Thermador PCD484EE Installation Manual

INSTALLATION MANUAL

For Thermador Professional® Cooktops

MANUEL D'INSTALLATION

Des tables de cuisson Thermador Professional

®

MANUAL DE INSTALACIÓN

Para Parrillas de Thermador Professional®

Models/

Modèles/

Modelos:

PCG24

PCD24

PCG30

PCG36

PCG48

PCD48

Table of Contents

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Before you Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Important Installation Information . . . . . . . . . . . . . . .3

Step 1: Ventilation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Step 2: Cabinet Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Step 3: Unpacking, Moving, Placing and Anchoring the Cooktop . . . . . . . . . . . . . . . . . . . . . . 10

Step 4: Gas Requirements and Hookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Step 5: Electrical Requirements, Connection and Grounding . . . . . . . . . . . . . . . . . . . . . . . . . 12

Step 6: Backguard Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Step 7: Burner Test and Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Installer Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

To Clean and Protect Exterior Surfaces . . . . . . . . .16

This Thermador Appliance is made by

BSH Home Appliances Corporation

5551 McFadden Ave.

Huntington Beach, CA 92649

Questions?

1-800-735-4328

www.thermador.com

We look forward to hearing from you!

For Massachusetts Installations:

1. Installation must be performed by a qualified or licensed contractor, plumber or gas fitter qualified or licensed by the state, province or region where this appliance is being installed.

2. Shut-off valve must be a “T” handle gas cock.

3. Flexible gas connector must not be longer than 36 inches.

WARNING:

If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal injury or

death.

-- Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

-- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

-- Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

English 1

Safety Instructions

Important Safety Instructions

READ AND SAVE THESE INSTRUCTIONS

APPROVED FOR ALL RESIDENTIAL APPLIANCES

FOR RESIDENTIAL USE ONLY

IMPORTANT: LOCAL CODES VARY. INSTALLATION,

ELECTRICAL CONNECTIONS, GAS CONNECTIONS,

AND GROUNDING MUST COMPLY WITH ALL

APPLICABLE CODES.

Electrical Power Supply

Before you Begin

IMPORTANT: Save these Instructions for the Local

Electrical Inspector’s use.

INSTALLER: Please leave these Instructions with this unit

for the owner.

OWNER: Please retain these instructions for future

reference.

WARNING:

Improper installation, adjustment, alteration,

service or maintenance can cause injury or

property damage. Refer to this manual. For

assistance or additional information consult a

qualified installer, service agency, manufacturer

(dealer) or the gas supplier.

NOTE:

This Cooktop is NOT designed for installation in

manufactured (mobile) homes or for installation in

Recreational Park Trailers.

DO NOT install this appliance outdoors.

Data Rating Plate

Cooktop Models:

The data rating plate showing the model and serial

numbers of your Cooktop or Wok is located on the

underside of the Cooktop or Wok chassis near the gas inlet

connection and electric power cord. This information is

required if customer service is requested. Before

installation, the model and serial numbers should be

entered in the appropriate spaces in the "BEFORE

CALLING FOR SERVICE" section near the back of the

Care and Use Manual. After installation accessing the

information is difficult.

PLEASE READ ENTIRE INSTRUCTIONS BEFORE

PROCEEDING

24" Models:

with Wok - 120 VAC, 60 Hz., 1 Ph., 10 Amp circuit

with Griddle - 240 VAC, 60 Hz., 1 Ph., 30 Amp circuit

30'' Models:

4 Burners - 120 VAC, 60 Hz., 1 Ph., 10 Amp circuit

36" Models:

6 Burners - 120 VAC, 60 Hz., 1 Ph., 10 Amp circuit

with Grill - 120 VAC, 60 Hz., 1 Ph., 10 Amp circuit

with 12" Electric Griddle - 120 VAC, 60 Hz., 1 Ph., 15 Amp

circuit

48" Models:

6 Burners with Grill - 120 VAC, 60 Hz., 1 Ph., 10 Amp

circuit

6 Burners with 12" Electric Griddle - 120 VAC, 60 Hz., 1

Ph., 15 Amp circuit

4 Burners with 12" Electric Griddle and Grill - 120 VAC, 60

Hz., 1 Ph., 15 Amp circuit

4 Burners with Wok - 120 VAC, 60 Hz., 1 Ph., 10 Amp

circuit

4 Burners with 24" Electric Griddle - 240 VAC, 60 Hz., 1

Ph., 30 Amp circuit

Gas Supply

Natural Gas – 6” min. to 14” max. water column (14.9 mb

to 34.9 mb)

Propane Gas – 11”min. to 14”max. water column (27.4 mb

to 34.9 mb)

WARNING

Disconnect power before installing.

Before turning power ON, be sure that all

controls are in the OFF position.

All sealed burners are rated at 15,000 BTU/HR (*13,000

BTU/HR on LP). *All models, except 24” Griddle, are

convertible to LP/Propane gas using an accessory

conversion kit.

English 2

IMPORTANT

• A backguard must be utilized when there is less than a

12" horizontal clearance between combustible

materials and the back edge of the cooktop. The

Thermador Low Back backguard must be ordered

separately and installed at the rear of the cooktop. For

island installations and other installations with more

than 12" clearance, an optional stainless steel Island

Trim is available to cover the backguard mounting

flanges.

• Verify that the appliance is correct for the type of gas

being provided. Refer to “Step 4: Gas Requirements

and Hookup” on page 11 before proceeding with the

installation.

Important Installation Information

This appliance has been CSA certified for safe operation

up to an elevation of 10,200 ft. without any modifications.

Exception

converted per the LP Conversion Instructions.

It is strongly recommended

in conjunction with a suitable overhead vent hood. (See

“Step 1: Ventilation Requirements”.)

Check local building codes for the proper method of

appliance installation. Local codes vary. Installation,

electrical connections and grounding must comply with all

applicable codes. In the absence of local codes the

appliance should be installed in accordance with the

National Electric Code ANSI Z223.1 current issue and

National Gas Code ANSI/NFPA 70 – current issue. In

Canada, installation must be in accordance with the CAN

1-B149.1 and .2 – Installation Codes for Gas Burning

Appliances and/or local codes.

This appliance is equipped with an intermittent/interrupted

ignition device that cycles the two far left surface burners

on and off when in the ExtraLow setting.

: For use with Propane, the appliance must be

that this appliance be installed

CAUTION

(1) When connecting the unit to propane gas,

make certain the propane gas tank is equipped

with its own high-pressure regulator in addition

to the pressure regulator supplied with this unit.

The maximum gas pressure to this appliance is

not to exceed 14.0 inches water column (34.9

mb) from the propane gas tank regulator.

(2) This unit is designed as a cooking appliance.

Based on safety considerations, never use it for

warming or heating a room.

Due to the high heat of the cooktop burners, installing a

microwave oven with a ventilation system over the cooktop

is not recommended.

This appliance complies with one or more of the following

standards:

• UL 858, Standard for the Safety of Household Electric

Ranges

• UL 923, Standard for the Safety of Microwave Cooking

Appliances

• UL 507, Standard for the Safety of Electric Fans

• ANSI Z21.1 American National Standard for Household

Cooking Gas Appliances

• CAN/CSA-C22.2 No. 113-M1984 Fans and Ventilators

• CAN/CSA-C22.2 No. 61-M89 Household Cooking

Ranges

CAUTION

To eliminate risk of burns or fire caused by

reaching over heated surface units, cabinet

storage located above the surface units should

be avoided.

It is the responsibility of the owner and the installer to

determine if additional requirements and/or standards

apply to specific installations.

Remove all tape and packaging before using the appliance.

Destroy the packaging after unpacking the appliance.

Never allow children to play with packaging material.

Step 1: Ventilation Requirements

It is strongly recommended that a suitable exhaust hood be

installed above the appliance. Downdraft ventilation should

not be used. The following table indicates the ventilation

hood options and blower capacity guidelines that are

recommended for use with all Thermador cooktops.

Due to the high heat capability of this unit, particular

attention should be paid to the hood and duct work

installation to assure it meets local building codes.

Do not install a microwave oven/ ventilator combination

above the cooktop, as these types of units do not provide

English 3

the proper ventilation and are not suitable for use with the

cooktop.

Select Hood and Blower Models:

• For wall installations the hood width must, at a

minimum, equal the nominal width of the appliance

cooking surface. Where space permits, a hood larger in

width than the cooking surface may be desirable for

improved ventilation performance.

• For island installations the hood width should, at a

minimum, overhang the appliance cooking surface by

3" on each side.

Hood Placement:

• For best smoke elimination, the lower edge of the hood

should be installed 30" above the appliance cooking

surface. (See Figure 1).

• If the hood contains any combustible materials (i.e., a

wood covering), it must be 36"or greater distance

above the cooking surface.

NOTICE:

Most hoods contain combustible components which must

be considered when planning the installation.

Consider Make-Up Air:

• Due to the high volume of ventilation air, a source of

outside replacement air is recommended. This is

particularly important for tightly sealed and insulated

homes.

• A qualified heating and ventilating contractor should be

consulted.

