Page 1

For Thermador ProfessionaP Cooktops

'l

Des tables de cuisson Thermador

Professional ®

ModeLs

P24GE

P24WK

PC30

PC36

PC48

IAnAmer_co,_Ico_°

Page 2

Contents

Warnings .................................................................................... Below

Introduction ........................................................................................ 1

Important Installation Information ........................................................ 2

Step 1: Ventilation Requirements ...................................................... 3

Step 2: Cabinet Preparation ......................................................... 4 - 7

Step 3: Unpacking, Moving, Placing and Anchoring the Cooktop ....... 8

Step 4: Gas Requirements and Hookup ..................................... 9- 10

Step 5: Electrical Requirements, Connection and Grounding .......... 11

Step 6: Backguard Installation .......................................................... 12

Step 7: Burner Test and Adjustment ........................................... 13 - 14

Installer Checklist ............................................................................. 15

To Clean and Protect Exterior Surfaces ............................................ 15

mMPORTANT mNSTALLATmON mNFORMATmON

WARNtNG:

If the information in this manual is not

followed exactly, a fire or explosion may

result causing property damage, personal

injury or death.

-- Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

-- WHAT TO DO _F YOU SMELL GAS

• Do not try to fight any appliance.

Improper installation, adjustment, alteration,

service or maintenance can cause injury or

property damage. Refer to this manual. For

assistance or additional information consult

a qualified installer, service agency, manu-

facturer (dealer) or the gas supplier.

Note: This Cooktop is NOT designed for

installation in manufactured (mobile) homes or

for installation in Recreational Park Trailers.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call

the fire department.

-- Installation and service must be performed

by a qualified installer, service agency or the

gas suppler.

For Massachusetts mnstaHations:

1. Installation must be performed by a qualified or licensed contractor, plumber or gas

fitter qualified or licensed by the state, province or region where this appliance is being

installed.

2. Shut-off valve must be a "T" handle gas cock.

3. Flexible gas connector must not be longer than 36 inches.

DO NOT install this appliance outdoors.

DATA RATING PLATE

Cooktop Mode_s:

The data rating plate showing the model and serial

numbers of your Cooktop or Wok is located on the

underside of the Cooktop or Wok chassis near

the gas inlet connection and electdc power cord.

This information is required if customer service is

requested. Before installation the model and serial

numbers should be entered in the a_riate

spaces in the "BEFORE CALLING FOR SERVICE"

section near the back of the Care and Use Manual.

After installation accessing the information is

difficult.

Page 3

PLEASE READ ENTmRE mNSTRUCTmONS BEFORE PROCEEDmNG

mMPORTANT: LOCAL CODES VARY. INSTALLATION, ELECTRICAL CONNECTIONS,

GAS CONNECTIONS, AND GROUNDING MUST COMPLY WITH ALLAPPLICABLE CODES.

H'_PORTANT: Save these instructions for the Local Electrical Inspector's use.

_NSTALLER: Please leave these Installation instructions with this unit for the owner.

OWNER: Please retain these instructions for future reference.

ELECTRICAL POWER SUPPLY:

24" Models

with Wok - 120 VAC, 60 Hz., 1 Ph., 10Amp circuit

with Griddle - 240 VAC, 60 Hz., 1 Ph., 30 Amp circuit

30" Models:

4 Burners- 120 VAC, 60 Hz., Ph., 10Amp circuit

36" Models:

6 Burners - 120 VAC, 60 Hz., 1 Ph., 10 Amp circuit

with Grill - 120 VAC, 60 Hz., 1 Ph., 10 Amp circuit

with 12" Electric Griddle - 120 VAC, 60 Hz., 1 Ph., 15Amp circuit

48" Models:

6 Burners with Grill - 120 VAC, 60 Hz., 1 Ph., 10Amp circuit

6 Burners with 12" Electric Griddle - 120 VAC, 60 Hz., 1 Ph., 15Amp circuit

4 Burners with 12" Electric Griddle and Grill - 120 VAC, 60 Hz., 1 Ph., 15Amp circuit

4 Burners with Wok - 120 VAC, 60 Hz., 1 Ph., 10 Amp circuit

4 Burners with 24" Electric Griddle - 240 VAC, 60 Hz., 1 Ph., 30 Amp circuit

GAS SUPPLY:

Natural Gas -

Propane Gas -

6" min. to 14" max. water column.

(14.9 to 34.9 mb)

11"min. to 14"max. water column.

(27.4 mb to 34.9 mb)

Introduction

All sealed burners are rated at 15,000 BTUiHR

('13,000 BTUiHR on LP), *All models, except 24"

Griddle, are convertible to LPiPropane gas using

an accessory conversion kit.

H'vlPORTANT

A backguard must be utilized when there is

less than a 12" horizontal clearance between

combustible materials and the back edge

of the cooktop. The Thermador Low Back

backguard must be ordered separately and

installed at the rear of the cooktop. For island

installations and other installations with more

than 12" clearance, an optional stainless steel

Island Trim is available to cover the backguard

mounting flanges.

WARNING

Disconnect power before installing.

Before turning power ON, be sure that

all controls are in the OFF position.

• Verify that the appliance is correct for the type

of gas being provided. Refer to Step 4 before

proceeding with the installation.

Page 4

Important Installation information

This appliance has been CSA

certified for safe operation up to

an elevation of 10,200 ft. without

any modifications. Exception: For

use with Propane, the appliance

must be converted per the LP

Conversion Instructions.

It is stron Ig_ recommended

that this appliance be installed

in conjunction with a suitable

overhead vent hood. (See Step

1 for Ventilation Requirements.)

Check local building codes for

the proper method of appliance

installation. Local codes vary.

Installation, electrical connections

and grounding must comply

with all applicable codes. In

the absence of local codes the

appliance should be installed

in accordance with the National

Electric Code ANSI Z223.1

current issue and National Gas

Code ANSI/NFPA 70 - current

issue. In Canada, installation

must be in accordance with

the CAN 1-B149.1 and .2-

Installation Codes for Gas

Burning Appliances and/or local

codes.

This appliance is equipped

with an intermittent/interrupted

ignition device that cycles the

two far left surface burners on

and off when in the ExtraLow _R*

setting.

CAUTION

(1) Whenconnectingtheunitto

propane gas, make certain

the propane gas tank is

equipped with its own

high-pressure regulator in

addition to the pressure

regulator su pplied with this

unit. The maximum gas

pressure to this appliance

is not to exceed 14.0

inches water column (34.9

mb) from the propane gas

tank regulator.

(2) This unit is designed as a

cooking appliance. Based

on safety considerations,

never use it for warming

or heating a room.

Due to the high heat of the

cooktop burners, installing a

microwave oven with a ventilation

system over the cooktop is not

recommended.

This appliance complies with

one or more of the following

standards:

UL 858, Standard for the

Safety of Household Electric

Ranges

• UL 923, Standard for the

Safety of Microwave Cooking

Appliances

UL 507, Standard for the

Safety of Electric Fans

• ANSI Z21.1 American National

Standard for Household Cooking

Gas Appliances

CANiCSA-C22.2 No. 113-

M1984 Fans and Ventilators

CANiCSA-C22.2 No. 61-M89

Household Cooking Ranges

It isthe responsibility of the owner

and the installer to determine if

additional requirements and/or

standards apply to specific

installations.

CAUTION

To eliminate risk of burns or

fire caused by reaching over

heated surface units, cabinet

storage located above the

surface units should be

avoided.

Remove all tape and packaging

before using the appliance.

Destroy the packaging after

unpacking the appliance. Never

allow children to play with

packaging material.

Page 5

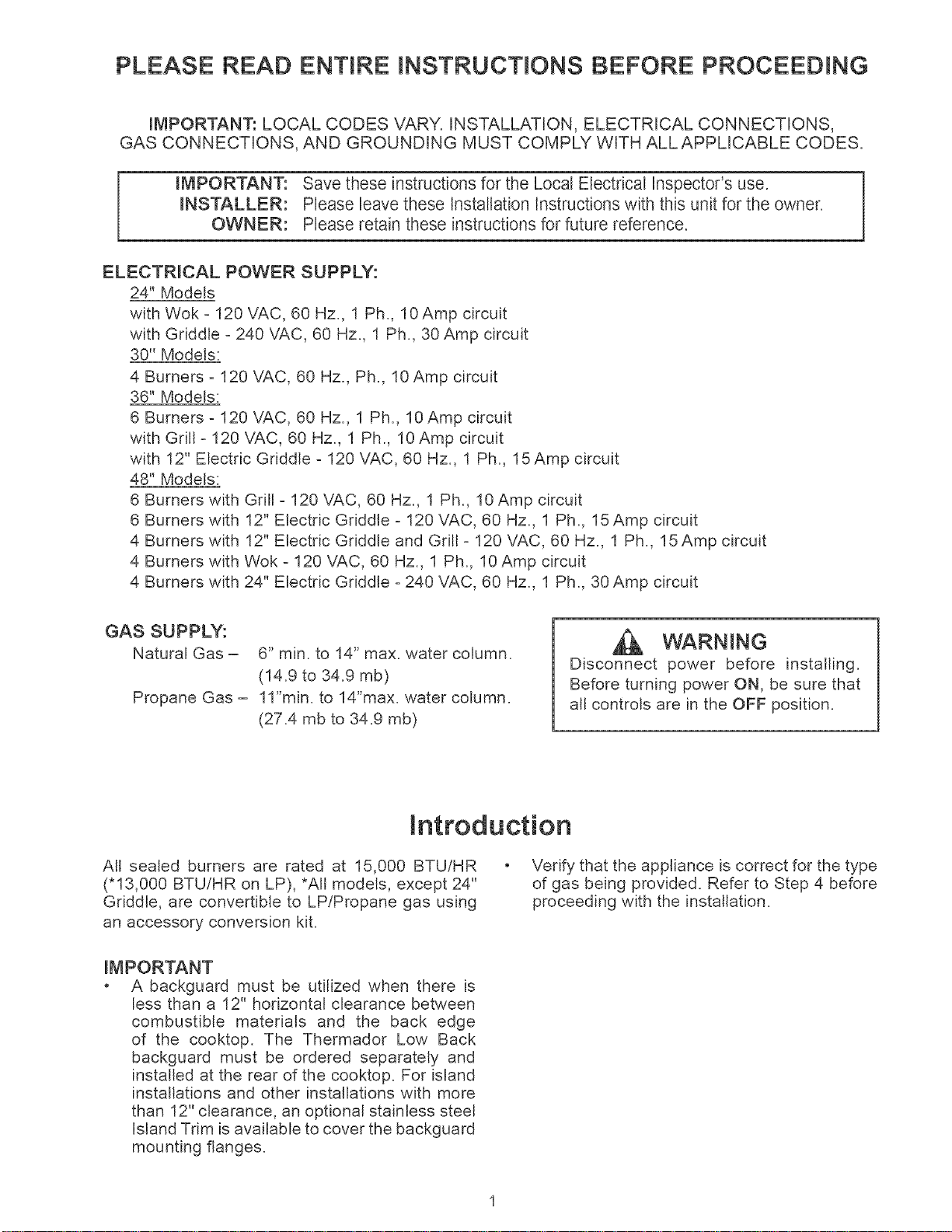

Step 1 Ventilation Requirements

It is strongL_L recommended

that a suitable exhaust hood be

installed above the appliance.

