Page 1

INSTALLATION

INSTRUCTIONS

PH SERIES Professional ®Wall Hoods

I STRUCTI

NSTALLATION

Hottes murales de gamme PH Professional ®

INSTRUCCIONES DE

f

INSTALAC

Campanas de Pared de la Serie PH

Professional ®

Models

PH30

PH36

PH42

PH48

PH54

Page 2

iMPORTANT SAFETY iNSTRUCTiONS

APPROVED FOR ALL RESIDENTIAL APPLIANCES

FOR RESIDENTIAL USE ONLY

PLEASE READ ENTIRE INSTRUCTIONS BEFORE PROCEEDING.

IMPORTANT: Save these Instructions for the Local Electrical Inspector's use.

INSTALLER: Please leave these Instructions with this unit for the owner.

OWNER: Please retain these instructions for future reference.

WARNING

If the information in this manual is not

followed exactly, fire or shock may result

causing property damage or personal injury.

Do not repair or replace any part of the

appliance unless specifically recommended

in the manuals. Improper installation, service

or maintenance can cause injury or property

damage. Refer to this manual for guidance.

All other servicing should be done by a

qualified technician.

Unit is heavy and requires at least two people

or proper equipment to move.

Hidden surfaces may have sharp edges. Use

caution when reaching behind or under

appliance.

This appliance complies with one or more of

the following Standards:

• UL 858, Standard for the Safety of

Household Electric Ranges

• UL 923, Standard for the Safety of

Microwave Cooking Appliances

• UL 507, Standard for the Safety of

Electrical Fans

• ANSI Z21.1-American National

Standard for Household Cooking Gas

Appliances

• CAN/CSA-C22.2 No. 113-M1984 Fans

and Ventilators

• CAN/CSA-C22.2 No. 61-M89 Household

Cooking Ranges

It is the responsibility of the owner and installer

to determine if additional requirements and/

or standards apply to specific installations.

SAFETY WARNING

Turn off power circuit at service panel and

lock out panel, before wiring this appliance.

REQUIREMENT: 120 VAC, 60 Hz 20A

WARNING

To reduce the risk of fire,

use only metal duct work.

If required by the National Electrical Code (or

Canadian Electrical Code), this appliance

must be installed on a separate branch circuit.

Installer - show the owner the location of the

circuit breaker or fuse. Mark it for easy

reference.

Remove all tape and packaging before using

the appliance. Destroy the packaging after

unpacking the appliance. Never allow children

to play with packaging material.

Never modify or alter the construction of the

appliance. For example, do not remove

leveling legs, panels, wire covers or anti-tip

brackets/screws.

GROUNDING INSTRUCTIONS

This appliance must be grounded. Inthe event

of an electrical short circuit, grounding reduces

the risk of electric shock by providing an

escape wire for the electric current.

This appliance is equipped with a cord having

a grounding wire with a grounding plug. The

plug must be plugged into an outlet that is

properly installed and grounded.

Page 3

iMPORTANT SAFETY iNSTRUCTiONS

WARNING

Improper grounding can result in a risk of

electric shock. Consult a qualified electrician

if the grounding instructions are not

completely understood, or if doubt exists as

to whether the appliance is properly

grounded. Do not use an extension cord. If

the power cord is too short, have a qualified

electrician install an outlet near the

appliance.

To reduce the risk of fire or electric shock,

do not use this fan with any solid-state speed

control devices.

TO REDUCE THE RISK OF FIRE,

ELECTRIC SHOCK AND INJURY TO

PERSONS:

This ventilator assembly must be installed

with blower model(s) VTN1030C, VTR630D,

VTR1030D, VTR1330E, or VTR1530D.

Other ventilator blowers cannot be

substituted.

a. Use this unit only in the manner intended

by the manufacturer. If you have questions,

contact the manufacturer. (Thermador

Customer Service at 800-735-4328).

b. Before servicing or cleaning unit,

switch power OFF at service panel and

lock the service disconnecting means to

prevent power from being switched on

accidentally. When the service

disconnecting means cannot be locked,

securely fasten a prominent warning device,

such as a tag, to the service panel.

c. Installation work and electrical wiring must

be done by qualified person(s) in

accordance with all applicable codes and

standards, including fire-rated construction.

d. Sufficient air is needed for proper

combustion and exhausting of gases through

the flue (chimney) of fuel burning equipment

to prevent back drafting. Follow the heating

equipment manufacturer's guideline and

safety standards such as those published

by the National Fire Protection Association

(NFPA), and the American Society for

Heating, Refrigeration and Air Conditioning

Engineers (ASHRAE), and the local code

authorities.

e. When cutting or drilling into wall or ceiling,

do not damage electrical wiring and other

hidden utilities.

f. Ducted fans must always be vented to the

outdoors.

g. To properly exhaust air, be sure to duct

air outside. Do not vent exhaust air into

spaces within walls, ceilings, attics, crawl

spaces, or garages.

h. Before you plug in an electrical cord, be

sure all controls are in the OFF position.

CAUTION

For general ventilating use only. DO NOT use

to exhaust hazardous or explosive materials

or vapors.

CAUTION

Vent unit to the outside.

Page 4

Parts Included with your Hood Parts Not Included with your Hood

• Hood Canopy

• 12-Volt halogen bulbs, installed

• Filters (2, 3, or 4 depending on model and size)

• Metal Transition with backdraft damper installed

• Fasteners

• Remote Blower ("pigtail")Adaptor

• Wooden Strip for Hood Support

• Wire Nuts

• 2 - 175W PAR-38 Heat Lamps or

2 - 250W PAR-40 Heat Lamps

• Use & Care Manual/Installation Instructions

• Registration Card

• Duct Tape

• 1/2" Conduit

• Ventilator- The hood can be installed with

ventilator models VTN 1030C, VTR630D,

VTR1030D, VTR1330E, or VTR1530D.

• Optional duct cover, 6" DC**US or 12" DCT**US

height (available for purchase seperately)

•* = width of hood

• Optional Remote Control (available for purchase

separately)

CONSIDERATIONS BEFORE INSTALLING HOOD

1. For the most efficient air flow exhaust, use a

straight run or as few elbows as possible.

2. Do not use flex ducting.

3. COLD WEATHER installations should have an

additional backdraft damper installed to

minimize backward cold air flow and a

nonmetallic thermal break to minimize

conduction of outside temperatures as part of

the ductwork. The damper should be on the cold

air side of the thermal break. The break should

be as close as possible to where the ducting

enters the heated portion of the house.

4. Hood installation height above a cooktop or

range can vary. To obtain the necessary

installation height above a Thermador

Professional Cooktop or Range, consult the

appliance's installation manual.

* For indoor grill installations, Thermador

recommends a minimum of 36" clearance and

remote blowers only (VTR1030D, VTR1330E, or

VTR1530D).

5. Remote blowers require a five wire installation.

6. Make-Up Air: Local building codes may require

the use of make-up air systems when using

ducted ventilation systems greater than specified

CFM of air movement. The specified CFM varies

from locale to locale. Consult your HVAC

professional for specific requirements in your

area.

, Refer to Remote Control Installation Instructions

if applicable.

3

Page 5

Appliance Installation

CAUTION:

Vent unit to outside of building, only.

The hood can be mounted on awall or suspended

from a cabinet, Both vertical and horizontal discharge

are possible with either mounting method.

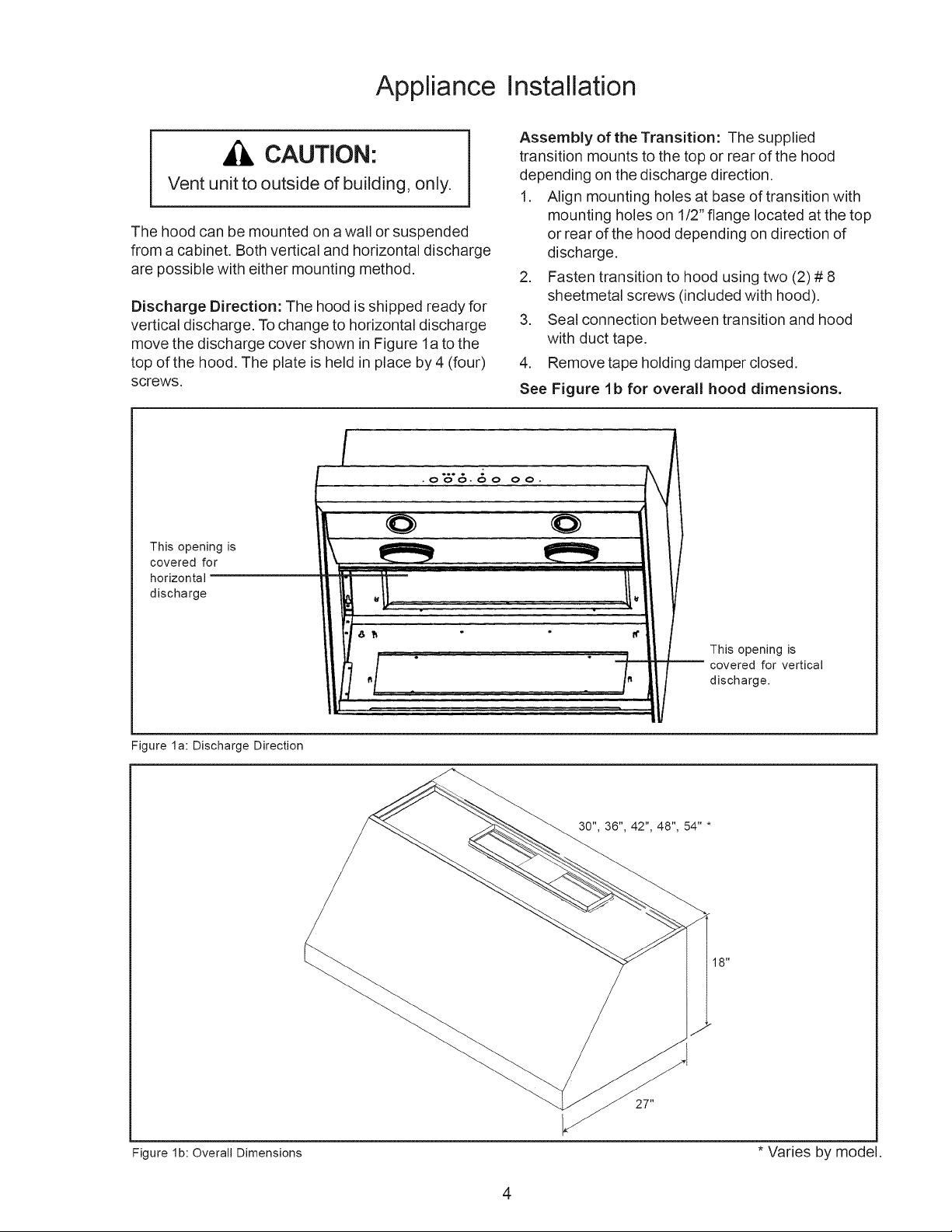

Discharge Direction: The hood is shipped ready for

vertical discharge, To change to horizontal discharge

move the discharge cover shown in Figure I a to the

top of the hood. The plate is held in place by 4 (four)

screws.

Assembly of the Transition: The supplied

transition mounts to the top or rear of the hood

depending on the discharge direction.

1. Align mounting holes at base of transition with

mounting holes on 1/2" flange located at the top

or rear of the hood depending on direction of

discharge.

2. Fasten transition to hood using two (2) # 8

sheetmetal screws (included with hood).

3. Seal connection between transition and hood

with duct tape.

4. Remove tape holding damper closed.

See Figure I b for overall hood dimensions.

This opening is

covered for

horizontal

discharge

Figure la: Discharge Direction

This opening is

covered for vertical

discharge.

Figure lb: Overall Dimensions * Varies by model.

Page 6

Note: Read Remote Control Installation

Instructions before continuing if using this

accessory.

