Page 1

INSTALLATION MANUAL

For Thermador Professional® Cooktops

MANUEL D'INSTALLATION

Des tables de cuisson Thermador Professional

®

MANUAL DE INSTALACIÓN

Para Parrillas de Thermador Professional®

Models/

Modèles/

Modelos:

PCG24

PCD24

PCG30

PCG36

PCG48

PCD48

Page 2

Table of Contents

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Before you Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Important Installation Information . . . . . . . . . . . . . . .3

Step 1: Ventilation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Step 2: Cabinet Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Step 3: Unpacking, Moving, Placing and Anchoring the Cooktop . . . . . . . . . . . . . . . . . . . . . . 10

Step 4: Gas Requirements and Hookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Step 5: Electrical Requirements, Connection and Grounding . . . . . . . . . . . . . . . . . . . . . . . . . 12

Step 6: Backguard Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Step 7: Burner Test and Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Installer Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

To Clean and Protect Exterior Surfaces . . . . . . . . .16

This Thermador Appliance is made by

BSH Home Appliances Corporation

5551 McFadden Ave.

Huntington Beach, CA 92649

Questions?

1-800-735-4328

www.thermador.com

We look forward to hearing from you!

Page 3

For Massachusetts Installations:

1. Installation must be performed by a qualified or licensed contractor, plumber or gas fitter qualified or licensed by the state, province or region where this appliance is being installed.

2. Shut-off valve must be a “T” handle gas cock.

3. Flexible gas connector must not be longer than 36 inches.

WARNING:

If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal injury or

death.

-- Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

-- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

-- Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

English 1

Page 4

Safety Instructions

Important Safety Instructions

READ AND SAVE THESE INSTRUCTIONS

APPROVED FOR ALL RESIDENTIAL APPLIANCES

FOR RESIDENTIAL USE ONLY

IMPORTANT: LOCAL CODES VARY. INSTALLATION,

ELECTRICAL CONNECTIONS, GAS CONNECTIONS,

AND GROUNDING MUST COMPLY WITH ALL

APPLICABLE CODES.

Electrical Power Supply

Before you Begin

IMPORTANT: Save these Instructions for the Local

Electrical Inspector’s use.

INSTALLER: Please leave these Instructions with this unit

for the owner.

OWNER: Please retain these instructions for future

reference.

WARNING:

Improper installation, adjustment, alteration,

service or maintenance can cause injury or

property damage. Refer to this manual. For

assistance or additional information consult a

qualified installer, service agency, manufacturer

(dealer) or the gas supplier.

NOTE:

This Cooktop is NOT designed for installation in

manufactured (mobile) homes or for installation in

Recreational Park Trailers.

DO NOT install this appliance outdoors.

Data Rating Plate

Cooktop Models:

The data rating plate showing the model and serial

numbers of your Cooktop or Wok is located on the

underside of the Cooktop or Wok chassis near the gas inlet

connection and electric power cord. This information is

required if customer service is requested. Before

installation, the model and serial numbers should be

entered in the appropriate spaces in the "BEFORE

CALLING FOR SERVICE" section near the back of the

Care and Use Manual. After installation accessing the

information is difficult.

PLEASE READ ENTIRE INSTRUCTIONS BEFORE

PROCEEDING

24" Models:

with Wok - 120 VAC, 60 Hz., 1 Ph., 10 Amp circuit

with Griddle - 240 VAC, 60 Hz., 1 Ph., 30 Amp circuit

30'' Models:

4 Burners - 120 VAC, 60 Hz., 1 Ph., 10 Amp circuit

36" Models:

6 Burners - 120 VAC, 60 Hz., 1 Ph., 10 Amp circuit

with Grill - 120 VAC, 60 Hz., 1 Ph., 10 Amp circuit

with 12" Electric Griddle - 120 VAC, 60 Hz., 1 Ph., 15 Amp

circuit

48" Models:

6 Burners with Grill - 120 VAC, 60 Hz., 1 Ph., 10 Amp

circuit

6 Burners with 12" Electric Griddle - 120 VAC, 60 Hz., 1

Ph., 15 Amp circuit

4 Burners with 12" Electric Griddle and Grill - 120 VAC, 60

Hz., 1 Ph., 15 Amp circuit

4 Burners with Wok - 120 VAC, 60 Hz., 1 Ph., 10 Amp

circuit

4 Burners with 24" Electric Griddle - 240 VAC, 60 Hz., 1

Ph., 30 Amp circuit

Gas Supply

Natural Gas – 6” min. to 14” max. water column (14.9 mb

to 34.9 mb)

Propane Gas – 11”min. to 14”max. water column (27.4 mb

to 34.9 mb)

WARNING

Disconnect power before installing.

Before turning power ON, be sure that all

controls are in the OFF position.

All sealed burners are rated at 15,000 BTU/HR (*13,000

BTU/HR on LP). *All models, except 24” Griddle, are

convertible to LP/Propane gas using an accessory

conversion kit.

English 2

Page 5

IMPORTANT

• A backguard must be utilized when there is less than a

12" horizontal clearance between combustible

materials and the back edge of the cooktop. The

Thermador Low Back backguard must be ordered

separately and installed at the rear of the cooktop. For

island installations and other installations with more

than 12" clearance, an optional stainless steel Island

Trim is available to cover the backguard mounting

flanges.

• Verify that the appliance is correct for the type of gas

being provided. Refer to “Step 4: Gas Requirements

and Hookup” on page 11 before proceeding with the

installation.

Important Installation Information

This appliance has been CSA certified for safe operation

up to an elevation of 10,200 ft. without any modifications.

Exception

converted per the LP Conversion Instructions.

It is strongly recommended

in conjunction with a suitable overhead vent hood. (See

“Step 1: Ventilation Requirements”.)

Check local building codes for the proper method of

appliance installation. Local codes vary. Installation,

electrical connections and grounding must comply with all

applicable codes. In the absence of local codes the

appliance should be installed in accordance with the

National Electric Code ANSI Z223.1 current issue and

National Gas Code ANSI/NFPA 70 – current issue. In

Canada, installation must be in accordance with the CAN

1-B149.1 and .2 – Installation Codes for Gas Burning

Appliances and/or local codes.

This appliance is equipped with an intermittent/interrupted

ignition device that cycles the two far left surface burners

on and off when in the ExtraLow setting.

: For use with Propane, the appliance must be

that this appliance be installed

CAUTION

(1) When connecting the unit to propane gas,

make certain the propane gas tank is equipped

with its own high-pressure regulator in addition

to the pressure regulator supplied with this unit.

The maximum gas pressure to this appliance is

not to exceed 14.0 inches water column (34.9

mb) from the propane gas tank regulator.

(2) This unit is designed as a cooking appliance.

Based on safety considerations, never use it for

warming or heating a room.

Due to the high heat of the cooktop burners, installing a

microwave oven with a ventilation system over the cooktop

is not recommended.

This appliance complies with one or more of the following

standards:

• UL 858, Standard for the Safety of Household Electric

Ranges

• UL 923, Standard for the Safety of Microwave Cooking

Appliances

• UL 507, Standard for the Safety of Electric Fans

• ANSI Z21.1 American National Standard for Household

Cooking Gas Appliances

• CAN/CSA-C22.2 No. 113-M1984 Fans and Ventilators

• CAN/CSA-C22.2 No. 61-M89 Household Cooking

Ranges

CAUTION

To eliminate risk of burns or fire caused by

reaching over heated surface units, cabinet

storage located above the surface units should

be avoided.

It is the responsibility of the owner and the installer to

determine if additional requirements and/or standards

apply to specific installations.

Remove all tape and packaging before using the appliance.

Destroy the packaging after unpacking the appliance.

Never allow children to play with packaging material.

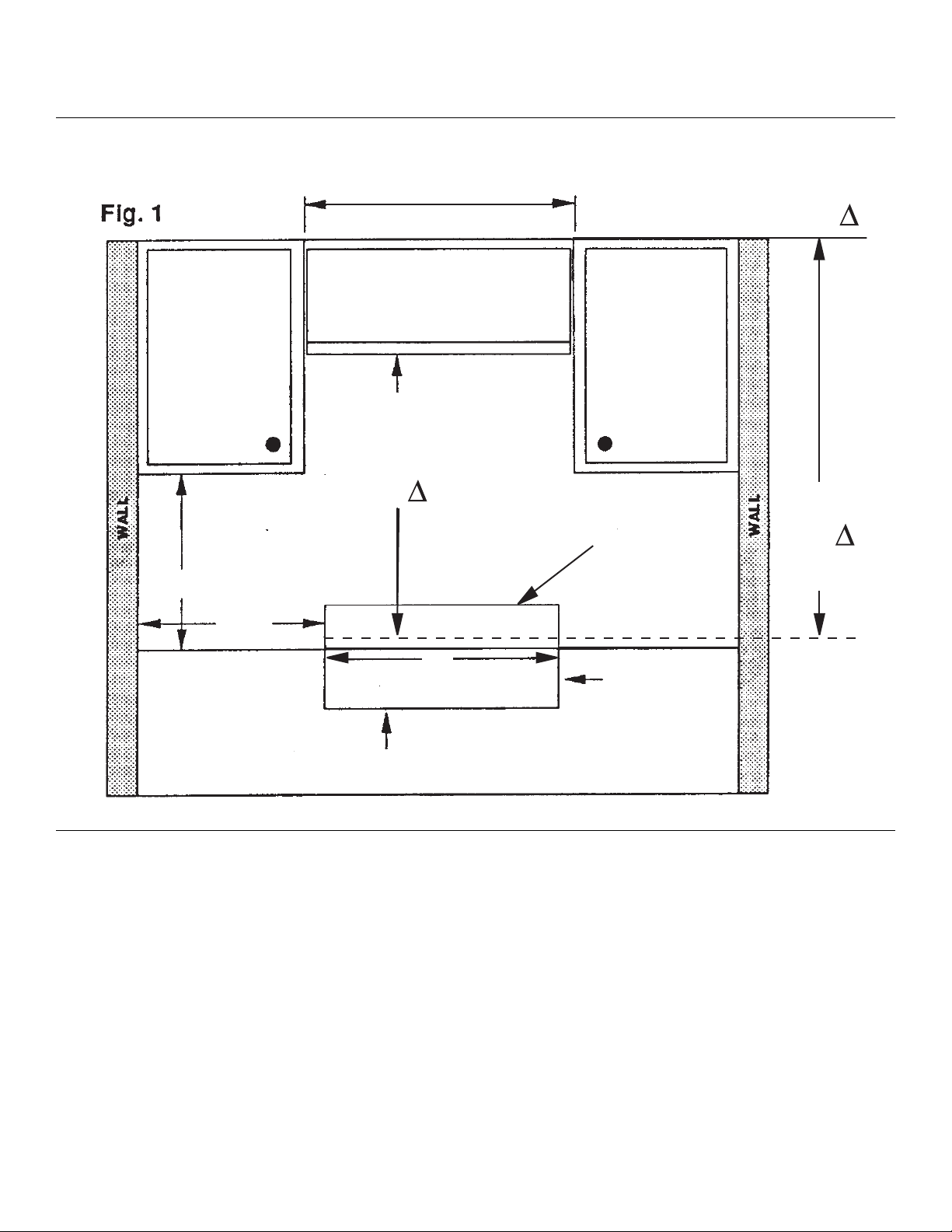

Step 1: Ventilation Requirements

It is strongly recommended that a suitable exhaust hood be

installed above the appliance. Downdraft ventilation should

not be used. The following table indicates the ventilation

hood options and blower capacity guidelines that are

recommended for use with all Thermador cooktops.

Due to the high heat capability of this unit, particular

attention should be paid to the hood and duct work

installation to assure it meets local building codes.

Do not install a microwave oven/ ventilator combination

above the cooktop, as these types of units do not provide

English 3

Page 6

the proper ventilation and are not suitable for use with the

cooktop.

Select Hood and Blower Models:

• For wall installations the hood width must, at a

minimum, equal the nominal width of the appliance

cooking surface. Where space permits, a hood larger in

width than the cooking surface may be desirable for

improved ventilation performance.

• For island installations the hood width should, at a

minimum, overhang the appliance cooking surface by

3" on each side.

Hood Placement:

• For best smoke elimination, the lower edge of the hood

should be installed 30" above the appliance cooking

surface. (See Figure 1).

• If the hood contains any combustible materials (i.e., a

wood covering), it must be 36"or greater distance

above the cooking surface.

NOTICE:

Most hoods contain combustible components which must

be considered when planning the installation.

Consider Make-Up Air:

• Due to the high volume of ventilation air, a source of

outside replacement air is recommended. This is

particularly important for tightly sealed and insulated

homes.

• A qualified heating and ventilating contractor should be

consulted.

NOTE:

Ventilation hoods and blowers are designed for use with

single-wall ducting. Some local building codes may require

double-wall ducting. Before starting installation, consult

local building codes and agencies to insure that the

installation will meet local requirements.