NOTE:

Ventilation hoods and blowers are designed for use with

single-wall ducting. Some local building codes may require

double-wall ducting. Before starting installation, consult

local building codes and agencies to insure that the

installation will meet local requirements.

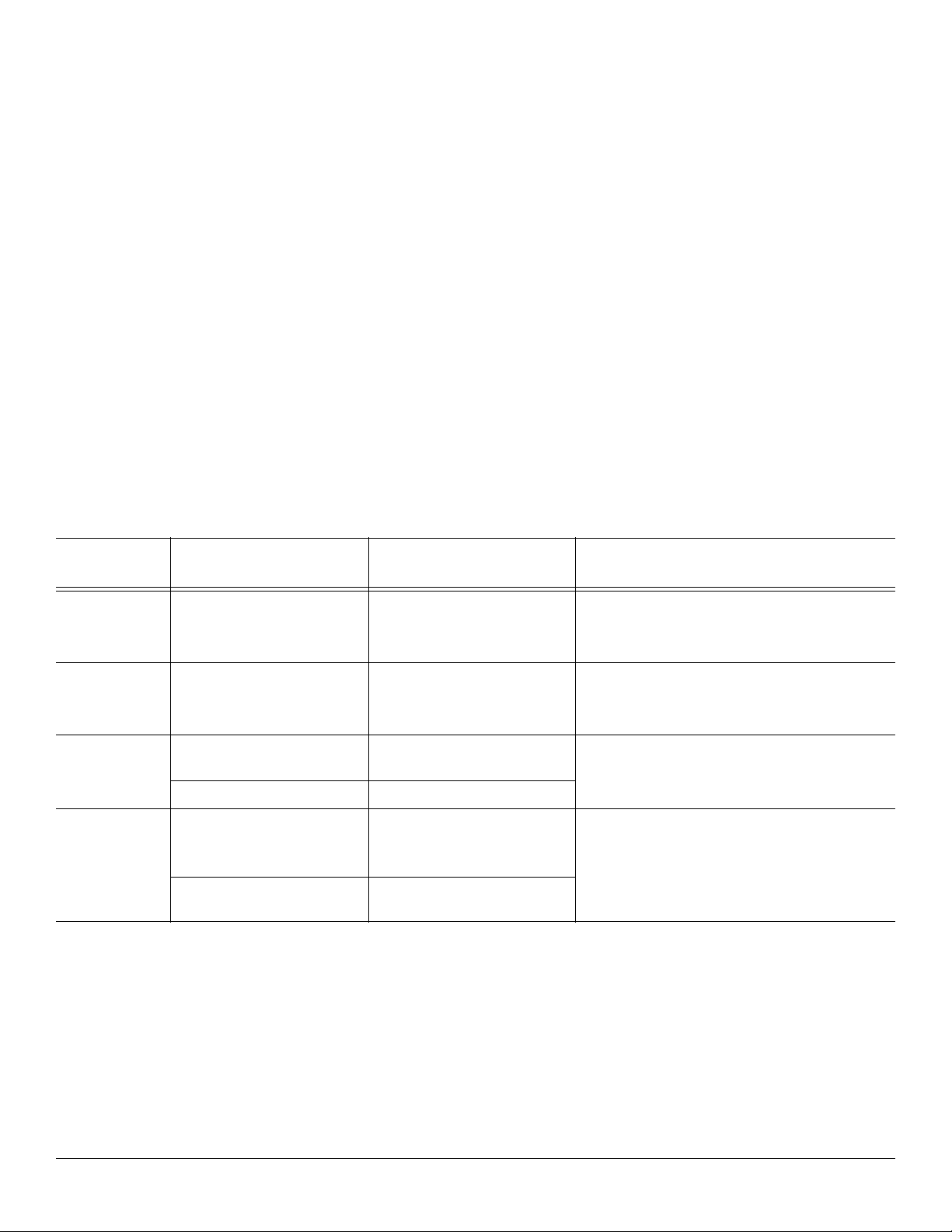

Cooktop

Width

24” 24” griddle -or-24” wok 600 CFM

30” 4 burners 600 CFM

4 burners w/ grill -or-

36”

48”

Important Notes:

• It is recommended that a Thermador Professional wall or island hood or custom insert is used with Thermador

Professional Cooktops.

• Refer to www.Thermador.com for a complete selection of Professional Ventilation options, Blowers, and

Accessories.

• * For high output gas cooktops (60,000 BTU or greater), the minimum of one (1) CFM of ventilation per 100 BTU is

recommended. If the cooktop has a grill or griddle, add 200 CFM to the estimated blower capacity. Add 400 CFM if

the cooktop has a 24” griddle or wok. Additional blower capacity may be required for longer duct runs.

• For island applications, it is recommended to use a hood width that exceeds the width of the cooktop by 6”

(overlapping the cooktop by 3” on each end).

• CFM = “cubic feet per minute” (standard blower capacity rating).

