Thermador PALPKITHW Installation manual

Installation

INSTRUCTIONS

Pro Harmony®, Pro Grand®, and Pro Rangetop Propane (LP) Conversion Kit

THERMADOR.COM

Installation

INSTRUCTIONS

Pro Harmony®, Pro Grand®, and Pro Rangetop Propane (LP) Conversion Kit

Table of contents (English) ................................................................ 3

Table de matières (Français)............................................................ 19

Índice de materias (Español)............................................................ 35

Models |

Modèles |

Modelos:

PALPKITHW

PALPKITHW5

PALPKITGW

PALPKITGW5

THERMADOR.COM

Table of

Safety

CONTENTS

Safety ......................................................................................4

Important safety instructions .......................................... 4

Propane (LP) gas conversion instructions ............................... 6

Before you begin ............................................................ 6

Checklist.......................................................................... 7

Installation procedure............................................................. 8

Disassembling the rangetop...........................................8

Converting the regulator to LP....................................... 9

Changing the STAR® burner orifices ............................. 9

Propane (LP) burner orifice conversion tables................ 10

Setting the STAR burner valve screws ............................ 12

Changing the broil orifice, on GAS ranges only.............13

Changing the bake orifice, on GAS ranges only ............14

Checking for gas leaks.................................................... 16

Reassembling the appliance ...........................................16

DEFINITIONS

9 WARNING

This indicates that death or serious injuries may occur as a

result of non-observance of this warning.

9 CAUTION

This indicates that minor or moderate injuries may occur as a

result of non-observance of this warning.

NOTICE: This indicates that damage to the appliance or

property may occur as a result of non-compliance with this

advisory.

Note: This alerts you to important information and/or tips.

Checking the flame and burner performance................. 17

Placing the conversion label ........................................... 18

Support, accessories, and parts..................................back page

This THERMADOR® appliance is made by

BSH Home Appliances Corporation

1901 Main Street, Suite 600

Irvine, CA 92614

Questions?

1-800-735-4328

www.thermador.com

We look forward to hearing from you!

Page. 3

Safety

9 IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

Please read carefully

Save the original gas parts for possible conversion back in

the future.

Important: Only a qualified service technician or installer

should make this conversion.

Installer: Please leave these instructions with this unit for

the owner.

Owner: Please retain these instructions for future

reference.

WARNING

If the information in this manual is

not followed exactly, a fire or

explosion may result causing

property damage, personal injury or

death.

-- DO NOT store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

-- WHAT TO DO IF YOU SMELL GAS

• DO NOT try to light any appliance.

• DO NOT touch any electrical switch.

• DO NOT use any phone in your

building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

This kit is for converting Thermador appliances for

operation with propane (LP) gas. This kit contains orifices

for proper LP conversion for oven bake, broiler, and

®

STAR

This kit is used to convert select models of Pro Rangetop,

Pro Harmony, and Pro Grand ranges to propane (LP) gas

usage. This kit cannot be used to convert older models of

rangetops or ranges. This kit cannot be used to convert

any other brand of appliance.

WARNING

For Massachusetts installations

1. Installation must be performed by a qualified or

2. Shut-off valve must be a “T” handle gas cock.

3. Flexible gas connector must not be longer than 36

burners.

This conversion kit shall be installed by a

qualified service agency in accordance with the

manufacturer’s instructions and all applicable

codes and requirements of the authority having

jurisdiction. If the information in these

instructions is not followed exactly, a fire,

explosion or production of carbon monoxide

may result causing property damage, personal

injury or loss of life. The qualified service

agency is responsible for the proper installation

of this kit. The installation is not proper and

complete until the operation of the converted

appliance is checked as specified in the

manufacturer’s instructions supplied with the

kit.

licensed contractor, plumber, or gas fitter qualified or

licensed by the state, province or region.

inches.

-- Installation and service must be

performed by a qualified installer, service

agency or the gas supplier.

Page. 4

9 IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

The following must be met when testing supply piping

system:

• The appliance and its individual shut-off valve

must be disconnected from the gas supply piping

system at test pressures in excess of 1/2 psig

(3.5 kPa).

• The appliance must be isolated from the gas

supply piping system by closing its individual

manual shut-off valve during any pressure testing

of the gas supply piping system at test pressures

equal to or less than 1/ 2 psig (3.5 kPa).

CAUTION

When connecting the unit to propane gas, make

certain the propane gas tank is equipped with its own

high pressure regulator. The maximum gas pressure to

this appliance is not to exceed 14.0 inches water

column from the propane gas tank regulator.

State of California Proposition 65 Warning:

: WARNING

This product can expose you to chemicals including

vinyl chloride, which is known to the State of California

to cause cancer and birth defects or other

reproductive harm. For more information go to

www.P65Warnings.ca.gov.

To the service agent

It is important that you know the following BEFORE you

begin the conversion of the appliance.

• Confirm that the gas supply system is available and

ready to use. This is particularly important for new

construction.

• Verify the type of gas supplied to the location. Ensure

that the appliance is connected to the type of gas for

which it is certified.

• You must plan for sufficient time and resources to

perform the conversion process properly and

completely before leaving the job site. Every step

described in these instructions must be performed to

safely convert the appliance for proper operation with

propane (LP) gas. INCOMPLETE OR INADEQUATE

CONVERSION OF THE APPLIANCE CAN CREATE A

SAFETY HAZARD.

Gas and dual fuel ranges converted for propane (LP)

gas and high altitude

The appliance must first be converted for use with

propane (LP) gas before it can be converted for use at

high altitude. It is required that a qualified technician

install the high altitude kit.

WARNING

NEVER leave the gas conversion partially completed.

If the appliance is operated while the gas conversion is

incomplete, high levels of carbon monoxide may be

emitted, or a fire or explosion may occur.

Page. 5

Propane (LP) gas conversion instructions

Before you begin

9 CAUTION

Before proceeding with the conversion, shut off the

gas supply to the appliance prior to disconnecting the

electrical power.

Tools needed

• T-20 torx driver

• 7/16'' box end wrench

• 13/16'' box end wrench

• 7 mm or a 9/32'' socket

• 1/4'' nut driver

• 16 mm hex bit or 5/8'' hex bit

• Adjustable wrench

• Soap and water mixture or leak-check solution

LP gas kit parts included

Gas Pro Harmony ranges with 5 burners

(PRG305WH)

Qty.

Dual fuel Pro Harmony ranges and Pro

Rangetop with 5 burners

(PRD305WH(U/C) or PCG305W)

Conversion label 1

Foam tape, 1'' piece 1

Screwdriver, 1/8'' x 0.20'' 1

Orifice, 0.73 mm (73) 2

Orifice, 0.90 mm (90) 1

Orifice, 1.05 mm (105) 1

Orifice, 1.15 mm (115) 1

Dual fuel Pro Harmony and Pro Grand ranges,

and Pro Rangetop with 4 or 6 burners

Conversion label 1

Foam tape, 1'' piece 1

Screwdriver, 1/8'' x 0.20'' 1

Orifice, 1.05 mm (105) 3

Orifice, 1.15 mm (115) 3

Orifice, 1.26 mm (126) 1

Qty.

Qty.

Conversion label 1

Foam tape, 1'' piece 1

Screwdriver, 1/8'' x 0.20'' 1

Orifice, 0.73 mm (73) 2

Orifice, 0.90 mm (90) 1

Orifice, 1.05 mm (105) 1

Orifice, 1.15 mm (115) 1

Orifice, 1.34 mm (134), Harmony, main oven

bake

Orifice, 1.25 mm (125), Grand and Harmony,

main oven broil

Gas Pro Harmony and Pro Grand ranges with

4 or 6 burners

Conversion label 1

Foam tape, 1'' piece 1

Screwdriver, 1/8'' x 0.20'' 1

Orifice, 1.05 mm (105) 3

Orifice, 1.15 mm (115) 3

1

1

Orifice, 1.26 mm (126) 1

Orifice, 1.34 mm (134), Harmony, main oven

bake

Orifice, 1.40 mm (140), Grand, main oven bake 1

Orifice, 1.13 mm (113), Grand and Harmony,

aux oven bake

Orifice, 1.25 mm (125), Grand and Harmony,

main oven broil

Orifice, 0.813 mm (813), Grand and Harmony,

aux oven broil

Qty.

