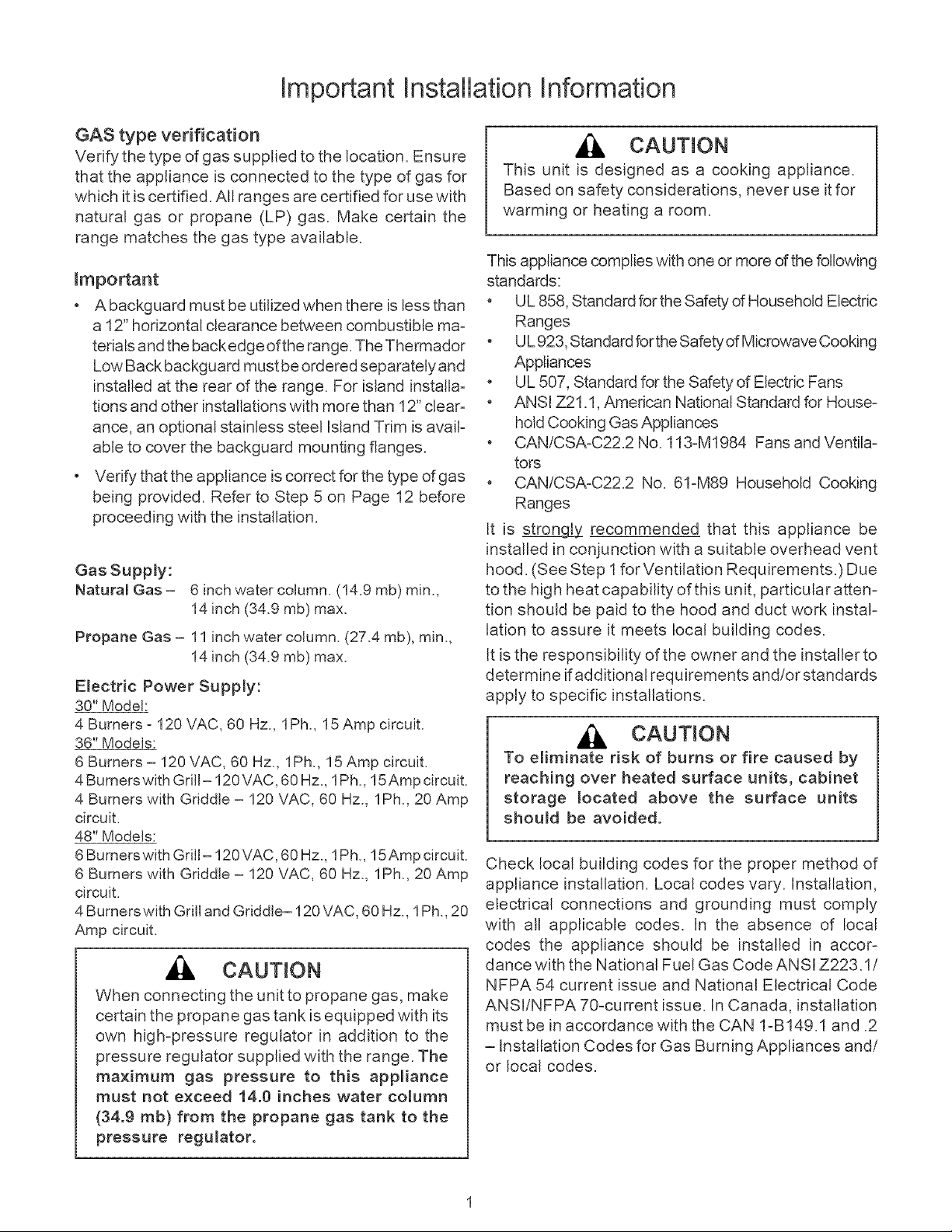

Important Installation Information

GAS type verification

Verify the type of gas supplied to the location. Ensure

that the appliance is connected to the type of gas for

which it is certified. All ranges are certified for use with

natural gas or propane (LP) gas. Make certain the

range matches the gas type available.

Important

* A backguard must be utilized when there is less than

a 12" horizontal clearance between combustible ma-

terials and the backedge of the range. The Thermador

Low Back backguard must be ordered separately and

installed at the rear of the range. For island installa-

tions and other installations with more than 12" clear-

ance, an optional stainless steel Island Trim is avail-

able to cover the backguard mounting flanges.

. Verify that the appliance is correct for the type of gas

being provided. Refer to Step 5 on Page 12 before

proceeding with the installation.

Gas Supply:

Natural Gas - 6 inch water column. (14.9 mb) min,

14 inch (34.9 rob) max.

Propane Gas - 11 inch water column. (27.4 mb), min,

14 inch (34.9 rob) max.

Electric Power Supply:

30" Model:

4 Burners - 120 VAC, 60 Hz, IPh. 15Amp circuit.

36" Models:

6 Burners- 120 VAC, 60 Hz., IPh, 15Amp circuit.

4 Burners with Grill- 120 VAC, 60 Hz, 1Ph, 15Amp circuit.

4 Burners with Griddle- 120 VAC, 60 Hz, IPh, 20 Amp

circuit.

48" Models:

6 Burners with Grill- 120 VAC, 60 Hz, 1Ph. 15Amp circuit.

6 Burners with Griddle- 120 VAC, 60 Hz. IPh. 20 Amp

circuit.

4 Burnerswith Grill and Griddle- 120 VAC, 60 Hz, 1Ph, 20

Amp circuit.

CAUTION

When connecting the unit to propane gas, make

certain the propane gas tank is equipped with its

own high-pressure regulator in addition to the

pressure regulator supplied with the range. The

maximum gas pressure to this appliance

must not exceed 14.0 inches water column

(34.9 rob) from the propane gas tank to the

pressure regulator.

CAUTION

This unit is designed as a cooking appliance.

Based on safety considerations, never use it for

warming or heating a room.

This appliance complies with one or more of the following

standards:

UL 858, Standard for the Safety of Household Electric

Ranges

UL 923, Standard for the Safety of Microwave Cooking

Appliances

• UL 507, Standard for the Safety of Electric Fans

ANSi Z21.1, American National Standard for House-

hold Cooking Gas Appliances

CANiCSA-C22.2 No. 113-M1984 Fans and Ventila-

tors

CAN/CSA-C22.2 No. 61-M89 Household Cooking

Ranges

It is strong_ recommended that this appliance be

installed in conjunction with a suitable overhead vent

hood. (See Step 1 for Ventilation Requirements.) Due

to the high heat capability of this unit, particular atten-

tion should be paid to the hood and duct work instal-

lation to assure it meets local building codes.

It is the responsibility of the owner and the installer to

determine if additional requirements and!or standards

apply to specific installations.

CAUTION

To eliminate risk of burns or fire caused by

reaching over heated surface units, cabinet

storage located above the surface units

should be avoided.

Check local building codes for the proper method of

appliance installation. Local codes vary. Installation,

electrical connections and grounding must comply

with all applicable codes. In the absence of local

codes the appliance should be installed in accor-

dance with the National Fuel Gas Code ANSI Z223.1/

NFPA 54 current issue and National Electrical Code

ANSI/NFPA 70-current issue. In Canada, installation

must be in accordance with the CAN 1-B149.1 and .2

-Installation Codes for Gas Burning Appliances and/

or local codes.

Page 5

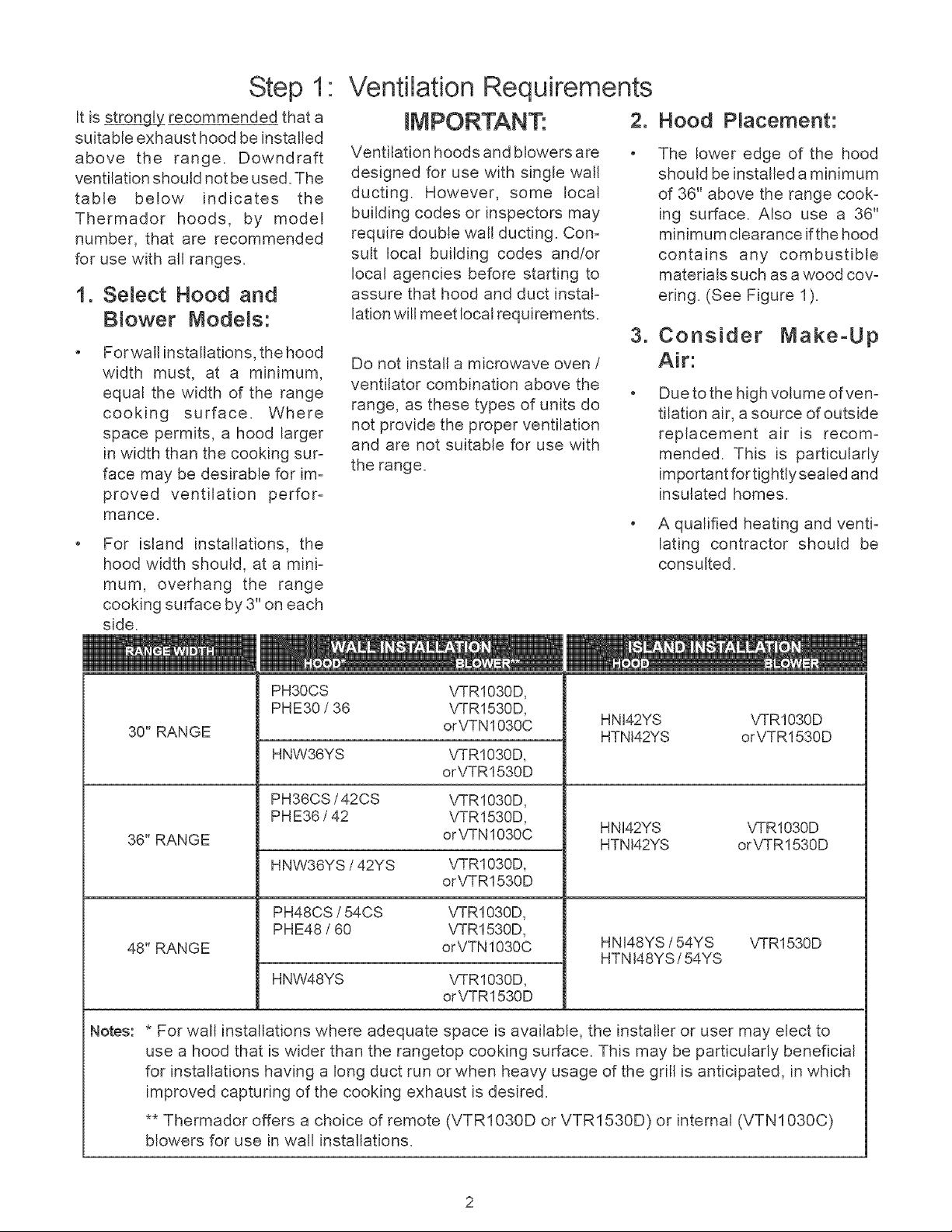

Step 1

It is stron IgLv_recommended that a

suitable exhaust hood be installed

above the range. Downdraft

ventilation should notbe used. The

table below indicates the

Thermador hoods, by model

number, that are recommended

for use with all ranges.

1. Select Hood and

B ower Modems:

Forwall installations, the hood

width must, at a minimum,

equal the width of the range

cooking surface. Where

space permits, a hood larger

in width than the cooking sur-

face may be desirable for im-

proved ventilation perfor-

mance.

For island installations, the

hood width should, at a mini-

mum, overhang the range

cooking surface by 3" on each

side.

Ventilation Requirements

Ventilation hoods and blowers are

designed for use with single wall

ducting. However, some local

building codes or inspectors may

require double wall ducting. Con-

suit local building codes and/or

local agencies before starting to

assure that hood and duct instal-

lation will meet local requirements.

Do not install a microwave oven /

ventilator combination above the

range, as these types of units do

not provide the proper ventilation

and are not suitable for use with

the range.

2.

Hood Placement:

The lower edge of the hood

should be installed a minimum

of 36" above the range cook-

ing surface. Also use a 36"

minimum clearance if the hood

contains any combustible

materials such as a wood cov-

ering. (See Figure 1).

3_

Consider Make-Up

Air:

Due to the high volume of ven-

tilation air, a source of outside

replacement air is recom-

mended. This is particularly

important for tightly sealed and

insulated homes.

A qualified heating and venti-

lating contractor should be

consulted.

PH30CS VTRI030D,

PHE30 / 36 VTR1530D,

30" RANGE

HNW36YS VTRI030D,

PH36CS/42CS

PHE36 / 42

36" RANGE

HNW36YS / 42YS

PH48CS / 54CS

PHE48 / 60

48" RANGE

HNW48YS VTR 1030D,

Notes: * For wall installations where adequate space is available, the installer or user may elect to

use a hood that is wider than the rangetop cooking surface. This may be particularly beneficial

for installations having a long duct run or when heavy usage of the grill is anticipated, in which

improved capturing of the cooking exhaust is desired.