griddle 6 burners 900 CFM 4 burners w/ grill-griddle

combo

24” griddle or wok

6 burners w/ grill -orgriddle

Cooktop

Configuration

Minimum Recommended

Blower Capacity*

800 CFM

1000 CFM

1100 CFM

Ventilation Options

30” Pro Wall Hood

30” Custom Insert w/ optional blower

42” Island Hood w/ optional blower

30” or 36” Pro Wall Hood

30” or 36” Custom Insert w/ optional blower

42” Island Hood w/ optional blower

36” or 42” Pro Wall Hood

36” Custom Insert w/ optional blower

42” or 48” Island Hood w/ optional blower

48” or 54” Pro Wall Hood

48” Custom Insert w/ optional blower

54” Island Hood w/ optional blower

English 4

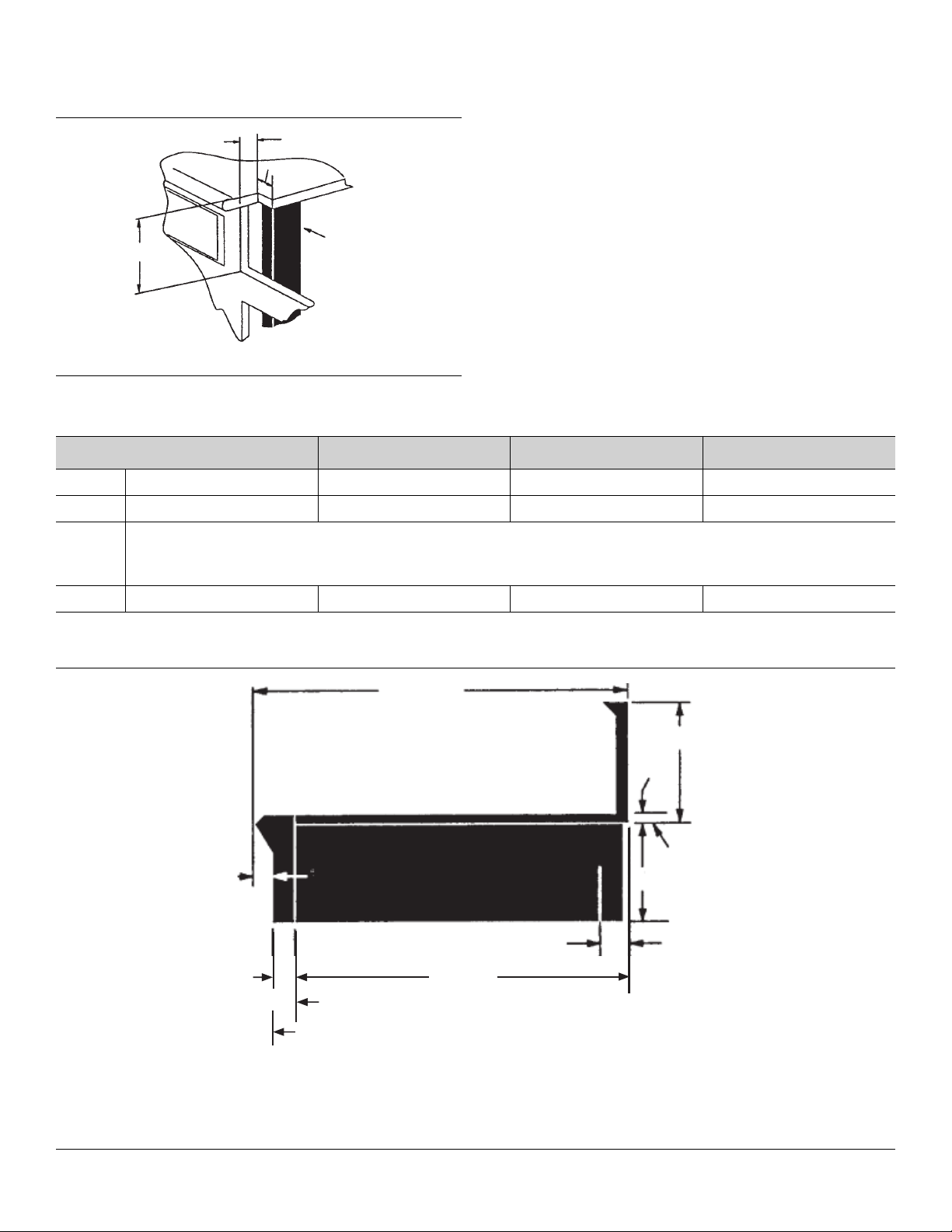

Step 2: Cabinet Preparation

1. To ensure professional results, the cabinet and countertop openings should be prepared by a qualified cabinet worker.

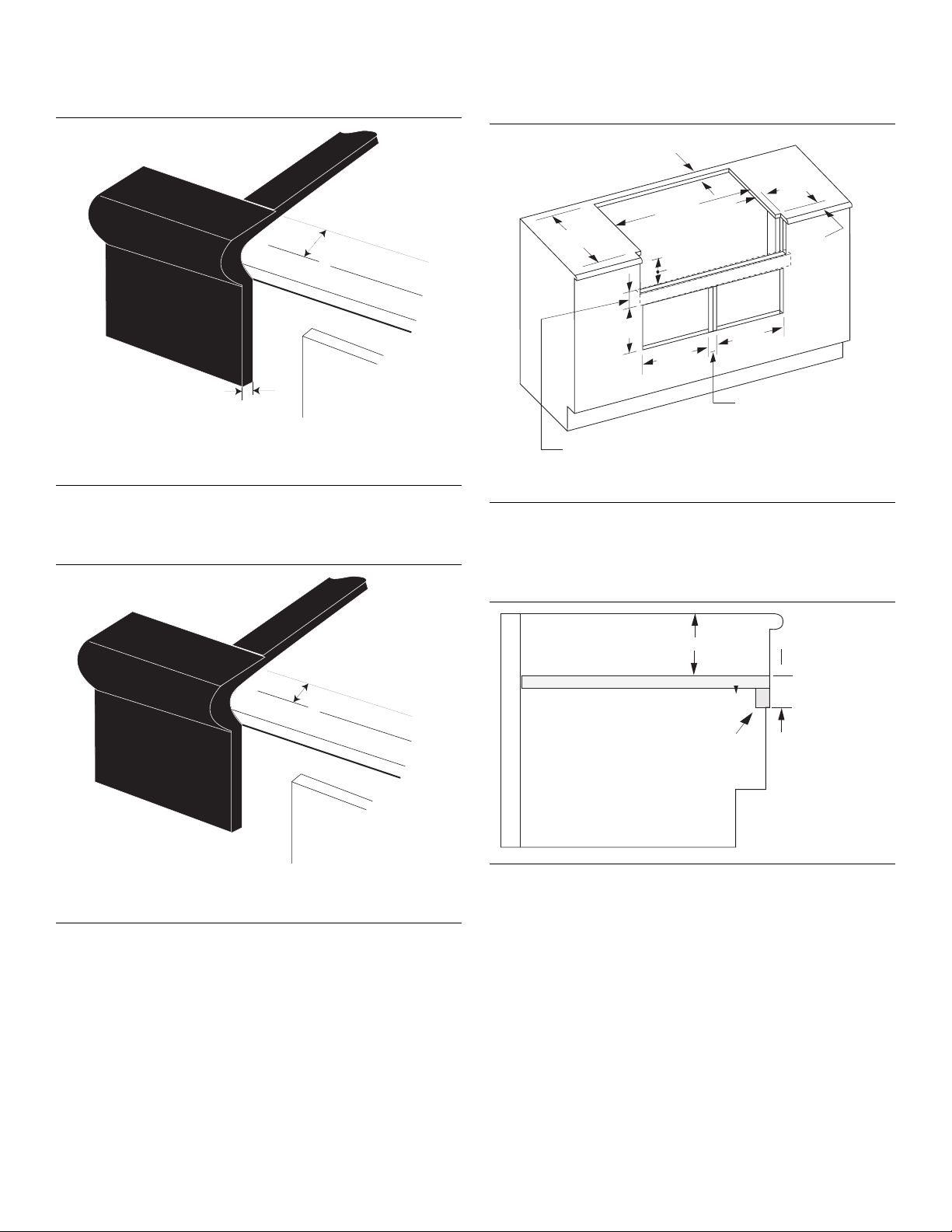

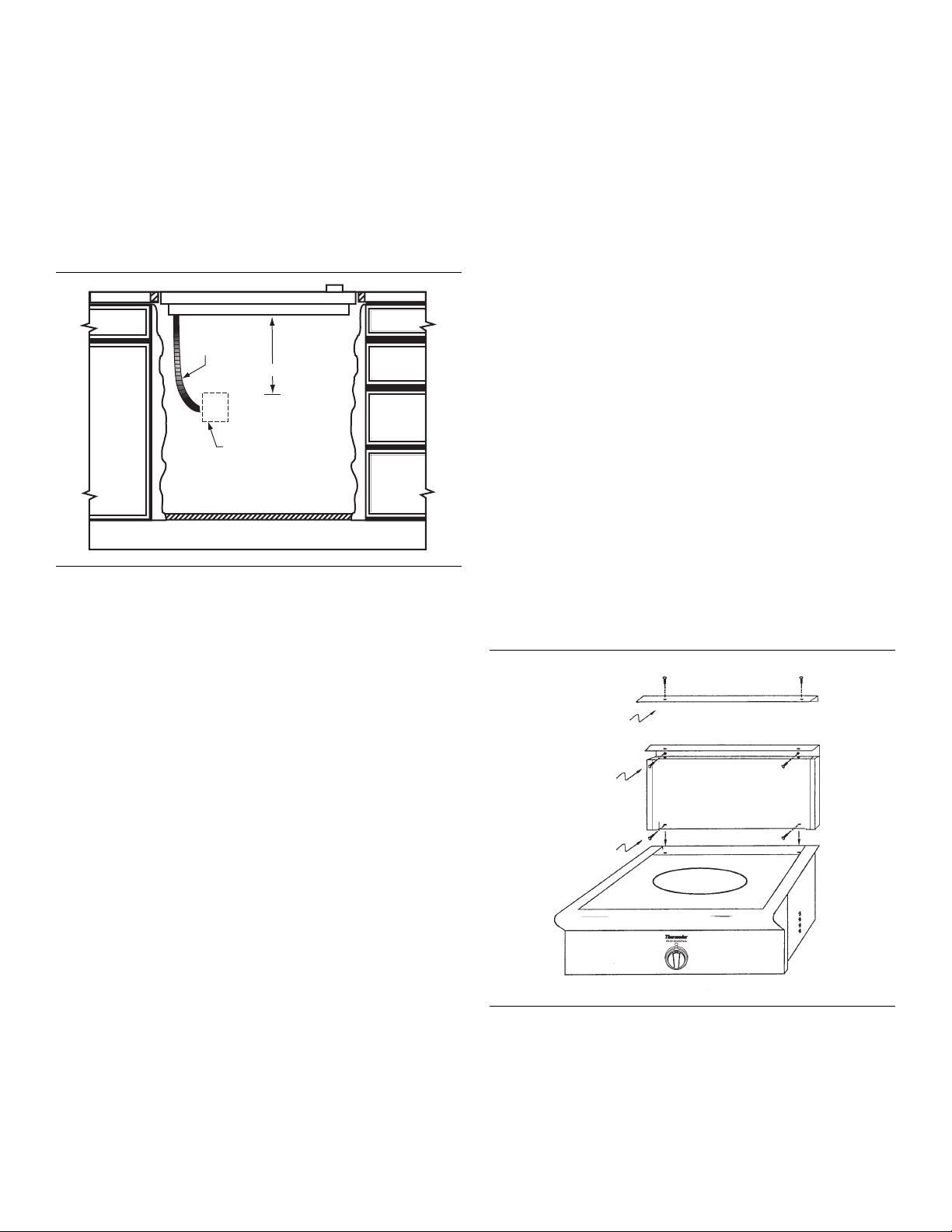

2. The clearances shown in Figure 1 are required. The same clearances apply to island installations, except for the overhead cabinets, which must have a space wide enough to accept the island hood.

