Page 1

I TALLATION UAL

For THERMADOR PROFESSIONAL ®

PRO HARMONY ® Dual Fuel Ranges

UEL 'INSTALLATIO

Pour toutes les cuisinieres mixtes THERMADOR

PROFESSIONAL McPRO HARMONY Mc

f

UAL El TALAC

Para Estufas de Todo Tipo de Gas THERMADOR

PROFESSIONAL ®PRO HARMONY ®

Models/

Mod¢les/

Modelos:

PRD304GHC

PRD304GHU

PRD364GDHC

PRD364GDHU

PRD366GHC

PRD366GHU

PRD486GDHC

PRD486GDHU

Th mador

REAL INNOVATIONS FOR REAL COOKS ®

Page 2

US

Page 3

Table of Contents

Safety Instructions ................................... 1

Installation .......................................... 3

Step 1: Ventilation Requirements ......................................... 3

Step 2: Cabinet Preparation ............................................. 4

Step 3: Unpacking, Moving and Placing the Range ........................... 9

Step 4: Installing Anti-Tip Device ........................................ 11

Step 5: Gas Requirements and Hookup ................................... 13

Step 6: Electrical Requirements, Connection & Grounding .................... 15

Step 7: Backguard Installation (optional) .................................... 18

Step 8: Door Removal and Reinstallation .................................. 23

Step 9: Placing and Leveling the Range ................................... 24

Step 10: Burner Test and Adjustment ..................................... 27

Installer Checklist ................................... 28

Customer Support, Accessories & Parts ........... back page

This THERMADOR ® appliance is made by

BSH Home Appliances Corporation

1901 Main Street, Suite 600

Irvine, CA 92614

Questions?

1-800-735-4328

www.thermador.com

We look forward to hearing from you!

Page 4

Safety

iMPORTANT SAFETY iNSTRUCTiONS

Read and Save These instructions

APPROVED FOR ALL RESiDENTiAL APPLIANCES

FOR RESiDENTiAL USE ONLY

DO NOT install this range outdoors.

WARNING:

Before You Begin

iMPORTANT: Save these Instructions for the Local Gas

Inspector's use.

INSTALLER: Please leave these Installation Instructions

with this unit for the owner.

OWNER: Please retain these instructions for future

reference.

, WARNING:

ELECTRICAL SHOCK HAZARD

Disconnect power before installing or servicing.

Before turning power ON, be sure that all

controls are in the OFF position. Failure to do

so can result in death or electrical shock.

iMPORTANT:

Local codes vary. Installer is responsible for ensuring that

the installation, gas connections, and grounding comply

with all applicable codes. Failure to follow appropriate local

codes and regulations may void the warranty.

For Massachusetts installations:

1. Installation must be performed by a qualified or

licensed contractor, plumber or gas fitter qualified or

licensed by the state, province or region where this

appliance is being installed.

2. Shut=off valve must be a "T" handle gas cock.

3. Flexible gas connector must not be longer than 36"

(914mm).

Note:

This range is NOT designed for installation in

manufactured (mobile) homes or Recreational Park

Trailers.

A child or adult can tip the range over and

be killed or seriously injured. Verify that the

anti-tip bracket is securely installed.

Ensure the anti=tip bracket is engaged

when the range is moved.

Do not operate the range without the anti-

tip bracket in place. Failure to follow the

instructions in this manual can result in

death or serious burns to children and

adults.

Check for proper installation and use of

anti-tip bracket. Carefully tip range forward

pulling from the back to ensure that the

anti-tip bracket engages the range leg and

prevents tip-over. Range should not move

more than 1" (2.5 cm).

, WARNING:

If the information in this manual is not followed exactly, a

fire or explosion may result causing property damage,

personal injury or death.

-- Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

WHAT TO DO iF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the

fire department.

Installation and service must be performed by a

qualified installer, service agency or the gas

supplier.

English 1

Page 5

iMPORTANT SAFETY iNSTRUCTiONS

READ AND SAVE THESE iNSTRUCTiONS

Gas type verification

Verify the type of gas supplied to the location. Ensure that

the appliance is connected to the type of gas for which it is

certified. All models are certified for use with natural gas.

Field conversion of the appliance for use with propane gas

supply will require a conversion kit (PALPKITHC).

Gas Supply:

Natural Gas -- 6 inch water column. (14.9 mb) min., 14

inch (34.9 rob) maximum

Propane Gas -- 11 inch water column. (27.4 mb) min., 14

inch (34.9 mb) maximum

, CAUTION

When connecting the unit to propane gas, make certain

the propane gas tank is equipped with its own high-

pressure regulator in addition to the pressure regulator

supplied with the range. The maximum gas pressure to

this appliance must not exceed 14.0" water column

(34.9 mb) from the propane gas tank to the pressure

regulator.

It is the responsibility of the owner and the installer to

determine if additional requirements and/or standards

apply to specific installations.

IMPORTANT:

When installing against a combustible surface, a High Shelf

or Low Backguard is required. A THERMADOR ® High

Shelf or Low Backguard must be purchased separately.

See Step 7 for backguard, kits and installation information.

When using the Flush Island Trim, THERMADOR

recommends a minimum 12" (305 mm) rear clearance to a

combustible surface (see Figure 1, Cabinet Clearances).

Clearances from non-combustible materials are not part of

the ANSI Z21.1 scope and are not certified by

CSA. Clearances of less than 12" (305 mm) must be

approved by the local codes and/or by the local authority

having jurisdiction.

Refer to Table 4, Backguard Kit Model Numbers, for the

correct backguard models that are designed for this range.

After selecting the correct backguard, the range must be

installed properly, using the minimum clearances to

combustible surfaces specified in the Cabinet Preparation

instructions beginning on page 4.

Electric Power Supply:

See "Step 6: Electrical Requirements, Connection &

Grounding" on page 15 for specifications.

Check local building codes for the proper method of

appliance installation. Local codes vary and it is the

_y of the installer to ensure installation is in

accordance with these codes. Installation, electrical

connections and grounding must comply with all applicable

codes. In the absence of local codes the appliance should

be installed in accordance with the National Fuel Gas Code

ANSI Z223. I/NFPA 54 current issue and National Electrical

Code ANSI/NFPA 70-current issue. In Canada, installation

must be in accordance with the CAN 1-B149.1 and .2 -

Installation Codes for Gas Burning Appliances and/or local

codes.

This appliance complies with the following standards:

* UL 858, Standard for the Safety of Household Electric

Ranges

* ANSI Z21.1, American National Standard for

Household Cooking Gas Appliances

* CAN 1-1. 1-M81, Domestic Gas Ranges

* CAN/CSA-C22.2 No. 61, Household Cooking Ranges

, WARNING

To avoid possible burn or fire hazard, a backguard

designed specifically for this range must be installed

whenever the range is used.

CAUTION:

To eliminate risk of burns or fire caused by reaching over

heated surface units, cabinet storage located above the

surface units should be avoided.

CAUTION:

This unit is designed as a cooking appliance. Based on

safety considerations, never use itfor warming or

heating a room.

English 2

Page 6

Installation

Planning information

Before using your appliance, be sure to read this manual.

Pay special attention to the Important Safety Instructions

located at the beginning of the manual.

Tools Needed

2 - ½" wrenches

3/16" (4.76 mm) drill bit

Hand or electric drill

T-20 Torx screwdriver

Level

Phillips & flathead

screwdrivers

Items Not included

Drywall / Concrete Anchors Pipe Compound / Tape

Rope/Twine ¾" (19 mm) Flex Line

Strain Relief Cord Kit or Conduit

2 - NPT Flare Adapters

Remove all tape and packaging before using the

appliance. Please, recycle the packaging

material, as all THERMADOR ® appliance

packaging material is recyclable. Never allow

children to play with packaging material.

1/8" (3.17 mm) drill bit

12" Adjustable wrench

Tape measure

Marking instrument

Furniture dolly

Protective gloves

Step 1: Ventilation

Requirements

It is strong.[y recommended that this appliance be installed

in conjunction with a suitable overhead vent hood. Due to

the high heat capability of this unit, particular attention

should be paid to the hood and duct work installation to

assure it meets local building codes.

Downdraft ventilation should not be used. The Table 1,

Blower Options indicates the ventilation hood options and

blower capacity guidelines that are recommended for use

with all THERMADOR ranges.

IMPORTANT:

Ventilation hoods and blowers are designed for use with

single wall ducting. However, some local building codes or

inspectors may require double wall ducting. Consult local

building codes and/or local agencies, before starting, to

assure that hood and duct installation will meet local

requirements.

NOTICE:

Most range hoods contain combustible components which

must be considered when planning the installation.

WARNING

This appliance should not be installed with a ventilation

system that directs air in a downward direction toward

the range. This type of ventilation system may cause

ignition and combustion problems with the appliance

resulting in personal injury, property damage, or

unintended operation. Ventilating systems that direct the

air upwards do not have any restriction.

Ventilation Preparation

1. Select Hood and Blower Models:

• For wall installations, the hood width must, at a

minimum, equal the width of the range. Where space

permits, a hood larger in width than the range/rangetop

may be desirable for improved ventilation performance.

• For island installations, the hood width should

overhang the width of the range by a minimum of 3"

(76 mm) on each side.

2. Hood Placement:

• For best smoke elimination, the lower edge of the hood

should be installed 30" (762 mm) above the range

cooking surface (see Figure 1).

• If the hood contains any combustible materials (i.e. a

wood covering), it must be installed a minimum of 36"

(914 mm) above the cooking surface (see Figure 1).

3. Consider Make-Up Air:

• Due to the high volume of ventilation air, a source of

outside replacement air is recommended. This is

particularly important for tightly sealed and insulated

homes. A qualified heating and ventilating contractor

should be consulted.

Due to the high heat of the rangetop burners, do not install

a microwave oven/ventilator combination above the range,

as these type of units do not provide the proper ventilation

and are not suitable for use with the range.

English 3

Page 7

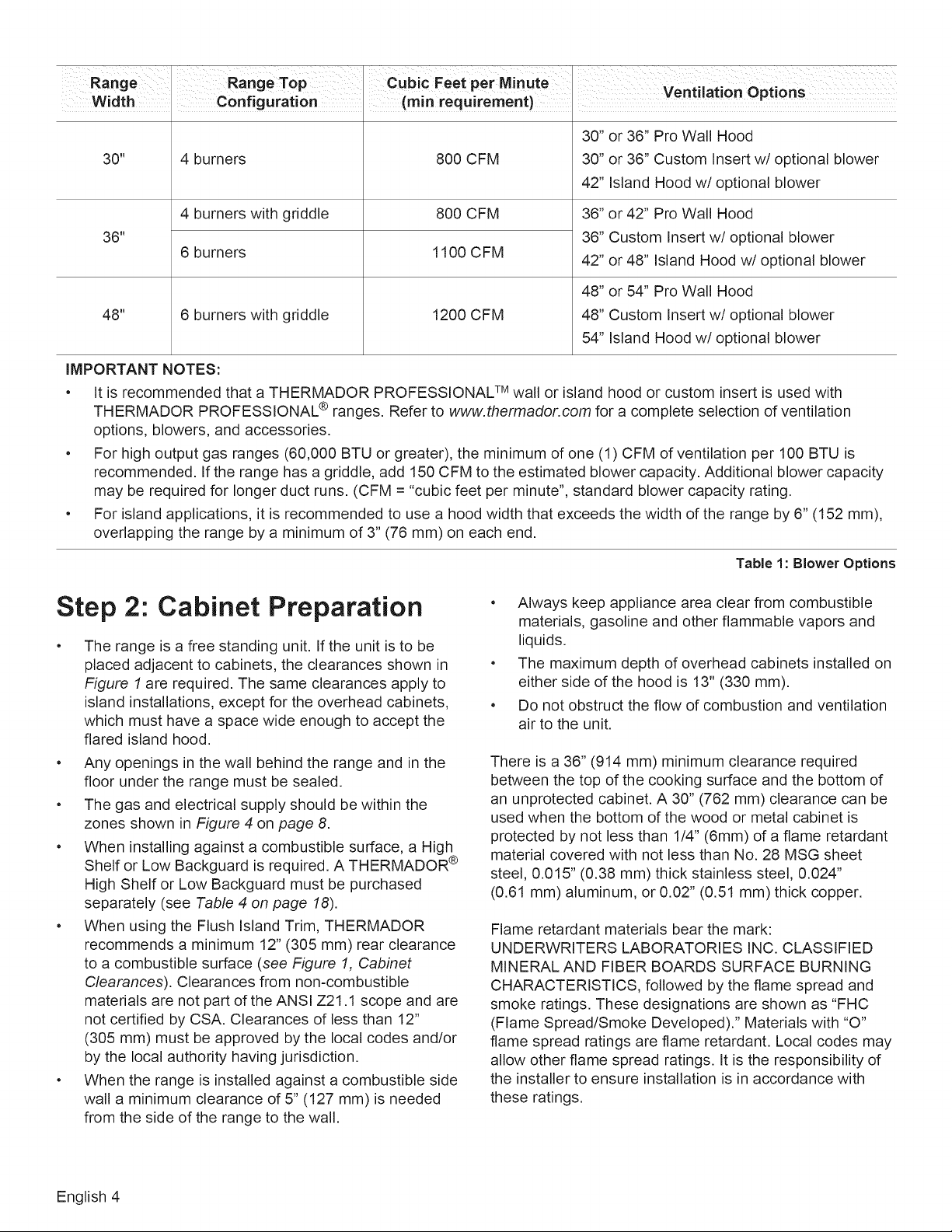

Range Range Top Cubic Feet per Nlinute

Width Configuration ! (rain requirement)vend,lab!on up_!ons

30" or 36" Pro Wall Hood

4 burners 800 CFM30"

30" or 36" Custom Insert w/optional blower

42" Island Hood w/optional blower

4 burners with griddle 800 CFM

36"

48" 6 burners with griddle 1200 CFM

IMPORTANT NOTES:

• It is recommended that a THERMADOR PROFESSIONAL TM wall or island hood or custom insert is used with

TH ERMADOR PROFESSIONAL ® ranges. Refer to www.thermador.com for a complete selection of ventilation

options, blowers, and accessories.

• For high output gas ranges (60,000 BTU or greater), the minimum of one (1) CFM of ventilation per 100 BTU is

recommended. If the range has a griddle, add 150 CFM to the estimated blower capacity. Additional blower capacity

may be required for longer duct runs. (CFM = "cubic feet per minute", standard blower capacity rating.

• For island applications, it is recommended to use a hood width that exceeds the width of the range by 6" (152 mm),

overlapping the range by a minimum of 3" (76 mm) on each end.

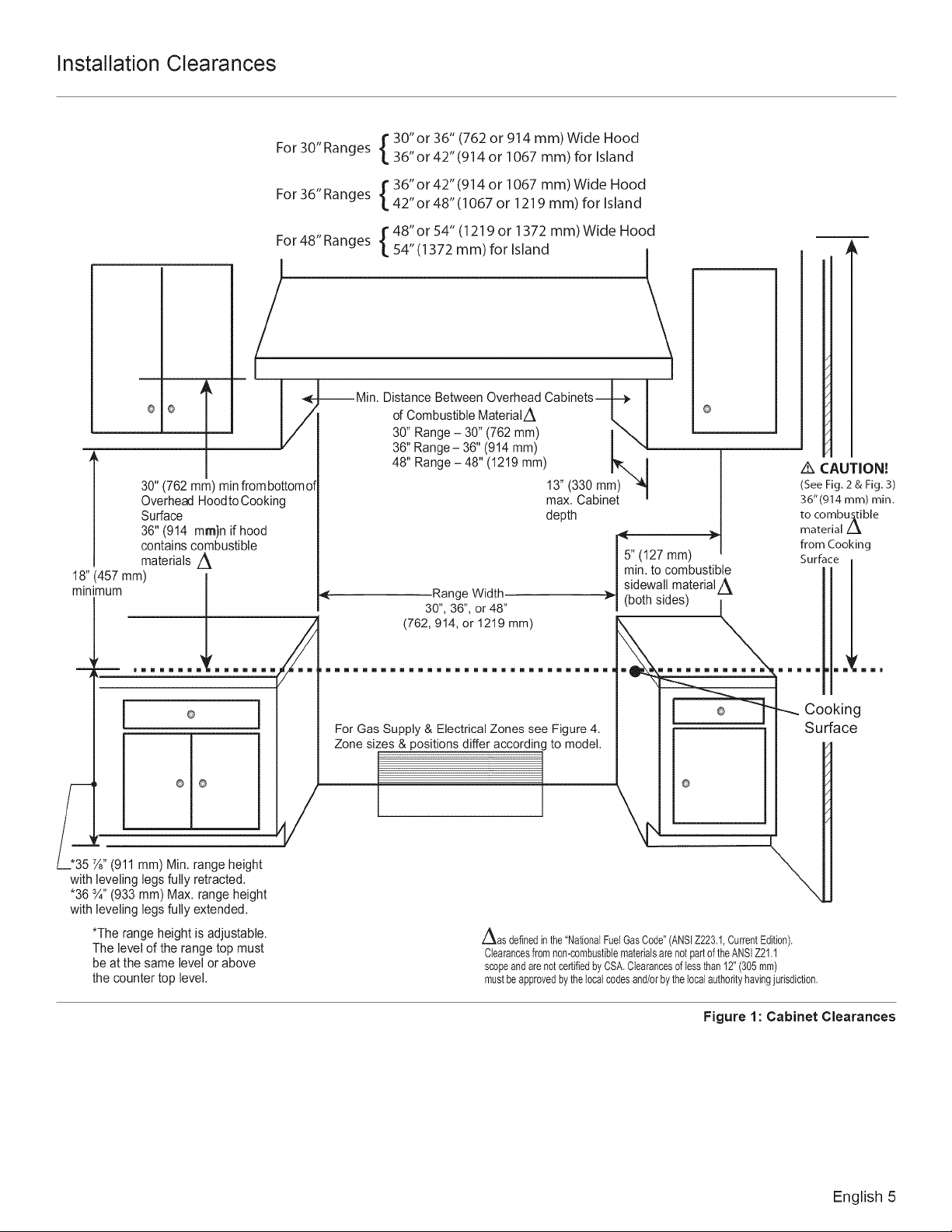

Step 2: Cabinet Preparation

The range is a free standing unit. If the unit is to be

placed adjacent to cabinets, the clearances shown in

Figure 1 are required. The same clearances apply to

island installations, except for the overhead cabinets,

which must have a space wide enough to accept the

flared island hood.