•* Thermador offers a choice of remote (VTRI03OD or VTR1530D) or internal (VTN1030C)

blowers for use in wall installations.

orVTN1030C

orVTRI530D

VTRI030D,

VTR1530D,

orVTNI030C

VTRI030D,

orVTRI530D

VTRI030D,

VTR1530D,

orVTNI030C

or VTR1530D

HNI42YS VTRI030D

HTNI42YS orVTR1530D

HNI42YS VTRI030D

HTNI42YS orVTR1530D

HNI48YS / 54YS

HTNN8YS/54YS

VTR1530D

Page 6

Step 2: Cabinet Preparation

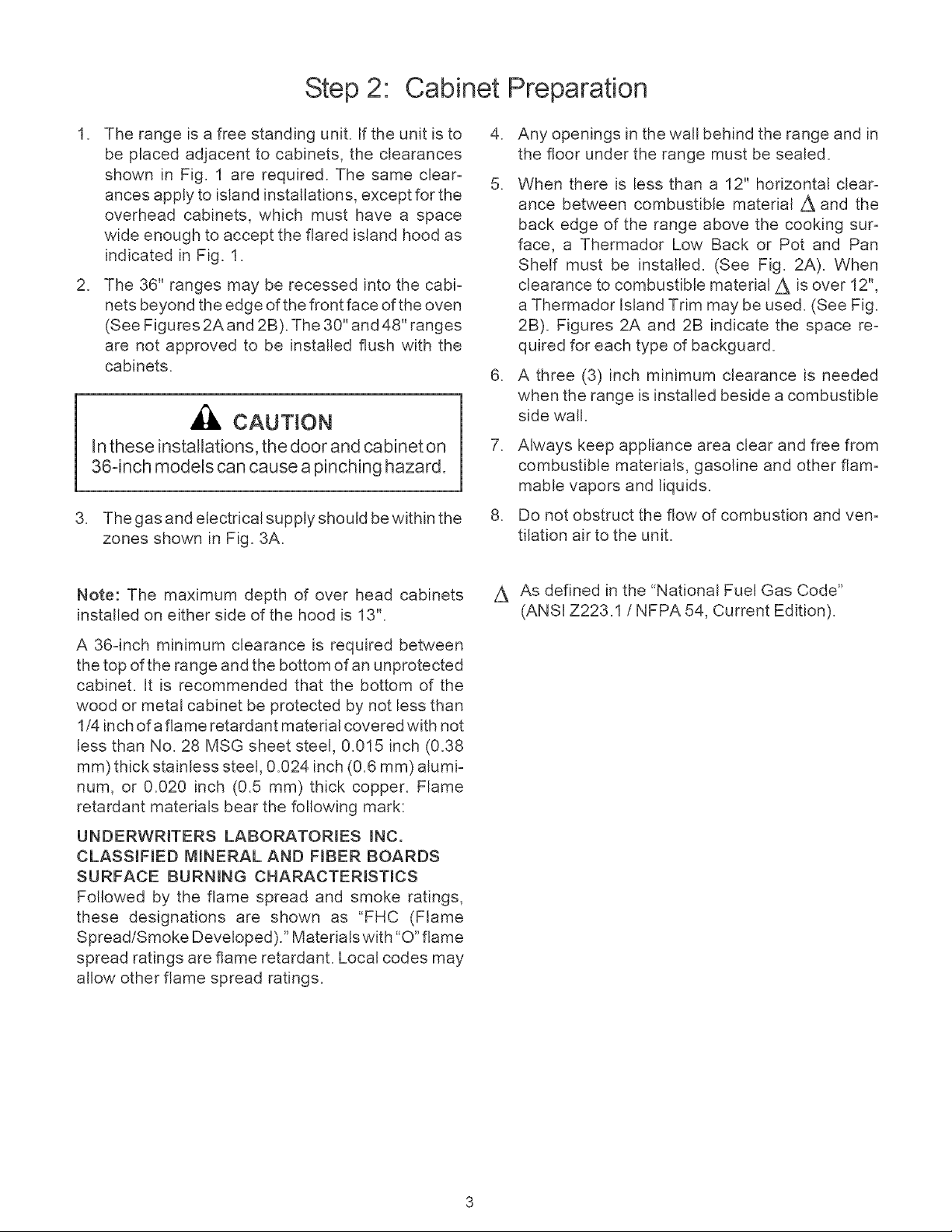

.

The range is a free standing unit. If the unit is to

be placed adjacent to cabinets, the clearances

shown in Fig. 1 are required. The same clear-

ances apply to island installations, except for the

overhead cabinets, which must have a space

wide enough to accept the flared island hood as

indicated in Fig. 1.

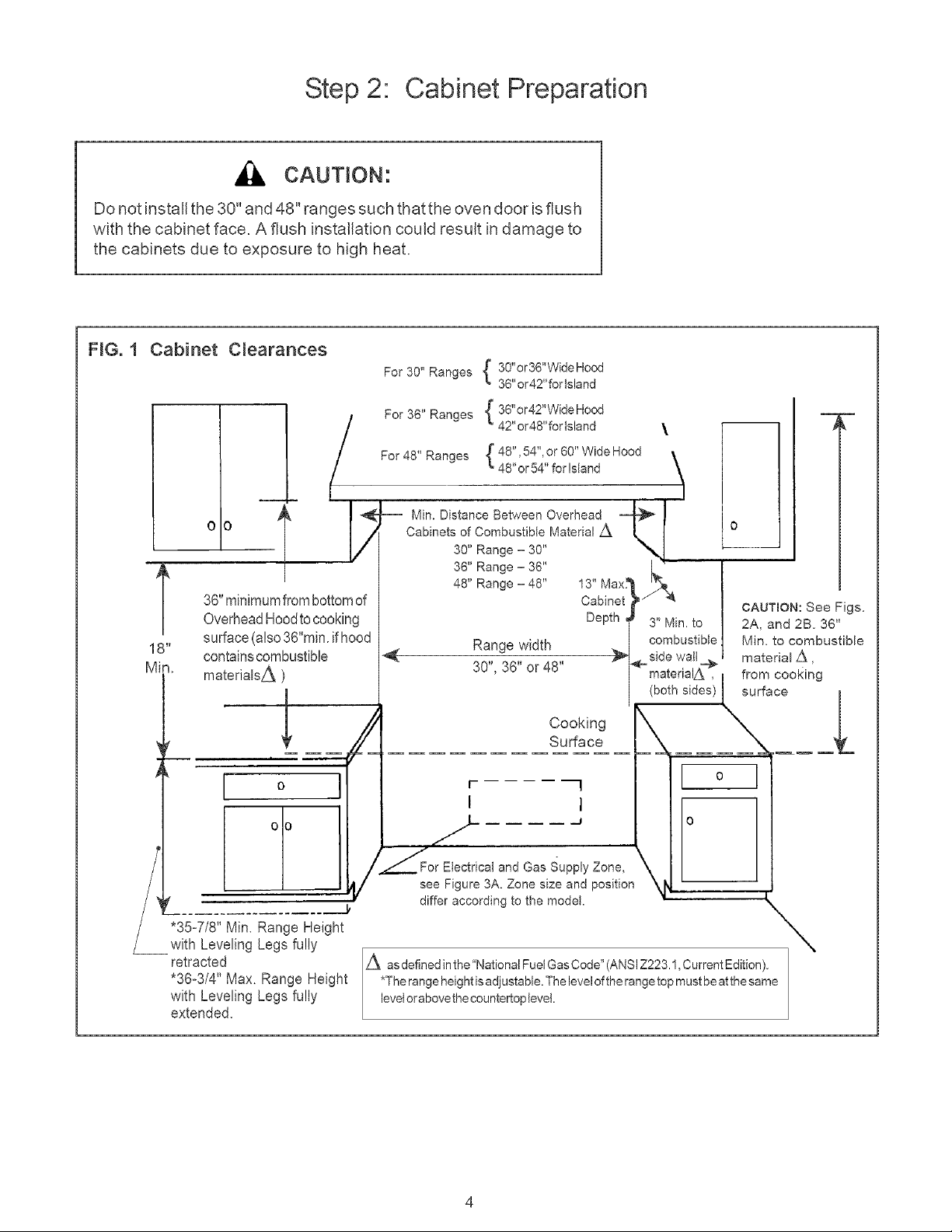

.

The 36" ranges may be recessed into the cabk

nets beyond the edge of the front face of the oven

(See Figures 2A and 2B). The 30" and 48" ranges

are not approved to be installed flush with the

cabinets.

CAUTION

In these installations, the door and cabinet on

36-inch models can cause a pinching hazard.

3. The gas and electrical supply should be within the

zones shown in Fig. 3A.

.

Any openings in the wall behind the range and in

the floor under the range must be sealed.

5.

When there is less than a 12" horizontal clear-

ance between combustible material A and the

back edge of the range above the cooking sur-

face, a Thermador Low Back or Pot and Pan

Shelf must be installed. (See Fig. 2A). When

clearance to combustible material A is over 12",

a Thermador Island Trim may be used. (See Fig.

2B). Figures 2A and 2B indicate the space re-

quired for each type of backguard.

.

A three (3) inch minimum clearance is needed

when the range is installed beside a combustible

side wall.

.

Always keep appliance area clear and free from

combustible materials, gasoline and other flam-

mable vapors and liquids.

.

Do not obstruct the flow of combustion and ven-

tilation air to the unit.

Note: The maximum depth of over head cabinets

installed on either side of the hood is 13".

A 36-inch minimum clearance is required between

the top of the range and the bottom of an unprotected

cabinet. It is recommended that the bottom of the

wood or metal cabinet be protected by not less than

1,1'4inch of aflame retardant material covered with not

less than No. 28 MSG sheet steel, 0.015 inch (0.38

mm) thick stainless steel, 0.024 inch (0.6 mm) alumk

num, or 0.020 inch (0.5 mm) thick copper. Flame

retardant materials bear the following mark:

UNDERWRITERS LABORATORIES INC.

CLASSIFIED MINERAL AND FIBER BOARDS

SURFACE BURNING CHARACTERISTICS

Followed by the flame spread and smoke ratings,

these designations are shown as "FHC (Flame

Spread/Smoke Developed)." Materials with "O" flame

spread ratings are flame retardant. Local codes may

allow other flame spread ratings.

A As defined in the "National Fuel Gas Code"

(ANSI Z223.1 / NFPA 54, Current Edition).

Page 7

Step 2: Cabinet Preparation

CAUTION:

Do not install the 30" and 48" ranges such that the oven door isflush

with the cabinet face. A flush installation could result in damage to

the cabinets due to exposure to high heat.

FIG. 1 Cabinet Clearances

For 30" Ranges _ 30"or36"WideHood

For 36" Ranges _.

36" or42" for Island

f

36"or42"Wide Hood

42" or48"for Island

m

\

18"

Min.

m

O0

36"minimumfrombottomof

OverheadHoodtocooking

surface(also 36"rain.ifhood

containscombustible

materialsA )

°°I

For 48" Ranges { 48", 54", or 60" Wide Hood

For Electrical and Gas Supply Zone,

see Figure 3A. Zone size and position ,_

differ according to the model.

48" or54" for Istand

Cooking

Surface

0

CAUTION: See Figs.

3" Min. to 2A, and 2B. 36"

combustible Min. to combustible

(_side watt_ material A,

materialA , I from cooking

(both sides) I surface

i

1

'35o7/8" iV]in,Range Height

with Leveling Legs fully

retracted

"36-3/4" Max. Range Height

with Leveling Legs fully

extended,

\

A as defined in the"National Fuet Gas Code" (ANSI Z223.1, Current Edition).

*The range height is adjustable. The level ofthe range top must beat the same

eve orabovethe countertop eve.

Page 8

Step 2: Cabinet Preparation

F{G. 2A - Side View

/i'll / /// ////. /1// //// -- Combustible

I _ 29-1/2" ,,

_ 32-5/8'"

I Potan d _,,,]2-7/&"

36"MIn. to ! Sh_tf "-4._ -I

Combustibles A I LOW L._

Pan _ I

I

I

'_---- 26-3/8"

I

_25-112" max./

/

/

!

I

./Front Face

M_ials &

/

3/8"

[o

Kickplate

///I

29-112"--

//// I

-'-Wall

////

,[_----28-3/8" -----_-

47-3/8" 71

A as defined in the "National Fuel Gas Code" (ANSI Z223.1, Current Issue).