Cooktop

Width

24” 24” griddle -or-24” wok 600 CFM

30” 4 burners 600 CFM

4 burners w/ grill -or-

36”

48”

Important Notes:

• It is recommended that a Thermador Professional wall or island hood or custom insert is used with Thermador

Professional Cooktops.

• Refer to www.Thermador.com for a complete selection of Professional Ventilation options, Blowers, and

Accessories.

• * For high output gas cooktops (60,000 BTU or greater), the minimum of one (1) CFM of ventilation per 100 BTU is

recommended. If the cooktop has a grill or griddle, add 200 CFM to the estimated blower capacity. Add 400 CFM if

the cooktop has a 24” griddle or wok. Additional blower capacity may be required for longer duct runs.

• For island applications, it is recommended to use a hood width that exceeds the width of the cooktop by 6”

(overlapping the cooktop by 3” on each end).

• CFM = “cubic feet per minute” (standard blower capacity rating).

griddle 6 burners 900 CFM 4 burners w/ grill-griddle

combo

24” griddle or wok

6 burners w/ grill -orgriddle

Cooktop

Configuration

Minimum Recommended

Blower Capacity*

800 CFM

1000 CFM

1100 CFM

Ventilation Options

30” Pro Wall Hood

30” Custom Insert w/ optional blower

42” Island Hood w/ optional blower

30” or 36” Pro Wall Hood

30” or 36” Custom Insert w/ optional blower

42” Island Hood w/ optional blower

36” or 42” Pro Wall Hood

36” Custom Insert w/ optional blower

42” or 48” Island Hood w/ optional blower

48” or 54” Pro Wall Hood

48” Custom Insert w/ optional blower

54” Island Hood w/ optional blower

English 4

Page 7

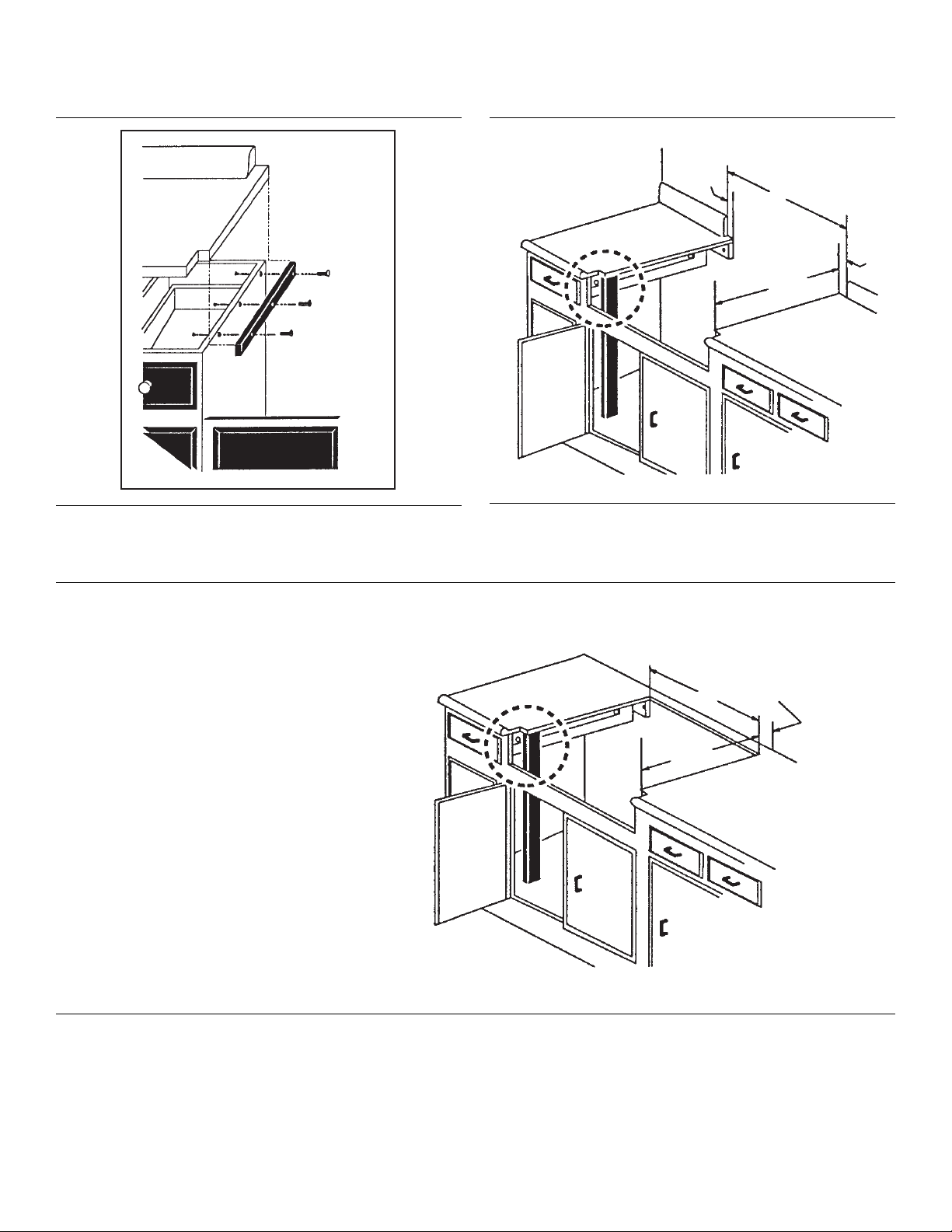

Step 2: Cabinet Preparation

1. To ensure professional results, the cabinet and countertop openings should be prepared by a qualified cabinet worker.

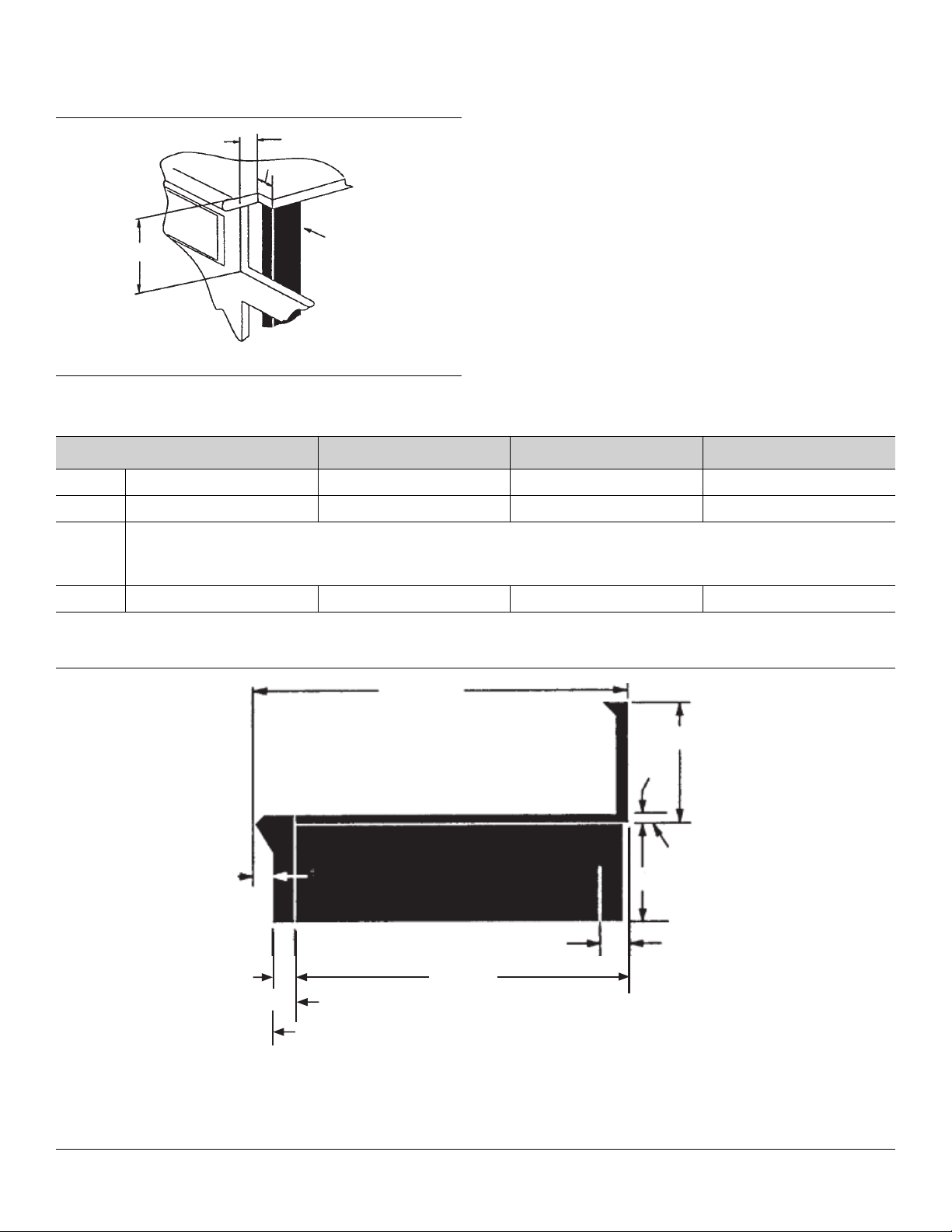

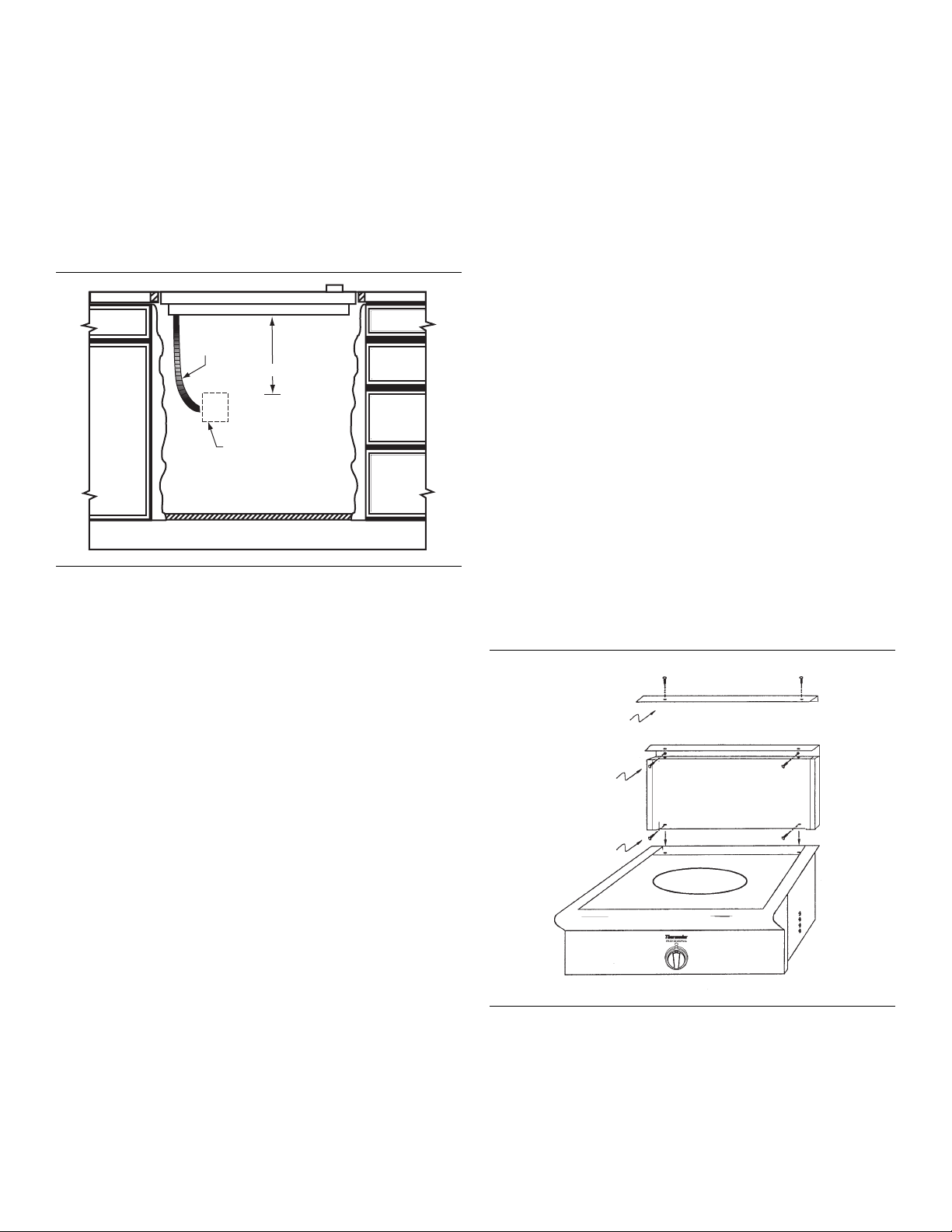

2. The clearances shown in Figure 1 are required. The same clearances apply to island installations, except for the overhead cabinets, which must have a space wide enough to accept the island hood.