• Any openings in the wall behind the range and in the

floor under the range must be sealed.

• The gas and electrical supply should be within the

zones shown in Figure 4 on page 8.

• When installing against a combustible surface, a High

Shelf or Low Backguard is required. A THERMADOR ®

High Shelf or Low Backguard must be purchased

separately (see Table 4 on page 18).

• When using the Flush Island Trim, THERMADOR

recommends a minimum 12" (305 mm) rear clearance

to a combustible surface (see Figure 1, Cabinet

Clearances). Clearances from non-combustible

materials are not part of the ANSI Z21.1 scope and are

not certified by CSA. Clearances of less than 12"

(305 mm) must be approved by the local codes and/or

by the local authority having jurisdiction.

• When the range is installed against a combustible side

wall a minimum clearance of 5" (127 mm) is needed

from the side of the range to the wall.

6 burners 1100 CFM

• Always keep appliance area clear from combustible

materials, gasoline and other flammable vapors and

liquids.

• The maximum depth of overhead cabinets installed on

either side of the hood is 13" (330 mm).

• Do not obstruct the flow of combustion and ventilation

air to the unit.

There is a 36" (914 mm) minimum clearance required

between the top of the cooking surface and the bottom of

an unprotected cabinet. A 30" (762 mm) clearance can be

used when the bottom of the wood or metal cabinet is

protected by not less than 1/4" (6mm) of a flame retardant

material covered with not less than No. 28 MSG sheet

steel, 0.015" (0.38 mm) thick stainless steel, 0.024"

(0.61 mm) aluminum, or 0.02" (0.51 mm) thick copper.

Flame retardant materials bear the mark:

UNDERWRITERS LABORATORIES INC. CLASSIFIED

MINERAL AND FIBER BOARDS SURFACE BURNING

CHARACTERISTICS, followed by the flame spread and

smoke ratings. These designations are shown as "FHC

(Flame Spread/Smoke Developed)." Materials with "O"

flame spread ratings are flame retardant. Local codes may

allow other flame spread ratings. It is the responsibility of

the installer to ensure installation is in accordance with

these ratings.

36" or 42" Pro Wall Hood

36" Custom Insert w/optional blower

42" or 48" Island Hood w/optional blower

48" or 54" Pro Wall Hood

48" Custom Insert w/optional blower

54" Island Hood w/optional blower

Table 1: Blower Options

English 4

Page 8

Installation Clearances

e ® of Combustible MaterialA L I O

30" (762 mm) minfrombottomof 13" (330 mm) _

Overhead HoodtoCooking max. Cabinet ' /

Surface depth _36" (914 mm}n if hood I<_

contains combustible

materials A

18"(457 mm) I

minimum

For 30"Ranges 36"or 42"(914 or 1067 mm) for Island

For 36" Ranges 42"or 48" (1067 or 1219 mm) for Island

For 48" Ranges 54" (1372 mm) for Island

30"or 36" (762 or 914 mm) Wide Hood

36"or 42" (914 or 1067 mm)Wide Hood

48"or 54" (1219 or 1372 mm) Wide Hood

l I

l -- Min' Distance aet_/veen Overhead Cabinets -_ I

I 36::Range- 36 (914 mm) I "4 _

I 48 Range- 48" (1219mm) I_,,_, I I

I

30" Range - 30:'(762mm) I _ I =

, RangeWidth

30", 36", or 48" d iboth sides) =1

_'i_1_7mm)bustible

idewall materialA

CAUTION!

(See Fig. 2 & Fig. 3)

36"(914 ram) rain.

to combustible

material Z__

from Cooking

Surface

_ mmllmml llmmllm

I

_*_5 ¼" (911 mm) Min. range height

with leveling legsfully retracted.

*36 ¾" (933 mm) Max. range height

with leveling legsfully extended.

*The range height is adjustable.

The level ofthe range top must

be at the same level or above

the counter top level.

° I °

© o

...................................

For Gas Supply & Electrical Zones see Figure 4.

Zone sizes & positions differ accordin( to model.

(762..914 or1219mm) ii.-'_._

/

z_as definedinthe"NationalFuelGasCode"(ANSIZ223.1,CurrentEdition).

Clearancesfromnon-combustiblematerialsarenotpartoftheANSIZ21.1

scopeandarenotcertifiedbyCSA.Clearancesoflessthan12"(305mm)

mustbeapprovedbythelocalcodesand/orbythelocalauthorityhavingjurisdiction.

Cooking

Surface

e

Figure 1: Cabinet Clearances

English 5

Page 9

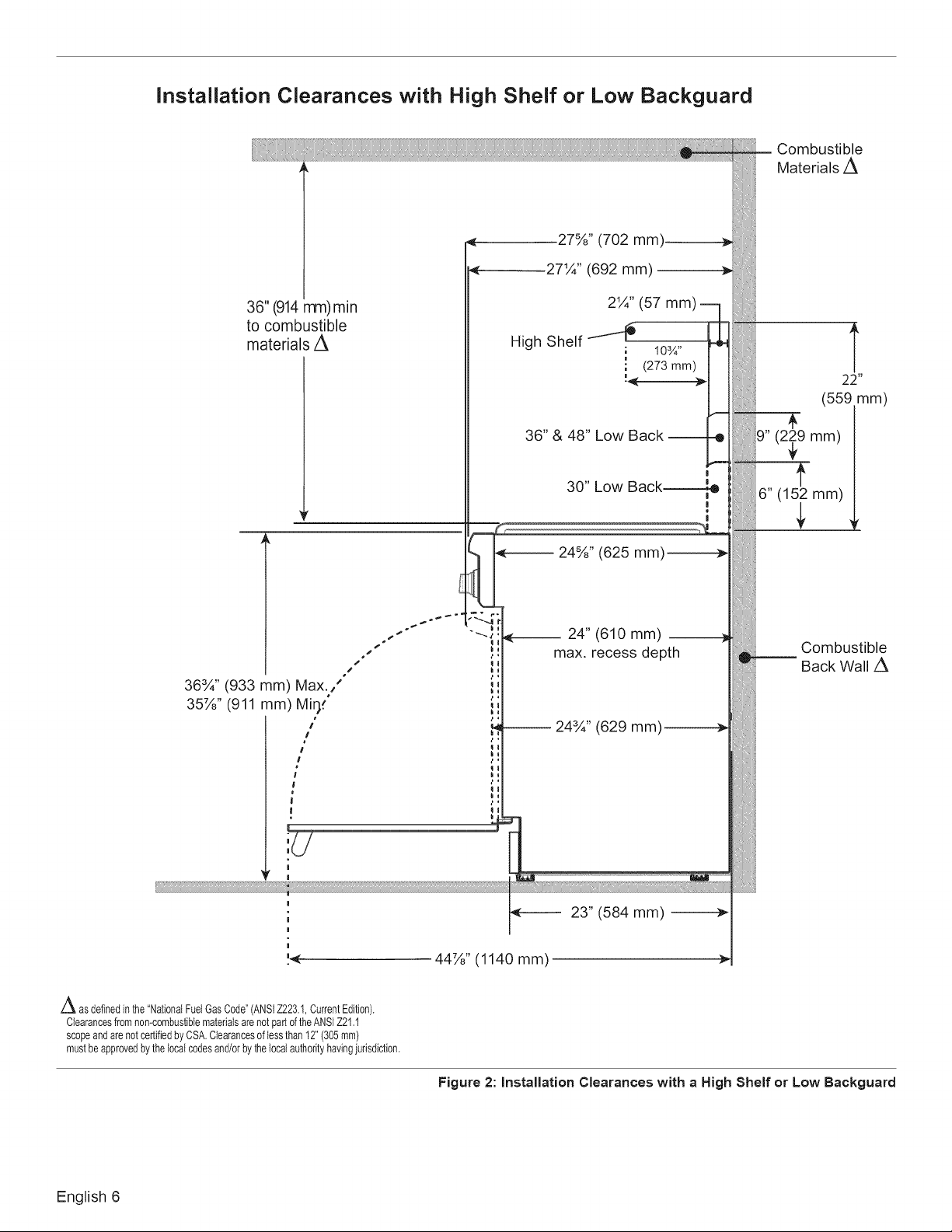

Installation Clearances with High Shelf or Low Backguard

2T¼" (692 mm)

Combustible

Materials/_

36" (914 mm)rain

to combustible

material_ /_

2_¼'' (57 mm)

High Shelf

36"& 48" Low Back --

-- 24%" (625 mm)

__ 24" (610 mm) __

max. recess depth

; 10¾"

m

; (273 mm)

L< ;>

t

22"

(559 mm)

(2_9 mm)

6" mm)

Combustible

Back Wall A

A asdefinedinthe"NationalFuelGasCode"(ANSIZ223.I,CurrentEdition).

Clearancesfromnon-combustiblematerialsarenotpartoftheANSIZ21.1

scopeandarenotcertifiedbyCSA.Clearancesoflessthan12"(305mm)

mustbe approvedbythelocalcodesand/orbythelocalauthorityhavingjurisdiction.

English 6

44½" (1140 mm)

Figure 2: Installation Clearances with a High Shelf or Low Backguard

Page 10

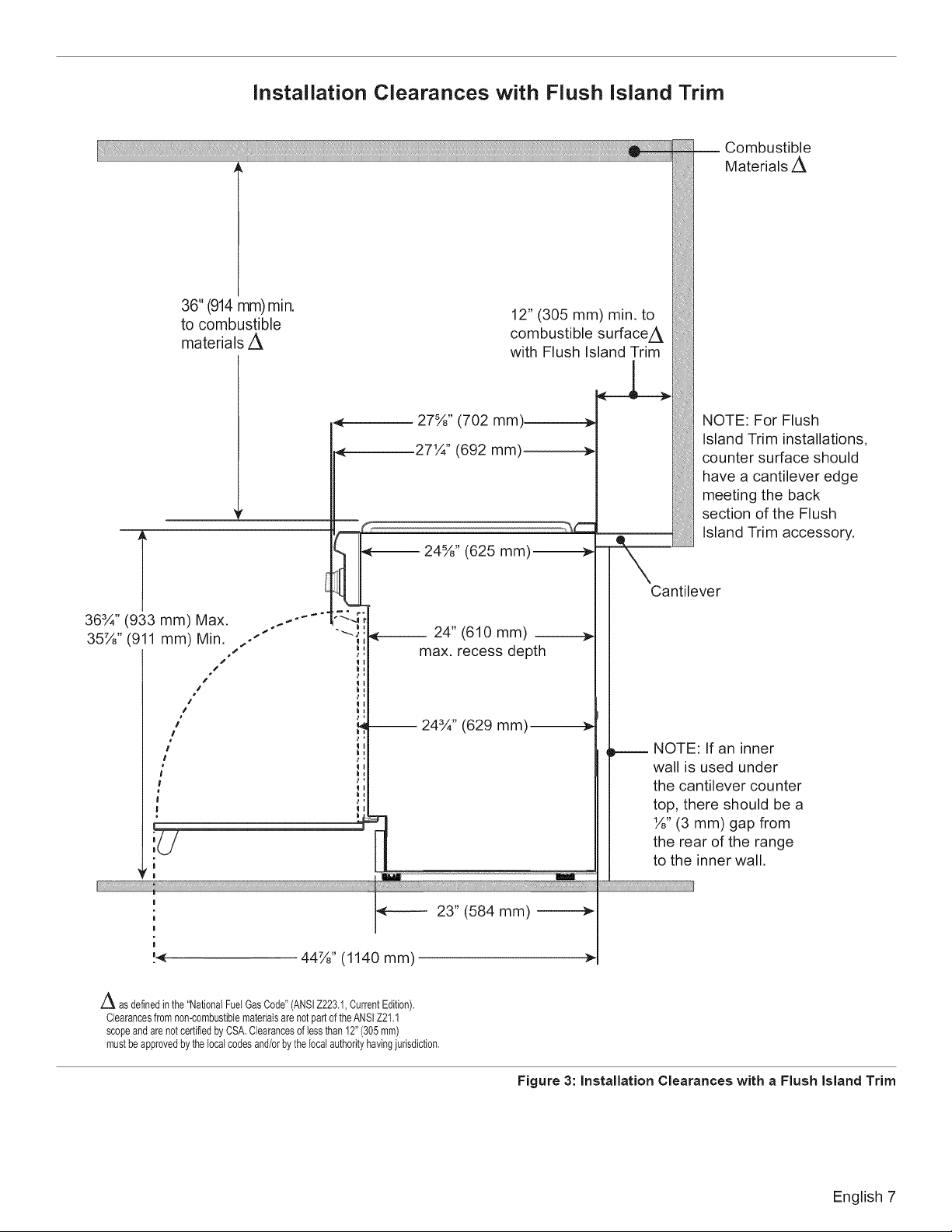

Installation Clearances with Flush Island Trim

Combustible

Materials/_

36" (914 mm)rain.

to combustible

material_ A

12" (305 mm) min. to

combustible surfaceA

with Flush Island Trim

27%" (702 mm)

271/4'' (692 mm)

-- 24%" (625 mm)_

__ 24" (610 mm) __

max. recess depth

24¾" (629 mm)

NOTE: For Flush

Island Trim installations,

counter surface should

have a cantilever edge

meeting the back

section of the Flush

Island Trim accessory.

\ n:,err

44½" (1140 mm)

Z_ asdefinedinthe"NationalFuelGasCode"(ANSIZ223.1,CurrentEdition).

Clearancesfromnon-combustiblematerialsarenotpartoftheANSIZ21.1

scopeandarenotcertifiedbyCSA.Clearancesoflessthan12"(305mm)

mustbeapprovedbythelocalcodesand/orbythelocalauthorityhavingjurisdiction.

_ _i_itrimle_sV_iii?:_ear

| the rear of the range

toth inner wall.

Figure 3: Installation Clearances with a Flush Island Trim

English 7

Page 11

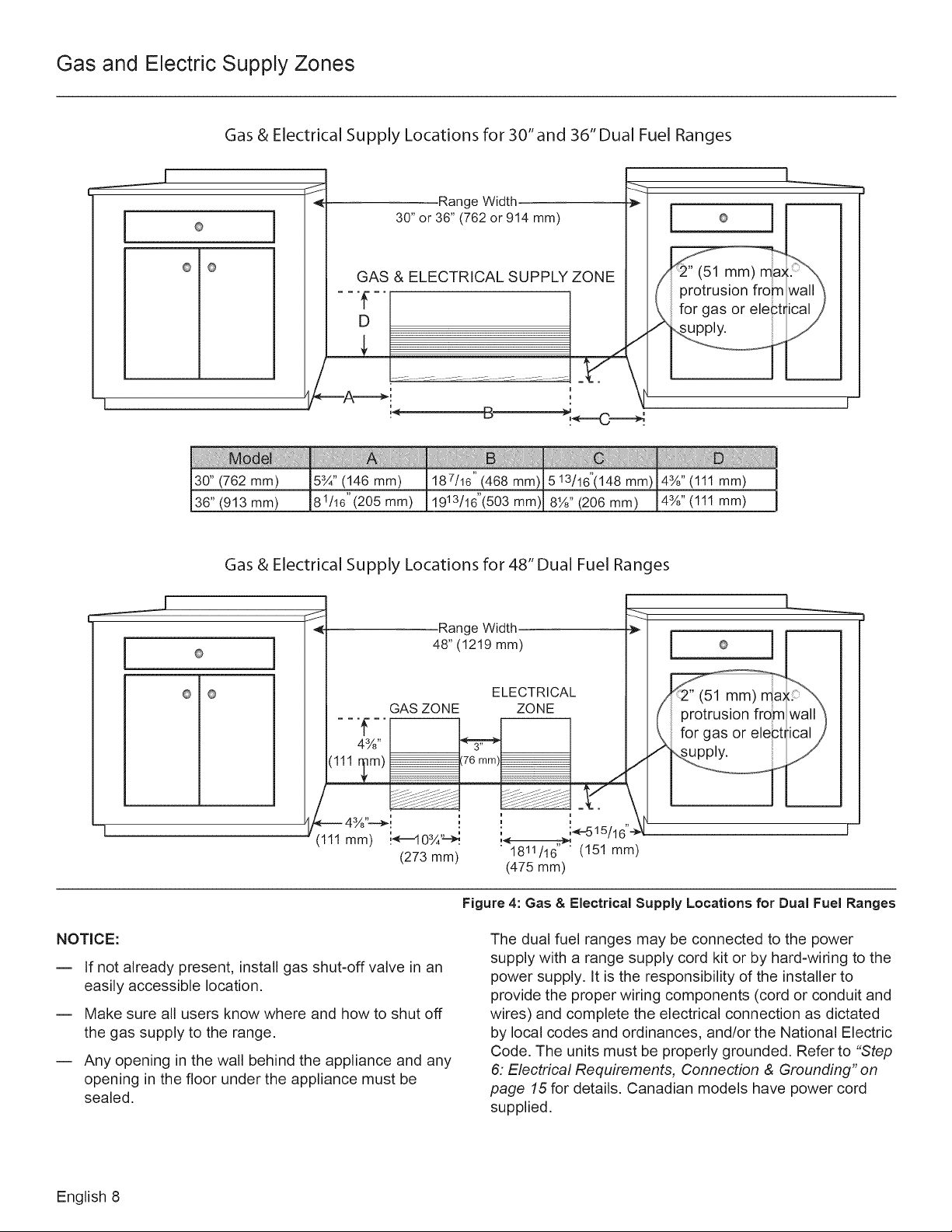

Gas and Electric Supply Zones

Gas & Electrical Supply Locations for 30"and 36" Dual Fuel Ranges

I[

Range Width

@

@ @

30" or 36" (762 or 914 mm)

GAS & ELECTRICAL SUPPLY ZONE

I

J

i5¼ (146 mm)30"(762 mm) , 3 .

36" (913 mm) 181/16"(205mm)

187"/16 '' (468 mm) 5 13/16"(148mm) 4%" (111mm)

1913/16"(503mm) 8½" (206 mm) 4%" (111mm)

Gas & Electrical Supply Locations for 48" Dual Fuel Ranges

I

Range Width _-

@

48"(1219 mm)

@ @

__ GAS ZONE ZONE

11_m)_76mm)_ ,. /.