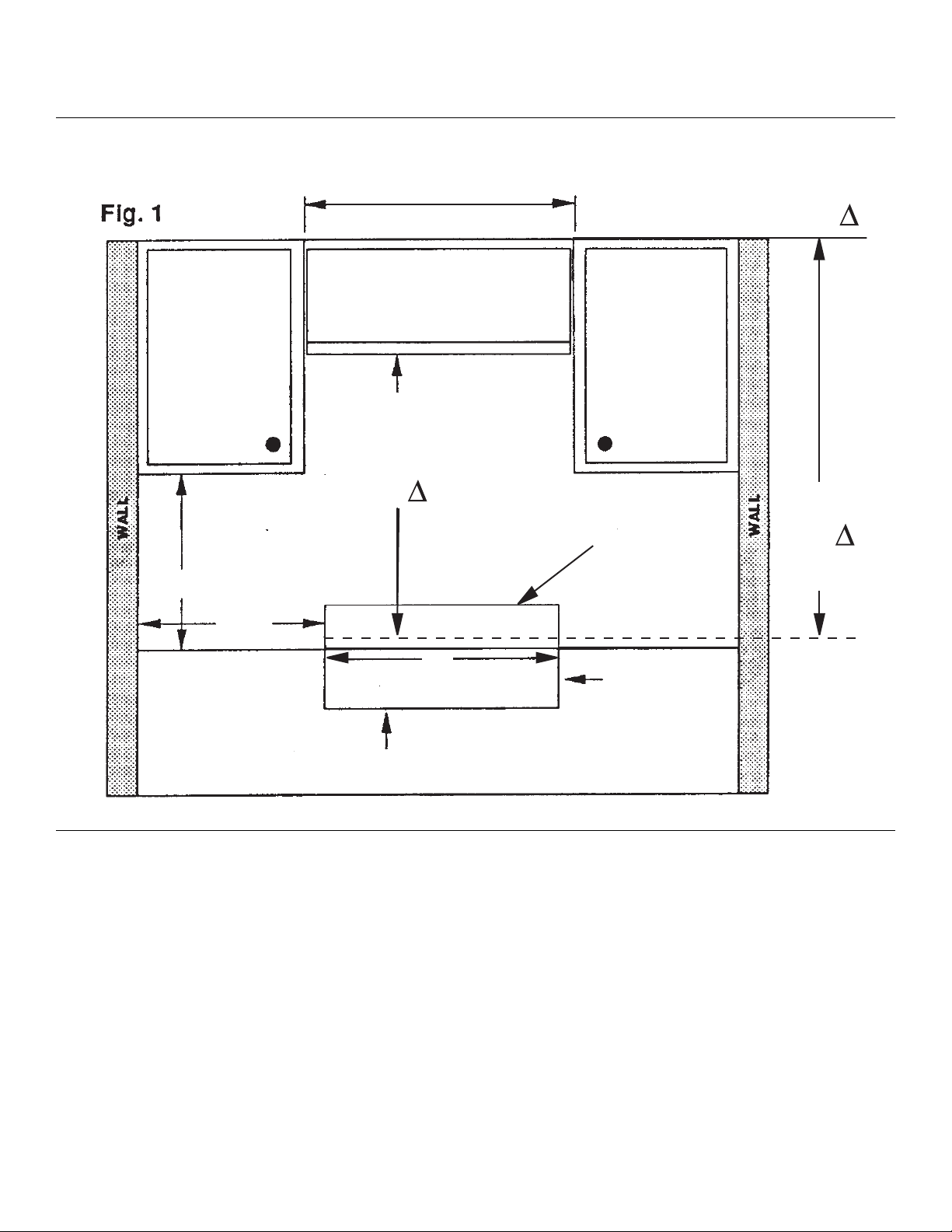

3. The cooktop is designed to hang from the countertop

by its side flanges. The countertop however, must be

strong enough to support this cooktop. It may be

necessary to add a supporting cleat along each side

(see Figure 2) or a 2 x 4 corner brace (see Figure 3

and Figure 4 and Detail A). Another alternative would

be to construct a deck to set the cooktop on.

4. The cooktop can be installed in various positions with the front either flush or projecting, depending on the countertop’s depth. (See Figure 5, side view of cooktop; see Figure 3, Figure 4, Figure 6 and Figure 7 for alternate mounting positions.)

5. The gas and electrical supply must be located in an

area that is accessible without requiring removal of the

cooktop. The appliance electrical power cord and gas

pipe connection are located on the left rear underside

of the cooktop (except on models with a 24" griddle

where power cord is located in the center), as shown in

Figure 5 and Figure 9.

6. The maximum depth of over head cabinets installed on either side of the hood is 13".

A 36-inch minimum clearance is required between the

cooking surface of the cooktop and the bottom of an

unprotected cabinet. A 30-inch distance can be used when

the bottom of the wood or metal cabinet is protected by not

less than 1/4 inch of a flame retardant material covered

with not less than No. 28 MSG sheet steel, 0.015 inch (0.4

mm) thick stainless steel, 0.024 inch (0.6 mm) aluminum,

or 0.020inch (0.5 mm) thick copper. Flame retardant

materials bear the mark:

UNDERWRITERS LABORATORIES INC. CLASSIFIED

MINERAL AND FIBER BOARDS SURFACE BURNING

CHARACTERISTICS

followed by the flame spread and smoke ratings. These

designations are shown as "FHC (FIame Spread/Smoke

Developed)." Materials with "O" flame spread ratings are

flame retardant. Local codes may allow other flame spread

ratings.

7. When there is less than a 12" horizontal clearance

between combustible material and the back edge of

the cooktop above the cooking surface, a Thermador

Low Backguard must be installed. (See Step 6). When

clearance to combustible material is over 12", a

Thermador Island Trim may be used. Attach the

backguard before sliding the appliance into the final

installed position.

8. Establish the centerline of the cooktop’s desired location. It should be the same as the center of the overhead ventilation hood.

9. Cut the openings for the following installations:

• Wall installation, see Figure 3.

• Island installation, see Figure 4.

10. For models with a 24” griddle, attach the foam strip to countertop centered along the rear about 1/16” from the edge.

11. For installation of a 48" cooktop above two side-by-side

Thermador Warming Drawers, Model No. WD24, refer

to Figure 8. Completing the installation as per Figure 8

will result in the left and right edges of the cooktop

being aligned with the left edge of the left-side warming

drawer and right edge of the right-side warming

drawer. If different alignment is desired, the 1-7/8"

horizontal distance between warming drawer cutouts

may be varied. However, maintain at least a 1-1/8"

distance to avoid interference between the warming

drawers. Attach a 90-degree elbow to the gas cooktop

inlet pipe. All above-the-countertop clearances must be

maintained, as shown in Figure 1.

As defined in the "National Fuel Gas Code" (ANSI

Z223.1/NFPA54-current issue).

NOTES:

• If a solid side cabinet wall exists on one or both sides,

you will need to notch the front corner of the cabinet to

match the countertop notch and to allow clearance for

the cooktop front (see Detail A, Figure 3 and Figure 4).

• If a supporting deck is used, the sides or bottom of the

cutout may be solid combustible or non-combustible

material. If the bottom is solid, provide a 8" by 8" cutout

in the left rear corner of the supporting deck. This will

provide clearance for the gas inlet and power cord,

while also allowing viewing of the product rating label.

• On models which have a 24" griddle with power cord in

the center, provide 2 (two) separate pieces of

supporting deck to allow clearance in center for cord to

pass through.

• Always keep appliance area clean and free from

combustible materials, gasoline and other flammable

vapors and liquids.

• Do not obstruct the flow of combustion and ventilation

air to the unit.

English 5

18" Min

13" Max.

depth of

overhead

cabinets

30" to 36" Wide Hood for 24" Wok or 24" Griddle

30" to 36" Wide Hood for 30" Cooktop

to 42" Wide Hood for 36" Cooktop

36"

48"

to 60" Wide Hood for 48" Cooktop

VENT HOOD

30" Min. from bottom of

Overhead Hood to Cooking

Surface (36"

hood contains combustible

materials ).

or greater if

Horizontal

Min. Clearance

to Rear Wall:

0" with Backguard

12" with Island Trim

Combustible

Material

36" Min. to

Combustible

Material

from Cooking

Surface.

3" min.

.

both sides

"A"

0" Bottom

Cooking Surface

0" Sides

Figure 1: Clearance Requirements

English 6

Counter

Sunk

Screws

B

D

See Detail A

B

23-5/16”

Figure 2: Installing Side Supports (both sides)

Vent Hood

Island – 42" or 48"

Island – 42" or 48"

Island –

Width Requirements

Wide Hood

Wide Hood for 36" Cooktop

54" or 60"

Wide Hood for 48" Cooktop

for 24" Wok or Griddle

Figure 3: Wall Installation with Countertop Backsplash

See Detail A

22-13/16”

3/4” Min.

D

Figure 4: Island Installation (No Countertop Backsplash)

English 7

C

B

7-11/16”

Corner Notch Detail

Detail A: (Front Face of Cabinet)

24” Wok/Griddle 30” Cooktop 36” Cooktop 48” Cooktop

A 24-3/4” 29-7/8” 35-7/8” 47-7/8”

B 3/8” 3/8” 3/8” 13/16”

C 0” (Control Panel Projecting 1-1/4” from Base Cabinet Face)

11/16” (Notch Required for Standard 24” - Deep Base Cabinet, Control Panel Projecting 9/16” from Base

Cabinet Face) 1-1/4” (Control Panel Flush to Cabinet Face - Min. 24-9/16” - Deep Base Cabinet Required)

D 24” 29-1/8” 35-1/8” 46-1/4”

2 x 4 Corner

Support

25-3/8”

1/2”

Flange

7-5/8”

5-1/4” TO CENTERLINE OF

GAS INLET

23-5/16”

1-1/4”

Cabinet face for installation with projecting control panel

Cabinet face for installation with flush control panel

* Low Back required when there is less than 12”

horizontal clearance from back of cooktop to combustible

material. With more than 12” of clearance, the Island

Trim may be used.

