Thermador PRG486NLH Installation

THERMADOR PROFESSIONALTM PRO HARMONY® Gas Ranges

THERMADOR PROFESSIONALTM PRO HARMONY® Gas Ranges

Models | Modèles | Modelos

Cuisinières Gaz PROFESSIONAL PRO HARMONY

mc

de THERMADOR

Estufas Gas PROFESSIONAL PRO HARMONY® de THERMADOR

Table of Contents............................................................................... 2

Table de Matières ............................................................................ 26

Índice de Materias ........................................................................... 50

PRG304GH

PRG364GDH

PRG366GH

PRG486GDH

PRG364NLH

PRG486NLH

PRL304GH

PRL364GDH

PRL366GH

PRL486GDH

PRL364NLH

PRL486NLH

Table of Contents

Safety Instructions ....................................................................................................................................................... 3

Installation...................................................................................................................................................................... 5

Planning Information ................................................................................................................................................. 5

STEP 1: Ventilation Requirements .......................................................................................................................... 5

STEP 2: Cabinet Preparation ................................................................................................................................... 6

STEP 3: Unpacking, Moving and Placing the Range ............................................................................................. 12

STEP 4: Installing Anti-Tip Device ......................................................................................................................... 13

STEP 5: Gas Requirements and Hookup .............................................................................................................. 14

STEP 6: Electrical Requirements, Connection & Grounding ................................................................................. 15

STEP 7: Backguard Installation (optional) ............................................................................................................. 16

STEP 8: Door Removal and Reinstallation ............................................................................................................ 20

STEP 9: Placing and Leveling the Range .............................................................................................................. 22

STEP 10: Burner Test............................................................................................................................................. 24

Installer Checklist ....................................................................................................................................................... 25

Customer Support, Accessories & Parts .....................................................................................................back page

Safety Definitions

WARNING

This indicates that death or serious injuries may occur as

a result of non-observance of this warning.

CAUTION

This indicates that minor or moderate injuries may occur

as a result of non-observance of this warning.

NOTICE: This indicates that damage to the appliance or property may occur as a result of non-compliance with this

advisory.

Note: This alerts you to important information and/or tips.

This THERMADOR® appliance is made by

BSH Home Appliances Corporation

1901 Main Street, Suite 600

Irvine, CA 92614

Questions?

1-800-735-4328

www.thermador.com

We look forward to hearing from you!

Table of Contents English 2

Safety

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

Before You Begin

IMPORTANT: Save these Instructions for the Local Gas

Inspector’s use.

GROUNDING INSTRUCTIONS

This appliance must be grounded. Grounding reduces the

risk of electric shock by providing a safe pathway for

electric current in the event of a short circuit.

DO NOT install this range outdoors.

INSTALLER: Please leave these Installation Instructions

with this unit for the owner.

OWNER: Please retain these instructions for future

reference.

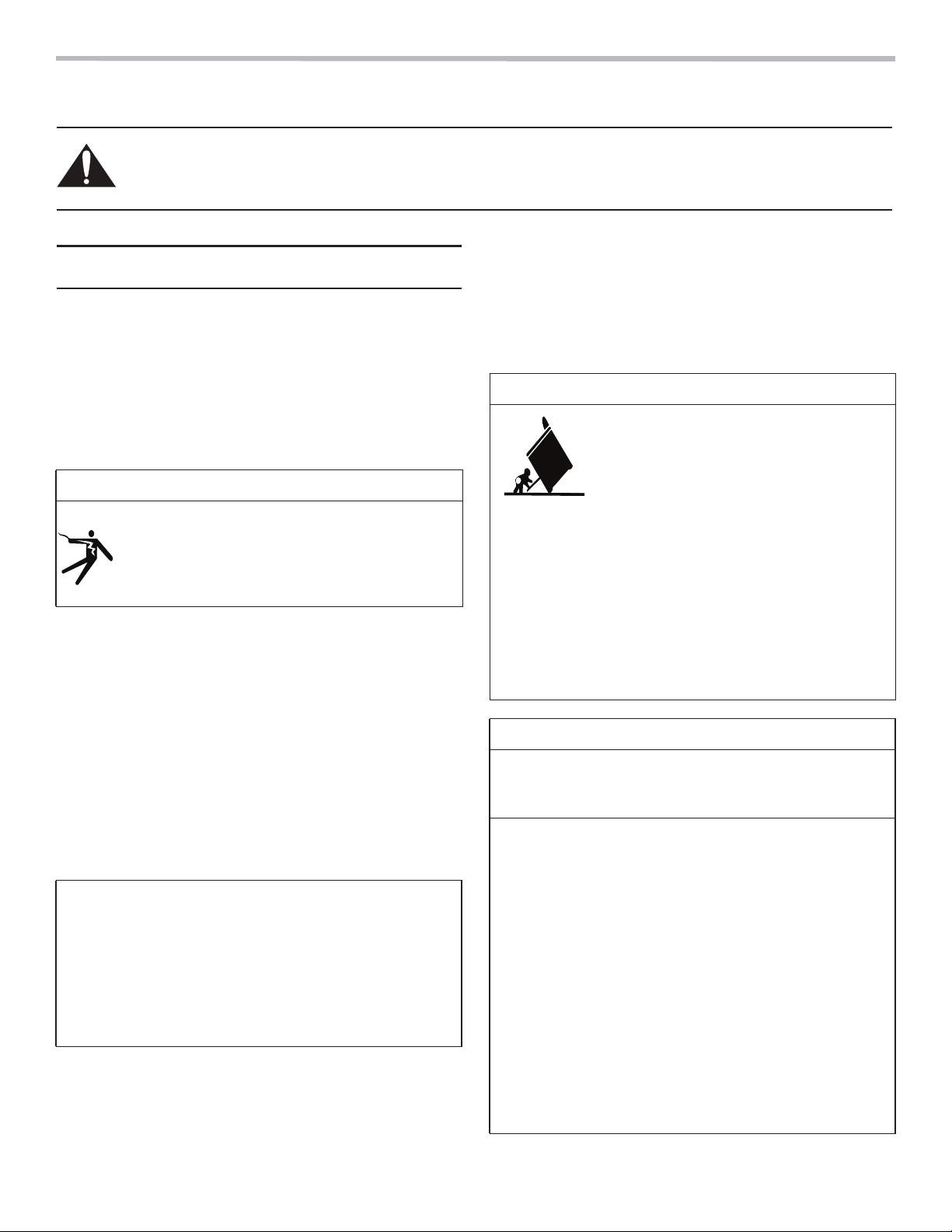

WARNING

ELECTRICAL SHOCK HAZARD

Disconnect power before installing or servicing.

Before turning power ON, be sure that all

controls are in the OFF position. Failure to do

so can result in death or electrical shock.

Examine the appliance after unpacking it. In the event of

transport damage, do not plug it in.

Remove all tape and packaging before using the appliance.

Destroy the packaging after install. Never allow children to

play with packaging material.

IMPORTANT:

Local codes vary. Installer is responsible for ensuring that

the installation, gas connections, and grounding comply

with all applicable codes. Failure to follow appropriate local

codes and regulations may void the warranty.

FOR MASSACHUSETTS INSTALLATIONS:

1. Installation must be performed by a qualified or

licensed contractor, plumber or gas fitter qualified or

licensed by the state, province or region where this

appliance is being installed.

2. Shut-off valve must be a “T” handle gas cock.

3. Flexible gas connector must not be longer than 36''

(914 mm).

NOTE: This range is NOT designed for installation in

manufactured (mobile) homes or Recreational Park

Trailers.

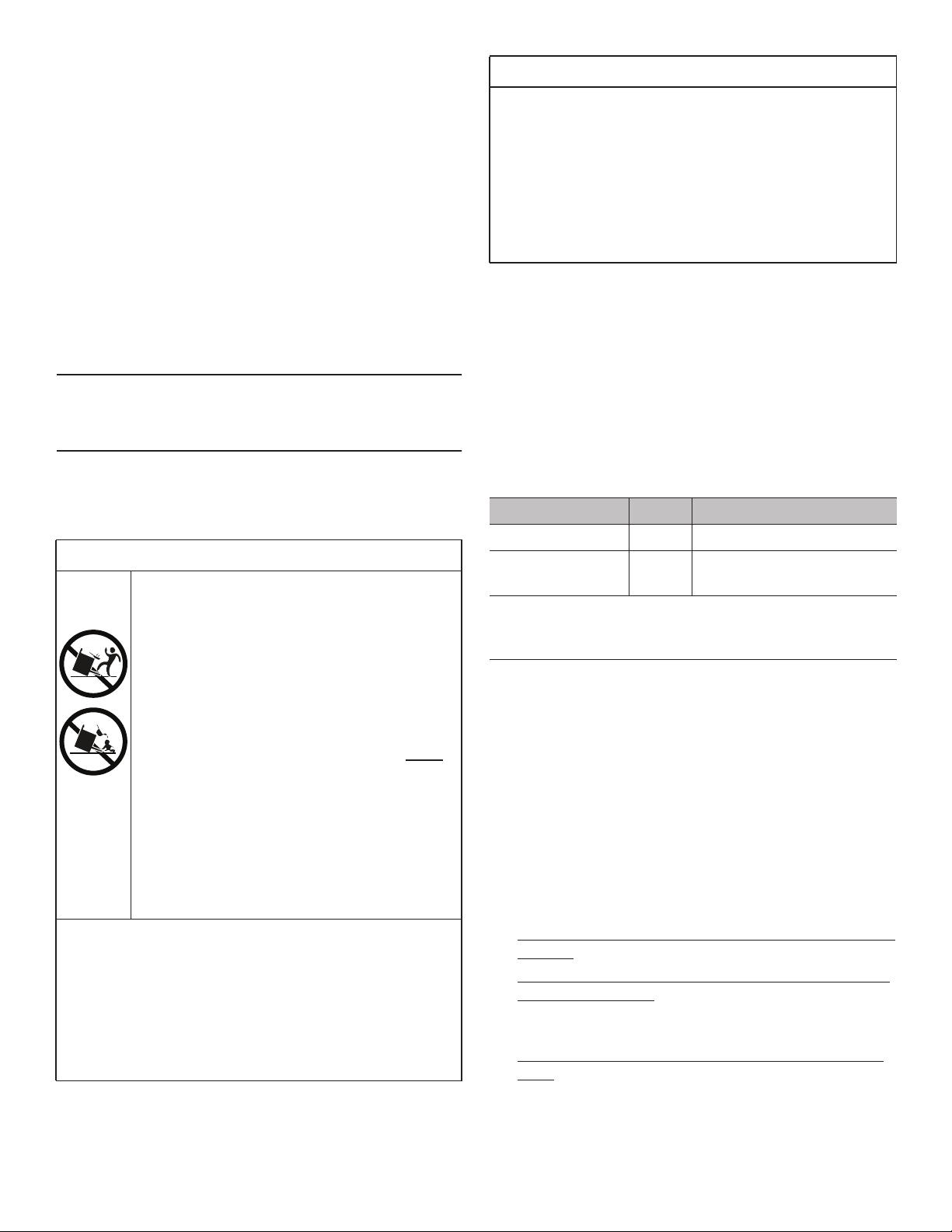

WARNING

A child or adult can tip the range over and

be killed or seriously injured. Verify that

the anti-tip bracket is securely installed.

Ensure the anti-tip bracket is engaged

when the range is moved.

DO NOT operate the range without the anti-tip bracket in

place. Failure to follow the instructions in this manual

can result in death or serious burns to children and

adults.

Check for proper installation and use of anti-tip bracket.

Carefully tip range forward pulling from the back to

ensure that the anti-tip bracket engages the range leg

and prevents tip-over. Range should not move more

than 1'' (2.5 cm).

WARNING

If the information in this manual is not followed exactly, a

fire or explosion may result causing property damage,

personal injury or death.

— DO NOT store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

— WHAT TO DO IF YOU SMELL GAS

• DO NOT try to light any appliance.

• DO NOT touch any electrical switch.

• DO NOT use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the

fire department.

— Installation and service must be performed by a

qualified installer, service agency or the gas

supplier.

Installation Instructions English 3

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

Gas type verification

Verify the type of gas supplied to the location. Ensure that

the appliance is connected to the type of gas for which it is

certified. Ranges are certified for use with only natural gas

or propane (LP) gas. Make certain the range matches the

gas type available; these ranges are NOT convertible

between gas types.

Gas Supply

Natural Gas — 6 inch water column. (14.9 mb) min., 14

inch (34.9 mb) maximum

Propane Gas — 11 inch water column. (27.4 mb) min., 14

inch (34.9 mb) maximum

CAUTION

When connecting the unit to propane gas, make certain

the propane gas tank is equipped with its own highpressure regulator in addition to the pressure regulator

supplied with the range. The maximum gas pressure to

this appliance must not exceed 14.0” water column (34.9

mb) from the propane gas tank to the pressure regulator.

It is the responsibility of the owner and the installer to

determine if additional requirements and/or standards

apply to specific installations.

IMPORTANT:

When installing against a combustible surface, a Low

Backguard is required. A THERMADOR

must be purchased separately. See Step 7 for backguard,

kits and installation information.

When using the Flush Island Trim, THERMADOR

recommends a minimum 12'' (305 mm) rear clearance to a

combustible surface (see “Installation Clearances”).

Clearances from non-combustible materials are not part of

the ANSI Z21.1 scope and are not certified by

CSA. Clearances of less than 12'' (305 mm) must be

approved by the local codes and/or by the local authority

having jurisdiction.