FiG. 2B - Side View t

I

t

36" MIn._to

Combustibles A

I

t

t

t

t

Combustibles A

with Island Trim

I

12" Min. to

Island

Note:

For Island Trim installations,

counter surface should have a

cantilever edge meeting the back

section of the Island Trim

accessory,

Countertop

/ Front Face

L J,

Note:

If an inner wall is used under the

cantilever counter top, there

should be a 1/8" gap from the rear

of the range to the inner wall,

Page 9

Step 2: Cabinet Preparation

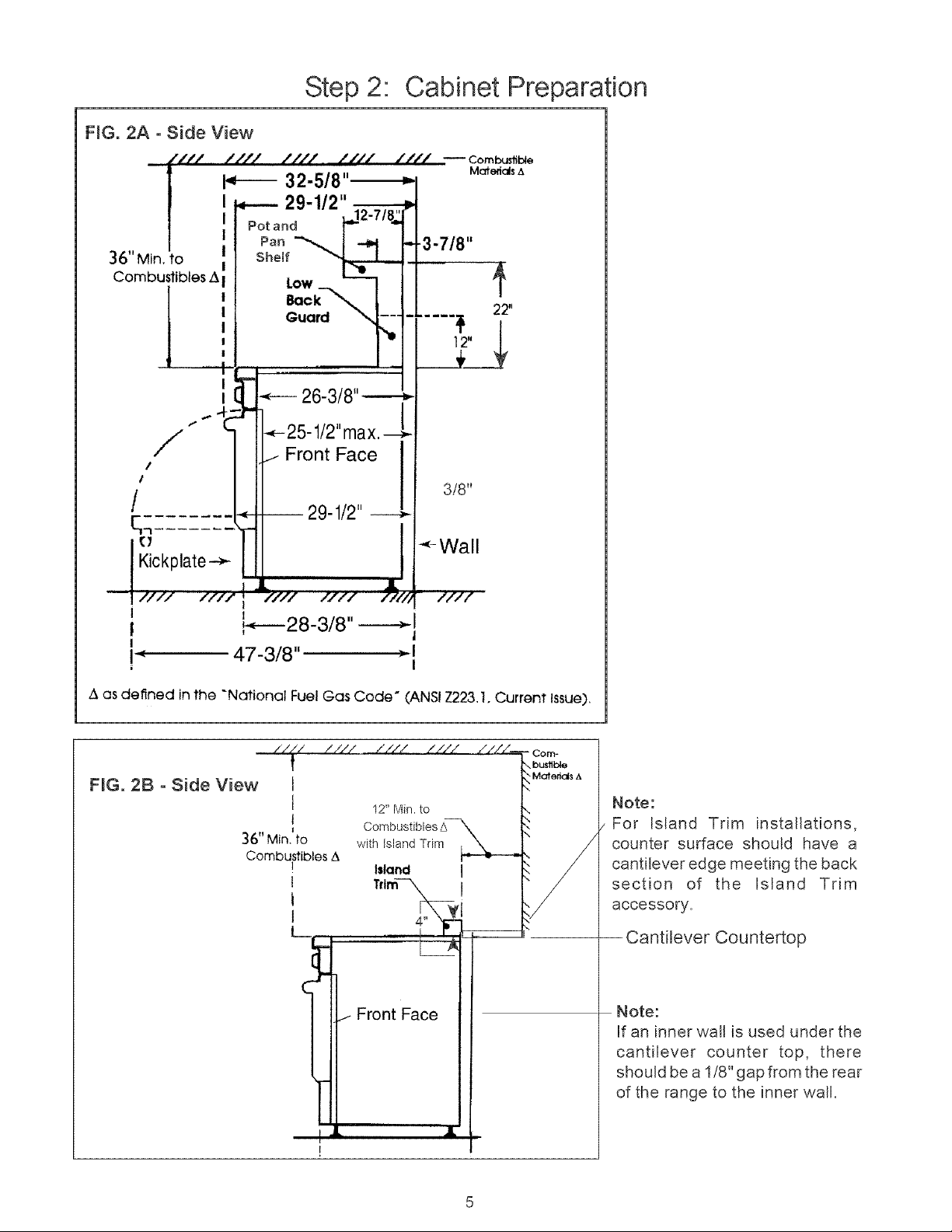

GAS AND ELECTRIC SUPPLY ZONES:

F_G. 3A Gas & E_ectrica_ Supply Zones for AH Gas Ranges

Typical placement shown.

Other placement of

Electrical Supply and

Receptacle within the

Electrical and Gas Supply

Zone is acceptable.

NOTE:

If not already

present, install

gas shut-offvalve

in an easiJy

accessible

location. Make

Protrusion from Wait "_

sure all users

knowwhere and

how to shut off

the gas supply to

the range.

NOTE: The

installershould

inform the

Model A B C D E

30" 8" 12" 10" 6-1/2" 5ol/4"

36" 10ol/2" 15" 10ol/2" 6ol/2" 5ol/4"

48" 16-1/2" 16" 15-1/2" 6ol/2" 5ol/4"

consumer of the

location of the

gasshutzoffvalve.

NOTE:Any opening in the wall behind the appliance

and any opening in the floor under the appliance

must be sealed.

2" Maximum

for Gas Supply

3/4" Ftex Line to

Appliance

1/2"

NPT 120 VAC Receptacle

(Shown) or Junction

I Box

I .... Centerline of

Electrical

I

Floor

The All Gas ranges may be con-

nected to the power supply with a

range supply cord (supplied with

range) or by hard-wiring to the power

supply. It is the responsibility of the

installer to provide the proper wiring

components (cord or conduit and

wires) and complete the gas con-

nection as dictated by local codes

and ordinances, and/or the National

Electric Code. The units must be

properly grounded. Refer to Step 6

for details.

_ a

The range must be connected

only to the type of gas for which

it is certified. If the range is to be

connected to propane gas, ensure

that the propane gas supply tank is

equipped with its own high pressure

regulator in addition to the pressure

regulator supplied with the range.

(See Step 5.)

mMPORTANT:

The cord supplied with gas ranges having electric griddle requires

a NEMA 5-20 receptacle, shown here. Local codes may require

a different wiring method.

PLUG

NEMA 5z20

RECEPTACLE

Page 10

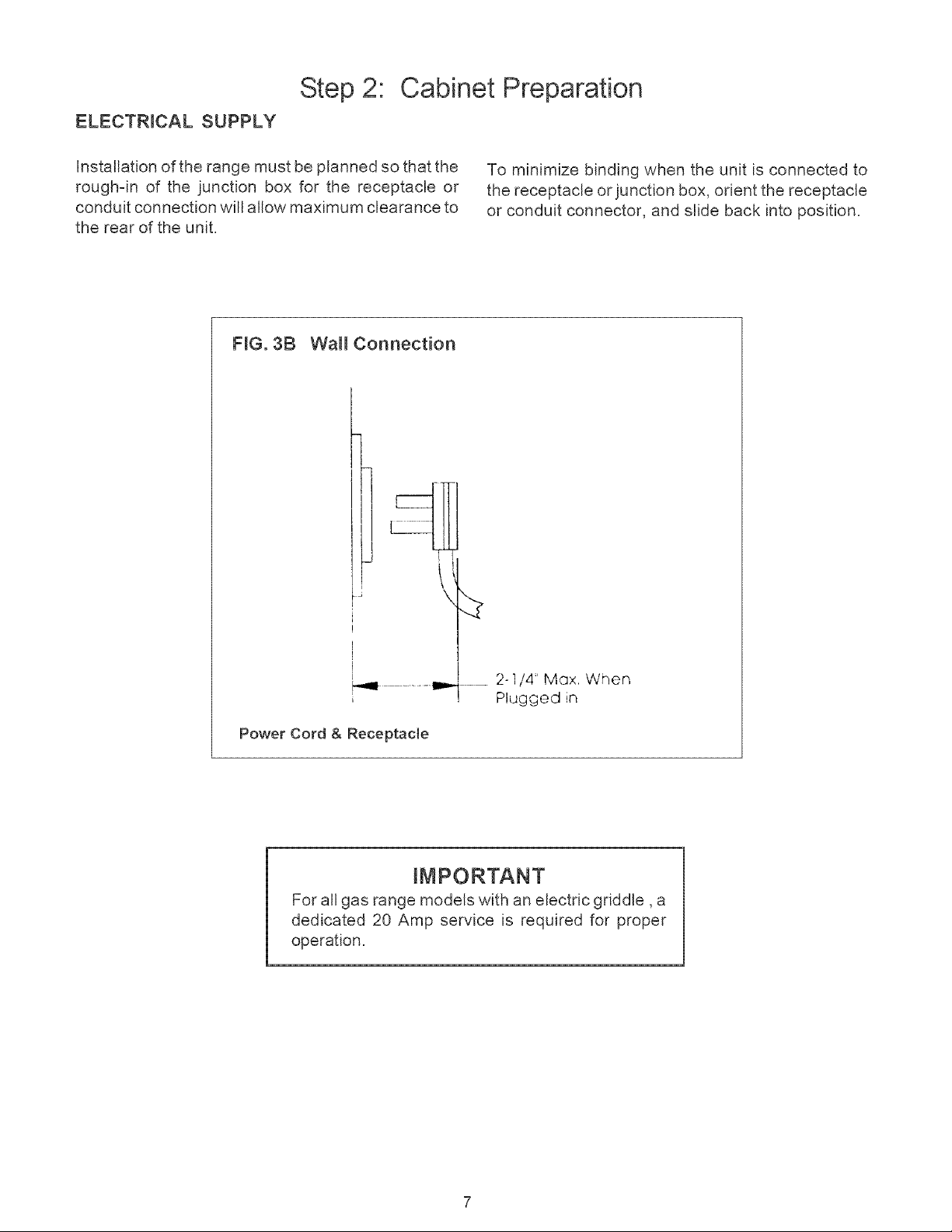

ELECTRICAL SUPPLY

Step 2 Cabinet Preparation

Installation of the range must be planned so that the

rough-in of the junction box for the receptacle or

conduit connection will allow maximum clearance to

the rear of the unit.

F_G. 3B Wall Connection

To minimize binding when the unit is connected to

the receptacle or junction box, orient the receptacle

or conduit connector, and slide back into position.

' . Plugged in

Power Cord & Receptacle

For all gas range models with an electric griddle, a

dedicated 20 Amp service is required for proper

operation.

I -1/4" Max. When

IMPORTANT

Page 11

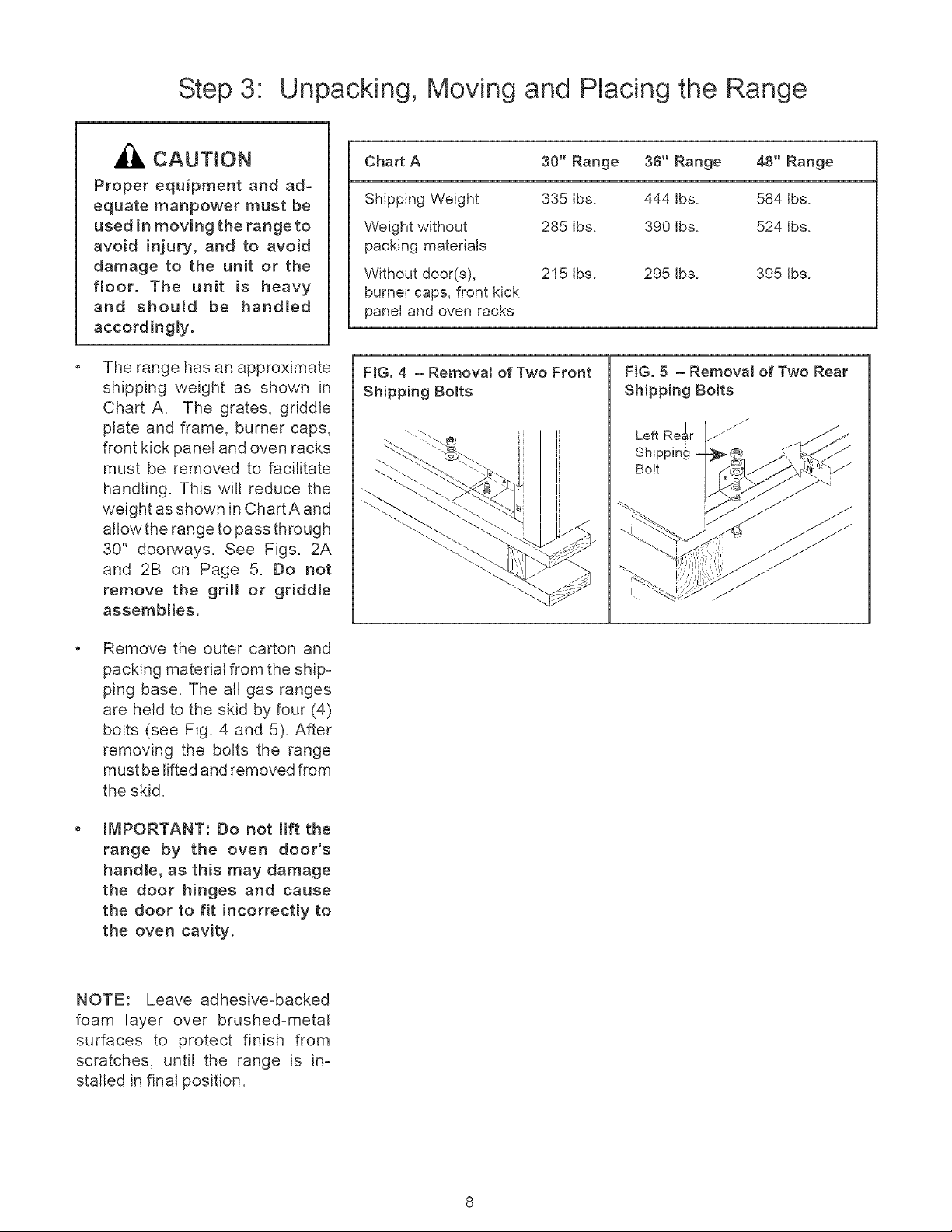

Step 3 Unpacking, Moving and Placing the Range

CAUTION

Proper equipment and ad-

equate manpower must be

used in moving the range to

avoid injury, and to avoid

damage to the unit or the

floor. The unit is heavy

and shouJd be handled

accordingJy.