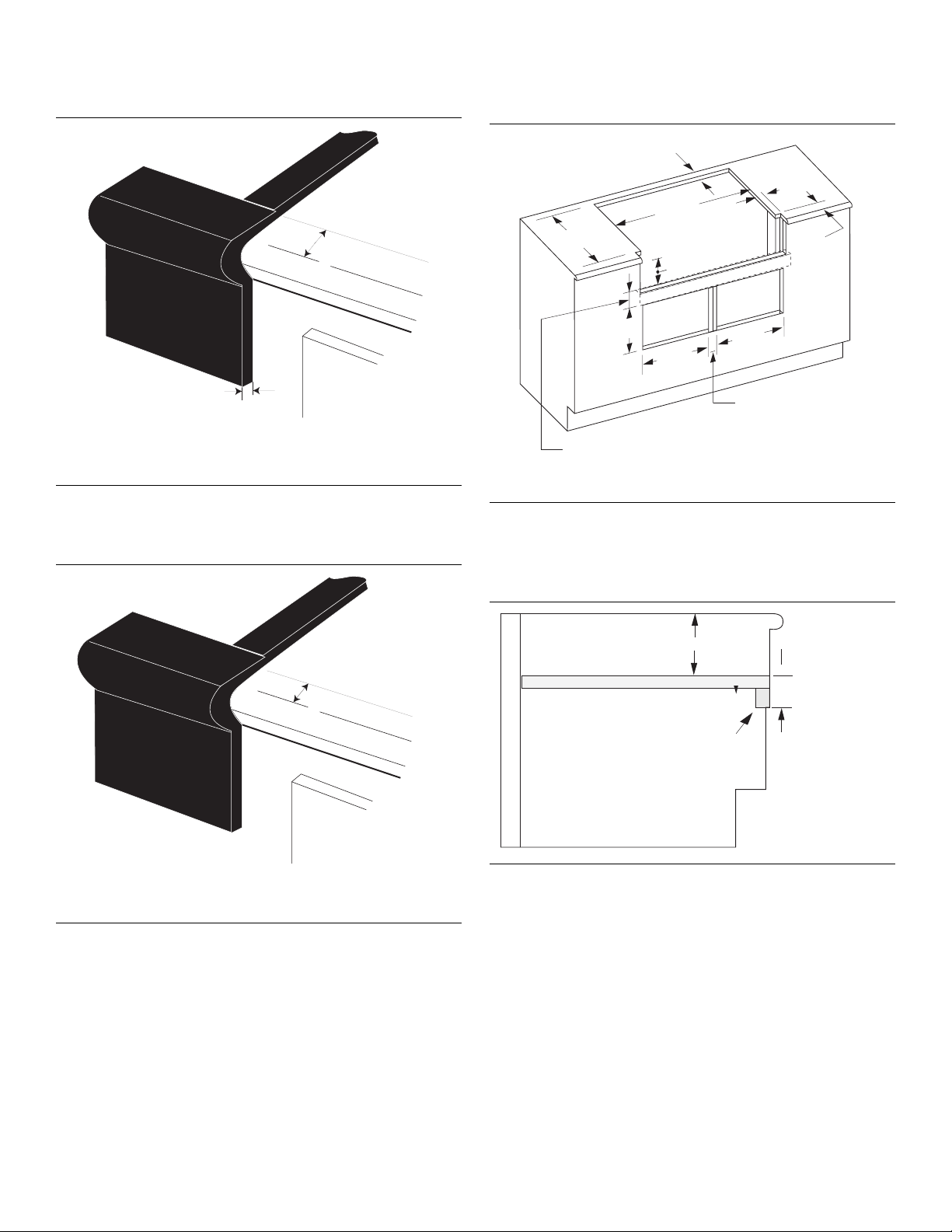

3. The cooktop is designed to hang from the countertop

by its side flanges. The countertop however, must be

strong enough to support this cooktop. It may be

necessary to add a supporting cleat along each side

(see Figure 2) or a 2 x 4 corner brace (see Figure 3

and Figure 4 and Detail A). Another alternative would

be to construct a deck to set the cooktop on.

4. The cooktop can be installed in various positions with the front either flush or projecting, depending on the countertop’s depth. (See Figure 5, side view of cooktop; see Figure 3, Figure 4, Figure 6 and Figure 7 for alternate mounting positions.)

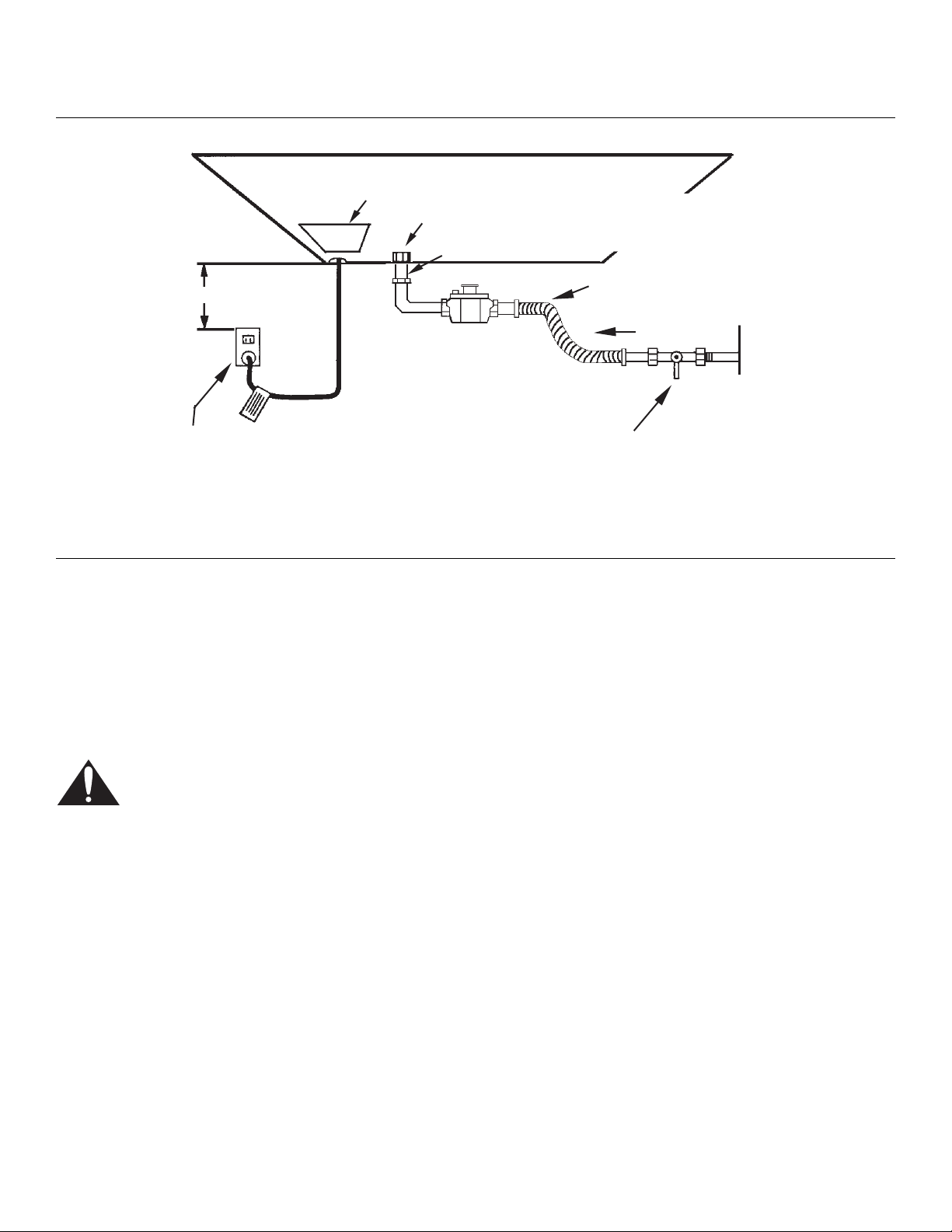

5. The gas and electrical supply must be located in an

area that is accessible without requiring removal of the

cooktop. The appliance electrical power cord and gas

pipe connection are located on the left rear underside

of the cooktop (except on models with a 24" griddle

where power cord is located in the center), as shown in

Figure 5 and Figure 9.

6. The maximum depth of over head cabinets installed on either side of the hood is 13".

A 36-inch minimum clearance is required between the

cooking surface of the cooktop and the bottom of an

unprotected cabinet. A 30-inch distance can be used when

the bottom of the wood or metal cabinet is protected by not

less than 1/4 inch of a flame retardant material covered

with not less than No. 28 MSG sheet steel, 0.015 inch (0.4

mm) thick stainless steel, 0.024 inch (0.6 mm) aluminum,

or 0.020inch (0.5 mm) thick copper. Flame retardant

materials bear the mark:

UNDERWRITERS LABORATORIES INC. CLASSIFIED

MINERAL AND FIBER BOARDS SURFACE BURNING

CHARACTERISTICS

followed by the flame spread and smoke ratings. These

designations are shown as "FHC (FIame Spread/Smoke

Developed)." Materials with "O" flame spread ratings are

flame retardant. Local codes may allow other flame spread

ratings.

7. When there is less than a 12" horizontal clearance

between combustible material and the back edge of

the cooktop above the cooking surface, a Thermador

Low Backguard must be installed. (See Step 6). When

clearance to combustible material is over 12", a

Thermador Island Trim may be used. Attach the

backguard before sliding the appliance into the final

installed position.

8. Establish the centerline of the cooktop’s desired location. It should be the same as the center of the overhead ventilation hood.

9. Cut the openings for the following installations:

• Wall installation, see Figure 3.

• Island installation, see Figure 4.

10. For models with a 24” griddle, attach the foam strip to countertop centered along the rear about 1/16” from the edge.

11. For installation of a 48" cooktop above two side-by-side

Thermador Warming Drawers, Model No. WD24, refer

to Figure 8. Completing the installation as per Figure 8

will result in the left and right edges of the cooktop

being aligned with the left edge of the left-side warming

drawer and right edge of the right-side warming

drawer. If different alignment is desired, the 1-7/8"

horizontal distance between warming drawer cutouts

may be varied. However, maintain at least a 1-1/8"

distance to avoid interference between the warming

drawers. Attach a 90-degree elbow to the gas cooktop

inlet pipe. All above-the-countertop clearances must be

maintained, as shown in Figure 1.

As defined in the "National Fuel Gas Code" (ANSI

Z223.1/NFPA54-current issue).

NOTES:

• If a solid side cabinet wall exists on one or both sides,

you will need to notch the front corner of the cabinet to

match the countertop notch and to allow clearance for

the cooktop front (see Detail A, Figure 3 and Figure 4).

• If a supporting deck is used, the sides or bottom of the

cutout may be solid combustible or non-combustible

material. If the bottom is solid, provide a 8" by 8" cutout

in the left rear corner of the supporting deck. This will

provide clearance for the gas inlet and power cord,

while also allowing viewing of the product rating label.

• On models which have a 24" griddle with power cord in

the center, provide 2 (two) separate pieces of

supporting deck to allow clearance in center for cord to

pass through.

• Always keep appliance area clean and free from

combustible materials, gasoline and other flammable

vapors and liquids.

• Do not obstruct the flow of combustion and ventilation

air to the unit.

English 5

Page 8

18" Min

13" Max.

depth of

overhead

cabinets

30" to 36" Wide Hood for 24" Wok or 24" Griddle

30" to 36" Wide Hood for 30" Cooktop

to 42" Wide Hood for 36" Cooktop

36"

48"

to 60" Wide Hood for 48" Cooktop

VENT HOOD

30" Min. from bottom of

Overhead Hood to Cooking

Surface (36"

hood contains combustible

materials ).

or greater if

Horizontal

Min. Clearance

to Rear Wall:

0" with Backguard

12" with Island Trim

Combustible

Material

36" Min. to

Combustible

Material

from Cooking

Surface.

3" min.

.

both sides

"A"

0" Bottom

Cooking Surface

0" Sides

Figure 1: Clearance Requirements

English 6

Page 9

Counter

Sunk

Screws

B

D

See Detail A

B

23-5/16”

Figure 2: Installing Side Supports (both sides)

Vent Hood

Island – 42" or 48"

Island – 42" or 48"

Island –

Width Requirements

Wide Hood

Wide Hood for 36" Cooktop

54" or 60"

Wide Hood for 48" Cooktop

for 24" Wok or Griddle

Figure 3: Wall Installation with Countertop Backsplash

See Detail A

22-13/16”

3/4” Min.