_---- 4%"--_i i i i .... ,,_\I

(111mm) i<-_10¾'_-_.'

NOTICE:

If not already present, install gas shut-off valve in an

easily accessible location.

Make sure all users know where and how to shut off

the gas supply to the range.

Any opening in the wall behind the appliance and any

opening in the floor under the appliance must be

sealed.

ELECTRICAL

,_a JW16 -_

(273 mm) '_ (151 mm)

(475 mm)

Figure 4: Gas & Electrical Supply Locations for Dual Fuel Ranges

The dual fuel ranges may be connected to the power

supply with a range supply cord kit or by hard-wiring to the

power supply. It is the responsibility of the installer to

provide the proper wiring components (cord or conduit and

wires) and complete the electrical connection as dictated

by local codes and ordinances, and/or the National Electric

Code. The units must be properly grounded. Refer to "Step

6: Electrical Requirements, Connection & Grounding" on

page 15 for details. Canadian models have power cord

supplied.

_L

i !

i-

English 8

Page 12

The range must be connected only to the type of gas

for which it is certified, if the range is to be connected to

propane gas, ensure that the propane gas supply tank is

equipped with its own high pressure regulator in addition to

the pressure regulator supplied with the range (See "Step

5: Gas Requirements and Hookup" on page 13.).

NOTE:

The range is designed for flush installation to the back wall.

For a successful installation, it may be necessary to

reposition the gas supply line and the electrical cord as the

range is pushed back to its final position.

SUGGESTION: This may be accomplished by carefully

pulling on a rope or twine looped around the gas or

electrical supply line as the range is pushed back into

its final installed position.

When using a 240VAC receptacle having its own housing,

it will be necessary to recess the receptacle's housing into

the rear wall. Mount the receptacle securely to a wall stud,

then seal around the receptacle's housing. Follow all local

electrical codes.

NOTE:

Canadian models have power cord supplied with range.

Step 3: Unpacking

and Moving

the Range

, CAUTION

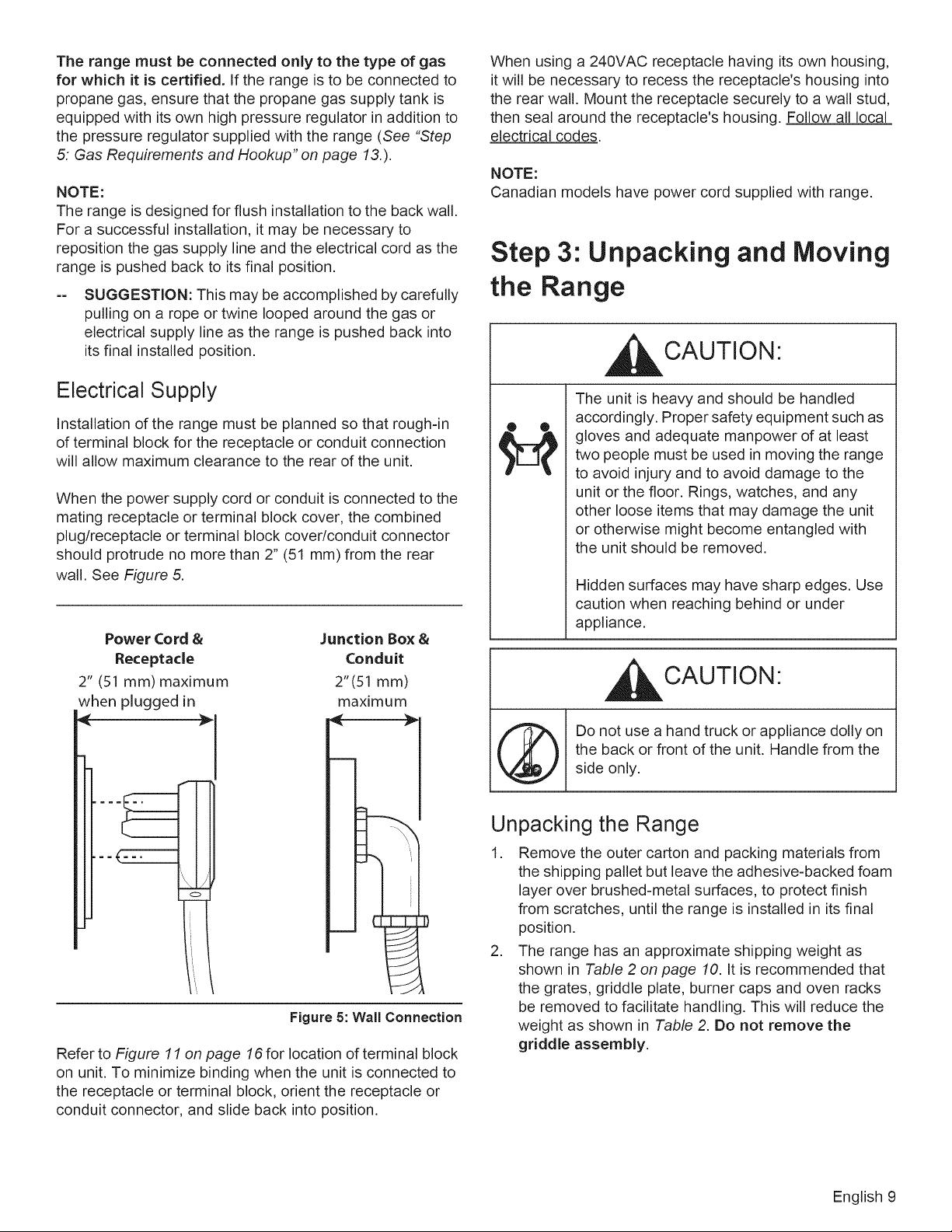

Electrical Supply

Installation of the range must be planned so that rough-in

of terminal block for the receptacle or conduit connection

will allow maximum clearance to the rear of the unit.

When the power supply cord or conduit is connected to the

mating receptacle or terminal block cover, the combined

plug/receptacle or terminal block cover/conduit connector

should protrude no more than 2" (51 mm) from the rear

wall. See Figure 5.

Power Cord &

Receptacle

2" (51 mm)maximum

when plugged in

Junction Box &

Conduit

2"(51 mm)

maximum

The unit is heavy and should be handled

accordingly. Proper safety equipment such as

gloves and adequate manpower of at least

two people must be used in moving the range

to avoid injury and to avoid damage to the

unit or the floor. Rings, watches, and any

other loose items that may damage the unit

or otherwise might become entangled with

the unit should be removed.

Hidden surfaces may have sharp edges. Use

caution when reaching behind or under

appliance.

, CAUTION

the back or front of the unit. Handle from the

Do not use a hand truck or appliance dolly on

side only.

Unpacking the Range

1

Figure 5: Wall Connection

Refer to Figure 11 on page 16 for location of terminal block

on unit. To minimize binding when the unit is connected to

the receptacle or terminal block, orient the receptacle or

conduit connector, and slide back into position.

1. Remove the outer carton and packing materials from

the shipping pallet but leave the adhesive-backed foam

layer over brushed-metal surfaces, to protect finish

from scratches, until the range is installed in its final

position.

2. The range has an approximate shipping weight as

shown in Table 2 on page 10. It is recommended that

the grates, griddle plate, burner caps and oven racks

be removed to facilitate handling. This will reduce the

weight as shown in Table 2. Do not remove the

griddle assembly,

English 9

Page 13

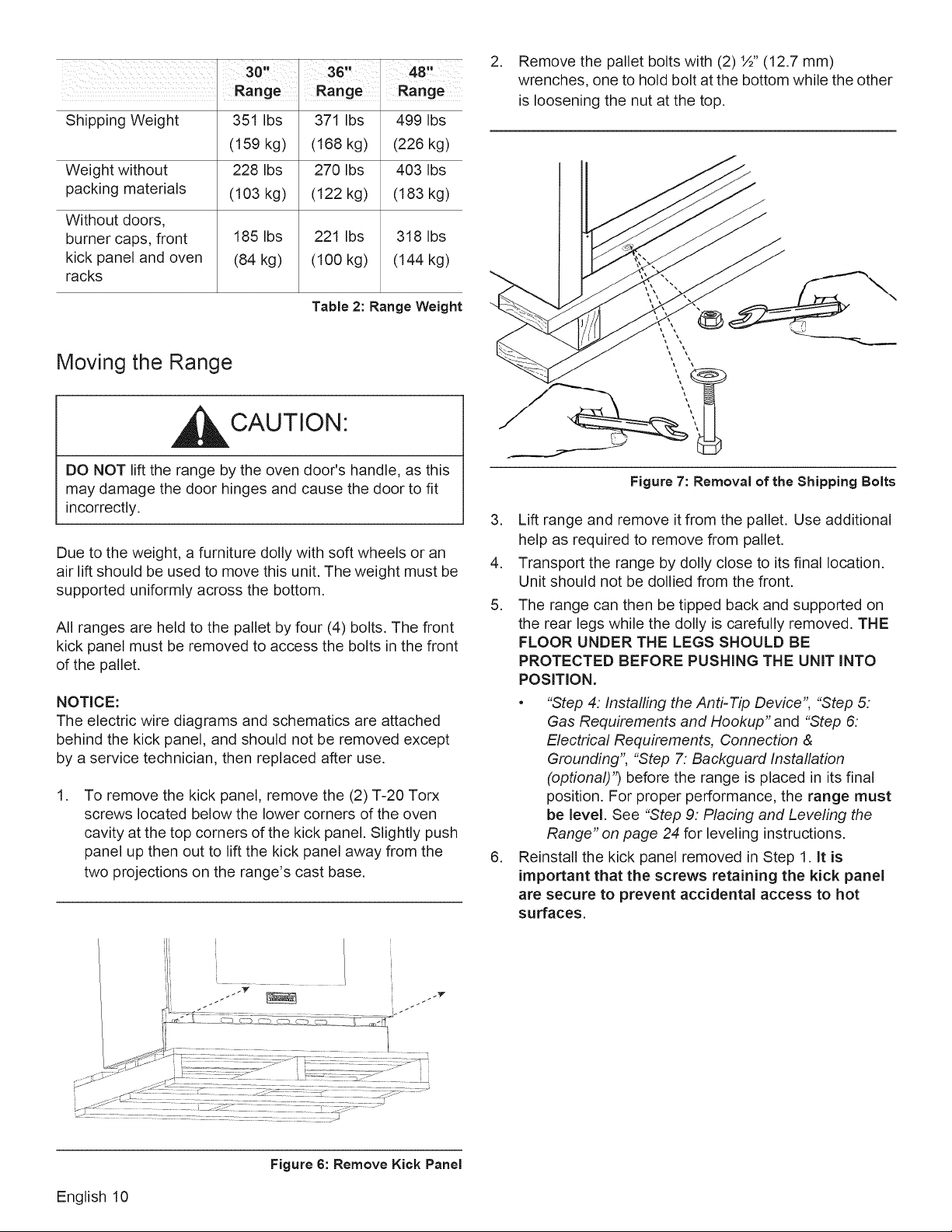

i i i iii ii iii ii iii ii ii ii iii ii Iil Iil

Shipping Weight

Range Range Range

351 Ibs 371 Ibs

(159 kg) (168 kg)

Weight without

packing materials

228 Ibs 270 Ibs

(103 kg) (122 kg)

Without doors,

burner caps, front

kick panel and oven

185 Ibs 221 Ibs

(84 kg) (100 kg)

racks

Moving the Range

, CAUTION

36" 48"

499 Ibs

(226 kg)

403 Ibs

(183 kg)

318 Ibs

(144 kg)

Table 2: Range Weight

,

Remove the pallet bolts with (2) ½" (12.7 mm)

wrenches, one to hold bolt at the bottom while the other

is loosening the nut at the top.

\

DO NOT lift the range by the oven door's handle, as this

may damage the door hinges and cause the door to fit

incorrectly.

Due to the weight, a furniture dolly with soft wheels or an

air lift should be used to move this unit. The weight must be

supported uniformly across the bottom.

All ranges are held to the pallet by four (4) bolts. The front

kick panel must be removed to access the bolts in the front

of the pallet.

NOTICE:

The electric wire diagrams and schematics are attached

behind the kick panel, and should not be removed except

by a service technician, then replaced after use.

,

To remove the kick panel, remove the (2) T-20 Torx

screws located below the lower corners of the oven

cavity at the top corners of the kick panel. Slightly push

panel up then out to lift the kick panel away from the

two projections on the range's cast base.

Figure 7: Removal of the Shipping Bolts

3. Lift range and remove it from the pallet. Use additional

help as required to remove from pallet.

4. Transport the range by dolly close to its final location.

Unit should not be dollied from the front.

5.

The range can then be tipped back and supported on

the rear legs while the dolly is carefully removed. THE

FLOOR UNDER THE LEGS SHOULD BE

PROTECTED BEFORE PUSHING THE UNIT INTO

POSITION.

• %tep 4: Installing the Anti-Tip Device", "Step 5:

Gas Requirements and Hookup" and %tep 6:

Electrical Requirements, Connection &

Grounding", "Step 7: Backguard Installation

(optional)') before the range is placed in its final

position. For proper performance, the range must

be level. See "Step 9: Placing and Leveling the

Range" on page 24 for leveling instructions.

,

Reinstall the kick panel removed in Step 1. It is

important that the screws retaining the kick panel

are secure to prevent accidental access to hot

surfaces.

English 10

Figure 6: Remove Kick Panel

Page 14

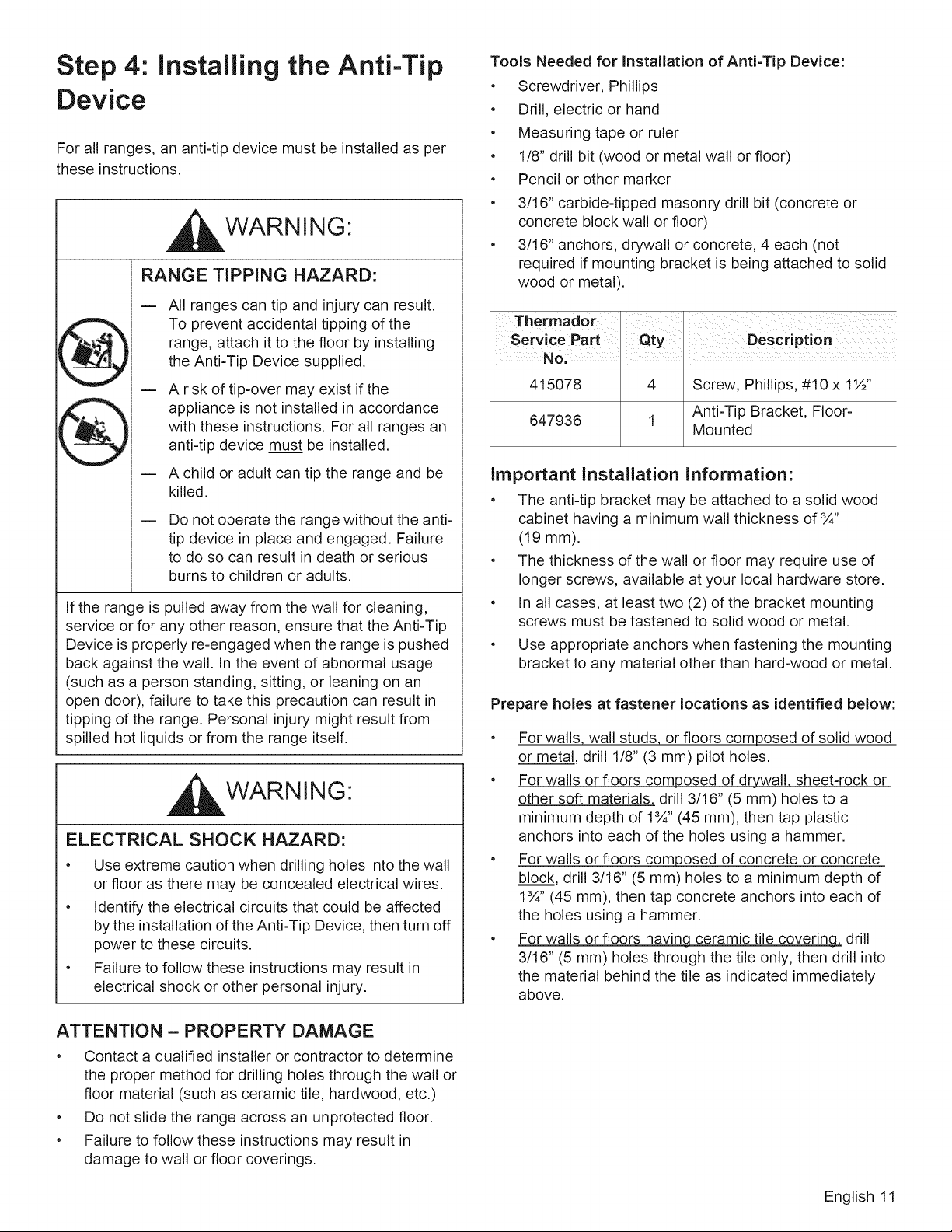

Step 4: Installing the Anti-Tip

Device

For all ranges, an anti-tip device must be installed as per

these instructions.

, WARNING:

RANGE TiPPiNG HAZARD"

All ranges can tip and injury can result.

To prevent accidental tipping of the

range, attach it to the floor by installing

the Anti-Tip Device supplied.

A risk of tip-over may exist if the

appliance is not installed in accordance

with these instructions. For all ranges an

anti-tip device must be installed.

Tools Needed for Installation of Anti=Tip Device:

• Screwdriver, Phillips

• Drill, electric or hand

• Measuring tape or ruler

• 1/8" drill bit (wood or metal wall or floor)

• Pencil or other marker

• 3/16" carbide-tipped masonry drill bit (concrete or

concrete block wall or floor)

• 3/16" anchors, drywall or concrete, 4 each (not

required if mounting bracket is being attached to solid

wood or metal).

Thermador

service Part Qty Descript!on

NO'

415078 4 Screw, Phillips, #10 x 1½"

647936 1 Anti-Tip Bracket, Floor-

Mounted

A child or adult can tip the range and be

killed.

Do not operate the range without the anti-

tip device in place and engaged. Failure

to do so can result in death or serious

burns to children or adults.