1

1

1

1

Page. 6

Checklist

Ù Step 8

Place the conversion label (page 18).

Each of the following steps must be completed correctly

for the appliance to function properly. Check off each step

as it is finished.

Pro Harmony gas models

Ù Step 1

Ù Step 2

Ù Step 3

Ù Step 4

Ù Step 5

Ù Step 6

Ù Step 7

Ù Step 8

Ù Step 9

Ù Step 10

Ù Step 11

Ù Step 12

Ù Step 13

Ù Step 14

Disassemble the rangetop (page 8).

Convert the regulator to LP gas (page 9).

Change the STAR® burner orifices according

to your model and the corresponding table

(page 9).

Set the valve screws for the STAR burners

(page 12).

Check the flame and burner performance

(page 17).

Remove the oven door (page 14).

Remove the kick and front panels (page 15).

Change the main oven broil burner orifice to

the 1.25 mm (125) orifice (page 13).

48'' models – change the aux oven broil

burner orifice to the 0.813 mm (813) orifice

(page 13).

Change the main oven bake burner orifice to

the 1.34 mm (134) orifice (page 14).

48'' models – change the aux oven bake

burner orifice to the 1.13 mm (113) orifice

(page 14).

Check the rangetop and oven for gas leaks

(page 16).

Reassemble the rangetop, door, kick and

front panels.

Place the conversion label (page 18).

Pro Grand gas models

Ù Step 1

Ù Step 2

Ù Step 3

Ù Step 4

Ù Step 5

Ù Step 6

Ù Step 7

Ù Step 8

Ù Step 9

Ù Step 10

Ù Step 11

Ù Step 12

Ù Step 13

Ù Step 14

Pro Grand dual fuel models

Ù Step 1

Disassemble the rangetop (page 8).

Convert the regulator to LP gas (page 9).

Change the STAR burner orifices according

to your model and the corresponding table

(page 9).

Set the valve screws for the STAR burners

(page 12).

Check the flame and burner performance

(page 17).

Remove the oven door (page 14).

Remove the kick and front panels (page 15).

Change the main oven bake burner orifice to

the 1.40 mm (140) orifice (page 14).

48'' models – change the aux oven bake

burner orifice to the 1.13 mm (113) orifice

(page 14).

Change the main oven broil burner orifice to

the 1.25 mm (125) orifice (page 13).

48'' models – change the aux oven broil

burner orifice to the 0.813 mm (813) orifice

(page 13).

Check the rangetop and oven for gas leaks

(page 16).

Reassemble the rangetop, door, kick and

front panels.

Place the conversion label (page 18).

Disassemble the rangetop (page 8).

Pro Harmony dual fuel models

Ù Step 1

Ù Step 2

Ù Step 3

Ù Step 4

Ù Step 5

Ù Step 6

Ù Step 7

Disassemble the rangetop (page 8).

Convert the regulator to LP gas (page 9).

Change the STAR burner orifices according

to your model and the corresponding table

(page 9).

Set the valve screws for the STAR burners

(page 12).

Check the flame and burner performance

(page 17).

Check the rangetop for gas leaks (page 16).

Reassemble the rangetop.

Ù Step 2

Ù Step 3

Ù Step 4

Ù Step 5

Ù Step 6

Ù Step 7

Ù Step 8

Convert the regulator to LP gas (page 9).

Change the burner orifices according to your

model and the corresponding table

(page 10).

Set the valve screws for the STAR burners

(page 16).

Check the rangetop for gas leaks (page 16).

Reassemble the rangetop.

Check the flame and burner performance

(page 17).

Place the conversion label (page 18).