Wall Mount Installation

k

2 _ n

I, 1 8Duc61'CoverF_

The hood installation height is the user's prefer-

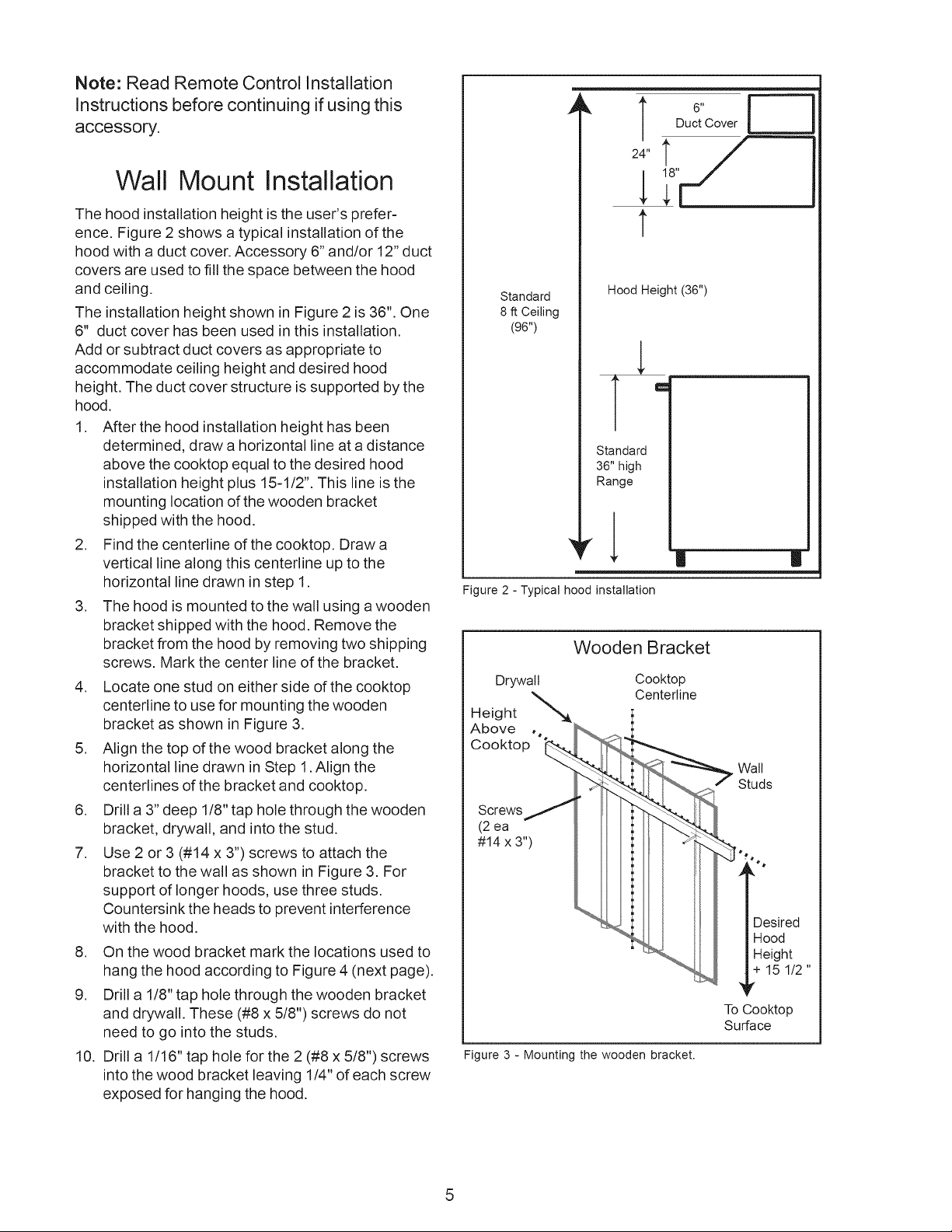

ence. Figure 2 shows a typical installation of the

hood with a duct cover. Accessory 6" and/or 12" duct

covers are used to fill the space between the hood

and ceiling.

The installation height shown in Figure 2 is 36". One

6" duct cover has been used in this installation.

Add or subtract duct covers as appropriate to

accommodate ceiling height and desired hood

height. The duct cover structure is supported by the

hood.

1. After the hood installation height has been

determined, draw a horizontal line at a distance

above the cooktop equal to the desired hood

installation height plus 15-1/2". This line is the

mounting location of the wooden bracket

shipped with the hood.

2. Find the centerline of the cooktop. Draw a

vertical line along this centerline up to the

horizontal line drawn in step 1.

3. The hood is mounted to the wall using a wooden

bracket shipped with the hood. Remove the

bracket from the hood by removing two shipping

screws. Mark the center line of the bracket.

4. Locate one stud on either side of the cooktop

centerline to use for mounting the wooden

bracket as shown in Figure 3.

5. Align the top of the wood bracket along the

horizontal line drawn in Step 1. Align the

centerlines of the bracket and cooktop.

6. Drill a 3" deep 1/8" tap hole through the wooden

bracket, drywall, and into the stud.

7. Use 2 or 3 (#14 x 3") screws to attach the

bracket to the wall as shown in Figure 3. For

support of longer hoods, use three studs.

Countersink the heads to prevent interference

with the hood.

8. On the wood bracket mark the locations used to

hang the hood according to Figure 4 (next page).

9. Drill a 1/8" tap hole through the wooden bracket

and drywall. These (#8 x 5/8") screws do not

need to go into the studs.

10. Drill a 1/16" tap hole for the 2 (#8 x 5/8") screws

into the wood bracket leaving 1/4" of each screw

exposed for hanging the hood.

t

Standard

8 ft Ceiling

(96")

Figure 2 - Typical hood installation

Drywall Cooktop

Height

Above ,,

Cooktop

Screws

(2 ea

#14 x 3")

Figure 3 - Mounting the wooden bracket.

Hood Height (36")

Standard

36" high

Range

¢

Wooden Bracket

Centerline

%

Wall

Studs

::)esired

Hood

Height

+ 15 1/2"

r

ToCooktop

Surface

Page 7

-%

Screws

(2 ea. #14 x 3")

Cooktop

Centerline

i

|

.)"

Ameasurement

I

11.

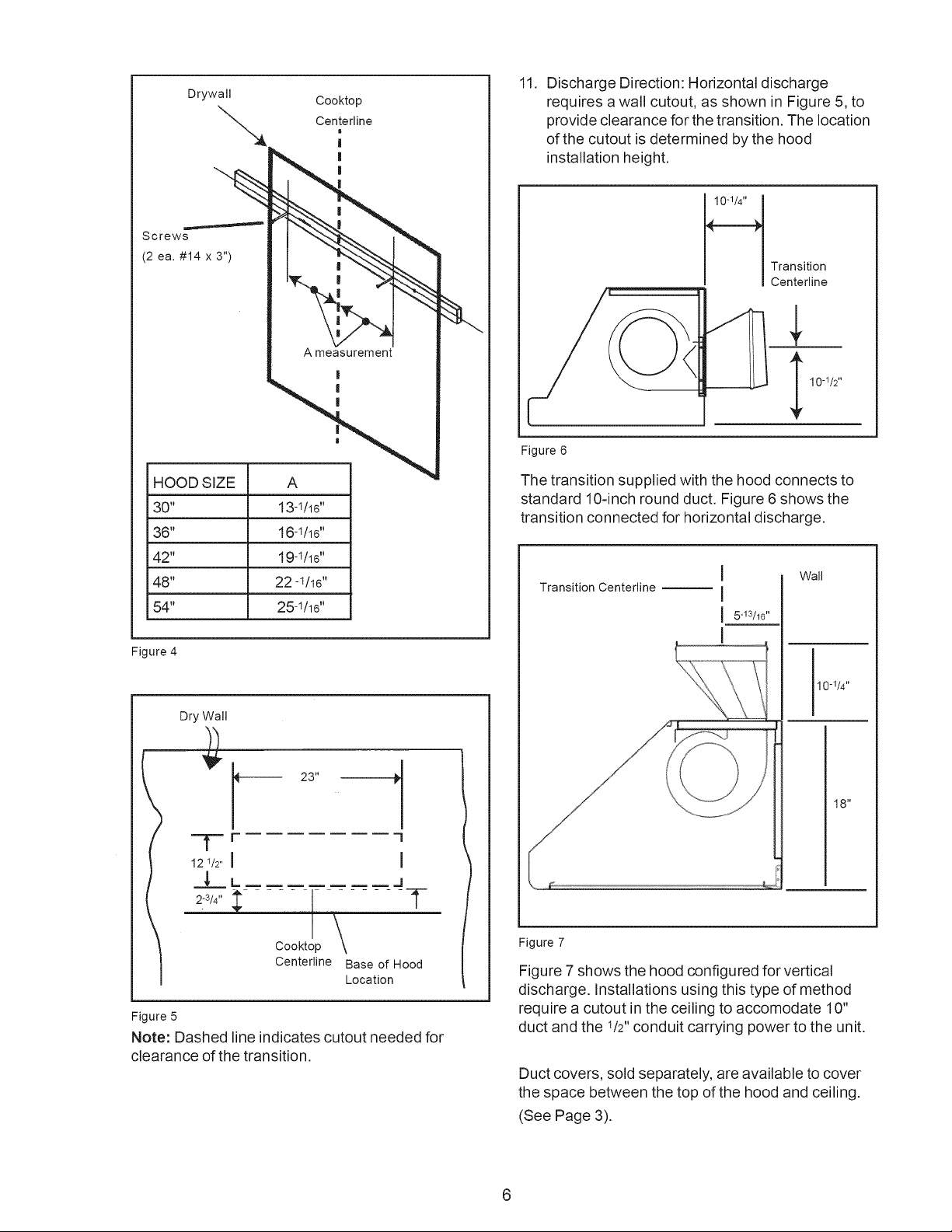

Discharge Direction: Horizontal discharge

requires a wall cutout, as shown in Figure 5, to

provide clearance for the transition. The location

of the cutout is determined by the hood

installation height.

_ Transition

Centerline

I 10-1/2"

Figure 6

HOOD SIZE

30" 13-1/16"

36" 16-1/16"

42" 19-1/16"

48" 22 -1/16"

54" 25-1/16''

Figure 4

A

The transition supplied with the hood connects to

standard 10-inch round duct. Figure 6 shows the

transition connected for horizontal discharge.

Transition Centerline

I

I

5-13/16"

I

Wall

I

23"

18"

J

L_

Cooktop

Centerline Base of Hood

Location

Figure 5

Note: Dashed line indicates cutout needed for

clearance of the transition,

Figure 7

Figure 7 shows the hood configured for vertical

discharge. Installations using this type of method

require a cutout in the ceiling to accomodate 10"

duct and the 1/2"conduit carrying power to the unit.

Duct covers, sold separately, are available to cover

the space between the top of the hood and ceiling.

(See Page 3).

Page 8

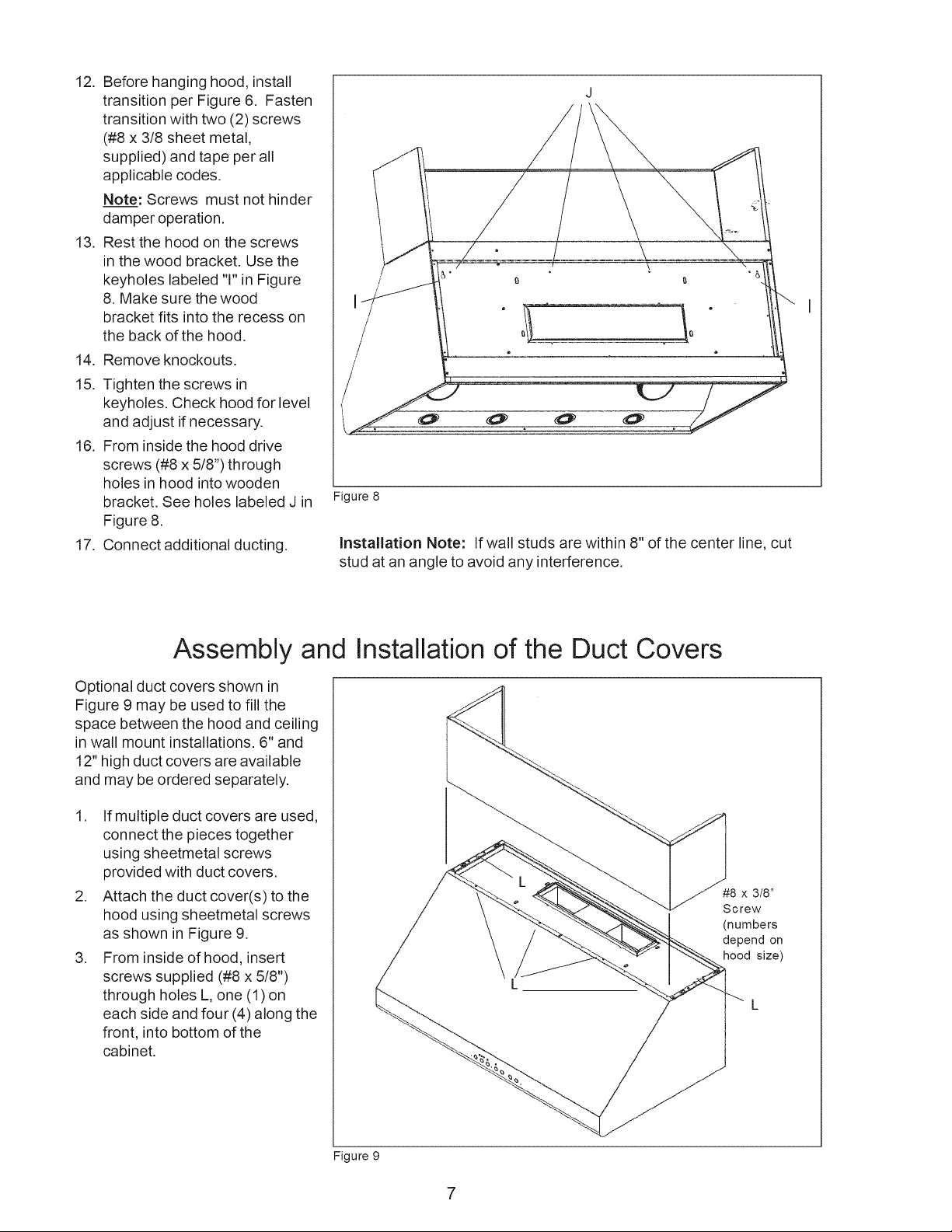

12.Beforehanginghood,install

transitionperFigure6. Fasten

transitionwithtwo(2)screws

(#8x3/8sheetmetal,

supplied)andtapeperall

applicablecodes.