12”

Side

Figure 5: Side View of Cooktop

English 8

11/16” Notch

Depth

Minimum 3/4" (19 mm)

46-1/4"

22-13/16"

(57, 9 cm)

(22, 9 cm) 9"

(117,5 cm)

7-11/16"

(19,52 cm)

WD24

Cutout

WD24

Cutout

22-1/2"

(57,2 cm)

13/16"

(21 mm)

0" to

1-1/4"

(0 - 32 mm)

See Fig. 4

and Table

Dimension C

9/16”

Front projects outward 9/16" as shown from

standard 24"-deep base.

Figure 6: Projecting from Cabinet Front

1-1/4” Notch

Depth

1-7/8" (4,8 cm)

Horizontal Distance

Between Cutouts

2-3/4" (7 cm) Vertical Distance

Between Cutouts

(See Side View for Wood Support)

Figure 8a: Installation of 48” Cooktop above two side-by-

side Thermador Warming Drawers - Model No. WD24

7-11/16”

Plywood support

(19,52 cm)

2-3/4" (70 mm)

minimum

between

cutouts

REAR

Install additional

wood support along

front edge of cutout

Front flush with cabinets; minimum of 24-9/16" cabinet

depth required.

Figure 7: Flush to Cabinet Front

Figure 8b: Installation of 48” Cooktop above two side-by-side

Thermador Warming Drawers - Model No. WD24

(Side View)

English 9

Product Rating

Label/Serial Tag

Threading compounds must be

resistant to Propane Gas

P24WOK 1/2" NPT

3” Min.

3-Prong grounding type receptacle

connected to a properly grounded and

polarized electrical supply rated at 120VAC,

10 Amps, (or 15A*) Single Phase, 60 HZ.

NOTE: This is not applicable to 240 VAC

models with 24" electric griddle.**

All Installer supplied parts must conform to Local Codes.

*15 Amp 120 VAC electrical supply is required for 36" and 48" models with a 24" electric griddle.

**30 Amp 240 VAC electrical supply is required for models with a 24" electric griddle.

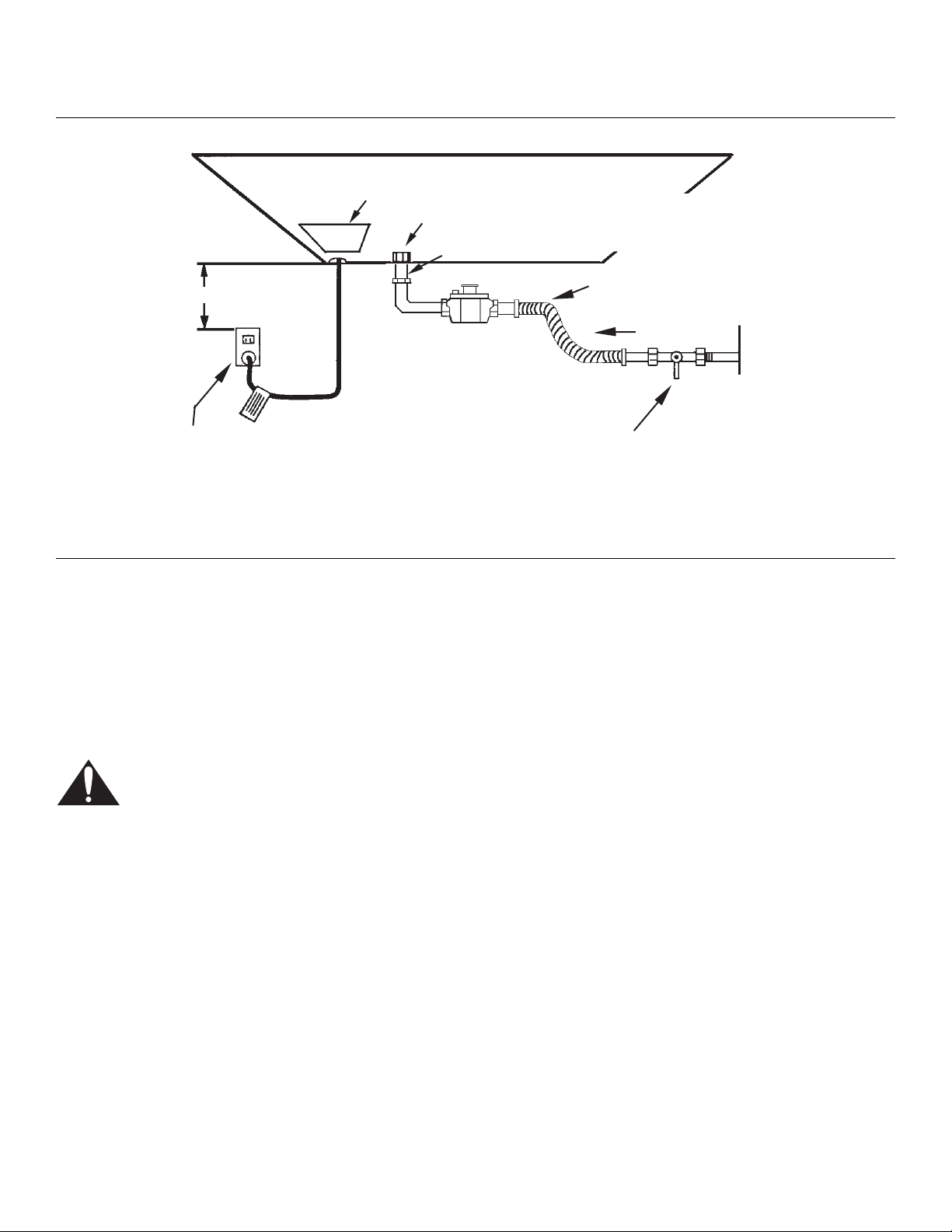

Step 3: Unpacking, Moving, Placing and Anchoring the Cooktop

Power

Cord or

Conduit

A manual valve must be installed

external to the appliance, in an accessible location from the front, for the

purpose of shutting off the gas supply.

2. Remove the top grate castings, burner caps

grate (if so equipped) to reduce unit weight.

3/4” flex line

gas flow

Figure 9: Front - Bottom of Unit

and grill

CAUTION

Proper equipment and adequate manpower

must be used in moving the appliance to avoid

damage and/or personal injury. The unit is

heavy and should be handled accordingly.

Important

• Verify that the appliance is correct for the type of gas

being provided. Refer to Step 4 before proceeding with

the installation.

• Attach the backguard before sliding the appliance into

the final installed position. See Step 6.

1. Remove the outer carton and packing material from the

shipping base. Ensure that you have

components before proceeding.

English 10

all cooktop

NOTE:

Leave adhesive-backed foam layer

surfaces, to protect finish from scratches, until the cooktop

is installed in its final position.

3. Lift and place the cooktop in the opening. Be careful not to pinch the power cord or gas inlet. Care should be used not to scratch the griddle cooking plate.

4. Make sure that the power cord is free and hanging loose.

5. The cooktop must be level for proper performance.

6. The grill frame (if so equipped) has been leveled during assembly so do not attempt to level the grill.

7. Replace the cooking grates, burner caps and grill plate (if so equipped). Ensure that the burner caps are correctly seated on the burner bases.

over brushed-metal

Grill/Griddle Tilt Adjustment (not all models)

Check the grill or griddle adjustment by pouring two

tablespoons of water on the back of the grill or griddle

plate. The water should slowly roll into the grease tray. If

not, adjust the two screws under the back of the plate. Start

with one half turn counter-clockwise (CCW) of the screws.

Further adjustment should be made by one-quarter turn

until water slowly flows into the grease tray.

Step 4: Gas Requirements and Hookup

Cooktops are shipped by the factory to operate on

natural gas.They must be converted for use with

propane. Verify the type of gas being used at the

installation site matches the type of gas used by the

appliance. If the location/job site requires conversion from

natural gas to propane (LP), contact the dealer where the

unit was purchased or contact Thermador. The field

conversion kit for the Professional Cooktops in this series is

Thermador Model PLPKIT. Obey all instructions in PLPKIT

for correct conversion of the gas regulator and settings for

the gas valves. Field conversion must be done by qualified

service personnel only.

This appliance has been CSA certified for safe operation

up to an elevation of 10,200 ft. without any modifications.

Exception

converted per the LP conversion instructions. Please refer

to the LP Conversion Instructions for further information.

Natural Gas Requirements:

Inlet Connection: 1/2” NPT (min. 3/4” dia. flex line)

Supply Pressure: 6” min. to 14” max. water column (14.9 to

34.9 mb)

Manifold Pressure: 5” water column (12.5 mb)

Propane Gas Requirements:

Inlet Connection: 1/2” NPT (min. 3/4” dia. flex line)

Supply Pressure: 11” min. to 14” max. water column (27.4

mb to 34.9 mb)

Manifold Pressure: 10” water column (24.9 mb)

: For use with propane, the appliance must be

WARNING

If a gas conversion kit is used, the kit shall be

installed by a qualified service agency in

accordance with the manufacturer’s instructions

and all applicable codes and requirements of

the authority having jurisdiction. If the

information in the instructions is not followed

exactly, a fire, explosion or production of carbon

monoxide may result causing property damage,

personal injury or loss of life. The qualified

service agency is responsible for the proper

installation of the kit. The installation is not

proper and complete until the operation of the

converted appliance is checked as specified in

the manufacturer’s instructions supplied with the

kit.

