INSTALLATION INSTRUCTIONS

PH SERIES WALL HOOD

APPROVED FOR ALL RESIDENTIAL APPLIANCES

FOR RESIDENTIAL USE ONLY

PLEASE READ ENTIRE INSTRUCTIONS BEFORE PROCEEDING.

INSTALLATION MUST COMPLY WITH ALL LOCAL CODES.

IMPORTANT: Save these Instructions for the Local Electrical Inspector’s use.

INSTALLER: Please leave these Instructions with this unit for the owner.

OWNER: Please retain these instructions for future reference.

SAFETY WARNING

Turn off power circuit at service panel and lock out panel

before wiring this appliance.

REQUIREMENT: 120 V AC, 60 Hz. 20 A Branch Circuit

READ AND SAVE THESE INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

C. Installation work and electrical wiring

SAFETY WARNING

Turn off power circuit at service panel and

lock out panel, before wiring this appliance.

must be done by qualified person(s) in

accordance with all applicable codes &

standards, including fire-rated

construction.

REQUIREMENT: 120 V AC, 60 Hz. 20 A

CAUTION

FOR GENERAL VENTILATING USE

ONLY.

HAZARDOUS OR EXPLOSIVE

MATERIALS OR VAPORS.

DO NOT USE TO EXHAUST

WARNING

TO REDUCE THE RISK OF FIRE,

ELECTRIC SHOCK, OR INJURY TO

PERSONS, OBSERVE THE

FOLLOWING:

A. Use this unit only in the manner

intended by the manufacturer. If you

have questions, contact the

manufacturer. (Thermador Customer

Service at 800/735-4328.

D. Sufficient make-up air is needed for

proper combustion and exhausting of

gases through the flue (chimney) of fuel

burning equipment to prevent backdrafting. Follow the heating equipment

manufacturers guideline and safety

standards such as those published by

the National Fire Protection Association

(NFPA), the American Society for

Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE),

and the local code authorities.

E. Due to size and weight of this unit two

installers are recommended.

F. When cutting or drilling into wall or

ceiling, do not damage electrical wiring

and other hidden utilities.

G. To properly exhaust air, be sure to duct

air outside. Do not vent exhaust air into

spaces within walls, ceilings, attics,

crawl spaces, or garages.

B. Before servicing or cleaning the unit,

switch power off at service panel and

lock service panel. This will prevent

power from being switched on

accidentally. When the service panel

cannot be locked, securely fasten a

prominent warning device, such as a

tag, to the service panel.

CAUTION:

Vent Unit to the Outside.

WARNING

TO REDUCE THE RISK OF FIRE,

USE ONLY METAL DUCT WORK.

H. Install this hood in accordance with all

requirements specified.

Page 2

Parts Included with your Hood

Parts Not Included with your Hood

• Hood Canopy

• 12-Volt halogen bulbs, installed

• Care & Use /Installation Instructions

• Registration Card

• Filters (2, 3, or 4 depending on model and size)

• Metal Transition with Back draft damper installed

• Fasteners

• Remote Blower (“pigtail”) Adaptor

• Wooden Strip for Hood Support

• Wire Nuts

CONSIDERATIONS BEFORE INSTALLING HOOD

• Duct Tape

• 1/2" Conduit

• 2 175W PAR-38 Heat Lamps or

2 250W PAR-40 Heat Lamps

• Ventilator- The hood can be installed with

ventilator models VTN1000Q, VTR600R,

VTR1000Q, and VTR1400Q

• Optional duct cover, 6" DC**US or 12" DCT**US

height (available for purchase seperately)

** = width of hood

• Optional Remote Control (available for purchase

separately)

1. For the most efficient air flow exhaust, use a

straight run or as few elbows as possible.

CAUTION:

Vent unit to outside of building, only.

2. Do not use flex ducting.

3. COLD WEATHER installations should have an

additional backdraft damper installed to

minimize backward cold air flow and a

nonmetallic thermal break to minimize

conduction of outside temperatures as part of

the ductwork. The damper should be on the cold

air side of the thermal break. The break should

be as close as possible to where the ducting

enters the heated portion of the house.

4. Hood installation height above cooktop is the

users preference. The lower the hood above the

cooktop, the more efficient the capturing of

cooking odors, grease, and smoke. This hood

has been approved for installations as low as 24

inches* above the cooktop. The lower height

may be inconvenient for tall people and large

cooking vessels. Consequently, Thermador

recommends the hood be installed 30-to-36

inches above the countertop.

* For indoor grill installations, Thermador

recommends a minimum of 30" clearance and

remote blowers only (VTR1000Q or VTR 1400Q)

5. Remote blowers require a five wire installation.

6. Make-Up Air: Local building codes may require

the use of make-up air systems when using

ducted ventilation systems greater than specified

CFM of air movement. The specified CFM varies

from locale to locale. Consult your HVAC

professional for specific requirements in your

area.

7. Refer to Remote Control Installation Instructions

if applicable.

Page 3

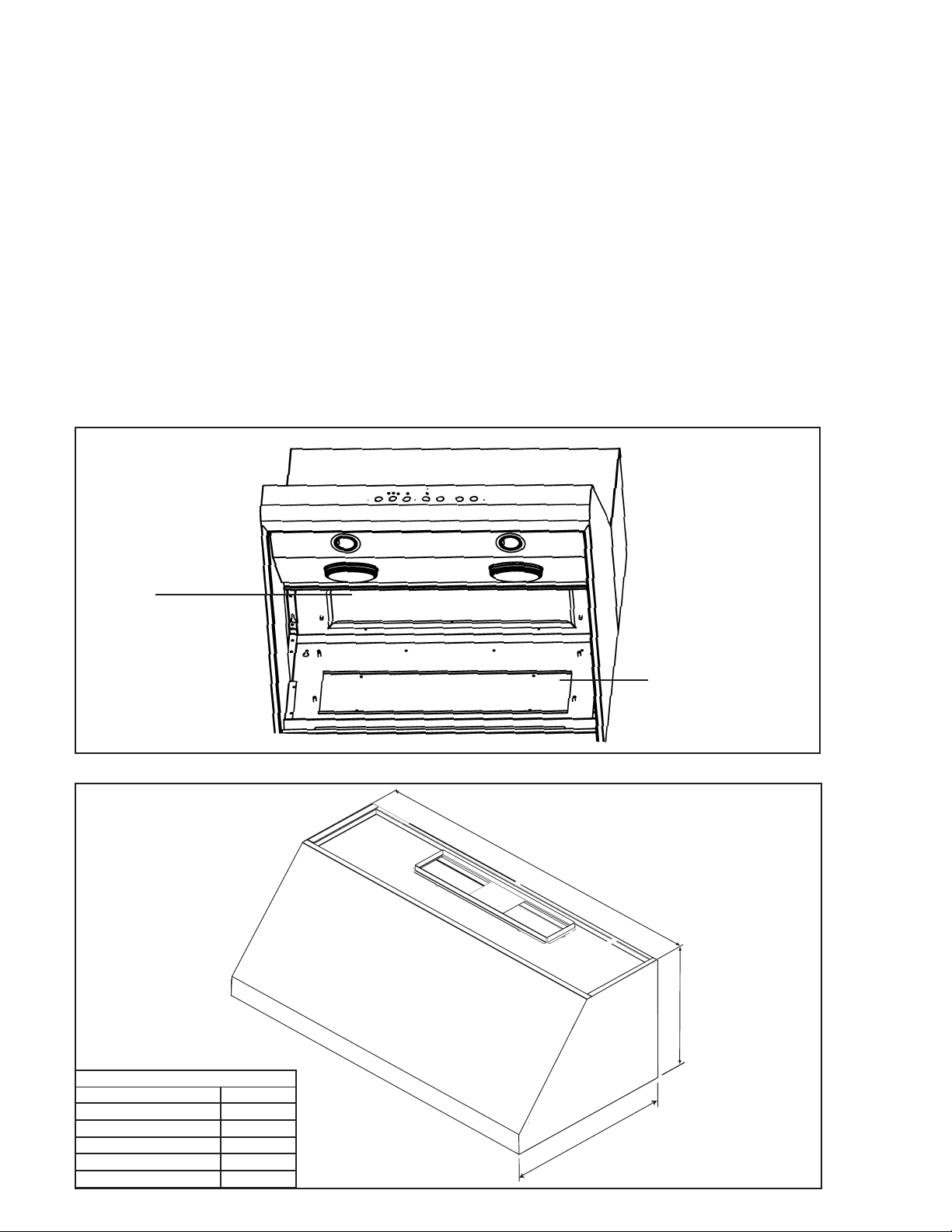

Appliance Installation

The hood can be mounted on a wall or suspended

from a cabinet. Both vertical and horizontal

discharge are possible with either mounting method.

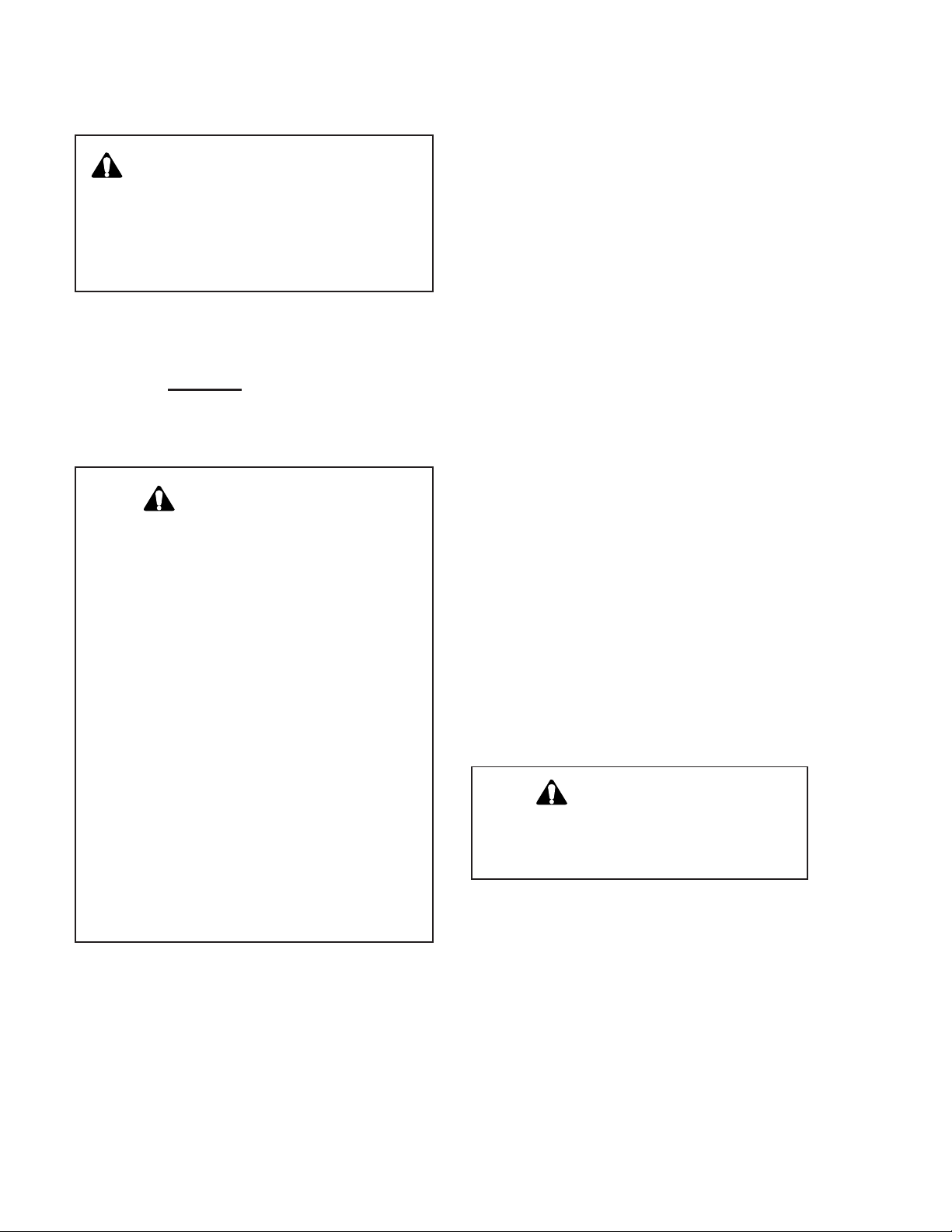

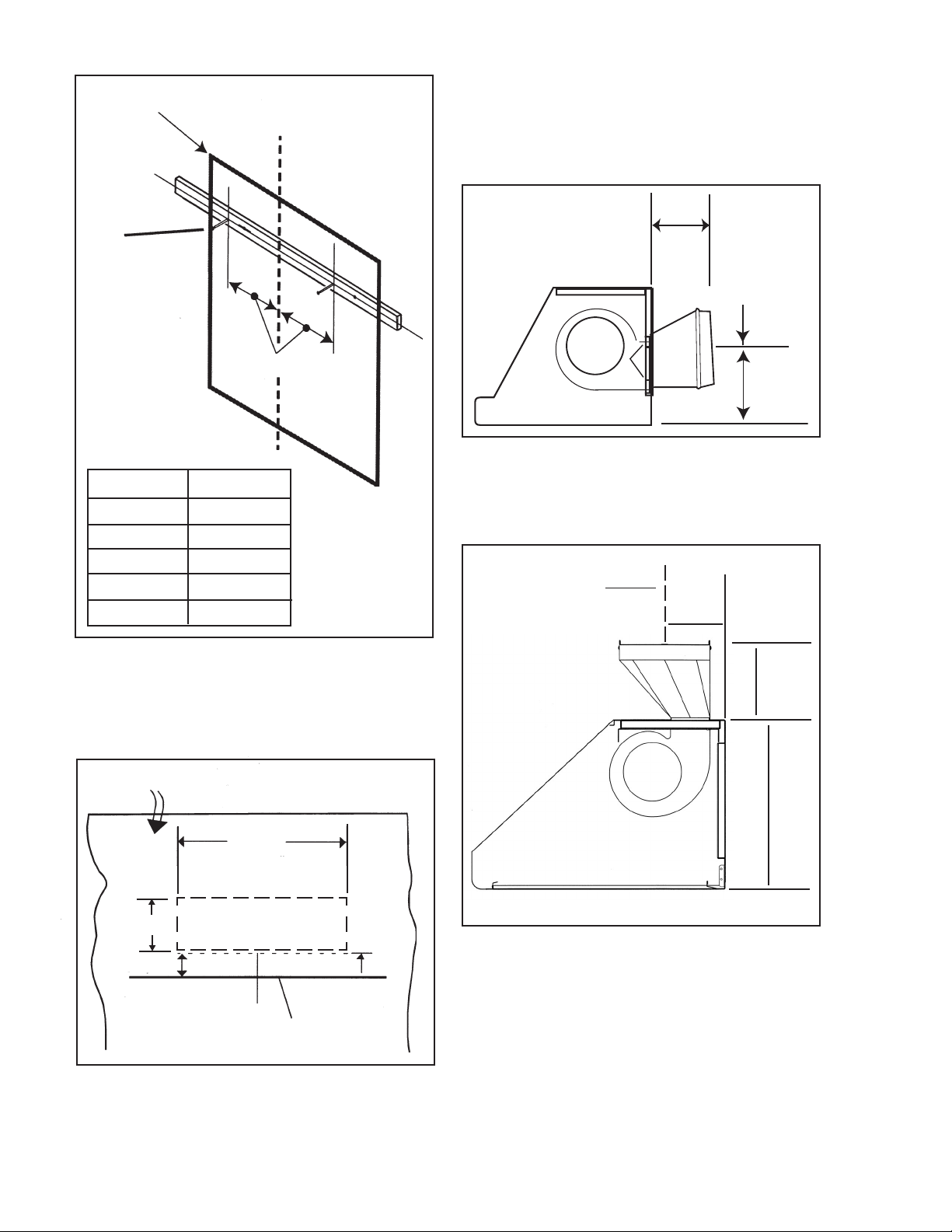

Discharge Direction: The hood is shipped ready for

vertical discharge. To change to horizontal discharge

move the discharge cover shown in Figure 1a to the

top of the hood. The plate is held in place by four

screws.