The range has an approximate

shipping weight as shown in

Chart A. The grates, griddle

plate and frame, burner caps,

front kick panel and oven racks

must be removed to facilitate

handling. This will reduce the

weight as shown in ChartA and

allow the range to pass through

30" doorways. See Figs. 2A

and 2B on Page 5. Do not

remove the grill or griddle

assemblies.

Cha_ A 30" Range 36" Range 48" Range

Shipping Weight 335 Jbs. 444 Ibs. 584 Jbs.

Weight without 285 Ibs. 390 Ibs. 524 Ibs.

packing materials

Without door(s),

burner caps, front kick

panel and oven racks

FIG. 4 - Removat of Two Front

Shipping BoJts

215 Ibs. 295 Ibs. 395 Ibs.

FiG. 5 - RernovaJ of Two Rear

Shipping BoJts

Left Rear ,if'Y"

Shipping

Bolt

!

Remove the outer carton and

packing material from the ship-

ping base. The all gas ranges

are held to the skid by four (4)

bolts (see Fig. 4 and 5). After

removing the bolts the range

must be lifted and removed from

the skid.

mMPORTANT: Do not lift the

range by the oven door's

handJe, as this may damage

the door hinges and cause

the door to fit incorrectJy to

the oven cavity.

NOTE: Leave adhesive-backed

foam layer over brushed-metal

surfaces to protect finish from

scratches, until the range is in-

stalled in final position.

Page 12

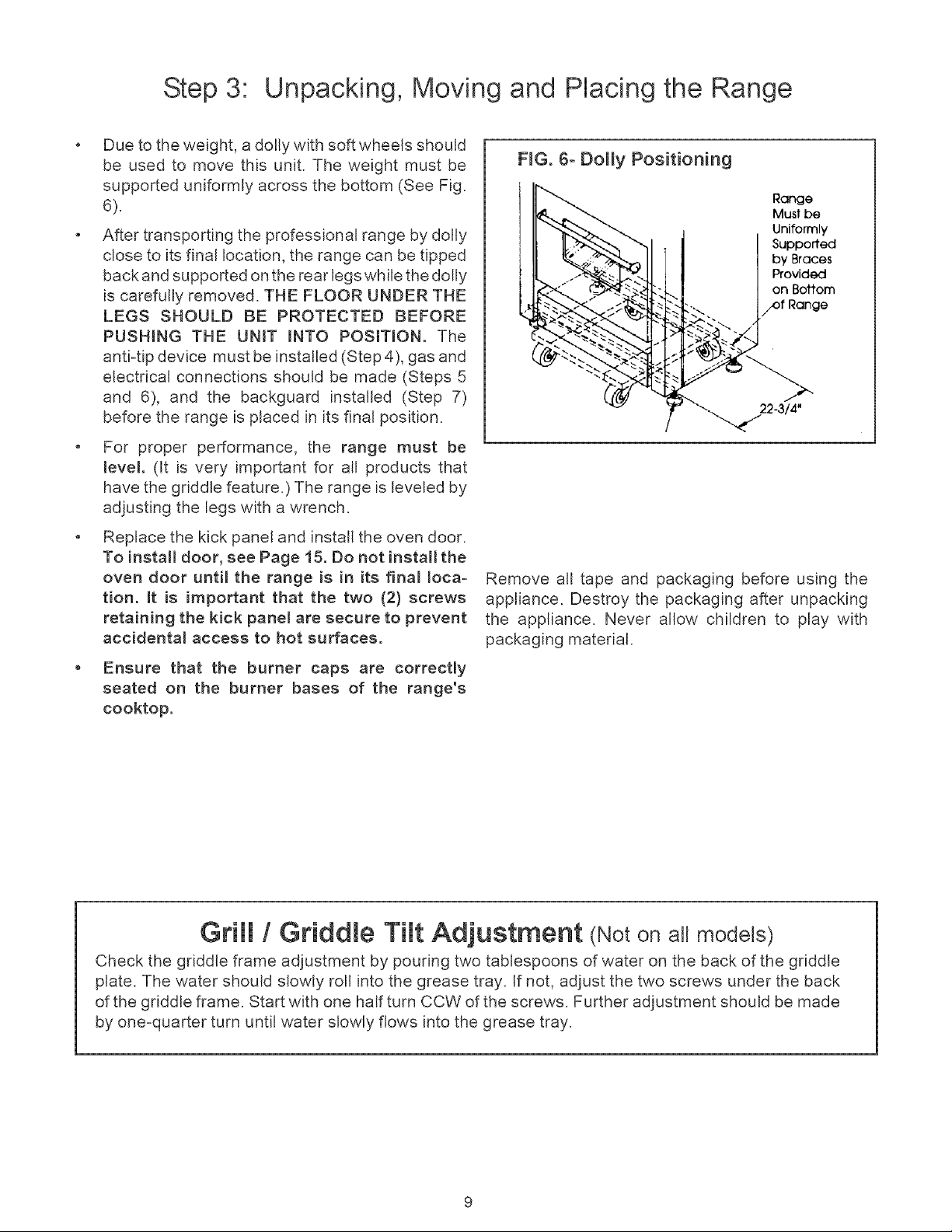

Step 3: Unpacking, Moving and Placing the Range

Due to the weight, a dolly with soft wheels should

be used to move this unit. The weight must be

supported uniformly across the bottom (See Fig.

6).

After transporting the professional range by dolly

close to its final location, the range can be tipped

back and supported on the rear legs while the dolly

is carefully removed. THE FLOOR UNDER THE

LEGS SHOULD BE PROTECTED BEFORE

PUSHING THE UNiT mNTO POSlTmON. The

anti-tip device must be installed (Step 4), gas and

electrical connections should be made (Steps 5

and 6), and the backguard installed (Step 7)

before the range is placed in its final position.

For proper performance, the range must be

_eveL (It is very important for all products that

have the griddle feature.) The range is leveled by

adjusting the legs with a wrench.

Replace the kick panel and install the oven door.

To install door, see Page 15. Do not install the

oven door until the range is in its final loca-

tion. ff is important that the two (2) screws

retaining the kick pane_ are secure to prevent

accidenta_ access to hot surfaces.

Range

Musl be

Uniformly

Supported

by Braces

Provided

on Bottom

Range

22-3t4"

Remove all tape and packaging before using the

appliance. Destroy the packaging after unpacking

the appliance. Never allow children to play with

packaging material.

Ensure that the burner caps are correctly

seated on the burner bases of the range's

cooktop.

Grill / Griddle Tilt Adjustment (Notonall models)

Check the griddle frame adjustment by pouring two tablespoons of water on the back of the griddle

plate. The water should slowly roll into the grease tray. If not, adjust the two screws under the back

of the griddle frame. Start with one half turn CCW of the screws. Further adjustment should be made

by one=quarter turn until water slowly flows into the grease tray.

Page 13

Step 4: Installing Anti-Tip Device

For aH 30" and 36" ranges, an anti-tip device must be installed as per these

instructions.

_, WARNING

RANGE TtPPING HAZARD

AH ranges can tip and injury can result.

To prevent accidental tipping of the range,

attach it to the floor, wall or cabinet by

installing the Anti-Tip Device supplied.

A risk of tip-over may exist if the appmi-

ance is not installed in accordance with

these instructions.

mfthe range is pulled away from the wall

for c_eaning, service or any other reason,

ensure that the Anti-Tip Device is prop-

er_y reengaged when the range is pushed

back against the wall. mnthe event of

abnorma_ usage (such as a person stand-

ing, sitting, or _eaning on an open door},

failure to take this precaution can result

in tipping of the range. Persona_ injury

might result from spilled hot _iquids or

from the range itself.

_, WARNING

o ALL RANGES CAN

T_P

o _NJURY TO PER-

SONS COULD RE-

SULT

o _NSTALL ANT_-T_P

DEVICES PACKED

W_TH RANGE

o SEE _NSTALLAT_ON

_NSTRUCT_ONS

WARNtNG

ELECTRICAL SHOCK HAZARD

. Use extreme caution when drilling ho_es

into the wall or floor. There may be con-

cealed electrica_ wires _ocated behind the

wall or under the floor.

. mdentify the e_ectricaL circuits that could

be affected by the installation of the Anti-

Tip Device, then turn off power to these

c ircu its.

. Failure to follow these instructions may

result in e_ectrica_ shock or other per-

sona_ injury.

PROPERTY DAMAGE

. Contact a qualified installer or contrac-

tor to determine the proper method for

drilling ho_es through the wall or floor

materia_ (such as ceramic the, hardwood,

etc.}

. Do not s_ide the range across an unpro_

tected floor.

. Failure to follow these instructions may

result in damage to wall or floor cover-

ings.

ATTENTION

Too_s Needed for Installation of Anti-Tip Device:

•Screwdriver, Phillips •Hammer

• Drill, electric or hand • Pencil or other marker

• Measuring tape or ruler

• 1/8" drill bit (wood or metal wall or floor)

•3/16" carbide:tipped masonry drill bit (concrete or concrete block wall or floor)

• 3/16" anchors, drywall or concrete, 4 each (not required if mounting bracket is being attached to solid wood or metal)

10

Page 14

Step 4 Installing Anti -Tip Device

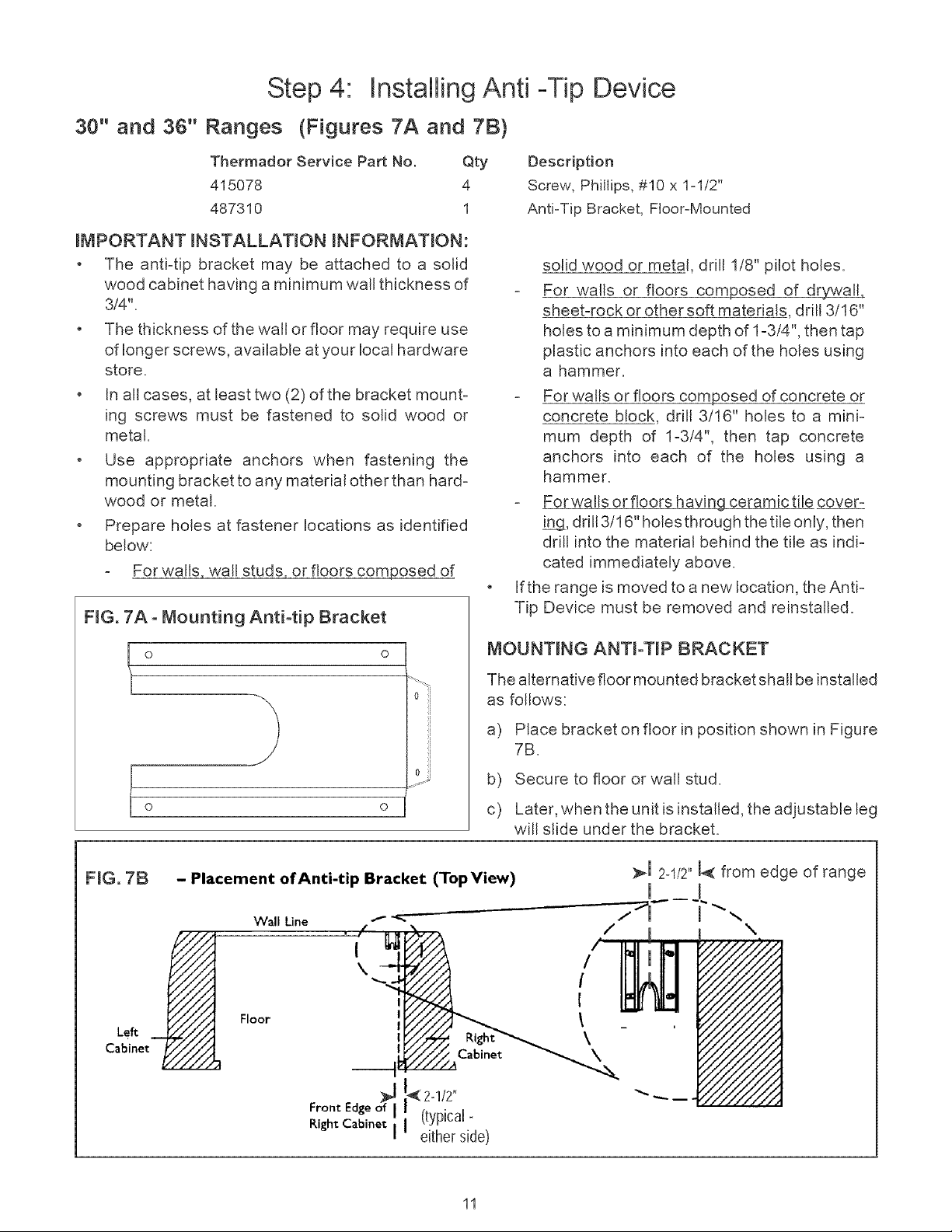

30" and 36" Ranges (Figures 7A and 7B)

Thermador Service Pa_ No. Qty

415078 4

487310 1

_MPORTANT _NSTALLAT_ON _NFORMAT_ON:

• The anti-tip bracket may be attached to a solid

wood cabinet having a minimum wall thickness of

3/4".