D

Figure 4: Island Installation (No Countertop Backsplash)

English 7

Page 10

C

B

7-11/16”

Corner Notch Detail

Detail A: (Front Face of Cabinet)

24” Wok/Griddle 30” Cooktop 36” Cooktop 48” Cooktop

A 24-3/4” 29-7/8” 35-7/8” 47-7/8”

B 3/8” 3/8” 3/8” 13/16”

C 0” (Control Panel Projecting 1-1/4” from Base Cabinet Face)

11/16” (Notch Required for Standard 24” - Deep Base Cabinet, Control Panel Projecting 9/16” from Base

Cabinet Face) 1-1/4” (Control Panel Flush to Cabinet Face - Min. 24-9/16” - Deep Base Cabinet Required)

D 24” 29-1/8” 35-1/8” 46-1/4”

2 x 4 Corner

Support

25-3/8”

1/2”

Flange

7-5/8”

5-1/4” TO CENTERLINE OF

GAS INLET

23-5/16”

1-1/4”

Cabinet face for installation with projecting control panel

Cabinet face for installation with flush control panel

* Low Back required when there is less than 12”

horizontal clearance from back of cooktop to combustible

material. With more than 12” of clearance, the Island

Trim may be used.

12”

Side

Figure 5: Side View of Cooktop

English 8

Page 11

11/16” Notch

Depth

Minimum 3/4" (19 mm)

46-1/4"

22-13/16"

(57, 9 cm)

(22, 9 cm) 9"

(117,5 cm)

7-11/16"

(19,52 cm)

WD24

Cutout

WD24

Cutout

22-1/2"

(57,2 cm)

13/16"

(21 mm)

0" to

1-1/4"

(0 - 32 mm)

See Fig. 4

and Table

Dimension C

9/16”

Front projects outward 9/16" as shown from

standard 24"-deep base.

Figure 6: Projecting from Cabinet Front

1-1/4” Notch

Depth

1-7/8" (4,8 cm)

Horizontal Distance

Between Cutouts

2-3/4" (7 cm) Vertical Distance

Between Cutouts

(See Side View for Wood Support)

Figure 8a: Installation of 48” Cooktop above two side-by-

side Thermador Warming Drawers - Model No. WD24

7-11/16”

Plywood support

(19,52 cm)

2-3/4" (70 mm)

minimum

between

cutouts

REAR

Install additional

wood support along

front edge of cutout

Front flush with cabinets; minimum of 24-9/16" cabinet

depth required.

Figure 7: Flush to Cabinet Front

Figure 8b: Installation of 48” Cooktop above two side-by-side

Thermador Warming Drawers - Model No. WD24

(Side View)

English 9

Page 12

Product Rating

Label/Serial Tag

Threading compounds must be

resistant to Propane Gas

P24WOK 1/2" NPT

3” Min.

3-Prong grounding type receptacle

connected to a properly grounded and

polarized electrical supply rated at 120VAC,

10 Amps, (or 15A*) Single Phase, 60 HZ.

NOTE: This is not applicable to 240 VAC

models with 24" electric griddle.**

All Installer supplied parts must conform to Local Codes.

*15 Amp 120 VAC electrical supply is required for 36" and 48" models with a 24" electric griddle.

**30 Amp 240 VAC electrical supply is required for models with a 24" electric griddle.

Step 3: Unpacking, Moving, Placing and Anchoring the Cooktop

Power

Cord or

Conduit

A manual valve must be installed

external to the appliance, in an accessible location from the front, for the

purpose of shutting off the gas supply.

2. Remove the top grate castings, burner caps

grate (if so equipped) to reduce unit weight.

3/4” flex line

gas flow

Figure 9: Front - Bottom of Unit

and grill

CAUTION

Proper equipment and adequate manpower

must be used in moving the appliance to avoid

damage and/or personal injury. The unit is

heavy and should be handled accordingly.

Important

• Verify that the appliance is correct for the type of gas

being provided. Refer to Step 4 before proceeding with

the installation.

• Attach the backguard before sliding the appliance into

the final installed position. See Step 6.

1. Remove the outer carton and packing material from the

shipping base. Ensure that you have

components before proceeding.

English 10

all cooktop

NOTE:

Leave adhesive-backed foam layer

surfaces, to protect finish from scratches, until the cooktop

is installed in its final position.

3. Lift and place the cooktop in the opening. Be careful not to pinch the power cord or gas inlet. Care should be used not to scratch the griddle cooking plate.

4. Make sure that the power cord is free and hanging loose.

5. The cooktop must be level for proper performance.

6. The grill frame (if so equipped) has been leveled during assembly so do not attempt to level the grill.

7. Replace the cooking grates, burner caps and grill plate (if so equipped). Ensure that the burner caps are correctly seated on the burner bases.

over brushed-metal

Page 13

Grill/Griddle Tilt Adjustment (not all models)

Check the grill or griddle adjustment by pouring two

tablespoons of water on the back of the grill or griddle

plate. The water should slowly roll into the grease tray. If

not, adjust the two screws under the back of the plate. Start

with one half turn counter-clockwise (CCW) of the screws.

Further adjustment should be made by one-quarter turn

until water slowly flows into the grease tray.

Step 4: Gas Requirements and Hookup

Cooktops are shipped by the factory to operate on

natural gas.They must be converted for use with

propane. Verify the type of gas being used at the

installation site matches the type of gas used by the

appliance. If the location/job site requires conversion from

natural gas to propane (LP), contact the dealer where the

unit was purchased or contact Thermador. The field

conversion kit for the Professional Cooktops in this series is

Thermador Model PLPKIT. Obey all instructions in PLPKIT

for correct conversion of the gas regulator and settings for

the gas valves. Field conversion must be done by qualified

service personnel only.

This appliance has been CSA certified for safe operation

up to an elevation of 10,200 ft. without any modifications.

Exception

converted per the LP conversion instructions. Please refer

to the LP Conversion Instructions for further information.

Natural Gas Requirements:

Inlet Connection: 1/2” NPT (min. 3/4” dia. flex line)

Supply Pressure: 6” min. to 14” max. water column (14.9 to

34.9 mb)

Manifold Pressure: 5” water column (12.5 mb)

Propane Gas Requirements:

Inlet Connection: 1/2” NPT (min. 3/4” dia. flex line)

Supply Pressure: 11” min. to 14” max. water column (27.4

mb to 34.9 mb)

Manifold Pressure: 10” water column (24.9 mb)

: For use with propane, the appliance must be

WARNING

If a gas conversion kit is used, the kit shall be

installed by a qualified service agency in

accordance with the manufacturer’s instructions

and all applicable codes and requirements of

the authority having jurisdiction. If the

information in the instructions is not followed

exactly, a fire, explosion or production of carbon

monoxide may result causing property damage,

personal injury or loss of life. The qualified

service agency is responsible for the proper

installation of the kit. The installation is not

proper and complete until the operation of the

converted appliance is checked as specified in

the manufacturer’s instructions supplied with the

kit.

Hook Up

• A manual gas shut-off valve must be installed external

to the appliance, in a location accessible from the front,

for the purpose of shutting off the gas supply. The

supply line must not interfere with the back of the unit.

Make sure the gas supply is turned off at the manual

shut-off valve before connecting the appliance.

• The installer should inform the consumer of the

location of the gas shut-off valve. Make sure all users

know where and how to shut off the gas supply to the

cooktop.

• The gas supply connections shall be made by a

competent technician and in accordance with local

codes or ordinances. In the absence of local codes, the

installation must conform to the National Fuel Gas

Code ANSI Z223.1/NFPA54-current issue.

• Always use pipe-sealing compound or Teflon® tape on

the pipe threads, and be careful not to apply excessive

pressure when tightening the fittings.

• Leak testing of the appliance shall be in accordance

with the following instructions.

• Turn on gas and check supply line connections for

leaks using a soap and water solution.

• Bubbles forming indicate a gas leak. Repair all

leaks immediately after finding them.

• Do not use a flame of any kind to check for gas

leaks.

• All installer-supplied parts must conform to applicable

codes.

CAUTION

When connecting unit to propane gas, make

certain the propane gas tank is equipped with its

own high pressure regulator in addition to the

pressure regulator supplied with the appliance.

The pressure of the gas supplied to the

appliance regulator must not exceed a 14” water

column (34.9 mb).

English 11

Page 14

CAUTION

The appliance must be isolated from the gas

supply piping system by closing its individual

manual shut-off valve during any pressure

testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig

(3.5kPa).

The appliance and its individual shut off valve

must be disconnected from the gas supply

piping system during any pressure testing of the

system at test pressures in excess of 1/2 psig

(3.5kPa.).

When checking the manifold gas pressure, the

inlet pressure to the regulator should be at least

6.0" W.C. for natural gas or 11.0" for propane.

Do not attempt any adjustment of the pressure

regulator.

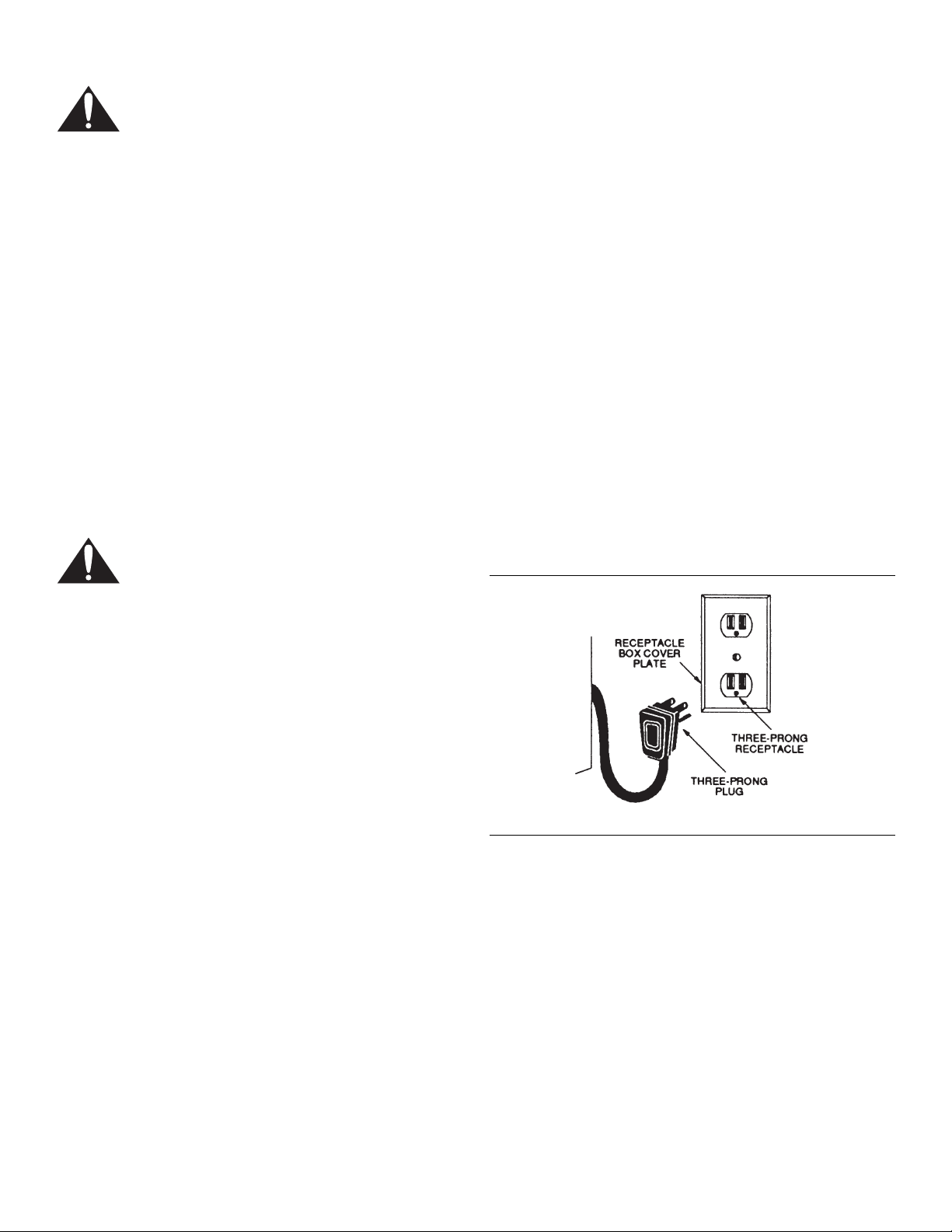

Step 5: Electrical Requirements, Connection and Grounding

• All 240 Volt cooktop models require hard wire

connections.

• Observe all governing codes and ordinances when

grounding. In the absence of these codes or

ordinances observe National Electrical Code ANSI/

NFPA No. 70 current issue. See Figure 10 for

recommended grounding method.

• An electrical wiring diagram and schematic have been

attached to the bottom of the cooktop chassis for

access by a qualified service technician. Do not

remove or discard this important information.

