Page 1

INSTALLATION

INSTRUCTIONS

For Thermador Professional® Cooktops

Models

P24WK

PC36

PC48

Page 2

Contents

Warnings . .................................................................................. Below

Introduction........................................................................................ 1

Important Installation Information....................................................... 2

Step 1: Ventilation Requirements...................................................... 3

Step 2: Cabinet Preparation ......................................................... 4 – 7

Step 3: Unpacking, Moving, Placing and Anchoring the Cooktop ...... 8

Step 4: Gas Requirements and Hookup..................................... 9 – 10

Step 5: Electrical Requirements, Connection and Grounding ......... 11

Step 6: Backguard Installation.......................................................... 12

Step 7: Test Adjustment................................................................... 13

Installer Checklist ............................................................................. 14

IMPORT ANT INST ALLA TION INFORMA TION

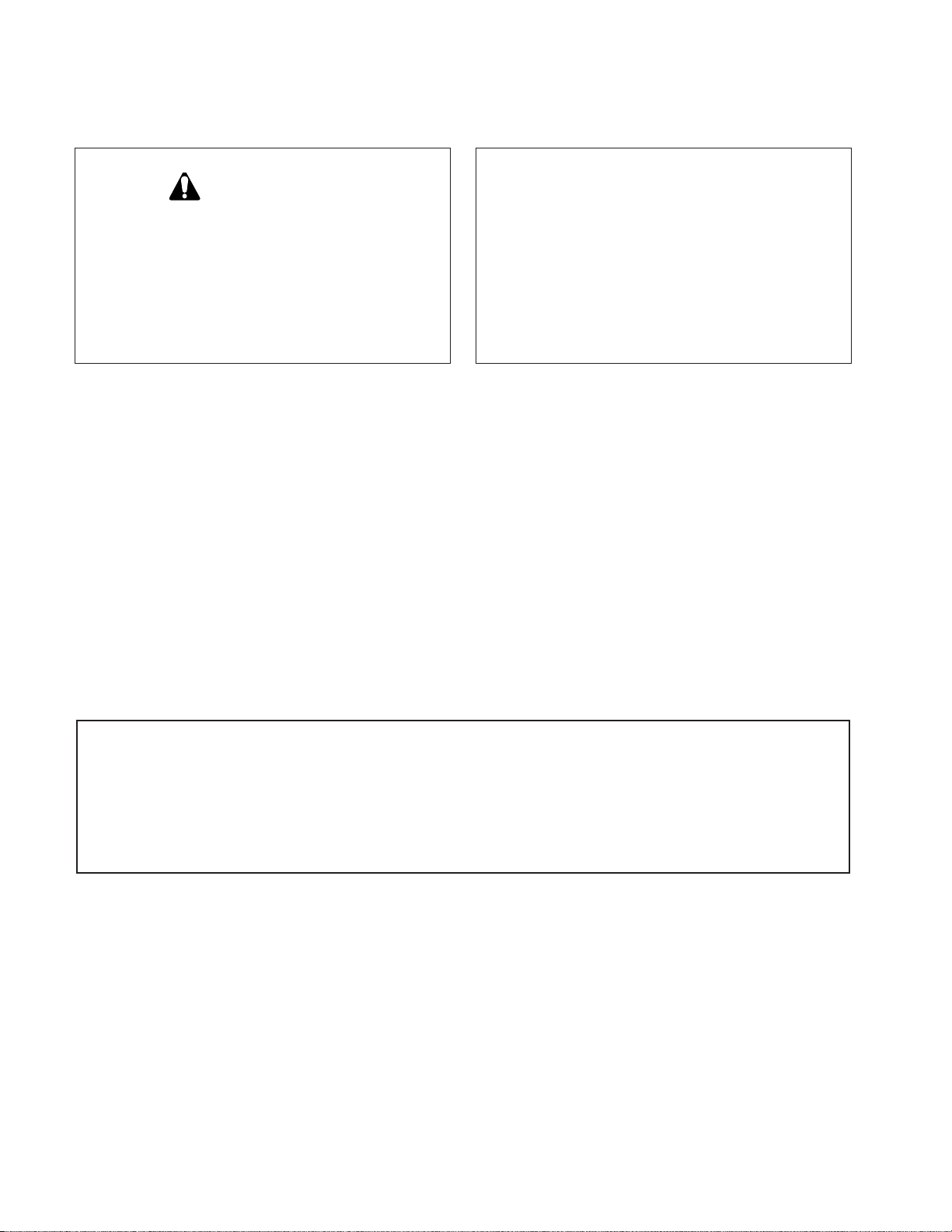

WARNING

Improper installation, adjustment, alteration,

service or maintenance can cause injury or

property damage. Refer to this manual. For

assistance or additional information consult a

qualified installer, service agency, manufacturer (dealer) or the gas supplier.

For Massachusetts Installations:

1. Installation must be performed by a qualified or licensed contractor, plumber or gas

fitter qualified or licensed by the state, province or region where this appliance is being

installed.

2. Shut-off valve must be a "T" handl0 11 8T7ed installe0cumber [(1. 03.c-1.17eingUc-268ocumoba "T" hanement(seff vno valvlongamag be 19 tathes.6(1)-6.30d1 w 1 1 1 sc76.09 1...70 143306.-99306.4 -11(4)]TJET...06 162306.48 407.38 089.54 11N0 J 0...06 i 336.48 524.538 089.54 117.04 reS/GS2 gsBT/TT3 1 Tf141 0 00)Tj72 492.96 Tm0.13725 0.12157 0.1254129 TD0.0014 W)ounTc[(W)5:2.9(ARNING)]TJ/TT2 1 Tf71315.4770 0 84.96 120 TD0.1279 Tc0.ficensdditional inin. Refer to t appno e is being Instaye is being.6364 -96 12T*-0.2019 Tc0remationancand .1372 Tw(prope,on m-e is being)Tj0 -1.1720 TD0.0075 Tc0s or addn cause (tth(install,)Tj-9 T1270 -1.178jT*0.267 Tc-0— Dovno vst(a, prnce T" oltep, procenmanuall,)Tj-ing)Tj0 -1.172 Tm-0.0069 Tc0flammaba "va396equirelitridsnin. R "vioviityanual. For

Page 3

PLEASE READ ENTIRE INSTRUCTIONS BEFORE PROCEEDING

IMPORTANT: LOCAL CODES VARY. INSTALLATION, ELECTRICAL CONNECTIONS,

GAS CONNECTIONS, AND GROUNDING MUST COMPLY WITH ALL APPLICABLE CODES.

IMPORTANT:

INSTALLER:

OWNER:

Save these instructions for the Local Electrical Inspector’s use.

Please leave these Installation Instructions with this unit for the owner.

Please retain these instructions for future reference.

GAS SUPPLY:

Natural Gas – 6 inch water column.

Propane Gas – 11 inch water column.

ELECTRICAL POWER SUPPLY:

36" Models:

PC366- 120 VAC, 60 Hz., 1 Ph., 10 Amp circuit.

PC364GL- 120 VAC, 60 Hz., 1 Ph., 10 Amp circuit.

PC364GE

48" Models:

PC486GL- 120 VAC, 60 Hz., 1 Ph., 10 Amp circuit.

PC486GE- 120 VAC, 60 Hz., 1 Ph., 15 Amp circuit.

PC486GGE

PC484WK- 120 VAC, 60 Hz., 1 Ph., 10 Amp circuit.

P24WK- 120 VAC, 60 Hz., 1 Ph., 10 Amp circuit.

(with electric griddle)

(with electric griddle)

- 120 VAC, 60 Hz., 1 Ph., 15 Amp circuit

- 120 VAC, 60 Hz., 1 Ph., 15 Amp circuit

WARNING

Disconnect power before installing. Before

turning power ON, be sure that all controls are

in the OFF position.

.

.

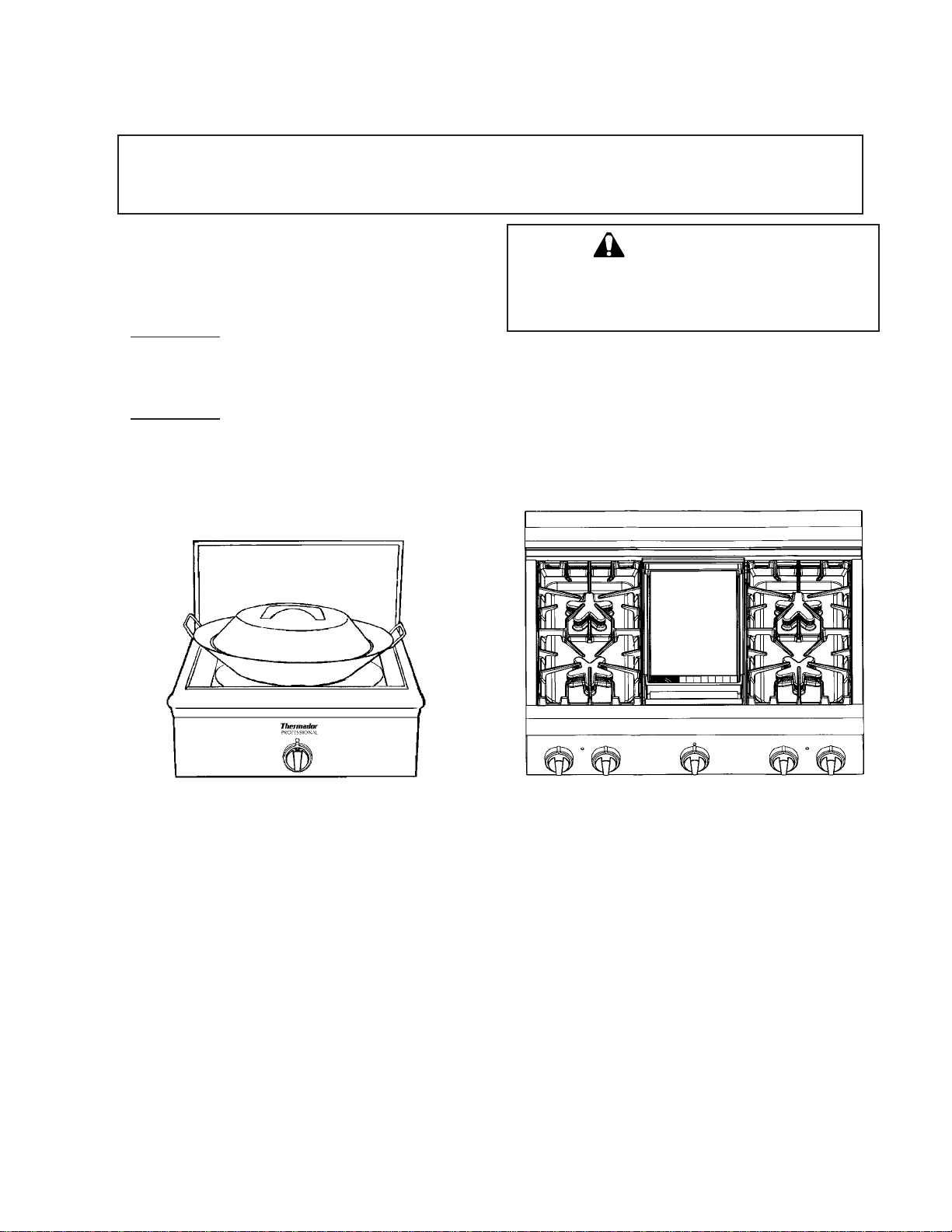

Model P24WK

(Shown with Low Back Model GP24LB)

Introduction

The Thermador Professional

able in a number of sizes and configurations. Model

P24WK is a 24"-wide wok unit featuring a power

burner rated at 30,000 BTU/HR. The 36"-wide Models PC364GE, PC364GL, and PC366 feature four

sealed burners and an electric griddle, four sealed

burners and a gas grill, or six sealed burners,

respectively. The 48"-wide Models PC484GGE,

PC486GE, PC486GL and PC484WK feature four

sealed burners, electric griddle and gas grill, six

sealed burners and an electric griddle, six sealed

burners and a gas grill, or four sealed burners and

a 30,000 BTU/HR WOK, respectively. All sealed

burners are rated at 15,000 BTU/HR, electric

griddles at 1,600 watts, and grills at 18,000 BTU/HR.