Downdraft ventilation should

not be used. The table below

indicates the Thermador hoods,

by model number, that are

recommended for use with the

24" wok, 24" griddle, 30", 36" and

48" cooktops.

Due to the high heat capability

of this unit, particular attention

should be paid to the hood and

duct work installation to assure it

meets local building codes.

Do not install a microwave oven/

ventilator combination above

the cooktop, as these types of

units do not provide the proper

ventilation and are not suitable

for use with the cooktop.

1. Semect Hood and B_ower

Models:

+ For wall installations the

hood width must, at a

minimum, equal the nominal

width of the appliance

cooking surface. Where

space permits, a hood larger

in width than the cooking

surface may be desirable

for improved ventilation

performance.

+ For island installations the

hood width should, at a

minimum, overhang the

appliance cooking surface

by 3" on each side.

2. Hood Placement:

+ For best smoke elimination,

the lower edge of the hood

should be installed 36"

above the appliance cooking

surface. (See Fig. 1).

+ If the hood contains any

combustible materials (i.e.,

a wood covering), it must be

36" or greater distance above

the cooking surface.

3. Consider Make-Up Air:

+ Due to the high volume of

ventilation air, a source of

outside replacement air

is recommended. This is

particularly important for

tightly sealed and insulated

homes.

+ A qualified heating and

ventilating contractor should

be consulted.

NOTE: Ventilation hoods and

blowers are designed for use

with single-wall ducting. Some

local building codes may require

double-wall ducting. Before

starting installation, consult local

building codes and agencies to

insure that the installation will

meet local requirements.

24" WOK

24" GRIDDLE

30" COOKTOP

36" COOKTOP

48" COOKTOP

PH30CS, PHE30/36 VTR1030D, VTR1530D

HNW36YS

PHH30DS***

PH36CS/42CS

PHE36/42

HNW36YS/42YS

PH36DS***

PH48CS/54CS

PHE48/60

HNW48YS

or VTN1030C

VTR 1030D, VTR1530D

N/A

VTR 1030D, VTR1530D

or VTN1030C

VTR 1030D, VTR1530D

N/A

VTR 1030D, VTR1530D

or VTN1030C

VTR 1030D, VTR1530D

HNI42YS VTR1030D or

HTNI42YS VTR1530D

HNI42YS VTR1030D or

HTNI42YS VTR1530D

HNI48YS/54YS, VTR1530D

HTNI48YS/54YS

NOTES: * For wall installations where adequate space is available, the installer or user may elect to use

a hood that is wider than the cooktop cooking surface. This may be particularly beneficial for

installations having a long duct run or when heavy usage of the grill or wok is anticipated, in

which improved capturing of the cooking exhaust is desired.

•* Thermador offers a choice of remote (VTRI030D or VTR1530D) or internal (VTN 1030C)

blowers for use in wail installations.

•** Hood models PHH30DS and PHH36DS include a 600-CFM built-in blower. For optimal

ventilation, a hood model with 1000-CFM blower or greater is recommended for cooktops

having a griddle, grill, or wok.

Page 6

Step 2: Cabinet Preparation

I. To ensure professional results, the cabinet and

countertop openings should be prepared by a qualified

cabinet worker.

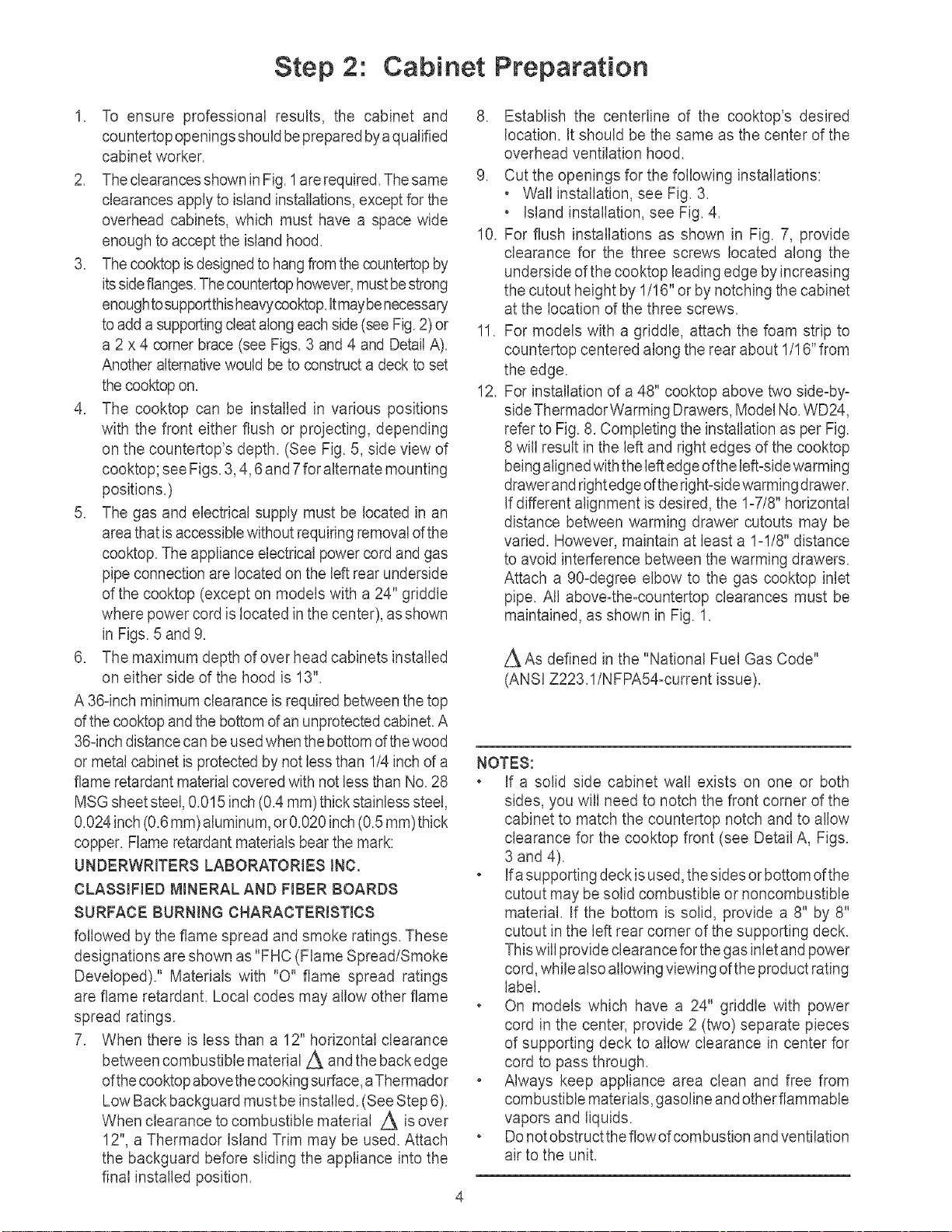

2. The clearances shown in Fig. I are required. The same

clearances apply to island installations, except for the

overhead cabinets, which must have a space wide

enough to accept the island hood.

3. The cooktop is designed to hangfrom the countertop by

its sideflanges. Thecountertop however, must bestrong

enoughtosupportthis heavycooktop. Itmaybe necessaq/

to add a supporting cleat along each side (see Fig. 2) or

a 2 x 4 corner brace (see Figs. 3 and 4 and Detail A).

Another alternative would be to construct a deck to set

the cooktop on.

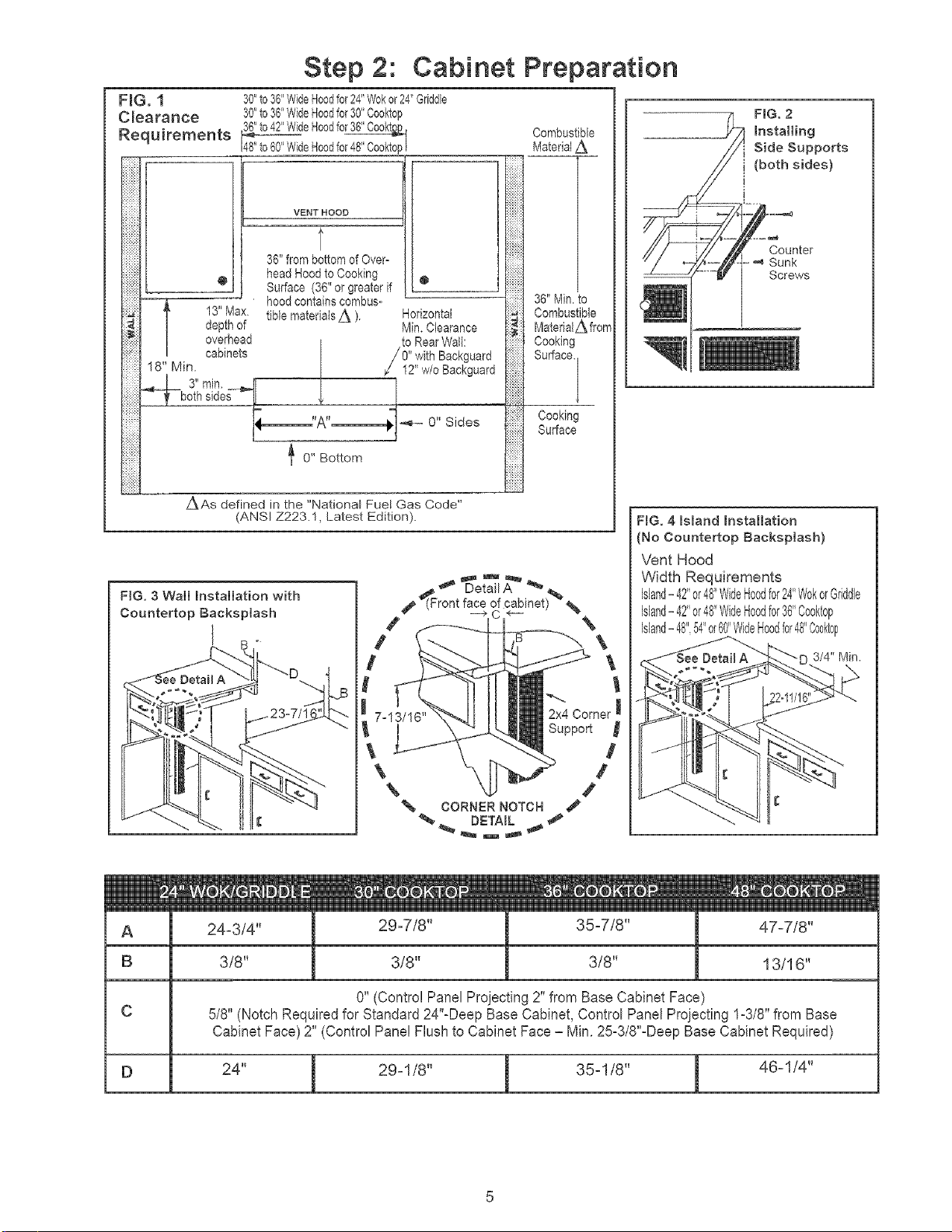

4. The cooktop can be installed in various positions

with the front either flush or projecting, depending

on the countertop's depth. (See Fig. 5, side view of

cooktop; see Figs. 3,4, 6 and 7for alternate mounting

positions.)

