Thermador PD366BS/12, PD366BS/09, PD366BS/10, PD366BS/06, PD366BS/07 Installation Guide

...Page 1

INSTALLATION

INSTRUCTIONS

For Thermador Professional ®PRO-GRAND TM

Dual Fuel Ranges

Models

PD304

PD36

PD48

Thermador Ao

Page 2

Please Read Entire Instructions

Before Proceeding

IMPORTANT:

INSTALLER:

OWNER:

Save these instructions for the Local Gas Inspector's use.

Please leave these Installation Instructions with this unit for the owner.

Please retain these instructions for future reference.

_, WARNING

Disconnect power before installing. Before

turning power ON, be sure that all controls

are in the OFF position.

IMPORTANT

Local codes vary. Installation, gas

connections and grounding must

comply with all applicable codes.

WARNING:

If the information in this manual is not

followed exactly, a fire or explosion may

result causing property damage, personal

injury or death.

For Massachusetts Installations:

.

Installation must be performed by a qualified

or licensed contractor, plumber or gas fitter

qualified or licensed by the state, province or

region where this appliance is being installed.

.

Shut-off valve must be a "T" handle gas

cock.

.

Flexible gas connector must not be longer

than 36 inches.

WARNING

• ALL RANGES CAN TIP

• INJURY TO PERSONS

COULD RESULT

-- Do not store or use gasoline or other flam-

mable vapors and liquids in the vicinity of this

or any other appliance.

-- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the

fire department.

-- Installation and service must be performed

by a qualified installer, service agency or the

gas suppler.

• INSTALL ANTI-TIP

DEVICE

• SEE INSTALLATION

INSTRUCTIONS

TO REDUCE THE RISK OF TIPPING OF THE

APPLIANCE, IT MUST BE SECURED BY A

PROPERLY INSTALLED ANTI-TIP DEVICE.

VERIFY THAT THE ANTI-TIP DEVICE IS

ENGAGED PER INSTALLATION IN

STRUCTIONS. (NOTE: ANTI-TIP DEVICE IS

REQUIRED ON ALL 30" AND 36" RANGES)

Note: This Range is NOT designed for installa-

tion in manufactured (mobile) homes orfor instal-

lation in Recreational Park Trailers.

DO NOT install this range outdoors.

Page 3

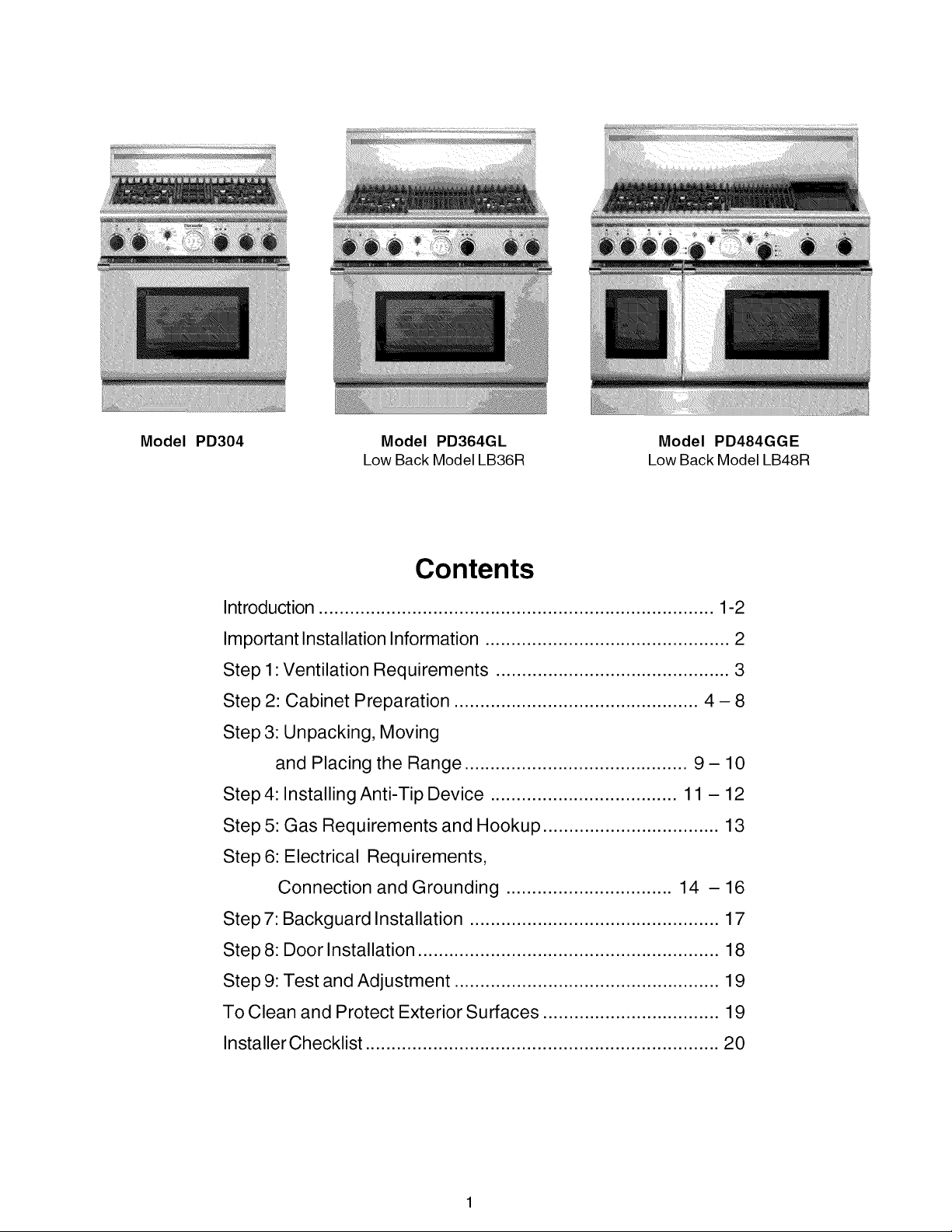

Model PD304 Model PD364GL

Low Back Model LB36R

Contents

Introduction ............................................................................ 1-2

Important Installation Information ............................................... 2

Step 1: Ventilation Requirements ............................................. 3

Step 2: Cabinet Preparation ............................................... 4 - 8

Step 3: Unpacking, Moving

and Placing the Range ........................................... 9 - 10

Step 4: Installing Anti-Tip Device .................................... 11 - 12

Step 5: Gas Requirements and Hookup .................................. 13

Step 6: Electrical Requirements,

Connection and Grounding ................................ 14 - 16

Model PD484GGE

Low Back Model LB48R

Step 7: Backguard Installation ................................................ 17

Step 8: Door Installation .......................................................... 18

Step 9: Test and Adjustment ................................................... 19

To Clean and Protect Exterior Surfaces .................................. 19

InstallerChecklist .................................................................... 20

Page 4

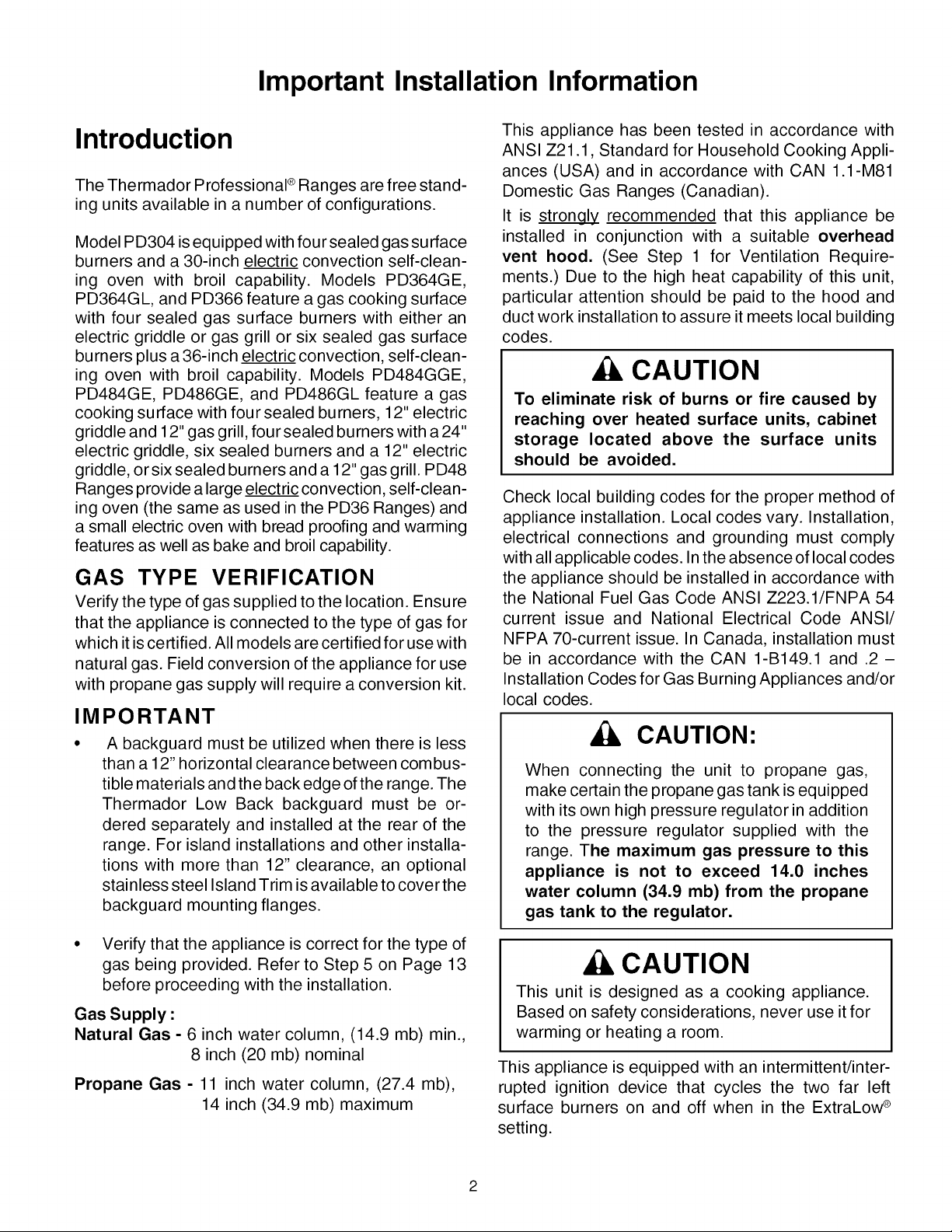

Important Installation Information

Introduction

The Thermador Professional ® Ranges are free stand-

ing units available in a number of configurations.

Model PD304 is equipped with four sealed gas surface

burners and a 30-inch electric convection self-clean-

ing oven with broil capability. Models PD364GE,

PD364GL, and PD366 feature a gas cooking surface

with four sealed gas surface burners with either an

electric griddle or gas grill or six sealed gas surface

burners plus a 36-inch electric convection, self-clean-

ing oven with broil capability. Models PD484GGE,

PD484GE, PD486GE, and PD486GL feature a gas

cooking surface with four sealed burners, 12" electric

griddle and 12" gas grill, four sealed burners with a 24"

electric griddle, six sealed burners and a 12" electric

griddle, orsix sealed burners and a 12" gas grill. PD48

Ranges provide a large electric convection, self-clean-

ing oven (the same as used in the PD36 Ranges) and

a small electric oven with bread proofing and warming

features as well as bake and broil capability.

GAS TYPE VERIFICATION

Verify the type of gas supplied to the location. Ensure

that the appliance is connected to the type of gas for

which it is certified. All models are certified for use with

natural gas. Field conversion of the appliance for use

with propane gas supply will require a conversion kit.

IMPORTANT

A backguard must be utilized when there is less

than a 12" horizontal clearance between combus-

tible materials and the back edge of the range. The

Thermador Low Back backguard must be or-

dered separately and installed at the rear of the

range. For island installations and other installa-

tions with more than 12" clearance, an optional

stainless steel Island Trim is available to cover the

backguard mounting flanges.

This appliance has been tested in accordance with

ANSI Z21.1, Standard for Household Cooking Appli-

ances (USA) and in accordance with CAN 1.1-M81

Domestic Gas Ranges (Canadian).

It is strongly recommended that this appliance be

installed in conjunction with a suitable overhead

vent hood. (See Step 1 for Ventilation Require-

ments.) Due to the high heat capability of this unit,

particular attention should be paid to the hood and

duct work installation to assure it meets local building

codes.

CAUTION

To eliminate risk of burns or fire caused by

reaching over heated surface units, cabinet

storage located above the surface units

should be avoided.

Check local building codes for the proper method of

appliance installation. Local codes vary. Installation,

electrical connections and grounding must comply

with all applicable codes. In the absence of local codes

the appliance should be installed in accordance with

the National Fuel Gas Code ANSI Z223.1/FNPA 54

current issue and National Electrical Code ANSI/

NFPA 70-current issue. In Canada, installation must

be in accordance with the CAN 1-B149.1 and .2 -

Installation Codes for Gas Burning Appliances and/or

local codes.

CAUTION:

When connecting the unit to propane gas,

make certain the propane gas tank is equipped

with its own high pressure regulator in addition

to the pressure regulator supplied with the

range. The maximum gas pressure to this

appliance is not to exceed 14.0 inches

water column (34.9 mb) from the propane

gas tank to the regulator.

• Verify that the appliance is correct for the type of

gas being provided. Refer to Step 5 on Page 13

before proceeding with the installation.

Gas Supply :

Natural Gas - 6 inch water column, (14.9 mb) min.,

8 inch (20 mb) nominal

Propane Gas - 11 inch water column, (27.4 mb),

14 inch (34.9 mb) maximum

CAUTION

This unit is designed as a cooking appliance.

Based on safety considerations, never use it for

warming or heating a room.

This appliance is equipped with an intermittent/inter-

rupted ignition device that cycles the two far left

surface burners on and off when in the ExtraLow ®

setting.

Page 5

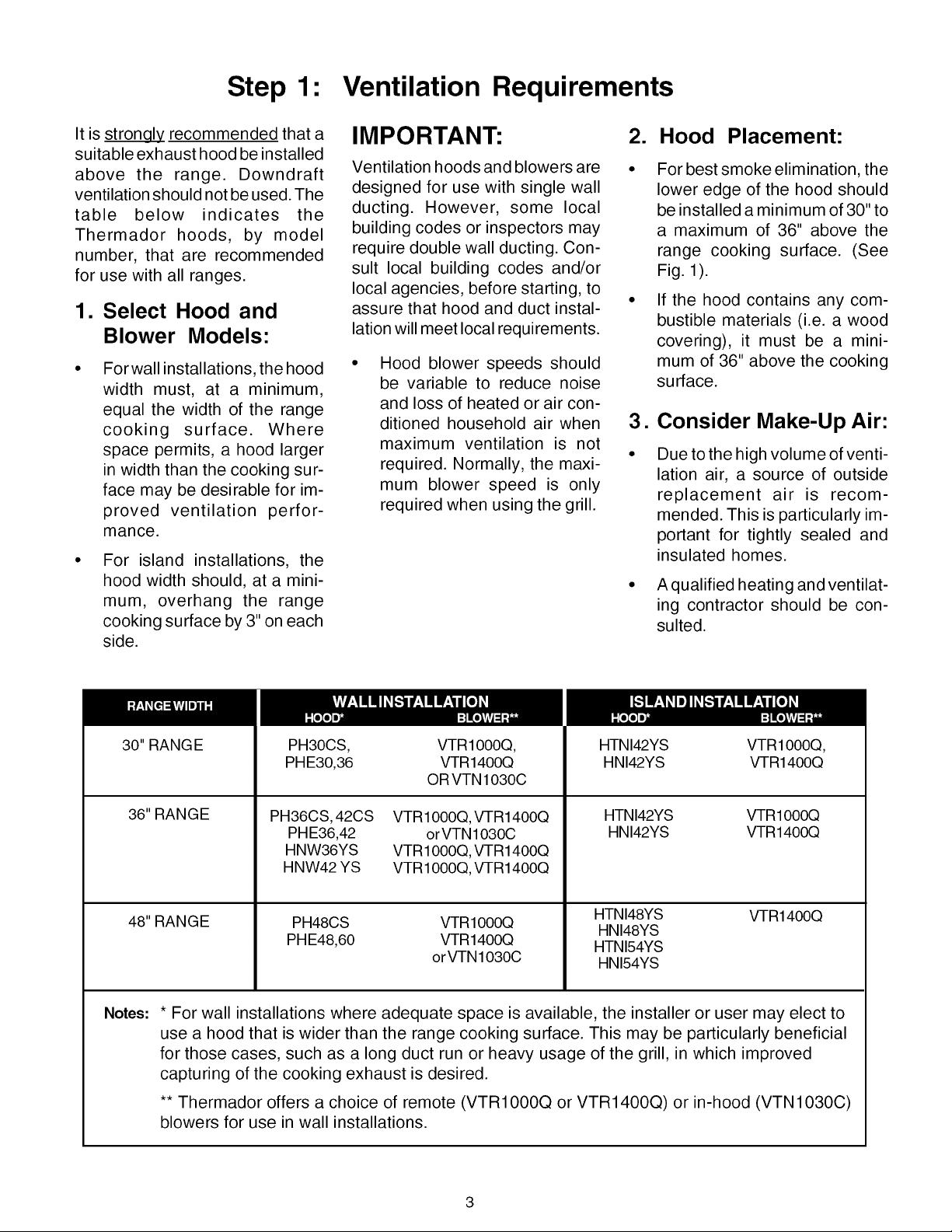

Step 1: Ventilation Requirements

It is strongly recommended that a

suitable exhaust hood be installed

above the range. Downdraft

ventilation should not be used. The

table below indicates the

Thermador hoods, by model

number, that are recommended

for use with all ranges.