Hook Up

• A manual gas shut-off valve must be installed external

to the appliance, in a location accessible from the front,

for the purpose of shutting off the gas supply. The

supply line must not interfere with the back of the unit.

Make sure the gas supply is turned off at the manual

shut-off valve before connecting the appliance.

• The installer should inform the consumer of the

location of the gas shut-off valve. Make sure all users

know where and how to shut off the gas supply to the

cooktop.

• The gas supply connections shall be made by a

competent technician and in accordance with local

codes or ordinances. In the absence of local codes, the

installation must conform to the National Fuel Gas

Code ANSI Z223.1/NFPA54-current issue.

• Always use pipe-sealing compound or Teflon® tape on

the pipe threads, and be careful not to apply excessive

pressure when tightening the fittings.

• Leak testing of the appliance shall be in accordance

with the following instructions.

• Turn on gas and check supply line connections for

leaks using a soap and water solution.

• Bubbles forming indicate a gas leak. Repair all

leaks immediately after finding them.

• Do not use a flame of any kind to check for gas

leaks.

• All installer-supplied parts must conform to applicable

codes.

CAUTION

When connecting unit to propane gas, make

certain the propane gas tank is equipped with its

own high pressure regulator in addition to the

pressure regulator supplied with the appliance.

The pressure of the gas supplied to the

appliance regulator must not exceed a 14” water

column (34.9 mb).

English 11

CAUTION

The appliance must be isolated from the gas

supply piping system by closing its individual

manual shut-off valve during any pressure

testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig

(3.5kPa).

The appliance and its individual shut off valve

must be disconnected from the gas supply

piping system during any pressure testing of the

system at test pressures in excess of 1/2 psig

(3.5kPa.).

When checking the manifold gas pressure, the

inlet pressure to the regulator should be at least

6.0" W.C. for natural gas or 11.0" for propane.

Do not attempt any adjustment of the pressure

regulator.

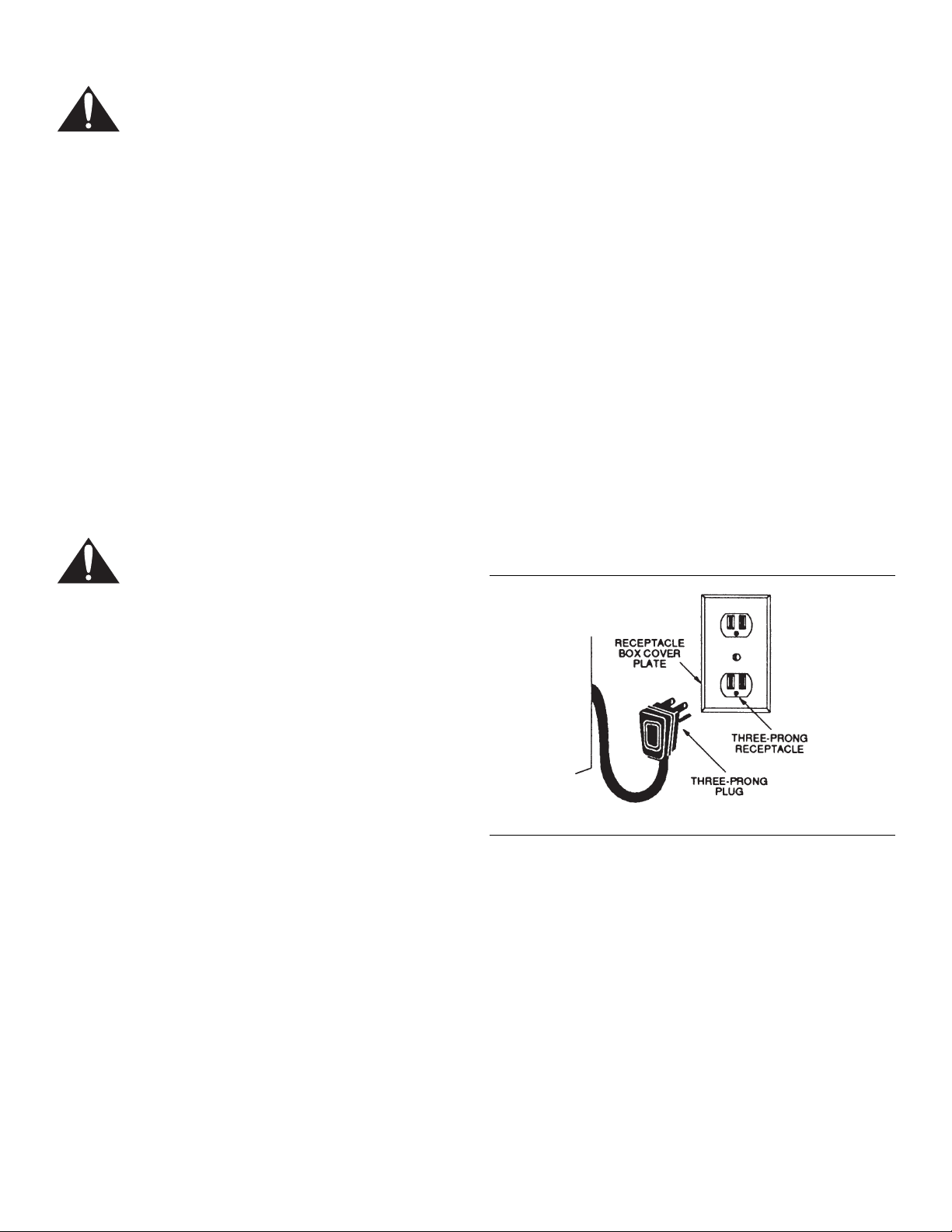

Step 5: Electrical Requirements, Connection and Grounding

• All 240 Volt cooktop models require hard wire

connections.

• Observe all governing codes and ordinances when

grounding. In the absence of these codes or

ordinances observe National Electrical Code ANSI/

NFPA No. 70 current issue. See Figure 10 for

recommended grounding method.

• An electrical wiring diagram and schematic have been

attached to the bottom of the cooktop chassis for

access by a qualified service technician. Do not

remove or discard this important information.

Grounding Method for 120 VAC Models

The cooktop is factory equipped with a power supply cord

with a three-prong grounding plug (with polarized parallel

blades).

IT MUST BE PLUGGED INTO A MATING, GROUNDING

TYPE RECEPTACLE THAT IS CONNECTED TO A

CORRECTLY POLARIZED 120 VOLT CIRCUIT (240

VOLT CIRCUIT FOR MODELS WITH 24" ELECTRIC

GRIDDLE. (See Figure 10).

CAUTION

Improper grounding or reverse polarization will

cause malfunction (such as continuous sparking

of the burner igniters). This can damage the

appliance and can create a condition of shock

hazard. If the circuit is not correctly grounded

and polarized, it is the responsibility and

obligation of the installer and user to have the

existing receptacle changed to a properly

grounded and polarized receptacle. This must

be accomplished in accordance with all

applicable local codes and ordinances by a

qualified electrician. In the absence of local

codes and ordinances, the receptacle

replacement shall be in accordance with the

National Electric Code. (See Figure 10.)

• Before installing, turn power OFF at the service panel.

Lock service panel to prevent power from being turned

ON accidentally.

• Always disconnect appliance from the electric supply

either by disconnecting power cord or shutting off the

breaker before servicing the appliance.

• Before you plug in an electrical cord, be sure all

controls are in the OFF position.

• All 120 Volt cooktop models must be plugged into a

mating 3-Prong, Grounding-Type Receptacle. The

receptacle must be connected to a properly grounded

and polarized electrical power supply rated at 120VAC,

Single Phase, 60HZ. See “Electrical Power Supply

Over-current Protection Requirements” on page 13 on

this page for proper over-current protection

requirements for each model.

Figure 10: Recommended Grounding Method for 120V

Models

THE THIRD, GROUND PRONG MUST NOT BE CUT OR

REMOVED UNDER ANY CIRCUMSTANCES.

Electrical Connection for 240 VAC Models

1. Attach flexible conduit to the junction box.

2. Connect the cooktop lead wires to the junction box supply wires in proper phase:

For all 240 VAC models, connect black (L1) to black,

red (L2) to red, white wire to neutral and green wire

to ground.

English 12

NOTE:

If the 120V cooktop is installed and connected as specified

above, it will be completely grounded in compliance with

the National Electric Code.

Cooktop with a wok - 10 Amp circuit protection

Cooktop with a 24" electric griddle - 30 Amp circuit

protection 240 VAC.

3. Turn on power supply.

4. Test operation.

Conduit

(Approx. 3”)

12” APPROXIMATE

“J” Box

Figure 11: Junction Box Location

Electrical Power Supply Over-current Protection Requirements

Installer - show the owner the location of the circuit

breaker or fuse. Mark it for easy reference.