Note: Screws must not hinder

damper operation.

13. Rest the hood on the screws

in the wood bracket. Use the

keyholes labeled "l" in Figure

8. Make sure the wood

bracket fits into the recess on

the back of the hood.

14. Remove knockouts.

15. Tighten the screws in

keyholes. Check hood for level

and adjust if necessary.

16. From inside the hood drive

screws (#8 x 5/8") through

holes in hood into wooden

bracket. See holes labeled J in

Figure 8.

17. Connect additional ducting.

Figure 8

Installation Note: If wall studs are within 8" of the center line, cut

stud at an angle to avoid any interference.

Assembly and

Optional duct covers shown in

Figure 9 may be used to fill the

space between the hood and ceiling

in wall mount installations. 6" and

12" high duct covers are available

and may be ordered separately.

1. If multiple duct covers are used,

connect the pieces together

using sheetmetal screws

provided with duct covers.

2. Attach the duct cover(s) to the

hood using sheetmetal screws

as shown in Figure 9.

3. From insideofhood, insert

screws supplied (#8 x 5/8")

through holes L, one (1)on

each side and four (4) along the

front, into bottom of the

cabinet.

Installation of the Duct Covers

#8 x 3/8"

Screw

(numbers

depend on

hood size)

Figure 9

7

Page 9

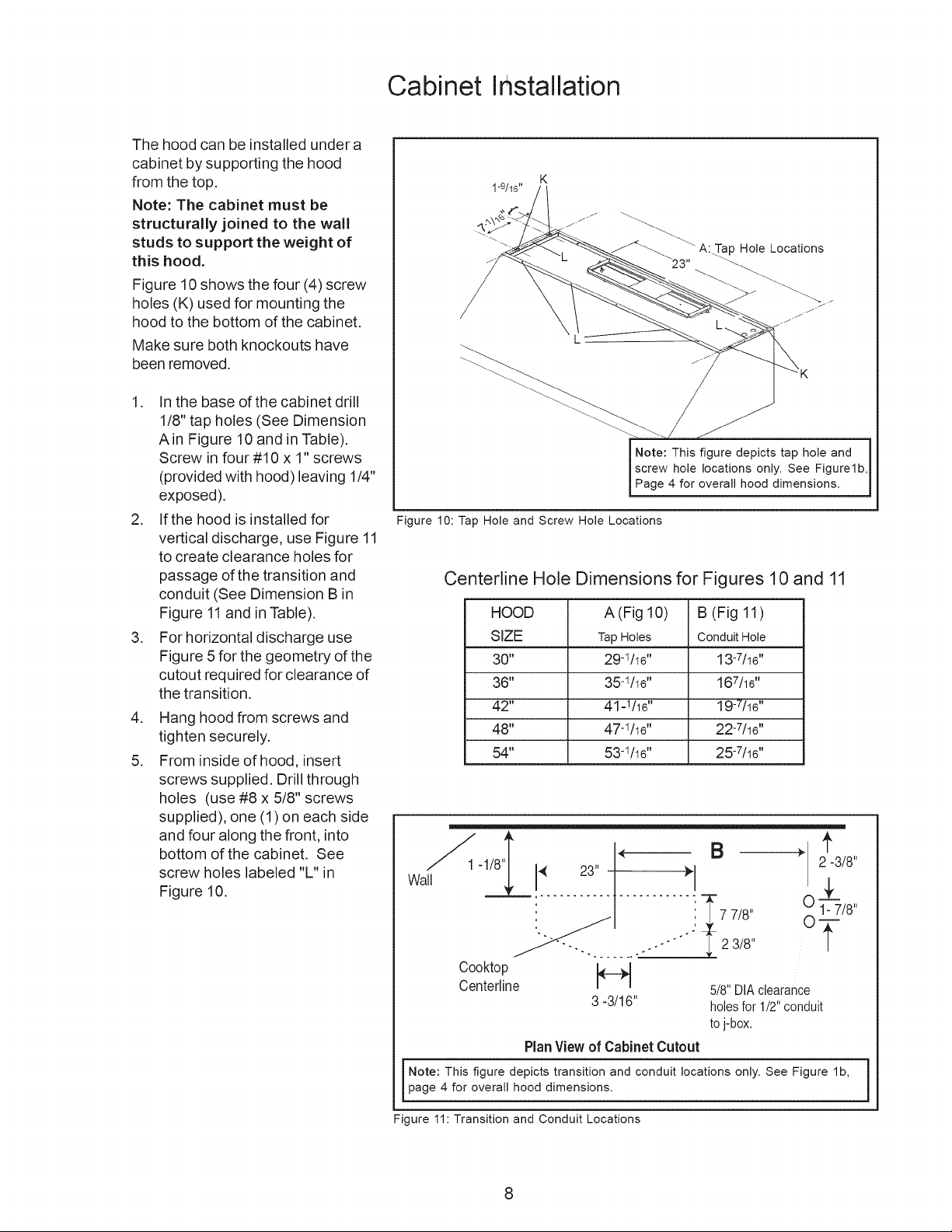

The hood can be installed under a

cabinet by supporting the hood

from the top.

Note: The cabinet must be

structurally joined to the wall

studs to support the weight of

this hood.

Figure 10 shows the four (4) screw

holes (K) used for mounting the

hood to the bottom of the cabinet.

Make sure both knockouts have

been removed.

1. In the base of the cabinet drill

1/8" tap holes (See Dimension

Ain Figure 10 and in Table).

Screw in four #10 x 1" screws

(provided with hood)leaving 1/4"

exposed).

2. If the hood is installed for

vertical discharge, use Figure 11

to create clearance holes for

passage of the transition and

conduit (See Dimension B in

Figure 11 and in Table).

3. For horizontal discharge use

Figure 5 for the geometry of the

cutout required for clearance of

the transition.

,

Hang hood from screws and

tighten securely.

5.

From inside of hood, insert

screws supplied. Drill through

holes (use #8 x 5/8" screws

supplied), one (1) on each side

and four along the front, into

bottom of the cabinet. See

screw holes labeled "L" in

Figure 10.

Cabinet Installation

1-9/16"

Note: This figure depicts tap hole and

I screw hole locations only. See Figurelb,

Page 4 for overall hood dimensions.

Figure 10: Tap Hole and Screw Hole Locations

Centerline Hole Dimensions for Figures 10 and 11

HOOD A (Fig 10) B (Fig 11)

SIZE Tap Holes Conduit Hole

30" 29-1/16" 13-7/16"

36" 35-1/16" 167/16"

42" 41-1/16" 19-7/16''

48" 47-1h6'' 22-7/16''

54" 53-1/16 '' 25-7/16 ''

/ 1' ,

i "1 T7 7/8" O .

...... 23/8" or

Cooktop

Centerline 5/8"DIAclearance

3 -3/16" holesfor1/2"conduit

toj-box.

PlanViewof Cabinet Cutout

I Note: This figure depicts transition and conduit locations only. See Figure lb,

page 4 for overall hood dimensions.

Figure 11: Transition and Conduit Locations

Page 10

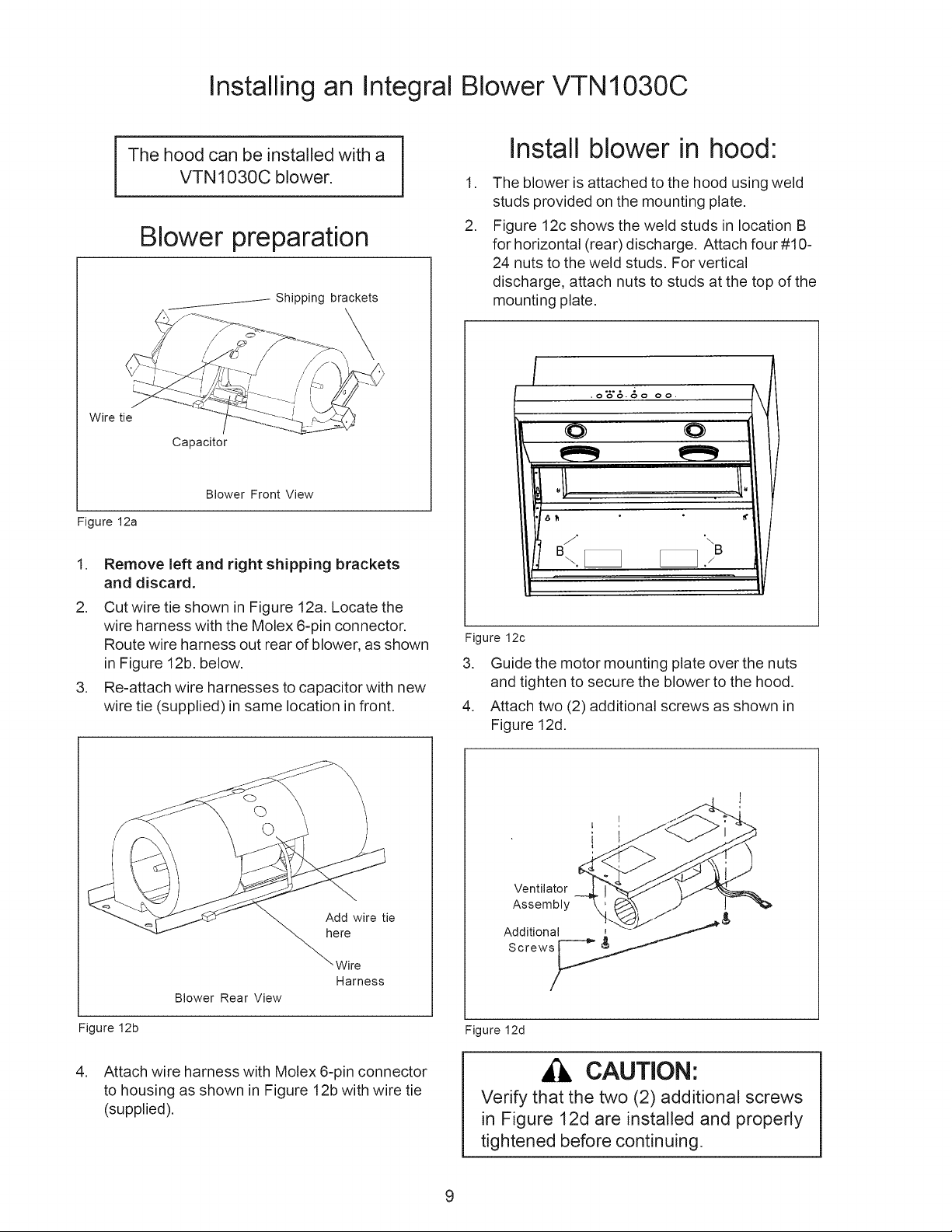

Installing an Integral Blower VTN1030C

The hood can be installed with a

VTN 1030C blower.

Blower preparation

Shipping brackets

\

Wire tie

Capacitor

Blower Front View

Figure 12a

,

Remove left and right shipping brackets

and discard.

2.

Cut wire tie shown in Figure 12a. Locate the

wire harness with the Molex 6-pin connector.

Route wire harness out rear of blower, as shown

in Figure 12b. below.

,

Re-attach wire harnesses to capacitor with new

wire tie (supplied) in same location in front.

Install blower in hood:

,

The blower is attached to the hood using weld

studs provided on the mounting plate.

2.

Figure 12c shows the weld studs in location B

for horizontal (rear) discharge. Attach four #10-

24 nuts to the weld studs. For vertical

discharge, attach nuts to studs at the top of the

mounting plate.

Figure 12c

3. Guide the motor mounting plate over the nuts

and tighten to secure the blower to the hood.

4. Attach two (2) additional screws as shown in

Figure 12d.