1. Select Hood and

Blower Models:

Forwall installations, the hood

width must, at a minimum,

equal the width of the range

cooking surface. Where

space permits, a hood larger

in width than the cooking sur-

face may be desirable for im-

proved ventilation perfor-

mance.

For island installations, the

hood width should, at a mini-

mum, overhang the range

cooking surface by 3" on each

side.

IMPORTANT: 2. Hood Placement:

Ventilation hoods and blowers are •

designed for use with single wall

ducting. However, some local

building codes or inspectors may

require double wall ducting. Con-

sult local building codes and/or

local agencies, before starting, to

assure that hood and duct instal-

lation will meet local requirements.

Hood blower speeds should

be variable to reduce noise

and loss of heated or air con-

ditioned household air when

maximum ventilation is not

required. Normally, the maxi-

mum blower speed is only

required when using the grill.

For best smoke elimination, the

lower edge of the hood should

be installed a minimum of 30" to

a maximum of 36" above the

range cooking surface. (See

Fig. 1).

If the hood contains any com-

bustible materials (i.e. a wood

covering), it must be a mini-

mum of 36" above the cooking

surface.

=

Consider Make-Up Air:

Due to the high volume of venti-

lation air, a source of outside

replacement air is recom-

mended. This is particularly im-

portant for tightly sealed and

insulated homes.

A qualified heating and ventilat-

ing contractor should be con-

sulted.

30" RANGE

36" RANGE

48" RANGE

Notes:

PH30CS,

PHE30,36

PH36CS, 42CS

PHE36,42

HNW36YS

HNW42 YS

PH48CS VTR1000Q

PHE48,60 VTR1400Q

* For wall installations where adequate space is available, the installer or user may elect to

use a hood that is wider than the range cooking surface. This may be particularly beneficial

for those cases, such as a long duct run or heavy usage of the grill, in which improved

capturing of the cooking exhaust is desired.

** Thermador offers a choice of remote (VTRIOOOQ or VTR1400Q) or in-hood (VTNI030C)

blowers for use in wall installations.

VTR 1O00Q,

VTR1400Q

OR VTN 1030C

VTRIOOOQ,VTR1400Q

orVTN 1030C

VTRIOOOQ,VTR1400Q

VTRIOOOQ,VTR1400Q

or VTN1030C

HTN142YS

HNI42YS

HTNI42YS

HNI42YS

HTNI48YS

HNI48YS

HTNI54YS

HNI54YS

VTR 1O00Q,

VTR1400Q

VTR1000Q

VTR1400Q

VTR1400Q

Page 6

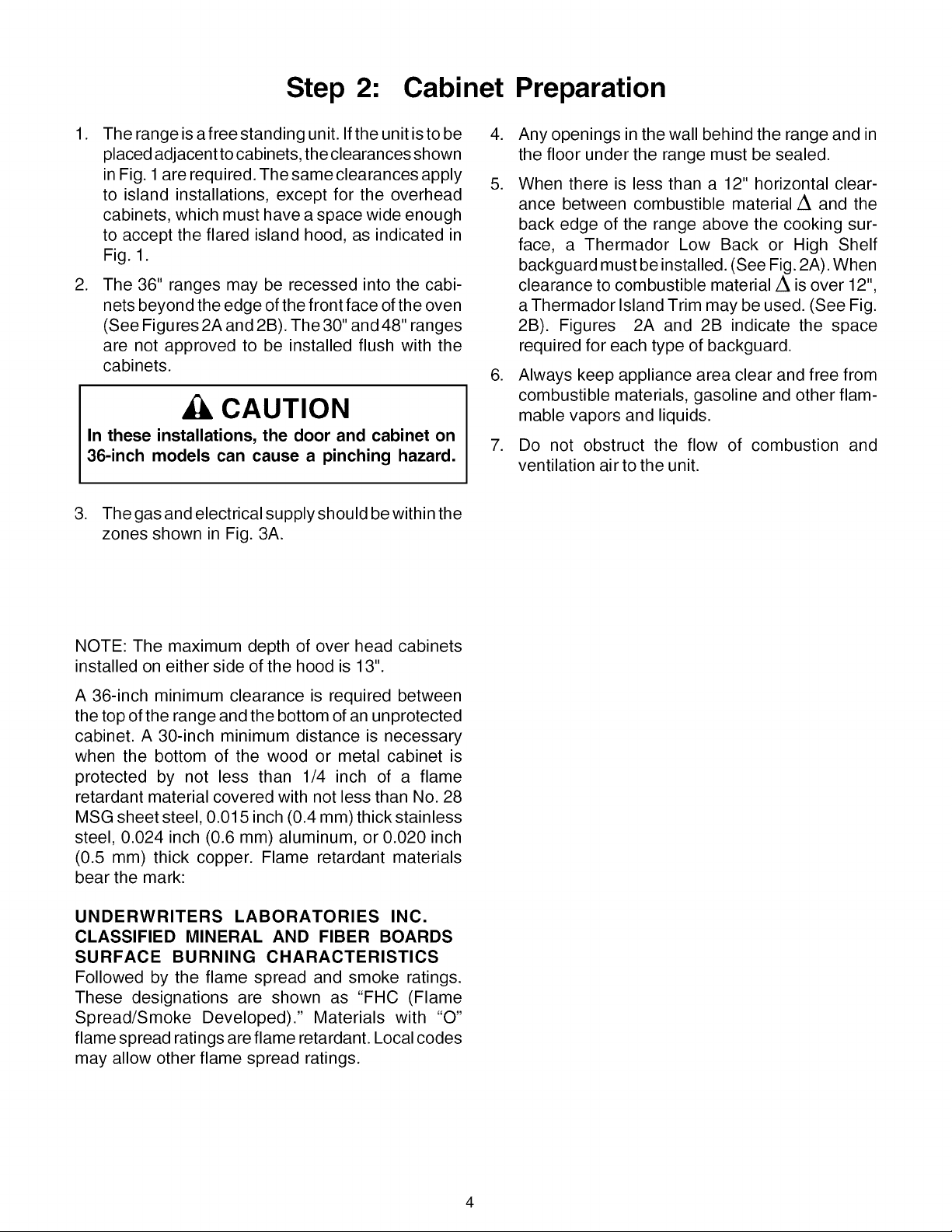

Step 2: Cabinet Preparation

.

The range is a free standing unit. If the unit is to be

placed adjacent to cabinets, the clearances shown

in Fig. 1 are required. The same clearances apply

to island installations, except for the overhead

cabinets, which must have a space wide enough

to accept the flared island hood, as indicated in

Fig. 1.

.

The 36" ranges may be recessed into the cabi-

nets beyond the edge of the front face of the oven

(See Figures 2A and 2B). The 30" and 48" ranges

are not approved to be installed flush with the

cabinets.

CAUTION

In these installations, the door and cabinet on

36-inch models can cause a pinching hazard.

3. The gas and electrical supply should be within the

zones shown in Fig. 3A.

.

Any openings in the wall behind the range and in

the floor under the range must be sealed.

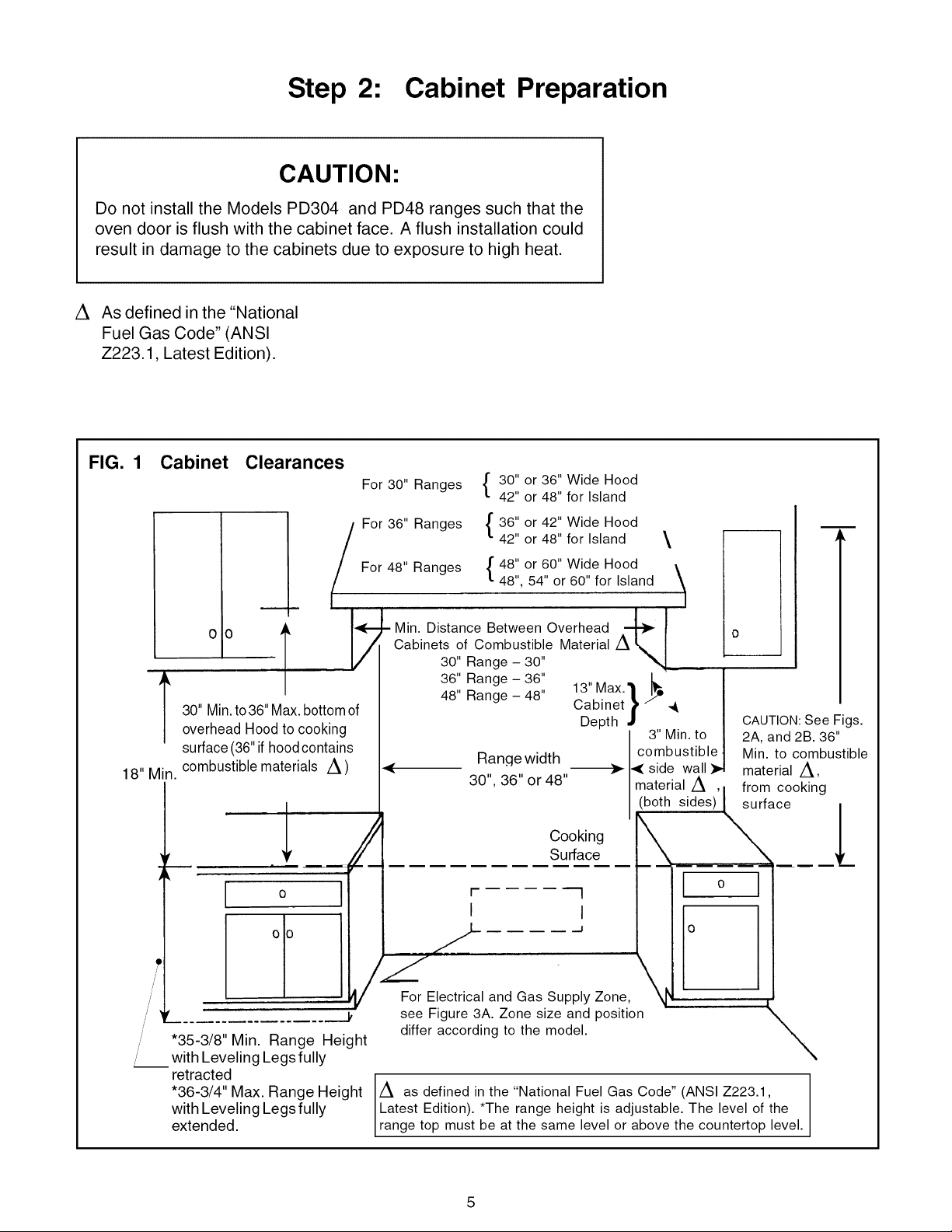

.

When there is less than a 12" horizontal clear-

ance between combustible material A and the

back edge of the range above the cooking sur-

face, a Thermador Low Back or High Shelf

backguard must be installed. (See Fig. 2A). When

clearance to combustible material A is over 12",

a Thermador Island Trim may be used. (See Fig.

2B). Figures 2A and 2B indicate the space

required for each type of backguard.

.

Always keep appliance area clear and free from

combustible materials, gasoline and other flam-

mable vapors and liquids.

.

Do not obstruct the flow of combustion and

ventilation airto the unit.

NOTE: The maximum depth of over head cabinets

installed on either side of the hood is 13".

A 36-inch minimum clearance is required between

the top of the range and the bottom of an unprotected

cabinet. A 30-inch minimum distance is necessary

when the bottom of the wood or metal cabinet is

protected by not less than 1/4 inch of a flame

retardant material covered with not less than No. 28

MSG sheet steel, 0.015 inch (0.4 mm) thick stainless

steel, 0.024 inch (0.6 mm) aluminum, or 0.020 inch

(0.5 mm) thick copper. Flame retardant materials

bear the mark:

UNDERWRITERS LABORATORIES INC.

CLASSIFIED MINERAL AND FIBER BOARDS

SURFACE BURNING CHARACTERISTICS

Followed by the flame spread and smoke ratings.

These designations are shown as "FHC (Flame

Spread/Smoke Developed)." Materials with "O"

flame spread ratings are flame retardant. Local codes

may allow other flame spread ratings.

4

Page 7

Step 2: Cabinet Preparation

CAUTION:

Do not install the Models PD304 and PD48 ranges such that the

oven door is flush with the cabinet face. A flush installation could

result in damage to the cabinets due to exposure to high heat.

As defined in the "National

Fuel Gas Code" (ANSI

Z223.1, Latest Edition).

FIG. 1 Cabinet Clearances

For 30" Ranges _ 30" or 36" Wide Hood

L

42" or 48" for Island

00

_|Ik 30" Min. to 36" Max. bottom of

overhead Hood to cooking

/

surface (36" if hood contains

18" Min. combustible materials /_ )

For 36" Ranges _ 36" or 42" Wide Hood

For 48" Ranges _ 48" or 60" Wide Hood \

Min. Distance Between Overhead Ul--_, ! o

Cabinets of Combustible Material

.4._ Rangewidth ___}_ 4( side wall }_1 material A,

L

42" or 48" for Island \ l

L

48", 54" or 60" for Island

30" Range - 30"

48" Range - 48" 13" Max.

36" Range - 36" }'_': !

30", 36" or 48" material/_ ,i from cooking

I !

Cabinet

Depth CAUTION: See Figs.

3" Min. to _ 2A, and 2B. 36"

combustible] Min. to combustible

SurfaceC°°king (both sides) _ace

o

I I

-J

o

"35-3/8" Min. Range Height

with Leveling Legs fully

retracted

"36-3/4" Max. Range Height

with Leveling Legs fully

extended.

For Electrical and Gas Supply Zone,

see Figure 3A. Zone size and position

differ according to the model.

\

/_ as defined in the "National Fuel Gas Code" (ANSI Z223.1,

Latest Edition). *The range height is adjustable. The level of the

range top must be at the same level or above the countertop level.

Page 8

FIG. 2A - Side View

////

I _ 29-1/2" 12.7/8,,=

I

36" Min, to I

Combustibles A I

!

I

t '

#

t

!

!

I

I

I

f

/

_:_.....

(_

Kickplate--_

Step 2: Cabinet Preparation

//_//_ //J/ //// -- Combustible

32-5/8"

3-7/8"

%

Low L_ [

Back_'_ [ /

..... _ 1

I"Fr°ntFace!

-*-Wall

Matedals A

t

22"

]2"

3/8"

//// ////

- //// if// ////_

I

Ili l

,L*-----28- 3/8" --------_

(

A as defined in the "National Fuel Gas Code" (ANSI Z223.1, Current Issue),

FIG. 2B - Side View i

47-3/8" ,. 1

////

//// //// //// ////-- - Corm

f

t

i

36" Min.'to

Combustibles z_

1

t

12" Min, to

Combustibles L_

without Backguard

or with Island Trim

Island

1

\ busflble

_ Materials &

I

I

Tri_-_ 41,_,;

7 Front Face

1/_

NOTE:

For Island trim installations,

counter surface should have a

cantilever edge meeting the back

section of the island trim

accessory.

CantileverCountertop

f NOTE:

If an inner wall is used under the

cantilever counter top, there

should be a 1/8" gap from the rear

of the range to the inner wall.