Assembly of the Transition: The supplied

transition mounts to the top or rear of the hood

depending on the discharge direction.

This opening is

covered for

horizontal

discharge

1. Align mounting holes at base of transition with

mounting holes on 1/2” flange located at the

top or rear of the hood depending on direction

of discharge.

2. Fasten transition to hood using two (2) #8

sheetmetal screws (included with hood).

3. Seal connection between transition and hood

with duct tape.

4. Remove tape holding damper closed.

See Figure 1b for overall hood dimensions.

Figure 1a: Discharge Direction

Dimension A

Model Number

PH30ZS

PH36ZS

PH42ZS

PH48ZS

PH54ZS

Figure 1b: Overall Dimensions

Dimension

30"

36"

42"

48"

54"

This opening is

covered for vertical

discharge.

A

18"

27"

Page 4

Height

Above

p

Cooktop

Centerline

Drywall

Wall

Studs

Screws

(2 EA.

#14 x 3")

Desired

Cooktop

Height

+ 15 1/2 "

To Cooktop

Surface

Note: Read Remote Control Installation

Instructions before continuing if using this

accessory.

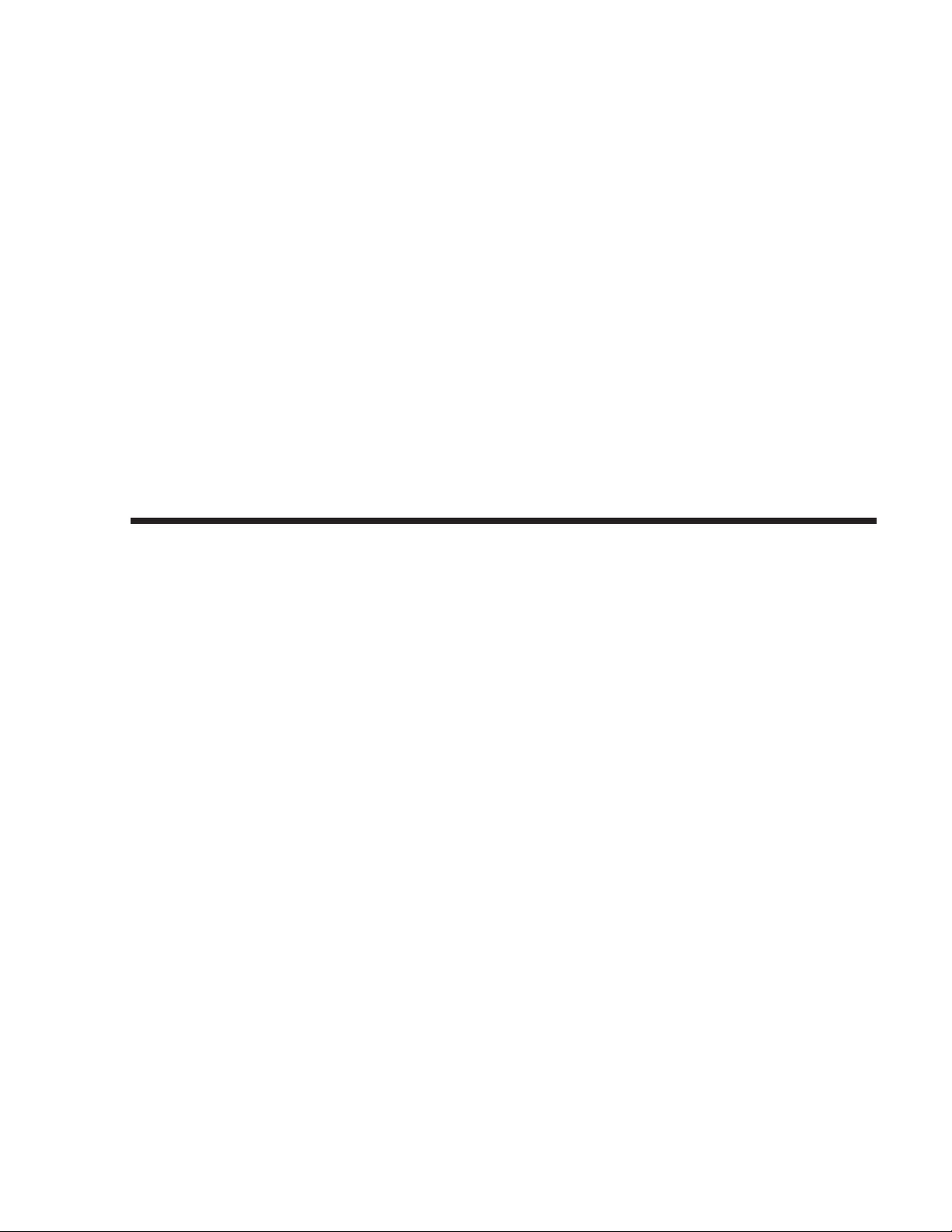

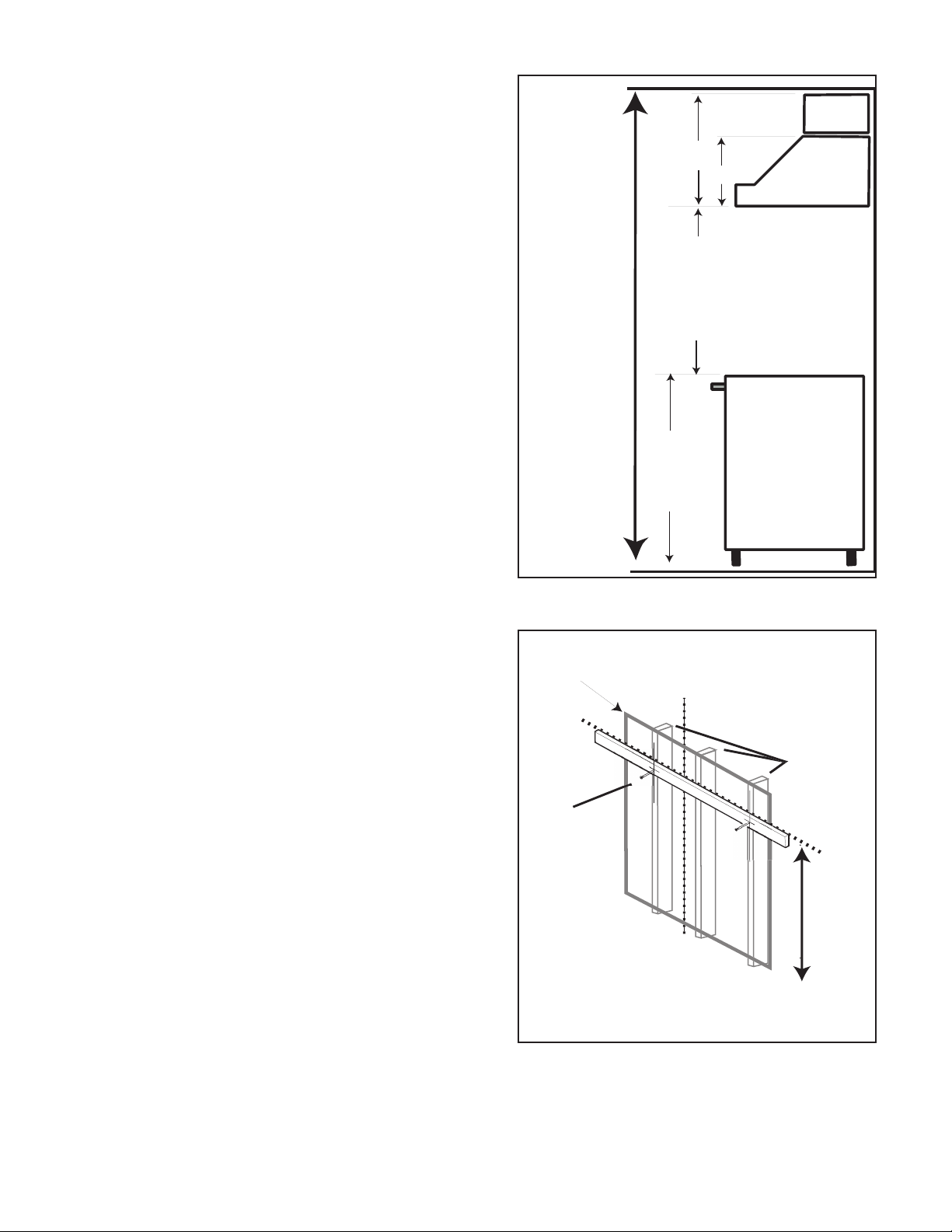

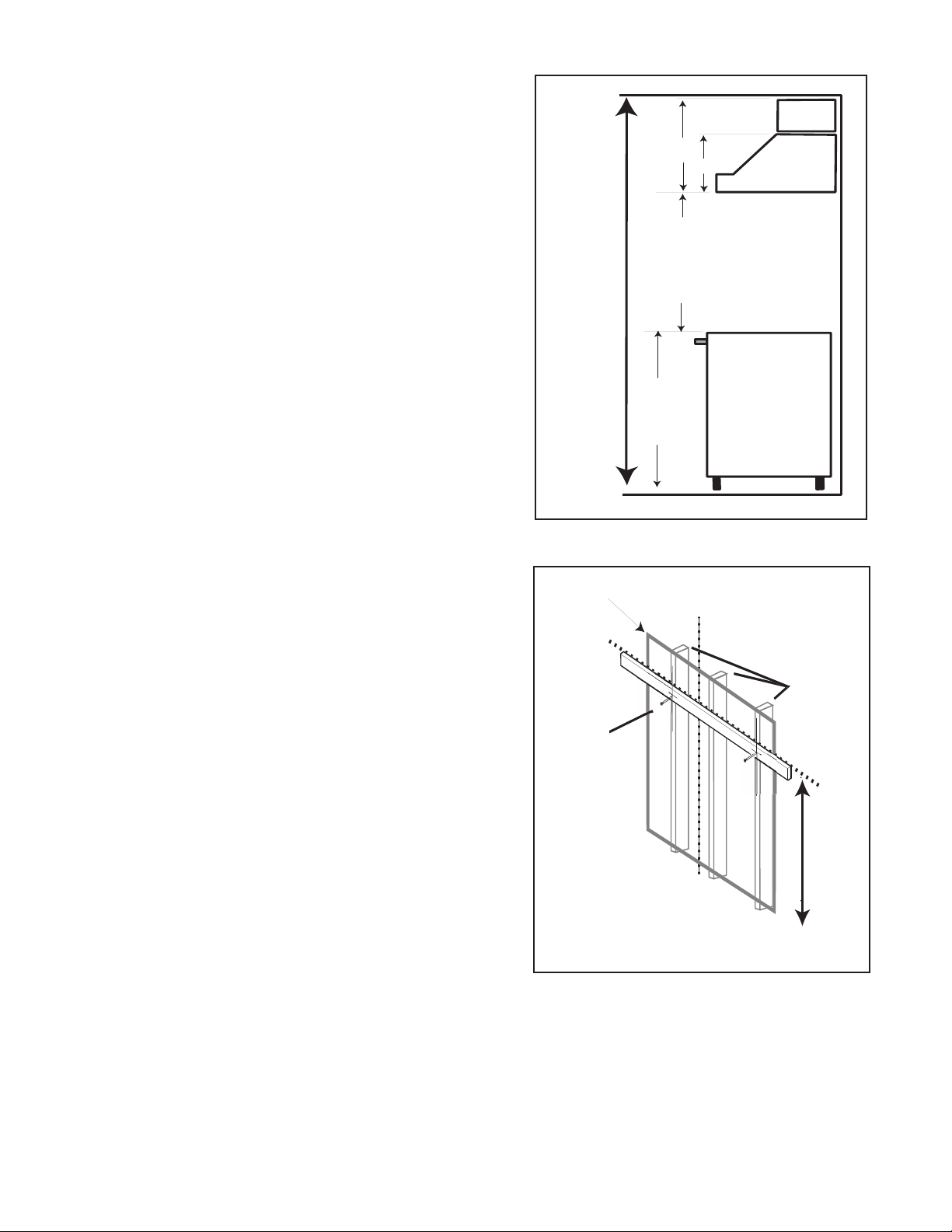

Wall Mount Installation

The hood installation height is the user’s preference. Figure 2 shows a typical installation of the

hood with two duct covers. Accessory 6” and/or 12”

duct covers are used to fill the space between the

hood and ceiling.

The installation height shown in Figure 2 is 36

inches. One 6" duct cover has been used in this

installation. Add or subtract duct covers as

appropriate to accommodate ceiling height and

desired hood height. The duct cover structure is

supported by the hood.

1. After the hood installation height has been

determined, draw a horizontal line at a distance

above the cooktop equal to the desired hood

installation height plus 15.5”. This line is the

mounting location of the wooden bracket

shipped with the hood.

2. Find the centerline of the cooktop. Draw a

vertical line along this centerline up to the

horizontal line drawn in step 1.

3. The hood is mounted to the wall using a wooden

bracket shipped with the hood. Remove the

bracket from the hood by removing two shipping

screws. Mark the center line of the bracket.

4. Locate one stud on either side of the cooktop

centerline to use for mounting the wooden

bracket as shown in Figure 3.

5. Align the top of the wood bracket along the

horizontal line drawn in Step 1. Align the

centerlines of the bracket and cooktop.

6. Drill a 3” deep 1/8" tap hole through the wooden

bracket, drywall, and into the stud.