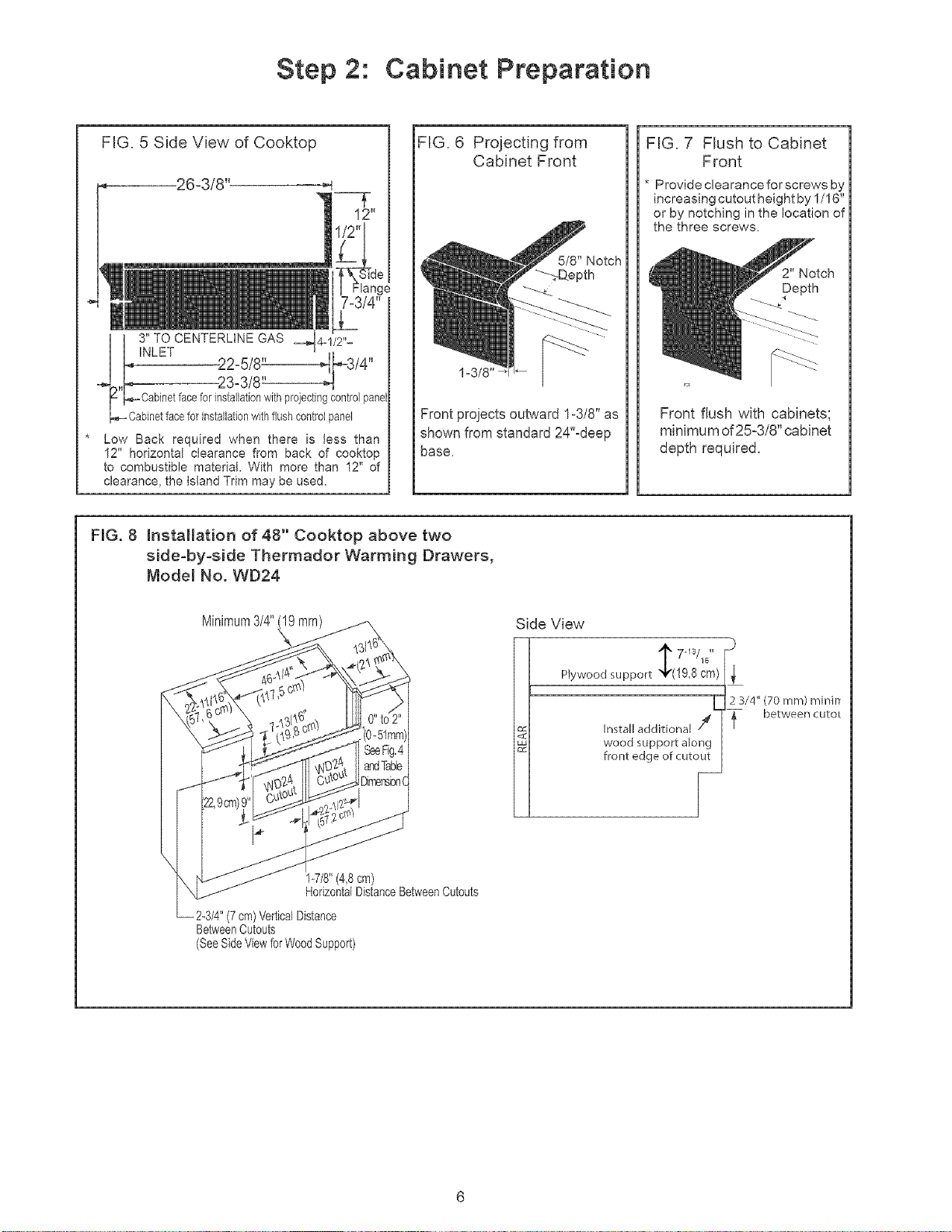

5. The gas and electrical supply must be located in an

area that isaccessible without requiring removal ofthe

cooktop. The appliance electrical power cord and gas

pipe connection are located on the left rear underside

of the cooktop (except on models with a 24" griddle

where power cord is located in the center), as shown

in Figs. 5 and 9.

6. The maximum depth of over head cabinets installed

on either side of the hood is 13".

A 364nch minimum clearance is required between the top

of the cooktop and the bottom of anunprotected cabinet. A

364nch distance can be used when the bottom d thewood

or metal cabinet is protected by not less than I/4 inch d a

flame retardant material covered with not less than No. 28

MSG sheet steel, 0.015 inch (0A mm) thick stainless steel,

0.024 inch (0.6 ram)aluminum, or 0.020 inch (0.5 mm)thick

copper. Flame retardant materials bear the mark:

UNDERWRITERS LABORATORIES INC.

CLASSIFIED MINERAL AND FIBER BOARDS

SURFACE BURNING CHARACTERISTICS

followed by the flame spread and smoke ratings. These

designations are shown as "FHC (Flame Spread/Smoke

Developed)." Materials with "O" flame spread ratings

are flame retardant. Local codes may allow other flame

spread ratings.

7. When there is less than a 12" horizontal clearance

between combustible material A and the back edge

ofthe cooktop above thecooking su dace,aThermador

Low Back backguard must be installed. (See Step 6).

When clearance to combustible material A isover

12", a Thermador Island Trim may be used. Attach

the backguard before sliding the appliance into the

final installed position.

8. Establish the centerline of the cooktop's desired

location. It should be the same as the center of the

overhead ventilation hood.

9. Cut the openings for the following installations:

• Wail installation, see Fig. 3.

• Island installation, see Fig. 4.

I0. For flush installations as shown in Fig. 7, provide

clearance for the three screws located along the

underside of the cooktop leading edge by increasing

the cutout height by 1/16" or by notching the cabinet

at the location of the three screws.

11. For models with a griddle, attach the foam strip to

countertop centered along the rear about 1/16" from

the edge.

12. For installation of a 48" cooktop above two side-by-

side Thermador Warming Drawers, Model No.WD24,

refer to Fig. 8. Completing the installation as per Fig.

8 will result in the left and right edges of the cooktop

being aligned with the left edge ofthe ieftosidewarming

drawer and rightedge tithe right-side warming drawer.

If different alignment is desired, the IW/8" horizontal

distance between warming drawer cutouts may be

varied. However, maintain at least a 1-I/8" distance

to avoid interference between the warming drawers.

Attach a 90-degree elbow to the gas cooktop inlet

pipe. All above4he-countertop clearances must be

maintained, as shown in Fig. I.

AAs defined in the "National Fuel Gas Code"

(ANSI Z223.1/NFPA54-current issue).

NOTES:

• If a solid side cabinet wall exists on one or both

sides, you will need to notch the front corner of the

cabinet to match the countertop notch and to allow

clearance for the cooktop front (see Detail A, Figs.

3 and 4).

• Ifa supporting deck isused, the sides or bottom ofthe

cutout may be solid combustible or noncombustible

material. If the bottom is solid, provide a 8" by 8"

cutout in the left rear corner of the supporting deck.

This will provide clearance for the gas inlet and power

cord, while also allowing viewing of the product rating

label.

• On models which have a 24" griddle with power

cord in the center, provide 2 (two) separate pieces

of supporting deck to allow clearance in center for

cord to pass through.

. Always keep appliance area clean and free from

combustible materials, gasoline and other flammable

vapors and liquids.

• Donotobstructthe flowofcombustion and ventilation

air to the unit.

Page 7

FIG. 1

Clearance

Requirements

Step 2: Cabinet Preparation

30"to38"WideHoodfor24"Wokor 24"Griddle

30"to38"WideHoodfor30"Cooktop

_' to42"WideHoodfo_ Combustible

48"to80"WideHoodfor48"Cooktopt Material A

VENT HOOD _ _ --

FIG. 2

Installing

Side Supports

(both sides)

t

i

@ Surface (36" or greater if

,, hood contains combus° 36" Min. to

13 Max. tible materials A ). Horizontal [:ii_!:l Combustible

| depth of Min. Clearance [!ii_i] MaterialZ_,from

I

18" Min,,bothside _- .4L_ --[ / 12" W/OBackguard __ 0" Bottom

FIG. 3 War[ Installation with

Countertop Backsp[ash

overhead to,Rear Wa [-_:!] Cooking

cabinets [ /0 withBackguard I_i_i:1 Surface.!

AAs defined in the "National Fue! Gas Code"

36" from bottom of Over-

head Hood to Cooking @

(ANSI Z223.1, Latest Edition).

/

I

M

_ DetailA _

(Front face of cabinet) _ %

%

Counter

'_ Sunk

Screws

FBG. 4 Island Installation

No Countertop Backsp[ash)

Vent Hood

Width Requirements

Island-42"or48"WideHoodfor24"WokorGriddle

Island-42"or48"WideHoodfor36"Cooktop

Island-48"54"or60"WideHoodfor48"C00kt0p

_ 7o13/16"

\

CORNER NOTCH

_%_ DETAIL _

A 24-3/4" 29-7/8" 35-7/8" 47-7/8"

B 3/8" 3/8" 3/8" 13/1 6"

0" (Control PanelProjecting2" from BaseCabinet Face)

C 5/8" (Notch Recuired for Standard 24"-Deep Base Cabinet, Control Panel Projecting 1-3/8" from Base

Cabinet Face) 2" (Control Panel Flush to Cabinet Face - Min. 25-3/8"-Deep Base Cabinet Required)

D 24" 29-1/8" 35-1/8" 46-1/4"

Page 8

Step 2: Cabinet Preparation

FIG. 5 Side View of Cooktop

Low Back required when there is tess than

12" horizontal clearance from back of cooktop

to combustible matedat. With more than 12" of

clearance, the Island Trim may be used.

FIG. 6 Projecting from

Front projects outward 1o3/8" as

shown from standard 24"-deep

base,

HG. 8 mnstaLlation of 48" Cooktop above two

side=by=side Thermador Warming Drawers,

Model No. WD24

Cabinet Front

1=3/8"

FIG. 7 Flush to Cabinet

Front

* Provide clearance for screws by

increasing cutout height by 1/16"

or by notching in the location of

the three screws,

_>"Notch

Depth

Front flush with cabinets;

minimu mof 25=3/8"cabinet

depth required.