Refer to Table 3, Backguard Kit Model Numbers, for the

correct backguard models that are designed for this range.

After selecting the correct backguard, the range must be

installed properly, using the minimum clearances to

combustible surfaces specified in the Cabinet Preparation

instructions beginning on page 6.

TM

Low Backguard

Electric Power Supply

See “STEP 6: Electrical Requirements, Connection &

Grounding” on page 15 for specifications.

Check local building codes for the proper method of

appliance installation. Local codes vary and it is the

responsibility of the installer to ensure installation is in

accordance with these codes. Installation, electrical

connections and grounding must comply with all applicable

codes. In the absence of local codes the appliance should

be installed in accordance with the National Fuel Gas Code

ANSI Z223.1/NFPA 54 current issue and National Electrical

Code ANSI/NFPA 70-current issue. In Canada, installation

must be in accordance with the CAN 1-B149.1 and .2 –

Installation Codes for Gas Burning Appliances and/or local

codes.

This appliance complies with one or more of the

following standards:

• UL 858, Standard for the Safety of Household Electric

Ranges

• ANSI Z21.1, American National Standard for

Household Cooking Gas Appliances

• CAN 1-1.1-M81, Domestic Gas Ranges

• CAN/CSA-C22.2 No. 61-M89 Household Cooking

Ranges

WARNING

To avoid possible burn or fire hazard, a backguard

designed specifically for this range must be installed

whenever the range is used.

CAUTION

To eliminate risk of burns or fire caused by reaching over

heated surface units, cabinet storage located above the

surface units should be avoided.

CAUTION

This unit is designed as a cooking appliance. Based on

safety considerations, never use it for warming or

heating a room.

WARNING

State of California Proposition 65 Warnings:

This product contains chemicals known to the State of

California to cause cancer, birth defects or other

reproductive harm.

Installation Instructions English 4

Installation

Planning Information

Before using your appliance, be sure to read this manual.

Pay special attention to the Important Safety Instructions

located at the beginning of the manual.

TOOLS NEEDED

7/16" box end wrench or

ratchet

3/16'' (4.76 mm) drill bit 12'' Adjustable wrench

Hand or electric drill Tape measure

Phillips & flathead

screwdrivers

Level Furniture dolly

T-20 Torx screwdriver Protective gloves

ITEMS NOT INCLUDED

3/16'' (4.76 mm) Drywall /

Concrete Anchors

Rope/Twine 3/4'' (19 mm) Flex Line

2 – NPT Flare Adapters

1/8'' (3.17 mm) drill bit

Marking instrument

Pipe Compound / Tape

Due to the high heat of the rangetop burners, do not install

a microwave oven/ventilator combination above the range,

as these type of units do not provide the proper ventilation

and are not suitable for use with the range.

IMPORTANT:

Ventilation hoods and blowers are designed for use with

single wall ducting. However, some local building codes or

inspectors may require double wall ducting. Consult local

building codes and/or local agencies, before starting, to

assure that hood and duct installation will meet local

requirements.

NOTICE: Most range hoods contain combustible

components which must be considered when planning the

installation.

WARNING

This appliance should not be installed with a ventilation

system that directs air in a downward direction toward

the range. This type of ventilation system may cause

ignition and combustion problems with the appliance

resulting in personal injury, property damage, or

unintended operation. Ventilating systems that direct the

air upwards do not have any restriction.

STEP 1: Ventilation

Requirements

Refer to the Ventilation Planning Guide for approved

ventilation combinations.

It is

strongly recommended that this appliance be installed

in conjunction with a THERMADOR vent hood. Due to the

high heat capability of this unit, particular attention should

be paid to the hood and duct work installation to assure it

meets local building codes.

Downdraft ventilation should not be used. The Ventilation

Planning Guide indicates the ventilation hood options and

blower capacity guidelines that are recommended for use

with all THERMADOR ranges.

Ventilation Preparation

1. Select Hood and Blower Models:

• For wall installations, the hood width must, at a

minimum, equal the width of the range. Where

space permits, a hood larger in width than the

range/rangetop may be desirable for improved

ventilation performance.

• For island installations, the hood width should

overhang the width of the range by a minimum of

3" (76 mm) on each side.

2. Hood Placement:

• For best smoke elimination, the lower edge of the

hood should be installed 30" (762 mm) above the

range cooking surface (see “Installation

Clearances”).

• If the hood contains any combustible materials (i.e.

a wood covering), it must be installed a minimum of

36" (914 mm) above the cooking surface (see

“Installation Clearances”).

Installation Instructions English 5

3. Consider Make-Up Air:

• Due to the high volume of ventilation air, a source

of outside replacement air is recommended. This is

particularly important for tightly sealed and

insulated homes. A qualified heating and

ventilating contractor should be consulted.

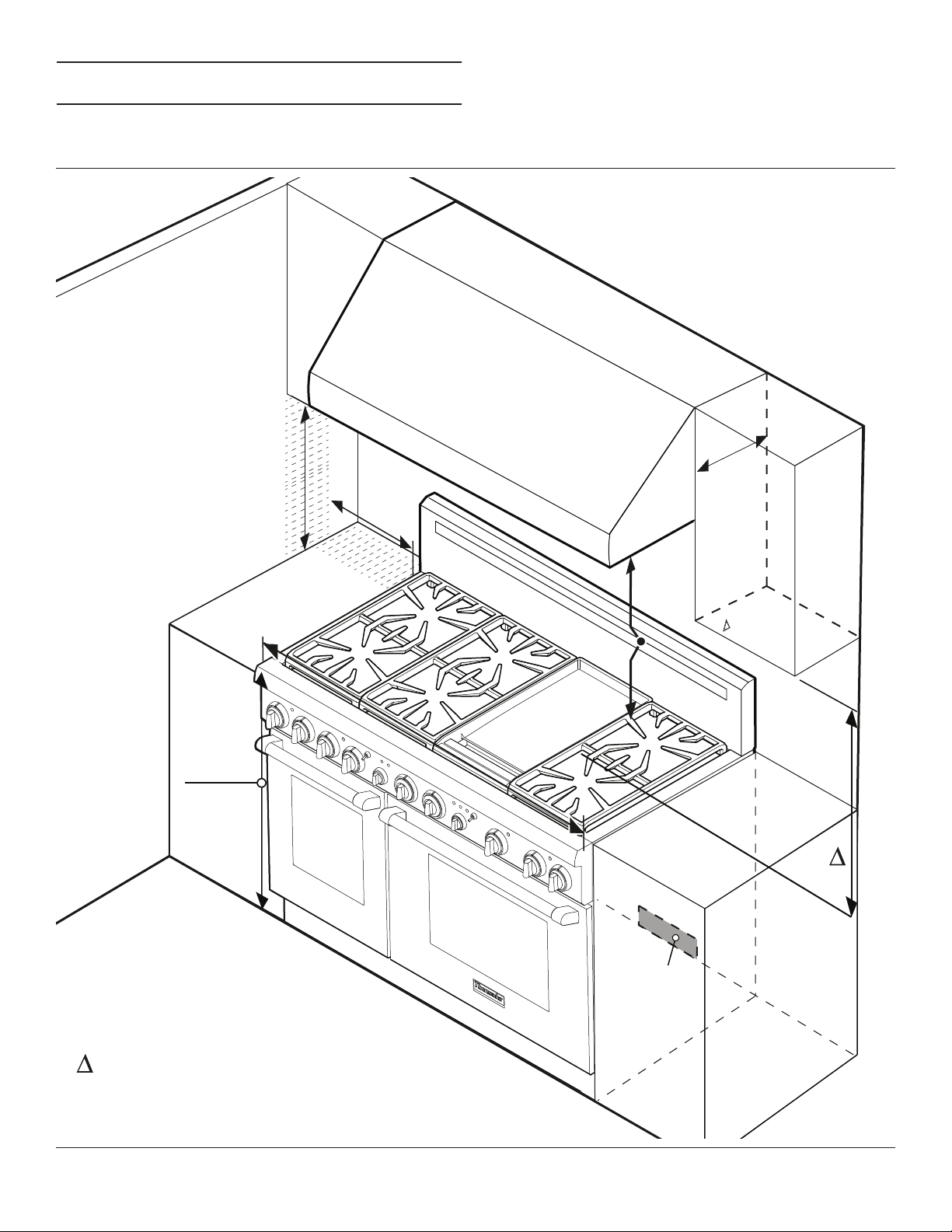

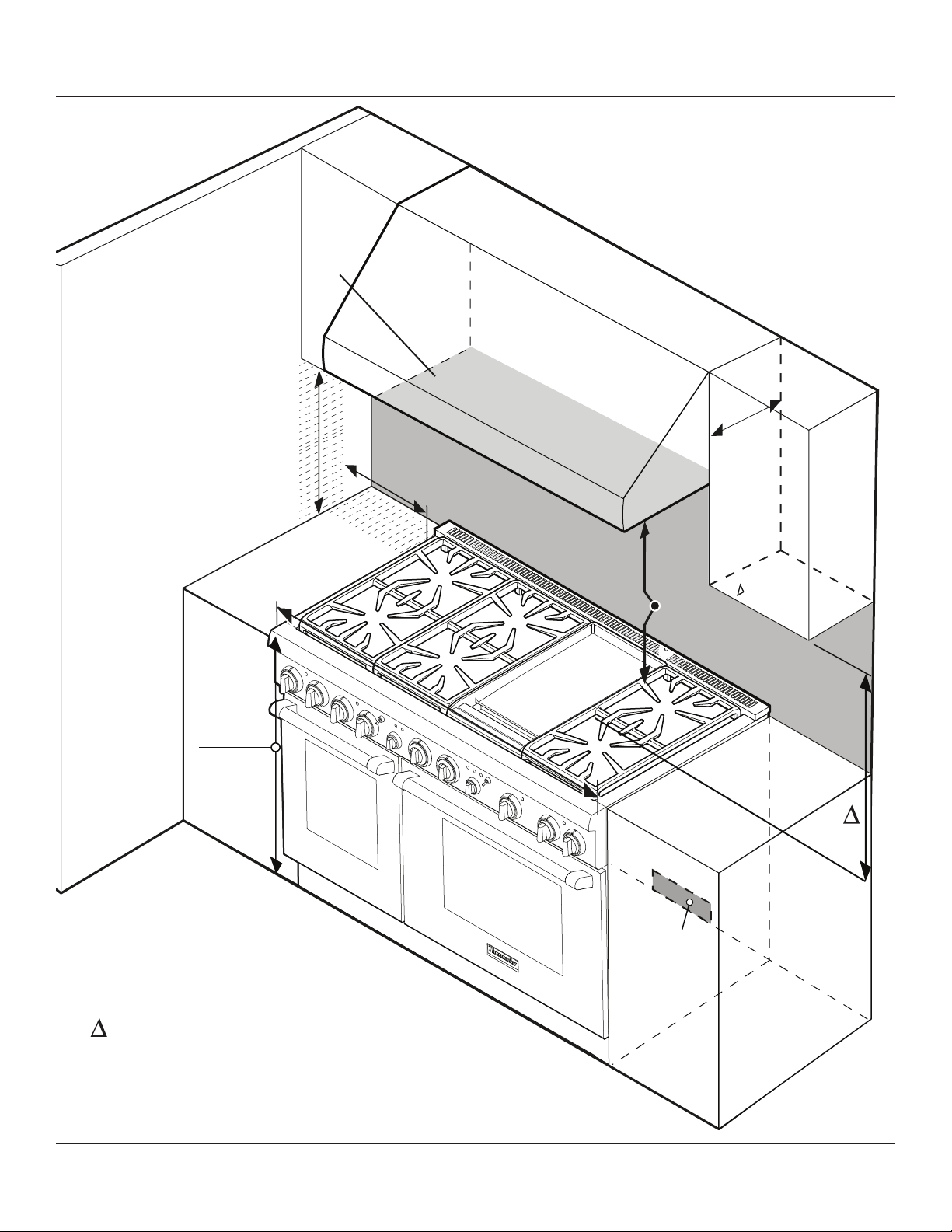

STEP 2: Cabinet Preparation

• The range is a free standing unit. If the unit is to be

placed adjacent to cabinets, the clearances shown in

“Installation Clearances” are required. The same

clearances apply to island installations, except for the

overhead cabinets, which must have a space wide

enough to accept the flared island hood.

• Any openings in the wall behind the range and in the

floor under the range must be sealed.

• The gas and electrical supply should be within the

zones shown in Figure 5 on page 11.

• When installing against a combustible surface, a Low

Backguard is required. A THERMADOR

Backguard must be purchased separately (see Table 3

on page 16).

• When using the Flush Island Trim, THERMADOR

recommends a minimum 12'' (305 mm) rear clearance

to a combustible surface (see “Installation Clearances”

beginning on page 7). Clearances from noncombustible materials are not part of the ANSI Z21.1

scope and are not certified by CSA. Clearances of less

than 12'' (305 mm) must be approved by the local

codes and/or by the local authority having jurisdiction.

• When the range is installed against a combustible side

wall a minimum clearance of 5'' (127 mm) is needed

from the side of the range to the wall.

TM

Low

• Always keep appliance area clear from combustible

materials, gasoline and other flammable vapors and

liquids.

• The maximum depth of overhead cabinets installed on

either side of the hood is 13" (330 mm). Wall cabinets

must be 18'' (457 mm) above the countertop.

• The top edges of the range’s side panels must be on

the same or higher level as the adjacent countertop. If

the range is operated while at a lower height relative to

the adjacent cabinet, the cabinet could be exposed to

excessive temperatures, causing damage to the

cabinet and countertop.