Page. 7

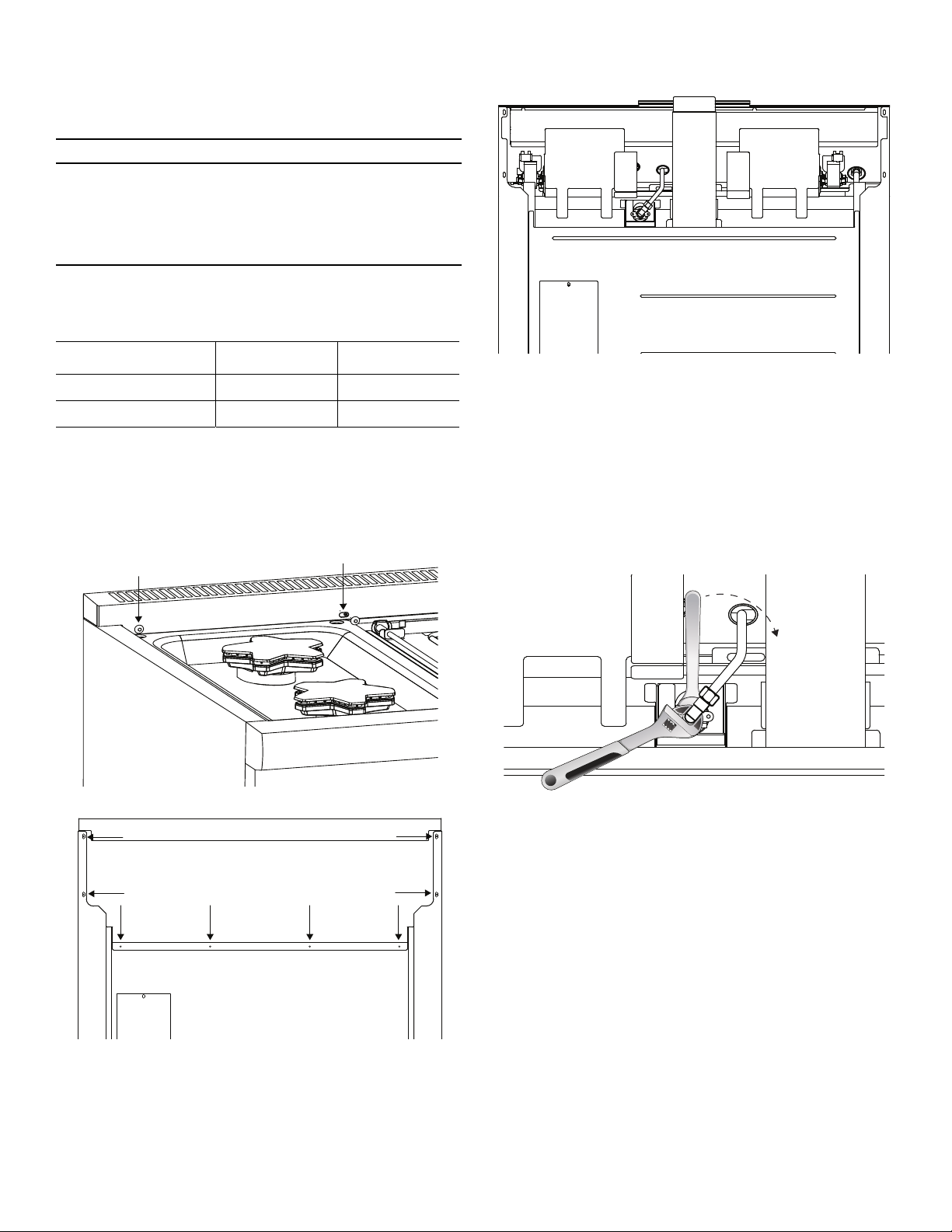

Installation procedure

1

2

a

b

c

d

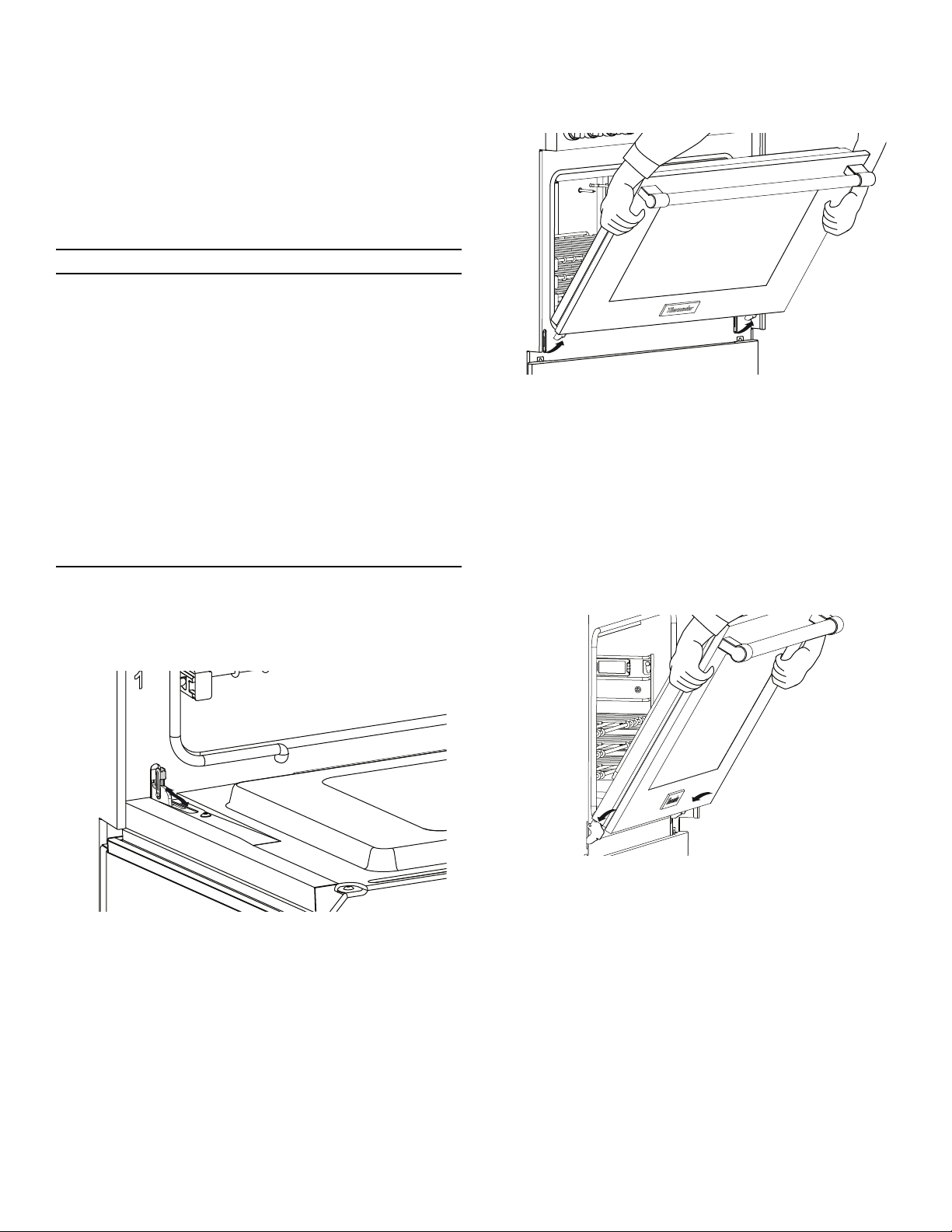

Disassembling the rangetop

9 CAUTION

Shut off the gas supply to the appliance prior to

disconnecting the electrical power.

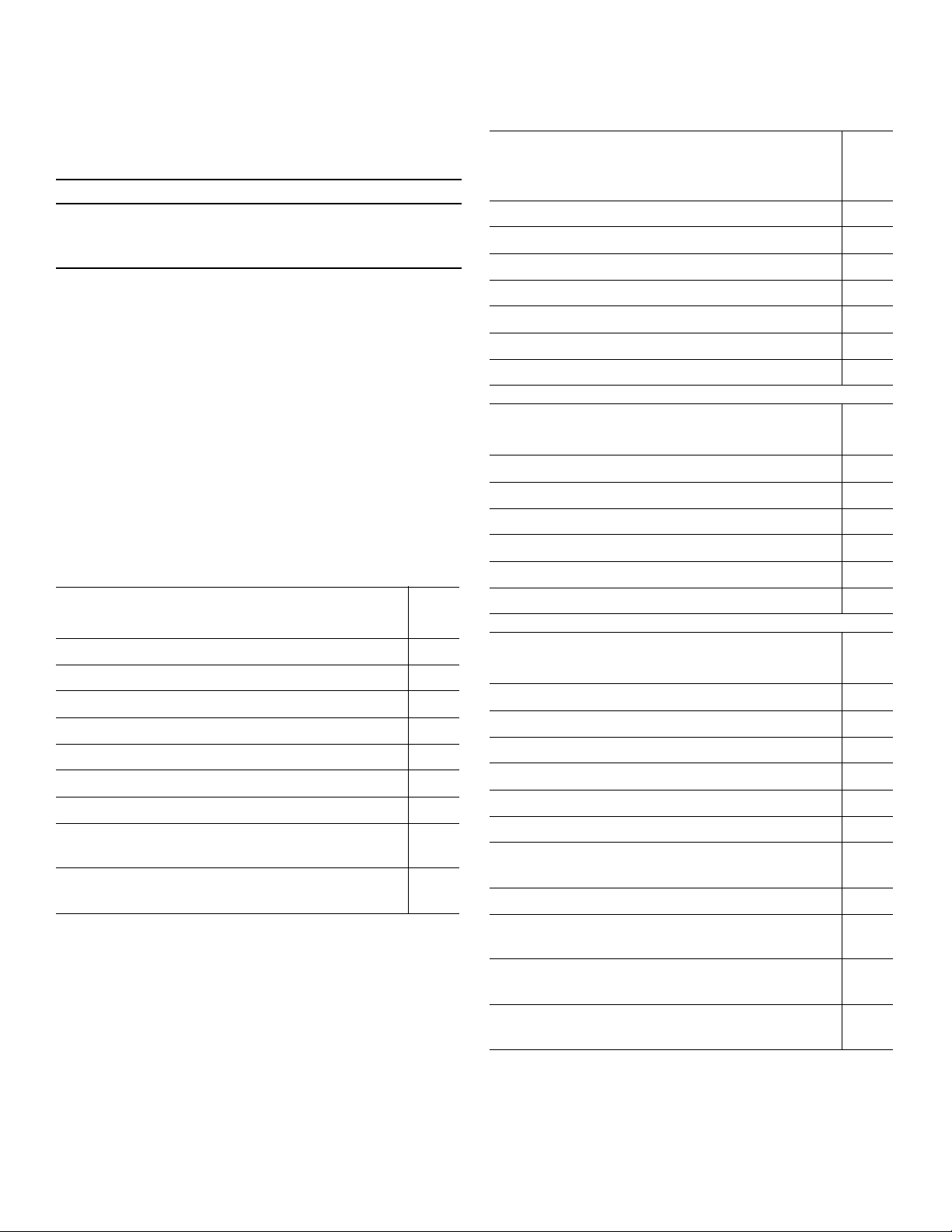

To disassemble the rangetop

1. Remove the rangetop grates and the burner caps.

2. To facilitate the removal of the spill tray, remove the T20 torx screws in the front face of the island trim or

backguard.

4. Disconnect the igniter. Carefully pull up on the burner

base.

a. Burner base

b. Electrode

c. Igniter housing

d. Igniter wire

5. Carefully remove each burner pedestal.

6. Remove the spill trays by rotating the trays up and out

the back.

7. Remove the heat shield on some models. Some

models have a double-width shield that extends under

adjacent spill tray.

3. Use a 16 mm hex head bit for burners labeled ‘D’ or

‘F’. Use a 9 mm hex head bit for burners labeled ‘B’ to

remove the burner venturi from each burner base.

TIP: If a 16 mm hex head bit is not readily available, a

5/8'' hex bit can be selected. Alternatively, a bolt with

5/8'' head either “double-nutted” or tightened into

the chuck of a power driver can be used.