L .,i

6

Page 9

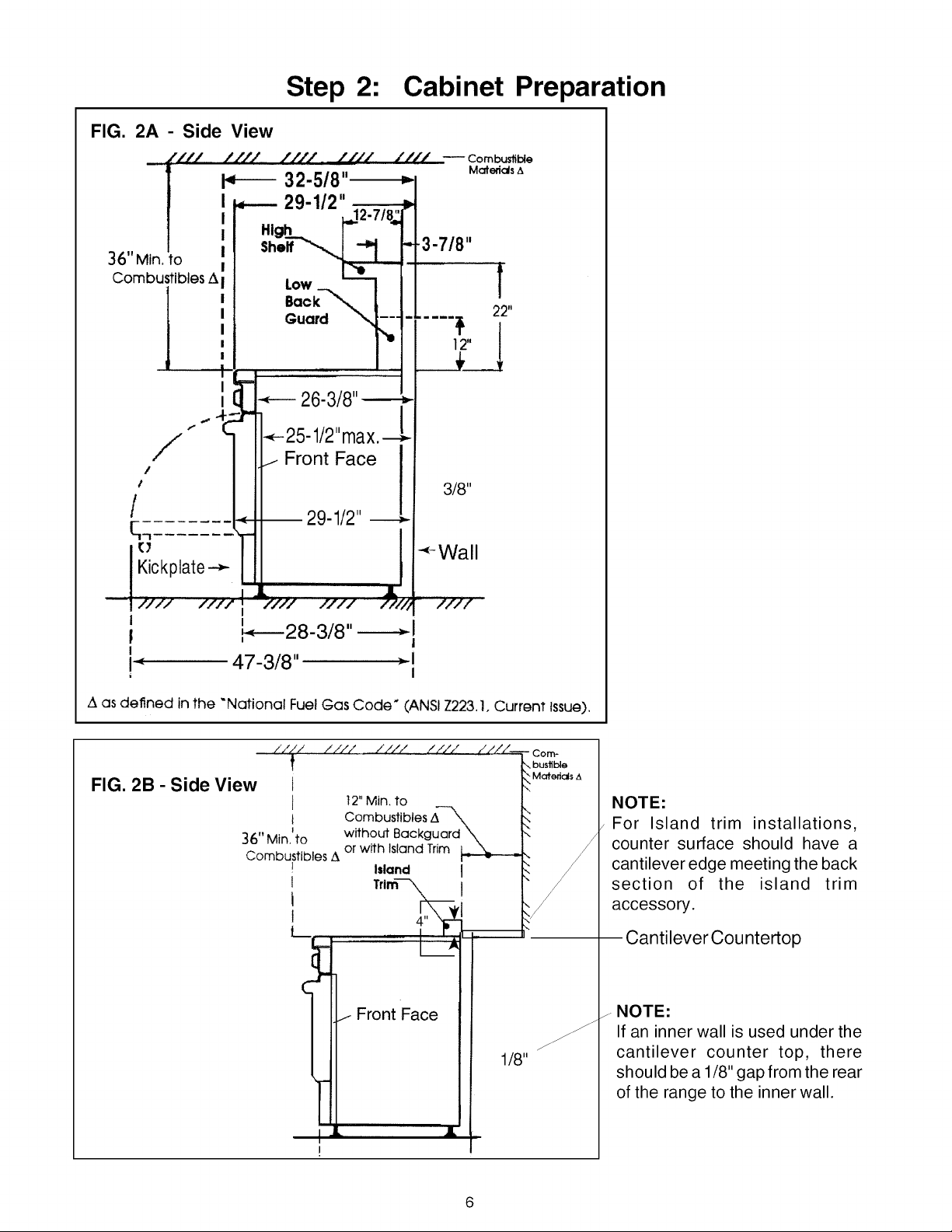

Step 2: Cabinet Preparation

GAS AND ELECTRIC SUPPLY ZONES:

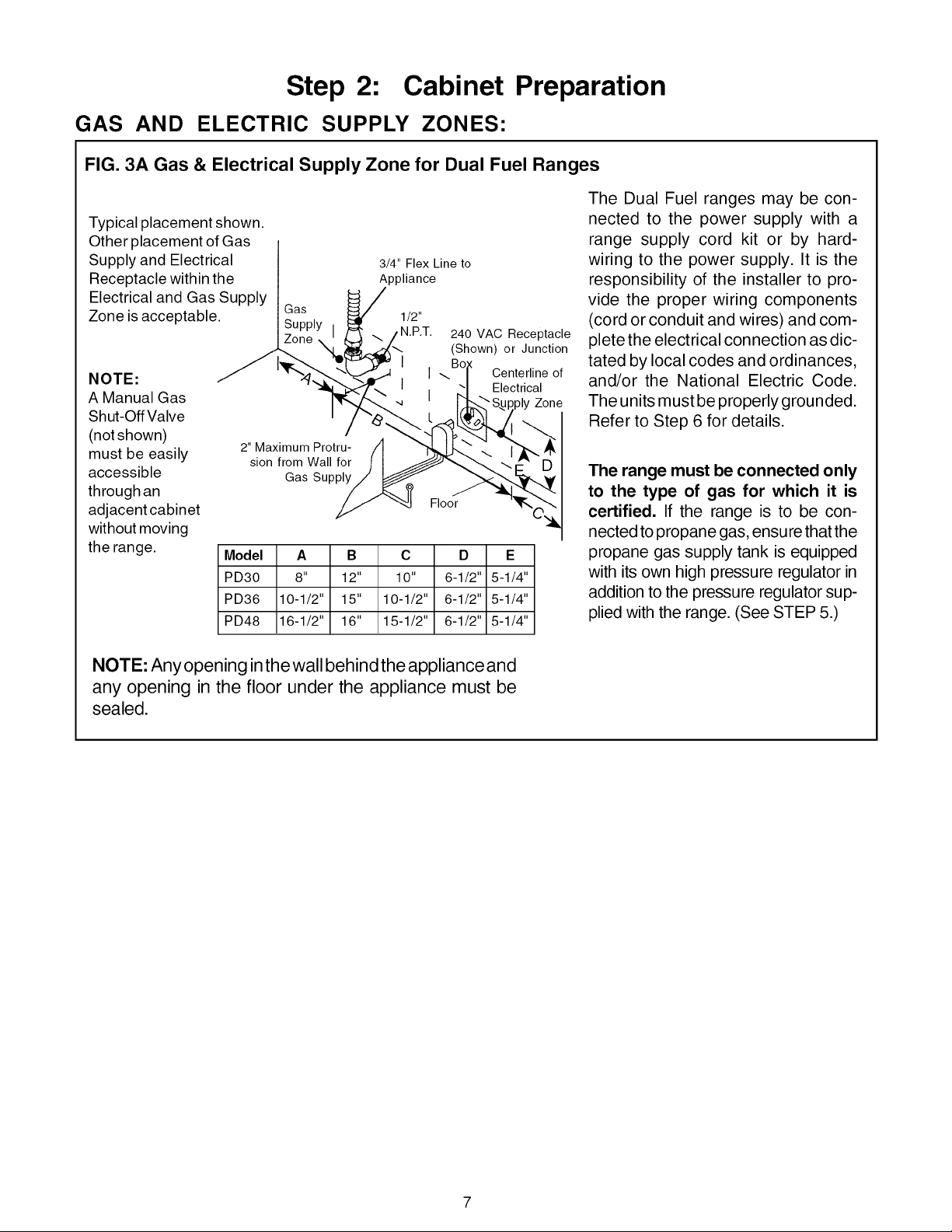

FIG. 3A Gas & Electrical Supply Zone for Dual Fuel Ranges

Typical placement shown.

Other placement of Gas

Supply and Electrical

Receptacle within the

Electrical and Gas Supply

Zone is acceptable.

NOTE:

A Manual Gas

Shut-Off Valve

(not shown)

must be easily

2" Maximum Protru-

accessible

through an

adjacent cabinet

without moving

the range.

Model A B C D E

PD30 8" 12" 10" 6-1/2" 5-1/4"

PD36 10-1/2" 15" 10-1/2" 6-1/2" 5-1/4"

PD48 16-1/2" 16" 15-1/2" 6-1/2" 5-1/4"

Gas

sion from Wall for

Gas Supply

3/4" Flex Line to

Appliance

240 VAC Receptacle

(Shown) or Junction

Centerline of

Electrical

Zone

Floor

The Dual Fuel ranges may be con-

nected to the power supply with a

range supply cord kit or by hard-

wiring to the power supply. It is the

responsibility of the installer to pro-

vide the proper wiring components

(cord or conduit and wires) and com-

plete the electrical connection as dic-

tated by local codes and ordinances,

and/or the National Electric Code.

The units must be properly grounded.

Refer to Step 6 for details.

The range must be connected only

to the type of gas for which it is

certified. If the range is to be con-

nected to propane gas, ensu re that the

propane gas supply tank is equipped

with its own high pressure regulator in

addition to the pressure regulator sup-

plied with the range. (See STEP 5.)

NOTE: Any opening inthe wall behind the appliance and

any opening in the floor under the appliance must be

sealed.

Page 10

Step 2: Cabinet Preparation

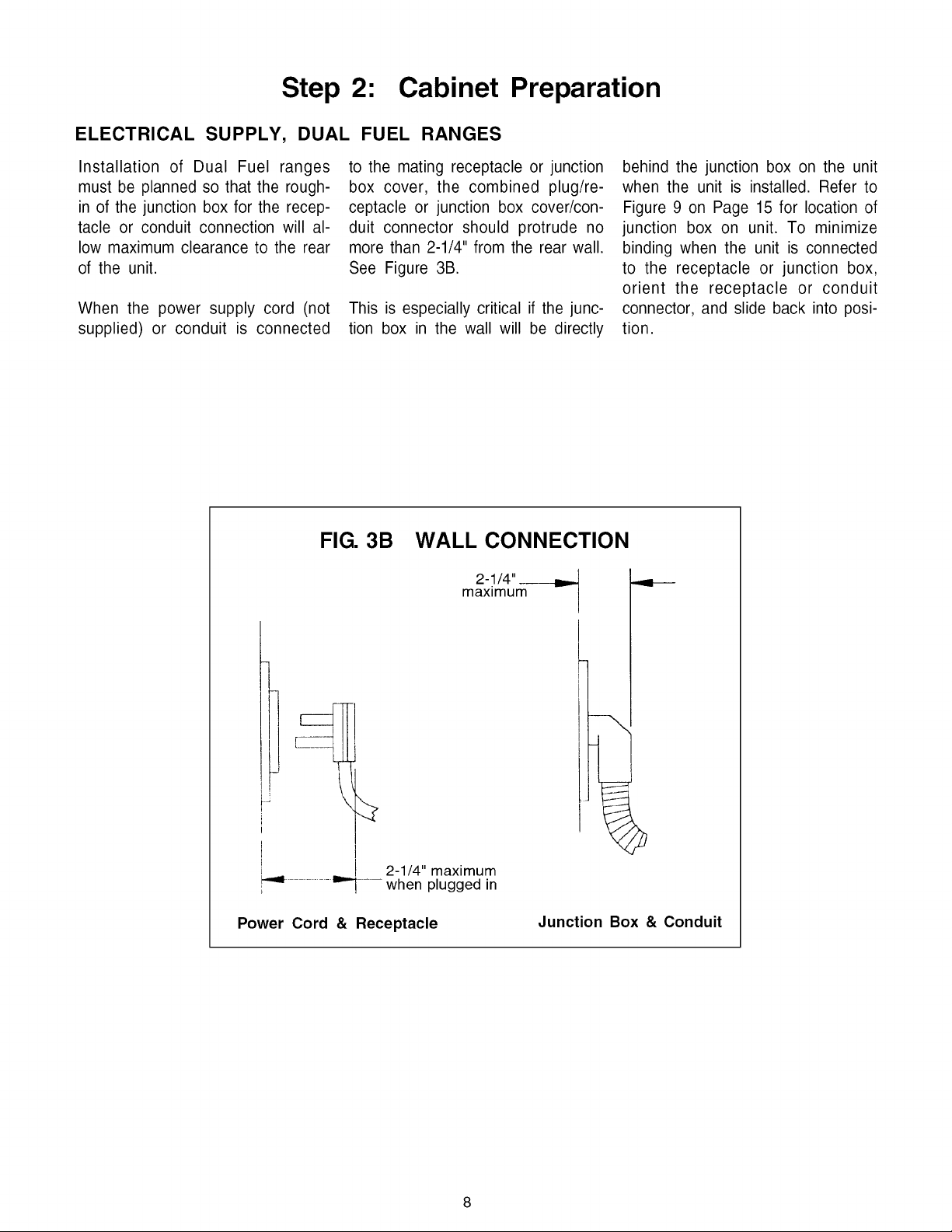

ELECTRICAL SUPPLY, DUAL FUEL RANGES

Installation of Dual Fuel ranges

must be planned so that the rough-

in of the junction box for the recep-

tacle or conduit connection will al-

low maximum clearance to the rear

of the unit.

to the mating receptacle or junction

box cover, the combined plug/re-

ceptacle or junction box cover/con-

duit connector should protrude no

more than 2-1/4" from the rear wall.

See Figure 3B.

When the power supply cord (not This is especially critical if the junc-

supplied) or conduit is connected tion box in the wall will be directly

FIG. 3B WALL CONNECTION

2-_1/4"_

maximum

behind the junction box on the unit

when the unit is installed. Refer to

Figure 9 on Page 15 for location of

junction box on unit. To minimize

binding when the unit is connected

to the receptacle or junction box,

orient the receptacle or conduit

connector, and slide back into posi-

tion.

,!I I-

I

I

2-1/4" maximum

---when plugged in

Power Cord & Receptacle

Junction Box & Conduit

Page 11

Step 3: Unpacking, Moving and Placing The Range

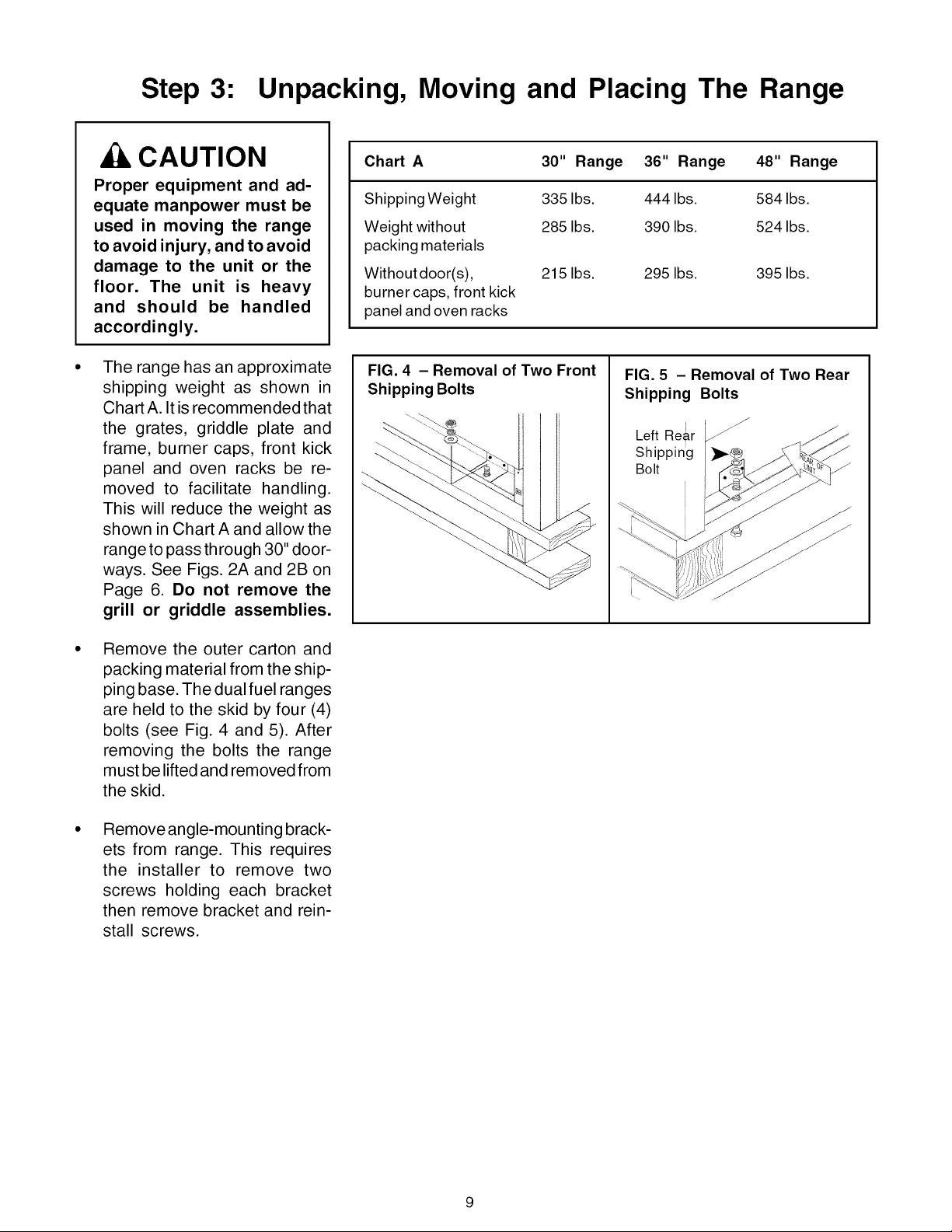

CAUTION

Proper equipment and ad-

equate manpower must be

used in moving the range

to avoid injury, and to avoid

damage to the unit or the

floor. The unit is heavy

and should be handled

accordingly.

The range has an approximate

shipping weight as shown in

Chart A. It is recommended that

the grates, griddle plate and

frame, burner caps, front kick

panel and oven racks be re-

moved to facilitate handling.

This will reduce the weight as

shown in Chart A and allow the

range to pass th rough 30" door-

ways. See Figs. 2A and 2B on

Page 6. Do not remove the

grill or griddle assemblies.

Chart A 30" Range 36" Range 48" Range

Shipping Weight 335 Ibs. 444 Ibs. 584 Ibs.