If the range is pulled away from the wall for cleaning,

service or for any other reason, ensure that the Anti-Tip

Device is properly re-engaged when the range is pushed

back against the wall. In the event of abnormal usage

(such as a person standing, sitting, or leaning on an

open door), failure to take this precaution can result in

tipping of the range. Personal injury might result from

spilled hot liquids or from the range itself.

, WARNING:

ELECTRICAL SHOCK HAZARD:

• Use extreme caution when drilling holes into the wall

or floor as there may be concealed electrical wires.

• Identify the electrical circuits that could be affected

by the installation of the Anti=Tip Device, then turn off

power to these circuits.

• Failure to follow these instructions may result in

electrical shock or other personal injury.

important Installation information:

• The anti=tip bracket may be attached to a solid wood

cabinet having a minimum wall thickness of ¾"

(19 mm).

• The thickness of the wall or floor may require use of

longer screws, available at your local hardware store.

• In all cases, at least two (2) of the bracket mounting

screws must be fastened to solid wood or metal.

• Use appropriate anchors when fastening the mounting

bracket to any material other than hard-wood or metal.

Prepare holes at fastener locations as identified below:

• For walls wall studs or floors com osed of solid wood

or metal, drill 1/8" (3 mm) pilot holes.

• For walls or floors composed of dr wall sheet-rock or

other soft materials drill 3/16" (5 mm) holes to a

minimum depth of 1¾" (45 mm), then tap plastic

anchors into each of the holes using a hammer.

• For walls or floors composed of concrete or concrete

block, drill 3/16" (5 mm) holes to a minimum depth of

1¾" (45 mm), then tap concrete anchors into each of

the holes using a hammer.

• For walls or floors havinq ceramic tile coverin& drill

3/16" (5 mm) holes through the tile only, then drill into

the material behind the tile as indicated immediately

above.

ATTENTION - PROPERTY DAMAGE

• Contact a qualified installer or contractor to determine

the proper method for drilling holes through the wall or

floor material (such as ceramic tile, hardwood, etc.)

• Do not slide the range across an unprotected floor.

• Failure to follow these instructions may result in

damage to wall or floor coverings.

English 11

Page 15

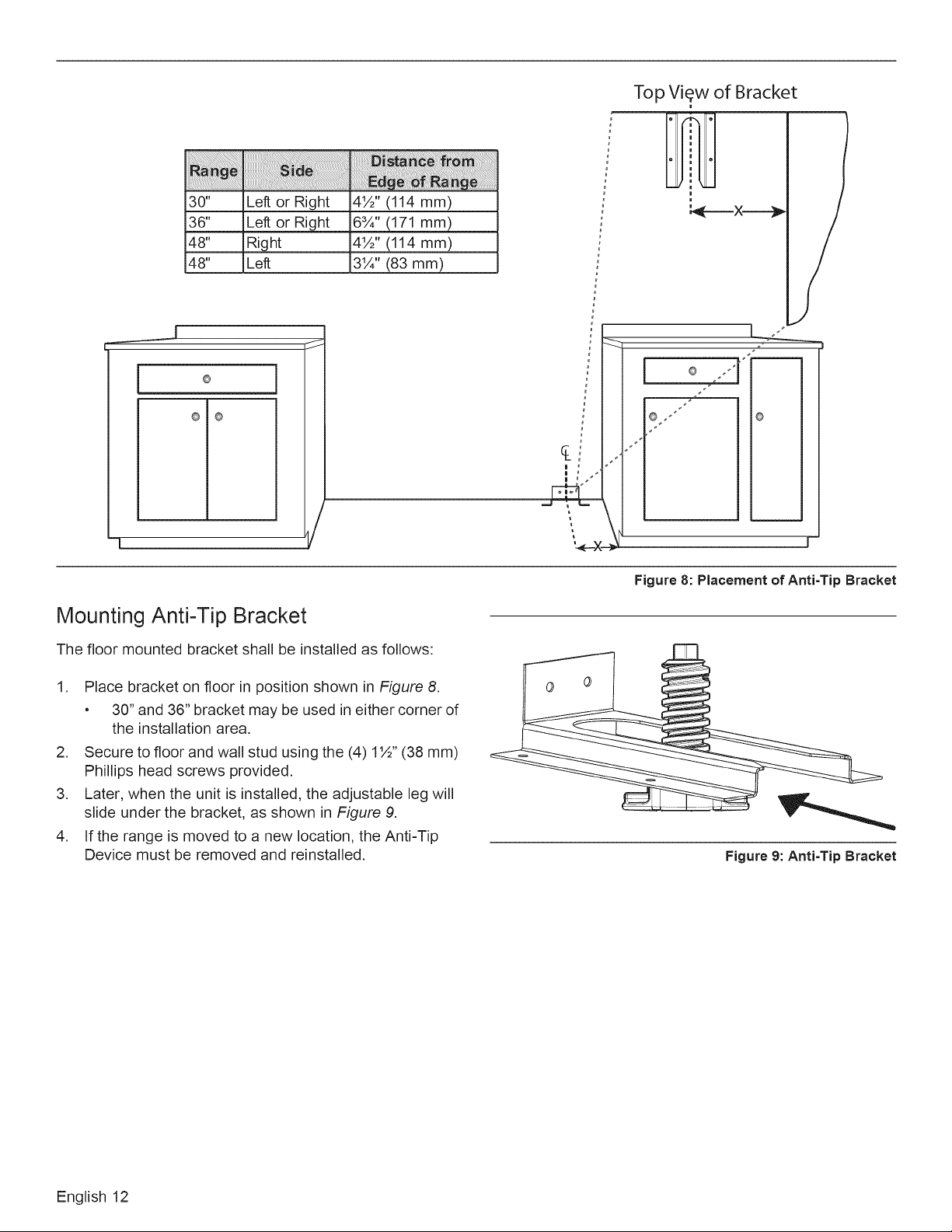

30" LeftorRight 4½"(114mm)

36" LeftorRight 6¾"(171mm)

48" Right 4½"(114mm)

48" Left 3_¼''(83mm)

©

© ©

Mounting Anti-Tip Bracket

The floor mounted bracket shall be installed as follows:

Figure 8: Placement of Anti=Tip Bracket

,

Place bracket on floor in position shown in Figure 8.

• 30" and 36" bracket may be used in either corner of

the installation area.

2. Secure to floor and wall stud using the (4) 1½" (38 mm)

Phillips head screws provided.

3. Later, when the unit is installed, the adjustable leg will

slide under the bracket, as shown in Figure 9.

4. If the range is moved to a new location, the Anti-Tip

Device must be removed and reinstalled.

Figure 9: Anti-Tip Bracket

English 12

Page 16

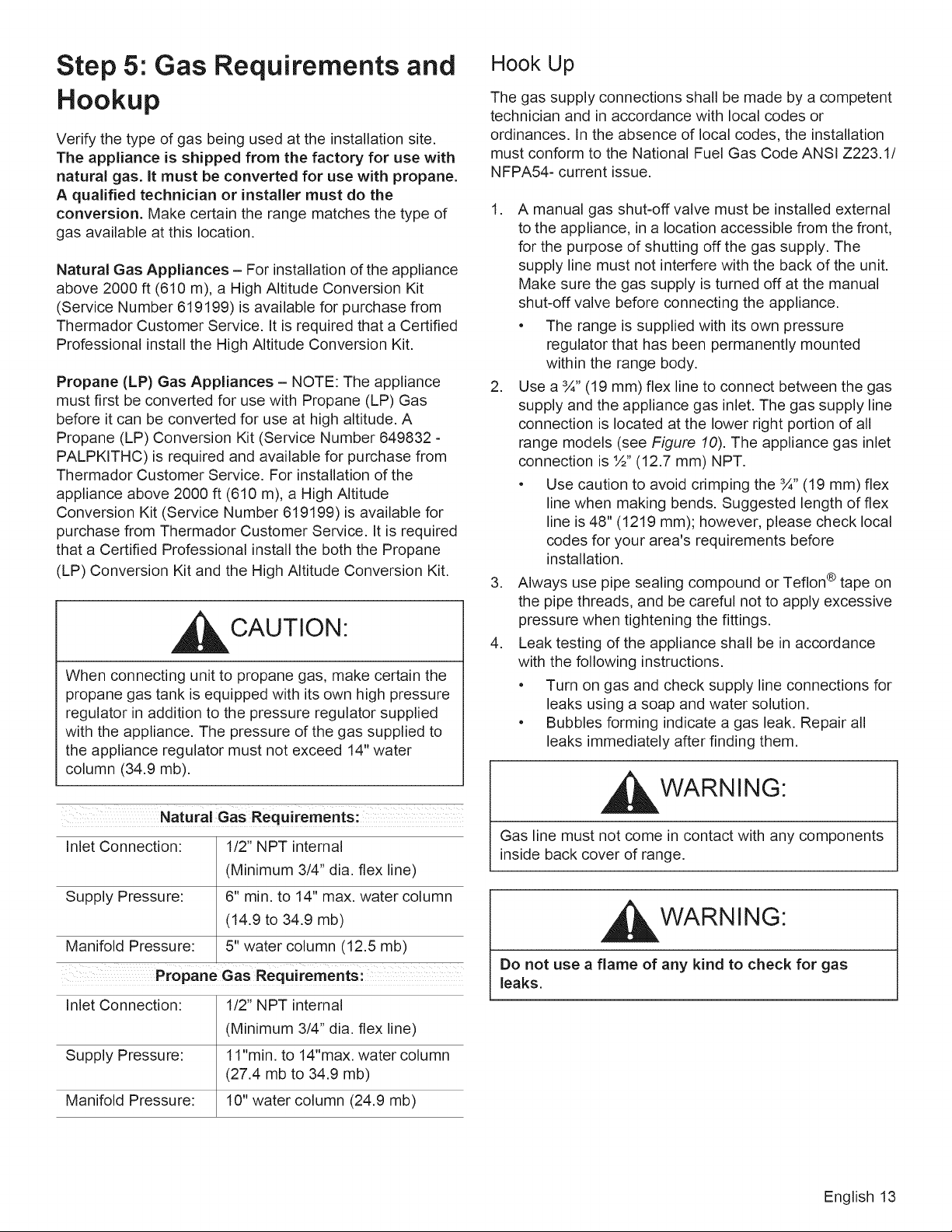

Step 5: Gas

Requirements and

Hook Up

Hookup

Verify the type of gas being used at the installation site.

The appliance is shipped from the factory for use with

natural gas. It must be converted for use with propane.

A qualified technician or installer must do the

conversion. Make certain the range matches the type of

gas available at this location.

Natural Gas Appliances - For installation of the appliance

above 2000 ft (610 m), a High Altitude Conversion Kit

(Service Number 619199) is available for purchase from

Thermador Customer Service, It is required that a Certified

Professional install the High Altitude Conversion Kit.

Propane (LP) Gas Appliances - NOTE: The appliance

must first be converted for use with Propane (LP) Gas

before it can be converted for use at high altitude. A

Propane (LP) Conversion Kit (Service Number 649832 -

PALPKITHC) is required and available for purchase from

Thermador Customer Service. For installation of the

appliance above 2000 ft (610 m), a High Altitude

Conversion Kit (Service Number 619199) is available for

purchase from Thermador Customer Service. It is required

that a Certified Professional install the both the Propane

(LP) Conversion Kit and the High Altitude Conversion Kit.

CAUTION

When connecting unit to propane gas, make certain the

propane gas tank is equipped with its own high pressure

regulator in addition to the pressure regulator supplied

with the appliance. The pressure of the gas supplied to

the appliance regulator must not exceed 14" water

column (34.9 mb).

The gas supply connections shall be made by a competent

technician and in accordance with local codes or

ordinances. In the absence of local codes, the installation

must conform to the National Fuel Gas Code ANSI Z223.1/

NFPA54- current issue.

1. A manual gas shut-off valve must be installed external

to the appliance, in a location accessible from the front,

for the purpose of shutting off the gas supply. The

supply line must not interfere with the back of the unit.

Make sure the gas supply is turned off at the manual

shut-off valve before connecting the appliance.

• The range is supplied with its own pressure

regulator that has been permanently mounted

within the range body.

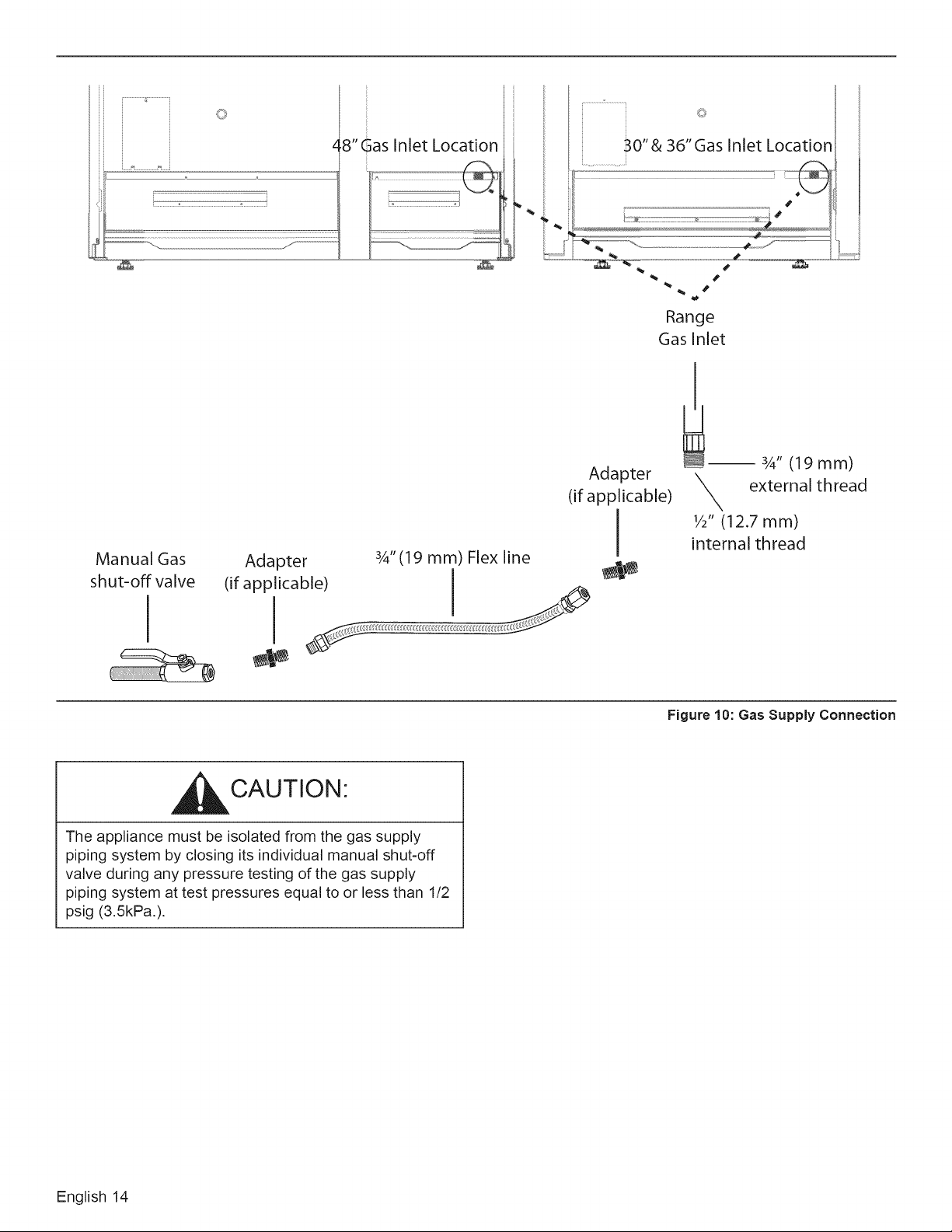

2. Use a ¾" (19 mm) flex line to connect between the gas

supply and the appliance gas inlet. The gas supply line

connection is located at the lower right portion of all

range models (see Figure 10). The appliance gas inlet

connection is ½" (12.7 mm) NPT.

• Use caution to avoid crimping the ¾" (19 mm) flex

line when making bends. Suggested length of flex

line is 48" (1219 mm); however, please check local

codes for your area's requirements before

installation.

3. Always use pipe sealing compound or Teflon ® tape on

the pipe threads, and be careful not to apply excessive

pressure when tightening the fittings.

4. Leak testing of the appliance shall be in accordance

with the following instructions.

• Turn on gas and check supply line connections for

leaks using a soap and water solution.

• Bubbles forming indicate a gas leak. Repair all

leaks immediately after finding them.

Natural Gas Requirements:

Inlet Connection: 1/2" NPT internal

(Minimum 3/4" dia. flex line)

Supply Pressure: 6" min. to 14" max. water column

(14.9 to 34.9 mb)

Manifold Pressure: 5" water column (12.5 mb)

Propane Gas Requirements:

Inlet Connection: 1/2" NPT internal

(Minimum 3/4" dia. flex line)

Supply Pressure: 1l"min, to 14"max. water column

(27.4 mb to 34.9 mb)

Manifold Pressure: 10" water column (24.9 mb)

WARNING

Gas line must not come in contact with any components

inside back cover of range.

WARNING

Do not use a flame of any kind to check for gas

leaks.

English 13

Page 17

©

©

- [

Manual Gas

shut-off valve

Adapter

(if applicable)

8"Gas Inlet Location

3/4"(19 mm) Flex line

30"& 36"Gas Inlet Location

Adapter

(if applicable)

I

_ S

_ S

Range

Gas Inlet

_m

\

1/2"(12.7 mm)

internal thread

S

S

3/4,,(19 mm)

external thread

CAUTION

The appliance must be isolated from the gas supply

piping system by closing its individual manual shut-off

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than 1/2

psig (3.5kPa.).

Figure 10: Gas Supply Connection

English 14

Page 18

Step 6: Electrical Requirements, Connection & Grounding

MODEL TYPE I VOLTAGE' CIRCUIT RATING' FREQUENCY' PHASE

30" 240/208 VAC 35 Amps

36" 240/208 VAC 35 Amps

48" 240/208 VAC 50 Amps

Before installing, turn power OFF at the service panel.

Lock service panel to prevent power from being turned

ON accidentally.

Prior to servicing appliance, always disconnect appliance

electrical supply cord, if so equipped, from wall receptacle.