• DO NOT obstruct the flow of combustion and

ventilation air to the unit.

• There is a 36'' (914 mm) minimum clearance required

between the top of the cooking surface and the bottom

of an unprotected cabinet. A 30'' (762 mm) clearance

can be used when the bottom of the wood or metal

cabinet is protected by not less than 1/4'' (6 mm) of a

flame retardant material covered with not less than No.

28 MSG sheet steel, 0.015'' (0.38 mm) thick stainless

steel, 0.024'' (0.61 mm) aluminum, or 0.02'' (0.51 mm)

thick copper.

Flame retardant materials bear the mark:

UNDERWRITERS LABORATORIES INC. CLASSIFIED

MINERAL AND FIBER BOARDS SURFACE BURNING

CHARACTERISTICS, followed by the flame spread and

smoke ratings. These designations are shown as “FHC

(FIame Spread/Smoke Developed).” Materials with “O”

flame spread ratings are flame retardant. Local codes may

allow other flame spread ratings. It is the responsibility of

the installer to ensure installation is in accordance with

these ratings.

Installation Instructions English 6

Installation Clearances

5

" (127 mm) min.

to combustible

si

dewall

s

30" (762 m

m)

min.

from bo

ttom of

overhead

hood to cookin

g surfa

ce.

36" (914 m

m) min. if

hood contains

combustible materi

al

13" max.

cabinet

dep

th

CAUTION!

36" (914 mm) min.

to combustible

material

from Cooking

Surface

The range height is adjustable.

The level of the range top must

be at the same level or above

the counter top level.

*35 ¾" (908 mm) Min. range

height with leveling legs fully

retracted.

*37 ¼" (946 mm) Max. range

height with leveling legs fully

extended.

3

0", 36", or 48"

(7

62, 914, or 1219 mm

)

For Gas Supply &

Electrical Zones

see Figure 5.

18

" (457 mm)

minimum

See t

he Ventilation

Plan

ning Guid

e

for recommended hood opt

ions.

Installation Clearances with Lowback

" (457 mm)

" (457 mm)

18

18

minimum

minimum

The range height is adjustable.

The range height is adjustable.

The level of the range top must

The level of the range top must

be at the same level or above

be at the same level or above

the counter top level.

the counter top level.

*35 ¾" (908 mm) Min. range

*35 ¾" (908 mm) Min. range

height with leveling legs fully

height with leveling legs fully

retracted.

retracted.

*37 ¼" (946 mm) Max. range

*37 ¼" (946 mm) Max. range

height with leveling legs fully

height with leveling legs fully

extended.

extended.

5

5

" (127 mm) min.

" (127 mm) min.

to combustible

to combustible

sidewalls

sidewalls

30", 36", or 48"

30", 36", or 48"

(762, 914, or 1219 mm)

(762, 914, or 1219 mm)

See the Ventilation Planning Guide

See the Ventilation Planning Guide

for recommended hood options.

for recommended hood options.

30" (762 mm) min.

30" (762 mm) min.

from bottom of overhead

from bottom of overhead

hood to cooking surface.

hood to cooking surface.

36" (914 mm) min. if

36" (914 mm) min. if

hood contains

hood contains

combustible material

combustible material

13" max.

13" max.

cabinet

cabinet

depth

depth

m CAUTION!

CAUTION!

36" (914 mm) min.

36" (914 mm) min.

to combustible

to combustible

material

material

from Cooking

from Cooking

Surface

Surface

For Gas Supply &

For Gas Supply &

Electrical Zones

Electrical Zones

see Figure 5.

see Figure 5.

as defined in the “National Fuel Gas Code” (ANSI Z223.1, Current Edition).

Clearances from non-combustible materials are not part of the ANSI Z21.1

scope and are not certified by CSA. Clearances of less than 12" (305 mm)

must be approved by the local codes and/or by the local authority having

jurisdiction.

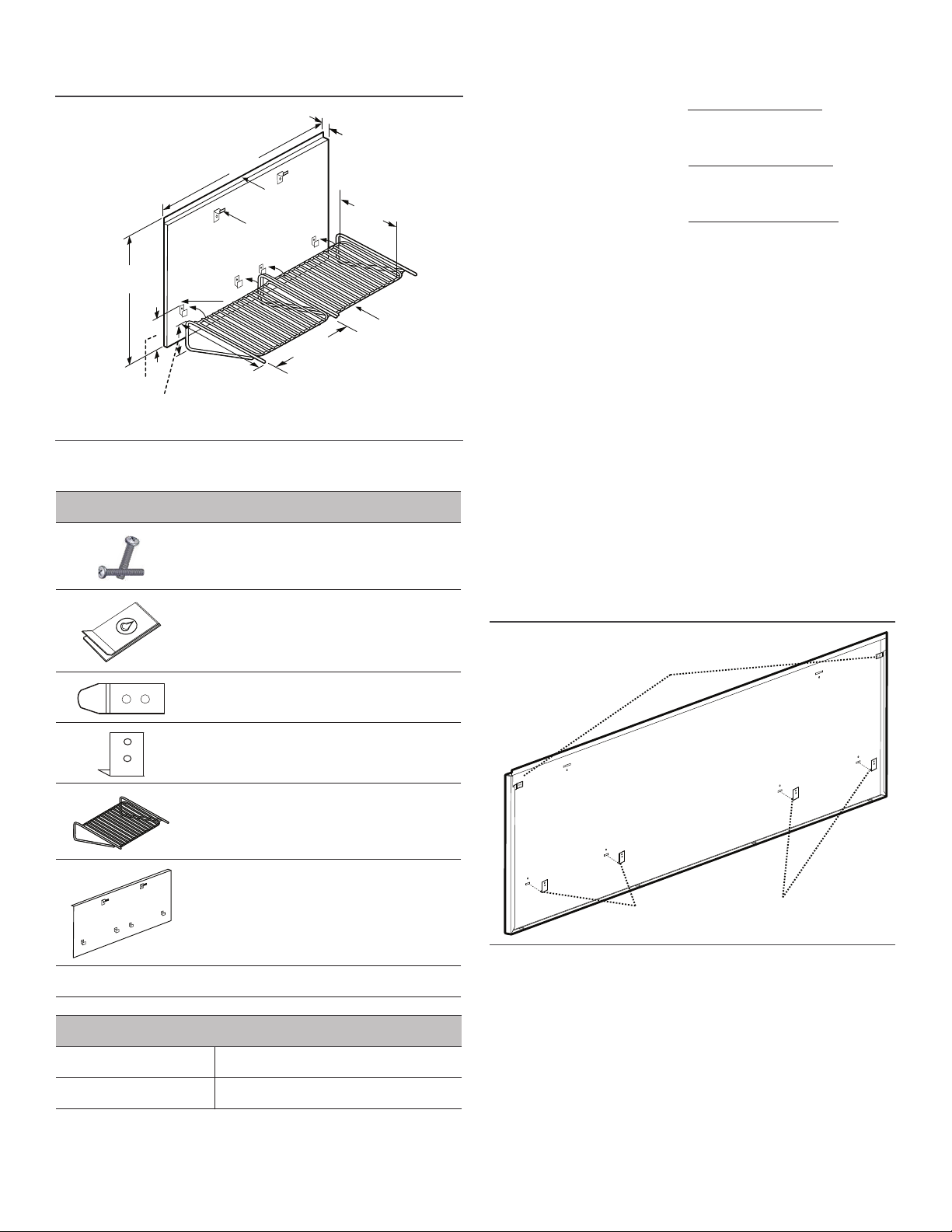

Figure 1: Cabinet Clearances

Installation Instructions English 7

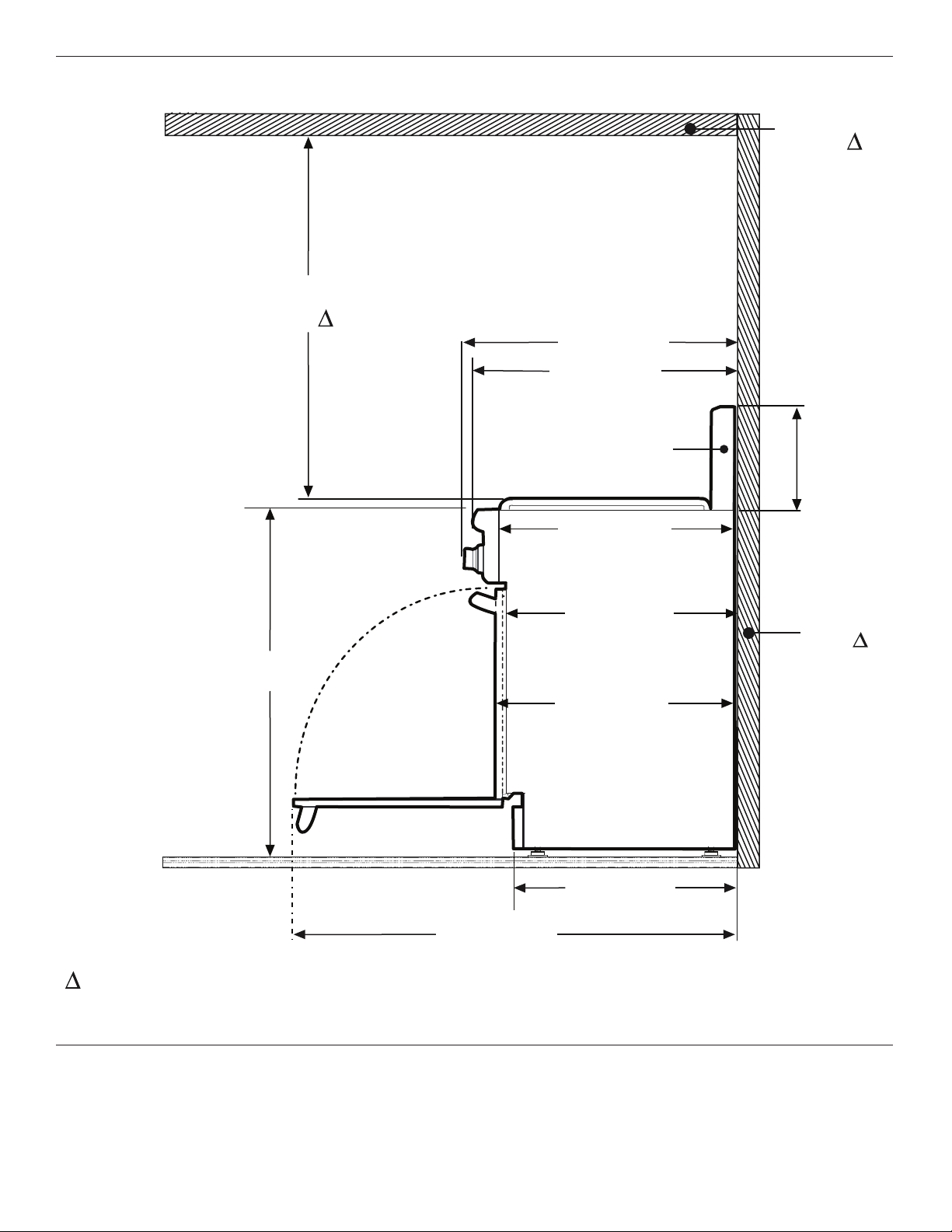

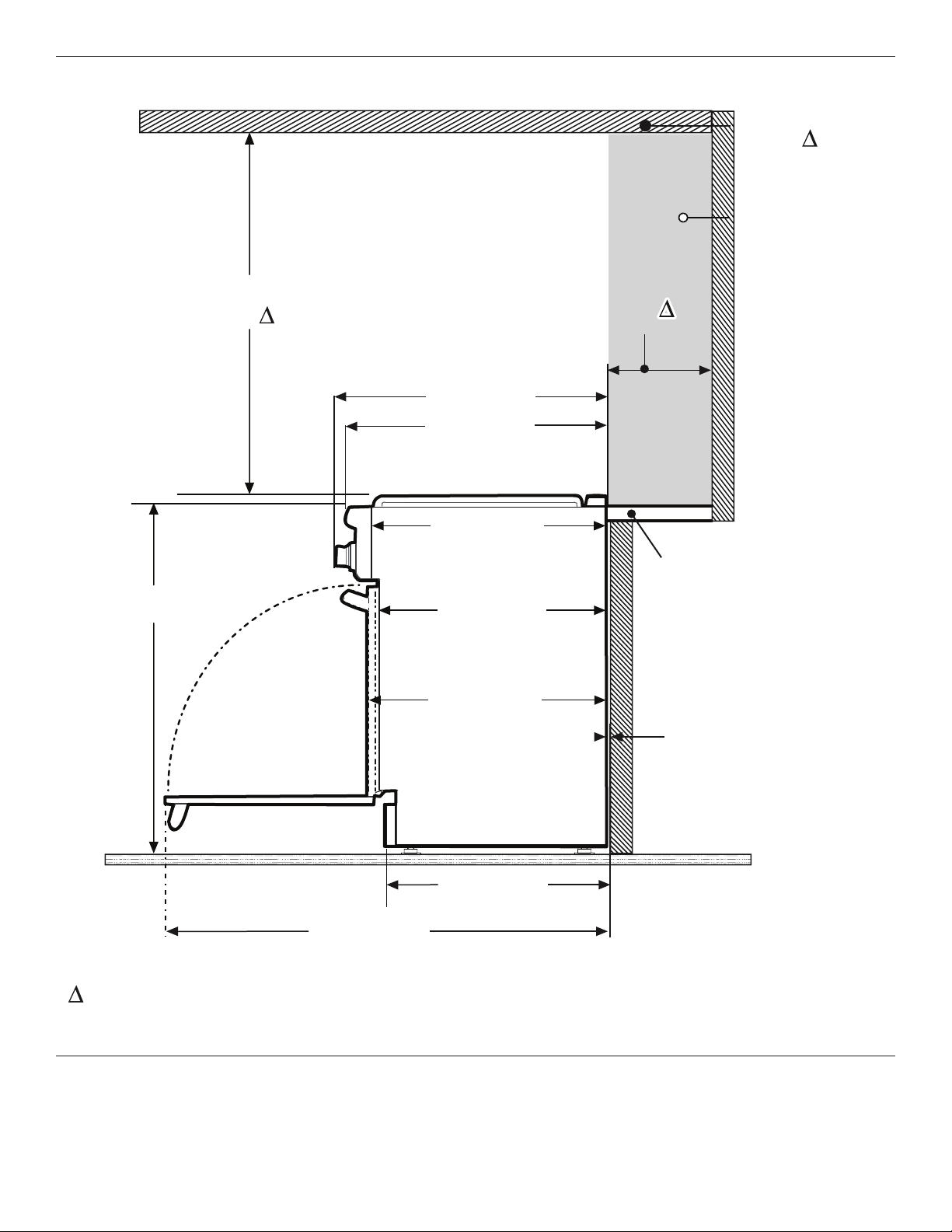

Installation Clearances with Low Backguard

9" (229 mm)

36" (914 mm) min.

to combustible

materials

28" (711 mm)

27¼" (692 mm)

Low Back

Combustible

Materials

9" (229 mm)

9" (229 mm)

35 ¾" (908 mm) Min.