Minimum3/4"

1-7/8"(4,8cm)

H0riz0ntdDistanceBetweenCutouts

2-3/4"(7 cm) VerticalDistance

BetweenCutouts

(SeeSideViewfor WoodSupport)

Side View

Plywood support "_(19,8 cm)

t 7-W16"

Install additional `2#

wood support along

front edge of cutout

P

3/4" (70 ram) minin

[

between cutot

Page 9

Step 2: Cabinet Preparation

F_G, 9 Front = Bottom of Unit, See Detail B, Below

9

3-Prong grounding type

receptacleconnected to

a properly grounded and

polarized electrical supply

ratedat 120VAC, I0 Amps,

( or 15A*) Single Phase,

60 HZ. NOTE: This is not

applicable to 240 VAC

models with 24" electric

griddle. **

AH _nstaHer supplied parts

must conform to Loca_ Codes.

A manual valve must be

installed external to the

appliance, in an accessible

location from the front, for

the purpose of shutting off

the gas supply.

"15 Amp 120 VAC electrical supply is required for 36" and

48" models with a 24" electric griddle.

**30 Amp 240 VAC electrical supply is required for models

with a 24" electric griddle.

Page 10

Step 3: Unpacking, Moving, Placing

and Anchoring the Cooktop

CAUTION

Proper equipment and adequate manpower

must be used in moving the appliance to avoid

damage and/or personal injury. The unit is

heavy and should be handled accordingly.

,

Remove the outer carton and packing material

from the shipping base. Ensure that you have

all cooktop components before proceeding.

.

Remove the top grate castings, burner caps

and grill grate (if so equipped) to reduce unit

weight.

NOTE: Leave adhesive-backed foam layer

over brushed-metal surfaces, to protect finish

from scratches, until the cooktop is installed

in its final position.

.

Lift and place the cooktop in the opening. Be

careful not to pinch the power cord or gas inlet.

Care should be taken not to scratch the griddle

or the griddle frame.

IMPORTANT

• Verify that the appliance is correct for

the type of gas being provided. Refer

to Step 4 before proceeding with the

installation.

• Attach the backguard before sliding the

appliance into the final installed position.

See Step 6.

.

Ensure that the power line cord is free and

hanging loose.

5. Level the appliance. For proper performance,

the appliance must be level.

6. The grill frame (if so equipped) has been leveled

during assembly so do not attempt to level the

grill.

.

Replace the top grate castings, burner caps

and grill grate (if so equipped). Ensure that the

burner caps are correctly seated on the burner

bases.

Griddle Ti t Adjustment

Check the griddle adjustment by pouring two tablespoons of water on the back of the griddle

plate. The water should slowly roll into the grease tray. If not, adjust the two screws under the

back of the griddle. Start with one half turn counter-clockwise (CCW) of the screws. Further

adjustment should be made by one-quarter turn until water slowly flows into the grease tray.

Page 11

Step 4: Gas Requirements and Hookup

Cooktops are shipped by the factory to operate

on natura_ gas. They must be converted for use

with propane. Verify the type of gas being used

at the installation site matches the type of gas

used by the appliance, If the Eocat{onijob site re-

quires conversion from natural gas to propane (LP),

contact the dealer where the unit was purchased

or contact Thermador. The field conversion kit for

all Professional cooktops (PC series) is Thermador

Model PLPKIT. Obey all instructions in PLPKIT for

correct conversion of the gas regulator and settings

for the gas valves. Field conversion must be done

by qualified service personnel only.

This appliance has been CSA certified for safe op-

eration up to an elevation of 10,200 ft. without any

modifications. Exception: For usewith propane, the

appliance must be converted per the LP conversion

instructions.

Please refer to your LP Conversion Instructions for

further information.

Natural Gas Requirements:

Inlet Connection: 1/2" NPT (min. 3/4" dia. flex line)

Supply Pressure: 6" min. to 14" max. water

column (14.9 to 34.9 mb)

Manifold Pressure: 5" water column (12.5 mb)

Propane Gas Requirements:

Inlet Connection: I/2" NPT (min. 3/4" dia. flex line)

Supply Pressure: 11" min. to 14" max. water

column (27.4 mb to 34.9 mb)

Manifold Pressure: 10" water column (24.9 mb)

WARNING"

This conversion kit shall be installed by

a qualified service agency in accordance

with the manufacturer's instructions and

all applicable codes and requirements

of the authority having jurisdiction. If the

information in these instructions is not

followed exactly, a fire, explosion or pro-

duction of carbon monoxide may result

causing property damage, personal in-

jury or loss of life. The qualified service

agency is responsible for the proper in-

stallation of this kit. The installation is not

proper and complete until the operation

of the converted appliance is checked as

specified in the manufacturer's instruc-

tions supplied with the kit.

HOOK UP

A manual gas shut-off valve must be installed

external to the appliance, in a location acces-

sible from the front, for the purpose of shutting

off the gas supply. The supply line must not

interfere with the back of the unit. Make sure the

gas supply is turned off at the manual shut-off

valve before connecting the appliance.

The installer should inform the consumer of the

location of the gas shut-off valve. Make sure all

users know where and how to shut off the gas

supply to the cooktop.

The gas supply connections shall be made by

a competent technician and in accordance with

local codes or ordinances. In the absence of a

local code, the installation must conform to the

National Fuel Gas CodeANSI Z223.1iNFPA54=

current issue.

Always use pipe-sealing compound or Teflon _

tape on the pipe threads, and be careful not to

apply excessive pressure when tightening the

fittings.

Leak testing of the appliance shall be in

accordance with the following instructions.

Turn on gas and check supply line connections

for leaks using a soap and water solution.

Bubbles forming indicate a gas leak. Repair

all leaks immediately after finding them.

Do not use a flame of any kind to check

for gas _eaks.

• All installer-supplied parts must conform to

applicable codes.

Page 12

Step 4: Gas Requirements and Hookup

CAUTION:

When connecting unit to propane gas, make

certain the propane gas tank is equipped with

its own high pressure regulator in addition

to the pressure regulator supplied with the

appliance. The pressure of the gas supplied

to the appliance regulator must not exceed

14" water column (34.9 mb).

CAUTION

The appliance must be isolated from the gas

supply piping system by closing its individual

manual shut-off valve during any pressure

testing of the gas supply piping system at

test pressures equal to or less than 1/2 psig

(3.5kPa.).

"The appliance and its individual shut off valve

must be disconnected from the gas supply

piping system during any pressure testing of

the system at test pressures in excess of 1/2

psig (3.5kPa.)."

When checking the manifold gas pressure,

the inlet pressure to the regulator should be

at least 6.0" W.C. for natural gas or 11.0" for

propane.

Do not attempt any adjustment of the pressure

regulator.

10

Page 13

Step S: Electrical Requirements,

Connection and Grounding

CAUTnON: mmproper

grounding or reverse

_o_arization will cause

malfunction (such as

continuous sparking of the

burner igniters). This can

damage the appliance and

can create a condition of

shock hazard. If the circuit

is not correctly grounded

and polarized, it is the

responsibility and obligation

of the installer and user to

have the existing receptacle

changed to a properly

grounded and polarized

receptacle. This must be

accomplished in accordance

with aH applicable _ocal codes

and ordinances bya qualified

e_ectrician, mnthe absence of

_oca_ codes and ordinances,

the receptacle repRacement

shah be in accordance with

the Nationa_ Electric Code.

(See Fig.10.)

Before installing, turn power

OFF at the service panel. Lock

service panel to prevent power

from being turned ON acci-

dentally.

Always disconnect appliance

from the electric supply either

by disconnecting power cord or

shutting off the breaker before

servicing the appliance.

Before you plug in an electri-

cal cord, be sure all controls

are in the OFF position.

All 120 Volt cooktop models

must be plugged into a mating

3-Prong, Grounding-Type

Receptacle. The receptacle

must be connected to a properly

grounded and polarized electrical

power supply rated at 120VAC,

Single Phase, 60HZ. See list on

this page for proper over-current

protection requirements for each

model.

All 240 Volt cooktop models

require hard wire connections.

, Observe allgoverningcodes and

ordinances when grounding. In

the absence of these codes or

ordinances observe National

Electrical Code AN SI/N FPA No.

70 current issue. See Fig. 10

for recommended grounding

method.

o An electrical wiring diagram

and schematic have been

attached to the bottom of the

cooktop chassis for access by

a qualified service technician.

Do not remove or discard this

important information.

Grounding Method for

120 VAC Models

The cooktop is factory equipped

with a power supply cord with a

three-prong grounding plug (with

polarized parallel blades).

IT MUST BE PLUGGED INTO

A MATING, GROUNDING

TYPE RECEPTACLE THAT IS

CON NECTEDTOACORRECTLY

POLARIZED 120 VOLT CIRCUIT

(240 VOLT CIRCUIT FOR

MODELS WITH 24" ELECTRIC

GRIDDLE. (See Fig. 10).

FiG. 10 Recommended

Grounding Method for 120V

models

THE THIRD, GROUND

PRONG MUST NOT BE CUT

OR REMOVED UNDER ANY

C_RCUMSTANCES.

ElectricaJ Connection

240 VAC Models

I.

Attach flexible conduit to the

junction box.

.

Connect the cooktop lead wires

to the junction box supply wires

in proper phase:

11

for

For aii 240 VAC models, connect

Mack (L!) to black, red (L2) to

red, white wire to neutral and

green wire to ground.

Note: Ifthe 120V cooktop is install-

ed and connected as specified

above, it will be completely

grounded in compliance with the

National Electric Code.

3. Turn on power supply.

4. Test operation.

FIG. 11 Junction Box

Location

Conduit

L 12" APPROXIMATE _

1 j

"J" Box

Electrical Power Supply

Over-current Protection

Requirements:

4 Burners - 10 Amp circuit

protection

6 Burners - 10 Amp circuit

protection

4 Burners with a grill- 10Amp

circuit protection

4 Burners with a 12" electric

griddle - 15 Amp circuit protection

6 Burners with a grill- 10Amp

circuit protection

6 Burners with a 12" electric

griddle - 15 Amp circuit protection

4 Burners with a grill and a 12"

electric griddle - 15 Amp circuit

protection

4 Burners with a wok- 10Amp

circuit protection

4 Burners with a 24" electric

griddle -30 Amp circuit protection,

240VAC

Cooktop with a wok - 10 Amp

circuit protection

Cooktop with a 24" electdc

griddle - 30 Amp circuit

protection 240 VAC.

Installer - show the owner the

location of the circuit breaker or

fuse. Mark it for easy reference.