Weight without 285 Ibs. 390 Ibs. 524 Ibs.

packing materials

Without door(s),

burner caps, front kick

panel and oven racks

FIG. 4 - Removal of Two Front

Shipping Bolts

215 Ibs. 295 Ibs. 395 Ibs.

FIG. 5 - Removal of Two Rear

Shipping Bolts

Left Re_tr

Shipping

Bolt

J

Remove the outer carton and

packing material from the ship-

ping base. The dual fuel ranges

are held to the skid by four (4)

bolts (see Fig. 4 and 5). After

removing the bolts the range

must be lifted and removed from

the skid.

Remove angle-mounting brack-

ets from range. This requires

the installer to remove two

screws holding each bracket

then remove bracket and rein-

stall screws.

Page 12

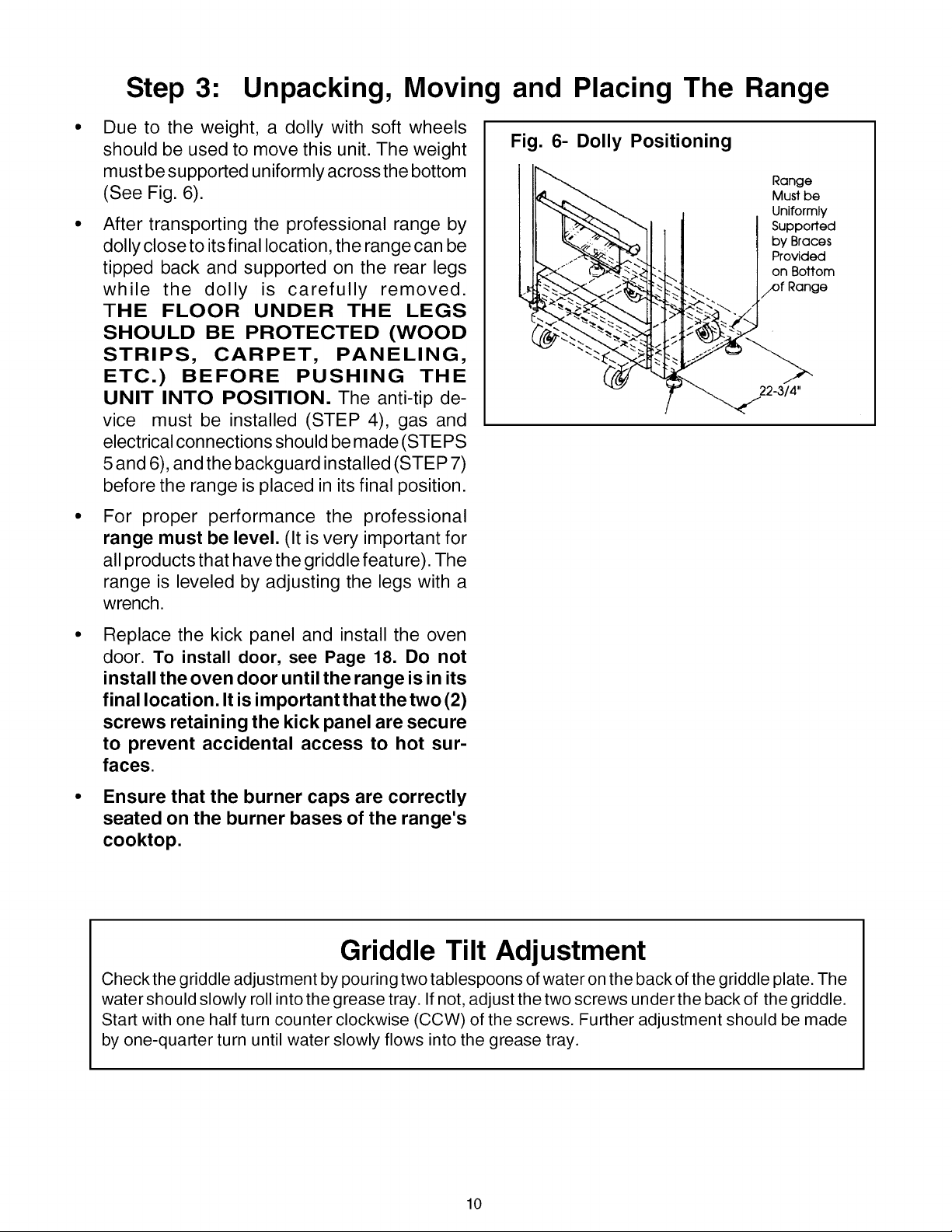

Step 3: Unpacking, Moving and Placing The Range

Due to the weight, a dolly with soft wheels

should be used to move this unit. The weight

must be supported uniformly across the bottom

(See Fig. 6).

After transporting the professional range by

dolly close to its final location, the range can be

tipped back and supported on the rear legs

while the dolly is carefully removed.

THE FLOOR UNDER THE LEGS

SHOULD BE PROTECTED (WOOD

STRIPS, CARPET, PANELING,

ETC.) BEFORE PUSHING THE

UNIT INTO POSITION. The anti-tip de-

vice must be installed (STEP 4), gas and

electrical connections should be made (STEPS

5 and 6), and the backguard installed (STEP 7)

before the range is placed in its final position.

For proper performance the professional

range must be level. (It is very important for

all products that have the griddle feature). The

range is leveled by adjusting the legs with a

wrench.

Fig. 6- Dolly Positioning

22-3/4"

Replace the kick panel and install the oven

door. To install door, see Page 18. Do not

install the oven door until the range is in its

final location. It is important that the two (2)

screws retaining the kick panel are secure

to prevent accidental access to hot sur-

faces.

Ensure that the burner caps are correctly

seated on the burner bases of the range's

cooktop.

Griddle Tilt Adjustment

Check the griddle adjustment by pouring two tablespoons of water on the back of the griddle plate. The

water should slowly roll into the grease tray. If not, adjust the two screws under the back of the griddle.

Start with one half turn counter clockwise (CCW) of the screws. Further adjustment should be made

by one-quarter turn until water slowly flows into the grease tray.

10

Page 13

Step 4: Installing Anti-Tip Device

For all 30" and 36" ranges, an anti-tip device must be installed as per these

instructions.

RANG TIPPING HAZARD

All ranges can tip and injury can result. To

prevent accidental tipping of the range,

attach it to the floor, wall or cabinet by

installing the Anti-Tip Device supplied.

A risk of tip-over may exist if the appliance

is not installed in accordance with these

instructions.

If the range is pulled away from the wall

for cleaning, service or any other reason,

ensure that the Anti-Tip Device is prop-

erly reengaged when the range is pushed

back against the wall. In the event of

abnormal usage (such as a person stand-

ing, sitting, or leaning on an open door),

failure to take this precaution can result

in tipping of the range. Personal injury

might result from spilled hot liquids or

from the range itself.

E_ WARNING

WARNING

ELECTRICAL SHOCK HAZARD

• Use extreme caution when drilling holes

into the wall or floor. There may be

concealed electrical wires located

behind the wall or under the floor.

• Identify the electrical circuits that could

be affected by the installation of the

Anti-Tip Device, then turn off power to

these circuits.

• Failure to follow these instructions may

result in electrical shock or other per-

sonal injury.

_WARNING

INJURY TO PER-

ALL RANGES CAN

SONS COULD

RESULT

DEVICES PACKED

t WITH RANGE

SEE INSTALLATION

INSTRUCTIONS

CAUTION

PROPERTY DAMAGE

• Contact a qualified installer or contractor

to determine the proper method for drill-

ing holes through the wall or floor material

(such as ceramic tile, hardwood, etc.)

• Do not slide the range across an unpro-

tected floor.

• Failure to follow these instructions may

result in damage to wall or floor cover-

ings.

Tools Needed for Installation of Anti-Tip Device:

- Screwdriver, Phillips - Hammer

- Drill, electric or hand - Pencil or other marker

- Measuring tape or ruler

- 1/8" drill bit (wood or metal wall or floor)

- 3/16" carbide-tipped masonry drill bit (concrete or concrete block wall or floor)

- 3/16" anchors, drywall or concrete, 2 each (not required if mounting bracket is being attached to solid wood or

metal)

11

Page 14

Step 4: Installing Anti-Tip Device

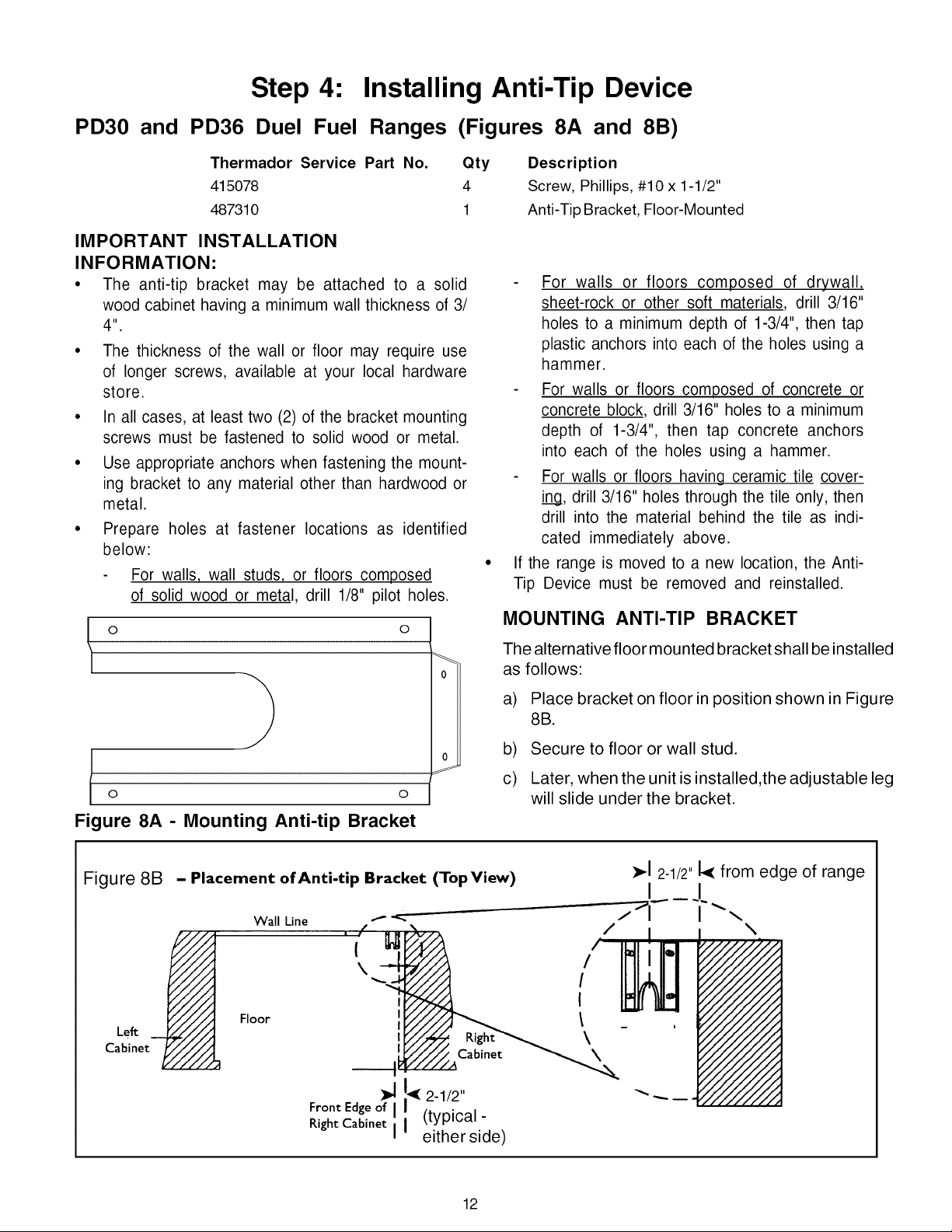

PD30 and PD36 Duel Fuel Ranges (Figures 8A and 8B)

Thermador Service Pa_ No. Qty

415078 4

487310 1

IMPORTANT INSTALLATION

INFORMATION:

• The anti-tip bracket may be attached to a solid

wood cabinet having a minimum wall thickness of 3/

11,

• The thickness of the wall or floor may require use

of longer screws, available at your local hardware

store.

• In all cases, at least two (2) of the bracket mounting

screws must be fastened to solid wood or metal.

• Use appropriate anchors when fastening the mount-

ing bracket to any material other than hardwood or

metal.

• Prepare holes at fastener locations as identified

below:

For walls, wall studs, or floors composed

of solid wood or metal, drill 1/8" pilot holes.

O O

Description

Screw, Phillips, #10 x 1-1/2"

Anti-Tip Bracket, Floor-Mounted

For walls or floors composed of drywall,

sheet-rock or other soft materials, drill 3/16"

holes to a minimum depth of 1-3/4", then tap

plastic anchors into each of the holes using a

hammer.

For walls or floors composed of concrete or

concrete block, drill 3/16" holes to a minimum

depth of 1-3/4", then tap concrete anchors

into each of the holes using a hammer.

For walls or floors having ceramic tile cover-

in_0_g,drill 3/16" holes through the tile only, then

drill into the material behind the tile as indi-

cated immediately above.

If the range is moved to a new location, the Anti-

Tip Device must be removed and reinstalled.

MOUNTING ANTI-TIP BRACKET

The alternative floor mounted bracket shall be installed

as follows:

O O

Figure 8A - Mounting Anti-tip Bracket

Figure 8B

- Placement of Anti-tip Bracket (TopView)

Wall Line

,/

I

-4 /

\

Floor

Le,

Cabinet

Front Edge of I

Right Cabinet I

I

I

I

I

I

_ 2-1/2"

(typical -

either side)

a) Place bracket on floor in position shown in Figure

8B.

b) Secure to floor or wall stud.

c) Later, when the unit is installed,the adjustable leg

will slide under the bracket.

12

Page 15

Step 5: Gas Requirements and Hookup

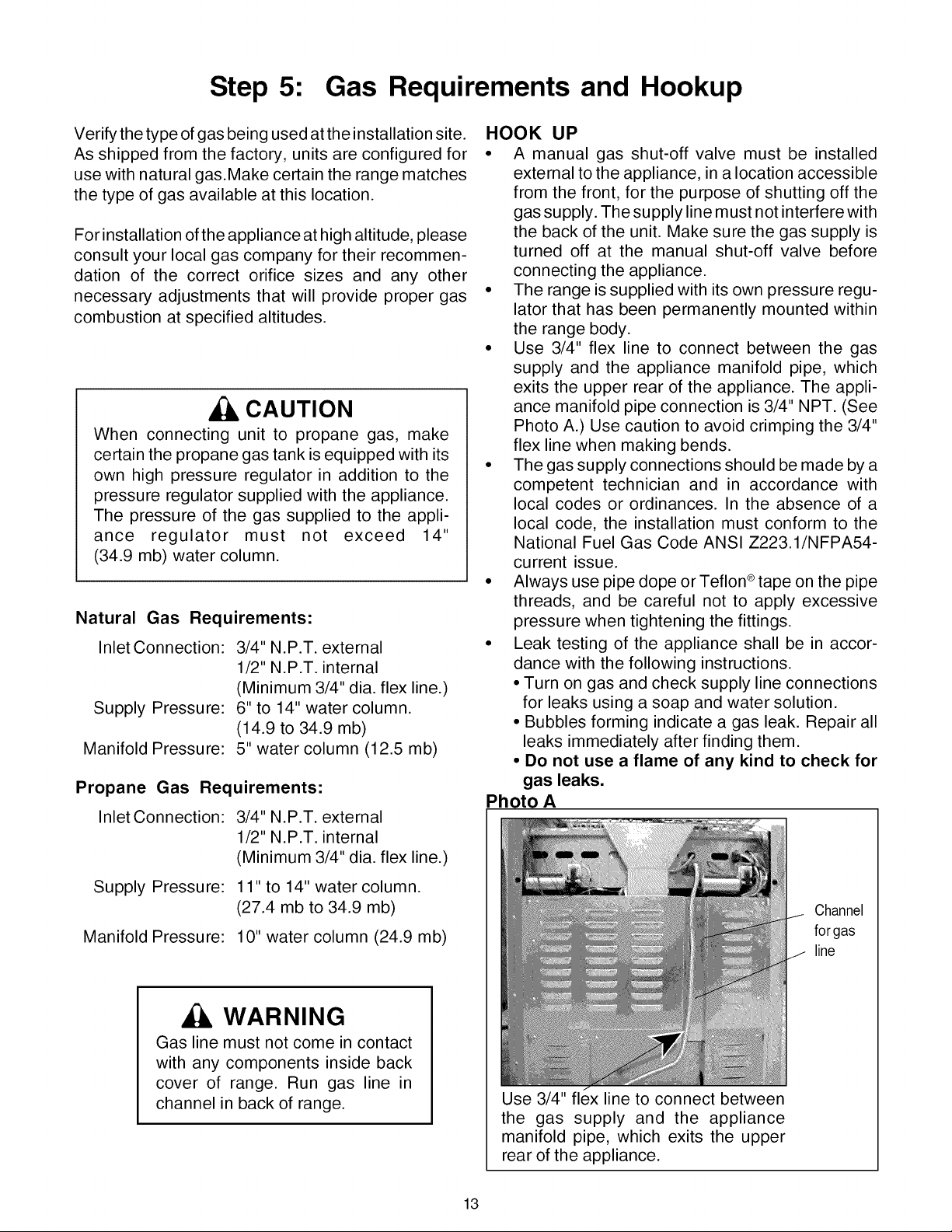

Verify the type of gas being used at the installation site.