• The thickness of the wall or floor may require use

of longer screws, available at your local hardware

store.

• In aJl cases, at least two (2) of the bracket mount-

ing screws must be fastened to solid wood or

metal.

• Use appropriate anchors when fastening the

mounting bracket to any material other than hard-

wood or metal.

• Prepare holes at fastener locations as identified

below:

For walls, wall studs, or floors composed of

F_G. 7A - Mounting Anti-tip Bracket

Description

Screw, Phillips, #10 x 1-1/2"

Anti-Tip Bracket, Floor-Mounted

solid wood or metal, drill 1/8" pilot holes.

For walls or floors composed of drywall,

sheet-rock or other soft materials, drill 3/16"

holes to a minimum depth of 1-3/4", then tap

plastic anchors into each of the holes using

a hammer.

For walls or floors composed of concrete or

concrete block, drill 3/16" holes to a mini-

mum depth of 1-3/4", then tap concrete

anchors into each of the holes using a

hammer.

For walls orfloors having ceramic tile cover-

_, drill 3/16" holes through the tile only, then

drill into the material behind the tile as indi-

cated immediately above.

If the range is moved to a new location, the Anti-

Tip Device must be removed and reinstalled.

F_G. 7B

Cabinet

o e !

o oJ

- Placement of Anti-tip Bracket (Top View)

Wall Line

Floor

./ /

\--

MOUNTING ANT_-T_P BRACKET

The alternative floor mounted bracket shall be installed

as follows:

a) Place bracket on floor in position shown in Figure

7B.

b) Secure to floor or wall stud.

c) Later, when the unit is installed, the adjustable leg

will slide under the bracket.

:_m 2oi/2, _ from edge of range

\

Front (typical-

Right Cabinet I ether s de)

11

Page 15

Step 5:

Gas Requirements and Hookup

Verify the type of gas being used at the installation site.

As shipped from the factory, units are configured

for use with only natural gas or propane (LP) gas.

Make certain the range matches the type of gas

available at this location. These ranges are NOT

convertible between different types of gas.

For installation of the appliance at high altitude, please

consult your local gas company for their recommen-

dation of the correct orifice sizes and any other

necessary adjustments that will provide proper gas

combustion at specified altitudes.

CAUTION

When connecting unit to propane gas, make

certain the propane gas tank is equipped with its

own high pressure regulator in addition to the

pressure regulator supplied with the appliance.

The pressure of the gas supplied to the appli-

ance regulator must not exceed 14"

(34.9 mb) water column.

Natural Gas Requirements:

Inlet Connection: 3/4" NPT external

1/2" NPT internal

(Minimum 3/4" dia. flex line.)

Supply Pressure:

Manifold Pressure:

Propane Gas Requirements:

Inlet Connection: 3/4" NPT external

Supply Pressure:

Manifold Pressure:

6" min. to 14" max. water column.

(14.9 to 34.9 mb)

5" water column (12.5 mb)

1/2" NPT internal

(Minimum 3,14'' dia. flex line.)

11" min. to 14" max. water column.

(27.4 mb to 34.9 mb)

10" water column (24.9 mb)

HOOK UP

• A manual gas shut-off valve must be installed

external to the appliance, in a location accessible

from the front, for the purpose of shutting off the

gas supply. The supply line must not interfere with

the back of the unit. Make sure the gas supply is

turned off at the manual shut-off valve before

connecting the appliance.

• The range is supplied with its own pressure regu-

lator that has been permanently mounted within

the range body.

Use 3/4" flex line to connect between the gas

supply and the appliance inlet pipe, which exits the

upper rear of the appliance. The appliance pipe

connection has a 3/4" NPT external thread and a

1/2" NPT internal thread. (See Photo A.) Use

caution to avoid crimping the 3/4" flex line when

making bends.

• The gas supply connections shall be made by a

competent technician and in accordance with

local codes or ordinances. In the absence of a

local code, the installation must conform to the

National Fuel Gas Code ANSI Z223.1iNFPA54-

current issue.

Always use pipe sealing compound or Teflon®

tape on the pipe threads, and be careful not to

apply excessive pressure when tightening the

fittings.

• Leak testing of the appliance shall be in accor-

dance with the following instructions.

• Turn on gas and check supply line connections

for beaks using a soap and water solution,

Bubbles forming indicate a gas leak. Repair all

beaks immediately after finding them.

• Do not use a flame of any kind to check for

gas leaks.

Photo A

WARNING

Gas line must not come in contact with any

components inside back cover of range. Run

gas line in channel in back of range.

Use 3/4" flex line to connect between the gas supply

and the appliance manifold pipe, which exits the

upper left rear of the appliance.

12

Page 16

Step 6: Electrical Requirements, Connection & Grounding

Before installing, turn power OFF at the service

panel. Lock service panel to prevent power from

being turned ON accidentally.

Chart B: Electrica_ Suppmy Circuit Requirements

MODEL TYPE VOLTAGE CURRENTRATING FREQUENCY PHASE

30" 120 VAC 15 Amps 60 Hz. Single

36" 120 VAC 15 Amps 60 Hz. Single

36" with Grill 120VAC 15 Amps 60 Hz. Single

36" with Griddle 120 VAC 20 Amps 60 Hz. Single

48" with Grill 120VAC 15 Amps 60 Hz. Single

48" with Griddle 120 VAC 20 Amps 60 Hz. Single

48" with Grill 120 VAC 20 Amps 60 Hz. Single

and Griddle

A neutral supply wire must be provided from the

power source (breaker/fuse panel) because criti-

cal range components, including the surface

burner spark re-ignition modules, require 120

VAC to operate safely and properly. An improper

120 VAC power supply will cause malfunction,

damage to this appliance, and possibly create a

condition of shock hazard. If the correct power

supply circuit is not provided, it is the responsibil-

ity and obligation of the installer and user to have

proper power supply connected. This must be

accomplished in accordance with all applicable

For all gas ranges with electric griddle, dedicated 20 AMP service is required for proper operation.

Before you plug in an electrical cord, be sure all controls are in the OFF position.

For appliances equipped with a cord and plug, do not cut or remove the ground prong. It must be plugged into

a matching grounding type receptacle to avoid electrical shock. If there is any doubt as to whether the wall

receptacle is properly grounded, the customer should have it checked by a qualified electrician.

Installer - show the owner the location of the circuit breaker or fuse. Mark it for easy reference.

iMPORTANT

local codes and ordinances by a qualified electri-

cian. In the absence of local codes and ordi-

nances, the power supply connection shall be in

accordance with the National Electrical Code.

Observe all governing codes and ordinances

when grounding. In the absence of these codes

or ordinances observe National Electrical Code

ANSI/NFPA No. 70 current issue.

Electric wiring diagrams and schematics have

been placed in the toe kick area of the range for

access by a qualified service technician.

_, CAUTION

The appliance must be isolated from the gas supply piping system by closing its individual manual shut-

off valve during any pressure testing of the gas supply piping system at test pressures equal to or less

than 1/2 psig (3.5kPa.).

The appliance and its individual shut off valve must be disconnected from the gas supply piping system

during any pressure testing of the system at test pressures in excess of 1/2 psig (3.5kPa.).

When checking the manifold gas pressure, the inlet pressure to the regulator should be at least 6.0" (14.9

mb) W.C. for natural gas or 11.0" (27.4 mb) for propane.

Do not attempt any adjustment of the pressure regulator.

13

Page 17

Step 7: Backguard Installation

The backguard must be attached before sliding the

range into the final installed position. A Low Back or

Pot and Pan Shelf must be installed when there is less

than a 12" clearance between combustibles and the

back of the range above the cooking surface. (See

Fig. 2A and 2B on Page 5).

An Island Trim is available for covering the backguard

mounting flanges for island installations, where there

is a minimum of 12" of horizontal clearance between

combustibles and the back of the range. (See Fig. 2B

on Page 5).

The backguard is inserted, as shown in Fig. 8, into the

guide channels on the back of the range. Secure the

backguard with the (4) sheet metal screws provided.

Front of Unit

Chart C: Backguard Kit Mode_ Numbers

Model Width 9" Std. Low Back 12" Low Back 22" Pot and Pan Shelf

30" Included N!A HS30R

36" NiA LB36R HS36R

48" NiA LB48R HS48R

14

Backguard

Installed

3o3/4" island Trim

IT30R

IT36R

IT48R

Page 18

Step 8: Door Removal and Installation

CAUTtON

USE CAUTION WHEN REMOVING THE

DOOR. THE DOOR IS VERY HEAVY.

o Make sure oven is cool and power to oven has

been turned off. Failure to do so could result in

electrical shock or burns.

, The oven door is heavy and fragile. Use both

hands to remove or replace the door.

o Grasp only the ends of the oven door handle.

o Failure to grasp the oven door firmly and properly

could result in personal injury and product

damage.

o With the door off, never release the levers and

try to close the hinges. Without the weight of the

door, the powerful springs will snap the hinges

closed with great force.

To Remove the Oven Door:

• Open the door fully and use a screwdriver to pry the

hinge clips away from the hinge slots. (See Photo

B.)

• Flip the hinge clip toward you. (See Photo C.)

• Close the door until it stops against the hinge clips.

The open hinge clips wilt hold the door open at a

slight angle.

• Grasp the door firmly on the ends of the door

handle, and lift the door up. (There will be some

spring resistance to overcome.) When the door is

lifted sufficient to clear the hinge hooks, the door

can be pulled straight out. (See Photo D.)

• Place the door in a safe and stable location.

To Reinstall the Oven Door:

• Position the door at a slight angle and insert the

hinges into the hinge slots - one on each side of the

range. The hinges will securely hook into the slots

when properly installed. Do not force, bend, or twist

the door.

Tip: Rest the door on your foot while using your leg for

stability.

• Open the door fully and use a screwdriver to push

the hinge clips all the way into the hinge slots. Be

careful not to scratch the range during this process.

To Check Door Fit and Operation:

• Open and close the door slowly to test the movement

and the fit of the door to the oven cavity. Do not force

the door to open or close, tf the door is properly

installed, it should move smoothly and rest straight

on the front of the range when closed.

• tfthe door does not operate correctly, verify that the

hinges are properly seated into the hinge slots, and

that the hinge clips are fully engaged into the slots.

Photo B. Pry hinge clips out using a screwdriver.

Photo C. Flip hinge clips toward you.

Photo D. Hinges removed from oven.

15

Page 19

Step 9 Burner Test and Adjustment

Install any loose components, such as burner caps

and grates that may have been removed earlier. Be

certain that burner caps seat properly into the burner

bases. Before testing operation of the appliance,

verify that the unit and the gas supply have been

carefully checked for leaks and that the unit has been

connected to the electrical power supply. Turn the

manual gas shut-off valve to the open position.

Test Rangetop Burners

Test Burner Ignition. Select a rangetop burner

knob. Push in and turn counterclockwise to HI. The

ignitor/spark module will produce a clicking sound.

Once the air has been purged from the supply lines,

the burner should light within four (4) seconds.

Test Flame: High Setting. Turn burner on to HI. See

Figure 9 for appropriate flame characteristics.

If any of the rangetop burners continue to burn mostly

or completely yellow, verify that the burner cap is

positioned properly on the burner base, then re-test. If

flame characteristics do not improve, call

Thermador@.