7. Use 2 or 3 (#14 x 3”) screws to attach the

bracket to the wall as shown in Figure 3. For

support of longer hoods, use three studs.

Countersink the heads to prevent interference

with the hood.

8. On the wood bracket mark the locations used to

hang the hood according to Figure 4 (next page).

9. Drill a 1/8" tap hole through the wooden bracket

and drywall. These (#8 x 5/8") screws do not

need to go into the studs.

10. Drill a 1/16" tap hole for the 2 (#8 x 5/8") screws

into the wood bracket leaving 1/4" of each screw

exposed for hanging the hood.

Figure 2

Cookto

Figure 3

Standard

8 ft Ceiling

(96")

6"

Duct Cover

24"

18"

Hood Height (36")

Standard

36" high

Range

Page 5

Drywall

Screws

(2 ea. #14 x 3")

Cooktop

Centerline

A measurement

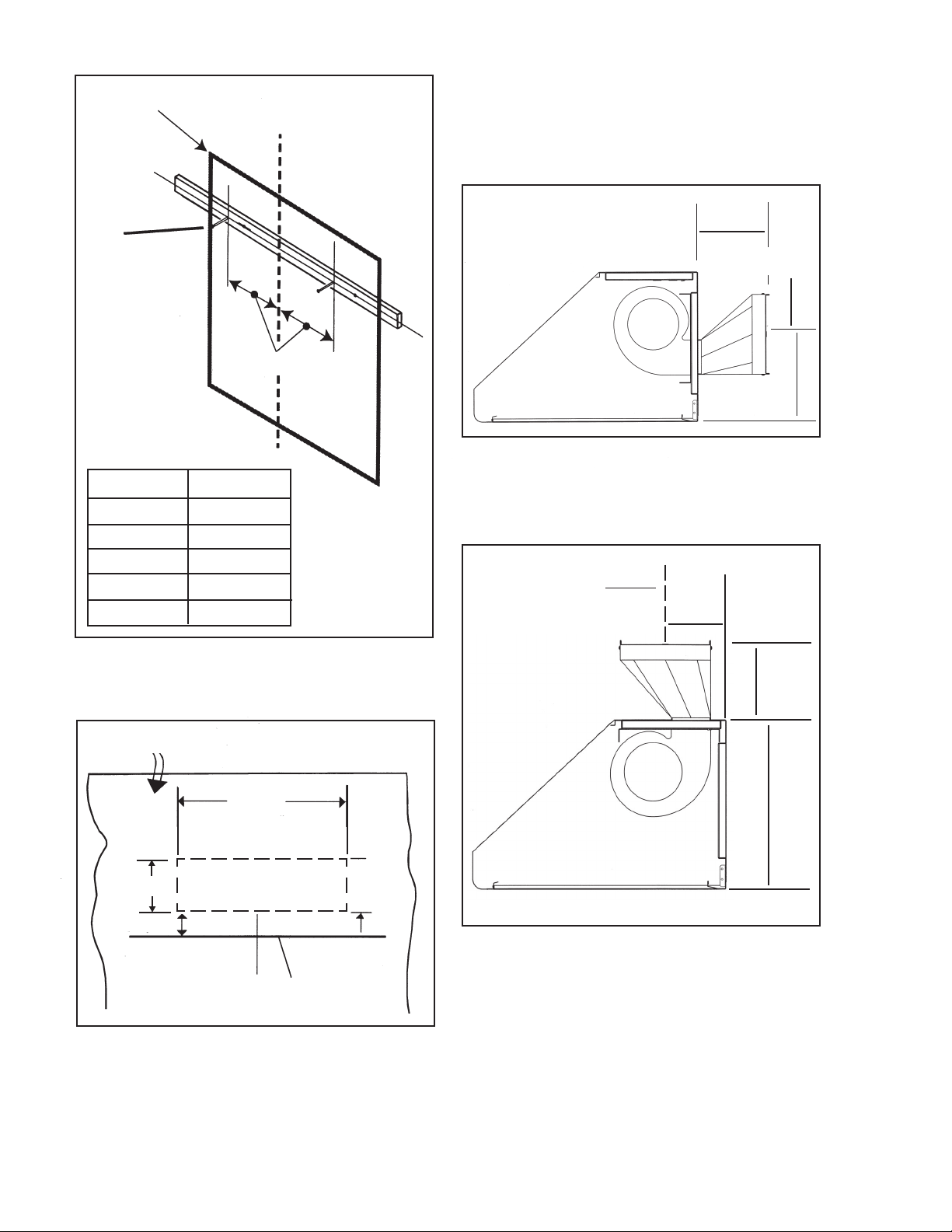

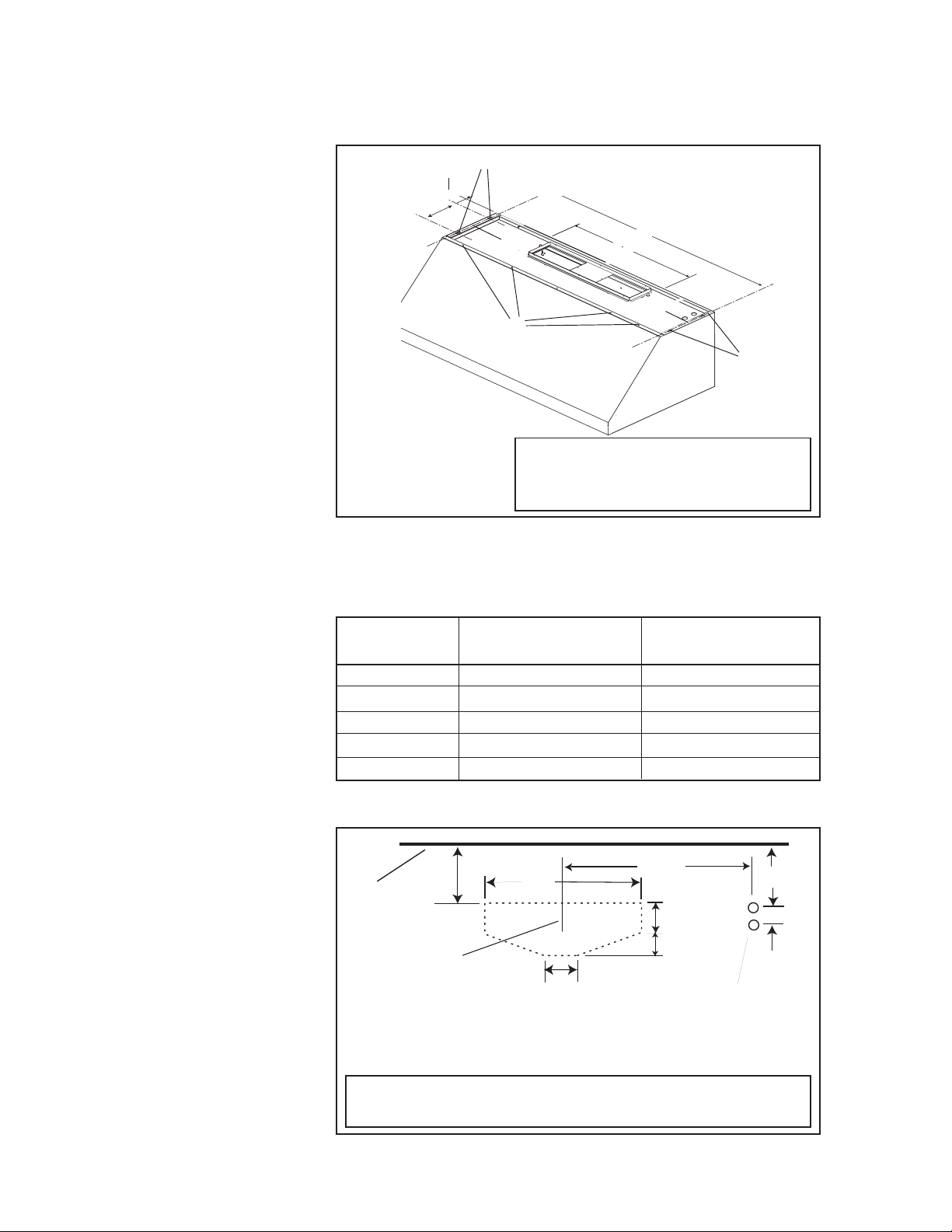

11. Discharge Direction: Horizontal discharge

requires a wall cutout, as shown in Figure 5, to

provide clearance for the transition. The location

of the cutout is determined by the hood

installation height.

10-1/4"

Transition

Centerline

10-1/2"

Figure 6

MODEL A

PHH30ZS 13-1/16"

PH36ZS 16

PH42ZS 19

PH48ZS 22

PH54ZS 25

Figure 4

Dry Wall

12 1/2"

2-3/4"

-1

/16"

-1

/16"

-1

/16"

-1

/16"

23"

Cooktop

Centerline

Base of Hood

Location

The transition supplied with the hood connects to

standard 10-inch round duct. Figure 6 shows the

transition connected for horizontal discharge.

Transition Centerline

Figure 7

-13

5

Wall

/16"

10-1/4"

18"

Figure 7 shows the hood configured for vertical

discharge. Installations using this type of method

require a cutout in the ceiling to accomodate 10"

duct and the 1/2" conduit carrying power to the unit.

Figure 5

Note: Dashed line indicates cutout needed for

clearance of the transition.

Duct covers, sold separately, are available to cover

the space between the top of the hood and ceiling.

(See Page 4).

Page 6

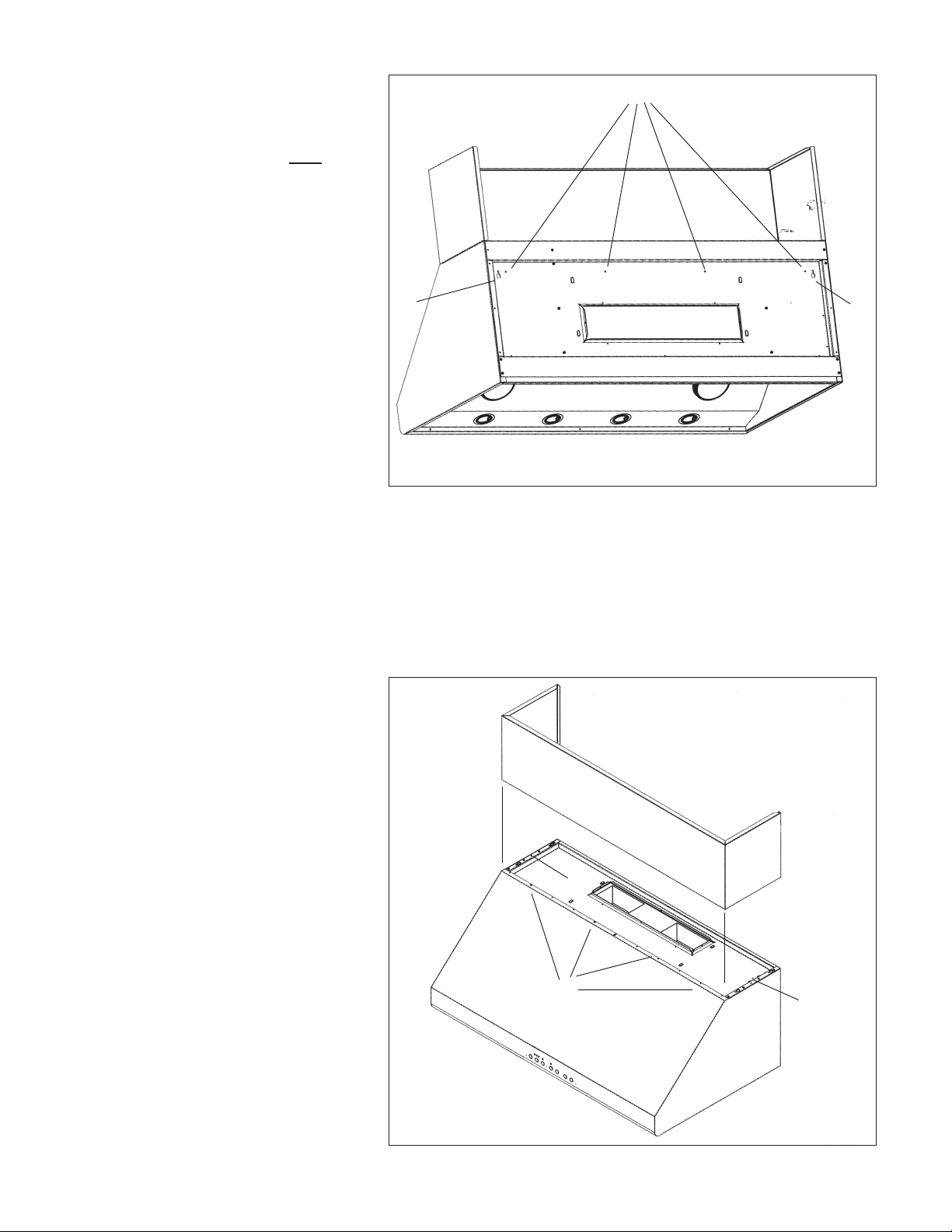

12. Before hanging hood, install

transition per Fig. 6. Fasten

transition with 2 screws (#8 x

3/8 sheet metal, supplied)

and tape per code.

Note:

screws must not hinder

damper operation.

13. Rest the hood on the screws

in the wood bracket. Use the

keyholes labeled "I" in Figure

8. Make sure the wood

bracket fits into the recess

on the back of the hood.

14. Remove knockouts.

15. Tighten the screws in

keyholes. Check hood for

level and adjust if necessary.

J

I

I

16. From inside the hood drive

screws (#8 x 5/8”) through

holes in hood into wooden

bracket. See holes labeled J

in Figure 8.

17. Connect additional ducting.

Assembly and Installation of the Duct Covers

Optional duct covers shown in

Figure 9 may be used to fill the

space between the hood and

ceiling in wall mount installations.

6" and 12" high duct covers are

available and may be ordered

separately.

1. If multiple duct covers are

used, connect the pieces

together using sheetmetal

screws provided with duct

covers.

2. Attach the duct cover(s) to

the hood using sheetmetal

screws as shown in Figure 9.

3. From inside of hood, insert

screws supplied (#8 x 5/8")

through holes L, one on each

side and four along the front,

into bottom of the cabinet.

Figure 8

Installation Note: If wall studs are within 8" of the center line, cut stud

at an angle to avoid any interference.