Page. 8

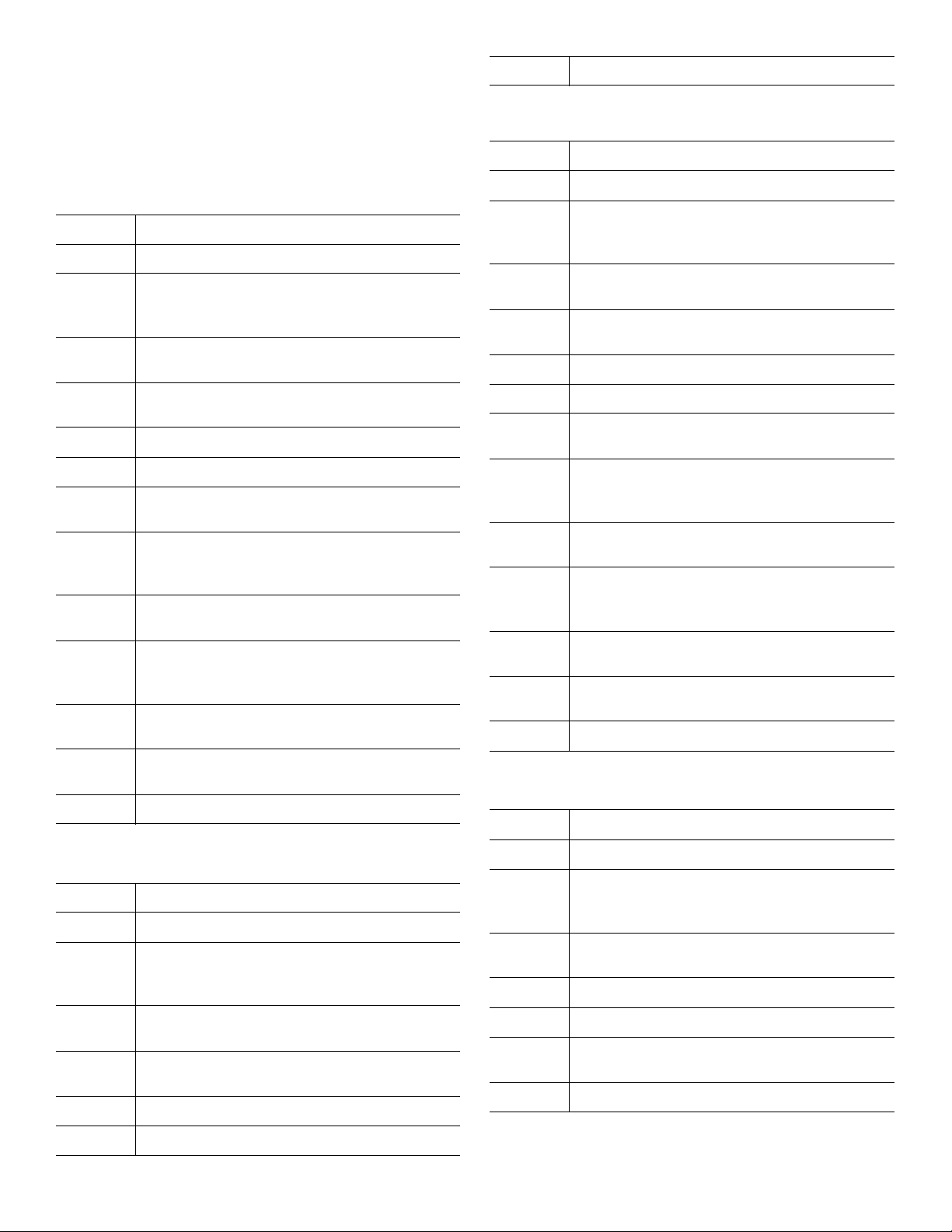

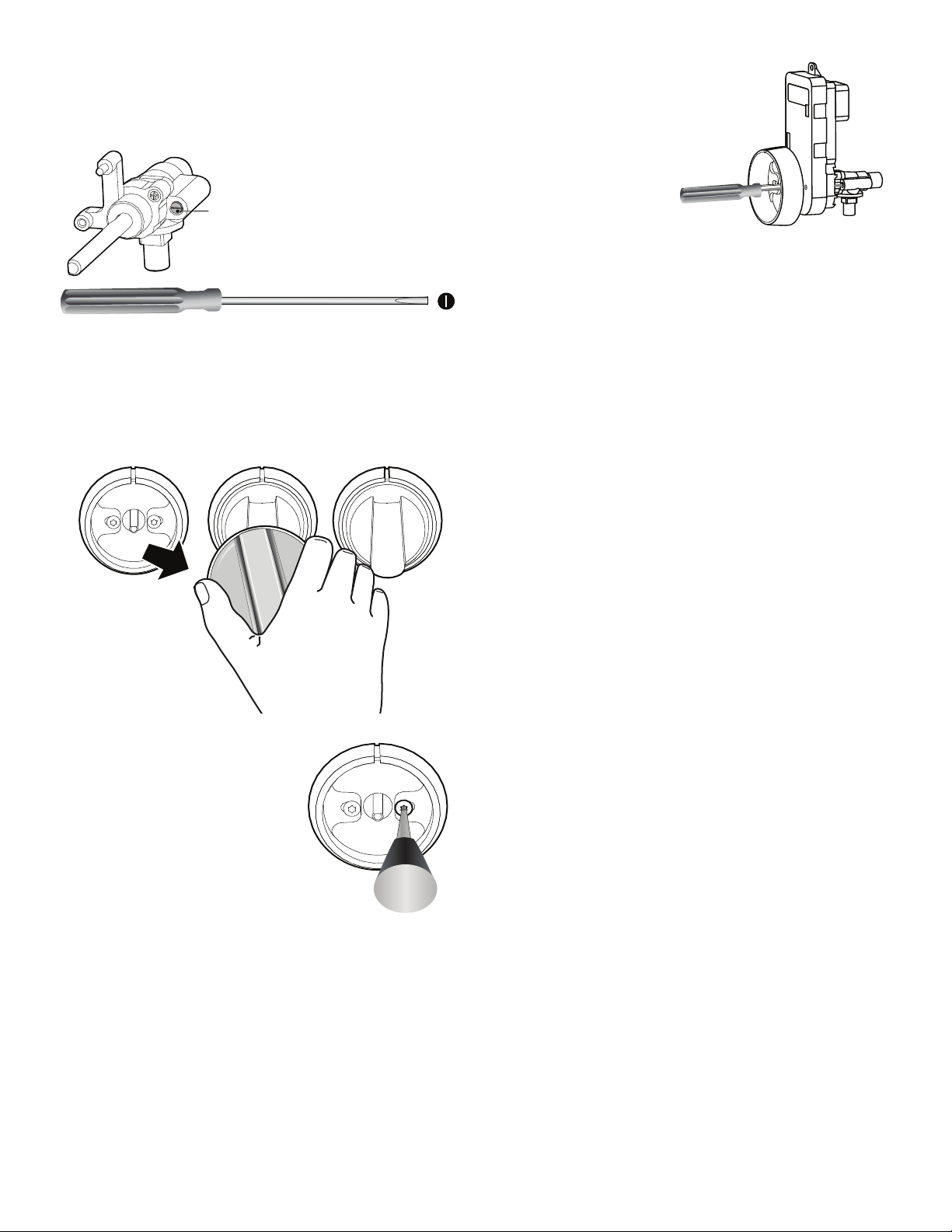

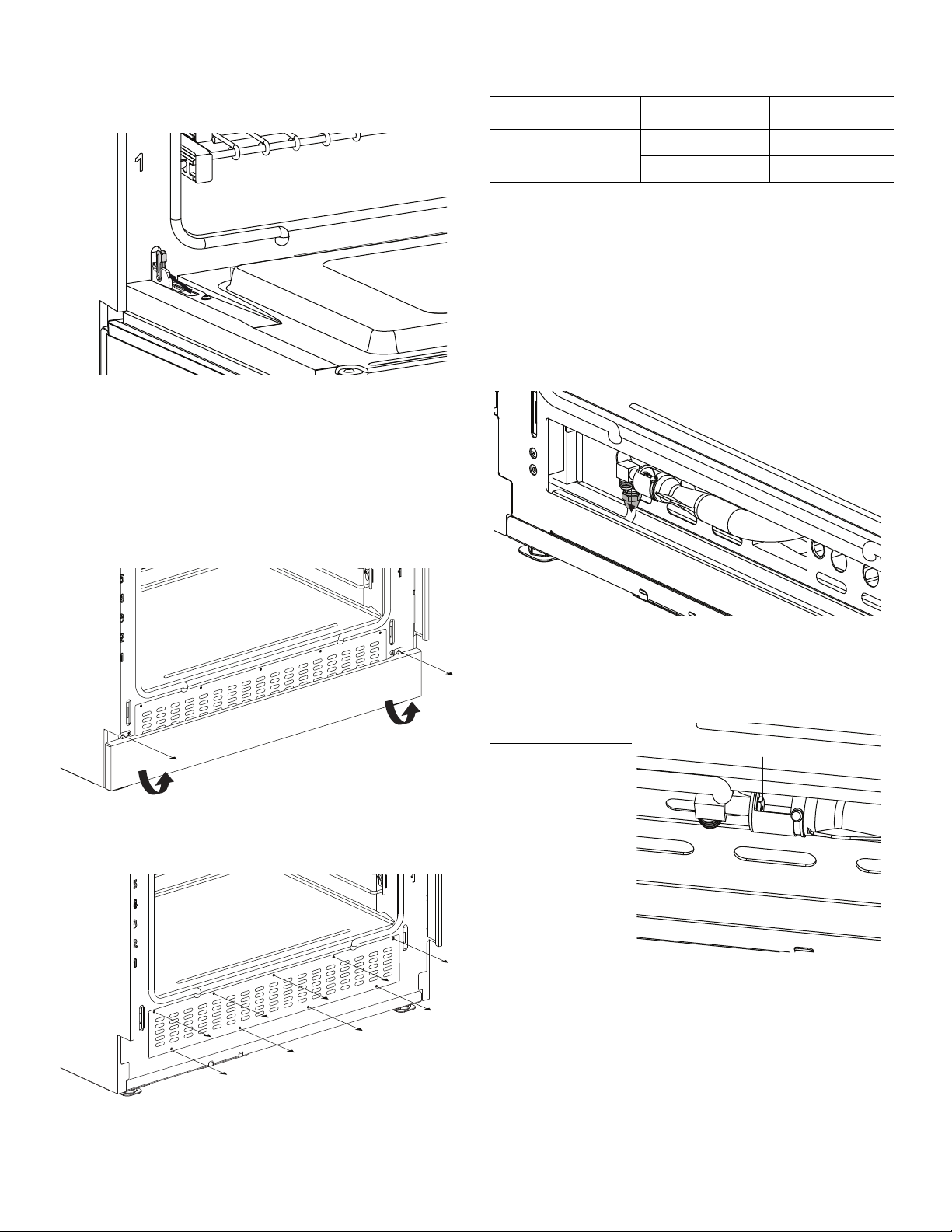

Converting the regulator to LP

a

b

c

a

b

1

2

Changing the burner orifices

The gas regulator is located in the rangetop, left side of

appliance. Exact location will vary per model.

1. Remove the

conversion cap with

a 7/8'' socket or

wrench.

2. Grasp the plastic button stem firmly and pull it

forcefully from the metal cap. The stem snaps snugly

into an indent in the cap and may require a strong pull

to remove. (Hint: it may be helpful to gently “rock”

the plastic stem while pulling it from the metal cap.)

To prepare the nut driver for burner orifice conversions

The foam tape helps to retain the orifice in the end of the

nut driver so it will not fall inside the appliance during

orifice removal or installation.

1. Trim a small piece of the foam tape provided with this

kit (about 1/4'' x 1/2'' / 6 x 12 mm).

2. Place foam tape over the edge of a 7 mm or a 9/32''

socket with 1/4'' nut driver used to replace the burner

orifices, as shown below.

To replace the STAR

®

burner orifices

a. Spring

b. Plastic button stem

c. Gasket

3. Rotate the stem 180° so the letters “LP” on the stem

are upside down when the cap is set flat on its head.

Snap the stem back in place in this position inserting it

into the indent in the metal cap.The stem should snap

into place.

a. Natural gas

b. LP gas

4. Reinstall conversion cap, configured for LP gas, back

into top of the regulator.

1. With the foam tape wrapped nut driver, reach down

through the jet holders and remove the gas orifice

from the STAR burner’s jet holder.

2. Locate the proper STAR burner

orifices included with the kit.

Orifices are stamped with the

orifice diameter size on the side.

3. Replace orifices as indicated in “Propane (LP) burner

orifice conversion tables” on page 10.

NOTE: All of the replacement orifices in the conversion kit

have straight threads (not pipe threads) and do not

require thread sealing compound.