37 ¼" (946 mm) Max.

44⅞" (1140 mm)

Total Clearance

24⅝" (625 mm)

24" (610 mm)

max. recess depth

24¾" (629 mm)

23" (584 mm)

Combustible

Back Wall

as defined in the “National Fuel Gas Code” (ANSI Z223.1, Current Edition).

Clearances from non-combustible materials are not part of the ANSI Z21.1

scope and are not certified by CSA. Clearances of less than 12” (305 mm)

must be approved by the local codes and/or by the local authority having jurisdiction.

Figure 2: Installation Clearances with a Low Backguard

Installation Instructions English 8

Installation Clearances with Flush Island Trim

5

" (127 mm) min.

to combustible

sidewalls

30" (762 m

m)

min.

from bo

ttom of

overhead

hood to cookin

g surfa

ce.

36" (914 m

m) min. if

hood contains

combustible materi

al

13" max.

cabinet

dep

th

CAUTION!

36" (914 mm) min.

to combustible

material

from Cooking

Surface

The range height is adjustable.

The level of the range top must

be at the same level or above

the counter top level.

*35 ¾" (908 mm) Min. range

height with leveling legs fully

retracted.

*37 ¼" (946 mm) Max. range

height with leveling legs fully

extended.

3

0", 36", or 48"

(7

62, 914, or 1219 mm

)

For Gas Supply &

Electrical Zones

see Figure 5.

18

" (457 mm)

m

inimum

See

the Ventilati

on

Plan

ning Guide

for recommended hood options.

Shaded area above

countertop indicates min.

clearance

to combustible

surfaces, combusti

ble

materi

als cannot be located

within this area.

See the Ventilation Planning Guide

See the Ventilation Planning Guide

for recommended hood options.

for recommended hood options.

Shaded area above

Shaded area above

countertop indicates min.

countertop indicates min.

clearance to combustible

clearance to combustible

surfaces, combustible

surfaces, combustible

materials cannot be located

materials cannot be located

within this area.

within this area.

The range height is adjustable.

The range height is adjustable.

The level of the range top must

The level of the range top must

be at the same level or above

be at the same level or above

the counter top level.

the counter top level.

*35 ¾" (908 mm) Min. range

*35 ¾" (908 mm) Min. range

height with leveling legs fully

height with leveling legs fully

retracted.

retracted.

*37 ¼" (946 mm) Max. range

*37 ¼" (946 mm) Max. range

height with leveling legs fully

height with leveling legs fully

extended.

extended.

5

5

" (127 mm) min.

" (127 mm) min.

" (457 mm)

" (457 mm)

18

18

minimum

minimum

to combustible

to combustible

sidewalls

sidewalls

(762, 914, or 1219 mm)

(762, 914, or 1219 mm)

30", 36", or 48"

30", 36", or 48"

30" (762 mm) min.

30" (762 mm) min.

from bottom of overhead

from bottom of overhead

hood to cooking surface.

hood to cooking surface.

36" (914 mm) min. if

36" (914 mm) min. if

hood contains

hood contains

combustible material

combustible material

For Gas Supply &

For Gas Supply &

Electrical Zones

Electrical Zones

see Figure 5.

see Figure 5.

13" max.

13" max.

cabinet

cabinet

depth

depth

m CAUTION!

CAUTION!

36" (914 mm) mi

36" (914 mm) mi

to combustible

to combustible

material

material

from Cooking

from Cooking

Surface

Surface

as defined in the “National Fuel Gas Code” (ANSI Z223.1, Current Edition).

Clearances from non-combustible materials are not part of the ANSI Z21.1

scope and are not certified by CSA. Clearances of less than 12" (305 mm)

must be approved by the local codes and/or by the local authority having

jurisdiction.

Figure 3: Cabinet Clearances with Flush Island Trim

Installation Instructions English 9

Installation Clearances with Flush Island Trim

12" (305 mm) min. to

combustible surface

with Flush Island Trim

For Flush Island

Trim installations,

counter surface should

have a cantilever edge

meeting the back

section of the Flush

Island Trim accessory.

Shaded area behind

range indicates

minimum clearance

to combustible surfaces,

combustible materials

cannot be located within

this area.

36 " (914 mm) mi n .

to combustible

materials

28" (711 mm)

27¼" (692 mm)

24⅝" (625 mm)

12" (305 mm) min. to

12" (305 mm) min. to

combustible surface

combustible surface

with Flush Island Trim

with Flush Island Trim

Combustible

Materials

Shaded area behind

Shaded area behind

range indicates

range indicates

minimum clearance

minimum clearance

to combustible surfaces,

to combustible surfaces,

combustible materials

combustible materials

cannot be located within

cannot be located within

this area.

this area.

For Flush Island

For Flush Island

Trim installations,

Trim installations,

counter surface should

counter surface should

have a cantilever edge

have a cantilever edge

meeting the back

meeting the back

section of the Flush

section of the Flush

Island Trim accessory.

Island Trim accessory.

35 ¾" (908 mm) Min.

37 ¼" (946 mm) Max.

max. recess depth

44⅞" (1140 mm)

Total Clearance

as defined in the “National Fuel Gas Code” (ANSI Z223.1, Current Edition).

Clearances from non-combustible materials are not part of the ANSI Z21.1

scope and are not certified by CSA. Clearances of less than 12” (305 mm)

must be approved by the local codes and/or by the local authority having jurisdiction.

24" (610 mm)

24¾" (629 mm)

23" (584 mm)

Cantilever

If an inner wall

is used under

the cantilever counter

top, there should be a

⅛" (3 mm) gap from

the rear of the range

to the inner wall.

Figure 4: Installation Clearances with a Flush Island Trim

Installation Instructions English 10

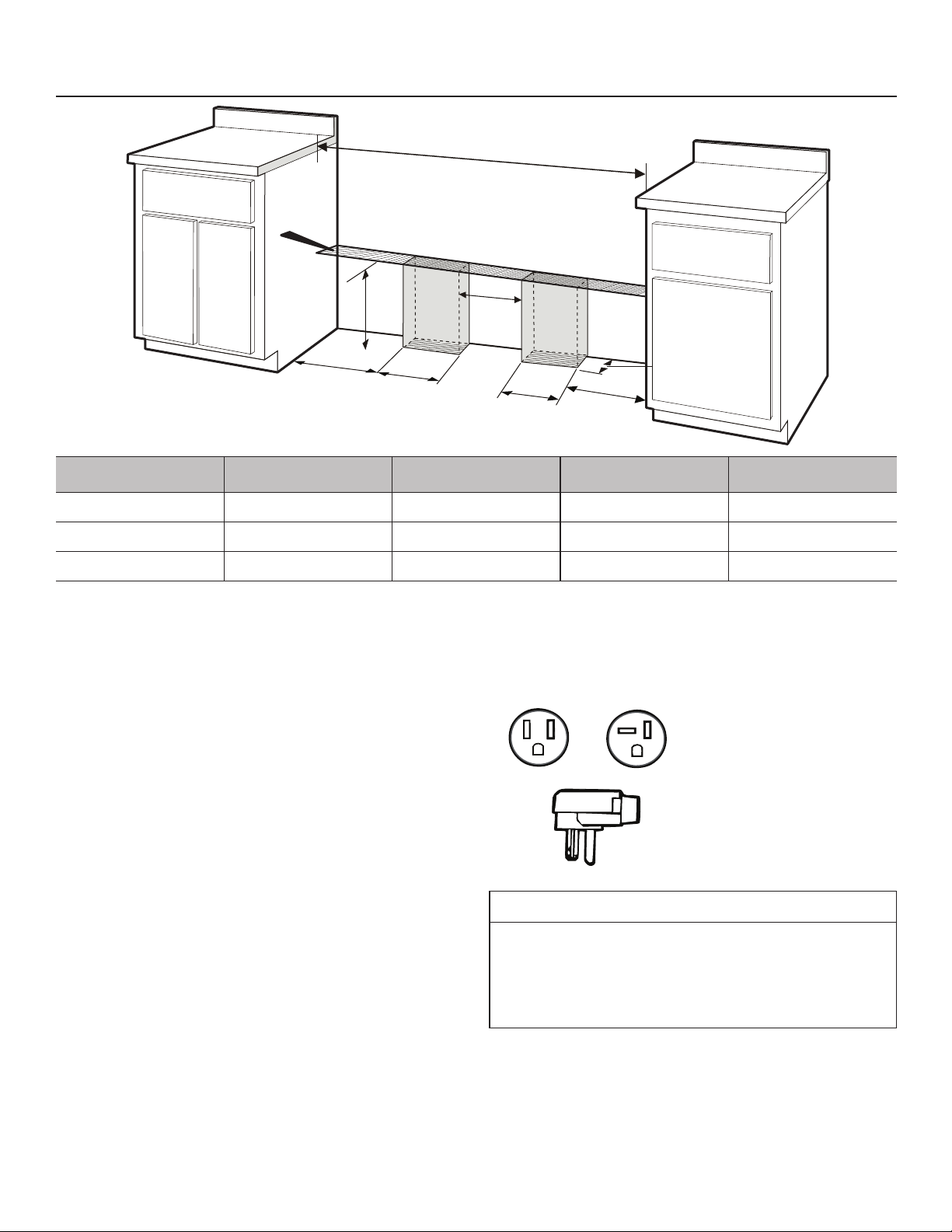

Gas and Electric Supply Clearances

10"

(254 mm)

B

C

3"

(76 mm)

A

D

2" (51 mm) max.

protrusion from wall

for gas or electrical

supply.

30", 36" or 48" (762, 914 or 1219 mm)

For nearly-flush installation to

the back wall, the gas supply

line and electrical cord should

not go above this line.

Electric Zone

30", 36" or 48" (762, 914 or 1219 mm)

30", 36" or 48" (762, 914 or 1219 mm)

For nearly-flush installation to

For nearly-flush installation to

the back wall, the gas supply

the back wall, the gas supply

line and electrical cord should

line and electrical cord should

not go above this line.

not go above this line.

10"

10"

(254 mm)

(254 mm)

A

Model A B C D

30'' (762 mm) 5¾'' (146 mm) 157/16'' (392 mm) 513/16'' (148 mm) 4Ǫ'' (111 mm)

36'' (913 mm) 8

1

/16'' (205 mm) 1613/16'' (503 mm) 8ǩ'' (206 mm) 4Ǫ'' (111 mm)

Gas Zone

B

3"

3"

(76 mm)

(76 mm)

Electric Zone

Electric Zone

C

2" (51 mm) max.

2" (51 mm) max.

protrusion from wall

protrusion from wall

for gas or electrical

for gas or electrical

supply.

supply.

D

48'' (1219 mm) 4Ǫ'' (111 mm) 10¾'' (273 mm) 1811/16'' (475 mm) 515/16'' (151 mm)

NOTICE:

— If not already present, install gas shut-off valve in

an easily accessible location.

— Make sure all users know where and how to shut

off the gas supply to the range.

— Any opening in the wall behind the appliance and

any opening in the floor under the appliance must

be sealed.

The range must be connected only to the type of gas

for which it is certified. If the range is to be connected to

propane gas, ensure that the propane gas supply tank is

equipped with its own high pressure regulator in addition to

the pressure regulator supplied with the range (see “STEP

5: Gas Requirements and Hookup”).

NOTE: The range is designed for flush installation to the

back wall. For a successful installation, it may be

necessary to reposition the gas supply line and electrical

cord as the range is pushed back to its final position.

-- SUGGESTION: This may be accomplished by carefully

pulling on a rope or twine looped around the gas or

electrical supply line as the range is pushed back into

its final installed position.