®

Cooktops are avail-

Model PC364GD

(Shown with Low Back Model GPS36LB)

IMPORTANT

• A backguard must be utilized when there is

less than a 12" horizontal clearance between

combustible materials and the back edge of the

cooktop. The Thermador Low Back backguard

must be ordered separately and installed at the

rear of the cooktop. For island installations and

other installations with more than 12" clearance, an optional stainless steel Island Trim is

available to cover the backguard mounting

flanges.

• Verify that the appliance is correct for the type

of gas being provided. Refer to Step 4 before

proceeding with the installation.

1

Page 4

Important Installation Information

This appliance has been tested

in accordance with ANSI Z21.1,

Standard for Household Cooking

Appliances (USA) and in accordance with CAN 1.1-M81 Domestic Gas Ranges (Canadian).

strongly recommended that

It is

this appliance be installed in conjunction with a suitable overhead

vent hood. (See Step 1 for Ventilation Requirements.) Due to

the high heat capability of this

unit, particular attention should

CAUTION

To eliminate risk of burns or

fire caused by reaching over

heated surface units, cabinet

storage located above the surface units should be avoided.

be paid to the hood and duct

work installation to assure it

meets local building codes.

Check local building codes for

the proper method of appliance

installation. Local codes vary.

Installation, electrical connections and grounding must comply with all applicable codes. In

the absense of local codes the

appliance should be installed in

accordance with the National Fuel

CAUTION

(1) When connecting the unit to

propane gas, make certain

the propane gas tank is

equipped with its own highpressure regulator in addition to the pressure regulator supplied with this unit.

The maximum gas pressure

to this appliance is not to

exceed 14.0 inches water

column from the propane

gas tank regulator.

(2) This unit is designed as a

cooking appliance. Based

on safety considerations,

never use it for warming or

heating a room.

Gas Code ANSI Z223.1 current

issue and National Gas Code

ANSI/NFPA 70 – current issue. In

Canada, installation must be in

accordance with the CAN 1B149.1 and .2 – Installation Codes

for Gas Burning Appliances and/

or local codes.

This appliance is equipped with

an intermittent/interrupted ignition device that cycles the two far

left surface burners on and off

when in the ExtraLow

®

setting.

2

Page 5

Step 1: Ventilation Requirements

It is strongly recommended that

a suitable exhaust hood be installed above the appliance.

Downdraft ventilation should not

be used. The table below indicates the Thermador hoods, by

model number, that are recommended for use with the 24" Wok

and 36" and 48" cooktops.

1. Select Hood and Blower Models:

• For wall installations, the

hood width must, at a minimum, equal the nominal

width of the appliance cooking surface. Where space

permits, a hood larger in width

than the cooking surface may

be desirable for improved

ventilation performance.

• For island installations, the

hood width should, at a mini-

mum, overhang the appliance cooking surface by 6"

on each side.

• Hood blower speeds should

be variable to reduce noise

and loss of heated or air conditioned household air when

maximum ventilation is not

required. Normally, the maximum blower speed is only

required when using the grill.

2. Hood Placement:

• For best smoke elimination,

the lower edge of the hood

should be installed a minimum of 30" to a maximum of

36" above the appliance

cooking surface. (See Fig.

1).

• If the hood contains any combustible materials (i.e., a

wood covering), it must be a

minimum of 36" above the

cooking surface.

3. Consider Make-Up Air:

• Due to the high volume of

ventilation air, a source of

outside replacement air is

recommended. This is particularly important for tightly

sealed and insulated homes.

• A qualified heating and ventilating contractor should be

consulted.

NOTE: Ventilation hoods and

blowers are designed for use

with single-wall ducting. Some

local building codes may require

double-wall ducting. Before starting installation, consult local

building codes and agencies to

insure that the installation will

meet local requirements.

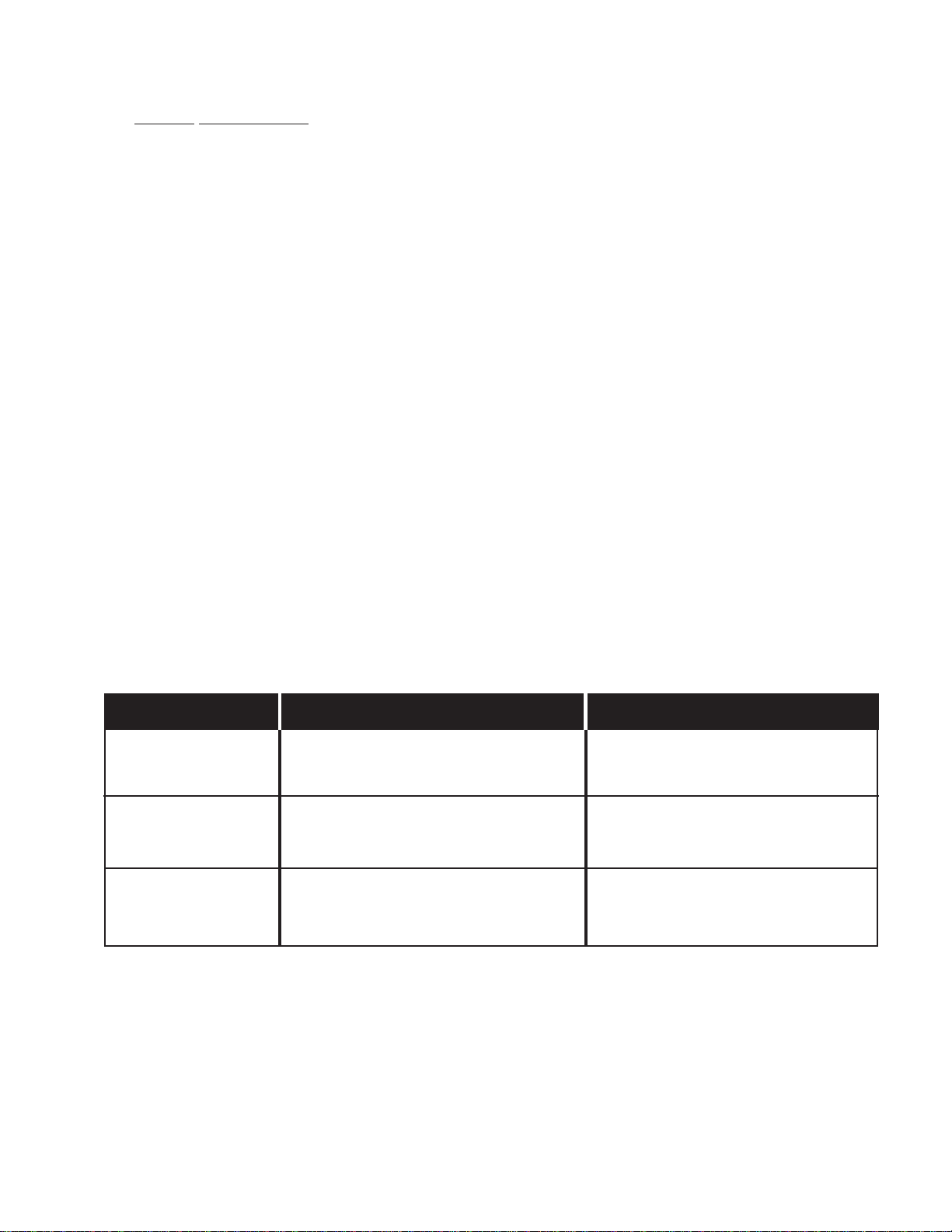

NOMINAL COOKTOP WIDTH

24" WOK

36" COOKTOP

48" COOKTOP

PH30ZS, PHE30,36

PH36ZS, PH42ZS

HNW 36,42 YS

PH48ZS, PH54ZS

WALL INST ALLATION ISLAND INSTALLA TION

HOOD* BLOWER** HOOD* BLOWER**

HNW36YS

PHE36, 42

PHE48, 60

HNW48YS

VTR1000Q

VTR1400Q

or VTN1000Q

VTR1000Q

VTR1400Q

or VTN1000Q

VTR1000Q

VTR1400Q

or VTN1000Q

HTNI42YS

HNI42YS

PHI48ZS

HTNI42YS

HNI42YS

PHI48ZS

HTNI48YS, HNI48YS

HTNI54YS, HNI54YS

PHI60ZS

VTR1000Q

VTR1400Q

VTR1000Q

VTR1400Q

VTR1400Q

NOTES: * For wall installations where adequate sp ace is available, the installer or user may elect to use

a hood that is wider than the cooktop cooking surface. This may be particularly beneficial for

those cases, such as a long duct run or heavy usage of the grill, in which improved capturing

of the cooking exhaust is desired.

** Thermador offers a choice of remote (VTR1000Q or VTR1400Q) or in-hood (VTN1000Q)

blowers for use in wall installations.

3

Page 6

Step 2: Cabinet Preparation

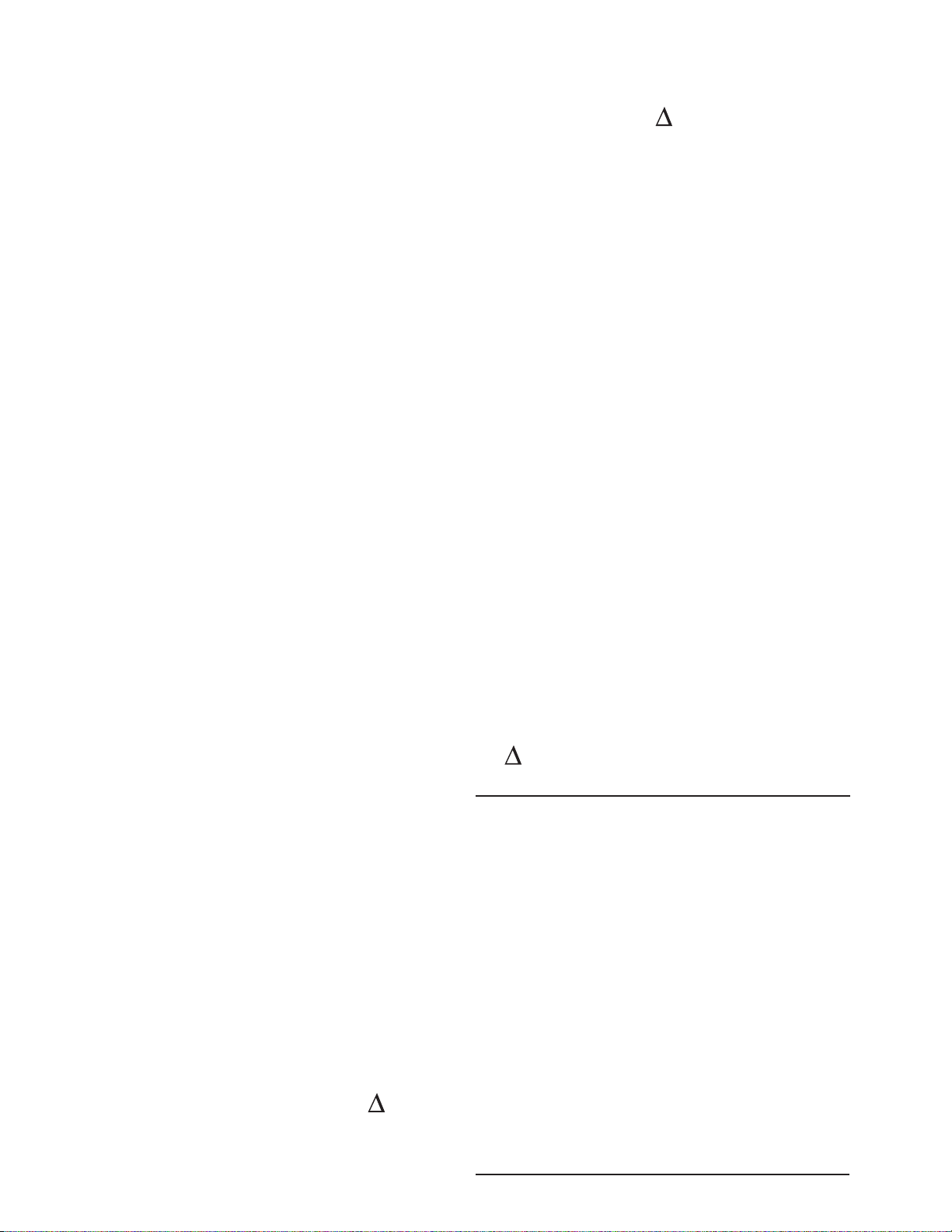

1. To ensure professional results, the cabinet and

countertop openings should be prepared by a qualified cabinet worker.