L

L

#8 x 3/8”

Screw

(numbers

depend on

hood size)

L

Figure 9

Page 7

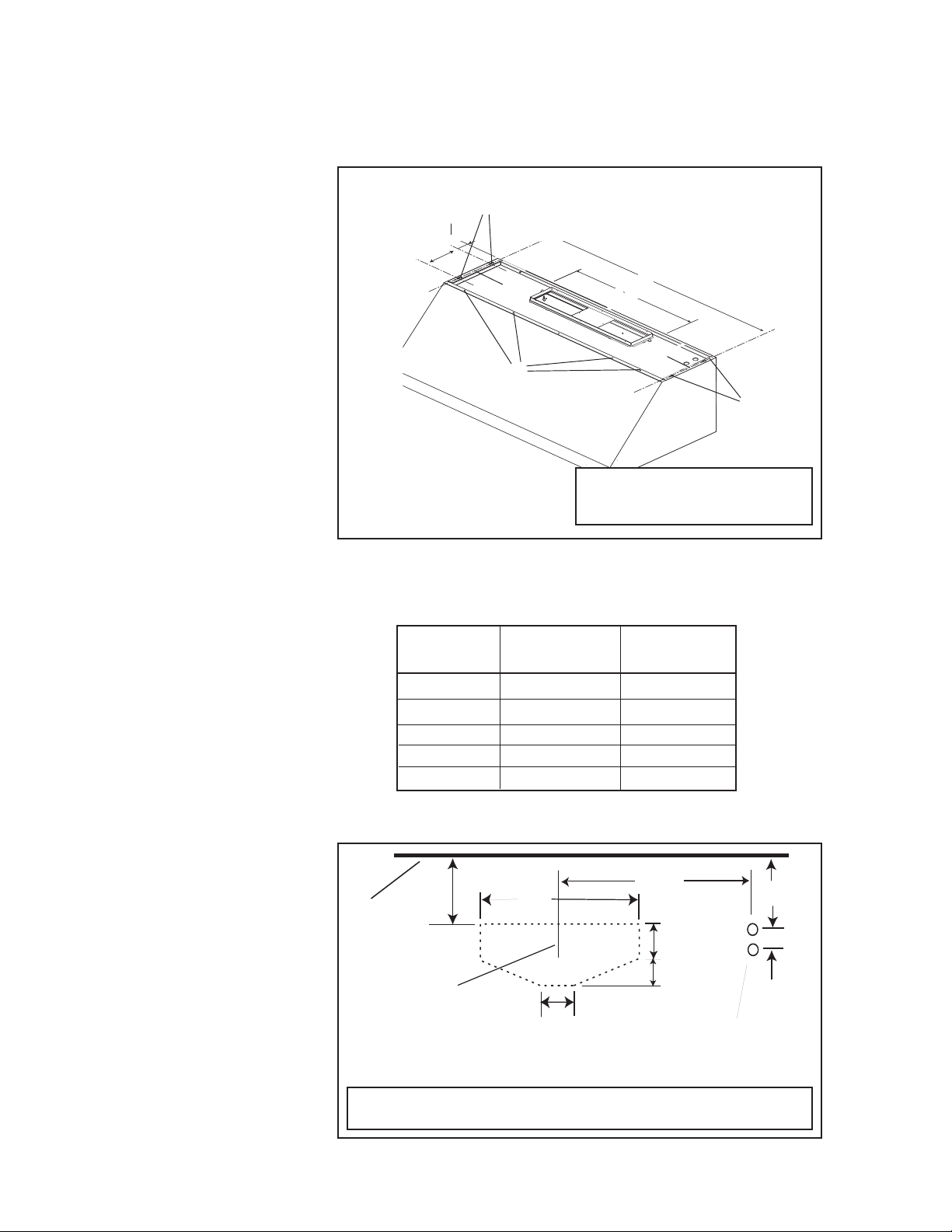

The hood can be installed under

a cabinet by supporting the

hood from the top.

Note: The cabinet must be

structurally joined to the wall

studs to support the weight

of this hood.

Figure 10 shows the four screw

holes (K) used for mounting the

hood to the bottom of the

cabinet.

Make sure both knockouts have

been removed.

Cabinet Installation

K

{

"

16

L

L

-1

7

1-9/16"

/

A: Tap Hole Locations

23"

L

K

1. In the base of the cabinet

drill 1/8" tap holes (See

dimension A in Figure 10

and in Table). Screw in four

#10 x 1" screws (provided

with hood) leaving 1/4"

exposed).

2. If the hood is installed for

vertical discharge, use

Figure 11 to create

clearance holes for passage

of the transition and conduit

(See dimension B in Figure

11 and in Table).

3. For horizontal discharge use

Figure 5 for the geometry of

the cutout required for

clearance of the transition.

4. Hang hood from screws and

tighten securely.

5. From inside of hood, insert

screws supplied. Drill

through holes (use #8 x 5/

8" screws supplied), one on

each side and four along the

front, into bottom of the

cabinet. See screws holes

labelled "L" in Figure 10.

Note: This figure depicts tap hole and

screw hole locations only. See Figue 1b,

page 4 for overall hood dimensions.

Figure 10: Tap Hole and Screw Hole Locations

Centerline Hole Dimensions for Figures 10 and 11

Model A (Fig 10) B (Fig 11)

Tap Holes Conduit Hole

PH30ZS 29-1/16"13

PH36ZS 35-1/16"16

PH42ZS 41-1/16"19

PH48ZS 47-1/16"22

PH54ZS 53-1/16"25

1 -1/8"

Wall

23"

Cooktop

Centerline

3 -3/16"

Plan View of Cabinet Cutout

Note: This figure depicts transition and conduit locations only. See Figure 1b,

page 4 for overall hood dimensions.

-7

/16"

7

/16"

-7

/16"

-7

/16"

-7

/16"

B

7 7/8"

2 -3/8"

1- 7/8"

2 3/8"

5/8" DIA clearance

holes for 1/2" conduit

to j-box.

Figure 11: Transition and Conduit Locations

Page 8

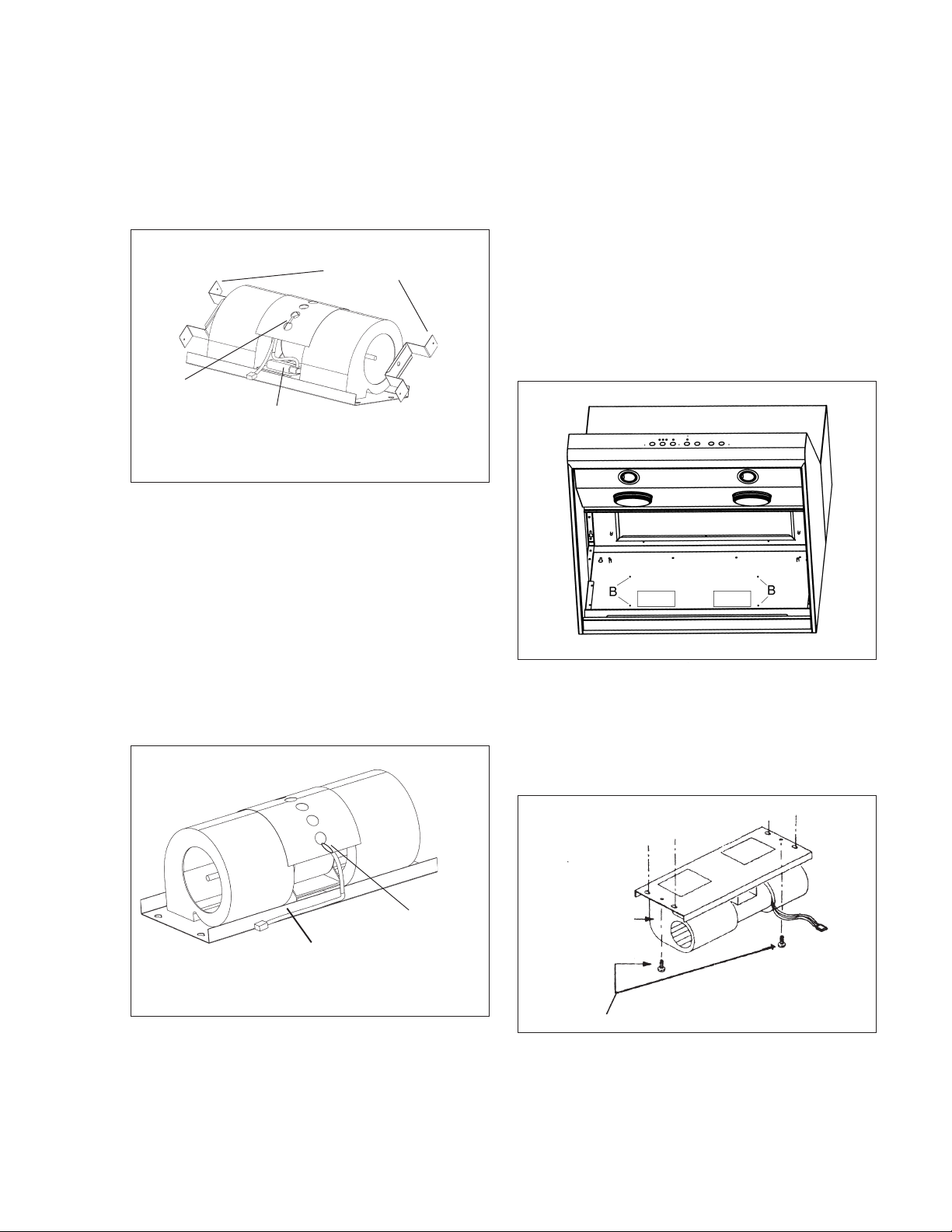

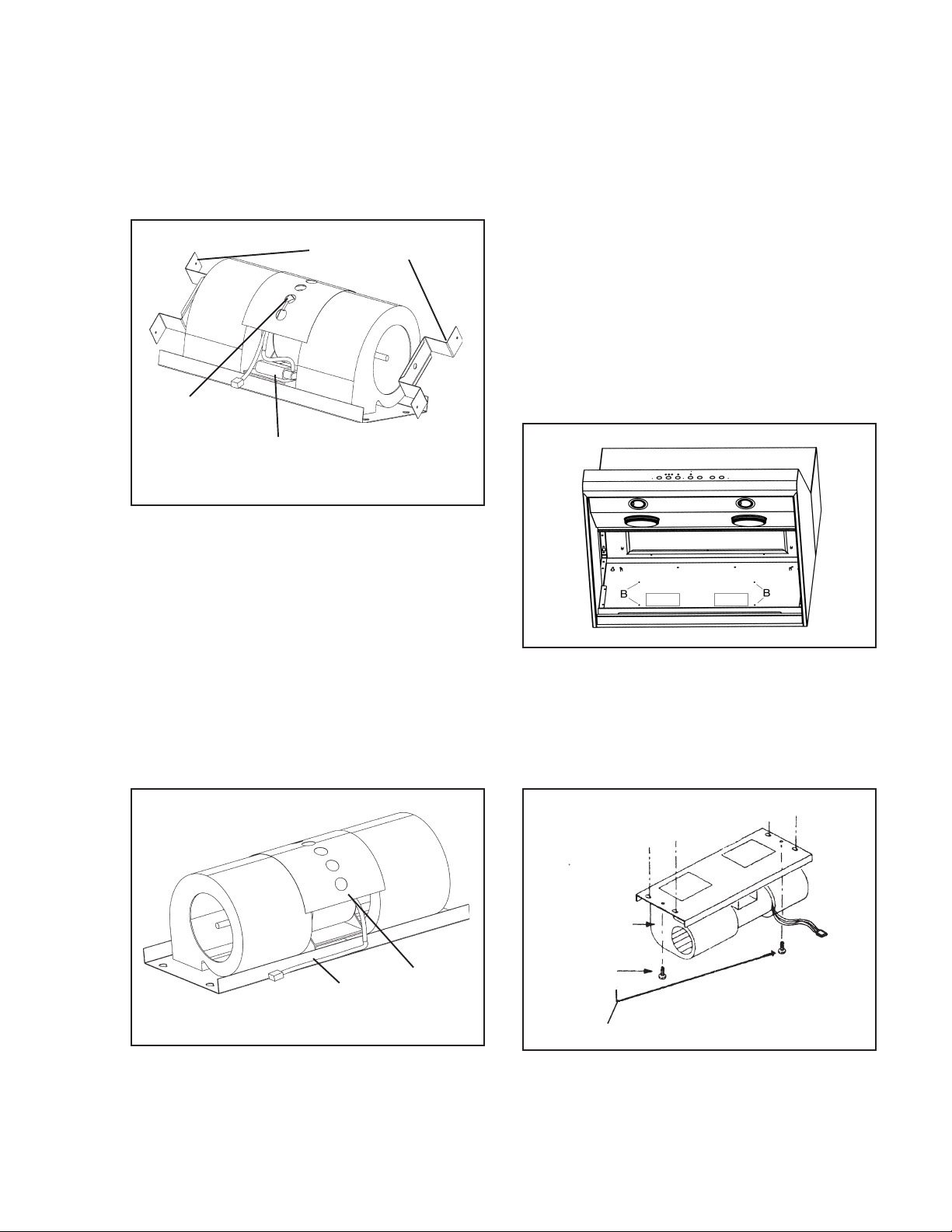

Installing an Integral Blower VTN1000Q

The hood can be installed with a VTN1000Q

blower.