Figure 5: Gas and Electrical Supply Locations

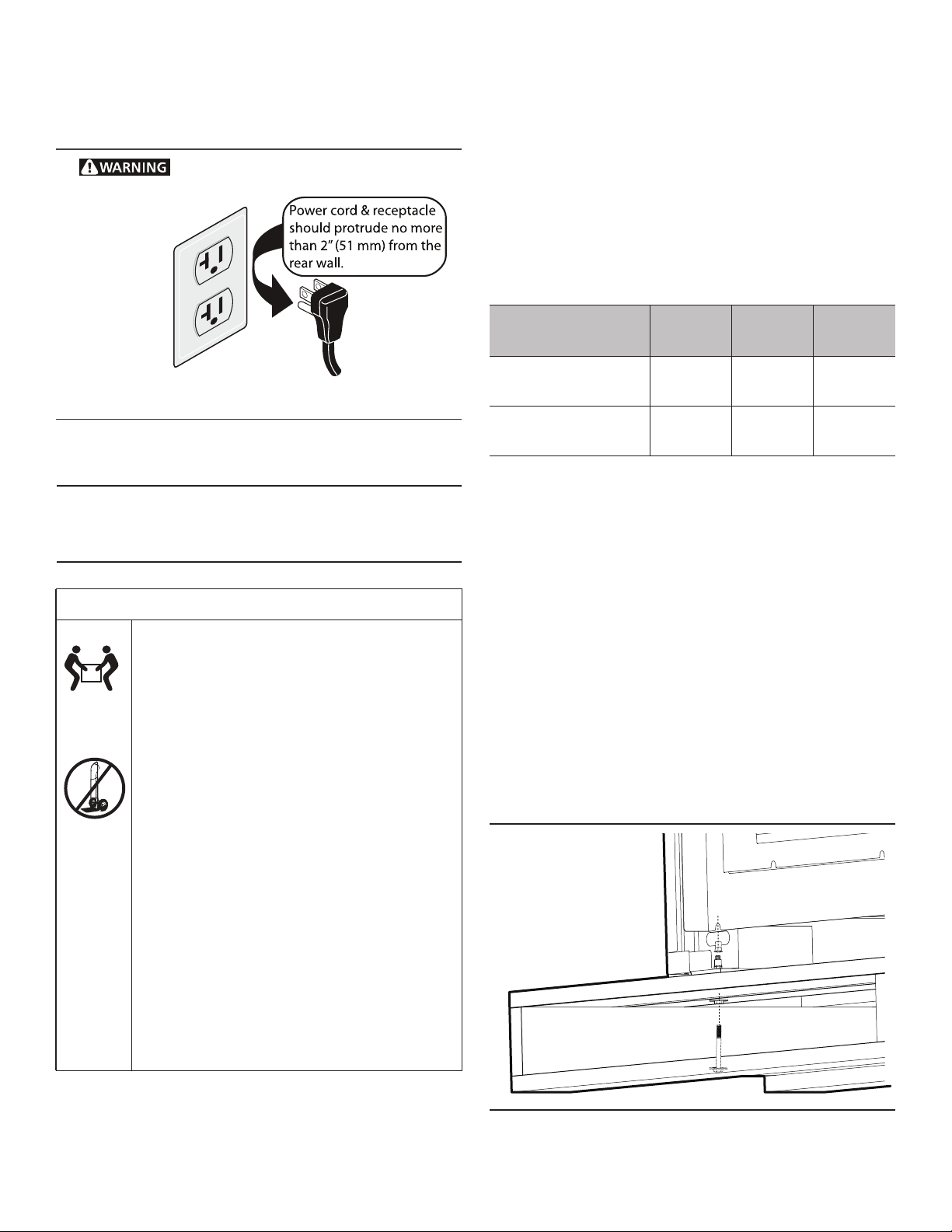

Electrical Supply

1(0$

5(&(37$&/(

1(0$

5(&(37$&/(

3/8*

WARNING

This appliance is equipped with a three-prong grounding

plug for protection against shock hazard and should be

plugged directly into a properly grounded receptacle. DO

NOT cut or remove the grounding prong from this plug.

DO NOT ALTER THIS PLUG.

Installation of the range must be planned so that the roughin of the terminal block for the receptacle will allow

maximum clearance to the rear of the unit. To minimize

binding when the unit is connected to the receptacle or

terminal block, orient the receptacle and slide back into

position.

IMPORTANT:

The cord supplied with the

gas ranges having an

electric griddle requires a

NEMA 5-20 receptacle. All

other gas units require a

NEMA 5-15 receptacle.

Installation Instructions English 11

When the power supply cord is connected to the mating

receptacle, the combined plug/receptacle connection

should protrude no more than 2” (51 mm) from the rear

wall, see Figure 6.

7KLVSURGXFWPXVWEHSURSHUO\JURXQGHG

Unpacking the Range

1. Remove the outer carton and packing materials from

the shipping pallet but leave the adhesive-backed foam

layer over brushed-metal surfaces, to protect finish

from scratches, until the range is installed in its final

position.

2. It is recommended that the grates, griddle plate, burner

caps and oven racks be removed to facilitate handling.

If desired, the oven doors may also be removed (see

“STEP 8: Door Removal and Adjustment” on page 20).

Do not remove the griddle assembly.

/05&1MVHTUZMFTNBZWBSZ

Figure 6: Wall Connection

STEP 3: Unpacking and

Moving the Range

CAUTION

DO NOT lift the range by the oven door’s

handle, as this may damage the door hinges

and cause the door to fit incorrectly.

DO NOT lift the appliance by the range’s

control panel.

The unit is heavy and should be handled

accordingly. Proper safety equipment such as

gloves and adequate manpower of at least

two people must be used in moving the range

to avoid injury and to avoid damage to the

unit or the floor.

30"

RANGE

Shipping Weight 372 lbs

(169 kg)

Weight without

packing materials

290 lbs

(132 kg)

36"

RANGE

419 lbs

(190 kg)

310 lbs

(141 kg)

Table 1: Range Weight

48"

RANGE

565 lbs

(256 kg)

421 lbs

(191 kg)

Moving the Range

Due to the weight, a furniture dolly with soft wheels or an

air lift should be used to move this unit. The weight must be

supported uniformly across the bottom.

NOTICE: The electric wire diagrams and schematics are

attached behind the kick panel, and should not be removed

except by a service technician, then replaced after use.

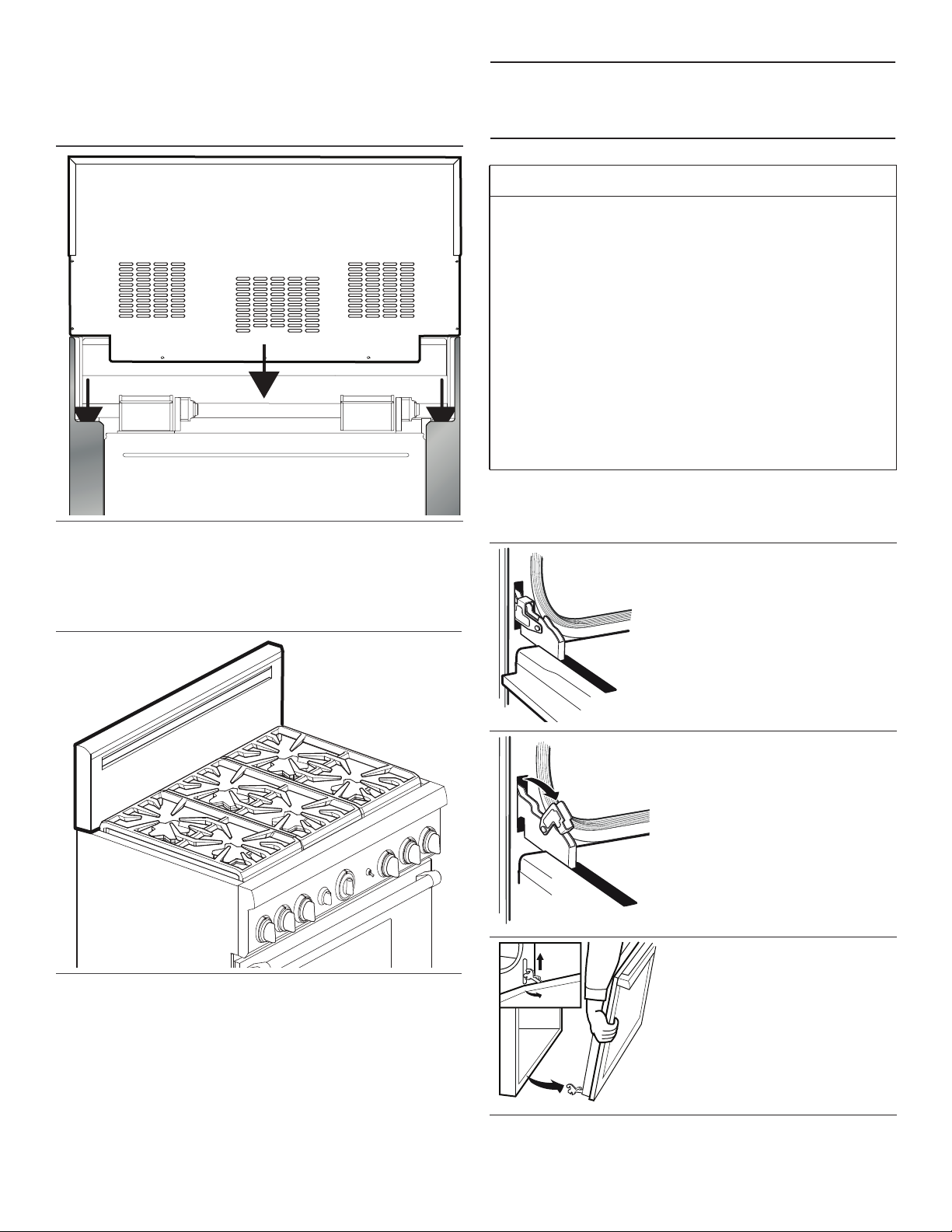

Removing the Pallet Bolts

1. To remove the (4) pallet bolts in the front and in the

back, use a 7/16'' wrench or ratchet and socket to

remove the pallet bolt from the bottom of the pallet.

Discard the wood packing block inserts.

Rings, watches, and any other loose items

that may damage the unit or otherwise might

become entangled with the unit should be

removed.

Hidden surfaces may have sharp edges. Use

caution when reaching behind or under

appliance.

DO NOT use a hand truck or appliance dolly

on the back or front of the unit. Handle from

the side only.

Figure 7: Removal of Shipping Bolts

Installation Instructions English 12

2. Lift range and remove it from the pallet.

help as required to remove from pallet.

3. Transport the range by dolly close to its final location.

Unit should not be dollied from the front.

4. The range can then be tipped back and supported on

the rear legs while the dolly is carefully removed. THE

FLOOR UNDER THE LEGS SHOULD BE

PROTECTED BEFORE PUSHING THE UNIT INTO

POSITION.

• Step 4 through Step 8 must be completed before

the range is placed in its final position. For proper

performance, the range must be level. See

“STEP 9: Placing and Leveling the Range” on

page 22 for leveling instructions.

Use additional

STEP 4: Installing the Anti-Tip

Device

For all ranges, an anti-tip device must be installed as per

these instructions.

WARNING

RANGE TIPPING HAZARD:

— All ranges can tip and injury can

result. To prevent accidental tipping of

the range, attach it to the floor by

installing the Anti-Tip Device supplied.

— A risk of tip-over may exist if the

appliance is not installed in

accordance with these instructions.

For all ranges an anti-tip device

be installed.

— A child or adult can tip the range and

be killed.

— DO NOT operate the range without the

anti-tip device in place and engaged.

Failure to do so can result in death or

serious burns to children or adults.

must

WARNING

ELECTRICAL SHOCK HAZARD:

• Use extreme caution when drilling holes into the wall

or floor as there may be concealed electrical wires.

• Identify the electrical circuits that could be affected by

the installation of the Anti-Tip Device, then turn off

power to these circuits.

• Failure to follow these instructions may result in

electrical shock or other personal injury.

ATTENTION – PROPERTY DAMAGE

• Contact a qualified installer or contractor to determine

the proper method for drilling holes through the wall or

floor material (such as ceramic tile, hardwood, etc.)

• Do not slide the range across an unprotected floor.

• Failure to follow these instructions may result in

damage to wall or floor coverings.

Important Installation Information

Service Part No. Qty Description

00415078 4 Screw, Phillips, #10 x 1½''

00647936 1

Hardware provided is for mounting through standard

thickness wood studs. Installers are responsible to

provide hardware for other types of mounting situations.

• The anti-tip bracket may be attached to a solid wood

surface having a minimum wall thickness of ¾''

(19 mm).

• The thickness of the wall or floor may require use of

longer screws, available at your local hardware store.

• In all cases, at least two (2) of the bracket mounting

screws must be fastened to solid wood surface.

• Use appropriate anchors when fastening the mounting

bracket to any material other than hard-wood or metal.

Anti-Tip Bracket, Floor-

Mounted

Hole location preparation

If the range is pulled away from the wall for cleaning,

service or for any other reason, ensure that the Anti-Tip

Device is properly re-engaged when the range is pushed

back against the wall. In the event of abnormal usage

(such as a person standing, sitting, or leaning on an

open door), failure to take this precaution can result in

tipping of the range. Personal injury might result from

spilled hot liquids or from the range itself.

Installation Instructions English 13

• For walls, wall studs, or floors composed of solid wood

or metal, drill 1/8'' (3 mm) pilot holes.

•

For walls or floors composed of drywall, sheet-rock or

other soft materials, drill 3/16'' (5 mm) holes to a

minimum depth of 1¾'' (45 mm), then tap plastic

anchors into each of the holes using a hammer.