2. The clearances shown in Fig. 1 are required. The

same clearances apply to island installations, except for the overhead cabinets, which must have a

space wide enough to accept the island hood.

3 . The cooktop is designed to hang from the countertop

by its side flanges. The countertop however, must be

strong enough to support this heavy cooktop. It may

be necessary to add a supporting cleat along each

side (see Fig. 2) or a 2 x 4 corner brace (see Figs. 3

and 4 and Detail A). Another alternative would be to

construct a deck to set the cooktop on.

4 . The cooktop can be installed in various positions

with the front either flush or projecting, depending on

the countertop’s depth. (See Fig. 5, side view of

cooktop; see Figs. 3, 4, 6 and 7 for alternate mounting positions.)

5 . The gas and electrical supply must be located in an

area that is accessible without requiring removal of

the cooktop. The appliance electrical power cord

and gas pipe connection are located on the left

rear underside of the cooktop, as shown in Figs. 5

and 9. Make sure the gas regulator is horizontal

when installed in the gas supply line.

6. The maximum depth of over head cabinets installed on either side of the hood is 13".

A 36-inch minimum clearance is required between the

top of the cooktop and the bottom of an unprotected

cabinet. A 30-inch minimum distance is necessary

when the bottom of the wood or metal cabinet is

protected by not less than 1/4 inch of a flame retardant

material covered with not less than No. 28 MSG sheet

steel, 0.015 inch (0.4 mm) thick stainless steel, 0.024

inch (0.6 mm) aluminum, or 0.020 inch (0.5 mm) thick

copper. Flame retardant materials bear the mark:

UNDERWRITERS LABORATORIES INC.

CLASSIFIED

MINERAL AND FIBER BOARDS

SURFACE BURNING CHARACTERISTICS

Followed by the flame spread and smoke ratings.

These designations are shown as "FHC (FIame

Spread/Smoke Developed)." Materials with "O" flame

spread ratings are flame retardant. Local codes may

allow other flame spread ratings.

7. When there is less than a 12" horizontal clearance between combustible material and the

back edge of the cooktop above the cooking

surface, a Thermador Low Back backguard must

be installed. (See Step 6). When clearance to

8. Establish the centerline of the cooktop’s desired

9. Cut the openings for the following installations:

10. For flush installations as shown in Fig. 7, provide

11. For installation of a 48" cooktop above two side-

NOTE:

• If a solid side cabinet wall exists on one or both

• If a supporting deck is used, the sides or bottom of

• Always keep appliance area clean and free from

• Do not obstruct the flow of combustion and ventila-

combustible material is over 12", a Thermador

Island Trim may be used. Attach the backguard

before sliding the appliance into the final installed position.

location. It should be the same as the center of the

overhead ventilation hood.

• Wall installation, see Fig. 3.

• Island installation, see Fig. 4.

clearance for the three screws located along the

underside of the cooktop leading edge by increasing the cutout height by 1/16" or by notching the

cabinet at the location of the three screws.

by-side Thermador Warming Drawers, Model

No. WD24, refer to Fig. 8. Completing the installation as per Fig. 8 will result in the left and right

edges of the cooktop being aligned with the left

edge of the left-side warming drawer and right

edge of the right-side warming drawer. If different

alignment is desired, the 1-7/8" horizontal distance between warming drawer cutouts may be

varied. However, maintain at least a 1-1/8" distance to avoid interference between the warming

drawers. Attach a 90-degree elbow to the gas

cooktop inlet pipe and remotely mount the pressure regulator to avoid interference with the

warming drawer. All above-the-countertop clearances must be maintained, as shown in Fig. 1.

As defined in the "National Fuel Gas Code"

(ANSI Z223.1/NFPA54-current issue).

sides, you will need to notch the front corner of the

cabinet to match the countertop notch and to allow

clearance for the cooktop front (see Detail A, Figs.

3 and 4).

the cutout may be solid combustible or noncombustible material. If the bottom is solid, provide a 6" by

6" cutout in the left rear corner of the supporting

deck. This will provide clearance for the gas inlet and

power cord, while also allowing viewing of the product rating label.

combustible materials, gasoline and other flammable vapors and liquids.

tion air to the unit.

4

Page 7

Step 2: Cabinet Preparation

FIG. 1

Clearance

Requirements

13" Max.

depth of

overhead

18" Min.

cabinets

3" min.

both sides

As defined in the "National Fuel Gas Code"

30" or 36" for 24" Wok

36" or 42" for 36" Cooktop

48" or 60" for 48" Cooktop

Island – 42" or 48" for 24" Wok

Island – 42" or 48" for 36" Cooktop

Island –

48", 54" or 60" for 48"

VENT HOOD

30" Min. to 36" Max.,

bottom of Overhead

Hood to Cooking Surface

(36" if hood

contains combustible

materials ).

"A"

0" Bottom

(ANSI Z223.1, Latest Edition).

V

V

Cooktop

Horizontal

Min. Clearance

to Rear Wall:

0" with Backguard

V

12" w/o Backguard

0" Sides

Combustible

Material

V

36" Min. to

Combustible

Material

from Cooking

Surface.

V

Cooking

Surface

FIG. 2

Installing

Side Supports

(both sides)

Counter

Sunk

Screws

FIG. 3 Wall Installation with

Countertop Backsplash

B

See Detail A

23-7/16"

A

B

C

2" (Control Panel Flush to Cabinet Face – Min. 25-3/8"-Deep Base Cabinet Required)

D

B

24" WOK

24-3/4"

3/8"

5/8" (Notch Required for Standard 24"-Deep Base Cabinet,

7-13/16"

Detail A

(Front face of cabinet)

CORNER NOTCH

C

³

DETAIL

³

B

2x4 Corner

Support

36" COOKTOP

35-7/8"

3/8"

FIG. 4 Island Installation

(No Countertop Backsplash)

See Detail A

48" COOKTOP

48" COOKTOP

47-7/8"

13/16"

0" (Control Panel Projecting 2" from Base Cabinet Face)

Control Panel Projecting 1-3/8" from Base Cabinet Face)

3/4" Min.

D

22-11/16"

D

24"

35-1/8"

46-1/4"

5

Page 8

Step 2: Cabinet Preparation

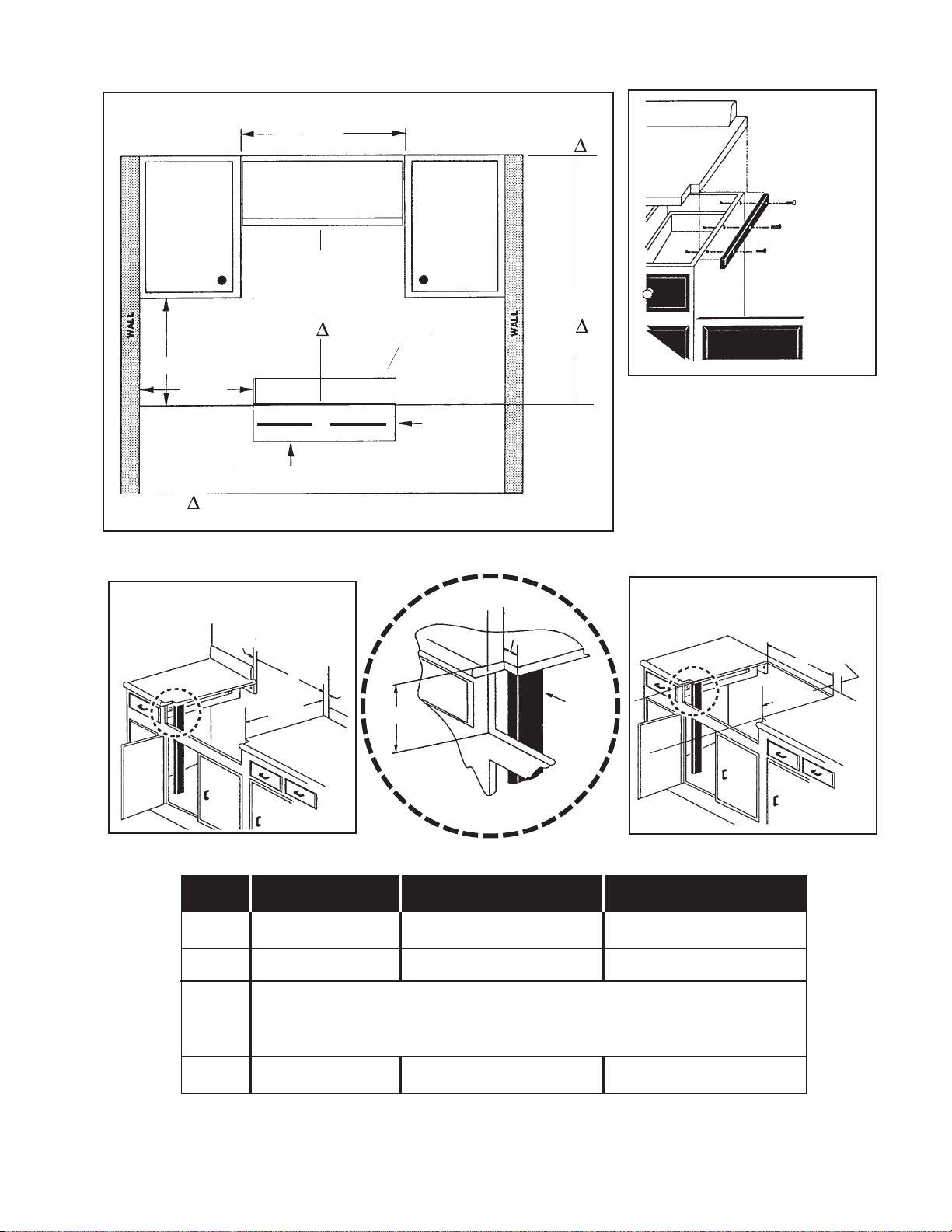

FIG. 5 Side View of Cooktop

FIG. 6 Projecting from

26-3/8"

12"

1/2"

Side Flange

7-3/4"

3" TO CENTERLINE GAS

INLET

22-5/8"

2"

Cabinet face for installation with projecting control panel

Cabinet face for installation with flush control panel

* Low Back required when there is less than

12" horizontal clearance from back of cooktop to

combustible material. With more than 12" of clearance, the Island Trim may be used.

23-3/8"

3"

3/4"

Front projects outward 1-3/8" as

shown from standard 24"-deep

base.

FIG. 8 Installation of 48" Cooktop above two

side-by-side Thermador Warming Drawers,

Model No. WD24

Minimum 3/4" (19 mm)

13/16"

(21 mm)

46-1/4"

22-11/16"

(57, 6 cm)

(22, 9 cm) 9"

(117,5 cm)

7-13/16"

(19,8 cm)

WD24

Cutout

WD24

Cutout

22-1/2"

(57,2 cm)

0" to 2"

(0 - 51mm)

See Fig. 4

and Table

Dimension C

Cabinet Front

1-3/8"

Side View

REAR

5/8"

Notch

Depth

Plywood support

Install additional

wood support along

front edge of cutout

FIG. 7 Flush to Cabinet

Front

* Provide clearance for screws

by increasing cutout height by

1/16" or by notching in the location of the three screws.

2" Notch

Depth

Front flush with cabinets;

minimum

of 25-3/8" cabinet depth

required.