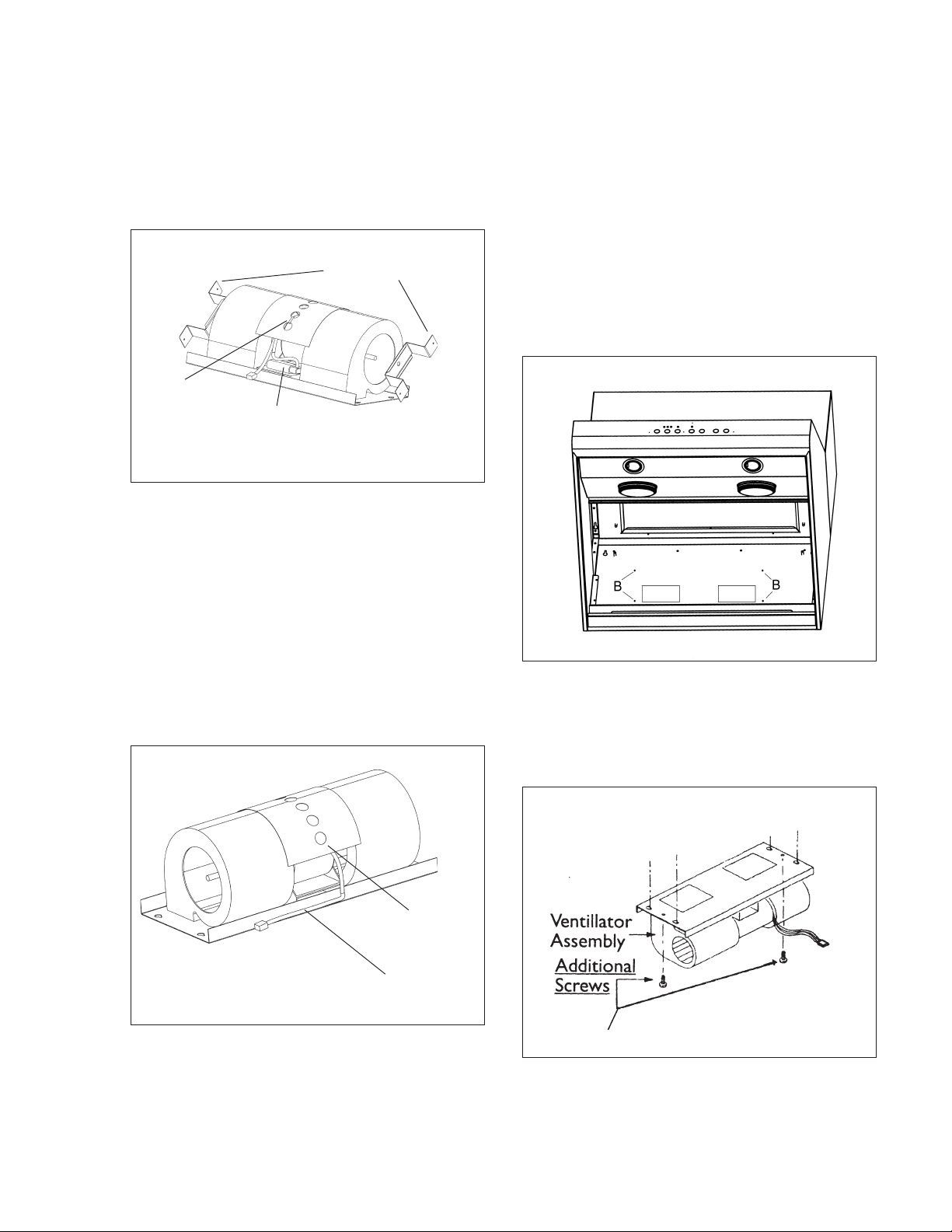

Blower preparation

Shipping brackets

Wire tie

Capacitor

Blower Front View

Figure 12a

1. Remove left and right shipping brackets

and discard.

2. Cut wire tie shown in Figure 12a. Locate the

wire harness with the Molex 6-pin connector.

Route wire harness out rear of blower, as shown

in figure 12 b. below.

3. Re-attach wire harnesses to capacitor with new

wire tie (supplied) in same location in front.

Install blower in hood:

1. The blower is attached to the hood using weld

studs provided on the mounting plate.

2. Figure 12c shows the weld studs in location B

for horizontal (rear) discharge. Attach four #1024 nuts to the weld studs. For vertical

discharge, attach nuts to studs at the top of the

mounting plate.

Figure 12c

Add wire tie

here

Wire

Harness

Blower Rear View

Figure 12b

4. Attach wire harness with Molex 6-pin connector

to housing as shown in Figure 12b with wire tie

(supplied).

3. Guide the motor mounting plate over the nuts

and tighten to secure the blower to the hood.

4. Attach two additional screws as shown in

Figure 12d.

Figure 12d

CAUTION:

Verify that the two additional screws in

Figure 12d are installed and properly

tightened before continuing.

Page 9

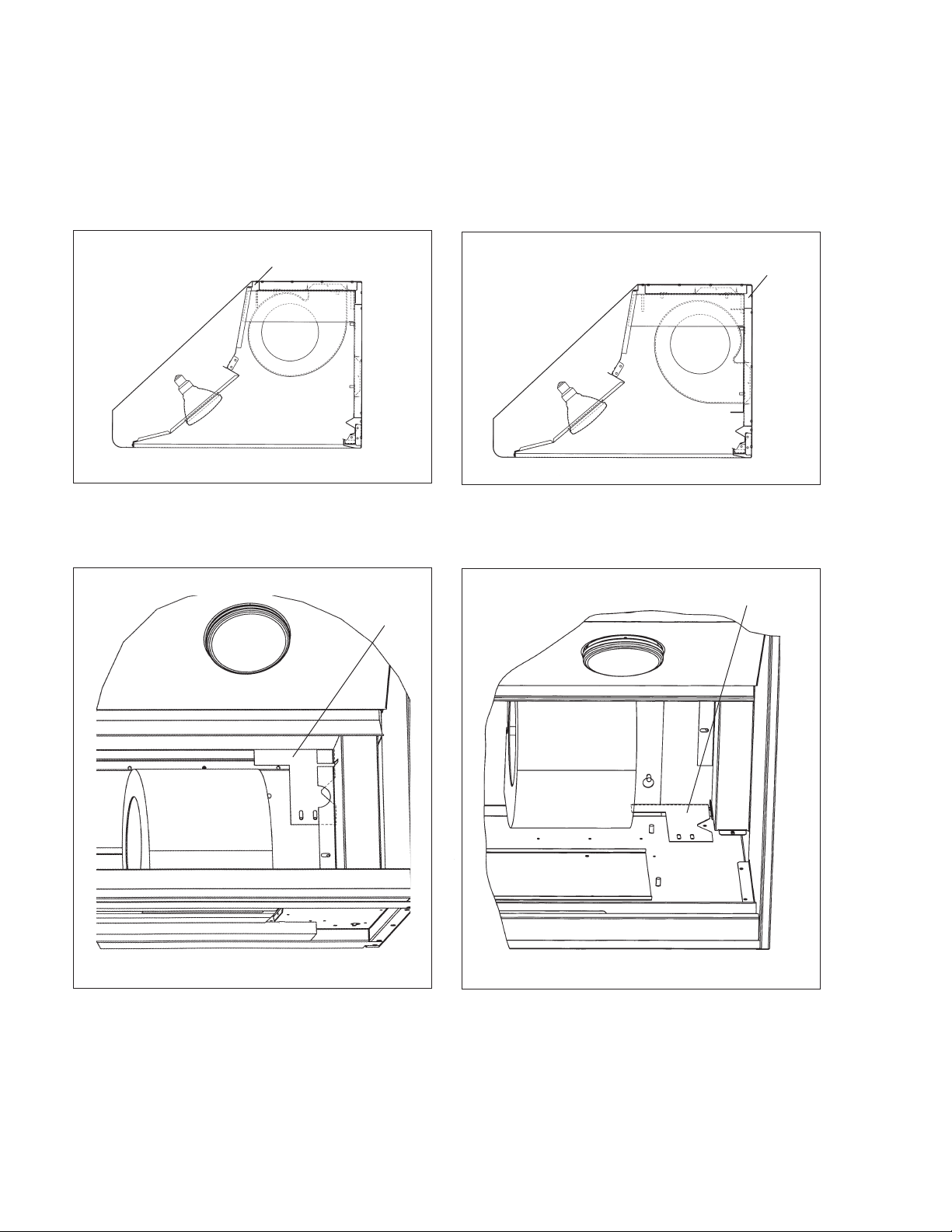

Wire Routing Instruction

Figure 12e

Vertical Discharge

Route wires here

Wire cover

Horizontal Discharge

Route wires here

Figure 12g

Wire cover

Figure 12f

Install wire cover per Figure 12F. The 30"-wide

model does not need a wire cover.

Figure 12h

Install wire cover per Figure 12H. The 30"-wide

model does not need a wire cover.

Page 10

Wiring the Hood with an

l

or

Wiring the Hood with a

Integral Motor

WARNING

Turn off electricity at the service panel

before wiring the unit. (See Safety

Instructions, Page 2).

1. Remove the j-box cover.

2. Connect the VTN1000Q molex plug connector to

the connector present inside the hood as shown

in Figure 13.

3. Install 1/2” conduit connector in j-box.

From Ventilat

From Control Pane

Figure 13

4. Run black, white, and green wires (#12 AWG) in

1/2" conduit from power supply to J-box.

5. Connect the power supply wires to the hood

wires in the following order: black to black, white

to white, and green wire to green ground screw

on chasis. Use spring type wire nuts supplied.

(Lost or missing wire nuts should only be

replaced with: Spring type wire nuts, rated for a

minimum of (2) # 18ga wires and maximum of

(4) #14ga wires, UL & CSA rated to 600V and

302 deg. F./150 deg. C).

6. Close J-box cover. Check to see that light bulbs

are secure in their sockets. Replace filters as

described in the Care & Use Manual. Turn power

on at service panel. Check operation of the

hood.

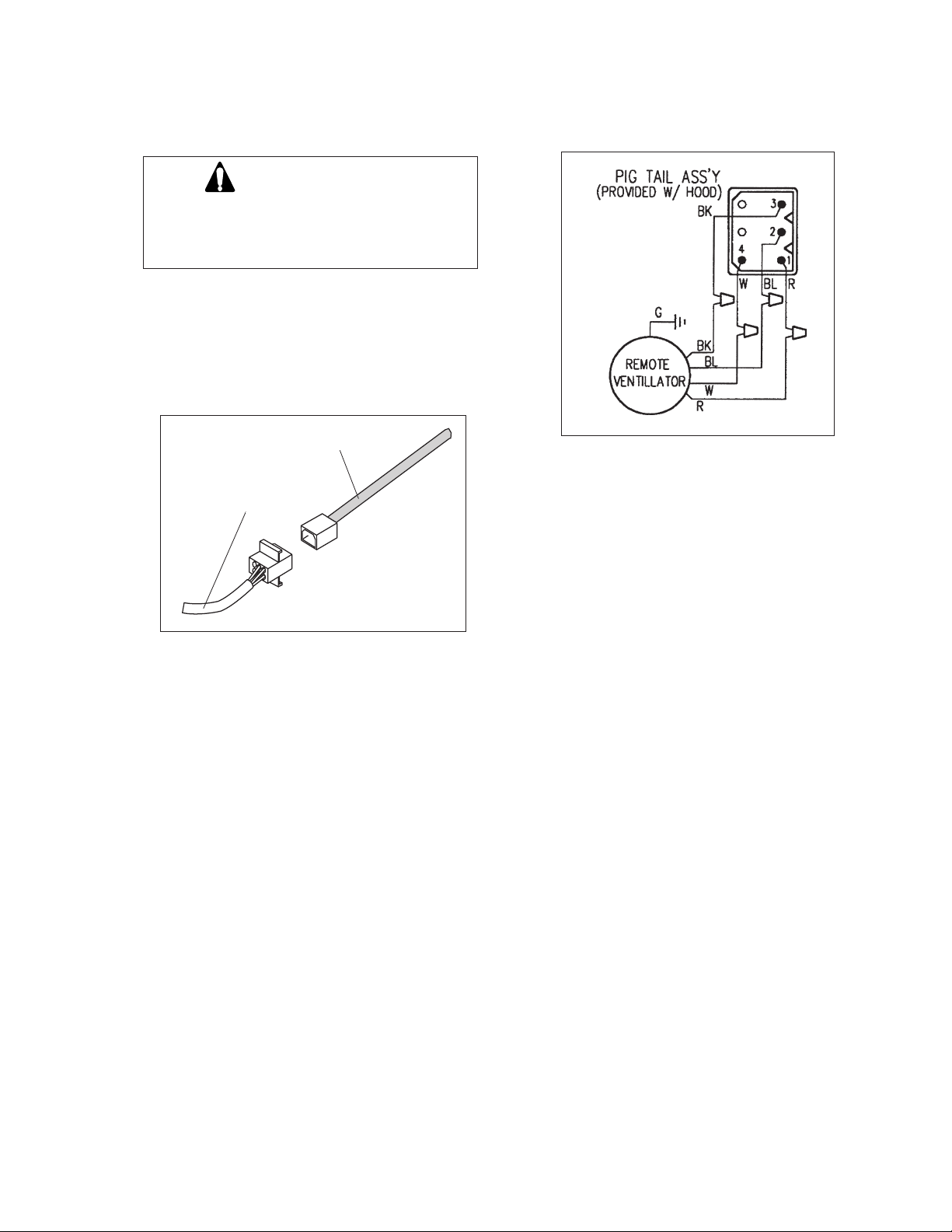

Remote Blower Installation

The PHZ hood models are designed to work with

VTR600R, VTR1000Q, and VTR1400Q remote

blowers. For installation instructions see the

instructions supplied with the blower unit.

Remote Blower:

Figure 14

1. Remove the J-box cover.

2. Install 1/2" conduit connectors.

3. Run black, white, and green wires (#12 AWG) in

1/2" conduit from power supply to j-box.

4. Connect the power supply wires to the hood

wires in the following order: black to black,

white to white, and greenwire to green ground

screw on chassis. Use spring type wire nuts

supplied. (Lost or missing wire nuts should

only be replaced with: Spring type wire nuts,

rated for a minimum of (2) # 18ga wires and

maximum of (4) #14ga wires, UL & CSA rated

to 600V and 302 deg. F./150 deg. C).

5. Connect the “pigtail” to the connector inside the

junction box.

6. Run five wires (#14 AWG) in 1/2" conduit from

the remote blower to the second conduit

connector.

7. Connect the remote ventilator to the pigtail

wires (Step 6) as per Figure 14. Connect the

remote blower green (ground) wire to the ground

screw in the junction box.

8. Close junction box cover. Check that all light

bulbs are secure in their sockets. Install filters.

Turn power on at service panel, and check

lights and blower operation per Care & Use

Manual.

Page 11

INSTRUCTIONS DE SÉCURITÉ

IMPORTANTES

AVERTISSEMENT

Fermer l'alimentation électrique au

panneau de service et verrouiller avant

d'effectuer le câblage de l'appareil.

EXIGENCE : 120 V AC, 60 Hz. 20 A

ATTENTION

À DES FINS DE VENTILATION

GÉNÉRALE SEULEMENT.

UTILISER POUR VENTILER DES

VAPEURS OU MATÉRIAUX

HASARDEUX OU EXPLOSIFS.

NE PAS

AVERTISSEMENT

POUR RÉDUIRE LES RISQUES

D'INCENDIE, DE CHOC ÉLECTRIQUE

OU DE BLESSURES, OBSERVER CE

QUI SUIT:

A. Utiliser cet appareil seulement de la

façon indiquée par le fabricant. S'il y a

des questions, communiquer avec le

fabricant. (service à la clientèle

Thermador : 800-735-4328.

B. Avant d'effectuer le service ou le

nettoyage de l'appareil, fermer

l'alimentation au panneau de service et

verrouiller. Ceci empêchera une mise

en circuit accidentelle. Si le panneau ne

peut être verrouillé, apposer une affiche

AVERTISSEMENT sur le panneau.

C. L'installation et le câblage électrique

doivent être effectués par une(des)

personne(s) qualifiée(s) conformément

aux codes et normes applicables,

incluant les cotes d'incendie pour la

construction.