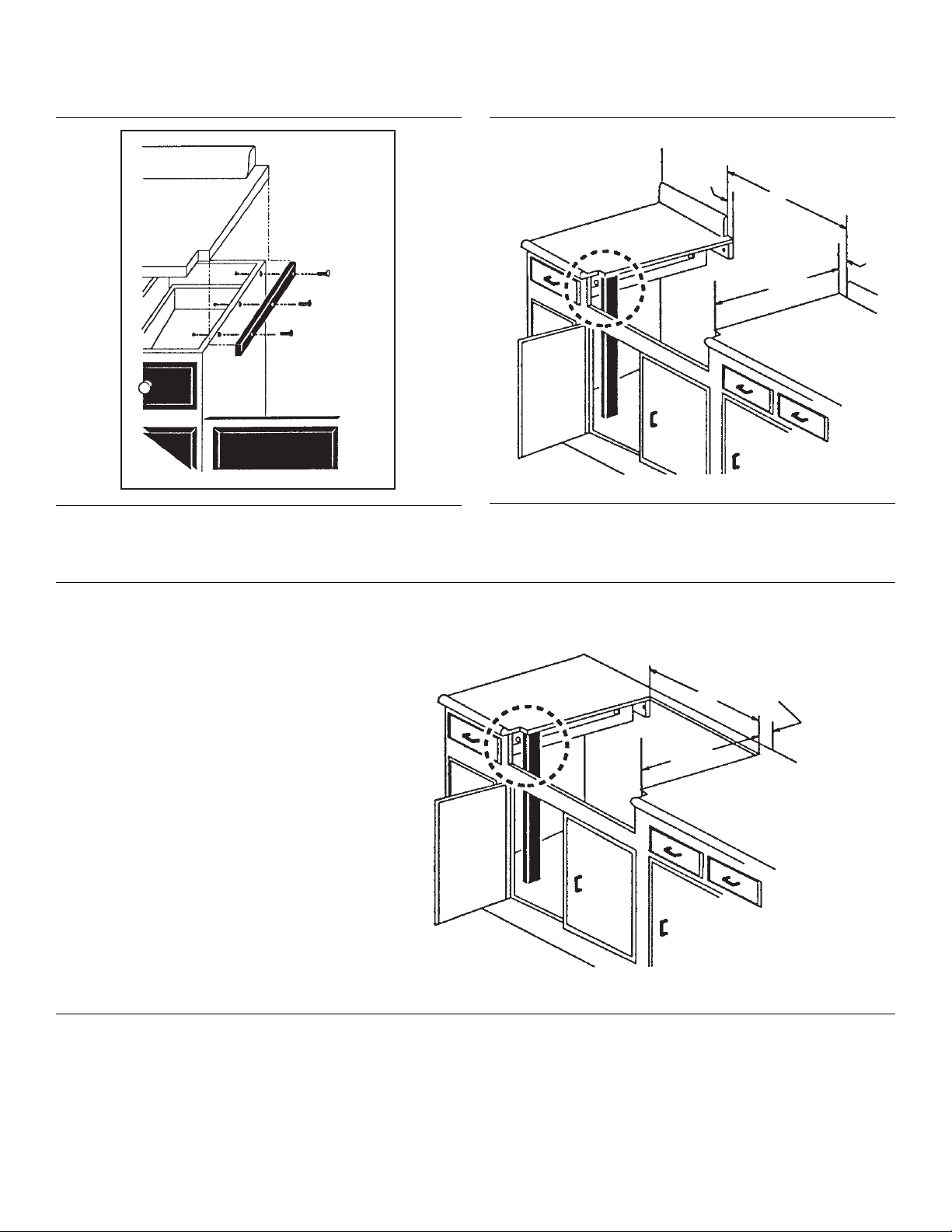

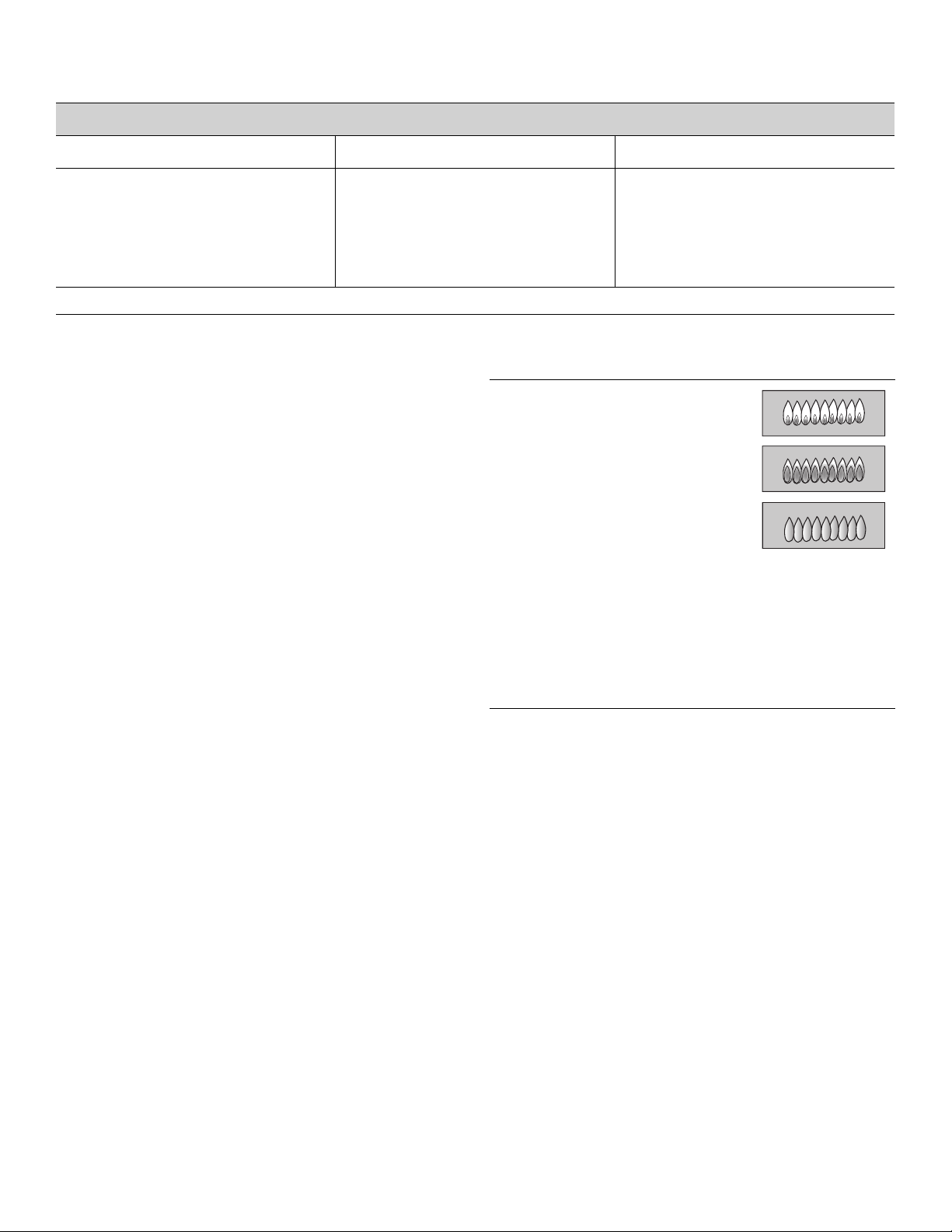

Step 6: Backguard Installation

A Low Back backguard must be installed when there is less

than a 12" clearance between combustible materials and

back edge of cooktop. (See Figure 1 and Figure 5.) For

island installations and other installations with over 12"

clearance, an optional stainless

available to cover the backguard mounting flanges. Attach

the backguard before sliding the appliance into the final

installed position. Follow Steps A through C below:

1. Slide backguard over the two flanges on the rear of the appliance. Fasten the front and back with the two screws (see A, Figure 12) provided.

2. Fasten the top of the backguard to the wall with two screws through the backguard. (See B, Figure 12.)

3. Place the backguard cap on top and fasten using the two counter-sink screws provided. (See C, Figure 12.)

steel trim channel is

4 Burners - 10 Amp circuit protection

6 Burners - 10 Amp circuit protection

4 Burners with a grill - 10 Amp circuit protection

4 Burners with a 12" electric griddle - 15 Amp circuit

protection

6 Burners with a grill - 10 Amp circuit protection

6 Burners with a 12" electric griddle -15 Amp circuit

protection

4 Burners with a grill and a 12" electric griddle - 15 Amp

circuit protection

4 Burners with a wok- 10 Amp circuit protection

4 Burners with a 24" electric griddle -30 Amp circuit

protection, 240VAC

C

B

A

Figure 12: Low Back Attachment

English 13

Low Back and Island Trim Model Numbers

Cooktop Size/Type 12” Low Back Island Trim*

24” Griddle

24” Wok

30”

36”

48”

*Requires a minimum of 12” horizontal clearance between back of appliance and combustible materials.