Page 14

Step 6: Backguard Installation

ALow Back backguard must be installed

when there is less than a 12" clearance

between combustibles and back edge of

cooktop. (See Fig. 1 and 5.) For island

installations and other installations with

over 12" clearance, an optional stainless

steel trim channel isavailable to cover the

backguard mounting flanges. Attach the

backguard before sliding the appliance

into the final installed position. Follow

Steps A through C below:

A. Slide backguard over the two flanges

on the rear of the appliance. Fasten

the front and back with the two screws

(see A, Fig. 12)provided.

B. Fasten the top of the backguard to

the wall with two screws through the

backguard. (See B, Fig. 12.)

C. Place the backguard cap on top and

fasten using the two counter-sink

screws provided. (See C, Fig. 12.)

FIG. 12 Low Back Attachment

C _/

A

®

LOW BACK AND ISLAND TRIM MODEL NUMBERS

Cooktop Size/Type 12" Low Back

24" Griddle PC24LB

24" Wok GP24LBS

30" PC3OLB

36" GPS36LBS

48" GPS48LBS

*Requires a minimum of 12" horizontal clearance between back of appliance and combustible materials.

Island Trim*

PC241T

GP241TS

PC301T

GPS361TS

GPS481TS

12

Page 15

Step 7: Burner Test and Adjustment

Install any loose components, such as burner caps

and grates that may have been removed earlier.

Be certain that burner caps seat properly into the

burner bases. Before testing operation of the appli-

ance, verify that the unit and the gas supply have

been carefully checked for leaks and that the unit

has been connected to the electrical power sup-

ply. Turn the manual gas shut-off valve to the open

position.

Test Cooktop Burners

Test Burner Ignition. Select a cooktop burner

knob. Push in and turn counterclockwise to HI.

The ignitor/spark module will produce a clicking

sound. Once the air has been purged from the

supply lines, the burner should light within four (4)

seconds.

Test Flame: High Setting. Turn burner on to HI.

See Figure 13 for appropriate flame characteris-

tics.

If any of the cooktop burners continue to burn

mostly or completely yellow, verify that the burner

cap is positioned properly on the burner base, then

re-test. If flame characteristics do not improve, call

Thermador@.

Test Flame: Low Setting. Turn burner on to LO.

Verify that the flame completely surrounds the

burner. There should be a flame at each burner

port and there should be no air gap between the

flame and the burner. If any burners do not carry

over, call Thermador®.

The two far left burners feature XLO®, causing the

flame to cycle on and off when the knob is set to

the XLO range. This is normal operation.

Repeat the Ignition and Flame Test procedures

described above for each cooktop burner and the

grill burner (if so equipped).

FiG. 13 Flame Characteristics

Yellow Flames:

Further adjustment is required.

Yellow Tips on Outer Cones:

Normal for LP Gas.

Soft Blue Flames:

Normal for Natural Gas.

If the flame is completely or mostly yellow,

verify that the regulator is set for the correct

fuel. After adjustment, retest.

Some orange-colored streaking is normal

during the initial start-up.

Allow unit to operate 4-5 minutes and re-eval-

uate before making adjustments.

WHEN FLAME IS PROPERLY ADJUSTED:

. There should be a flame at each burner

port.

. There should be no air gap between the

flame and burner port.

The gas grill uses a tube-style burner that has an

air shutter which allows adjustment to the amount

of primary air inside the burner tube.

Air shutters of tube-style burners are pre-adjust-

ed at the factory, and usually do not require re-

adjustment except under rare conditions such as

installation at high altitude.

If grill burnedftame adjustment is required, go

to the procedure: "Flame Adjustment (if neces-

sary)".

13

Page 16

Step 7: Burner Test and Adjustment

Flame Adjustment (if necessary):

Tube=style gas burners used in Thermador©

appliances have air shutter systems which are

similar to the illustration in Figure 14, and can be

adjusted using the following method (unless ad-

justment is not recommended). It is necessary to

remove the burner from the appliance in order to

perform air-shutter adjustments.

• Loosen shutter screw(s) and turn shutter to

new position.

Adjust the shutter to more-closed position if

the flame is lifting or blowing, or is not carry-

ing over.

Adjust the shutter to more-open position if

the flame is too yellow. (See Figure 14.)

• Retighten the shutter screw(s).

After adjustment, reinstall the burner and

perform flame evaluation. The air shutter

must fit over the orifice hood for proper opera-

tion of the burner.

• Repeat procedure as needed until flame char-

acteristics are acceptable. (See Figure 13.)

FiG. 14

Air Shutter Adjustment (if necessary)

Screw

More Open:

Less Yellow Ffame/_

Nore CJosed: \

Less Blue Flame

More Carryover

Less Lifting or Blowing

Air

Shutter

WARNING

Burner adjustments must be performed by a

qualified technician. Improper adjustments

may cause harmful by=products or void the

appliance's warranty.

Allow burners to cool before attempting to re=

move them!

Ca[[ Thermador@ if:

1. Any of the burners do not light.

2. Any of the burners continue to burn

yellow.

14

Page 17

FmNAL CHECK UST

GAS SUPPLY

OPERATION

Cooktop correctly positioned

in countertop recess.

Specified clearances

maintained to cabinet

surfaces.

Burner caps positioned

propedy on burner bases.

All packaging material

removed. Note: Wok models

have tie-down straps around

the burner, which must be

removed before using the

appliance.

Island Trim or Backguard

attached according to

instructions.

The griddle/grill plate tilted

slightly forward. (See page 8

for adjustment procedure.)

Connection: 1/2" NPTwith a

minimum 3/4" diameter flex

line.

If converting from natural to

LP gas, refer to LP Conver-

sion Instructions for details.

Manual gas shut off valve

installed in an accessible

location (without requiring

removal of appliance).

Unit tested and free of gas

_eaks.

ELECTRICAL

For models with the 12" electric

griddle, a polarized and

grounded 120VAC receptacle

with 15 AMP overcurrent

protection is provided for

service cord connection.

All internal packing materials

removed. (Check below

grates and grill pans.)

Bezels centered on burner

knobs, and knobs turn

freely.

Purge unit with first burner.

Each burner lights

satisfactorily, both individually

and with other burners

operating.

Burner grates correctly

positioned.

mNSTALLER: Give CARE

and USE MANUAL

and INSTALLATION

INSTRUCTIONS to your

customer.

For models with the 24" electric

griddle, a propedy grounded,

240 VAC service connection

with 30 AMP overcurrent

protection is provided.

To C ean And Protect Exterior Surfaces

The stainless steel surfaces may be cleaned by

wiping with a damp soapy cloth. Any mild glass

cleaner will remove fingerprints and smears.

Follow all cleaning by rinsing with clearwater. Wipe

dry with a clean soft cloth to avoid water marks.

For discolorations or deposits that persist, use a

non-scratching household cleanser or stainless

steel polishing powder with a little water and a soft

cloth. For stubborn cases, use a plastic scouring

pad or soft bristle brush together with cleanser and

water. Rub lightly in direction of polishing lines or

"grain" of the stainless finish. Avoid using too much

pressure which may mar the surface.

Use a stainless steel cleaner/polish to protect the

finish and maintain appearance.

DO NOT allow deposits to remain for long periods

of time.

DO NOT use ordinary steel wool or steel brushes.

Small bits of steel may adhere to the surface

causing rust.

DO NOT allow salt solutions, disinfectants, bleaches

or cleaning compounds to remain in contact with

stainless steel for extended periods. Many of these

compounds contain chemicals which could prove

harmful. Rinse with water after exposure and wipe

dry with a clean cloth.

15

Page 18

Table des mati res

Avertissements ..................................................................... 16 (ci-dessous)

Introduction ................................................................................................ 17

Information importante & propos de I'installation ........................................ 18

Chapitre 1 : Exigences de ventilation ......................................................... 19

Chapitre 2 : Pr6paration de Femplacement ........................................ 20 - 23

Chapitre 3 : D6ballage, manutention, mise en place et fixation

de la table de cuisson ................................................................................ 24

Chapitre 4 : Exigences pour I'alimentation du gaz et raccordement .... 25°26

Chapitre 5 : Exigences pour Falimentation 61ectrique, Je

branchement et la mise & la terre .............................................................. 27

Chapitre 6 : Installation de la plaque de protection .................................... 28

Chapitre 7 : Test et r6glage de brOleur ................................................. 29°30

Liste de v6rification de I'installateur ........................................................... 31

Nettoyage et protection des surfaces ext6rieures ...................................... 31

INFORMATIONS IMPORTANTES RELATIVES ,A,L'INSTALLATION

AVERTtSSEMENT ,"

L'information fournie darts le present

manuel dolt 6tre tres rigoureusement

respectee, sous peine d'incendie ou

d'explosion entra'_'nant des dommages,

des biessures ou la mort.

-- Ne stockez paset n'utilisez pas d'essence ou autres

produits inflammables a proximite des appareils.

--81VOUS SENTEZUNEODEURDE GAZ

• N'allumezaucun appareil.

• Ne touchez pas aux interrupteurs electriques.

• N'utilisez pas les tel6phones du b&timent.

• Appelez immediatement votre compagnie de gaz

de chez un voisin. Suivez les instructions de la

compagnie.

• Si vous n'arrivez pas & contacter la compagnie de

gaz, appelez les pompiers.

-- L'installation et les reparations doivent 6tre realisces

par un installateur qualifie, un centre de reparation

agr6e ou la compagnie de gaz.

,_ AVERTtSSEMENT

Une installation, un reglage, une modification,

une reparation ou un entretien adequat

peuvent entra'fner des bJessures ou des

d6g&ts materiels. Consultez le present manuel.

Pour de I'information supplementaire ou de

I'assistance, consultez un installateur qualifie,

un centre de reparation, le fabricant (revendeur)

ou la compagnie distributdce de gaz.

Remarque : Cette table de cuisson N'EST PAS

con_;ue pour les maisons mobiles ni pour les

vehicules recr6atifs.

NE PAS installer ce table de cuisson dehors.

FICHE SIGNALETJQUE

Modeles de tables de cuisson :

La plaque de caracteristiques indique le modele et

le numero de serie de votre table de cuisson ou de

votre wok. Erie est placee sur le dessous du chassis

de la table de cuisson ou du wok, prCs du raccord

d'arrivCe de gaz et du cordon d'alimentation elec-

trique. Cette information est requise par le Service

la clientele. Avant

les numeros de serie devrait 8tre entre darts les

esApaces a la rubricLue AVANT D'EFFECTUER UN

APPEL DE SERVICE a la fin du guide d'utilisation

et d'entretien. Lorsque I'appareil est installe, il est

difficile d'acceder a I'information.

Pour _es installations au Massachusetts :

1. L'installation doit 6tre realisee par un entrepreneur qualifie ou agree, un plombier ou

un installateur de gaz qualifie ou autorise par I'€:tat ou la region oQ cet appareil est

pose.