D. Un débit d'air suffisant est nécessaire

pour une combustion appropriée et un

échappement des gaz par le tirage

(cheminée) des appareils à combustion

afin d'éviter un tirage arrière. Suivre les

directives du fabricant des appareils de

chauffage ainsi que les normes de

sécurité comme le National Fire

Protection Association (NFPA), the

American Society for Heating,

Refrigeration and Air Conditioning

Engineers (ASHRAE), et les codes

locaux ayant juridiction.

E. À cause de la dimension et du poids de

l'appareil, il est recommandé que deux

personnes effectuent l'installation.

F. Au moment de couper ou de percer un

mur ouu un plafond, ne pas endommager

le câblage électrique ou autre.

G. Pour évacuer l'air adéquatement,

s'assurer d'acheminer l'air vers

l'extérieur. Ne pas évacuer l'air dans des

espaces, des murs, plafonds, greniers,

espaces restreints ou garage.

ATTENTION :

Ventiler l'appareil vers l'extérieur

de l'édifice seulement

AVERTISSEMENT

POUR RÉDUIRE LE RISQUE

D'INCENDIE, UTILISER SEULEMENT

DES CONDUITS EN MÉTAL.

H. Installer cette hotte conformément aux

exigences spécifiées.

Page 2

Pièces comprises avec la hotte

• Hotte

• Ampoules halogènes 12 volts, installées

• Instructions d'installation et d'entretien et

utilisation.

• Carte d'enregistrement

• FIltres, 2, 3 ou 4 selon le modèle et la dimension

• Transition en métal et registre de tirage arrière

installés

• Attaches

• Adaptateur («tire-bouchon») de soufflerie à

distance

• Montant en bois pour supporter la hotte

• Serre-fils

Pièces non comprises

• Ruban à conduit

• Conduit 1/2 po

• 2 ampoules 175W PAR-38 ou

2 ampoules 250W PAR-40

• Ventilateur - la hotte peut être installée avec les

modèles de ventilateur VTN1000Q, VTR600R,

VTR1000Q et VTR1400Q.

• Couvercle de conduit optionnel, 6 po DC**US ou

12 po DCT**US de haut, disponible séparément

(** = largeur de la hotte.)

• Télécommande optionnelle (disponible, vendue

séparément)

À CONSIDÉRER AVANT L'INSTALLATION

1. Pour un échappement du débit d'air efficace,

utiliser un chemin droit ou ayant le moins de

coudes possible.

ATTENTION :

Ventiler l'appareil vers l'extérieur de

l'édifice seulement

2. Ne pas utiliser de conduit flexible.

3. Les installation où il FAIT FROID doivent avoir

un registre de tirage additionnel installé afin de

minimiser un débit d'air froid arrière et une

résistance thermique non métallique pour

minimiser la conduction des températures

extérieures faisant partie des conduits. Le

registre doit être du côté de l'air froid de la

résistance thermique. Cette dernière doit être

aussi près que possible de l'endroit où le

conduit entre dans la portion chauffée de la

maison.

4. La hauteur de l'installation de la hotte au-dessus

de la plaque de cuisson est selon la préférence

de l'utilisateur. Plus la hotte est basse audessus de la plaque de cuisson, plus il sera

facile de capteur les odeurs de cuisson, graisse

et fumée. Cette hotte est approuvée pour les

installations aussi basses que 24 po* audessus de la plaque de cuisson. Une

installation basse peut causer des inconvénients

pour les grandes personnes ou les grosses

casseroles. Par conséquent, Thermador

recommande que la hotte soit installée de 30 à

36 po au-dessus de la plaque de cuisson.

* Pour les installations de gril extérieur, Thermador

recommande un dégagement minimum de 30 po

et soufflerie à distance seulement (VTR1000Q

ou VTR 1400Q)

5. Les souffleries à distance requièrent une

installation à 5 fils.

6. Air d'appoint : les codes de construction locaux

peuvent exiger l'utilisation de système d'air

d'appoint au moment d'utiliser des systèmes de

ventilation à conduit plus grand que le

mouvement d'air CFM spécifié. Le CFM spécifié

varie d'un endroit à l'autre. Consulter un

professionnel HVAC concernant les exigences

spécifiques dans la région.

7. Consulter les instructions d’installation de la

télécommande, au besoin.

Page 3

Installation de l'appareil

La hotte peut être installée au mur ou suspendue d'une

armoire. Une décharge verticale ou horizontale est

possible avec une ou l'autre des méthodes.

Direction de la décharge: La hotte est expédiée prête

pour une décharge verticale. Pour passer en position

horizontale, simplement déplacer le couvercle de

décharge, illustré à la figure 1, vers le haut de la hotte.

La plaque est maintenue en place par 4 vis.

Assemblage de la transition: La transition fournie

se fixe sur le haut ou l'arrière de la hotte selon la direction

de la décharge.

1. Aligner les trous de fixation à la base de la

transition avec les trous de fixation sur le rebord

Cette ouverture

est couverte pour

la décharge

horizontale

1/2 po situé au haut ou à l'arrière de la hotte

selon la direction de la décharge.

2. Attacher la transition à la hotte à l'aide de deux

(2) vis à métal n° 8 x 3/8 po (comprises avec la

hotte).

3. Sceller la connexion entre la transition et la

hotte avec du ruban à conduit.

4. Enlever le ruban qui maintient le registre fermé.

Voir figure 1b pour les dimensions hors tout de

la hotte.

Figure 1a. Direction de la décharge

Dimensión A

No. modèle

PH30ZS

PH36ZS

PH42ZS

PH48ZS

PH54ZS

Figure 1b : Dimensions hors tout

Dimensión

30 po

36 po

42 po

48 po

54 po

Cette ouverture est

couverte pour la

décharge verticale

A

18 po

27 po

Page 4

Height

Above

p

Cooktop

Centerline

Drywall

Wall

Studs

Screws

(2 EA.

#14 x 3")

Desired

Cooktop

Height

+ 15 1/2 "

To Cooktop

Surface

Remarque : Lire les instructions

d’installation de la télécommande avant de

continuer si cet accessoire est utilisé.

Installation murale

La hauteur de l'installation de la hotte est selon les

préférences de l'utilisateur. La figure 2 illustre une

installation typique avec deux couvercles de conduit.

Les couvercles de conduit 6 po et/ou 12 po

(accessoires) sont utilisés pour remplir l'espace

entre la hotte et le plafond.

La hauteur de l'installation montrée à la figure 2 est

de 36 po. Un couvercle de conduit 6 po a été utilisé

dans cette installation. Ajouter ou enlever des

couvercles de conduit pour accomoder la hauteur de

plafond et la hauteur désirée de la hotte.

1. Une fois la hauteur désirée établie, tirer une

ligne horizontale à une distance au-dessus de la

plaque de cuisson égale à la hauteur désirée de

l'installation de la hotte plus 15,5 po. Cette ligne

est l'emplacement du montant en bois expédié

ave la hotte.

2. Repérer la ligne centrale de la plaque de

cuisson. Tirer une ligne verticale le long de cette

ligne centrale jusqu'à la ligne horizontale,

dessinée à l'étape 1.

3. La hotte est fixée au mur à l'aide du montant en

bois expédié avec la hotte. Enlever la fixation de

la hotte en enlevant les deux vis d'expédition.

Marquer la ligne centrale du montant.

4. Repérer un montant d'un côté ou de l'autre de la

ligne centrale de la plaque de cuisson pour

utiliser avec le montant en bois tel qu'il est

illustré à la figure 3.

5. Aligner le haut du montant en bois le long de la

ligne horizontale dessinée à l'étape 1. Aligner les

lignes centrales du montant en bois et de la

plaque de cuisson.

6. Percer un trou 1/8 po de 3 po de profondeur

dans le montant à travers le montant en bois, le

placoplâtre et dans le montant du mur.

7. Utiliser 2 ou 3 vis (n° 14 x 3 po) pour fixer la

fixation au mur, comme à la figure 3. Pour le

support des hottes plus longues, utiliser trois

montants. Fraiser les têtes pour empêcher

l'interférence avec la hotte.

8. Sur le montant en bois, marquer les

emplacements utilisés pour suspendre la hotte

selon la figure 4 (page suivante).

9. Percer un trou de 1/8 po à travers le montant en

bois et le placoplâtre. Ces vis (n° 8 x 5/8 po)

Couvercle de

6"

Duct Cover

conduit 6 po

24 po

24"

18 po

18"

Plafond

Standard

standard 8

8 ft Ceiling

pi (96 po)

(96")

Figure 2

Placôplatre

Hauteur

au-dessus

Cookto

plaque de

cuisson

Vis (2 de

chaque, n°

14x 3 po)

Figure 3

Hood Height (36")

Hauteur de hotte (36 po)

Cuisinière

Standard

36" high

standard 36 po

Range

de haut

Ligne centrale

plaque de

cuisson

Montants

muraux

Hauteur

désirée

plaque de

cuisson

+ 15 1/2

po

Vers surface

de plaque de

cuisson

n'ont pas besoin d'aller jusqu'aux montants.

10. Percer un trou de 1/16 po pour les deux vis (n° 8

x 5/8 po) dans le montant en bois en laissant 1/

4 po de chaque vis exposé pour suspendre la

hotte.

Page 5

Placôplatre

Ligne centrale

plaque de cuisson

11. Direction de la décharge : La décharge horizontale

requiert une découpe murale, comme à la figure 5,

pour assurer un dégagement pour la transition.

L'emplaement de la découpe est déterminé par la

hauteur d'installation de la hotte.

Vis

(2 ch. N° 14

x 3 po)

MODÈLE A

PHH30ZS 13 1/16 PO

PH36ZS 16

PH42ZS 19

PH48ZS 22

PH54ZS 25

Figure 4

1

1

1

1

Mesure A

/16 PO

/16 PO

/16 PO

/16 PO

10-1/4 po

Ligne centrale

transition

10-1/2 po

Figure 6

La transition fournie avec la hotte se branche sur un

conduit rond 10 po standard. La figure 6 montre la

transition branchée sur la décharge horizontale.

Ligne centrale

transition

-13

5

mur

/16 po

Placôplatre

23 po

12-1/2 po

2-3/4 po

Ligne

centrale

plaque de

cuisson

Figure 5

Emplacement

base de la hotte

Remarque : La ligne pointillée indique la découpe

nécessaire pour le dégagement de la transition.

10-1/4 po

18 po

Figure 7

La figure 7 montre la hotte configurée pour une

décharge verticale. Les installations utilisant ce type

de méthode requièrent une découpe dans le plafond

pour accomoder un conduit de 10 po et un conduit

de 12 po pour l'alimentation de l'appareil.

Des couvercles de conduits, vendus séparément,

sont disponibles pour couvrir l'espace entre le haut

de la hotte et le plafond. (Voir page 4).

Page 6

12. Avant de suspendre la hotte,

installer la transition selon la

figure 6. Fixer la transition avec

2 vis (n° 8 x 3/8 po, à métal,

fournies) et apposer du ruban

selon le code. Remarque : les

vis ne doivent pas nuire au

fonctionnement du registre

13. Déposer la hotte sur les vis

dans la fixation en bois. Utiliser

les trous marqués «I» à la

figure 8. S’assurer que les

fixations en bois s’ajustent

dans le retrait au dos de la

hotte.

14. Retirer les trous à estamper.

15. Serrer les vis dans les trous.

Vérifier si la hotte est de

niveau, régler au besoin.

16. Depuis l’intérieur de la hotte,

insérer les vis (n° 8 x 5/8 po)

par les trous de la hotte dans

les fixations en bois. Voir les

trous marqués J à la figure 8.

17. Connecter conduit

supplémentaire.

J

I

Figure 8

Remarque sur l'installation : Si les montants muraux sont à moins de

8 po de la ligne centrale, couper le montant en angle pour éviter toute

interférence.

I

Assemblage et installation des couvercles de conduit :

Des couvercles de conduit

optionnels montrés à la figure 9

peuvent être utilisés pour combler

l'espace entre la hotte et le

plafond. Des couvercles de

conduit 6 po ou 12 po sont

disponibles et peuvent être

commandés séparément.

1. Si plusieurs couvercles de

conduit sont utilisés,

connecteur les pièces

ensemble à l'aide de vis à

métal fournies avec le

couvercle de conduit.

2. Fixer le(s) conduit(s) de

couvercle à la hotte à l'aide

de vis à métal, comme à la

figure 9.

3. Depuis l'intérieur de la hotte,

insérer les vis (n° 8 x 5/8 po

fournies) par les trous L, une

de chaque côté et quatre le

long du devant, dans le bas

de l'armoire.

L

L

Vis n° 8 x

3/8 po

(nombre

dépendant

du format

de la hotte)

L

Figure 9

Page 7

Installation de l'armoire

La hotte peut être installée

sous l'armoire en supportant la

hotte par le haut.

Remarque : La structure de

l'armoire doit être jointe aux

montants du mur afin de

supporter le poids de la

hotte.

La figure 10 montre les quatre

trous de vis (K) utilisés pour

installer la hotte au bas de

l’armoire.

S’assurer que les deux

pastilles enlevables ont été

retirées.

1. À la base de l’armoire,

percer un trou de 1/8 po

(voir dimension A à la figure

10 et dans le tableau).

Visser quatre vis n° 10 x 1

po (fournies avec la hotte),

laissant 1/4 po exposé.

po

K

{

L

L

1-9/16 po

16

/

-1

7

Figure 10 : Emplacement du trou et de la vis.

A : emplacement du trou

23 po

L

K

Remarque : Cette figure montre les

emplacements de trous et de vis

seulement. Voir figure 1b, page 4 pour

les dimensions hors tout de la hotte.

2. Si la hotte est installée

pour une décharge

verticale, utiliser la figure 11

pour créer les trous de

dégagement pour le

passage de la transition et

du conduit. La dimension B

de la figure 11 dépend du

modèle de la hotte à être

installée et peut être située

dans le tableau à droite.

(Voir dimension B à la

figure 11 et au tableau)

3. Pour la décharge

horizontale, utiliser la figure

5 pour la géométrie de la

découpe requise pour le

dégagement de la

transition.

4. Suspendre la hotte sur les

vis et visser de façon

sécuritaire.

5. Depuis l’intérieur de la

hotte, insérer les vis

fournies. Percer par les

trous (utiliser les vis n° 8 x

5/8 po fournies), une de

chaque côté et quatre le

long du devant, dans le bas

de l’armoire. Voir les trous

de vis étiquetées «L»,

figure 10.

Dimensions du trou de la ligne centrale pour les

figures 10 et 11.

Modèle A (Fig 10) B (Fig 11)

Trou Trou de conduit

PH30ZS 29-1/16 po 13-7/16 po

PH36ZS 35-1/16 po 16-7/16 po

PH42ZS 41-1/16 po 19-7/16 po

PH48ZS 47-1/16 po 22-7/16 po

PH54ZS 53-1/16 po 25-7/16 po

1 -1/8 po

Mur

Ligne centrale

plaque de cuisson

Vue de la découpe de l'armoire

Remarque : Cette figure montre les emplacements de conduit et de transition

seulement. Voir figure 1b, page 4, pour les dimensions hors tout de la hotte.