As shipped from the factory, units are configured for

use with natural gas.Make certain the range matches

the type of gas available at this location.

For installation of the appliance at high altitude, please

consult your local gas company for their recommen-

dation of the correct orifice sizes and any other

necessary adjustments that will provide proper gas

combustion at specified altitudes.

CAUTION

When connecting unit to propane gas, make

certain the propane gas tank is equipped with its

own high pressure regulator in addition to the

pressure regulator supplied with the appliance.

The pressure of the gas supplied to the appli-

ance regulator must not exceed 14"

(34.9 mb) water column.

Natural Gas Requirements:

Inlet Connection: 3/4" N.P.T. external

1/2" N.P.T. internal

(Minimum 3/4" dia. flex line.)

Supply Pressure:

Manifold Pressure:

Propane Gas Requirements:

Inlet Connection: 3/4" N.P.T. external

6" to 14" water column.

(14.9 to 34.9 mb)

5" water column (12.5 mb)

1/2" N.P.T. internal

(Minimum 3/4" dia. flex line.)

HOOK UP

• A manual gas shut-off valve must be installed

external to the appliance, in a location accessible

from the front, for the purpose of shutting off the

gas supply. The supply line must not interfere with

the back of the unit. Make sure the gas supply is

turned off at the manual shut-off valve before

connecting the appliance.

• The range is supplied with its own pressure regu-

lator that has been permanently mounted within

the range body.

• Use 3/4" flex line to connect between the gas

supply and the appliance manifold pipe, which

exits the upper rear of the appliance. The appli-

ance manifold pipe connection is 3/4" NPT. (See

Photo A.) Use caution to avoid crimping the 3/4"

flex line when making bends.

• The gas supply connections should be made by a

competent technician and in accordance with

local codes or ordinances. In the absence of a

local code, the installation must conform to the

National Fuel Gas Code ANSI Z223.1/NFPA54-

current issue.

• Always use pipe dope or Teflon ®tape on the pipe

threads, and be careful not to apply excessive

pressure when tightening the fittings.

• Leak testing of the appliance shall be in accor-

dance with the following instructions.

• Turn on gas and check supply line connections

for leaks using a soap and water solution.

• Bubbles forming indicate a gas leak. Repair all

leaks immediately after finding them.

• Do not use a flame of any kind to check for

gas leaks.

Photo A

Supply Pressure: 11" to 14" water column.

(27.4 mb to 34.9 mb)

Manifold Pressure: 10" water column (24.9 mb)

WARNING

Gas line must not come in contact

with any components inside back

cover of range. Run gas line in

channel in back of range.

Channel

forgas

line

Use 3/4" flex line to connect between

the gas supply and the appliance

manifold pipe, which exits the upper

rear of the appliance.

13

Page 16

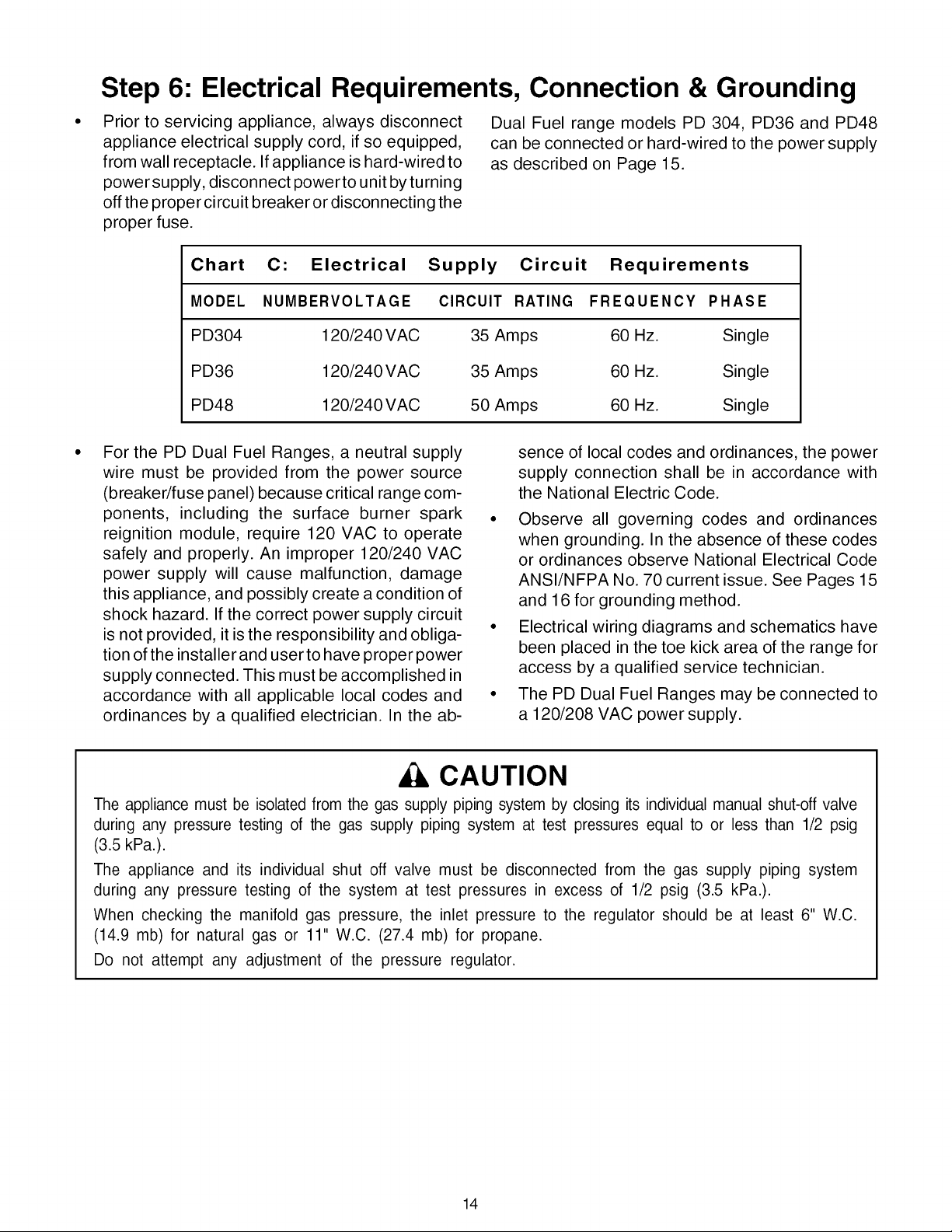

Step 6: Electrical Requirements, Connection & Grounding

Prior to servicing appliance, always disconnect

appliance electrical supply cord, if so equipped,

from wall receptacle. If appliance is hard-wired to

power supply, disconnect power to unit by turning

off the proper circuit breaker or disconnecting the

proper fuse.

Chart

MODEL

PD304

PD36

PD48

For the PD Dual Fuel Ranges, a neutral supply

wire must be provided from the power source

(breaker/fuse panel) because critical range com-

ponents, including the surface burner spark

reignition module, require 120 VAC to operate

safely and properly. An improper 120/240 VAC

power supply will cause malfunction, damage

this appliance, and possibly create a condition of

shock hazard. If the correct power supply circuit

is not provided, it is the responsibility and obliga-

tion of the installer and user to have proper power

supply connected. This must be accomplished in

accordance with all applicable local codes and

ordinances by a qualified electrician. In the ab-

C: Electrical

NUMBERVOLTAGE

120/240 VAC

120/240 VAC

120/240 VAC

Supply Circuit Requirements

CIRCUIT RATING FREQUENCY PHASE

Dual Fuel range models PD 304, PD36 and PD48

can be connected or hard-wired to the power supply

as described on Page 15.

35 Amps 60 Hz. Single

35 Amps 60 Hz. Single

50 Amps 60 Hz. Single

sence of local codes and ordinances, the power

supply connection shall be in accordance with

the National Electric Code.

• Observe all governing codes and ordinances

when grounding. In the absence of these codes

or ordinances observe National Electrical Code

ANSI/NFPA No. 70 current issue. See Pages 15

and 16 for grounding method.

• Electrical wiring diagrams and schematics have

been placed in the toe kick area of the range for

access by a qualified service technician.

• The PD Dual Fuel Ranges may be connected to

a 120/208 VAC power supply.

CAUTION

The appliance must be isolated from the gas supply piping system by closing its individual manual shut-off valve

during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psig

(3.5 kPa.).

The appliance and its individual shut off valve must be disconnected from the gas supply piping system

during any pressure testing of the system at test pressures in excess of 1/2 psig (3.5 kPa.).

When checking the manifold gas pressure, the inlet pressure to the regulator should be at least 6" W.C.

(14.9 mb) for natural gas or 11" W.C. (27.4 mb) for propane.

Do not attempt any adjustment of the pressure regulator.

14

Page 17

Step 6: Electrical Requirements, Connection & Grounding

Dual Fuel models must be connected to the power supply utilizing one of the following methods. For all methods

of connection, the length of the cord or conduit/wiring must allow the unit to be slid completely out of the cabinet

without having to unplug or disconnect the unit from the power supply. Recommended minimum free length of

cord or conduit is four feet. Electrical installations and grounding must be in accordance with all local codes and

ordinances, and/or the National Electric Code, as applicable.

4-CONDUCTOR CORD -

NORMALLY, A UNIT MUST

BE CONNECTED TO THE

POWER SUPPLY WITH A

3-POLE, 4-CONDUCTOR

CORD KIT RATED 125/

250 VOLTS, 50 AMPERES,

AND MARKED FOR USE

WITH RANGES. The cord

kit must be attached to the

range junction box with astrain

relief which will fit a 1" diam-

eter hole. If not already

equipped, the cord must have

1/4" faston closed-loop lugs

attached to the free ends of

the individual conductors, pref-

erably soldered in place.

PERMANENT CONNECTION

(HARD WIRING)- Units may

be hard wired to the power

supply. The installer must

provide approved flexible

aluminum conduit, 3/4" trade

size, maximum 6 feet long.

Locate the junction box on the

rear of the unit and remove

cover. Referto Fig. 9. Remove

the ground strap retaining

screw and bend the ground

strap up. Refer to Fig. 10. The

conduit must be installed to

the junction box using an

approved conduit connector.

Wiring for the unit is to be

brought into the junction box

through the conduit. The ends

of the wiring must have

1/4" faston closed-loop lugs

attached, preferably soldered

in place. Make the connec-

tions to the terminal block pro-

vided. Secure the ground lead

to the junction box with the

screw previously used to se-

cure the ground strap. Refer

to Fig. 11. The free end of the

conduit must be connected to

a junction box provided in the

gas and electrical supply zone,

as shown in Figure 3A on Page

8.

3-CONDUCTOR CORD -

WHERE LOCAL CODES

AND ORDINANCES PERMIT

GROUNDING THROUGH

NEUTRAL, AND CONVER-

SION OF SUPPLY TO 4

WIRE IS IMPRACTICAL,

UNIT MAY BE CON-

NECTED TO THE POWER

SUPPLY WITH A 3-POLE,

3-CONDUCTOR CORD KIT

RATED 125/250 VOLTS, 50

AMPERES, AND MARKED

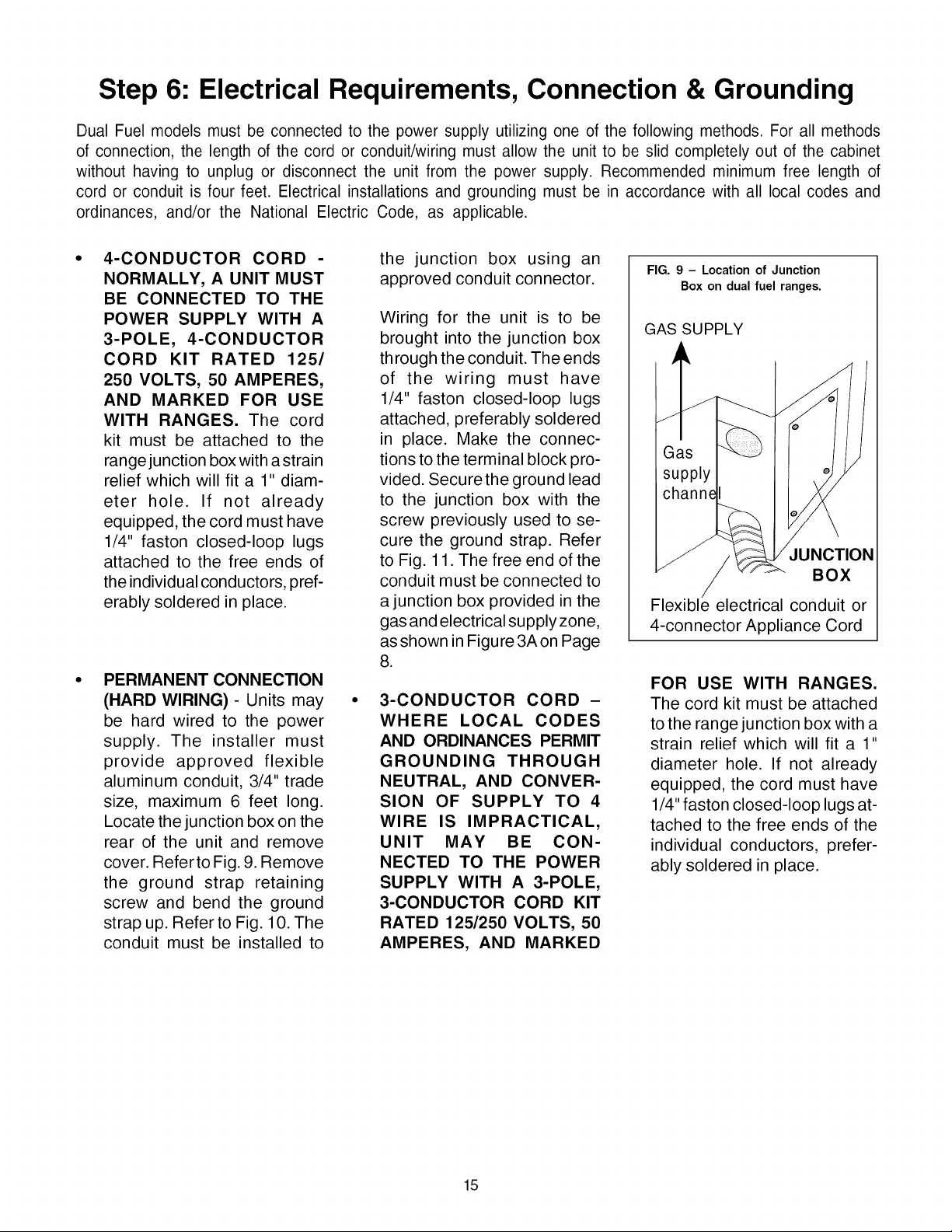

FIG. 9 - Locationof Junction

Box on dualfuel ranges.

GAS SUPPLY

JUNCTION

BOX

Flexible electrical conduit or

4-connector Appliance Cord

FOR USE WITH RANGES.

The cord kit must be attached

to the range junction box with a

strain relief which will fit a 1"

diameter hole. If not already

equipped, the cord must have

1/4" faston closed-loop lugs at-

tached to the free ends of the

individual conductors, prefer-

ably soldered in place.

15

Page 18

Step 6: Electrical Requirements, Connection & Grounding

A 3- or 4-conductor supply may be connected to the

terminal block.