Grounding Method for 120 VAC Models

The cooktop is factory equipped with a power supply cord

with a three-prong grounding plug (with polarized parallel

blades).

IT MUST BE PLUGGED INTO A MATING, GROUNDING

TYPE RECEPTACLE THAT IS CONNECTED TO A

CORRECTLY POLARIZED 120 VOLT CIRCUIT (240

VOLT CIRCUIT FOR MODELS WITH 24" ELECTRIC

GRIDDLE. (See Figure 10).

CAUTION

Improper grounding or reverse polarization will

cause malfunction (such as continuous sparking

of the burner igniters). This can damage the

appliance and can create a condition of shock

hazard. If the circuit is not correctly grounded

and polarized, it is the responsibility and

obligation of the installer and user to have the

existing receptacle changed to a properly

grounded and polarized receptacle. This must

be accomplished in accordance with all

applicable local codes and ordinances by a

qualified electrician. In the absence of local

codes and ordinances, the receptacle

replacement shall be in accordance with the

National Electric Code. (See Figure 10.)

• Before installing, turn power OFF at the service panel.

Lock service panel to prevent power from being turned

ON accidentally.

• Always disconnect appliance from the electric supply

either by disconnecting power cord or shutting off the

breaker before servicing the appliance.

• Before you plug in an electrical cord, be sure all

controls are in the OFF position.

• All 120 Volt cooktop models must be plugged into a

mating 3-Prong, Grounding-Type Receptacle. The

receptacle must be connected to a properly grounded

and polarized electrical power supply rated at 120VAC,

Single Phase, 60HZ. See “Electrical Power Supply

Over-current Protection Requirements” on page 13 on

this page for proper over-current protection

requirements for each model.

Figure 10: Recommended Grounding Method for 120V

Models

THE THIRD, GROUND PRONG MUST NOT BE CUT OR

REMOVED UNDER ANY CIRCUMSTANCES.

Electrical Connection for 240 VAC Models

1. Attach flexible conduit to the junction box.

2. Connect the cooktop lead wires to the junction box supply wires in proper phase:

For all 240 VAC models, connect black (L1) to black,

red (L2) to red, white wire to neutral and green wire

to ground.

English 12

Page 15

NOTE:

If the 120V cooktop is installed and connected as specified

above, it will be completely grounded in compliance with

the National Electric Code.

Cooktop with a wok - 10 Amp circuit protection

Cooktop with a 24" electric griddle - 30 Amp circuit

protection 240 VAC.

3. Turn on power supply.

4. Test operation.

Conduit

(Approx. 3”)

12” APPROXIMATE

“J” Box

Figure 11: Junction Box Location

Electrical Power Supply Over-current Protection Requirements

Installer - show the owner the location of the circuit

breaker or fuse. Mark it for easy reference.

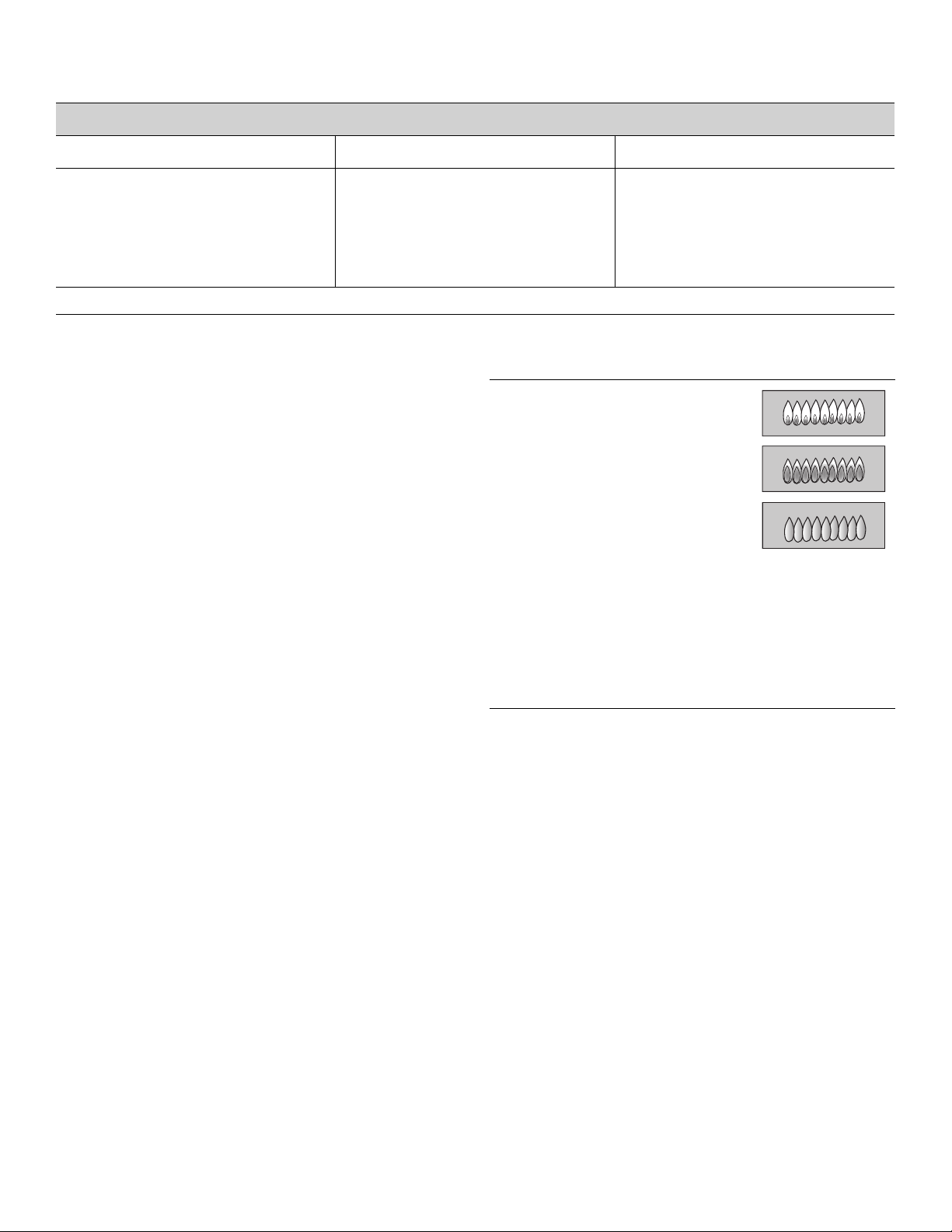

Step 6: Backguard Installation

A Low Back backguard must be installed when there is less

than a 12" clearance between combustible materials and

back edge of cooktop. (See Figure 1 and Figure 5.) For

island installations and other installations with over 12"

clearance, an optional stainless

available to cover the backguard mounting flanges. Attach

the backguard before sliding the appliance into the final

installed position. Follow Steps A through C below:

1. Slide backguard over the two flanges on the rear of the appliance. Fasten the front and back with the two screws (see A, Figure 12) provided.

2. Fasten the top of the backguard to the wall with two screws through the backguard. (See B, Figure 12.)

3. Place the backguard cap on top and fasten using the two counter-sink screws provided. (See C, Figure 12.)

steel trim channel is

4 Burners - 10 Amp circuit protection

6 Burners - 10 Amp circuit protection

4 Burners with a grill - 10 Amp circuit protection

4 Burners with a 12" electric griddle - 15 Amp circuit

protection

6 Burners with a grill - 10 Amp circuit protection

6 Burners with a 12" electric griddle -15 Amp circuit

protection

4 Burners with a grill and a 12" electric griddle - 15 Amp

circuit protection

4 Burners with a wok- 10 Amp circuit protection

4 Burners with a 24" electric griddle -30 Amp circuit

protection, 240VAC

C

B

A

Figure 12: Low Back Attachment

English 13

Page 16

Low Back and Island Trim Model Numbers

Cooktop Size/Type 12” Low Back Island Trim*

24” Griddle

24” Wok

30”

36”

48”

*Requires a minimum of 12” horizontal clearance between back of appliance and combustible materials.

PC24LB

GP24LBS

PC30LB

GPS36LBS

GPS48LBS

PC24IT

GP24ITS

PC30IT

GPS36ITS

GPS48ITS

Step 7: Burner Test and Adjustment

Install any loose components, such as burner caps and

grates that may have been removed earlier.

Be certain that burner caps seat properly into the burner

bases. Before testing operation of the appliance, verify that

the unit and the gas supply have been carefully checked for

leaks and that the unit has been connected to the electrical

power supply. Turn the manual gas shut-off valve to the

open position.

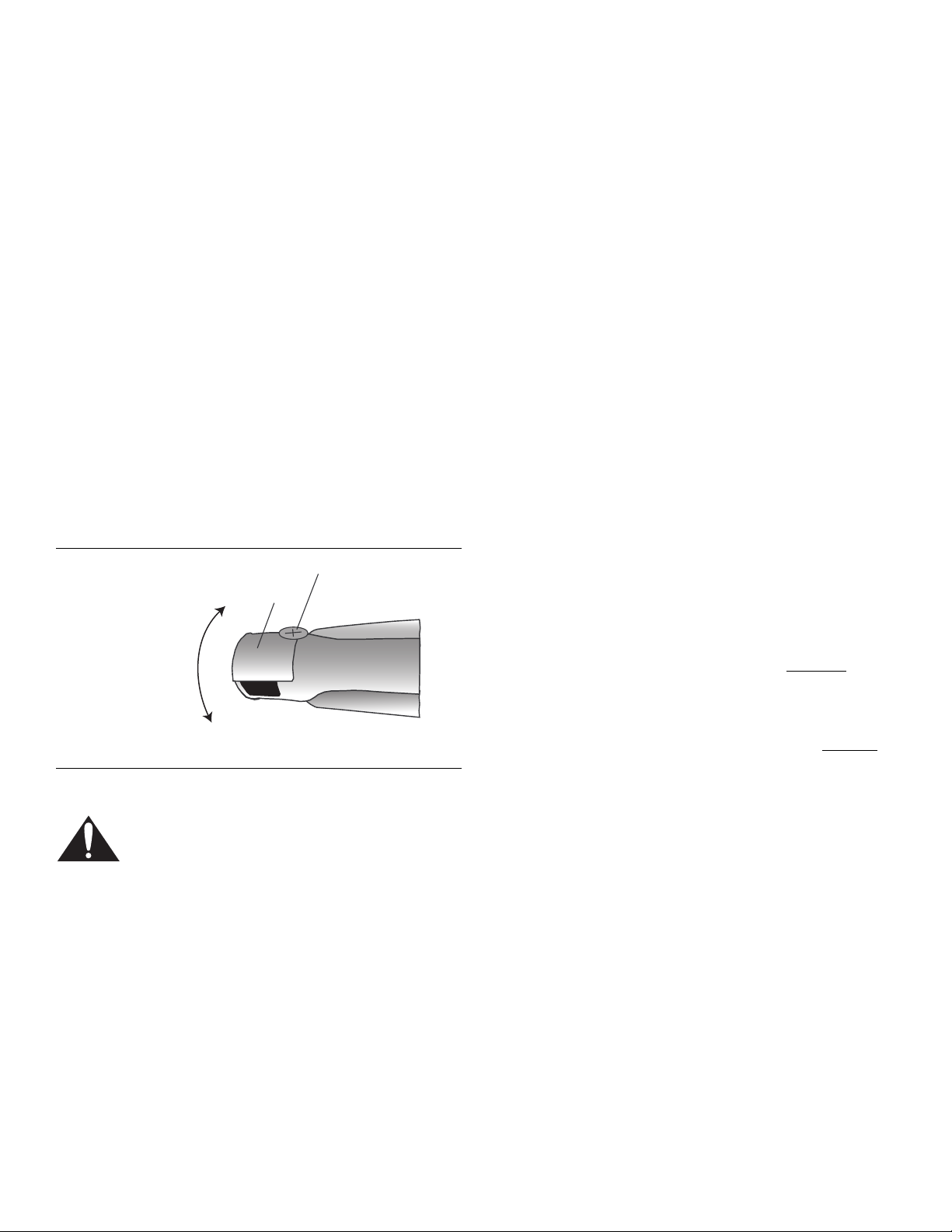

Test Cooktop Burners

Test Burner Ignition. Select a cooktop burner knob. Push

in and turn counterclockwise to HI. The ignitor/spark

module will produce a clicking sound. Once the air has

been purged from the supply lines, the burner should light

within four (4) seconds.

Yellow Flames:

Further adjustment is required.

Yellow Tips on Outer Cones:

Normal for LP Gas.

Soft Blue Flames:

Normal for Natural Gas.

If the flame is completely or mostly yellow, verify that the

regulator is set for the correct fuel. After adjustment,

retest.

Some orange-colored streaking is normal during the

initial start-up.

Allow unit to operate 4-5 minutes and re-evaluate before

making adjustments.