Add wire tie

here

¢Tire

Harness

Blower Rear View

Figure 12b

4. Attach wire harness with Molex 6-pin connector

to housing as shown in Figure 12b with wire tie

(supplied).

I

Ventilator

Assembly

Additional _ _'"_ _

Screw_

Figure 12d

CAUTION"

Verify that the two (2) additional screws

in Figure 12d are installed and properly

tightened before continuing.

Page 11

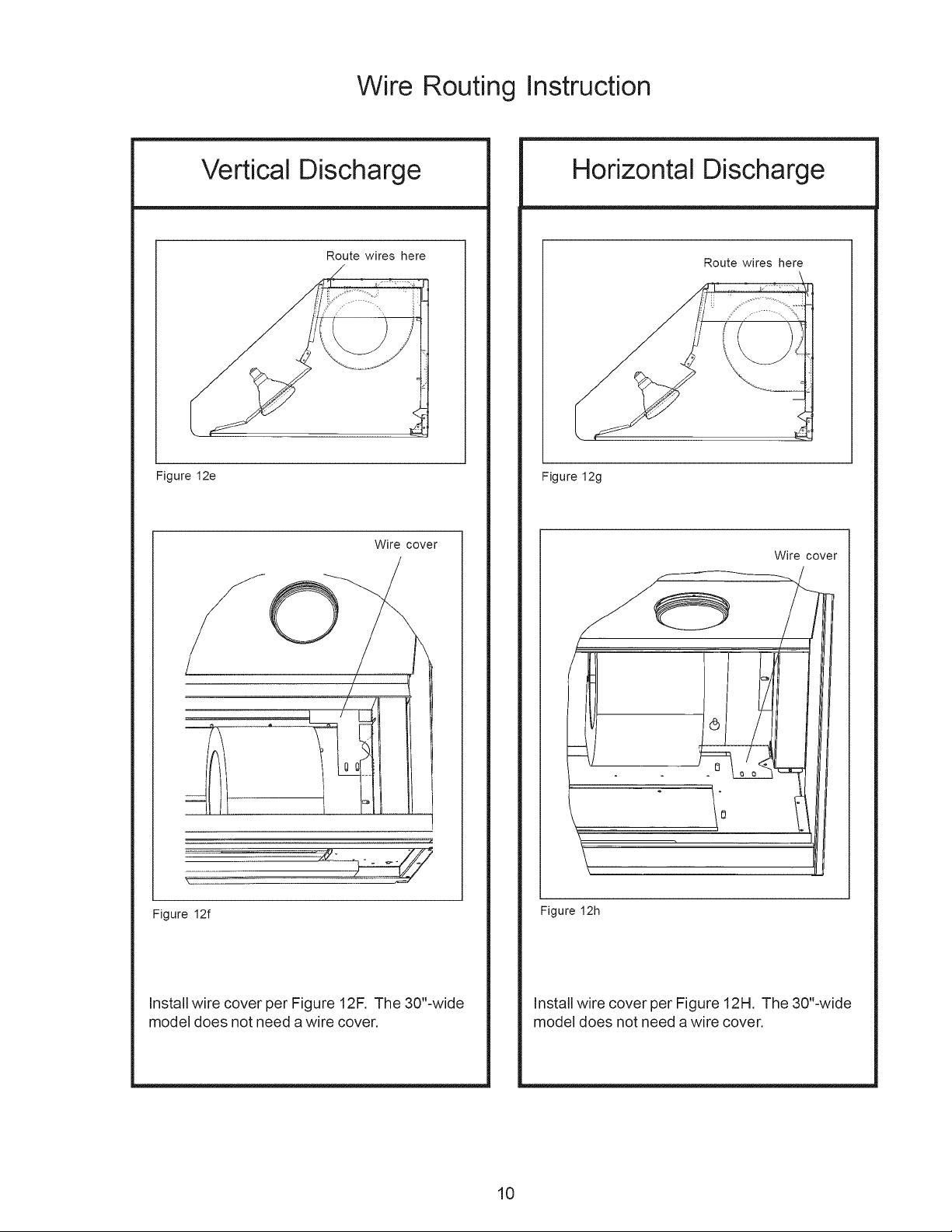

Wire Routing Instruction

Vertical Discharge

Figure 12e

Route wires here

Wire cover

Horizontal Discharge

Route wires here

Figure 12g

Wire cover

\

Figure 12f

Install wire cover per Figure 12F. The 30"-wide

model does not need a wire cover,

Figure 12h

Install wire cover per Figure 12H. The 30"-wide

model does not need a wire cover,

10

Page 12

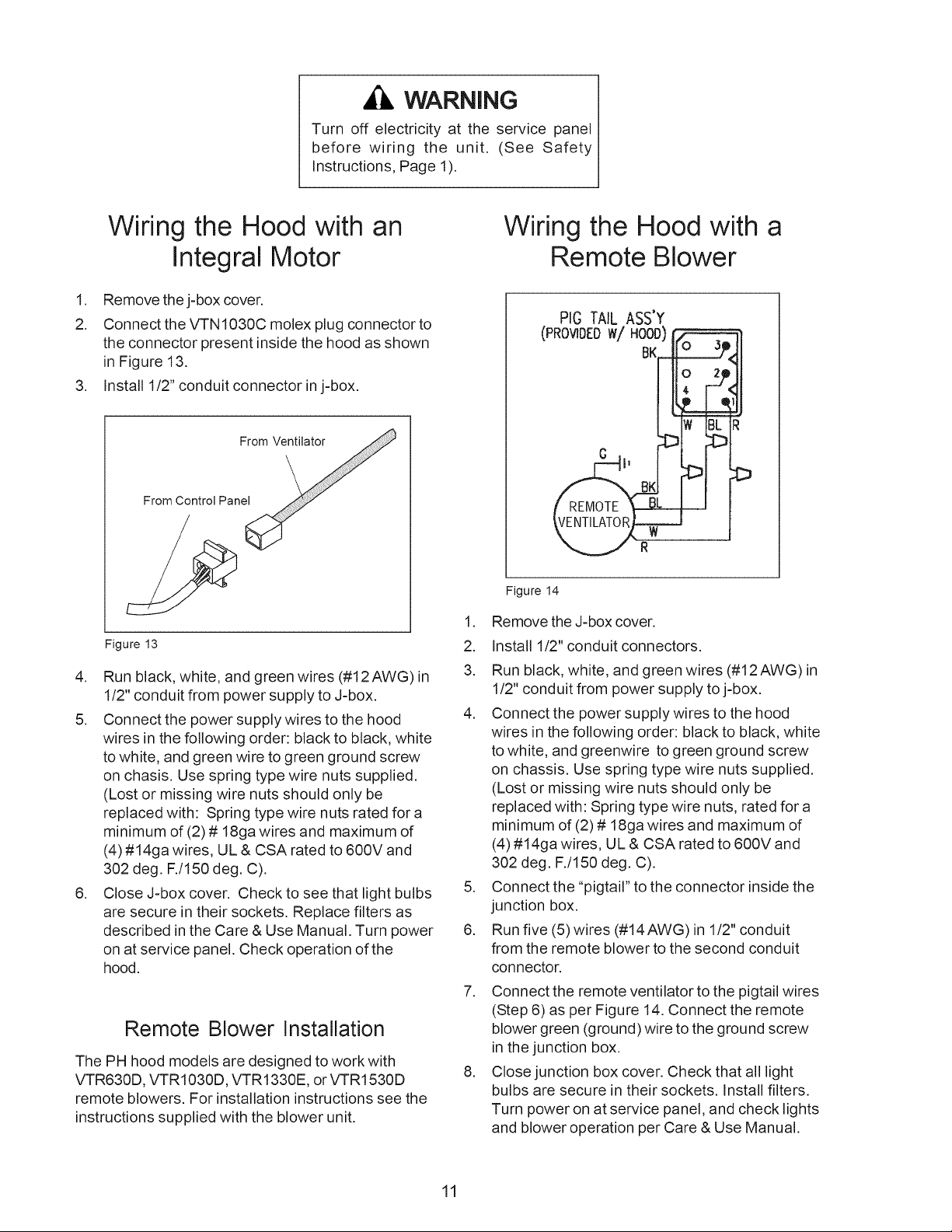

WARNING

Turn off electricity at the service panel

before wiring the unit. (See Safety

Instructions, Page 1).

Wiring the Hood with an

Integral Motor

1. Remove the j-box cover.

2. Connect the VTNI030C molex plug connector to

the connector present inside the hood as shown

in Figure 13.

3. Install 1/2" conduit connector inj-box.

From Ventilator

From Control Panel

Figure 13

4. Run black, white, and green wires (#12 AWG)in

1/2" conduit from power supply to J-box.

5. Connect the power supply wires to the hood

wires in the following order: black to black, white

to white, and green wire to green ground screw

on chasis. Use spring type wire nuts supplied.

(Lost or missing wire nuts should only be

replaced with: Spring type wire nuts rated for a

minimum of (2) # 18ga wires and maximum of

(4) #14ga wires, UL & CSA rated to 6OOVand

302 deg. F./150 deg. C).

6. Close J-box cover. Check to see that light bulbs

are secure in their sockets. Replace filters as

described in the Care & Use Manual. Turn power

on at service panel. Check operation of the

hood.

Remote Blower Installation

The PH hood models are designed to work with

VTR630D, VTRI030D, VTR1330E, or VTR1530D

remote blowers. For installation instructions see the

instructions supplied with the blower unit.

Wiring the Hood with a

Remote Blower

PIG TAIL ASS'Y

(PROVIDEDW/HOOD)

G I,

K

Figure 14

,

Remove the J-box cover.

2.

Install 1/2" conduit connectors.

3.

Run black, white, and green wires (#12 AWG)in

1/2" conduit from power supply to j-box.

4. Connect the power supply wires to the hood

wires in the following order: black to black, white

to white, and greenwire to green ground screw

on chassis. Use spring type wire nuts supplied.

(Lost or missing wire nuts should only be

replaced with: Spring type wire nuts, rated for a

minimum of (2)# 18ga wires and maximum of

(4) #14ga wires, UL & CSA rated to 6OOVand

302 deg. F./150 deg. C).

5. Connect the "pigtail" to the connector inside the

junction box.

6. Run five (5) wires (#14AWG)in 1/2" conduit

from the remote blower to the second conduit

connector.

7. Connect the remote ventilator to the pigtail wires

(Step 6) as per Figure 14. Connect the remote

blower green (ground) wire to the ground screw

in the junction box.

8. Close junction box cover. Check that all light

bulbs are secure in their sockets. Install filters.

Turn power on at service panel, and check lights

and blower operation per Care & Use Manual.

11

Page 13

iNSTRUCTiONS DE SECURITE IMPORTANTES

APPROUV¢: POUR TOUT APPAREIL RESIDENTIEL

POUR UTILISATION RI SIDENTILLE SEULEMENT

LIRE TOUTES LES INSTRUCTIONS AVANT DE PROC¢:DER

IMPORTANT • conserver ces instructions pour utilisation par I'inspecteur en electricit6 local.

INSTALLATEUR • laisser ces instructions avec I'appareil pour le proprietaire

PROPRI#TAIRE • conserver ces instructions a des fins de ref6rences.

AVERTISSEMENT

Si I'information contenue dans ce guide n'est

pas suivie, il peut en resulter un incendie ou

un choc electrique pouvant causer des

dommages a la propriet6 ou des blessures.

Ne pas reparer ni remplacer toute piece de

I'appareil a moins que cela ne soit

specifiquement recommande dans les guides.

Une installation, un service ou un entretien

inadequats peuvent causer des dommages

la propriet6 ou des blessures. Consulter ce

guide. Tout autre service doit etre effectue par

un technicien qualifie.

L'appareil est Iourd et requiert au moins deux

personnes ou un equipement approprie pour le

deplacer.

Les surfaces dissimulees peuvent avoir des

bords tranchants. Faire attention au moment

d'aller derriere ou sous I'appareil.

Cet appareil est conforme a une ou plusieurs des

normes suivantes.

, UL858 - norme pour la securit6 des

cuisinieres electriques domestiques.

, UL923 - norme pour la securite des appareils

de cuisson a micro-ondes.

, ULS07 - norme pour la s6curite des

ventilateurs electriques.

, ANSI Z21.1 - norme americaine nationale

pour les appareils de cuisson a gaz

, CAN/CSA-C22.2, n° 113-M1984-ventilateurs

, CAN/CSA-C22.2 n ° 61-M89 - cuisinieres

domestiques

II incombe au proprietaire eta I'installateur de

determiner si des exigences additionnelles et/ou

des normes s'appliquent pour des installations

specifiques.

AVERTISSEMENT DE

Sl CURITi

Fermer I'alimentation electrique au panneau

de service et verrouiller avant d'effectuer le

c_blage de I'appareil.