-13

7

/16"

³

³

(19,8 cm)

2 3/4" (70 mm) minimum

between cutouts

1-7/8" (4,8 cm)

Horizontal Distance Between Cutouts

2-3/4" (7 cm) Vertical Distance

Between Cutouts

(See Side View for Wood Support)

6

Page 9

Step 2: Cabinet Preparation

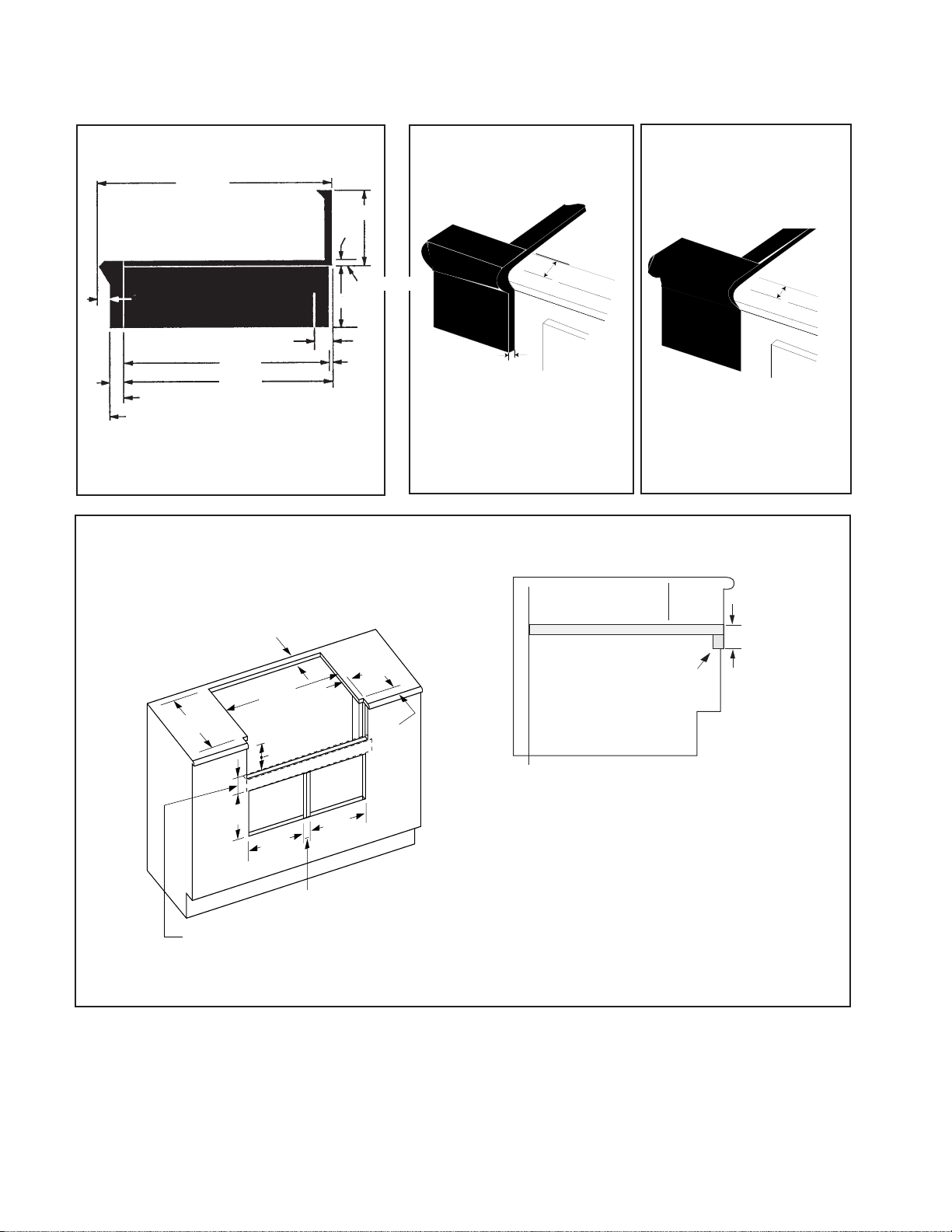

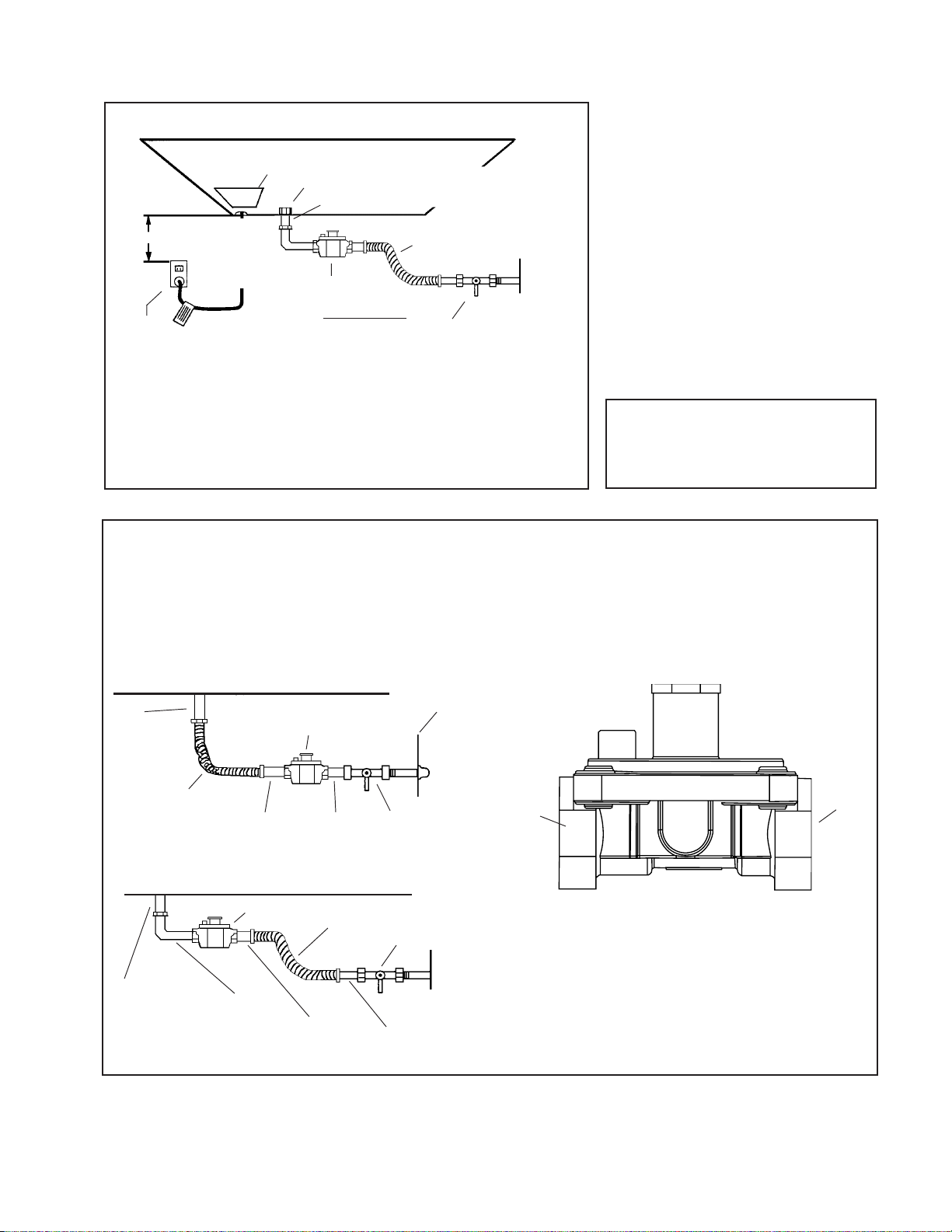

FIG. 9

3"

Min.

3-Prong grounding type

receptacle connected to

a properly grounded and

polarized electrical supply

rated at 120VAC, 10 Amps,

( or 15A*) Single Phase,

60 HZ.

Front - Bottom of Unit, See Detail B, Below

Product Rating

Label/Serial Tag

36"

Power

Cord

V

Threading compounds

must be resistant to

Propane Gas

V

V

P24WOK 1/2" NPT

V

V

Regulator (supplied with unit)

Install

horizontally,

See Detail B,

Below.

All Installer supplied parts must

conform to Local Codes.

Detail B – See FIG. 9, above

3/4" flex line

V

A manual valve must be

installed external to the

appliance, in an accessible

location from the front, for

the purpose of shutting off

the gas supply.

gas flow

V

*15 Amp electrical supply

required for models PC364GE,

PC486GE, and PC484GGE.

Suggested Regulator Installation

Installation Options

Installation Option 1. From Shut-off Valve

Manifold

3/4"

Manifold

flex

adapter

3/4"

flex

line

Installation Option 2. From Manifold

3/4" Manifold

nipple

3/4" x 3/4" x 3"

Street

Ell 3/4"

Regulator

3/4" flex

adapter

Regulator

3/4"

nipple

3/4"

flex

line

3/4" flex

adapter

gas flow

Shut-off

Valve

Shut-off

Valve

3/4" flex

adapter

Wall

gas flow

3/4 "

NPT

Outlet

GAS SUPPLY REGULATOR

Gas Flow

®

Make sure gas

regulator is horizontal

after installation

3/4 "

NPT

®

Inlet

7

Page 10

Step 3: Unpacking, Moving, Placing

and Anchoring the Cooktop

CAUTION

Proper equipment and adequate manpower

must be used in moving the appliance to

avoid damage and/or personal injury. The

unit is heavy and should be handled accordingly.

IMPORTANT

• Verify that the appliance is correct for

the type of gas being provided. Refer to

Step 4 before proceeding with the installation.

• Attach the backguard before sliding the

appliance into the final installed position. See Step 6.

1. Remove the outer carton and packing material

from the shipping base. Ensure that you have

all cooktop components before proceeding.

2. Remove the top grate castings, burner caps

and grill grate (if so equipped) to reduce unit

weight.

3. Lift and place the cooktop in the opening. Be

careful not to pinch the power cord or gas inlet.

Care should be taken not to scratch the griddle

or the griddle frame.

4. Ensure that the power line cord is free and

hanging loose.

5. Level the appliance. For proper performance,

the appliance must be level.

6. The grill frame (if so equipped) has been leveled

during assembly so do not attempt to level the

grill.

7. Replace the top grate castings, burner caps

and grill grate (if so equipped). Ensure that the

burner caps are correctly seated on the burner

bases.

Griddle Tilt Adjustment

Check the griddle frame adjustment by pouring two tablespoons of water on the back of the

griddle plate. The water should slowly roll into the grease tray. If not, adjust the two screws

under the back of the griddle frame. Start with one half turn CCW of the screws. Further

adjustment should be made by one-quarter turn until water slowly flows into the grease tray.

8

Page 11

Step 4: Gas Requirements and Hookup

Cooktops are shipped by the factory to operate on

natural gas. Verify the type of gas being used at the

installation site matches the type of gas used by the

appliance. If the location/job site requires conversion from one type of gas to another, contact the

dealer where the unit was purchased or contact

Thermador (800/735-4328). The field conversion

kit for all Professional cooktops (PC series) is

Thermador Model PLPKIT. Obey all instructions in

PLPKIT for correct conversion of the gas regulator

and settings for the gas valves. Field conversion

must be done by qualified service personnel only.

Natural Gas Requirements:

Inlet Connection: 3/4" N.P.T. (Minimum 3/4"

dia. flex line.)

Supply Pressure: 6" to 14" water column

Manifold Pressure: 5" water column

Propane Gas Requirements:

Inlet Connection: 3/4" N.P.T. (Minimum 3/4"

dia. flex line.)

Supply Pressure: 11" to 14" water column

Manifold Pressure: 10" water column

HOOK UP

• A manual gas shut-off valve must be installed

external to the appliance, in a location accessible from the front, for the purpose of shutting

off the gas supply. The supply line must not

interfere with the back of the unit. Make sure the

gas supply is turned off at the manual shut-off

valve before connecting the appliance.

• The gas supply connections should be made by

a competent technician and in accordance with

local codes or ordinances. In the absence of a

local code, the installation must conform to the

National Fuel Gas Code ANSI Z223.1/NFPA54current issue.

• Install the gas pressure regulator (supplied) to

the manifold pipe. Ensure that the appliance

pressure regulator is set to 5" W.C. for natural

gas and 10" W.C. for propane gas, and that the

arrow points in the direction of the gas flow

towards the appliance. Connect the gas supply

line to the unit pressure regulator using a

3/4" flex gas line between the manual gas shutoff valve and pressure regulator. (See Fig. 9.)

®

• Always use pipe dope or Teflon

pipe threads, and be careful not to apply excessive pressure when tightening the fittings.

• Leak testing of the appliance shall be in

accordance with the following instructions.

• Turn on gas and check supply line

connections for leaks using a soap and water

solution.

• Bubbles forming indicate a gas leak. Repair

all leaks immediatley after finding them.

• Do not use a flame of any kind to check

for gas leaks.