If appliance is hard-wired to power supply, disconnect

power to unit by turning off the proper circuit breaker. Lock

service panel to prevent power from being turned ON

accidentally.

A neutral supply wire must be provided from the power

source (breaker) because critical range components,

including the surface burner spark re=ignition module,

require 120 VAC to operate safely and properly.

WARNING:

An improper 120/240 VAC power supply will cause

malfunction, damage to this appliance, and possibly

create a condition of shock hazard.

If the correct power supply circuit is not provided, it is the

responsibility and obligation of the installer and user to

have proper power supply connected. This must be

accomplished in accordance with all applicable local codes

and ordinances by a qualified electrician. It is the

responsibility of the installer to ensure compliance of local

codes. In the absence of local codes and ordinances, the

power supply connection shall be in accordance with the

National Electric Code.

Observe all governing codes and ordinances when

grounding. In the absence of these codes or ordinances

observe National Electrical Code ANSI/NFPA No. 70

current issue. See the following information in this section

for grounding method.

60 Hz. Single

60 Hz. Single

60 Hz. Single

Table 3: Electrical Supply Circuit Requirements

Dual Fuel models must be connected to the power supply

utilizing one of the following methods. For all methods of

connection, the length of the cord or conduit/wiring must

allow the unit to be slid completely out of the cabinet

without having to unplug or disconnect the unit from the

power supply.

Recommended minimum free length of cord or conduit is

4ft (1.2 m). Electrical installations and grounding must be in

accordance with all local codes and ordinances, and/or the

National Electric Code, as applicable.

Permanent Connection (Hard Wiring)

Units may be hard wired to the power supply. The installer

must provide approved flexible aluminum conduit, ¾"

(19 mm) trade size, maximum 6ft (1.8 m) long.

Locate the terminal block on the rear of the unit and

remove cover (refer to Figure 11). The conduit must be

installed to the terminal block using an approved conduit

connector. The free end of the conduit must be connected

to a terminal block provided in the electrical supply zone,

as shown in Figure 4 on page 8.

Mount a strain relief (not provided) into the 1" (25.4 mm)

diameter hole located below the terminal block (see

Figure 11). Wiring for the unit is to be brought into the

terminal block through the conduit and through the strain

relief. The ends of the wiring must have 1/4" (6 mm) faston

closed-loop lugs attached, preferably soldered in place.

Make the connections to the terminal block provided.

If aluminum supply wiring exists in the installation, splice

the aluminum house wiring with appropriate=thickness

gauge copper wire for adapting to the range, using special

connectors designed and certified for joining copper and

aluminum wire. Follow the connector manufacturer's

recommended installation procedure.

Electrical wiring diagrams and schematics have been

placed in the kick panel area of the range for access by a

qualified service technician (see Figure 28 on page 24).

The ranges are to be connected to a 240/208 VAC power

supply.

WARNING

Improper connection of aluminum house wiring can

result in a fire or shock hazard. Use only connectors

designed and certified for connecting to aluminum wire.

English 15

Page 19

4-Wire Connection

Normally, a unit must be connected to the power supply

with a 3-POLE, 4-CONDUCTOR cord kit rated 125/250

VOLTS, 50 AMPERES, and marked for use with ranges.

The cord kit must be attached to the range terminal block

with a strain relief (not provided) which will fit a 1"

(25.4 mm) diameter hole. If not already equipped, the cord

must also have 1/4" (6 mm) faston closed-loop lugs

attached to the free ends of the individual conductors,

preferably soldered in place.

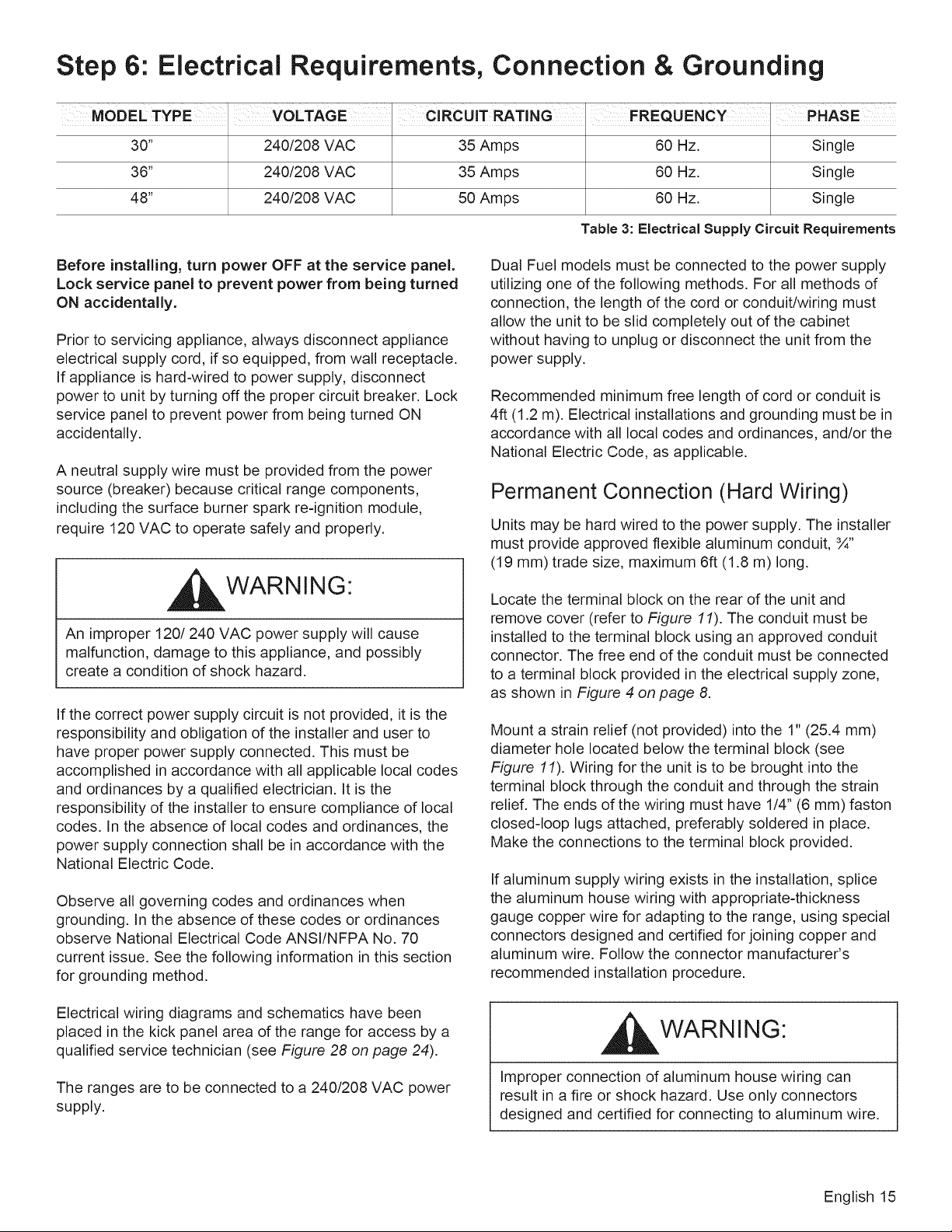

1. Locate the terminal block on the rear of the unit and

remove cover (see Figure 11).

2. Remove upper nuts only from the terminal block studs.

Do not remove lower nuts which secure range internal

wiring leads.

3. Mount strain relief (not provided with range) into the 1"

(25.4 mm) diameter hole in the back panel located

below the terminal block. Route wires up through strain

relief.

Terminal Block

4. Secure the neutral, grounded wire of the supply circuit,

to the center stud of the terminal block with nut (see

Figure 12).

5. Secure the LI (red) and L2 (black) power leads to the

outside terminal studs (brass colored) with nuts.

6. Remove green ground screw located beneath the

terminal block. Discard white wire.

7.

Secure the bare copper ground lead to the range

chassis using the ground screw previously used for the

white wire. Be sure that neutral and ground terminals

do not touch.

8. Tighten all connections securely.

,_ Black/L2

White/ Wire

Red/L1 I_

Neutral Wire

Wire

Strain Relief

Figure 11: Strain Relief Location

Green/ I1_

Ground

Wire

Figure 12: 4=Wire Connection

9. Reinstall the terminal block cover.

INSTALLER -- show the owner the location of the circuit

breaker. Mark it for easy reference.

English 16

Page 20

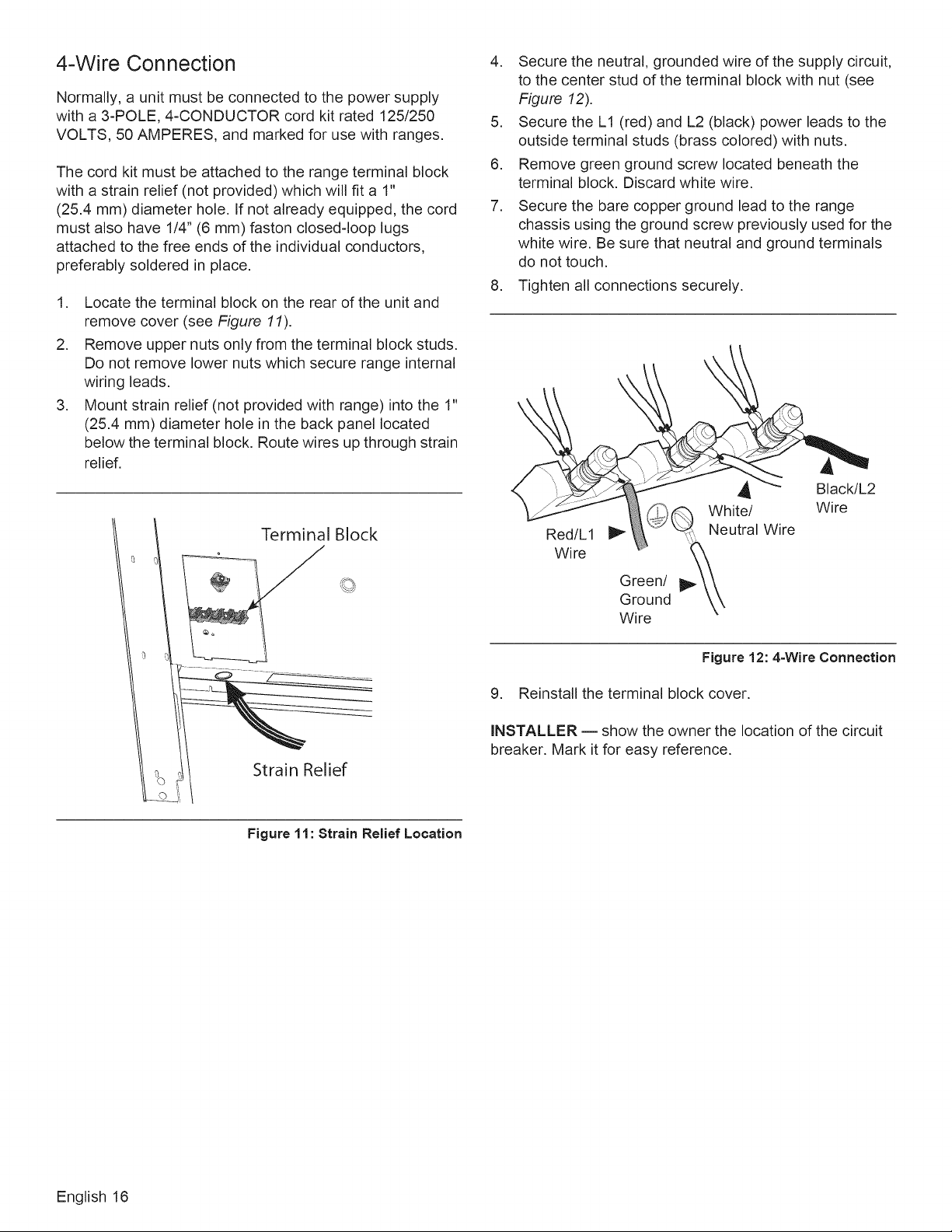

3-Wire Lead Connection

Where local codes and ordinances permit grounding

through neutral, and conversion of supply to 4 wire is

impractical, unit may be connected to the power supply

with a 3-POLE, 3-CONDUCTOR cord kit rated 125/250

VOLTS, 50 AMPERES, and marked for use with ranges.

The cord kit must be attached to the range back panel with

a strain relief which will fit a 1" (25.4 mm) diameter hole. If

not already equipped, the cord must also have 1/4" (6 mm)

faston closed-loop lugs attached to the free ends of the

individual conductors, preferably soldered in place.

,

Locate the terminal block on the rear of the unit and

remove cover.

2.

Remove upper nuts only from the terminal block studs.

Do not remove nuts which secure range internal wiring

leads.

,

Mount strain relief (not provided with range) into the 1"

(25.4 mm) diameter hole in the back panel located

below the terminal block (see Figure 13). Route wires

up through strain relief.

4. Secure the neutral, grounded wire of the supply circuit,

to the center stud (silver colored) of the terminal block

(see Figure 14).

5. Secure the LI (red) and L2 (black) power leads to the

outside corresponding terminal block studs (brass

colored).

6. Secure one end of the mounted looped neutral wire,

located beneath terminal block, to the center stud of

the terminal block with nut and keep the other end of

the wire screwed into the back of the range.

7. Tighten nuts securely.

,l

Black/L2

Wire

Red/L1 I!_

Wire

White/

Neutral Wire

Terminal Block

Strain Relief

Figure 13: Strain Relief Location

Ground _"

link provided

on range

Figure 14: 3-Wire Connection

8. Reinstall the Terminal Block Cover.

INSTALLER -- show the owner the location of the circuit

breaker. Mark it for easy reference.

English 17

Page 21

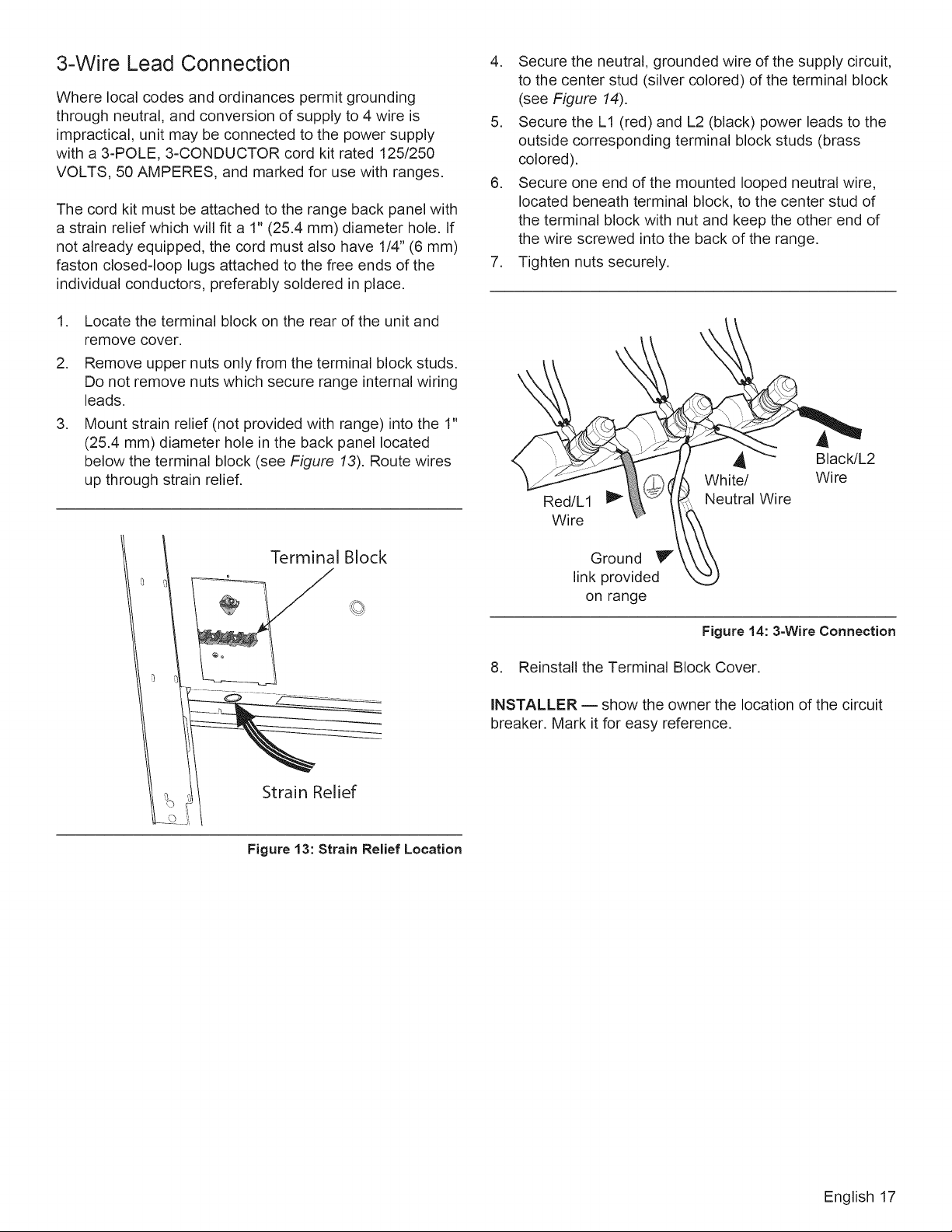

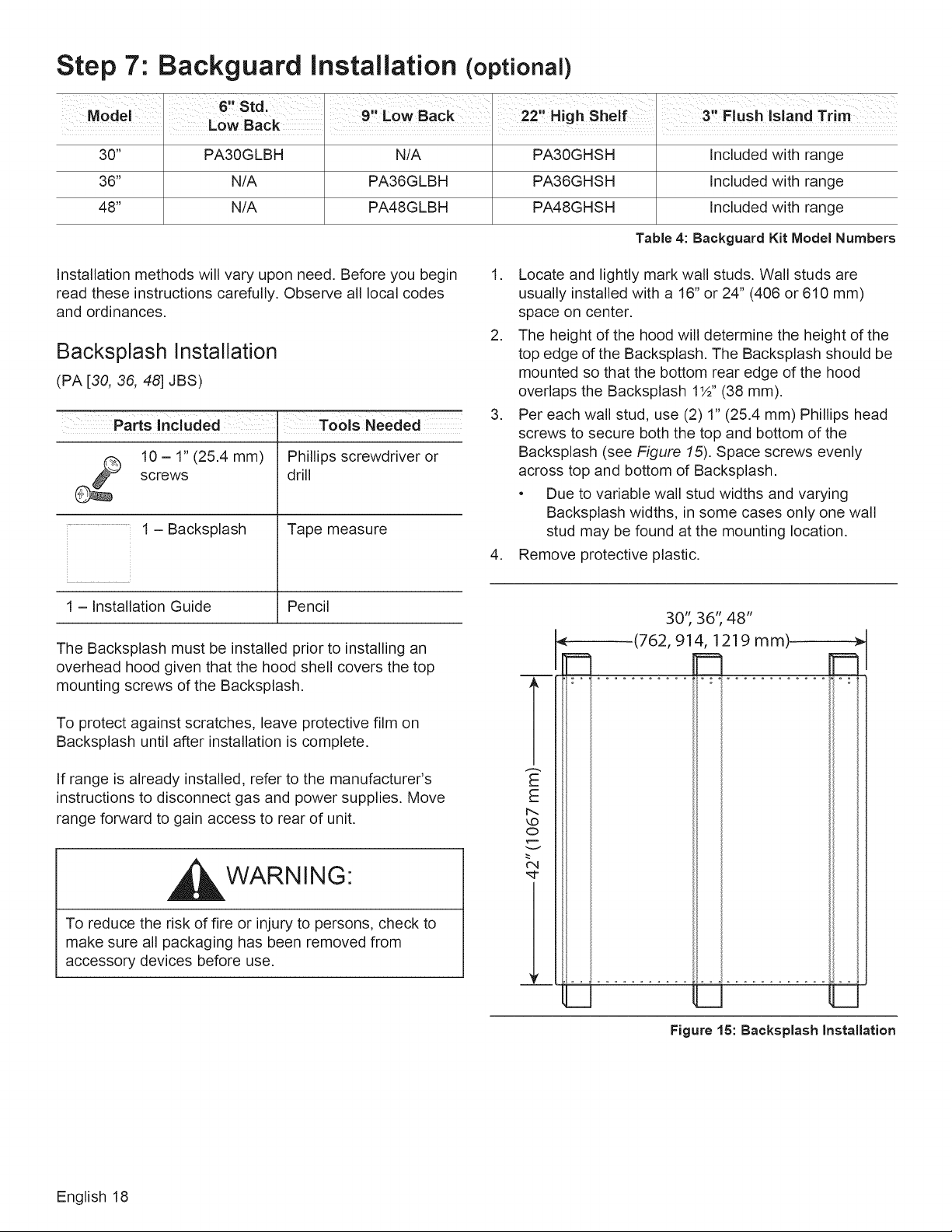

Step 7: Backguard Installation (optional)