EXIGENCE : 120VAC, 60 Hz20A

AVERTISSEMENT

Pour reduire le risque d'incendie, utiliser

seulement des conduits en metal.

Si requis par le Code national d'electricite (ou le

code canadien d'61ectricite), cet appareil doit etre

installe sur un circuit separ6.

Installateur indiquer au proprietaire

I'emplacement du coupe=circuit ou du fusible. Le

noter a des fins de ref6rences.

Enlever tout ruban et emballage avant d'utiliser

I'appareil. Jeter I'emballage apres avoir deball6

I'appareil. Ne jamais laisser les enfants jouer avec

le materiel d'emballage.

Ne jamais modifier la fabrication de I'appareil. Par

exemple, ne pas enlever les pieds niveleurs, les

panneaux, les couvercles de ills ni le dispositif

anti bascule et les vis.

INSTRUCTIONS DE MISE A LA TERRE

Cet appareil doit etre mis a la terre. Dans le cas

d'un court-circuit, la mise a la terre reduit le risque

de choc electrique en fournissant un detour au

courant electrique.

Cet appareil est dote d'un cordon avec fil de mise

la terre et d'une fiche mise a la terre. Cette

fiche doit etre branchee sur une prise

adequatement installee et mise a la terre.

Page 14

iNSTRUCTiONS DE SECURITE IMPORTANTES

AVERTISSEMENT

Une mise a terre inadequate peut causer un

risque de choc electrique. Consulter un

electricien qualifie si les instructions de mise

la terre ne sont pas entierement comprises

ou si un doute existe quanta la mise a la

terre appropriee de I'apparei!. NE pas

utiliser de rallonge. Si le cordon

d'alimentation est trop court, demander a un

electricien qualifie d'installer une prise

proximite de I'appareil.

Pour reduire le risque d'incendie ou de choc

electrique, ne pas utitiser ce ventilateur avec

tout appareil a contr61e de vitesse a semi-

conducteur.

POUR RFtDUIRE LE RISQUE D'INCENDIE,

DE CHOC I_LECTRIQUE OU DE

BLESSURES

Cet assemblage de ventilateur doit _tre

installe avec une soufflerie, modele

VTNI030C, VTR630D, VTRI030D,

VTR1330E, ou VTR1530D. Ne pas

substituer d'autres souffleries.

a. Utiliser cet appareil seulement de la fa(_on

prevue par le fabricant. Pour toute question,

communiquer avec le fabricant. (Service

la clientele Thermador au 800.735.4328.)

b. Avant le service ou de nettoyer

I'appareil, fermer I'alimentation au

panneau de service et le verrouiller afin

d'emp_cher I'alimentation d'etre raise

en circuit accidentellement. Lorsque le

panneau de service ne peut _tre verrouille,

apposer en evidence un avertissement sur

le panneau de service.

c. L'instatlation et le c_blage electrique doivenl

_tre effectues par des techniciens qualifies

conformement a tousles codes applicables

et les normes, incluant celtes pour les

constructions retardateur de feu.

d. Suffisamment d'air est necessaire pour une

combustion appropriee et I'echappement des

gaz par la cheminee pour I'equipement

combustion pour emp_cher un retour. Suivre

les directives du fabricant d'equipement de

chauffage et les normes de securit6 telles

celles publiees par I'Association nationale pour

la protection contre les incendies (NFPA) el

la Societ6 americaine des ingenieurs en

chauffage, refrig6ration et climatisation

(ASHRAE) ainsi que les autorites locales.

e. Au moment de couper ou de percer un mur

ou un plafond, ne pas endommager lec_blage

electrique et autres installations utilitaires.

f. Les ventilateurs _ conduit doivent toujours

_tre ventiles vers I'exterieur.

g. Pour un echappement approprie de I'air,

s'assurer que le conduit est achemine vers

I'exterieur. Ne pas ventiler dans des espaces

dans les murs, plafonds, greniers, espaces

restreints ou garages.

h. Avant de brancher le cordon electrique,

s'assurer que tous les contr61es sont en

position ARRFt:T (OFF).

ATTENTION

,_ des fins de ventilation gen6rale

seulement. NE PAS utiliser pour ventiler

des vapeurs ou materiaux hasardeux ou

explosifs.

ATTENTION

Ventiler I'appareil vers I'exterieur de

I'edifice seulement

Page 15

Pieces comprises avec la hotte

Pieces non comprises

• Hotte

• Ampoules halogenes 12 volts, instaflees

• FIItres, 2, 3 ou 4 selon le modele et la

dimension

• Transition en metal et registre de tirage arriere

installes

• Attaches

Adaptateur (<<tire-bouchon)>)de soufflerie

distance

Montant en bois pour supporter lahotte

Serre-fils

2 ampoules 175W PAR-38 ou

2 ampoules 250W PAR-40

Instructions d'installation et d'entretien et

utilisation.

Carte d'enregistrement

]k CONSIDERERAVANT L'INSTALLATION

Ii

Ruban &conduit

Ii

Conduit 1/2 po

Ii

Ventilateur - la hotte peut etre installee avec les

modeles de ventilateur VTN 1030C, VTR630D,

VTRI030D, VTR1330E, ou VTR1530D.

Couvercle de conduit optionnel, 6 po DC**US ou

12 po DCT**US de haut, disponible separement

(** = largeur de la hotte.)

Telecommande optionnelle (disponible, vendue

separement)

,

Pour un 6chappement du d6bit d'air efficace,

utiliser un chemin droit ou ayant le moins de

coudes possible.

,

Ne pas utiliser de conduit flexible.

3.

Les installation oQil FAIT FROID doivent avoir

un registre de tirage additionnel installe afin de

minimiser un debit d'air froid arriere et une

resistance thermique non metallique pour

minimiser la conduction des temperatures

exterieures faisant pattie des conduits. Le

registre dolt etre du c6te de I'air froid de la

resistance thermique. Cette derniere dolt 6tre

aussi pres que possible de I'endroit oQ le

conduit entre dans la portion chauffee de la

maison.

,

La hauteur de I'installation de la hotte au-dessus

de la surface de cuisson ou de la cuisiniere

varie. Pour obtenir la hauteur d'instaflation au-

dessus d'une surface de cuisson ou d'une

cuisiniere Professional Thermador, consulter le

guide d'installation de I'appareil.

Pour les installations de gril ext6rieur, Thermador

recommande un degagement minimum de 36 po

et soufflerie a distance seulement (VTR1030D,

VTR1330E, ou VTR1530D).

,

Les souffleries a distance requierent une

installation a 5 ills.

6.

Air d'appoint : les codes de construction Iocaux

peuvent exiger I'utilisation de systeme d'air

d'appoint au moment d'utiliser des systemes de

ventilation a conduit plus grand que le

mouvement d'air CFM specifi& Le CFM specific

varie d'un endroit a I'autre. Consulter un

professionnel HVAC concernant les exigences

specifiques dans la region.

,

Consulter les instructions d'installation de la

telecommande, au besoin.

Page 16

Installation de I'appareil

ATTENTION

Ventiler I'appareil vers I'exterieur de

I'edifice seulement

La hotte peut _tre install6e au mur ou suspendue d'une

armoire, Une d6charge verticale ou horizontale est

possible avec une ou I'autre des m6thodes.

Direction de la d_charge: La hotte est exp6di6e prete

pour une d6charge verticale. Pour passer en position

horizontale, simplement d6placer le couvercle de

d6charge, illustr6 & la figure 1, vers le haut de la hotte.

La plaque est maintenue en place par 4 vis.

Cette ouverture

est couverte pour

la decharge

horizontale

Assemblage de la transition: La transition fournie

se fixe sur le haut ou I'arri_re de la hotte selon la

direction de la d6charge.

1. Aligner les trous de fixation &la base de la

transition avec les trous de fixation sur le

rebord 1/2 po situ6 au haut ou & I'arri_re de la

hotte selon la direction de la d6charge.

2. Attacher la transition & la hotte & I'aide de deux

(2) vis & m6tal n° 8 x 3/8 po (comprises avec la

hotte).

3. Sceller la connexion entre la transition et la

hotte avec du ruban & conduit.

4. Enlever le ruban qui maintient le registre ferm6.

Voir figure lb pour les dimensions hors tout de

la hotte.

Figure la • Direction de la decharge

Cette ouverture est

couverte pour la

decharge verticale

30 po, 36 po, 42 po, 48 po, 54 po *

18 po

27 po

Figure lb • Dimensions hors tout * Varie selon le modele

4

Page 17

Remarque Lire les instructions

d'installation de la tel6commande avant de

continuer si cet accessoire est utilis&

I ouvercle deconduit 6 po

Installation murale

La hauteur de I'installation de la hotte est selon les

pr6f@ences de I'utilisateur. Lafigure 2 illustre une

installation typique avec un couvercle de conduit.

Les couvercles de conduit 6 po et/ou 12 po

(accessoires) sont utilis6s pour remplir I'espace

entre la hotte et le plafond.

La hauteur de I'installation montr6e & la figure 2 est

de 36 po. Un couvercle de conduit 6 po a 6t6 utilis6

dans cette installation. Ajouter ou enlever des

couvercles de conduit pour accomoder la hauteur de

plafond et la hauteur d6sir6e de la hotte.

,

Une fois la hauteur d6sir6e 6tablie, tirer une

ligne horizontale a une distance au-dessus de la

plaque de cuisson 6gale a la hauteur d6sir6e de

I'installation de la hotte plus 15 1/2 po. Cette

ligne est I'emplacement du montant en bois

exp6di6 ave la hotte.

,

Rep@er la ligne centrale de la plaque de

cuisson. Tirer une ligne verticale le long de cette

ligne centrale jusqu'a la ligne horizontale,

dessin6e a 1'6tape 1.

,

La hotte est fix6e au mur a I'aide du montant en

bois exp6di6 avec la hotte. Enlever la fixation de

la hotte en enlevant les deux vis d'exp6dition.

Marquer la ligne centrale du montant.

,

Rep@er un montant d'un c6t6 ou de I'autre de la

ligne centrale de la plaque de cuisson pour

utiliser avec le montant en bois tel qu'il est

illustr6 a la figure 3.

,

Aligner le haut du montant en bois le long de la

ligne horizontale dessin6e & 1'6tape 1.Aligner les

lignes centrales du montant en bois et de la

plaque de cuisson.

,

Percer un trou 1/8 po de 3 po de profondeur

dans le montant a travers le montant en bois, le

placopl&tre et dans le montant du mur.

,

Utiliser 2 ou 3 vis (n° 14 x 3 po) pour fixer la

fixation au mur, comme & la figure 3. Pour le

support des hottes plus Iongues, utiliser trois

montants. Fraiser les tetes pour empecher

I'interf@ence avec lahotte.

,

Sur le montant en bois, marquer les

emplacements utilis6s pour suspendre la hotte

selon lafigure 4 (page suivante).

24 P° _porj,___1

t

Plafond

standard 8

pi (96 po)

Hauteur de hotte (36 po)

T1

Cuisini@e

standard 36 po

de haut

Jr

Figure 2 - installation de hotte typique

Fixation a bois

Plac6platre

Hauteur

au-dessus

plaque de

cuisson

Vis (2 de

chaque, n°

14x 3 po)

Figure 3 - Installation des fixations a bois

9. Percer un trou de 1/8 po & travers le montant en

bois et le placopl&tre. Ces vis (n° 8 x 5/8 po)

n'ont pas besoin d'allerjusqu'aux montants.

10. Percer un trou de 1/16 po pour les deux vis (n° 8

x 5/8 po) dans le montant en bois en laissant

1/4 po de chaque vis expos6 pour suspendre la

hotte.

Ligne centrale

plaque de

cuisson

,-Montants

muraux

Hauteur

desir6e

de hotte

+ 15 1/2

po

Vers surface

de plaque de

cuisson

Page 18

Plac6platre

Vis _

(2 ch. N° 14

x 3 po)

\

-%

Ligne centrale

plaque de cuisson

|

|

Mesure A

|

11.Direction de lad6charge : La d6charge horizontale

requiert une d6coupe murale, comme &la figure 5,

pour assurer un d6gagement pour latransition.

L'emplaement de lad6coupe est d6termin6 par la

hauteur d'installation dela hotte.

10-1/4po

Ligne centrale

transition

I

10-I/2 po

k ,C

FORMAT

DE HOTTE

30 po 13 1/16po

36 po 16 1/16po

42 po 19 1/16po

48 po 22 1/16po

54 po 25 lh6 po

Figure 4

Plac6platre

l-

-i-r

12-1/2 po I

_LL

2-3/4 po _

Figure 5

Remarque : La ligne pointill6e indique la d6coupe

n6cessaire pour le d6gagement de la transition.