• All installer-supplied parts must conform to all

applicable codes.

tape on the

9

Page 12

Step 4: Gas Requirements and Hookup

CAUTION:

When connecting unit to propane gas, make

certain the propane gas tank is equipped with

its own high pressure regulator in addition to

the pressure regulator supplied with the appliance. The pressure of the gas supplied to the

appliance regulator must not exceed 14" water column.

CAUTION

The appliance must be isolated from the gas

supply piping system by closing its individual

manual shut-off valve during any pressure

testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig

(3.5kPa.).

"The appliance and its individual shut off valve

must be disconnected from the gas supply

piping system during any pressure testing of

the system at test pressures in excess of 1/2

psig (3.5kPa.)."

When checking the manifold gas pressure,

the inlet pressure to the regulator should be at

least 6.0" W.C. for natural gas or 11.0" for

propane.

Do not attempt any adjustment of the pressure regulator.

10

Page 13

Step 5: Electrical Requirements,

Connection and Grounding

• Always disconnect appliance

electric supply cord from wall

receptacle before servicing

this appliance.

• All cooktop models must be

plugged into a mating 3Prong, Grounding-Type Receptacle. The receptacle

must be connected to a properly grounded and polarized

electrical power supply rated

at 120VAC, Single Phase,

60HZ. See list below for

proper over-current protection requitements for each

model.

CAUTION: Im-

proper grounding or polarization will cause malfunction (such as continuous

sparking of the burner igniters). This can damage this

appliance and can create a

condition of shock hazard.

the circuit is not correctly

grounded and polarized, it is

the responsibility and obligation of the installer and user to

have the existing receptacle

changed to a properly

grounded and polarized receptacle. This must be accomplished in accordance with all

applicable local codes and ordinances by a qualified electrician. In the absence of local

codes and ordinances, the receptacle replacement shall be

in accordance with the National

Electric Code.

(See Fig.11)

• Observe all governing codes

and ordinances when

grounding. In the absence of

these codes or ordinances

observe National Electrical

Code ANSI/NFPA No. 70

current issue. See Fig. 11 for

recommended grounding

method.

• An electrical wiring diagram

and schematic have been

attached to the bottom of the

cooktop chassis for access

by a qualified service technician. Do not remove or discard this important information.

FIG. 11 Recommended

Grounding Method

THE THIRD, GROUND

PRONG MUST NOT BE CUT

OR REMOVED UNDER ANY

CIRCUMSTANCES.

Grounding Method

The cooktop is factory equipped

with a power supply cord with a

three-prong grounding plug (with

polarized parallel blades). IT

MUST BE PLUGGED INTO A

If

MATING, GROUNDING TYPE

RECEPTACLE THAT IS CONNECTED TO A CORRECTLY

POLARIZED 120 VOLT CIRCUIT. (See Fig. 11). Improper

grounding or polarization will

cause malfunction (such as continuous sparking of the burner

igniters), may damage this appliance, and can create a condition

of shock hazard.

Electrical Power Supply Over-current Protection Requirements:

(Each cooktop model requires either a 10 Amp or a 15 Amp

circuit breaker as shown below)

PC366- 10 Amp circuit protection.

PC364GL- 10 Amp circuit protection.

PC364GE

PC486GL- 10 Amp circuit protection.

PC486GEPC484GGE

PC484WK- 10 Amp circuit protection.

P24WK- 10 Amp circuit protection.

- (with electric griddle)

(with electric griddle)-

- (with electric griddle)

11

- 15 Amp circuit protection.

15 Amp circuit protection.

- 15 Amp circuit protection.

Page 14

Step 6: Backguard Installation

A Low Back backguard must be installed when there is less than a 12"

clearance between combustibles and

back edge of cooktop. (See Fig. 1 and

5.) For island installations and other

installations with over 12" clearance, an

optional stainless steel trim channel is

available to cover the backguard mounting flanges. Attach the backguard before sliding the appliance into the final

installed position. Follow Steps A through

C below:

A. Slide backguard over the two flanges

on the rear of the appliance. Fasten

the front and back with two screws

(see A, Fig. 12) provided. No screws

are required behind the griddle section.

B. Fasten the top of the backguard to

the wall with two screws through the

backguard. (See B, Fig. 12.)

C. Place the backguard cap on top and

fasten using the two counter-sink

screws provided. (See C, Fig. 12.)

FIG. 12 Low Back Attachment

C

B

A

LOW BACK AND ISLAND TRIM MODEL NUMBERS

COOKTOP MODEL NO. 12" LOW BACK Island Trim*

P24WK GP24LBS GP24ITS

PC36 GPS36LBS GPS36ITS

PC48 GPS48LBS GPS48ITS

*Requires a minimum of 12" horizontal clearance between back of appliance and combustible materials.

TO CLEAN AND PROTECT EXTERIOR SURFACES

The stainless steel surfaces may be cleaned by

wiping with a damp soapy cloth. Any mild glass

cleaner will remove fingerprints and smears.

Follow all cleaning by rinsing with clear water. Wipe

dry with a clean soft cloth to avoid water marks. For

discolorations or deposits that persist, use a nonscratching household cleanser or stainless steel

polishing powder with a little water and a soft cloth.

For stubborn cases, use a plastic scouring pad or

soft bristle brush together with cleanser and water.

Rub lightly in direction of polishing lines or "grain"

of the stainless finish. Avoid using too much pressure which may mar the surface.

Use a stainless steel cleaner/polish to protect the

finish and maintain appearance.

DO NOT allow deposits to remain for long periods

of time.

DO NOT use ordinary steel wool or steel brushes.

Small bits of steel may adhere to the surface

causing rust.

DO NOT allow salt solutions, disinfectants, bleaches

or cleaning compounds to remain in contact with

stainless steel for extended periods. Many of these

compounds contain chemicals which could prove

harmful. Rinse with water after exposure and wipe

dry with a clean cloth.

12

Page 15

Step 7: Test and Adjustment

CAUTION

Thermador recommends that

burner adjustments be made by

a qualified technician at the time

of installation. Extreme care

should be used when adjustments are made after installation. Improper or lack of adjustments may create harmful by

products and may void your warranty.

Fig. 13

Burners

1 to 1-1/2"

-

Proper Flame

Top

³

³

(Approx.)

Grill

1

/2 to 1"

³

³

Install any loose components, such as burner caps and grates, that

may have been removed earlier. Before testing operation of the

appliance, verify that the unit and the gas supply have been carefully

checked for leaks and that the unit has been connected to the electric

power supply. Turn the manual gas shut-off valve to the open position.

Check operation of the sealed gas burners, griddle and grill by

pushing and turning each knob counterclockwise to HI. Check that the

burner caps are correctly seated on the burner bases. The burner

igniters will click until the flame ignites. The two far left sealed burners

®

feature XLO

, causing the flame to cycle on and off when the knob is

set to the XLO range. This is normal operation.

EACH GAS BURNER MUST BE EVALUATED FOR CORRECT

FLAME PERFORMANCE IMMEDIA TELY AFTER INST ALLA TION OF

THIS APPLIANCE. In PC Cooktop models, air shutter for the grill

burner (NOT top burners) is preadjusted at the factory. However,

environmental or installation conditions may require readjustments.

Flame evaluation is performed with burner's control knob at highest

setting.

If the PLPKIT is used to convert this appliance from Natural to

Propane Gas, flame evaluation and air shutter readjustments must

be performed — see instructions provided with the PLPKIT for correct

recommendations.

Burner flames should be blue and stable with no yellow tips, excessive noise, or lifting of the flame from the burner. If any of these

conditions exist, check that the air shutter (grill only) or burner ports

are not blocked or clogged. Remove any blockages that exist.

If the flame is too yellow, indicating insufficient air, adjust the shutter

more open to increase air inlet (grill only).

The sealed top burner flames should be approximately 1 to 1-1/2"

high. The grill burner flame should be 1/2" to 1". (See Fig. 13).

NOTE: No air shutter or low flame adjustment is necessary or

possible with the sealed top burners.

13

Page 16

INSTALLER CHECKLIST

FINAL CHECK LIST

❑ Cooktop correctly positioned

and anchored in countertop

recess.

❑ Specified clearances main-

tained to cabinet surfaces.

❑ Unit Level – front to back –

side to side.

❑ Burner caps positioned prop-

erly on sealed burner bases.

❑ All packaging material re-

moved.

❑ Backguard attached (if hori-

zontal clearance to combustible materials behind cooking surface is less than 12").

❑ The stainless steel radiant

and porcelain grill grate is in

place (not all models).

❑ The griddle plate and frame

is correctly positioned, tilted

slightly forward. (See page 8

for adjustment procedure.)

GAS SUPPLY

❑ Connection: 3/4" NPT with a

minimum 3/4" diameter flex

line.

❑ The appliance is connected

only to the type of gas for

which it is certified for use.

❑ The pressure regulator

(shipped with unit) has been

connected to the manifold and

is set for 5" W.C. for natural

gas or 10" W.C. for propane.

❑ Manual gas shut off valve in-

stalled in an accessible location (without requiring removal

of appliance).

❑ Unit tested and free of gas

leaks.

❑ Gas supply pressure does not

exceed 14" W.C.

ELECTRICAL

❑ Polarized and grounded

120VAC, 10 Amp receptacle

with 10 Amp over-current protection is provided for service

cord connection.

OPERATION

❑ All internal packing materials

removed. Check below

grates and grill pans.

❑ Burner caps properly seated

into burner bases.

❑ Grill components properly

seated (not all models). Refer to Care & Use Manual for

Grill details.

❑ Bezels centered on burner

knobs, and knobs turn freely.

❑ Each burner lights satisfac-

torily, both individually and

with other burners operating.

❑ Air Shutter adjustment for

proper flame made for the

Grill. See Fig. 13.

❑ Griddle is tilted

ward and does not rock (not

all models).

❑ Burner grates correctly posi-

tioned, level, and do not rock.

slightly for-

❑ For models with electric griddle

(PC364GE, PC486GE, and

PC484GGE), a polarized and

grounded 120VAC receptacle

with

15 AMP overcurrent protection is provided for service

cord connection.

14

Page 17

INSTRUCTIONS

D’INSTALLATION

Des tables de cuisson Thermador Professional

®

Modèles

P24WK

PC36

PC48

Page 18

Table des matières

Avertissements................................................................... Ci-dessous

Introduction........................................................................................ 17

Information importante à propos de l’installation ................................ 18

Chapitre 1 : Exigences de ventilation................................................. 19

Chapitre 2 : Préparation de l’emplacement ............................... 20 – 23

Chapitre 3 : Déballage, manutention, mise en place et fixation

de la table de cuisson ....................................................................... 24

Chapitre 4 : Exigences pour l'alimentation du gaz et raccordement.... 25

Chapitre 5 : Exigences pour l’alimentation électrique, le

branchement et la mise à la terre...................................................... 26

Chapitre 6 : Installation de la plaque de protection ............................. 27

Chapitre 7 : Test et réglage............................................................... 28

Liste de vérification de l’installateur ................................................... 29

INFORMATIONS IMPORTANTES RELATIVES À L’INSTALLATION

AVERTISSEMENT :

L’information fournie dans le présent

manuel doit être très rigoureusement

respectée, sous peine d’incendie ou

d’explosion entraînant des dommages,

des blessures ou la mort.

—

Ne stockez pas et n’utilisez pas d’essence ou autres

produits inflammables à proximité des appareils.

—

SI VOUS SENTEZ UNE ODEUR DE GAZ

Q

N’allumez aucun appareil.

Q

Ne touchez pas aux interrupteurs électriques.

Q

N’utilisez pas les téléphones du bâtiment.

Q

Appelez immédiatement votre compagnie de gaz de chez

un voisin. Suivez les instructions de la compagnie.

Q

Si vous n’arrivez pas à contacter la compagnie de gaz,

appelez les pompiers.

—

L’inst allation et les réparations doivent être réalisées

par un installateur qualifié, un centre de réparation

agréé ou la compagnie de gaz.

AVERTISSEMENT

Une installation, un réglage, une modification,

une réparation ou un entretien adéquat

peuvent entraîner des blessures ou des

dégâts matériels. Consultez le présent

manuel. Pour de l’information supplémentaire

ou de l’assistance, consultez un installateur

qualifié, un centre de réparation, le fabricant

(revendeur) ou la compagnie distributrice de

gaz.