Test Flame: High Setting. Turn burner on to HI. See

Figure 13 for appropriate flame characteristics. If any of the

cooktop burners continue to burn mostly or completely

yellow, verify that the burner cap is positioned properly on

the burner base, then re-test. If flame characteristics do not

improve, call Thermador.

Test Flame: Low Setting. Turn burner on to LO. Verify

that the flame completely surrounds the burner. There

should be a flame at each burner port and there should be

no air gap between the flame and the burner. If any burners

do not carry over, call Thermador.

The two far left burners feature XLO, causing the flame to

cycle on and off when the knob is set to the XLO range.

This is normal operation.

Repeat the Ignition and Flame Test procedures described

above for each cooktop burner and the grill burner (if so

equipped).

Figure 13: Flame Characteristics

WHEN FLAME IS PROPERLY ADJUSTED:

• There should be a flame at each burner port.

• There should be no air gap between the flame and

burner port.

The gas grill uses a tube-style burner that has an air shutter

which allows adjustment to the amount of primary air inside

the burner tube.

Air shutters of tube-style burners are pre-adjusted at the

factory, and usually do not require readjustment except

under rare conditions such as installation at high altitude.

If grill burner/flame adjustment is required, go to the

procedure: “Flame Adjustment (if necessary)”.

English 14

Page 17

Flame Adjustment (if necessary)

Tube-style gas burners used in Thermador appliances

have air shutter systems which are similar to the illustration

in Figure 14, and can be adjusted using the following

method (unless adjustment is not recommended). It is

necessary to remove the burner from the appliance in order

to perform air-shutter adjustments.

• Loosen shutter screw(s) and turn shutter to new

position.

• Adjust the shutter to more-closed position if the flame

is lifting or blowing, or is not carrying over.

• Adjust the shutter to more-open position if the flame is

too yellow. (See Figure 14.)

• Retighten the shutter screw(s).

• After adjustment, reinstall the burner and perform

flame evaluation. The air shutter must fit over the

orifice hood for proper operation of the burner.

• Repeat procedure as needed until flame characteristics

are acceptable. (See Figure 13.)

Screw

More Open:

Less Yellow Flame

Air

Shutter

Installer Checklist

Final Check List

• Cooktop correctly positioned in countertop recess.

• Specified clearances maintained to cabinet surfaces.

• Burner caps positioned properly on burner bases.

• All packaging material removed. (NOTE: Wok models

have tie-down straps around the burner, which must be

removed before using the appliance.)

• Island Trim or Backguard attached according to

instructions.

• The griddle/ grill plate tilted slightly forward. (See “Grill/

Griddle Tilt Adjustment (not all models)” on page 11.)

Gas Supply

• Connection: 1/2" NPT with a minimum 3/4" diameter

flex line.

• If converting from natural to LP gas, refer to LP

Conversion Instructions for details.

• Manual gas shut off valve installed in an accessible

location (without requiring removal of appliance).

• Unit tested and free of gas leaks.

Electrical

More Closed:

Less Blue Flame

More Carryover

Less Lifting or Blowing

Figure 14: Air Shutter Adjustment (if necessary)

WARNING

Burner adjustments must be performed by a

qualified technician. Improper adjustments may

cause harmful by-products or void the

appliance’s warranty.

Allow burners to cool before attempting to

remove them!

Call Thermador if:

1. Any of the burners do not light.

2. Any of the burners continue to burn yellow.

• For models with the 12" electric griddle, a polarized

and grounded 120VAC receptacle with 15 AMP

current protection is provided for service cord

connection.

• For models with the 24" electric griddle, a properly

grounded, 240 VAC service connection with 30 AMP

over current protection is provided.

Operation

• All internal packing materials removed. (Check below

grates and grill pans.)

• Bezels centered on burner knobs, and knobs turn

freely.

• Purge air from gas system by operating one of the top

burners for several minutes.

• Each burner lights satisfactorily, both individually and

with other burners operating.

• Burner grates are correctly positioned.

Installer

• Give CARE and USE MANUAL and INSTALLATION

INSTRUCTIONS to your customer.

over

English 15

Page 18

To Clean and Protect Exterior Surfaces

The stainless steel surfaces may be cleaned by wiping with

a damp soapy cloth. Any mild glass cleaner will remove

fingerprints and smears.

Follow all cleaning by rinsing with clear water. Wipe dry

with a clean soft cloth to avoid water marks. For

discolorations or deposits that persist, use a non-scratching

household cleanser or stainless steel polishing powder with

a little water and a soft cloth. For stubborn cases, use a

plastic scouring pad or soft bristle brush together with

cleanser and water. Rub lightly in direction of polishing

lines or "grain" of the stainless finish. Avoid using too much

pressure which may mar the surface.

Use a stainless steel cleaner/polish to protect the finish and

maintain appearance.

DO NOT allow deposits to remain for long periods of time.

DO NOT use ordinary steel wool or steel brushes. Small

bits of steel may adhere to the surface causing rust.

DO NOT allow salt solutions, disinfectants, bleaches or

cleaning compounds to remain in contact with stainless

steel for extended periods. Many of these compounds

contain chemicals which could prove harmful. Rinse with

water after exposure and wipe dry with a clean cloth.

English 16

Page 19

Page 20

Table des matières

Instructions de sécurite . . . . . . . . . . . . . . . . . . . . . . .2

Avant de comencer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Information importante à propos de l’installation . .3

Chapitre 1 : Exigences de ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapitre 2 : Préparation de l’emplacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapitre 3 : Déballage, manutention et mise en place et fixation de la table de cuisson . . . . 12

Chapitre 4 : Exigences pour l'alimentation du gaz et raccordement . . . . . . . . . . . . . . . . . . . . 12

Chapitre 5 : Exigences pour l’alimentation électrique, le branchement et la mise à la terre . . 13

Chapitre 6 : Installation de la plaque de protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapitre 7 : Test et réglage de brûler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Liste de vérification pour l’installateur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Nettoyage et protection des surfaces extérieures .17

Cet appareil électroménager de Thermador est fait par

We look forward to hearing from you!

Nous attendons de vos nouvelles !

This Thermador Appliance is made by

BSH Home Appliances Corporation

BSH Home Appliances Corporation

5551 McFadden Ave.

5551 McFadden Ave.

Huntington Beach, CA 92649

Huntington Beach, CA 92649

Questions?

Questions ?

1-800-735-4328

1-800-735-4328

www.thermador.com

www.thermador.com

Page 21

Pour les installations au Massachusetts :

1. L’installation doit être réalisée par un entrepreneur qualifié ou agréé, un plombier ou un installateur de gaz qualifié ou autorisé par l’État ou la région dans laquelle cet appareil est installé.

2. Le robinet d’arrêt de gaz doit être pourvu d’une poignée en « T ».

3. La longueur maximum autorisée du tuyau de gaz est de 91,4 centimètres (36").

AVERTISSEMENT

L’information fournie dans le présent manuel doit être très

rigoureusement respectée, sous peine d’incendie ou d’explosion

entraînant des dommages, des blessures ou la mort.

• Ne stockez pas et n’utilisez pas d’essence ou autres ou la

compagnie distributrice de gaz.

• SI VOUS SENTEZ UNE ODEUR DE GAZ :

• N’allumez aucun appareil.

• Ne touchez pas aux interrupteurs électriques.

• N’utilisez pas les téléphones du bâtiment.

• Appelez immédiatement votre compagnie de gaz de chez

un voisin. Suivez les instructions de la compagnie.

• Si vous n’arrivez pas à contacter la compagnie de gaz,

appelez les pompiers.

• L’installation et les réparations doivent être réalisées par un

installateur qualié, un centre de réparation agréé ou la

compagnie de gaz.

Français 1

Page 22

Instructions de sécurite

Instructions importants de sécurite

LIRE TOUTES LES INSTRUCTIONS AVANT DE PROCÉDER

APPROUVÉ POUR TOUT APPAREIL RÉSIDENTIEL

POUR UTILISATION RÉSIDENTILLE SEULEMENT

Avant de comencer

IMPORTANT : conserver ces instructions pour utilisation

par l’inspecteur en électricité local.

INSTALLATEUR : laisser ces instructions avec l’appareil

pour le propriétaire

PROPRIÉTAIRE : conserver ces instructions à des fins de

références.

AVERTISSEMENT

L’information fournie dans le présent manuel

doit être très rigoureusement respectée, sous

peine d’incendie ou d’explosion entraînant des

dommages, des blessures ou la mort.

le modèle et les numéros de série devrait être entré dans

les espaces à la rubrique AVANT D’EFFECTUER UN

APPEL DE SERVICE à la fin du guide d’utilisation et

d’entretien. Lorsque l'appareil est installé, il est difficile

d'accéder à l'information.

Veuillez lire toutes les instructions avant de poursuivre.

IMPORTANT : LES RÉGLEMENTATIONS LOCALES

VARIENT. L’INSTALLATION, LES BRANCHEMENTS

ÉLECTRIQUES, LES RACCORDEMENTS AU GAZ ET LA

MISE À LA TERRE DOIVENT SATISFAIRE À TOUTES

LES RÉGLEMENTATIONS APPLICABLES.

Alimentation électrique :

Modèles 60,9 cm (24 po)

avec wok : 120 VAC, 60 Hz., 1 Ph., circuit de 10 A

avec grille : 240 VAC, 60 Hz., 1 Ph., circuit de 30 A

Modèle 76,2 cm (30 po)

Brûleurs 4 : 120 VCA, 60 Hz, monophasé, circuit de 10 A

Une installation, un réglage, une modification,

une réparation ou un entretien adéquat peuvent

entraîner des blessures ou des dégâts

matériels. Consultez le présent manuel. Pour de

l’information supplémentaire ou de l’assistance,

consultez un installateur qualifié, un centre de

réparation, le fabricant (revendeur) ou la

compagnie distributrice de gaz.

Remarque :

Cette table de cuisson N’EST PAS conçue pour les

maisons mobiles ni pour les véhicules récréatifs.

NE PAS installer ce table de cuisson dehors.

Fiche signalétique

Modèles de tables de cuisson :

La plaque de caractéristiques indique le modèle et le

numéro de série de votre table de cuisson ou de votre wok.

Elle est placée sur le dessous du châssis de la table de

cuisson ou du wok, près du raccord d’arrivée de gaz et du

cordon d’alimentation électrique. Cette information est

requise par le Service à la clientèle. Avant que l'installation,

Modèles de 91,4 cm (36 po)

Brûleurs 6 : 120 VCA, 60 Hz, monophasé, circuit de 10 A

avec gril : 120 VCA, 60 Hz, monophasé, circuit de 10 A

avec grille électrique 12 po : 120 VAC, 60 Hz, monophasé,

circuit de 15 A

Modèles de 1,22 m (48 po)

Brûleurs 6 avec gril : 120 VCA, 60 Hz, monophasé, circuit

de 10 A

Brûleurs 6 avec grille électrique 12 po : 120 VCA, 60 Hz,

monophasé, circuit de 15 A

Brûleurs 4 avec grille électrique 12 po et gril : 120 VAC, 60

Hz, monophasé, circuit de 15 A

Brûleurs 4 avec wok : 120 VCA, 60 Hz, monophasé, circuit

de 10 A

Brûleurs 4 avec grille électrique 24 po (avec grille

électrique 24 po) : 240 VAC, 60 Hz., 1 Ph., circuit de 30 A

Alimentation en gaz :

Gaz naturel : 14,9 mb (6 po) min. à 34,9 mb (14 po) max. à

la colonne d’eau.

Gaz propane : 27,4 mb (11 po) min. à 34,9 (14 po) max. à

la colonne d’eau).

Français 2

Page 23

AVERTISSEMENT

Coupez l’électricité avant d’installer l’appareil.

Avant de remettre (ON) l’électricité, assurezvous que toutes les commandes sont à la

position OFF.

Tous les brûleurs scellés sont cotés à 15 000 Btu/h (*13

000Btu/h pour LP). *Tous les modèles, sauf celui avec la

grille 24 po, sont convertibles au gaz propane/LP à l’aide

du nécessaire de conversion.

IMPORTANT

• Une plaque de protection doit être mise en place

lorsque le dégagement horizontal entre les matériaux

combustibles et le bord arrière de la table de cuisson

est de moins de 30,5 cm (12’’). La plaque de protection

basse Thermador est à commander séparément et doit

être installée à l’arrière de la table de cuisson. Pour les

installations en îlot avec un dégagement de plus de

30,5 cm (12’’), un que l’installation des conduites rpond

aux exigences locales.

• Assurez-vous que l’appareil correspond au type de gaz

utilisé sur le lieu d’installation. Reportez-vous au

“Chapitre 4 : Exigences pour l'alimentation du gaz et

raccordement” on page 12 avant de poursuivre

l’installation.

Information importante à propos de l’installation

Cet appareil est certié ACNOR à des ns de fonctionnement

sécuritaire jusqu’à une élévation de 10 200 pi sans

modication. Exception :

propane, l’appareil doit être converti selon les instructions

de conversion au LP.