PC24LB

GP24LBS

PC30LB

GPS36LBS

GPS48LBS

PC24IT

GP24ITS

PC30IT

GPS36ITS

GPS48ITS

Step 7: Burner Test and Adjustment

Install any loose components, such as burner caps and

grates that may have been removed earlier.

Be certain that burner caps seat properly into the burner

bases. Before testing operation of the appliance, verify that

the unit and the gas supply have been carefully checked for

leaks and that the unit has been connected to the electrical

power supply. Turn the manual gas shut-off valve to the

open position.

Test Cooktop Burners

Test Burner Ignition. Select a cooktop burner knob. Push

in and turn counterclockwise to HI. The ignitor/spark

module will produce a clicking sound. Once the air has

been purged from the supply lines, the burner should light

within four (4) seconds.

Yellow Flames:

Further adjustment is required.

Yellow Tips on Outer Cones:

Normal for LP Gas.

Soft Blue Flames:

Normal for Natural Gas.

If the flame is completely or mostly yellow, verify that the

regulator is set for the correct fuel. After adjustment,

retest.

Some orange-colored streaking is normal during the

initial start-up.

Allow unit to operate 4-5 minutes and re-evaluate before

making adjustments.

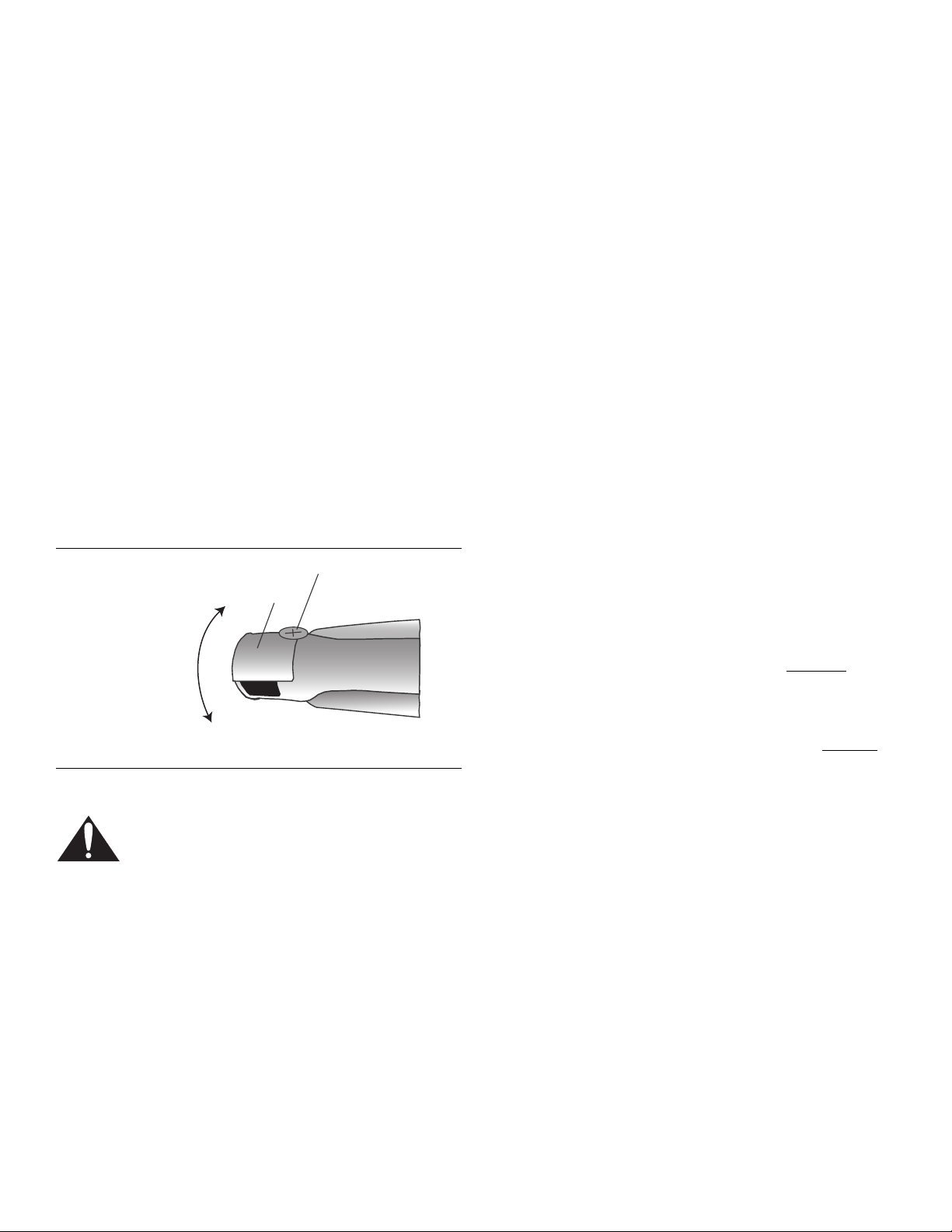

Test Flame: High Setting. Turn burner on to HI. See

Figure 13 for appropriate flame characteristics. If any of the

cooktop burners continue to burn mostly or completely

yellow, verify that the burner cap is positioned properly on

the burner base, then re-test. If flame characteristics do not

improve, call Thermador.

Test Flame: Low Setting. Turn burner on to LO. Verify

that the flame completely surrounds the burner. There

should be a flame at each burner port and there should be

no air gap between the flame and the burner. If any burners

do not carry over, call Thermador.

The two far left burners feature XLO, causing the flame to

cycle on and off when the knob is set to the XLO range.

This is normal operation.

Repeat the Ignition and Flame Test procedures described

above for each cooktop burner and the grill burner (if so

equipped).

Figure 13: Flame Characteristics

WHEN FLAME IS PROPERLY ADJUSTED:

• There should be a flame at each burner port.

• There should be no air gap between the flame and

burner port.

The gas grill uses a tube-style burner that has an air shutter

which allows adjustment to the amount of primary air inside

the burner tube.

Air shutters of tube-style burners are pre-adjusted at the

factory, and usually do not require readjustment except

under rare conditions such as installation at high altitude.

If grill burner/flame adjustment is required, go to the

procedure: “Flame Adjustment (if necessary)”.

English 14

Flame Adjustment (if necessary)

Tube-style gas burners used in Thermador appliances

have air shutter systems which are similar to the illustration

in Figure 14, and can be adjusted using the following

method (unless adjustment is not recommended). It is

necessary to remove the burner from the appliance in order

to perform air-shutter adjustments.

• Loosen shutter screw(s) and turn shutter to new

position.

• Adjust the shutter to more-closed position if the flame

is lifting or blowing, or is not carrying over.

• Adjust the shutter to more-open position if the flame is

too yellow. (See Figure 14.)

• Retighten the shutter screw(s).

• After adjustment, reinstall the burner and perform

flame evaluation. The air shutter must fit over the

orifice hood for proper operation of the burner.

• Repeat procedure as needed until flame characteristics

are acceptable. (See Figure 13.)

Screw

More Open:

Less Yellow Flame

Air

Shutter

Installer Checklist

Final Check List

• Cooktop correctly positioned in countertop recess.

• Specified clearances maintained to cabinet surfaces.

• Burner caps positioned properly on burner bases.

• All packaging material removed. (NOTE: Wok models

have tie-down straps around the burner, which must be

removed before using the appliance.)

• Island Trim or Backguard attached according to

instructions.

• The griddle/ grill plate tilted slightly forward. (See “Grill/

Griddle Tilt Adjustment (not all models)” on page 11.)

Gas Supply

• Connection: 1/2" NPT with a minimum 3/4" diameter

flex line.

• If converting from natural to LP gas, refer to LP

Conversion Instructions for details.

• Manual gas shut off valve installed in an accessible

location (without requiring removal of appliance).

• Unit tested and free of gas leaks.

Electrical

More Closed:

Less Blue Flame

More Carryover

Less Lifting or Blowing

Figure 14: Air Shutter Adjustment (if necessary)

WARNING

Burner adjustments must be performed by a

qualified technician. Improper adjustments may

cause harmful by-products or void the

appliance’s warranty.

Allow burners to cool before attempting to

remove them!

Call Thermador if:

1. Any of the burners do not light.

2. Any of the burners continue to burn yellow.

• For models with the 12" electric griddle, a polarized

and grounded 120VAC receptacle with 15 AMP

current protection is provided for service cord

connection.

• For models with the 24" electric griddle, a properly

grounded, 240 VAC service connection with 30 AMP

over current protection is provided.

Operation

• All internal packing materials removed. (Check below

grates and grill pans.)

• Bezels centered on burner knobs, and knobs turn

freely.

• Purge air from gas system by operating one of the top

burners for several minutes.

• Each burner lights satisfactorily, both individually and

with other burners operating.

• Burner grates are correctly positioned.

Installer

• Give CARE and USE MANUAL and INSTALLATION

INSTRUCTIONS to your customer.

over

English 15

Loading...

Loading...