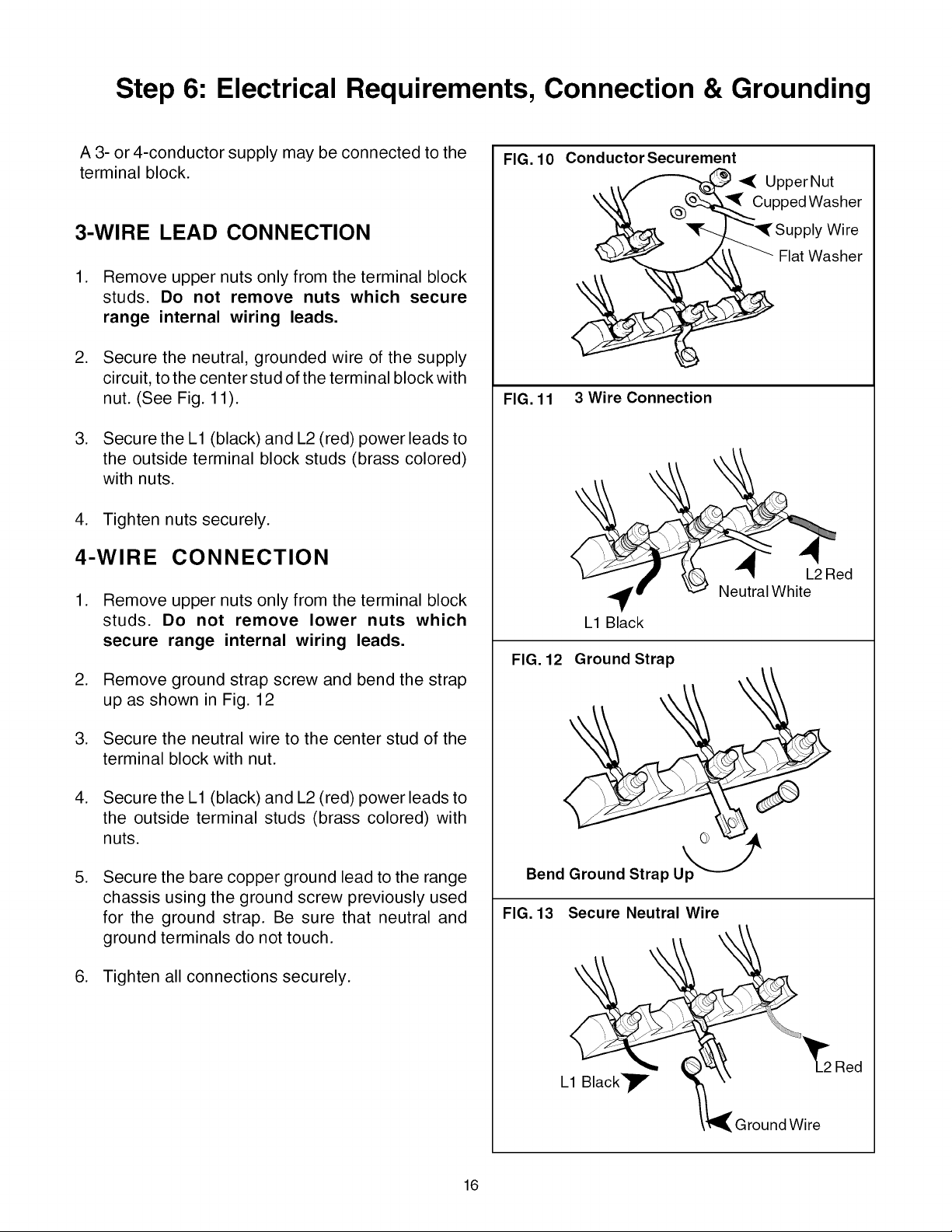

3-WIRE LEAD CONNECTION

1. Remove upper nuts only from the terminal block

studs. Do not remove nuts which secure

range internal wiring leads.

2. Secure the neutral, grounded wire of the supply

circuit, to the center stud of the terminal block with

nut. (See Fig. 11).

3. Secure the L1 (black) and L2 (red) power leads to

the outside terminal block studs (brass colored)

with nuts.

4. Tighten nuts securely.

4-WIRE CONNECTION

.

Remove upper nuts only from the terminal block

studs. Do not remove lower nuts which

secure range internal wiring leads.

.

Remove ground strap screw and bend the strap

up as shown in Fig. 12

FIG. 10

Conductor Securement

_ _ _[ UpperNut

_X._X (___., Cupped Washer

FIG. 11

3 Wire Connection

L1 Black

FIG. 12 Ground Strap

__" SF_PtPlYaWih;r

L2 Red

Neutral White

.

Secure the neutral wire to the center stud of the

terminal block with nut.

4. Secure the L1 (black) and L2 (red) power leads to

the outside terminal studs (brass colored) with

nuts.

.

Secure the bare copper ground lead to the range

chassis using the ground screw previously used

for the ground strap. Be sure that neutral and

ground terminals do not touch.

6. Tighten all connections securely.

o

Bend Ground Strap Up

FIG. 13 Secure Neutral Wire

Ground Wire

16

Page 19

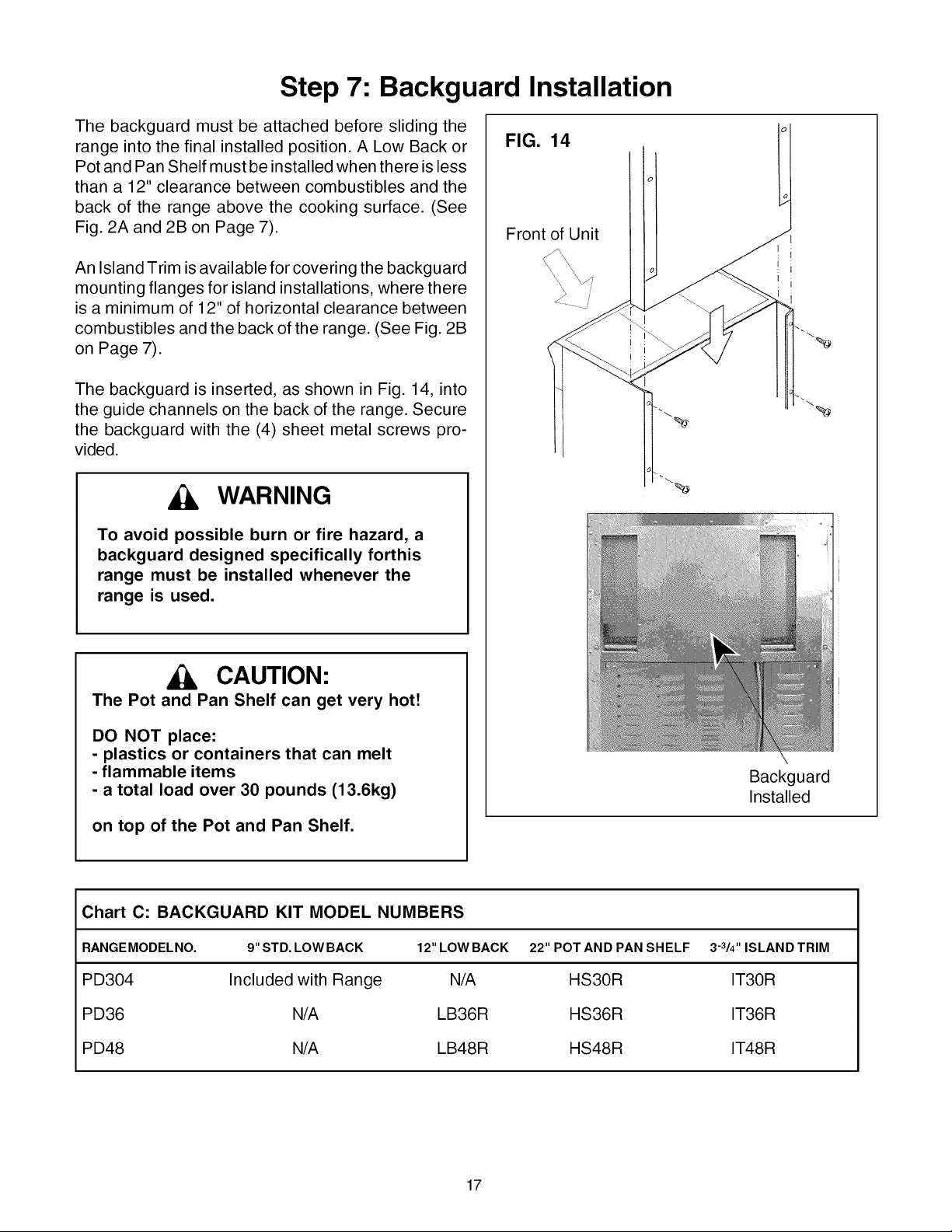

Step 7: Backguard Installation

The backguard must be attached before sliding the

range into the final installed position. A Low Back or

Pot and Pan Shelf must be installed when there is less

than a 12" clearance between combustibles and the

back of the range above the cooking surface. (See

Fig. 2A and 2B on Page 7).

An Island Trim is available for covering the backguard

mounting flanges for island installations, where there

is a minimum of 12" of horizontal clearance between

combustibles and the back of the range. (See Fig. 2B

on Page 7).

The backguard is inserted, as shown in Fig. 14, into

the guide channels on the back of the range. Secure

the backguard with the (4) sheet metal screws pro-

vided.

WARNING

To avoid possible burn or fire hazard, a

backguard designed specifically forthis

range must be installed whenever the

range is used.

FIG. 14

!

Front of Unit

CAUTION:

The Pot and Pan Shelf can get very hot!

DO NOT place:

- plastics or containers that can melt

- flammable items

- a total load over 30 pounds (13.6kg)

on top of the Pot and Pan Shelf.

Chart C: BACKGUARD KIT MODEL NUMBERS

RANGEMODELNO. 9"STD. LOW BACK 12"LOW BACK

PD304 Included with Range N/A

PD36 N/A LB36R

PD48 N/A LB48R

22" POT AND PAN SHELF

HS30R

HS36R

HS48R

Backguard

Installed

3-3/4'' ISLAND TRIM

IT30R

IT36R

IT48R

17

Page 20

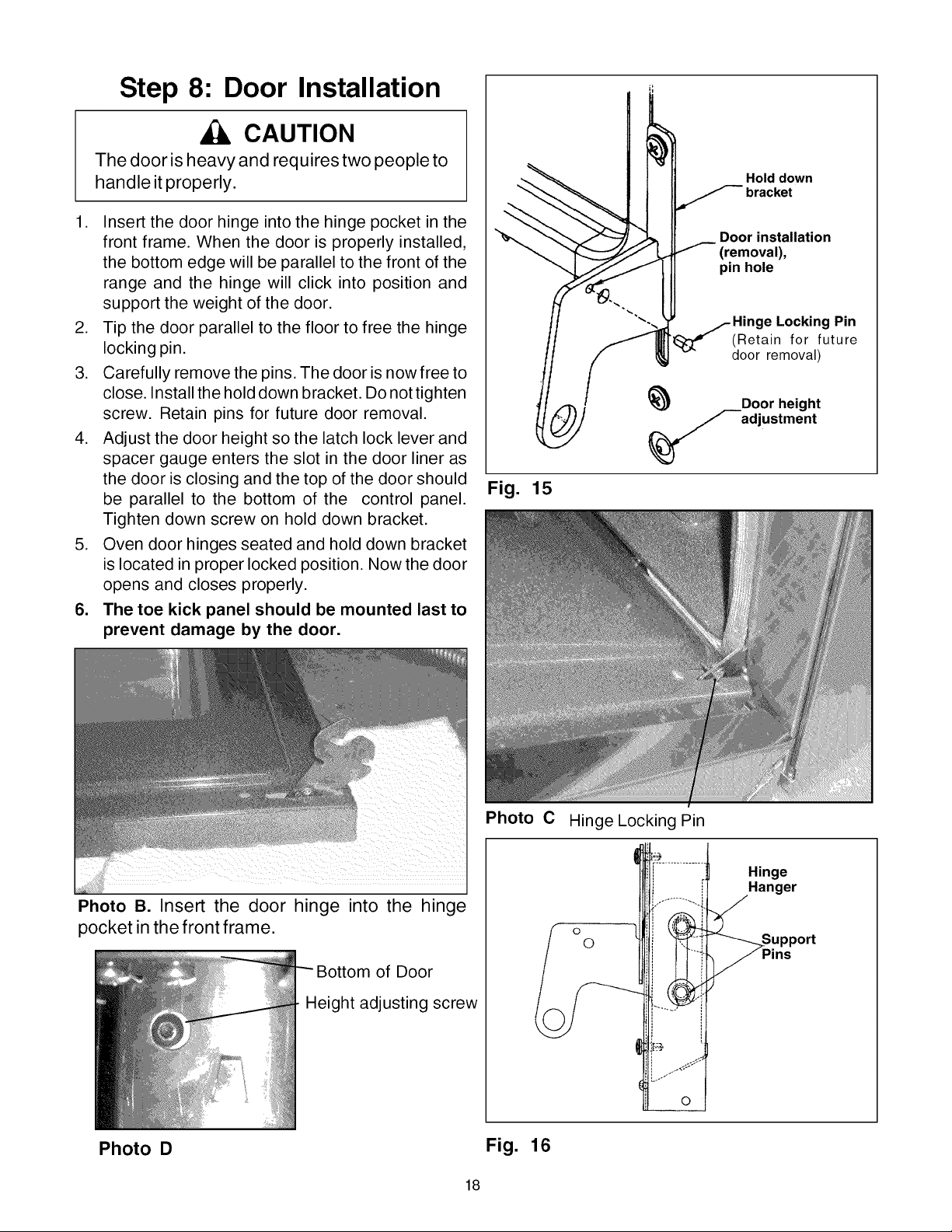

Step 8: Door Installation

CAUTION

The door is heavy and requires two people to

handle it properly.

1. Insert the door hinge into the hinge pocket in the

front frame. When the door is properly installed,

the bottom edge will be parallel to the front of the

range and the hinge will click into position and

support the weight of the door.

2. Tip the door parallel to the floor to free the hinge

locking pin.

3. Carefully remove the pins. The door is now free to

close. Install the hold down bracket. Do not tighten

screw. Retain pins for future door removal.

4. Adjust the door height so the latch lock lever and

spacer gauge enters the slot in the door liner as

the door is closing and the top of the door should

be parallel to the bottom of the control panel.

Tighten down screw on hold down bracket.

5. Oven door hinges seated and hold down bracket

is located in proper locked position. Now the door

opens and closes properly.

6. The toe kick panel should be mounted last to

prevent damage by the door.

Fig.

15

Hold down

'-'- bracket

Door installation

(removal),

pin hole

FHinge Locking Pin

"_,_r (Retain for future

(_ Door height

door removal)

adjustment

Photo B. Insert the door hinge into the hinge

pocket in the front frame.

Bottom of Door

Height adjusting screw

Photo D

Photo C

Fig. 16

18

Hinge Locking Pin

................!.l

O

©

V+I

C

Hinge

Hanger

Support

ins

Page 21

Step 9: Test and Adjustment

Install any loose components, such

as burner caps and grates, that

may have been removed earlier.

Be certain that burner caps seat

properly into the alignment slots in

the burner bases. Before testing

operation of the appliance, verify

that the unit and the gas supply

have been carefully checked for

leaks and that the unit has been

connected to the electrical power

supply. Turn the manual gas shut-

off valve to the open position. Check

operation of the sealed gas burn-

ers and grill by pushing and turning

each knob counterclockwise to"H r'.

The burner igniters will click until

the flame ignites. The two far left

sealed burners feature XLO ®,

causing the flame to cycle on and

off when the knob is set to the XLO

range. This is normal operation.

EACH GAS BURNER MUST BE

EVALUATED FOR CORRECT

FLAME PERFORMANCE IMME-

DIATELY AFTER INSTALLATION

OF THIS APPLIANCE. In PD

Range models, air shutter for the

grill burner (NOT top burners) is

preadjusted at the factory. How-

ever, environmental or installation

conditions may require readjust-

ments. Flame evaluation is per-

CAUTION

Burner adjustments must be

made by a qualified technician

at the time of installation.

Extreme care should be used

when adjustments are made

after installation. Improper or

lack of adjustments may

cause harmful by-products or

void you r warranty.

formed with burner's control knob

at highest setting.

If the PLPKIT is used to convert

this appliance from Natural to Pro-

pane Gas, flame evaluation and

air shutter readjustments must be

performed--see instructions pro-

vided with the PLPKIT for correct

recommendations.

Burner flames should be blue and

stable with no yellow tips, exces-

sive noise, or lifting of the flame

from the burner. If any of these

conditions exist, check that the air

shutter (grill only) or burner ports

are not blocked or clogged.

Remove any blockages that exist.

Ifthe flame is too yellow, indicating

insufficient air, increase the shut-

ter opening to increase air inlet (grill

only).