Remarque : Cette table de cuisson N’EST PAS

conçue pour les maisons mobiles ni pour les véhicules

récréatifs.

NE PAS installer ce ta

FICHE SIGNALÉTIQUE

Modèles de tables de cuisson :

La plaque de caractéristiques indique le modèle et

le numéro de série de votre table de cuisson ou de

votre wok. Elle est placée sur le dessous du châssis

de la table de cuisson ou du wok, près du raccord

d’arrivée de gaz et du cordon d’alimentation

électrique. Cette information est requise par le

Service à la clientèle.

modèle et les numéros de série devrait être entré

dans les espaces à la page 64 du Manuel

d’utilisation et d’entretien. Lorsque l'appareil est

installé, il est difficile d'accéder à l'information.

ble de cuisson dehors.

Avant que l'installation, le

Pour les installations au Massachusetts :

1. L’installation doit être réalisée par un entrepreneur qualifié ou agréé, un plombier ou

un installateur de gaz qualifié ou autorisé par l’État ou la région où cet appareil est posé.

2. Le robinet d’arrêt de gaz doit être pourvu d’une poignée en « T ».

3. La longueur maximum autorisée du tuyau de gaz est de 91,4 cm (36").

Page 19

VEUILLEZ LIRE TOUTES LES INSTRUCTIONS AVANT DE POURSUIVRE

IMPORTANT : LES RÉGLEMENTATIONS LOCALES VARIENT. L’INSTALLATION, LES

BRANCHEMENTS ÉLECTRIQUES, LES RACCORDEMENTS AU GAZ ET LA MISE À LA TERRE

DOIVENT SA TISF AIRE À TOUTES LES RÉGLEMENT A TIONS APPLICABLES.

IMPORTANT : Conservez ces instructions pour l’inspecteur local de la compagnie d’électricité.

INSTALLATEUR : Veuillez laisser ces instructions d’installation avec l’appareil pour le propriétaire.

PROPRIÉTAIRE : Veuillez conserver ces instructions pour consultation ultérieure.

ALIMENTATION EN GAZ :

Gaz naturel : 14,9 mb (6 pouces à la colonne d’eau).

Gaz propane : 27,4 mb (1 1 pouces à la colonne d’eau).

ALIMENTATION ÉLECTRIQUE :

Modèles de 91,4 cm (36") :

PC366 : 120 VCA, 60 Hz, monophasé, circuit de 10 A.

PC364GL : 120 VCA, 60 Hz, monophasé, circuit de 10 A.

PC364GE

Modèles de 1,22 m (48") :

PC486GL : 120 VCA, 60 Hz, monophasé, circuit de 10 A.

PC486GE : 120 VCA, 60 Hz, monophasé, circuit de 15 A.

PC486GGE

PC484WK- 120 VCA, 60 Hz, monophasé, circuit de 10 A.

(avec plaque de cuisson) :

(avec plaque de cuisson)

120 VAC, 60 Hz, monophasé, cuicuit de 15 A

: 120 VAC, 60 Hz, monophasé, circuit de 15 A

AVERTISSEMENT

Coupez l’électricité avant d’installer l’appareil.

Avant de remettre l’électricité, assurez-vous

que toutes les commandes sont à la position

OFF.

.

.

MODÈLE P24WK

(Représenté avec la plaque

de protection basse GP24LB)

Introduction

Les tables de cuisson Thermador Professional® sont disponibles

en plusieurs dimensions et configurations. Le modèle P24WK est

un appareil pour wok d’une largeur de 61 cm (24") équipé d’un

brûleur d’une puissance de 30 000 BTU/h. Les modèles PC364GE,

PC364GL et PC366, d’une largeur de 91,4 cm (36") comportent

quatre brûleurs hermétiquement encastrés et une plaque

chauffante, quatre brûleurs hermétiquement encastrés et un gril

ou six brûleurs hermétiquement encastré. Les modèles

PC484GGE, PC486GE, PC486GL et PC484WK de

1,22 m (48") sont pourvus de quatre brûleurs hermétiquement

encastrés, d’une plaque chauffante et d’un gril, de six brûleurs

hermétiquement encastrés et d’une plaque chauffante, de six

brûleurs hermétiquement encastrés et d’un gril ou de quatre

brûleurs hermétiquement encastrés et d’un brûleur pour wok d’une

puissance de 30 000 BTU/h Tous les brûleurs hermétiquement

encastrés ont une puissance de 15 000 BTU/h, les plaques de

cuisson de 1 600 watts et les grils de 18 000 BTU/h.

IMPORTANT

• Une plaque de protection doit être mise en place

• Assurez-vous que l’appareil convient au type de gaz

17

MODÈLE PC364GD

(Représenté avec la plaque

de protection basse GPS36LB)

lorsque le dégagement horizontal entre les matériaux

combustibles et le bord arrière de la table de cuisson

est de moins de 30,5 cm (12’’). La plaque de protection basse Thermador est à commander séparément

et doit être installée à l’arrière de la table de cuisson.

Pour les installations en îlot avec un dégagement de

plus de 30,5 cm (12’’), un enjoliveur en acier inoxydable

est vendu en option afin de recouvrir les brides de

montage de la plaque de protection.

fourni. Consultez le chapitre 4 avant de procéder à

l’installation.

Page 20

Information importante à propos de l’installation

Cet appareil a été testé

conformément à la version

actuelle de la norme ANSI Z21.1

régissant les appareils de

cuisson domestiques au gaz.

Cet appareil a aussi été testé

conformément à la version

actuelle de la norme canadienne

CAN/CGA 1.1-M81 régissant les

cuisinières domestiques à gas.

Il est

d’installer une hotte de

ventilation adaptée au-dessus

de cet appareil (voir chapitre 1,

Conditions de ventilation). À

fortement recommandé

MISE EN GARDE

Afin d'éliminer les risques de

brûlures ou d’incendie

provoqués par la chaleur, il

est conseillé d’éviter

d’installer des armoires audessus des appareils.

cause de la chaleur intense que

peut dégager cet appareil, on doit

porter une attention particulière

à l'installation des conduits et de

la hotte afin qu'ils soient

conformes aux réglementations

locales de construction.

Vérifiez la réglementation locale

applicable à la construction pour

connaître la méthode appropriée d’installation de l’appareil.

À défaut de réglementation,

l’appareil doit être installé

conformément aux versions

actuelles du Code national du

gaz combustible no Z223.1 et du

Code national de l’électricité

ANSI/NFPA70 ou aux Codes

d’installation pour les appareils

à gaz Can B149 et au Code

électrique canadien C22.1,

première partie.

Assurez-vous que l’appareil à

installer correspond au type de

gaz utilisé sur le site.

Cet appareil est équipé d’un

système d’allumage intermittent

qui allume et éteint les deux

brûleurs de gauche lorsqu’ils sont

réglés sur ExtraLow

MISE EN GARDE

(1) Si l’appareil est alimenté au gaz propane, assurez-vous

que le réservoir de propane est équipé de son propre

détendeur en plus du détendeur fourni avec l’appareil.

La pression maximum d’arrivée du gaz dans cet appareil

ne doit pas dépasser les 34,9 millibars (14 pouces à la

colonne d’eau) à partir du détendeur du réservoir de

propane.

(2) Cet appareil est conçu pour un usage culinaire. Pour

des raisons de sécurité, ne l’utilisez jamais pour chauffer

une pièce.

®

.

18

Page 21

Chapitre 1 : Exigences de ventilation

Il est fortement recommandé

d’installer une hotte de

ventilation appropriée au-dessus

de l’appareil. Une ventilation par

contre-tirage ne devrait pas être

utilisée. Le tableau ci-dessous

énumère, par numéro de

modèle, les hottes Thermador

qu’il est conseillé d’utiliser avec

le wok de 61 cm (24") et avec

les tables de cuisson de 91,4 cm

(36") et de 121,9 cm (48").

1. Choix du modèle de hotte

et de ventilateur

- Pour les installations

murales, la largeur de la

hotte doit être au moins égale

à celle de la table de cuisson

de l’appareil. Si l’espace le

permet, il est souhaitable

d’installer une hotte plus

large que la table de cuisson

pour améliorer les

performances de ventilation.

- Pour les installations en îlot,

la largeur de la hotte devrait

dépasser d'au moins

15,2 cm (6") des deux côtés

de la table de cuisson de

l’appareil.

- La vitesse du ventilateur de

la hotte doit être réglable afin

de réduire le bruit et la perte

d’air chaud ou climatisé

lorsque la ventilation

maximum n’est pas

nécessaire. Normalement, la

vitesse maximum du

ventilateur n’est nécessaire

que lorsqu'on utilise le gril.

2. Emplacement de la hotte

- Pour une meilleure

élimination des fumées, le

bord inférieur de la hotte doit

être placé à une distance

minimale de 76,2 cm (30") et

maximale de 91,4 cm (36")

au-dessus de la table de

cuisson. (Voir figure 1).

- Si la hotte comporte des

matériaux combustibles (par

exemple, un placage en

bois), elle doit être placée à

au moins 91,4 cm (36")

au-dessus de la table de

cuisson.

3. Apport d’air

- Un important volume d’air

étant nécessaire pour la

ventilation, il est recommandé

de prévoir un apport d’air de

l’extérieur. Cet aspect revêt

une importance particulière

dans les logements bien

isolés et très étanches.

- Il est conseillé de consulter

un entrepreneur en

chauffage et en climatisation.

REMARQUE : Les hottes de

ventilation et les ventilateurs

sont conçus pour une seule

conduite murale. Certaines

réglementations locales du

secteur du bâtiment exigent

toutefois une double conduite.

Consultez les normes

applicables et les autorités

municipales avant de

commencer les travaux afin de

vous assurer que l’installation

des conduites répond aux

exigences locales.

LARGEUR NOMINALE DE LA

TABLE DE CUISSON

(24" WOK)

WOK DE 61 CM

(36" COOKTOP)

TABLE DE CUISSON

DE 91,4 CM

(48" COOKTOP)

TABLE DE CUISSON

DE 121,9 CM

PH30ZS, PHE30,36

PH36ZS, PH42ZS

PH48ZS, PH54ZS

INST ALLATION MURALE INST ALLATION EN ÎLOT

HOTTE* VENTILATEUR ** HOTTE* VENTILATEUR **

HNW36YS

PHE36, 42

HNW 36,42 YS

PHE48, 60

HNW48YS

VTR1000Q

VTR1400Q

ou VTN1000Q

VTR1000Q

VTR1400Q

ou VTN1000Q

VTR1000Q

VTR1400Q

ou VTN1000Q

HTNI42YS

HNI42YS

PHI48ZS

HTNI42YS

HNI42YS

PHI48ZS

HTNI48YS, HNI48YS

HTNI54YS, HNI54YS

PHI60ZS

VTR1000Q

VTR1400Q

VTR1000Q

VTR1400Q

VTR1400Q

REMARQUES : * Pour les installations murales, si l’espace est suffisant, l’installateur ou l’utilisateur peut

choisir une hotte plus large que la surface de la table de cuisson. Elle améliorera

l’évacuation des fumées si l’on utilise par exemple beaucoup le gril ou si la conduite est

longue.

**Pour les installations murales, Thermador propose des modèles de ventilateurs à

distance (VTR1000Q ou VTR1400Q) ou incorporés dans la hotte (VTN1000Q).

19

Page 22

Chapitre 2 : Préparation de l’emplacement

1 . Pour garantir des résultats professionnels, les ouvertures

dans l’armoire et dans l'espace de travail doivent être

effectuées par du personnel qualifié.

2 . Les dégagements requis sont indiqués à la Figure 1. Les

mêmes dégagements s’appliquent aux installations en

îlot, excepté pour les armoires suspendues qui doivent

laisser un espace suffisamment grand pour y loger la

hotte de l’îlot.

3. La table de cuisson est conçue pour être accrochée au

plan de travail par ses brides latérales. Le plan de travail

doit toutefois être suffisamment solide pour porter ce

lourd appareil. Il sera éventuellement nécessaire d’ajouter

un tasseau de chaque côté (voir figure 2) ou 2x4 montants

d’angle (voir figures 3 et 4 et la vue éclatée A). L’autre

possibilité est de construire un plan de support pour y

installer la table de cuisson.