Mode LowBack .!gh She f I

30" PA30GLBH N/A PA30GHSH

36" N/A PA36GLBH PA36GHSH

48" N/A PA48GLBH PA48GHSH

Installation methods will vary upon need. Before you begin

read these instructions carefully. Observe all local codes

and ordinances.

Backsplash Installation

(PA [30, 36, 48] JBS)

PaNs Included Tools Needed

screws

_ 10- 1" (25.4 mm)

1 - Backsplash Tape measure

6"Std .... ,

1. Locate and lightly mark wall studs. Wall studs are

usually installed with a 16" or 24" (406 or 610 mm)

space on center.

2. The height of the hood will determine the height of the

top edge of the Backsplash. The Backsplash should be

mounted so that the bottom rear edge of the hood

overlaps the Backsplash 1½" (38 mm).

3. Per each wall stud, use (2) 1" (25.4 mm) Phillips head

screws to secure both the top and bottom of the

Phillips screwdriver or

drill

Backsplash (see Figure 15). Space screws evenly

across top and bottom of Backsplash.

• Due to variable wall stud widths and varying

Backsplash widths, in some cases only one wall

stud may be found at the mounting location.

4. Remove protective plastic.

Included with range

Included with range

Included with range

Table 4: Baekguard Kit Model Numbers

1 - Installation Guide Pencil

The Backsplash must be installed prior to installing an

overhead hood given that the hood shell covers the top

mounting screws of the Backsplash.

To protect against scratches, leave protective film on

Backsplash until after installation is complete.

If range is already installed, refer to the manufacturer's

instructions to disconnect gas and power supplies. Move

range forward to gain access to rear of unit.

, WARNING:

To reduce the risk of fire or injury to persons, check to

make sure all packaging has been removed from

accessory devices before use.

,..,=..,

P_

kO

O

30':36':48"

(762,914,1219 mm)--_

o

E

E

Figure 15: Backsplash Installation

English 18

Page 22

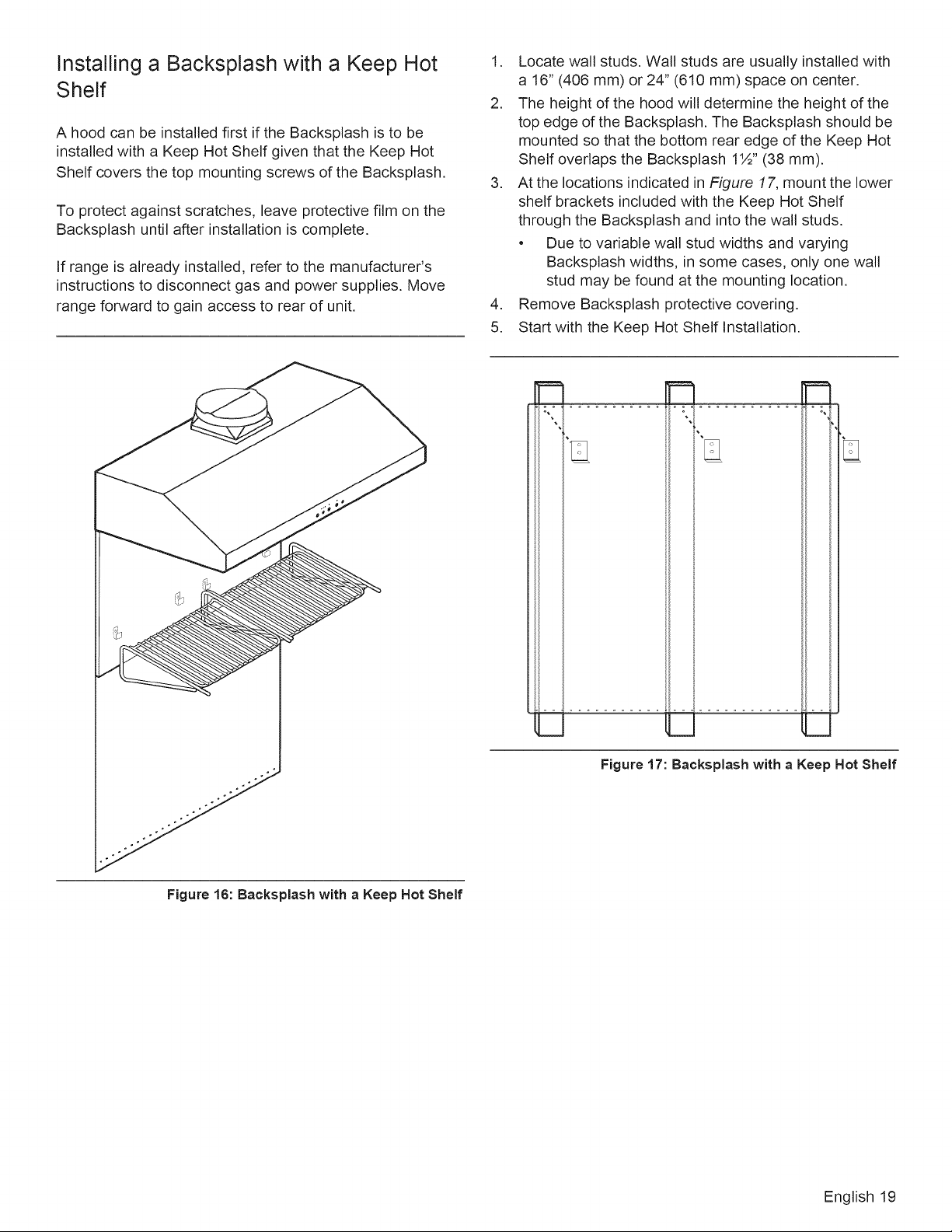

Installing a Backsplash with a Keep Hot

Shelf

A hood can be installed first if the Backsplash is to be

installed with a Keep Hot Shelf given that the Keep Hot

Shelf covers the top mounting screws of the Backsplash.

To protect against scratches, leave protective film on the

Backsplash until after installation is complete.

If range is already installed, refer to the manufacturer's

instructions to disconnect gas and power supplies. Move

range forward to gain access to rear of unit.

1. Locate wall studs. Wall studs are usually installed with

a 16" (406 mm) or 24" (610 mm) space on center,

2. The height of the hood will determine the height of the

top edge of the Backsplash. The Backsplash should be

mounted so that the bottom rear edge of the Keep Hot

Shelf overlaps the Backsplash 1½" (38 mm).

3. At the locations indicated in Figure 17, mount the lower

shelf brackets included with the Keep Hot Shelf

through the Backsplash and into the wall studs.

• Due to variable wall stud widths and varying

Backsplash widths, in some cases, only one wall

stud may be found at the mounting location.

4. Remove Backsplash protective covering.

5. Start with the Keep Hot Shelf Installation.

_° :,I

i+ i

+

+

+

+

+

+

+

+

+

Figure 16: Backsplash with a Keep Hot Shelf

U

t+

I+ +

+

++ +

Figure 17: Backsplash with a Keep Hot Shelf

English 19

Page 23

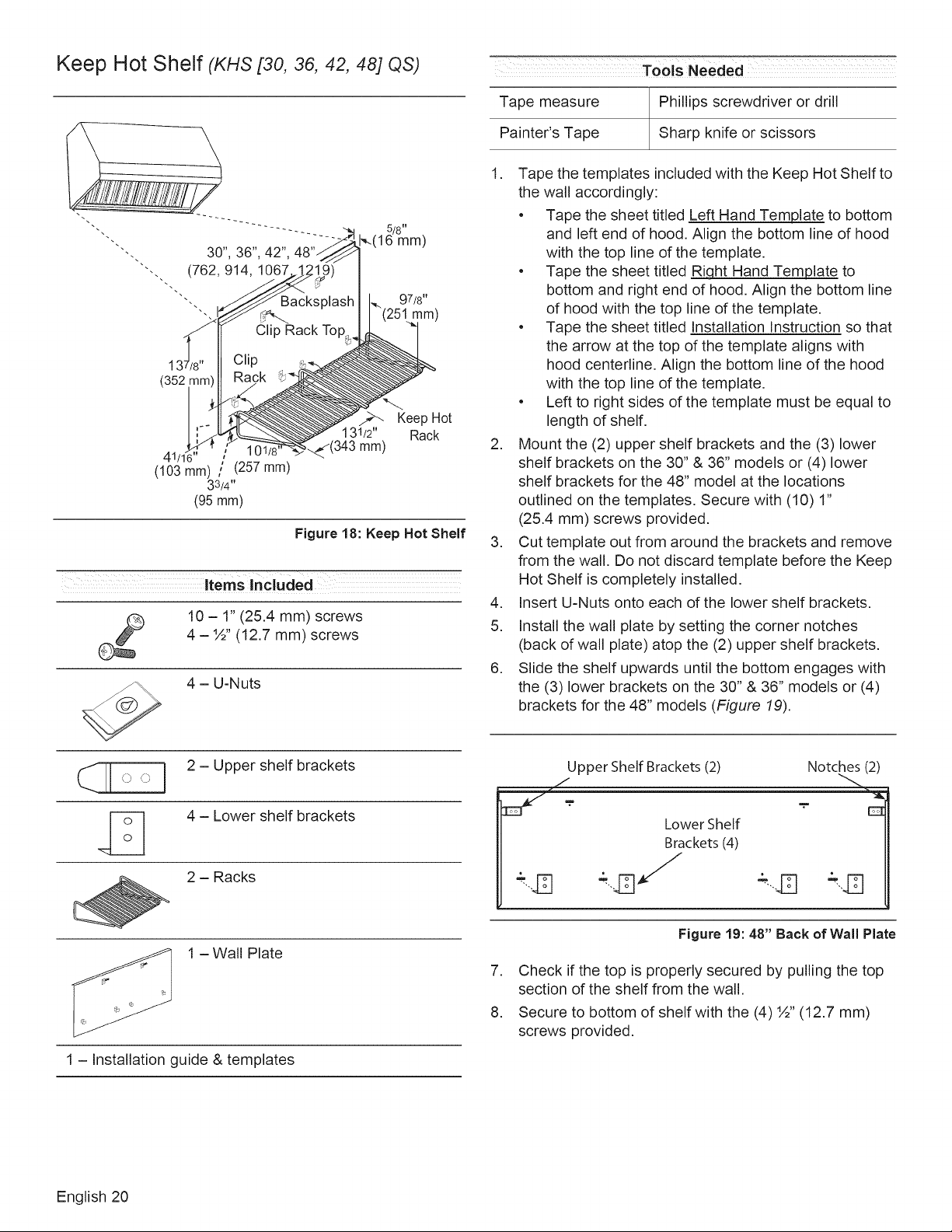

Keep Hot Shelf (KHS [30, 36, 42, 48] QS)

\

1 Clip

(352 Rack

7>'-- Keep Hot

131/2" Rack

mm)

(103 mm) / (257 mm)

33/4.

(95 mm)

Figure 18: Keep Hot Shelf

Items Included

10 - 1" (25,4 mm) screws

4 - ½" (12,7 mm) screws

4 - U-Nuts

Tape measure Phillips screwdriver or drill

Painter's Tape Sharp knife or scissors

1. Tape the templates included with the Keep Hot Shelf to

the wall accordingly:

• Tape the sheet titled Left Hand Template to bottom

and left end of hood. Align the bottom line of hood

with the top line of the template.

• Tape the sheet titled RiqhthtHand Template to

bottom and right end of hood. Align the bottom line

of hood with the top line of the template.

• Tape the sheet titled Installation Instruction so that

the arrow at the top of the template aligns with

hood centerline. Align the bottom line of the hood

with the top line of the template.

• Left to right sides of the template must be equal to

length of shelf.

2. Mount the (2) upper shelf brackets and the (3) lower

shelf brackets on the 30" & 36" models or (4) lower

shelf brackets for the 48" model at the locations

outlined on the templates. Secure with (10) 1"

(25.4 mm) screws provided.

3. Cut template out from around the brackets and remove

from the wall. Do not discard template before the Keep

Hot Shelf is completely installed.

4.

Insert U-Nuts onto each of the lower shelf brackets,

5.

Install the wall plate by setting the corner notches

(back of wall plate) atop the (2) upper shelf brackets,

6.

Slide the shelf upwards until the bottom engages with

the (3) lower brackets on the 30" & 36" models or (4)

brackets for the 48" models (Figure 19).

_ I C _ I 2 - Upper shelf brackets

._ 4 - Lower shelf brackets

2 - Racks

1 - Wall Plate 7.8.

1 - Installation guide & templates

English 20

Upper Shelf Brackets (2) Notches (2)

Lower Shelf

Brackets (4)

Figure 19: 48" Back of Wall Plate

Check if the top is properly secured by pulling the top

section of the shelf from the wall.

Secure to bottom of shelf with the (4) ½" (12.7 mm)

screws provided,

Page 24

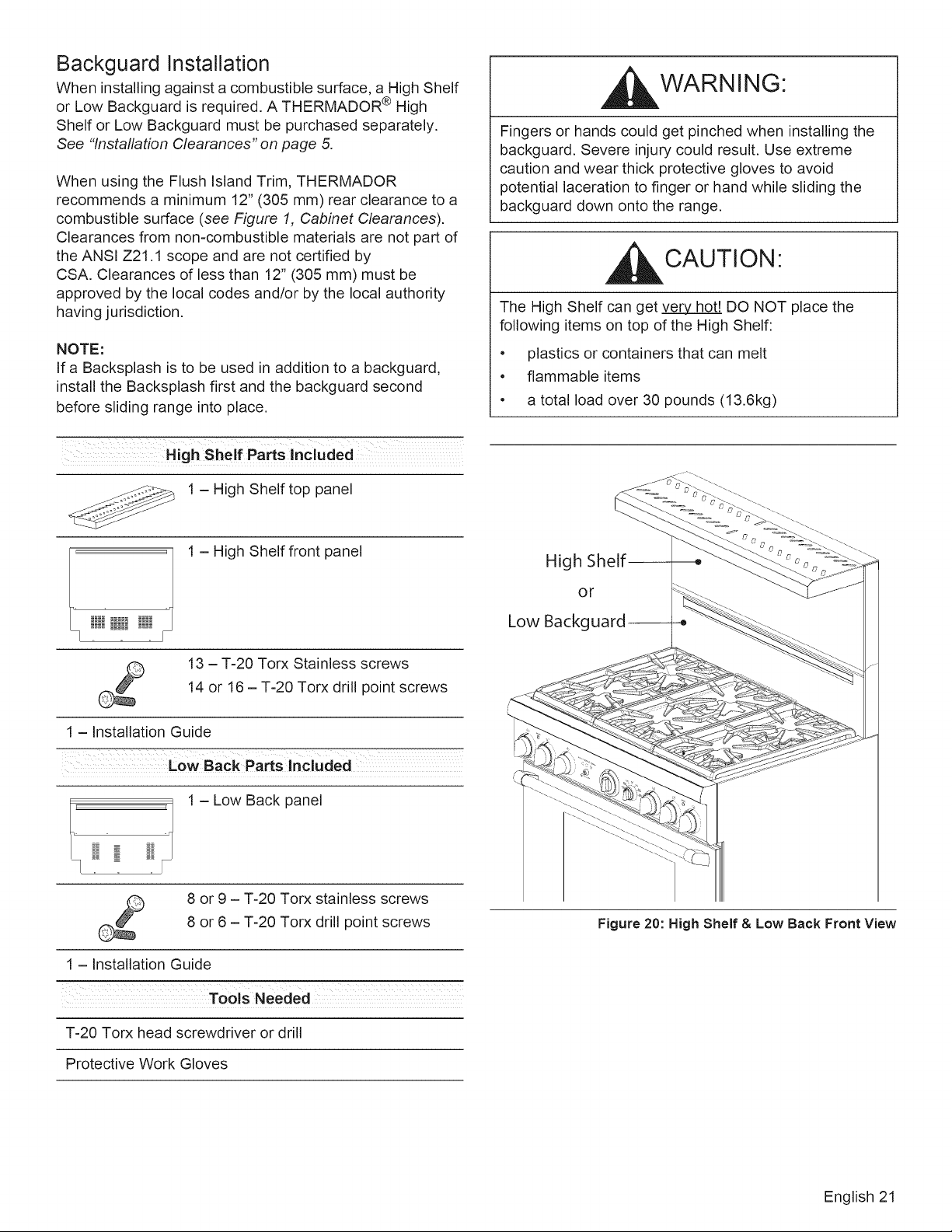

Backguard Installation

When installing against a combustible surface, a High Shelf

or Low Backguard is required. A THERMADOR ® High

Shelf or Low Backguard must be purchased separately.