•

For walls or floors composed of concrete or concrete

block, drill 3/16'' (5 mm) holes to a minimum depth of

1¾'' (45 mm), then tap concrete anchors into each of

the holes using a hammer.

For walls or floors having ceramic tile covering, drill

x

x

•

3/16'' (5 mm) holes through the tile only, then drill into

the material behind the tile as indicated immediately

above.

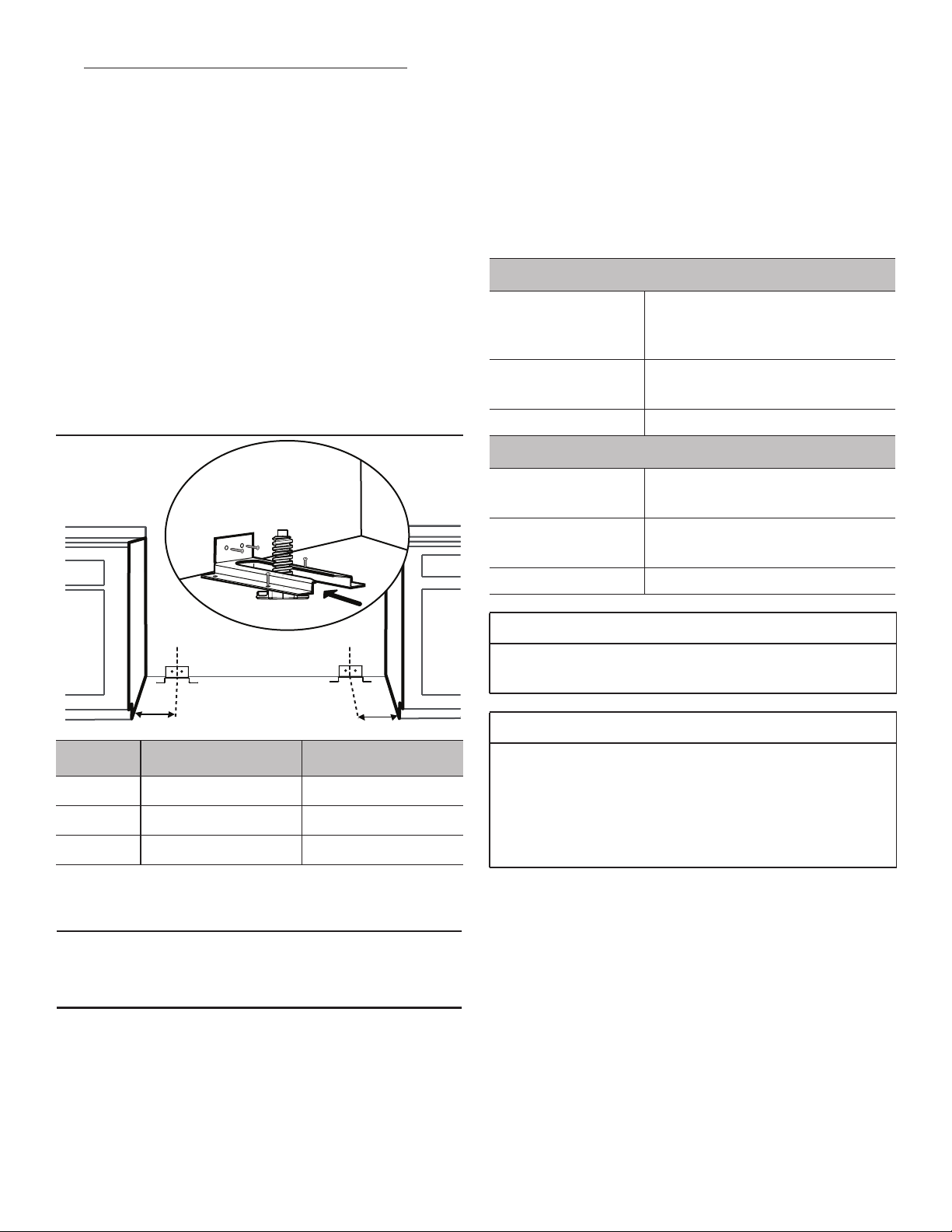

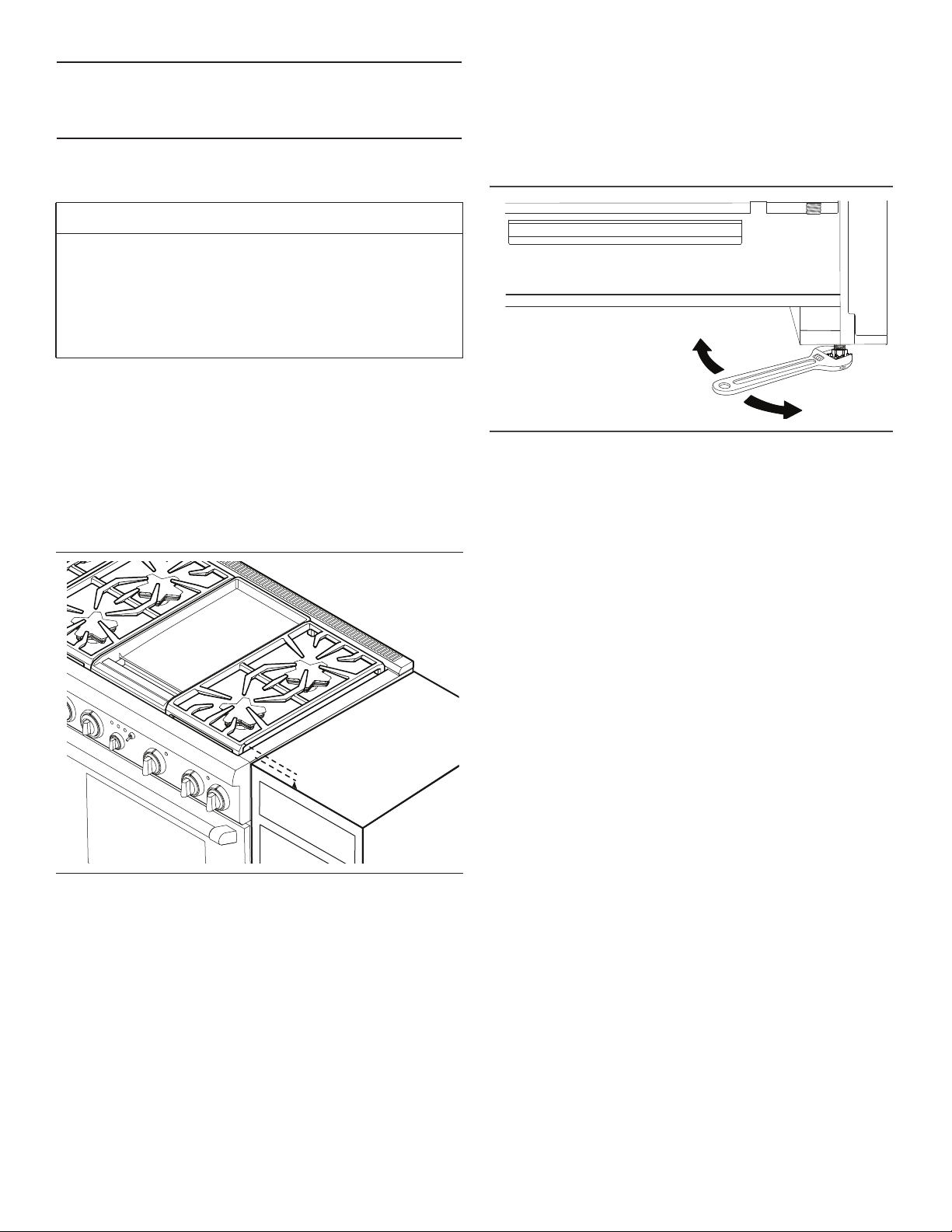

Mounting Anti-Tip Bracket

The floor mounted bracket shall be installed as follows:

1. Place bracket on floor in position shown in Figure 8.

• 30'' and 36'' bracket may be used in either corner

of the installation area.

2. Secure to floor and wall stud using the (4) 1½'' (38 mm)

Phillips head screws provided.

3. Later, when the unit is installed, the adjustable leg will

slide under the bracket, as shown in Figure 8.

4. If the range is moved to a new location, the Anti-Tip

Device must be removed and reinstalled.

This appliance has been CSA certified for safe operation

up to an altitude of 2,000 ft (610 m) elevation above sea

level.

High Altitude — For altitudes above 2,000 feet (610 m)

elevation above sea level, adjustments can be made with

the High Altitude Packet included with the unit. If flame

performance is satisfactory, the contents in this packet will

not be required. It is required that a Certified Professional

make the high altitude adjustments during installation.

NATURAL GAS REQUIREMENTS:

Inlet Connection: ½'' (13 mm) NPT internal

[Minimum ¾” (19 mm) dia. flex

line]

Supply Pressure: 6" min. to 14" max. water column.

(14.9 to 34.9 mb)

Manifold Pressure: 5" water column (12.5 mb)

PROPANE GAS REQUIREMENTS:

Inlet Connection: ½'' (13mm) NPT internal

[Min. 3/4” (19 mm) dia. flex line]

Supply Pressure: 11" min. to 14"max. water column.

(27.4 mb to 34.9 mb)

C

L

x

Range Side Distance of X

30'' Left or Right 2¼'' (57 mm)

36'' Left or Right 2ǫ'' (67 mm)

48'' Left or Right 2½'' (64 mm)

Figure 8: Placement of Anti-Tip Bracket

C

L

x

STEP 5: Gas Requirements

and Hookup

Manifold Pressure: 10" water column (24.9 mb)

WARNING

Gas line must not come in contact with any components

inside back cover of range.

CAUTION

When connecting unit to propane gas, make certain the

propane gas tank is equipped with its own high pressure

regulator in addition to the pressure regulator supplied

with the appliance. The pressure of the gas supplied to

the appliance regulator must not exceed 14" water

column (34.9 mb).

Hook Up

The gas supply connections shall be made by a competent

technician and in accordance with local codes or

ordinances. In the absence of local codes, the installation

must conform to the National Fuel Gas Code ANSI Z223.1/

NFPA54- current issue.

Verify the type of gas being used at the installation site. As

shipped from the factory, units are configured for use with

only natural gas or propane (LP) gas. Make certain the

range matches the type of gas available at this location.

These ranges are NOT convertible between different

types of gas.

Installation Instructions English 14

1. A manual gas shut-off valve must be installed external

to the appliance, in a location accessible from the front,

for the purpose of shutting off the gas supply. The

supply line must not interfere with the back of the unit.

Make sure the gas supply is turned off at the manual

shut-off valve before connecting the appliance.

• The range is supplied with its own pressure

Adapter

¾" (19 mm)

Flex line

regulator that has been permanently mounted

within the range body.

2. Use a ¾'' (19 mm) flex line to connect between the gas

supply and the appliance gas inlet. The gas supply line

connection is located at the lower right portion of all

range models (see Figure 9). The appliance gas inlet

connection is ½'' (12.7 mm) NPT.

• Use caution to avoid crimping the ¾'' (19 mm) flex

line when making bends. Suggested length of flex

line is 48" (1219 mm); however, please check local

codes for your area's requirements before

installation.

®

3. Use pipe sealing compound or Teflon

pipe threads. DO NOT apply sealing compound or tape

to flare fittings. Take care not to apply excessive

pressure when tightening the fittings.

tape on the

• Bubbles forming indicate a gas leak. Repair all

leaks immediately after finding them.

WARNING

Do not use a flame of any kind to check for gas

leaks.

CAUTION

The appliance must be isolated from the gas supply

piping system by closing its individual manual shut-off

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than 1/2

psig (3.5kPa.).

STEP 6: Electrical

Requirements, Connection &

Grounding

¾" (19 mm) external threads

½" (12.7 mm) internal threads

Manual gas shut-off valve

Manual gas shut-off valve

Figure 9: Gas Supply Connection

or

Adapter

{

Adapter

Adapter

or

¾" (19 mm)

¾" (19 mm)

Flex line

Flex line

Model Voltage

30" with 4

burners

36" with 6

burners

36'' with griddle

or grill

48'' with griddle

or grill

WARNING

An improper 120 VAC power supply will cause

malfunction, damage to this appliance, and possibly

create a condition of shock hazard.

Before installing, turn power OFF at the service panel.

Lock service panel to prevent power from being turned

ON accidentally.

120 VAC 10 Amps 60 Hz. Single

120 VAC 10 Amps 60 Hz. Single

120 VAC 20 Amps 60 Hz. Single

120 VAC 20 Amps 60 Hz. Single

Table 2: Electrical Supply Circuit Requirements

Circuit

Rating

Frequency Phase

4. Leak testing of the appliance shall be in accordance

with the following instructions.

• Turn on gas and check supply line connections for

leaks using a soap and water solution.

Installation Instructions English 15

For these gas range models, a neutral supply wire must be

provided from the power source (breaker) because critical

range components, including the surface burner spark

reignition modules, require 120 VAC to operate safely and

properly.

If the correct power supply circuit is not provided, it is the

responsibility and obligation of the installer and user to

have proper power supply connected. This must be

accomplished in accordance with all applicable local codes

and ordinances by a qualified electrician. In the absence of

local codes and ordinances, the power supply connection

shall be in accordance with the National Electrical Code.

WARNING

Fingers or hands could get pinched when installing the

backguard. Severe injury could result. Use extreme

caution and wear thick protective gloves to avoid

potential laceration to finger or hand while sliding the

backguard down onto the range.