2. Le robinet d'arr6t de gaz doit _tre pourvu d'une poignee en <<T >>.

3. La Iongueur maximum autorisee du tuyau de gaz est de 91,4 cm (36").

16

Page 19

VEUILLEZ LIRE TOUTES LES INSTRUCTIONS AVANT DE POURSUiVRE

IMPORTANT: LES R¢:GLEMENTATIONS LOCALES VARIENT. L'INSTALLATION, LES

BRANCHEMENTS €:LECTRIQUES, LES RACCORDEMENTS AU GAZ ET LA MISE A LA TERRE

DOWENT SATISFAIRE A TOUTES LES RE_GLEMENTATIONS APPLICABLES.

IMPORTANT : Conservez ces instructions pour Hnspecteur local de la compagnie d'electdcit&

iNSTALLATEUR : Veuillez laisser ces instructions d'installation avec I'appareil pour le propfietaire.

PROPRIETAJRE : Veuillez conserver ces instructions pour consultation ulterieure.

ALIMENTATJON _:LECTRJQUE :

Modeles 60 9 c_24_

avec wok- 120 VAC, 60 Hz., 1 Ph. circuit de 10A

avec grille - 240 VAC, 60 Hz. 1 Ph. circuit de 30 A

BrQleurs 4- 120 VCA, 60 Hz, monophas& circuit de 10 A

Modeles de

BrQleurs 6 : 120 VCA, 60 Hz, monophas& circuit de 10A

avec griJ: 120 VCA, 60 Hz, monophas& circuit de 10A

avec grille electrique 12po :120 VAC, 60 Hz, monophas& cuicuit de 15 A

BrQleurs 6 avec gril : 120 VCA, 60 Hz, monophase, circuit de 10A

BrQleurs 6 avec grille electrique 12 po : 120 VCA, 60 Hz, monophase, circuit de 15 A

BrQleurs 4 avec grille electrique 12 po et gril : 120 VAC, 60 Hz, monophas& circuit de 15 A

BrQleurs 4 avec wok - 120 VCA, 60 Hz, monophas& circuit de 10 A

BrQieurs 4 avec grille electrique 24 po ((avec grille electrique 24 po) - 240 VAC, 60 Hz. 1 Ph. circuit de 30 A

]

ALIMENTATION EN GAZ :

Gaz naturei : 14,9 mb (6 po) min. a 34,9 mb (14 po) max.

& la colonne d'eau.

Gaz propane :27,4 mb (11 po) min. a 34,9 (14 po) max.

la colonne d'eau).

Introduction

Tousles brQleurs scelles sont cotes a 15 000 Btu/h ('13

000 BTu/h pour LP). *Tous les modeles, sauf celui avec

la grille 24 po, sont convertibles au gaz propane/LP

l'aide du necessaire de conversion.

IMPORTANT

° Une plaque de protection doit @tre mise en place

lorsque ledegagement horizontal entre les matedaux

combustibles et le bord arriere de la table de

cuisson est de moins de 30,5 cm (12"). La plaque

de protection basse Thermador est a commander

separ6ment et doit @tre installee a I'arriere de

la table de cuisson. Pour les installations en riot

avec un degagement de plus de 30,5 cm (12"), un

AVERTISSEMENT

Coupez 1'61ectdcite avant d'installer I'appareil.

Avant de remettre I'electdcit6, assurez-vous

que toutes les commandes sont a la position

OFF.

enjoliveur en acier inoxydable est vendu en option

afin de recouvrir les brides de montage de la plaque

de protection.

Assurez-vous que I'appareil convient au type de gaz

fourni. Consultez le chapitre 4 avant de proceder

l'instalJation.

17

Page 20

Information importante a propos de l'installation

Cet appareil est certifie ACNOR

& des fins de fonctionnement

secudtaire jusqu'& une el6va-

tion de 10 200 pi sans modifica-

tion. Exception : pour I'utilisation

avec le gaz propane, I'appareil

dolt 6tre converti selon les in-

structions de conversion au LP.

II est fortement recommande

d'installer une hotte de

ventilation adaptee au-dessus

de cet appareil (voir chapitre

1, Conditions de ventilation). A

cause de la chaleur intense que

peut degager cet appareiJ, on doit

porter une attention particuliere &

I'installation des conduits et de la

hotte afin quqls soient conformes

aux reglementations locales de

construction.

Vedfiez la reglementation locale

applicable & la construction pour

connaftre la methode appro-

priee d'installation de I'appareil.

,_ defaut de reglementation,

I'appareil doit etre installe

conformement aux versions

actuelles du Code national du

gaz combustible no Z223.1 et

du Code national de I'electricite

ANSIiNFPA70 ou aux Codes

d'installation pour les appareils

& gaz CAN 1-B149.1 et .2 et au

Code electrique canadien C22.1,

premiere pattie.

Assurez-vous que I'appareil

installer correspond au type de

gaz utilise sur le site.

Cet appareil est equipe d'un

systeme d'allumage intermittent

qui allume et eteint les deux

br01eurs de gauche Iorsqu'ils sont

r6gles sur ExtraLovT'RL

MtSE EN GARDE

(1) Si I'appareil est alimente

au gaz propane, assurez-

vous que le reservoir de

propane est equip6 de son

propre detendeur en plus

du detendeur foumi avec

I'appareil. La pression

maximum d'arrivee du

gaz dans cet appareil ne

doit pas depasser les 34,9

millibars (14 pouces & la

colonne d'eau) a partir du

detendeur du reservoir de

propane.

(2) Cet appareil est congu pour

un usage culinaire. Pour

des raisons de securite,

ne I'utilisez jamais pour

chauffer une piece.

A cause de la chaleur intense

produite par cet appareil, il faut

porter une attention particuliere

I'installation de la hotte et des

conduits afin de s'assurer qu'ils

repondent aux codes de con-

struction Iocaux.

Cet appareil est conforme avec

une ou plusieurs des normes

suivantes •

UL 858, norme pour la secu-

rite des cuisinieres electriques

domestiques

• UL 923, norme pour la secu-

rite des appareils de cuisson &

micro-ondes

• UL 507, norme pour les venti-

lateurs electriques

• ANSI Z21.1, norme nationale

americaine pour les appareils

de cuisson & gaz domestiques

•CAN/CSA-C22.2 n°113-M1984

ventilateurs et hottes

• CANiCSA-C22.2 n° 61-M89

cuisinieres domestiques

M!SE EN GARDE

Afin d'_[iminer [es

risques de br_lures

ou d'incendie pro-

voqu_s par la chal-

eur, il est conseiH_

d'_viter d'installer

des armoires au-des-

sus des appareils.

II incombe au proprietaire et &

I'installateur de determiner si

des exigences et/ou normes

additionnelles s'appliquent pour

une installation specifique.

Enlever tout le materiel

d'emballage et le ruban adhesif

avant d'utiliser I'appareil. Detru-

ire le materiel d'emballage une

fois I'appareil deball& Nejamais

laisser les enfants jouer avec ce

materiel d'emballage.

18

Page 21

Chapitre 1 : Exigences de ventilation

II est fortement recommande

d'instalJer une hotte de ventilation

appropriee au-dessus de I'appareil.

Une ventilation par contre-tirage

ne devrait pas 6tre utilisee. Le

tableau ci-dessous indique les

hottes Thermador, par num@o

de modele, recommandees pour

une utiiisation avec le wok 24 po,

la grille 24 po et les surfaces de

cuisson de 30, 36 et 48 po.

A cause de la chaleur intense

produite par cet appareil, il faut

porter une attention particuliere

I'instalJation de la hotte et

des conduits afin de s'assurer

qu'ils repondent aux codes de

construction Iocaux.

Ne pas installer un combine hotte/

four a micro-ondes au-dessus des

surfaces de cuisson. Ces appareils

n'assurent pas une ventilation

appropdee et ne conviennent pas

aux surfaces de cuisson.

1. Choix du rnodele de hotte et

de ventilateur

. Pour les installations muraJes,

la largeur de la hotte doit etre

au moins egale a celle de la

table de cuisson de I'appareil.

Si I'espace le permet, il est

souhaitabie d'installer une

hotte plus large que la table

de cuisson pour ameliorer les

performances de ventilation.

o Pour les installations en "_lot,

la largeur de la hotte dewar

depasser d'au moins 7,62 cm

(3") des deux c6tes de la table

de cuisson de I'appareil.

2. Emplacement de la hotte

. Pour une meiJleure elimination

des fumees, le bord inferieur

de la hotte doit etre place a une

distance de 91,4 cm (36") au-

dessus de la table de cuisson.

(Voir figure I).

. Si la hotte contient des

mat@iaux combustibles (ex. :

recouvrement en bois), elle dolt

etre a une distance de 91,4 cm

(36 po) ou plus au-dessus de

la table de cuisson.

3. Apport d'air

Un important volume d'air etant

necessaire pour la ventilation, il

est recommande de prevoir un

apport d'air de I'exterieur. Cet

aspect revet une importance

particuli@e dans les Iogements

bien isoles et tres etanches.

. IIest conseille de consulter un

entrepreneur en chauffage et

en climatisation.

REMARQUE : Les hottes de

ventilation et les ventilateurs sont

con_;us pour une seule conduite

murale. Certaines reglementations

locales du secteur du b_timent

exigent toutefois une double

conduite. Consultez les normes

applicables et les autorites

municipales avant de commencer

les travaux afin de vous assurer

WOK 24 po

GRILLE 24 po

TABLE DE CUISSON

30 po

TABLE DE CUISSON

36 po

TABLE DE CUISSON

48 po

REMARQUES:

PH30CS, PHE30/36 VTR1030D, VTRI530D

HNW36YS

PHH30DS***

PH36CS/42CS

PHE36/42

HNW36YS/42YS

PH36DS***

PH48CS/54CS

PHE48/60

HNW48YS

ou VTN1030C

VTR1030D, VTR1530D

N/A

VTR1030D, VTRI530D

ou VTN 1030C

VTR1030D, VTR1530D

N/A

VTR1030D, VTR1530D

ou VTN1030C

VTR1030D, VTR1530D

HNI42YS VTR1030D ou

HTNI42YS VTR1530D

HNI42YS VTR1030D ou

HTNI42YS VTR1530D

HNI48YS/54YS, VTR1530D

HTNI48YS/54YS

* Pour les installations muraJes, si l'espace est suffisant, I'installateur ou l'utilisateur peut choisir

une hotte plus large que la surface de la table de cuisson. Ceci peut 6tre avantageux pour les

installations ayant un long conduit ou une utilisation accrue du gril ou du wok ; d'oQ l'importance

de capter l'echappement de cuisson.

**Thermador offre un choix de souffleries a distance (VTRI030D ou VTR1530D) ou interne

(VTNI030C) pour utiJisation avec les installations murales.