4. La table de cuisson peut être installée sur plusieurs

positions, avec la partie frontale au même niveau que le

plan de travail ou en projection avant, selon la profondeur

de ce plan (voir Figure 5, vue latérale de la table de cuisson;

voir Figures 3, 4, 6 et 7 pour les autres positions de montage).

5 . Les arrivées d’électricité et de gaz doivent se trouver dans

une zone accessible sans avoir à enlever la table de

cuisson. Le cordon d’alimentation électrique et le raccord

du tuyau de gaz de l’appareil sont placés dans la partie

arrière gauche sous la table de cuisson, tel qu'indiqué aux

Figures 5 et 9. Veillez à ce que le détendeur de gaz soit installé

en position horizontale sur le tuyau d’arrivée de gaz.

6. La profondeur maximum des armoires suspendues de chaque

côté de la hotte est de 33 cm (13").

Un dégagement minimal de 91,4 cm (36") est nécessaire entre le

dessus de la table de cuisson et le dessous d’une armoire non

protégée. Si le dessous de l’armoire en bois ou en métal est

protégé par un matériau ignifuge d’une épaisseur d'au moins

6,35 mm (1/4") recouvert d’une feuille d’acier no 28 MSG de la

même épaisseur, de 0,4 mm (0,015") d’acier inoxydable, de 0,6 mm

(0,024") d’aluminium ou de 0,5 mm (0,02") de cuivre, alors la

distance minimale est de 76,2 cm (30").

Les matériaux ignifuges portent la marque :

UNDERWRITERS LABORA TORIES INC.

CLASSIFIED MINERAL AND FIBER BOARDS

SURFACE BURNING CHARACTERISTICS,

(panneaux de fibres et minéraux classés, caractéristiques

d’inflammation des surfaces), suivie des taux de progression

des flammes et des fumées. Ces désignations sont indiquées

par « FHC » (Flame Spread/Smoke Developed – Progression

des flammes/Production de fumée). Les matériaux ayant un

taux « O » de progression de flammes sont ignifuges. Les

réglementations locales peuvent autoriser d’autres taux de

progression des flammes.

7 . Si la distance entre un matériau combustible et le bord

arrière de la table de cuisson au-dessus de la surface de

travail est de moins de 30,5 cm (12’’), on doit obligatoirement

installer une plaque de protection basse Thermador

(voir Chapitre 6). Si la distance du matériau combustible

8 . Définissez la ligne centrale de l’emplacement destiné à la

9. Découpez les ouvertures pour les installations suivantes :

10 . Pour les installations à ras de l'aire de travail, représentées

11 . Pour l’installation de la table de cuisson de 1,22 m (48") sur

Tel que défini dans le « Code national du gaz

REMARQUES :

•

• Si vous construisez un plan de support, les côtés ou le bas

• L’appareil ne doit jamais se trouver à proximité de

• L’air de combustion et de ventilation arrivant à l’appareil

est de plus de 30,5 cm (12"), on peut utiliser un enjoliveur

Thermador pour îlot. Installez la plaque de protection avant

de glisser l’appareil dans sa position d’installation définitive.

table de cuisson. Elle doit correspondre au centre de la

hotte de ventilation suspendue.

• Installation murale, voir Figure 3.

• Installation en îlot, voir Figure 4.

à la Figure 7, prévoyez le dégagement nécessaire aux trois

vis placées au long du dessous du bord d’attaque de la table

de cuisson en augmentant la hauteur de la découpe de 1,6 mm

(1/16’’) ou en faisant des encoches dans l’armoire à

l’emplacement des trois vis.

les deux tiroirs chauffe-plats côte à côte de Thermador

(modèle WD24), reportez-vous à la Figure 8. Si vous réalisez

l’installation conformément à la Figure 8, le bord gauche de

la table de cuisson sera aligné avec le bord gauche du tiroir

chauffe-plats gauche et le bord droit de la table de cuisson

sera aligné avec le bord droit du tiroir chauffe-plats droit. Pour

obtenir un alignement différent, vous pouvez modifier la

distance horizontale de 4,76 cm (1-7/8") entre les découpes

des tiroirs chauffe-plats. Vous devez toutefois conserver une

distance d’au moins 2,85 cm (1-1/8") pour éviter les

interférences entre les tiroirs chauffe-plats. Montez un coude

de 90º sur le tuyau d’arrivée de gaz de la table de cuisson et

montez le détendeur plus loin pour éviter les interférences

avec les tiroirs chauffe-plats. Tous les autres dégagements

au-dessus du plan de travail doivent être maintenus comme

indiqués à la Figure 1.

combustible » (Version actuelle des normes ANSI Z223.1/

NFPA54)

Si vous avez d’un ou des deux côtés des parois latérales

pleines d’armoires, vous devrez encocher le coin avant

de l’armoire pour l’adapter à l’encoche du plan de travail

et laisser l’espace à la partie frontale de la table de

cuisson (voir vue éclatée A, Figures 3 et 4).

de la découpe peuvent être en matériau plein combustible

ou non combustible. Si le bas est plein, prévoyez une

découpe de 15,2 x 15,2 cm (6" x 6") dans le coin arrière

gauche de ce plan. Vous aurez ainsi l’espace nécessaire

à l’arrivée de gaz et au cordon d’alimentation, et cela vous

permettra de voir la plaque de caractéristiques du produit.

matériaux combustibles, d’essence et d’autres produits

inflammables (vapeurs ou liquides).

doit pouvoir circuler librement.

20

Page 23

Chapitre 2 : Préparation de l’emplacement

FIG. 1

Dégagements

45,7 cm

(18’’) min.

7,6 cm (3") min.

des deux côtés

76,2 ou 91,4 cm pour wok de 61 cm (24")

91,4 ou 106,7 cm pour table de cuisson de 91,4 cm (36")

121,9 ou 152,4 cm pour table de cuisson de 48" (121,9 cm)

Îlot – 42" ou 48" pour wok de 61 cm (24")

Îlot – 42" ou 48" pour 36" tab. de cuisson

Îlot – 48", 54" ou 60" pour 48" tab. de cuisson

HOTTE DE VENTILATION

VENT HOOD

V

76,2 cm (30’’) min. à

91,4 cm (36’’) max. entre

le dessous de la hotte et

Profondeur

max. des

armoires

suspendues :

33 cm (13’’)

la table de cuisson

(91,4 cm [36’’] si la hotte

contient des matériaux

combustibles ).

V

"A"

Bas 0 cm (0’’)

76,2 cm =30"

91,4 cm = 36"

106,7 cm = 42"

121,9 cm = 48"

137,2 cm = 54"

152,4 cm = 60"

Distance

horizontale min. du

mur arrière : 0 cm

(0’’) avec plaque de

protection, 30,5 cm

V

(12’’) sans plaque

de protection

Côtés 0 cm (0")

tel que défini dans le « Code national du gaz combustible »

(ANSI Z223.1 – Dernière édition).

MATÉRIAUX

COMBUSTIBLES

V

Distance min.

de 91,4 cm

(36’’) des

matériaux

combustibles

de la table

de cuisson

V

Table

de

cuisson

FIG. 2

Installation de

supports

latéraux (des

deux côtés)

Vis à tête

fraisée

FIG. 3

Installation murale avec

rebord de plan de travail

B

Voir vue éclatée A

59,5 cm

(23-7/16’’ )

WOK DE 24"

WOK DE 61 CM

A

B

C

62,8 cm (24-3/4")

9,5 cm (3/8")

15,9 mm (5/8’’) (Encoche nécessaire pour armoire de support standard de 61 cm (24’’) de profondeur.

Panneau de commande projeté de 3,4 cm (1 3/8’’) devant le panneau frontal de l’armoire de support)

5 cm (2’’) (Panneau de commande au ras du panneau frontal de l’armoire – armoire de support d’une

Vue éclatée A

(Face frontale de l’armoire)

D

B

19,8 cm

(7-13/16")

DÉTAIL DE L’ENCOCHE

T ABLE DE CUISSON DE 48"

TABLE DE CUISSON DE 91,4 CM TABLE DE CUISSON DE 121, 9 CM

C

³

B

EN COIN

³

Montant

d’angle 2x4

91 cm (35-7/8")

9,5 cm (3/8")

FIG. 4 Installation en îlot (sans

rebord de plan de travail)

T ABLE DE CUISSON DE 48"

121, 6 cm (47-7/8")

20,6 cm (13/16")

0 mm (0’’) (Panneau de commande projeté de 5 cm (2’’) devant le panneau frontal

de l’armoire de support)

profondeur min. de 64,4 cm [25-3/8’’] requise)

Voir vue

éclatée A

19 mm min.

(3/4’’)

D

57,6 cm

(22-11/16’’)

D

60,9 cm (24")

89,2 cm (35-1/8")

117,4 cm (46-1/4")

21

Page 24

Chapitre 2 : Préparation de l’emplacement

FIG. 5 - Vue latérale de la table

de cuisson

66,9 cm

(26 3/8’’)

7,6 cm (3") À LA LIGNE CENTRALE

DE L’ARRIVÉE DE GAZ

5

cm

(2")

• Une plaque de protection basse est nécessaire si la

distance horizontale entre l’arrière de la table de

cuisson et les matériaux combustibles est inférieure à

30,5 cm (12’’). Avec plus de 30,5 cm (12’’), il est

possible d’utiliser l’enjoliveur pour îlot.

57,4 cm (22-5/8")

59,3 cm (23-3/8")

Panneau frontal de l’armoire pour installation

avec panneau de commande projeté

Panneau frontal de l’armoire pour installation

avec tableau de commande au ras

12,7

mm

(1/2")

19,6 cm

(7-3/4")

3"

30,5

cm

(12’’)

Bride latérale

19 mm

(3/4")

FIG. 6 - Projection

devant l’armoire

3,4 cm

(1 3/8’’)

Sur la figure, l’avant est

projeté de 3,4 cm (1 3/8’’)

vers l’extérieur avec un

support standard de 60,9 cm

(24’’) de profondeur .

FIG . 8 - Installation d’une t able de cuisson de 121,9 cm (48’’) sur

deux tiroirs chauffe-plats côte à côte, modèle WD24.

Encoche de

15,9 mm

(5/8’’)

FIG. 7 - Au ras du

Laissez de l’espace pour les vis en

augmentant la hauteur de la

découpe de 1,6 mm (1/16’’) ou en

faisant des encoches pour

l’emplacement des trois vis.

Avant au ras des

armoires : profondeur

d’armoire de 64,4 cm

(25 3/8’’) minimum.

Minimum 19 mm (3/4" )

21 mm

(13/16")

117, 5 cm

Découpe

(46-1/4")

19,8 cm

WD24

57,2 cm

(22-1/2")

(7-13/16")

Découpe

WD24

57,2 cm

(22-1/2")

4,8 cm (1-7/8")

Distance horizontale entre les découpes

(0" to 2")

0 - 51mm

(Voir Fig. 4

et cote

C dans

le tableau)

57,6 cm

(22-11/16")

22,9 cm (9")

7 cm (2-3/4") Distance verticale entre les

découpes (Voir vue latérale pour les supports en bois)

Vue latérale

Support en

contreplaqué

ARRIÈRE

Installez un tasseau

supplémentaire le

long du bord avant

de la découpe.

³

19,8 cm

-13

³

(7

/16")

6,9 cm (2 3/4") minimum

entre découpes

Page 25

Chapitre 2 : Préparation de l’emplacement

FIG. 9

Plaque de caractéristiques du

produit/Étiquette de série

7,6 cm (3")

Min.

V

Prise murale à 3 fiches, avec

prise de terre, connectée à

un circuit d’alimentation

électrique adéquatement

polarisé et relié à la terre de

120 VCA, 10 A, (*15 A)

monophasé, 60 Hz.

Partie frontale inférieure de l’appareil, voir vue

éclatée B ci-dessous

Les enduits de joints doivent être

résistants au gaz propane.

V

V

Cordon

d’alimentation

de 91,4 cm

(36")

V

Détendeur (fourni

avec l’appareil).

Installé à

l’horizontale.

Un robinet d’arrêt doit être

installé à l’extérieur de

l’appareil, à un endroit

accessible de l’avant, dans

le but de pouvoir couper

l’arrivée de gaz.

Toutes les pièces fournies par

l’installateur doivent satisfaire aux

réglementations locales.