Test Flame: Low Setting. Turn burner on to LO.

Verify that the flame completely surrounds the burner.

There should be a flame at each burner port and there

should be no air gap between the flame and the

burner. If any burners do not carry over, call

Thermador@.

The two far left burners feature XLO®, causing the

flame to cycle on and off when the knob is set to the

XLO range. This is normal operation.

Repeat the Ignition and Flame Test procedures de-

scribed above for each rangetop burner and the grill

burner (if so equipped).

FIG. 9 Flame Characteristics

Yellow Flames:

Further adjustment is required.

Yellow Tips on Outer Cones:

Normal for LP Gas.

Soft Blue Flames:

Normal for Natural Gas.

Ifthe flame iscompletely or mostly yellow, verify that the

regulator is set for the correct fuel. After adjustment,

retest.

Some orange-colored streaking is normal during the

initial start-up.

Allow unit tooperate 4-5 minutes and re-evaluate before

making adjustments.

WHEN FLAME IS PROPERLY ADJUSTED:

. There should be a flame at each burner port.

. There should be no air gap between the flame

and burner port.

The gas grill uses a tube-style burner that has an air

shutter which allows adjustment to the amount of

primary air inside the burner tube.

Air shutters of tube-style burners are pre-adjusted at

the factory, and usually do not require re-adjustment

except under rare conditions such as installation at

high altitude.

If grill burner/flame adjustment is required, go to the

procedure: "Flame Adjustment (if necessary)".

16

Page 20

Step 9: Burner Test and Adjustment

Test Oven Burners

Remove the oven bottom cover. Remove the 4 screws

that attach the cover to the bottom of the oven, then lift

the cover and angled baffle plate out to expose the U-

shaped bake burner.

Test Bake Burner mgnition

Set the oven to BAKE at 350°F. After a short delay, the

burner will ignite. The burner will stay lit until 350°F is

reached and then shutoff. From this point forward, the

burner will cycle on and off to maintain the tempera-

ture.

Test Bake Burner Flame

While the bake burner is lit, inspect the flame. See

Figure 9 for proper flame characteristics. If the flame

burns completely or mostly yellow, it is necessary to

adjust the bake burner air shutter. See Figure 10 and

the Flame Adjustment procedure in the following

section.

Test Broil mgnition

Set cooking mode to BROIL. The broil burners will

ignite after 30-75 seconds.

F_ame Adjustment _if necessary}i."

Tube-style gas burners used in Thermador© appli-

ances have air shutter systems which are similar to

the illustration in Figure 10, and can be adjusted using

the following method (unless adjustment is not rec-

ommended). It is necessary to remove the burner

from the appliance in order to perform air-shutter

adjustments.

• Loosen shutter screw(s) and turn shutter to new

position.

• Adjust the shutter to more-closed position if the

flame is lifting or blowing, or is not carrying over.

Adjust the shutter to more-open position if the

flame is too yellow. (See Figure 10.)

• Re-tighten the shutter screw(s).

• After adjustment, re-installthe burnerand perform

flame evaluation. The air shutter must fit over the

orifice hood for proper operation of the burner.

• Repeat procedure as needed until flame char-

acteristics are acceptable. (See Figure 9.)

NOTE: The two infrared ceramic broil burners do not

have air shutters, so no adjustment is provided.

RepLace oven bottom cover. Slide cover into place

and reattach to bottom of oven cavity.

WARNtNG

Burner adjustments must be performed by a

qualified technician. Rmproper adjustments may

cause harmfu_ by-products or void the

appliance's warranty.

AHow burners to coo_ before attempting to

remove them!

F_G. 10 Air Shutter Adjustment (if necessary)

Screw

More Carryover

Less Lifting or Blowing

Call Thermador@ if:

1. Any of the burners do not light.

2. The broil burner or bake burner flame goes

out before the oven heats to the desired

temperature.

3. Any of the burners continue to burn yellow.

17

Page 21

INSTALLER CHECKLIST

FINAL CHECK LiST

[] Specified clearances main-

tained to cabinet surfaces.

[] Unit Level - front to back -

side to side.

[] Burner caps positioned prop-

erly on sealed burner bases.

[] Allpackaging materialremoved.

[] Island trim or backguard at-

tached (if horizontal clearance

to combustible materials be-

hind cooking surface is less

than 12").

[] Check door adjustment and

hold down brackets.

[] Kick panel in place and two (2)

screws secure.

[] The griddle plate and frame is

correctly positioned, tilted

slightly forward. (See page 9

for adjustment procedure.)

GAS SUPPLY

[] Connection: 3/4" NPT with

a minimum 3/4" diameter

flex line.

[] Theapplianceisconnectedonly

to the type of gas for which it is

certified for use.

[] Manual gas shut off valve in- []

stalled in an accessible loca-

tion (without requiring removal

of range).

[] Unit tested and free of gas []

leaks.

[] Gas supply pressure does not []

exceed 14" W.C. (34.9 mb).

ELECTRICAL

[] Receptacle with correct over-

current protection is provided

for service cord connection.

[]

Proper ground connection.

[]

Proper polarity at receptacle. []

[]

A NEMA 5-20,120 VAC recep-

tacle is used for gas range

models with electricgriddlewith

20 AMP over-current protec-

tion.

OPERATION

[]

If used on propane gas, verify

that the propane gas supply is

equipped with its own high pres-

sure regulator in addition to the

pressure regulator supplied

with the appliance.

Grill components properly

seated (not all models). Refer

to Use & Care Manual for Grill

details.

Bezels centered on burner

knobs, and knobs turn freely.

Each burner lights satisfacto-

rily, both individually and with

other burners operating.

[]

Air Shutter adjustment for

proper flame made for Grill.

See Step 9 and Fig.10.

[]

Griddle is tilted _forward

and does not rock (not all mod-

els).

Oven door hinges seated and

hinge locks in proper position.

Door opens and closes prop-

erly.

[]

Burner grates correctly posi-

tioned, level, and do not rock.

[]

INSTALLER: Leave the Care

and Use Manual and Installa-

tion Instructions with the owner

of the appliance.

To Clean and Protect Exterior Surfaces

The stainless steel surfaces may be cleaned by

wiping with a damp soapy cloth, rinsing with clear

water and drying with a soft cloth to avoid water

marks. Any mild glass cleaner will remove fingerprints

and smears.

For discolorations or deposits that persist, refer to the

Care and Use Manual.

To polish and protect the stainless steel, use a cleaner/

polish such as Stainless Steel Magic _.

DO NOT allow deposits to remain for long periods of

time.

DO NOT use ordinary steel wool or steel brushes.

Small bits of steel may adhere to the surface causing

rust.

DO NOT allow salt solutions, disinfectants, bleaches

or cleaning compounds to remain in contact with

stainless steel for extended periods. Many of these

compounds contain chemicals which could prove

harmful. Rinse with water after exposure and wipe dry

with a clean cloth.

18

Page 22

NOTES

Page 23

Veuillez lire toutes les instructions

avant de poursuivre

Important : Conservez ces instructions pour I'inspecteur local de la compagnie de gaz.

Installateur : Veuillez laisser ces instructions d'installation avec I'appareil pour le propdetaire.

Propri_taire : Veuillez conserver ces instructions pour consultation ulterieure.

AVERTISSEMENT

Coupez I'electdcit6 avec d'installer I'appareil.

Avant de remettre I'electricit6, assurez-vous

que toutes les commandes sont sur la position

OFF.

IMPORTANT

Les reglementations locales varient.

L'installation, les raccordements au gaz et les

mises & la terre doivent 6tre conformes &toutes

les reglementations appficables.

AVERTISSEMENT ".

L'information fournie dans le present

manuel dolt _tre tres rigoureusement

respectee, sous peine d'incendie ou

d'explosion entraTnant des dommages,

des blessures ou la mort.

Ne stockez pas et n'utilisez pas d'essence ou

autres produits inflammables a proximite des

appareils.

oSl VOUS DETECTEZ UNE ODEUR DE GAZ

Pour les installations au Massachusetts •

1. L'installation doit _tre realis6e par un

entrepreneur qualifie ou agre6, un plombier

ou un installateur de gaz qualifie ou autodse

par I'€:tat ou la region darts laquelle cet

appareil est installe.

2. Le robinet d'arr6t de gaz doit _tre pourvu

d'une poignee en <<T >>.

3. La Iongueur maximum autorisee du tuyau de

gaz est de 91,4 centimetres (36").

_ AVERTISSEMENT

m Toutes ruescuisini@res

peuvent basculer

m Des personnes peuvent

_tre bless_es

m InstaHez un dispositif

antibascu_e

m Consu_tez _es instructions

d'instaHation

[] N'allumez aucun appareil.

[] Ne touchez pas aux interrupteurs electriques.

[] N'utilisez pas les tel6phones du b&timent.

[] Appelez immediatement votre compagnie de

gaz de chez un voisin. Suivez Jes instructions

de Ja compagnie.

[] Si vous n'arrivez pas a contacter votre

compagnie de gaz, appeJez Jes pompiers.

--L'instaJJation et les reparations doivent 6tre

reaJis6es par un instaflateur qualifie, un centre

de reparation agre6 ou Jacompagnie de gaz.

AFIN DE DIMINUER LES RISQUES DE

BASCULEMENT, INSTALLEZ UN DISPOSITIF

ANTIBASCULE. ASSUREZ-VOUS QUE LE

DiSPOSITIF ANTIBASCULE EST BIEN EN

PLACE, CONFORMEMENT AUX INSTRUC-

TIONS D'INSTALLATION (REMARQUE : LE

DISPOSITIF ANTIBASCULE EST OBLIGATOIRE

POUR TOUTES LES CUISINII_RES DE 76,2 CM

[30"] ET DE 91,4 CM [36 "]).

Remarque: Cette cuisiniere N'EST PAS congue

pour les maisons mobiles ni pour les vehicules

recr6atifs.

NE PAS installer cette gamme dehors.

Page 24

Table des matieres

Informations importantes apropos de Finstallation .......... 1

Chapitre I : Exigences pour JaventiJation ....................... 2

Chapitre 2 : Pr6paration de Femplacement ............... 3 - 7

Chapitre 3 : D6balJage, manutention et mise

en pJace de Jacuisini6re ........................................... 8 - 9

Chapitre 4 : Installation du dispositifantibascuJe... 10 - 11

Chapitre 5 : Exigences pour Falimentation de gaz et

raccordement ............................................................... 12

Chapitre 6 : Exigences pour Falimentation 6Jectdque,

le branchement et Lamise a Laterre .............................. 13

Chapitre 7 : InstaJlation de Japlaque de protection ........ 14

Chapitre 8 : Enlever et installation de Japorte ............... 15

Chapitre 9 :Tests et r6glages de brOleurs ............. 16 - 17

Liste de v6rification de J'installateur .............................. 18

Nettoyage et protection des surfaces externes .............. 18

Page 25

Informations importantes a propos de l'installation

VERIFICATION DU TYPE DE GAZ

V@ifiezletyped'aJimentationaugazfournidulieud'instalJation.

L'appareil doit 6tre raccorde au type degaz pour lequel ilest

certifie. Toutes les cuisini@es sont certifiees pour une

utilisation avec du gaz naturel ou du gaz propane.Assurez-

vous que la cuisini@e correspond au type de gazdisponible.

IMPORTANT

• On dolt mettre en pJace une pJaque de protection

lorsque l'espace horizontal entre les mat@iaux combus-

tibles et le bord arri@e de la cuisiniere est de moins de

30,5 cm (12"). On doit commander separ6ement la plaque

de protection basse Thermador et on doit I'installer

l'arri@e de la cuisini@e. Pour les instalJations en riot et

autres installations avec un espace de plus de 30,5 cm

(12"), un enjoliveur en acier inoxydable est vendu en

option afin de recouvrir les brides de montage de la plaque

de protection.

• Assurez-vous que I'appareiJ convient au type de gaz

fourni. Consultez le Chapitre 5 de la page 12 avant de

proceder a l'instalJation.

Alimentation en gaz :

Gaznaturel : 14,9mbmin.(6poucesalacolonned'eau),min.

34,9 mb (14 pouces) max.

Gaz propane : 27,4 mb (11 pouces a lacolonne d'eau),min.

34,9 mb (14 pouces) max.

Alimentation _[ectrique :

Mode[es de 76,2 cm (30")

4brOleurs:120VCA,60Hz,monophase,circuitde 15A.

Modeles de 91,4 cm (36")

6brOleurs:120VCA,60Hz,monophase,circuitde15A.

4brOleursavecgri!:120VCA,60Hz,monophase,circuitde15A.

4brOleursavecgrille:120VCA,60Hz,monophase,circuitde20.

Modeles de 121,9 cm (48")

6brO[eursavecgril:120VCA,60Hz,monophase,circuitde15A.