***Les modeles de hotte PHH30DS et PHH36DS comprennent une soufflerie integr6 de 600

PCM. Pour une ventilation optimale, un modele de hotte avec soufflerie de 1000 PCM ou plus

est recommande pour les surfaces de cuisson ayant une grille, un gril ou un wok.

19

Page 22

Chapitre 2 :

Pourgarantir des resultats professionnels,les ouvertures

darts I'armoire et darts I'espace de travail doivent _tre

effectuees par du personnel qualifie.

Lesdegagements requis sont indiques & laFigure 1.Les

m6mesdegagements s'appliquentauxinstallationsenriot,

exceptepour les armoiressuspenduesquidoiventlaisser

un espace suffisamment grand pour y Ioger la hotte de

R!ot.

La table de cu[sson est congue pour6tre accrochee au

plan de travail parsesbrides laterales. Le plan de travail

doittoutefois6tre suffisammentsolidepour porterceIourd

apparei!. IIsera eventuellement necessaire d'ajouter un

tasseau de chaque c6te (voir figure 2)ou 2x4 montants

d'angle (voir figures 3 et 4 et la vue eclat6e A). L'autre

possibilite est de construire un plan de support pour y

installer la table de cuisson.

.

La table de cuisson peut _tre installee sur plusieurs

positions, avec la partie frontale au m6me niveau que le

plan detravail ou en projectionavant, selon la profondeur

de ce plan (voir Figure 5, vue laterale de la table de

cuisson; voir Figures 3,4, 8 et7pour les autres positions

de montage).

Les arrivees d'electricit6 et de gaz doivent se trouver

dans une zone accessible sans avoir a enlever la table

de cuisson. Le cordon d'alimentation electrique et le

raccord du tuyau de gaz de Fappareilsont places dans

la partiearriere gauche sous latable de cuisson (sauf sur

les modeles avec grille electrique 24 po oQle cordon

d'alimentation est situe au centre), te! qu'indique aux

Figures 5 et 9.

6. La profondeur maximum des armoires suspendues de

chaque c6te de la hotte est de 33 cm (13").

Un degagement minimal de 91,4 cm (36") est necessaire

entre le dessus de la table de cuisson et le dessous d'une

armoirenon prot6g6e.Unedistancede36po doit 6treassuree

Iorsque le bas des armoires enbois ou en metal est proteg6

par un materiauignifuged'une epaisseur d'au moins6,35 mm

(1/4") recouvert d'une feuille d'acier no28 MSG de la m6me

epaisseur,de 0,4 mm (0,015") d'acier inoxydable,de 0,6 mm

(0,024") d'aluminium ou de 0,5 mm (0,02") de cuivre. Les

materiaux ignifuges portent la marque :

UNDERWRITERS LABORATORIES INC.

CLASSiFiED MINERAL AND FIBER BOARDS

SURFACE BURNING CHARACTERISTICS,

(panneaux de fibres et mineraux classes, caracteristiques

d'inflammation des surfaces), suivie des taux de progression

desflammes et desfumees.Ces designations sent indiquees

par <<FHC >>(Flame Spread/SmokeDeveloped= Progression

des flammes/Production defumee). Les materiaux ayant un

taux <<O >>de progression de flammes sont ignifuges. Les

reglementations locales peuvent autoriser d'autres taux de

progression des flammes.

7. Siladistance entreunmateriaucombustible Z_ etleherd

arriere de latable de cuisson au-dessusde la surfacede

travailestdemoinsde30,5cm(I 2"), ondoltobligatoirement

installer une plaque de protection basse Thermador

(voir Chapitre 6). Si ladistancedu materiau combustible

Z_ est de plus de 30,5 cm (12), on peut utiliser un

enjoliveur Thermador pour riot. Insta!lez la plaque de

protection avant de glisser I'apparei! darts sa position

d'insta!lation definitive.

Pr6paration de l'emplacement

8. Definissez la ligne centrale de I'emplacement destine

la table de cuisson. Elle doit correspondreau centre de

la hotte de ventilation suspendue.

9. Decoupez les ouvertures pour les installations

suivantes :

, Installation murale, voir Figure 3.

, Installation en "riot,voir Figure 4.

10. Pourles installationsa rasde I'airedetravail,represent6es

la Figure 7, prevoyez le degagement necessaire aux

trois vis placees au long du dessous du herd d'attaque

de la table de cuisson en augmentant la hauteur de la

decoupe de 1,6 mm(1/16") ou en faisant des encoches

darts !'armoire a I'emplacement des trois vis.

11. Pourles modelesavecunegrille,fixerlabandede mousse

surle plan de travail, centree lelongdeI'arriereaenviron

1/16 po du bord.

12. Pour Finsta!lationde la table de cuisson de 1,22 m (48")

surles deuxtiroirs chauffe°platsc6teacStedeThermador

(modele WD24), reportezovous a la Figure 8. Si vous

realisez I'installation conformementa la Figure 8, le bord

gauche de la table de cuisson sera aligne avec le bord

gauche du tiroir chauffeoplatsgauche et le bord droit de

la table de cuisson seraaligne avec le herd droit dutiroir

chauffeoplatsdroit. Pour obtenir unalignement different,

vous pouvez modifier la distance horizontale de 4,76

cm (1o7/8")entre les decoupes des tiroirs chauffeoplats.

Vousdevez toutefois conserver une distance d'au moins

2,85 cm (1ol/8") pour eviter les interferences entre les

tiroirs chauffeoplats.Montezun coude de 900surletuyau

d'arrivee de gaz de la table de cu[sson. Tousles autres

degagements auodessusdu plan detravail doivent _tre

maintenus comme indiques a la Figure 1.

,AT el que defini dans le <<Code national du gaz

combustible >>(Versionactue!ledesnormesANSIZ223.1/

NFPA54)

REMARQUES :

• Si vous avez d'un ou des deuxc6tes desparois laterales

pleinesd'armoires,vous devrezencocher lecoinavant de

I'armoire pour I'adapter a !'encoche du plan de travail et

laisser !'espace&lapartiefrontale de latable decuisson

(voir vue eclatee A, Figures 3 et 4).

, Sivous construisezunplande support, lesc6tesoulebas

de ladecoupepeuvent8tre enmateriau pleincombustible

ou non combustible. Si le has est plein, prevoyez une

decoupede20,32x 20,32cm (8" x 8")dans lecoinarriere

gauchede ce plan.Vousaurez ainsi I'espacenecessaire

!'arrivee de gaz et au cordon d'alimentation, et cela

vous permettra de voir laplaque de caracteristiques du

produit.

, Pour les modeles ayant une grille 24 po avec cordon

d'alimentationaucentre, ilfaut prevoir2piecesseparees

(support) pour permettre un degagement au centre pour

passer le cordon.

, L'appareilnedoitjamaissetrouveraproximitede materiaux

combustibles,d'essenceetd'autresproduitsinflammables

(vapeurs ou liquides).

, L'a[rdecombustion et de ventilation arrivant a I'appareil

doit pouvoir circuler librement.

2O

Page 23

Chapitre 2 : Preparation de l'emplacement

FIG. 1

D6gagements

i

'_ Profondeur [36"] ou plus si {ahotte Distance honzontale

... armoires combustibles A ). arnere :0 cm (0)

I_,! cm suspendues: /avec plaque de

(]u) rain. 33 cm 13" ,/'protection, 30,5 cm

I 7_6cm(3)min_ _ (12) sans plaque

_es deuxo616s_ 4 de protect,on

Z_ telquedefinidartsle<<Codenationaldugazcombustible>>

FiG. 3 InstaJlation muraJe avec

rebord de plan de travail

30poa 36pohottelargepourwokou grillede 24po

30poa 36pohottelargepourtabledecuissonde30 po

,36 poa 42pohottelar_ cuissonde36po

_po hottelargepourtabledecuissonde48po

76,2cm=30"

91,4cm=36"

HOTTEDEVENTILATION 106,7cm= 42"

l 137,2cm= 54"

76,2 cm (30") rain.a 152,4cm=60"

@ ledessous de la hotte et la O

max.des contient des mat@iaux ram: du mar ,,

ir -- "

91,4 cm (36") max. entre

• table de caisson (91,4 cm . .

_,_,,,,,,,,,,J'A"_ -.,,,_-C6t6s 0 cm (0")

} Bas 0 cm (0")

(ANSI Z223.1 - Derniereedition).

B

121,9cm=48"

S vVue eclat@A _ %

(Face frontate de t'armoire)_

!

(7o13/16")

COMBUSTIBLES

de 91,4 cm

(36") des

mat@iaux

;_ combustibles

:._ Ade ta table

de caisson

1

Table

de

CUiSSOR

:::;2V

"" !

Montant

d'angle 2x4

FIG. 2

Installation

de supports

lat_raux (des

! deux c6t_s)

Vis & t6te

fraisee

FIG. 4 hstatlation en _lot (sans

rebord de plan de travaiJ)

Hotte de ventilation

Exigences de largeur

hot - hotte large de 42" ou 48" pour

wok ou grille de 24"

riot - hotte large de 42" ou 48" pour

36" table de cuisson

riot - hotte large de 48", 54" oa 60"

pour 48" table de cuisson

Voir v_e _. 19 mm rain.

(3/4")

I

l

S

% DI_TAILDE L'ENCOCHE

'% ENCOiN S

A

B

C necessaire pour armoire de support standard de 61 cm (24") de profondeur. Panneau de commande projete de 3,4 cm (1 3/8") devant le

D 24" 29-1/8" 35-1/8" 46-1/4"

24-3/4"

3/8"

0 mm (0") (Panneau de commande projete de 5 cm (2") devant lepanneau frontal de Farmoirede support) I5,9 mm (5/8") (Encoche

panneau frontal de I'armoire de support) 5 cm (2") (Panneau de commande auras du panneau frontal de I'armoire _ armoire de support d'une

2%7/8"

3/8" 3/8" 13/16"

profondeur rain. de 64,4 cm [25-3/8"] requise)

21

35W/8" 47-7/8"

Page 24

Chapitre 2 : Pr6paration de l'emplacement

FIG. 5 =Vue lat6rale de la table

de cuisson

12,730,5

mrs1cm

!"} (12")

7,6cm(3")A LAL[GNECENTRALEDE _ 1/9,,.

JL'ARRIVEE DEGAZ _'4'_ 19 mm

I _ 57,4 cm (22-5/8")_-._-_,_ 3/4"

o_ 5_-_59,3 om (23-3/8") _( )

/c,,m_ Panneau frontal de I'arrnoire pour installation

avec panneau de commande projete

Panneau frontal de I'armoire pour installation

avec tableau de commande auras

Une plaque de protection basse estnecessaire si

la distance hodzontale entre I'arriere de la table de

cuisson et les materiaux combustiNes est inferieure

30,5 cm (12"). Avec plus de 30,5 cm (12"), il est

possible d'utiliser I'enjoliveur pour Tlot.