Figure 11 : emplacement du conduit et de la transition

23 po

3 -3/16 po

B

7 7/8 po

2 3/8 po

Trous de dégagement

5/8 po dia. pour conduit

1/2 po vers boîte de jonction

2 -3/8 po

1- 7/8 po

Page 8

Installation de la soufflerie intégrée VTN1000Q

La hotte peut être installée avec la soufflerie

VTN1000Q.

Préparation de la soufflerie

Fixations

d'expédition

Attache

Capaciteur

Vue avant de la soufflerie

Figure 12a

1. Enlever les attaches d'expédition gauche et

droite et jeter.

2. Couper l'attache de fil montrée à la figure 12a.

Repérer le faisceau de câblage avec le

connecteur à 6 broches Molex. Acheminer le

faisceau de câblage par l’arrière de la soufflerie,

comme à la figure 12b, ci-dessous.

3. Rattacher le faisceau de fils capaciteur avec la

nouvelle attache de fil (fournie) au même endroit

à l'avant.

Installer la soufflerie dans la

hotte:

1. La soufflerie est fixée à la hotte à l'aide des

montants soudés fournis avec la plaque de

fixation.

2. La figure 12c montre les montants soudés à

l'endroit B pour la décharge (arrière) horizontale.

Mettre 4 écrous n° 10 x 24 sur les montants

soudés. Pour la décharge verticale, mettre les

écrous sur les montants au haut de la plaque de

fixation.

Figure 12c

3. Guider la plaque de fixation du moteur sur les

écrous et serrer de façon sécuritaire la soufflerie

à la hotte.

4. Fixer deux vis additionnelles, figure 12d.

Ajouter

Faisceau

de

câblage

Vue arrière de la soufflerie

Figure 12b

4. Attacher le faisceau de fils avec connecteur

Molex à 6 broches au boîtier comme à la figure

12b avec une attache de fil (fournie).

attache ici

Assemblage

ventilateur

Vis

additionnelles

Figure 12d

ATTENTION:

S’assurer que les deux vis additionnelles,

figure 12d, sont installées et adéquatement

serrées avant de continuer.

Page 9

Instructions de câblage

Figure 12e

Décharge verticale

Acheminer fil ici

Couvercle

de fil

Décharge horizontale

Acheminer fil ici

Figure 12g

Couvercle

de fil

Figure 12f

Installer le couvercle comme la figure 12F. Le

modèle 30 po de large n'a pas besoin de couvercle

de fil.

Figure 12h

Installer le couvercle comme à la figure 12H. Le

modèle 30 po de large n'a pas besoin de couvercle

de fil.

Page 10

Câblage de la hotte avec

l

or

Câblage de la hotte avec

moteur intégré

AVERTISSEMENT

Fermer l'électricité au panneau de service

avant d'effectuer le câblage de l'appareil.

(Voir instructions de sécurité, page 2).

1. Enlever le couvercle de la boîte de jonction.

2. Brancher le connecteur à fiche Molex du

VTN1000Q sur le connecteur à l'intérieur de la

hotte comme à la figure 13.

3. Installer un connecteur de conduit 1/2 po dans la

boîte de jonction.

Depuis le ventilateur

From Ventilat

Depuis le panneau

From Control Pane

de contrôle

Figure 13

4. Acheminer les fils noir, blanc et vert (n° 12

AWG) dans le conduit 1/2 po depuis

l'alimentation à la boîte de jonction.

5. Brancher les fils d'alimentation sur les fils de la

hotte dans l'ordre suivant : noir avec noir, blanc

avec blanc et vert sur la vis de mise à la terre

verte sur le châssis. Utiliser des écrous à

ailettes de type à ressort. (Des écrous

manquants ou perdus doivent être remplacés

seulement par : écrou métallique de type à

ressort, coté pour un minimum de (2) fils n°

18ga et maximum de (4) fils n° 14ga, UL et

ACNOR coté à 600 V et 302 deg.

6. Fermer le couvercle de la boîte de jonction.

Vérifier que toutes les ampoules sont

sécuritaires dans leurs douilles. Replacer les

filtres comme il est décrit dans le guide

d'entretien et d'utilisation. Mettre en circuit au

panneau de service. Vérifier le fonctionnement

de la hotte.

Installation de la soufflerie à distance

Les hottes PHZ sont conçues pour fonctionner avec

les souffleries VTR600R, VTR1000Q et VTR1400Q

à distance. Pour les instructions d'installation, voir

les instructions fournies avec l'appareil de la

soufflerie.

une soufflerie à distance :

Ass. tire bouchon

(fourni avec hotte)

Ventilateur

à distance

Figure 14

1. Enlever le couvercle de la boîte de jonction.

2. Installer un connecteur de conduit 1/2 po.

3. Acheminer les fils noir, blanc et vert (n° 12

AWG) dans le conduit 1/2 po depuis

l'alimentation de la boîte de jonction.

4. Brancher les fils d'alimentation sur les fils de la

hotte comme suit : noir avec noir, blanc avec

blanc et vert sur la vis de mise à la terre verte

sur le châssis. Utiliser des écrous à ailettes de

type à ressort. (Des écrous manquants ou

perdus doivent être remplacés seulement par :

écrou métallique de type à ressort, coté pour un

minimum de (2) fils n° 18ga et maximum de (4)

fils n° 14ga, UL et ACNOR coté à 600 V et 302

deg.

5. Brancher le «tire-bouchon» sur le connecteur à

l'intérieur de la boîte de jonction.

6. Acheminer les 5 fils (n° 14 AWG) dans le

conduit 1/2 po depuis la soufflerie à distance au

second connecteur de conduit.

7. Brancher le ventilateur à distance sur les fils

«tire-bouchon» (étape 6) comme à la figure 14

en utilisant les écrous de fils fournis. Brancher le

fil vert (mise à la terre) de la soufflerie à distance

sur la vis de mise à la terre dans la boîte de

jonction.

8. Fermer le couvercle de la boîte de jonction.

Vérifier que toutes les ampoules sont

sécuritaires dans leurs douilles. Installer les

filtres. Mettre en circuit au panneau de service et

vérifier le fonctionnement des ampoules et de la

soufflerie à distance comme il est indiqué dans

le guide d'utilisation et d'entretien.

Page 11

INSTRUCCIONES IMPORTANTES DE

SEGURIDAD

ATENCIÓN

Apague el circuito de alimentación en el

panel de servicio y bloquee el panel antes

de instalar este aparato.

REQUERIMIENTO: 120 VAC, 60 Hz. 20 A

CUIDADO

SÓLO PARA USO DE VENTILACIÓN

GENERAL.

EXHAUSTAR MATERIALES

PELIGROSOS O EXPLOSIVOS O

VAPOR.

PARA REDUCIR EL RIESGO DE UN

INCENDIO, DESCARGA ELÉCTRICA O

HERIDAS A PERSONAS, OBSERVE LO

SIGUIENTE:

A. Utilice esta unidad sólo en la forma que

el fabricante la diseñó. Si tiene alguna

pregunta, contacte al fabricante.

(Servicio a Clientes de Thermador al

800/735-4328).

B. Antes de dar servicio o limpiar la unidad,

apague la corriente en el panel de

servicio y bloquee el panel de servicio.

Esto evitará que se prenda la corriente

accidentalmente. Cuando no es posible

bloquear el panel de servicio, coloque un

aviso bien visible, tal como una etiqueta

al panel de servicio.

NO LO UTILICE PARA

ATENCIÓN

C. Una persona calificada debe realizar

todos los trabajos de instalación y

conexión de acuerdo con todas las

normas y códigos aplicables, incluyendo

los códigos de construcción e incendios.

D. Se necesita suficiente aire de relleno

para una combustión y exhaustación

correcta de los gases a través del

conducto (chimenea) del equipo

quemador de combustible para prevenir

una contracorriente. Siga las

instrucciones del fabricante del equipo

de calentamiento y los estándares de

seguridad como aquellos publicados por

la Asociación Nacional de Protección

contra Incendios (NFPA), la Sociedad

Americana para Ingenieros de

Calefacción, Refrigeración y

Acondicionamiento de Aire (ASHRAE) y

las autoridades locales.

E. Debido al tamaño y peso de esta unidad

se recomienda tener a dos instaladores.

F. Cuando perfore la pared o el techo,

tenga cuidado de no dañar los cables

eléctricos u otras conexiones ocultas.

G. Para exhaustar el aire correctamente,

asegúrese de conducir el aire hacia

afuera. No ventile el aire de escape a

espacios dentro de paredes, techos,

áticos, espacios donde debe gatear o

garajes.

ATENCIÓN

PARA REDUCIR EL RIESGO DE UN

INCENDIO, SÓLO UTILICE

CONDUCTOS DE METAL.

CUIDADO:

Ventile la unidad hacia afuera del edificio.

H. Instale esta campana de acuerdo con todos los

requerimientos especificados.

Page 2

Partes Incluidas con su Campana Partes No Incluidas con su Campana

• Toldo de la Campana

• Focos de halógeno de 12 volts, instalados

• Lámparas de calentamiento de 175 W PAR-38,

instaladas

• Instrucciones de Instalación/Cuidado y Uso

• Tarjeta de Registro

• Filtros, 2, 3 o 4 dependiendo del modelo y

tamaño

• Transición Metálica con amortiguador de Contracorriente instalado

• Sujetadores

• Adaptador de Soplante Remoto ("rabillo")

• Tira de Madera para el Soporte de la Campana

• Tuercas para Cables

• Cinta de Electricista

• Conducto de 1/2"

• Ventilador - Se puede instalar la campana con

los modelos de ventilador VTN1000Q, VTR600R,

VTR1000Q, y VTR1400Q.

• Cubierta opcional para el conducto, altura 6"

DC**US o 12" DCT**US, se tiene que comprar

por separado. (** = ancho de la campana).

• Control Remoto Opcional (se debe pedir por

separado)

CONSIDERACIONES ANTES DE INSTALAR LA CAMPANA

1. Para tener el escape de aire más eficiente,

utilice un conducto recto o la menor cantidad de

codos posibles.

CUIDADO:

Ventile la unidad hacia afuera del edificio.

2. No utilice conductos flexibles.

3. Las instalaciones en CLIMA FRÍO debe contar

con un amortiguador extra para la

contracorriente para minimizar el flujo de retorno

del aire fría y una barrera térmica no metálica

para minimizar la conducción de las

temperaturas externas como parte del trabajo

de conductos. El amortiguador debe colocarse

en el lado del aire fria de la barrera térmica. La

barrera debe estar lo más cerca posible al lugar

donde los conductos entran en la parte caliente

de la casa.

4. Es cuestión de preferencia del usuario a qué

altura desea instalar la campana arriba de la

estufa. Entre más baja queda la campana arriba

de la estufa, más eficiente capta los olores,

grasa y humo de los alimentos cocinados. Esta

campana ha sido aprobada para instalaciones

tan bajas como 24 pulgadas* (61 cm) arriba de

la estufa. La altura más baja puede ser

inconveniente para personas altas y ollas

Por lo tanto, Thermador recomienda instalar la

campana a una distancia de 30 a 36 pulgadas

(76 a 91 cm) arriba de la mesa de trabajo.

* Para instalaciones de asado en el interior,

Thermador recomienda una altura mínima de

30" (76 cm) y sólo sopladores remotos

(VTR1000Q o VTR1400Q).

5. Los sopladores remotos requieren de una

instalación con cinco hilos.

6. Aire de Relleno: Tal vez los códigos locales

para regular las construcciones requieren el uso

de sistemas de aire de relleno cuando se están

usando sistemas de ventilación con conductos

más grandes que los CFM del movimiento de

aire especificados. Los CFM especificados

varían de lugar a lugar. Consulte a su experto

HVAC para los requerimientos específicos en

su área.

7. Consulte las instrucciones de instalación del

control remoto si aplica.

Page 3

Instalación del Aparato

Se puede montar la campana en una pared o en

forma suspendida de un gabinete. Con cualquiera

de estos dos métodos se puede instalar la

descarga vertical u horizontal.

Dirección de la Descarga: La campana viene

preparada para la descarga vertical. Para cambiar a

la descarga horizontal, simplemente cambie la

cubierta de descarga que se muestra en la Figura 1

a la parte superior de la campana. Cuatro tornillo

mantienen en su lugar a la placa.

Conjunto de Transición: La transición incluida es

instalada en la parte superior o trasera de la

campana dependiendo de la dirección de descarga.

Se cubre esta

abertura para la

descarga

horizontal.

1. Alinee los orificios de montaje en la base de

transición con los orificios de montaje en la

brida de 1/2" que se localiza en la parte

superior o trasera de la campana dependiendo

de la dirección de descarga.

2. Fije la transición a la campana utilizando dos

(2) tornillos de chapa #8 x 3/8 (incluidos con la

campana).

3. Selle la conexión entre la transición y la

campana con cinta para conductos.

4. Quite la cinta que mantiene cerrado el

amortiguador.

Vea la Figura 1b para las dimensiones

generales de la campana.

Figura 1a: Dirección de descarga

Dimensión A

Numero del Modelo

PH30ZS

PH36ZS

PH42ZS

PH48ZS

PH54ZS

Figura 1b: Dimensiones generales

Dimensión

30"

36"

42"

48"

54"

Se cubre esta

abertura para la

decarga vertical.

A

.

18"

27"

Page 4

p

Nota: Lea las instrucciones de instalación

del control remoto antes de seguir utilizando

este accesorio.

Instalación con Montaje en

Pared

Cubierta de

6"

Duct Cover

conducto de 6"

24"

18"

Es cuestión de preferencia del usuario a qué altura

desea instalar la campana. La Figura 2 muestra una

instalación típica de la campana con dos cubiertas

de conducto. Se usan las cubiertas de conductos

de 6" y 12" para llenar el espacio entre la campana

y el techo.

La altura de instalación que se muestra enla Figura

2 es de 36 pulgadas (91 cm). Se utilizó una

cubierta de conducto de 6" en esta instalación.

Agregue o quite cubiertas de conductos como sea

apropiado para acomodar la altura de techo y la

altura deseada de la campana. La campana soporta

la estructura de la cubierta del conducto.

1. Después de haber determinado la altura de la

instalación de la campana, dibuje una línea

horizontal a una distancia arriba de la estufa

igual a la altura deseada de instalación de la

campana más 15.5" (39.4 cm). Esta línea es el

lugar de montaje del soporte de madera que

viene incluido con la campana.

2. Encuentre la línea central de la estufa. Dibuje

una línea vertical a lo largo de la línea central

hasta llegar a la línea horizontal dibujada en el

paso 1.