Page. 9

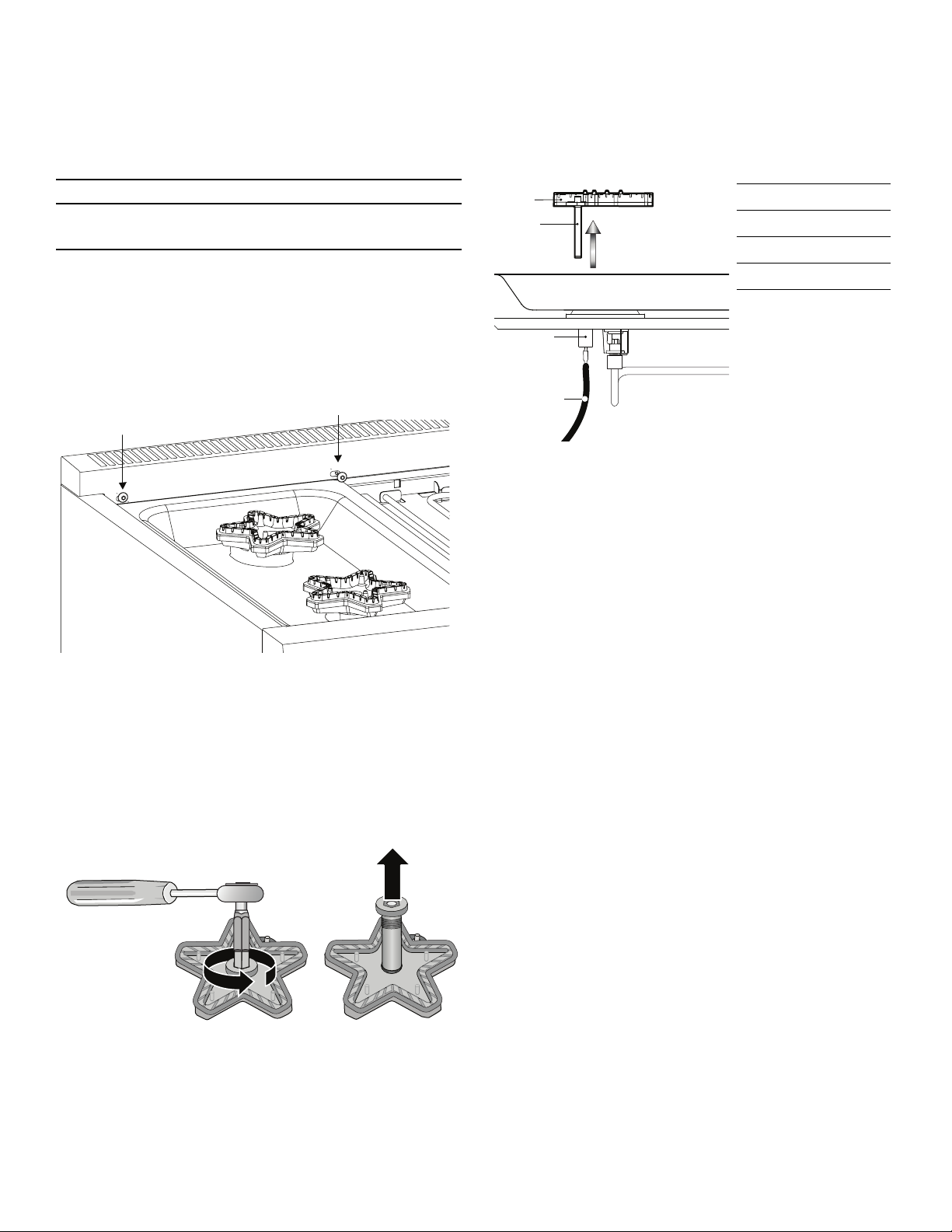

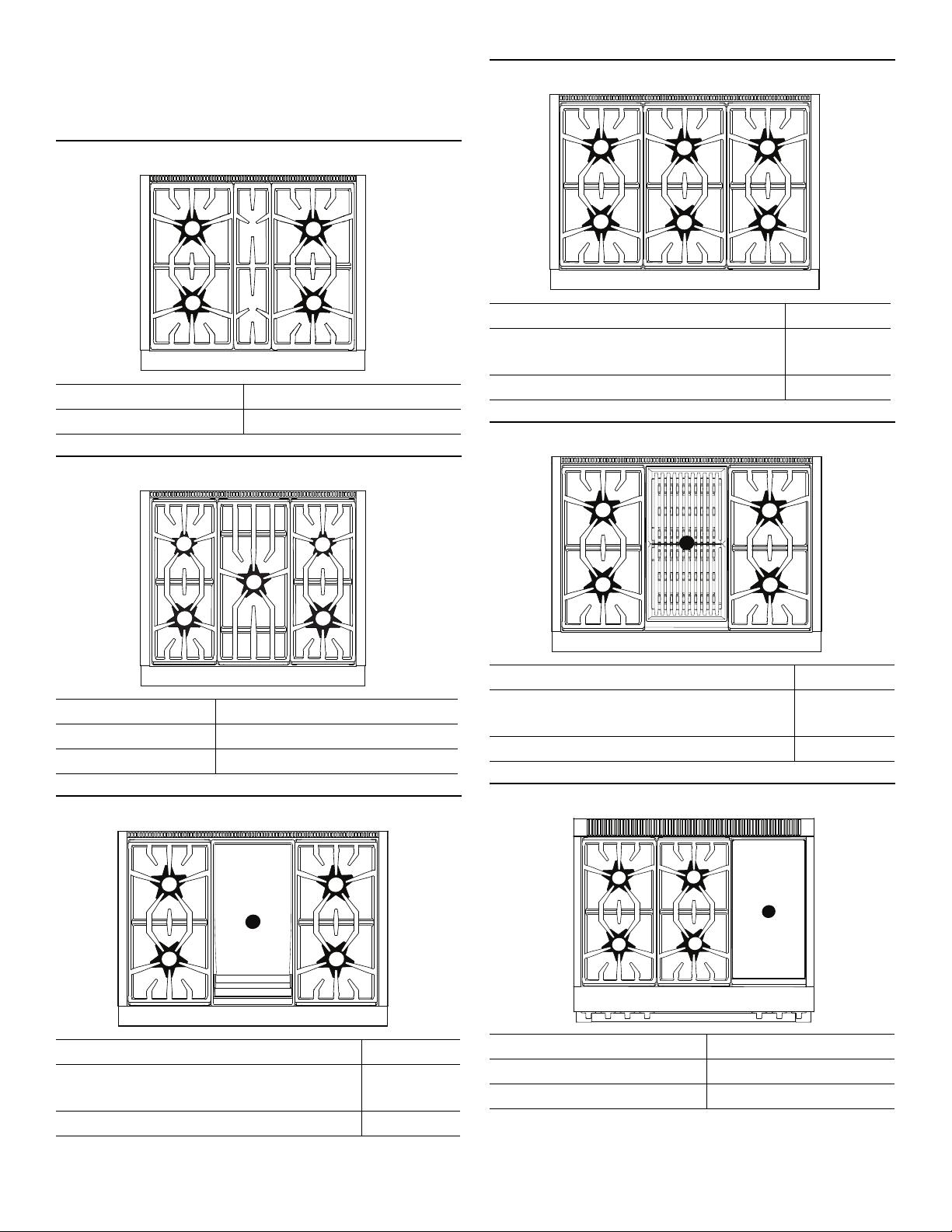

Propane (LP) burner orifice

44

11

22

33

33

55

11

22

44

33

55

11

22

44

conversion tables

Model 366

Model 304

(1)105 (3)105

(2)115 (4)115

Model 305

11

22

33

44

55

66

(1) 105 (4) 115

(2) 115 Pro Harmony and Rangetop

(5) 105

126 Pro Grand

(3) 105 (6) 115

Model 364 with grill

11

33

22

44

55

(1) 73 (4) 73

(2) 115 (5) 105

(3) 90

Model 364 with griddle

(1) 105 (4) 105

(2) 115 Pro Harmony and Rangetop

(3) —

126 Pro Grand

(5) 115

(1) 105 (4) 105

(2) 115 Pro Harmony and Rangetop

(5) 115

126 Pro Grand

(3) —

Model 364 with induction

11

22

33

55

44

(1)105 (4)115

(2)126 (5)—

(3) 105

Page. 10

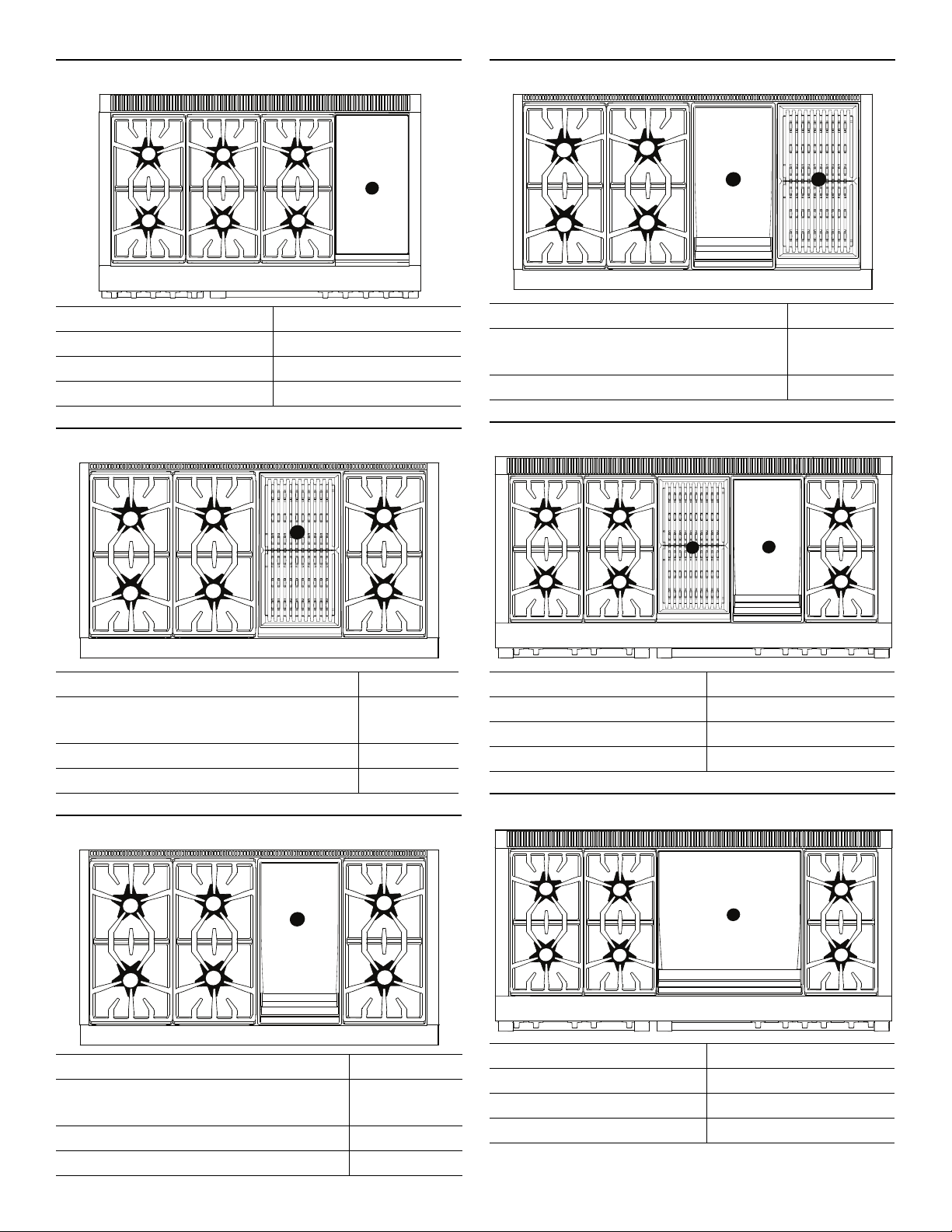

Model 486 with induction

33

44

66

11

22

55

77

33

44

77

11

22

66

55

33

44

77

11

22

66

55

33

44

11

22

55

66

Model 486 with griddle and grill

(1) 105 (5) 105

(2) 126 (6) 115

(3) 105 (7) —

(4) 115

Model 486 with grill

(1) 105 (5) —

(2) 115 Pro Harmony and Rangetop

(6) 105

126 Pro Grand

(3) 105 (7) 115

(4) 115

Model 486 with griddle

(1) 105 (4) 115

(2) 115 Pro Harmony and Rangetop

(5) —

126 Pro Grand

(3) 105 (6) —

Model 606 with griddle and grill

11

22

33

55

44

66

(1)105 (5)—

(2)126 (6)—

(3)105 (7)105

(4)115 (8)115

Model 606 with griddle and grill

77

88

(1) 105 (5) —

(2) 115 Pro Harmony and Rangetop

126 Pro Grand

(6) 105

(3) 105 (7) 115

(4) 115

11

22

33

55

44

(1)105 (5)—

(2)126 (6)105

(3)105 (7)115

(4) 115

66

77

Page. 11

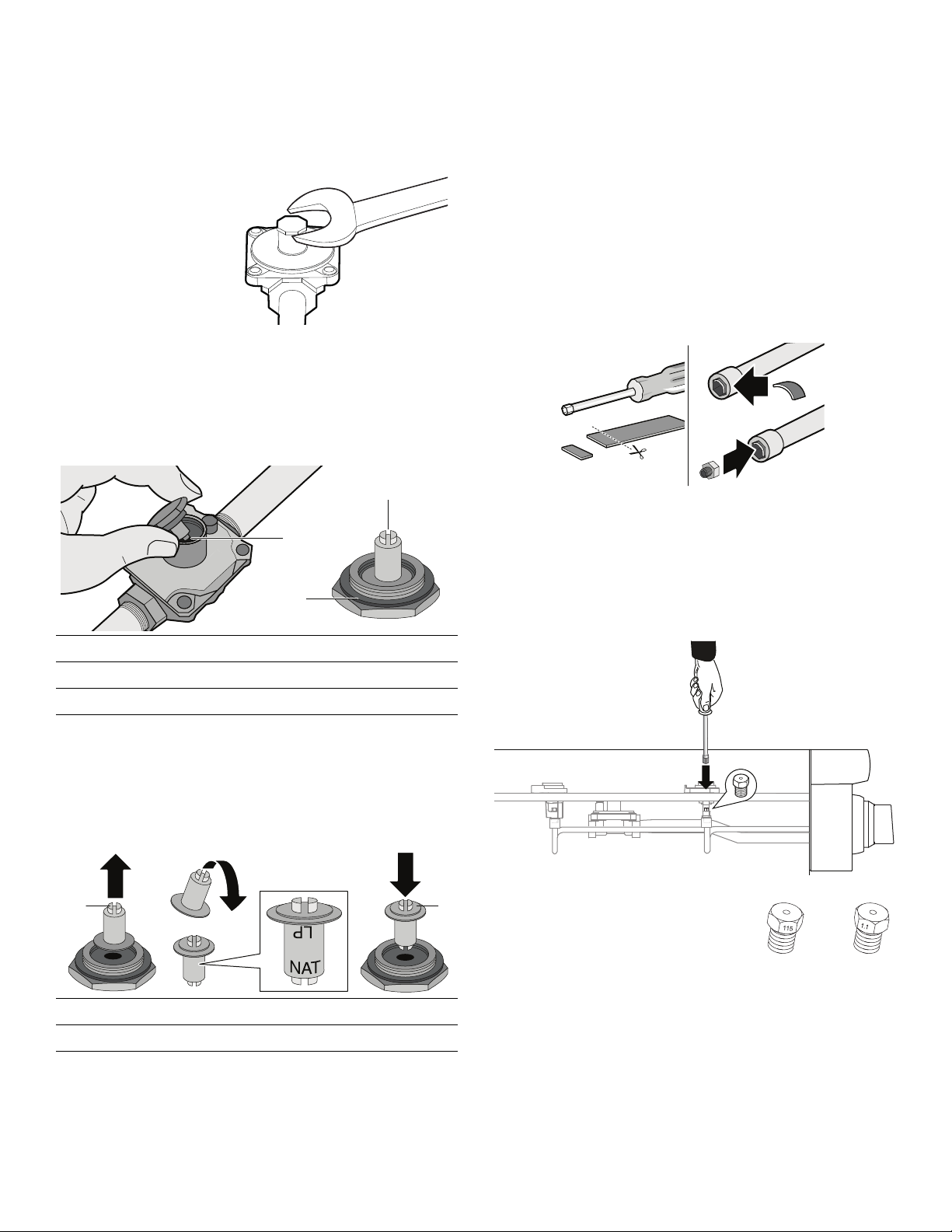

Setting STAR® burner valve

screws

A flat-head screwdriver with an

1/8" [3.0 mm] wide, .020"

[0.50 mm] thickness tip

(included) is used to adjust the

valve screws.

To set the burner valve screws

1. Remove the knob from the valve stem by slowly

pulling knob straight out, away from the control panel.

3. Insert a 1/8'' flatblade screwdriver

into the hole of the

bezel mounting

screw. Access to the

valve screws through

clearance hole in the

spark module. You

should feel the

engagement of the