See "Installation Clearances" on page 5.

When using the Flush Island Trim, THERMADOR

recommends a minimum 12" (305 mm) rear clearance to a

combustible surface (see Figure 1, Cabinet Clearances).

Clearances from non-combustible materials are not part of

the ANSI Z21.1 scope and are not certified by

CSA. Clearances of less than 12" (305 mm) must be

approved by the local codes and/or by the local authority

having jurisdiction.

NOTE:

If a Backsplash is to be used in addition to a backguard,

install the Backsplash first and the backguard second

before sliding range into place.

S.e fP rts nc uded

1 - High Shelf top panel

WARNING

Fingers or hands could get pinched when installing the

backguard. Severe injury could result. Use extreme

caution and wear thick protective gloves to avoid

potential laceration to finger or hand while sliding the

backguard down onto the range.

, CAUTION:

The High Shelf can get very hot! DO NOT place the

following items on top of the High Shelf:

• plastics or containers that can melt

• flammable items

• a total load over 30 pounds (13.6kg)

i0 0] 1-HighShelffrontpanel

13 - T-20 Torx Stainless screws

14 or 16 - T-20 Torx drill point screws

1 - Installation Guide

Low Back Parts Included

1 - Low Back panel

8 or 9 - T-20 Torx stainless screws

8 or 6 - T-20 Torx drill point screws

1 - Installation Guide

Tools Needed

High

or

Low Backg

Figure 20: High Shelf & Low Back Front View

T-20 Torx head screwdriver or drill

Protective Work Gloves

English 21

Page 25

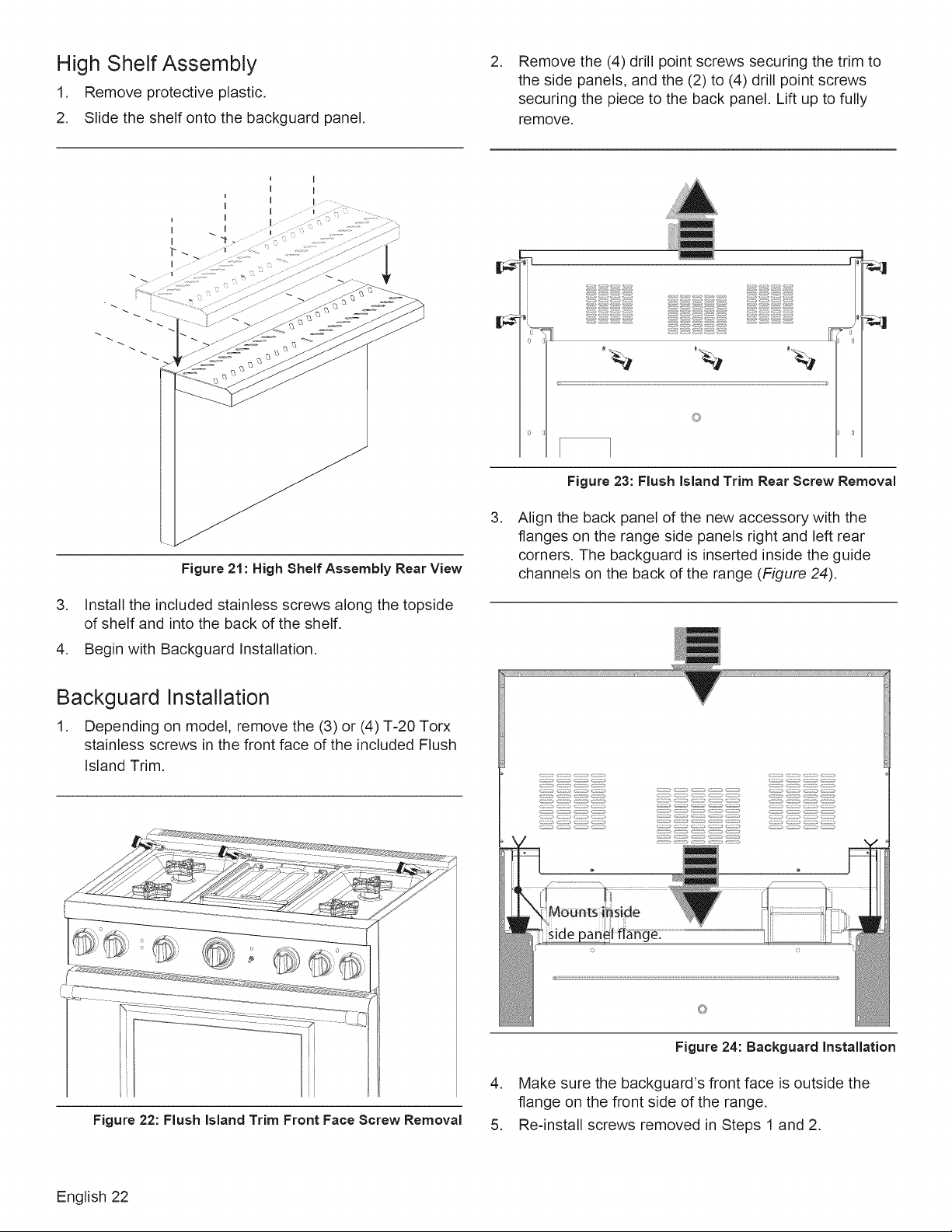

High Shelf Assembly

1. Remove protective plastic.

2. Slide the shelf onto the backguard panel.

i

I

I

I

I

I

.

Remove the (4) drill point screws securing the trim to

the side panels, and the (2) to (4) drill point screws

securing the piece to the back panel. Lift up to fully

remove.

©

Figure 23: Flush Island Trim Rear Screw Removal

Figure21: High Shelf Assembly Rear View

3. Install the included stainless screws along the topside

of shelf and into the back of the shelf.

4. Begin with Backguard Installation.

Backguard Installation

1. Depending on model, remove the (3) or (4) T-20 Torx

stainless screws in the front face of the included Flush

Island Trim.

.

Align the back panel of the new accessory with the

flanges on the range side panels right and left rear

corners. The backguard is inserted inside the guide

channels on the back of the range (Figure 24).

Figure 22: Flush Island Trim Front Face Screw Removal

English 22

©

Figure 24: Backguard Installation

4. Make sure the backguard's front face is outside the

flange on the front side of the range.

5. Re-install screws removed in Steps 1 and 2.

Page 26

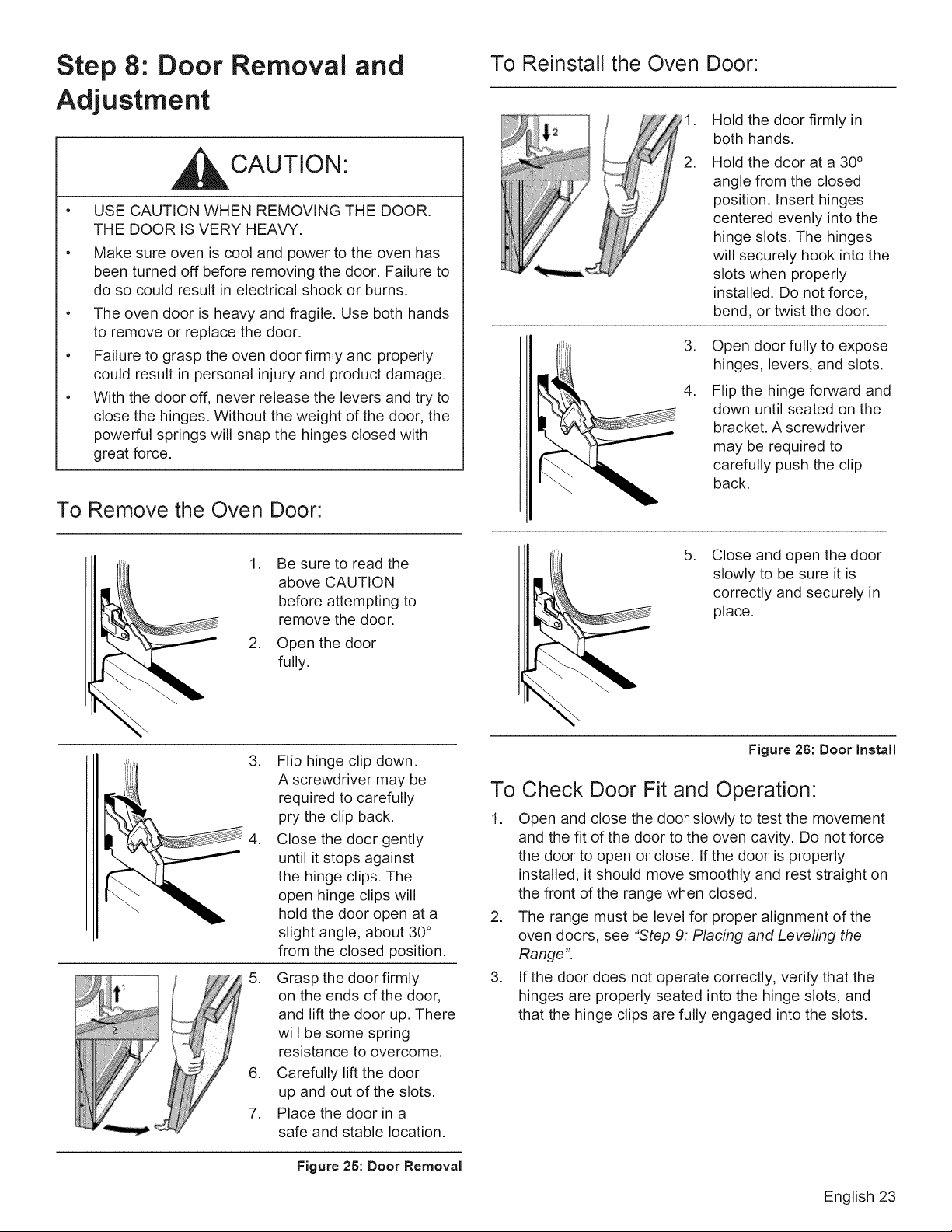

Step 8: Door Removal and

Adjustment

, CAUTION

USE CAUTION WHEN REMOVING THE DOOR.

THE DOOR IS VERY HEAVY.

Make sure oven is cool and power to the oven has

been turned off before removing the door. Failure to

do so could result in electrical shock or burns.

• The oven door is heavy and fragile. Use both hands

to remove or replace the door.

• Failure to grasp the oven door firmly and properly

could result in personal injury and product damage.

• With the door off, never release the levers and try to

close the hinges. Without the weight of the door, the

powerful springs will snap the hinges closed with

great force.

To Remove the Oven Door:

To Reinstall the Oven Door:

Hold the door firmly in

both hands.

Hold the door at a 30°

angle from the closed

position. Insert hinges

centered evenly into the

hinge slots. The hinges

will securely hook into the

slots when properly

installed. Do not force,

bend, or twist the door.

,

Open door fully to expose

hinges, levers, and slots.

,

Flip the hinge forward and

down until seated on the

bracket. A screwdriver

may be required to

carefully push the clip

back.

!

1. Be sure to read the

above CAUTION

before attempting to

remove the door.

2. Open the door

fully.

Flip hinge clip down.

A screwdriver may be

required to carefully

pry the clip back.

Close the door gently

until it stops against

the hinge clips. The

open hinge clips will

hold the door open at a

slight angle, about 30°

from the closed position.

5. Grasp the door firmly

on the ends of the door,

and lift the door up. There

will be some spring

resistance to overcome.

6. Carefully lift the door

up and out of the slots.

7. Place the door in a

safe and stable location.

,

Close and open the door

slowly to be sure it is

correctly and securely in

place.

Figure 26: Door Install

To Check Door Fit and Operation

1. Open and close the door slowly to test the movement

and the fit of the door to the oven cavity. Do not force

the door to open or close. If the door is properly

installed, it should move smoothly and rest straight on

the front of the range when closed.

2. The range must be level for proper alignment of the

oven doors, see "Step 9: Placing and Leveling the

Range".

3. If the door does not operate correctly, verify that the

hinges are properly seated into the hinge slots, and

that the hinge clips are fully engaged into the slots.

Figure 25: Door Removal

English 23

Page 27

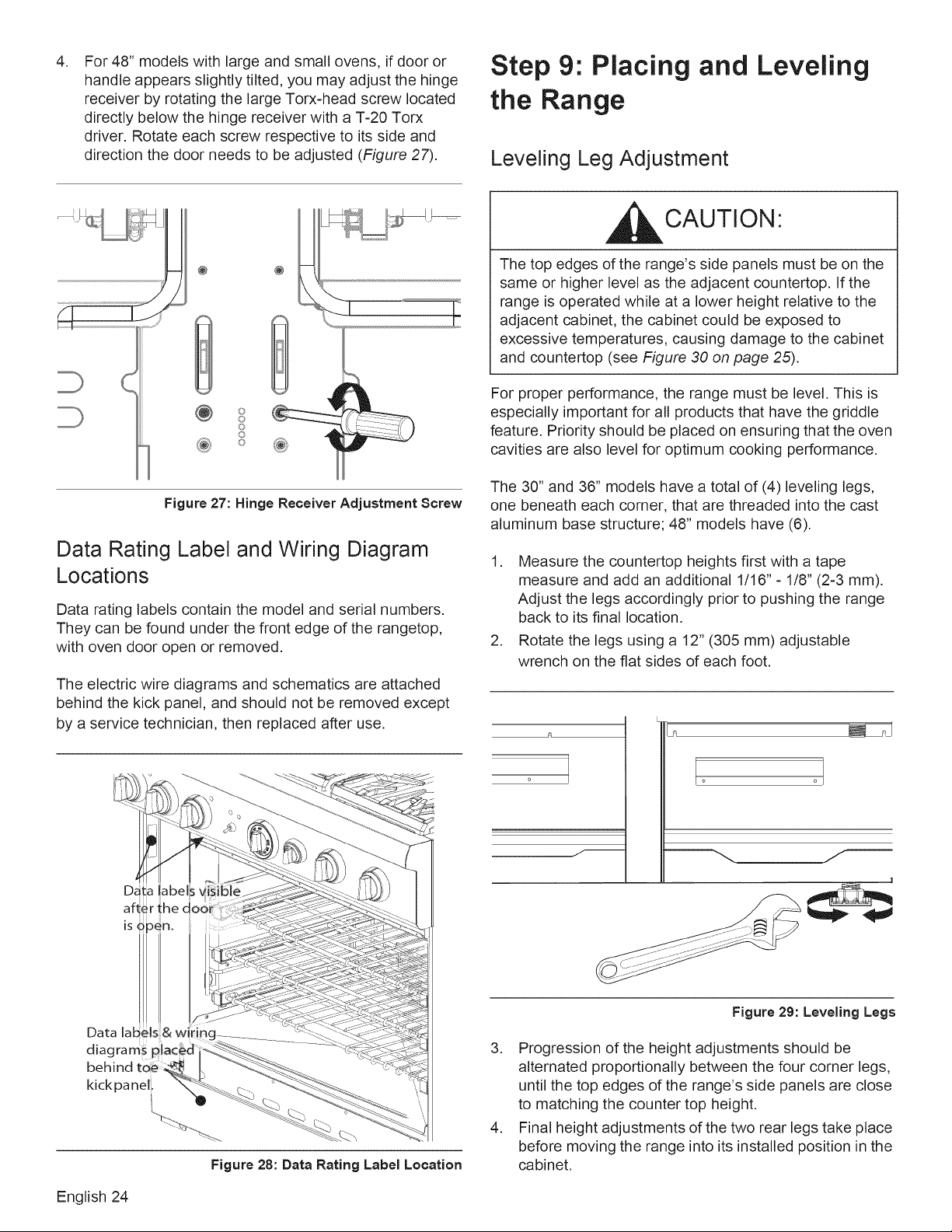

,

For 48" models with large and small ovens, if door or

handle appears slightly tilted, you may adjust the hinge

receiver by rotating the large Torx-head screw located

directly below the hinge receiver with a T-20 Torx

driver. Rotate each screw respective to its side and

direction the door needs to be adjusted (Figure 27).

Step 9: Placing and

the Range

Leveling Leg Adjustment

CAUTION:

Leveling

@ @

@

i

Figure 27: Hinge Receiver Adjustment Screw

Data Rating Label and Wiring Diagram

Locations

Data rating labels contain the model and serial numbers.

They can be found under the front edge of the rangetop,

with oven door open or removed.

The electric wire diagrams and schematics are attached

behind the kick panel, and should not be removed except

by a service technician, then replaced after use.

The top edges of the range's side panels must be on the

same or higher level as the adjacent countertop. If the

range is operated while at a lower height relative to the

adjacent cabinet, the cabinet could be exposed to

excessive temperatures, causing damage to the cabinet

and countertop (see Figure 30 on page 25).

For proper performance, the range must be level. This is

especially important for all products that have the griddle

feature. Priority should be placed on ensuring that the oven

cavities are also level for optimum cooking performance.

The 30" and 36" models have a total of (4) leveling legs,

one beneath each corner, that are threaded into the cast

aluminum base structure; 48" models have (6).

,

Measure the countertop heights first with a tape

measure and add an additional 1/16" - 1/8" (2-3 mm).

Adjust the legs accordingly prior to pushing the range

back to its final location.

,

Rotate the legs using a 12" (305 mm) adjustable

wrench on the flat sides of each foot.