6brOleursavecgrille:120VCA,60Hz,monophase,circuitde20A.

4brOleursavecgri!etgri!le:120VCA,60Hz,monophase,circuitde20A.

MtSE EN GARDE

Si I'appareil est aliment_ au gaz propane,

assurez-vous que le r_servoir de propane est

_quip_ de son propre d_tendeur en su$ du

d_tendeur fourni avec la cuisini_re. La pression

maximum d'arrivee du gaz de cet appareil ne doit

pas depasser les 34,9 miJlibars (14 pouces a la

colonne d'eau) entre le reservoir de propane et le

detendeur.

MtSE EN GARDE

Cet appareil est congu pour un usage cuJinaire.

Pour des raisons de securit6, ne I'utilisezjamais

pour chauffer une piece.

Cet appareil est conforme a une ou plusieurs normes

ci-dessous

UL858 - norme pour la securit6 des cuisini@es

electriques domestiques.

UL923 - norme pour la s¢curite des fours a micro-

ondes

UL507 - norme pour la s6curite des ventilateurs

electriques

o ANSI Z21.1- norme nationale am@icaine pour les

appareiJs de cuisson a gaz domestiques

, CAN/CSA-C22.2 n° 113-M1984 - ventilateurs

o CAN/CSA-C22.2 n°6 I-M89 cuisini@es domestiques

On recommande fortement d'installer une hotte de ventilation

adaptee au-dessus de cet appareil (voir Chapitre 1,Exigences

de ventilation). Comme cet appareil peut degager une forte

chaleur, on doit porter une attention particuliere aux travaux

d'instalJations des conduits et de la hotte, lesquels doivent

6tre conformes a la reglementation locale de construction.

C'est la responsabilite du propri@taire et l'instalJateur pour

determiner si les normes de et/ou de conditions

supplementaires s'appliquent aux instalJations specifiques.

MtSE EN GARDE

Afin d'_liminer les risques de br01ures ou

d'incendie provoqu_s par la chaleur, il est

eonseill_ d'_viter d'installer des armoires au-

dessus des tables de cuisson des appareils.

V@ifiez la reglementation IocaJeapplicable pour connattre la

bonne methode d'instalJation de l'appareil. Les

reglementations IocaJesvarient. L'instalJation,le branchement

electrique et la mise a la terre doivent respecter toutes les

reglementations applicables. ,_defaut de reglementation,

l'appareil doit _tre installe conformement aux normes

am@icaines en vigueur sur legaz combustibleANS JZ223.1/

NFPA54 et l'electricite ANSI/NFPA70. Au Canada,

l'installation doit _tre conforme aux normes canadiennes

CAN 1zB149.1 et .2du Code du bgtiment pour I'installation

d'appareils fonctionnant au gazet/ou le code de construction

local.

Page 26

Chapitre 1

"Exigences pour la ventilation

IIest fortement recommande d'installer

une hotte de ventilation appropriee au-

dessus de lacuisini@e. Une ventilation

par contre-tirage ne devrait pas 6tre

utilisee. Le tableau ci-dessous

enum@e, par num@o de modeJe, les

hottes Thermador que I'on conseille

d'utiliser avec les cuisini@es.

1, Choi× du mod¢le de

hotte et de ventilateur

• Pour les installations muraJes, la

largeur de la hotte doit _tre au

moins egale a celle de la table de

cuisson dela cuisini@e. Si l'espace

le permet, il est souhaitable

d'installer une hotte plus large que

la table de cuisson pour ameJiorer

les performances de ventilation.

• Pour les installations en riot, la

largeur de lahotte devrait depasser

d'au moins 7,62 cm (3") des deux

c6tes de la table de cuisson de la

cuisini@e.

Les hottes de ventilation et les

ventilateurs sont congus pour une seule

conduite murale. Certaines

reglementations municipales du

batiment exigent toutefois une double

conduite. Consultez les normes

appJicables et/ou la municipalite avant

de debuter les travaux pour vous

assurer que l'installation des conduites

repond aux exigences locales.

Nepas installer lecombine four a micro-

ondes et ventilateur au-dessus de la

cuisini@e, car ces types d'appareils

n'assurent pasune ventilation adequate

et ne conviennent pas pour une

utilisation avec les cuisini@es.

2_

Emplacement de l;i hotte

Le bord inf@ieur de la hotte doit

6tre installe a un minimum de 36

po au-dessus de la surface de

cuisson de la cuisini@e. De plus,

utiliser un degagement minimum

de 36 po si la hotte contient des

materiaux combustibles tels

recouvrement en bois (figure 1).

3_

Apport d'air

Un important volume d'air etant

n6cessaire pour la ventilation, il

est recommande de prevoir un

apport d'air de l'ext6rieur. Cet as-

pect rev6t une importance

particuliere dans les Iogements

bien isoJ6s et tres 6tanches.

II est conseiJJ6 de consulter un

entrepreneur en chauffage et en

climatisation.

PH30CS VTR1030D,

CUISINIERE

DE 76,2 CM(30po)

CUISINIERE

DE 91,4 CM (36 po)

CUISINJE_RE

DE 121,9 CM(48po)

Remarques : * Pour les installations murales, si I'espace est suffisant, I'instaJJateur ou l'utilisateur peut choisir

une hotte plus large que la surface de cuisson de la cuisini@e. Ceci peut 6tre particuli@ement

ben6fique pour les installations ayant un long chemin de conduits ou lorsque l'utilisation du grilest

prevue, ce qui permet d'ameliorer l'echappement de cuisson.

** Pour les installations murales, Thermador propose des modeles de ventilateurs a distance

(VTRI030D ouVTR1530D)ou interne (VTNI030C).

PHE30 / 36 VTR1530D,

orVTN1030C

HNW36YS VTRI030D,

or VTR1530D

PH36CS/42CS

PHE36/42

HNW36YS /42YS

PH48CS / 54CS

PHE48 / 60

HNW48YS VTR1030D,

VTRI030D,

VTR1530D,

orVTNI030C

VTRI030D,

orVTRI530D

VTRI030D,

VTR1530D,

orVTNI030C

orVTRI530D

HNI42YS VTR1030D

HTNI42YS orVTR 1530D

HNI42YS VTR1030D

HTNI42YS orVTR1530D

HNI48YS / 54YS

HTNI48YS / 54YS

VTR1530D

Page 27

Chapitre 2 Preparation de l'emplacement

.

La cuisiniere est un appareil monobloc. Si elle est

placee au milieu des armoires, les degagements

requis sont indiques a la Figure 1. Les m6mes

degagements s'applJquent aux installations en

riot, excepte pour les armoires suspendues qui

doivent laisser un espace suffisamment grand

pour poser la hotte d"flot evas6e, comme le montre

la Figure 1.

.

Les cuisinieres de 91,4 cm (36") peuvent etre

encastrees entre les armoires au-del& du bord de

la pattie frontale du four (voir Figures 2A et 2B).

Les cuisinieres de 76,2 cm (30") et de 121,9 cm

(48") ne sont pas homologuees pour etre installees

ras des armoires.

MISE EN GARDE

Darts ce type d'instaHation pour Jes cuisini_res

de 91,4 cm (36"), la porte et I'armoire peuvent

comporter un risque de pincement.

3. Les arrivees d'electricite et de gaz doivent se

trouver darts les zones indiquees a la Figure 3A.

REMARQUE :La profondeur maximum des armoires

en hauteur installees d'un cete ou de I'autre de la hotte

est de 33 cm (13").

Un degagement minimum de 91,4 cm (36") est

necessaire entre le dessus de la cuisiniere et le

dessous d'une armoire non protegee. II est

recommande que le bas de I'armoire en bois ou en

metal soit proteg6 par un materiau ignifuge d'au

moins 6,35 mm (1/4") revetu d'une feuille d'acier n° 28

MSG d'au moins la meme epaisseur, de 0,38 mm

(0.015") d'acier inoxydable, de 0,6 mm (0.024")

d'aluminium ou de 0,5 mm (0.02") de cuivre. Les

materiaux ignifuges portent la marque suivante :

UNDERWRITERS LABORATORIES iNC.

CLASSIFIED MINERAL AND FIBER BOARDS

SURFACE BURNING CHARACTERISTICS,

(PANNEAUX DE FIBRES ET MINERAUX CLASSES

CARACTERISTIQUES D'INFLAMMATION DES SUR-

FACES)

Suivie des taux de progression des flammes et des

fumees. Ces designations sont indiquees par <<FHC >>

(Flame Spread/Smoke Developed - Progression des

flammesiProduction de fumee). Les matedaux ayant

un taux <<O >>de progression de flammes sont

ignifuges. La reglementation municipale peut autoriser

un taux de progression des flammes different.

4. Toute ouverture dans lemur qui se trouve derriere

la cuisiniere et dans le plancher sous la cuisiniere

doit etre refermee.

.

Si la distance entre un matedau combustibleA et

le bord arriere de la cuisiniere au-dessus de la

table de cuisson est de moins de 30,5 cm (12"), il

est obligatoire d'installer un basse ou a tablette

pour casseroles Thermador (voir Figure 2A). Si la

distance du matedau combustible Aest supedeure

30,5 cm (12"), il est possible d'utiliser un enjoliveur

Thermador pour Tlot (voir Figure 2B). Les Figures

2A et2B indiquent Fespace necessaire pour chaque

type de plaque de protection.

6. Un degagement minimum de 3 po est necessaire

Iorsque la cuisiniere est installee & c6te d'un mur

lateral combustible.

.

L'appareil ne doitjamais se trouver Aproximite de

materiaux combustibles, d'essence et d'autres

produits inflammables (vapeurs ou liquides).

.

L'air de combustion et de ventilation arrivant

I'appareil dolt pouvoir circuler librement darts les

conduites.

A Tel qu'il est defini par le Code national de

combustible & gaz (ANSI Z223.1 / NFPA 54, derniere

edition.)

Page 28

Chapitre 2 " Preparation de l'emplacement

_I, MISE EN GARDE

N'installez pas les modeles de cuisinieres de 30" et 48" que Japorte

du four soit au ras de la pattie frontale des armoires. Une installation

& m6me niveau risque d'endommager les armoires dO a leur exposi-

tion a la chaleur.

FIG. 1 - Degagement des armoires

.... ( _f Hottede76 2cm (30")ou de91 4cm (36")

Culslnlere de76,2 cm,30 , ,.... , . . .

Culstnlerede91 4cm(36 ) ....

...... { 36"ou42" Hotte I

C_u ' 106,7cm(42 )ou 121,9cm(48 )pour installation en_lot #

isinierede 121 9cm(48"/< t H°tte de 121,9 cm(48"), 137,2 cm (54") ou 152,4cm(60")

' " "L 121,9 cm (48")ou 137,2 cm (54") pourinstallation enTlot

_ 91,4cm (36)ou 106,7cm(42 )pourtnstallatlonemlot

1

Conversion des mesures

76,2 cm = 30"

91,4cm=36"

106,7 cm = 42"

121,9 cm = 48"

137,2 cm = 54"

152,4 cm = 60"

• I

T

Distance min.

de 45,8 cm

(18")

oo T

Distance rain.de 91,4 cm (36")

entre le dessous de la hotte et la

table de cuisson (aussi 91,4 cm

rain. [36" min.] si la hotte

contient desmateriaux

combustibles A).

1

o j

oo

*Hauteur min. de la cuisiniere

avec pieds 61evateursentierement

r6tractes : 91,1 cm (35-7/8")

*Hauteur max. de la cuisinWre

avec pieds 61evateursentierement

deploycs : 93,3 cm (36-3/4").

suspenduescomposees de materiaux I. I O

-- Distance minimum entre les armoires -_ I

combustibles Z_ "_ --

Cuisinieres de 30 ° 76,2 am Profondeur._

Cuisinieres de 36" = 91,4 cm max. de _,.._..e

.... ,, I'armolre : f "_

Culsmleres de 48 = 121,9 cm 33 cm (13")J MISE EN GARDE : Voir

Largeur de la cuisini@re _ <laterale _ entre la table de cuisson

76,2 cm (30"), 91,4 cm (36") combustibleen

ou 121,9 cm (48") msteriauA (de etlesmateriaux

r- "1 o

I I

Table de I

" o

-- Fig. 3A). Les dimensions etta position de

/ Zone d'arrivee d'6tectricit6 etde gaz (voir X

.I,

cette zone varien selon temod@te. ,_

Min.7,6cm Fig. 2A et 2B. Distance

(3")a paroi rain. de 91,4 cm (36")

deuxc6tes), combustibles A.

",,,

Page 29

Chapitre 2 " Preparation de l'emplacement

FiG. 2A - Vue [at_ra[e

'/ //// //// 1t// --combustiNes A

32-5/8"--_

I

I

I

Min. 91,4 cm (36") !

des combustibles A I

29-1/2" ,,_

TaMette _.12-7/8._

Plaque de _ I t

protection _ I I |

b_se \ l__J....... 22"

1

I I

,_-_--- 26-3/8" ----_ I"

! _-25-1/2"max, Z

/

1

!