screwdriver and the

valve screw.

4. Adjust the valve screw by turning the valve screw

about an 1/8th turn. Turn the screw clockwise to

reduce simmer flame size. Turn the screw counterclockwise to make the simmer flame larger. Adjust the

valve screw as little as required to reach satisfactory

simmer results. Due to normal fluctuations in gas

pressure, over-adjustment of valve screw may affect

flame stability.

5. Perform a gas leak test of each orifice and associated

supply tube fittings. See “Checking for gas leaks” on

page 16. Leak-checking should occur after the orifice

conversion is complete, and before the burner is

reassembled and tested.

2. Remove the bezel-mounting

screw located to the right of

the valve stem, using a T-20

torx screwdriver.

Page. 12

Changing the broil orifice, on

GAS ranges only (PRG models)

9 CAUTION

After the replacement of the broiler orifice, and

before reassembly of the back panel and backguard to

the range, perform a brief gas leakage check of the

orifice and associated fittings, per the “Check for Gas

Leaks” section of these instructions.

NOTE: Dual fuel (PRD models) ranges have electric

ovens and do not have a broil orifice.

Description Main oven broil Aux oven broil

2. Carefully lift the backguard assembly from the range.

Pro Grand 1.25 mm (125) 0.813 mm (813)

Pro Harmony 1.25 mm (125) 0.813 mm (813)

Removing the backguard assembly

1. Use a T-20 torx screwdriver to remove the screws from

the front and rear panel of the backguard assembly.

Changing the broil burner orifice

1. Remove broil orifice using a 7/16'' box end wrench,

while restraining the elbow fitting from rotation using

a small adjustable wrench.

IMPORTANT: DO NOT bend the broil burner orifice

bracket. Ensure that the broiler orifice is aligned to the

center of the burner tube inlet.

NOTE: The replacement broil orifices have straight

threads (not tapered threads) and DO NOT require thread

sealing compound.

2. Perform a gas leakage check of the orifice and

associated supply tube fittings, per the “Check for gas

leaks” section of these instructions.