23 po --1

1--

J

L_ T

Ligne I

centrale

plaque de Emplacement

cuisson base de la hotte

Figure 6

La transition fournie avec la hotte se branche sur un

conduit rond 10po standard. La figure 6 montre la

transition branch6e sur la d6charge horizontale.

Ligne centrale

transition

I

I 5-13/I6 PO

mur

I

po

10-I/4

/

Figure 7

La figure 7 montre la hotte configur6e pour une

d6charge verticale. Les installations utilisant ce type

de m6thode requi_rent une d6coupe dans le plafond

pour accomoder un conduit de 10 poet un conduit

de 1/2 po pour I'alimentation de I'appareil.

Des couvercles de conduits, vendus s6par6ment,

sont disponibles pour couvrir I'espace entre le haut

de la hotte et le plafond. (Volt page 3).

18 po

Page 19

12.Avantdesuspendrelahotte,

installerlatransitionselonla

figure6.Fixerlatransitionavec

2vis(n°8x3/8po,&m6tal,

foumies)etapposerduruban

adh6sifselonlescodes

applicables.

Remarque : les vis nedoivent

pas nuire au fonctionnement du

registre

13.

D6poser la hotte sur les vis dans

la fixation en bois. Utiliser les

trous marqu6s <<1>>& lafigure 8.

S'assurer que lesfixations en

bois s'ajustent dans le retrait au

dos de la hotte.

14. Retirer les trous &estamper.

15. Setter les vis dans les trous.

V6rifier si lahotte est de niveau,

r6gler au besoin.

16.

Depuis I'int6rieur de la hotte,

ins6rer lesvis (n°8 x 5/8 po) par

les trous de la hotte darts les

fixations en bois. Voir les trous

marqu6s J a lafigure 8.

17. Connecter conduit

suppl6mentaire.

Assemblage et

Des couvercles de conduit

optionnels montr6s a la figure 9

peuvent etre utilis6s pour combler

I'espace entre la hotte et le

plafond. Des couvercles de

conduit 6 po ou 12 po sont

disponibles et peuvent etre

command6s s6par6ment.

1. Si plusieurs couvercles de

conduit sont utilis6s,

connecteur les pi_ces

ensemble a I'aide de vis

m6tal fournies avec le

couvercle de conduit.

,

Fixer le(s) conduit(s) de

couvercle & la hotte &I'aide

de vis & m6tal, comme a la

figure 9.

,

Depuis I'int6rieur de la hotte,

ins6rer les vis (n° 8 x 5/8 po

fournies) par les trous L, une

de chaque c6t6 et quatre le

long du devant, dans le bas

de I'armoire.

I

Figure 8

Remarque sur I'installation : Si les montants muraux sont a moins

de 8 po de la ligne centrale, couper le montant en angle pour 6viter

toute interf6rence.

installation des couvercles de conduit

Vis n ° 8 x

3/8 po

(nombre

dependant

du format

de la hotte)

Figure 9

Page 20

La hotte peut etre install6e sous

I'armoire en supportant la hotte

par le haut.

Remarque : La structure de

I'armoire dolt _tre jointe au×

montants du mur afin de

supporter le poids de la hotte.

La figure 10 montre les quatre

trous de vis (K) utilis6s pour

installer la hotte au bas de

I'armoire.

S'assurer que les deux pastilles

enlevables ont 6t6 retir6es.

,

A la base de I'armoire, percer

un trou de 1/8 po (voir

dimension A &la figure 10 et

dans le tableau). Visser

quatre vis n° 10 x 1 po

(fournies avec la hotte),

laissant 1/4 po expos&

,

Si la hotte est install6e pour

une d6charge verticale,

utiliser la figure 11 pour cr6er

les trous de d6gagement pour

le passage de la transition et

du conduit. La dimension B

de la figure 11 d6pend du

module de la hotte a _tre

install6e et peut _tre situ6e

dans le tableau a droite. (Volt

dimension B a la figure 11 et

au tableau)

,

Pour la d6charge horizontale,

utiliser la figure 5 pour la

g6om6trie de la d6coupe

requise pour le d6gagement

de la transition.

Installation de I'armoire

1-9/16

placement du trou

Remarque : Cette figure montre les

emplacements de trous et de vis

seulement. Voir figure lb, page 4 pour

les dimensions hors tout de la hotte.

Figure 10 • Emplacement du trou et de la vis.

Dimensions du trou de la ligne centrale pour les

figures 10 et 11

FORMAT DE A (Fig 10) B (Fig 11)

HOTTE Trou Trou de conduit

30 po 29-1/16po 13-7/16po

36 po 35-1/16po 16-7/16po

42 po 41-1/16po 19-7/16po

48 po 47-1/16po 22-7/16po

54 po 53-1/16po 25-7/16po

,

Suspendre la hotte sur les vis

et visser de fagon s6curitaire.

,

Depuis I'int6rieur de la hotte,

ins6rer les visfournies.

Percer par les trous (utiliser

les vis n° 8 x 5/8 po fournies),

une de chaque c6t6 et quatre

le long du devant, dans le bas

de I'armoire. Voir les trous de

vis 6tiquet6es <<L)>,figure 10.

_1 1' I1_ _ B " 2-3/8f

-1/8 po 4 23 po

= ...........I..........:!

ill 7 7/8 - 7/8 po

_o.'" _ ....... _23/8po t

Ligne centrale |

plaque de cuisson Trousded_gagement

3 -3/16 po 5/8podia.pourconduit

Vue de la d_coupe de rarrnoire

I Remarque : Cette figure montre les emplacements de conduit et de transition

seulement. Voir figure lb, page 4, pour les dimensions hors tout de la hotte.

Figure 11 • emplacement du conduit et de la transition

po °1o_L

1/2poversboftedejonction

po

Page 21

Installation de la soufflerie int6gree VTN1030C

La hotte peut _tre installee avec la

soufflerie VTN 1030C.

Preparation de la soufflerie

Fixations

d'expedition

\

Attache

Capaciteur

Vue avant de la souffierie

Figure 12a

1. Enlever les attaches d'exp_dition gauche et

droite et jeter.

2. Couper I'attache de fil montr6e & la figure 12a.

Rep6rer le faisceau de c&blage avec le

connecteur a 6 broches Molex. Acheminer le

faisceau de c&blage par I'arri_re de lasoufflerie,

comme a la figure 12b, ci-dessous.

3. Rattacher le faisceau de ills capaciteur avec la

nouvelle attache de fil (fournie) au m_me endroit

I'avant.

Installer la soufflerie dans la

hotte:

,

La soufflerie est fix6e a la hotte a I'aide des

montants soud6s fournis avec la plaque de

fixation.

,

La figure 12c montre les montants soud6s &

I'endroit B pour la d6charge (arri_re) horizontale.

Mettre 4 6crous n° 10 x 24 sur les montants

soud6s. Pour la d6charge verticale, mettre les

6crous sur les montants au haut de la plaque de

fixation.

. o_'$. & o oo.

0 0

I J' "\

Figure 12c

,

Guider la plaque de fixation du moteur sur les

6crous et serrer de fagon s6curitaire la soufflerie

la hotte.

4. Fixer deux vis additionnelles, figure 12d.

Ajouter

Faisceau

de

c_blage

Vue arriere de la soufflerie

Figure 12b

, Attacher le faisceau de ills avec connecteur

Molex & 6 broches au boftier comme a la figure

12b avec une attache de fil (fournie).

attache ici

I

I

i

Assemblage

ventilateur

additi°nne_ $

Figure 12d

_, ATTENTION:

S'assurer que les deux vis additionnelles,

figure !2d, sont installees et

adequatement settees avant de continuer.

Page 22

Instructions

de c&blage

Decharge verticale

Figure 12e

Acheminer fil ici

Couvercle

de fil

Decharge horizontale

Acheminer fil ici

Figure 12g

Couvercle

I

// :

Figure 12f

Installer le couvercle comme la figure 12F. Le

module 30 po de large n'a pas besoin de

couvercle de ill.

Figure 12h

Installer le couvercle comme & la figure 12H.

Le module 30 po de large n'a pas besoin de

couvercle de ill.

10

Page 23

AVERTISSEMENT

Fermer 1'61ectricit6au panneau de service avant d'effectuer le

c&blage de I'appareil. (Volt instructions de s6curit6, page 1).

C&blage de la hotte avec

moteur int6gre

1. Enlever le couvercle de la bofte de jonction.

2. Brancher le connecteur a fiche Molex du

VTNI030C sur le connecteur a I'int6rieur de la

hotte comme a la figure 13.

3. Installer un connecteur de conduit 1/2 po dans la

bofte de jonction.

Depuis le ventilateur

Depuis le panneau

de contr61e

Figure 13

4. Acheminerlesfils noir, blancetvert (n° 12

AWG) dans le conduit 1/2 po depuis

I'alimentation a la bofte de jonction.

5. Brancher les fils d'alimentation sur les ills de la

hotte dans I'ordre suivant : noir avec noir, blanc

avec blanc et vert sur lavis de mise a la terre

verte sur le ch&ssis. Utiliser des 6crous

ailettes de type a ressort. (Des 6crous

manquants ou perdus doivent etre remplac6s

seulement par : 6crou m6tallique de type

ressort, cot6 pour un minimum de (2) fils n°

18ga et maximum de (4)fils n° 14ga, UL et

ACNOR cot6 a 600 V et 302 deg.

6. Fermer le couvercle de la bofte de jonction.

V6rifier que toutes les ampoules sont

s6curitaires dans leurs douilles. Replacer les

filtres comme il est d6crit dans le guide

d'entretien et d'utilisation. Mettre en circuit au

panneau de service. V6rifier lefonctionnement

de la hotte.

Installation de la soufflerie a distance

Les hottes PH sont con£;ues pour fonctionner avec

les souffleries VTR630D, VTRI030D, VTR1330E, ou

VTR1530D a distance. Pour les instructions

d'installation, voir les instructions fournies avec

I'appareil de lasouffierie.

C&blage de la hotte avec

une soufflerie a distance

Ass. tire bouchon

(fourni avec hotte)BK o_2_ _

BLKR

:DJ

Figure 14

1. Enlever le couvercle de la bofte de jonction.

2. Installer un connecteur de conduit 1/2 po.

3. Acheminerlesfilsnoir, blancetvert(n ° 12

AWG) dans le conduit 1/2 po depuis

I'alimentation de la bofte de jonction.

4. Brancher les ills d'alimentation sur les fils de la

hotte comme suit : noir avec noir, blanc avec

blanc et vert sur la vis de mise a la terre verte

sur le ch&ssis. Utiliser des 6crous a ailettes de

type a ressort. (Des 6crous manquants ou

perdus doivent _tre remplac6s seulement par :

6crou m6tallique de type a ressort, cot6 pour un

minimum de (2) fils n° 18ga et maximum de (4)

ills n° 14ga, UL et ACNOR cot6 a 600 Vet 302

deg.

5. Brancher le <<tire-bouchon>>sur leconnecteur

I'int6rieur de la bofte de jonction.

6. Acheminer les 5 fils (n° 14AWG) dans le

conduit 1/2 po depuis la soufflerie a distance au

second connecteur de conduit.

7. Brancher le ventilateur & distance sur les ills

<<tire-bouchon>>(6tape 6) comme a lafigure 14

en utilisant les 6crous de fils fournis. Brancher le

fil vert (mise a la terre) de la soufflerie a distance

sur la vis de mise a la terre dans la bofte de

jonction.

8. Fermer le couvercle de la bofte de jonction.

V6rifier que toutes les ampoules sont

s6curitaires dans leurs douilles. Installer les

filtres. Mettre en circuit au panneau de service et

v6rifier le fonctionnement des ampoules et de la

soufflerie a distance comme il est indiqu6 dans

le guide d'utilisation et d'entretien.

11

Page 24

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

APROBADO PARATODAS LAS UNIDADES RESIDENCIALES

0NICAMENTE PARAUSO RESIDENCIAL

POR FAVOR LEACOMPLEATMENTE LAS INSTRUCClONESANTES DE PROCEDER.

IMPORTANTE: Guarde estas instrucciones para el uso del Inspector Local de Electricidad.

INSTALADOR: Por favor deje estas instrucciones con esta unidad para el propietario.

PROPIETARIO: Por favor retenga estas instrucciones para referencia futura.

ADVERTENCIA

Si la informaci6n en este manual no es

seguida exactamente, puede resultar en incen=

dio o choque electrico, provocando dafios a

su propiedad o dafios personales. No intente

repara o reemplazar ninguna parte de la unidad

a menos que sea especificamente

recomendado en los manuales. Una

instalaci6n, servicio o mantenimiento

inapropiados puede producir lesiones o dafios

a su propiedad. Refierase a este manual para

instrucciones. Todo el resto de los servicios

debera ser realizado por un tecnico calificado.