English 24

Dai

Figure 28: Data Rating Label Location

o ol

,, |

Figure 29: Leveling Legs

3. Progression of the height adjustments should be

alternated proportionally between the four corner legs,

until the top edges of the range's side panels are close

to matching the counter top height.

4. Final height adjustments of the two rear legs take place

before moving the range into its installed position in the

cabinet.

Page 28

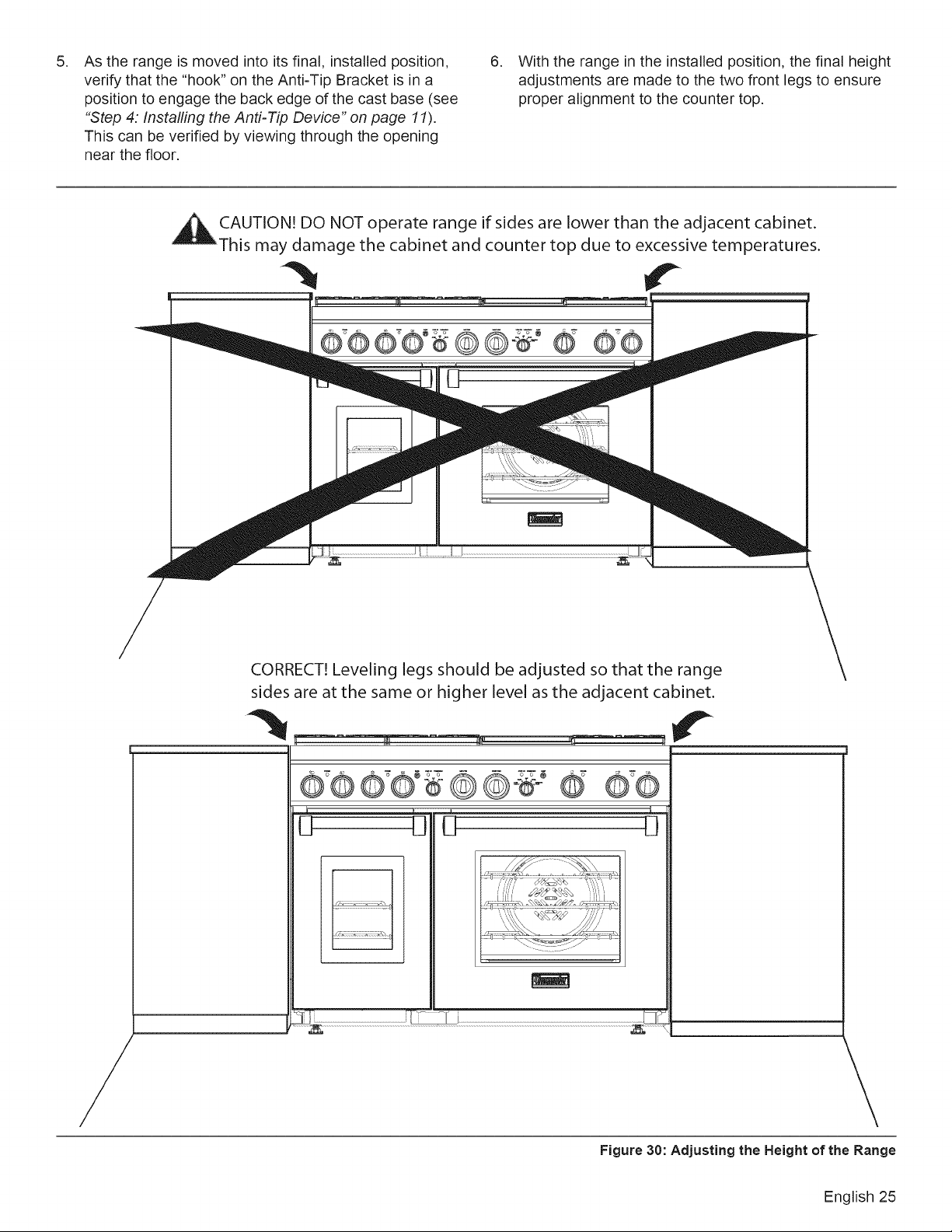

.

As the range is moved into its final, installed position,

verify that the "hook" on the Anti-Tip Bracket is in a

position to engage the back edge of the cast base (see

"Step 4: Installing the Anti-Tip Device" on page 11).

This can be verified by viewing through the opening

near the floor.

CAUTION! DO NOT operate range if sides are lower than the adjacent cabinet.

_This may damage the cabinet and counter top due to excessive temperatures.

6. With the range in the installed position, the final height

adjustments are made to the two front legs to ensure

proper alignment to the counter top.

!

CORRECT! Leveling legs should be adjusted so that the range

sides are at the same or higher level as the adjacent cabinet.

dO°£ © d

I

@ [?

/

Figure 30: Adjusting the Height of the Range

English 25

Page 29

Griddle Tilt Adjustment (not all models)

Adjusting the Kick Panel

If the range is equipped with an electric griddle, check the

griddle frame adjustment by pouring two tablespoons of

water on the back of the griddle plate. The water should

slowly roll into the grease tray. If not, adjust the two screws

under the back of the frame. Start with one half turn

counterclockwise (CCW) of the screws. Further adjustment

should be made by one-quarter turn until water slowly flows

into the grease tray.

To adjust the kick panel do the following:

1. Remove the kick panel screws using a T-20 Torx

screwdriver.

2. Slightly push panel up then out to clear aluminum cast

base protrusions.

3. Relocate kick panel at one of the five screw hole

positions, as noted below. Reinstall Torx screw.

Kick Panel

Ad us_m

I(

I

Hole_ .....

Figure 31: Griddle Leveling Screws

, WARNING:

To avoid risk of injury, never operate the griddle without

the griddle plate installed. Never use griddle in a manner

that is not prescribed by the Use and Care Guide.

The griddle plate must always be in place when the

griddle is turned on.

Figure 32: Kick Panel Adjustment

.

Repeat with the remaining kick panel screws, assuring

kick panel is level.

• The range kick panel should maintain a minimum

½" (12.7 mm) clearance above the floor.

English 26

Page 30

Step 10: Burner Test and

Adjustment

Install any loose components, such as burner caps and

grates, that may have been removed earlier. Be certain that

burner caps seat properly into the burner bases. Before

testing operation of the appliance, verify that the unit and

the gas supply have been carefully checked for leaks and

that the unit has been connected to the electrical power

supply. Turn the manual gas shut-off valve to the open

position.

NOTICE:

All oven knobs and selectors must be set to OFF before

powering up the range. To prevent unintended operation at

power up, please set all oven knobs to OFF. To ensure

customer safety in the event of power failure, the unit will

display an error message upon reinstatement of power

unless all oven knobs are set to OFF. Set all oven knobs to

OFF and reset the breaker to clear the message.

Test Rangetop Burners

Test Burner Ignition

Select a rangetop burner knob. Push in and turn

counterclockwise to HI. The ignitor/spark module will

produce a clicking sound. Once the air has been purged

from the supply lines, the burner should light within four (4)

seconds.

Test Flame: High Setting

Turn burner on to HI. See Figure 33 for appropriate flame

characteristics.

If any of the rangetop burners continue to burn mostly or

completely yellow, verify that the burner cap is positioned

properly on the burner base, then retest. If flame

characteristics do not improve, call THERMADOR ®.

Repeat the Ignition and Flame Test procedures, described

above for each rangetop burner.

Yellow Flames:

Further Adjustment is

required.

Yellow Tips on Outer Cones:

Normal for LP Gas

Soft Blue Flames:

Normal for Natural Gas

If the flame is completely or mostly yellow, verify that the

regulator is set for the correct fuel. After adjustment,

retest.

Some orange=colored streaking is normal during the

initial start=up.

Allow unit to operate 4-5 minutes and re-evaluate before

making adjustments.

Figure 33: Flame Characteristics

When Flame is Properly Adjusted:

There should be a flame at each burner port. There should

be no air gap between the flame and burner port.

Call THERMADOR ® if:

1. Any of the burners do not light.

2. Any of the burners continue to burn yellow.

Test Flame: Simmer Setting

Turn burner on to SIM. Verify that the flame completely

surrounds the burner. There should be aflame at each

burner port and there should be no air gap between the

flame and the burner. If any burners do not carry over, call

THERMADOR.

The two rangetop burners on the left side feature XLO ®,

causing the flame to cycle on and off when the knob is set

to the XLO range. This is normal operation.

English 27

Page 31

Installer Checklist

[] Specified clearances maintained to cabinet surfaces.

[] Unit level - front to back - side to side.

[] Burner caps positioned properly on burner bases.

[] All packaging material removed. []

[] A Flush Island Trim or backguard attached according

to instructions. []

[] Kick panel in place screws secure.

[] Verify flame at each burner. The flame should appear []

as described in Step 10. Flame may need to burn for

several minutes to remove impurities from the gas

lines. []

[] Verify that the ExtraLow ®feature works and relights

around the entire burner. []

Gas Supply

[] Manual gas shut off valve installed in an accessible

location (without requiring removal of range).

[] The appliance is connected only to the type of gas for

which it is certified for use.

[]

Unit tested and free of gas leaks.

[]

If used on propane gas, verify that the propane gas

supply is equipped with its own high pressure

regulator in addition to the pressure regulator

supplied with the appliance.

[]

Gas supply pressure does not exceed 14" W.C.

(34.9 mb).

Operation

[] Bezels centered on burner knobs, and knobs turn

freely.

[] Each burner lights satisfactorily, both individually and

with other burners operating.

[] Griddle is tilted _ forward and does not rock (not

all models).

[] Oven door hinges seated and hinge locks in proper

position. Door opens and closes properly.

[] Burner grates correctly positioned, level and do not

rock.

[] Start self-clean. When CLEANING light comes on,

verify that door is locked. Cancel self clean mode.

Troubleshooting

If the dual fuel range does not operate properly, follow

these troubleshooting steps:

Verify that electrical power is being supplied to the

range.

Check electrical and gas supply connections to

ensure that the installation has been completed

correctly.

Check that the gas supply shut-off valve is in the open

position.

Follow troubleshooting procedures outlined in the Use

and Care Guide.

To reach a service representative, see the contact

information on the back page of this manual. Please

be prepared with the model and serial number

information from the product data rating labels (see

Figure 28 on page 24 for location).

INSTALLER: Write the model number and serial

[]

number (see "Data Rating Label Location" on page 24

for location) in the Use and Care Guide. Leave the

Use and Care Guide and Installation Manual with the

owner of the appliance.

To Clean and Protect Exterior Surfaces

• The stainless steel surfaces may be cleaned by wiping

with a damp soapy cloth, rinsing with clear water and

drying with a soft cloth to avoid water marks. Any mild

glass cleaner will remove fingerprints and smears.

• For discolorations or deposits that persist, refer to the

Use and Care Guide.

To polish and protect the stainless steel, use a cleaner/

polish such as Stainless Steel Magic ®.

DO NOT allow deposits to remain for long periods of

time.

DO NOT use ordinary steel wool or steel brushes.

Small bits of steel may adhere to the surface causing

rust.

DO NOT allow salt solutions, disinfectants, bleaches or

cleaning compounds to remain in contact with stainless

steel for extended periods. Many of these compounds

contain chemicals which could prove harmful. Rinse

with water after exposure and wipe dry with a clean

cloth.

Electrical

[]

Receptacle with correct over=current protection is

provided for service cord connection.

[]

Proper ground connection.

English 28

Page 32

Table des ati res

Consignes de S_curit_ ................................. 1

Consignes d'lnstallation ...................................... 3

#tape 1 :

#tape 2 :

#tape 3 :

#tape 4 :

#tape 5:

#tape 6 :

#tape 7 :

#tape 8 :

#tape 9:

Etape 10

Exigences pour la ventilation ..................................... 3

Preparation de I'emplacement de I'armoire .......................... 4

Deballage, manutention et mise en place de la cuisiniere ............... 9

Installation du dispositif antibascule .............................. 11

Exigences de I'alimentation du gaz et raccordement ................. 13

Exigences electriques, connexions et mise a la terre ................. 15

Installation du dosseret ........................................ 18

Retrait et installation de la porte ................................. 23

Mise en place et nivelage de la cuisiniere .......................... 24

: Test et reglage des brQleurs ................................... 27

Liste de v_rification b i'intention de i'installateur ........... 28

Entretien, Pi_ces et Accessories ................ page verso

Cet appareil electrom6nager de THERMADOR mc

est fait par BSH Home Appliances Ltd.

6696 Financial Drive, Unit 3

Mississauga, ON L5N 7J6

Des questions?

1=800-735-4328

www.thermador.ca

Nous attendons de vos nouvelles!

Page 33

CONSIGNES DE SI CURITI IMPORTANTES

LISEZ ET CONSERVEZ CES iNSTRUCTiONS

POUR UTILISATION RESIDENTIELLE SEULEMENT

Avant de commencer

IMPORTANT:

Les r6glementations locales varient. L'installation, le

branchement au gaz et la mise a la terre doivent etre

conformes a toutes les r_glementations en vigueur.

IMPORTANT : Conservez ces instructions pour

I'inspecteur de la soci6t6 gazi6re de votre localitY.

INSTALLATEUR : Veuillez laisser ces instructions

d'installation avec I'appareil pour le propri_taire.

PROPRI¢:TAIRE : Veuillez conserver ces instructions pour

consultation ult_rieure.

AVERTISSEMENT •

Coupez I'_lectricit6 avant d'installer I'appareil.

_ vant de r_tablir I'_lectricit_, assurez-vous que

toutes les commandes sont a la position OFF.

AVERTISSEMENT •

Si les directives du present manuel ne sont pas

respect6es scrupuleusement, des incendies ou des

d_charges _lectriques pourraient etre a I'origine de

dommages materiels ou de blessures corporelles, ou

m_me entrainer la mort.

-- N'entreposez pas et n'utilisez pas d'essence ou

d'autres produits inflammables a proximit_ de la

cuisini6re ou de tout autre appareil.

-- SI VOUS Dt_TECTEZ UNE ODEUR DE GAZ

• N'allumez aucun appareil.

• Ne touchez pas aux interrupteurs _lectriques.

• N'utilisez pas les t_l_phones du b_timent o0

vous vous trouvez.

• Appelez imm_diatement votre soci6t_ gaziere

chez un voisin et suivez les instructions qu'elle

vous donne.

• Si vous n'arrivez pas a contacter votre soci_t_

gazi6re, appelez le service d'incendie.

L'installation et les travaux d'entretien doivent etre

r_alis_s par un installateur qualifi_, un centre de

r_paration agr6_ ou une soci_t_ gaziere.

AVERTISSEMENT •

Un enfant ou un adulte pourrait faire

basculer I'appareil et perdre la vie.

Assurez-vous que le dispositif anti-bascule

a _t_ convenablement install_ et que la

patte de I'appareil est retenue par le

support Iorsque vous remettez la cuisini6re

en place.

Ne faites pas fonctionner I'appareil si le

support anti-bascule n'est pas en place.

La non-observation des instructions du

present manuel peut entrainer la mort ou

causer de graves br01ures a des enfants

ou des adultes.

Assurez-vous que le support anti-bascule

est bien install_ et d0ment utilis_. Faites

doucement basculer la cuisini_re vers

I'avant en la tirant par I'arri6re pour vous

assurer que la patte de I'appareil est bel et

bien entree dans le support anti-bascule et

que I'appareil ne peut se renverser. La

cuisini_re ne devrait pas pouvoir bouger

de plus d'un pouce (2,5 cm).

Pour les installations au Massachusetts :

1. L'installation dolt etre r_alis_e par un entrepreneur

qualifi6 ou accreditS, un plombier ou un installateur

de gaz qualifi_ ou autoris_e par I'€:tat, la povince ou

la r6gion dans laquelle cet appareil est

insd'unertall_.

2. La vanne d'arret de gaz dolt etre pourvue poign_e

en <<T >>.

3. La Iongueur du tuyau de gaz ne dolt pas exc_der

36 po (914 mm).

Note:

Cette cuisiniere WEST PAS congue pour les maisons

mobiles pr6fabriqu_es ni pour les v_hicules r_cr_atifs.

N'installez PAS cet appareil a I'ext6rieur.

Frangais 1

Page 34

CONSIGNES DE SI CURITI

IMPORTANTES

LISEZ ET CONSERVEZ CES

Verification du type de gaz

V@ifiez le type d'alimentation en gaz fourni sur le lieu

d'installation. L'appareil dolt etre raccord6 au type de gaz

pour lequel il est certifi6. Tousles modeles sont certifi6s

pour une utilisation avec gaz naturel. Conversion sur place

pour utilisation au gaz propane exigeant le n6cessaire de

conversion.

Approvisionnement en gaz

Gaz naturel--6 pc (14,9 mb)min, a 14 pc (34,9 mb)max.

de colonne d'eau

Gaz propane -- 11 pc (27,4 mb) min. a 14 pc (34,9 mb)

max. de colonne d'eau

ATTENTION •

Lorsque vous branchez I'appareil au gaz propane,

assurez-vous que le r6servoir de gaz propane est muni

de son propre m6canisme r6gulateur a haute pression

en plus du r6gulateur a haute pression fourni avec

I'appareil. La pression de gaz maximale de cet appareil

ne devrait pas exc6der 14,0 pouces (34,9 mb) de

colonne d'eau entre le r6servoir de propane et le

r6gulateur a haute pression.

Alimentation electrique

Consultez la section {_Etape 7 Installation du dosseret

(optionnel) _ pour obtenir des sp6cifications.

V@ifiez code de la construction locale en vigueur pour

connaftre la bonne m6thode d'installation de I'appareil.

L'installation, le branchement 61ectrique et la mise a la terre

doivent respecter toutes les r6glementations en vigueur.

Les r6glementations locales varient et il est de la

_onsabilit6 de I'installateur de s'assurer de la conformit6

de I'installation avec ces r6qlementations. S'il n'y a pas de

r6glementations locales, I'appareil dolt _tre install6

conform6ment au code national am@icain actuel sur les

gaz combustibles ANSI Z223.1/NFPA 54 et au code

national am6ricain actuel de 1'61ectricit6ANSI/NFPA No 70.

Au Canada, I'installation dolt etre conforme aux normes

canadiennes CAN 1-B149.1 et CAN 1-B149.2 pour

I'installation d'appareils fonctionnant au gaz, et/ou aux