FIG. 8 oInstallation d'une table de cuisson de 12!,9 cm (48") sur

deux tiroirs chauffeoplats c6te a c6te, modele WD24.

Bride

laterale

FIG. 6 = Projection

devant I'armoire

Sur la figure, ravant est

projete de 3,4 cm(I 3/8")

vers rexterieur avec un

support standard de 60,9cm

(24") de profondeur.

de

mm

FIG. 7 -Au ras du

panneau frontal de

l'armoire

LaissezdeI'espacepourlesvis

enaugmentantlahauteurdela

d_ooupede1,6mm(I/16')ou

enfaisantdesencochespour

I'emplacementdestroisvis.

5cmde

, profondeur

Avant au ras des armoires :

profondeur d'armoire

de 64,4 cm (25 3/8")

minimum.

Minimum 19 mm (3/4'7

4,8 cm (1-7/8")

Distance horizontale entre les decoupes

7 cm (2-3/4") Distance verticale entre les

decoupes (Voir vue lat6rale pour les supports en bois)

Vue laterale

Support en _, 19,8c_

contreplaqu6 $ (7w_G'

Installez un tasseau

supplementaire le

long du bord avant

dela decoupe . I

L

6,9c m (2 3/4") minimum

j[

T entre d6coupes

22

Page 25

Chapitre 2 : Pr6paration de l'emplacement

FiG, 9 Pattie frontale inf_rieute de I'appareil, voit

vue _clat_e B ci=dessous

Plaquedecaracteristiquesdu

- j

produit/Etiquettede scrie Les enduits de joints doivent &tre

Prise murale _ 3 fiches, 8ve¢

prise de terre, ¢onnect_,e

un circuit d'alimentation

_ectrique ad_quatement

poJaris_ et reli_ & _aterre

de 120 VCA, 10 A, ('15 A)

reonophas_, 60 Hz.

REMARQUE : ceci ne

s'appiique pas aux modetes

240VAC avec grille etectrique

24 po.

resistants aagaz propane.

R24WOK1/2"NPT

Un robinet d'arr_t doit

_tre ir_staH_ & Ve×t_rieur

de J'appareiJ, _ un endroit

accessible de I'avant, darts

_ebut de pouvoir couper

_'arriv_e de ga:,.

Toutes les pieces fournies par

i'instaJJateurdoivent satisfaire aux

reglementations locales.

9

*Alimentation electrique 15A, 120VAC pour les modeles 36 et

48 po avec gdlle electdque 24 po.

**Alimentation electrique 30A, 240VAC pour les modeles avec

une grille electdque 24 po.

23

Page 26

Chapitre 3 : D6ballage, manutention et raise en place et

fixation de la table de cuisson

MiSE EN GARDE

Un equipement adapte manipule par du

personnel experiment6 dolt _tre utilise

pour deplacer I'appareil afin de ne pas

I'endommager et d'eviter les blessures.

L'appareil est Iourd et doit faire I'objet d'une

manutention adequate.

,

Retirez I'emballage externe et les materiaux

d'emballage de la palette d'expedition. Assurez-

vous d'avoir tousles articles qui composent la

table de cuisson avant de poursuivre.

.

Retirez les grilles en fonte, les chapeaux des

brOleurs et Jagrille du gril (le cas ech6ant) pour

reduire le poids de I'appareil.

REMARQUE : laisser la mousse a c6te adhesif

sur les surfaces en metal brosse afin de proteger

le fini des egratignures jusqu'a ce que la surface

de cuisson soit en position finale.

.

Soulevez la table de cuisson et placezda dans

I'ouverture. Prenez garde a ne pas pincer le

cordon d'alimentation ni I'arrivee de gaz eta ne

pas rayer la plaque chauffante ou son cadre.

Assurez-vous que I'appareil

correspond au type de gaz utilis_ sur

le lieu d'installation. Reportez_vous

au Chapitre 4 avant de poursuivre

I'installation.

Posez la plaque de protection avant

de glisser I'appareil sur sa position

finaJe. Voir Chapitre 6.

.

Assurez-vous que le cordon d'alimentation est

degag6 et pend sans tension.

5.

Nivelez I'appareil. Pourobtenir de bons resultats,

I'appareil doit _tre nivel&

6.

Le gril (si I'appareil enest equip6) a et6 nivele

lots de I'assemblage. Ne tentez pas d'en

modifier la mise a niveau.

.

Replacez les grilles en fonte, les chapeaux

des brOleurs et la grille du gril (le cas ech6ant).

Assurez-vous que les chapeaux des brOleurs

sont correctement poses dans leurs bases.

Ajustement de l'inclinaison de la plaque de cuisson

Verifier le reglage de la grille en versant deux c. a table d'eau a I'arriere de la

plaque grille. L'eau devrait lentement couler dans le bac a graisse. Si non, regler

les deux vis sous I'arriere de la grille. Commencez par un demi-tour dans le sens

contraire des aiguilles d'une montre. Les corrections subsequentes doivent 6tre

faites au quart de tour jusqu'a ce que I'eau coule lement dans le bac a graisse.

24

Page 27

Chapitre 4 : E×igences pour M'aMimentationdu gaz et

raccordement

Los tables de ouisson sent pr_par_es _ J'usine

avant expedition pour _tre aliment_es par du gaz

nature{. Doivent _tre oenvertis pour utiJisatien

ave€ propane (surf=co de ouissen). Assurez-veus

que le type de gaz utiJis_ sur Je Jieu d'installatien

correspond au type de gaz utiJis_ par I'appareil. Sile

lieu necessite une conversion du gaz naturel au propane

(LP), cemmuniquer avec le marchand o_ J'appareil a et6

achete ou avec Thermader. Le medele de la trousse de

conversion pour toutes les tables de cuissen Professional

(serie PC) est le PLPKIT Thermader. Suivez toutes les

instructions du PLPKIT pour convertir correctement le

detendeur de gaz et effectuer le reglage des robinets

de gaz. La conversion sur site doit obJigatoirement _tre

realis6e par du personnel qualifie.

Cet appareil est certifie ACNOR a des fins de

fonctionnement securitaire jusqu'a une 616vation de 10

200 pi sans modification. Exception : pour I'utilisation

avec le gaz propane, I'appareil doit 6tre converti selon

les instructions de conversion au LP.

Consulter les instructions de conversion LP pour plus

de details.

Exigences peur Je ga_,naturet

Connexion d'entree : I/2 po NPT min. 3/4 po de

diametre, conduit flexible)

Pressien d"alimentation :6 po mln. a 14 po max,

colonne d'eau (14,9 a 34,9 mb)

Pression du distributeur : 5 po, colonne d'eau (12,5

mb)

Exigenee peur Jega_, prepane

Connexion d'entree : 1/2 po NPT min. 3/4 po de

diametre, conduit flexible)

Pressien d"alimentation : 11 pe mm. a 14 po max,

colonne d'eau (27,4 a 34,9 mb)

Pression du distributeur : 10 po, colonne d"eau

(24,9 mb)

RACCORDEMENT

o Un robinet manuel d"arr6t de gaz doit _tre installe

I'exterieur de i'appareil, a un endreit accessible par ie

devant, darts le but de pouvoir couper I'alimentatien

en gaz. Le tuyau d"arrivee de gaz ne doit pas g_ner

I'arriere de I'appareiJ.Assurez=vous que le rebinet

d"arr6t est ferme avant de raccorder I'appareiJ.

• Uinstallateur doit informer le consommateur de

I'emplacement de la seupape d"arr6t de gaz.

S'assurer que tousles utiJisateurs sachent comment

fermer I'alimentation en gaz a la surface de

cuisson.

° Les connexiens d'alimentation en gaz deivent _tre

effectuees parun technicien qualifie conformement

la r_glementatien locale. A defaut de reglementation

locale, I'installation devra _tre conforme au Code

national du gaz combustible ANSI Z223.1/NFPA54

= version actuelle.

• Toujours utiliser un scellant a tuyau ou du ruban

Teflon@ sur les filets de tuyaux et prenez garde

ne pas setter excessivement les raccords.

• Les tests de fuite de I'appareil seront reaiises

conformement aux instructions du fabricant.

• Ouvrez le gaz et assurez=vous qu'il n"y a pas

de fuites a I'aide d'une solution savonneuse.

• N'utilisez pas de flamme pour faire oette

v_rifioation.

• Toutesles pieces fournies par i'installateurdoivent

satisfaire aux reglementatiens applicables.

• Toutes les pieces foumies par I'instaJlateur doivent

_tre conformes aux codes applicables.

AVERTtSSEMENT:

Ce necessaire de conversion doit _tre installe

par un technicien qualifie conformement aux

instructiens du fabdcant et selon les exigenc-

es et codes applicables ayant juridiction. Si

I'informatien centenue dans ces instructiens

n'est pas suivie, il peut en resulter un risque

d'incendie, d'explosien ou de production de

menoxyde de carbene, causant des dom-

mages a la propriete, des blessures ou la mort.

L'agence de service qualifie est responsable

de I'installation appropriee de ce necessaire.

L'installation n'est pas adequate ni cempletee

tant que le fonctionnement de I'appareil cen-

verti n'est pas verifie tel qu'il est specifie dans

les instructiens du fabdcant et feumies avec le

necessaire.

25

Page 28

Chapitre 4 : E×igences pour FaHmentation du gaz et

raccordement

MtSE EN GARDE

Si I'appareil est alimente par du gaz propane,

assurez-vous que le reservoir de propane est

equip6 de son propre detendeur en sus du

detendeur fourni avec I'appareil. La pression

d"arrivee du gaz darts le detendeur de I'appareil ne

doit pas d@asser les 34,9 millibars (I4 pouces

la colonne d"eau).

MISE EN GARDE

Uappareil doit 6tre isole du systeme d"arrivee de

gaz en fermant le robinet manuel d'arr_t pendant

tousles tests de pression d"alimentation en gaz

Iorsque ces pressions sont 6gales ou inf@ieures

3,5 kPA (1/2 psig).

<<Uappareil et son robinet individuel d'arr_t doivent

_tre debranch6s du systeme d'arrivee de gaz

pendant tousles tests de pression du systeme si

ces pressions d@assent 3,5 kPa (1/2 psig). >>

Pour la v@ification de la pression de gaz du

collecteur, la pression d"entree du detendeur doit

_tre de 14,9 mb (6") au minimum pour le gaz

naturel et de 7,4 mb (I1") pour le propane,

Ne tentez pas de regler le detendeur.

26

Page 29

Chapitre 5 : Exigences pour l'aiimentation @lectrique, le

branchement et la raise a la terre

MISE EN GARDE

Une raise _ [a terre inadequate

ou une poladsation inversee peut

causer un mauvais fonctionnement

(tels qu'une production continueHe

d'_tincelIe au niveau des aiiumeurs

des brQieurs) pouvant endommager