La unidad es pesada y requiere de por Io menos

dos personas o equipo apropiado para ser

movida.

Superficies no visibles pueden tener esquinas

filosas.

Tenga cuidado cuando este tocando detras o

debajo de la unidad.

Esta unidad cumple con uno o mas de los

siguientes Estandares:

, UL 858, La norma para la seguridad de

estufas electrodomesticas

, UL 923, La norma para aparatos (hornos) de

microondas

, UL 507, La norma para la seguridad de

ventiladores electricos

, ANSI Z21.1, La norma americana nacional

para aparatos domesticos de cocina que

funcionan con gas

, CAN/CSA-C22.2 No. 113=M1984Ventiladores

, CAN/CSA=C22.2 No. 61=M89 Estufas

domesticas

Es responsabilidad del duefio de la unidad y del

instalador al determinar si aplican requerimientos

legales y/o estandares adicionales aplican para

instalaciones especificas.

ADVERTENCIA DE

SEGURIDAD

Apague el circuito de alimentaci6n en el panel

de servicio y bloquee el panel antes de instalar

este aparato.

REQUERIMIENTO: 120 VAC, 60 Hz 20 A

ADVERTENCIA

Para reducir el riesgo de un incendio, s61o

utilice conductos de metal.

Si es requerido por del C6digo Electrico Nacional

(o C6digo Electrico Canadiense), esta unidad

debe set instalada en un circuito ramificado

separado.

Instalador =muestre al propietario la Iocalizaci6n

de interruptor del circuito o fusible. Marquelo para

una referencia facil.

Retire toda la cinta y material de empaque antes

de utilizar la unidad. Destruya el material de

empaque posterior a desempacar la unidad.

Nunca permita que los nifios jueguen con

material de empaque.

Nunca modifique o altere la construcci6n de la

unidad. Por ejemplo, no retire las paras de

nivelaci6n, paneles, cubiertas de alambres o los

tornillos y soportes que evitan que la unidad se

incline.

INSTRUCCIONES DE CONEXION A TIERRA

Esta unidad debe estar conectada a tierra. En el

evento de un corto circuito, la tierra reduce el

riesgo de un choque electrico al proveer de un

cable de salida para la corriente electrica.

Eta unidad esta equipada con un cable que tie-

ne alambre a tierra con un enchufe a tierra. El

enchufe debe conectarse a una salida que esta

apropiadamente instalada y aterrizada.

Page 25

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

ADVERTENCIA

La conexi6n inapropiada a tierra puede resultar

en riesgo de choque electrico. Consulte a un

electricista calificado si las instrucciones de

conexi6n a tierra no son completamente

entendidas, o si existe alguna sobre si la unidad

qued6 conectada a tierra correctamente. No

utilice un cable de extensi6n. Si el cable de

corriente es demasiado corto, pida a un

electricista calificado que instale otro conector

cerca de la unidad.

Para reducir el riesgo de incendio o choque

electrico, no utilice este ventilador con ningQn

aparato de estado s61ido para el control de

velocidad.

PARA LA REDUCClON DEL RIESGO DE IN-

CENDIO, COQUE ELI_CTRICO Y LESIONES

A PERSONAS:

El ensamblado de este ventilador debe set

instalado con el soplador modelo(s)

VTN 1030C, VTR630D, VTR1030D, VTR1330E,

o VTR1530D. Otros sopladores para ventilador

no pueden set substituidos.

a. Utilice esta unidad _nicamente en la forma

intencionada por el fabricante. Si tiene

preguntas contacte al fabricante (Atrenci6n al

Cliente Thermador en 800/735=4328).

b. Antes de dar servicio o efectuar iimpieza

a la unidad, ponga el interruptor del panel

de servicio en APAGADO y bloque_ los

medios para prevenir que ia corriente sea

encendida accidentalmente. Cuando los

medios de servicio para desconectar no pueden

ser bloqueados, Sujete con seguridad un aviso

de advertencia prominente, como una etiqueta

al panel de servicio.

c. El trabajo de instalaci6n y el cableado

electrico debe ser realizado por una pesona

calificada de acuerdo con todos los c6digos y

estandares aplicables. Incluyendo construcci6n

clasificada en incendio.

d. El suficiente aire es necesario para una

combusti6n apropiada y el escape de los gases

a traves del tubo (chimenea) o un equipo

quemador de combustible para prevenir retorno

de corriente. Siga la instrucciones del fabricante

del equipo de calentamiento, ase como los

estandares de seguddad como los publicados

pot la Asociaci6n Nacional de Protecci6n contra

Incendios (NFPA), y (ASHRAE)la Sociedad

Americana para Ingenieros de Calefacci6n,

Refrigeraci6n y Aire Acondicionado, y las

autoddades de c6digos locales.

e. Cuando corte o efectOe trabajos con taladro

en las paredes o techos, no dafie alambrado

electrico y otras utilerias no visibles.

f. Ventiladores con ductos siempre deben set

ventilados al exterior.

g. Para dejar escapar el aire apropiadamente,

asegQrese de que los ductos sean ventilados

al exterior. No ventile el aire de escape a

espacios dentro de paredes, techos, aticos,

espacios de arrastre, o cocheras.

h. Antes de conectar un cable electrico,

asegQrese que todos los controles esten en la

posici6n de APAGADO.

CUIDADO

$61o para uso de ventilaci6n general. NO LO

utilice para exhaustar materiales peligrosos

o explosivos o vapor.

CUIDADO

Ventile la unidad hacia afuera del edificio.

Page 26

Partes Incluidas con su Campana Partes No Incluidas con su Campana

• Toldo de laCampana

• Focos de hal6geno de 12 volts, instalados

• Filtros, 2, 3 o 4 dependiendo del modelo y

tamafio

• Transici6n Met_lica con amortiguador de contra-

corriente instalado

• Sujetadores

• Adaptador de Soplante Remoto ("rabillo")

• Tira de Madera para el Soporte de la Campana

• Tuercas para Cables

• 2 I_mparas de calentamiento 175W PAR 38 o

2 I_mparas de calentamiento 250W PAR 40

• Instrucciones de Instalaci6n/Cuidado y Uso

• Tarjeta de Registro

Cinta de Electricista

Conducto de 1/2"

Ventilador - Se puede instalar la campana con

los modelos de ventilador VTN 1030C, VTR630D,

VTR1030D, VTR1330E, o VTR1530D

Cubierta opcional para el conducto, altura 6"

DC**US o 12" DCT**US, se tiene que comprar

pot separado. (** = ancho de la campana).

Ii

Control Remoto Opcional (se debe pedir por

separado)

CONSIDERACIONES ANTES DE INSTALAR LA CAMPANA

,

Para tener el escape de aire m_s eficiente,

utilice un conducto recto o la menor cantidad de

codos posibles.

,

No utilice conductos flexibles.

Las instalaciones en CLIMA FRJO debe contar

3.

con un amortiguador extra para la

contracorriente para minimizar el flujo de retorno

del aire fria y una barrera t6rmica no met_lica

para minimizar la conducci6n de las

temperaturas externas como parte del trabajo

de conductos. El amortiguador debe colocarse

en el lado del aire fria de la barrera t@mica. La

barrera debe estar Io m_s cerca posible al lugar

donde los conductos entran en la parte caliente

de la casa.

,

La altura de instalaci6n de una campana sobre

una parrilla o estufa puede variar. Para obtener la

altura de instalaci6n necesaria sobre una Parrilla

o Estufa Profesional Thermador, consulte el

manual de instalaci6n de la unidad.

Por Iotanto, Thermador recomienda instalar la

campana a una distancia minimum de 36

pulgadas (91 cm) arriba de la mesa de trabajo.

Para instalaciones de asado en el interior,

Thermador recomienda una altura minima de 36"

(91,4 cm) y s61osopladores remotos

(VTR1030D, VTR1330E, o VTR1530D).

,

Los sopladores remotos requieren de una

instalaci6n con cinco hilos.

6.

Aire de Relleno: Tal vez los c6digos locales para

regular las construcciones requieren el uso de

sistemas de aire de relleno cuando se est_n

usando sistemas de ventilaci6n con conductos

m_s grandes que los CFM del movimiento de

aire especificados. Los CFM especificados

vadan de lugar a lugar. Consulte a su experto

HVAC para los requerimientos especificos en su

_rea.

,

Consulte las instrucciones de instalaci6n del

control remoto si aplica.

3

Page 27

Instalaci6n

CUIDADO:

Ventile la unidad hacia afuera del edificio.

Se puede montar la campana en una pared o en

forma suspendida de un gabinete. Con cualquiera de

estos dos m6todos se puede instalar la descarga

vertical u horizontal.

Direcci6n de la Descarga: La campana viene

preparada para ladescarga vertical. Para cambiar a

la descarga horizontal, simplemente cambie la

cubierta de descarga que se muestra en la Figura 1

a la parte superior de la campana. Cuatro tornillo

mantienen en su lugar ala placa.

del Aparato

Conjunto de Transici6n: La transici6n incluida es

instalada en la parte superior o trasera de la campa-

na dependiendo de la direcci6n de descarga.

1. Alinee los orificios de montaje en la base de

transici6n con los orificios de montaje en la

brida de 1/2" que se Iocaliza en la parte superior

o trasera de la campana dependiendo de la

direcci6n de descarga.

2. Fije la transici6n a la campana utilizando dos (2)

tornillos de chapa #8 x 3/8 (incluidos con la

campana).

.

Selle la conexi6n entre la transici6n y la campa-

na con cinta para conductos.

.

Quite la cinta que mantiene cerrado el

amortiguador.

Yea la Figura lb para las dimensiones

generales de la campana.

Se cubre esta

abertura para la

descarga

horizontal•

Figura la: Direcci6n de descarga

Se cubre esta

abertura para la

decarga vertical.

18"

Figura lb: Dimensiones generales

* Varia segOn modelo.

Page 28

Nota: Lea las instrucciones de instalaci6n

del control remoto antes de seguir utilizando

este accesorio.

Instalaci6n con Montaje en

Pared

Es cuesti6n de preferencia del usuario a qu6 altura

desea instalar la campana. La Figura 2 muestra una

instalaci6n tipica de la campana con una cubierta de

conducto. Se usan las cubiertas de conductos de 6"

y 12" para Ilenar el espacio entre la campana y el

techo.

La altura de instalaci6n que se muestra enla Figura

2 es de 36 pulgadas (91 cm). Se utiliz6 una cubierta

de conducto de 6" en esta instalaci6n. Agregue o

quite cubiertas de conductos como sea apropiado

para acomodar la altura de techo y la altura deseada

de la campana. La campana soporta la estructura de

la cubierta del conducto.

1. Despu6s de haber determinado la altura de la

instalaci6n de la campana, dibuje una linea

horizontal a una distancia arriba de la estufa

igual a la altura deseada de instalaci6n de la

campana m_s 15 1/2" (39.4 cm). Esta linea es

el ugar de montaje del soporte de madera que

viene incluido con la campana.

2. Encuentre la linea central de la estufa. Dibuje

una linea vertical a Io largo de la linea central

hasta Ilegar a la linea horizontal dibujada en el

paso 1.

3. Se fija la campana a la pared usando un soporte

de madera que viene incluido. Quite el soporte

de la campana quitando dos tornillos. Marque la

linea de centro del soporte.

4. Localice un resalto en cada lado de la linea

central de la estufa que se usa para montar el

soporte de madera como se indica en la Figura

3.

,

Alinee la parte superior del soporte de madera a

Io largo de la linea horizontal dibujada en el

Paso 1.Alinee las lineas centrales del soporte y

de la estufa.

6. Per[ore dos orificios de 1/8" a una profundidad

de 3" por resalto a trav6s del soporte de madera,

el muro de piedra en seco y en los resaltos de

la pared.

7. Use cuatro 2 o 3 tornillos de campana (#14x3",

vienen incluidos) para fijar el soporte a la pared

como se indica en la Figura 3. Para soportar las

campanas m&s largas, use seis tornillos de

madera y tres resaltos, Avellana las cabezas

para evitar la interferencia con la campana.

8. Marque los lugares en el soporte de madera que

se usan para colgar la campana como se indica

en la Figura 4 (p_gina siguiente).

t Cubierta de

|conducto de 6"1 I

T /---3

l I

T

Altura al

techo

estandar de

8 pies (96")

(244 cm)

Figura 2 - Instalaci6n tipica de campana

Muro seco Linea central

Altura

arriba

de la ) _,,

estufa' k,_

Tornillos /

(2 cada

#14X3) )

Figura 3 - Montando el soporte de madera

9. Per[ore un orificio roscado de 1/8" a trav6s del

soporte de madera y el muro de piedra en seco.