Il est fortement recommandé

ventilation adaptée au-dessus de cet appareil (voir

“Chapitre 1 : Exigences de ventilation”).

Vériez la réglementation locale applicable à la construction

pour connaître la méthode approprié d’installation de

l’appareil. À défaut de réglementation, l’appareil doit être

installé conformément aux versions actuelles du Code

national du gaz combustible no Z223.1 et du Code national

de l’électricité ANSI/NFPA70 ou aux Codes d’installation

pour les appareils à gaz CAN 1-B149.1 et .2 et au Code

électrique canadien C22.1, première partie.

Cet appareil est équipé d’un système d’allumage

intermittent qui allume et éteint les deux brûleurs de

gauche lorsqu’ils sont réglés sur ExtraLow.

pour l’utilisation avec le gaz

d’installer une hotte de

MISE EN GUARDE

(1) Si l’appareil est alimenté au gaz propane,

assurez-vous que le réservoir de propane est

équipé de son propre détendeur en plus du

détendeur fourni avec l’appareil. La pression

maximum d’arrivée du gaz dans cet appareil ne

doit pas dépasser les 34,9 millibars (14 pouces

à la colonne d’eau) à partir du détendeur du

réservoir de propane.

(2) Cet appareil est conçu pour un usage

culinaire. Pour des raisons de sécurité, ne

l’utilisez jamais pour chauffer une pièce.

À cause de la chaleur intense produite par cet appareil, il

faut porter une attention particulière à l’installation de la

hotte et des conduits an de s’assurer qu’ils répondent aux

codes de construction locaux.

Cet appareil est conforme avec une ou plusieurs des

normes suivantes :

• UL 858, norme pour la sécurité des cuisinières

électriques domestiques

• UL 923, norme pour la sécurité des appareils de

cuisson à micro-ondes

• UL 507, norme pour les ventilateurs électriques

• ANSI Z21.1, norme nationale américaine pour les

appareils de cuisson à gaz domestiques

• CAN/CSA-C22.2 n°113-M1984 ventilateurs et hottes

• CAN/CSA-C22.2 n° 61-M89 cuisinières domestiques

Français 3

Page 24

MISE EN GARDE

Afin d'éliminer les risques de brûlures ou

d’incendie provoqués par la chaleur, il est

conseillé d’éviter d’installer des armoires audessus des appareils.

d’installer une hotte plus large que la table de cuisson

pour améliorer les performances de ventilation.

• Pour les installations en îlot, la largeur de la hotte

devrait dépasser d'au moins 7,62 cm (3 po) des deux

côtés de la table de cuisson de l’appareil.

Il incombe au propriétaire et à l’installateur de déterminer si

des exigences et/ou normes additionnelles s’appliquent

pour une installation spécique.

Enlever tout le matériel d’emballage et le ruban adhésif

avant d’utiliser l’appareil. Détruire le matériel d’emballage

une fois l’appareil déballé. Ne jamais laisser les enfants

jouer avec ce matériel d’emballage.

Chapitre 1 : Exigences de ventilation

Il est fortement recommandé d’installer une hotte de

ventilation appropriée au-dessus del’appareil. Une

ventilation par contre-tirage ne devrait pas être utilisée. Le

tableau suivant comprend des recommandations

concernant la capacité du ventilateur et les options de

ventilation de la hotte pour toutes les surfaces de cuisson

Thermador.

À cause de la chaleur intense produite par cet appareil, il

faut porter une attention particulière à l’installation de la

hotte et des conduits afin de s’assurer qu’ils répondent aux

codes de construction locaux.

Ne pas installer un combiné hotte/ four à micro-ondes audessus des surfaces de cuisson. Ces appareils n’assurent

pas une ventilation appropriée et ne conviennent pas aux

surfaces de cuisson.

Choix du modèle de hotte et de ventilateur

• Pour les installations murales, la largeur de la hotte

doit être au moins égale à celle de la table de cuisson

de l’appareil. Si l’espace le permet, il est souhaitable

Emplacement de la hotte

• Pour une meilleure élimination des fumées, le bord

inférieur dela hotte doit être placé à une distance de

91,4 cm (30 po) au dessus de la table de cuisson. (Voir

Figure 1).

• Si la hotte contient des matériaux combustibles (ex. :

recouvrement en bois), elle doit être à une distance de

91,4 cm (36 po) ou plus au-dessus de la table de

cuisson.

AVIS :

La plupart des hottes contiennent des composantes

combustibles qui doivent être prises en considération lors

de la planification de l'installation.

Apport d’air

• Un important volume d’air étant nécessaire pour la

ventilation, il est recommandé de prévoir un apport

d’air de l’extérieur. Cet aspect revêt une importance

particulière dans les logements bien isolés et très

étanches.

• Il est conseillé de consulter un entrepreneur en

chauffage et en climatisation.

Remarque :

Les hottes de ventilation et les ventilateurs sont conçus

pour une seule conduite murale. Certaines réglementations

locales du secteur du bâtiment exigent toutefois une

double conduite. Consultez les normes applicables et les

autorités municipales avant de commencer les travaux an

de vous assurer que l’installation des conduites répond aux

exigences locales.

Français 4

Page 25

Largeur de

la surface de

cuisson

24”

30” 4 brûleurs 600 pi³/min

36”

Configuration de la

surface de cuisson

Plaque chauffante ou wok

de 24”

4 brûleurs avec grill ou

plaque chauffante

6 brûleurs 900 pi³/min

Minimum recommandé

Capacité du ventilateur*

600 pi³/min

800 pi³/min

Options de ventilation

Hotte murale Pro de 30”

Hotte à encastrement sur mesure de 30”

avec ventilateur optionnel

Hotte d’îlot de 42” avec ventilateur

optionneler

Hotte murale Pro de 30” ou 36”

Hotte à encastrement sur mesure de 30” ou

36” avec ventilateur optionnel

Hotte d’îlot de 42” avec ventilateur optionnel

Hotte murale Pro de 36” ou 42”

Hotte à encastrement sur mesure de 36”

avec ventilateur optionnel

Hotte d’îlot de 42” ou 48” avec ventilateur

optionnel

4 brûleurs avec combo

gril/plaque chauffante,

48”

Notes importantes :

• Nous recommandons l’utilisation d’une hotte murale ou d’une hotte d’îlot Thermador Professional avec les surfaces

de cuisson Thermador

• Consultez le www.Thermador.com pour une sélection complète des options de ventilation, des ventilateurs et des

accessoires.

• * Pour les surfaces de cuisson au gaz à haut rendement (60 000 BTU ou plus), une ventilation minimale d’un (1) pi³/

min par 100 BTU est recommandée. Si la surface de cuisson est munie d’un gril ou d’une plaque chauffante, ajoutez

200 pi³/min à la capacité de ventilation estimée. Ajoutez 400 pi³/min si la surface de cuisson est munie d’une plaque

chauffante ou d’un wok de 24”. Une plus grande capacité de ventilation pourrait s’avérer nécessaire pour de plus

longs conduits d’aération.

• Pour les hottes d’îlot, il est recommandé d’utiliser une largeur de hotte qui excède la largeur de la surface de cuisson

de 6” (chevauchement de 3” de chaque côté de la surface de cuisson).

• pi³/min = pied cube par minute (capacité standard de ventilation).

Plaque chauffante ou wok

de 24”

6 brûleurs avec grill ou

plaque chauffante

Chapitre 2 : Préparation de l’emplacement

1. Pour garantir des résultats professionnels, les ouvertures dans l’armoire et dans l'espace de travail doivent être effectuées par du personnel qualié.

2. Les dégagements requis sont indiqués à la Figure 1. Les mêmes dégagements s’appliquent auxinstallations enîlot, excepté pour les armoires suspendues qui doivent laisser un espace sufsamment grand pour y loger la hotte de l’îlot.

3. La table de cuisson est conçue pour être accrochée au

plan de travail par ses brides latérales. Le plan de

travail doit toutefois être sufsamment solide pour porter

ce appareil. Il sera éventuellement nécessaire d’ajouter

1000 pi³/min

1100 pi³/min

un tasseau de chaque côté (voir Figure 2) ou 2x4

montants d’angle (voir Figure 3 et Figure 4 et la vue

Éclatée A). L’autre possibilité est de construire un plan

de support pour y installer la table de cuisson.

4. La table de cuisson peut être installée sur plusieurs

positions, avec la partie frontale au même niveau que

le plan de travail ou en projection avant, selon la

profondeur de ce plan (voir Figure 5, vue latérale de la

table de cuisson; voir Figure 3, Figure 4, Figure 6 et

Figure 7 pour les autres positions de montage).

5. Les arrivées d’électricité et de gaz doivent se trouver

dans une zone accessible sans avoir à enlever la table

de cuisson. Le cordon d’alimentation électrique et le

Hotte murale Pro de 48” ou 54”

Hotte à encastrement sur mesure de 48”

avec ventilateur optionnel

Hotte d’îlot de 54” avec ventilateur optionnel

Français 5

Page 26

raccord du tuyau de gaz de l’appareil sont placés dans

la partie arrière gauche sous la table de cuisson (sauf

sur les modèles avec grille électrique 24 po où le

cordon d’alimentation est situé au centre), tel

qu'indiqué aux Figure 5 et Figure 9.

6. La profondeur maximum des armoires suspendues de chaque côté de la hotte est de 33 cm (13 po).

Un dégagement minimal de 91,4 cm (36 po) est nécessaire

entre le dessus de la table de cuisson et le dessous d’une

armoire non protégée. Une distance de 30 po doit être

assurée lorsque le bas des armoires en bois ou en métal

est protégé par un matériau ignifuge d’une épaisseur d'au

moins 6,35 mm (1/4 po) recouvert d’une feuille d’acier n

o

28

MSG de la même épaisseur, de 0,4 mm (0,015 po) d’acier

inoxydable, de 0,6 mm (0,024 po) d’aluminium ou de 0,5

mm (0,02 po) de cuivre. Les matériaux ignifuges portent la

marque :

UNDERWRITERS LABORATORIES INC. CLASSIFIED

MINERAL AND FIBER BOARDS SURFACE BURNING

CHARACTERISTICS,

(panneaux de bres et minéraux classés, caractéristiques

d’inammation des surfaces), suivie des taux de progression

des flammes et des fumées. Ces désignations sont

indiquées par « FHC » (Flame Spread/Smoke Developed –

Progression des flammes/Production de fumée). Les

matériaux ayant un taux « O » de progression de flammes

sont ignifuges. Les réglementations locales peuvent

autoriser d’autres taux de progression des flammes.

7. Si la distance entre un matériau combustible et le

bord arrière de la table de cuisson au-dessus de la

surface de travailest de moins de 30,5 cm(12’’), on doit

obligatoirement installer une plaque de protection

basse Thermador (voir Chapitre 6). Si la distance du

matériau combustible est de plus de 30,5 cm (12

po), on peut utiliser un enjoliveur Thermador pour îlot.

Installez la plaque de protection avant de glisser

l’appareil dans sa position d’installation dénitive.

8. Dénissez la ligne centrale de l’emplacement destiné à

la table de cuisson. Elle doit correspondre au centre de

la hotte de ventilation suspendue.

9. Découpez les ouvertures pour les installations

suivantes :

• Installation murale, voir Figure 3.

• Installation en îlot, voir Figure 4.

10. Pour les modèles avec une grille, xer la bande de

mousse sur le plan de travail, centrée le long de

l’arrière à environ 1/16 po du bord.

11. Pour l’installation de la table de cuisson de 1,22 m (48

po) sur les deux tiroirs chauffe-plats côte à côte de

Thermador (modèle WD24), reportez-vous à la

Figure 8. Si vous réalisez l’installation conformément à

la Figure 8, le bord gauche de la table de cuisson sera

aligné avec le bord gauche du tiroir chauffe-plats

gauche et le bord droit de la table de cuisson sera

aligné avec le bord droit du tiroir chauffe-plats droit.

Pour obtenir un alignement différent, vous pouvez

modier la distance horizontale de 4,76 cm (1-7/8 po)

entre les découpes des tiroirs chauffe-plats. Vous

devez toutefois conserver une distance d’au moins

2,85 cm (1-1/8 po) pour éviter les interférences entre

les tiroirs chauffe-plats. Montez un coude de 90º sur le

tuyau d’arrivée de gaz de la table de cuisson. Tous les

autres dégagements au-dessus du plan de travail

doivent être maintenus comme indiqués à la Figure 1.

Tel que déni dans le « Code national du gaz

combustible » (Version actuelle des normes ANSIZ223.1/

NFPA54).

Remarques :

• Si vous avez d’un ou des deux côtés des parois

latérales pleines d’armoires, vous devrez encocher le

coin avant de l’armoire pour l’adapter à l’encoche du

plan de travail et laisser l’espace à la partie frontale de

la table de cuisson (voir vue Éclatée A, Figure 3 et

Figure 4).