Observe all governing codes and ordinances when

grounding. In the absence of these codes or ordinances

observe National Electrical Code ANSI/NFPA No. 70

current issue. Electric wiring diagrams and schematics

have been placed in the kick panel area of the range for

access by a qualified service technician (refer to Figure 25

on page 23).

Before you plug in an electrical cord, be sure all controls

are in the OFF position.

Do not cut or remove the ground prong. It must be plugged

into a matching grounding type receptacle to avoid

electrical shock. If there is any doubt as to whether the wall

receptacle is properly grounded, the customer should have

it checked by a qualified electrician.

INSTALLER — show the owner the location of the circuit

breaker. Mark it for easy reference.

IMPORTANT:

Dedicated 20 AMP service is required for ranges with an

electric griddle or grill.

STEP 7: Backguard

Installation (optional)

Model 30'' 36' 48''

Flush Island Trim Included Included Included

9" Low Back PA30GLBH PA36GLBH PA48GLBH

Table 3: Backguard Kit Model Numbers

WARNING

To reduce the risk of fire or injury to persons, check to

make sure all packaging has been removed from

accessory devices before use.

Installation methods will vary upon need. Before you begin

read these instructions carefully. Observe all local codes

and ordinances.

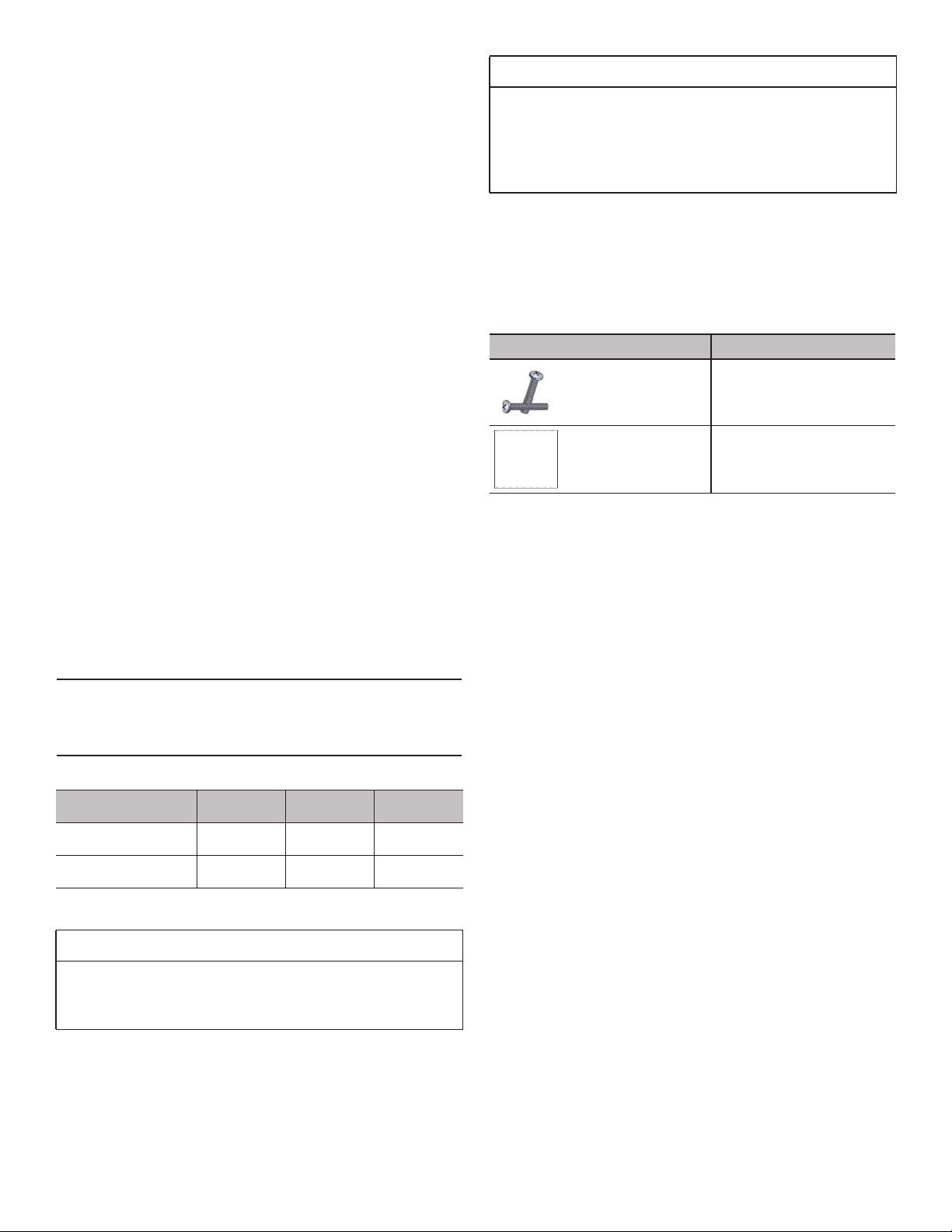

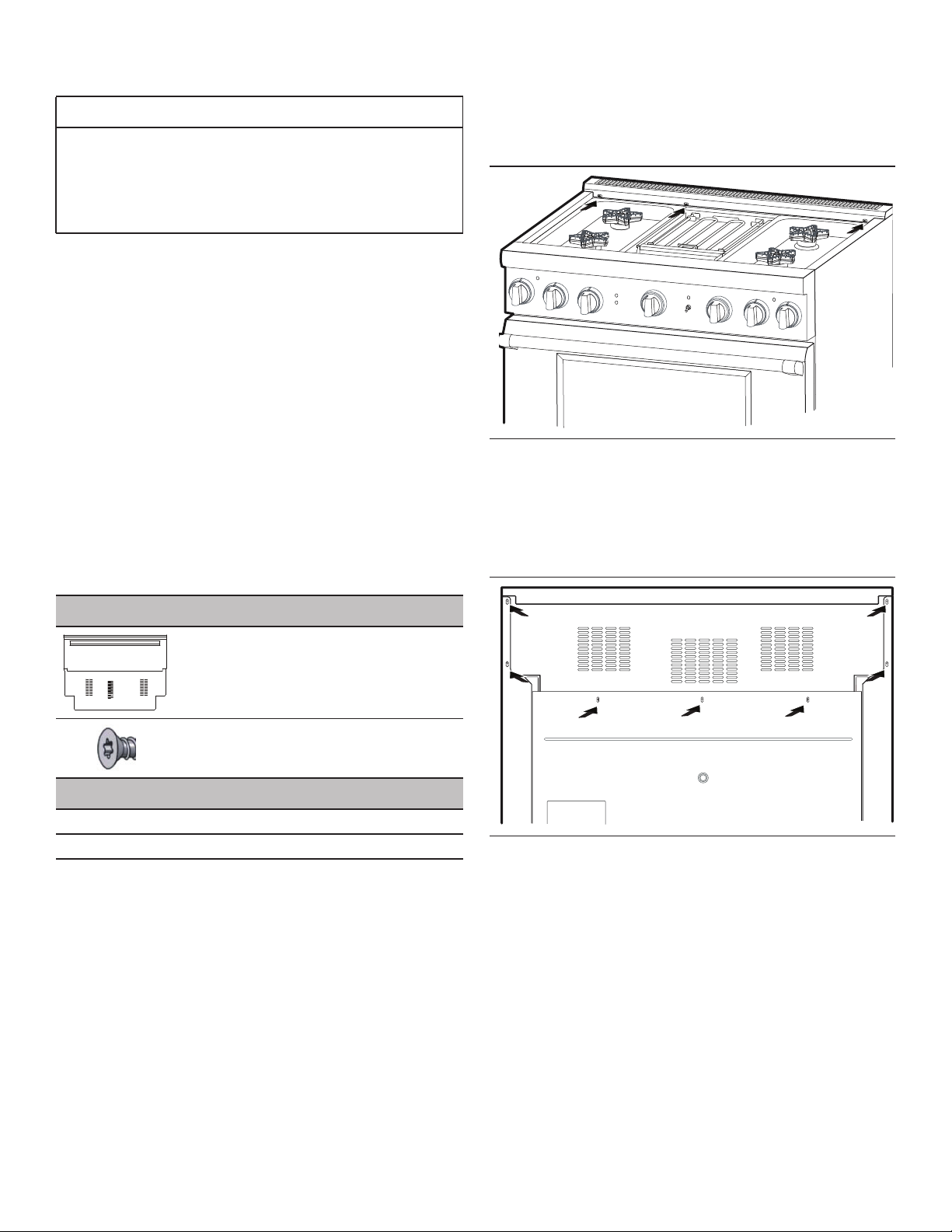

Backsplash Installation (PA [30, 36, 48] JBS)

Parts Included Tools Needed

10 – 1” (25.4 mm)

screws

1 – Backsplash Tape measure

The Backsplash must be installed prior to installing an

overhead hood given that the hood shell covers the top

mounting screws of the Backsplash.

To protect against scratches, leave protective film on

Backsplash until after installation is complete.

If range is already installed, refer to the manufacturer’s

instructions to disconnect gas and power supplies. Move

range forward to gain access to rear of unit.

1. Locate and lightly mark wall studs. Wall studs are

usually installed with a 16'' or 24'' (406 or 610 mm)

space on center.

2. The height of the hood will determine the height of the

top edge of the Backsplash. The Backsplash should be

mounted so that the bottom rear edge of the hood

overlaps the Backsplash 1

3. Per each wall stud, use (2) 1'' (25.4 mm) Phillips head

screws to secure both the top and bottom of the

Backsplash (see Figure 10). Space screws evenly

across top and bottom of Backsplash.

• Due to variable wall stud widths and varying

Backsplash widths, in some cases only one wall

stud may be found at the mounting location.

Phillips screwdriver or

drill

½'' (38 mm).

Installation Instructions English 16

4. Remove protective plastic.

A hood can be installed first if the Backsplash is to be

installed with a Keep Hot Shelf given that the Keep Hot

Shelf covers the top mounting screws of the Backsplash.

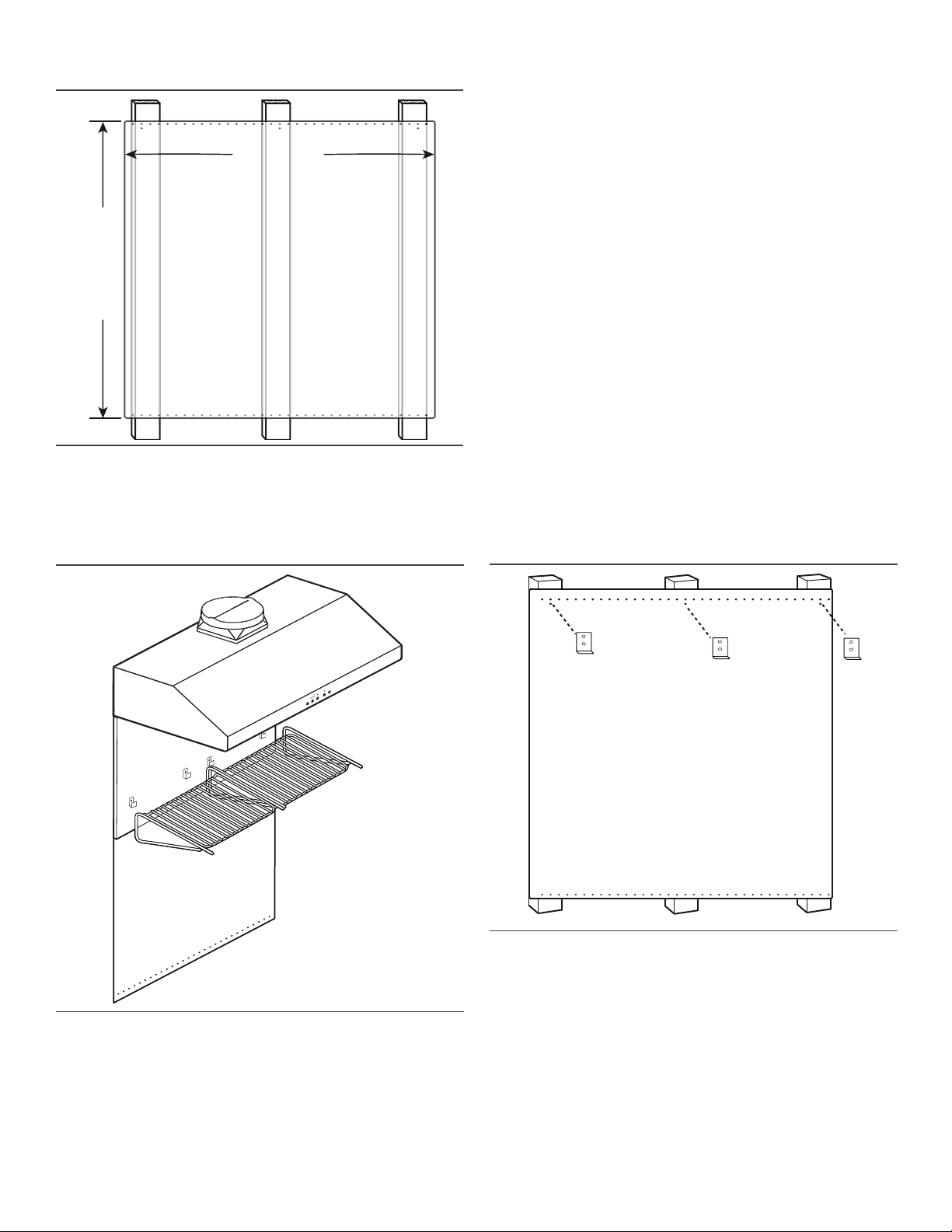

30”, 36”, 48”

(762, 914, 1219 mm)

42” (1067 mm)

Figure 10: Backsplash Installation

Backsplash with a Keep Hot Shelf

Installation

To protect against scratches, leave protective film on the

Backsplash until after installation is complete.