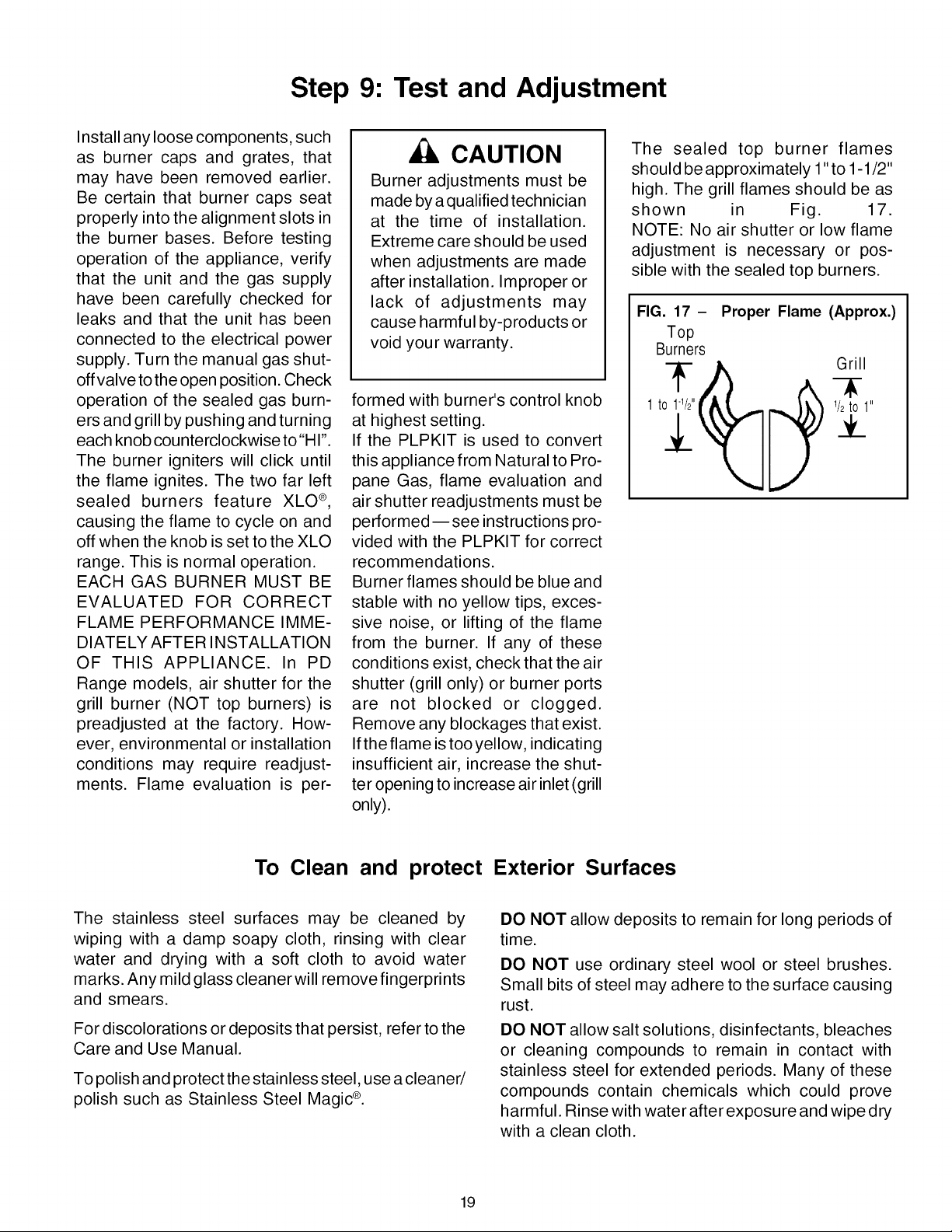

The sealed top burner flames

should be approximately 1"to 1-1/2"

high. The grill flames should be as

shown in Fig. 17.

NOTE: No air shutter or low flame

adjustment is necessary or pos-

sible with the sealed top burners.

FIG. 17 - Proper Flame (Approx.)

Top

Burners

1 t0 11/2 1/2to

-'-_'1"

_t_

To Clean and protect Exterior Surfaces

The stainless steel surfaces may be cleaned by

wiping with a damp soapy cloth, rinsing with clear

water and drying with a soft cloth to avoid water

marks. Any mild glass cleaner will remove fingerprints

and smears.

For discolorations or deposits that persist, refer to the

Care and Use Manual.

To polish and protect the stainless steel, use a cleaner/

polish such as Stainless Steel Magic ®.

DO NOT allow deposits to remain for long periods of

time.

DO NOT use ordinary steel wool or steel brushes.

Small bits of steel may adhere to the surface causing

rust.

DO NOT allow salt solutions, disinfectants, bleaches

or cleaning compounds to remain in contact with

stainless steel for extended periods. Many of these

compounds contain chemicals which could prove

harmful. Rinse with water after exposure and wipe dry

with a clean cloth.

19

Page 22

FINAL CHECK LIST

[][]Placement of unit.

Specified clearances main-

tained to cabinet surfaces.

[] Unit Level - front to back -

side to side.

[]

Burner caps positioned prop-

erly on sealed burner bases.

[]

All packaging material removed. []

[]

Island trim or backguard at-

tached (if horizontal clearance

to combustible materials be-

hind cooking surface is less

than 12").

[]

Check door adjustment and

hold down brackets.

[]

Kick panel in place and two (2)

screws secure.

[]

The griddle plate and frame is

correctly positioned, tilted

slightly forward. (See page 10

for adjustment procedure.)

GAS SUPPLY

INSTALLER CHECKLIST

ELECTRICAL

[]

Receptacle with correct over-

current protection is provided

for service cord connection.

[] Proper ground connection.

[] Proper polarity at receptacle.

OPERATION

All internal packing materials

removed. Check below grates

and grill pans and within

oven(s).

[]

If used on propane gas, verify

that the propane gas supply is

equipped with its own high pres-

su re regulator in addition to the

pressure regulator supplied

with the appliance.

[]

Burner caps properly seated

into burner bases.

[]

Grill components properly

seated (not all models). Refer

to Use & Care Manual for Grill

details.

[]

Bezels centered on burner

knobs, and knobs turn freely.

[]

Each burner lights satisfacto-

rily, both individually and with

other burners operating.

[]

Air Shutter adjustment for

proper flame made for Grill.

See Step 9 and Fig.17.

[]

Griddle is tilted _forward

and does not rock (not all mod-

els).

[]

Oven door hinges seated and

hinge locks in proper position.

Door opens and closes prop-

erly.

[]

Burner grates correctly posi-

tioned, level, and do not rock.

Connection: 3/4" N.P.T. with

[]

a minimum 3/4" diameter

flex line.

[]

The appliance is connected only

to the type of gas for which it is

certified for use.

[]

Manual gas shut off valve in-

stalled in an accessible loca-

tion (without requiring removal

of range).

[]

Unit tested an d free of gas leaks.

[]

Gas supply pressure does not

exceed 14" W.C. (34.9 mb)

20

Page 23

NOTES

Page 24

NOTES

Page 25

INSTRUCTIONS

D'INSTALLATION

Pour toutes les cuisinieres mixtes

Thermador Professional®PRO-GRANDTM

Modeles

PD304

PD36

PD48

Thermador Ao

[€aFt

Page 26

Veuillez lire toutes les instructions

avant de poursuivre

Important : Conservez ces instructions pour I'inspecteur local de la compagnie de gaz.

Installateur : Veuillez laisser ces instructions d'installation avec I'appareil pour le proprietaire.

Proprietaire : Veuillez conserver ces instructions pour consultation ulterieure.

AVERTISSEMENT

Coupe-'_-Felectricite avec d'installer I'appareil.

Avant de remettre I'electricite, assurez-vous

que toutes les commandes sont & la position

OFF.

IMPORTANT

Les reglementations locales varient.

L'installation, les raccordements au gaz et les

mises & la terre doivent 6tre conformes &toutes

les reglementations applicables.

AVERTISSEMENT

L'information fournie dans ce manuel doit

6tre tres rigoureusement respectee, sous

peine d'incendie ou d'explosion entrafnant

des dommages, des blessures ou la mort.

-- Ne stockez pas et n'utilisez pas d'essence ou autres

produitsinflammablesa proximitedesappareils.

-- SIVOUSSENTEZUNEODEURDEGAZ

Pour les installations au Massachusetts :

L'installationdoit_trerealiseeparunentrepreneurqualifie

ou agree,unplombierouun installateurdegaz qualifie

ou autorise par I'Etat ou la region dans laquelle cet

appareilest pos&

Lerobinetd'arr_tde gazdoit_tre pourvud'une poignee

en <<T ,,.

3. LaIongueurmaximumautoriseedutuyaudegazestde

91,4cm (36").

AVERTISSEMENT

• LES CUlSINIERES PEUVENT

BASCULER.

• DES PERSONNES PEUVENT ETRE

BLESSI_ES.

• INSTALLEZUNDISPOSITIF

ANTIBASCULE.

• CONSULTEZLESINSTRUCTIONS

D'INSTALLATION.

• N'allumezaucunappareil.

• Netouchezpasauxinterrupteurselectriques.

• N'utilisezpaslestelephonesdub_.timent.

• Appelezimmediatementvotrecompagniedegazde chez

unvoisin.Suivezles instructionsdelacompagnie.

• Si vous n'arrivez pas_.contactervotre compagnie de

gaz,appelezlespompiers.

-- L'installationetlesreparationsdoivent_trerealiseespar

uninstallateurqualifi& uncentre deserviceagree oula

compagniedegaz.

POUR DIMINUERLES RISQUES DE BASCULEMENTDE

L'APPAREIL,INSTALLEZUN DISPOSITIFANTIBASCULE.

ASSUREZ-VOUSQUE LE DISPOSlTIFANTIBASCULEEST

CORRECTEMENT PLACE,CONFORMEMENT

AUXlNSTRUCTIONSD'INSTALLATION.(REMARQUE: LE

DISPOSlTIFANTIBASCULEESTOBLIGATOIRESURTOUTES

LESCUISlNIERESDE76,2CM [30"]E-r DE 91,4CM [36"]).

Remarque: Cette cuisiniere N'EST PAS con_ue

pour les maisons mobiles ni pour les vehicules

recreatifs.

NE PAS installer cette cuisiniere a I'exterieur.

Page 27

Modble PD304 Modble PD364GL

Modele LB36R & plaque de

protection basse

Table des matibres

Introduction ................................................................... 25

Informations importantes & propos de I'installation ........ 27

Chapitre 1 : Exigences de ventilation ............................ 28

Chapitre 2 : Preparation de I'emplacement ........... 29 - 33

Chapitre 3 : Deballage, manutention et

mise en place de la cuisiniere .............................. 34 - 35

Modble PD484GGE

Modele LB48R & plaque de

protection basse

Chapitre 4 :Installation du dispositif antibascule... 36 - 37

Chapitre 5 : Exigences pour I'alimentation du gaz

et raccordement ........................................................... 38

Chapitre 6 : Exigences pour I'alimentation electrique,

le branchement et la mise & la terre ...................... 39 - 41

Chapitre 7 : Installation de la plaque de protection ........ 42

Chapitre 8 : Installation de la porte ................................ 43

Chapitre 9 : Test et reglage .......................................... 44

Nettoyage et protection des surfaces exterieures .......... 44

Liste de verification de I'installateur .............................. 45

25

Page 28

Introduction

Les cuisinieres Thermador Professional ® sont des

appareils monoblocs disponibles en plusieurs

configurations.

Le modele PD304 est equipe d'une table de cuisson

de quatre brt_leurs a. gaz hermetiquement encastres et

d'un four electrique a. convection autonettoyant de

76,2 cm (30") avec gril. La table de cuisson des

modeles PD364GE, PD364GL et PD366 comporte

quatre brt_leurs a. gaz hermetiquement encastres avec

soit une plaque chauffante, soit un gril ou encore six

brt_leurs a. gaz hermetiquement encastres plus un four

electrique a. convection autonettoyant de 91,4 cm

(36") avec gril. La table de cuisson des modeles

PD484GGE, PD484GE, PD486GE et PD486GL est

equipee de quatre brt_leurs a. gaz hermetiquement

encastres, d'une plaque de cuisson 12 poet d'un gril

12 po, quatre brt_leurs scelles avec grille 24 po, de six

brt_leurs hermetiquement encastres et d'une plaque

de cuisson 12 po ou de six brt_leurs et d'un gril 12 po.

Les cuisinieres PD48 ont un grand four electrique a.

convection autonettoyant (le m_me que celui des

cuisinieres PD36) et un four electrique auxiliaire avec

fonctions de cuisson de pain, de maintien au chaud et

de cuisson et un gril.

IMPORTANT

• Une plaque de protection dolt _tre mise en place

Iorsque le degagement horizontal entre les

materiaux combustibles et le bord arriere de la

cuisiniere est inferieur a. 30,5 cm (12"). La

plaque de protection basse Thermador doit _tre

commandee separement et installee a. I'arriere

de la cuisiniere. Pour les installations en

riot et autres installations avec un degagement

de plus de 30,5 cm (12"), un enjoliveur en acier

inoxydable est vendu en option afin de recouvrir

les brides de montage de la plaque de

protection.

• Assurez-vous que I'appareil convient au type de

gaz fourni. Consultez le Chapitre 5 a. la page

38 avant de proceder a. I'installation.

VITRIFICATION DU TYPE DE GAZ

Verifiez quel est le type de gaz fourni sur le lieu

d'installation. L'appareil doit _tre raccorde au type de

gaz pour lequel il est certifi& Toutes les cuisinieres

sont certifiees pour une utilisation avec du gaz naturel.

Pour convertir I'appareil au gaz propane sur le lieu

d'installation, une trousse de conversion est

necessaire.

26

Page 29

Information Importante concernant I'installation

Cet appareil a ete teste conformement & la norme

americaine ANSI Z21.1 en vigueur regissant les

appareils electromenagers de cuisson au gaz et

conformement a. la norme canadienne CAN 1.1-M81

regissant les cuisinieres a. gaz domestiques.

II est fortement recommande d'installer une hotte de

ventilation adaptee au-dessus de cet appareil (voir

Chapitre 1, Conditions de ventilation). Comme la

cuisiniere peut degager une forte chaleur, une atten-

tion particuliere dolt _tre portee aux travaux

d'installation des conduites et de la hotte, lesquels

doivent _tre conformes aux reglementations locales

de construction.

MISEENGARDE

Pour eliminer les risques de brt_lures ou d'incendie

provoques par la chaleur, il est conseille d'eviter

d'installer des armoires au-dessus des tables de

cuisson des appareils.

MISEENGARDE

Si I'appareil est alimente au gaz

propane, assurez-vous que le reservoir de

propane est equipe de son propre detendeur

en plus du detendeur fourni avec la

cuisiniere. La pression maximum d'arrivee du

gaz clans cet appareil ne doit pas depasser les

34,9 millibars (14 pouces a la colonne d'eau)

entre le reservoir de propane et le detendeur.

MISEENGARDE

Cet appareil est con_u pour un usage culinaire.

Pour des raisons de securite, ne rutilisez

jamais pour chauffer une piece

Verifiez la reglementation locale applicable a. la

construction pour connaftre la methode appropriee

d'installation de I'appareil. Les reglementations

locales varient. L'installation, le branchement electrique

et la mise a. la terre doivent respecter toutes les

reglementations applicables. ,&, defaut d'une

reglementation specifique applicable, I'appareil doit

_tre installe conformement a. la norme americaine en

vigueur regisssant le gaz combustible ANSI Z223.1/

NFPA54 et I'electricite ANSI/NFPA70. Au Canada,

I'installation dolt _tre conforme aux normes

canadiennes CAN 1-B149.1 and .2 regissant les

cuisinieres a. gaz domestiques et la reglementation

locale.

27

Page 30

Chapitre 1

•Conditions de ventilation

II est fortement recommande

d'installer une hotte de ventilation

appropriee au-dessus de la

cuisiniere. Une ventilation par

contre-tirage ne devrait pas 6tre

utilisee. Le tableau ci-dessous

enumere, par numero de modele,

les hottes Thermador qu'il est

conseille d'utiliser avec les

cuisinieres.

1. Choix du modele de

hotte et de ventilateur

Pour les installations murales, la

largeur de la hotte doit _tre au

minimum egale a. celle de table

de cuisson de la cuisiniere. Si

I'espace le permet, il est

souhaitable d'installer une hotte

plus large que la table de

cuisson pour ameliorer les

performances de ventilation.

Pour les installations en riot, la

largeur de la hotte devrait

depasser d'au minimum 8 cm

(3") des deux c6tes de la table

de cuisson de la cuisiniere.

MISE EN GARDE

Les hottes de ventilation et les

ventilateu rs sont con gus pour une

seule conduite murale. Certaines

reglementations locales du

secteur du b&timent exigent

toutefois une double conduite.

Consultez les normes applicables

et/ou I'administration locale avant

de commencer les travaux afin de

vous assu rer que I'installation des

conduites repond aux exigences

locales.

II convient que la vitesse du

ventilateur de la hotte soit

reglable afin de reduire le bruit

et la perte d'air chaud ou

climatise Iorsque la ventilation

maximum n'est pas necessaire.

Normalement, la vitesse

maximum du ventilateur n'est

necessaire que quand on utilise

le gril.

2. Emplacement de la

hotte

• Pour une meilleure elimination

des fumees, le bord inferieur de

la hotte doit _tre place a. une

distance minimum de 76,2 cm

(30") et maximum de 91,4 cm

(36") au-dessus de la table de

cuisson (voir Figure 1).

• Si la hotte contient des

materiaux combustibles (par

exemple, un placage en bois),

elle doit _tre placee a. 91,4 cm

(36") au minimum au-dessus de

la table de cuisson.

3. Apport d'air

• Un important volume d'air etant

necessaire pour la ventilation, il

est recommande de prevoir un

apport d'air de I'exterieur. Cet

aspect rev_t une importance

particuliere dans les Iogements

bien isoles et tres etanches.

• II est conseille de consulter un

entrepreneur en chauffage et

en climatisation.

PH30CS,

CUISINIt_REDE76,2CM(30p0:

CUISINIEREDE91,4CM(36p0)

CUISINIEREDE121,9CM(48p0)

Remarques :* Pour lesinstallationsmurales, si I'espace estsuffisant, I'installateurou I'utilisateurpeutchoisir une

hottepluslargeque latablede cuissonde lacuisiniere.Elle amelioreraI'evacuationdes fumeessi I'on

utilisebeaucouple grilousi laconduiteest Iongue.

** Pourlesinstallationsmurales,Thermadorproposedesmodelesdeventilateursa distance(VTRIOOOQou

VTR1400Q)ouincorporesdanslahotte(VTNI030C).