Vue éclatée B – Voir Figure 9 ci-dessus

Tuyau flexible de 19 mm (3/4")

V

Arrivée de gaz.

V

*Alimentation électrique de15

ampères requise pour tous les

modèles PC364GE,

PC486GE et PC484GGE.

Installation proposée pour le détendeur

Options d’installation

Option 1. À partir du robinet d’arrêt

Collecteur

Adaptateur

flexible de

collecteur

de 19 mm

(3/4")

Tuyau

flexible de

19 mm

(3/4")

Détendeur

Adaptateur

de flexible

de 19 mm

(3/4")

Arrivée

de gaz

Téton de

19 mm

(3/4’’)

Option 2. À partir du collecteur

Tuyau

flexible

de

19 mm

(3/4’’)

Adaptateur

de flexible

de 19 mm

(3/4")

Adaptateur de

flexible de 19 mm

(3/4")

Téton de

collecteur de

19 mm (3/4’’)

19 mm x 19 mm x

76 mm

(3/4" x 3/4" x 3")

Détendeur

Canalisation

EII de

19 mm

(3/4")

Mur

Robinet

d’arrêt

Robinet

d’arrêt

Arrivée

de gaz

RÉGULATEUR D’ARRIVÉE DE GAZ

Sortie

raccord

NPT de

19 mm

(3/4’’)

¯

Vérifiez après l’installation que

le détendeur de gaz

est placé à l’horizontale.

Arrivée de

gaz

¯

Entrée

raccord

NPT

de

19 mm

(3/4’’)

23

Page 26

Chapitre 3 : Déballage, manutention et mise en place et

fixation de la table de cuisson

MISE EN GARDE

Un équipement adapté manipulé par du personnel expérimenté doit être utilisé pour

déplacer l’appareil afin de ne pas

l’endommager et d’éviter les blessures.

L’appareil est lourd et doit faire l’objet d’une

manutention adéquate.

1. Retirez l’emballage externe et les matériaux

d’emballage de la palette d’expédition.

Assurez-vous d'avoir tous les articles qui

composent la table de cuisson avant de

poursuivre.

2. Retirez les grilles en fonte, les chapeaux des

brûleurs et la grille du gril (le cas échéant) pour

réduire le poids de l’appareil.

3. Soulevez la table de cuisson et placez-la dans

l’ouverture. Prenez garde à ne pas pincer le

cordon d’alimentation ni l’arrivée de gaz et à

ne pas rayer la plaque chauffante ou son

cadre.

IMPORTANT

• Assurez-vous que l’appareil

correspond au type de gaz utilisé sur

le lieu d’installation. Reportez-vous au

Chapitre 4 avant de poursuivre

l’installation.

• Posez la plaque de protection avant de

glisser l’appareil sur sa position finale.

Voir Chapitre 6.

4. Assurez-vous que le cordon d’alimentation est

dégagé et pend sans tension.

5. Nivelez l’appareil. Pour obtenir de bons résultats,

l’appareil doit être nivelé.

6. Le gril (si l’appareil en est équipé) a été nivelé

lors de l’assemblage. Ne tentez pas d’en

modifier la mise à niveau.

7. Replacez les grilles en fonte, les chapeaux des

brûleurs et la grille du gril (le cas échéant).

Assurez-vous que les chapeaux des brûleurs

sont correctement posés dans leurs bases.

Ajustement de l'inclinaison de la plaque de cuisson

Vérifiez l'ajustement du cadre de la plaque de cuisson en versant deux cuillères à soupe d'eau

sur la plaque de cuisson. L'eau devrait lentement couler dans le bac à graisse. Si ce n'est pas

le cas, corrigez l'angle à l'aide des deux vis sous le cadre de la plaque de cuisson. Commencez

par un demi-tour dans le sens contraire des aiguilles d'une montre. Les corrections subséquentes

doivent être faites au quart de tour jusqu'à ce que l'eau coule lement dans le bac à graisse.

24

Page 27

Chapitre 4 : Exigences pour l'alimentation du gaz et raccordement

RACCORDEMENT

Les tables de cuisson sont préparées à l’usine avant

expédition pour être alimentées par du gaz naturel.

Assurez-vous que le type de gaz utilisé sur le lieu

d’installation correspond au type de gaz utilisé par

l’appareil. Si l’emplacement ou le lieu d’installation

exigent une conversion d’un type de gaz à un autre,

contactez votre revendeur ou Thermador

(1 (800) 735-4328). Le modèle de la trousse de

conversion pour toutes les tables de cuisson

Professional (série PC) est le PLPKIT Thermador.

Suivez toutes les instructions du PLPKIT pour

convertir correctement le détendeur de gaz et

effectuer le réglage des robinets de gaz. La

conversion sur site doit obligatoirement être réalisée

par du personnel qualifié.

Conditions pour le gaz naturel :

Raccord d’entrée : filetage NPT de 19 mm

(3/4") (tuyau flexible d’un diamètre minimum de

19 mm (3/4").

Pression d’alimentation : 14,9 à 34,9 mb (6" à 14" à

la colonne d’eau).

Pression du collecteur : 12,5 mb (5" à la colonne

d’eau).

Conditions pour le gaz propane :

Raccord d’entrée : filetage NPT de 19 mm

(3/4’’) (tuyau flexible d’un diamètre minimum de

19 mm (3/4").

Pression d’alimentation : 27,4 à 34,9 mb (11" à 14"

à la colonne d’eau ).

Pression du collecteur : 24,9 mb (10" à la colonne

d’eau).

• Un robinet manuel d’arrêt de gaz doit être

installé à l’extérieur de l’appareil, à un endroit

accessible par le devant, dans le but de pouvoir

couper l’alimentation en gaz. Le tuyau d’arrivée

de gaz ne doit pas gêner à l’arrière de l’appareil.

Assurez-vous que le robinet d’arrêt est fermé

avant de raccorder l’appareil.

• Le raccordement à l’arrivée de gaz doit être effectué

par un technicien compétent conformément à la

réglementation locale. À défaut de réglementation

locale, l’installation devra être conforme au Code

national du gaz combustible ANSI Z223.1/NFPA54

– version actuelle.

• Installez le détendeur de gaz (fourni) sur le tuyau du

collecteur. Assurez-vous que le détendeur de

l’appareil est réglé sur 12,5 mb (5" à la colonne

d’eau) pour le gaz naturel et sur 24,9 mb (10" à la

colonne d’eau) pour le gaz propane. La flèche doit

être orientée dans le sens de l’arrivée de gaz vers

l’appareil. Raccordez le tuyau d’alimentation en gaz

au détendeur de l’appareil à l’aide d’un tuyau

flexible de 19 mm (3/4") entre le robinet d’arrêt

de gaz et le détendeur. (Voir Figure 9).

• Utilisez toujours de la pâte à joint ou du ruban

Teflon® sur les filets du tuyau et prenez garde à ne

pas serrer excessivement les raccords.

• Les tests de fuite de l’appareil seront réalisés

conformément aux instructions du fabricant.

• Ouvrez le gaz et assurez-vous qu’il n’y a pas de

fuites à l’aide d’une solution savonneuse. N’utilisez

pas de flamme pour faire cette vérification.

• Toutes les pièces fournies par l’installateur doivent

satisfaire aux réglementations applicables.

MISE EN GARDE

Si l’appareil est alimenté par du gaz propane,

assurez-vous que le réservoir de propane est

équipé de son propre détendeur en sus du

détendeur fourni avec l’appareil. La pression

d’arrivée du gaz dans le détendeur de l’appareil ne

doit pas dépasser les 34,9 millibars (14 pouces à

la colonne d’eau).

25

MISE EN GARDE

L’appareil doit être isolé du système d’arrivée

de gaz en fermant le robinet manuel d’arrêt

pendant tous les tests de pression

d’alimentation en gaz lorsque ces pressions

sont égales ou inférieures à 3,5 kPA (1/2 psig).

« L’appareil et son robinet individuel d’arrêt

doivent être débranchés du système d’arrivée de

gaz pendant tous les tests de pression du système

si ces pressions dépassent 3,5 kPa (1/2 psig). »

Pour la vérification de la pression de gaz du

collecteur, la pression d’entrée du détendeur doit

être de 14,9 mb (6") au minimum pour le gaz

naturel et de 7,4 mb (11") pour le propane.

Ne tentez pas de régler le détendeur.

Page 28

Chapitre 5 : Exigences pour l’alimentation électrique, le

branchement et la mise à la terre

• Avant d’intervenir sur

l’appareil, débranchez

toujours le cordon

d’alimentation électrique de

• Les schémas de câblage

la prise murale.

• Tous les modèles de tables

de cuisson doivent être

branchés à une prise murale

de terre à 3 fiches. Cette

prise sera reliée à un circuit

d’alimentation électrique

correctement mis à la terre

et polarisé, de 120 VCA, 10

A, monophasé, 60 Hz. Le

courant maximum de

l’appareil est de 7 A.

MÉTHODE DE MISE

À LA TERRE

La table de cuisson vous est

fournie avec un cordon

d’alimentation électrique pourvu

d’une prise avec mise à la terre

MISE EN GARDE

Une mise à la terre ou une polarisation

incorrectes provoqueront des

dysfonction-nements (tels qu’une

production continuelle d’étincelle au

niveau des allumeurs des brûleurs)

pouvant endommager l’appareil et

comporter un risque de décharge

électrique. Si le circuit n’est pas

correctement mis à la terre et polarisé,

l’installateur ou l’utilisateur est tenu de

faire appel à un électricien qualifié pour

qu’il installe une prise dûment mise à la

terre et polarisée, conforme à toutes les

réglementations locales applicables. À

défaut de réglementation locale, le

à trois fiches (à lames parallèles

polarisées).

ÊTRE BRANCHÉE DANS UNE PRISE

MURALE A VEC MISE À LA TERRE

RELIÉE À UN CIRCUIT

CORRECTEMENT POLARISÉ DE

120 VOL TS

Une mise à la terre ou une

polarisation incorrectes provoqueront des dysfonctionnements

(tels qu’une production continuelle

d’étincelle au niveau des

allumeurs des brûleurs) pouvant

endommager l’appareil et

présenter des risques de

décharge électrique.

changement de prise doit être effectué

conformément au Code national de

l’électricité (Voir Figure 11).

• Respectez toutes les

réglementations locales

applicables lors de la mise à

la terre. À défaut, le Code

national de l’électricité ANSI/

o

NFPA n

70 – Édition actuelle

sera appliqué. Reportezvous à la figure 11 pour la

Si le circuit ne comporte pas de

prise murale avec mise à la

terre, l’installateur ou l’utilisateur

est tenu de faire appel à un

Exigences pour l'alimentation électrique pour la protection de

surintensité

(chaque modèle de plaque de cuisson requiert un disjoncteur

de 10 ou 15 A tel qu'indiqué ci-dessous) :

PC366 : protection de circuit de 10 A.

PC364GL : protection de circuit de 10 A.

PC364GE

PC486GL : protection de circuit de 10 A.

PC486GE

PC484GGE

PC484WK : protection de circuit de 10 A.

P24WK : protection de circuit de 10 A.

méthode conseillée de mise

à la terre.

électrique destinés au

technicien qualifié sont

attachés au bas du châssis

de la table de cuisson.

N’enlevez pas et ne jetez pas

cette importante information.

CETTE PRISE DOIT

(V oir Figure 1 1).

(avec plaque de cuisson) :

(avec plaque de cuisson) :

(avec plaque de cuisson)

FIG. 11. Méthode

recommandée de mise à

la terre

PLAQUE

COUVRANT LE

BOÎTIER DE LA

PRISE MURALE

PRISE

MURALE À 3

FICHES

PRISE MÂLE À

3 FICHES.

électricien qualifié pour qu’il

transforme la prise actuelle en

une prise correctement mise à

la terre, conforme à toutes les

réglementations locales

applicables. À défaut de

réglementation locale, le

changement de prise doit être

effectué conformément au Code

national de l’électricité. LA

FICHE DE TERRE DE LA

PRISE NE DOIT EN AUCUN

CAS ÊTRE COUPÉE NI

SUPPRIMÉE.

protection de circuit de15 A.

protection de circuit de 15 A.

:protection de circuit de 15 A.

26

Page 29

Chapitre 6 : Installation de la plaque de protection

Il est obligatoire d’installer une plaque

de protection basse si la distance entre