Page. 13

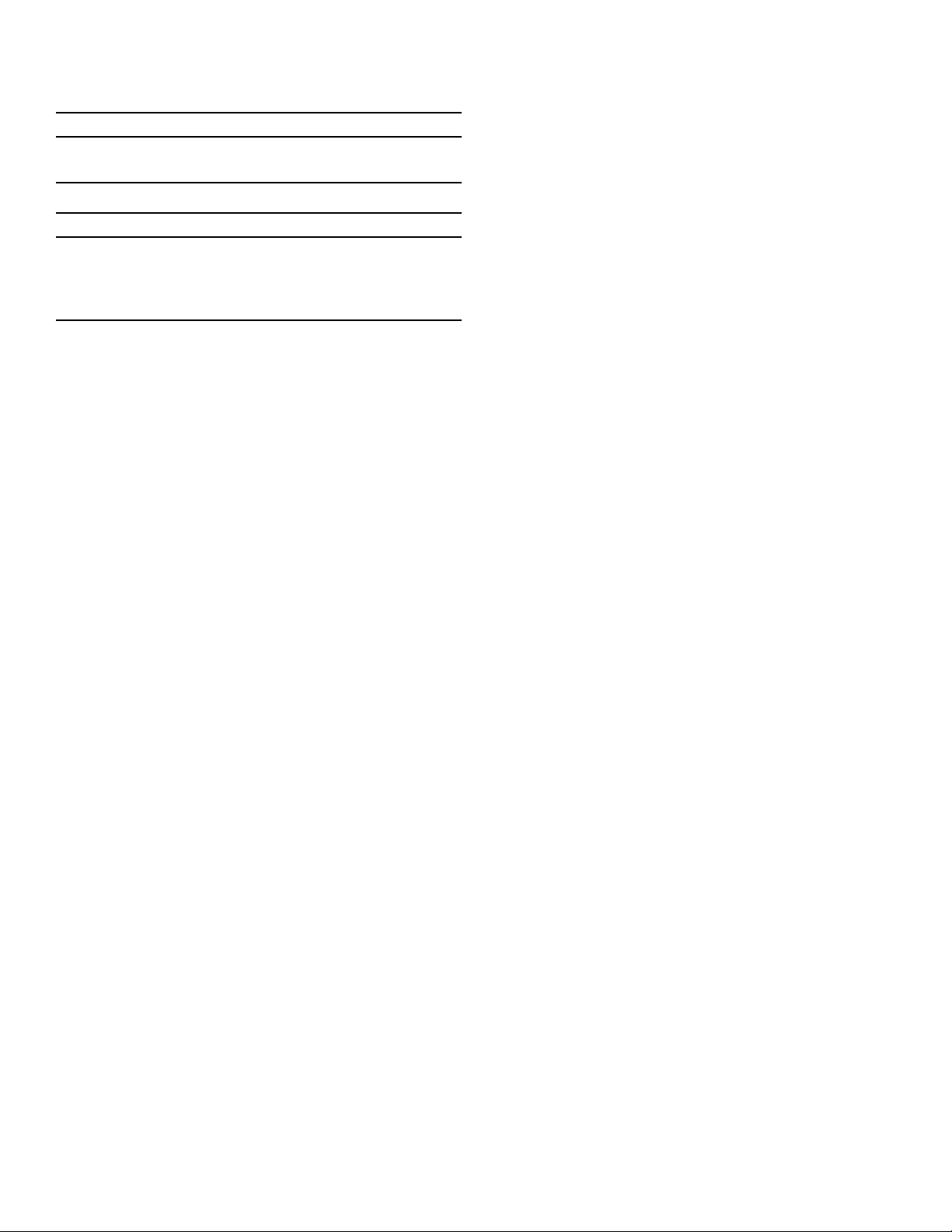

Changing the bake orifice, on

GAS ranges only (PRG models)

NOTE: Dual fuel (PRD models) ranges have electric

ovens and do not have a bake orifice.

Removing the oven door

9 CAUTION

• USE CAUTION WHEN REMOVING THE DOOR.

THE DOOR IS VERY HEAVY.

• Make sure oven is cool and power to the oven has

been turned off before removing the door. Failure

to do so could result in electrical shock or burns.

• The oven door is heavy and fragile. Use both

hands to remove or replace the door.

• Failure to grasp the oven door firmly and properly

could result in personal injury and product

damage.

• With the door off, never release the levers and try

to close the hinges. Without the weight of the

door, the powerful springs will snap the hinges

closed with great force.

1. Open the door fully. Flip the hinge clips down for both

sides of the door. A screwdriver may be required to

carefully pry the clip back.

3. Grasp the door firmly on the ends of the door. Lift the

door up and out. There will be some spring resistance

to overcome.

4. Place the door in a safe and stable location.

Reinstalling the oven door

1. Hold the door firmly in both hands.

2. Hold the door at a 30° angle from the closed position.

Insert hinges centered evenly into the hinge slots. The

hinges will securely hook into the slots when properly

installed. DO NOT force, bend or twist the door.

2. Close the door gently until it stops against the hinge

clips. The open hinge clips will hold the door open at

a slight angle, about 30°, from the closed position.

Page. 14

3. Open door fully to expose hinges, levers, and slots.

4. Flip the hinge forward until seated on the bracket. A

b

a

screwdriver may be required to carefully push the clip

back.

5. Close and open the door slowly to ensure it is

correctly and securely in place.

Removing the kick and front panels

Changing the bake burner orifice

Description Main oven bake Aux oven bake

Pro Grand 1.40 mm (140) 1.13 mm (113)

Pro Harmony 1.34 mm (134) 1.13 mm (113)

To change the bake burner orifice

1. Remove the bake gas line using a 13/16'' box end

wrench, while restraining the elbow fitting from

rotation using an adjustable wrench.

IMPORTANT: DO NOT bend the bake burner tube or

shutter. Ensure that the bake orifice is aligned to the

center of the burner tube inlet.

1. Remove the kick panel screws using a T-20 torx

screwdriver.

2. Remove the front panel screws using a T-20 torx

screwdriver.

2. Hand twist the orifice elbow (a) while restraining the

bake orifice (b) from rotation using an adjustable

wrench.

a. Orifice elbow

b. Bake orifice

3. Replace the orifices as indicated in the tables above.

NOTE: The replacement broil orifices have straight

threads (not tapered threads) and DO NOT require thread

sealing compound.

4. Perform a gas leakage check of the orifice and

associated supply tube fittings, per the “Check for gas

leaks” section of these instructions.

Page. 15

Checking for gas leaks

Reassembling the appliance

9 WARNING

DO NOT use a flame of any kind to check for gas

leaks.

9 CAUTION

DO NOT spray water solution onto exposed electrical

devices. If solution does drip onto electrical

components, shut the power off before wiping off the

parts.

Gas leak check using a liquid solution

The replacement orifices in the high-altitude conversion

kit, have straight threads (not tapered threads) and do not

require thread sealing compound.

Leak-checking should occur after the orifices are replaced,

and before the appliance is reassembled and tested.

1. Make sure that the orifice has been tightened and that

all valves and controls are in the OFF position.

Reassemble the appliance in the following order:

1. Rangetop heat shield, if applicable

2. Spill trays

3. Burner pedestals

4. Burner bases

5. Burner caps

6. Backguard

7. Grates

8. Conversion label placement

9. Front panel, if applicable

10. Kick panel, if applicable

11. Oven door, if applicable

2. Turn on electric and gas supplies.

3. Spray a generous amount of soap and water

mixture—or other solution designed for checking gas

leaks—on the threaded junction at the base of the

orifice, the elbow fitting, and gas tube compression

nut. (A 25% dishwashing liquid to water mixture is

effective for this.) Avoid spraying electrical devices.

4. Turn the mode knob and the oven temperature knob

to “BROIL” while blocking the broil orifice hole with a

soft pencil eraser, your finger, or something similar.

• There will be a delay of approximately 45 to 90

seconds as the safety valve coil heats to release

the valve’s actuator. A single pop noise can usually

be heard as the broiler’s safety valve opens.

5. Monitor the base of the orifice junction, elbow fitting,

and compression nut to see if bubbles are forming

anywhere around the connections.

• Bubbles forming are indications of gas leaks.

6. If appliance leaks, repair all gas leaks immediately.

7. Repeat for the bake orifice.

8. Turn off the gas and electric supplies.

Page. 16

Loading...

Loading...