3. Se fija la campana a la pared usando un

soporte de madera que viene incluido. Quite el

soporte de la campana quitando dos tornillos.

Marque la línea de centro del soporte.

4. Localice un resalto en cada lado de la línea

central de la estufa que se usa para montar el

soporte de madera como se indica en la Figura

3.

5. Alinee la parte superior del soporte de madera a

lo largo de la línea horizontal dibujada en el

Paso 1. Alinee las líneas centrales del soporte

y de la estufa.

6. Perfore dos orificios de 1/8" a una profundidad

de 3" por resalto a través del soporte de

madera, el muro de piedra en seco y en los

resaltos de la pared.

7. Use cuatro 2 o 3 tornillos de campana (#14x3",

vienen incluidos) para fijar el soporte a la pared

como se indica en la Figura 3. Para soportar

las campanas más largas, PH48ZS y PH54ZS,

use seis tornillos de madera y tres resaltos,

Avellana las cabezas para evitar la interferencia

con la campana.

8. Marque los lugares en el soporte de madera

Altura al

Standard

techo

8 ft Ceiling

estándar de 8

(96")

pies (96")

(244 cm)

Figura 2

Muro seco

Drywall

Altura

Height

arriba

Above

Cookto

de la

estufa

Screws

Tornillos

(2 EA.

(2 cada

#14 x 3")

#14X3)

Figura 3

Altura de la

Hood Height (36")

campana (36"")

Rango

Standard

estándar

36" high

36" de

Range

altura

Cooktop

Línea central

Centerline

de la estufa

Resalto

Wall

de

Studs

pared

Altura

Desired

deseada

Cooktop

de la

Height

estufa

+ 15 1/2 "

+15-½"

To Cooktop

A la superficie

Surface

de la estufa

que se usan para colgar la campana como se

indica en la Figura 4 (página siguiente).

9. Perfore un orificio roscado de 1/8" a través del

soporte de madera y el muro de piedra en seco.

Estos tornillos (#8 x 5/8") no deben entrar en

los resaltos.

10. Perfore un agujero de 1/16" para los 2 tornillos

Page 5

Muro seco

Tornillos cada

2 #14 x 3"

Línea central de la estufa

11. Dirección de Descarga: La descarga horizontal

requiere un recorte de la pared como se indica

en la Figura 5, para proporcionar un espacio

libre para la transición. El lugar del recorte se

determina por la altura de instalación de la

campana.

Medición A

MODELO A

PHH30ZS 13-1/16"

PH36ZS 16

PH42ZS 19

PH48ZS 22

PH54ZS 25

Figura 4

Muro seco

-1

-1

-1

-1

/16"

/16"

/16"

/16"

Línea central de la

transición

Figura 6

La transición incluida con la campana se conecta al

conducto redondo estándar de 10 pulgadas. La

Figura 6 muestra la transición conectada para la

descarga horizontal.

Línea central

de la transición

Muro

Línea Central

de la Estufa

Figura 5

Base de la

Campana

Nota: La línea punteada indica el recorte que se

necesita para el espacio libre de la transición.

Figura 7

La Figura 7 muestra la campana configurada para

una descarga vertical. Las instalaciones que usan

este tipo de método requieren un recorte en el

techo para acomodar el conducto de 10" y el

conducto de alimentación de ½" a la unidad.

Las cubiertas de conducto que se venden por

separado, están disponibles para cubrir el espacio

entre la parte superior de la campana y el techo.

(Vea la Página 4).

Page 6

12. Antes de colgar la campana, instale la

transición según la Fig. 6. Fije la transición con

2 tornillos (tornillo autorroscante o de plancha

#8 x 3/8, incluidos) y encíntela de acuerdo al

código. Nota: los tornillos no deben interferir

con la operación del regulador de tiro.

13. Coloque la campana sobre los tornillos en el

soporte de madera. Use los orificios marcados

“I” en la Figura 8. Asegúrese que el soporte de

madera quepa en la ranura en la parte trasera

de la campana.

14. Quite los agujeros ciegos.

15. Apriete los tornillos en los orificios. Revise que

la campana esté nivelada y ajústela si es

necesario.

16. Fije los tornillos (#8 x 5/8") a través de los

agujeros en la campana al soporte de madera

desde el interior de la campana. Vea los

agujeros marcados J en la Figura 8.

17. Conecte el conducto adicional.

J

I

I

Figura 8

Nota de Instalación: Cuando los soportes de pared

quedan a una distancia de 8" de la línea de centro,

corte el soporte en un ángulo para evitar cualquier

interferencia.

Montaje e Instalación de las Cubiertas de

Conducto:

Se pueden usar las cubiertas de conducto

opcionales que se indican en la Figura 9 para llenar

el espacio entre la campana y el techo en

instalaciones con montaje en pared. Están

disponibles cubiertas de conducto con una altura de

6" y 12" (15 y 13 cm) y se pueden pedir por

separado.

1. Cuando se usan múltiples cubiertas de

conducto, conecte las piezas juntas usando

tornillos de hojalata que vienen incluidos con

las cubiertas de conducto.

2. Fije la cubierta(s) de conducto a la campana

usando los tornillos de hojalata como se indica

en la Figura 9.

3. Desde el interior de la campana, atornille a

través de los agujeros L (#8 x 5/8", incluidos)

en cada lado y cuatro a lo largo del frente,

hasta el fondo de la cubierta de conducto.

Figura 9

Tornillo #8 x

L

L

3/8"

(número

depende del

tamaño de

la campana)

L

Page 7

Instalación con Gabinete

Se puede instalar la campana

abajo de un gabinete que

soporte la campana desde

arriba.

Nota: EL gabinete debe estar

unido estructuralmente a los

resaltos de pared para

soportar el peso de la

campana.

La Figura 10 muestra los cuatro

agujeros (K) de tornillo que se

usan para fijar la campana a la

parte inferior del gabinete.

Asegurase de que las dos tapas

fueron quitadas.

1. Perfore agujeros para rosca

interior de 1/8" en la base

del gabinete (Vea la

dimensión A en la Figura 10

y en la Tabla). Fije cuatro

tornillos #10 x 1" (vienen

incluidos con la campana),

dejando ¼” expuesto.

2. Cuando se instala la

campana para la descarga

vertical, use la Figura 11

para crear los orificios de

espacio libre para el paso de

la transición y del conducto.

(See dimension B in Figure

11 and in Table).

3. Para la descarga horizontal,

use la Figura 5 para la

geometría del recorte que se

requiere para el espacio libre

de la transición.

4. Cuelgue la campana desde

los tornillos y aprietela bien.

5. Inserte los tornillos que se

incluyen desde la parte

interna de la campana.

Perfore agujeros (use los

tornillos de #8 x 5/8" que se

incluyen), en la parte inferior

del gabinete, uno en cada

lado y cuatro a lo largo del

frente. Vea los agujeros

para tornillos marcados “L”

en la Figura 10.

1-9/16"

16

/

-1

7

Figura 10: Ubicaciones de los agujeros para rosca interna y para los tornillos

K

{

"

L

L

Nota: Esta figura muestra sólo las ubicaciones

del agujero para rosca interna y para el tornillo.

Vea la Figura 1b, página 4 para las dimensiones

generales de la campana.

A: Ubicaciones de los agujeros

para rosca interna

23"

L

K

Dimensiones del agujero de la línea de centro

para las Figuras 10 y 11

Modelo A (Fig 10) B (Fig 11)

Agujeros para rosca interna Agujero del conducto

7 7/8"

2 3/8"

-7

/16"

-7

/16"

-7

/16"

-7

/16"

2 -3/8"

1- 7/8"

PH30ZS 29-1/16"13

PH36ZS 35-1/16" 16-7/16"

PH42ZS 41-1/16"19

PH48ZS 47-1/16"22

PH54ZS 53-1/16"25

Pared

1 -1/8"

Línea Central de la Estufa

Vista del Plano para el Recorte del Gabinete

Nota: Esta figura muestra sólo las ubicaciones del agujero para rosca interna y

para el tornillo. Vea la Figura 1b, página 4 para las dimensiones generales de la

campana.

Figura 11: Ubicaciones de la transición y del conducto

23"

3 -3/16"

B

Agujeros de espacio libre

DIA de 5/8" para el

conducto de 1/2" a la caja

de conexiones

Page 8

Instalar un Soplador Integral VTN1000Q

Se puede instalar la campana con un

soplador VTN1000Q.

Preparación del soplador

Soportes de transporte

Unión de cable

Capacitor

Vista frontal del soplador

Figura 12a

1. Quite los soportes de transporte a la

izquierda y derecha y deséchelos.

2. Corte la unión de cable como se indica en la

Figura 12a. Ubique el arnés de cables con el

conector Molex de 6 pines. Coloque el arnés de

cables para que salga por la parte trasera del

ventilador, como se muestra en la Figura 12b

abajo.

3. Vuelva a fijar el capacitor con el arnés del cable

con la nueva unión de cable (incluida) en el

mismo lugar en el frente.

Instalar el soplador en la

campana:

1. Se fija el soplado a la campana usando los

pernos de soldadura que vienen incluidos en la

placa de montaje.

2. La Figura 12 c muestra los pernos de soldadura

en el lugar B para la descarga horizontal

(trasera). Fije cuatro tuercas #10-24 a los

pernos de soldadura con un espacio libre de 1/

8" abajo de las tuercas. Para una descarga

vertical, fije las tuercas a los pernos en la parte

superior de la placa de montaje.

Figura 12c

3. Coloque la placa de montaje del motor encima

de las tuercas y apriete para asegurar el

soplador a la camapana.

4. Fije dos tornillos adicionales como se muestra

en la Figura 12d.

Agregar

unión de

Arnés de

cable

Vista tarsera del soplador

Figura 12b

4. Conecte el arnés de cable con el conector

Molex de 6 clavijas a la caja como se indica en

la Figura 12b con la unión de cable (incluida).

cable aquí

Conjunto del

Ventilador

Tornillos

Adicionales

Figura 12d

CUIDADO:

Verifique que los dos tornillos adicionales

en la Figura 12d estén instalados y bien

apretados antes de proceder.

Page 9

Instrucción para encaminar los cables

Descarga Vertical

Encamine los cables aquí Encamine los cables aquí

Figura 12e Figura 12g

Cubierta de cable

Descarga Horizontal

Cubierta de cable

Figura 12f

Instale la cubierta de cable como se indica en la

Figura 12f. El modelo con ancho de 30" no necesita

una cubierta para cables.

Figura 12h

Instale la cubierta de cable como se indica en la

Figura 12h. El modelo con ancho de 30" no

necesita una cubierta para cables.

Page 10

Conectar la campana con un

l

or

Conectar la campana con un

motor integral

ATTENCIÓN

Apague la electricidad en el panel de

servicio antes de conectar la unidad. (vea

las Instrucciones de Seguridad, Página 2).

1. Quite la cubierta de la caja de conexiones.

2. Enchufe el conector molex VTN1000Q al

conector presente adentro de la campana como

se indica en la Figura 13.

3. Instale el conector del conducto de 1/2" en la

caja de conexiones.

Del Panel de Control

From Ventilat

Del Ventilador

From Control Pane

Figura 13

4. Encamine los cables negro, blanco y verde

(#12AWG) en el conducto de 1/2" desde la

fuente de alimentación a la caja de conexiones.

5. Conecte los cables de la fuente de alimentación

a los cables de la campana en el siguiente

orden: cable negro con negro, blanco con

blanco y el cable verde al tornillo verde de tierra

en el bastidor. Use los conectores de alambre

tipo resorte que vienen incluidos. (Los

conectores de alambre que faltan o que se

perdieron deben ser reemplazados solamente

con: Conectores de alambre tipo resorte,

diseñados para un mínimo de (2) alambres

calibre #18 y un máximo de (4) alambres

calibre #14, aprobados por UL y CSA y una

capacidad nominal de 600V y 302 grados F /

150 grados C.

6. Cierre la cubierta de la caja de conexiones.

Revise para estar seguro que los focos están

en sus casquillos. Reemplace los filtros como

se describe en el Manual de Cuidado y Uso.

Prenda la corriente en el panel de servicio.

Revise la operación de la campana.

Instalación del Soplador Remoto:

Los modelos de campana PHZ están diseñados

para trabajar con los sopladores remotos VTR600R,

VTR1000Q y VTR1400Q. Para las instrucciones de

instalación, consulte las instrucciones incluidas con

el soplador.

Soplador Remoto:

Conjunto del cable

flexible de conexión

viene incluido con la

campana

Ventilador

Remoto

Figura 14

1. Quite la cubierta de la caja de conexiones.

2. Instale el conector del conducto de 1/2" en la

caja de conexiones.

3. Encamine los cables negro, blanco y verde

(#12AWG) en el conducto de 1/2" desde la

fuente de alimentación a la caja de conexiones.

4. Conecte los cables de la fuente de alimentación

a los cables de la campana en el siguiente

orden: cable negro con negro, blanco con

blanco y el cable verde al tornillo verde de tierra

en el bastidor. Use los conectores de alambre

tipo resorte que vienen incluidos. (Los

conectores de alambre que faltan o que se

perdieron deben ser reemplazados solamente

con: Conectores de alambre tipo resorte,

diseñados para un mínimo de (2) alambres

calibre #18 y un máximo de (4) alambres

calibre #14, aprobados por UL y CSA y una

capacidad nominal de 600V y 302 grados F /

150 grados C.

5. Conecte el enchufe "rabillo" al conector dentro

de la caja de conexiones.

6. Encamine cinco cables (#14AWG) en el

conducto de 1/2" del soplador remoto al

segundo conector de conducto.

7. Conecte el ventilador remoto a los cables de

conexión flexible (rabillo) (Paso 6) como se

indica en la Figura 14 usando las tuercas de

cable incluidas. Conecte el cable verde (tierra)

del soplador remoto al tornillo de tierra en la

caja de conexiones.

8. Cierre la cubierta de la caja de conexiones.

Revise para estar seguro que todos los focos

están en sus casquillos. Instale los filtros.

Prenda la corriente en el panel de servicio y

revise las luces y la operación del soplador

como se indica en el manual de Cuidado y Uso.

Page 11

We reserve the right to change specifications or design without notice. Some models are certified for use in

Canada. Thermador is not responsible for products which are transported from the U.S. for use in Canada.

Check with your local Canadian distributor or dealer.

For the most up to date critical dimensions by fax, use your fax handset and call 775-833-3600. Use code #

8030.

BSH Home Appliances Corp. 5551 McFadden Avenue, Huntington Beach, CA 92649 • 800/735-4328

© BSH Home Appliances Corporation 2004 • 5060009136 Rev. B (No ECO) • 11/04 • Litho in U. S.A

Page 12

Loading...

Loading...