PHE30,36

PH36CS, 42CS

PHE36,42

HNW36YS

HNW42 YS

PH48CS, VTR1000Q

PHE48,60 VTR1400Q

VTR 1O00Q,

VTR1400Q

ouVTN 1030C

VTRIOOOQ,VTR1400Q

ouVTN 1030C

VTRIOOOQ,VTR1400Q

VTRIOOOQ,VTR1400Q

ouVTN 1030C

28

HTN142YS VTR 1O00Q,

HNI42YS VTR1400Q

HTN142YS VTR1000Q

HN142YS VTR1400Q

HTNI48YS

HNI48YS

HTNI54YS

HNI54YS

VTR1400Q

Page 31

Chapitre 2 Preparation de I'emplacement

1. La cuisiniere est un appareil monobloc. Si elle est 4.

placee au milieu des armoires, les degagements

requis sont indiques a. la Figure 1. Les m_mes

degagements s'appliquent aux installations en riot, 5.

excepte pour les armoires suspendues qui doivent

laisser un espace suffisamment grand pour poser

la hotte d'flot evasee, comme le montre la Figure 1. 6.

2. Les cuisinieres de 91,4 cm (36") peuvent _tre

encastrees entre les armoires au-dela, du bord de

la partie frontale du four (voir Figures 2A et 2B).

Les cuisinieres de 76,2 cm (30") et de 121,9 cm (48")

ne sont pas homologuees pour _tre installees a. ras

des armoires.

MISE EN GARDE

Dans ce type d'installation pour les cuisinieres

de 91,4 cm (36"), la porte et I'armoire peuvent

comporter un risque de pincement.

3. Les arrivees d'electricite et de gaz doivent se trouver

dans les zones indiquees a. la Figure 3A.

REMARQUE : La profondeur maximum des armoires

en hauteur installees d'un c(Steou de I'autre de la hotte

est de 33 cm (13").

La profondeur maximum des armoires installees de

chaque c6te de la hotte est de 33 cm (13").

Toute ouverture dans lemur qui se trouve derriere

la cuisiniere et dans le plancher sous la cuisiniere

dolt _tre refermee.

Si la distance entre un materiau combustible /k et le

bord arriere de la cuisiniere au-dessus de la table

de cuisson est de moins de 30,5 cm (12"), il est

obligatoire d'installer une plaque Thermador de

protection arriere, basse ou a. etagere superieure

(voir Figure 2A). Si la distance du materiau

combustible /k est superieure a. 30,5 cm (12"), il est

possible d'utiliser un enjoliveur Thermador pour riot

(voir Figure 2B). Les Figures 2A et 2B indiquent

I'espace necessaire pour chaque type de plaque

de protection.

.

L'appareil ne dolt jamais se trouver a. proximite de

materiaux combustibles, d'essence et d'autres

produits inflammables (vapeurs ou liquides).

.

L'air de combustion et de ventilation arrivant a.

I'appareil dolt pouvoir circuler librement dans les

conduites

Un degagement minimum de 91,4 cm (36") est

necessaire entre le dessus de la cuisiniere et le

dessous d'une armoire non protegee. Si le dessous

de I'armoire en bois ou en metal est protege par un

materiau ignifuge d'au moins 6,35 mm (1/4") rev6tu

d'une feuille d'acier no 28 MSG d'au moins la m6me

epaisseur, de 0,38 mm (0.015") d'acier inoxydable,

de0,6 mm (0.024") d'aluminium ou de0,5 mm (0.02")

de cuivre, la distance minimum est de 76,2 cm (30").

Les materiaux ignifuges portent la marque :

UNDERWRITERS LABORATORIES INC.

CLASSIFIED MINERAL AND FIBER BOARDS

SURFACE BURNING CHARACTERISTICS,

(panneaux de fibres et mineraux classes,

caracteristiques d'inflammation des surfaces),

suivie des taux de progression des flammes et des

fumees. Ces designationssont indiquees par _ FHC _,

(Flame Spread/Smoke Developed- Progression des

flammes/Production de fumee). Les materiaux ayant

un taux _ O ,_ de progression de flammes sont

ignifuges. Les reglementations locales peuvent

autoriser d'autres taux de progression des flammes.

29

Page 32

Chapitre 2

Preparation de I'emplacement

MISE EN GARDE

N'installez pas les modeles de cuisinieres PD304 et PD48 de telle

sorte que la porte du four soit auras de la partie frontale des

armoires. Une installation & m6me niveau risque d'endommager

les armoires de & leur exposition & la chaleur.

Conversion deS mesures

/_ Telquedefini dartsle ,, Codenational

dugazcombustible ,,(Derniere

versiondelanormeANSIZ223.1).

FIG. 1 - Degagement des armoires

Cuisinierede76,2 cm(30 ")J"Hottede76.2CM(30")oude91,4cm (36")

76,2 cm = 30"

91,4 cm = 36"

106,7 cm = 42"

121,9 cm = 48"

137,2 cm = 54"

152,4 cm = 60"

t 106,7cm(42")ou121,9cm(48")pourinstallationenriot

O 0 I )l suspenduescomposeesdemateriauxcom-/ I o

__ __ Vl bustiblesA "_, -

.... Cuisinieresde 762 cm(30") Profondeur1 _-

Min. 76,2 cm (30') & 91,4 cm I Cuisinieresde1219cm'48"' 33cm'1:3"'J MISEEN GARDE :Voir

(36") max. entre le dessous ' ,"', • ") FiN 2A et2B Distance

45,8 cm

(18")min.

/'

/,'

/

-- r_tract_s : 89,8 cm (35-3/8")

de la hotte et la table de I I aparotlaterale m_n'g14cm'_"'entrela

cuisson (91 4cm [36"] si la i Largeurdelacuisiniere _ i .... ' ' .

hotte contient des materiaux i-'_, 762cm30" 91 4cm36"ou vl_L_,, , _ ,_m,-,

combustibles A ). ' 121,9cm48" . mat6riauxcombCi_tibles

__ ' __. _ Taibslseodne k_ _ ,

Hauteur min. de la cuisini_re avec

pieds _l_vateurs enti_rement

Hauteur max. de la cuisini_re

avec pieds _l_vateurs

enti_rement d_ploy_s •

93,3 cm (36-3/4").

• ' - • -_' _-- a[erlau tablede cuisson et des

Cuisinierede91,4 cm(36") J'H°tte de91,4cm(36")ou 106,7cm(42")

............... I'Hottede 121,9cm(48")ou 152,4\cm(60'')

uisiniereae]z] ,ucm[4_ )_.121,9cm(48"),137,2cm(54")ou _'

, I _-_ Distance minimum entre les armoires--_ J--

, i Culsnleresde 914 cm(36") 'armore' _' -4,

O0 .,,_ .... -J 0

I| ' ' I -

J / _'_one d'arriv_e d'_lectricit_ et de gaz,_

I r "_voir Fig. 3A. Les dimensions et la

I 1/ position de cette zone d_pendent

__j, du module.

.... ' max de 7

/_ Tel que d_fini dans le ,, Code national du gaz combustible >_

(ANSI Z223.1 - Derni_re _dition). * La hauteur de la cuisini_re est

r_glable. Le dessus de la cuisini_re doit _tre au m_me niveau ou

plus haut que le plan de travail.

[106,7 cm(42")ou 121,9cm (48")pourinstallationenflot

152,4cm(60")pourinstallationenfl_

/

t ) t ) Mtn76cm3

combustlbleen ( )

\

30

Page 33

Chapitre 2 Preparation de I'emplacement

FIG. 2A- Vue laterale

',." /z_//_ //// //// --combustibles/_

,---- 29-1/2

I

€:tag_re_ 1 /

I

Min. 91,4 cm (36") !

des combustibles Z_i

t

superieure"'_,._J _

Plaque de _ t

protection -._ I |

I

i basse "_1

.,,, ;63! -

I -

f

,q

7C -.-25-1/2 max.- -

/

!

I

/

c_

Placpe

d'habillage

.1 Partie frontale

_ l 29-1/2"

I /'/// /,I,// ///,/)

,L*---28-3/8" ---_

32-5/8"

_2-7/8;i

,3-7/8"

3/8"

•,_F[vlu r

/il/

Mat_riaux

1

22"

Conversions de mesures

9,5 mm = 3/8"

9,8 cm = 3-7/8"

30,4 cm = 12"

32,7 cm = 12-7/8"

55,9 cm = 22"

64,7 cm = 25-1/2"

66,9 cm = 26-3/8"

72,1 cm = 28-3/8"

74,9 cm = 29-1/2"

82,9 cm = 32-5/8"

120,3 cm = 47-3/8"

', 47-3/8" ,. 1

A tel que defini dans le Code national du gaz combustible

(ANSI Z223.1, Version actuelle).

FIG. 2B - Vue laterale

Min.9114cm(36")&

combustibles_

Conversion des mesures

91,4 cm = 36"

30,5 cm = 12"

3,2 mm= 1/8"

/_ Min.30,48cm (12")a.

combustiblessiaucune

plaquedeprotectionn'est

install_eouinstallationen

ilet

Enjoliveur I

t

I

I

pour riot. 4,,__ II

Partie

./frontale

i

1

" Materiaux I

, combustibles/_

3,2 mm

(1/8")

REMARQUE :

Pour installer I'enjoliveur pour "ilot,

le plan de travail dolt avoir un bord

en porte-a.-faux venant se placer

bord a. bord avec I'arriere de

I'enjoliveur.

Plan de travail en porte-a.-

faux

REMARQUE :

Si une paroi interne est utilisee

sous le plan de travail en porte-

a.-faux, la distance entre cette

paroi et I'arriere de la cuisiniere

dolt _tre de 3,2 mm (1/8")

31

Page 34

Chapitre 2: Preparation de I'emplacement

ARRIVI_E DU GAZ ET DE L'I_LECTRIClTI_

Figure 3A • Arrivee du gaz et de I'electricite

de toutes les cuisinieres mixtes

Le placement typique

montr& L'autre place-

ment de provision de

gaz et la prise

electrique dans la pro-

vision electrique et de

zone de gaz est ac-

ceptable.

REMARQUE :

dolt pouvoir

acceder facilement

par I'une des

armoires

adjacentes au

robinet manuel

d'arr_t de gaz (non

represente sur la

fig.) sans avoir a.

deplacer la

cuisiniere.

Modele A

PD30 20,3cm

PD36 26,4cm

PD48 41,9cm

Zone

d'arrivee

du gaz I

Saillie max.'5,1 cm

(2") a partir du tour

pour I'arrivee de gaz

30,5cm 25,4cm 16,5cm 13,3cm

38,1cm 26,4cm 16,5cm 13,3cm

40,6cm 39,4cm 16,5cm 13,3cm

Tuyau flexible de

19 mm (3/4") vers

I'appareil

Filetage NPT

12,7 mm (1/2")

Prise 240 VCA

(representee) ou Bofte

de d@ivation

m

I d'arrivee de

"-I I'electricit6

Sol

B C D E

Zone

Toutes les cuisinieres mixtes

peuvent 6tre raccordees au secteur

&I'aide du cordon d'alimentation fou rni

avec la cuisiniere ou bien directement

c&blees. L'installateu rdoit fou rnir les

elements de c&blage qui conviennent

(cordon ou conduite et c&bles) et

realiser le raccordement au gaz

conformement & la reglementation

locale et/ou au Code national

d'electricit& Les appareils doivent

6tre mis & la terre. Voir le Chapitre 6

pour plus de details.

La cuisiniere ne doit 6tre

raccordee qu'au type de gaz

pour lequel elle est certifiee. Si

elle est raccordee au gaz propane,

lereservoirdepropanedoit6tre dote

de son propre detendeur en

plus du detendeur fourni

avec la cuisiniere (voir Chapitre 5).

REMARQUE : Toute ouverture dans le mur se trouvant

derriere I'appareil ou dans le plancher sous I'appareil

dolt _tre bouchee.

Conversions de mesures

20,3 cm = 8"

30,5cm = 12"

25,4cm = 10"

16,5 cm = 6-1/2"

26,4 cm = 10-1/2"

38,1 cm = 15"

39,4 cm = 15-1/2"

40,6cm = 16"

41, 9 cm = 16-1/2"

32

Page 35

Chapitre 2 Preparation de I'emplacement

ALIMENTATION I_LECTRIQUE, CUISINIERES MIXTES

L'installation des cuisinieres mixtes

doit _tre planifiee de sorte que la

bofte de derivation pour la prise ou

la connexion de la conduite laisse

le maximum d'espace a. I'arriere de

I'appareil.

Quand le cordon d'alimentation

electrique (non fourni) ou la

conduite sont connectes a. la prise

ou a. la bofte de derivation,

FIG. 3B - RACCORDEMENT AU MUR

I'ensemble prise/prise murale ou

couvre de bofte de connexion/

connecteur de conduite ne doit pas

former une saillie de plus de 5,7 cm

(2-1/4") a. I'arriere. Reportez-vous

a. la Figure 3B.

Ce point est particulierement

important si la bofte de derivation

murale se trouve juste derriere la

bofte de derivation de I'appareil une

(2 1/4")

5,7cm max. _.._

fois celui-ci install& Reportez-vous

a. la Figure 9 de la page 40 pour

I'emplacement de la bofte de

derivation sur rappareil. Afin de

minimiser les torsions Iors du

branchement de I'appareil a. la prise

ou a. la bofte, orientez en premier

lieu la prise ou le connecteur de la

conduite et faites glisser sur la

position.

I

_ __ 5,7 cm (2 1/4") max.

!

• une fois branche

Cordon d'alimentation et prise Boite de ddrivation et conduite

33

Page 36

Chapitre3 : Deballage,manutentionetmiseenplacede lacuisiniere

MISE EN GARDE

Un equipement adapte

manipule par du personnel

experimente doit _tre utilise

pour deplacer la cuisiniere

afin de ne pas endommager

I'appareil ni le plancher. La

cuisiniere est Iourde et

repose sur des pieds

reglables en acier.

Le poidsapproximatif de la cuisiniere _t

I'expeditionest celui qui est indique au

TableauA. IIest recommande d'6ter les

grillesdesbreleurs,la plaquedecuisson,

les chapeaux des breleurs, la plaque

d'habillage et les grilles du four pour

faciliter la manutention. Le poids de

I'appareils'entrouvera diminu&comme

indique auTableau A,et permettra _tla

cuisiniere de passer par une porte de

76,2cm (30").VoirFigures2Aet 2B _tla

Page 31. N'6tez pas le gril ni la

plaque de cuisson.

Tableau A Cuisinierede Cuisinierede Cuisinierede

76,2cm(30") 91,4cm(36") 121,9cm(48")

Poids& I'expedition

Poidssans materiaux

d'emballage

Poidshors porte(s),

chapeauxde brQleurs,plaque

d'habillageet grilles de four

Figure 4 - Retrait des deux

boulons avant pos_s pour

rexp_dition

152kg (335Ib) 201,4kg (444Ib) 264,9 kg (584 Ib)

129,3kg(285Ib) 176,9kg(390Ib) 237,6kg( 524Ib)

97,5kg(215Ib) 133,8kg(295Ib) 179,2kg (395Ib)

Figure 5 - Retrait des deux

boulons arri_re pos_s pour

rexp_dition

Boulon arne I'appar(

gauchepos_

pour

I'expedit!on

., _ Arriere de

I

Retirez I'emballage externe et les

materiaux d'emballage de la palette

d'expedition. Toutes les cuisinieres

mixtessontfixeessur unepalette,),raide

de quatre (4) boulons (voir Fig. 4 et5).

Apresavoirenleveles boulons,soulevez

lacuisiniereetenlevez-lade lapalette.

Retirezlesequerresdelacuisiniere.Pour

cefaire, I'installateurdoitretirerlesdeux

vis qui fixent chacune de ces equerres,

enlevez I'equerreet remettezlesvis.

34

Page 37

Chapitre3 : Deballage,manutentionet miseenplacede la cuisiniere

En raison du poids de la cuisiniere, il convient

d'utiliser une plate-forme & roulettes souples pour

la deplacer. Le poids doit 6tre uniformement reparti

sur la plate-forme (voir Figure 6).

Transportez la cuisiniere sur la plate-forme pres

de son emplacement definitif, basculez-la pour

qu'elle soit portee par les pieds arriere et retirez la

plate-forme. PROTI_GEZ LE SOL SE

TROUVANT SOUS LES PIEDS

(MORCEAUX DE BOIS, TAPIS,. ETC.)

AVANT DE METTRE LA CUISINIERE EN

PLACE. Installez le dispositif antibascule

(Chapitre 4), raccordez le gaz et I'electricite

(Chapitres 5 et 6) et installez la plaque de

protection (Chapitre 7) avant de placer

definitivement la cuisiniere.

Pour garantir son bon fonctionnement, la

cuisiniere professionnelle doit 6tre nivelee.

(Ce point est important pour tous les produits

equipes d'une plaque chauffante.) La cuisiniere

se nivelle en reglant les pieds avec une cl&

Rg.6-Miseenplacesurlaplate-formearoulettes

Lepoidsdela

cuisinieredoit6tre

uniforr_ment

j , repartiens'aidant

I I dessupportsplac6s

I su_ieiderSS°USde la

,4 I