If range is already installed, refer to the manufacturer’s

instructions to disconnect gas and power supplies. Move

range forward to gain access to rear of unit.

1. Locate wall studs. Wall studs are usually installed with

a 16'' (406 mm) or 24'' (610 mm) space on center.

2. The height of the hood will determine the height of the

top edge of the Backsplash. The Backsplash should be

mounted so that the bottom rear edge of the Keep Hot

Shelf overlaps the Backsplash 1½'' (38 mm).

3. At the locations indicated in Figure 12, mount the lower

shelf brackets included with the Keep Hot Shelf

through the Backsplash and into the wall studs.

• Due to variable wall stud widths and varying

Backsplash widths, in some cases, only one wall

stud may be found at the mounting location.

4. Remove Backsplash protective covering.

5. Start with the Keep Hot Shelf Installation.

Figure 12: Backsplash with a Keep Hot Shelf

Figure 11: Backsplash with a Keep Hot Shelf

Installation Instructions English 17

Keep Hot Shelf (KHS[30, 36, 42, 48]QS)

Varies

5

/8

"

(16 mm)

Varies

Varies

7

9

(251 mm)

Rack

Keep Hot

"

/8

"

7

"

/8

13

(352 mm)

1

4

"

/16

(103 mm)

(95 mm)

Backsplash

Clip Rack Top

Clip

Rack

1

10

"

/8

(257 mm)

3

/4

3

"

ITEMS INCLUDED

10 – 1'' (25.4 mm) screws

4 – ½'' (12.7 mm) screws

4 – U-Nuts

1

/2

13

(343 mm)

Figure 13: Keep Hot Shelf

1. Tape the templates included with the Keep Hot Shelf to

the wall accordingly:

• Tape the sheet titled

Left Hand Template to bottom

and left end of hood. Align the bottom line of hood

with the top line of the template.

• Tape the sheet titled Right Hand Template to

bottom and right end of hood. Align the bottom line

of hood with the top line of the template.

• Tape the sheet titled

Installation Instruction so that

the arrow at the top of the template aligns with

hood centerline. Align the bottom line of the hood

with the top line of the template.

• Left to right sides of the template must be equal to

length of shelf.

2. Mount the (2) upper shelf brackets and the (3) lower

shelf brackets on the 30'' & 36'' models or (4) lower

shelf brackets for the 48'' model at the locations

outlined on the templates. Secure with (10) 1''

(25.4 mm) screws provided.

3. Cut template out from around the brackets and remove

from the wall. DO NOT discard template before the

Keep Hot Shelf is completely installed.

4. Insert U-Nuts onto each of the lower shelf brackets.

5. Install the wall plate by setting the corner notches

(back of wall plate) atop the (2) upper shelf brackets.

6. Slide the shelf upwards until the bottom engages with

the (3) lower brackets on the 30'' & 36'' models or (4)

brackets for the 48'’ models (Figure 14).

2 – Upper shelf brackets

4 – Lower shelf brackets

2 – Racks

1 – Wall Plate

1 – Installation guide & templates

TOOLS NEEDED

Tape measure Phillips screwdriver or drill

Painter’s Tape Sharp knife or scissors

Upper Shelf Brackets x 2

Lower Shelf Brackets x 4

Figure 14: 48” Back of Wall Plate

7. Check if the top is properly secured by pulling the top

section of the shelf from the wall.

8. Secure to bottom of shelf with the (4) ½'' (12.7 mm)

screws provided.

Installation Instructions English 18

Backguard Installation

Backguard Installation

WARNING

Fingers or hands could get pinched when installing the

backguard. Severe injury could result. Use extreme

caution and wear thick protective gloves to avoid

potential laceration to finger or hand while sliding the

backguard down onto the range.

When installing against a combustible surface, a Low

Backguard is required. A THERMADORTM Low Backguard

must be purchased separately. See “Installation

Clearances with Lowback” beginning on page 7.

When using the Flush Island Trim, THERMADOR

recommends a minimum 12'' (305 mm) rear clearance to a

combustible surface (see “Installation Clearances”).

Clearances from non-combustible materials are not part of

the ANSI Z21.1 scope and are not certified by

CSA. Clearances of less than 12'' (305 mm) must be

approved by the local codes and/or by the local authority

having jurisdiction.

NOTE: If a Backsplash is to be used in addition to a

backguard, install the Backsplash first and the backguard

second before sliding range into place.

1. Depending on model, remove the (3) or (4) T-20 Torx

stainless screws in the front face of the included Flush

Island Trim.

Figure 15: Flush Island Trim Front Face Screw Removal

2. Remove the (4) drill point screws securing the trim to

the side panels, and the (2) to (4) drill point screws

securing the piece to the back panel. Lift up to fully

remove.

LOW BACK PARTS INCLUDED

1 – Low Back panel

8 or 9 – T-20 Torx stainless screws

8 or 6 – T-20 Torx drill point screws

TOOLS NEEDED

T-20 Torx head screwdriver or drill

Protective Work Gloves

Figure 16: Flush Island Trim Rear Screw Removal

Installation Instructions English 19

3. Align the back panel of the new accessory with the

flanges on the range side panels right and left rear

corners. The backguard is inserted inside the guide

channels on the back of the range (Figure 17).

Figure 17: Backguard Installation

4. Make sure the backguard’s front face is outside the

flange on the front side of the range.

STEP 8: Door Removal and

Adjustment

CAUTION

• USE CAUTION WHEN REMOVING THE DOOR.

THE DOOR IS VERY HEAVY.

• Make sure oven is cool and power to the oven has

been turned off before removing the door. Failure to

do so could result in electrical shock or burns.

• The oven door is heavy and fragile. Use both hands

to remove or replace the door.

• Failure to grasp the oven door firmly and properly

could result in personal injury and product damage.

• With the door off, never release the levers and try to

close the hinges. Without the weight of the door, the

powerful springs will snap the hinges closed with

great force.

To Remove the Oven Door

1. Be sure to read the above

CAUTION before

attempting to remove the

door.

2. Open the door fully.

Figure 18: Low Back Front View

5. Re-install screws removed in Steps 1 and 2.

3. Flip hinge clip down. A

screwdriver may be required

to carefully pry the clip back.

4. Close the door gently until it

stops against the hinge

clips. The open hinge clips

will hold the door open at a

slight angle, about 30°, from

the closed position.

5. Grasp the door firmly on the

ends of the door. Lift the

door up and out. There will

be some spring resistance

to overcome.

6. Place the door in a safe and

stable location.

Figure 19: Door Removal

Installation Instructions English 20

To Reinstall the Oven Door

1. Hold the door firmly in both

hands.

2. Hold the door at a 30° angle

from the closed position.

Insert hinges centered

evenly into the hinge slots.

The hinges will securely

hook into the slots when

properly installed. DO NOT

force, bend or twist the door.

3. Open door fully to expose

hinges, levers, and slots.

4. Flip the hinge forward and

down until seated on the

bracket. A screwdriver may

be required to carefully push

the clip back.

5. Close and open the door

slowly to ensure it is

correctly and securely in

place.

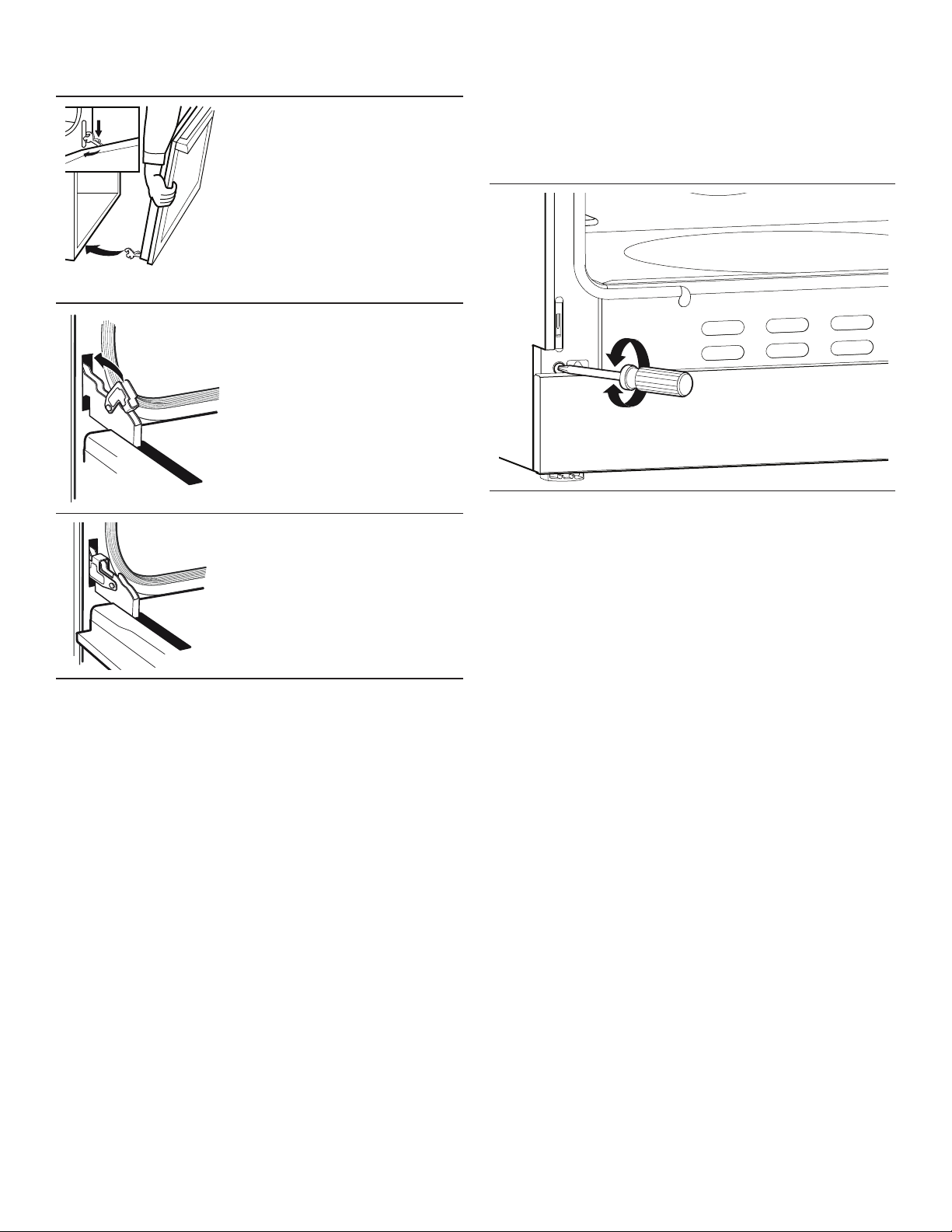

4. If door or handle appears slightly tilted, you may adjust

the hinge receiver by rotating the large Torx-head

screw located directly below the hinge receiver with a

T-20 Torx driver. Rotate each screw respective to its

side and direction the door needs to be adjusted

(Figure 21).

Figure 21: Hinge Receiver Adjustment Screw

Figure 20: Door Install

To Check Door Fit and Operation

1. Open and close the door slowly to test the movement

and the fit of the door to the oven cavity. Do not force

the door to open or close. If the door is properly

installed, it should move smoothly and rest straight on

the front of the range when closed.

2. The range must be level for proper alignment of the

oven doors, see “STEP 9: Placing and Leveling the

Range”.

3. If the door does not operate correctly, verify that the

hinges are properly seated into the hinge slots, and

that the hinge clips are fully engaged into the slots.

Installation Instructions English 21

STEP 9: Placing and Leveling

1/16''-1/8''

(2-3 mm)

the Range

Leveling Leg Adjustment

CAUTION

The top edges of the range’s side panels must be on the

same or higher level as the adjacent countertop. If the

range is operated while at a lower height relative to the

adjacent cabinet, the cabinet could be exposed to

excessive temperatures, causing damage to the cabinet

and countertop (see Figure 22).

For proper performance, the range must be level. This is

especially important for all products that have the griddle

feature. Priority should be placed on ensuring that the oven

cavities are also level for optimum cooking performance.

1. Measure the countertop heights first with a tape

measure and add an additional 1/16'' - 1/8'' (2-3 mm).

Adjust the legs accordingly prior to pushing the range

back to its final location.

2. Rotate the legs using a 12'' (305 mm) adjustable

wrench on the flat sides of each foot. Progression of

the height adjustments should be alternated

proportionally between the four corner legs, until the

top edges of the range’s side panels are close to

matching the counter top height.

Figure 23: Leveling Legs

3. Final height adjustments of the two rear legs take place

before moving the range into its installed position in the

cabinet.

4. As the range is moved into its final, installed position,

verify that the Anti-Tip Bracket is in a position to

engage the leg (see “STEP 4: Installing the Anti-Tip

Device” on page 13). This can be verified by viewing

through the opening near the floor.

5. With the range in the installed position, the final height

adjustments are made to the two front legs to ensure

proper alignment to the counter top.

1/16''-1/8''

1/16''-1/8''

(2-3 mm)

(2-3 mm)

Figure 22: Adjusting the Height of the Range

Griddle Tilt Adjustment (not all models)

Refer to “Using the Electric Griddle” in the Use and Care

Guide.

Assembling the Grill (not all models)

Refer to “Using the Electric Grill” in the Use and Care

Guide.

Installation Instructions English 22

Loading...

Loading...