• Si vous construisez un plan de support, les côtés ou le

bas de la découpe peuvent être en matériau plein

combustible ou non combustible. Si le bas est plein,

prévoyez une découpe de 20,32 x 20,32 cm (8 po x 8

po) dans le coin arrière gauche de ce plan. Vous aurez

ainsi l’espace nécessaire à l’arrivée de gaz et au

cordon d’alimentation, et cela vous permettra de voir la

plaque de caractéristiques du produit.

• Pour les modèles ayant une grille 24 po avec cordon

d’alimentation au centre, il faut prévoir 2 pièces

séparées (support) pour permettre un dégagement au

centre pour passer le cordon.

• L’appareil ne doit jamais se trouver à proximité de

matériaux combustibles, d’essence et d’autres produits

inammables (vapeurs ou liquides).

• L’air de combustion et de ventilation arrivant à

l’appareil doit pouvoir circuler librement.

Français 6

Page 27

.

s

MUR

.

Profundeur

max. des

armoires

suspendues :

33 cm (13 po)

45,7 cm

(18 po) min.

7,6 cm (3 po) min.

des deux côtés

30 po à 36 po hotte large pour wok ou grille de 24 po

30 po à 36 po hotte large pour table de cuisson de 30 po

à 42 po hotte largepour table de cuisson de 36 po

36 po

à 60 po hotte large pour table de cuisson de 48 po

48 po

76,2 cm = 30 po

91,4 cm = 36 po

HOTTE DE VENTILATION

106,7 cm = 42 po

121,9 cm = 48 po

76,2 cm (30 po) min. entre le dessou

la hotte et la table de cuisson

(91,4 cm (36 po) ou plus si la hotte

contient des matériaux

combustibles ).

Distance horizontale

min. du mur arriére :

0 cm (0 po) avec

plaque de protection,

30,5 cm (12 po) avec

d’enjoliveur pour îlot

Table de cuisson

"A"

MUR

Côtés 0 cm (0 po)

Matériaux

Combustible

Distance min. de

91,4 cm (36 po)

des matériaux

combustibles

de la table de

cuisson

Bas 0 cm (0 po)

Figure 1 : Dégagements

Français 7

Page 28

Vis à tête

fraisée

Voir vue éclatée A

B

D

59, 2 cm

(23-5/16 po)

B

Figure 2 : Installation de supports latéraux (des deux côtés)

Hotte de ventilation

Exigences de largeur

Îlot – hotte large de 42" ou 48" pour

wok ou grille de 24"

Îlot – hotte large de 42" ou 48" pour

36" table de cuisson

Îlot – hotte large de 54" ou 60"

pour 48" table de cuisson

Figure 3 : Installation murale avec rebord de plan de travail

19 mm min.

Voir vue éclatée A

57,9 cm

(22-13/16 po)

(3/4 po) Min.

D

Français 8

Figure 4 : Installation en îlot (sans rebord de plan de travail)

Page 29

C

B

19,5 cm

(7-11/16 po)

Détail de l’encoche en coin

Éclatée A : Vue éclatée A (Face frontale de l’armoire)

Montant

d’angle 2 x 4

Wok/Grille 24 po Cuisson 30 po Cuisson 36 po Cuisson 48 po

A 24-3/4 po 29-7/8 po 35-7/8 po 47-7/8 po

B 3/8 po 3/8 po 3/8 po 13/16 po

C 0 mm (0 po) (Panneau de commande projeté de 3,2 cm (1-1/4” po) devant le panneau frontal de l’armoire de

support), 17 mm (11/16 po) (Encoche nécessaire pour armoire de support standard de 61 cm (24 po) de

profondeur. Panneau de commande projeté de 1,4 cm (9/16 po) devant le panneau frontal de l’armoire de

support) 3,2 cm (1-1/4 po) (Panneau de commande au ras du panneau frontal de l’armoire – armoire de

support d’une profondeur min. de 62,4 cm [24-9/16 po] requise)

D 24 po 29-1/8 po 35-1/8 po 46-1/4 po

Français 9

Page 30

3.2 cm

(1-1/4 po)

* Une plaque de protection basse est nécessaire si la

distance horizontale entre l’arrière de la table de

cuisson et les matériaux combustibles est inférieure à

30,5 cm (12’’). Avec plus de 30,5 cm (12’’), il est

possible d’utiliser l’enjoliveur pour îlot.

64,5 cm

(25-3/8 po)

13.3 cm (5-1/4 po) À LA LIGNE

CENTRALE DE L’ARRIVÉE DE GAZ

59,2 cm

(23-5/16 po)

Panneau frontal de l’armoire pour installation avec

panneau de commande projeté

Panneau frontal de l’armoire pour installation avec

tableau de commande au ras

12,7

30,5 cm

mm

(12 po)

(1/2 po)

Bride

latérale

19,4 cm

(7-5/8 po)

Encoche de

17 mm (11/16 po)

14 mm

(9/16 po)

Sur la figure, l’avant est projeté de 14 mm (9/16 po)

vers l’extérieur avec un support standard de 60,9 cm

(24 po) de profondeur.

Figure 6 : Projection devant l’armoire

Figure 5 : Vue latérale de la table de cuisson

Encoche de 3,2 cm de

profondeur (1-1/4 po)

Avant au ras des armoires : profondeur d’armoire de

62,4 cm (24-9/16 po) minimum.

Figure 7 : Au ras du panneau frontal de l’armoire

Français 10

Page 31

Minimum 19 mm (3/4" )

21 mm

cm

, 5

17

1

cm

,9

57

2-

(2

22,9 cm (9")

7 cm (2-3/4") Distance verticale entre les

découpes (Voir vue latérale pour les

supports en bois)

Figure 8a : Installation d’une table de cuisson de 121,9 cm

(48po) sur deux tiroirs chauffe-plats côte à côte, modèle

)

6"

3/1

1

Déco

-1/4

(46

19,52 cm

up

WD

57,2 cm

(22-1/2")

")

(7-11/16")

u

Déco

2

e

4

2

D

W

57,2 cm

(22-1/2")

4,8 cm (1-7/8")

Distance horizontale

entre les découpes

pe

4

)

/1 6"

(13

(0" to

1-1/4")

0 - 32 mm

(Voir Fig. 4

et cote C

dans le

tableau)

WD24

Support en

contreplaqué

(19,52 cm)

7-11/16”

6,9 c m (2-3/4")

minimum

entre

découpes

ARRIÉRE

Installez un tasseau

supplémentaire le

longd u bo rd avant

de la découpe

Figure 8b : Installation d’une table de cuisson de 121,9 cm

(48po) sur deux tiroirs chauffe-plats côte à côte, modèle

WD24 (Vue latérale)

Plaque de caractéristiques du

produit/ Étiquette de série

Les enduits de joints

doivent être résistants au

gaz propane.

P24WOK 1/2" NPT

7,6 cm (3po) Min.

Cordon

Tuyau flexible de

19 mm (3/4 po)

d’alimentation

ou

conduit

Prise murale à 3 fiches, avec prise de terre,

connectée à un circuit d’alimentation électrique

adéquatement polarisé et relié à la terre de 120

VCA, 10 A, (*15 A) monophasé, 60 Hz.

Un robinet d’arrêt doit être installé à

l’extérieur de l’appareil, à un endroit

accessible de l’avant, dans le but de

pouvoir couper l’arrivée de gaz.

Arrivée de

gaz

REMARQUE : ceci ne s’applique pas aux

modèles 240VAC avec grille électrique 24 po.

Figure 9 : Partie frontale inférieure de l’appareil

Toutes les pièces fournies par l’installateur doivent satisfaire aux réglementations locales.

*Alimentation électrique 15A, 120VAC pour les modèles 36 et 48 po avec grille électrique 24 po.

**Alimentation électrique 30A, 240VAC pour les modèles avec une grille électrique 24 po.

Français 11

Page 32

Chapitre 3 : Déballage, manutention et mise en place et fixation de la table de cuisson

MISE EN GARDE

Un équipement adapté manipulé par du

personnel expérimenté doit être utilisé pour

déplacer l’appareil afin de ne pas l’endommager

et d’éviter les blessures. L’appareil est lourd et

doit faire l’objet d’une manutention adéquate.

Ajustement de l'inclinaison de le gril ou la plaque de cuisson

Assurez-vous que le gril ou la plaque de cuisson est bien

ajusté en versant deux cuillerées à soupe d’eau à l’arrière

du gril ou de la plaque chauffante. L'eau devrait lentement

couler dans le bac à graisse. Puis, ajustez les deux vis

situées à l’arrière, sous la plaque. Commencez par un

demi-tour dans le sens contraire des aiguilles d'une

montre. Les corrections subséquentes doivent être faites

au quart de tour jusqu'à ce que l'eau coulelement dans le

bac à graisse.

Important

• Assurez-vous que l’appareil sur correspond au type de

gaz utilisé sur le lieu d’installation. Reportez-vous au

Chapitre 4 avant de poursuivre l’installation.

• Posez la plaque de protection avant de glisser

l’appareil sur sa position finale. Voir Chapitre 6.

1. Retirez l’emballage externe et les matériaux d’emballage de la palette d’expédition. Assurez vous d'avoir tous les articles qui composent la tableau de cuisson avant de poursuivre.

2. Retirez les grilles en fonte, les chapeaux des brûleurs et la grille du gril (le cas échéant) pour réduire le poids de l’appareil.

Remarque :

Laisser la mousse à côté adhésif surles surfaces en

métalbrossé an de protéger le ni des égratignures jusqu’à

ce que la surface de cuisson soit en position finale.

3. Soulevez la table de cuisson et placez-la dans l’ouverture. Prenez garde à ne pas pincer le cordon d’alimentation ni l’arrivée de gaz. Faites attention de ne pas égratigner la plaque chauffante.

4. Assurez-vous que le cordon d’alimentation peut bouger librement et qu’il n’est pas tendu.

5. Pour un rendement adéquat, la surface de cuisson doit être de niveau.

6. Le gril (si l’appareil en est équipé) a été nivelé brûleurs et la grille du gril (le cas échéant) pour lors de l’assemblage. Ne tentez pas d’en modier la mise à niveau.

7. Remplacez les grilles et les cuvettes des brûleurs, le gril et la plaque (le cas échéant). Assurez-vous que les chapeaux des brûleurs sont correctement posés dans leurs bases.

Chapitre 4 : Exigences pour l'alimentation du gaz et raccordement

Les tables de cuisson sont préparées à l’usine avant

expédition pour être alimentées par du gaz naturel.

Doivent être convertis pour utilisation avec propane

(surface de cuisson). Assurez-vous que le type de gaz

utilisé sur le lieu d’installation correspond au type de

gaz utilisé par l’appareil. Si le lieu nécessite une

conversion du gaz naturel au propane (LP), communiquer

avecle marchand oùl’appareila été acheté ou avec

Thermador. La trousse de conversion des surfaces de

cuisson Professional de cette série est le modèle

Thermador PLPKIT. Suivez toutes les instructions du

PLPKIT pour convertir correctement le détendeur de gaz et

effectuer le réglage des robinets de gaz. La conversion sur

site doit obligatoirement être réalisée par du personnel

qualié.

Cet appareil est certifié ACNOR à des fins de

fonctionnement sécuritaire jusqu’à une élévation de 10 200

pi sans modication. Exception :

propane, l’appareil doit être converti selon les instructions

de conversion au LP. Consulter les instructions de

conversion LP pour plus de détails.

Exigences pour le gaz naturel

Connexion d’entrée : 1/2 po NPT ( min. 3/4 po de diamètre,

conduit souple)

Pression d’alimentation : 6 po min. à 14 po max, colonne

d’eau (14,9 à 34,9 mb)

Pression du distributeur : 5 po, colonne d’eau (12,5 mb)

Exigence pour le gaz propane

Connexion d’entrée : 1/2 po NPT ( min. 3/4 po de diamètre,

conduit souple)

Pression d’alimentation : 11 po min. à 14 po max, colonne

d’eau (27,4 à 34,9 mb)

Pression du distributeur : 10 po, colonne d’eau (24,9 mb)

pour l’utilisation avec le gaz

Français 12

Page 33

AVERTISSEMENT

Si une trousse de conversion au gaz est utilisée,

doit être installé par un technicien qualié

conformément aux instructions du fabricant et

selon les exigences et codes applicables ayant

juridiction. Si l’information contenue dans ces

instructions n’est pas suivie, il peut en résulter

un risque d’incendie, d’explosion ou de

production de monoxyde de carbone, causant

des dommages à la propriété, des blessures ou

la mort. L’agence de service qualié est

responsable de l’installation appropriée de ce

nécessaire. L’installation n’est pas adéquate ni

complétée tant que le fonctionnement de

l’appareil converti n’est pas vérié tel qu’il est