Estos tornillos (#8 x 5/8") no deben entrar en los

resaltos.

10. Per[ore un agujero de 1/16" para los 2 tornillos

(#8 x 5/8") en el soporte de madera dejando

expuesto ¼" de cada tornillo para colgar la

campana.

Altura de la

campana (36"")

Rango

estandar

36" de

altura

,l

k f

Soporte de Madera

de la estufa

Resalto

pared

_°°

Altura

deseada

de la

compana

+15-½"

r

A la superficie

de la estufa

5

Page 29

Muro seco

Tornillos cada

2 #14 x 3"

Linea central de la estufa

B

I

I

I

11.

Direcci6n de Descarga: La descarga horizontal

requiere un recorte de la pared como se indica

en la Figura 5, para proporcionar un espacio

libre para la transici6n. El lugar del recorte se

determina por la altura de instalaci6n de la

campana.

Linea central de

la transici6n

TAMANO DE

LA CAMPANA

30" 13-1/16"

36" 16-1/16"

42" 19-1/16''

48" 22 -lh6"

54" 25-1/16''

Figura 4

Medici6n A

i

A

23"

!

|

|

I 10-1/2"

Figura 6

La transici6n incluida con la campana se conecta al

conducto redondo est_ndar de 10 pulgadas. La

Figura 6 muestra la transici6n conectada para la

descarga horizontal.

Linea central

de la transici6n

J

L_

Linea Central

de la Estufa Base de la

Campana

Figura 5

T

Nota: La linea punteada indica el recorte que se

necesita para el espacio libre de la transici6n.

18"

Figura 7

La Figura 7 muestra la campana configurada para

una descarga vertical. Las instalaciones que usan

este tipo de m6todo requieren un recorte en el techo

para acomodar el conducto de 10"y el conducto de

alimentaci6n de ½"a la unidad.

Las cubiertas de conducto que se venden por

separado, est_n disponibles para cubrir el espacio

entre la parte superior de la campana y eltecho.

(Yea la P_gina 3).

6

Page 30

12. Antes de colgar la campana, instale la transici6n

segQn la Fig. 6. Fije la transici6n con 2 tornillos

(tornillo autorroscante o de plancha #8 x 3/8,

incluidos) y endntela de acuerdo a todos los

c6digos aplicables.

Nora: los tornillos no deben interferir con la

operaci6n del regulador de tiro.

13. Coloque la campana sobre los tornillos en el

soporte de madera. Use los orificios marcados

"1"en la Figura 8.Asegt3rese que el soporte de

madera quepa en la ranura en la parte trasera de

la campana.

14. Quite los agujeros ciegos.

15. Apriete los tornillos en los orificios. Revise que

la campana est6 nivelada y ajOstela si es

necesario.

16. Fije los tornillos (#8 x 5/8") a trav6s de los

agujeros en la campana al soporte de madera

desde el interior de la campana. Vea los

agujeros marcados J en la Figura 8.

17. Conecte el conducto adicional.

Figura 8

Nota de Instalaci6n: Cuando los soportes de pared

quedan a una distancia de 8" de la linea de centro,

corte el soporte en un _ngulo para evitar cualquier

interferencia.

Montaje e Instalaci6n

Se pueden usar las cubiertas de

conducto opcionales que se indican en

la Figura 9 para Ilenar el espacio entre

la campana y el techo en instalaciones

con montaje en pared. Est_n

disponibles cubiertas de conducto con

una altura de 6" y 12" (15 y 13 cm) y se

pueden pedir por separado.

1. Cuando se usan m_ltiples cubiertas

de conducto, conecte las piezas

juntas usando tornillos de hojalata

que vienen incluidos con las

cubiertas de conducto.

,

Fije la cubierta(s) de conducto a la

campana usando los tornillos de

hojalata como se indica en la Figura

9.

,

Desde el interior de la campana,

atornille a trav6s de los agujeros L

(#8 x 5/8", incluidos) en cada lado y

cuatro a Io largo del frente, hasta el

fondo de la cubierta de conducto.

de las Cubiertas de Conducto:

Tornillo #8 x

3/8"

(n_imero

depende dei

tamaSo de

la campana)

Figura 9

7

Page 31

Instalaci6n con Gabinete

Se puede instalar la campana abajo

de un gabinete que soporte la

campana desde arriba.

Nota: EL gabinete debe estar

unido estructuralmente a los

resaltos de pared para soportar

el peso de la campana.

La Figura 10 muestra los cuatro

agujeros (K) de tornillo que se usan

para fijar la campana a la parte

inferior del gabinete.

Asegurase de que las dos tapas

fueron quitadas.

,

Perfore agujeros para rosca

interior de 1/8" en la base del

gabinete (Vea la dimensi6n Aen

la Figura 10 yen la Tabla). Fije

cuatro tornillos #10 x 1" (vienen

incluidos con la campana),

dejando ¼" expuesto.

,

Cuando se instala la campana

para la descarga vertical, use la

Figura 11 para crear los orificios

de espacio libre para el paso de

la transici6n y del conducto.

(See dimension B in Figure 11

and in Table).

,

Para la descarga horizontal, use

la Figura 5 para la geometda del

recorte que se requiere para el

espacio libre de la transici6n.

,

Cuelgue la campana desde los

tornillos y aprietela bien.

,

Inserte los tornillos que se

incluyen desde la parte interna

de la campana. Perfore agujeros

(use los tornillos de #8 x 5/8"

que se incluyen), en la parte

inferior del gabinete, uno en

cada lado y cuatro a Io largo del

frente. Vea los agujeros para

tornillos marcados "L" en la

Figura 10.

1-9/16"

_A: Ubicaciones de los agujeros

_"'_23" pa_q_.ca interna

Nota: Esta figura muestra s61o las ubicaciones

del agujero para rosca interna y para el tornillo.

Vea la Figura lb, pagina 4 para las dimensiones

generales de la campana.

Figura 10: Ubicaciones de los agujeros para rosca interna y para los tornillos

Dimensiones del agujero de la linea

de centro para las Figuras 10 y 11

TAMANO DE A (Fig 10) B (Fig 11)

LACAMPANA Agujeros para rosca interna Agujero del conducto

30" 29-1/16" 13-7/16"

36" 35-1/16" 16=7/16"

42" 41=1/16'' 19-7/16''

48" 47-1/16" 22-7/16"

54" 53 -1/16" 25-7/16"

Pared

-1/8"_ _: 23" 114 _ B _ f2-3/8"

...........

...........I iT77 ,,

Linea Central de la Estufa

3 -3/16" Agujeros de espacio libre

Vista del Piano para el Recorte del Gabinete

DIA de 5/8" para el

conducto de 1/2"a la caja

de conexiones

Nota: Esta figura muestra s61o las ubicaciones del agujero para rosca interna y

para el tornillo. Vea la Figura lb, pagina 4 para las dimensiones generales de la

campana.

Figura 11: Ubicaciones de la transici6n y del conducto

8

Page 32

Instalar un Soplador

Integral VTNI030C

Se puede instalar la campana con un i

soplador VTN 1030C.

Preparaci6n del soplador

Soportes de transporte

Uni6n de cable

Capacitor

Vista frontal del soplador

Figura 12a

1. Quite los soportes de transporte a la

izquierda y derecha y des_chelos.

2. Corte la uni6n de cable como se indica en la

Figura 12a. Ubique el arn6s de cables con el

conector Molex de 6 pines. Coloque el arn6s de

cables para que salga por la parte trasera del

ventilador, como se muestra en la Figura 12b

abajo.

3. Vuelva a fijar el capacitor con el arn6s del cable

con la nueva uni6n de cable (incluida) en el

mismo lugar en el frente.

Instalar el soplador en la

1

,

Se fija el soplado a la campana usando los

pernos de soldadura que vienen incluidos en la

placa de montaje.

,

La Figura 12 c muestra los pernos de soldadura

en el lugar B para la descarga horizontal

(trasera). Fije cuatro tuercas #10-24 a los

pernos de soldadura. Para una descarga

vertical, fije las tuercas a los pernos en la parte

superior de la placa de montaje.

Figura 12c

3. Coloque la placa de montaje del motor encima

de las tuercas y apriete para asegurar el

soplador a la camapana,

4. Fije dos tornillos adicionales como se muestra

en la Figura 12d.

campana:

Agregar

uni6n de

Arnes de

cable

Vista tarsera del soplador

Figura 12b

4. Conecte el arn6s de cable con el conector

Molex de 6 clavijas a la caja como se indica en

la Figura 12b con la uni6n de cable (incluida).

cable aqui

Conjunto del

Ventilador

Adicionales

Tornillos __'

Figura 12d

CUIDADO:

Verifique que los dos tornillos adicionales

en la Figura 12d esten instalados y bien

apretados antes de proceder.

9

Page 33

Instrucci6n para encaminar los cables

Figura 12e

Descarga Vertical

Encamine los cables aqui

Cubierta de cable

Descarga Horizontal

Encamine los cables aqui

Figura 12g

Cubierta de cable

\

Figura 12f

Instale la cubierta de cable como se indica en

la Figura 12f. El modelo con ancho de 30" no

necesita una cubierta para cables,

Figura 12h

Instale la cubierta de cable como se indica en

la Figura 12h. El modelo con ancho de 30" no

necesita una cubierta para cables,

10

Page 34

ADVERTENCIA

Apague la electricidad en el panel de servicio antes de conectar

la unidad. (vea las Instrucciones de Seguridad, P_gina 1).

Conectar la campana con un

motor integral

1. Quite la cubierta de la caja de conexiones.

2. Enchufe el conector molex VTNI030C al

conector presente adentro de lacampana como

se indica en la Figura 13.

3. Instale el conector del conducto de 1/2" en la

caja de conexiones.

Dei Panel de Control

Del Ventilador

Figura 13

4. Encamine los cables negro, blanco y verde

(#12AWG) en el conducto de 1/2" desde la

fuente de alimentaci6n a la caja de conexiones.

5. Conecte los cables de la fuente de alimentaci6n

a los cables de la campana en el siguiente

orden: cable negro con negro, blanco con blanco

y el cable verde al tornillo verde de tierra en el

bastidor. Use los conectores de alambre tipo

resorte que vienen incluidos. (Los conectores de

alambre que faltan o que se perdieron deben set

reemplazados solamente con: Conectores de

alambre tipo resorte, dise_ados para un minimo

de (2) alambres calibre #18 y un m_ximo de (4)

alambres calibre #14, aprobados pot UL y CSA

y una capacidad nominal de 600V y 302 grados

F / 150 grados C.

6. Cierre la cubierta de la caja de conexiones.

Revise para estar seguro que los focos est&n en

sus casquillos. Reemplace los filtros como se

describe en el Manual de Cuidado y Uso.

Prenda la corriente en el panel de servicio.

Revise la operaci6n de lacampana.

Instalaci6n del Soplador Remoto:

Los modelos de campana PH est_n disedados para

trabajar con los sopladores remotos VTR630D,

VTRI030D, VTR1330E, o VTR1530D Para las

instrucciones de instalaci6n, consulte las

instrucciones incluidas con el soplador.

Conectar la campana con un

Soplador Remoto

Conjunto del cable flexible

de conexi6n viene incluido

con la campana BK

Figura 14

1. Quite la cubierta de la caja de conexiones.

2. Instale el conector del conducto de 1/2" en la

caja de conexiones.

3. Encamine los cables negro, blanco y verde

(#12AWG) en el conducto de 1/2" desde la

fuente de alimentaci6n a la caja de conexiones.

4. Conecte los cables de la fuente de alimentaci6n

a los cables de la campana en el siguiente

orden: cable negro con negro, blanco con blanco

y el cable verde al tornillo verde de tierra en el

bastidor. Use los conectores de alambre tipo

resorte que vienen incluidos. (Los conectores de

alambre que faltan o que se perdieron deben ser

reemplazados solamente con: Conectores de

alambre tipo resorte, dise_ados para un

minimo de (2) alambres calibre #18 y un

m_ximo de (4) alambres calibre #14, aprobados

por UL y CSA y una capacidad nominal de 600V

y 302 grados F/ 150 grados C.

5. Conecte el enchufe "rabillo" al conector dentro

de la caja de conexiones.

6. Encamine cinco cables (#14AWG) en el

conducto de 1/2" del soplador remoto al

segundo conector de conducto.

7. Conecte elventilador remoto a los cables de

conexi6n flexible (rabillo) (Paso 6) como se

indica en la Figura 14 usando las tuercas de

cable incluidas. Conecte el cable verde (tierra)

del soplador remoto al tornillo de tierra en la caja

de conexiones.

,

Cierre la cubierta de la caja de conexiones.

Revise para estar seguro que todos los focos

est_n en sus casquillos. Instale los filtros.

Prenda la corriente en el panel de servicio y