I l:?Plaque

I d'habitlage

|//// ///t"

i

!

I

I '_ 47-3/8" _,I

, I

A Tel que defini darts [e Code national du gaz combustible

(ANSI Z223.1, version courante).

/Partie frontale I

9,5 mm (3/8")

_-- 29-1/2"

II [ -._-Mur

'! -f//,/ /./// /_1_//'_r /,///

i._.---28_3/8" -----_

Materiaux

Conversion des mesures

9,5 mm = 3/8"

9,8 cm = 3-7/8"

30,4 cm = 12"

32,7 cm = 12-7/8"

55,9 cm = 22"

64,7 cm =25-1/2"

66,9 cm =26-3/8"

72,1 cm = 28-318"

74,9 cm = 29-1/2"

82,9 cm = 32o5/8"

120,3 cm = 47o3/8"

FiG. 2B - Vue [at_ra[e

CoRversioR des mesures

91,4 cm = 36"

30,5 cm = 12"

3,2 mm = 1/8"

10,6 cm = 4"

I

Distancerain.

de9_,4cm

(36"}avecles

materiaux

combustibles

I

At

i

I

L

C

i

Distance rain. de 30A

cm (12") entre les

avec installation

Enjoliveur

pour ?lot. _4"

Pattie

Jfrontale

_ Mat6riaux

combustibles A

REMARQUE :

/ Pour installer ['enjoliveur pour riot,

[e plan de travail doit avoir un bord

en porte=&=faux venant se placer

bord & bord avec I'arriere de

['enjoliveur.

--Aire de travail en porte=a=faux

REMARQUE :

Si une paroi interne est utilisee sous

I'aire de travail en cantilever, la dis-

tance entre cette paroiet farriere

de la cuisiniere doit ¢tre de 3,2 mm

(I/8").

Page 30

Chapitre 2 " Preparation de l'emplacement

GAZ ET ZONE ELECTRIQUE D'ARRIVEE

FiG. 3A • Gaz et zone eiectrique d'arrivee de routes tes cuisini@es

InstalJation typique

illustree. Un autre type

d'installation du gaz et de

l'alimentation electrique et

du receptacle darts la

zone d'alimentation du

gaz et de I'alimentation

electrique est acceptable.

REMARQUE :

Si non deja

presente, installer

unesoupaped'arrSt

de gaz dans un

endroit accessible.

S'assurer que tout

utilisateur

51 cm (2") _ partir

du tour de larriv@

connaisse o(4est la

soupape et sache

comment fermer

l'aJimentation a la

cuisini@e.

REMARQUE :

l'installateur doit in-

former le con-

sommateur de

l'emplacementde la

soupape d'arr6t de

gaz.

Tuyau flexible de

19 mm (3/4") vers

FappareiJ

Zone

d'arriv@e

Sail{ie maxde

des gaz

ModeJe A B C D E

30" 20,3 cm 30,5 cm 25,4 cm 16,5 cm 13,3 cm

36" 26,4 cm38,1 cm 26,4 cm16,5 cm 13,3 cm

48" 41,9 cm40,6 cm 39,4 cm 16,5 cm 13,3 cm

Plancher

REMARQUE : Toute ouverture dans le mur se

trouvant derriere I'appareil ou dans le plancher

sous I'appareil doit 6tre bouchee.

Toutes les cuisinieres a gaz

peuvent etre raccordees au

secteur a I'aide du cordon

d'alimentation fourni avec la

cuisiniere ou bien directement

c&blees. L'installateur doit foumir

les 61ements de c&blage qui

conviennent (cordon ou conduite

et c&bles) et realiser le

raccordement au gaz

conformement & la

reglementation locale etiou au

Code national de I'electricit& On

doit installer une mise a la terre

adequate pour les appareils. Voir

le Chapitre 6 pour plus de details.

La cuisini_re ne doit _tre

raccord_e qu'au type de gaz

pour lequel elle est certifi_e.

Si elle est raccordee au gaz pro-

pane, le reservoir de

propane doit etre dote de son

propre detendeur en plus du

detendeur fourni avec la cuisini@e

(volt Chapitre 5).

Conversion des mesures

20,3 cm = 8"

30,5 cm = 12"

25,4 cm = 10"

16,5 cm = 6-1/2"

13,3 cm = 5-1/4"

26,4 cm = 10-1/2"

38,1 cm = 15"

39,4 cm = 15-1/2"

40,6 cm = 16"

41,9 cm = 16-1/2"

IMPORTANT :

Les cordons fournis avec les cuisinieres au gaz dotees d'une

plaque de cuisson requi@ent un receptacle NEMA 5-20 tel

qu'indique ci-dessus. IIest possible que le code de la construction

local exige une methode differente de filtage.

PRISE

RECEPTACLE

NEMA5z20

Page 31

Chapitre 2 Preparation de l'emplacement

Alimentation electrique

L'installation des cuisinieres & gaz doit 6tre planifiee

de sorte que Ja boTte de derivation pour la prise ou la

connexion de la conduite laisse le maximum d'espace

I'arriere de I'appareil.

FIG. 3B - RACCORDEMENT AU MUR

Ce point est particulierement important si la botte de

derivation murale se trouve juste derriere la botte de

derivation de I'appareil une fois celuFci installe. Afin

de minimiser les torsions Iors du branchement de

I'appareil a la prise ou a la botte, odentez en premier

lieu la prise ou le connecteur de la conduite et faites

glisser sur la position.

/

.......D,,-4 __5,7 cm (2ol/4")

' !. unefoisbranche

Cordon d'aHmentation et prise

Pour tousles modeles dotes d'une plaque de cuisson,

une alimentation dedi6e de 20 A est requise pour bien

fonctionner.

max.

Page 32

Chapitre 3 " Deballage, manutention et mise en place de la cuisiniere

MtSE EN GARDE

Un _quipement adapt_

manipu[_ par du personnel

exp_riment_ doit _tre utilis_

pour d_plaeer la euisini_re

afin de ne pas endommager

I'appareil nile plancher. La

cuisini_re est Iourde et

repose sur des pieds

r_glables en acier.

Le poids approximatif de la

cuisiniere & I'expedition est celui

qui est indique au Tableau A. II

est necessaire d'6ter les grilles

des brOleurs, la plaque de

cuisson, les chapeaux des

brGleurs, la plaque d'habillage et

les grilles du four pour faciliter

la manutention. Le poids de

I'appareil s'en trouvera diminue,

tel qu'indique au Tableau A et

permettra a la cuisiniere de

passer par une porte de

76,2 cm (30"). Voir Figures 2A

et 2B a la Page 5. N'6tez pas

[e gri[ ni [a plaque de cuisson.

Tableau A Cuisini_rede Cuisini_rede Cuisinierede

76,2cm(30"} 91,4¢r_(36") 121,9¢mBS")

Poids a l'expedition

Poids sans materiaux

d'embalIage

Poidshors porte(s),

chapeauxde brOteurs,plaque

d'habiitageetgrillesde four

FIG. 4 - Retrait des deux boulons

avant instalJes pour I'expedition

152kg (335Jb) 201,4kg (444Ib) 264,9 kg (584Ib)

129_3kg(285Ib) 176,9kg(390Ib) 237_6kg( 524Ib)

97.5kg(215Ib) 133,8kg(295Ib) 1792kg(395Jb)

FIG. 5- Retrait des deux boulons

arriere instalJes pour I'expedition

Boulon #rlerp_" Arri6re de

gauche

installe I_OU_

I'expedition

, ,i jJ

I'apparei

Retirez I'emballage externe et

les materiaux d'emballage de la

palette d'expedition. Toutes les

cuisinieres a gaz sent fixees sur

une palette a I'aide de quatre (4)

boulons (voir Fig. 4 et 5). Apres

avoir enleve les boulons,

soulevez la cuisiniere et

enlevez-la de la palette.

IMPORTANT : ne pas

soulever la cuisini_re par la

poign_e de la porte. Cela

peut endommager les

charni_res et la porte peut

real refiner.

REMARQUE : laisser I'epaisseur

en mousse a adhesif sur les sur-

face en metal brosse afin de

proteger le fini des egratignures

tant que la cuisiniere n'est pas en

position finale.

Page 33

Chapitre 3 "Deballage, manutention et mise en place de la cuisiniere

En raison du poids de la cuisiniere, il convient

d'utiliser une plate4orme a roulettes souples

pour la deplacer. Le poids doit 6tre

uniformement reparti sur la plate4orme (voir

Figure 6).

Transportez la cuisiniere sur la plate-forme

pres de son emplacement definitif ,

basculez-la pour qu'elle soit repose sur les

pieds arriere puis retirez la plate4orme.

PROTEGFZ LF SOL SF TROUVANT SOUS

LFS PLEBS AVANT DE MFTTRF LA

CUISlNIERF FN PLACE. Installez le dispositif

antibascule (Chapitre 4), raccordez le gaz et

1'61ectricite (Chapitres 5 et 6) puis installez la

plaque de protection (Chapitre 7) avant de

placer definitivement la cuisiniere.

Pour garantir son bon fonctionnement, la

cuisini_re doit _tre nivel_e. (Ce point est

important pour tousles produits 6quipes d'une

plaque chauffante.) La cuisiniere se nivelle en

reglant les pieds avec une cle.

FIG. 6 - Mise en place sur la plate4orme

roulettes

Le poids de la

cuisiniere doit

6tre

uniformement

r6parti en s'aidant

des supports

plac6s sur te

dessousdela

cuisiniere

Remettez la plaque d'habillage en place puis

installez la porte du four. Pour installer la

porte, voir la page 15. Les deux (2} vis qui

maintiennent la plaque d'habillage doivent

_tre solidement fix_es pour _viter un

contact accidentel avec les surfaces

chaudes.

Assurez-vous que les chapeaux des

br_leurs sont correcternent ass[s sur les

bases des br01eurs de la table de cuisson

de la cuisini_re.

Retirer tout ruban et emballage avant d'utiliser

I'appareil. Detruire I'emballage apres avoir deballer

I'appareil. Nejamais laisser les enfants jouer avec

le materiel d'emballage.

Gril et grille or6glage d'inclinaison (selonle modele)

Verifiez I'ajustement du cadre de la plaque de cuisson en versant deux cuilleres a soupe d'eau sur

la surface de la plaque. L'eau devrait lentement glisser vers le bas a graisse. Si ce n'est pas le cas,

corrigez I'angle a I'aide des deux vis sous le cadre de la plaque de cuisson. Commencez en tournant

les vis d'un quart de tour dans le sens contraire des aiguilles d'une montre. Tout ajustement ulterieur

devrait _tre fait a I'aide des quart de tour jusqu'a ce que I'eau glisse darts le bac a graisse.

Page 34

Chapitre 4 Installation du dispositif antibascule

Pour routes tes cuisini@es de 30" et de 36", un dispositif antibascule doit _tre instaiie

conformement aux instructions suivantes.

AVERTtSSEMENT

DANGER DE BASCULEMENT

Toutes les cuisini@es peuvent basculer etblesser

quelqu'un. Pour eviter unbasculement accidentel,

elles doivent 6tre attachees au sol, au mur ou &

une armoire au moyen de l'installation dudispositif

antibascule qui vous est fourni.

Un risque de basculement demeure si l'appareil

n'est pas instalJe conformement a ces

instructions.

En deplagant la cuisini@e pour nettoyage,

reparation ou autre, assurez-vous que ledispositif

antibascule s'est bien reenclench6 Iorsque vous

repoussez la cuisini@e contre lemur. Sinon,

dans I'hypothese d'une utiJisation anormale

(personne montant, s'asseyant ou s'etendant

sur une porte ouverte), la cuisini@e risque de

basculer et deprovoquer des blessures dues aux

liquides chauds renverses ou au poids de la

cuisini@e.

AVERTISSEMENT

TOUTE8 LES CUI$1NtERES

PEUVI=NTBASOULI=R

DES PERSONNES

PEUVENT ETRE BLESSEES

INSTALLEZ LES

DISPOSlTIFS

ANTIBASCULE FOURNIS

AVEC LA CUISJNIERE

CONSULTEZ LES

INSTRUCTIONS

D'INSTALLATION

_, AVERTJSSEMENT

ATTENTION

RISQUE D'C:LECTROCUTtON

Soyez tr_s prudent Iorsque vous £ercez des

trous darts le tour ou le plancher. Des fiJs

_leetriques peuvent 8tre dissimut_s darts Jes

tours ou darts Jeplancher.

Identifiez les circuits _leetriques £ouvant se

trouver _ I'endroit oQle dispositif antibascute

est instalJ_ puis d_branehez4es.

Le non-respect de ces instructions risque